Abstract

In order to improve the tribological properties of the 7075-T6 aluminum alloy used on the rotor surface, a combined method of cryogenic treatment and laser surface texture treatment was applied. Various tests, including metallographic microscopy, scanning electron microscopy, elemental analysis, microhardness measurements, were conducted to examine the wear morphology and modification mechanism of the treated 7075-T6 aluminum alloy surface. A numerical simulation model of surface texture was established using computational fluid dynamics to analyze the lubrication characteristics of V-shaped texture. The research finding that the 7075-T6 aluminum alloy experienced grain refinement during the cryogenic treatment process, enhancing the wear resistance of the V-shaped textures. This improvement delayed the progression of fatigue wear, abrasive wear, and oxidative wear, thereby reducing friction losses. The designed V-shaped texture contributes to reducing contact area, facilitating the capture and retention of abrasives, and enhancing oil film load-bearing capacity, thereby improving tribological performance. The synergistic effect of cryogenic treatment reduced the friction coefficient by 24.8% and the wear loss by 66.4%. Thus, the combination of surface texture and cryogenic treatment significantly improved the tribological properties of the 7075-T6 aluminum alloy.

1. Introduction

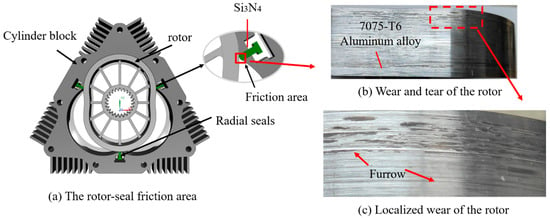

Due to global climate change, internal combustion engines have garnered widespread attention for energy saving and emissions reduction [1]. Surveys indicate that friction accounts for 20% of the world’s energy consumption, with 30% of energy used in road transport being lost in the form of friction. The close relationship between friction and energy underscores the significant impact of motion component performance on energy utilization [2]. In comparison to traditional internal combustion engines, rotary engines offer advantages such as a high power-to-weight ratio and compact structure, promising applications in aviation, energy, and transportation sectors. However, constrained by sealing and structural requirements, both the apex seal and rotor exhibit frictional wear as depicted in Figure 1, characterized by significant grooving and metal flaking on the friction pair surfaces, potentially leading to decreased sealing performance, increased fuel consumption, and elevated PM2.5 emissions [3,4,5]. Therefore, addressing the wear resistance of aluminum alloy rotor surfaces is an urgent concern.

Figure 1.

Rotor-seal wear.

Surface texture is a method that can effectively enhance the surface characteristics of friction [6]. Evolving over many years, surface texturing has emerged as a viable means of reducing friction and wear in mechanical components within internal combustion engines, encompassing components such as valve tappets [7], cylinder liner-piston rings [8], and sliding bearings [9]. Surface texture allows for improvements in the tribological performance of materials without altering the overall profile of the material [10]. This renders surface texture as one of the effective methods for enhancing rotor wear resistance as well.

The rotor material investigated in this study was 7075-T6 aluminum alloy, and research on surface texture enhancement of aluminum alloy frictional performance can be found in the literature. For instance, Yin et al. [11] employed Selective Laser Melting (SLM) technology to create wedge-shaped triangular textures on the surface of aluminum alloy, investigating their frictional characteristics. The findings indicated that counterclockwise wedge-shaped triangular textures exhibited superior wear resistance. Lu et al. [12] utilized laser technology to fabricate circular recesses, discovering that texture could continuously provide lubricating oil film and enhance the oil film support force, thereby improving the lifespan of PEO/PTFE coatings. Although the presence of texture effectively reduced aluminum alloy wear, the parameters of texture shape [13], depth [14], and area fraction [15] significantly influenced lubrication performance. The more severe the wear and deformation of the base material, the more pronounced the decrease in lubrication performance due to changes in texture parameters. Before conducting surface texture treatments, enhancing the material’s resistance to surface defects and localized plastic deformation can effectively enhance the friction reduction and wear resistance capabilities of the texture.

The 7075 aluminum alloy treated with the T6 method exhibits both strength and hardness. The T6 method involves rapid cooling and artificial aging after solution treatment. During this process, magnesium and zinc in the alloy form strengthening phases, thereby enhancing the alloy’s strength. However, partially precipitated magnesium and zinc compounds can form coarse second-phase particles, leading to alloy embrittlement and susceptibility to cracking under stress [16,17]. Numerous studies have confirmed that the introduction of cryogenic treatment can reduce the microstructural changes induced by aging treatment, improving the wear resistance and mechanical properties of aluminum alloys [18,19,20]. Zhang et al. [21] conducted cryogenic treatment on 7075-T6 aluminum alloy and investigated its machinability in high-speed cutting. Compared to untreated surfaces, cryogenically treated surfaces exhibited fewer microcracks.

Indeed, the introduction of texture alters surface roughness, decreases the contact stiffness of contacting components, resulting in reduced wear resistance [22]. Excessive cryogenic treatment may induce structural changes in aluminum alloy materials, promoting grain boundary clarification, potentially increasing material brittleness, thereby reducing its wear resistance [23]. Therefore, investigating how texture and cryogenic treatment synergistically influence the tribological performance of 7075-T6 aluminum alloy emerges as a profoundly significant endeavor.

In this study, during the T6 treatment process, cryogenic treatment was introduced to structurally modify the 7075-T6 aluminum alloy, combined with laser processing to treat a V-shaped texture to its surface. The tribological properties of the composite-treated 7075-T6 aluminum alloy samples were investigated using a pin-on-disc tribometer. The fluid dynamics of lubricants on textured surfaces were studied via laminar flow analysis. The frictional performance of the 7075-T6 aluminum alloy under the influence of V-texture was jointly analyzed through fluid simulation and experimental results. Surface morphology and composition of specimens after heat treatment and friction tests were obtained using metallographic microscope, scanning electron microscope, optical profilometer, and energy dispersive spectroscopy, while the hardness of heat-treated specimens was determined using a microhardness tester. This study holds certain guiding significance for enhancing the wear resistance of composite-treated aluminum alloy rotors and reducing the coefficient of friction.

2. Test Methodology

2.1. Test Materials

The 7075 aluminum alloy embodies characteristics of high strength as a heat-treatable alloy, excellent mechanical properties, and wear resistance, rendering it a prime material for the rotors of epicyclic rotary engines. This study utilized 7075-T6 aluminum alloy, as the rotor material, machined into 40 × 40 × 8 mm blocks at the factory, with its chemical composition detailed in Table 1. Meanwhile, this study employed hot-pressed silicon nitride as the material for apex seals in rotary engine rotor housings, which were machined in the factory into short cylindrical pins measuring 5 mm in diameter and 18 mm in length. Specific material properties can be found in the literature [24].

Table 1.

7075-T6 aluminum alloy chemical composition table (%).

2.2. Heat Treatment of Aluminium Alloy 7075-T6

Based on previous studies, subjecting aluminum alloys to cryogenic treatment prior to aging treatment has been shown to further enhance the material’s mechanical properties [25]. Therefore, in this study, specimens were subjected to solution treatment followed by sequential cryogenic treatment, aging treatment, and surface texture treatment.

