Evaluation of the Degree of Degradation of Brake Pad Friction Surfaces Using Image Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials of the Pulley and Friction Pads

- Asbestos: Chemical composition: CaMg3Si4O12, or CaO·3MgO·4SiO2. Insoluble in water, but destroyed by strong acids.

- Barite: Chemical composition: Ba[SO4]. Contains % BaO—65.7; SO3—34.3. Ca, Sr, Pb and Ra are present as impurities.

- Resin: Phenol–formaldehyde resins [–C6H3(OH)–CH2–]n are a type of condensation resins, products of polycondensation of phenol C6H5OH with formaldehyde CH2 = O in an alkaline environment, with a molecular weight of 400–1000, which can harden under the action of acids or under heating time.

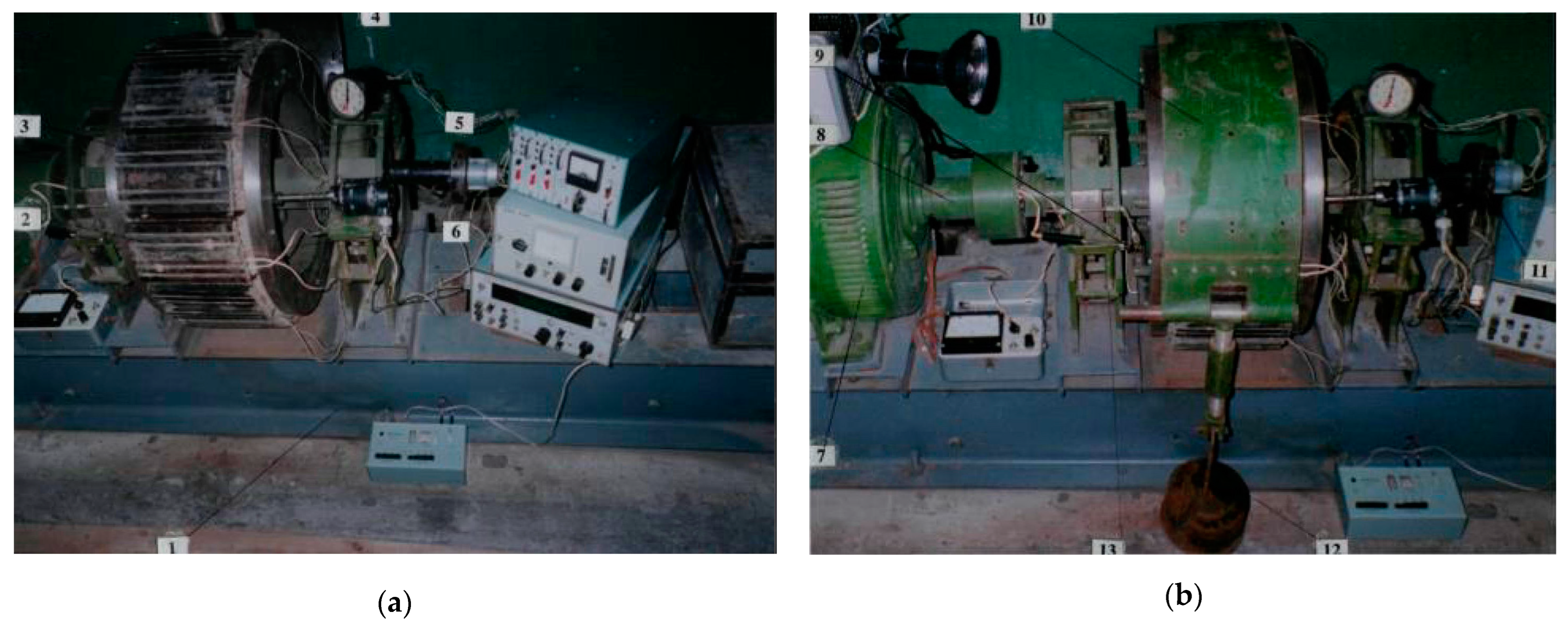

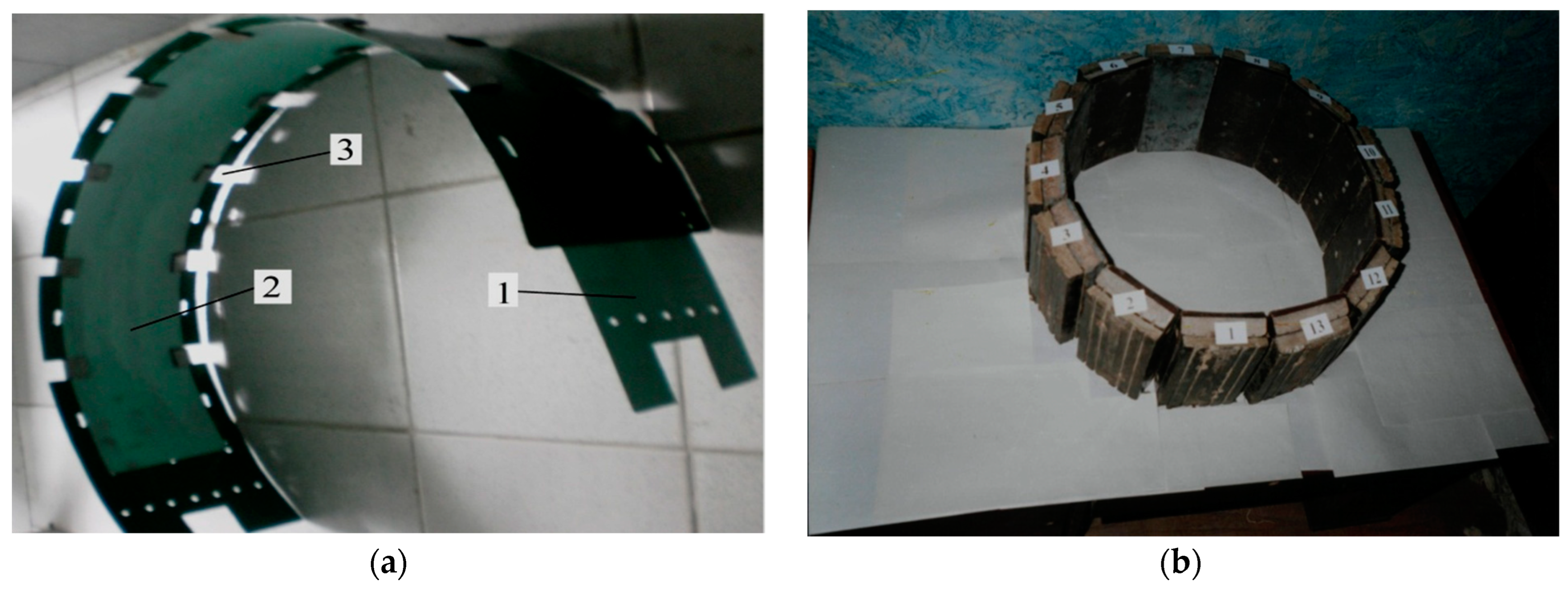

2.2. Workbench for Experimental Research on Band Brakes

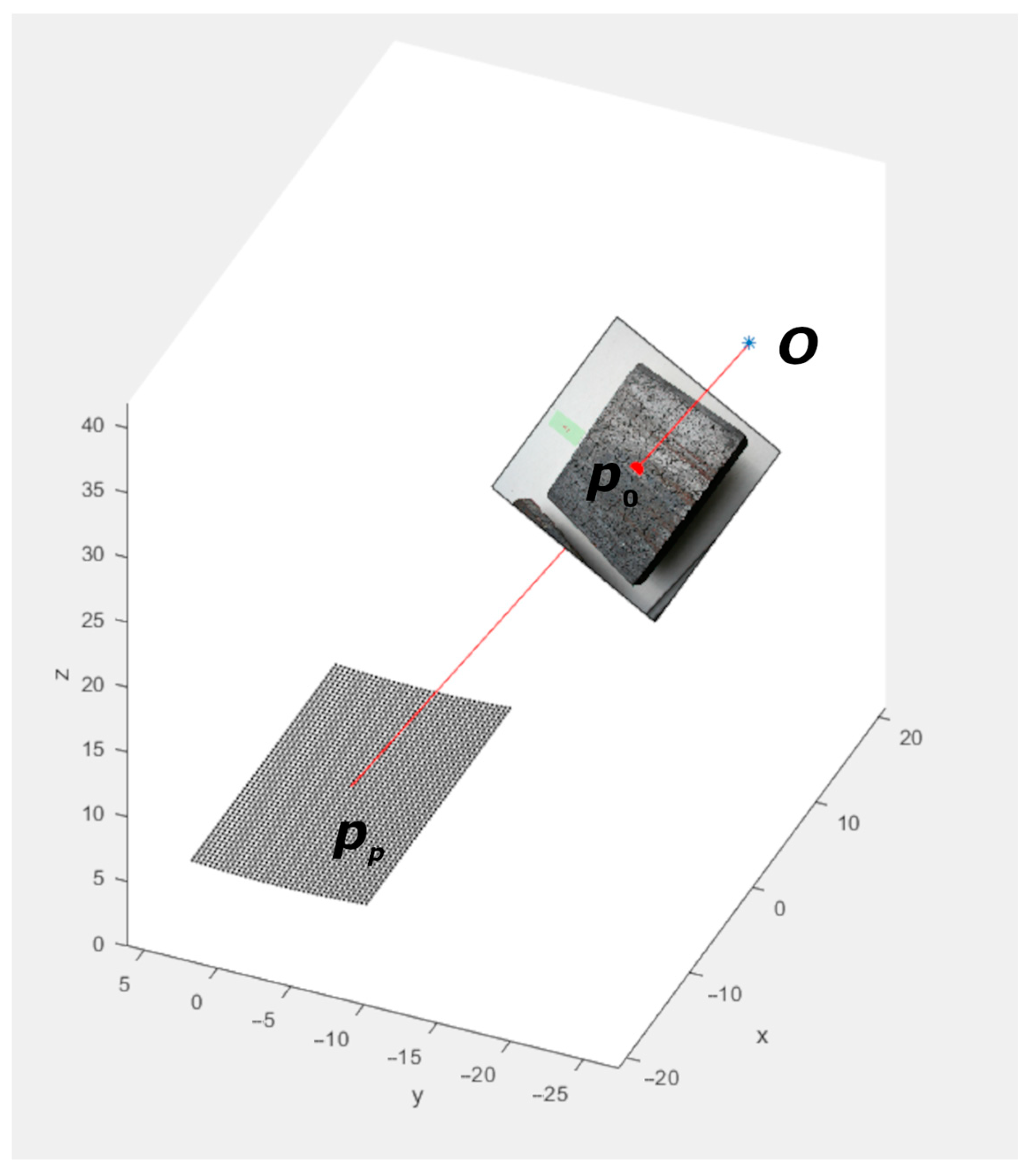

2.3. Image Acquisition and Geometric Transformation

2.4. Image Processing

- ₋

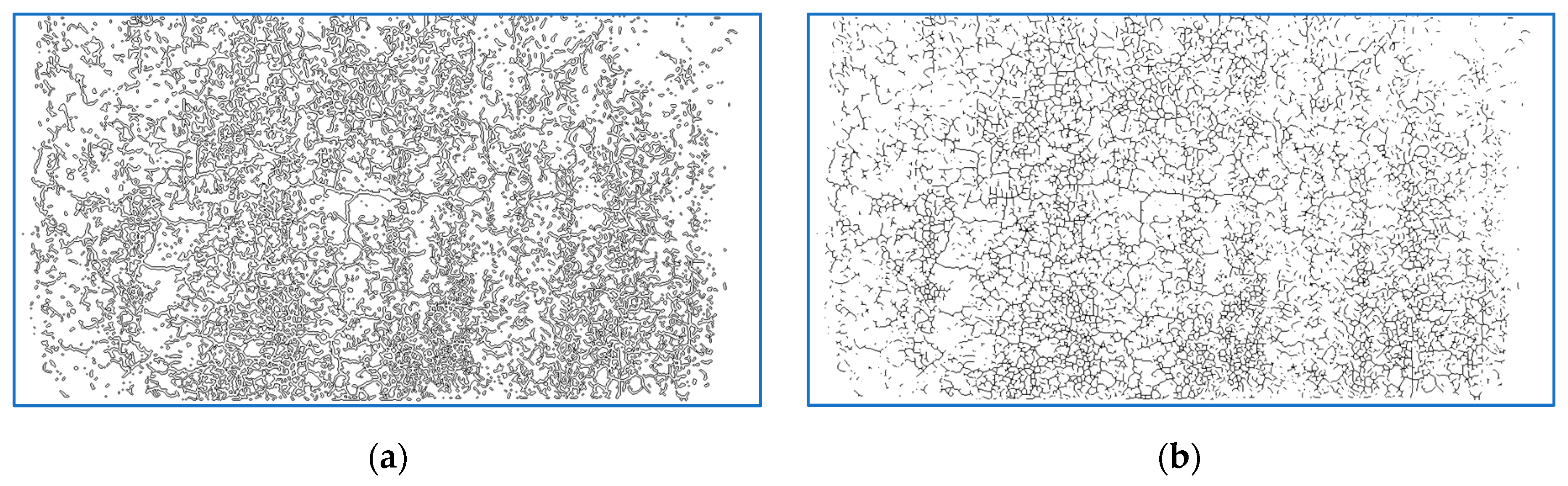

- The ratio of the area of segmented cracks to the total area

- ₋

- The ratio of the perimeter of segmented cracks to the total area

- ₋

- The ratio of the skeletonized cracks to the total area

3. Results and Discussion

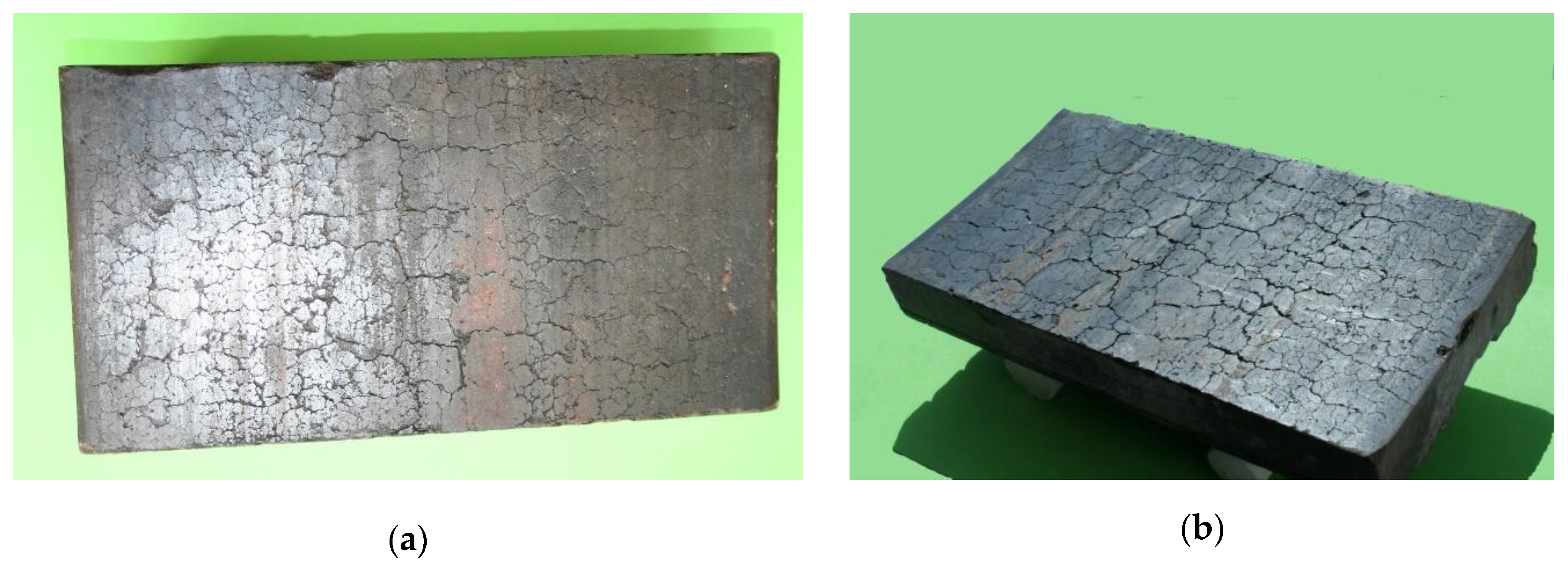

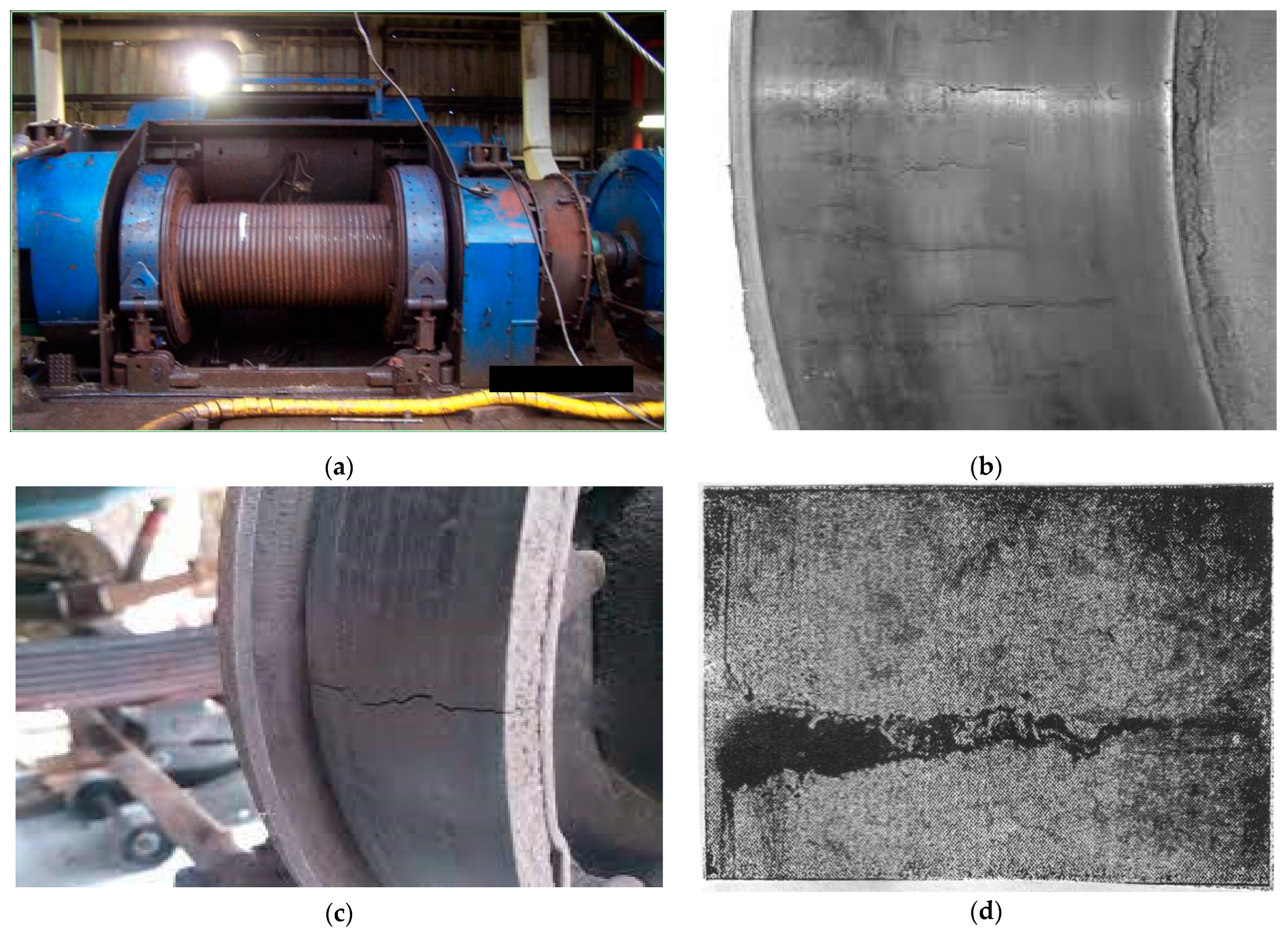

