Combined Effect of Fluid Cavitation and Inertia on the Pressure Buildup of Parallel Textured Surfaces

Abstract

1. Introduction

2. Theoretical Models

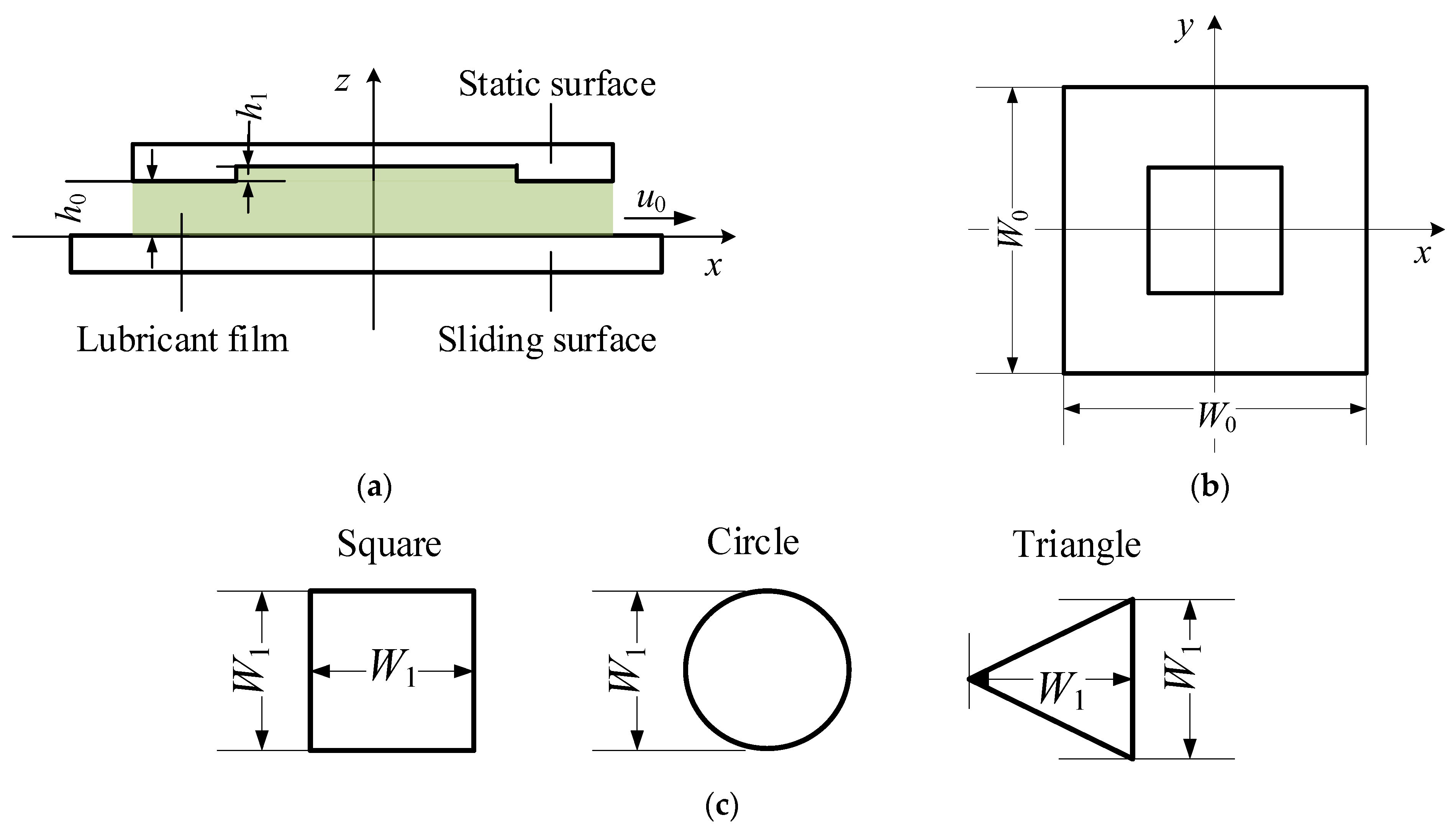

2.1. Geometrical Model

2.2. Mathematical Model

- The roughness of parallel surfaces is neglected, and the slip flow between the surfaces and the fluid film are not considered.

- The flow regime of the fluid film is laminar, as calculated from Re.