To enhance the mechanical properties of the aluminum alloy, a gradual heat treatment process similar to that outlined in Table 2 was devised. Following solution treatment and cryogenic processing, the specimens were allowed to cool to room temperature before proceeding to the next step. The thermal treatment procedure involved subjecting the aluminum alloy to a 1-h solution treatment at 465 °C, followed by water quenching to room temperature. Subsequently, the water-quenched samples were placed in a cryogenic apparatus, slowly cooled from room temperature to −120 °C, and held for 2 h. After removing the samples and allowing them to return to room temperature, they underwent aging treatment at 105 °C for 6 h and 165 °C for 18 h.

Table 2.

Heat treatment process.

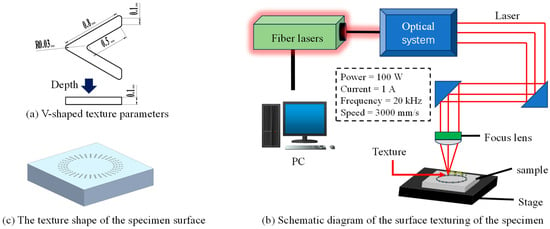

2.3. Methods of Preparation of Texture on Specimen Surfaces

Bhaumik et al. [26] investigated the friction-reducing capabilities of pit textures and groove textures, revealing that the pit texture exhibited superior friction-reducing performance due to its more stable fluid lubrication mechanism. Therefore, the design of an appropriate pit texture was deemed essential. Li et al. [27] utilized femtosecond laser machining techniques to fabricate a V-shaped texture on hard alloys. The findings indicated that a specific density of V-shaped texture contributed to stabilized friction coefficients and reduced wear. Shen et al. [28] conducted numerical simulations to investigate the oil film bearing capacity of V-shaped textures, revealing that optimizing the arrangement of V-shaped textures could effectively enhance lubrication performance. Building upon previous research, the design of texture parameters, as depicted in Figure 2a, was formulated. Employing a fiber laser marking machine, V-shaped textures were created on the surface of aluminum alloy. The processing procedure, as depicted in Figure 2b, entailed applying identical laser parameters to specimens subjected to different heat treatments. The processing parameters were as follows: power = 100 W, current = 1 A, frequency = 20 kHz, velocity = 3000 mm/s. Input parameters were controlled via keyboard interface. The laser emitter generated beams, which, after oscillation and convergence, facilitated the texture processing procedure. The surface morphology of the processed specimens resembled that depicted in Figure 2c, featured 144 circular V-shaped textures distributed within a circular ring surface with a diameter ranging from 20–30 mm. The texture dimensions were 0.8 mm along the outer long edge, 0.5 mm along the inner long edge, with a short edge of 0.1 mm and a depth of 0.1 mm, covering an area ratio of 19% (total textured area/circular area).

Figure 2.

Texture preparation of specimen surfaces.

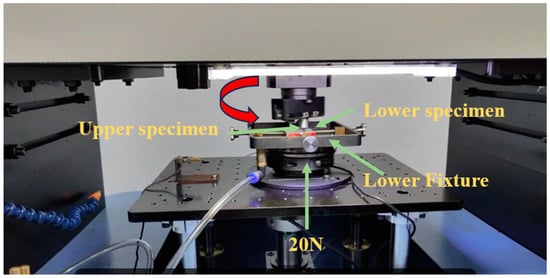

2.4. Tribological Tests

The actual contact mode between the rotor and the apex seal is illustrated in Figure 1. The rotor maintains constant contact with the apex seal, ensuring sealing between adjacent engine chambers through continuous conformity. During rotor operation, the arc surface of the apex seal slides relative to the rotor contour, resulting in friction. A rotary friction test was conducted on a multifunctional friction and wear testing machine (produced by Zhengzhou Yaoxuan Yuan Instrument Technology Co., Ltd., Zhengzhou, China) to evaluate the specimen. The friction and wear experimental testing is depicted in Figure 3. The friction test was conducted under conditions where the contact surface between the rotor and the apex seal was maintained sealed, with a rotor contour speed of 200 r/min and under an apex seal load of 20 N. Throughout the testing process, the computer recorded the friction coefficient in real-time at a sampling frequency of 1 Hz. The specific experimental procedures are outlined as follows:

Figure 3.

Friction and wear experimental testing.

- (1)

- To investigate the impact of cryogenic treatment and surface texture on the wear and abrasion characteristics of aluminum alloy 7075-T6, eight different surface treatment experimental schemes were devised and compared, denoted as ST (Solution treatment), SAT (Solution treatment and aging treatment), SCT (Solution treatment and cryogenic treatment), SCAT (Solution treatment, cryogenic treatment, and aging treatment), STT (Solution treatment and surface texture treatment), SATT (Solution treatment, aging treatment, and surface texture treatment), SCTT (Solution treatment, cryogenic treatment, and surface texture treatment), and SCATT (Solution treatment, cryogenic treatment, aging treatment, and surface texture treatment). Each set of experiments was conducted under identical rotational speed and load parameters. To ensure result reproducibility, three trials were performed for each factor. Prior to the commencement of the experiments, the surfaces of the specimens were uniformly coated with Mobil Special 2T lubricating oil, with a dynamic viscosity of 0.071 Pa·s. No lubricant was added during the friction and wear tests to simulate the authentic lubrication conditions of the rotor-apex seal friction pair during actual operation.

- (2)

- The specimens were subjected to ultrasonic cleaning using a CJ-009-1 machine before and after the experiments, immersed in anhydrous ethanol for 15 min. Subsequently, they were weighed three times using an electronic balance with an accuracy of 0.1 mg. The wear mass loss of each sample was then computed.

- (3)

- The friction coefficients post-experiment underwent smoothing using graphic software to eliminate noise and reduce data fluctuation, facilitating a clearer observation of data trends. Specifically, the smoothing parameters employed the Savitzky-Golay method with a window size of 2000 data points and a second-order polynomial.

2.5. Microstructural Analysis

To investigate the microstructural changes of 7075-T6 aluminum alloy specimens, the surfaces of the heart-treated specimens were sequentially ground with abrasives of 400, 600, 800, 1200, 1500, 2000, 3000, and 5000 grit. Subsequently, polishing was performed using polishing cloth and colloidal silica polishing solution. The samples were cleaned three times in anhydrous ethanol using an ultrasonic cleaning machine (CJ-009-1), with each cleaning session lasting 15 min. For the specimens that required additional textural processing following polishing, 5000-grit sandpaper was employed to remove burrs and perform a polishing treatment, after which the specimens were thoroughly cleaned once more.

Utilizing a Rockwell hardness tester (Rockwell hardness tester HR-150A), the hardness of the samples was assessed under a 10 kg load for 10 s. A diamond indenter was employed to create impressions at six points within the central region of each sample. The influence of heat treatment on the microstructure of the aluminum alloy was analyzed, preceded by etching the samples in a solution of 5% nitric acid (HNO3), 3% hydrochloric acid (HCl), 2% hydrofluoric acid (HF), and 90% distilled water (H2O) for 30 s. Microstructural analysis was conducted using an M-40MRT transmitted light metallurgical microscope and a Zeiss Sigma300 scanning electron microscope (SEM). Following friction testing, the wear tracks were observed using a metallurgical microscope in conjunction with scanning electron microscopy. Using the optical profilometer (Mahr MarSurf LD130, Göttingen, Germany), observe the morphological characteristics of the surface texture before and after friction testing. Based on the three-dimensional profile of the specimen, one can precisely capture the shapes, depths, and distribution of surface texture features.

