Effect of Ultrasonic Rolling on Surface Properties of GCr15 Spherical Joint Bearing

Abstract

1. Introduction

2. Materials and Methodology

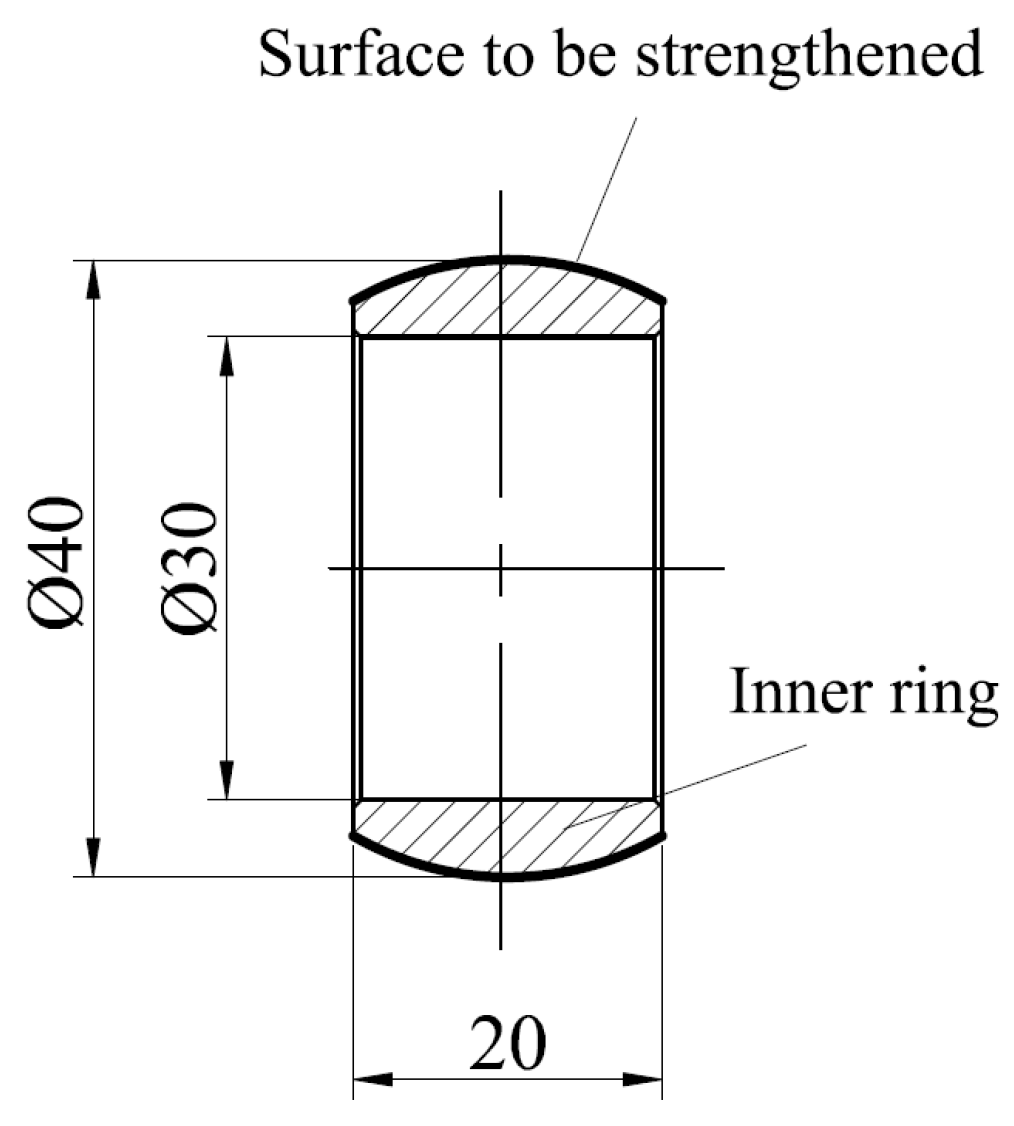

2.1. Materials

