Utilization of Magnetic Fraction Isolated from Steel Furnace Slag as a Mild Abrasive in Formulation of Cu-Free Friction Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

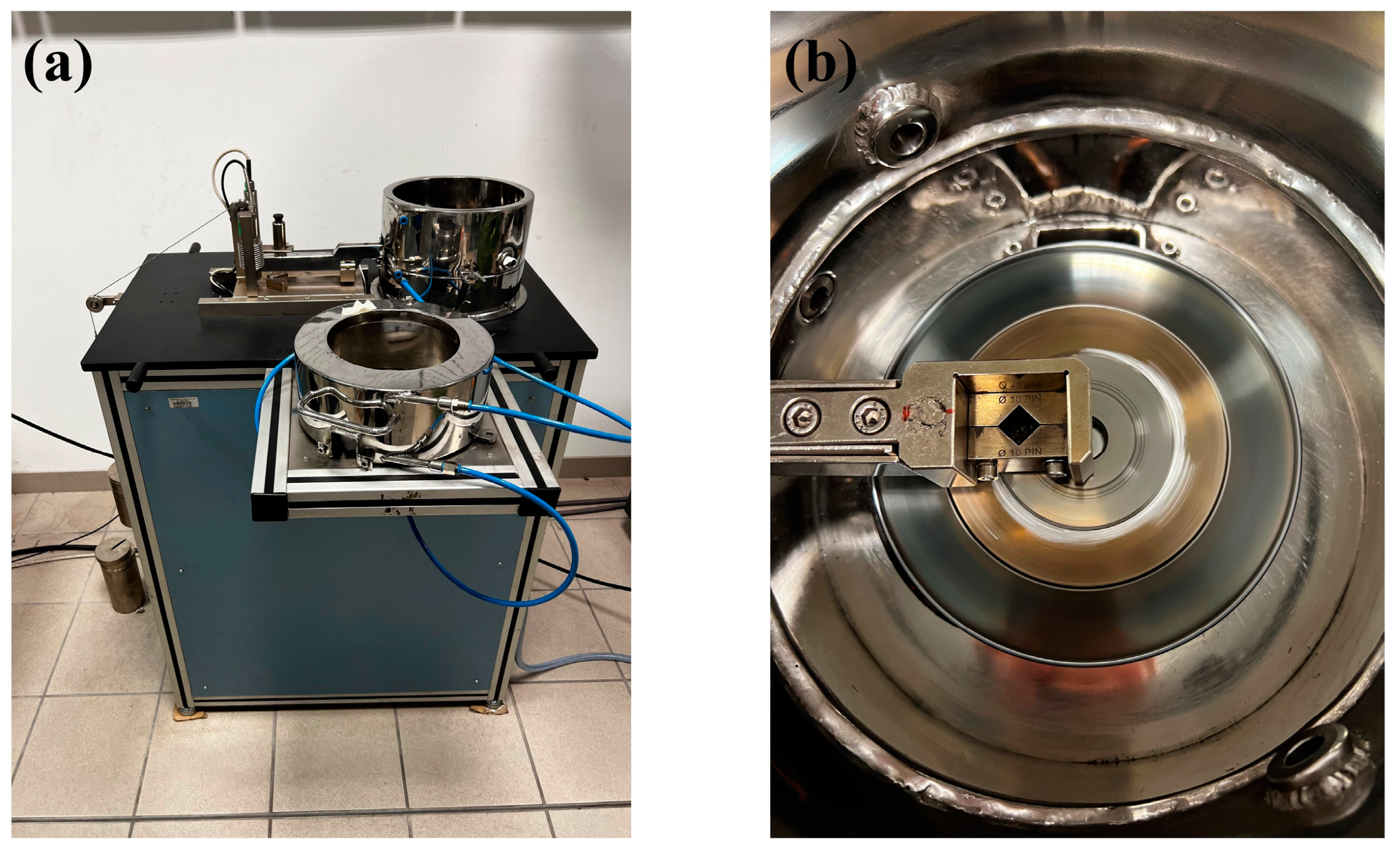