3. Computational Fluid Dynamics Simulation Models

Performing computational fluid dynamics simulations enables the investigation of fluid flow characteristics to analyze the lubricating oil film flow conditions. In this study, the flow of lubricating oil from the diverging region to the converging region of the V-shaped texture was simulated, along with the pressure and velocity distributions in the absence of texture.

The Navier-Stokes equations were employed to address the fluidic issues within the scope of this study. The following assumptions were made: (1) the lubricating oil behaved as an incompressible Newtonian fluid; (2) the temperature, density, and viscosity of the lubricating oil remained constant; (3) the influence of fluid gravity was disregarded. Incorporating these assumptions, the simplified continuity Equation (1) and momentum Equations (2) and (3) of the Navier-Stokes were derived:

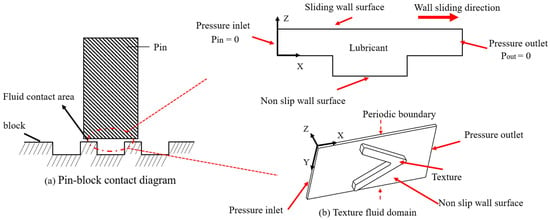

3.1. Simulation Model Building and Meshing

By establishing a texture lubrication model, the lubrication effects with and without texture design were predicted, thereby more effectively revealing the enhancement of lubrication performance attributed to the current texture parameters. This not only improved design efficiency but also reduced costs, holding significant practical implications for the optimization and application of material properties. During the research process, establishing the schematic of the pin-disk contact as depicted in Figure 4a was constructed through drafting software. Given the periodic arrangement of the texture, the entirety of the model could be streamlined into a lubrication model predicated on individual texture models. The simplified model of the fluid contact region, delineated by dashed lines within Figure 4a, is depicted in Figure 4b. The establishment process of a non-textured fluid simulation model parallels that of a textured simulation model.

Figure 4.

Texture simulation model.

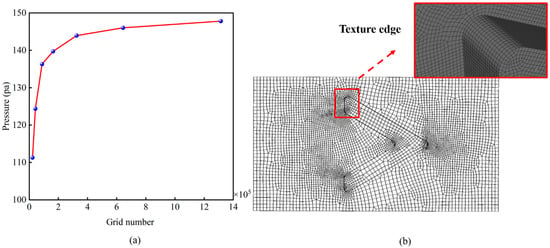

Diverse grid sizes exert significant influence on computational outcomes. To mitigate the impact of grid variation and enhance simulation data accuracy, grid independence validation is imperative prior to computational analyses. Establishing a minimum grid count of 21,799, the grid was systematically increased by multiples, and the sensitivity of the grid was observed by analyzing the average pressure variation on the internal surface of the texture. The textured grid model is depicted in Figure 5a. It is evident from Figure 5 that during the transition of the overall grid from 640,000 to 1.3 million, the average pressure on the internal surface of the texture fluctuates within a narrow range, with an error between adjacent solutions at 1.2%. Typically, errors between adjacent solutions ranging from 5% to 10% are considered acceptable. Therefore, the simulation experiment employed a grid of 640,000. Figure 5b illustrates the grid model and grid quality.

Figure 5.

Grid model diagram of texture: (a) The relationship between the average pressure on the internal surface of the texture and the number of grids; (b) Grid model of texture.

3.2. Boundary Conditions and Fluid Properties

During the experiment, the lower specimen was fixed on the loading platform, while the upper specimen underwent rotational motion. Consequently, the surface on top of the texture was designated as a moving wall in the fluid simulation model, with a velocity set at 0.26 m/s (200 r/min). The fluid region utilized Mobil Special 2T lubricating oil as its material, with a density of 878 kg·m−3 and a dynamic viscosity of 0.071 Pa·s. Following calculations, the Reynolds number of the fluid was less than 2300, thus, an laminar flow model was adopted. Based on the findings of Wang et al. [7], the minimum oil film thickness was set to 50 μm. The front wall of the divergent region was set as the pressure inlet, while the rear wall of the convergent region was designated as the pressure outlet, both values equating to standard atmospheric pressure. The walls on either side of the inlet were set as periodic boundaries, while the remaining walls were fixed. The solver employed a solvable, incompressible flow field, utilizing the pressure-based SIMPLE algorithm. To ensure convergence accuracy, residual values were set to 10−6. The computed structure was imported into post-processing software for analysis to acquire the pressure distribution in the XY plane and the velocity vector distribution in the ZX plane within the fluid domain.

4. Results and Discussion

4.1. Effect of Heat Treatment on Mechanical Properties of 7075-T6 Aluminum Alloy

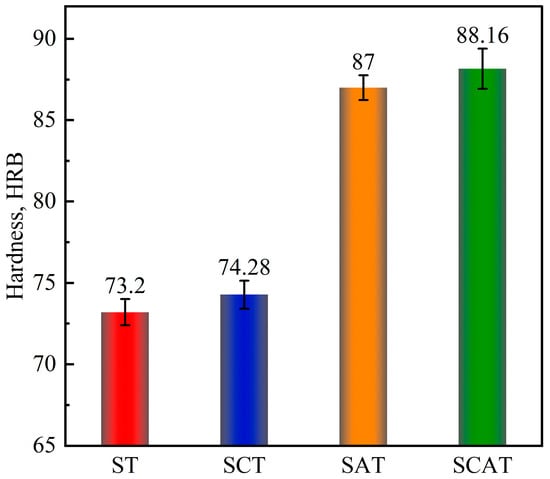

The microhardness of 7075-T6 aluminum alloy after various heat treatment processes is depicted in Figure 6. Cryogenic treatment enhances the microhardness of the specimens compared to those subjected solely to solution treatment. Although aging treatment significantly increases the hardness of the specimens (by 17.42% compared to cryogenic treatment alone), the introduction of cryogenic treatment further elevates this hardness, resulting in the highest hardness observed in the SCAT specimens.

Figure 6.

Microhardness of specimens with different heat treatment processes (The error line represents the standard error).