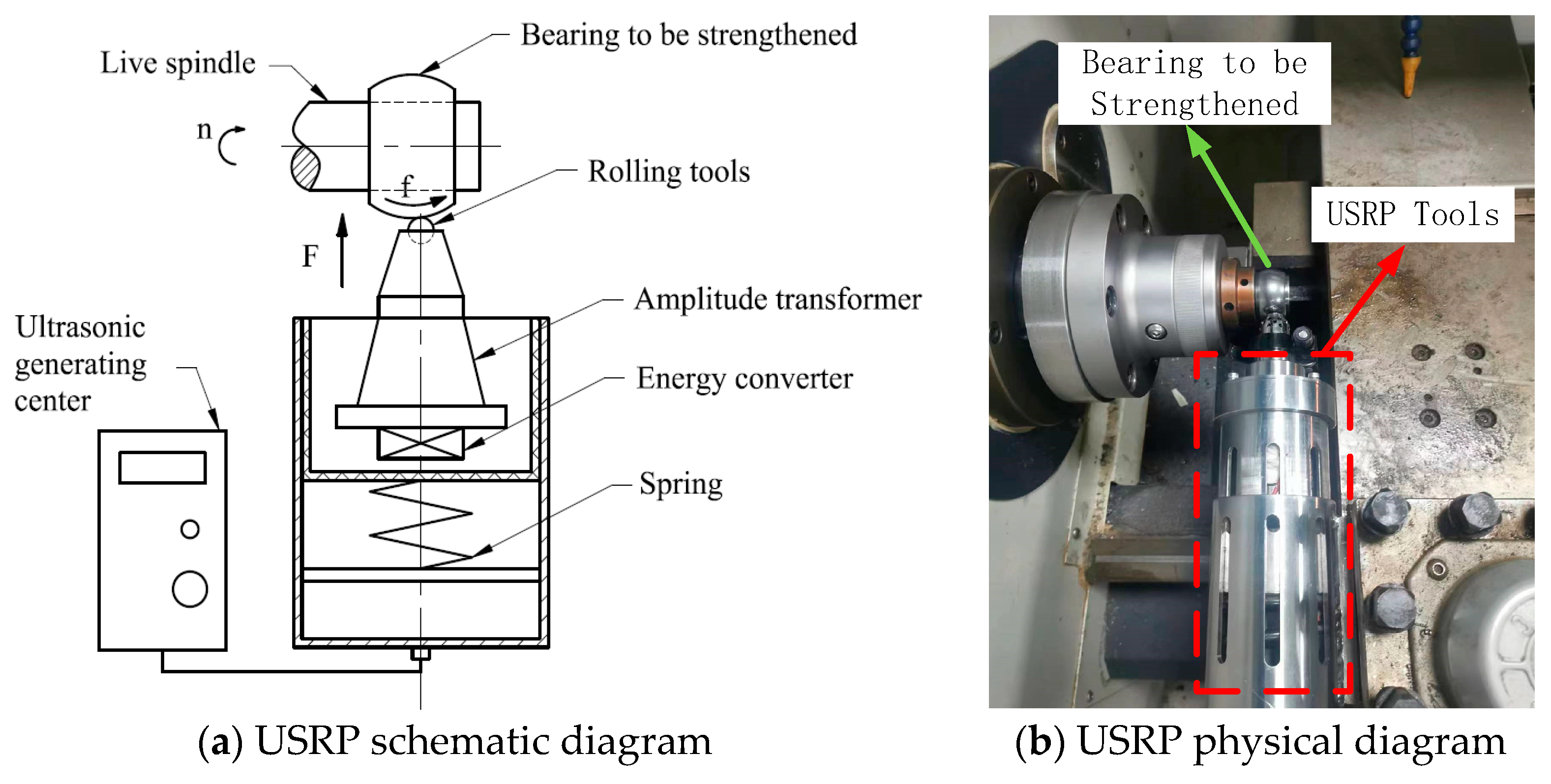

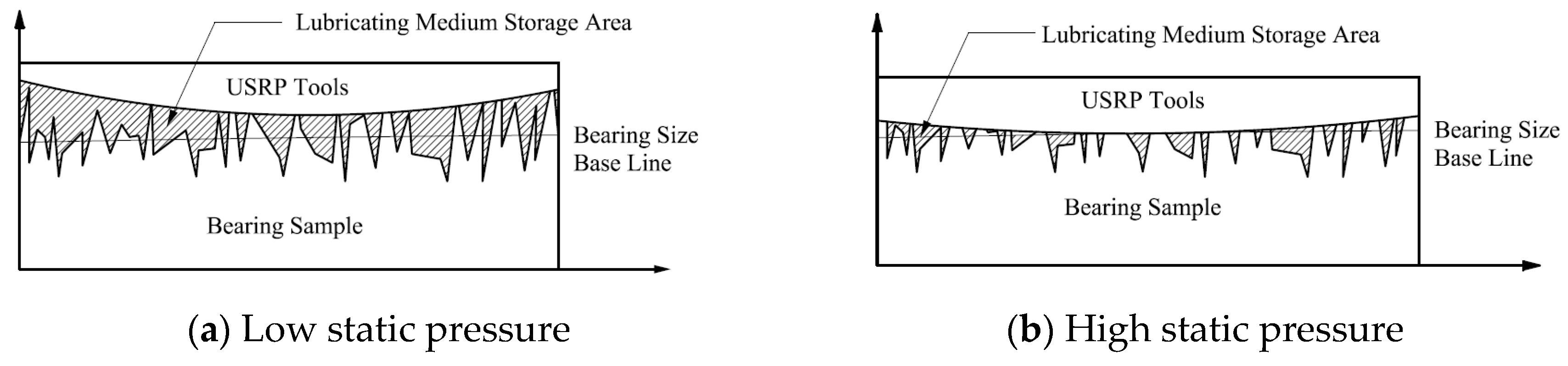

2.2. USRP Test

2.3. Characterization and Wear Tests

3. Results and Discussion