3.1. Study of the Drilling Drawwork Brake Wear

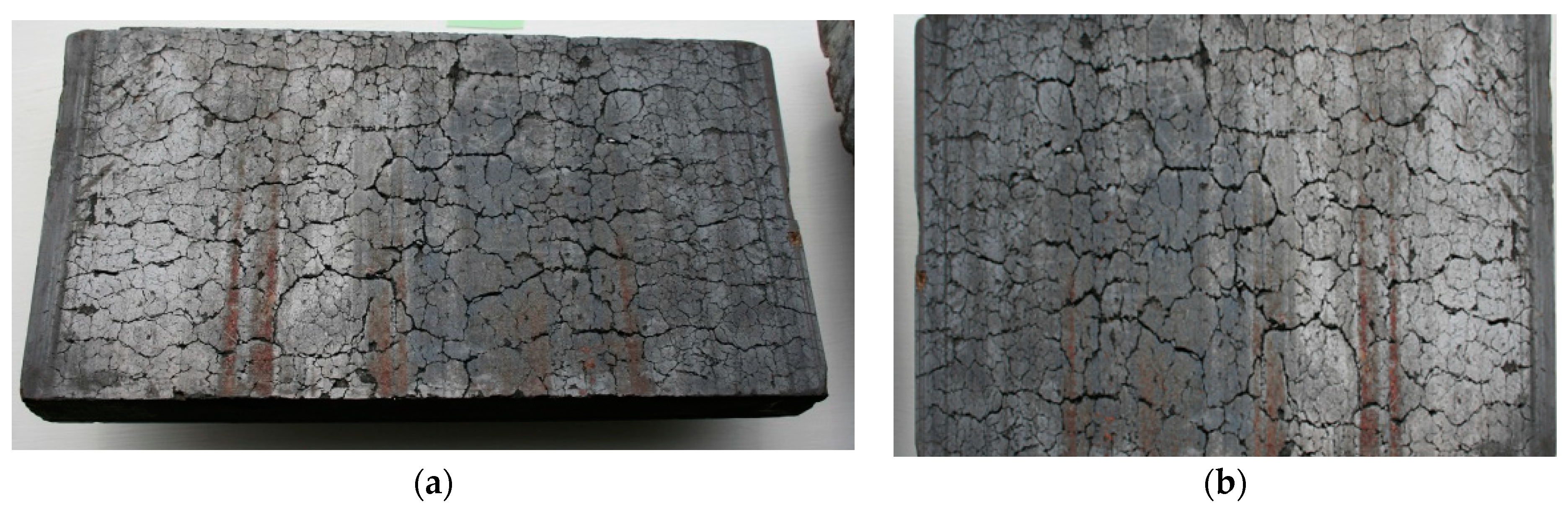

3.2. Results of Image Processing of the Worn Surface

4. Conclusions

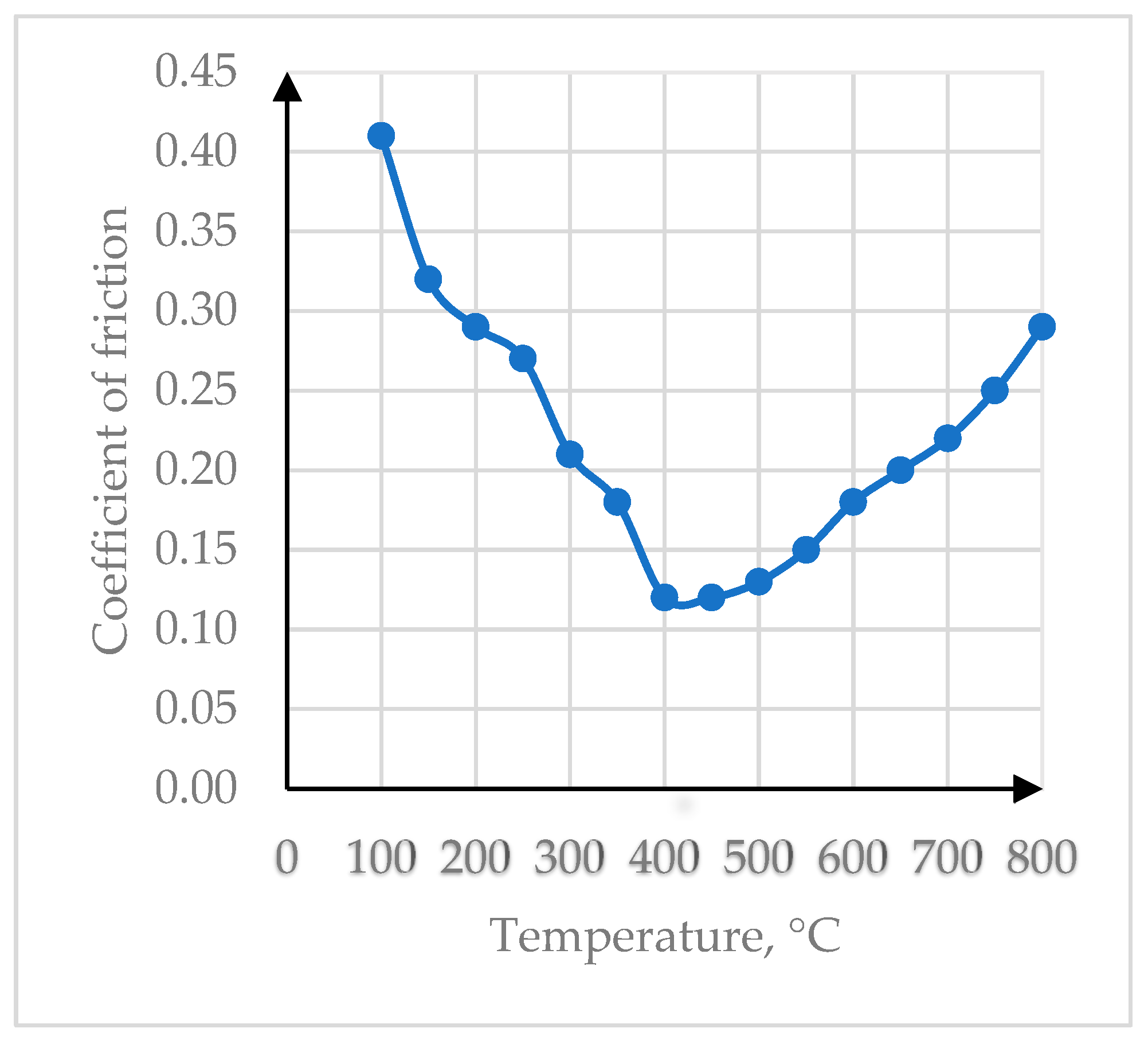

- The minimum value of the coefficient of friction (0.12) for band brakes equipped with retinax pads is achieved at temperatures on the friction surface of 400–470 °C. At this temperature, the decomposition products of the bond (phenol–formaldehyde resin) act as an effective solid lubricant;

- Thermal fatigue cracks appear on the working surface of the brake metal pulleys, which are directed along its longitudinal axis and do not cross each other;