2.2.1. Mixture Mass and Momentum Equations

2.2.2. Mass Transfer Equations

2.2.3. Cavitation Source Term: RPE Model

2.2.4. Boundary Conditions

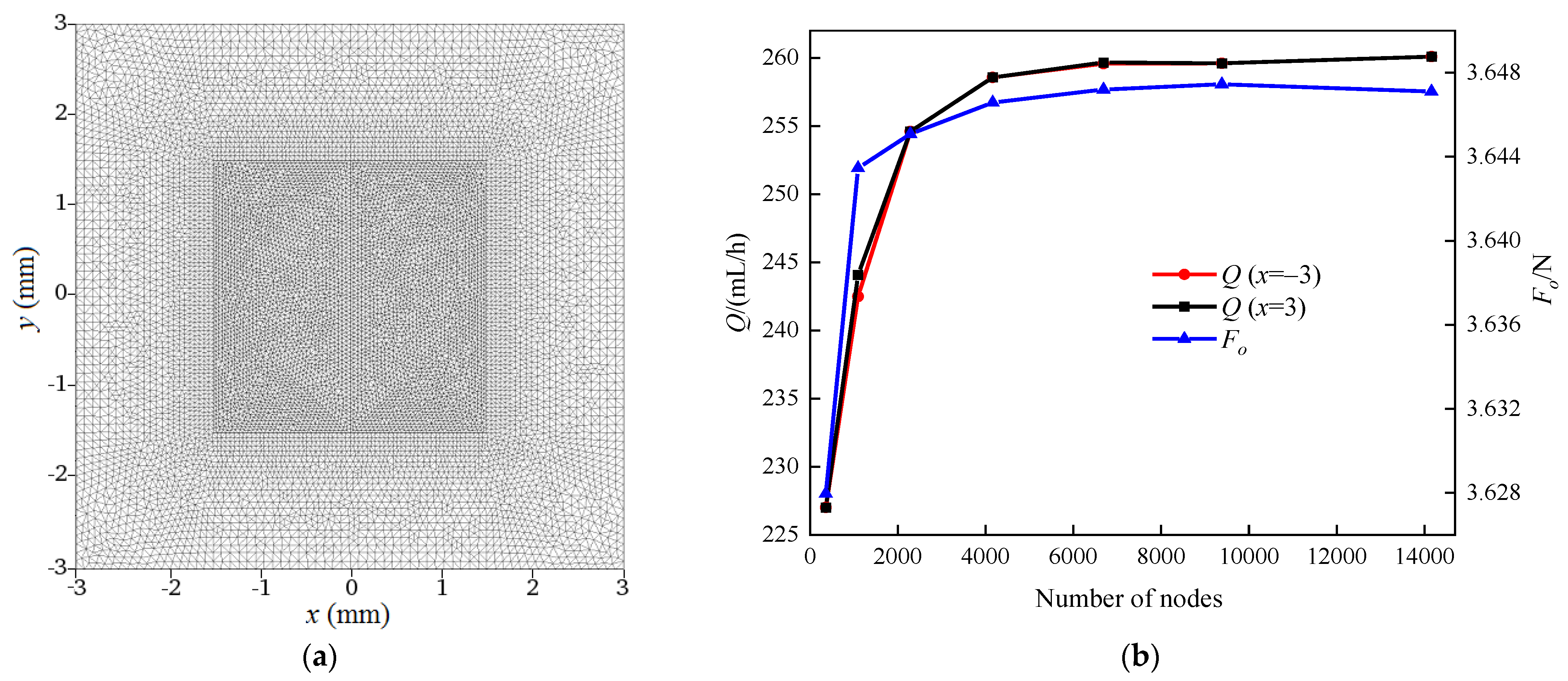

3. Numerical Procedure

- (1).

- Input geometric and operating parameters.

- (2).

- Give initial values X(0) (p(0), qx(0), qy(0), FL(0)) to unknown variables X (p, qx, qy, FL), and impose pre-boundary conditions.

- (3).

- Calculate the physical property parameters ρ, μ and flow characteristic parameters Ixx, Ixy, and Iyy.

- (4).

- Solve Equation (38) and obtain the pressure and flow rate distributions.

- (5).

- Solve Equation (39) based on step (4) and obtain the liquid volume fraction distribution.

- (6).

- Check the convergence criterion. If the unknowns meet the tolerance, end the iteration; otherwise, go to step (3) and repeat the procedure.

- (7).

- Output results and post-processing.

