High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy

Abstract

1. Introduction

2. Experiments

3. Results and Discussion

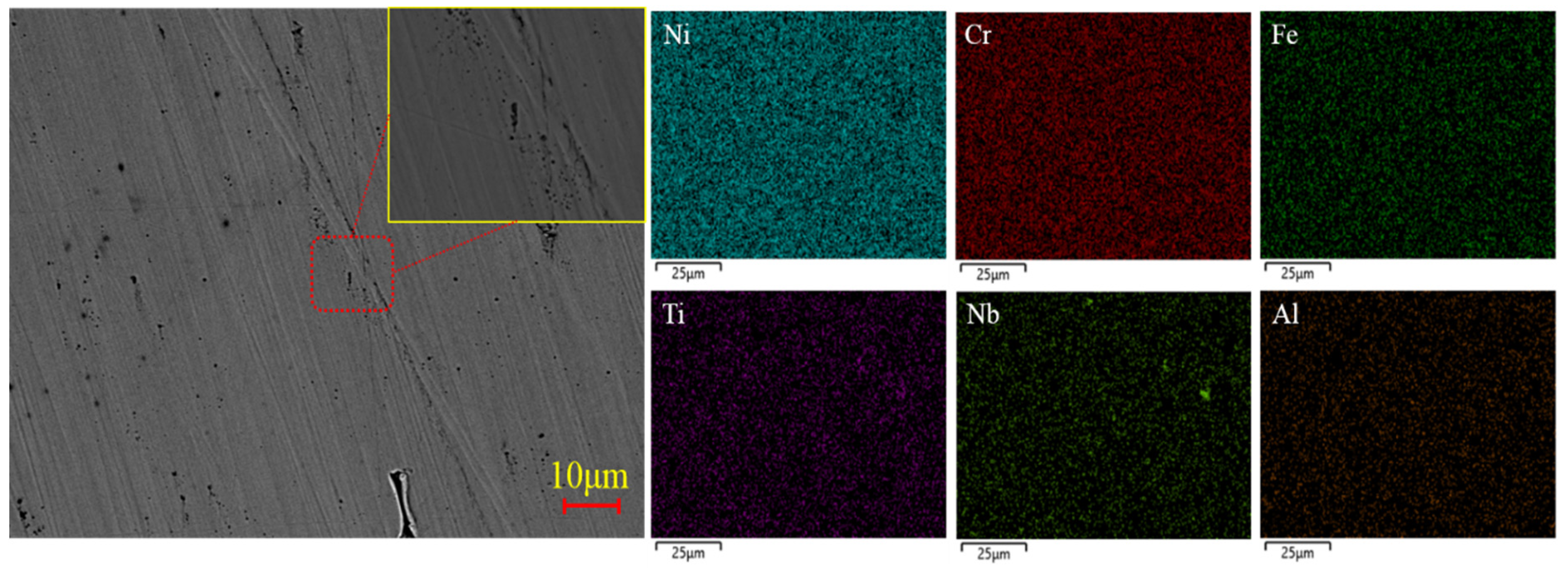

3.1. Composition of Inconel X750 Alloy

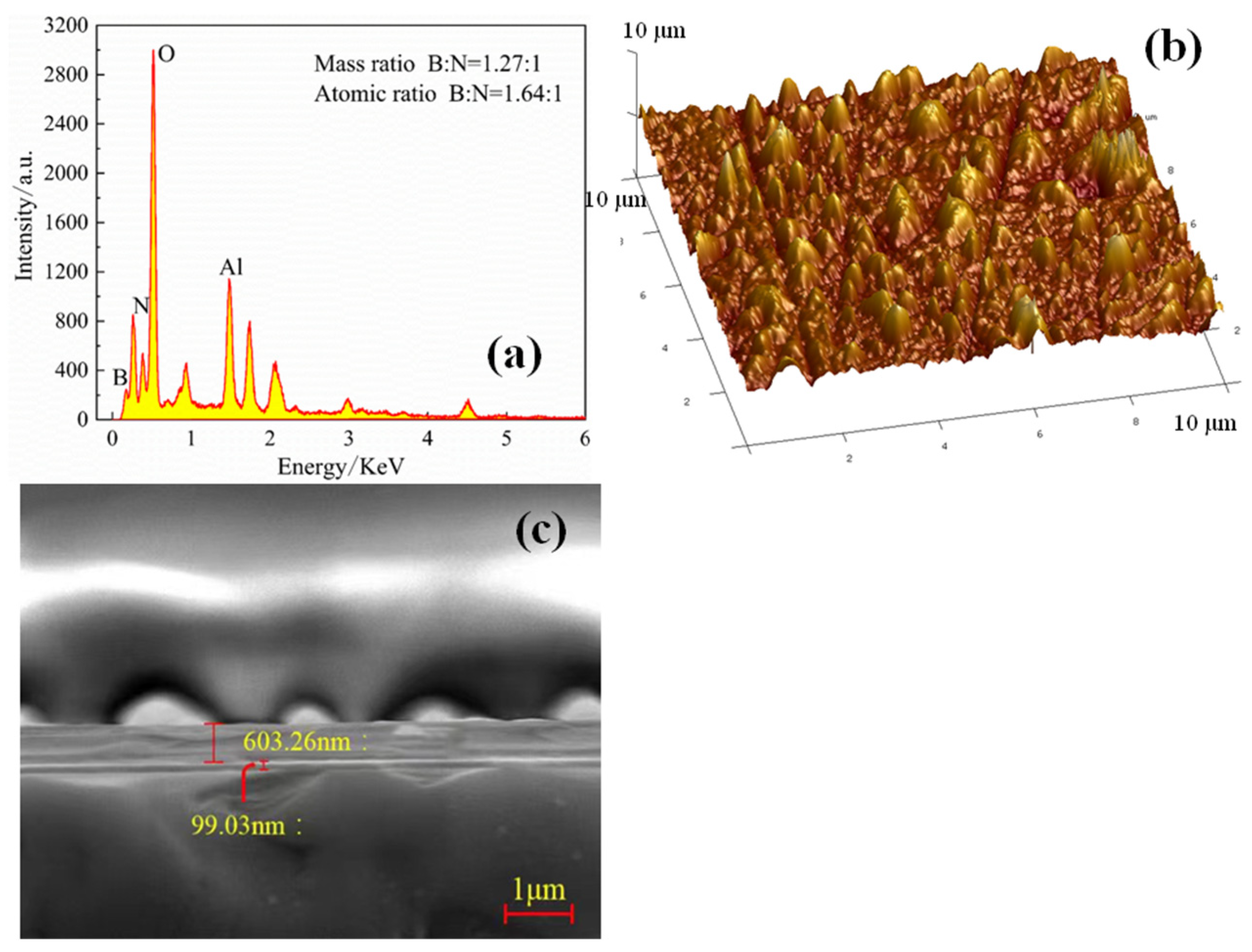