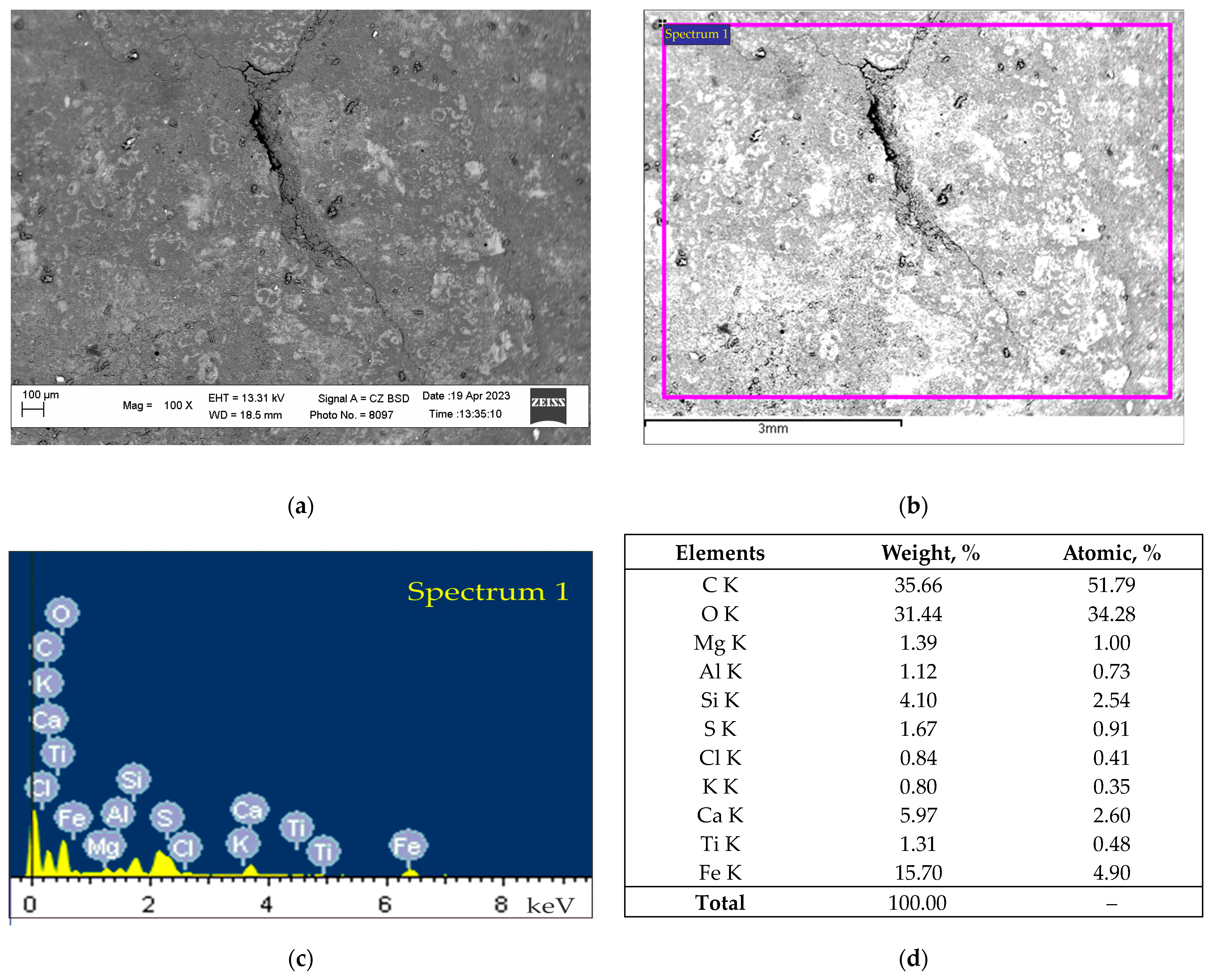

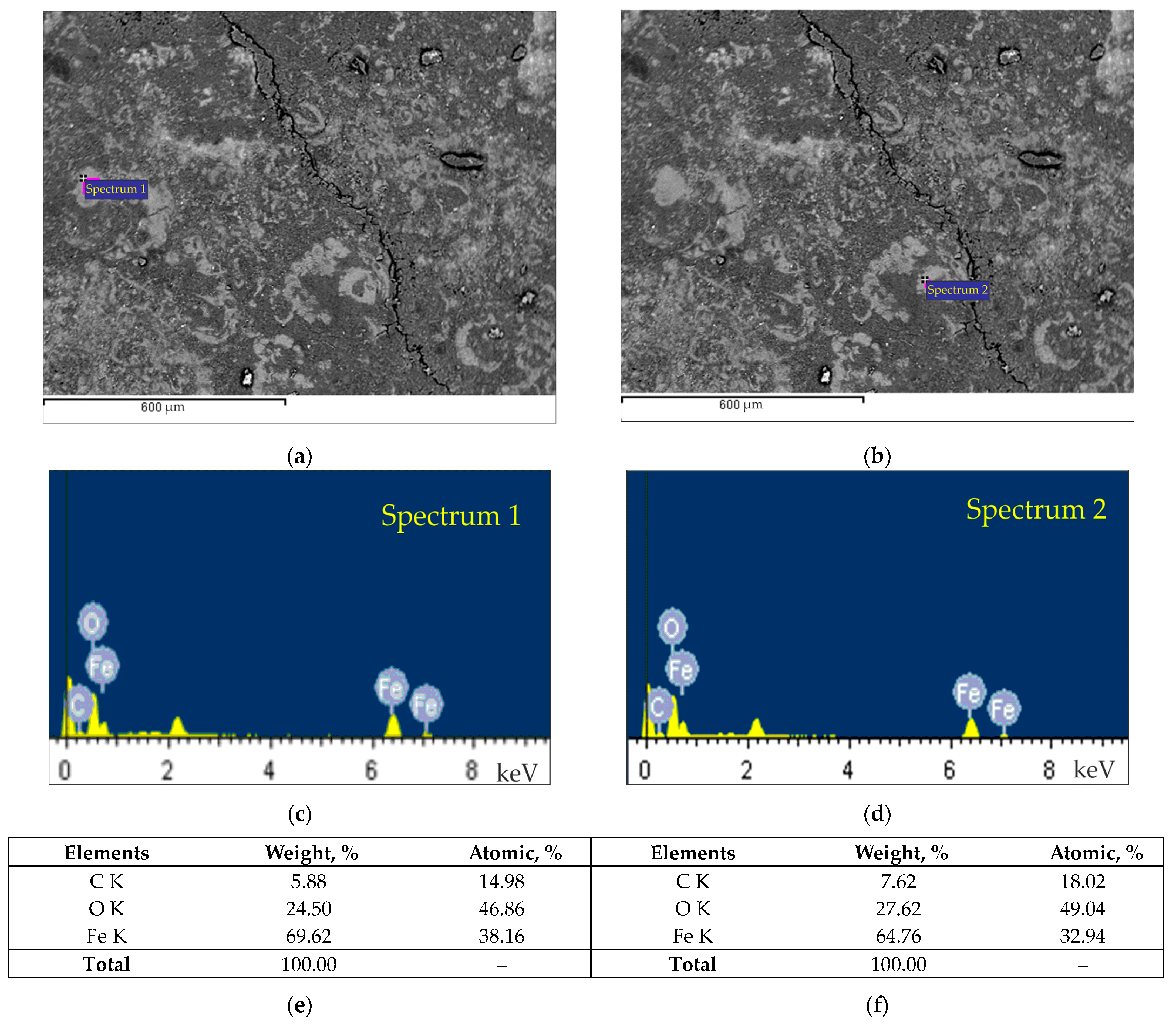

- Thermal fatigue cracks are formed on the worn working surface of non-metallic friction pads, which cross each other, forming separate islands, which is associated with both thermal destruction and shrinkage of the retinax. An uneven distribution of iron at different distances from the crack was revealed;

- A method for estimation of the degree of the degradation of the brake pad based on processing of their surface images was developed. This method consists of acquisition of a suitable input image taken from particular angle that allows us to avoid glares, mapping of the obtained image on the surface of a cylinder to cope with perspective distortion which appears due to the angle of view, application of the scale-space theory for crack detection with further contour detection and skeletonization and finding the integral characteristics of the brake pad surface which reflect the intensity with which the brake pad was operated. It was shown that such characteristics as the ratio of the area of segmented cracks to the total area, the ratio of the perimeter of segmented cracks to the total area and the ratio of the skeletonized cracks to the total area are good indicators of the degree of brake pad degradation during operation;

- The proposed taxonomy of images can be used both during the development of component compositions of new friction materials for brake pads, and during research into the performance of commercial materials during the justification of rational choices in the operating modes of brakes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrusiv, U.; Zelinska, H.; Galtsova, O.; Kupalova, H.; Goncharenk, N. The modeling and forecasting of fuel and energy resources usage in the context of the energy independence of Ukraine. Polityka Energetyczna 2021, 24, 29–47. [Google Scholar] [CrossRef]

- Kondrat, O.; Lukin, O.; Smolovyk, L. Analysis of possibilities to increase oil recovery with the use of nitrogen in the context of deep oil deposits of the dnipro-donetsk oil-and-gas Ukrainian province. Min. Miner. Depos. 2019, 13, 107–113. [Google Scholar] [CrossRef]

- Adeosun, O.; Anagreh, S.; Tabash, M.; Adedokun, A. Revisiting the connectedness between oil prices and uncertainty indicators in BRICS countries. Resour. Policy 2023, 86, 104278. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. A Review of Modern Approaches of Digitalization in Oil and Gas Industry. Upstream Oil Gas. Technol. 2023, 11, 100098. [Google Scholar] [CrossRef]

- Zang, C.; Lu, Z.; Ye, S.; Xu, X.; Xi, C.; Song, X.; Guo, Y.; Pan, T. Drilling Parameters Optimization for Horizontal Wells Based on a Multiobjective Genetic Algorithm to Improve the Rate of Penetration and Reduce Drill String Drag. Appl. Sci. 2022, 12, 11704. [Google Scholar] [CrossRef]

- Chen, X.; Du, X.; Weng, C.; Yang, J.; Gao, D.; Su, D.; Wang, G. A real-time drilling parameters optimization method for offshore large-scale cluster extended reach drilling based on intelligent optimization algorithm and machine learning. Ocean Eng. 2024, 291, 116375. [Google Scholar] [CrossRef]

- Bembenek, M.; Grydzhuk, Y.; Gajdzik, B.; Ropyak, L.; Pashechko, M.; Slabyi, O.; Al-Tanakchi, A.; Pryhorovska, T. An Analytical–Numerical Model for Determining “Drill String–Wellbore” Frictional Interaction Forces. Energies 2024, 17, 301. [Google Scholar] [CrossRef]

