Synergistic Effect of Acrylate of Dialkyl Dithiophosphoric Acid Combined with Molybdenum Dialkyl Dithiocarbamate as Additives in Gear Oil

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of ADDP

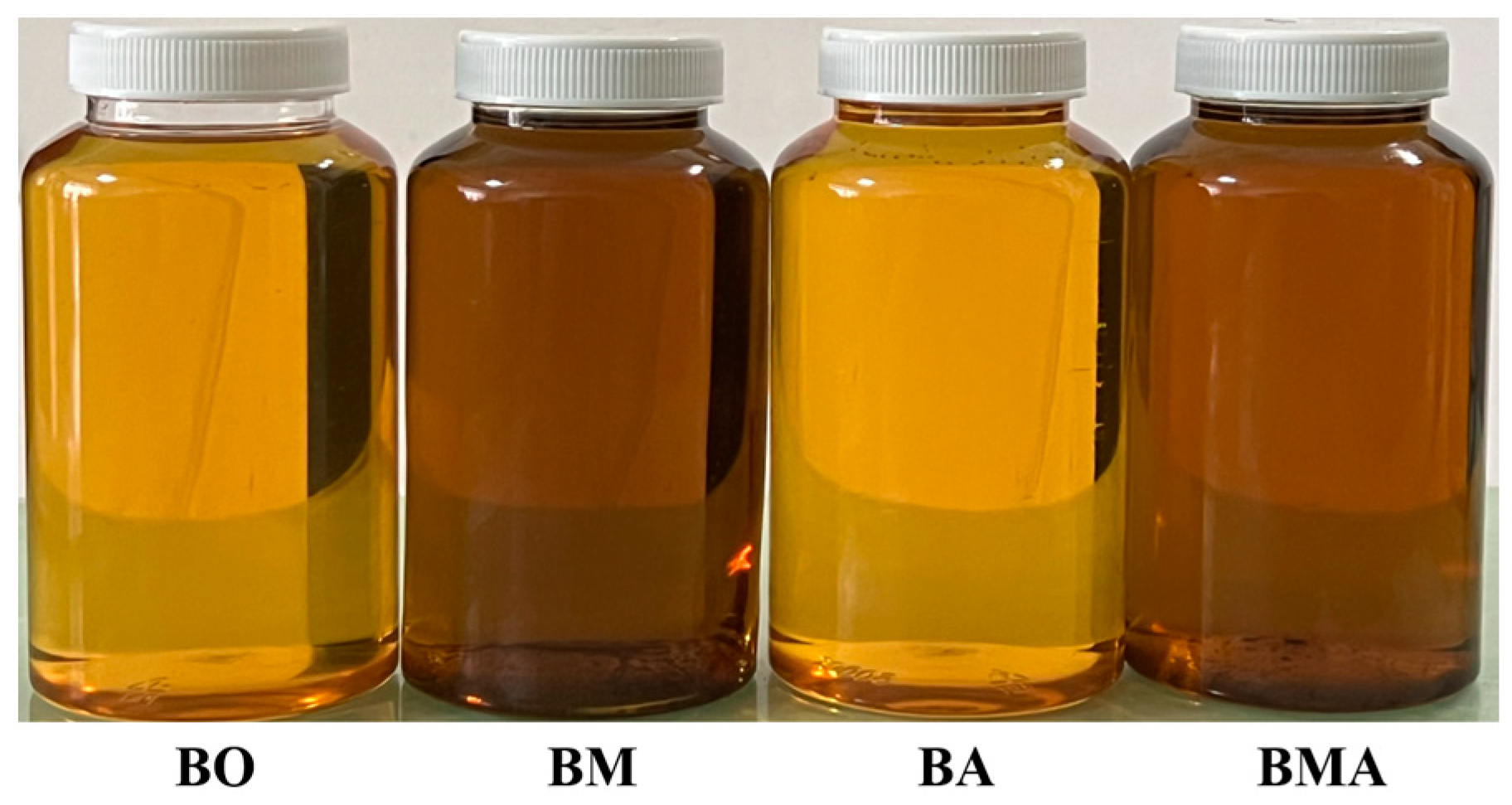

2.2. Preparation of Test Oil

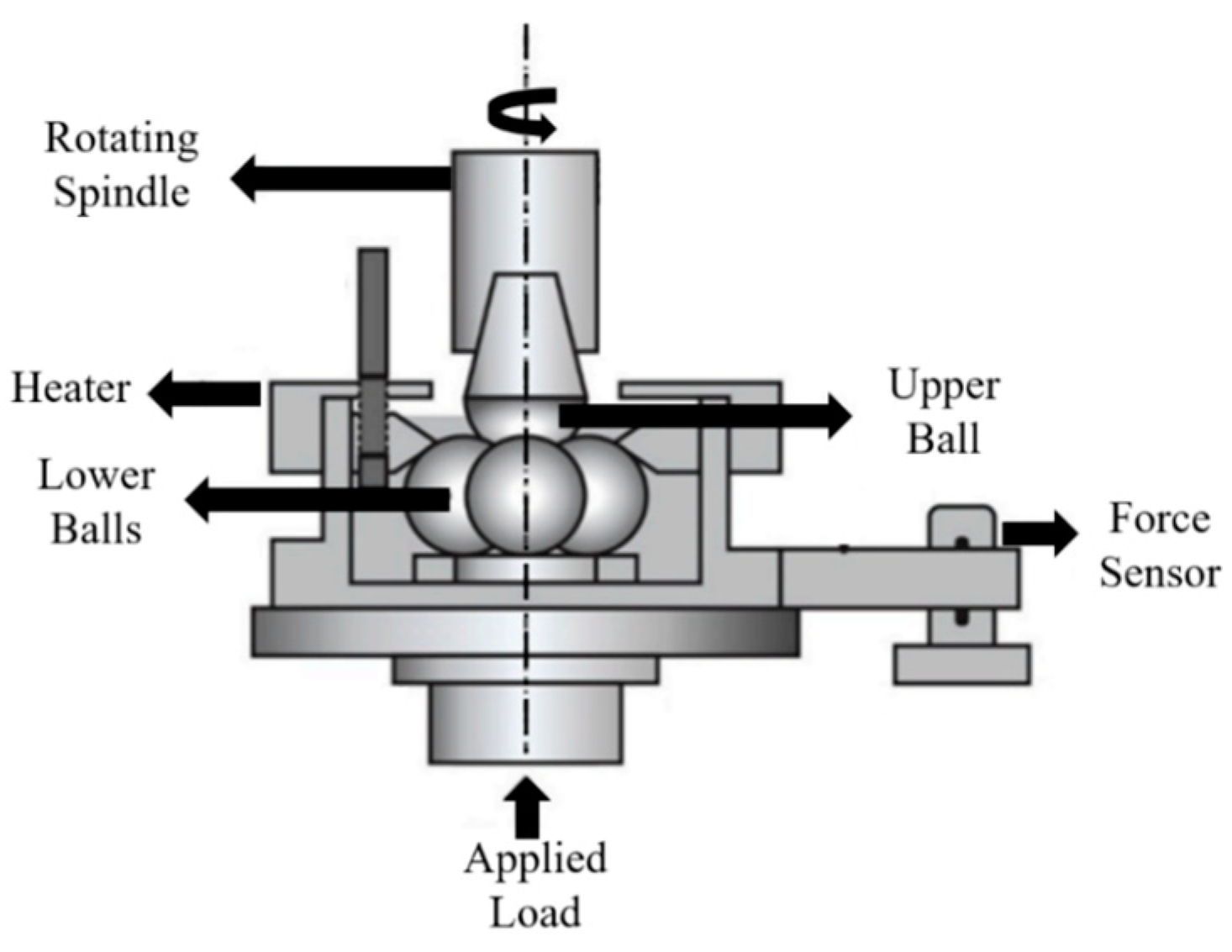

2.3. Tribological Test

2.4. Surface Analysis and Characterization

3. Results

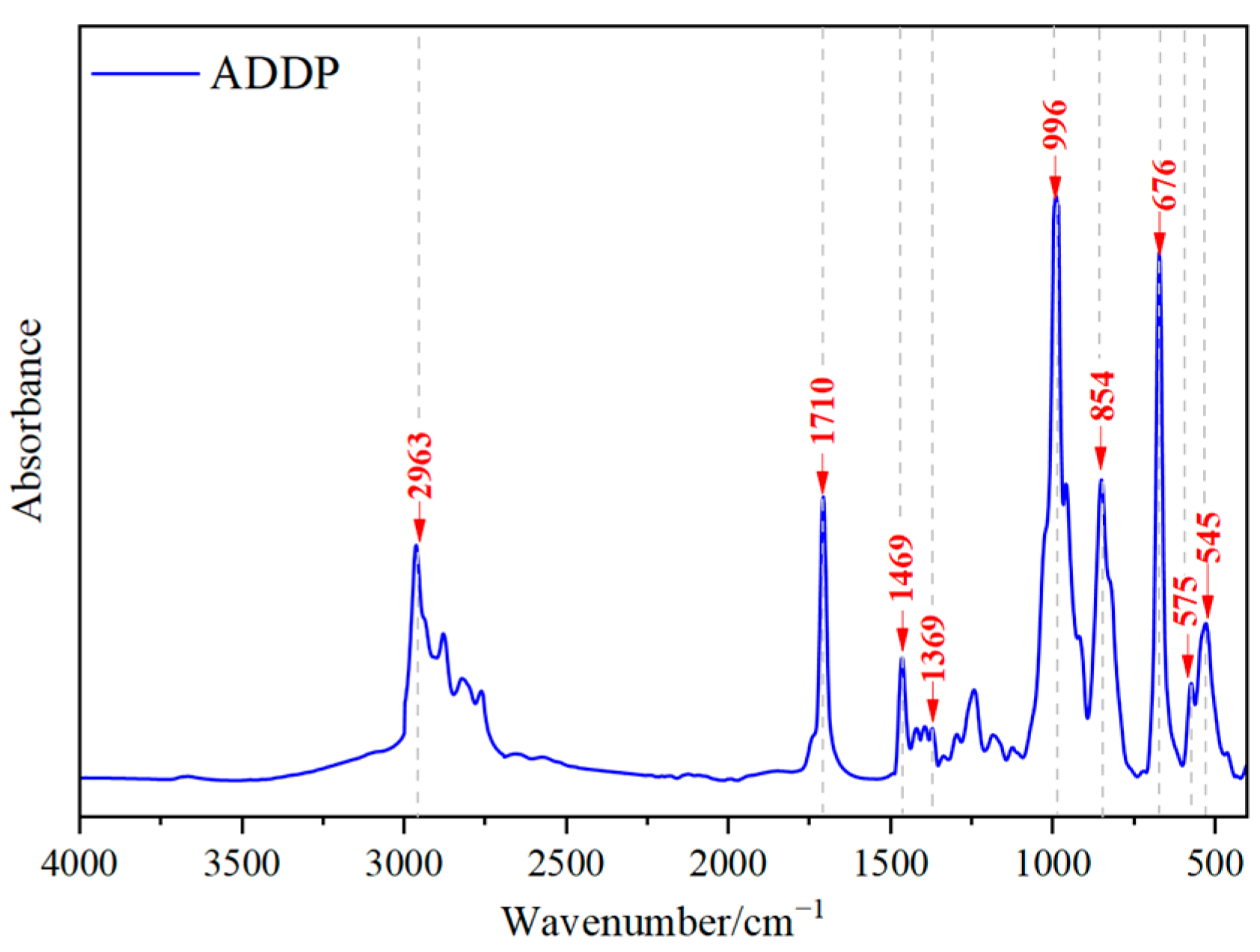

