Towards a Model-Based Methodology for Rating and Monitoring Wear Risk in Oscillating Grease-Lubricated Rolling Bearings

Abstract

1. Introduction

1.1. Oscillating Bearings in Wind Turbines and False Brinelling

1.2. Background on Model-Based Wear Assessment

2. Materials and Methods

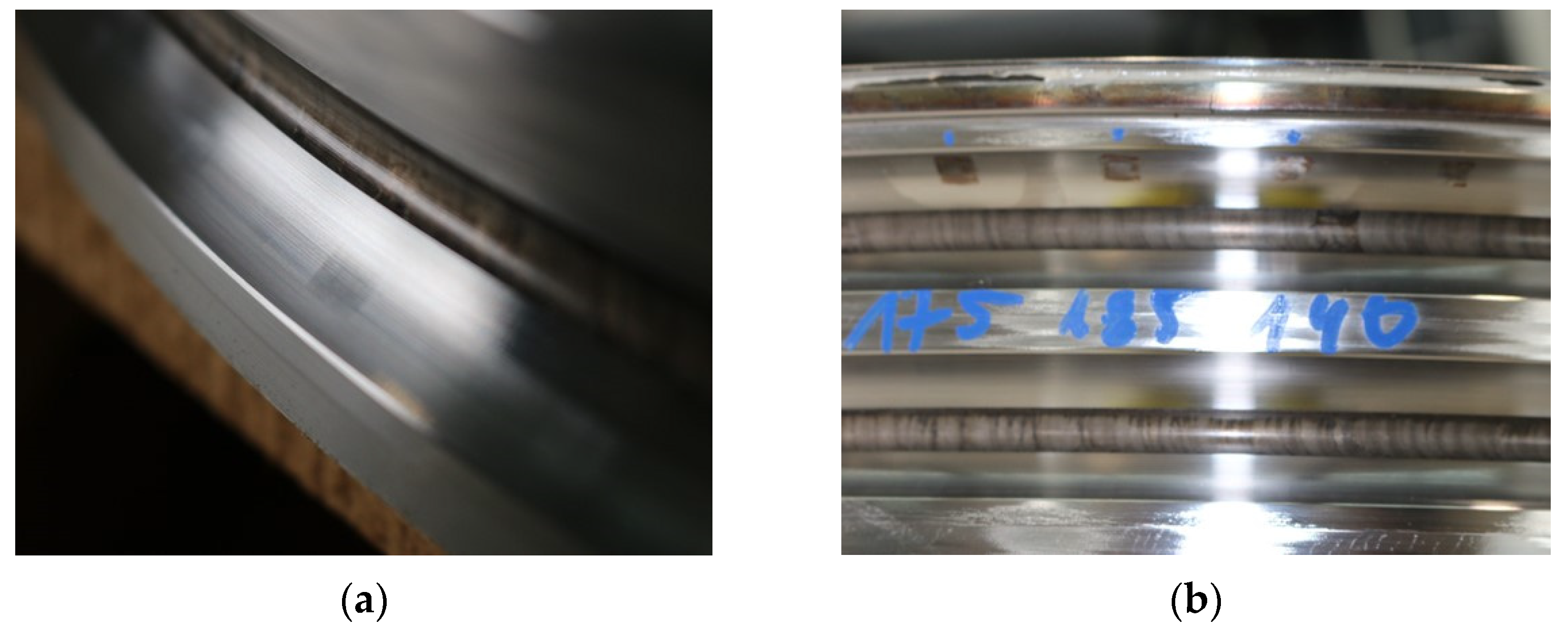

2.1. Experimental Setup

2.2. Empirical and Energy-Based Wear Model

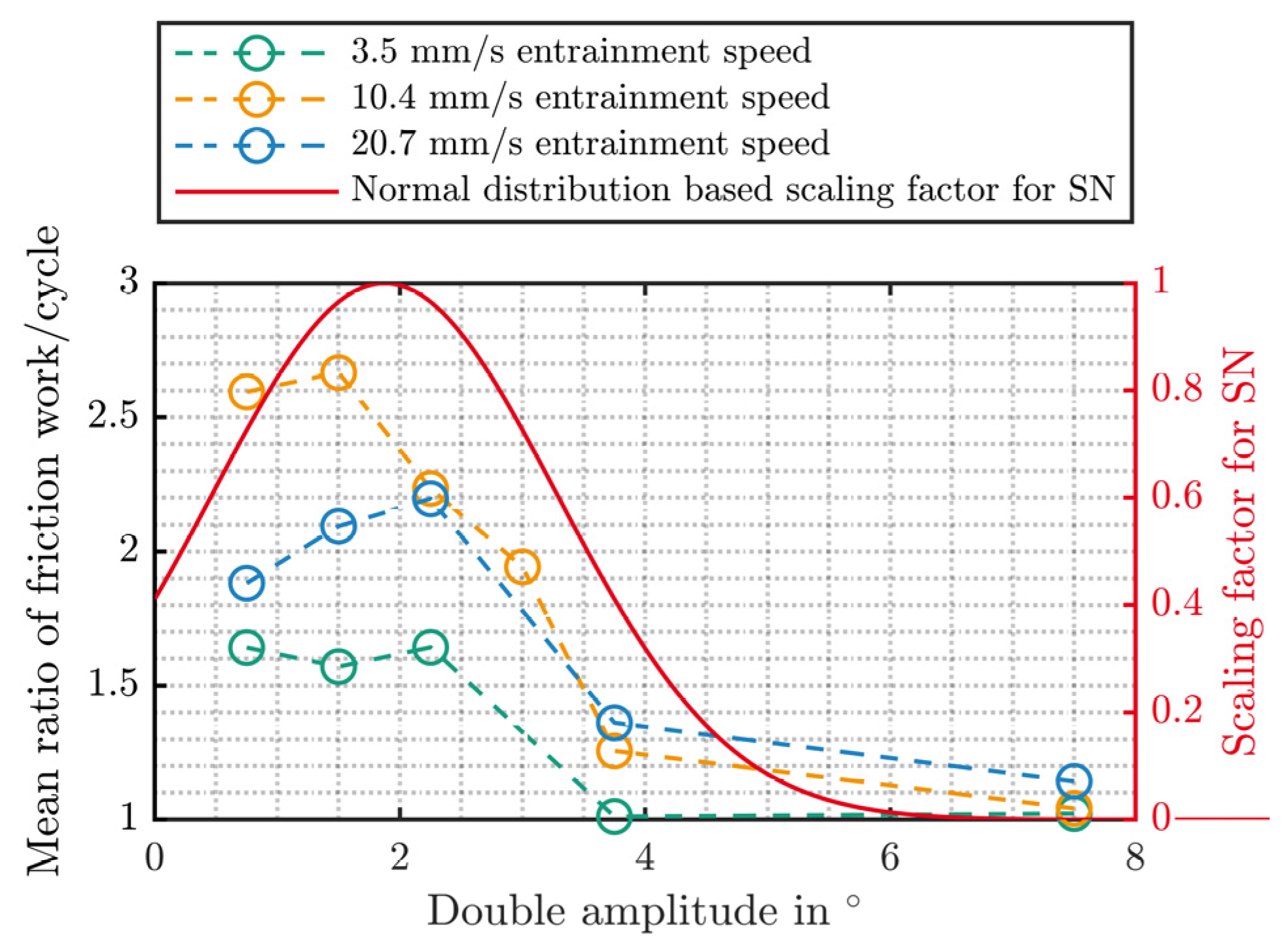

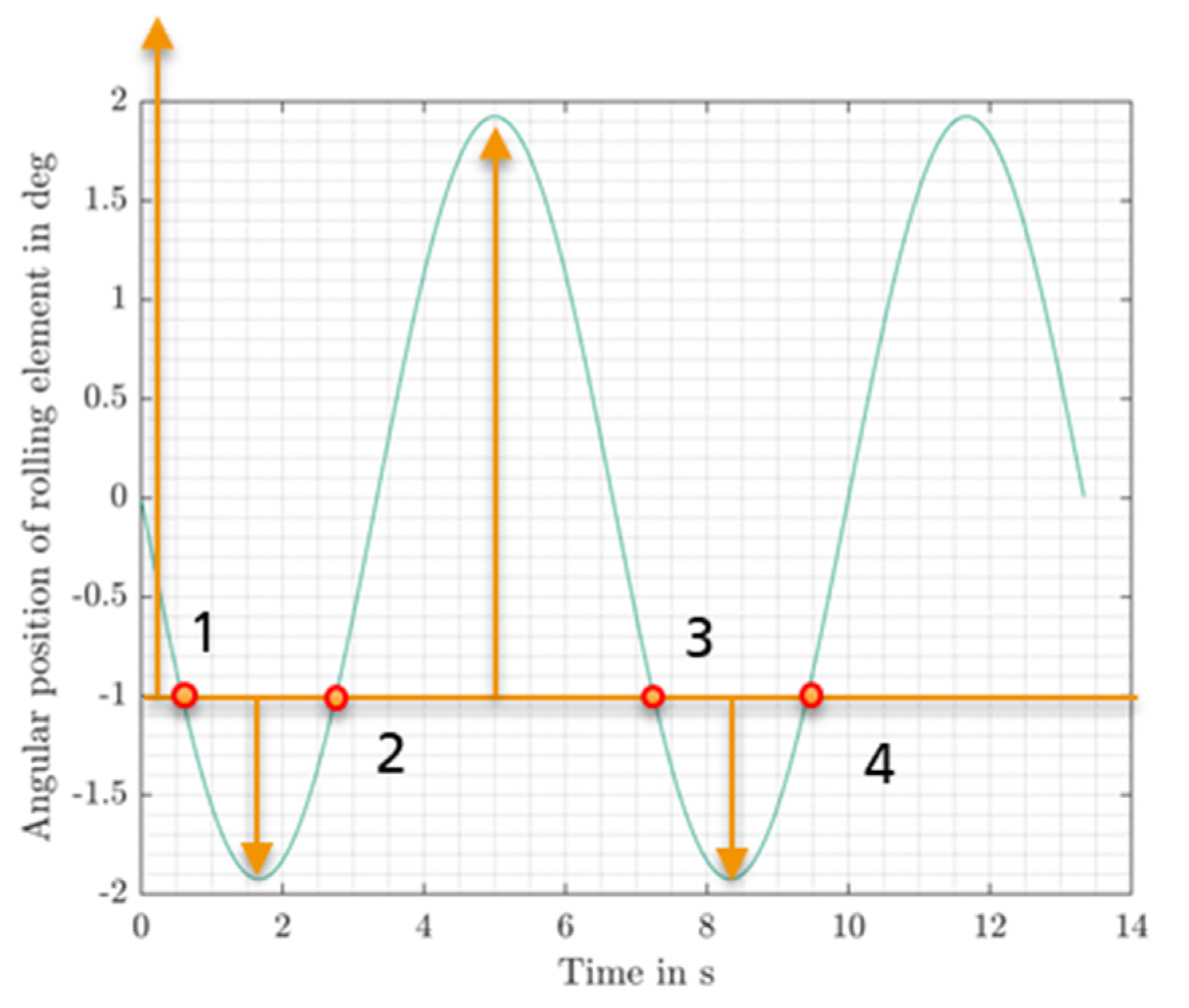

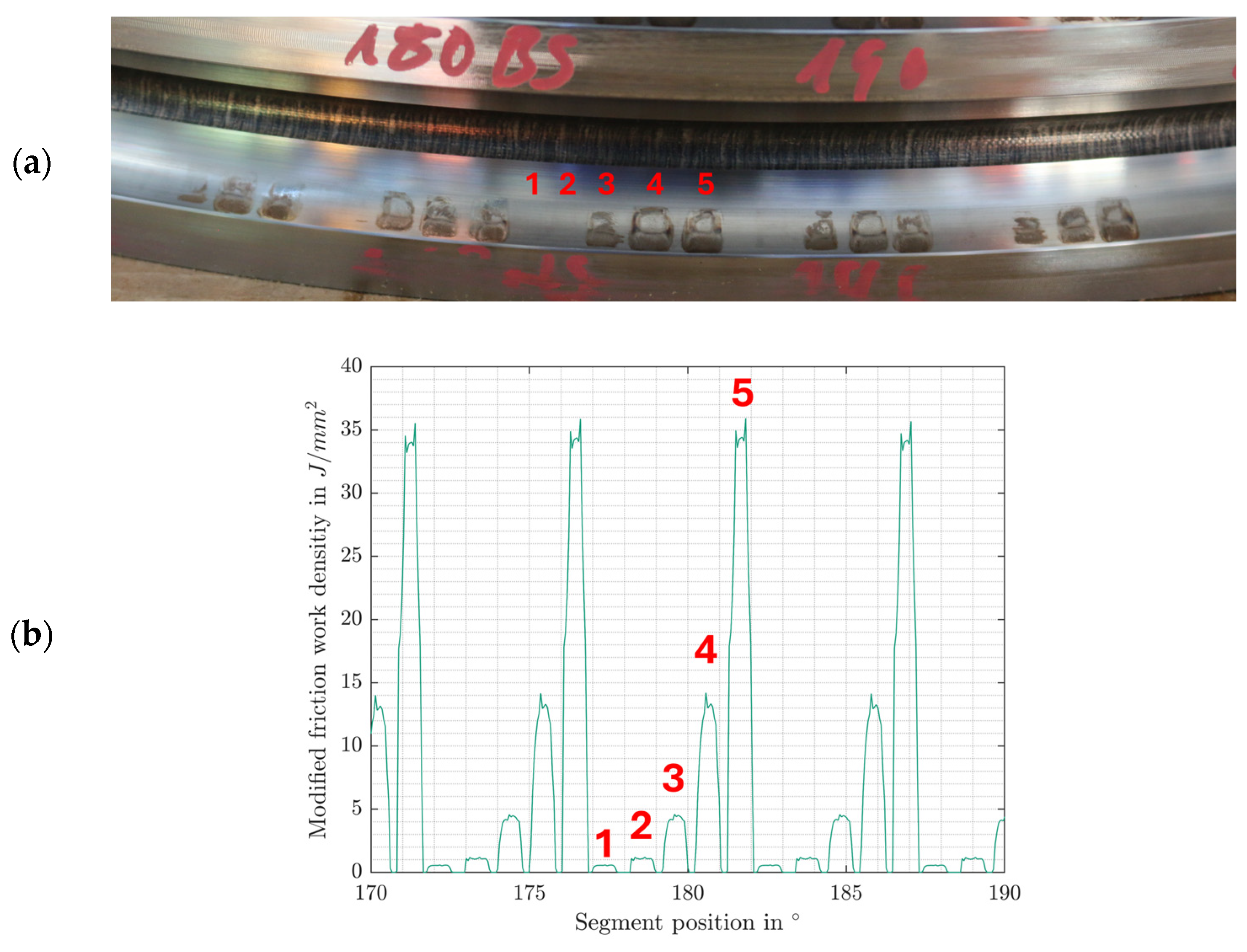

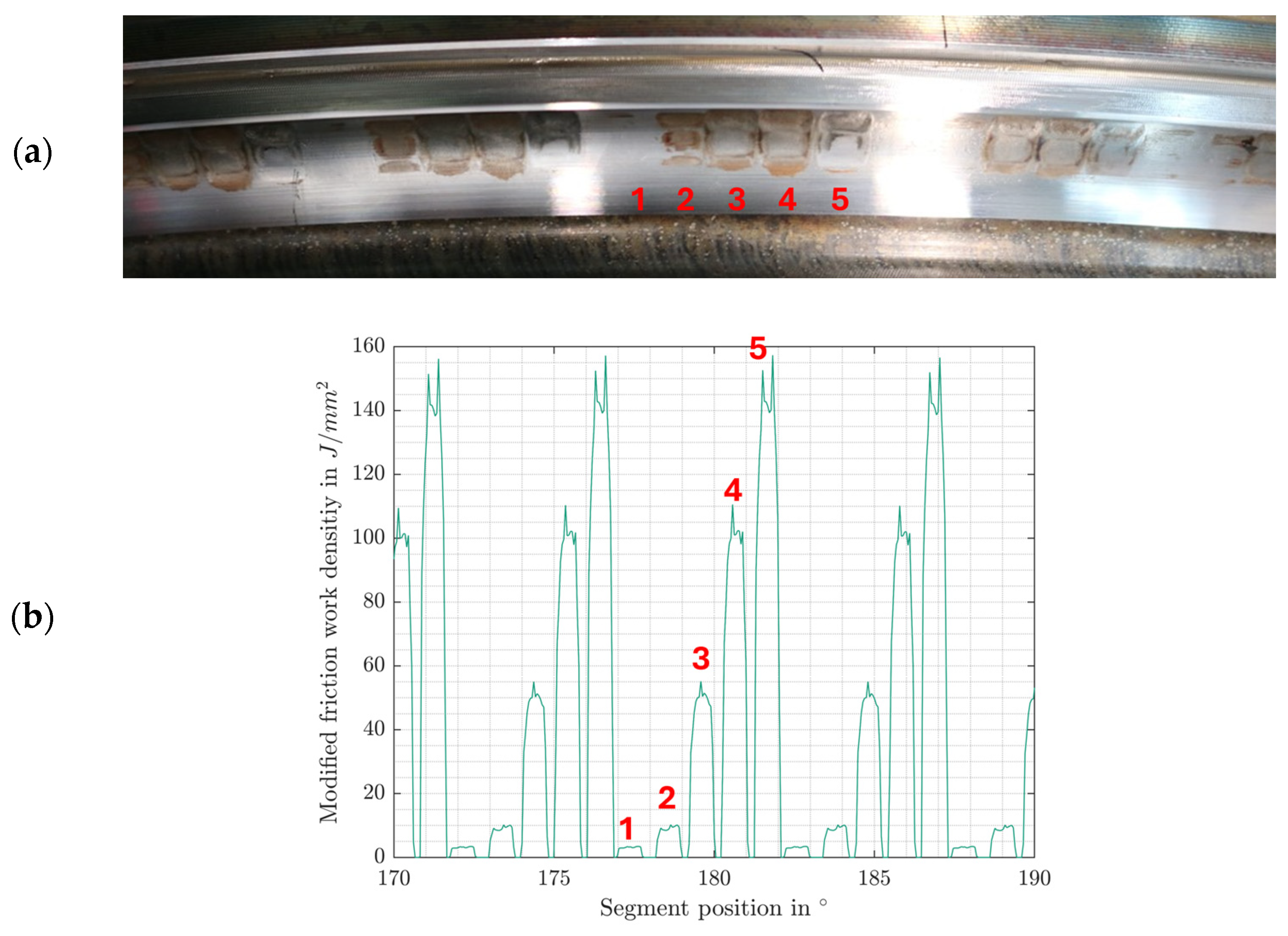

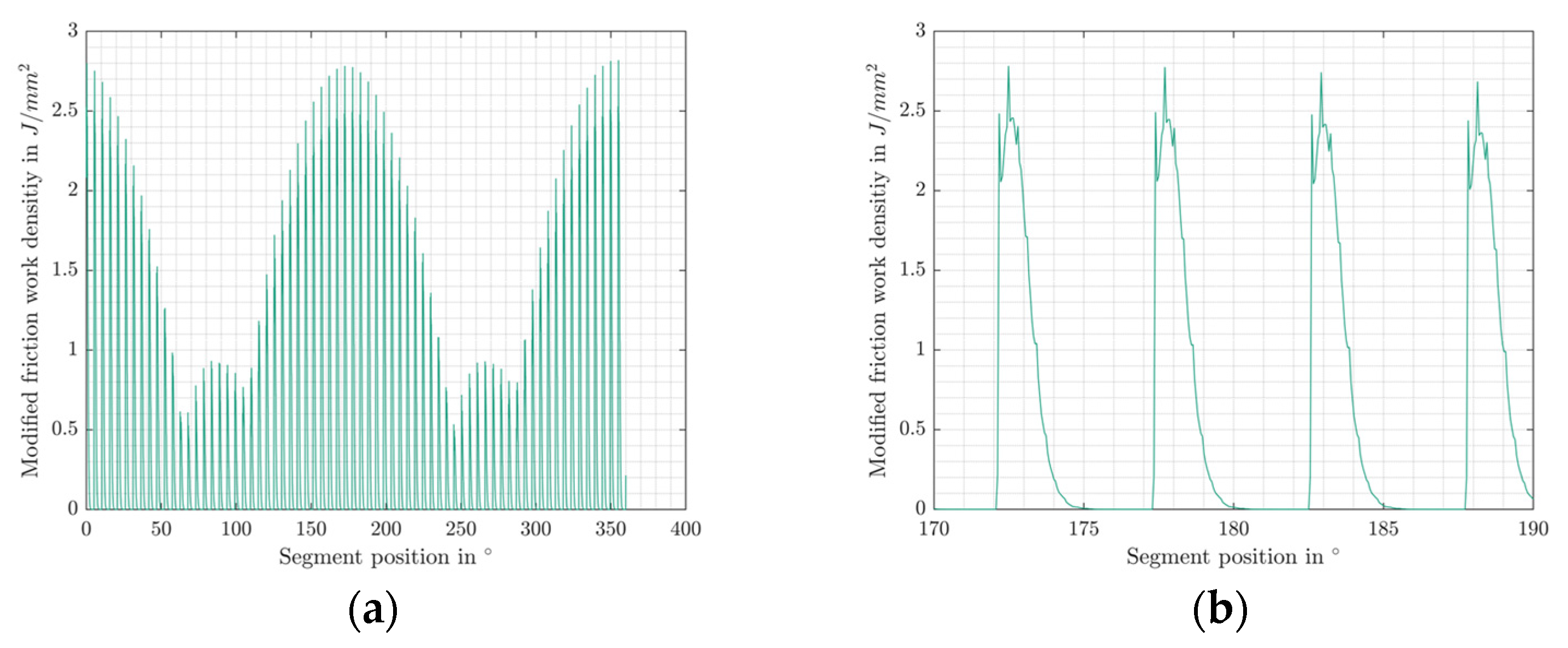

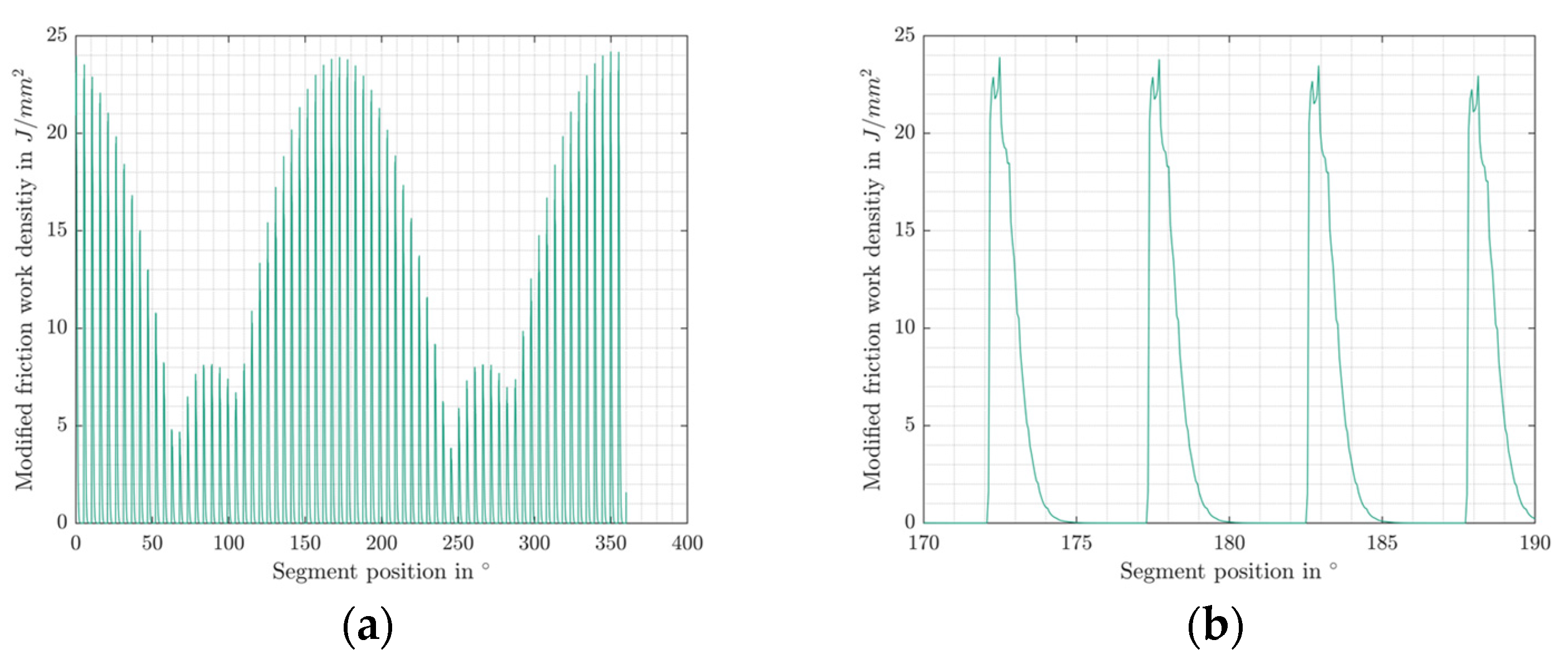

2.2.1. Friction Work Density

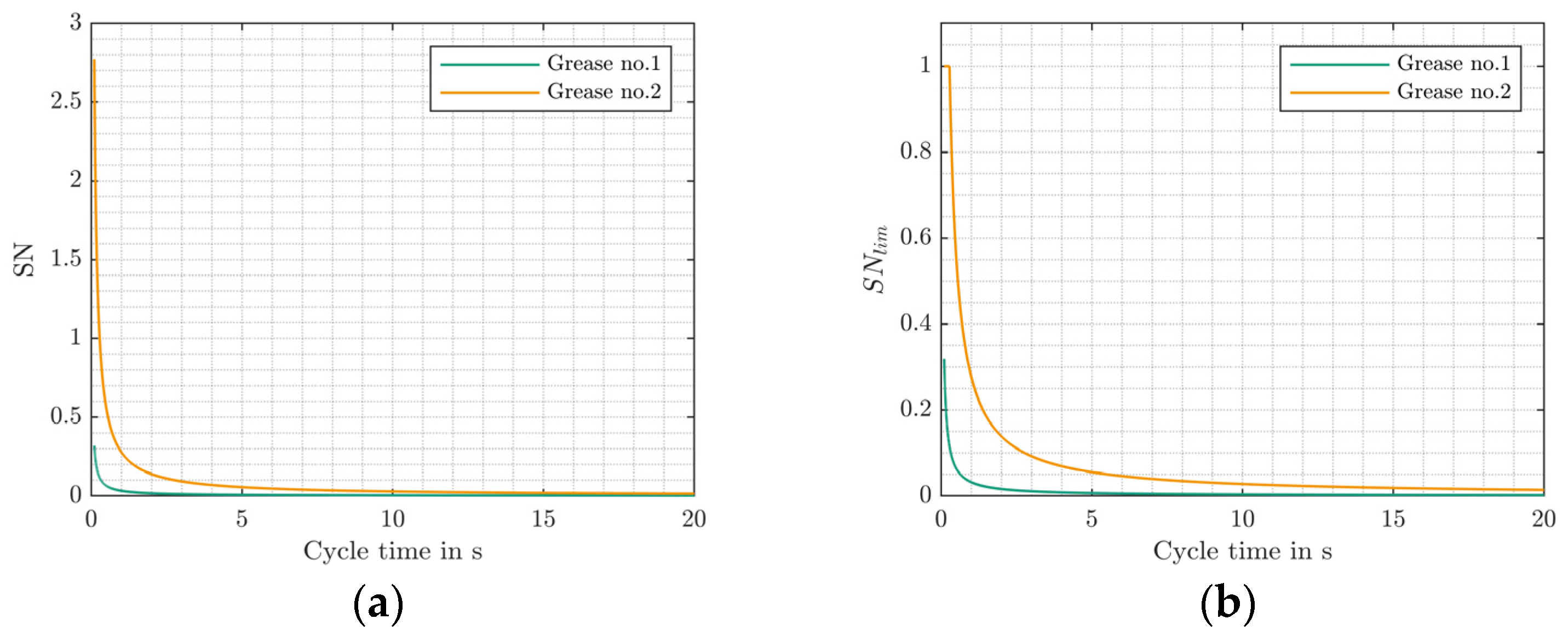