2.2. Pin-on-Disc (PoD) Tests

2.3. Characterization of Materials and Worn Surfaces

3. Results and Discussion

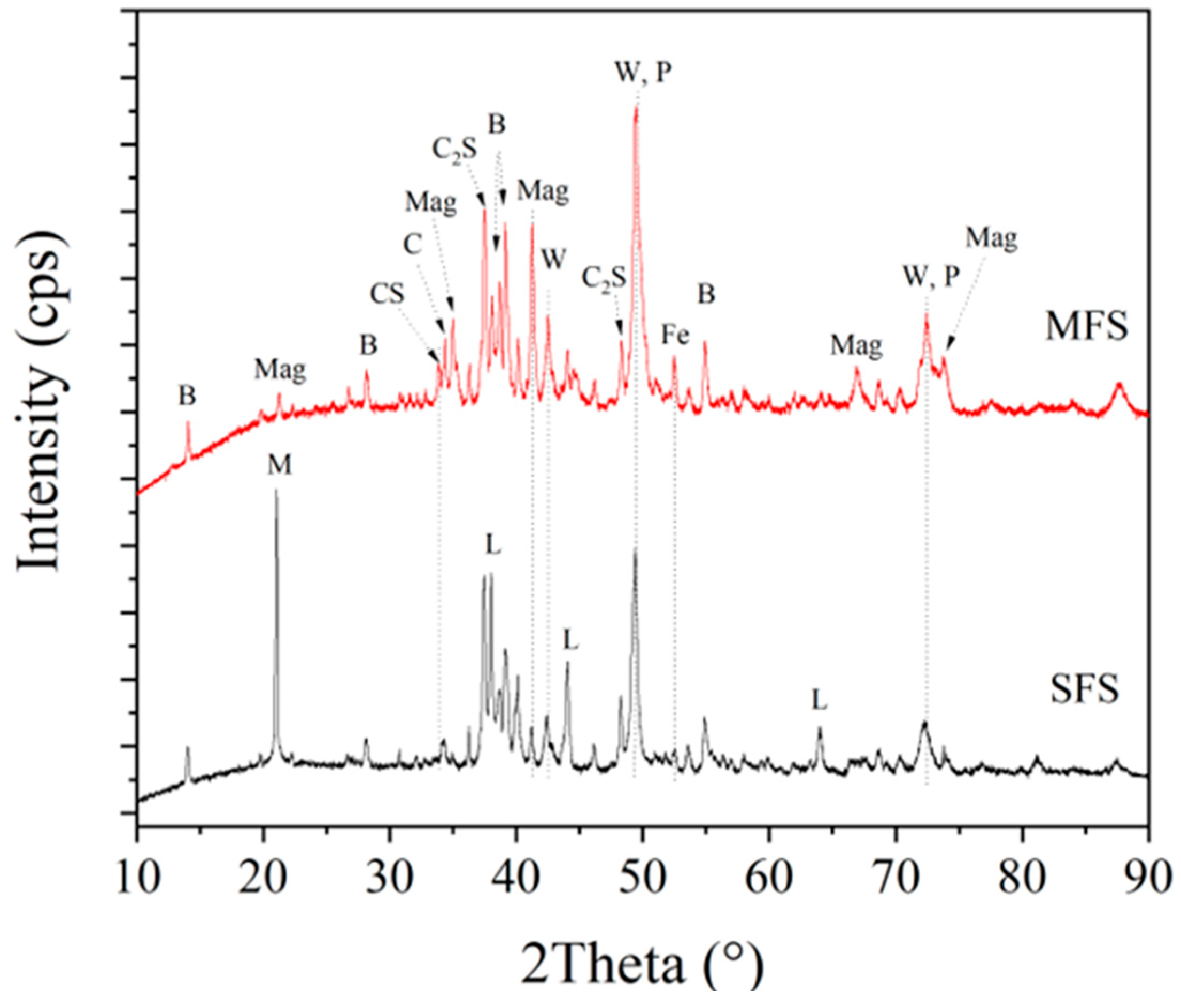

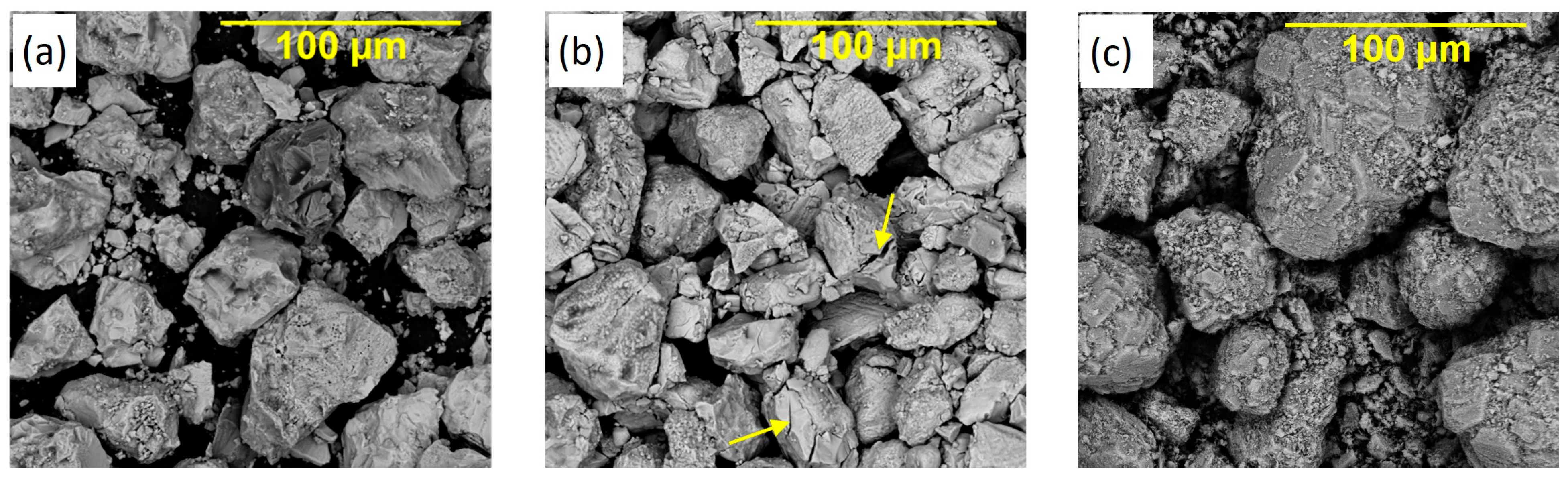

3.1. Characterization of SFS and MFS and Prepared Pins