3.1. Strengthening Effect of Ultrasonic Rolling on Surface

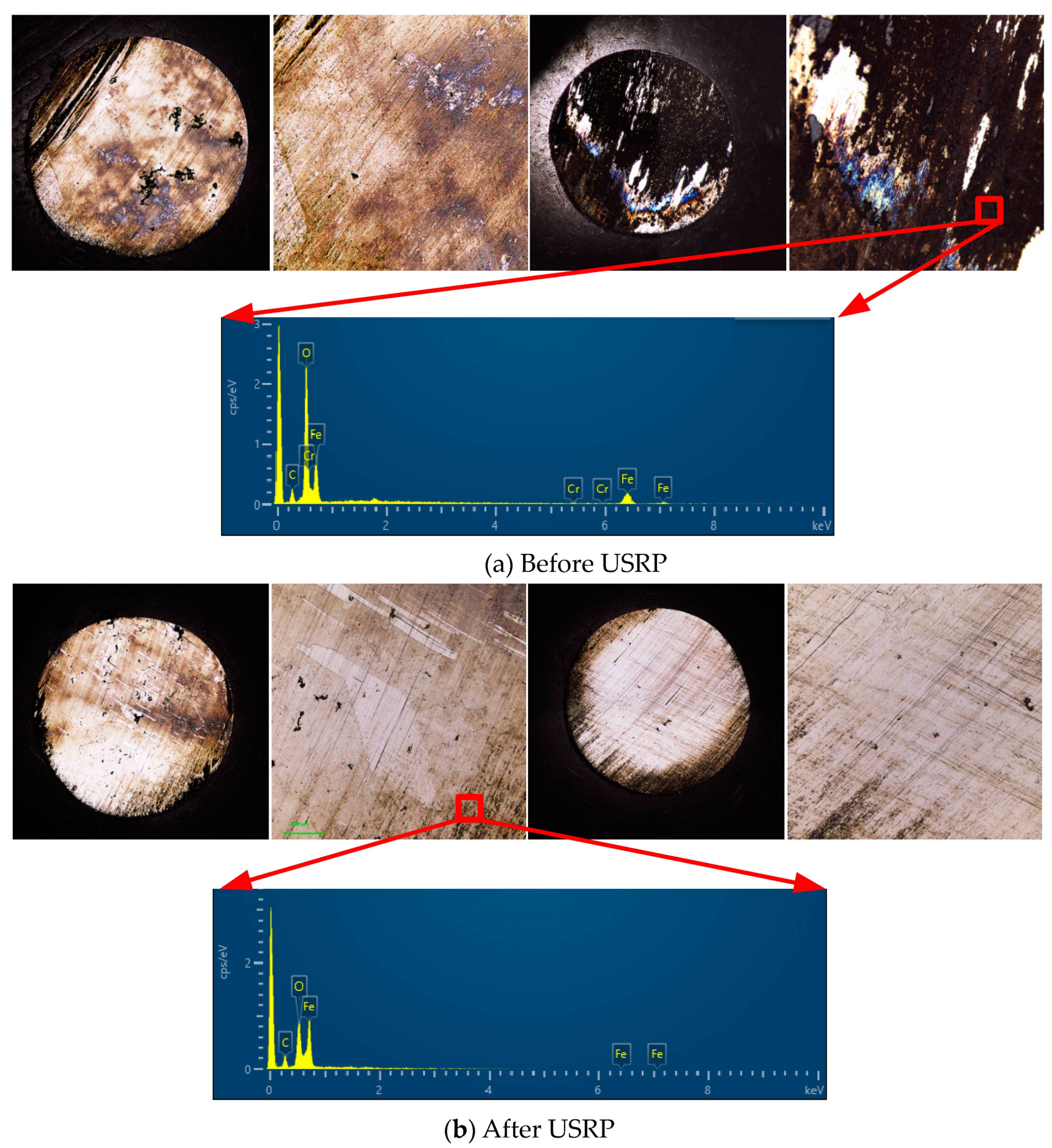

3.1.1. Surface Morphology

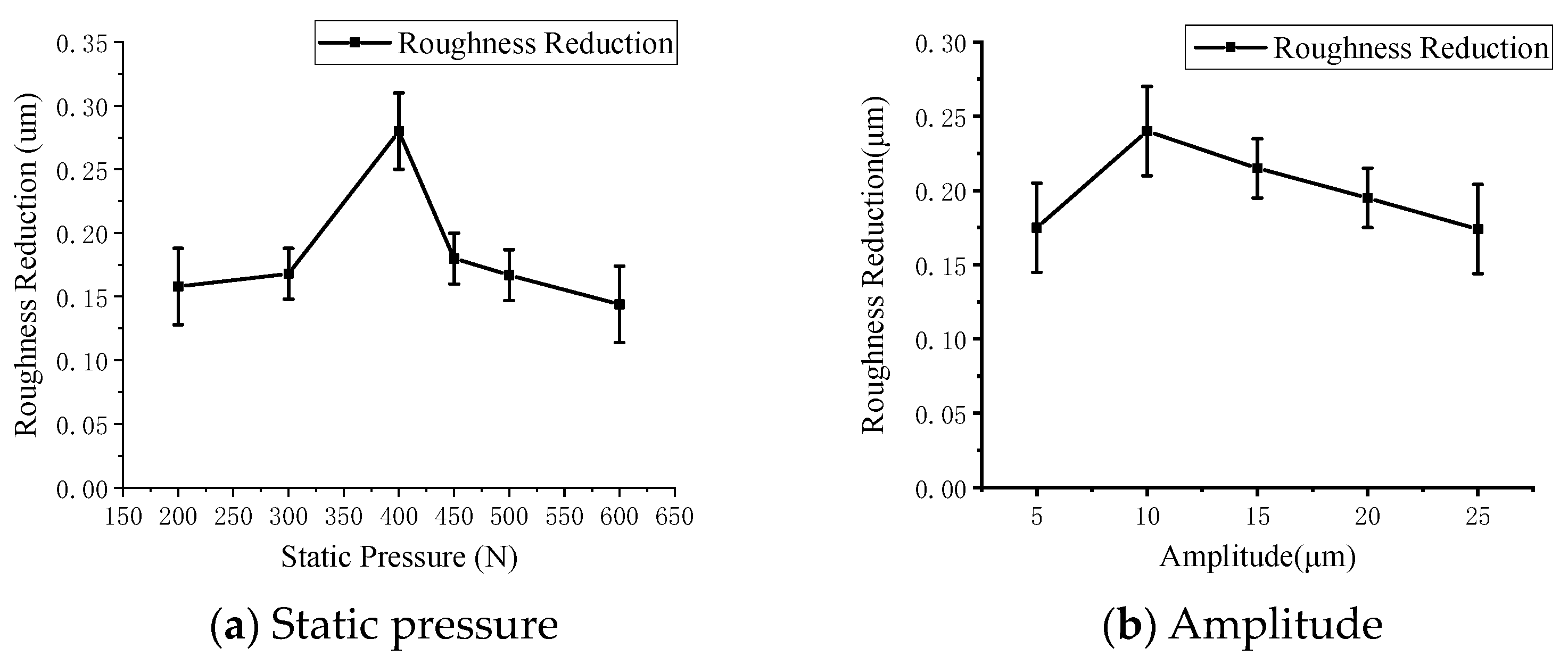

3.1.2. Effect of USRP Parameters on Surface Roughness Reduction

