Influence of Grease Properties on False Brinelling Damage of Rolling Bearings

Abstract

:1. Introduction

2. Materials and Methods

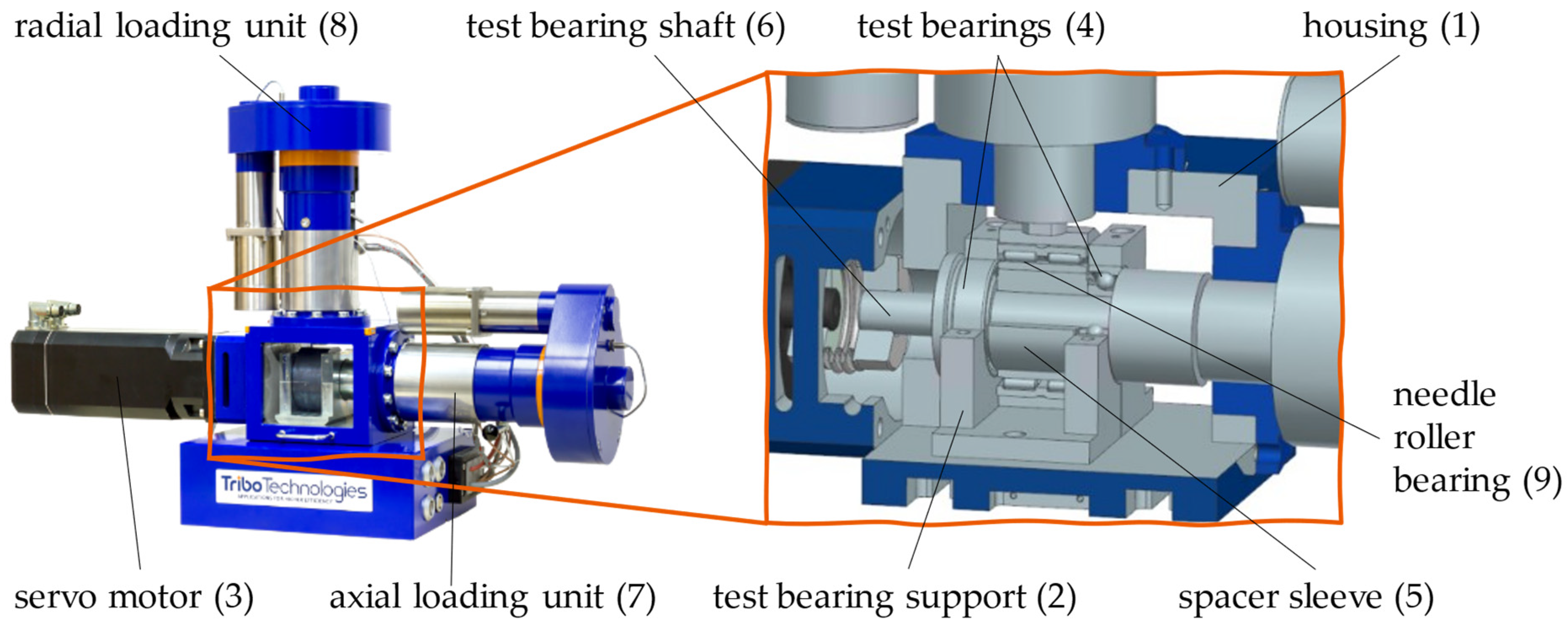

2.1. False Brinelling Test Rig

2.2. Methodology

2.2.1. Test Bearing Preparation

2.2.2. Grease Distribution

2.2.3. False Brinelling Test

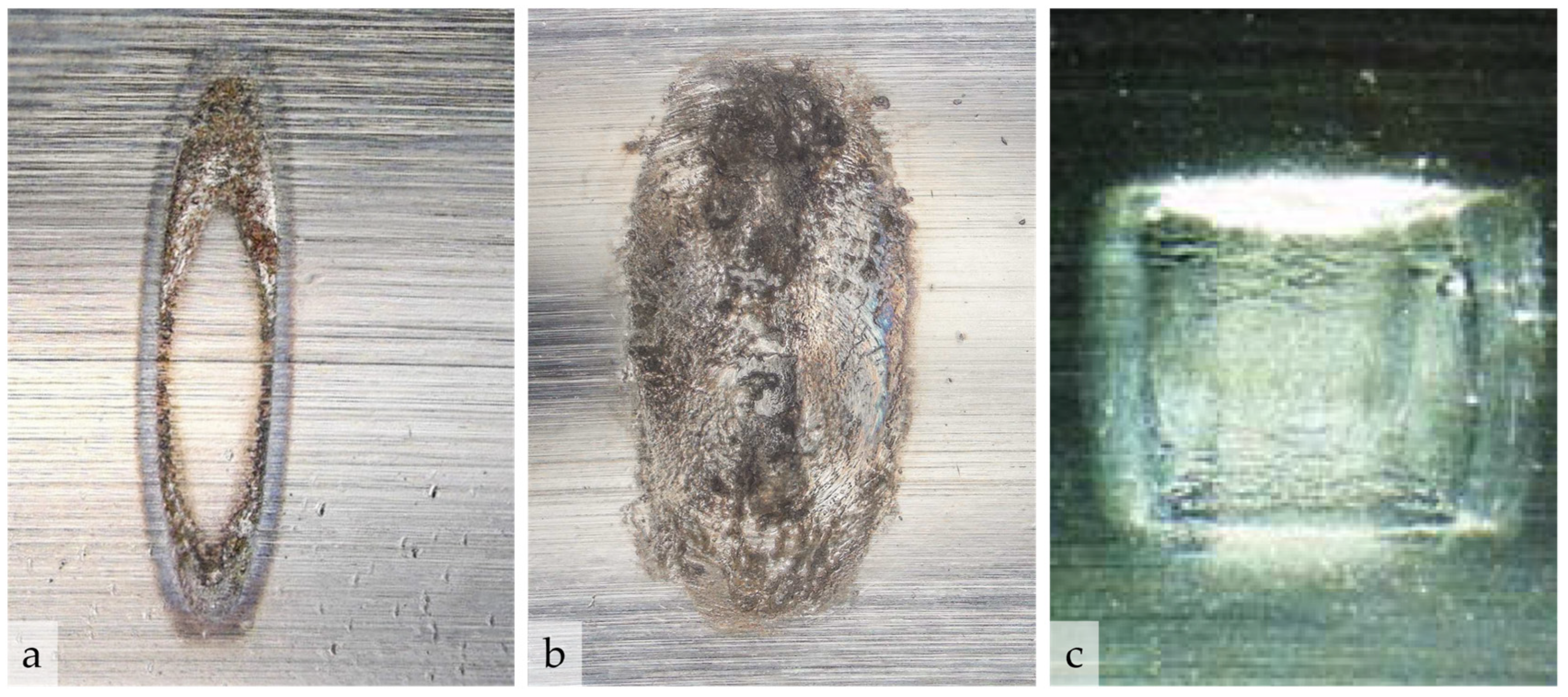

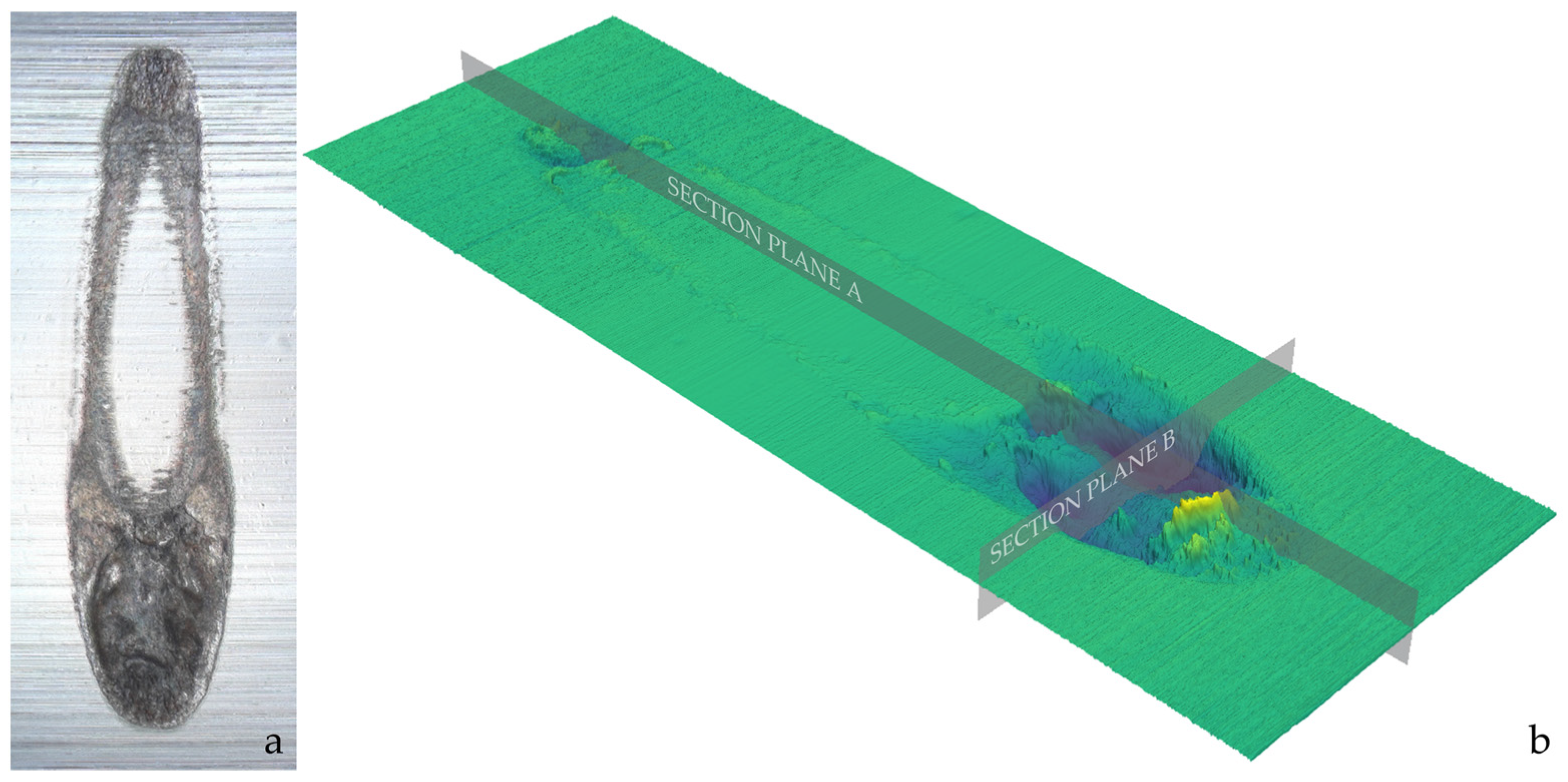

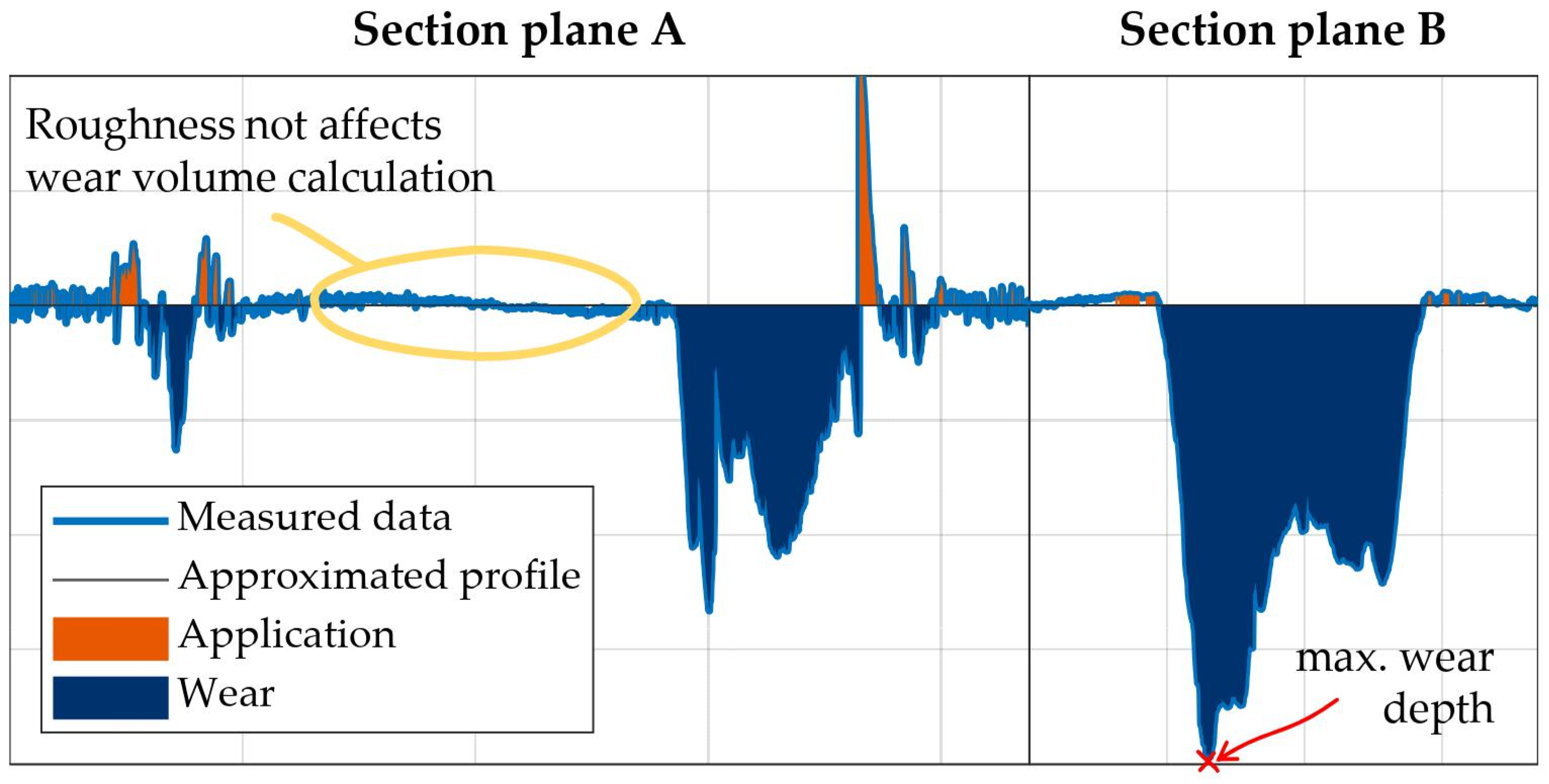

2.2.4. Test Results Evaluation

2.3. Sample Materials

3. Discussion of Experimental Results

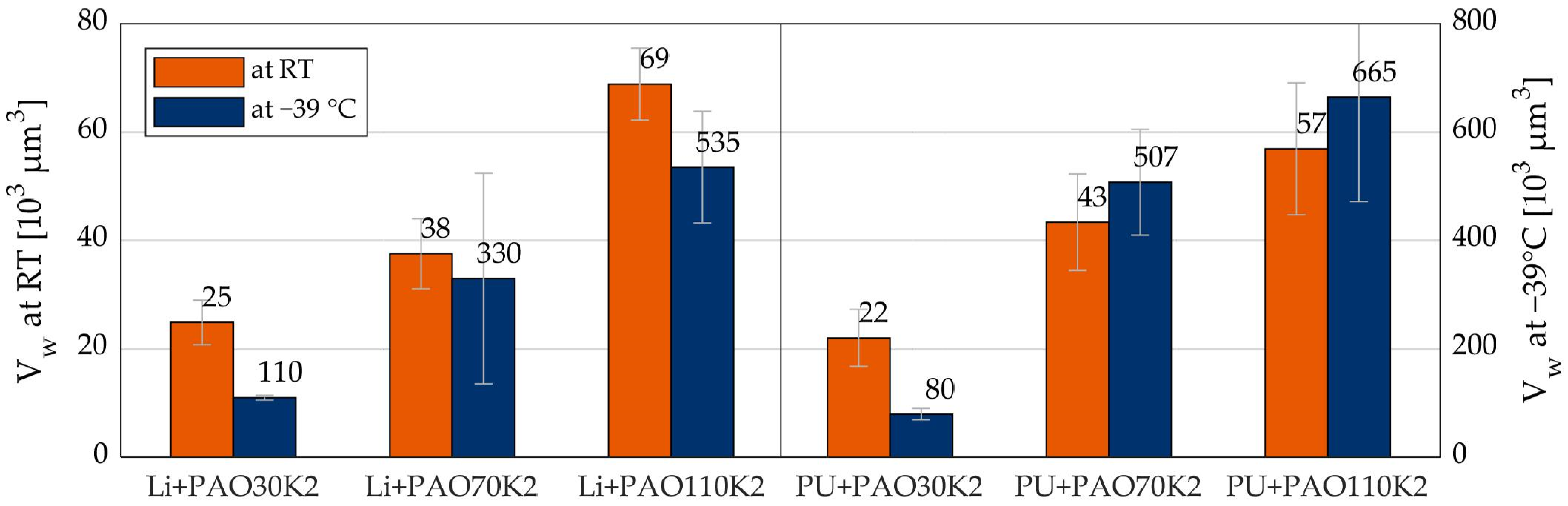

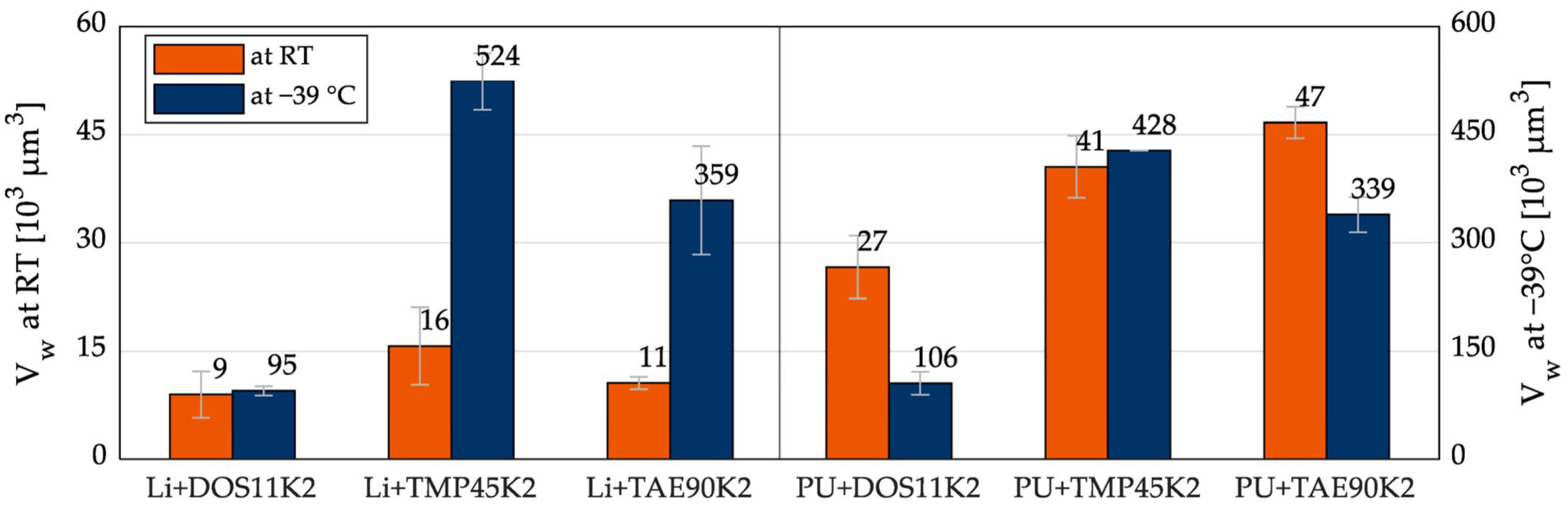

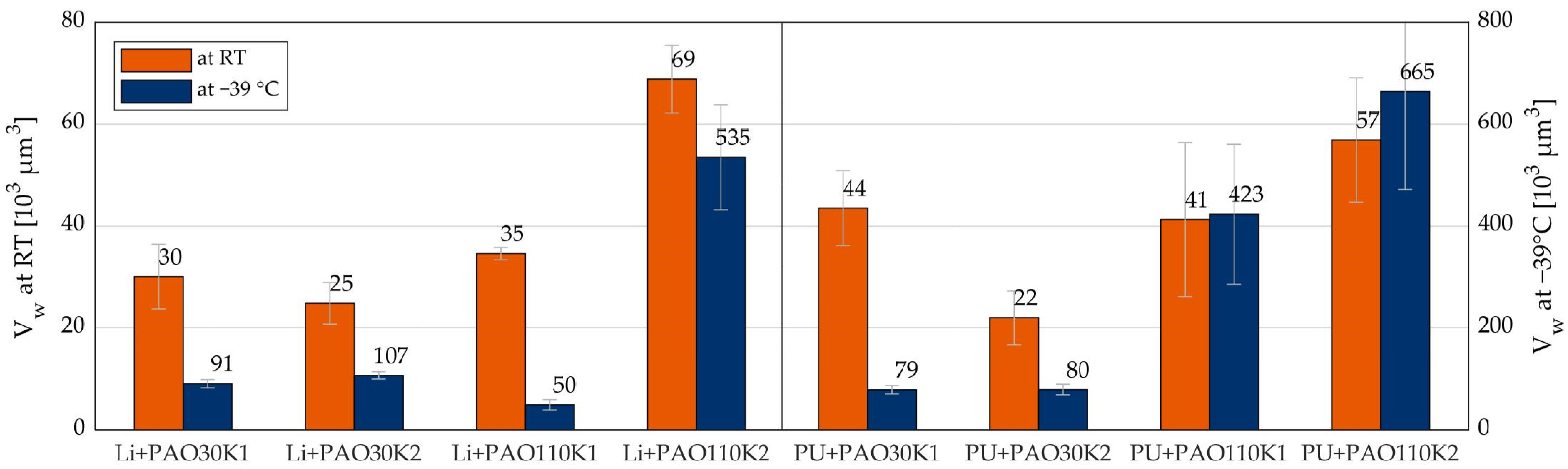

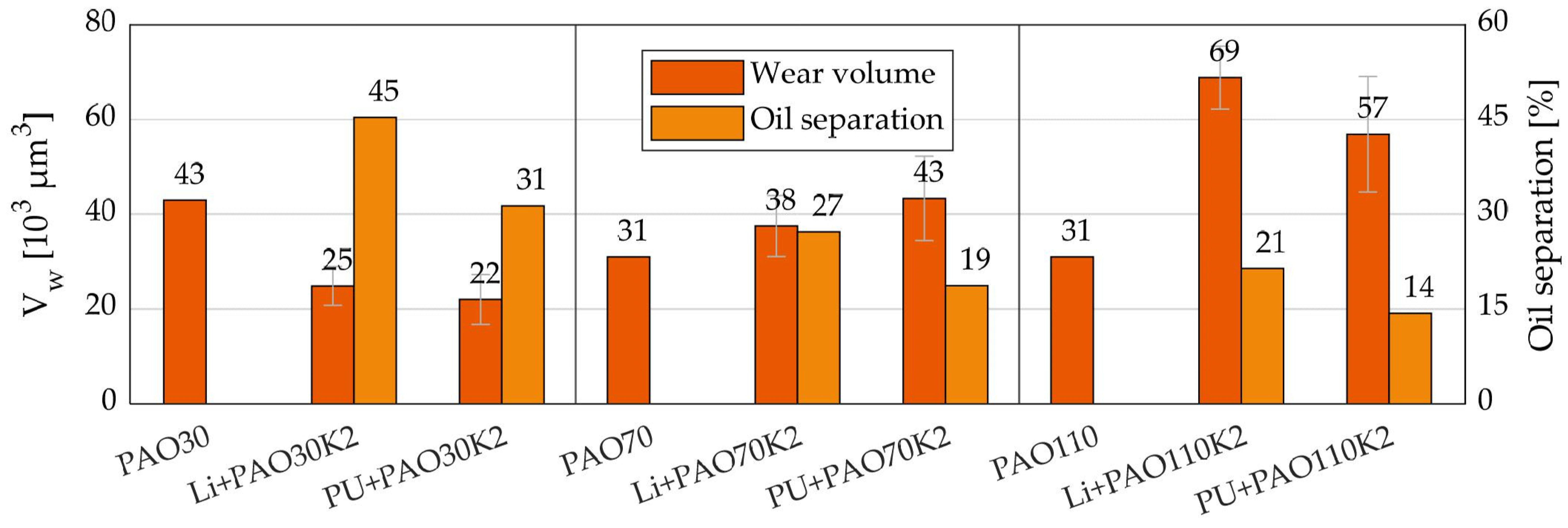

3.1. Influence of the Base Oil Viscosity and Type and the Grease Consistency Class

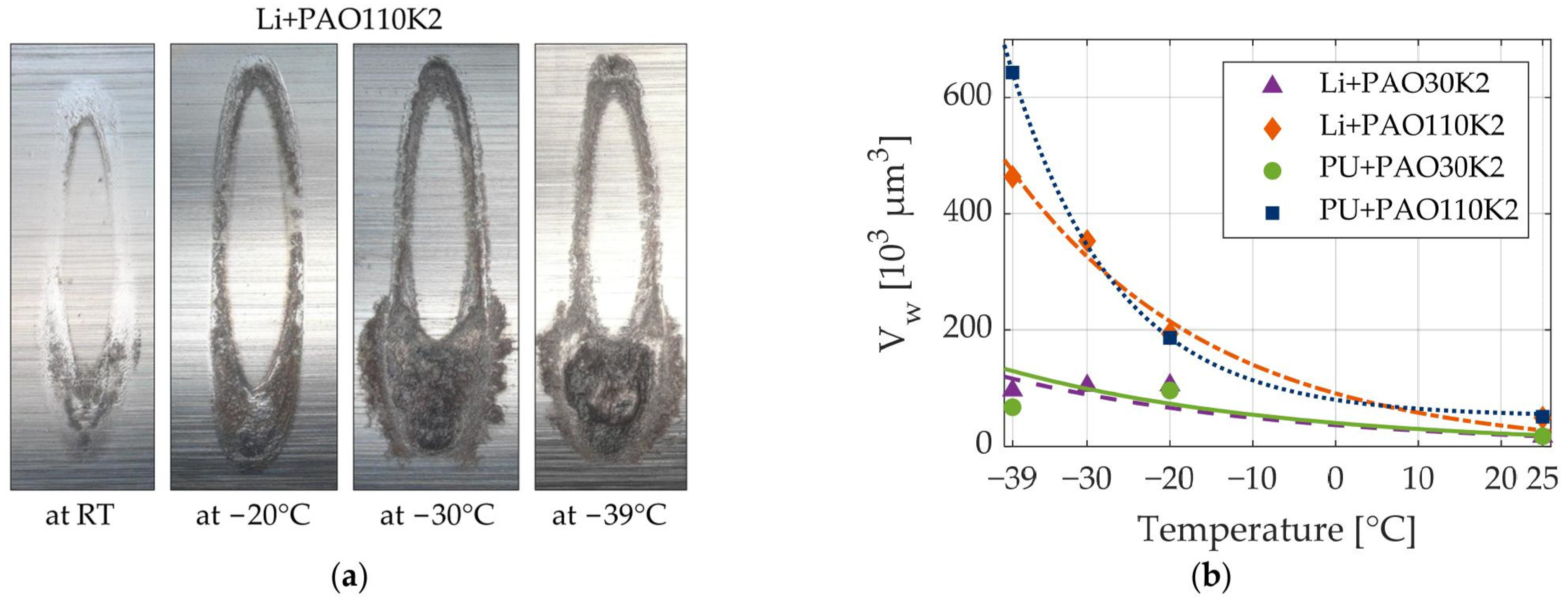

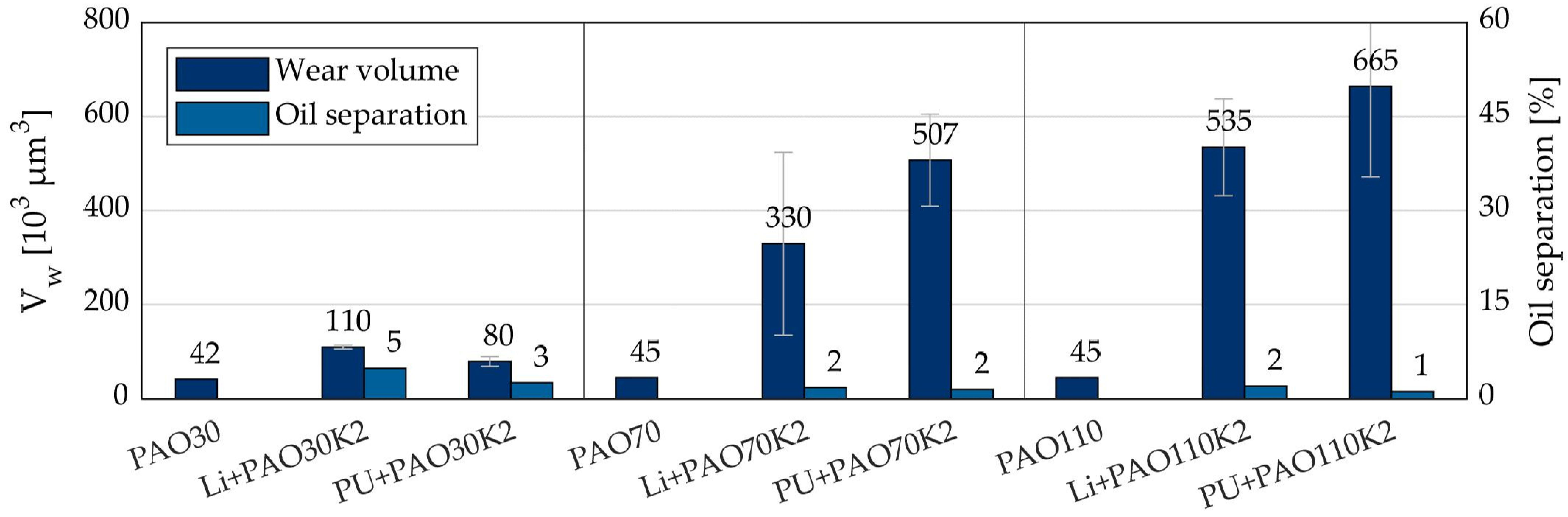