4. Results and Discussion

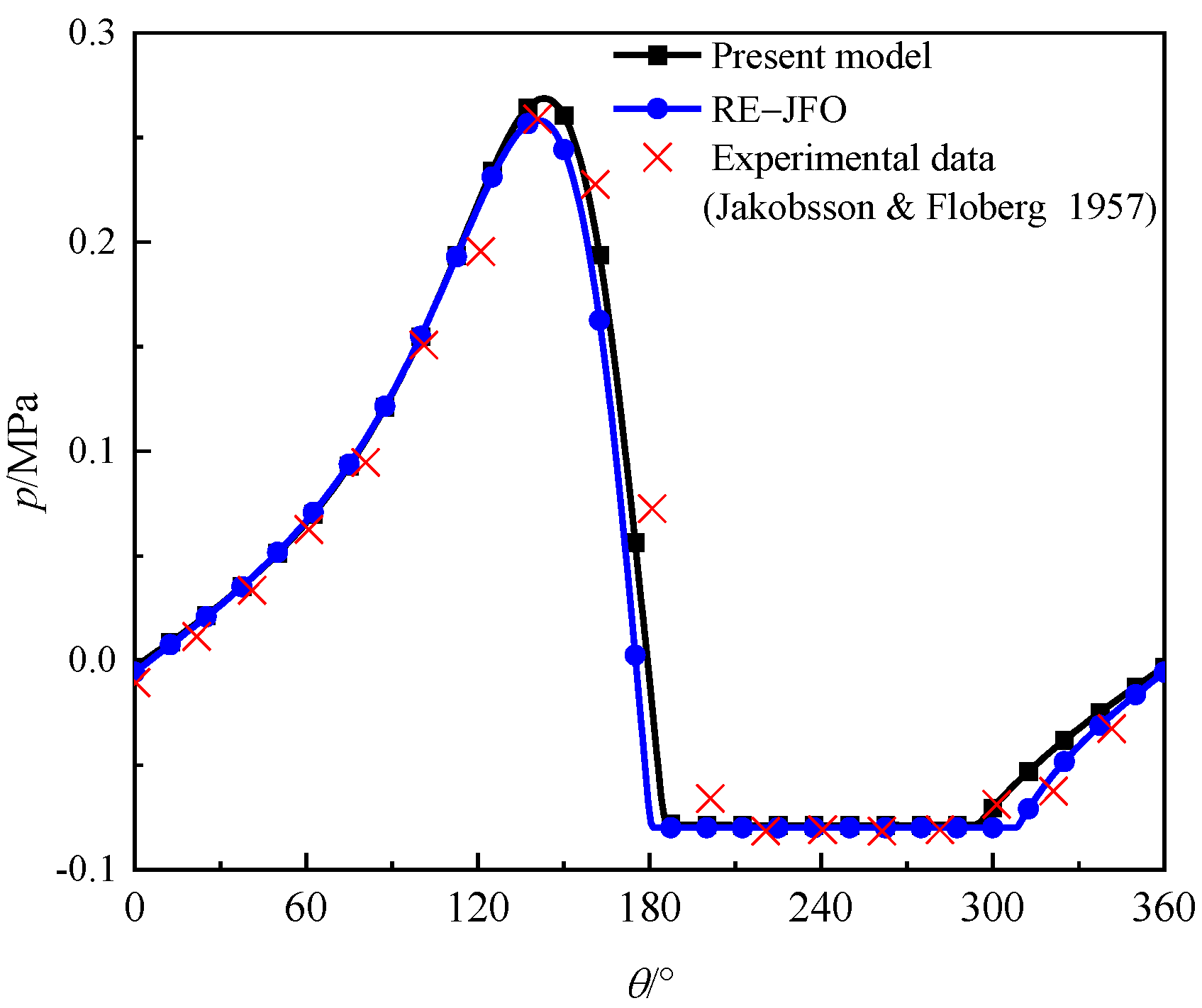

4.1. Validation

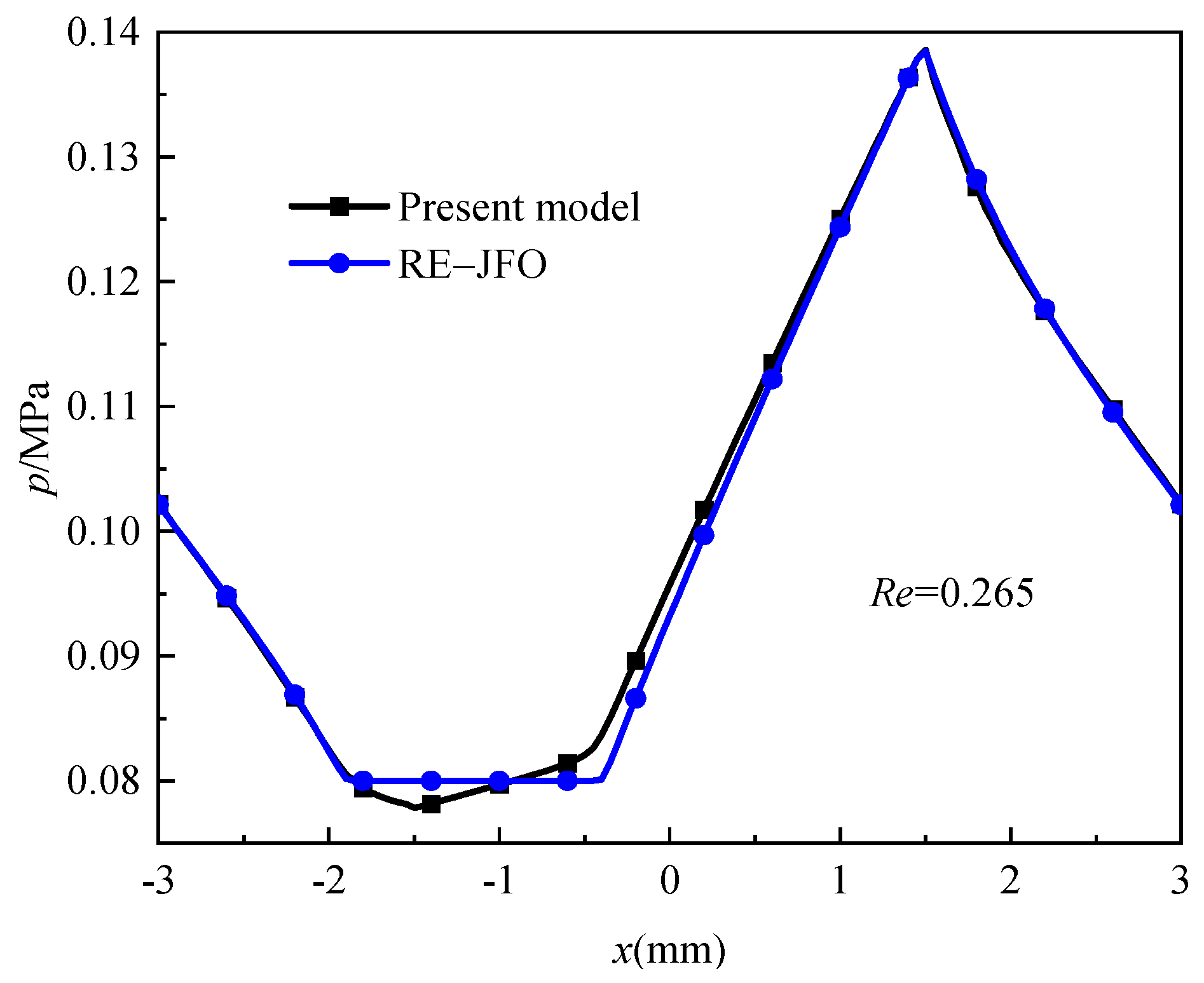

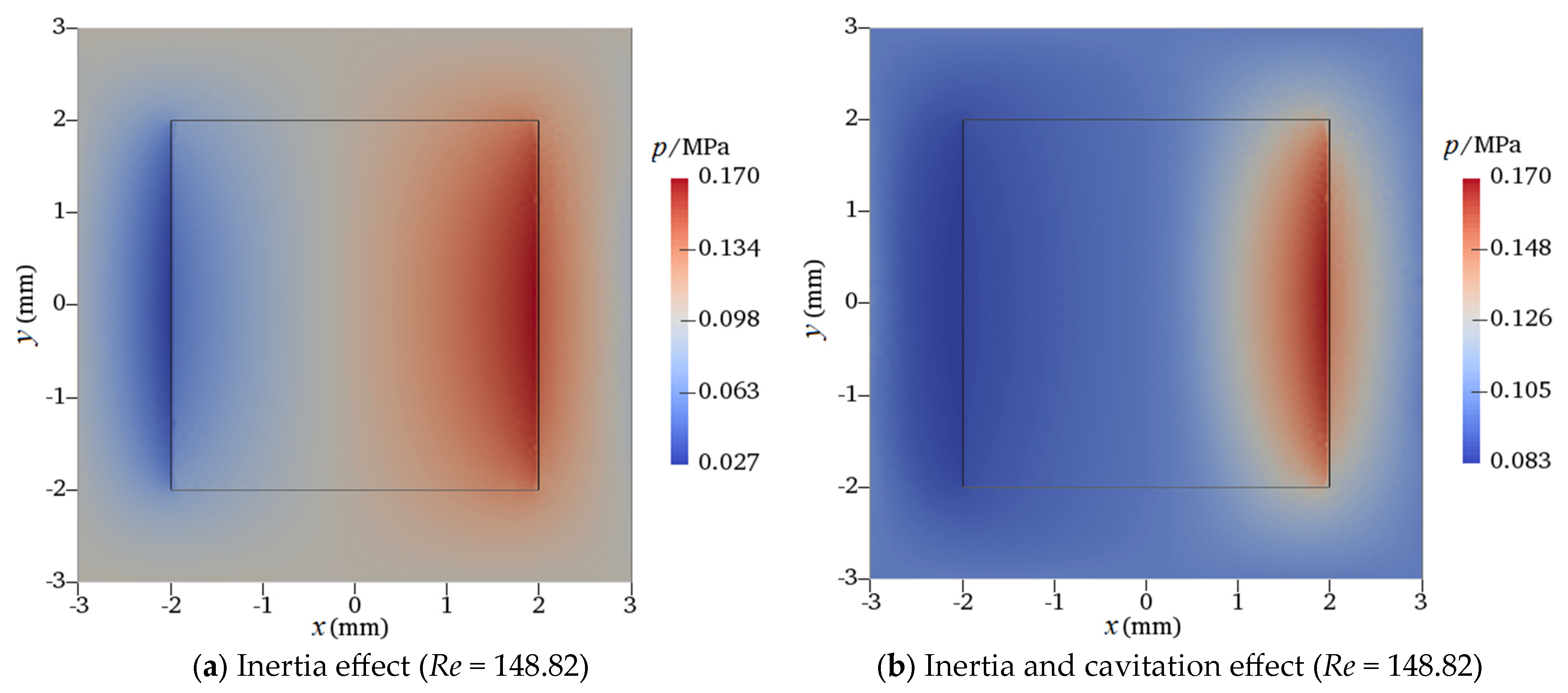

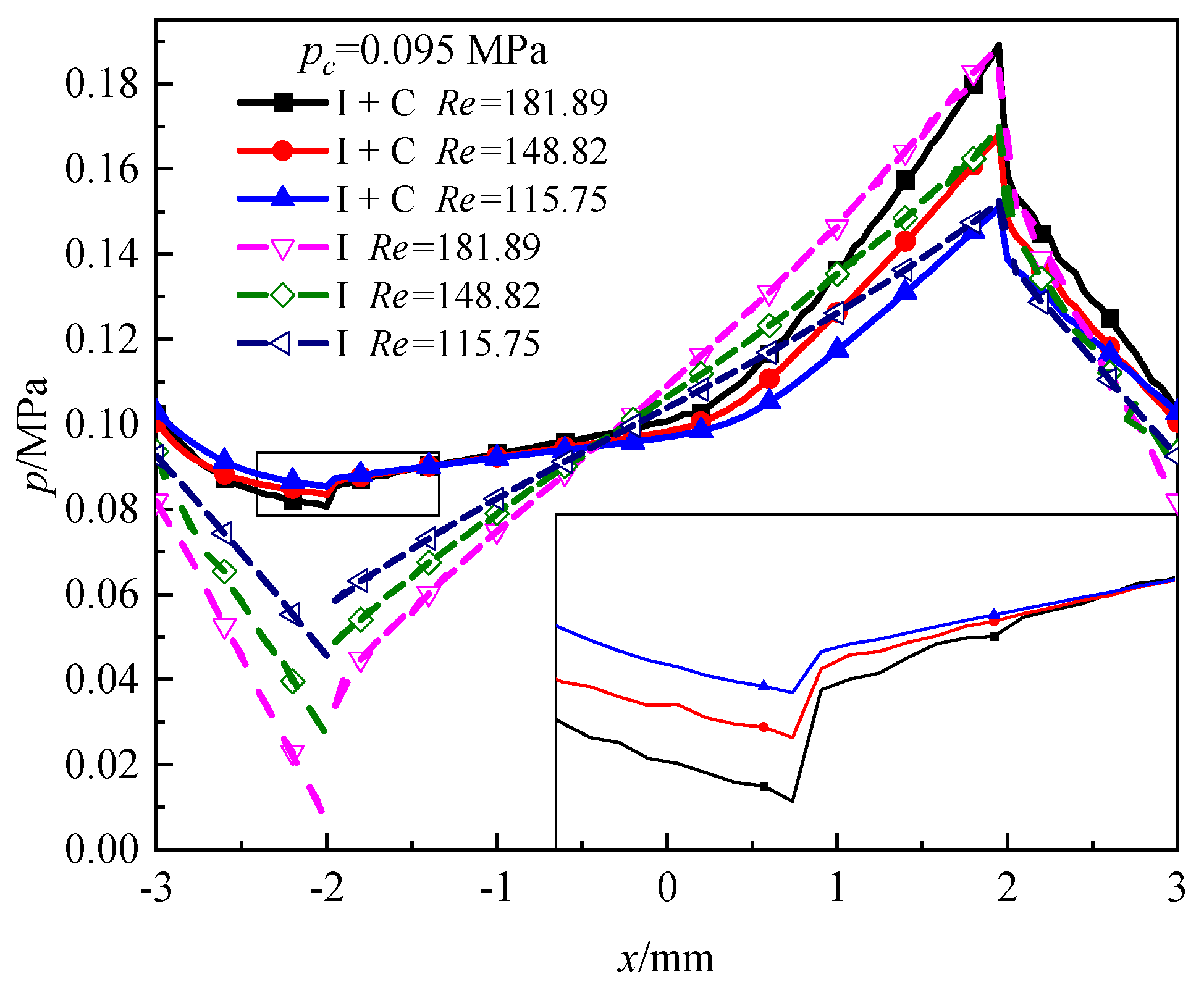

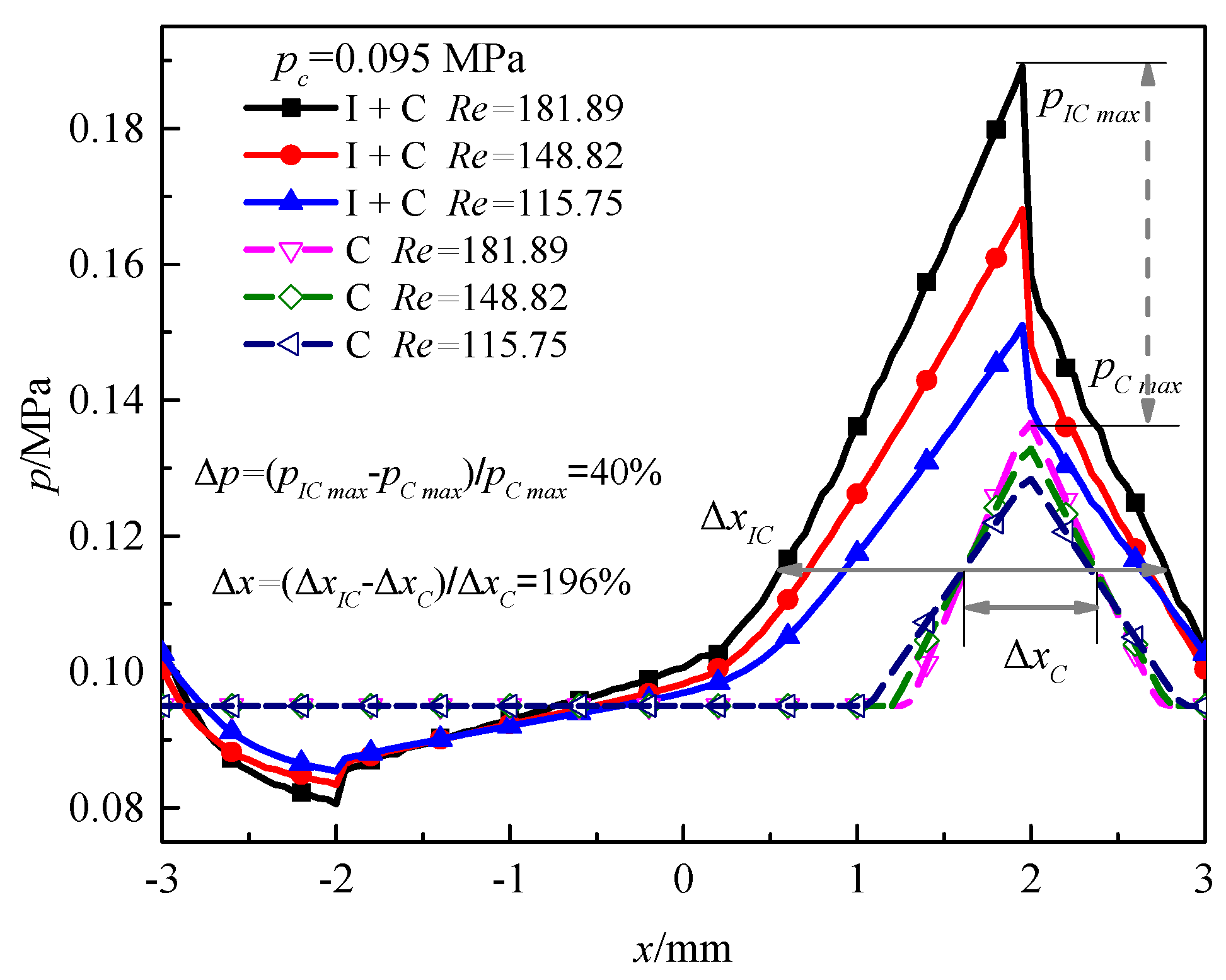

4.2. Effect of Re

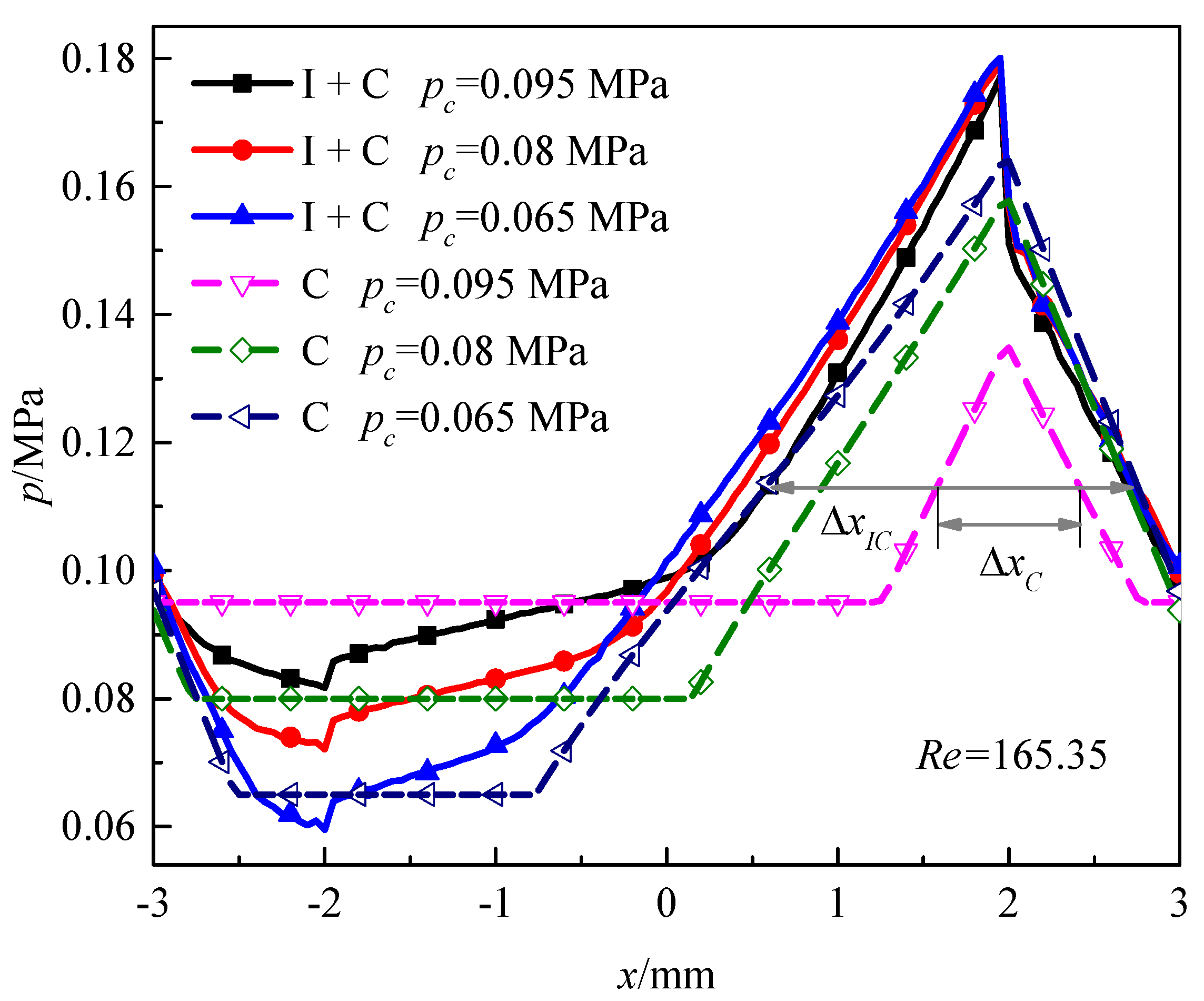

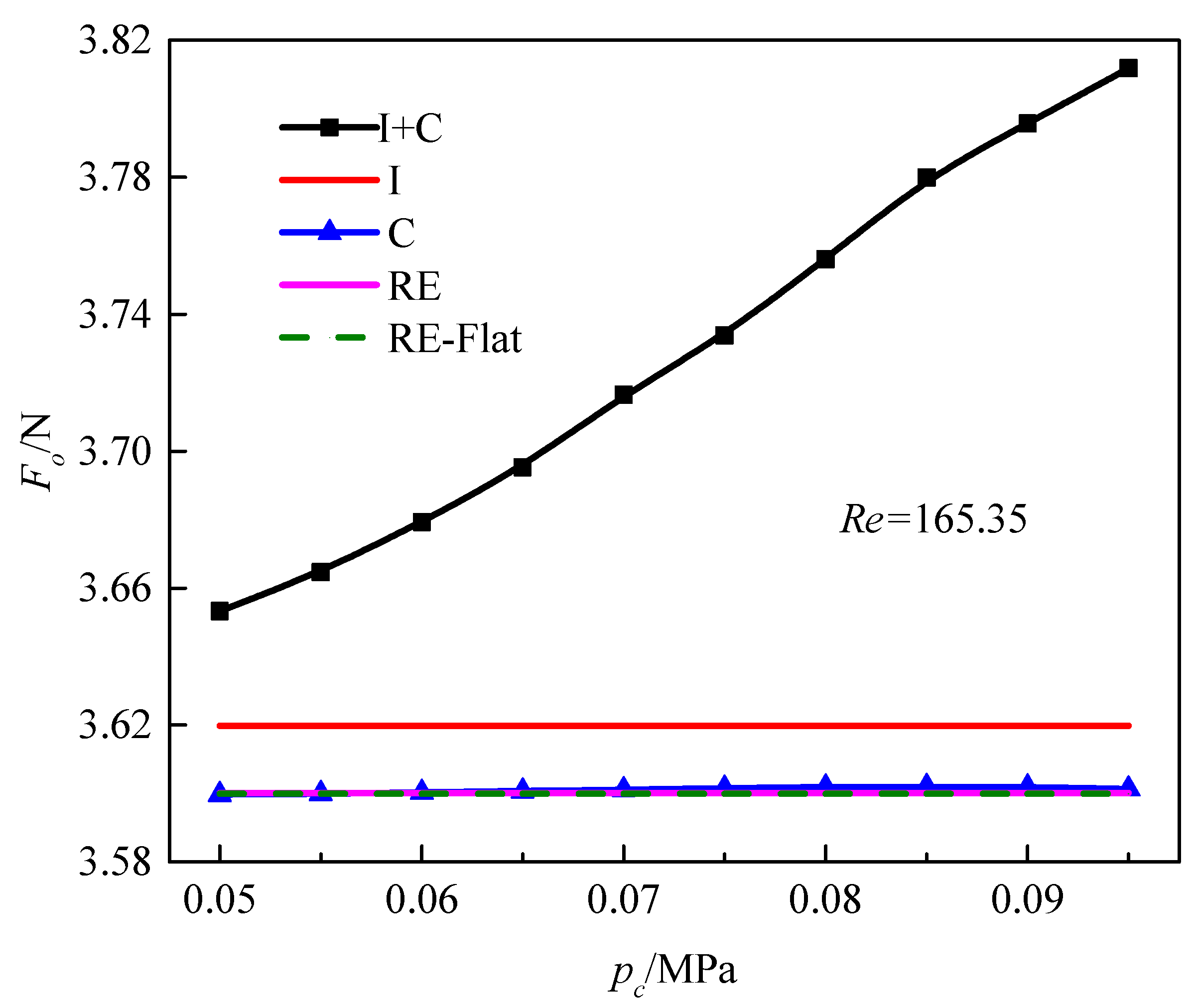

4.3. Effect of pc

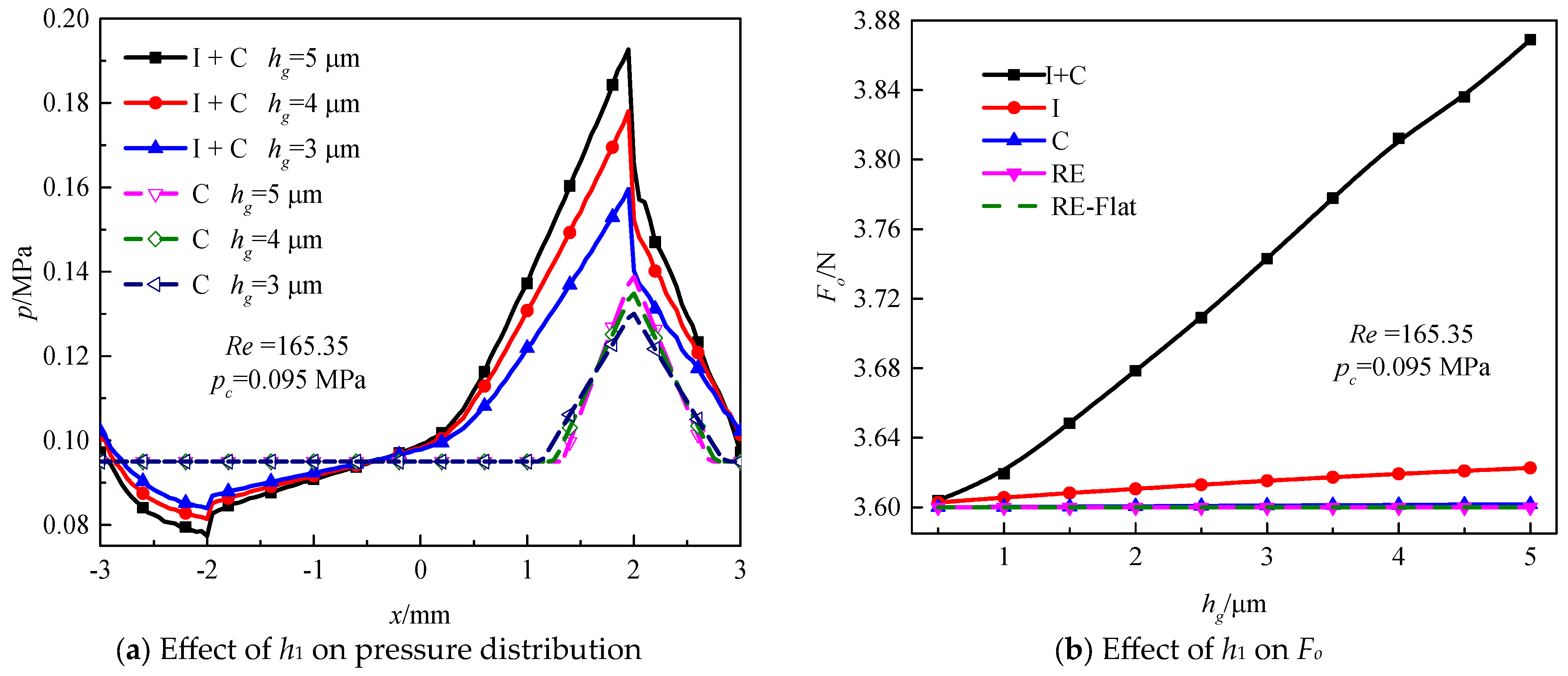

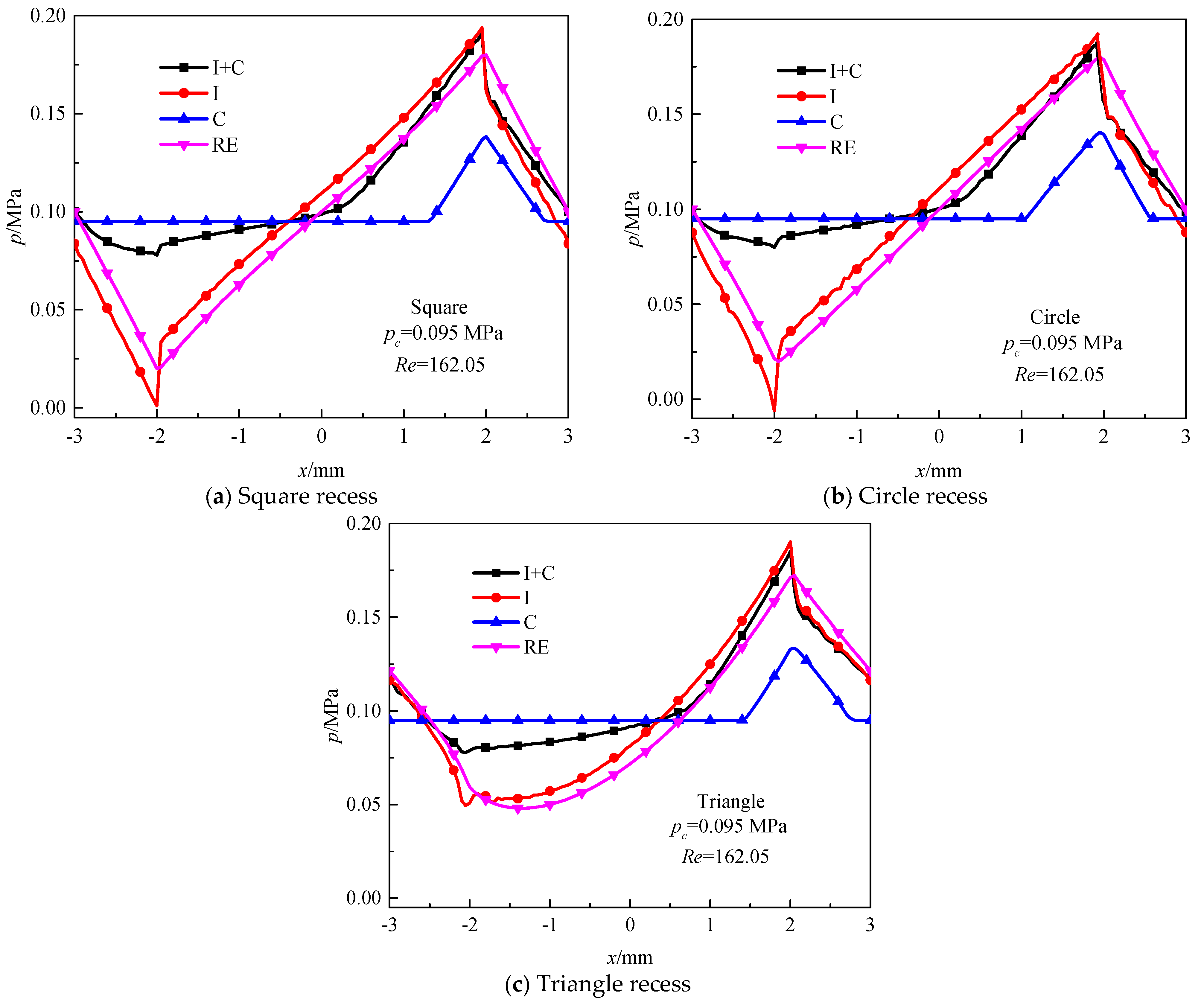

4.4. Effect of Sr, h1 and Shapes

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ŕb | Dynamic radius of cavitation bubbles, m | Re | Reynolds number, Re = ρLu0h0/μL |

| C1, C2 | Empirical coefficient of vapor liquid transition | S | Cavitation source term, kg/(m3∙s) |

| FG, FL | Vapor and liquid volume fraction per unit volume | T | Comprehensive coefficient |

| Fo | Load-carrying capacity, N | u | Velocity in x direction, m/s |