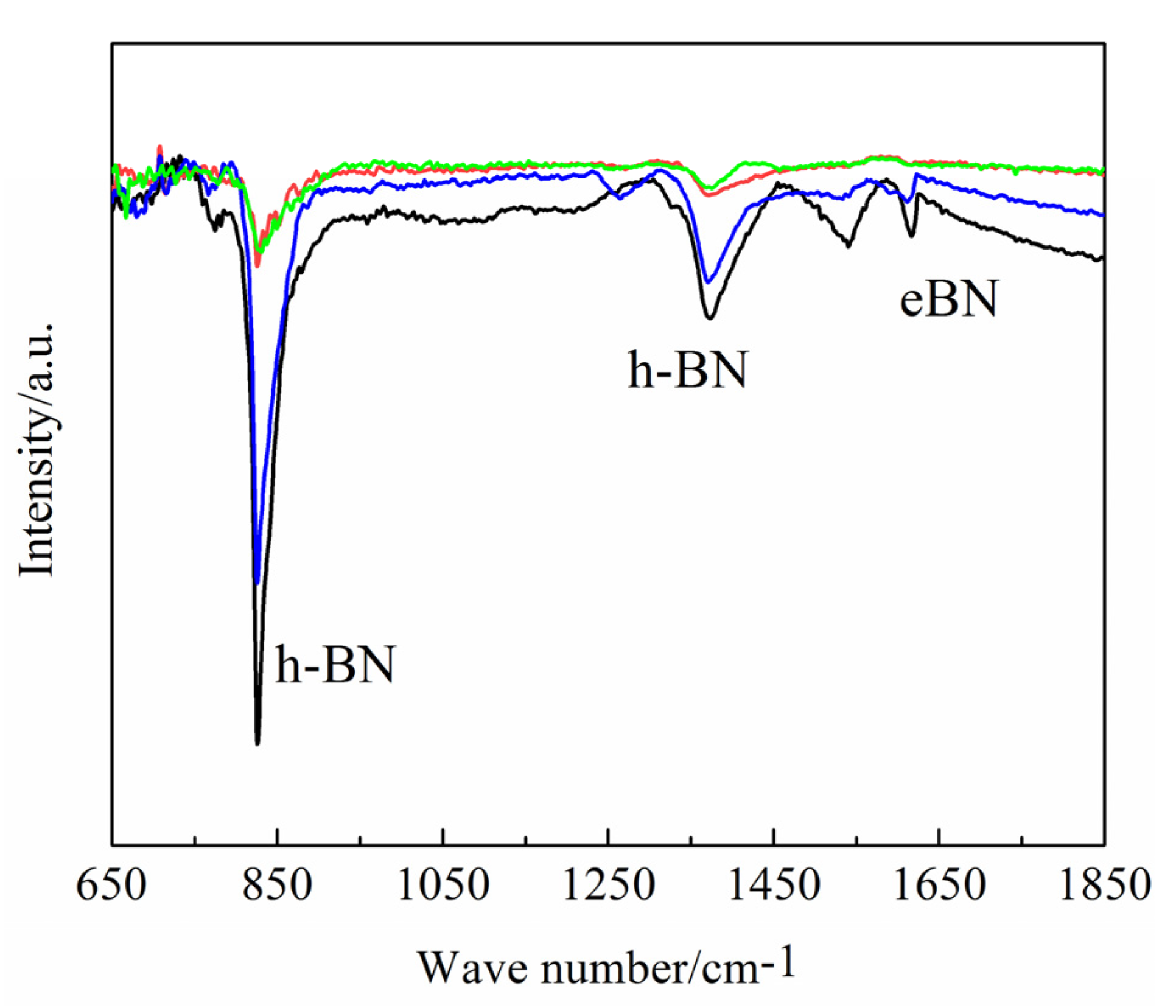

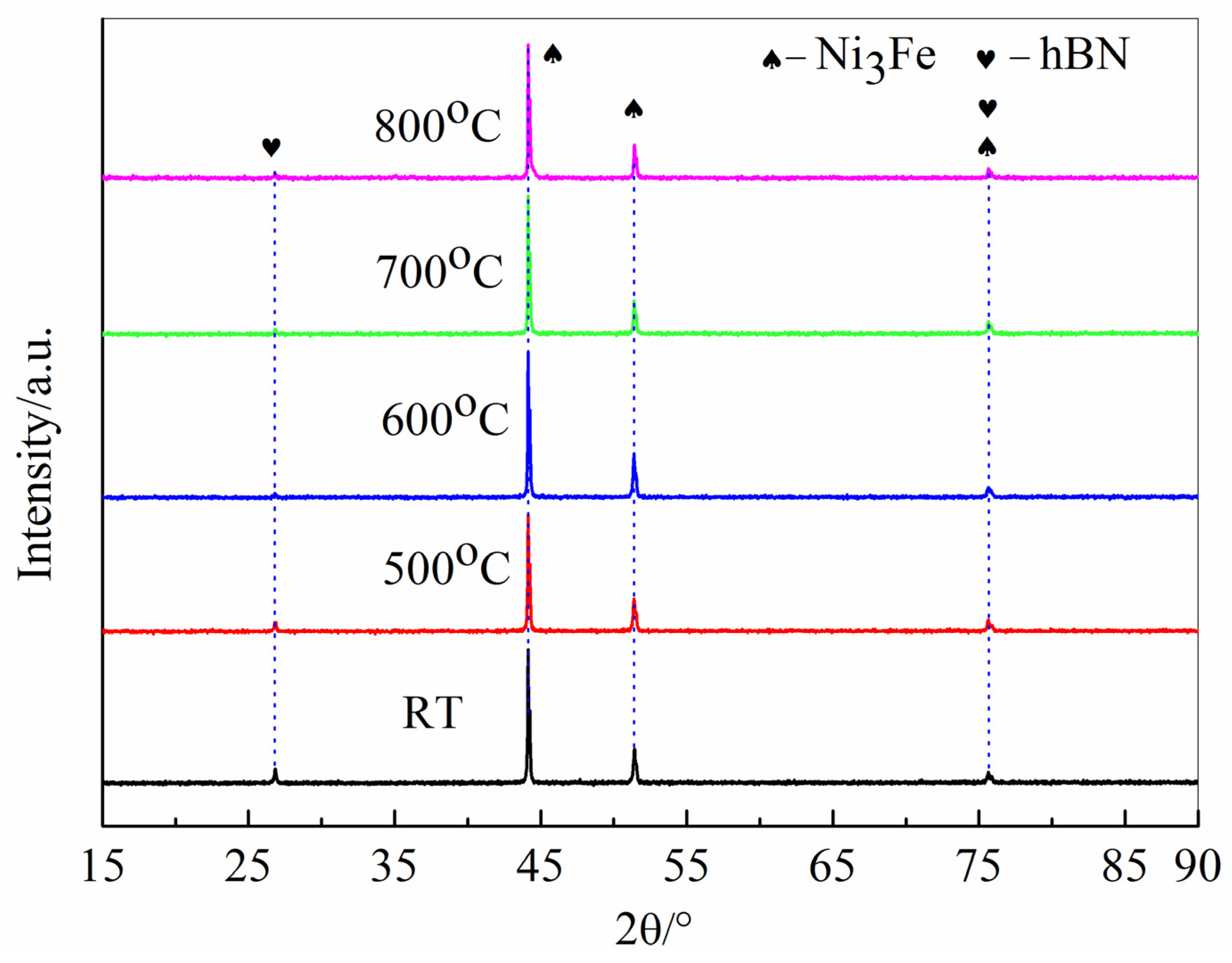

3.2. Structural Characterization and Mechanical Properties of h-BN Coatings on X750 Alloy

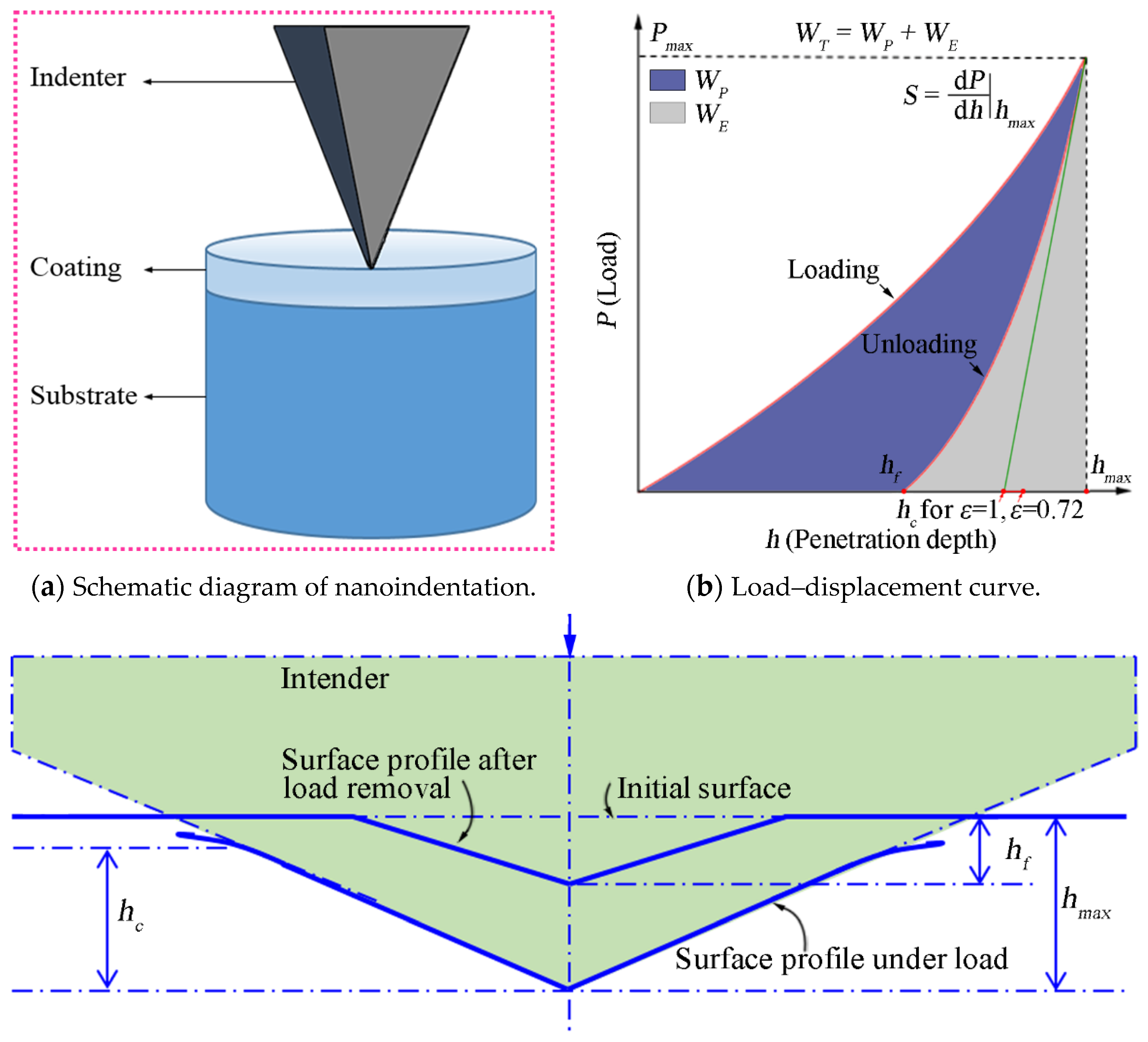

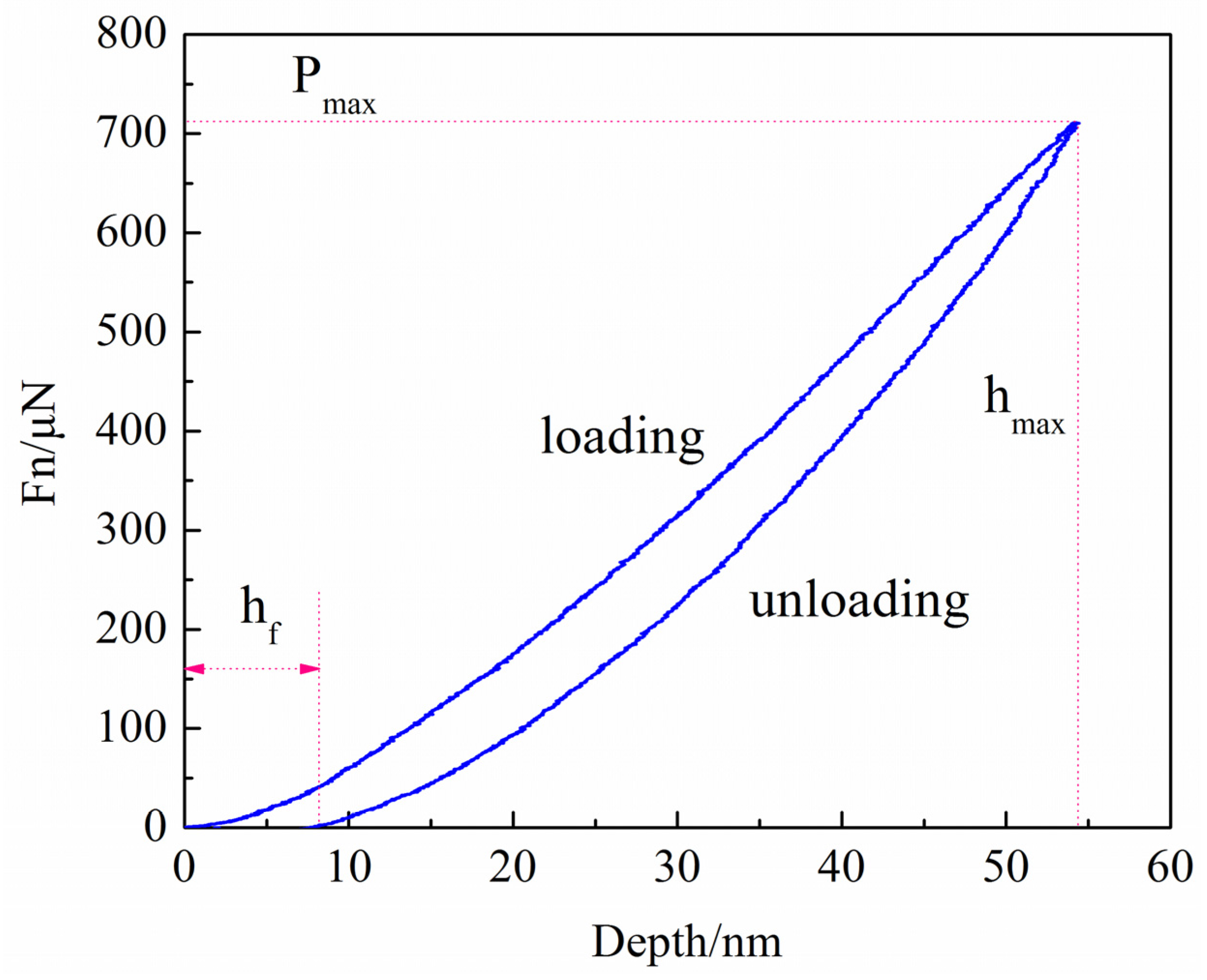