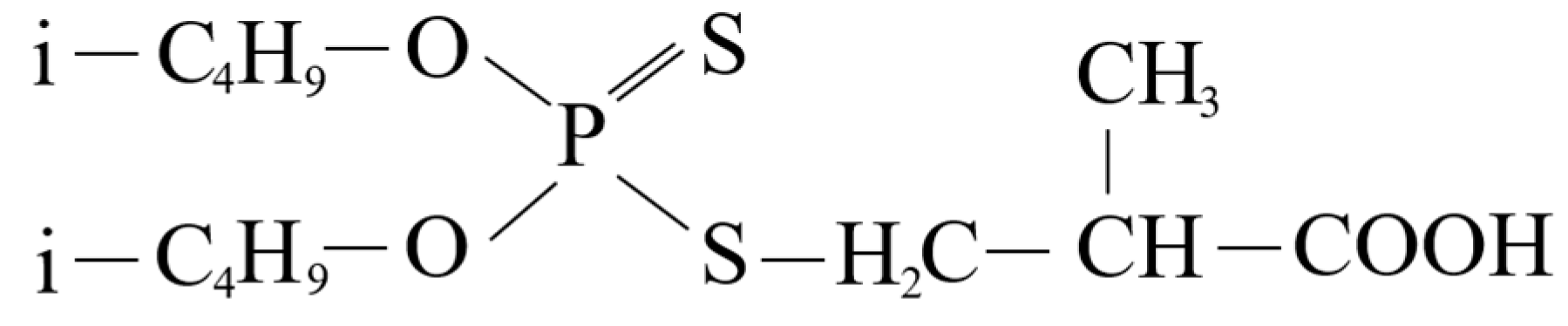

3.1. Molecular Structure of ADDP

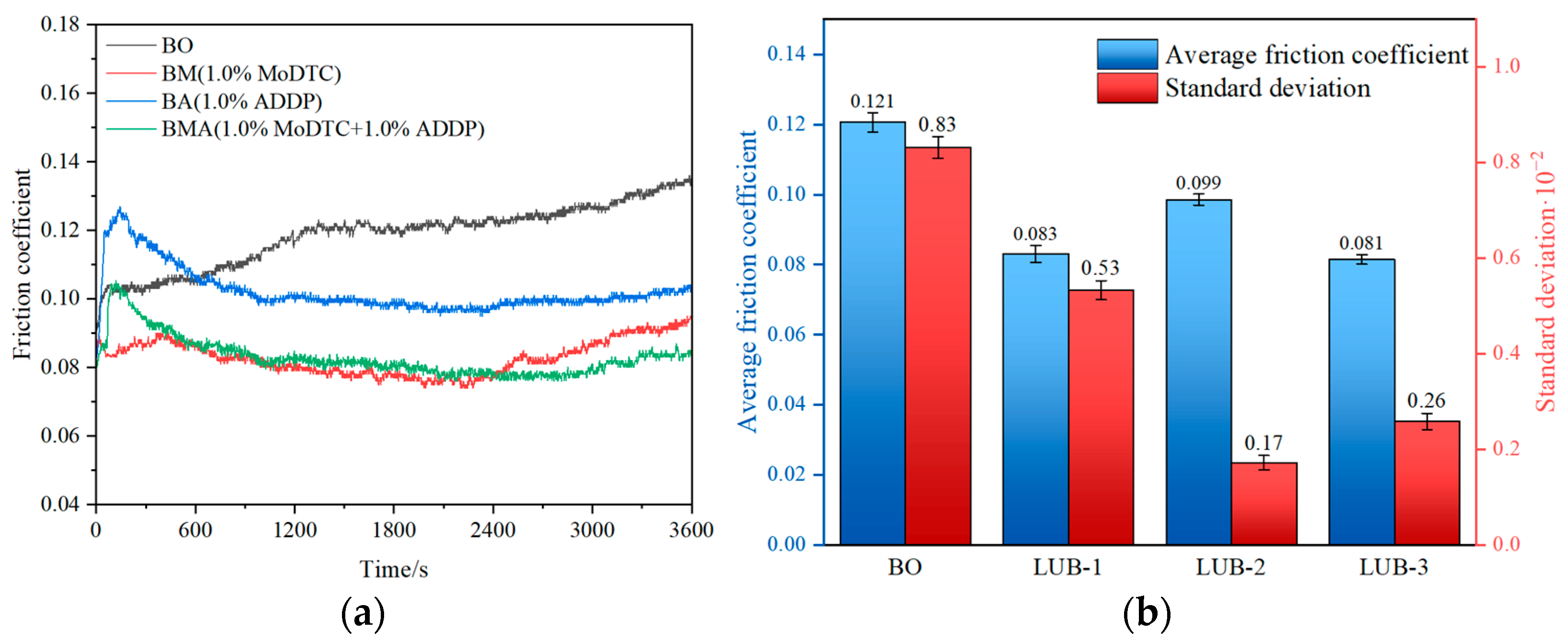

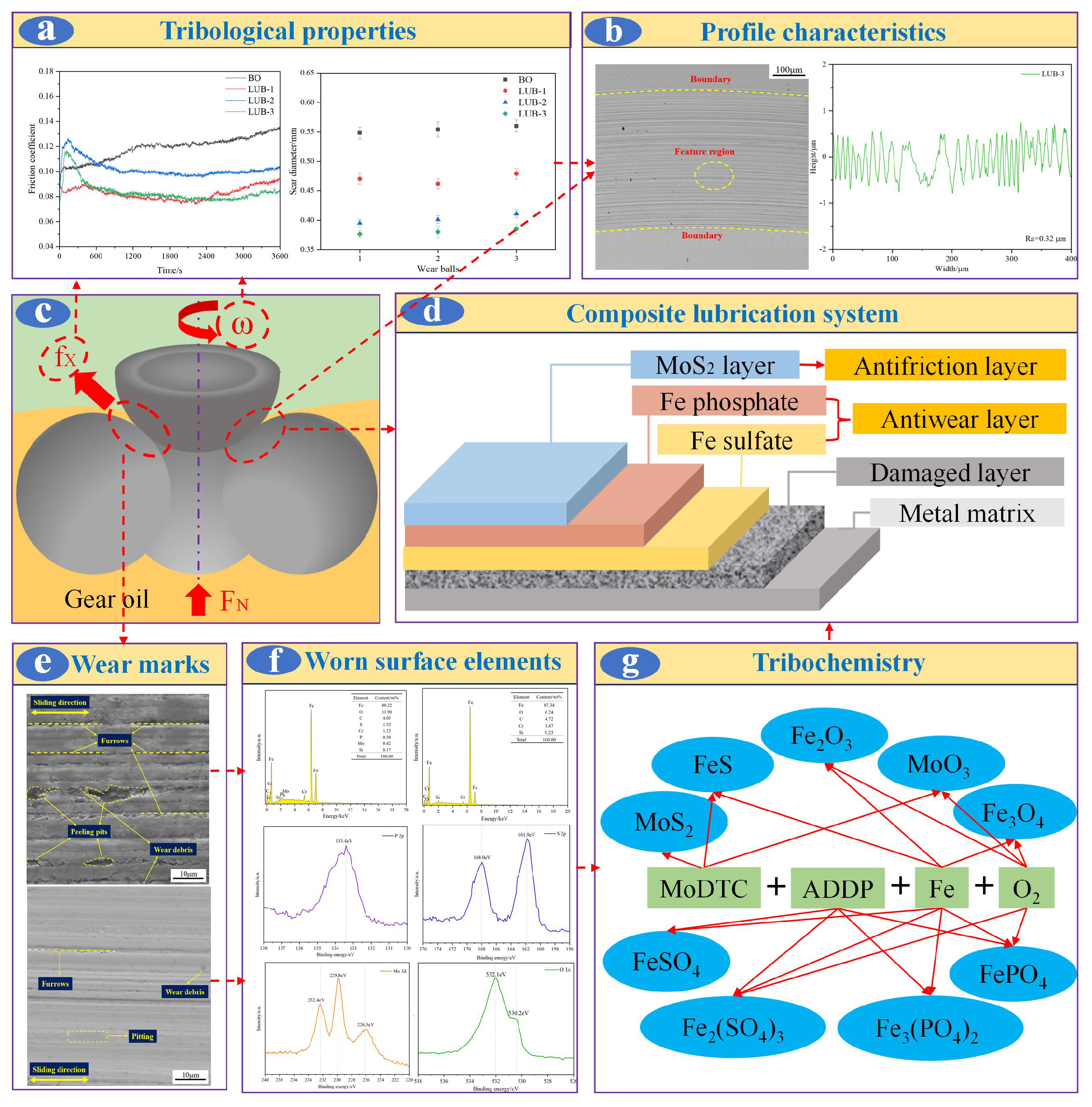

3.2. Tribological Properties of the Sample