| h | Fluid film thickness, m | u0 | Sliding velocity in x direction, m/s |

| h0, h1 | Gap thickness and square recess depth, m | v | Velocity in y direction, m/s |

| Ixx, Ixy, Iyy | Flow characteristic parameters, m3/s2 | v0 | Sliding velocity in y direction, m/s |

| lx, ly | Unit vectors in x and y directions | VG, VL | Vapor and liquid volume |

| N | Number of initial bubbles per unit volume | w | Velocity in z direction, m/s |

| p | Fluid film pressure, Pa | W0, W1 | Slider and square recess length, m |

| pa, pc | Ambient pressure and cavitation pressure, Pa | x, y, z | Cartesian coordinate, m |

| Q | Flow rate, m3/s | λF, λqp | Downhill factors |

| qx, qy | Flow rates of unit length in x and y directions, m2/s | μ, μG, μ L | Mixture, vapor and liquid dynamic viscosity, Pa∙s |

| Rb | Bubbles initial average radius, m | ρ, ρG, ρ L | Mixture, vapor and liquid density, kg/m3 |

References

- Braun, M.J.; Hannon, W.M. Cavitation formation and modelling for fluid film bearings: A review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 839–863. [Google Scholar] [CrossRef]

- Salant, R.F.; Homiller, S.J. Stiffness and leakage in spiral groove upstream pumping mechanical seals. Tribol. Trans. 1993, 36, 55–60. [Google Scholar] [CrossRef]

- Etsion, I.; Burstein, L. A model for mechanical seals with regular microsurface structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Qiu, Y.Y.; Khonsari, M.M. Performance analysis of full-film textured surfaces with consideration of roughness effects. J. Tribol. 2011, 133, 021704. [Google Scholar] [CrossRef]

- Ma, X.; Meng, X.; Wang, Y.; Peng, X. Suction effect of cavitation in the reverse-spiral-grooved mechanical face seals. Tribol. Int. 2019, 132, 142–153. [Google Scholar] [CrossRef]