- Peng, S.; Huang, Z.; Wang, M.; Xiong, C.; Chen, K. Study on the Influence of Surface Texture Parameters of Oil Production Screw Motor Rotor on the Tribological Properties of Its Friction Pair. Processes 2023, 11, 618. [Google Scholar] [CrossRef]

- Shats’kyi, I.P.; Shopa, V.M.; Velychkovych, A.S. Development of full-strength elastic element section with open shell. Strength Mater. 2021, 53, 277–282. [Google Scholar] [CrossRef]

- Prysyazhnyuk, P.; Molenda, M.; Romanyshyn, T.; Ropyak, L.; Romanyshyn, L.; Vytvytskyi, V. Development of a hardbanding material for drill pipes based on high-manganese steel reinforced with complex carbides. Acta Montan. Slovaca 2022, 27, 685–696. [Google Scholar] [CrossRef]

- Ropyak, L.; Shihab, T.; Velychkovych, A.; Bilinskyi, V.; Malinin, V.; Romaniv, M. Optimization of Plasma Electrolytic Oxidation Technological Parameters of Deformed Aluminum Alloy D16T in Flowing Electrolyte. Ceramics 2023, 6, 146–167. [Google Scholar] [CrossRef]

- Kotsyubynsky, V.; Shyyko, L.; Shihab, T.; Prysyazhnyuk, P.; Aulin, V.; Boichuk, V. Multilayered MoS2/C nanospheres as high performance additives to lubricating oils. Mater. Today Proc. 2019, 35, 538–541. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Antoszewski, B.; Tarelnyk, V.B.; Kurp, P.; Myslyvchenko, O.M.; Tarelnyk, N.V. Analysis of the quality of sulfomolybdenum coatings obtained by electrospark alloying methods. Materials 2021, 14, 6332. [Google Scholar] [CrossRef] [PubMed]

- Drach, I.; Goroshko, A.; Dwornicka, R. Design Principles of Horizontal Drum Machines with Low Vibration. Adv. Sci. Technol. Res. J. 2021, 15, 258–268. [Google Scholar] [CrossRef] [PubMed]

- Royzman, V.; Drach, I.; Bubulis, A. Movement of Working Fluid in the Field of Centrifugal Forcesand Forcesof Weight. In Proceedings of the 21st International Scientific Conference, Kaunas, Lithuania, 12–13 May 2016; pp. 222–224. [Google Scholar]

- Velichkovich, A.S.; Dalyak, T.M. Assessment of stressed state and performance characteristics of jacketed spring with a cut for drill shock absorber. Chem. Pet. Eng. 2015, 51, 188–193. [Google Scholar] [CrossRef]

- Moisyshyn, V.M.; Slabyi, O.O. Creation of the vibroprotective device for adjustment of dynamics of a column of steel drill pipes and a bit. Металлофизика И Новейшие Технологии 2018, 40, 541–550. [Google Scholar] [CrossRef][Green Version]

- Dutkiewicz, M.; Velychkovych, A.; Shatskyi, I.; Shopa, V. Efficient Model of the Interaction of Elastomeric Filler with an Open Shell and a Chrome-Plated Shaft in a Dry Friction Damper. Materials 2022, 15, 4671. [Google Scholar] [CrossRef]

- Wang, C.; Chen, W.; Wu, Z.; Li, J.; Liu, G. Stick–Slip Characteristics of Drill Strings and the Related Drilling Parameters Optimization. Processes 2023, 11, 2783. [Google Scholar] [CrossRef]

- Pryhorovska, T.O.; Chaplinskiy, S.S.; Kudriavtsev, I.O. Finite element modelling of rock mass cutting by cutters for PDC drill bits. Shiyou Kantan Yu Kaifa/Pet. Explor. Dev. 2015, 42, 812–816. [Google Scholar] [CrossRef]

- Chudyk, I.I.; Femiak, Y.M.; Orynchak, M.I.; Sudakov, A.K.; Riznychuk, A.I. New methods for preventing crumbling and collapse of the borehole walls. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 2021, 17–22. [Google Scholar] [CrossRef]

- Moisyshyn, V.; Voyevidko, I.; Tokaruk, V. Design of bottom hole assemblies with two rock cutting tools for drilling wells of large diameter. Min. Miner. Depos. 2020, 14, 128–133. [Google Scholar] [CrossRef]

- Grydzhuk, J.; Chudyk, I.; Velychkovych, A.; Andrusyak, A. Analytical estimation of inertial properties of the curved rotating section in a drill string. East. Eur. J. Enterp. Technol. 2019, 1, 6–14. [Google Scholar] [CrossRef]

- Goryk, O.; Buchynskyi, A.; Romanyshyn, L.; Nurkusheva, S.; Bembenek, M. Evaluation of the State of Innovative Activity of Machine-Building Enterprise. Manag. Syst. Prod. Eng. 2024, 32, 1–11. [Google Scholar] [CrossRef]

- Pavković, D.; Cipek, M.; Krznar, M.; Benić, J. A retrofitting control system design suitable for deep borehole drilling using legacy draw-works mechanical brake hardware. Energy Convers. Manag. 2022, 260, 115589. [Google Scholar] [CrossRef]

- Seo, H.; Lee, D.G.; Park, J.; Song, W.; Lee, J.J.; Sohn, S.S.; Jang, H. Quench hardening effect of gray iron brake discs on particulate matter emission. Wear 2023, 523, 204781. [Google Scholar] [CrossRef]

- Barros, L.; Poletto, J.; Buneder, D.; Neis, P.; Ferreira, N.; Pavlak, R.; Matozo, L. Effect of pressure in the transition between moderate and severe wear regimes in brake friction materials. Wear 2019, 438–439, 203112. [Google Scholar] [CrossRef]

- Yanar, H.; Purcek, G.; Ayar, H.H. Effect of steel fiber addition on the mechanical and tribological behavior of the composite brake pad materials. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 012018. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wei, D.; Wu, P.; Cao, J.; Shijia, C.; Qu, X. A high-performance copper-based brake pad for high-speed railway trains and its surface substance evolution and wear mechanism at high temperature. Wear 2020, 444–445, 203182. [Google Scholar] [CrossRef]

- Tatsii, R.M.; Stasyuk, M.F.; Pazen, O.Y. Direct Method of Calculating Nonstationary Temperature Fields in Bodies of Basic Geometric Shapes. J. Eng. Phys. Thermophys. 2021, 94, 298–310. [Google Scholar] [CrossRef]

- Tatsiy, R.M.; Pazen, O.Y.; Vovk, S.Y.; Kharyshyn, D.V. Direct method of studying heat exchange in multilayered bodies of basic geometric forms with imperfect heat contact. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 2021, 60–67. [Google Scholar] [CrossRef]

- Malanchuk, N.I.; Slobodyan, B.S.; Martynyak, R.M. Friction sliding of elastic bodies in the presence of subsurface inclusions. Mater. Sci. 2017, 52, 819–826. [Google Scholar] [CrossRef]

- Tatsiy, R.M.; Pazen, O.Y.; Vovk, S.Y.; Kharyshyn, D.V. Simulation of heat transfer process in a multilateral cylindrical shell taking into account the internal heat sources. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2020, 2020, 27–32. [Google Scholar] [CrossRef]

- Belhocine, A.; Wan Omar, W.Z. Computational fluid dynamics (CFD) analysis and numerical aerodynamic investigations of automotive disc brake rotor. Aust. J. Mech. Eng. 2018, 16, 188–205. [Google Scholar] [CrossRef]

- Wang, D.; Wang, R.; Zhang, J. Dynamic brake characteristics of disc brake during emergency braking of the kilometer deep coal mine hoist. Adv. Mech. Eng. 2020, 12, 1–23. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, J.; Liu, Y.; Liu, N.; Sha, Z.; Wang, Y.; Rolfe, B. Thermal–structural coupling analysis of brake friction pair based on the displacement gradient circulation method. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Wang, D.; Wang, R.; Heng, T.; Xie, G.; Zhang, D. Tribo-Brake Characteristics between Brake Disc and Brake Shoe during Emergency Braking of Deep Coal Mine Hoist with the High Speed and Heavy Load. Energies 2020, 13, 5094. [Google Scholar] [CrossRef]

- Wang, C.; Wang, S.; Jin, H.; Huo, H.; Xu, H.; Chen, Z. Thermal-mechanical coupling analysis and optimization of mine hoist brake disc. Adv. Mech. Eng. 2022, 14, 1–13. [Google Scholar] [CrossRef]

- Tsyrul’nyk, О.Т.; Kret, N.V.; Voloshyn, V.A.; Zvirko, O.I. A Procedure of Laboratory Degradation of Structural Steels. Mater. Sci. 2018, 53, 674–683. [Google Scholar] [CrossRef]

- Yusubov, F.F.; Hurey, І.V. Influence of Temperature on the Tribological Properties of Composites for Brake Pads. Mater. Sci. 2021, 57, 221–227. [Google Scholar] [CrossRef]

- Bembenek, M.; Tsyganov, V.; Sakhniuk, N.; Lazarieva, O.; Machnik, R.; Ropyak, L. Tribology Characteristics of Heatproof Alloys at a Dynamic Pin Ladening in the Variable Temperature Field. Adv. Sci. Technol. Res. J. 2023, 17, 140–152. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Chen, H.; Chen, Y.; Xie, D. An investigation into the failure mechanism of severe abrasion of high-speed train brake discs on snowy days. Eng. Fail. Anal. 2019, 101, 121–134. [Google Scholar] [CrossRef]

- Shatskii, I.P.; Perepichka, V.V. Shock-wave propagation in an elastic rod with a viscoplastic external resistance. J. Appl. Mech. Tech. Phys. 2013, 54, 1016–1020. [Google Scholar] [CrossRef]