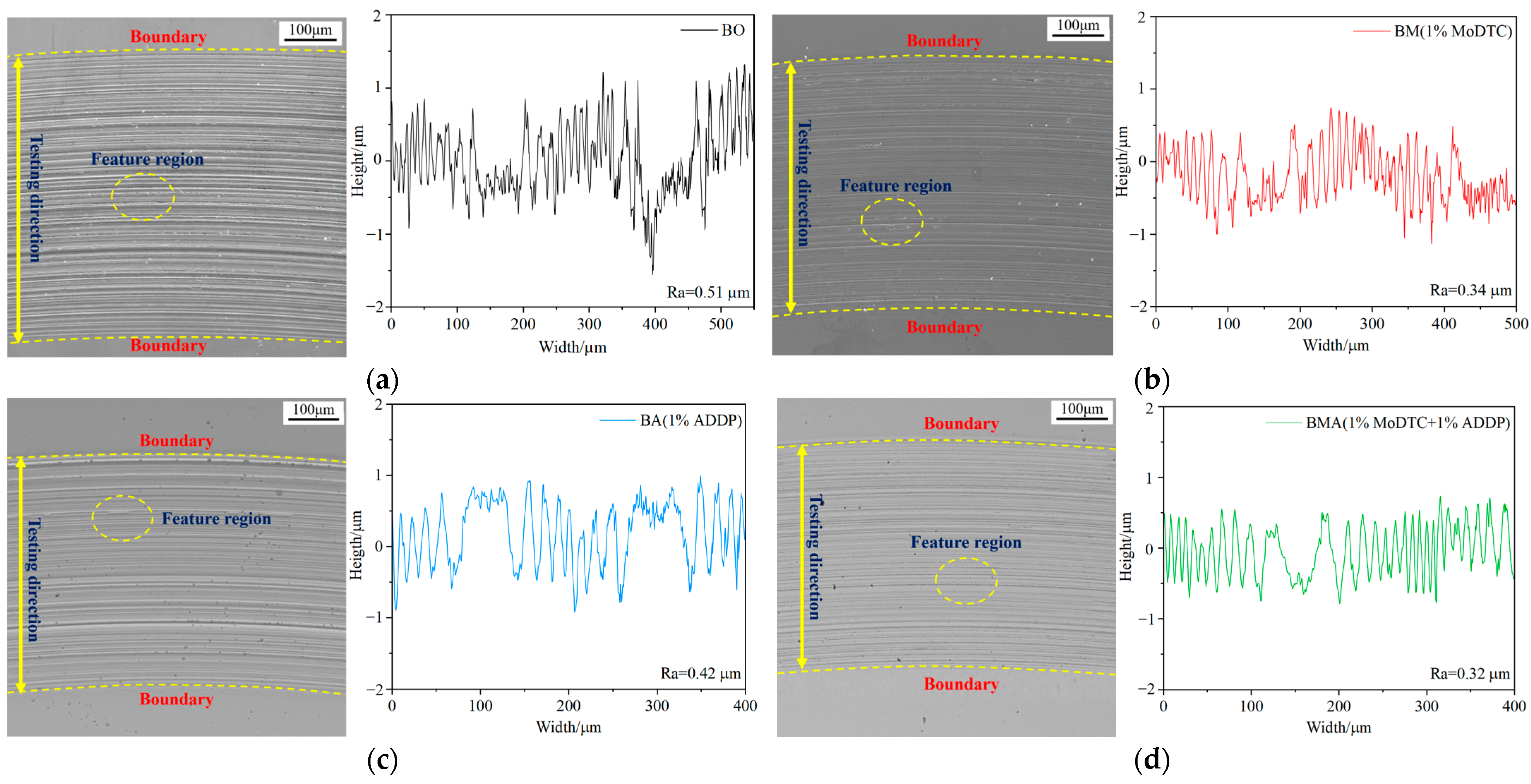

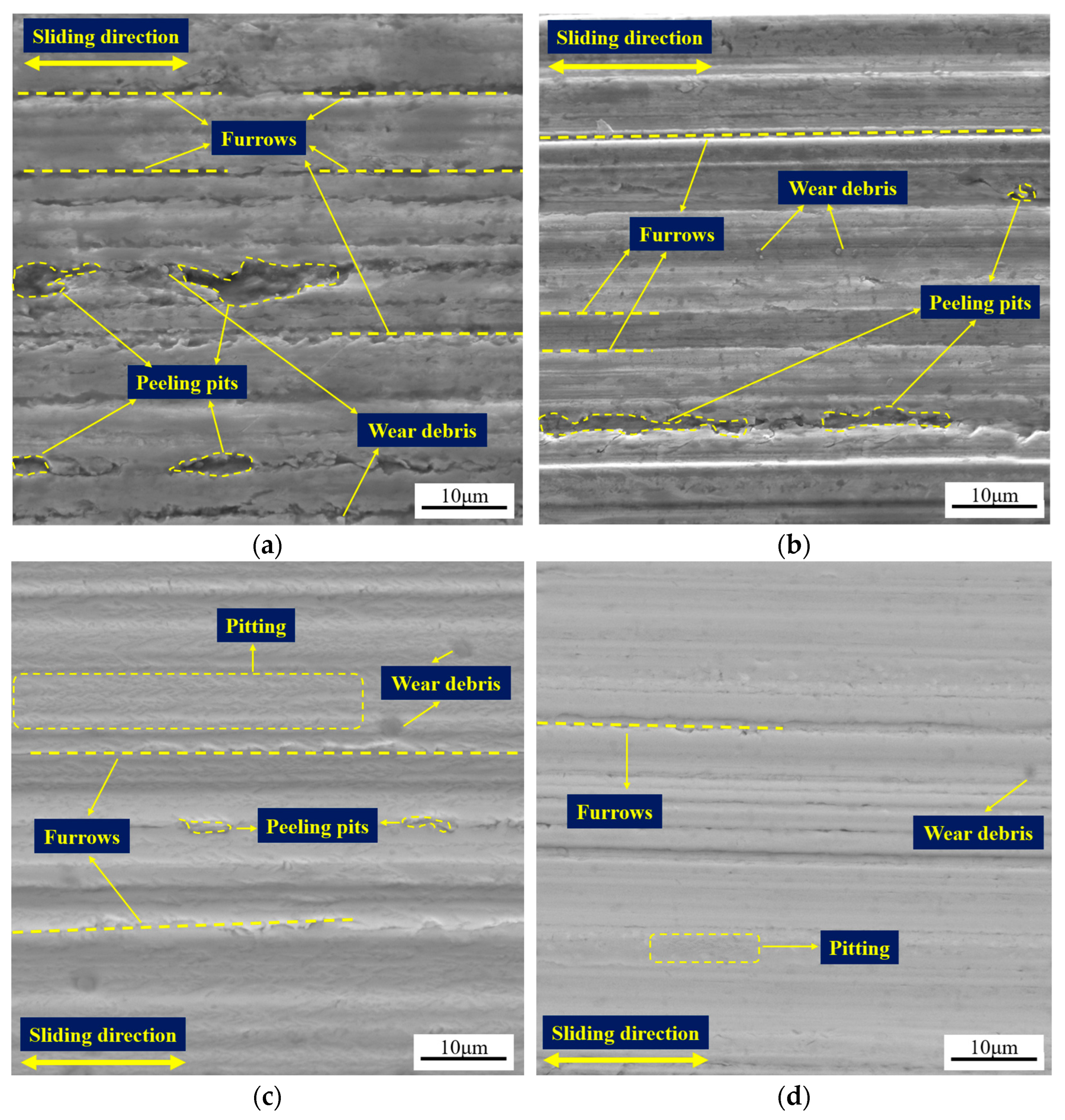

3.3. Microstructure Characteristics

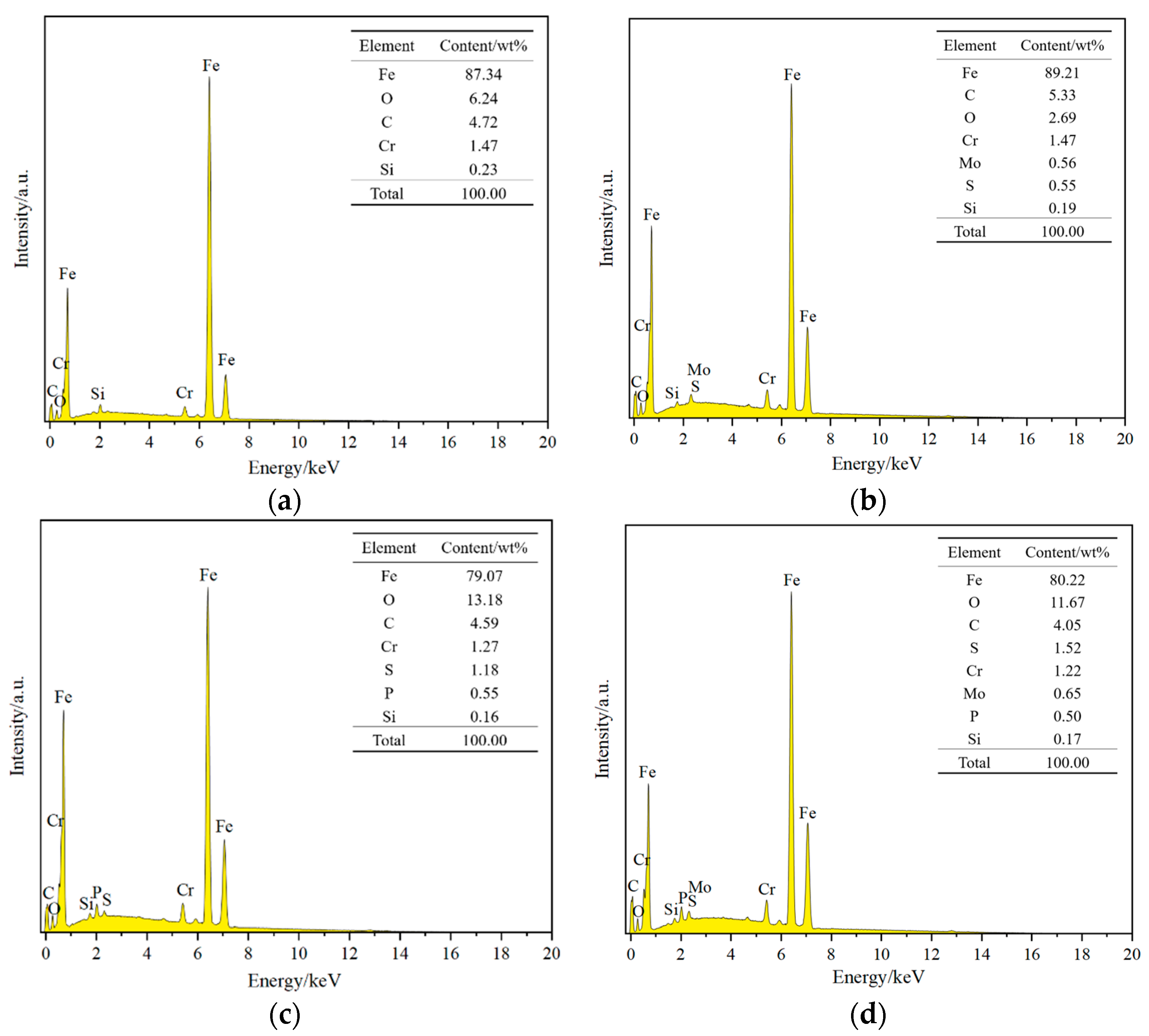

3.4. Worn Surface Element Analysis