3.3. Mechanical Properties of Coatings

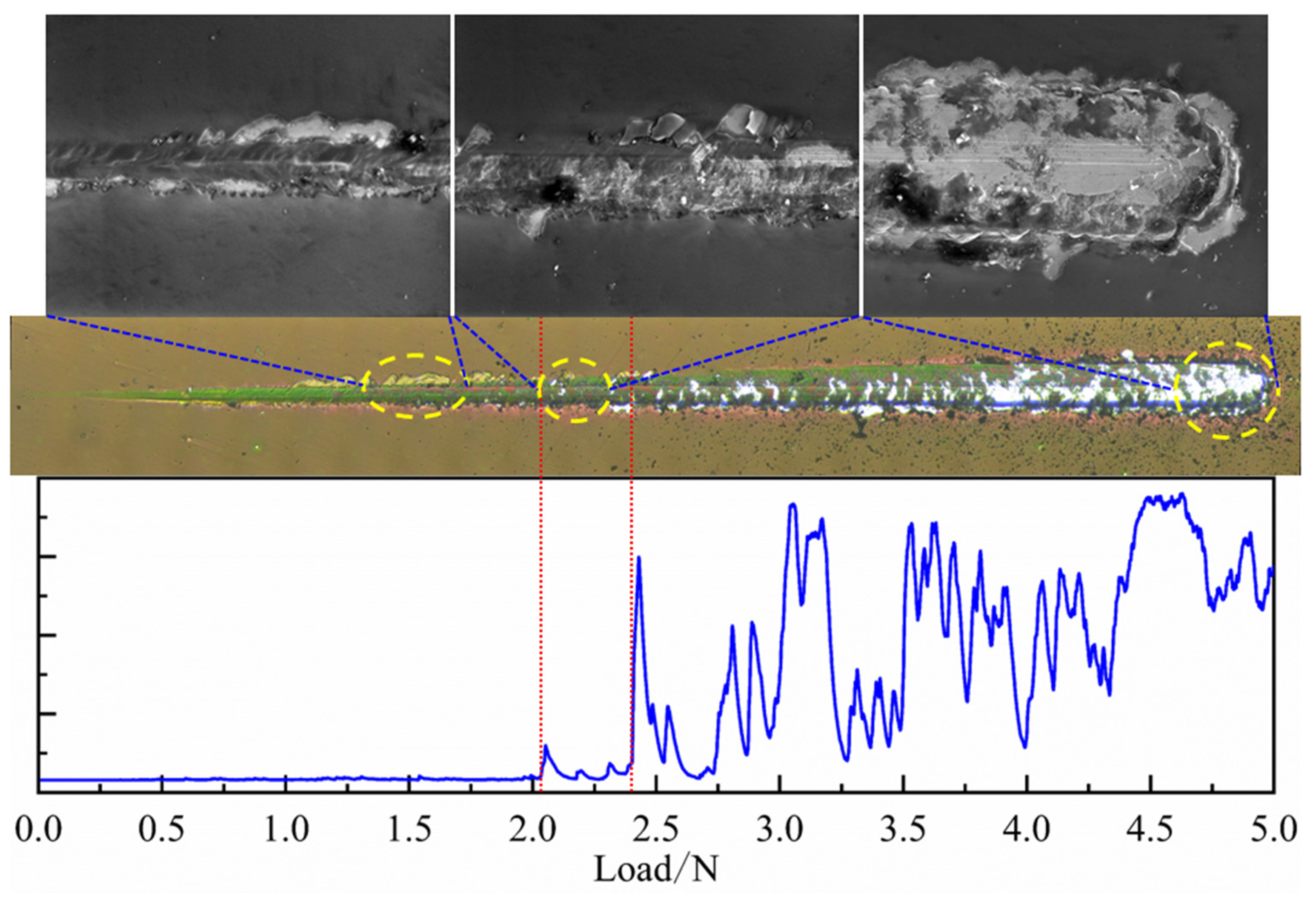

3.4. Bond Strength of h-BN Coatings

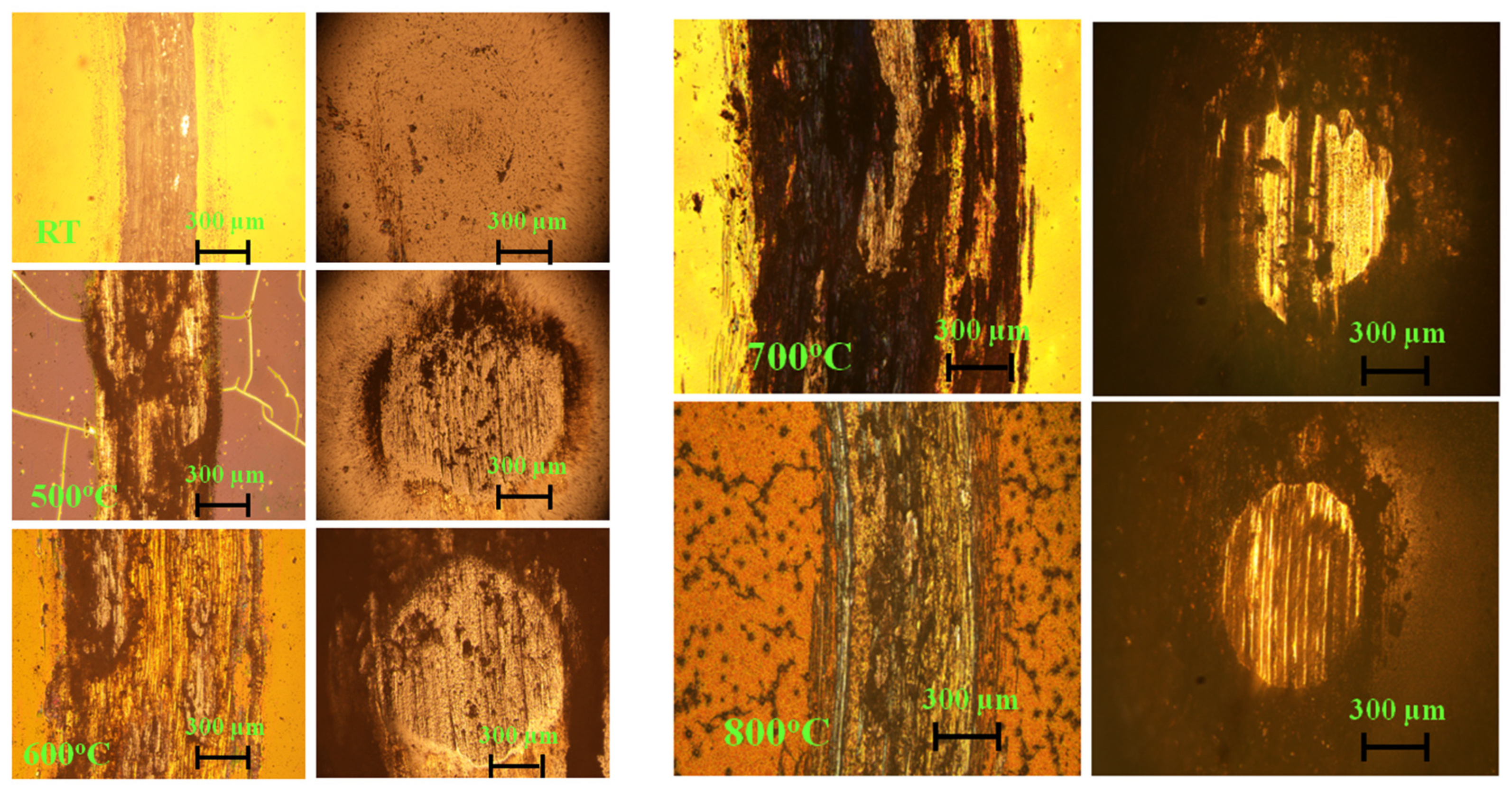

3.5. Tribological Properties of Inconel X750 Alloy

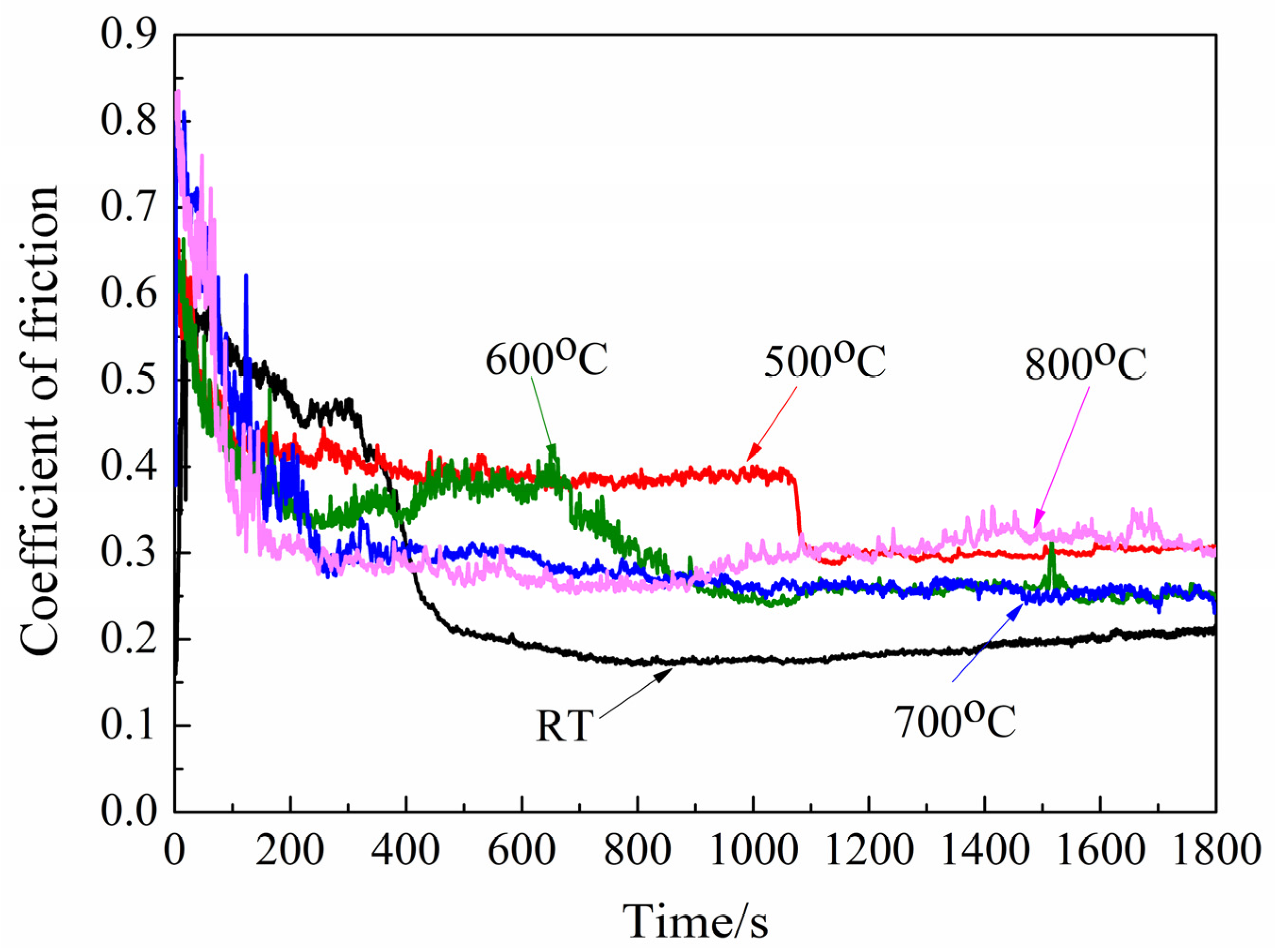