3.2. Influence of Temperature

3.3. Influence of Oil Separation

3.4. Sample Tests with Base Oils

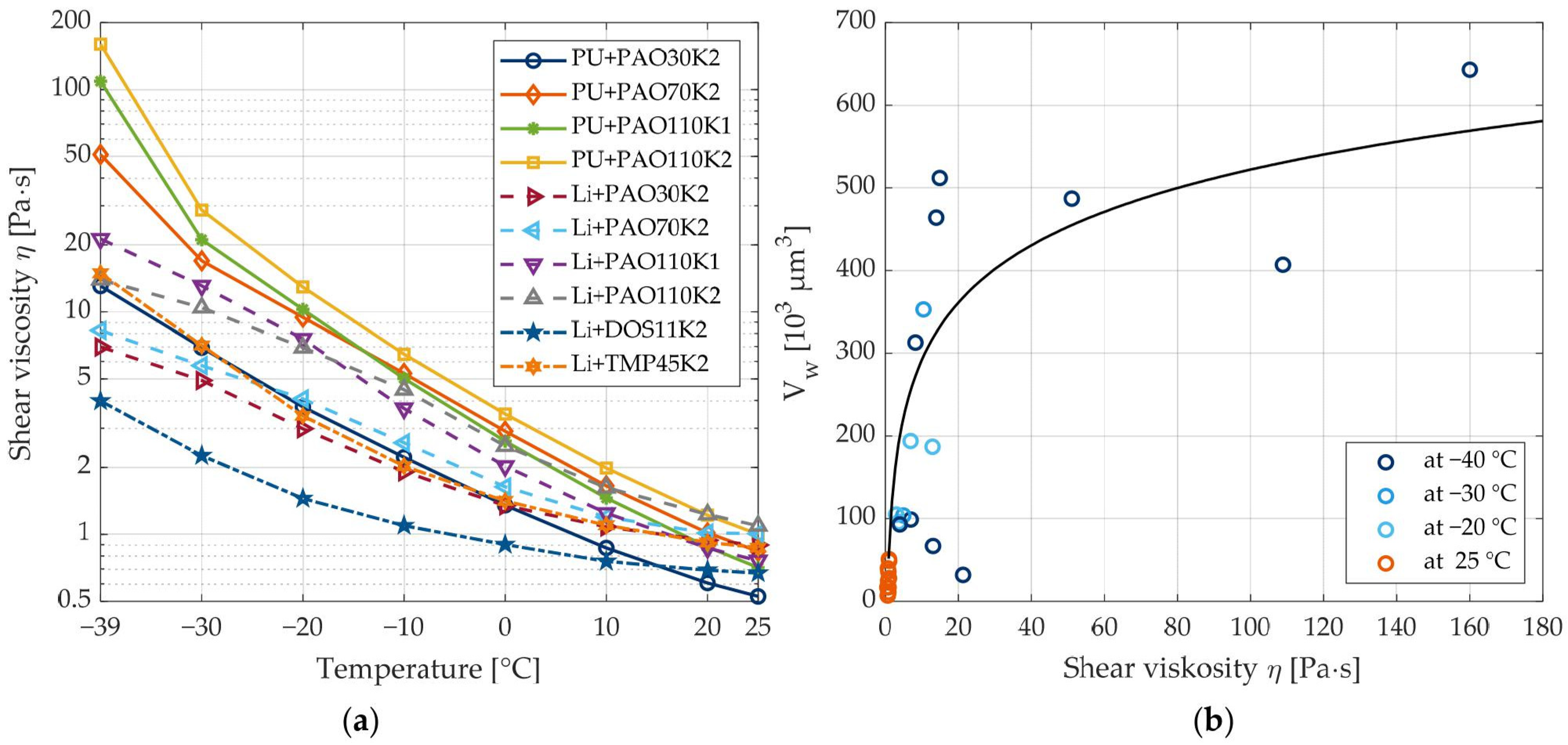

3.5. Influence of Shear Viscosity

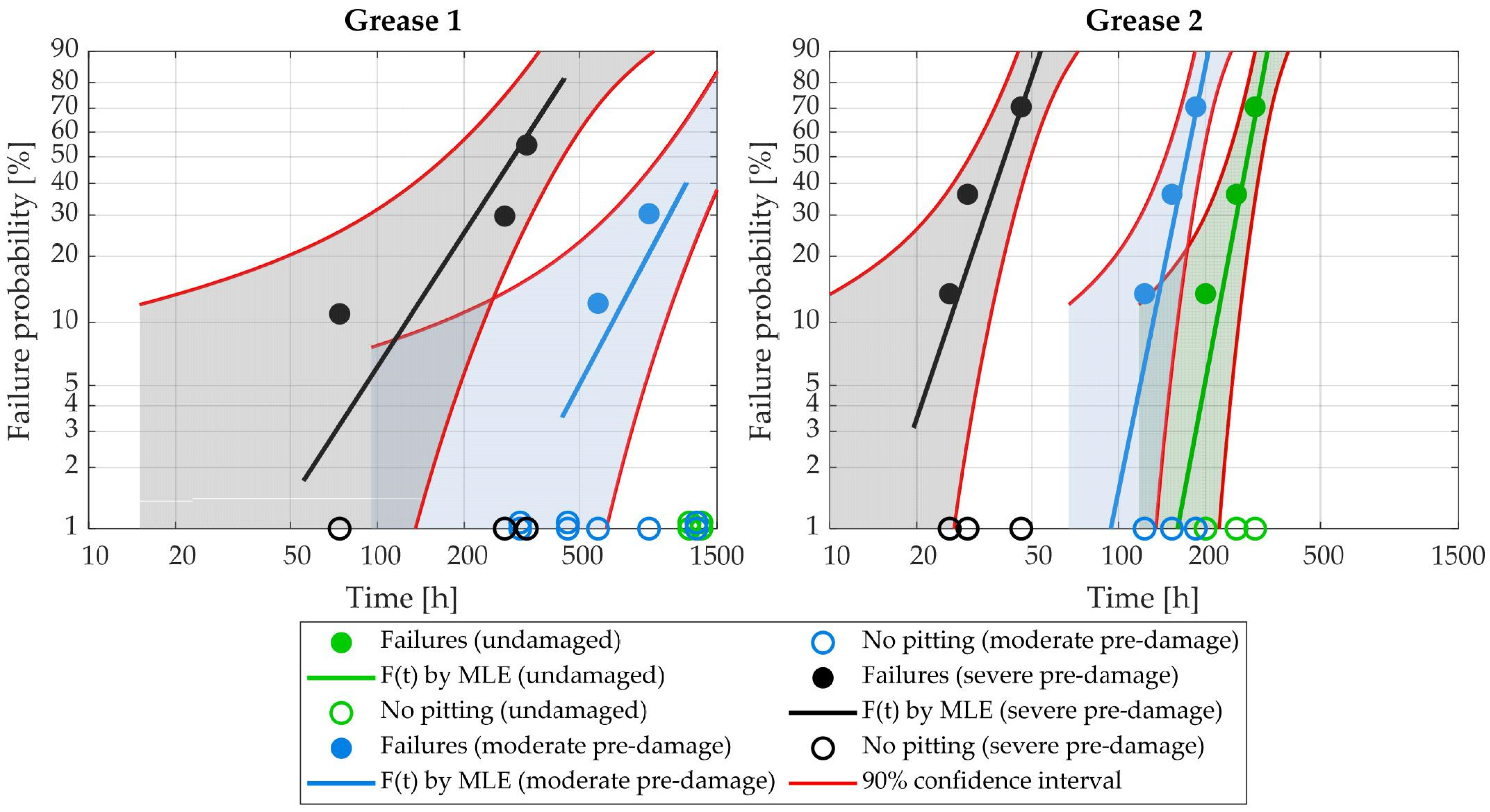

3.6. Durability Test Results

4. Conclusions

- The results suggest that the presence of lubricant in the rolling element raceway contact was necessary for a suitable lubricating grease to protect the surfaces with its additives.

- A reduction in the base oil viscosity led to a reduction in the false brinelling damage. This could be shown very clearly based on results in tests on model greases with chemically identical PAO base oils with different viscosity. However, when other chemically different base oil types (e.g., esters) were compared, such a tendency among PAO oils was not observed in all cases, e.g., bearings with Li+TMP45 received