2.2.2. The Starvation Number

2.2.3. Reset Feature and Threshold Value

3. Results

3.1. Results from False Brinelling Screening Tests

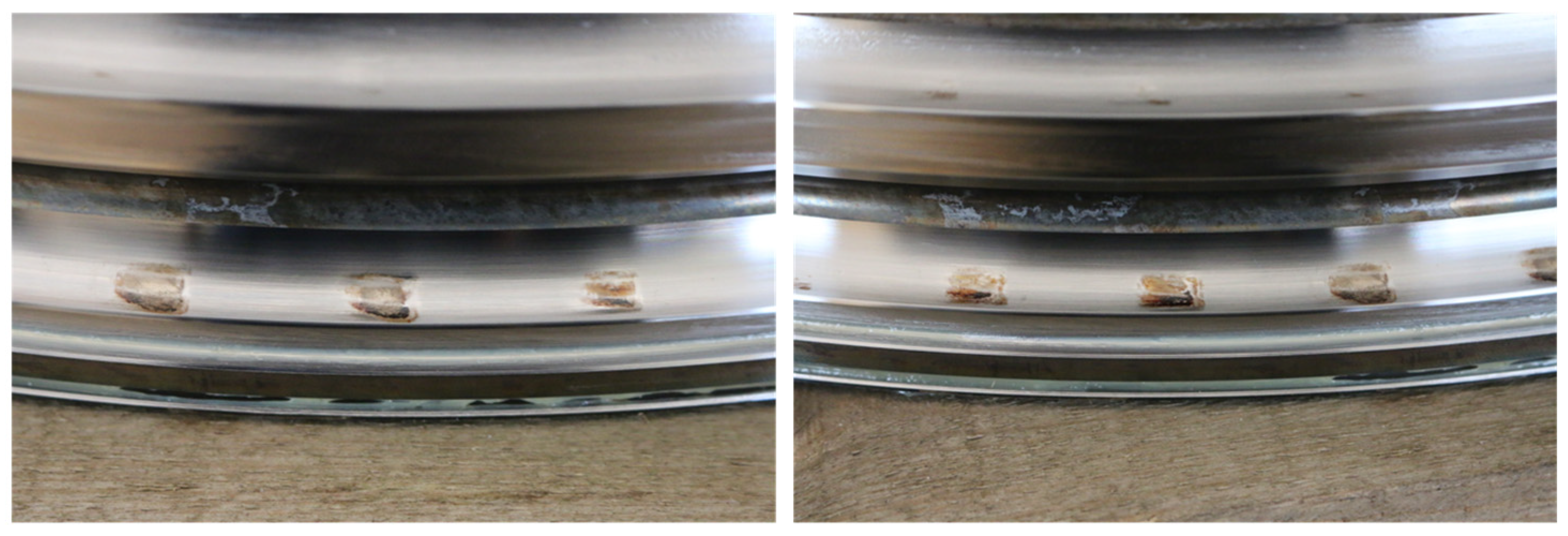

3.2. Results from Test with Protection Runs

3.3. Results from Test with Wind Turbine-Specific Operation Conditions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MFD | Modified friction work density |

| SBB | Small-scale blade bearings |

| 4P BB | 4-point contact ball bearing |

| CPC | Collective pitch control |

| IPC | Individual pitch control |

| BEAT1.1 | Bearing Endurance and Acceptance Test Rig 1.1 |

| DOF | Degree of freedom |

Nomenclature

| Area of a segment | Friction torque | ||