- Shatskyi, I.; Perepichka, V. Problem of dynamics of an elastic rod with decreasing function of elastic-plastic external resistance. In Dynamical Systems in Applications, Proceedings of the DSTA 2017, Lodz, Poland, 11–14 December 2017; Awrejcewicz, J., Ed.; Springer: Cham, Switzerland, 2018; Volume 249, pp. 335–342. [Google Scholar] [CrossRef]

- Petryna, D.Y.; Kozak, O.L.; Shulyar, B.R.; Petryna, Y.D.; Hredil, M.I. Influence of alloying by rare-earth metals on the mechanical properties of 17g1s pipe steel. Mater. Sci. 2013, 48, 575–581. [Google Scholar] [CrossRef]

- Kumar, V.V.; Kumaran, S.S. Friction material composite: Types of brake friction material formulations and effects of various ingredients on brake performance—A review. Mater. Res. Express 2019, 6, 082005. [Google Scholar] [CrossRef]

- Kumar, M.; Boidin, X.; Desplanques, Y.; Bijwe, J. Influence of various metallic fillers in friction materials on hot-spot appearance during stop braking. Wear 2011, 270, 371–381. [Google Scholar] [CrossRef]

- Elzayady, N.; Elsoeudy, R. Microstructure and wear mechanisms investigation on the brake pad. J. Mater. Res. Technol. 2021, 11, 2314–2335. [Google Scholar] [CrossRef]

- Kusyi, Y.; Onysko, O.; Kuk, A.; Solohub, B.; Kopei, V. Development of the Technique for Designing Rational Routes of the Functional Surfaces Processing of Products. In New Technologies, Development and Application V. NT 2022; Karabegović, I., Kovačević, A., Mandžuka, S., Eds.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2022; Volume 472, pp. 135–143. [Google Scholar] [CrossRef]

- Barandych, K.S.; Vysloukh, S.P.; Antonyuk, V.S. Ensuring Fatigue Life of Parts During Finish Turning with Cubic Boron Nitride Tools. J. Superhard Mater. 2018, 40, 206–215. [Google Scholar] [CrossRef]

- Pryhorovska, T.; Ropyak, L. Machining Error Influnce on Stress State of Conical Thread Joint Details. In Proceedings of the 2019 IEEE 8th International Conference on Advanced Optoelectronics and Lasers (CAOL), Sozopol, Bulgaria, 6–8 September 2019; pp. 493–497. [Google Scholar] [CrossRef]

- Danylchenko, Y.; Storchak, M.; Danylchenko, M.; Petryshyn, A. Cutting Process Consideration in Dynamic Models of Machine Tool Spindle Units. Machines 2023, 11, 582. [Google Scholar] [CrossRef]

- Kopei, V.B.; Onysko, O.R.; Panchuk, V.G. Computerized system based on FreeCAD for geometric simulation of the oil and gas equipment thread turning. IOP Conf. Ser. Mater. Sci. Eng. 2019, 477, 012032. [Google Scholar] [CrossRef]

- Kyryliv, V.; Maksymiv, O.; Gurey, V.; Hurey, I.; Kyryliv, Y.; Zvirko, O. The Mode Deformation Effect on Surface Nanocrystalline Structure Formation and Wear Resistance of Steel 41Cr4. Coatings 2023, 13, 249. [Google Scholar] [CrossRef]

- Vasyliev, M.O.; Mordyuk, B.M.; Sidorenko, S.I.; Voloshko, S.M.; Burmak, A.P.; Kindrachuk, M.V. Synthesis of deformation-induced nanocomposites on aluminium D16 alloy surface by ultrasonic impact treatment. Metallofiz. I Noveishie Tekhnologii 2016, 38, 545–563. [Google Scholar] [CrossRef]

- Pashechko, M.I.; Shyrokov, V.V.; Duryahina, Z.A.; Vasyliv, K.B. Structure and Corrosion-Mechanical Properties of the Surface Layers of Steels after Laser Alloying. Mater. Sci. 2003, 39, 108–117. [Google Scholar] [CrossRef]

- Prysyazhnyuk, P.; Di Tommaso, D. The thermodynamic and mechanical properties of Earth-abundant metal ternary boride Mo2(Fe,Mn)B2 solid solutions for impact- and wear-resistant alloys. Mater. Adv. 2023, 4, 3822–3838. [Google Scholar] [CrossRef]

- Yanchuk, V.; Kruhlov, I.; Zakiev, V.; Lozova, A.; Trembach, B.; Orlov, A.; Voloshko, S. Thermal and Ion Treatment Effect on Nanoscale Thin Films Scratch Resistance. Metallofiz. I Noveishie Tekhnologii 2022, 44, 1275–1292. [Google Scholar] [CrossRef]

- Holubets, V.М.; Dovhunyk, V.М.; Pashechko, M.І.; Kornii, S.А.; Shpulyar, Y.S. Friction Behavior of Electric-Spark Coatings Under the Conditions of Boundary Lubrication. Mater. Sci. 2020, 56, 43–49. [Google Scholar] [CrossRef]

- Umanskyi, O.P.; Storozhenko, M.S.; Tarelnyk, V.B.; Koval, O.Y.; Gubin, Y.V.; Tarelnyk, N.V.; Kurinna, T.V. Electrospark Deposition of Fenicrbsic–Meb2 Coatings on Steel. Powder Metall. Met. Ceram. 2020, 59, 57–67. [Google Scholar] [CrossRef]

- Tarelnik, V.B.; Gaponova, O.P.; Konoplyantschenko, E.V.; Yevtushenko, N.S.; Gerasimenko, V.A. Analysis of the structural state of the surface layer after electro-erosive alloying. II. Peculiarities of the formation of electroerosive coatings on special steels and stops by hard wear-resistant and soft antifriction materials. Metallofiz. I Noveishie Tekhnologii 2018, 11, 795–815. [Google Scholar] [CrossRef]

- Winter, L.; Hockauf, K.; Lampke, T. High cycle fatigue behavior of the severely plastically deformed 6082 aluminum alloy with an anodic and plasma electrolytic oxide coating. Surf. Coat. Technol. 2018, 349, 576–583. [Google Scholar] [CrossRef]

- Posuvailo, V.M.; Klapkiv, M.D.; Student, M.M.; Sirak, Y.Y.; Pokhmurska, H.V. Gibbs energy calculation of electrolytic plasma channel with inclusions of copper and copper oxide with Al-base. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 012045. [Google Scholar] [CrossRef]

- Ropyak, L.; Shihab, T.; Velychkovych, A.; Dubei, O.; Tutko, T.; Bilinskyi, V. Design of a Two-Layer Al–Al2O3 Coating with an Oxide Layer Formed by the Plasma Electrolytic Oxidation of Al for the Corrosion and Wear Protections of Steel. Prog. Phys. Met. 2023, 24, 319–365. [Google Scholar] [CrossRef]

- Shatskyi, I.; Makoviichuk, M.; Ropyak, L.; Velychkovych, A. Analytical model of deformation of a functionally graded ceramic coating under local load. Ceramics 2023, 46, 1879–1893. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Wang, F.; Du, C.; Zhou, W.; Yu, Z.; Ren, X. The effect of ultrasonic shot peening on micro-arc oxidation results of Ti-6Al-4V alloy. Mater. Today Commun. 2023, 37, 107557. [Google Scholar] [CrossRef]

- Wang, S.; Yu, T.; Pang, Z.; Liu, X.; Shi, C.; Du, N. Improving the fatigue resistance of plasma electrolytic oxidation coated titanium alloy by ultrasonic surface rolling pretreatment. Int. J. Fatigue 2024, 181, 108157. [Google Scholar] [CrossRef]

- Andreikiv, O.Y.; Dolins’ka, I.Y.; Shtoiko, I.P.; Raiter, O.K.; Matviiv, Y.Y. Evaluation of the Residual Service Life of Main Pipelines with Regard for the Action of Media and Degradation of Materials. Mater. Sci. 2019, 54, 638–646. [Google Scholar] [CrossRef]

- Shats’kyi, І.P.; Makoviichuk, М.V.; Shcherbii, А.B. Influence of a Flexible Coating on the Strength of a Shallow Cylindrical Shell with Longitudinal Crack. J. Math. Sci. 2019, 238, 165–173. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Influence of flexible coating on the limit equilibrium of a spherical shell with meridional crack. Mater. Sci. 2020, 55, 484–491. [Google Scholar] [CrossRef]

- Dutkiewicz, M.; Dalyak, T.; Shatskyi, I.; Venhrynyuk, T.; Velychkovych, A. Stress Analysis in Damaged Pipeline with Composite Coating. Appl. Sci. 2021, 11, 10676. [Google Scholar] [CrossRef]

- Panasyuk, V.V.; Sylovanyuk, V.P.; Marukha, V.I. Injection Technologies for the Repair of Damaged Concrete Structures; Springer: Dordrecht, The Netherlands, 2014; pp. 1–230. [Google Scholar] [CrossRef]

- Shatskyi, I.; Kurtash, I. Strength of plate with the filled crack under multiparameter loading. Procedia Struct. Integr. 2018, 13, 1482–1487. [Google Scholar] [CrossRef]

- Sylovanyuk, V.P.; Yukhim, R.Y. Material strengthening by crack and cavity healing. Strength Mater. 2011, 43, 33–41. [Google Scholar] [CrossRef]

- Shats’kyi, I.P. Limiting equilibrium of a plate with partially healed crack. Mater. Sci. 2015, 51, 322–330. [Google Scholar] [CrossRef]