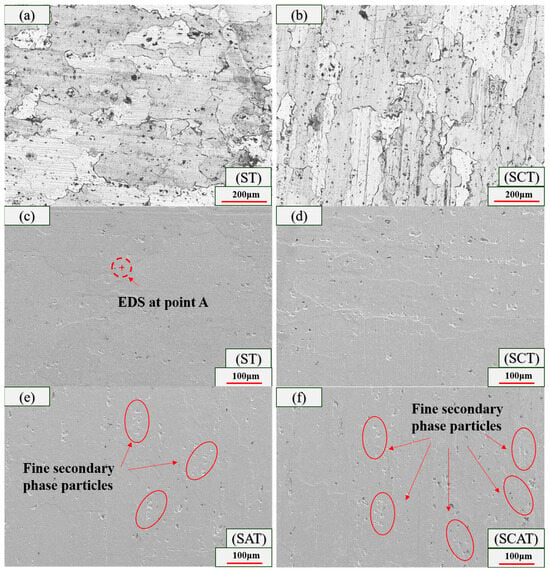

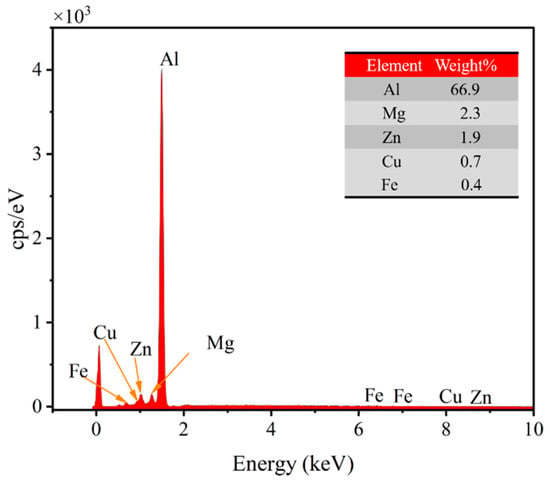

In order to elucidate the mechanisms behind the improvement in hardness resulting from heat treatment processes, macroscopic and microscopic structural observations were conducted on etched 7075-T6 aluminum alloy specimens using an M-40MRT transmitted light metallographic microscope and a Zeiss Sigma 300 scanning electron microscope, as depicted in Figure 7. From Figure 7a,b, it can be observed that the solid solution structure of the 7075-T6 aluminum alloy consists of α solid solution and a small amount of secondary phase particles. Within the matrix without cryogenic treatment, there is a relatively high distribution of coarse secondary phase particles (larger dark areas), as confirmed by the microstructure in Figure 7c,d. Figure 8 presents the chemical composition analysis (EDS) results of the coarse secondary phase particles at point A in Figure 7c, revealing the presence of elements Al, Cu, Zn, Mg, and Fe. According to prior research by Xu et al. [29] these coarse secondary phase particles are eutectic compounds, namely Al7Cu2Fe, CuMgAl2, and MgZn2. Due to the scarcity of alloying elements in the α matrix caused by the presence of coarse secondary phase particles, the precipitation of fine secondary phase particles during aging process decreases. It can be observed from Figure 7e,f that cryogenic treatment increases the quantity of fine second-phase particles, enhances precipitation strengthening during aging processes, thereby achieving improved hardness. These results are consistent with previous studies, indicating that aging treatment enhances the mechanical properties of aluminum alloys through precipitation strengthening, while the introduction of cryogenic treatment further enhances this performance [19].

Figure 7.

Microstructure of different process treatments: (a,b) under OM; (c–f) under SEM.

Figure 8.

Energy dispersive spectroscopy (EDS) results for coarse two-phase particles.

4.2. Texture Results

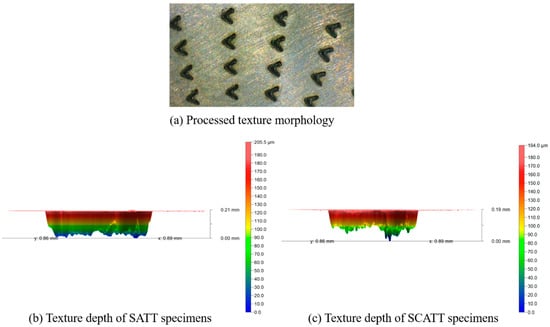

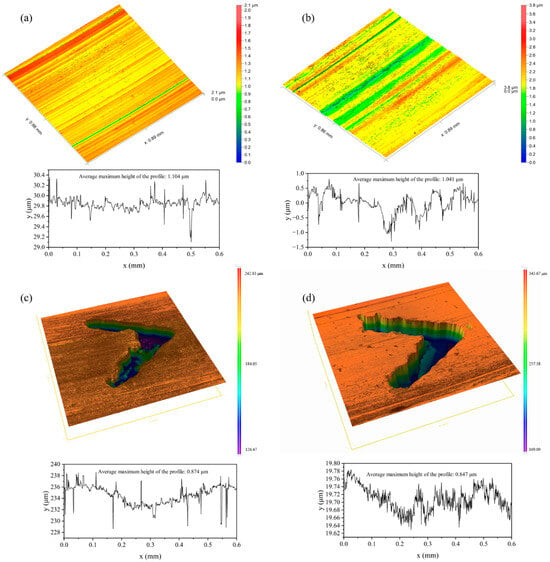

Figure 9 depicts the textural morphology, where the processed two-dimensional morphology is shown in Figure 9a, with textures uniformly distributed according to the arranged sequence. Figure 9b,c present the texture depths for the SATT and SCATT specimens, respectively, with depths of 180 μm for SATT and 100 μm for SCATT. Despite using identical processing parameters for texture generation, there exists variation due to the increased hardness post cryogenic treatment of the specimens. Therefore, the textured depth after cryogenic treatment is lower compared to untreated specimens. For numerical simulations investigating the impact of texture presence on lubrication performance, geometric model simulations were based on the texture parameters from Figure 2.

Figure 9.

Texture topography.

4.3. Analysis of the Effect of Texture on the Lubricity of Friction Surfaces

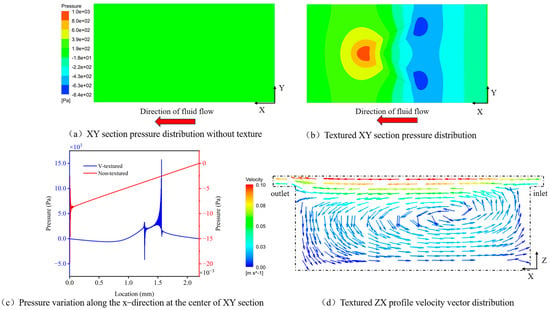

At a rotational speed of 200 r/min, the simulation results are depicted in Figure 10. Figure 10a illustrates the XY cross-sectional pressure distribution of the untextured surface, while Figure 10b portrays the XY cross-sectional pressure distribution of the textured surface. Comparison of the two results shows that the presence of the V-shaped weave causes a gradient change in the internal pressure of the lubricant in the direction of velocity, and a pressure dip and a pressure rise at the two inlet vertices of the weave and at the outlet vertex. To further analyze the impact of fluid pressure variations in textured and non-textured areas on oil film pressure, the pressure variation along the flow direction at the XY cross-section center is shown in Figure 10c. Here, V-textured represents the V-shaped texture, and Non-textured denotes the absence of texture. The oil film pressure with no texture set remains almost constant, the fluid with texture set goes through two phases of decreasing and increasing as it enters the textured region, but the region of the fluid with texture set eventually produces a large oil film pressure. This increase in fluid pressure occurs because lubricating oil often generates a divergence effect in textured areas, forming low-pressure zones and increasing pressure peaks at convergence gaps, thereby facilitating the generation of hydrodynamic lubrication conditions [30]. Currently, two widely recognized fundamental principles explain how surface textures can generate hydrodynamic lubrication: the cavitation mechanism [31] and the inertial mechanism [32]. Under the current study parameters, cavitation modeling has verified that the lubricating oil used does not undergo cavitation effects; thus, the hydrodynamic lubrication here primarily arises from inertial effects. The influence of fluid inertia on fluid dynamic performance has been extensively discussed by scholars. Sahlin [33] analyzed the inertial effects on circular textures using two-dimensional CFD and discovered that inertial effects produced additional load-bearing capacity, which became more pronounced with increasing Reynolds numbers.

Figure 10.

Pressure distribution and velocity vector distribution in the fluid domain.

From the flow velocity map of the ZX section in Figure 10d, it is evident that the flow velocity near the texture outlet was greater than that near the texture inlet. The internal flow direction was distributed in a counterclockwise manner, which facilitated the generation of backflow within the texture. This backflow reduced the flow velocity at the texture inlet while increasing it at the outlet, resulting in a pressure asymmetry of the oil film along the texture direction and providing additional oil film bearing capacity, thereby forming a stable hydrodynamic oil film between the two contacting surfaces.