higher damage than with Li+TAE90 even though the second has a higher base oil viscosity. The authors suggest that this behavior could have been caused by other factors, such as chemical properties (e.g., the polarity of oils) or wetting behavior, that were not investigated in the current work.

- A comparison of the model greases of different NLGI classes and base oil viscosities indicated that selecting a higher-viscosity base oil and lower NLGI class could lead to significant reductions in wear volumes at both low and room temperatures.

- Lower oil separation led to increased damage. While high oil separation can reduce false brinelling damage, a moderate and consistent release of oil over the service life is optimal for achieving the longest possible grease operating life.

- The results of the shear tests on various model greases showed that the shear viscosity of the greases increased with decreasing temperature. A lower shear viscosity of the grease led to improved flow properties, and thus, decreased the level of false brinelling damage.

- The damage level was significantly higher at low temperatures due to changes in rheological properties and oil separation.

- The results also demonstrated the extent to which different levels of false brinelling damage can reduce bearing life with different greases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almen, J.O. Lubricants and False Brinelling of Ball and Roller Bearings. Mech. Eng. 1937, 59, 415–422. [Google Scholar]

- Schadow, C. Stillstehende Fettgeschmierte Wälzlager unter Dynamischer Beanspruchung. (Standstill Grease-Lubricated Rolling Bearings under Dynamic Load). Ph.D. Thesis, Otto-von-Guericke-Universität Magdeburg, Shaker Verlag, Aachen, Germany, 2016. [Google Scholar]