- Dalyak, T.M.; Shatsky, I.P. On brittle fracture of a body with partial healed star-shaped crack. Bull. Taras Shevchenko Natl. Univ. Kyiv. Phys. Math. Sci. 2023, 100–103. [Google Scholar] [CrossRef]

- Spencer, B.F.; Hoskere, V.; Narazaki, Y. Advances in Computer Vision-Based Civil Infrastructure Inspection and Monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Dais, D.; Bal, İ.; Smyrou, E.; Sarhosis, V. Automatic crack classification and segmentation on masonry surfaces using convolutional neural networks and transfer learning. Autom. Constr. 2021, 125, 103606. [Google Scholar] [CrossRef]

- Vorobel, R.; Ivasenko, I.; Berehulyak, O. Automatized computer system for evaluation of rust using modified single-scale retinex. In Proceedings of the 2017 IEEE First Ukraine Conference on Electrical and Computer Engineering (UKRCON 2017), Kyiv, Ukraine, 29 May–2 June 2017; pp. 1002–1006. [Google Scholar] [CrossRef]

- Matarneh, S.; Elghaish, F.; Al-Ghraibah, A.; Abdellatef, E.; Edwards, D.J. An automatic image processing based on hough transform algorithm for pavement crack detection and classification. Smart Sustain. Built Environ. 2023. ahead of printing. [Google Scholar] [CrossRef]

- Javorskyj, I.; Matsko, I.; Yuzefovych, R.; Lychak, O.; Lys, R. Methods of Hidden Periodicity Discovering for Gearbox Fault Detection. Sensors 2021, 21, 6138. [Google Scholar] [CrossRef]

- Ivasenko, I.; Posuvailo, V.; Veselivska, H.; Vynar, V. Porosity segmentation and analysis of oxide ceramic coatings of D16T alloy. In Proceedings of the 2020 IEEE 15th International Conference on Computer Sciences and Information Technologies (CSIT), Zbarazh, Ukraine, 23–26 September 2020; pp. 50–53. [Google Scholar] [CrossRef]

- Murakami, K. Image processing for non-destructive testing. Weld. Int. 1990, 4, 144–149. [Google Scholar] [CrossRef]

- Bembenek, M.; Mandziy, T.; Ivasenko, I.; Berehulyak, O.; Vorobel, R.; Slobodyan, Z.; Ropyak, L. Multiclass Level-Set Segmentation of Rust and Coating Damages in Images of Metal Structures. Sensors 2022, 22, 7600. [Google Scholar] [CrossRef]

- Bredies, K.; Lorenz, D. Mathematical Image Processing, 1st ed.; Birkhäuser: Cham, Switzerland, 2018; 473p. [Google Scholar] [CrossRef]

- Ruthotto, L.; Haber, E. Deep Neural Networks Motivated by Partial Differential Equations. J. Math. Imaging 2020, 62, 352–364. [Google Scholar] [CrossRef]

- Vorobel, R. Logarithmic type image processing algebras. In Proceedings of the 2010 International Kharkov Symposium on Physics and Engineering of Microwaves, Millimeter and Submillimeter Waves, (MSMW’2010), Kharkiv, Ukraine, 21–26 June 2010; pp. 1–3. [Google Scholar] [CrossRef]

- Berehulyak, O.; Vorobel, R. The Algebraic Model with an Asymmetric Characteristic of Logarithmic Transformation. In Proceedings of the 2020 IEEE 15th International Conference on Computer Sciences and Information Technologies (CSIT), Zbarazh, Ukraine, 23–26 September 2020; pp. 119–122. [Google Scholar] [CrossRef]

- Huo, F.; Liu, Y.; Wang, D.; Sun, B. Bloch quantum artificial bee colony algorithm and its application in image threshold segmentation. Signal Image Video Process. 2017, 11, 1585–1592. [Google Scholar] [CrossRef]

- Minaee, S.; Boykov, Y.; Porikli, F.; Plaza, A.; Kehtarnavaz, N.; Terzopoulos, D. Image Segmentation Using Deep Learning: A Survey. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 44, 3523–3542. [Google Scholar] [CrossRef]

- Mandziy, T. Inhomogeneity inforced piecewise smooth Chan-Vese model for image segmentation. In Proceedings of the IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON 2019), Lviv, Ukraine, 2–6 July 2019; pp. 1158–1161, 8879904. [Google Scholar] [CrossRef]

- Mandziy, T.; Ivasenko, I.; Berehulyak, O.; Vorobel, R. Influence of Colour Restoration on Rust Image Segmentation. In Proceedings of the 2021 IEEE 3rd Ukraine Conference on Electrical and Computer Engineering (UKRCON 2021), Lviv, Ukraine, 26–28 August 2021; pp. 68–73. [Google Scholar] [CrossRef]

- Berehulyak, O.; Vorobel, R.; Mandziy, T.; Ivasenko, I. Segmentation of Partially Shadowed Rust Images. In Proceedings of the 2022 IEEE 16th International Conference on Advanced Trends in Radioelectronics, Telecommunications and Computer Engineering (TCSET), Lviv-Slavske, Ukraine, 22–26 February 2022; pp. 564–568. [Google Scholar] [CrossRef]

- Rytsar, Y.B.; Ivasenko, I.B. Application of (alpha, beta)-trimmed mean filtering for removal of additive noise from images. In Proceedings of the Current Ukrainian Research in Optics and Photonics: Optoelectronic and Hybrid Optical/Digital Systems for Image Processing, Lviv, Ukraine, 20 October 1997; Volume 3238, pp. 45–52. [Google Scholar] [CrossRef]

- Berehulyak, O.; Vorobel, R.; Ivasenko, I. Color Image Enhancement by Logarithmic Transformation in Fuzzy Domain. In Proceedings of the IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON 2019), Lviv, Ukraine, 2–6 July 2019; pp. 1147–1151. [Google Scholar] [CrossRef]

- Sieberg, P.M.; Kurtulan, D.; Hanke, S. Wear Mechanism Classification Using Artificial Intelligence. Materials 2022, 15, 2358. [Google Scholar] [CrossRef]

- Konovalenko, I.; Maruschak, P.; Brezinová, J.; Prentkovskis, O.; Brezina, J. Research of U-Net-Based CNN Architectures for Metal Surface Defect Detection. Machines 2022, 10, 327. [Google Scholar] [CrossRef]

- Jang, W.-K.; Kim, D.-W.; Seo, Y.-H.; Kim, B.-H. Tool-Wear-Estimation System in Milling Using Multi-View CNN Based on Reflected Infrared Images. Sensors 2023, 23, 1208. [Google Scholar] [CrossRef]

- Mengesha, B.N.; Grizzle, A.C.; Demisse, W.; Klein, K.L.; Elliott, A.; Tyagi, P. Machine Learning-Enabled Quantitative Analysis of Optically Obscure Scratches on Nickel-Plated Additively Manufactured (AM) Samples. Materials 2023, 16, 6301. [Google Scholar] [CrossRef]

- Soleimani, S.; Sukumaran, J.; Kumcu, A.; De Baets, P.; Philips, W. Quantifying Abrasion and Micro-Pits in Polymer Wear Using Image Processing Techniques. Wear 2014, 319, 123–137. [Google Scholar] [CrossRef]

- Gonzalez-Arias, C.; Viáfara, C.C.; Coronado, J.J.; Martinez, F. Automatic classification of severe and mild wear in worn surface images using histograms of oriented gradients as descriptor. Wear 2019, 426, 1702–1711. [Google Scholar] [CrossRef]

- Shashikala, T.D.; Sunitha, S.L.; Basavarajappa, S. Quantification of worn surface using digital image processing. Tribol. Int. 2022, 176, 107864. [Google Scholar] [CrossRef]

- Friedrich, M.; Gerber, T.; Dumler, J.; Döpper, F. A system for automated tool wear monitoring and classification using computer vision. Procedia CIRP 2023, 118, 425–430. [Google Scholar] [CrossRef]

- Interstate Standard GOST 4543–2016; Structural Alloy Steel. Specifications. Metrology and Certification: Minsk, Belarus, 2016.

- Interstate Standard GOST 10851–94; Friction Articles of Retinax. Specification. Metrology and Certification: Minsk, Belarus, 2017.

- Shvedkov, E.L.; Rovinsky, D.Y.; Zozulya, V.D.; Brown, E.D. Dictionary-Reference Book on Friction, Wear and Lubrication of Machine Parts; Fedorchenko, I.M., Ed.; Naukova Dumka: Kiev, Ukraine, 1979; pp. 18–19. [Google Scholar]

- Kryshtopa, S.I.; Prun’ko, I.B.; Dolishnii, B.V.; Panchuk, M.V.; Bogatchuk, I.M.; Mel’nyk, V.M. Regularities of Wear of Metal-Polymer Friction Couples Under the Influence of Tribocurrents. Mater. Sci. 2019, 55, 193–200. [Google Scholar] [CrossRef]

- Kryshtopa, S.; Kozhevnykov, A.; Panchuk, M.; Kryshtopa, L. Influence of triboelectric processes on friction characteristics of brake units of technological transport. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2018, 2018, 87–93. [Google Scholar] [CrossRef]

- Interstate Standard GOST 12.2.088–83; Standards System of Labor Safety. Field Equipment for Well Repair and Realization. Safety General Requirements. Metrology and Certification: Minsk, Belarus, 2017.