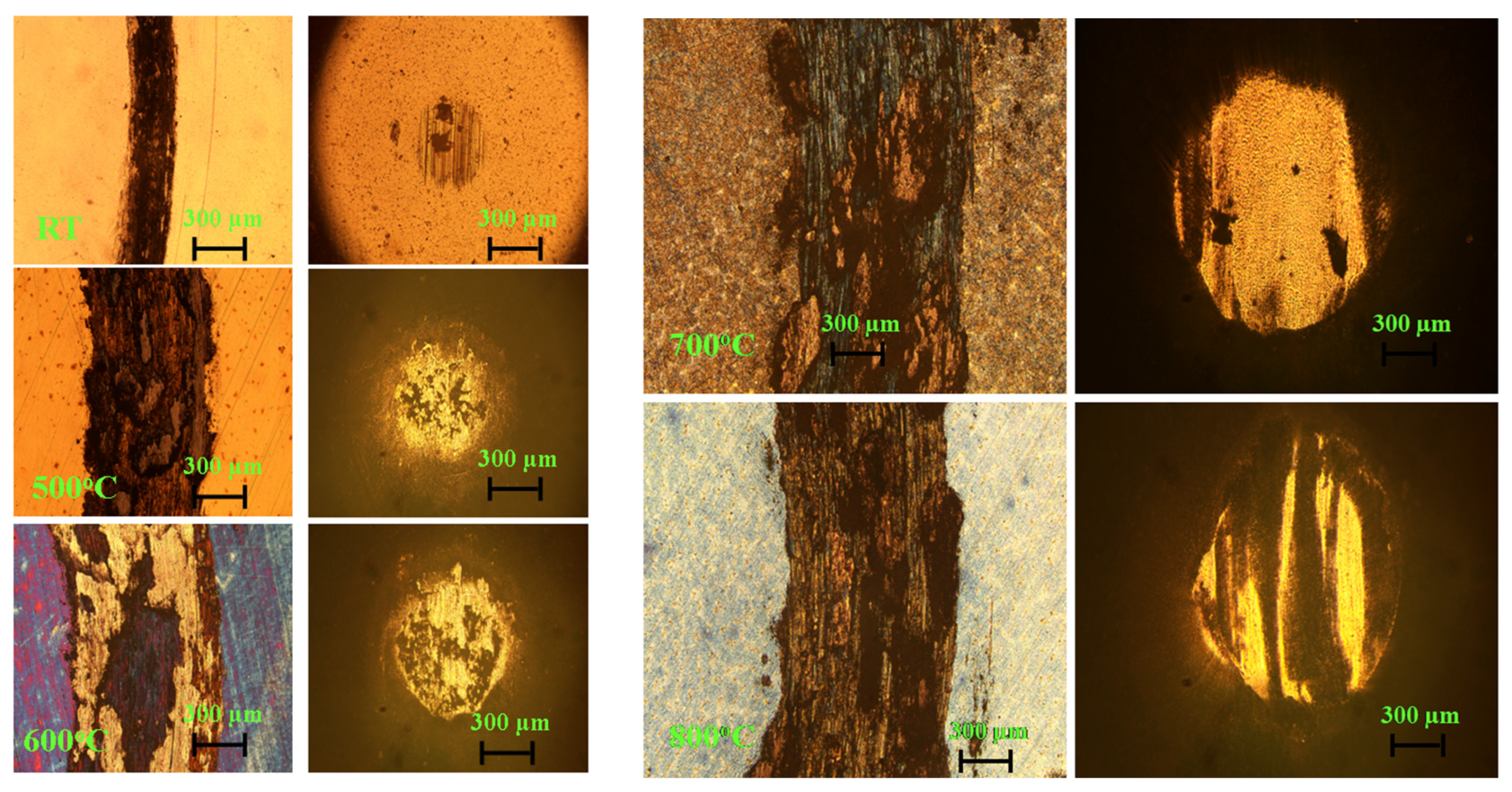

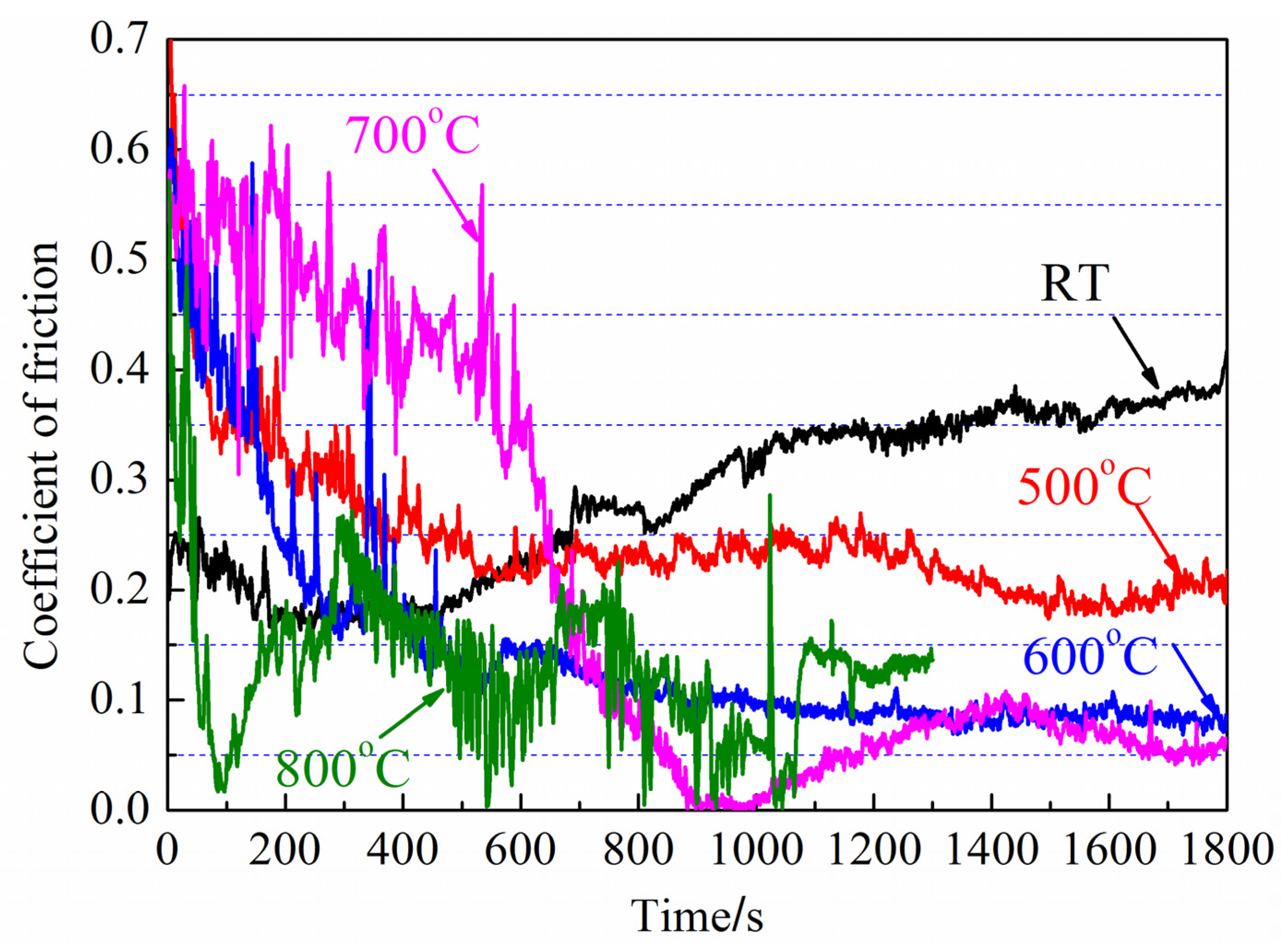

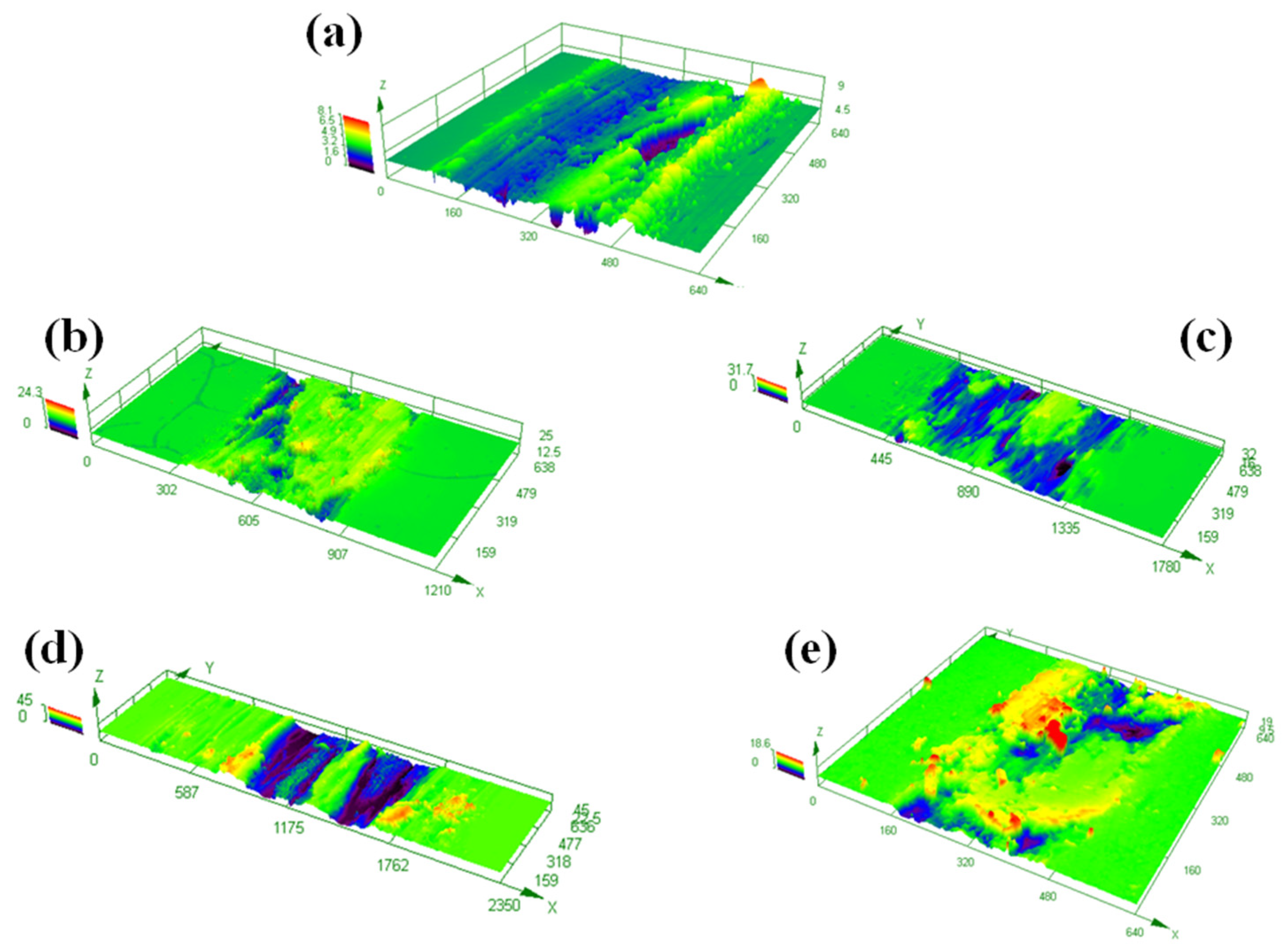

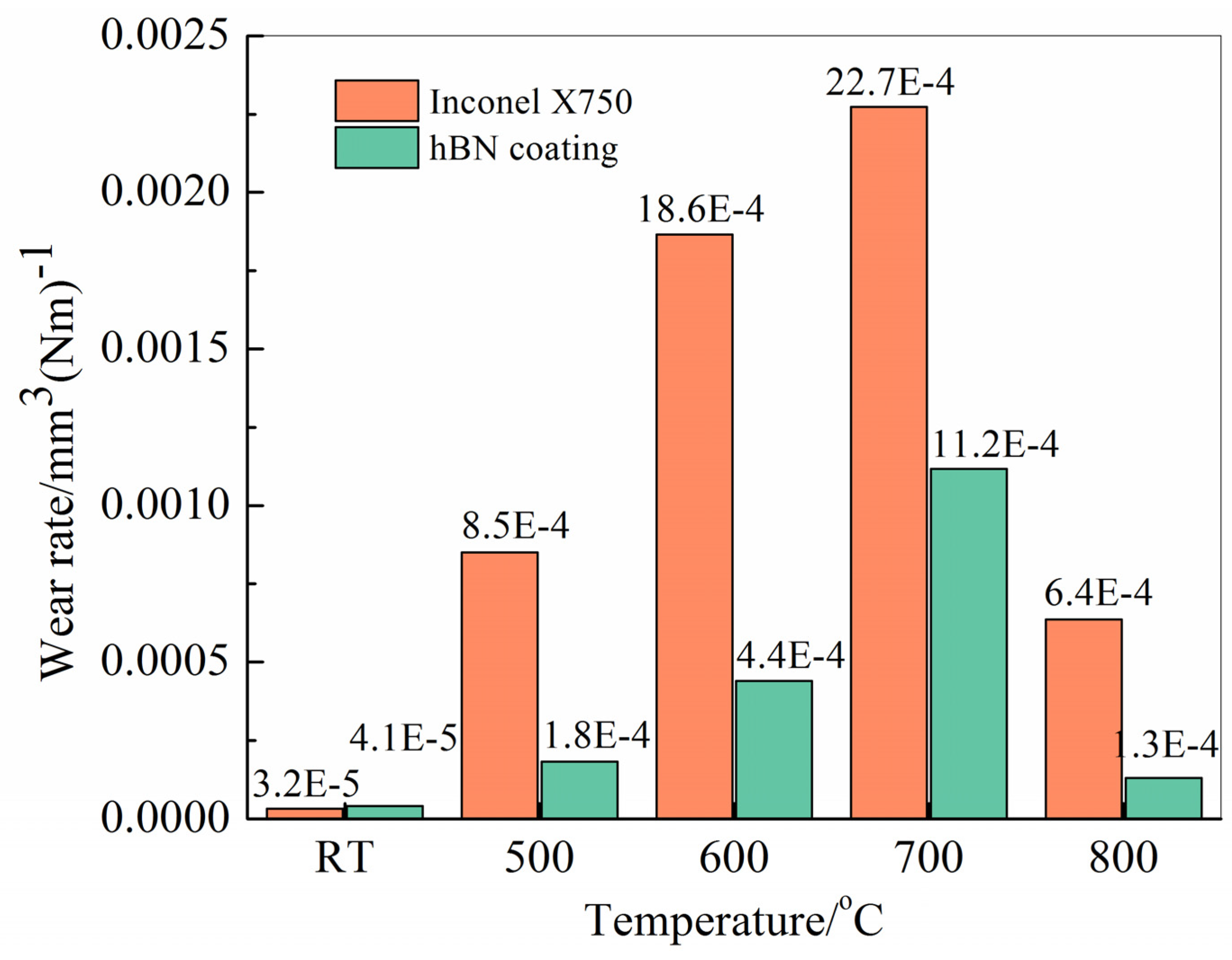

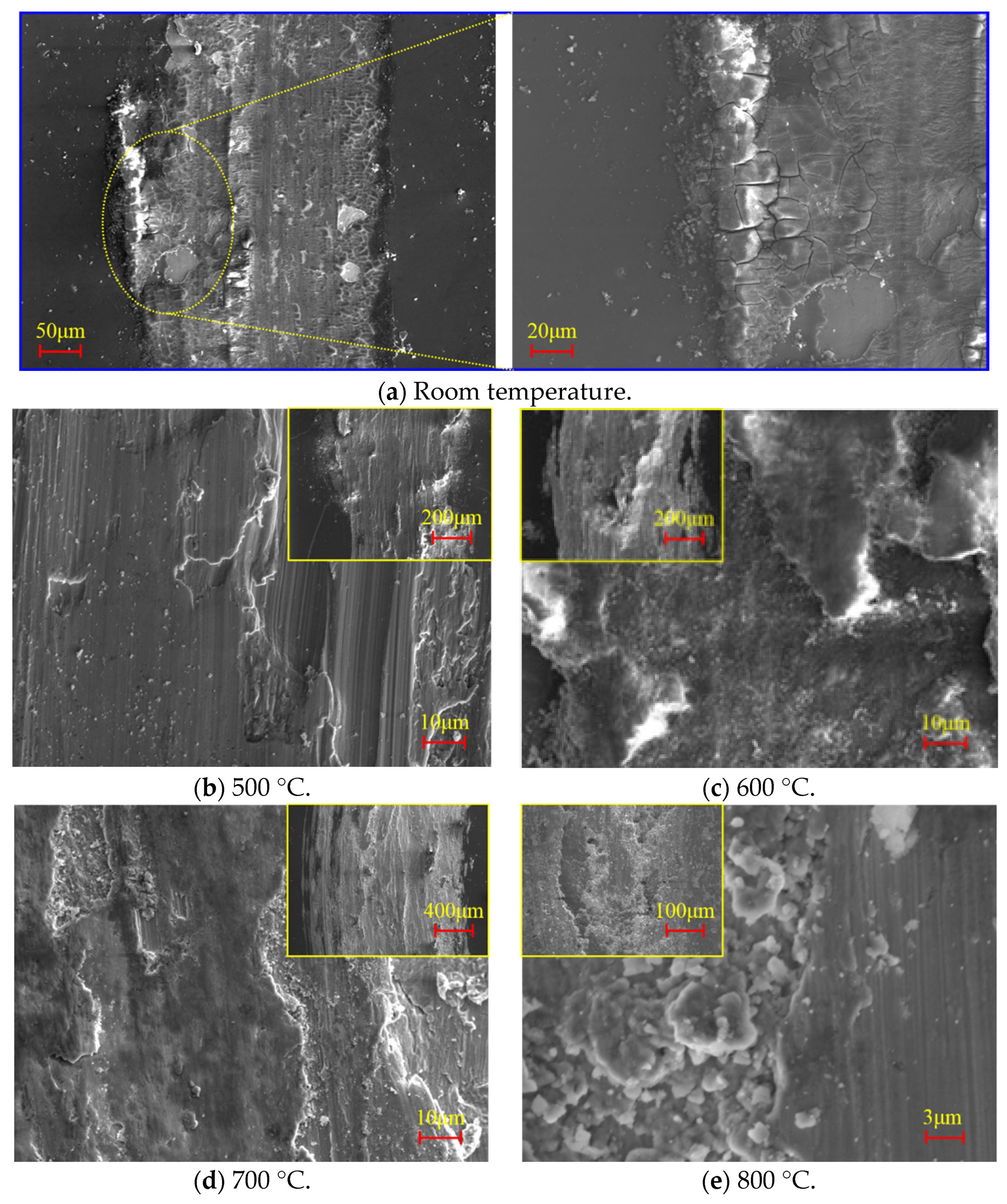