4.4. Study and Analysis of the Effect of Different Heat Treatments on the Friction Properties of Texture

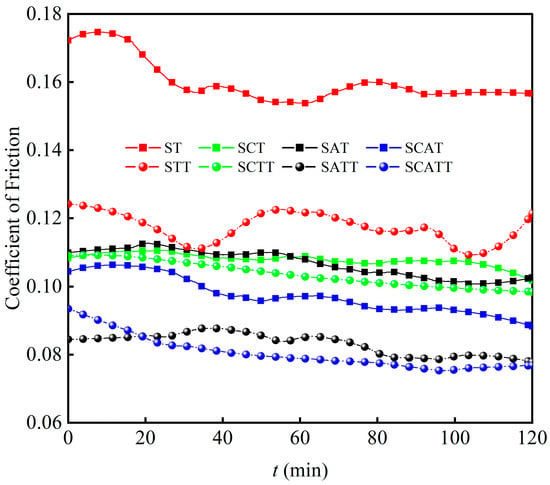

Figure 11 depicts the variation of friction coefficient versus time for 7075-T6 aluminum alloy/silicon nitride. As illustrated in Figure 11, under identical loading conditions, the friction coefficients exhibit varying trends with increasing test duration for all conditions. Throughout the entire experimental process, the friction coefficients show an initial increase followed by a decrease, primarily due to the micro-protrusion initiating contact when the two surfaces come into contact, whereby existing micro peaks may experience significant pressure, resulting in an increase in friction coefficient. Following this stage, minor elastic deformation occurs on the specimen surface. When the applied stress exceeds the yield strength of the aluminum alloy material, the material enters the plastic deformation stage and undergoes permanent plastic deformation. This leads to increased contact between irregular surface portions, augmenting friction [34]. With relative motion between surfaces, irregular surface portions collide and undergo abrasion, forming minute abrasives, thereby triggering abrasive wear. When the friction force reaches equilibrium, the friction process enters a stable wear stage, exhibiting minor fluctuations in the friction coefficient. However, due to the gradual adaptation of the aluminum alloy surface, peaks are gradually flattened, voids filled, thus resulting in an overall decreasing trend in the friction coefficient.

Figure 11.

Friction coefficient versus time.

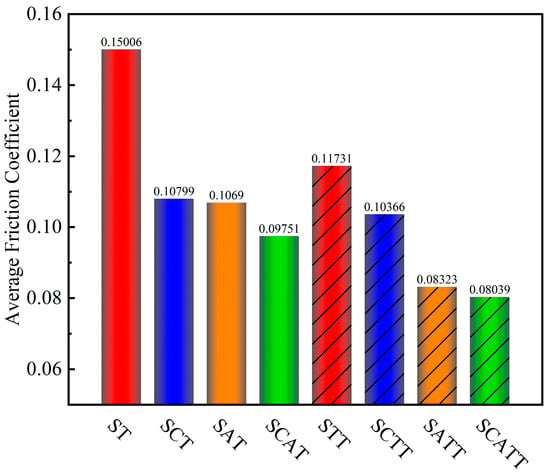

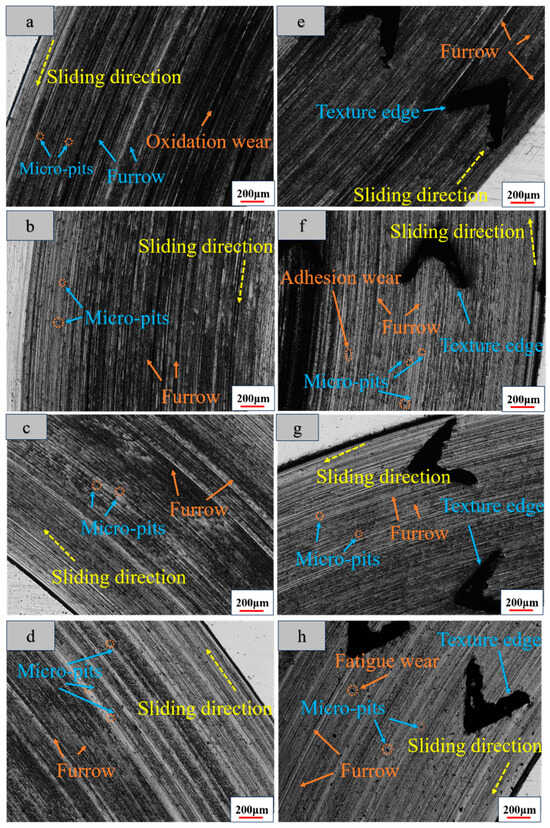

As illustrated in Figure 11, during the phase of stable wear operation, the friction coefficient of the ST specimen was at its maximum. Based on the average friction coefficient plot under different samples (Figure 12), the friction coefficient of the ST specimen remained around 0.15006. In Figure 13a, surface examination via optical microscopy reveals the presence of numerous parallel grooves, indicative of a certain degree of abrasive wear [35]. During the friction process, a significant amount of abrasive debris particles were generated on the mating surfaces. The particles generated from wear failed to promptly disengage from the contact surface and were acted upon by the forces generated by relative motion. This led to the further formation of new frictional losses on the contact surface, resulting in a pronounced plowing effect (grooved wear texture) on the surface. This outcome was confirmed by the micrographs of wear traces under a metallographic microscope in Figure 13a. Compared to the ST specimen, cryogenic treatment, aging treatment, and surface texture all effectively reduced the friction coefficients. The friction coefficients of SCT, SAT, and SCAT decreased by 28.04%, 28.76%, and 35.02%, respectively. This reduction is associated with the hardness changes under cryogenic treatment and aging treatment, where cryogenic treatment further enhanced the hardness improvement achieved by precipitation strengthening during aging treatment. It effectively controlled plastic deformation, reduced wear particles, and consequently resulted in lower friction coefficients. The variation in the friction coefficients of the SCT and STT samples depicted in Figure 11 indicated that the texture exhibited lower friction-reducing capabilities compared to the low-temperature treatment, whereas the SCAT and SATT samples demonstrated superior friction-reducing abilities relative to the low-temperature treatment. Combining the results from Figure 6 and Figure 12, it became evident that, in the absence of aging treatment, the inherent strength of the material was insufficient to maintain elastic deformation during the wear process, resulting in pronounced abrasive wear that exceeded the friction-reducing capacity of the specified texture parameters. Compared to the SAT specimens (treated with T6 method), the friction coefficients of the SCAT and SATT specimens decreased by 8.7% and 22.1% respectively, indicating that texture has a more pronounced impact on the friction coefficients of 7075-T6 aluminum alloy than cryogenic treatment.

Figure 12.

Average friction coefficients of different samples (Corresponding to the average friction coefficient in Figure 11).

Figure 13.

Metallurgical microscope wear marks: (a) ST; (b) SCT; (c) SAT; (d) SCAT; (e) STT; (f) SCTT; (g) SATT; (h) SCATT.

Under identical heat treatment parameters, specimens with texture exhibited lower friction coefficients compared to those without texture. Specifically, STT, SCTT, SATT, and SCATT specimens experienced reductions of 21.83%, 4.01%, 22.14%, and 17.56%, respectively, compared to ST, SCT, SAT, and SCAT. Combining friction experiments with numerical simulations of texture-induced oil film pressure, both methodologies yielded consistent conclusions. The presence of V texture generated oil film load-carrying capacity during frictional motion, simultaneously reducing frictional losses by increasing oil film pressure. It is evident from Figure 11 that the friction coefficient of the SCATT specimen was the lowest. Examination of the average friction coefficient plots under different treatment conditions (Figure 12) revealed a friction coefficient of approximately 0.08039 for SCATT. The lower friction damage shown in Figure 13h corresponded to the lowest friction coefficient among the specimens. In summary, surface texture, coupled with cryogenic treatment, effectively reduced the friction coefficient between 7075-T6 aluminum alloy and hot-pressed silicon nitride.