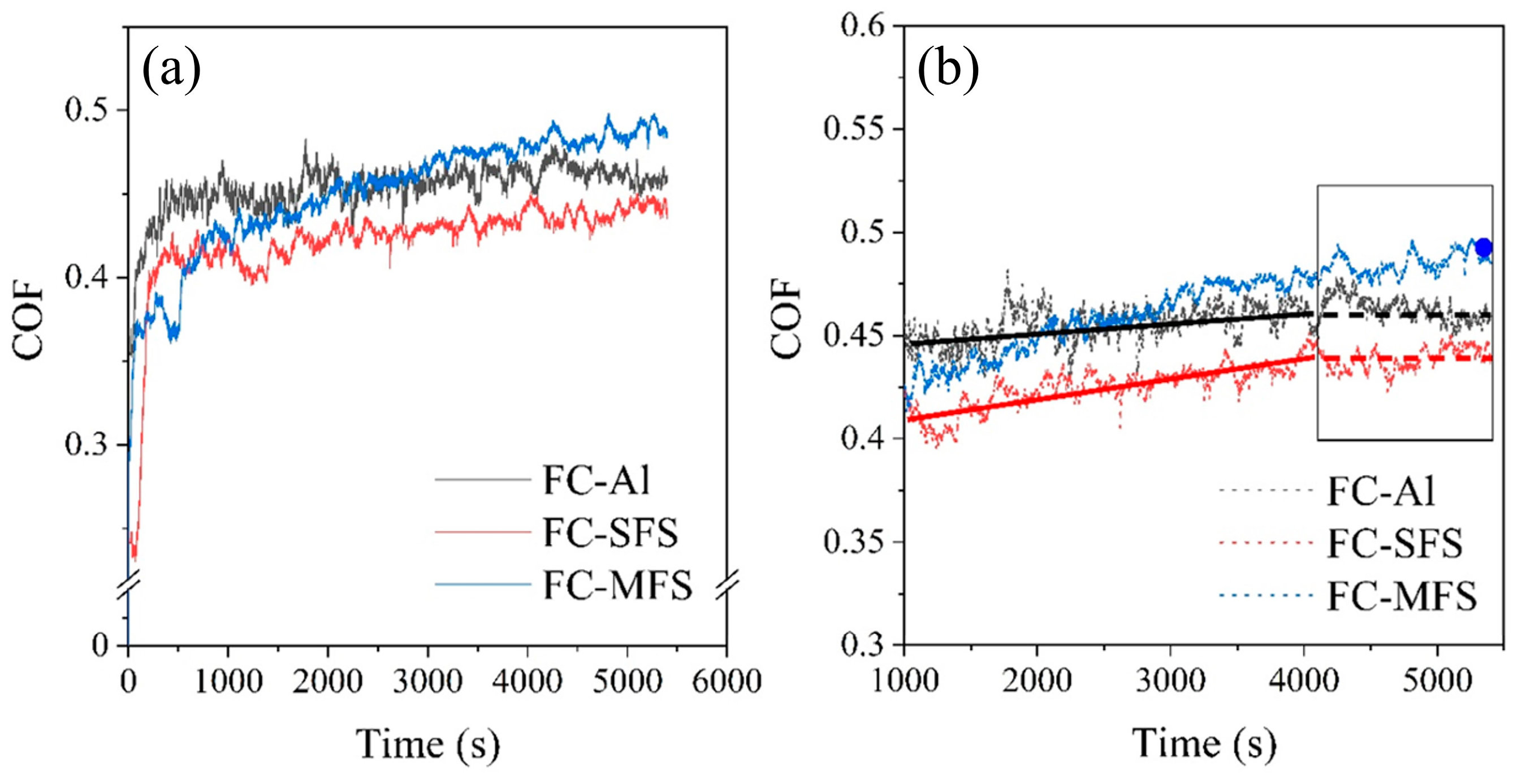

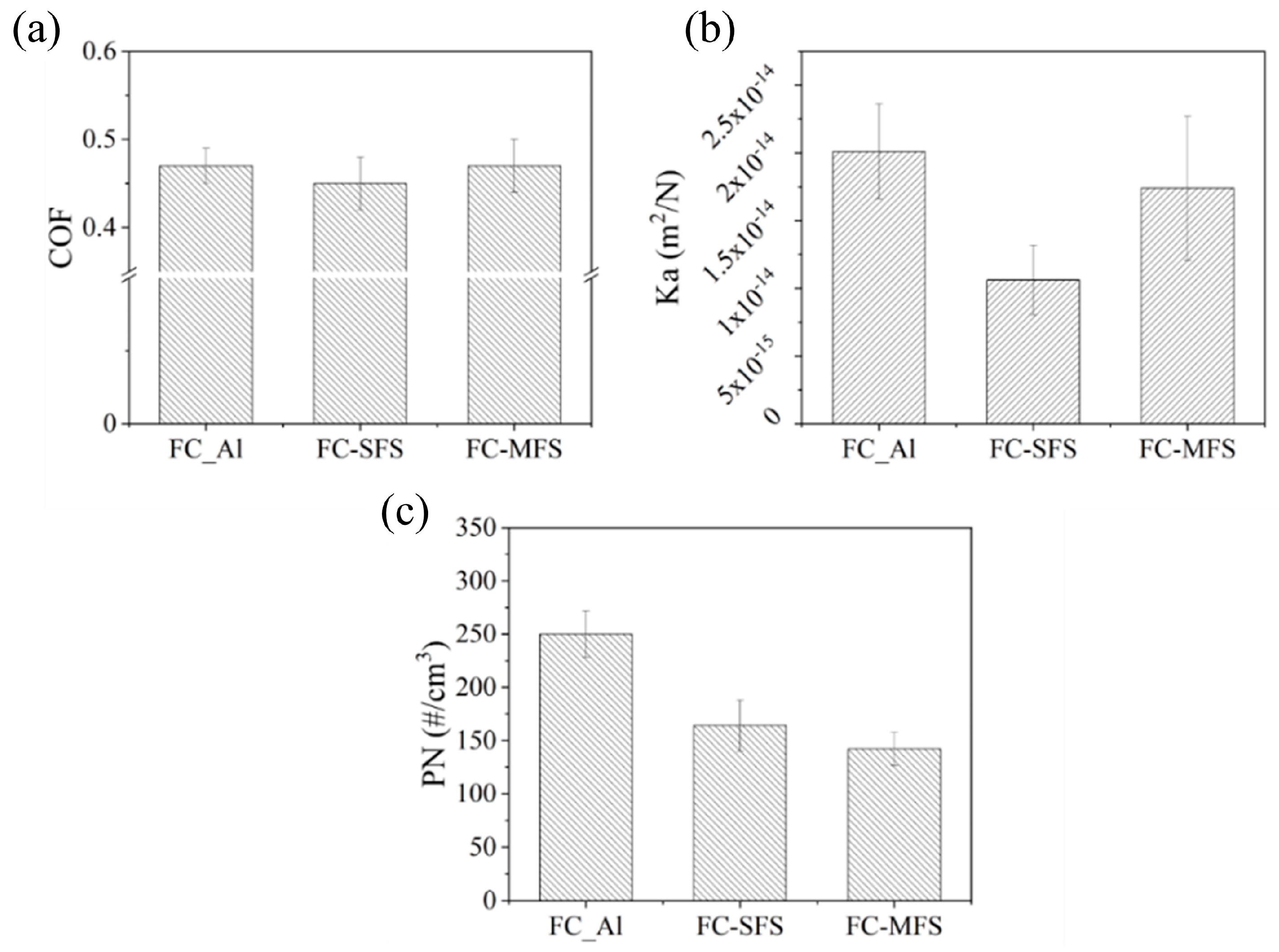

3.2. Friction–Wear Performance and Wear Particle Emissions Tested on PoD

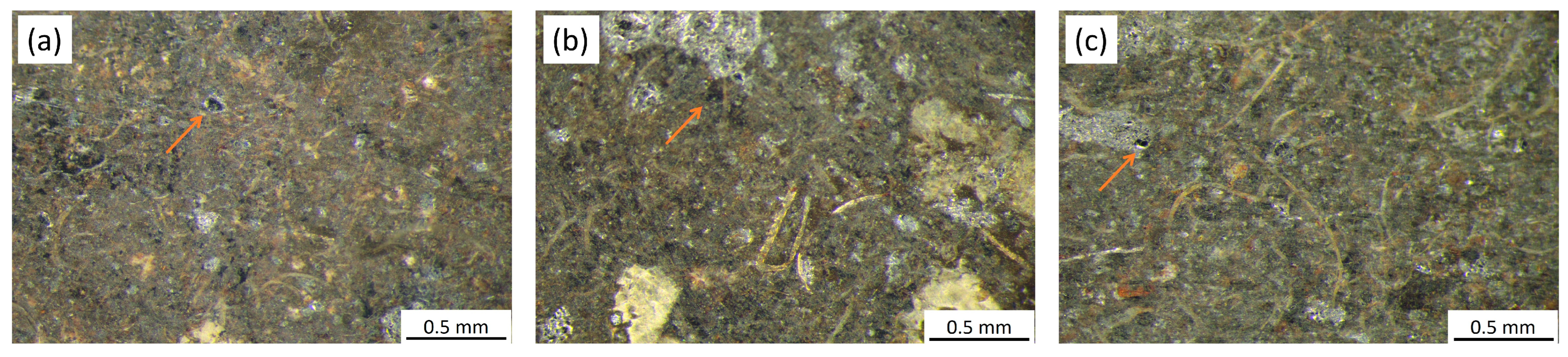