3.2. Effect of Ultrasonic Rolling on Surface Hardness

3.3. Effect of Ultrasonic Rolling on Bearing Wear Resistance

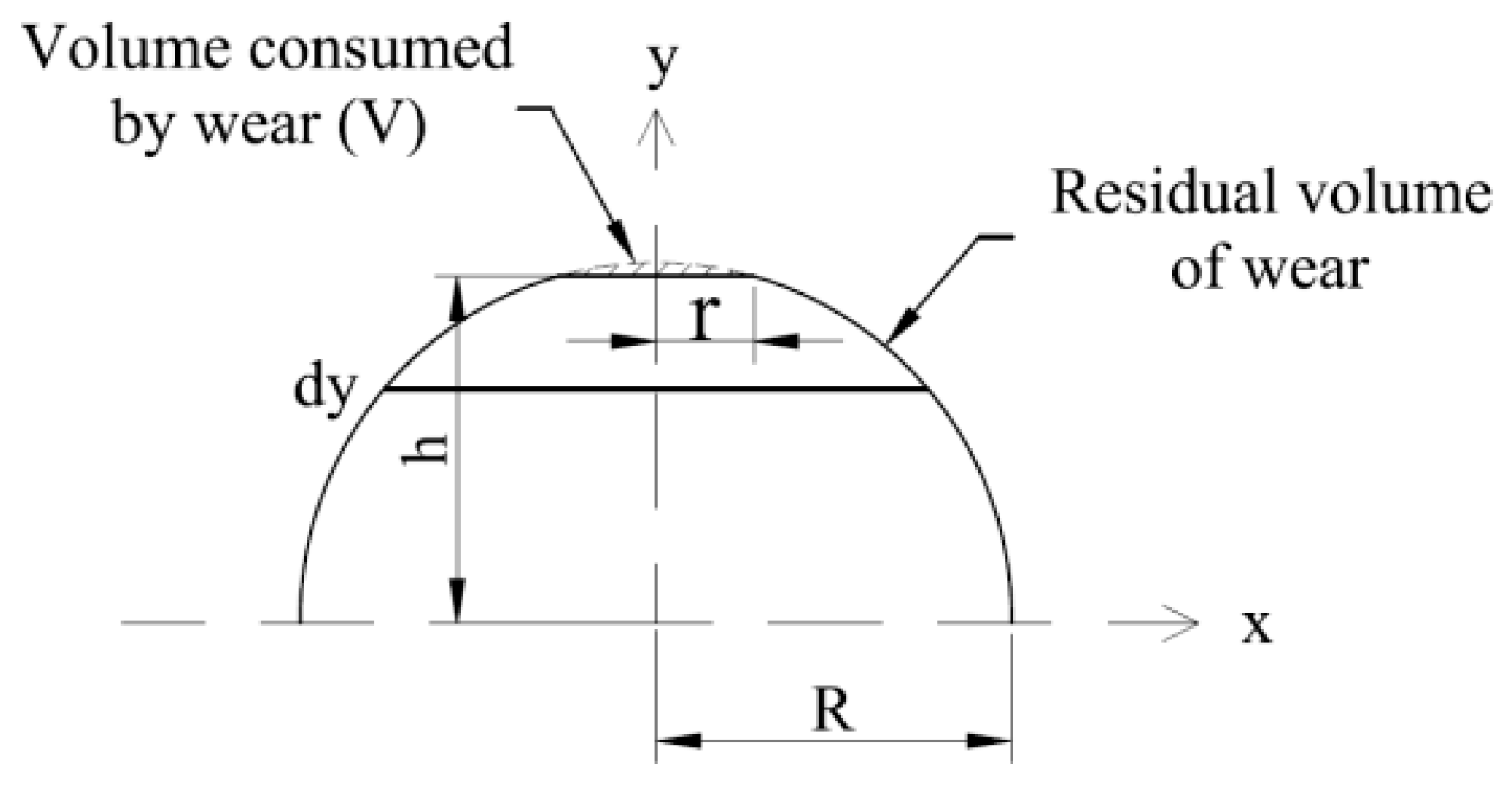

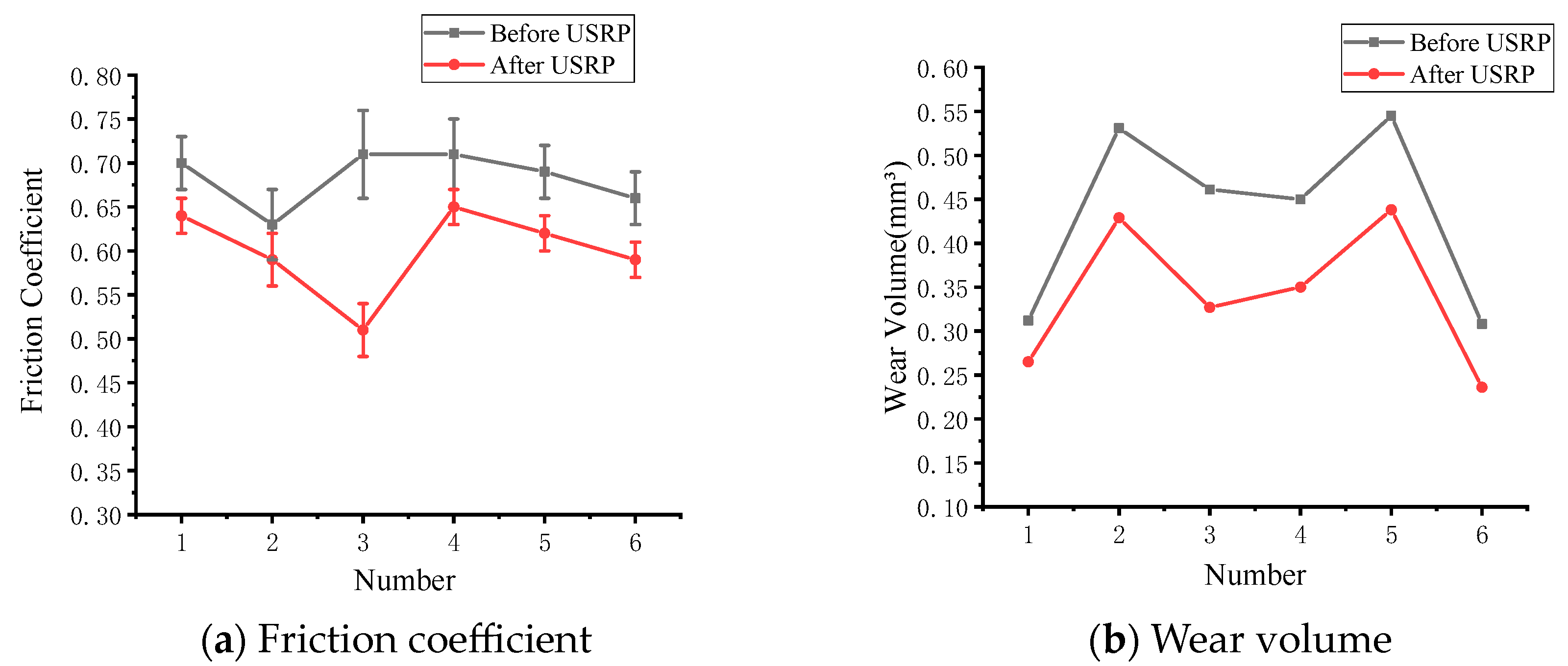

3.3.1. Friction and Wear Test

3.3.2. Analysis of Wear Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.; Wang, Y.; Lin, J.; Xu, S.; Zhang, P. Research status of the influence of machining processes and surface modification technology on the surface integrity of bearing steel materials. Int. J. Adv. Manuf. Technol. 2023, 125, 2897–2923. [Google Scholar] [CrossRef]