4.5. Wear and Tear Discussion

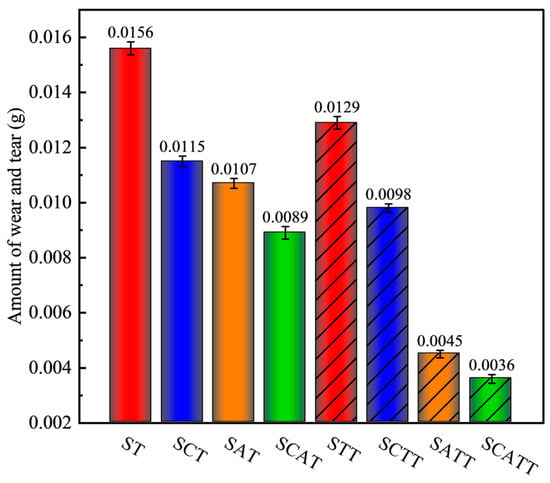

Determining wear volume can effectively assess the abrasion resistance of materials. As depicted in Figure 14, the wear volume of sample ST was the highest, reaching 0.0156 g. Figure 13a corroborated the severe wear of sample ST, evidenced by its surface displaying deeper and wider abrasions, with extensive abrasive wear resulting in noticeable mass loss. As shown in Figure 13b–d, the number of pits on the surfaces of SCT, SAT, and SCAT specimens gradually increased, while scratches diminished accordingly. This is because the pits predominantly formed during the early stages of running-in due to fatigue wear [36]. Following heat treatment, the specimens exhibited increased surface hardness, enhancing their resistance to fatigue wear. Compared to the ST specimen, this led to improvements in wear resistance for SCT, SAT, and SCAT specimens by 26.3%, 31.4%, and 42.9%, respectively. Compared to the SAT specimens (treated with the T6 method), the wear resistance of the SCAT and SATT specimens increased by 16.8% and 57.9% respectively, indicating that texture has a more pronounced effect on enhancing the wear resistance of 7075-T6 aluminum alloy compared to cryogenic treatment. As indicated in Figure 13e–h, the presence of texture effectively reduced wear. However, wear patterns still encompassed fatigue wear, abrasive wear, oxidative wear, and minor adhesive wear.

Figure 14.

Amount of wear and tear on the sample (The error line represents the standard error).

The three-dimensional morphology of the wear marks on the surface of aluminum alloy after frictional testing can accurately analyze the effects of cryogenic treatment and texture on wear, as illustrated in Figure 15. The SAT specimen exhibited the highest average maximum height of the profile, with a value of 1.104 μm, and its surface was characterized by a multitude of scratches. In comparison to the SAT specimen, the SCAT specimen, which underwent cryogenic treatment, displayed an enhancement in hardness, resulting in a lower average maximum height of the profile, with a value of 1.041 μm. However, specimens that were subjected to surface texturing exhibited a reduction in wear marks, with the SATT and SCATT specimens showing average maximum heights of the profile at 0.874 μm and 0.847 μm, respectively. This reduction is attributed to the texturing’s role in capturing abrasive particles, effectively controlling abrasive wear and mitigating the occurrence of plowing effects.

Figure 15.

3D images of wear mark (a) SAT; (b) SCAT; (c) SATT; (d) SCATT.

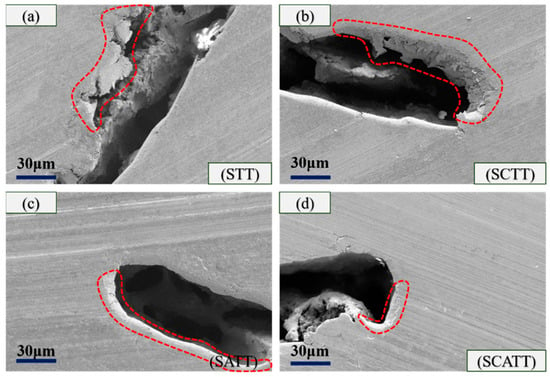

According to the numerical simulation results, a small oil film pressure will be generated at the entrance edge of the texture, which may make the texture easily damaged. To elucidate the extent of wear, a Zeiss Sigma 300 scanning electron microscope was employed to capture the wear morphology of the texture, as depicted in Figure 16.

Figure 16.

Wear patterns of fabrics (a) STT; (b) SCTT; (c) SATT; (d) SCATT.

From Figure 16, it can be seen that the wear of the V-shaped texture mainly occurs near the entrance vertex of the texture, which is consistent with the results of fluid simulation. The presence of texture altered the pressure distribution of the oil film. At the entrance of the texture, lubricant divergence led to a decrease in oil film pressure, amplifying the forces on the contact surface at the texture entrance, thus resulting in more pronounced wear at the apex. Contrasting Figure 16a–d, the edge frictional damage of the STT sample was the most severe, exhibiting signs of fracture; the SCTT sample displayed layered wear extending downward at a certain angle; while the edge wear morphology of the SATT and SCATT specimens was generally similar, with only minor wear occurring in the uppermost layer of the edges, yet the wear region of the composite-treated SCATT was smaller. From Figure 16, although wear occurred on the surface of the samples, there were no debris residues or significant abrasive damages around the texture, indicating the function of texture in retaining abrasives, reducing the possibility of secondary abrasive damage, and safeguarding the sample surface. Furthermore, Figure 16a–d revealed that cryogenic treatment enhanced the wear resistance of the texture, consequently reducing frictional losses.

4.6. Wear Mechanism Analysis

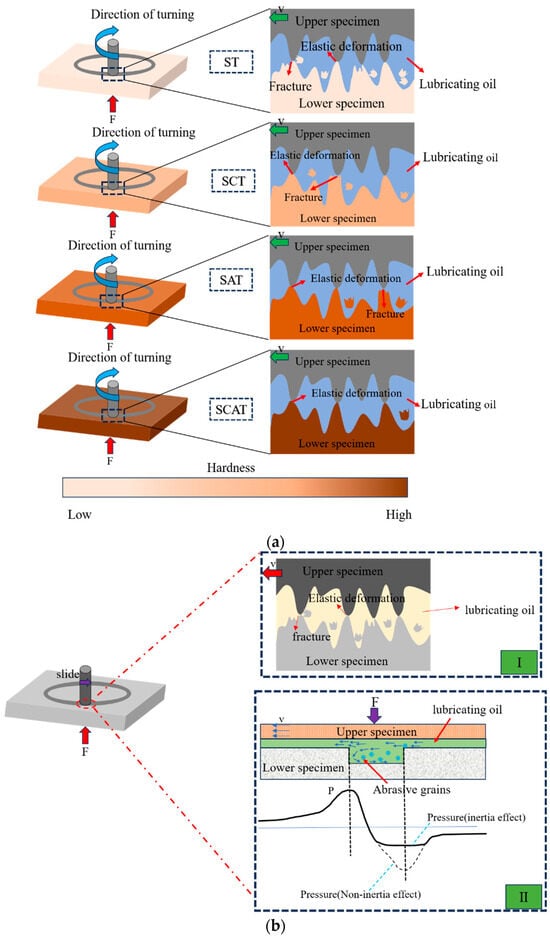

By analyzing the wear mechanism on the surface of 7075-T6 aluminum alloy, one can effectively comprehend the tribological behavior of 7075-T6 aluminum alloy. The schematic diagram of wear mechanism is depicted in Figure 17. As illustrated in Figure 17a, there are certain micro-protrusions between the friction surfaces in relative motion. When the stress threshold is reached, the higher micro-protrusions undergo shear fracture, generating a large number of wear particles. Cryogenic treatment of 7075-T6 aluminum alloy can maximize the plasticity of the specimen, leading to a predominant wear process characterized by plastic deformation and reduced occurrence of fatigue wear, thereby minimizing the generation of wear particles.