| Half height of a Hertzian contact ellipse | Time a rolling element leaves a segment | ||

| Width of a Hertzian contact ellipse | Time a rolling element enters a segment | ||

| Pitch diameter of a bearing | Translatory travel distance of rolling element | ||

| Pitch diameter of the rolling element | Amplitude ratio | ||

| Cumulative modified friction work density of a segment in of a bearing | Number of rolling elements | ||

| Threshold value of the modified friction work density of a segment of a bearing for wear initiation | Contact angle | ||

| Dissipated energy density in a segment per cycle | Angle of rotation of a rolling element | ||

| Friction work/energy per segment and oscillation cycle | Double amplitude oscillation angle of the inner ring | ||

| Frequency | Double amplitude oscillation angle of the inner ring for a protection run | ||

| Cycle of overrolling of a segment | Worst double amplitude oscillation angle of a rolling element for wear initiation | ||

| Finite segment of the bearing raceway | Critical standard deviation | ||

| Bleeding rate of the grease | Surface tension between base oil and air | ||

| Normal load of a rolling element within a segment | Dynamic base oil viscosity | ||

| Normal load of a rolling element | Base oil viscosity | ||

| Estimated degree of starvation per oscillation cycle and segment | Pitching speed |

References

- Haus, L.; Sheng, S.; Polikollu, R.V. Wind Turbine Major Systems Reliability Trends and Mitigation Strategies. Presented at the Drivetrain Reliability Collaborative Workshop; Chicago, IL, USA, 12–14 March 2024. [Google Scholar]

- Bossanyi, E.A. Individual Blade Pitch Control for Load Reduction. Wind Energ. 2003, 6, 119–128. [Google Scholar] [CrossRef]

- Stammler, M.; Thomas, P.; Reuter, A.; Schwack, F.; Poll, G. Effect of load reduction mechanisms on loads and blade bearing movements of wind turbines. Wind Energ. 2020, 23, 274–290. [Google Scholar] [CrossRef]

- Stammler, M. Wear test programs for roller-type pitch bearings of wind turbines. Wind Energ. Sci. 2023, 8, 1821–1837. [Google Scholar] [CrossRef]

- Stammler, M. Endurance Test Strategies for Pitch Bearings of Wind Turbines. Ph.D. Thesis, Gottfried Wilhelm Leibniz University, Hannover, Germany, 2020. [Google Scholar] [CrossRef]

- Wandel, S.; Bader, N.; Schwack, F.; Glodowski, J.; Lehnhardt, B.; Poll, G. Starvation and relubrication mechanisms in grease lubricated oscillating bearings. Tribol. Int. 2022, 165, 107276. [Google Scholar] [CrossRef]

- Poll, G.; Li, X.; Bader, N.; Guo, F. Starved Lubrication in Rolling Contacts-A Review. Bear. World J. 2019, 4, 69–81. [Google Scholar]

- Olofsson, U. Fatigue life reduction due to wear in boundary lubricated spherical roller thrust bearings. Wear 1997, 207, 74–78. [Google Scholar] [CrossRef]