- Han, J.; Wang, C.; Song, Y.; Liu, Z.; Sun, J.; Zhao, J. Simultaneously improving mechanical properties and corrosion resistance of as-cast AZ91 Mg alloy by ultrasonic surface rolling. Int. J. Miner. Metall. Mater. 2022, 29, 1551–1558. [Google Scholar] [CrossRef]

- Shahsavar, S.; Ketabchi, M.; Bagherzadeh, S. Fabrication of robust aluminum–carbon nanotube composites using ultrasonic assembly and rolling process. Int. J. Miner. Metall. Mater. 2021, 28, 160–167. [Google Scholar] [CrossRef]

- Liu, C.; Liu, D.; Zhang, X.; He, G.; Xu, X.; Ao, N.; Ma, A.; Liu, D. On the influence of ultrasonic surface rolling process on surface integrity and fatigue performance of Ti-6Al-4V alloy. Surf. Coat. Technol. 2019, 370, 24–34. [Google Scholar] [CrossRef]

- Yin, M.; Yin, H.; Zhang, Q.; Long, J. Effect of ultrasonic surface rolling process on the high temperature fretting wear behavior of Inconel 690 alloy. Wear 2022, 500, 204347. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M.; Andrew, S.S.K. A study on ultrasonic vibration cutting of low alloy steel. J. Mater. Process. Technol. 2007, 192, 159–165. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Tian, Y.; Ling, Y. Study on microstructure of 42CrMo steel by ultrasonic surface rolling process. Sci. Rep. 2023, 13, 21289. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Sun, Y.; Chen, L.; Chang, G.; Deng, G. Effect of ultrasonic surface rolling process on microstructure and properties of rolled Mg-Y-Nd-Zr alloy. J. Mater. Sci. 2023, 58, 9362–9381. [Google Scholar] [CrossRef]

- Zhou, Z.; Yao, C.F.; Tan, L.; Zhang, Y.; Fan, Y. Experimental study on surface integrity refactoring changes of Ti-17 under milling-ultrasonic rolling composite process. Adv. Manuf. 2023, 11, 492–508. [Google Scholar] [CrossRef]

- Su, C.J.; Xu, T.T.; Zhang, K.; Zhang, K.; Lou, S.M.; Wang, Q. Plastic deformation of magnesium alloy with different forming parameters during ultrasonic vibration-assisted single-point incremental forming. Rare Met. 2022, 41, 3878–3886. [Google Scholar] [CrossRef]

- Minghuan, W.; Shang, Y.; Changshun, L.; Jiajie, W.; Zheng, J.; Xufeng, X. 3D multiphysic simulations of energy field and material process in radial ultraso-nic rolling electrochemical micromachining. Chin. J. Aeronaut. 2022, 35, 494–508. [Google Scholar]

- Li, Y.; Geng, J.; Wang, Z.; Song, C.; Zhang, C.; Chen, D.; Wang, H. Influence of surface integrity on the fatigue performance of TiB2/Al composite treated byultrasonic deep rolling: Experime-nts and sim-ulations. Compos. Part B Eng. 2024, 271, 111160. [Google Scholar] [CrossRef]

- Yuan, Z.; Qin, Y.; Deng, C.; Zheng, P. Synergistic effects of surface strengthening and surface micro-texture on aviation spherical plain bearing tribological properties. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 797–808. [Google Scholar] [CrossRef]

- Yuan, Z.; Qin, Y.; Cheng, K.; Zhao, W.; Zheng, P. Investigation on surface morphology and tribological property generated by vibration assisted strengthening on aviation spherical plain bearings. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4091–4101. [Google Scholar] [CrossRef]

- Bae, K.C.; Kim, D.; Kim, Y.H.; Oak, J.J.; Lee, H.; Lee, W.; Park, Y.H. Effect of heat treatment, building direction, and sliding velocity on wear behavior of selectively laser-melted maraging 18Ni-300 steel against bearing steel. Wear 2021, 482, 203962. [Google Scholar]

- Meng, Y.; Deng, J.; Zhang, Y.; Wang, S.; Li, X.; Yue, H.; Ge, D. Tribological properties of textured surfaces fabricated on AISI 1045 steels by ultrasonic surface rolling under dry reciprocating sliding. Wear 2020, 460, 203488. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, H.; Liu, Y.; Zhao, X. Comprehensive Analysis of the Effect of Ultrasonic Surface Rolling Process on the Friction and Wear Properties of TB8 Titanium Alloy. J. Mater. Eng. Perform. 2023, 32, 9448–9459. [Google Scholar] [CrossRef]