Figure 17.

Schematic diagram of friction mechanism: (a) Schematic representation illustrating the improvement of friction mechanism through cryogenic treatment; (b) Schematic representation of the friction mechanism with surface texture, b-I is a schematic diagram of abrasive particle generation, b-II is the mechanism diagram of texture wear reduction.

From Figure 17b, it can be observed that under mixed lubrication conditions, the presence of texture reduces the contact area of friction from both a structural and fluid lubrication perspective, thereby lowering the mass wear of the specimen. Additionally, the presence of texture serves to store lubricating oil and capture particles, effectively reducing the possibility of secondary damage at the contact interface [37]. In the scenario depicted in Figure 17b-II, the lubricating oil flows into and out of the texture through narrow channels, altering the flow rate per unit length. To ensure continuity of flow within the flow field, there is a decrease in pressure at the entrance of the texture and an increase in pressure at the exit, resulting in a dynamic pressure effect. The presence of inertia effect prevents further reduction of pressure in the negative pressure zone, creating additional bearing capacity in the textured area.

Combining Figure 17a,b, it is evident that cryogenic treatment strengthens the material matrix, enhances the wear resistance of the texture. Even under wear conditions, it can still exhibit excellent frictional performance.

5. Conclusions

Using 7075-T6 aluminum alloy as the substrate, cryogenic treatment and surface texturing were conducted. The impact of synergistic effects between surface texture and cryogenic treatment on the tribological performance of 7075-T6 was investigated. The following conclusions were drawn:

- (1)

- Surface texture combined with cryogenic treatment effectively enhances the friction performance of 7075-T6 aluminum alloy, reducing the friction coefficient by 24.8% and wear volume by 66.4%.

- (2)

- The texture facilitates a reduction in the contact area of microasperities, concurrently decreasing the wear volume through the hydrodynamic lubrication effect. Simultaneously, cryogenic treatment effectively bolstered wear resistance of the texture, enhancing its wear reliability and retarding processes such as fatigue wear, abrasive wear, and oxidative wear on the material surface. Therefore, the combined approach of surface texture and cryogenic treatment significantly enhanced the tribological performance of 7075-T6 aluminum alloy.

- (3)

- Compared to cryogenic treatment, surface texture has a greater impact on the coefficient of friction and wear resistance of 7075-T6 aluminum alloy. Surface texture and cryogenic treatment can respectively reduce the coefficient of friction by 22.1% and 8.7%, while enhancing wear resistance by 57.9% and 16.8%, respectively.

- (4)

- Cryogenic treatment of 7075-T6 aluminum alloy facilitates the precipitation of fine secondary phase particles and enhances the precipitation strengthening during aging. Introducing cryogenic treatment prior to aging treatment can elevate the microhardness of 7075-T6 aluminum alloy.

Author Contributions

Conceptualization, X.D. and X.S.; Methodology, X.S. and W.C.; Validation, R.L.; Formal analysis, R.L.; Software, X.D. and X.S.; Data Curation, R.L.; Investigation, R.L. and Q.J.; Resources, D.J., W.C. and Q.J.; Writing—original draft, R.L., D.J., W.C. and Q.J.; Writing—review & editing, X.D., X.S. and J.L.; Supervision, X.D. and J.L.; Project administration, J.L. and D.J.; Funding acquisition, X, D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [Yunnan Science and Technology Plan Project ] grant number [202302AC080002] and [202202AB080011-02]. And The APC was funded by [Yunnan Science and Technology Plan Project ]. Numerical computations were performed on Hefei advanced computing center.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Wengang Chen was employed by the company Academician Dongyang Li Workstation. Qiang Ji was employed by the company Chengdu Zheng Heng Auto Parts Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature and Abbreviations

| ρ | The density of the lubricating oil (kg·m−3) |

| μ | The dynamic viscosity of the lubricating oil (Pa·s) |

| u | The velocity component of the lubricating oil along the x-axis (m·s−1) |

| v | The velocity component of the lubricating oil along the y-axis (m·s−1) |

| p | The pressure within the lubricating oil flow field (Pa) |

| ST | Solution treatment |

| SAT | Solution treatment and aging treatment |

| SCT | Solution treatment and cryogenic treatment |

| SCAT | Solution treatment, cryogenic treatment, and aging treatment |

| STT | Solution treatment and surface texture treatment |

| SATT | Solution treatment, aging treatment, and surface texture treatment |

| SCTT | Solution treatment, cryogenic treatment, and surface texture treatment |

| SCATT | Solution treatment, cryogenic treatment, aging treatment, and surface texture treatment |

References

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.K.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Zhou, Y. Effect of DLC coating on the friction power loss between apex seal and housing in small Wankel rotary engine. Tribol. Int. 2019, 134, 365–371. [Google Scholar] [CrossRef]

- Meng, H.; Ji, C.; Yang, J.; Chang, K.; Xin, G.; Wang, S. Experimental understanding of the relationship between combustion/flow/flame velocity and knock in a hydrogen-fueled Wankel rotary engine. Energy 2022, 258, 124828. [Google Scholar] [CrossRef]

- Kotchenruther, R.A. Recent changes in winter PM2.5 contributions from wood smoke, motor vehicles, and other sources in the Northwest U.S. Atmos. Environ. 2020, 237, 117724. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Lin, N.; Wang, W.; Zhang, H.; Liu, Z.; Yu, Y.; Zeng, Q.; Wu, Y. Correlation between surface textural parameter and tribological behaviour of four metal materials with laser surface texturing (LST). Appl. Surf. Sci. 2022, 583, 152410. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Zhang, L.; Li, D.; Guo, W.; Wang, Y.; Dai, Y.; Mao, Y.; Li, H.; Zheng, L. Surface texture and heat treatment on the friction performance of cam tappet experimental and fluid-solid coupling numerical study. Tribol. Int. 2023, 179, 108124. [Google Scholar] [CrossRef]

- Peng, E.; Huang, S. Wear performance of cylinder liner surface texturing on cylinder liner–piston ring assembly. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 291–306. [Google Scholar] [CrossRef]

- Song, F.; Yang, X.; Dong, W.; Zhu, Y.; Wang, Z.; Wu, M. Research and prospect of textured sliding bearing. Int. J. Adv. Manuf. Technol. 2022, 121, 1–25. [Google Scholar] [CrossRef]

- Zhao, C.; Jia, X.; Zhao, Q.; Ma, H.; Yu, Z.; Zhang, Z.; Du, W.; Zhang, H. Research progress on the effect of surface texture on the friction properties of CoCrMo alloys. Compos. Interfaces 2024, 31, 1269–1290. [Google Scholar] [CrossRef]