- Bandura, A.; Mulyava, O.; Sheremeta, M. On Dirichlet Series Similar to Hadamard Compositions in Half-Plane. Carpathian Math. Publ. 2023, 15, 180–195. [Google Scholar] [CrossRef]

- Bandura, A. Composition of entire functions and bounded L-index in direction. Mat. Stud. 2017, 4, 179–184. [Google Scholar] [CrossRef]

- Lindeberg, T. Edge Detection and Ridge Detection with Automatic Scale Selection. Int. J. Comput. Vis. 1998, 30, 117–154. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Wang, Z.; Han, J.; Domblesky, J.P.; Li, Z.; Fan, X.; Liu, X. Crack propagation and microstructural transformation on the friction surface of a high-speed railway brake disc. Wear 2019, 428–429, 45–54. [Google Scholar] [CrossRef]

- Hurey, I.; Hurey, T.; Lanets, O.; Dmyterko, P. The Durability of the Nanocrystalline Hardened Layer During the Fretting Wear. In Advances in Design, Simulation and Manufacturing IV. DSMIE 2021; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2021; pp. 23–32. [Google Scholar] [CrossRef]

- Kyryliv, V.І.; Gurey, V.І.; Maksymiv, О.V.; Hurey, І.V.; Kulyk, Y.О. Influence of the Deformation Mode on the Force Conditions of Formation of the Surface Nanostructure of 40 Kh Steel. Mater. Sci. 2021, 57, 422–427. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Lunarska, E.; Kyryliv, V.; Maksymiv, O. Influence of hydrogen on the mechanical properties of steels with the surface nanostructure. In Nanoplasmonics, Nano-Optics, Nanocomposites, and Surface Studies; Fesenko, O., Yatsenko, L., Eds.; Springer Proceedings in Physics; Springer: Cham, Switzerland, 2015; Volume 167, pp. 457–465. [Google Scholar] [CrossRef]

- Nykyforchyn, H.M.; Lunarska, E.; Kyryliv, V.I.; Maksymiv, О.V. Hydrogen permeability of the surface nanocrystalline structures of carbon steel. Mater. Sci. 2015, 50, 67–73. [Google Scholar] [CrossRef]

- Andreikiv, O.Y.; Skal’s’kyi, V.R.; Opanasovych, V.К.; Dolins’ka, I.Y.; Shtoiko, I.P. Determination of the Period of Subcritical Growth of Creep-Fatigue Cracks Under Block Loading. J. Math. Sci. 2017, 222, 103–113. [Google Scholar] [CrossRef]

- Andreikiv, O.E.; Dolins’ka, I.Y.; Lysyk, A.R.; Sas, N.B. Computational model of the propagation of stress-corrosion cracks at high temperatures. Mater. Sci. 2017, 52, 714–721. [Google Scholar] [CrossRef]

- Pokhmurskii, V.I.; Vynar, V.A.; Vasyliv, C.B.; Ratska, N.B. Effects of hydrogen exposure on the mechanical and tribological properties of α-titanium surfaces. Wear 2013, 306, 47–50. [Google Scholar] [CrossRef]

- Pokhmurskii, V.; Khoma, M.; Vynar, V.; Vasyliv, C.; Ratska, N.; Voronyak, T.; Stasyshyn, I. The influence of hydrogen desorption on micromechanical properties and tribological behavior of iron and carbon steels. Procedia Struct. Integr. 2018, 13, 2190–2195. [Google Scholar] [CrossRef]

- Khoma, M.; Vynar, V.; Chuchman, M.; Vasyliv, C. Corrosion-mechanical failure of pipe steels in hydrogen sulfide environments. In Degradation Assessment and Failure Prevention of Pipeline Systems; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2021; Volume 102, pp. 231–239. [Google Scholar] [CrossRef]

- Buketov, A.V.; Stukhlyak, P.D.; Levyts’kyi, V.V.; Dolgov, M.A.; Dobrotvor, I.G. A study of creep of epoxy composites with continuous fibers and modified fine filler in aggressive media. Strength Mater. 2011, 43, 338–346. [Google Scholar] [CrossRef]

- Park, J.; Joo, B.; Seo, H.; Song, W.; Lee, J.J.; Lee, W.K.; Jang, H. Analysis of wear induced particle emissions from brake pads during the worldwide harmonized light vehicles test procedure (WLTP). Wear 2021, 466–467, 203539. [Google Scholar] [CrossRef]

- Stojanovic, N.; Glisovic, J.; Abdullah, O.I.; Belhocine, A.; Grujic, I. Particle formation due to brake wear, influence on the people health and measures for their reduction: A review. Environ. Sci. Pollut. Res. 2022, 29, 9606–9625. [Google Scholar] [CrossRef] [PubMed]

- Mathissen, M.; Grochowicz, J.; Schmidt, C.; Vogt, R.; zum Hagen, F.H.F.; Grabiec, T.; Steven, H.; Grigoratos, T. A novel real-world braking cycle for studying brake wear particle emissions. Wear 2018, 414, 219–226. [Google Scholar] [CrossRef]

- Alemani, M.; Nosko, O.; Metinoz, I.; Olofsson, U. A study on emission of airborne wear particles from car brake friction pairs. SAE Int. J. Mater. Manuf. 2015, 9, 147–157. [Google Scholar] [CrossRef]

- Zum Hagen, F.H.F.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. Study of brake wear particle emissions: Impact of braking and cruising conditions. Environ. Sci. Technol. 2019, 53, 5143–5150. [Google Scholar] [CrossRef] [PubMed]

- Hagino, H.; Oyama, M.; Sasaki, S. Airborne brake wear particle emission due to braking and accelerating. Wear 2015, 334–335, 44–48. [Google Scholar] [CrossRef]

- Joo, B.S.; Chang, Y.H.; Seo, H.J.; Jang, H. Effects of binder resin on tribological properties and particle emission of brake linings. Wear 2019, 434, 202995. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.; Basch, R.; Fash, J. The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Kukutschova, J.; Roubícek, V.; Maslan, M.; Jancík, D.; Slovak, V.; Malachova, K.; Pavlíckova, Z.; Filip, P. Wear performance and wear debris of semimetallic automotive brake materials. Wear 2010, 268, 86–93. [Google Scholar] [CrossRef]

- Osterle, W.; Urban, I. Third body formation on brake pads and rotors. Tribol. Int. 2006, 39, 401–408. [Google Scholar] [CrossRef]

- Massi, F.; Berthier, Y.; Baillet, L. Contact surface topography and system dynamics of brake squeal. Wear 2008, 265, 1784–1792. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials, 2nd ed.; John Willey and Son’s: New York, NY, USA, 1995. [Google Scholar]

- Lee, S.; Jang, H. Effect of plateau distribution on friction instability of brake friction materials. Wear 2018, 400, 1–9. [Google Scholar] [CrossRef]

- Kim, J.W.; Joo, B.S.; Jang, H. The effect of contact area on velocity weakening of the friction coefficient and friction instability: A case study on brake friction materials. Tribol. Int. 2019, 135, 38–45. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | P | S | Fe |

|---|---|---|---|---|---|---|

| 0.28–0.34 | 0.90–1.20 | 0.80–1.10 | 0.80–1.10 | ≤0.035 | ≤0.035 | The rest |

| Hardness HB | Density, kg/m3 | Strength Limit, MPa | Young’s Modulus E·10–5, MPa | Impact Strength, kJ/m2 | Coefficient of Linear Expansion α·106, 1/°C | Thermal Conductivity Coefficient Wt/(м·°C) | Specific Heat Capacity, J/(kg·°C) |

|---|---|---|---|---|---|---|---|

| 220 | 7850 | 1080 | 2.1 | 490 | 11.7 | 38 | 496 |

| Friction Material | Hardness HB | Density, kg/m3 | Limit of Compressive Strength, MPa | Young’s Modulus E·10−5, MPa | Impact Strength, kJ/m2 | Thermal Conductivity Coefficient, Wt/(м·°C) | Thermal Conductivity Coefficient, kJ/(kg·°C) | Thermal Shrinkage, % |

|---|---|---|---|---|---|---|---|---|

| FK-24A | 30–49 | 2130–2450 | 73 | 690 | 2.5 | 0.58 | 0.96 | 0.45 |

| No | P1, % | P2, % | P3, % |

|---|---|---|---|

| 1 | 11.53 | 9.84 | 5.22 |

| 2 | 12.83 | 10.80 | 6.03 |

| 3 | 18.55 | 14.98 | 8.48 |

| 4 | 18.42 | 15.83 | 8.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandziy, T.; Ivasenko, I.; Berehulyak, O.; Vorobel, R.; Bembenek, M.; Kryshtopa, S.; Ropyak, L. Evaluation of the Degree of Degradation of Brake Pad Friction Surfaces Using Image Processing. Lubricants 2024, 12, 172. https://doi.org/10.3390/lubricants12050172

Mandziy T, Ivasenko I, Berehulyak O, Vorobel R, Bembenek M, Kryshtopa S, Ropyak L. Evaluation of the Degree of Degradation of Brake Pad Friction Surfaces Using Image Processing. Lubricants. 2024; 12(5):172. https://doi.org/10.3390/lubricants12050172

Chicago/Turabian StyleMandziy, Teodor, Iryna Ivasenko, Olena Berehulyak, Roman Vorobel, Michał Bembenek, Sviatoslav Kryshtopa, and Liubomyr Ropyak. 2024. "Evaluation of the Degree of Degradation of Brake Pad Friction Surfaces Using Image Processing" Lubricants 12, no. 5: 172. https://doi.org/10.3390/lubricants12050172

APA StyleMandziy, T., Ivasenko, I., Berehulyak, O., Vorobel, R., Bembenek, M., Kryshtopa, S., & Ropyak, L. (2024). Evaluation of the Degree of Degradation of Brake Pad Friction Surfaces Using Image Processing. Lubricants, 12(5), 172. https://doi.org/10.3390/lubricants12050172