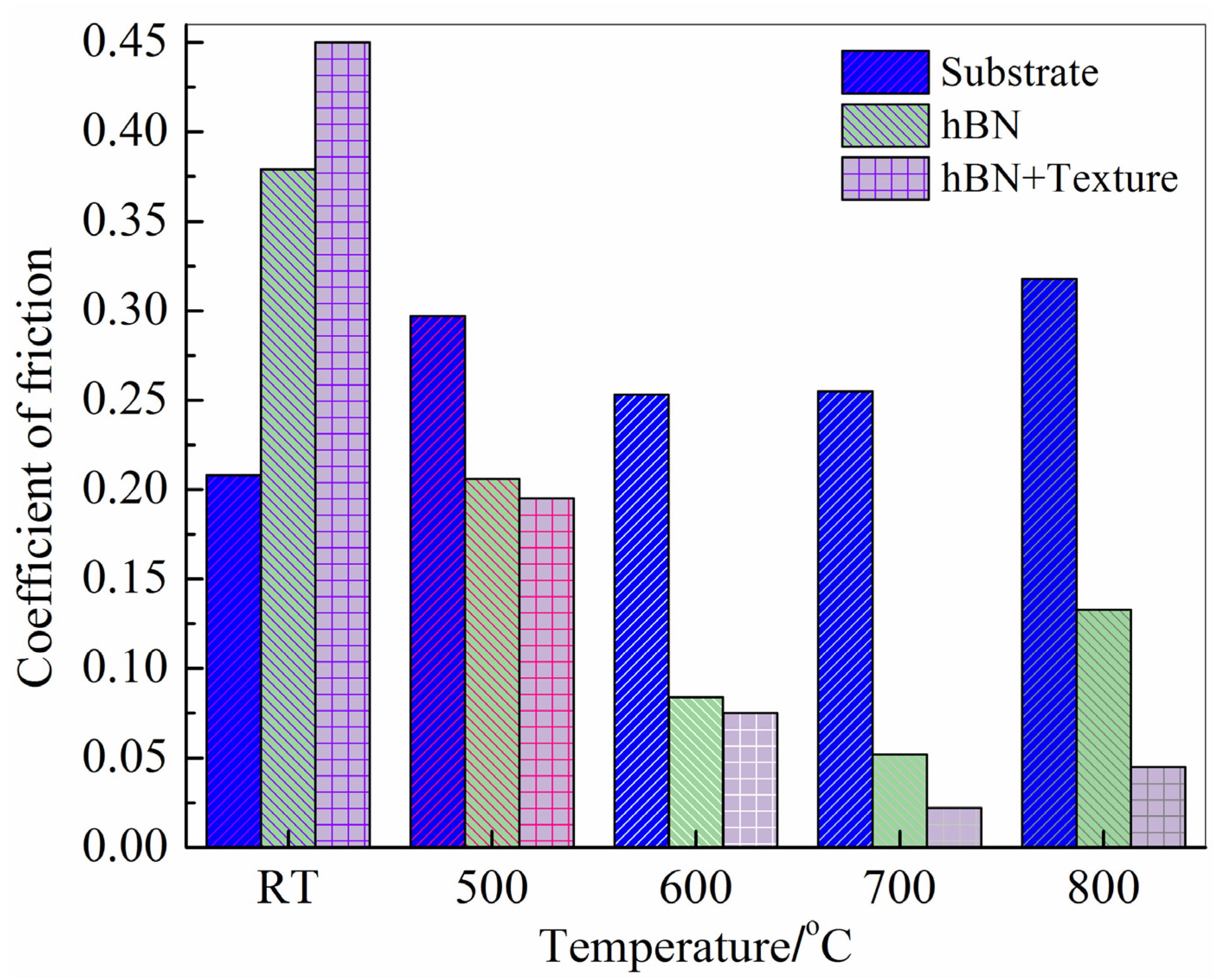

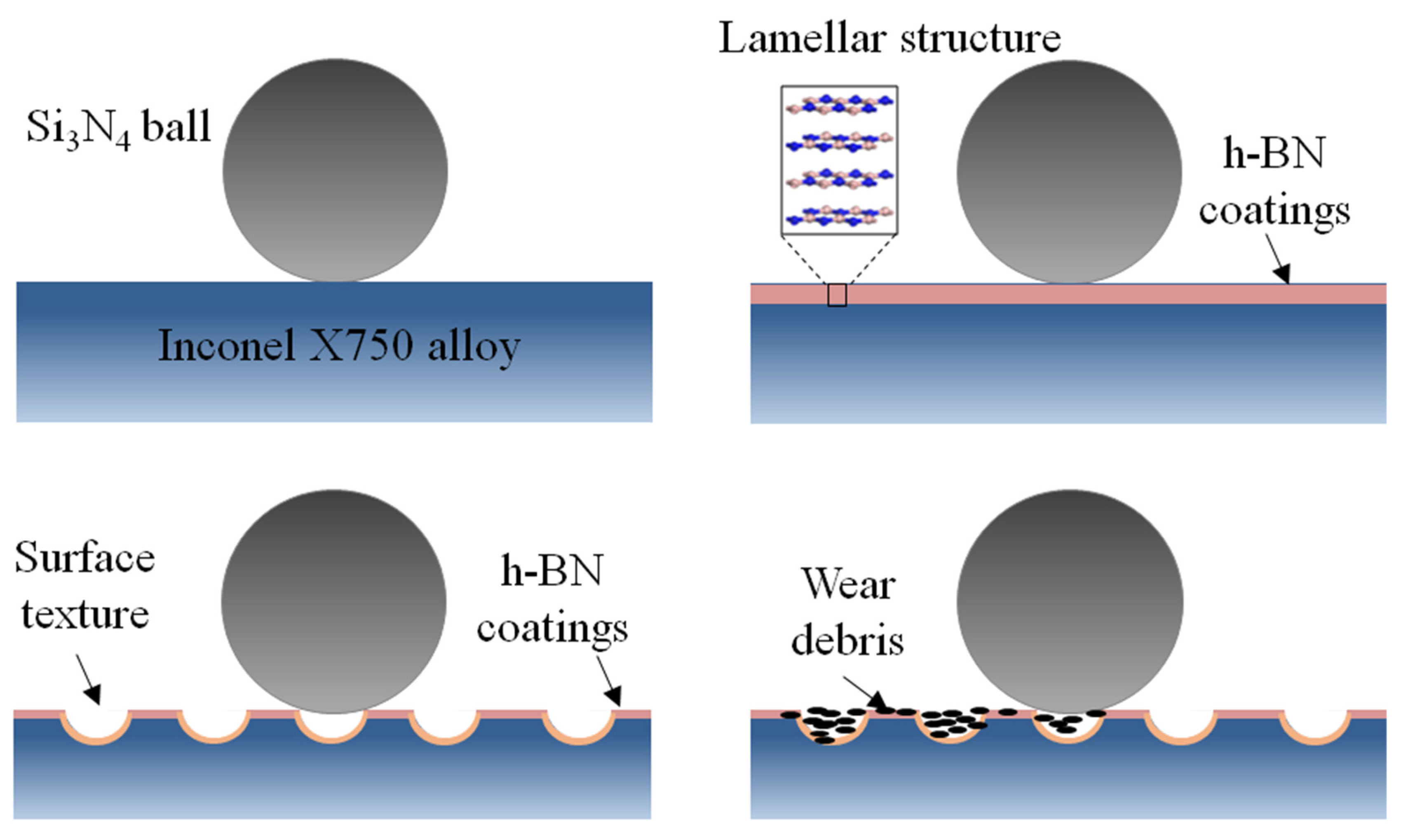

3.6. Tribological Properties of h-BN Coatings on the Surface of X750 Alloy

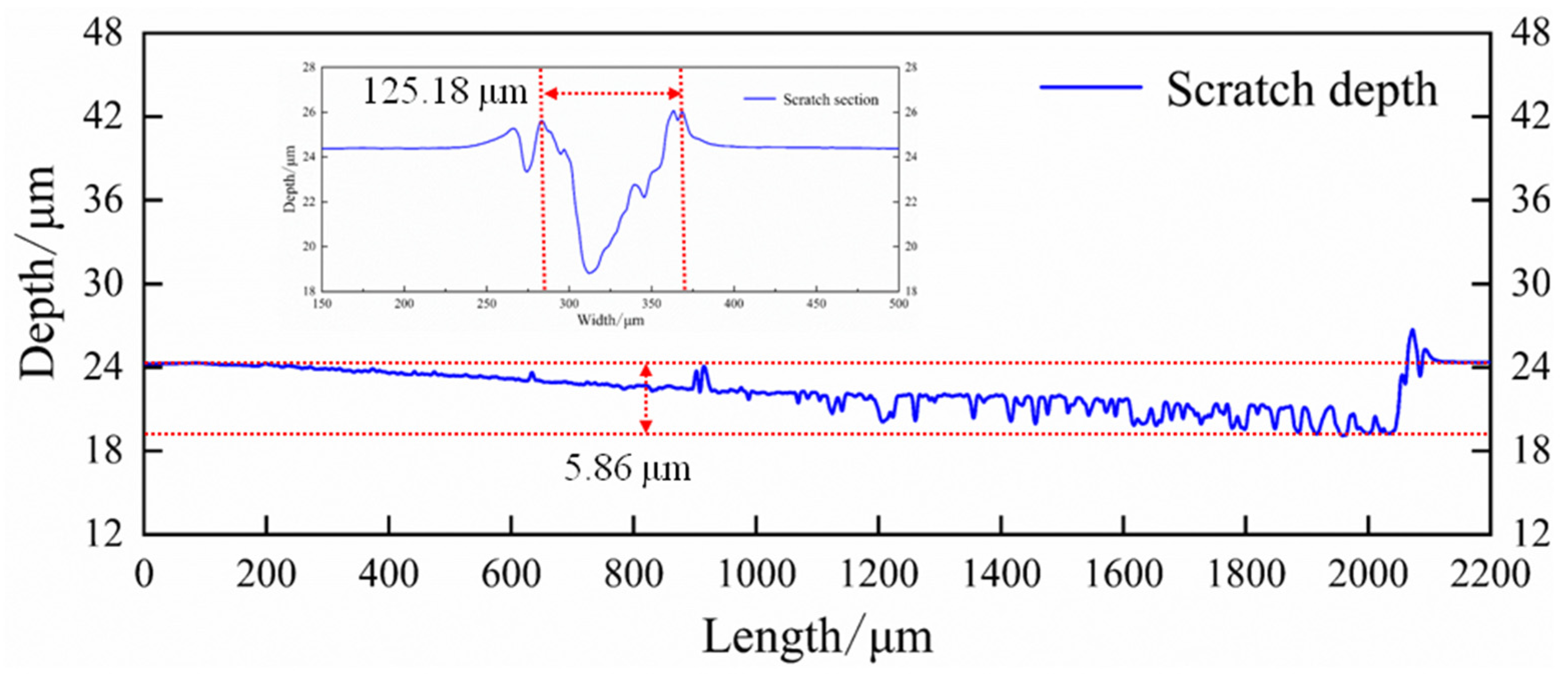

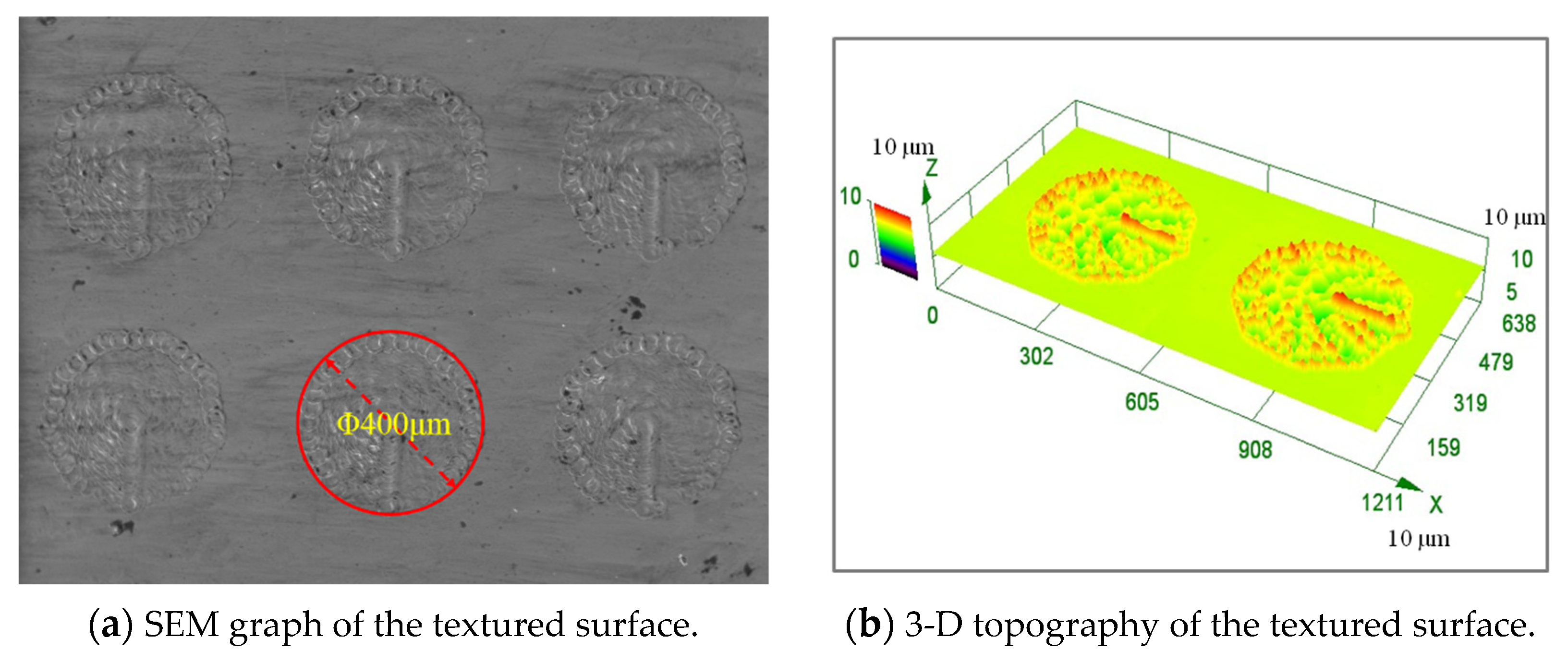

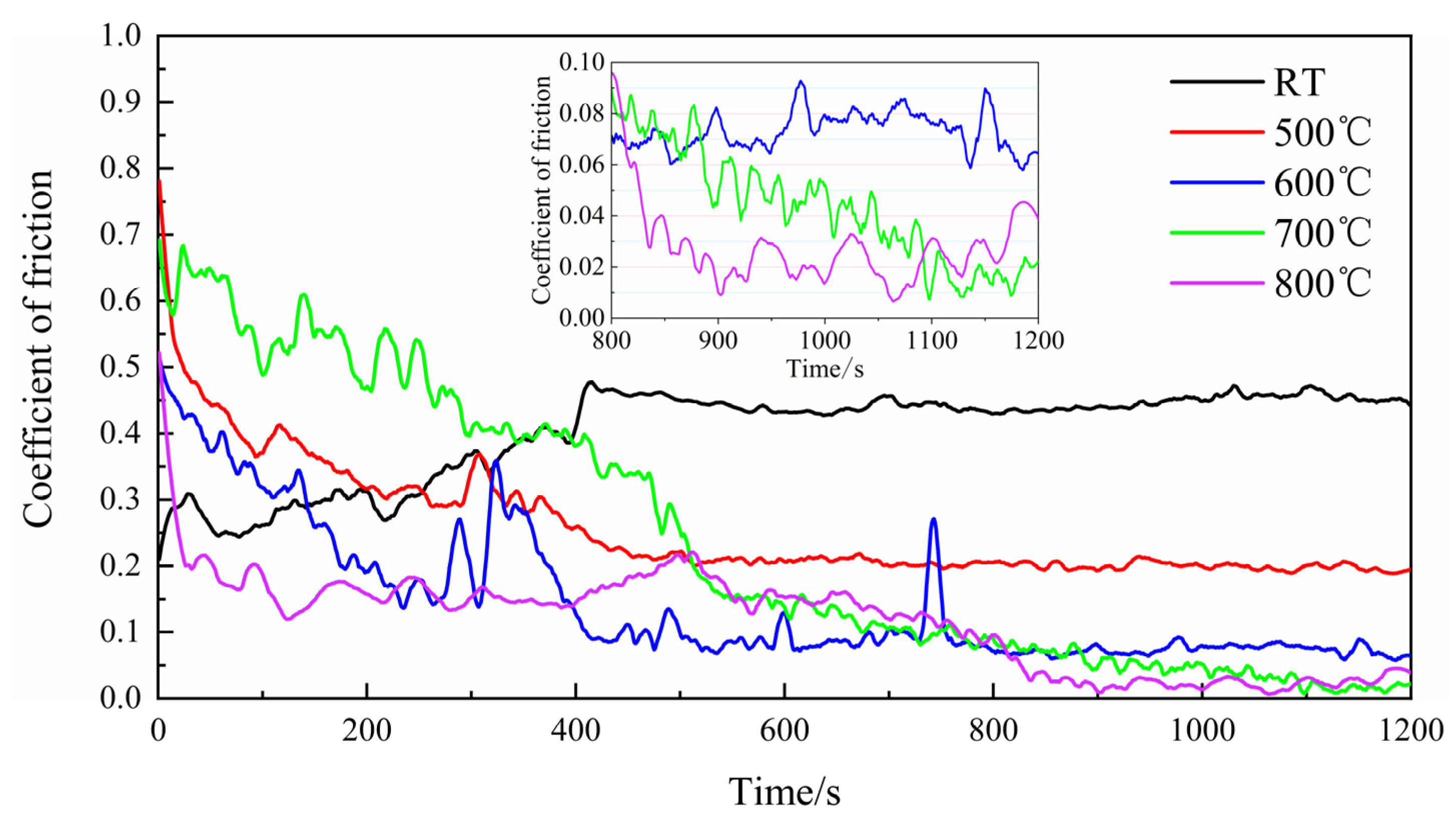