- Ye, H.; Chen, A.; Liu, S.; Zhang, C.; Gao, Y.; Li, Q.; Lv, J.; Chen, J.; Guo, H. Effect of ultrasonic surface rolling process on the surface properties of QAl10-3-1.5 aluminum bronze alloy. Surf. Coat. Technol. 2022, 433, 128126. [Google Scholar] [CrossRef]

- Duan, Y.; Qu, S.; Jia, S.; Li, X. Effects of ultrasonic surface rolling processing on microstructure and wear properties of high-carbon high-chromium steel. Surf. Coat. Technol. 2021, 422, 127531. [Google Scholar] [CrossRef]

- Meigui, Y.; Haiyan, Y.; Jiangqi, L. Effect of ultrasonic surface rolling process on the impact wear behavior of Inconel 690 alloy at 25 °C and 300 °C. Surf. Topogr. Metrol. Prop. 2022, 10, 025022. [Google Scholar]

- Yin, M.; Zhang, L.; Huang, L.; Zhang, X. Effect of ultrasonic surface rolling process on the fretting tribocorrosion behaviors of Inconel 690 alloy. Tribol. Int. 2023, 184, 108451. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Zhang, Y.; Liu, L.; Xu, G.; Wang, G.; Zhao, M. Wear resistance enhancement of Inconel 718 via high-speed ultrasonic vibration cutting and associated surface integrity evaluation under high-pressure coolant supply. Wear 2023, 530, 205027. [Google Scholar] [CrossRef]

- Djalab, A.; Sari, M.R.; Haiahem, A.; Flamand, L. Mathematical modeling and statistical analysis of wear and surface roughness in contaminated dry rolling contacts. J. Balk. Tribol. Assoc. 2016, 22 Pt 3, 4593–4617. [Google Scholar]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Dang, J.; Zhang, H.; An, Q.; Lian, G.; Li, Y.; Wang, H.; Chen, M. Surface integrity and wear behavior of 300M steel subjected to ultrasonic surface rolling process. Surf. Coat. Technol. 2021, 421, 127380. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Guan, S.; Wang, F. Study on the tensile and fatigue properties of the heat-treated HIP Ti-6Al-4V alloy after ultrasonic surface rolling treatment. Surf. Coat. Technol. 2019, 379, 124971. [Google Scholar] [CrossRef]

| Ingredient | C | Mn | Si | S | P | Cr |

| Proportion (wt%) | 0.95~1.05 | 0.20~0.40 | 0.15~0.35 | ≤0.02 | ≤0.027 | 1.30~1.65 |

| USRP Parameters | Parameter Value | |||||

|---|---|---|---|---|---|---|

| Amplitude (μm) | 5 | 10 | 15 | 20 | 25 | / |

| Static pressure (N) | 200 | 300 | 400 | 450 | 500 | 600 |

| Before (wt.%) | After (wt.%) | |

|---|---|---|

| Fe | 71.7 | 85.1 |

| O | 28.3 | 14.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Yang, X.; Ma, X.; Jin, D.; You, J. Effect of Ultrasonic Rolling on Surface Properties of GCr15 Spherical Joint Bearing. Lubricants 2024, 12, 208. https://doi.org/10.3390/lubricants12060208

Zhang H, Yang X, Ma X, Jin D, You J. Effect of Ultrasonic Rolling on Surface Properties of GCr15 Spherical Joint Bearing. Lubricants. 2024; 12(6):208. https://doi.org/10.3390/lubricants12060208

Chicago/Turabian StyleZhang, Hao, Xiuli Yang, Xiqiang Ma, Dongliang Jin, and Jinyuan You. 2024. "Effect of Ultrasonic Rolling on Surface Properties of GCr15 Spherical Joint Bearing" Lubricants 12, no. 6: 208. https://doi.org/10.3390/lubricants12060208

APA StyleZhang, H., Yang, X., Ma, X., Jin, D., & You, J. (2024). Effect of Ultrasonic Rolling on Surface Properties of GCr15 Spherical Joint Bearing. Lubricants, 12(6), 208. https://doi.org/10.3390/lubricants12060208