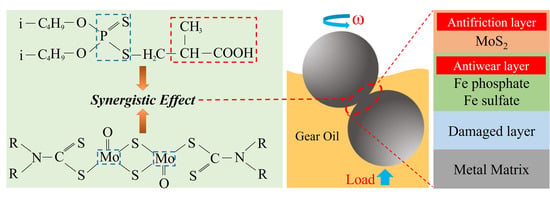

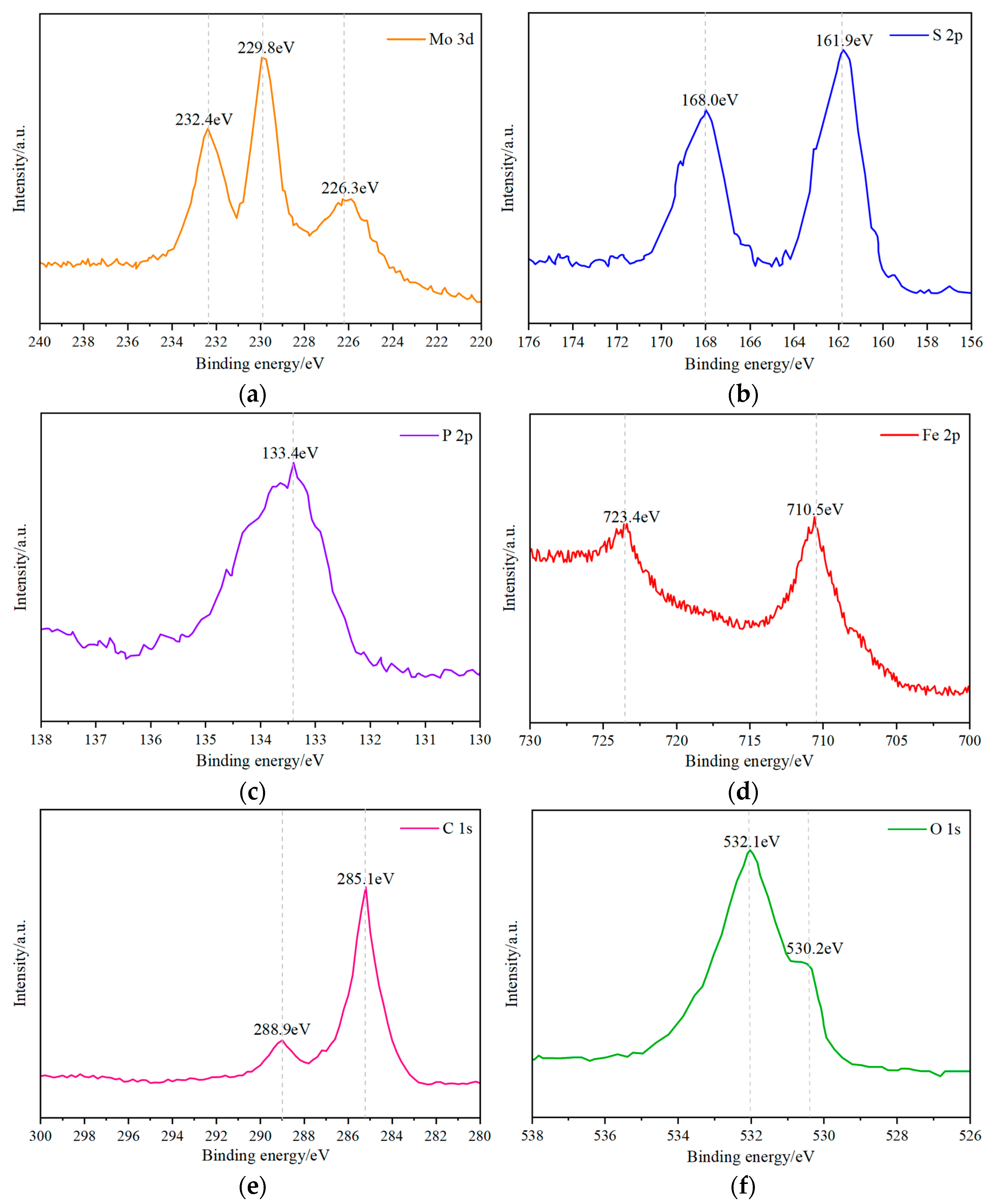

3.5. The Interaction Mechanism of ADDP and MoDTC

4. Conclusions

- (1)

- Compared with BO, the PB and PD values of BM do not change, the PB and PD values of BA and BMA significantly increase, and the PB and PD values of BMA increase by 26.98% and 25.00% compared with BA, respectively. ADDP combined with MoDTC possesses the best extreme pressure performance.