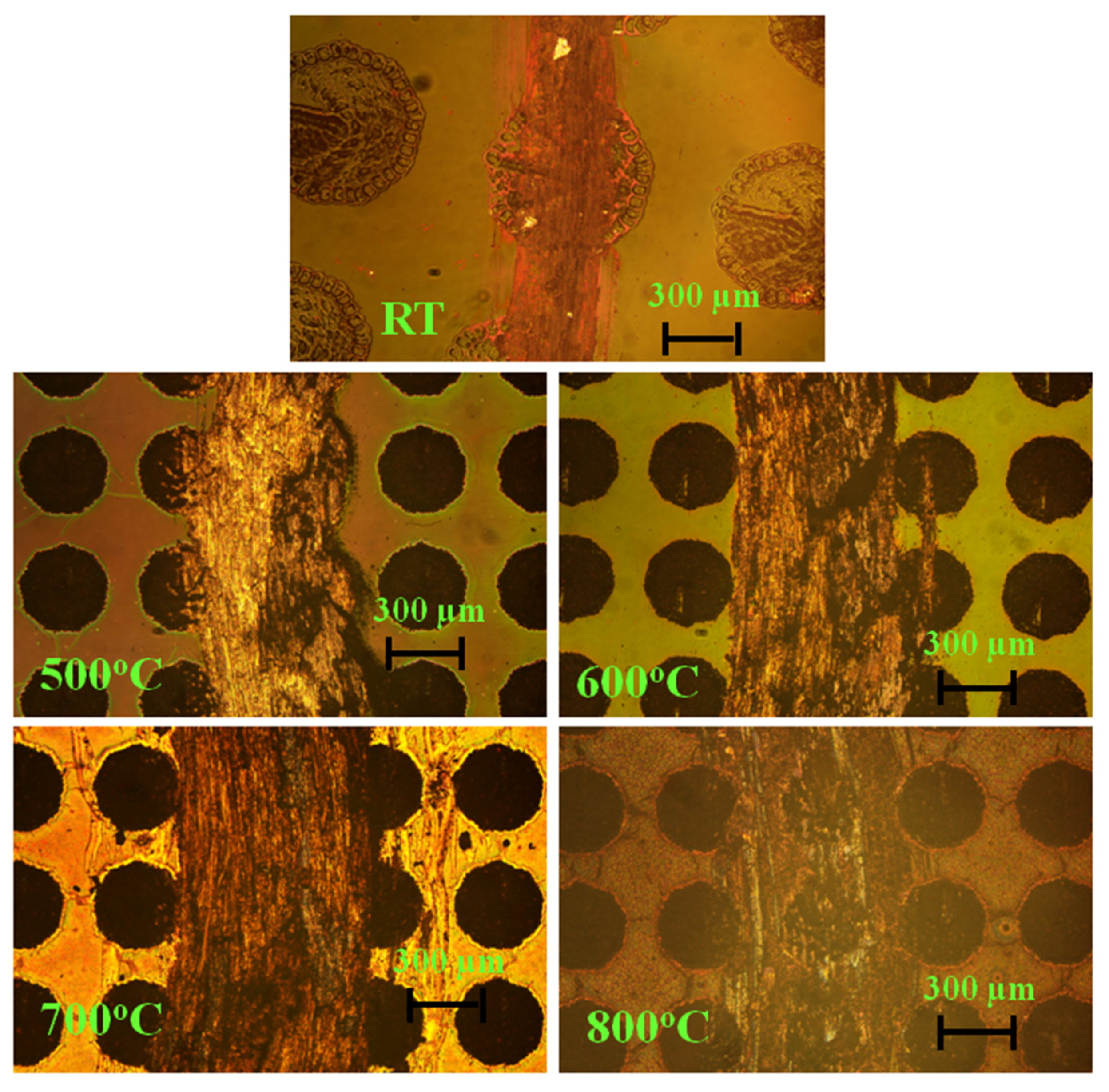

3.7. Tribological Properties of Coatings on Textured Alloy

4. Conclusions

- (1)

- The average hardness of the Inconel X750 alloy was217.7 HV. The CoF of the X750 alloy was the lowest at room temperature. The CoF was relatively high at an elevated temperature although the CoF was stable without fluctuation. At a high temperature, the running-in time was low compared with that at room temperature. The CoFs were between 0.25 and 0.32.