- Lin, Q.; Bao, Q.; Li, K.; Khonsari, M.M.; Zhao, H. An investigation into the transient behavior of journal bearing with surface texture based on fluid-structure interaction approach. Tribol. Int. 2018, 118, 246–255. [Google Scholar] [CrossRef]

- Han, J.; Fang, L.; Sun, J.P.; Ge, S.R. Hydrodynamic lubrication of microdimple textured surface using three-dimensional CFD. Tribol. Trans. 2010, 53, 860–870. [Google Scholar] [CrossRef]

- Han, J.; Fang, L.; Sun, J.P.; Wang, Y.Q.; Ge, S.R.; Zhu, H. Hydrodynamic lubrication of surfaces with asymmetric microdimple. Tribol. Trans. 2011, 54, 607–615. [Google Scholar] [CrossRef]

- Ma, X.; Meng, X.; Wang, Y.; Liang, Y.; Peng, X. Fluid inertia effect on spiral-grooved mechanical face seals considering cavitation effects. Tribol. Trans. 2021, 64, 367–380. [Google Scholar] [CrossRef]

- Ausas, R.; Ragot, P.; Leiva, J.; Jai, M.; Bayada, G.; Buscaglia, G.C. The impact of the cavitation model in the analysis of microtextured lubricated journal bearings. J. Tribol. 2007, 129, 868–875. [Google Scholar] [CrossRef]

- Qiu, Y.Y.; Khonsari, M.M. On the prediction of cavitation in dimples using a mass-conservative algorithm. J. Tribol. 2009, 131, 041702. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Meng, Y.G. Direct observation of cavitation phenomenon and hydrodynamic lubrication analysis of textured surfaces. Tribol. Lett. 2012, 46, 147–158. [Google Scholar] [CrossRef]

- Singhal, A.K.; Athavale, M.M.; Li, H.; Jiang, Y. Mathematical basis and validation of the full cavitation model. J. Fluids Eng. 2002, 124, 617–624. [Google Scholar] [CrossRef]

- Bakir, F.; Rey, R.; Gerber, A.G.; Belamri, T.; Hutchinson, B. Numerical and experimental investigations of the cavitating behavior of an inducer. Int. J. Rotating Mach. 2004, 10, 15–25. [Google Scholar] [CrossRef]