- Bosse, H.; Müller, F. Schmierungsverhalten bei oszillierenden Gleit- und Wälzbewegungen (Lubrication Behavior in Oscillating Sliding and Rolling Motions); Final Report to FVA Research Project 315 II; FVA: Frankfurt, Germany, 2003; Volume 714, Available online: https://www.tib.eu/en/search/id/TIBKAT:524126976/Schmierungsverhalten-bei-oszillierenden-Gleit-und?cHash=ee3ed44dabd8389a846005ee54ffb7ad (accessed on 24 May 2023).

- Fritzsche, R. Beschädigung eines Radlagers beim Pkw-Transport auf einem Lkw. (Damage to a wheel bearing during car transport on a truck). ATZ 2019, 121, 58–63. [Google Scholar]

- Fallahnezhad, K.; Brinji, O.; Desai, A.; Meehan, P.A. The influence of different types of loading on false brinelling. Wear 2019, 440–441, 203097. [Google Scholar] [CrossRef]

- Mannens, R.; Trauth, D.; Falker, J.; Brecher, C.; Klocke, F. Analysis of spindle bearing load with regard to the false brinelling effect caused by machine hammer peening. Int. J. Adv. Manuf. Technol. 2018, 95, 3969–3976. [Google Scholar] [CrossRef]

- Grebe, M. False-Brinelling und Stillstandsmarkierungen bei Wälzlagern: Schäden bei Vibrationsbelastung oder Kleinen Schwenkwinkeln (False Brinelling and Standstill Marks in Rolling Bearings: Damage under Vibration Load or Small Pivot Angles), 1st ed.; Expert Verlag: Renningen, Germany, 2017; ISBN 9783838551609. [Google Scholar]

- Schwack, F. Untersuchungen zum Betriebsverhalten Oszillierender Wälzlager am Beispiel von Rotorblattlagern in Windener-Gieanlagen. (Investigations into the Operating Behavior of Oscillating Rolling Bearings Using the Example of Rotor Blade Bearings in Wind Turbines). Ph.D. Thesis, Gottfried Wilhelm Leibniz Universität, Hannover, Germany, 2020. [Google Scholar]

- Schadow, C. Stillstehende fettgeschmierte Wälzlager unter dynamischer Belastung (Standstill Grease-Lubricated Rolling Bearings under Dynamic Load); Final Report to FVA Research Project 540 I; FVA: Frankfurt, Germany, 2010; Volume 951, Available online: https://www.tib.eu/en/search/id/TIBKAT:677756917/False-Brinelling-Stillstehende-fettgeschmierte?cHash=553cbd028f3c4ae0cd30c74565c592ee (accessed on 24 May 2023).

- Schadow, C. Stillstehende fettgeschmierte Wälzlager unter dynamischer Belastung (Standstill Grease-Lubricated Rolling Bearings under Dynamic Load); Final Report to FVA Research Project 540 II; FVA: Frankfurt, Germany, 2018; Volume 1268, Available online: https://www.tib.eu/en/search/id/TIBKAT:1026687241/Stillstehende-fettgeschmierte-W%C3%A4lzlager-Stillstehende?cHash=3d5b2af976990286dbdfb935d189a68e (accessed on 24 May 2023).