- Tetora, S. False Brinelling-Stillstehende Fettgeschmierte Wälzlager Unter Dynamischer Belastung; FVA 540 III, IGF-Nr. 19786-BR; FVA: Frankfurt, Germany, 2022. [Google Scholar]

- Schadow, C. False Brinelling-Stillstehende Fettgeschmierte Wälzlager Unter Dynamischer Beanspruchung: Abschlussbericht FVA-Nr. 540 II; FVA: Frankfurt, Germany, 2016. [Google Scholar]

- Presilla, R.D.L.; Wandel, S.; Stammler, M.; Grebe, M.; Poll, G.; Glavatskih, S. Oscillating rolling element bearings: A review of tribotesting and analysis approaches. Tribol. Int. 2023, 188, 108805. [Google Scholar] [CrossRef]

- Cubillas, D.; Olave, M.; Llavori, I.; Ulacia, I.; Larrañaga, J.; Zurutuza, A.; Lopez, A. Semi-Analytical Methodology for Fretting Wear Evaluation of the Pitch Bearing Raceways Under Operative and Non-Operative Periods. Wind. Energy Sci. Discuss. 2024, 2024, 1–23. [Google Scholar] [CrossRef]

- Schwack, F.; Prigge, F.; Poll, G. Finite element simulation and experimental analysis of false brinelling and fretting corrosion. Tribol. Int. 2018, 126, 352–362. [Google Scholar] [CrossRef]

- Meng, H.C.; Ludema, K.C. Wear models and predictive equations: Their form and content. Wear 1995, 181, 443–457. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Hanief, M.; Charoo, M.S. Archard’s wear law revisited to measure accurate wear coefficient considering actual sliding velocity. Mater. Today Proc. 2021, 47, 5598–5600. [Google Scholar] [CrossRef]

- Fouvry, S.; Liskiewicz, T.; Kapsa, P.; Hannel, S.; Sauger, E. An energy description of wear mechanisms and its applications to oscillating sliding contacts. Wear 2003, 255, 287–298. [Google Scholar] [CrossRef]

- Hart, E.; de Mello, E.; Dwyer-Joyce, R. Wind turbine main-bearing lubrication–Part 1: An introductory review of elastohydrodynamic lubrication theory. Wind Energ. Sci. 2022, 7, 1021–1042. [Google Scholar] [CrossRef]

- Wandel, S.; Bartschat, A.; Glodowski, J.; Bader, N.; Poll, G. Wear Development in Oscillating Rolling Element Bearings. Lubricants 2023, 11, 117. [Google Scholar] [CrossRef]

- Bayer, G.; Bartschat, A.; Wandel, S.; Baust, S.; Poll, G. Experimental Investigations on Wear in Oscillating Grease-Lubricated Rolling Element Bearings of Different Size and Type. Lubricants 2023, 11, 120. [Google Scholar] [CrossRef]

- Cann, P.; Damiens, B.; Lubrecht, A. The transition between fully flooded and starved regimes in EHL. Tribol. Int. 2004, 37, 859–864. [Google Scholar] [CrossRef]

- Wandel, S. Starvation in Oscillating Rolling Element Bearings. Ph.D. Thesis, Gottfried Wilhelm Leibniz University, Hannover, Germany, 2024. [Google Scholar] [CrossRef]

- Stammler, M.; Menck, O.; Guo, Y.; Keller, J. Wind Turbine Design Guideline DG03: Yaw and Pitch Bearings; NREL/TP-5000-89161; NREL: Golden, CO, USA, 2024. Available online: https://www.nrel.gov/docs/fy24osti/89161.pdf (accessed on 16 October 2024).

- Stammler, M.; Poll, G.; Reuter, A. The influence of oscillation sequences on rolling bearing wear. Bear. World J. 2019, 4, 19–25. [Google Scholar]

- Behnke, K.; Schleich, F. Exploring limiting factors of wear in pitch bearings of wind turbines with real-scale tests. Wind Energy Sci. 2023, 8, 289–301. [Google Scholar] [CrossRef]

- Schwack, F.; Stammler, M.; Bartschat, A. Solutions to Reduce Wear in Wind Turbine Blade Bearings. In Proceedings of the Bearing World Conference 2018, Kaiserslautern, Germany, 6 March 2018. [Google Scholar]

- Menck, O.; Behnke, K.; Stammler, M.; Bartschat, A.; Schleich, F.; Graßmann, M. Measurements and modeling of friction torque of wind turbine blade bearings. J. Phys. Conf. Ser. 2022, 2265, 22087. [Google Scholar] [CrossRef]

- Graßmann, M.; Schleich, F.; Stammler, M. Validation of a finite-element model of a wind turbine blade bearing. Finite Elem. Anal. Des. 2023, 221, 103957. [Google Scholar] [CrossRef]

- Bartschat, A.; Behnke, K.; Stammler, M. The effect of site-specific wind conditions and individual pitch control on wear of blade bearings. Wind Energ. Sci. 2023, 8, 1495–1510. [Google Scholar] [CrossRef]

- Hohmann, M.; Blechschmidt, E.; Menck, O. Prediction of the friction torque of scaled blade bearings in a test rig using machine learning. J. Phys. Conf. Ser. 2024, 2767, 52010. [Google Scholar] [CrossRef]

- Escanciano, I.; Heras, I.; Schleich, F.; Aguirrebeitia, J. Methodology for the assessment of the friction torque of ball slewing bearings considering preload scatter. Friction 2024, 12, 1838–1857. [Google Scholar] [CrossRef]

- Menck, O. The Finite Segment Method—A Numerical Rolling Contact Fatigue Life Model for Bearings Subjected to Stochastic Operating Conditions. J. Tribol. 2023, 145, 031201. [Google Scholar] [CrossRef]

- Palmgren, A. Neue Untersuchungen über Energieverluste in Wälzlagern; SKF Kugellagerfabriken: Gothenburg, Sweden, 1957. [Google Scholar]