- (2)

- The h-BN coating was prepared on the substrate of the X750 alloy with a thickness of 600 nm and Ra of 9.8 nm. The critical load of the bonding strength of the coatings and X750 alloy was about 2 N.

- (3)

- The h-BN coatings had a high CoF at room temperature, but the CoF reduced from 500 °C to 800 °C, and the CoF at the stable stage decreased to 30.6%, 66.8%, 79.6% and 58.2%. The antifriction behavior was obvious at a high temperature. The specific wear rate decreased to 78.8%, 75.5%, 50.7% and 79.7%.

- (4)

- The surface texture was prepared to avoid the cracking problem of the coatings at a high temperature, store the wear debris and reduce the coating peeling and the debris accumulation at a high temperature. The friction curve of the textured coatings at elevated temperatures was stable.

Funding

Data Availability Statement

Conflicts of Interest

References

- DellaCorte, C. The effect of counterface on the tribological performance of a high temperature solid lubricant composite from 25 to 650 °C. Surf. Coat. Technol. 1996, 86, 486–492. [Google Scholar] [CrossRef]

- Liu, J.; Liao, R.; Liao, B.; Luo, J.; Bao, K. Mechanical and tribological properties of CrN coated Inconel X750. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 804–810. [Google Scholar] [CrossRef]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid lubrication at high-temperatures—A review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.; Pu, J.; Lu, Z. Insight into the high-temperature tribological mechanism of VAlTiCrW high entropy alloy film: AlV3O9 from tribochemistry. Friction 2023, 11, 1165–1176. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Zhang, X.; Lu, X.; Han, W.; Hao, J.; Zhao, T. Tribological behavior of Cu-modified polymer-derived SiBCN ceramics at elevated temperature. Tribol. Int. 2023, 185, 108540. [Google Scholar] [CrossRef]

- Jia, J.; Yang, G.; Zhang, C.; Zhang, S.; Zhang, Y.; Zhang, P. Effects of magnetic ionic liquid as a lubricant on the friction and wear behavior of a steel-steel sliding contact under elevated temperatures. Friction 2021, 9, 61–74. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Ding, Q.; Feng, D.; Qin, B.; Hu, L. Liquid metal as novel lubricant in a wide temperature range from −10 to 800 °C. Mater. Lett. 2018, 215, 140–143. [Google Scholar] [CrossRef]

- Zeng, Q. High temperature low friction behavior of h-BN coatings against ZrO2. Coatings 2022, 12, 1772. [Google Scholar] [CrossRef]

- Mittal, D.; Singh, D.; Sharma, K. Thermal characteristics and tribological performances of solid lubricants: A mini review. In Advances in Rheology of Materials; Intechopen: London, UK, 2023. [Google Scholar]

- Chen, J.; Chen, J.; Wang, S.; Sun, Q.; Cheng, J.; Yu, Y.; Yang, J. Tribological properties of h-BN matrix solid-lubricating composites under elevated temperatures. Tribol. Int. 2020, 148, 106333. [Google Scholar] [CrossRef]

- Chen, J.; Sun, Q.; Chen, W.; Zhu, S.; Li, W.; Cheng, J.; Yang, J. High-temperature tribological behaviors of ZrO2/h-BN/SiC composite under air and vacuum environments. Tribol. Int. 2021, 154, 106748. [Google Scholar] [CrossRef]

- Lu, X.L.; Liu, X.B.; Yu, P.C.; Zhai, Y.J.; Qiao, S.J.; Wang, M.D.; Wang, Y.G.; Chen, Y. Effects of heat treatment on microstructure and mechanical properties of Ni60/h-BN self-lubricating anti-wear composite coatings on 304 stainless steel by laser cladding. Tribology 2015, 355, 350–358. [Google Scholar] [CrossRef]

- Tyagi, R.; Xiong, D.S.; Li, J.L.; Dai, J. High-temperature friction and wear of Ag/h-BN-containing Ni-based composites against steel. Tribol. Lett. 2010, 40, 181–186. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, X.; Jin, G.; Song, Q.; Yuan, C.; Fang, Y.; Wen, X. Microstructure and tribological performance of laser-cladded Ni60/h-BN coatings on Ti-6Al-4V alloy at high temperature. Tribol. Trans. 2019, 62, 779–788. [Google Scholar] [CrossRef]

- Yuan, S.; Toury, B.; Benayoun, S. Novel chemical process for preparing h-BN solid lubricant coatings on titanium-based substrates for high temperature tribological applications. Surf. Coat. Technol. 2015, 272, 366–372. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.; Li, Z. Effect of MoO3 on the microstructure and tribological properties of laser-clad Ni60/nanoCu/h-BN/MoO3 composite coatings over wide temperature range. Surf. Coat. Technol. 2020, 387, 125477. [Google Scholar] [CrossRef]

- Cao, J.; Huang, H.; Li, S.; Wu, X.; Yin, Z.; Abbas, Z. Tribological and mechanical behaviors of engine bearing with CuSn10 layer and h-BN/graphite coating prepared by spraying under different temperatures. Tribol. Int. 2020, 152, 106445. [Google Scholar] [CrossRef]

- Raadnui, S.; Mahathanabodee, S.; Tongsri, R.; Morakotjinda, M.; Wila, P. Comparison of dry sliding tribological behavior of SS 316L impregnated with MoS2 vs h-BN solid lubricants: A statistical point of view. Wear 2021, 476, 203676. [Google Scholar] [CrossRef]

- Guimarey, M.J.; Ratwani, C.R.; Xie, K.; Koohgilani, M.; Hadfield, M.; Kamali, A.R.; Abdelkader, A.M. Multifunctional Steel Surface through the Treatment with Graphene and h-BN. Tribol. Int. 2023, 180, 108264. [Google Scholar] [CrossRef]

- Singh, A.K.; Atheaya, D.; Tyagi, R.; Ranjan, V. Friction and wear behavior of atmospheric plasma sprayed NiMoAl-Ag-hBN coatings at elevated temperatures. Surf. Coat. Technol. 2023, 466, 129650. [Google Scholar] [CrossRef]

- Karpov, A.V.; Sychev, A.E.; Boyarchenko, O.D.; Kovalev, I.D.; Belousova, O.V.; Loryan, V.E. Dielectric properties of BN–ZrB2 and BN–ZrO2 based beramics produced by self-propagating high-temperature synthesis. Glass Ceram. 2023, 1–5. [Google Scholar]

- Zhang, H.; Pan, Y.; Zhang, Y.; Lian, G.; Cao, Q.; Que, L. A comparative study on microstructure and tribological characteristics of Mo2FeB2/WC self-lubricating composite coatings with addition of WS2, MoS2, and h-BN. Mater. Des. 2023, 111581. [Google Scholar] [CrossRef]

- Randhawa, K.S.; Prajapati, B. Hygroscopicity Analysis and tribo-mechanical characterizations of conditioned PA6/MoS2/h-BN hybrid composite. J. Inorg. Organomet. Polym. Mater. 2023, 33, 625–635. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhu, J.; Long, Y.; Bouchet, M.I.D.B.; Martin, J.M. Transformation-induced high temperature low friction behaviors of ZrO2-steel system at temperatures up to 900 °C. Mater. Res. Express 2019, 6, 0865f5. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, L. High temperature anti-friction behaviors of a-Si: H films and counterface material selection. Coatings 2019, 9, 450. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, T. Superlow friction and oxidation analysis of hydrogenated amorphous silicon films under high temperature. J. Non Cryst. Solids 2018, 493, 73–81. [Google Scholar] [CrossRef]

- Kosinova, M.L.; Rumyantsev, Y.M.; Golubenko, A.N.; Fainer, N.I.; Ayupov, B.M.; Dolgovesova, I.P.; Kolesov, B.A.; Kaichev, V.; Kuznetsov, F.A. Chemical composition of boron carbonitride films grown by plasma-enhanced chemical vapor deposition from trimethylamineborane. Inorg. Mater. 2003, 39, 366–373. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Zeng, G.; Wu, Z.; Liang, J.; Chen, X.; Leng, L.; Wang, H.; Wang, H. Metal-free efficient photocatalyst for stable visible-light photocatalytic degradation of refractory pollutant. Appl. Catal. B Environ. 2018, 221, 715–725. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Zhang, B.; Yan, C.; He, W. Elevated-temperature super-lubrication performance analysis of dispersion-strengthened WSN coatings: Experimental research and first-principles calculation. Surf. Coat. Technol. 2021, 406, 126651. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Yan, C.; He, W. WS2 nanopowders as high-temperature lubricants: An experimental and theoretical study. ACS Appl. Nano Mater. 2019, 2, 5604–5613. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Xiong, D.; Qin, Y.; Chen, J.; Zhu, H. Tribological properties of silver coatings with laser surface textured nickel as interlayer. Tribol. Int. 2016, 100, 178–185. [Google Scholar] [CrossRef]

- Ji, R.; Zhao, Q.; Zhao, L.; Liu, Y.; Jin, H.; Wang, L.; Wu, L.; Xu, Z. Study on high wear resistance surface texture of electrical discharge machining based on a new water-in-oil working fluid. Tribol. Int. 2023, 180, 108218. [Google Scholar] [CrossRef]

| Elements | Weight Percent (%) | Atom Percent (%) |

|---|---|---|

| Cr | 14.68 | 13.73 |

| Fe | 6.44 | 5.61 |

| Ni | 70.49 | 58.36 |

| Ti | 2.38 | 2.41 |

| Al | 0.55 | 0.99 |

| Nb | 0.9 | 0.47 |

| Total | 100 | 100 |

| Points | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Hardness (HV) | 226.4 | 208.5 | 210.9 | 221.2 | 212.1 | 227.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q. High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy. Lubricants 2023, 11, 258. https://doi.org/10.3390/lubricants11060258

Zeng Q. High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy. Lubricants. 2023; 11(6):258. https://doi.org/10.3390/lubricants11060258

Chicago/Turabian StyleZeng, Qunfeng. 2023. "High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy" Lubricants 11, no. 6: 258. https://doi.org/10.3390/lubricants11060258

APA StyleZeng, Q. (2023). High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy. Lubricants, 11(6), 258. https://doi.org/10.3390/lubricants11060258