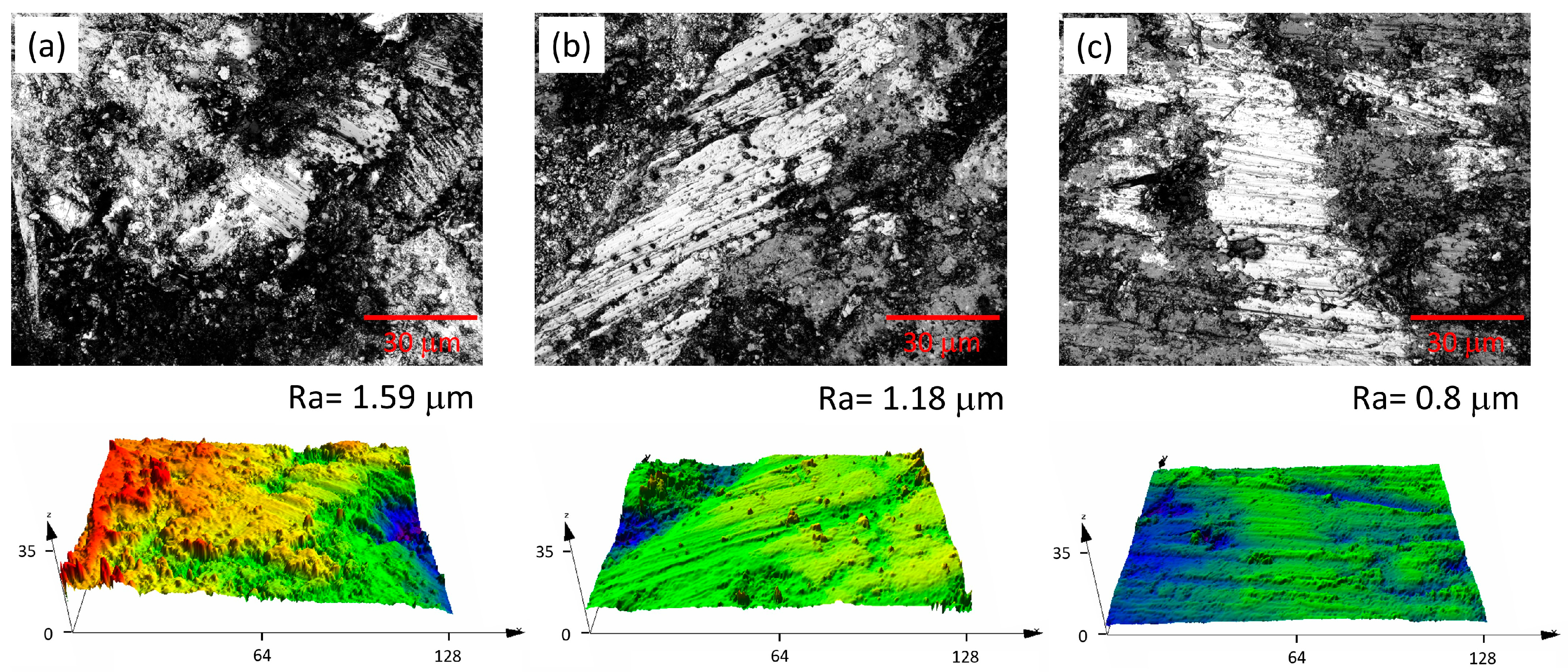

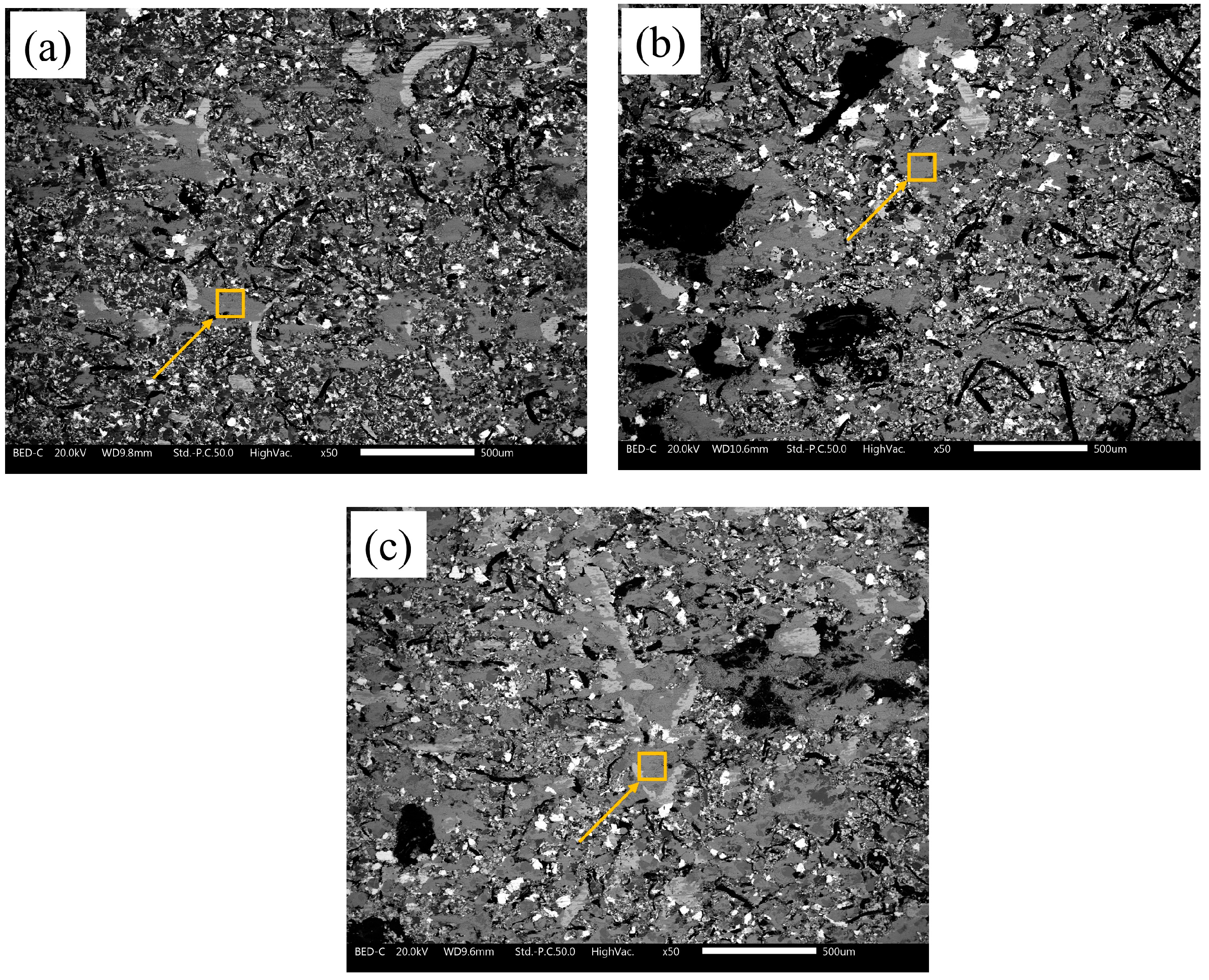

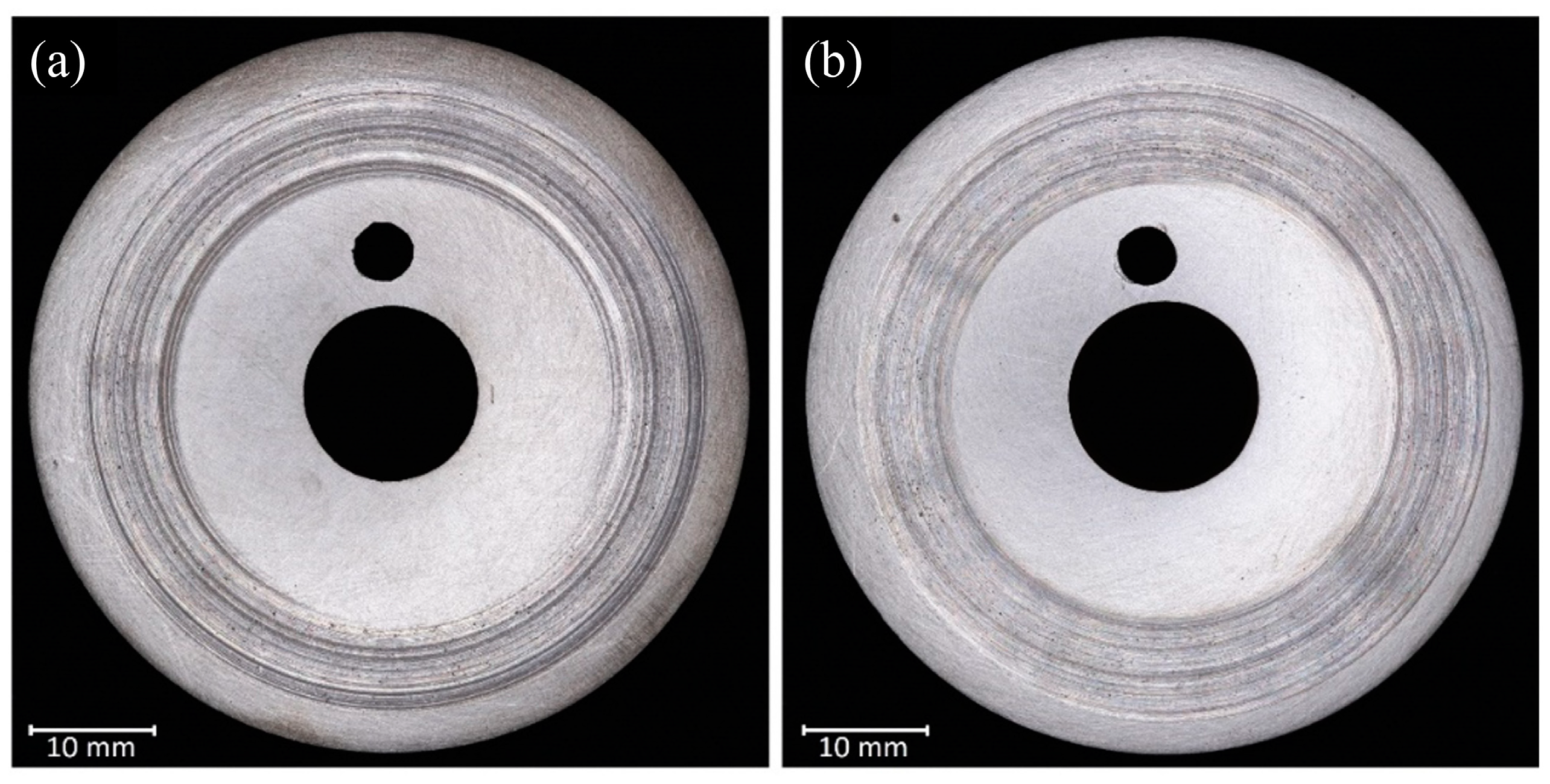

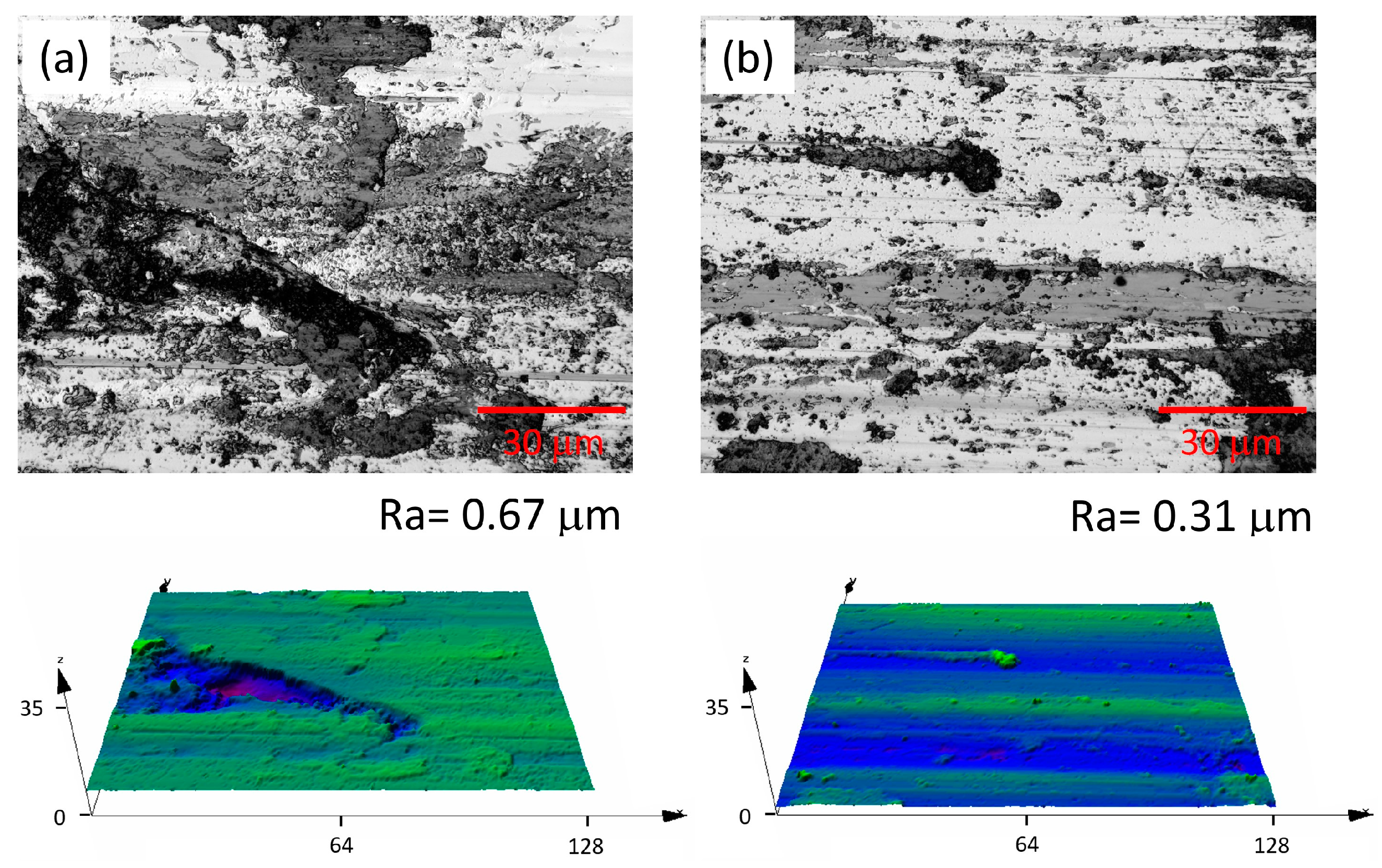

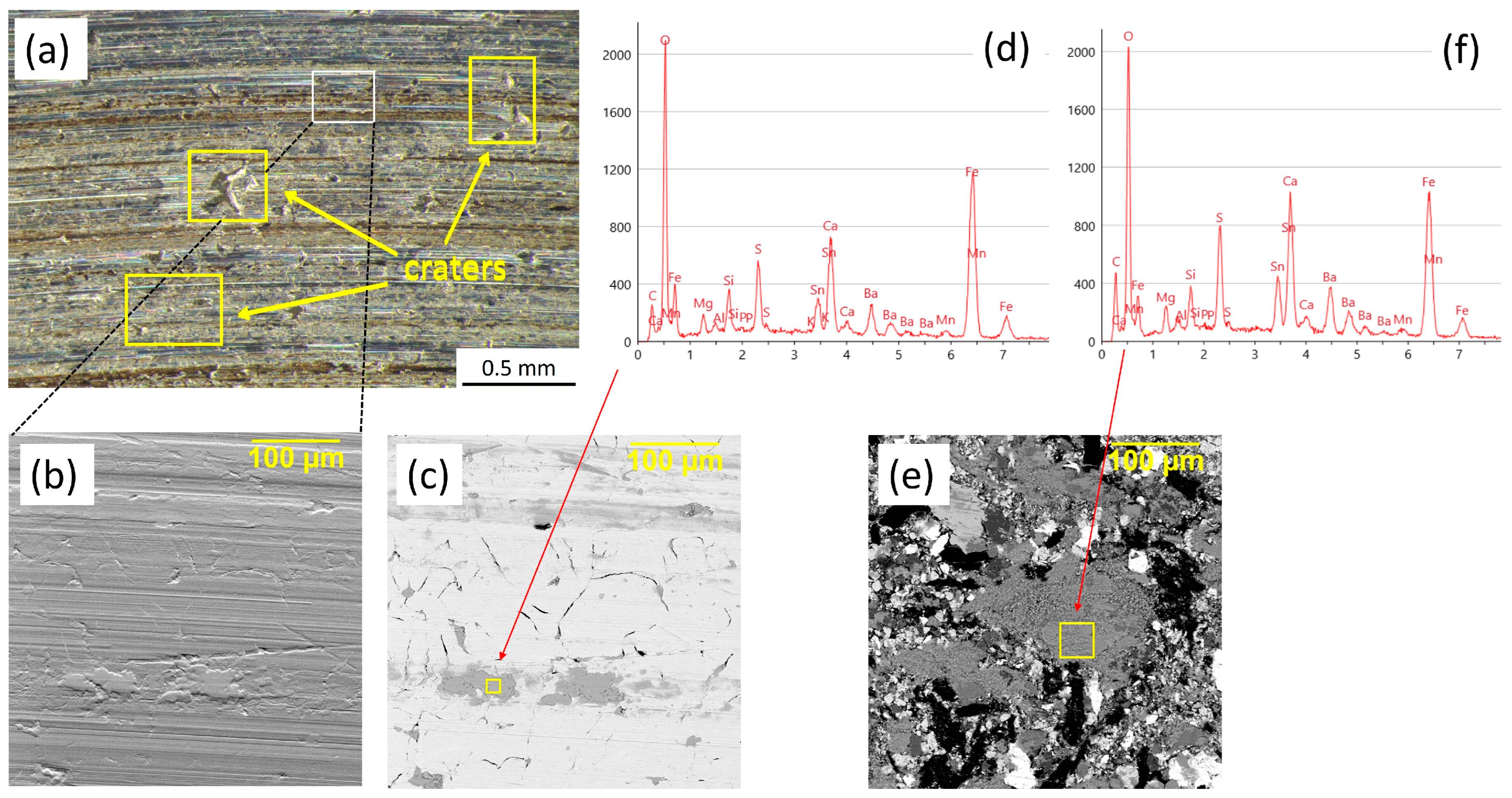

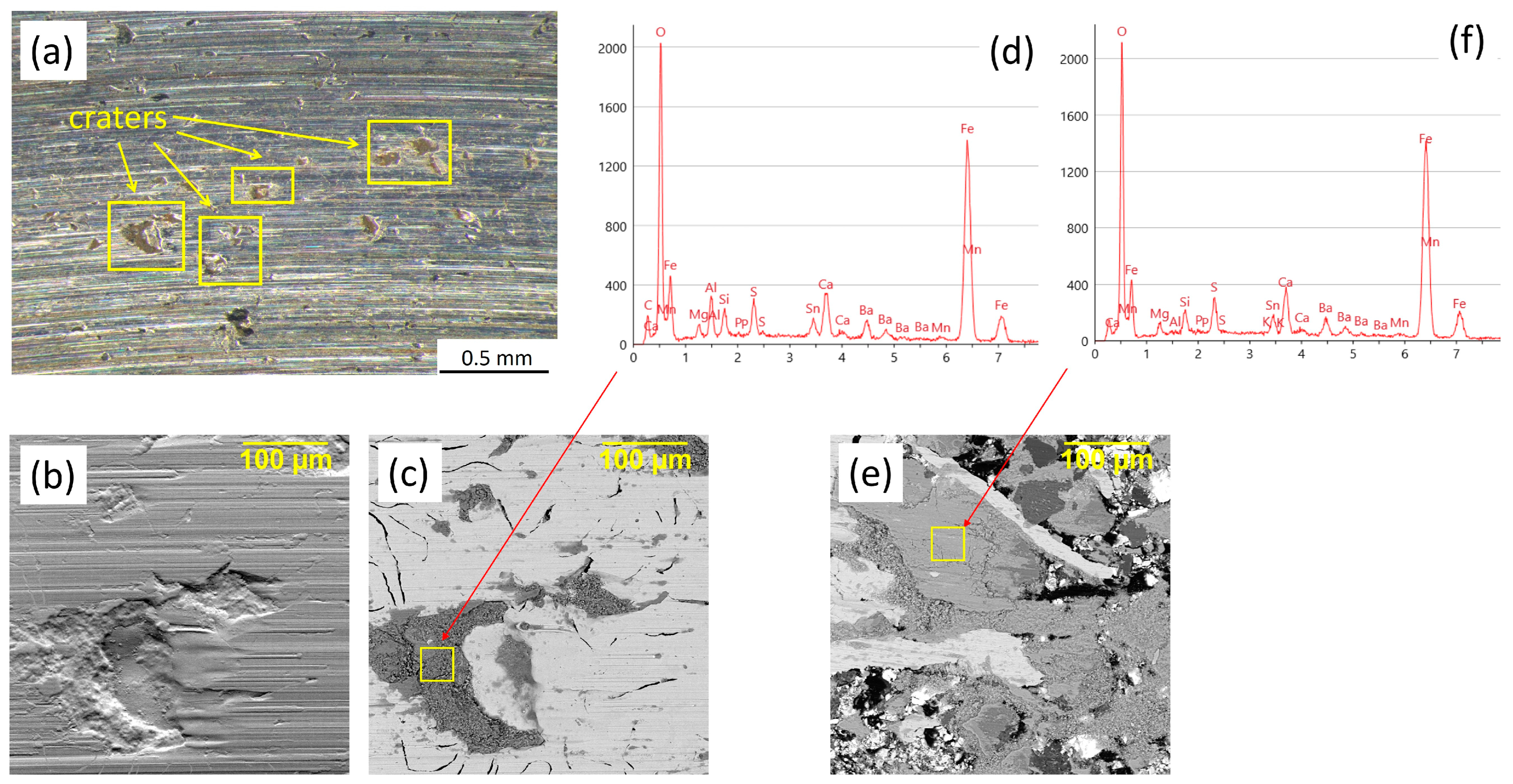

3.3. Characteristics of Worn Pin and Disc Surfaces

4. Conclusions

- (i)

- The higher content of iron-based phases in MFS, which makes the pins more compatible with the cast iron disc rotor, causing its lower wear rate;

- (ii)

- The cracked structure of MFS particles, which are easily fragmented during the friction process and effectively enrich the friction film that is formed on the pin/disc interface during the friction process;

- (iii)