- (2)

- Compared with BO, the WSD of BM, BA, and BMA decrease by 14.55%, 27.27%, and 29.09%, respectively. The worn surface of BMA is smooth, with the least number of defects; ADDP combined with MoDTC has the best antiwear performance.

- (3)

- Compared with BO, the average friction coefficients of BM, BA, and BMA decrease by 31.40%, 18.18%, and 33.06%, respectively. Although the addition of ADDP will increase the friction coefficient at the initial stage of friction, ADDP can extend the life of MoDTC. The combined use of the two can achieve a longer period of low friction.

- (4)

- MoDTC can alleviate the corrosion of metal on the worn surface by ADDP. ADDP can not only effectively adsorb on the metal surface by relying on strong polar groups, but can also help the MoS2 friction film with low shear performance stay on the worn surface for a longer time. This synergistic effect makes it easier to form a chemically reactive film with high load-bearing capacity, when the two are blended, obtaining excellent tribological properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Bicheng, C.; Turkson, R.F.; Qingping, C. Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 2016, 364, 270–281. [Google Scholar] [CrossRef]

- Liu, H.; Jurkschat, T.; Lohner, T.; Stahl, K. Detailed Investigations on the Oil Flow in Dip-Lubricated Gearboxes by the Finite Volume CFD Method. Lubricants 2018, 6, 47. [Google Scholar] [CrossRef]

- Roy, S.; Speed, L.; Viola, M.; Luo, H.; Leonard, D.; Qu, J. Oil miscible phosphonium-phosphate ionic liquid as novel antiwear and antipitting additive for low-viscosity rear axle lubricants. Wear 2021, 466–467, 203588. [Google Scholar] [CrossRef]

- Kotia, A.; Ghosh, G.K.; Srivastava, I.; Deval, P.; Ghosh, S.K. Mechanism for improvement of friction/wear by using Al2O3 and SiO2/Gear oil nanolubricants. J. Alloys Compd. 2019, 782, 592–599. [Google Scholar] [CrossRef]

- Rajendhran, N.; Palanisamy, S.; Shyma, A.P.; Venkatachalam, R. Enhancing the thermophysical and tribological performance of gear oil using Ni-promoted ultrathin MoS2 nanocomposites. Tribol. Int. 2018, 124, 156–168. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Cho, Y.-H.; Chiu, C.-T. Tribological Performance of EP Additives in Different Base Oils. Tribol. Trans. 2012, 55, 175–184. [Google Scholar] [CrossRef]

- Johnson, D.W.; Hils, J.E. Phosphate Esters, Thiophosphate Esters and Metal Thiophosphates as Lubricant Additives. Lubricants 2013, 1, 132–148. [Google Scholar] [CrossRef]

- Hashimoto, C.; Okubo, H.; Tadokoro, C.; Sasaki, S. Correlation between Nano-Mechanical and Macro-Tribological Properties of Tribofilms Derived from Organic Phosphoric Additives. Tribol. Online 2016, 11, 632–638. [Google Scholar] [CrossRef]

- Shen, W.; Hirayama, T.; Yamashita, N.; Adachi, M.; Oshio, T.; Tsuneoka, H.; Tagawa, K.; Yagishita, K.; Yamada, N.L. Relationship between interfacial adsorption of additive molecules and reduction of friction coefficient in the organic friction modifiers-ZDDP combinations. Tribol. Int. 2022, 167, 107365. [Google Scholar] [CrossRef]

- Acharya, B.; Pardue, T.N.; Avva, K.S.; Krim, J. In situ, real time studies of thermal reaction film formation temperatures for iron and 304SS surfaces immersed in 5% tricresyl phosphate in base oil. Tribol. Int. 2018, 126, 106–115. [Google Scholar] [CrossRef]

- Yamashita, N.; Hirayama, T. Effect of atmospheric gas on ZDDP tribofilm formation. Tribol. Int. 2024, 193, 109400. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, X.; Zhao, G.; Wang, X. Effect of a new phosphate compound (BAFDP) addition on the lubricating performance of engine oils at elevated temperatures. Tribol. Int. 2016, 104, 383–391. [Google Scholar] [CrossRef]

- Mangolini, F.; Rossi, A.; Spencer, N.D. Reactivity of triphenyl phosphorothionate in lubricant oil solution. Tribol. Lett. 2009, 35, 31–43. [Google Scholar] [CrossRef]

- Zhang, J.; Spikes, H. On the Mechanism of ZDDP Antiwear Film Formation. Tribol. Lett. 2016, 63, 24. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, T.; Shang, W.; Sun, L.; Liu, D.; Tong, D.; Liu, S. Environmental friendly polyisobutylene-based ionic liquid containing chelated orthoborate as lubricant additive: Synthesis, tribological properties and synergistic interactions with ZDDP in hydrocarbon oils. Tribol. Int. 2017, 115, 297–306. [Google Scholar] [CrossRef]

- Longhua, Z. Study of a novel anti-wear additive used in ashless anti-wear hydraulic fluid. Ind. Lubr. Tribol. 2009, 61, 271–276. [Google Scholar] [CrossRef]

- Garcia, C.E.; Ueda, M.; Spikes, H.; Wong, J.S.S. Temperature dependence of molybdenum dialkyl dithiocarbamate (MoDTC) tribofilms via time-resolved Raman spectroscopy. Sci. Rep. 2021, 11, 3621. [Google Scholar] [CrossRef]

- Liu, Y.; Han, J.-H.; Wang, T.; Hwang, Y.-H.; Xu, S.; Liu, W.; Kim, D.-E. Tribochemical reaction and wear mechanism of MoDTC based friction modifier. Tribol. Int. 2022, 165, 107302. [Google Scholar] [CrossRef]

- Bae, S.-M.; Horibata, S.; Miyauchi, Y.; Choi, J. Tribochemical investigation of Cr-doped diamond-like carbon with a MoDTC-containing engine oil under boundary lubricated condition. Tribol. Int. 2023, 188, 108849. [Google Scholar] [CrossRef]

- Komaba, M.; Kondo, S.; Suzuki, A.; Kurihara, K.; Mori, S. Kinetic Study on Lubricity of MoDTC as a Friction Modifier. Tribol. Online 2019, 14, 220–225. [Google Scholar] [CrossRef]