- Plesset, M.S. The dynamics of cavitation bubbles. J. Appl. Mech. 1949, 16, 277–282. [Google Scholar] [CrossRef]

- Morris, N.J.; Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.P. Combined experimental and multiphase computational fluid dynamics analysis of surface textured journal bearings in mixed regime of lubrication. Lubr. Sci. 2018, 30, 161–173. [Google Scholar] [CrossRef]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.P.; Dowson, D. Big end bearing losses with thermal cavitation flow under cylinder deactivation. Tribol. Lett. 2015, 57, 2. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Pande, D.W. Multiphase flow analysis of hydrodynamic journal bearing using CFD coupled fluid structure interaction considering cavitation. J. King Saud Univ.-Eng. Sci. 2018, 30, 345–354. [Google Scholar] [CrossRef]

- Cupillard, S.; Glavatskih, S.; Cervantes, M.J. Computational fluid dynamics analysis of a journal bearing with surface texturing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 97–107. [Google Scholar] [CrossRef]

- Mishra, S.; Choudhury, A.; Sahu, S. CFD investigation of influences of reverse textures on bearing surface of a journal bearing. J. Appl. Fluid Mech. 2014, 7, 395–399. [Google Scholar]

- Song, Y.; Gu, C.W. Development and validation of a three-dimensional computational fluid dynamics analysis for journal bearings considering cavitation and conjugate heat transfer. J. Eng. Gas Turbines Power 2015, 137, 122502. [Google Scholar] [CrossRef]

- Wang, T.; Huang, W.F.; Liu, Y.; Liu, X.F.; Wang, Y.M. A homogeneous phase change model for two-phase mechanical seals with three-dimensional face structures. J. Tribol. 2014, 136, 041708. [Google Scholar] [CrossRef]

- Constantinescu, V.N.; Galetuse, S. Operating characteristics of journal bearings in turbulent inertial flow. J. Lubr. Technol. 1982, 104, 173–179. [Google Scholar] [CrossRef]

- Brunetière, N.; Tournerie, B. Finite element solution of inertia influenced flow in thin fluid films. J. Tribol. 2007, 129, 876–886. [Google Scholar] [CrossRef]

- Wang, T.; Huang, W.F.; Liu, X.F.; Li, Y.J.; Wang, Y.M. Experimental study of two-phase mechanical face seals with laser surface texturing. Tribol. Int. 2014, 72, 90–97. [Google Scholar] [CrossRef]

- Li, W.; Stephens, L.S.; Wenk, J.F. Experimental benchmarking of the numerical model of a radial lip seal with a surface textured shaft. Tribol. Trans. 2013, 56, 75–87. [Google Scholar] [CrossRef]

- Rao, T.V.V.L.N.; Rani, A.M.A.; Nagarajan, T.; Hashim, F.M. Analysis of slider and journal bearing using partially textured slip surface. Tribol. Int. 2012, 56, 121–128. [Google Scholar] [CrossRef]

- Cross, A.T.; Sadeghi, F.; Rateick, G.R.; Rowan, S.; Laboda, D. Temperature distribution in pocketed thrust washers. Tribol. Trans. 2015, 58, 31–43. [Google Scholar] [CrossRef]

- Tomanik, E. Modelling the hydrodynamic support of cylinder bore and piston rings with laser textured surfaces. Tribol. Int. 2013, 59, 90–96. [Google Scholar] [CrossRef]

- Morgut, M.; Nobile, E.; Bilus, I. Comparison of mass transfer models for the numerical prediction of sheet cavitation around a hydrofoil. Int. J. Multiph. Flow 2011, 37, 620–626. [Google Scholar] [CrossRef]

- Jakobsson, B.; Floberg, L. The Finite Journal Bearing, Considering Vaporization; Chalmers Tekniska Högskolas Handlingar: Gothenburg, Sweden, 1957. [Google Scholar]

- Meng, X.K.; Bai, S.X.; Peng, X.D. Lubrication film flow control by oriented dimples for liquid lubricated mechanical seals. Tribol. Int. 2014, 77, 132–141. [Google Scholar] [CrossRef]

- Etsion, I.; Ludwig, L.P. Observation of pressure variation in the cavitation region of submerged journal bearings. ASME J. Lubr. Tech. 1982, 104, 157–163. [Google Scholar] [CrossRef]

- Sun, D.C.; Brewe, D.E. A high-speed photography study of cavitation in a dynamically loaded journal bearing. ASME J. Tribol. 1991, 113, 287–292. [Google Scholar] [CrossRef]

- Sun, D.C.; Brewe, D.E.; Abel, P.B. Simultaneous pressure measurement and high-speed photography study of cavitation in a dynamically loaded journal bearing. ASME J. Tribol. 1993, 115, 88–95. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Textured surface cell side length, W0/(mm) | 6 |

| Recess size length, W1/(mm) | 4 |

| Gap thickness, h0/(μm) | 50 |

| Recess depth, h1/(μm) | 4 |

| Ambient pressure, pa/(MPa) | 0.1 |

| Cavitation pressure, pc/(MPa) | 0.095 |

| Dynamic viscosity of liquid, μL/(Pa·s) | 0.0127 |

| Liquid density, ρL/(kg/m3) | 840 |

| Reynolds number, Re | 165.35 |

| Square | Circle | Triangle | ||

|---|---|---|---|---|

| ∆p | (pmax IC − pmax C)/ pmax C | 39.42% | 38.88% | 39.10% |

| (pmax I − pmax RE)/ pmax RE | 8.38% | 8.94% | 11.11% | |

| LCC | IC | 7.3% | 7% | 4.7% |

| I | 0.6% | 0.43% | 1.4% | |

| C | ≈0 | 0.4% | ≈0 | |

| RE | ≈0 | ≈0 | ≈0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X. Combined Effect of Fluid Cavitation and Inertia on the Pressure Buildup of Parallel Textured Surfaces. Lubricants 2023, 11, 270. https://doi.org/10.3390/lubricants11070270

Ma X. Combined Effect of Fluid Cavitation and Inertia on the Pressure Buildup of Parallel Textured Surfaces. Lubricants. 2023; 11(7):270. https://doi.org/10.3390/lubricants11070270

Chicago/Turabian StyleMa, Xuezhong. 2023. "Combined Effect of Fluid Cavitation and Inertia on the Pressure Buildup of Parallel Textured Surfaces" Lubricants 11, no. 7: 270. https://doi.org/10.3390/lubricants11070270

APA StyleMa, X. (2023). Combined Effect of Fluid Cavitation and Inertia on the Pressure Buildup of Parallel Textured Surfaces. Lubricants, 11(7), 270. https://doi.org/10.3390/lubricants11070270