- Tetora, S. Stillstehende fettgeschmierte Wälzlager unter dynamischer Belastung (Standstill Grease-Lubricated Rolling Bearings under Dynamic Load); Final Report to FVA Research Project 540 III; FVA: Frankfurt, Germany, 2022; Volume 1494, Available online: https://www.tib.eu/en/search/id/TIBKAT:1831095963/Stillstehende-fettgeschmierte-W%C3%A4lzlager-stillstehende?cHash=d3ff9311c29c42984cee58451ddc94b2 (accessed on 24 May 2023).

- ASTM D4170-16; Test Method for Fretting Wear Protection by Lubricating Greases. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM D7594-19; Test Method for Determining Fretting Wear Resistance of Lubricating Greases under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation (SRV) Test Machine. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Griesheimer, S. Einflussfaktoren auf die Entstehung von Stillstandsmarkierungen. (Influencing Factors on the Formation of Standstill Markings). Diploma Thesis, Hochschule Mannheim, Mannheim, Germany, 2007. [Google Scholar]

- Pittroff, H. Riffelbildung bei Wälzlagern infolge Stillstandserschütterungen. (Ripple Formation in Rolling Bearings due to Standstill Vibrations). Ph.D. Thesis, TU München, München, Germany, 1961. [Google Scholar]

- Januszewski, R.; Brizmer, V.; Kadiric, A. Effect of Lubricant Properties and Contact Conditions on False Brinelling Damage. Tribol. Trans. 2023, 66, 350–363. [Google Scholar] [CrossRef]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; Wiley: Chichester West Sussex, UK, 2013; ISBN 9781118353912. [Google Scholar]

- Schadow, C.; Tetora, S.; Bartel, D. Folgeschäden durch False-Brinelling in Radlagern durch geeignete Schmierfette vermei-den. (Consequential damage avoid by false brinelling in wheel bearings by using suitable lubricating greases). In Experten-Forum Powertrain: Reibung in Antrieb und Fahrzeug 2020; Liebl, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 15–29. ISBN 978-3-662-63607-7. [Google Scholar]

| Parameter | Value |

|---|---|

| Motor rotational speed | 0 to 1500 rpm |

| Motor pivot frequency | 0 to 20 Hz |

| Pivot angle | ±0.025° to ±2.0° |

| Radial and axial load (static) | 0 to 15 kN |

| Radial and axial load (dynamic) | 2 to 5 kN |

| Radial and axial load frequency | 0 to 50 Hz |

| Temperature | −40 °C to +40 °C |

| Lubricants | Grease, oil |

| Bearing type | Angular contact bearing (7205), tapered roller bearing 32005-X |

| Parameter | Value |

|---|---|

| Load scenario | Axial and radial static load + dynamic radial load + pivot movement |

| Load zone ψ | 180° |

| Average load C0/P0 | 10 |

| Load amplitude ΔP0/P0 | ±25% |

| Load frequency fL | 8 Hz |

| Pivot angle β | ±0.25° |

| Pivot frequency fβ | 5 Hz |

| Operating temperature θ | −40 °C to +40 °C |

| Oscillating cycles | 0.5 Mio |

| Bearing type | Angular contact bearing (7205) |

| Abbreviation | Thickener Type (Thickener Content) | Base Oil | ν40 [cSt] | Worked Penetration [mm/10] |

|---|---|---|---|---|

| Li+PAO30K2 | Li-12-OH-stearate (10%) | Poly alpha olefin | 30 | 275 |

| Li+PAO70K2 | Li-12-OH-stearate (10%) | Poly alpha olefin | 70 | 269 |

| Li+PAO110K2 | Li-12-OH-stearate (9.5%) | Poly alpha olefin | 110 | 279 |

| PU+PAO30K2 | Diurea (13.7%) | Poly alpha olefin | 30 | 275 |

| PU+PAO70K2 | Diurea (22.9%) | Poly alpha olefin | 70 | 280 |

| PU+PAO110K2 | Diurea (14.1%) | Poly alpha olefin | 110 | 273 |

| Li+DOS11K2 | Li-12-OH-stearate (9%) | Dioctyl sebacate | 11.6 | 280 |

| Li+TMP45K2 | Li-12-OH-stearate (7.5%) | Trimethylolpropane | 45.6 | 270 |

| Li+TAE90K2 | Li-12-OH-stearate (9.5%) | Trimelitic acid ester | 90 | 265 |

| PU+DOS11K2 | Diurea (16%) | Dioctyl sebacate | 11.6 | 276 |

| PU+TMP45K2 | Diurea (16%) | Trimethylolpropane | 45.6 | 270 |

| PU+TAE90K2 | Diurea (14%) | Trimelitic acid ester | 90 | 278 |

| Li+PAO30K1 | Li-12-OH-stearate | Poly alpha olefin | 30 | 327 |

| Li+PAO110K1 | Li-12-OH-stearate (7%) | Poly alpha olefin | 110 | 322 |

| PU+PAO30K1 | Diurea (12%) | Poly alpha olefin | 30 | 325 |

| PU+PAO110K1 | Diurea (11.7%) | Poly alpha olefin | 110 | 326 |

| Grease | Grease 1 | Grease 2 | |||

|---|---|---|---|---|---|

| Pre-damage | Severe | Moderate | Severe | Moderate | Undamaged |

| Experimentally determined service life L10 h,exp | 125.5 h | 651.9 h | 25.9 h | 131.6 h | 218.2 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetora, S.; Schadow, C.; Bartel, D. Influence of Grease Properties on False Brinelling Damage of Rolling Bearings. Lubricants 2023, 11, 279. https://doi.org/10.3390/lubricants11070279

Tetora S, Schadow C, Bartel D. Influence of Grease Properties on False Brinelling Damage of Rolling Bearings. Lubricants. 2023; 11(7):279. https://doi.org/10.3390/lubricants11070279

Chicago/Turabian StyleTetora, Serhii, Christian Schadow, and Dirk Bartel. 2023. "Influence of Grease Properties on False Brinelling Damage of Rolling Bearings" Lubricants 11, no. 7: 279. https://doi.org/10.3390/lubricants11070279

APA StyleTetora, S., Schadow, C., & Bartel, D. (2023). Influence of Grease Properties on False Brinelling Damage of Rolling Bearings. Lubricants, 11(7), 279. https://doi.org/10.3390/lubricants11070279