- Peeters, S.; Losi, G.; Restuccia, P.; Righi, M.C. Unraveling the mechanism to form MoS2 lubricant layers from MoDTC by ab initio simulations. Appl. Surf. Sci. 2022, 606, 154880. [Google Scholar] [CrossRef]

- Espejo, C.; Thiébaut, B.; Jarnias, F.; Wang, C.; Neville, A.; Morina, A. MoDTC Tribochemistry in Steel/Steel and Steel/Diamond-Like-Carbon Systems Lubricated with Model Lubricants and Fully Formulated Engine Oils. J. Tribol. 2018, 141, 012301. [Google Scholar] [CrossRef]

- Lee, S.-W.; Jo, J.-W.; Joun, M.-S.; Lee, J.-M. Effect of Friction conditions on Material Flow in FE Analysis of Al Piston Forging Process. Int. J. Precis. Eng. Manuf. 2019, 20, 1643–1652. [Google Scholar] [CrossRef]

- Lu, R.; Shiode, S.; Tani, H.; Tagawa, N.; Koganezawa, S. A Study on the Tribofilm Growth and Tribological Properties of Tribofilms Formed from Zinc Dialkyl Dithiophosphate (ZDDP) and Molybdenum Dialkyl Dithiocarbamate (MoDTC). Tribol. Online 2018, 13, 157–165. [Google Scholar] [CrossRef]

- Xu, D.; Wang, C.; Espejo, C.; Wang, J.; Neville, A.; Morina, A. Understanding the friction reduction mechanism based on the molybdenum disulfide tribofilm formation and removal. Langmuir 2018, 34, 13523–13533. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, W.; She, D.; Fu, Z.; Huang, H.; Liu, J. Effects of surface nanocrystallization on tribological properties of 316L stainless steel under MoDTC/ZDDP lubrications. Tribol. Int. 2014, 79, 42–51. [Google Scholar] [CrossRef]

- Segu, D.Z.; Kim, C.-L. Performance of composite ZrO2/MoDTC nanolubricant as an effective anti-friction and—Wear oil-based additive. Wear 2024, 536–537, 205178. [Google Scholar] [CrossRef]

- Segu, D.Z.; Chae, Y.; Lee, S.-J.; Kim, C.-L. Synergistic influences of laser surface texturing and ZrO2-MoDTC hybrid nanofluids for enhanced tribological performance. Tribol. Int. 2023, 183, 108377. [Google Scholar] [CrossRef]

- Wang, W.; Yu, M.; Ma, J.; Jia, Y. Tribological Properties of Nanoparticles in the Presence of MoDTC. Lubricants 2023, 11, 132. [Google Scholar] [CrossRef]

- Zhang, L.; Li, N. Tribological investigation of graphene or/and MoDTC as additives in PAO base oil. Diam. Relat. Mater. 2023, 136, 110043. [Google Scholar] [CrossRef]

- ISO 3104-2020; Petroleum products-Transparent and opaque liquids-Determination of kinematic viscosity and calculation of dynamic viscosity. ISO: Geneva, Switzerland, 2020.

- ASTM D2783-21-2022; Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-ball Method). ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D4172-21-2022; Standard Test Method for Wear Preventive Characteristics of Lubricating Fluids (Four-ball Method). ASTM: West Conshohocken, PA, USA, 2022.

- Xu, C.; Xigang, Y.; Yuening, L.; Xin, Z.; Tiancheng, A.; Guoshun, P.; Dan, G.; Guoxin, X. Tribological properties and synergetic self-lubricating mechanism of PS-PAO based nanocapsules with MoDTC addtives. Tribol. Int. 2023, 186, 108606. [Google Scholar] [CrossRef]

| Property | Additive Content | Viscosity at 40 °C/(mm2/s) | Viscosity at 100 °C/(mm2/s) | Test Method |

|---|---|---|---|---|

| BO | Base oil + Compound functional additive package | 26.96 | 5.67 | ISO 3104 [31] |

| BM | BO + MoDTC (1.0 wt%) | 29.24 | 6.13 | |

| BA | BO + ADDP (1.0 wt%) | 27.43 | 5.95 | |

| BMA | BO + MoDTC (1.0 wt%) + ADDP (1.0 wt%) | 28.12 | 6.04 |

| Specimen | PB/kg | PD/kg |

|---|---|---|

| BO | 80 | 100 |

| BM | 80 | 100 |

| BA | 126 | 160 |

| BMA | 160 | 200 |

| Specimen | Wear Scar Diameter/mm | Average Friction Coefficient | Frictional Torque/N∙m |

|---|---|---|---|

| BO | 0.55 | 0.121 | 0.19 |

| BM | 0.47 | 0.083 | 0.16 |

| BA | 0.40 | 0.099 | 0.17 |

| BMA | 0.38 | 0.081 | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, M.; Mo, Y.; Zhang, H.; Liu, Q. Synergistic Effect of Acrylate of Dialkyl Dithiophosphoric Acid Combined with Molybdenum Dialkyl Dithiocarbamate as Additives in Gear Oil. Lubricants 2024, 12, 165. https://doi.org/10.3390/lubricants12050165

Ding M, Mo Y, Zhang H, Liu Q. Synergistic Effect of Acrylate of Dialkyl Dithiophosphoric Acid Combined with Molybdenum Dialkyl Dithiocarbamate as Additives in Gear Oil. Lubricants. 2024; 12(5):165. https://doi.org/10.3390/lubricants12050165

Chicago/Turabian StyleDing, Minghao, Yimin Mo, Hong Zhang, and Qingchun Liu. 2024. "Synergistic Effect of Acrylate of Dialkyl Dithiophosphoric Acid Combined with Molybdenum Dialkyl Dithiocarbamate as Additives in Gear Oil" Lubricants 12, no. 5: 165. https://doi.org/10.3390/lubricants12050165

APA StyleDing, M., Mo, Y., Zhang, H., & Liu, Q. (2024). Synergistic Effect of Acrylate of Dialkyl Dithiophosphoric Acid Combined with Molybdenum Dialkyl Dithiocarbamate as Additives in Gear Oil. Lubricants, 12(5), 165. https://doi.org/10.3390/lubricants12050165