- Yin, H.; Chen, W.; Xia, D.; Wu, H.; Jing, P.; Chen, L.; Zhang, L.; Wang, Y.; Wang, Z.; Li, D. Friction properties of graphite coating deposited on wedge-shaped textured aluminum alloys prepared by 3D printing. J. Mater. Res. Technol. 2022, 20, 4452–4472. [Google Scholar] [CrossRef]

- Lu, C.; Shi, P.; Yang, J.; Jia, J.; Xie, E.; Sun, Y. Effects of surface texturing on the tribological behaviors of PEO/PTFE coating on aluminum alloy for heavy-load and long-performance applications. J. Mater. Res. Technol. 2020, 9, 12149–12156. [Google Scholar] [CrossRef]

- Kawasegi, N.; Kawashima, T.; Morita, N.; Nishimura, K.; Yamaguchi, M.; Takano, N. Effect of texture shape on machining performance of textured diamond cutting tool. Precis. Eng. 2019, 60, 21–27. [Google Scholar] [CrossRef]

- Wang, Z.; Dai, Z.; Wu, S.; Zhang, B.; Cao, J.; Ye, R. Combined effect of cavitation and multi-scale texture on the bearing properties of seawater-lubricated friction pair. Phys. Fluids 2023, 35, 087129. [Google Scholar] [CrossRef]

- Huang, J.; Guan, Y.; Ramakrishna, S. Tribological behavior of femtosecond laser-textured leaded brass. Tribol. Int. 2021, 162, 107115. [Google Scholar] [CrossRef]

- Liu, J.; Du, Z.; Su, J.; Tang, J.; Jiang, F.; Fu, D.; Teng, J.; Zhang, H. Effect of quenching residual stress on precipitation behaviour of 7085 aluminium alloy. J. Mater. Sci. Technol. 2023, 132, 154–165. [Google Scholar] [CrossRef]

- Tan, E. Change in the Wear Characteristics of T6 Heat-Treated 2024, 6063, and 7075 Alloys at Different Quenching Temperatures. J. Mater. Eng. Perform. 2023, 32, 5128–5140. [Google Scholar] [CrossRef]

- Yong, A.Y.L.; Seah, K.H.W.; Rahman, M. Performance evaluation of cryogenically treated tungsten carbide tools in turning. Int. J. Mach. Tools Manuf. 2006, 46, 2051–2056. [Google Scholar] [CrossRef]

- Weng, Z.; Liu, X.; Gu, K.; Guo, J.; Cui, C.; Wang, J. Modification of residual stress and microstructure in aluminium alloy by cryogenic treatment. Mater. Sci. Technol. 2020, 36, 1547–1555. [Google Scholar] [CrossRef]

- Wei, L.; Wang, D.; Li, H.; Xie, D.; Ye, F.; Song, R.; Zheng, G.; Wu, S. Effects of Cryogenic Treatment on the Microstructure and Residual Stress of 7075 Aluminum Alloy. Metals 2018, 8, 273. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, S.; Lin, Z.; Liu, Z.; Liu, J.; Mai, Q.; Yue, X. Corrosion mechanism and machinability of 7075-T6 aluminum alloy in high-speed cutting: With and without cryogenic treatment. Mater. Corros. 2023, 74, 872–886. [Google Scholar] [CrossRef]

- Sudeep, U.; Tandon, N.; Pandey, R.K. Vibration studies of lubricated textured point contacts of bearing steels due to surface topographies: Simulations and experiments. Tribol. Int. 2016, 102, 265–274. [Google Scholar] [CrossRef]

- Yao, E.; Zhang, H.; Ma, K.; Ai, C.; Gao, Q.; Lin, X. Effect of deep cryogenic treatment on microstructures and performances of aluminum alloys: A review. J. Mater. Res. Technol. 2023, 26, 3661–3675. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Q.; Pan, Z.; Lv, D.; Wu, S. Fabrication of silicon nitride with high thermal conductivity and flexural strength by hot-pressing flowing sintering. Int. J. Appl. Ceram. Technol. 2024, 21, 2841–2849. [Google Scholar] [CrossRef]

- Jovičević-Klug, M.; Rezar, R.; Jovičević-Klug, P.; Podgornik, B. Influence of deep cryogenic treatment on natural and artificial aging of Al-Mg-Si alloy EN AW 6026. J. Alloys Compd. 2022, 899, 163323. [Google Scholar] [CrossRef]

- Bhaumik, S.; Paleu, V.; Chowdhury, D.; Batham, A.; Sehgal, U.; Bhattacharya, B.; Ghosh, C.; Datta, S. Tribological Investigation of Textured Surfaces in Starved Lubrication Conditions. Materials 2022, 15, 8445. [Google Scholar] [CrossRef] [PubMed]

- Dan, L.; Xuefeng, Y.; Chongyang, L.; Jian, C.; Shouren, W.; Yanjun, W. Tribological characteristics of a cemented carbide friction surface with chevron pattern micro-texture based on different texture density. Tribol. Int. 2020, 142, 106016. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, F.; Chen, Z.; Ruan, X.; Zeng, H.; Wang, J.; An, Y.; Fan, X. Numerical simulation of lubrication performance on chevron textured surface under hydrodynamic lubrication. Tribol. Int. 2021, 154, 106704. [Google Scholar] [CrossRef]

- Xu, D.K.; Birbilis, N.; Lashansky, D.; Rometsch, P.A.; Muddle, B.C. Effect of solution treatment on the corrosion behaviour of aluminium alloy AA7150: Optimisation for corrosion resistance. Corros. Sci. 2011, 53, 217–225. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Cui, Y.; Wang, J.; Wang, M. Effects of Snake-Bioinspired Surface Texture on the Finger-Sealing Performance under Varied Working Conditions. Machines 2022, 10, 569. [Google Scholar] [CrossRef]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A theory of lubrication by micro-irregularities. J. Basic Eng. 1966, 88, 177. [Google Scholar] [CrossRef]

- Arghir, M.; Roucou, N.; Helene, M.; Frene, J. Theoretical Analysis of the Incompressible Laminar Flow in a Macro-Roughness Cell. J. Tribol. 2003, 125, 309–318. [Google Scholar] [CrossRef]

- Sahlin, F.; Glavatskih, S.B.; Almqvist, T.; Larsson, R. Two-Dimensional CFD-Analysis of Micro-Patterned Surfaces in Hydrodynamic Lubrication. J. Tribol. 2005, 127, 96–102. [Google Scholar] [CrossRef]

- Rapoport, L. Steady friction state and contact models of asperity interaction. Wear 2009, 267, 1305–1310. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, B.; Liu, Y.; Cai, Y.; Hu, C. Research on friction and wear behavior of gradient nano-structured 40Cr steel induced by high frequency impacting and rolling. Eng. Fail. Anal. 2018, 83, 167–177. [Google Scholar] [CrossRef]

- Wan, S.; Wang, H.; Xia, Y.; Tieu, A.K.; Tran, B.H.; Zhu, H.; Zhang, G.; Zhu, Q. Investigating the corrosion-fatigue wear on CrN coated piston rings from laboratory wear tests and field trial studies. Wear 2019, 432–433, 202940. [Google Scholar] [CrossRef]

- Ibatan, T.; Uddin, M.S.; Chowdhury, M.A.K. Recent development on surface texturing in enhancing tribological performance of bearing sliders. Surf. Coat. Technol. 2015, 272, 102–120. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).