- Stammler, M.; Schwack, F.; Bader, N.; Reuter, A.; Poll, G. Friction torque of wind-turbine pitch bearings–comparison of experimental results with available models. Wind Energ. Sci. 2018, 3, 97–105. [Google Scholar] [CrossRef]

- Rezaei, A.; Schleich, F.; Menck, O.; Grassmann, M.; Bartschat, A.; Nejad, A.R. Comparative analysis of rolling contact fatigue life in a wind turbine pitch bearing with different modeling approaches. J. Phys. Conf. Ser. 2024, 2767, 52036. [Google Scholar] [CrossRef]

| Property | Small-Scale Blade Bearing (SBB) |

|---|---|

| Bearing Type | 2 row 4P BB |

| Inner diameter | 596 mm |

| Outer diameter | 750 mm |

| Pitch diameter | 673 mm |

| Number of rolling elements | 2 × 69 |

| Diameter rolling element | 25.4 mm |

| Grease volume per bearing | 600 mL |

| Initial contact angle | 45° |

| Cage design | Sheet metal |

| Cage thickness | 4.2 mm |

| Parameter | Value |

|---|---|

| Axial load | 0 |

| Bending moment | 150 kNm |

| Maximum contact pressure | 2.5 GPa |

| Shape of oscillating movement | Sinusoidal |

| Operating temperature | Ambient temperature between 18 °C and 28 °C |

| Double amplitude of oscillation | 0.75°–7.5° |

| Ratio of x/2b for 2.5 GPa of contact pressure | 2.1–21 |

| Oscillation frequency | 0.05 Hz–3 Hz |

| Resulting max. entrainment speeds | 3.5 mm/s–20.7 mm/s |

| Oscillation cycles per test | for x/2b = 2.1–4.2: 500, 1000, 3000, 5000, 10,000 for x/2b = 6.3–21: 1000, 5000, 10,000 |

| Grease | Grease No. 1 for all and grease No. 2 only for selected test parameters |

| Property | Grease No. 1 | Grease No. 2 |

|---|---|---|

| Base oil viscosity at 40 °C in cSt | 52 | 473 |

| Dynamic base oil viscosity at 40 °C in Pas | 0.0425 | 0.4163 |

| Oil separation rate at 40° in % | 4.7 | 4.7 |

| Surface tension in N/m | 0.03 | 0.03 |

| Parameter | Value |

|---|---|

| Axial load | 0 |

| Bending moment | 150 kNm |

| Maximum contact pressure | 2.5 GPa |

| Shape of oscillating movement | Sinusoidal |

| Operating temperature | Ambient temperature between 18 °C and 28 °C |

| Double amplitude of wear-critical oscillation | 0.75°–3.75° |

| Corresponding Ratio of x/2b | 2.1–10.5 |

| Oscillation frequency of the wear sequences | 0.3 Hz–1.5 Hz |

| Resulting max. entrainment speed of the wear sequences | 10.4 mm/s |

| Double amplitude of protection run | 7.5°, 10°, 12.5° |

| Oscillation cycles per test | 10,000 + protection runs |

| Grease | Grease No. 1 only |

| Test Condition in Hz | Cycles | ||||

|---|---|---|---|---|---|

| Damage | No Damage | Damage | No Damage | ||

| 2.1, 0.5 | 3000 | 1000 | 1.59 | 0.48 | 1.04 |

| 2.1, 1.5 | 3000 | 1000 | 4.37 | 0.98 | 2.68 |

| 2.1, 3 | 3000 | 1000 | 6.57 | 1.74 | 4.16 |

| 4.2, 0.25 | 3000 | 1000 | 1.91 | 0.49 | 1.20 |

| 4.2, 0.75 | 3000 | 1000 | 4.59 | 1.20 | 2.90 |

| 4.2, 1.5 | 3000 | 1000 | 2.76 | 1.74 | 2.25 |

| 6.3, 0.17 | 5000 | 1000 | 2.22 | 0.42 | 1.32 |

| 6.3, 0.5 | 5000 | 1000 | 5.57 | 0.83 | 3.20 |

| 6.3, 1 | 5000 | 1000 | 7.10 | 1.10 | 4.10 |

| 8.4, 0.38 | 5000 | 1000 | 1.25 | 0.22 | 0.74 |

| 10.5, 0.1 | 10,000 | 5000 | 1.00 | 0.46 | 0.73 |

| 10.5, 0.3 | 10,000 | 5000 | 2.47 | 1.03 | 1.75 |

| 10.5, 0.6 | 10,000 | 5000 | 3.96 | 1.48 | 2.72 |

| 20.1, 0.05 | - | - | - | ||

| 20.1, 0.15 | - | - | - | ||

| 20.1, 0.3 | - | - | - | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartschat, A.; Stammler, M.; Wenske, J. Towards a Model-Based Methodology for Rating and Monitoring Wear Risk in Oscillating Grease-Lubricated Rolling Bearings. Lubricants 2024, 12, 415. https://doi.org/10.3390/lubricants12120415

Bartschat A, Stammler M, Wenske J. Towards a Model-Based Methodology for Rating and Monitoring Wear Risk in Oscillating Grease-Lubricated Rolling Bearings. Lubricants. 2024; 12(12):415. https://doi.org/10.3390/lubricants12120415

Chicago/Turabian StyleBartschat, Arne, Matthias Stammler, and Jan Wenske. 2024. "Towards a Model-Based Methodology for Rating and Monitoring Wear Risk in Oscillating Grease-Lubricated Rolling Bearings" Lubricants 12, no. 12: 415. https://doi.org/10.3390/lubricants12120415

APA StyleBartschat, A., Stammler, M., & Wenske, J. (2024). Towards a Model-Based Methodology for Rating and Monitoring Wear Risk in Oscillating Grease-Lubricated Rolling Bearings. Lubricants, 12(12), 415. https://doi.org/10.3390/lubricants12120415