- The positive effect of the absence of water-reactive phases in MFS, causing better distribution of the friction film over the pin to surface contact;

- (iv)

- The greater extent to which the craters were filled with wear particles on the disc surface, which makes the craters effective sources of particles for friction film formation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chan, D.; Stachowiak, G.W. Review of automotive brake friction materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Sathyamoorthy, G.; Vijay, R.; Lenin Singaravelu, D. Brake friction composite materials: A review on classifications and influences of friction materials in braking performance with characterizations. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1674–1706. [Google Scholar] [CrossRef]

- Pizzi, A.; Ibeh, C.C. Chapter 2—Phenol-formaldehyde resins. In Handbook of Thermoset Plastics, 4th ed.; Dodiuk, H., Ed.; William Andrew Publishing: Boston, MA, USA, 2022; pp. 13–40. [Google Scholar]

- Vijay, R.; Singaravelu, D.L.; Jayaganthan, R. Development and characterization of stainless steel fiber-based copper-free brake liner formulation: A positive solution for steel fiber replacement. Friction 2020, 8, 396–420. [Google Scholar] [CrossRef]

- Singh, T.; Pruncu, C.I.; Gangil, B.; Singh, V.; Fekete, G. Comparative performance assessment of pineapple and Kevlar fibers based friction composites. J. Mater. Res. Technol. 2020, 9, 1491–1499. [Google Scholar] [CrossRef]

- Mehta, V.; Kumar, N.; Algahtani, A.; Tirth, V.; Al-Mughanam, T.; Chau, K.-W. Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites. Molecules 2023, 28, 4861. [Google Scholar] [CrossRef]

- Machado Pinto, R.L.; Horta Gutiérrez, J.C.; Pereira, R.B.D.; de Faria, P.E.; Rubio, J.C.C. Influence of Contact Plateaus Characteristics Formed on the Surface of Brake Friction Materials in Braking Performance through Experimental Tests. Materials 2021, 14, 4931. [Google Scholar] [CrossRef]

- Eriksson, M.; Bergman, F.; Jacobson, S. On the nature of tribological contact in automotive brakes. Wear 2002, 252, 26–36. [Google Scholar] [CrossRef]

- Akıncıoğlu, G.; Akıncıoğlu, S.; Öktem, H.; Uygur, I. Wear response of non-asbestos brake pad composites reinforced with walnut shell dust. J. Aust. Ceram. Soc. 2020, 56, 1061–1072. [Google Scholar] [CrossRef]

- Park, J.; Gweon, J.; Seo, H.; Song, W.; Lee, D.; Choi, J.; Kim, Y.C.; Jang, H. Effect of space fillers in brake friction composites on airborne particle emission: A case study with BaSO4, Ca(OH)2, and CaCO3. Tribol. Int. 2022, 165, 107334. [Google Scholar] [CrossRef]

- Ammar, Z.; Ibrahim, H.; Adly, M.; Sarris, I.; Mehanny, S. Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review. J. Compos. Sci. 2023, 7, 72. [Google Scholar] [CrossRef]

- Vineeth, V.K.; Senthil, S.K. Characterization of Various Properties of Chemically Treated Allium sativum Fiber for Brake Pad Application. J. Nat. Fibers 2022, 19, 523–535. [Google Scholar]

- Österle, W.; Dmitriev, A.I. The Role of Solid Lubricants for Brake Friction Materials. Lubricants 2016, 4, 5. [Google Scholar] [CrossRef]

- Baskara Sethupathi, P.; Chandradass, J. Effect of zirconium silicate and mullite with three different particle sizes on tribo performance in a non-asbestos brake pad. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 314–325. [Google Scholar] [CrossRef]

- Matejka, V.; Lu, Y.F.; Jiao, L.; Huang, L.; Martynkova, G.S.; Tomasek, V. Effects of silicon carbide particle sizes on friction-wear properties of friction composites designed for car brake lining applications. Tribol. Int. 2010, 43, 144–151. [Google Scholar] [CrossRef]

- Russo, C.; Gautier di Confiengo, G.; Magnacca, G.; Faga, M.G.; Apicella, B. Insights on non-exhaust emissions: An approach for the chemical characterization of debris generated during braking. Heliyon 2023, 9, e20672. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H.; He, Z.; Mo, J.; Jin, W.; Shen, M.; Zhao, C. Impact of initial braking temperature on thermal-induced brake fade during long-downhill operations. Eng. Fail. Anal. 2025, 167, 109077. [Google Scholar] [CrossRef]

- Lee, W.K.; Rhee, T.H.; Kim, H.S.; Jang, H. Effects of antimony trisulfide (Sb2S3) on sliding friction of automotive brake friction materials. Met. Mater. Int. 2013, 19, 1101–1107. [Google Scholar] [CrossRef]

- Perricone, G.; Matějka, V.; Alemani, M.; Valota, G.; Bonfanti, A.; Ciotti, A.; Olofsson, U.; Söderberg, A.; Wahlström, J.; Nosko, O.; et al. A concept for reducing PM10 emissions for car brakes by 50%. Wear 2018, 396–397, 135–145. [Google Scholar] [CrossRef]

- Song, W.; Gweon, J.; Park, J.; Kwon, S.U.; Lee, J.J.; Kim, Y.C.; Jang, H. Effects of abrasive particles on the particulate matter emission of brake friction composites. Wear 2022, 504–505, 204436. [Google Scholar] [CrossRef]

- Song, W.; Park, J.; Choi, J.; Lee, J.J.; Jang, H. Effects of reinforcing fibers on airborne particle emissions from brake pads. Wear 2021, 484–485, 203996. [Google Scholar] [CrossRef]

- Park, J.; Song, W.; Gweon, J.; Seo, H.; Lee, J.J.; Jang, H. Size effect of zircon particles in brake pads on the composition and size distribution of emitted particulate matter. Tribol. Int. 2021, 160, 106995. [Google Scholar] [CrossRef]

- Rees, D.; Murray, J. Silica, silicosis and tuberculosis. Int. J. Tuberc. Lung Dis. 2007, 11, 474–484. [Google Scholar] [PubMed]

- Chauhan, V.; Bijwe, J.; Darpe, A. Functionalization of alumina particles to improve the performance of eco-friendly brake-pads. Friction 2021, 9, 1213–1226. [Google Scholar] [CrossRef]

- Etemadi, H.; Shojaei, A.; Jahanmard, P. Effect of alumina nanoparticle on the tribological performance of automotive brake friction materials. J. Reinf. Plast. Compos. 2014, 33, 166–178. [Google Scholar] [CrossRef]

- Chauhan, V.; Darpe, A.; Bijwe, J. Susceptibility of eco-friendly brake-pads to noise-vibration emanation due to siloxane treatment on alumina particles. Appl. Acoust. 2022, 185, 108377. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- López-Perales, J.F.; Contreras, J.E.; Vázquez-Rodríguez, F.J.; Gómez-Rodríguez, C.; Díaz-Tato, L.; Banda-Muñoz, F.; Rodríguez, E.A. Partial replacement of a traditional raw material by blast furnace slag in developing a sustainable conventional refractory castable of improved physical-mechanical properties. J. Clean. Prod. 2021, 306, 127266. [Google Scholar] [CrossRef]

- Wang, J.; Yang, L.; Luo, W.; Yang, G.; Miao, C.; Fu, J.; Xing, S.; Fan, P.; Lv, P.; Wang, Z. Sustainable biodiesel production via transesterification by using recyclable Ca2MgSi2O7 catalyst. Fuel 2017, 196, 306–313. [Google Scholar] [CrossRef]

- Santos, W.F.; Schollbach, K.; Melzer, S.; van der Laan, S.R.; Brouwers, H.J.H. Quantitative analysis and phase assemblage of basic oxygen furnace slag hydration. J. Hazard. Mater. 2023, 450, 131029. [Google Scholar] [CrossRef]

- Wang, G.C. Ferrous metal production and ferrous slags. In The Utilization of Slag in Civil Infrastructure Construction, 1st ed.; Wang, G.C., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 9–33. [Google Scholar]

- Matějka, V.; Jayashree, P.; Leonardi, M.; Vlček, J.; Sabovčík, T.; Straffelini, G. Utilization of Metallurgical Slags in Cu-free Friction Material Formulations. Lubricants 2022, 10, 219. [Google Scholar] [CrossRef]

- Jayashree, P.; Matějka, V.; Leonardi, M.; Straffelini, G. A novel path towards limiting non-exhaust particulate matter emissions of a commercial friction material through the addition of metallurgical slag. Sci. Rep. 2023, 13, 666. [Google Scholar] [CrossRef] [PubMed]

- Jayashree, P.; Matejka, V.; Sinha, A.; Gialanella, S.; Straffelini, G. A comprehensive study on the particulate matter characteristics of a friction material containing blast furnace slags. Tribol. Int. 2023, 186, 108567. [Google Scholar] [CrossRef]

- Chandra Verma, P.; Menapace, L.; Bonfanti, A.; Ciudin, R.; Gialanella, S.; Straffelini, G. Braking pad-disc system: Wear mechanisms and formation of wear fragments. Wear 2015, 322–323, 251–258. [Google Scholar] [CrossRef]

- Österle, W.; Dörfel, I.; Prietzel, C.; Rooch, H.; Cristol-Bulthé, A.L.; Degallaix, G.; Desplanques, Y. A comprehensive microscopic study of third body formation at the interface between a brake pad and brake disc during the final stage of a pin-on-disc test. Wear 2009, 267, 781–788. [Google Scholar] [CrossRef]

- Eriksson, M.; Lord, J.; Jacobson, S. Wear and contact conditions of brake pads: Dynamical in situ studies of pad on glass. Wear 2001, 249, 272–278. [Google Scholar] [CrossRef]

- Zheng, K.; Lin, Y.; Lai, T.; Gao, C.; Liu, M.; Ren, Z. Replacing copper in composites with waste foundry sand: A novel approach for Cu-free resin-based braking material. Tribol. Int. 2024, 191, 109110. [Google Scholar] [CrossRef]

- Singh, V.K. Hydration and setting of Portland cement. In The Science and Technology of Cement and Other Hydraulic Binders, 1st ed.; Singh, V.K., Ed.; Woodhead Publishing: Sawston, UK, 2023; pp. 423–466. [Google Scholar]

- Koehler, A.; Neubauer, J.; Goetz-Neunhoeffer, F. How C12A7 influences the early hydration of calcium aluminate cement at different temperatures. Cem. Concr. Res. 2022, 162, 106972. [Google Scholar] [CrossRef]

- Křístková, M.; Filip, P.; Weiss, Z.; Peter, R. Influence of metals on the phenol–formaldehyde resin degradation in friction composites. Polym. Degrad. Stab. 2004, 84, 49–60. [Google Scholar] [CrossRef]

| Component | Specimen Code Name | ||

|---|---|---|---|

| FC–Al | FC–SFS | FC–MFS | |

| Phenolic Binder | 8 | 8 | 8 |

| Graphite | 10 | 10 | 10 |

| Tin Sulfide | 10 | 10 | 10 |

| Barite and Calcite | 25 | 25 | 25 |

| Vermiculite | 10 | 10 | 10 |

| Steel Wool | 5 | 5 | 5 |

| Iron Powder | 5 | 5 | 5 |

| Aramid Fibers | 7 | 7 | 7 |

| Alumina | 20 | 0 | 0 |

| SFS | 0 | 20 | 0 |

| MFS | 0 | 0 | 20 |

| Sample | Fe2O3 | CaO | SiO2 | MnO | MgO | Al2O3 | P2O5 | TiO2 |

|---|---|---|---|---|---|---|---|---|

| SFS | 31.2 | 48.6 | 8.83 | 4.59 | 3.00 | 1.40 | 1.01 | 0.683 |

| MFS | 52.5 | 29.9 | 3.78 | 7.59 | 3.71 | 0.724 | 0.746 | 0.385 |

| Parameter | Specimen Code Name | ||

|---|---|---|---|

| FC–Al | FC–SFS | FC–MFS | |

| Bulk density (g∙cm−3) | 2.419 | 2.661 | 2.683 |

| Hardness, HBW1/10 | 41 | 57 | 51 |

| Compressive strength (MPa) | 89.9 | 146.8 | 153.9 |

| Composite | Fe | Ba | Al | Sn | S | Ca | Mg | Si | O |

|---|---|---|---|---|---|---|---|---|---|

| FC–Al | 38.0 | 7.29 | 7.35 | 5.40 | 3.32 | 2.55 | 1.61 | 1.61 | 19.8 |

| FC–SFS | 50.7 | 5.31 | 0.21 | 3.56 | 2.33 | 4.26 | 1.11 | 1.53 | 18.6 |

| FC–MFS | 57.3 | 4.94 | 0.21 | 3.78 | 2.26 | 3.59 | 1.41 | 1.42 | 16.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matějka, V.; Jayashree, P.; Foniok, K.; Vlček, J.; Matějková, P.; Straffelini, G. Utilization of Magnetic Fraction Isolated from Steel Furnace Slag as a Mild Abrasive in Formulation of Cu-Free Friction Composites. Lubricants 2024, 12, 440. https://doi.org/10.3390/lubricants12120440

Matějka V, Jayashree P, Foniok K, Vlček J, Matějková P, Straffelini G. Utilization of Magnetic Fraction Isolated from Steel Furnace Slag as a Mild Abrasive in Formulation of Cu-Free Friction Composites. Lubricants. 2024; 12(12):440. https://doi.org/10.3390/lubricants12120440

Chicago/Turabian StyleMatějka, Vlastimil, Priyadarshini Jayashree, Kryštof Foniok, Jozef Vlček, Petra Matějková, and Giovanni Straffelini. 2024. "Utilization of Magnetic Fraction Isolated from Steel Furnace Slag as a Mild Abrasive in Formulation of Cu-Free Friction Composites" Lubricants 12, no. 12: 440. https://doi.org/10.3390/lubricants12120440

APA StyleMatějka, V., Jayashree, P., Foniok, K., Vlček, J., Matějková, P., & Straffelini, G. (2024). Utilization of Magnetic Fraction Isolated from Steel Furnace Slag as a Mild Abrasive in Formulation of Cu-Free Friction Composites. Lubricants, 12(12), 440. https://doi.org/10.3390/lubricants12120440