1. Introduction

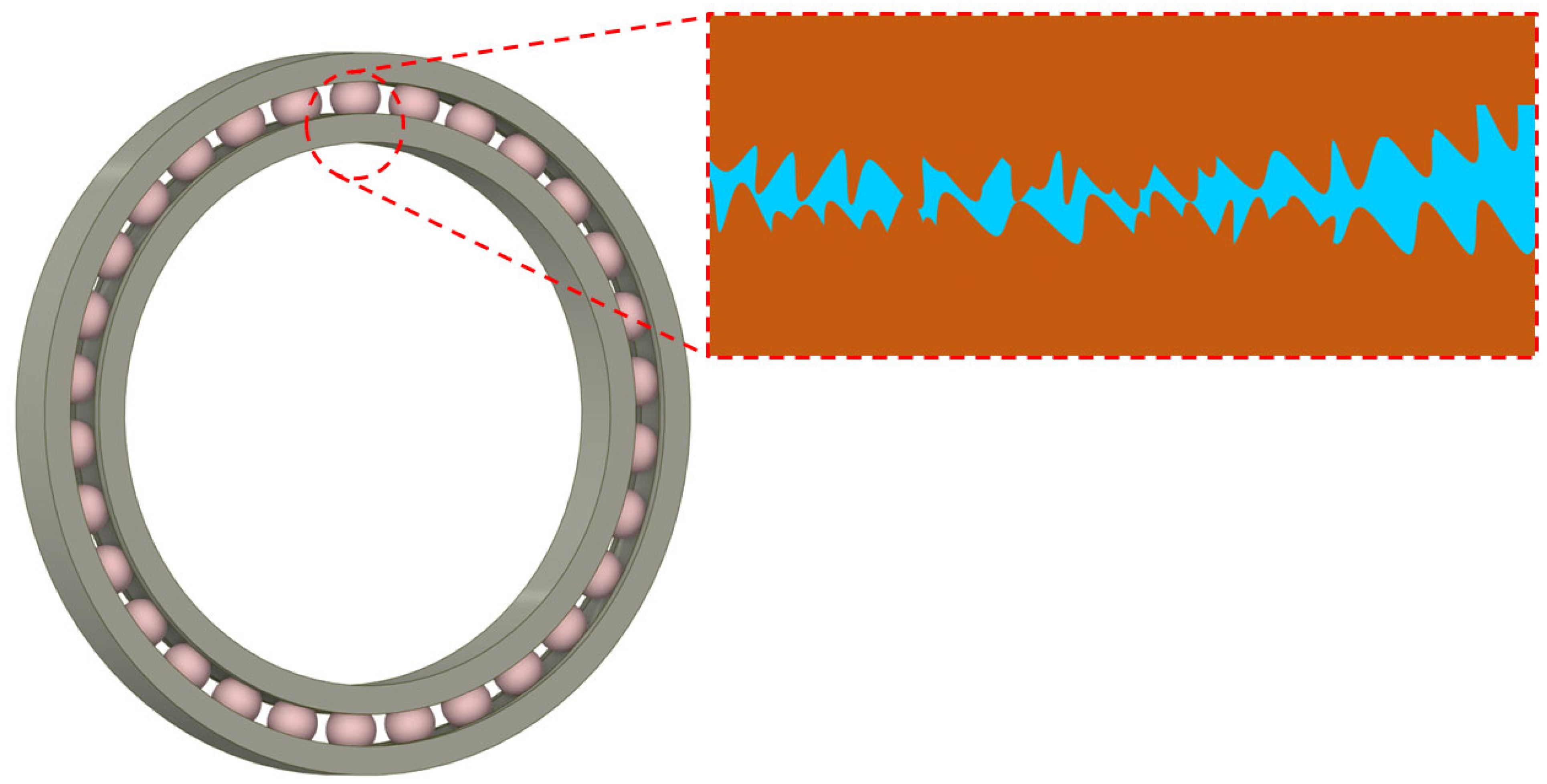

The lubrication of machine components is critical for the reliable and long-term performance of any mechanical system. Numerical simulation is a more cost-effective method than experimental methods for designing and investigating lubricated systems for a variety of applications. In lubrication, the hydrodynamic effect generates internal fluid pressure, which maintains separation between relatively moving surfaces. The traditional Reynolds equation is employed for calculating fluid pressure in most cases. The basis for this is founded on the fact that the film thickness is relatively smaller compared to the length of smooth and near-parallel interacting surfaces. The Reynolds equation can be applied in situations when the opposite surfaces and their topographical features can be completely pushed away by the developed lubricating film, in full-film lubrication and elasto-hydrodynamic lubrication (EHL) regions. However, the majority of the lubricated machine components change their lubrication regime as the external load and speed vary. In engineering applications, rough surfaces are common (see

Figure 1), which results in an inevitable effect on lubrication performance, especially when concentrated contacts operate under heavy-load and low-speed conditions, known as ML conditions. Many power and motion transition components, for example, gears, cams, followers, and bearings, generally work in the mixed region of lubrication (ML) where solid and fluid contacts coexist. Therefore, proper boundary conditions are required to numerically simulate the ML using the Reynolds equation.

In the worst circumstances of lubrication where different surface features take part to support the external load, local experimentation is nearly impossible or very expensive, even though expensive ML experimentation can only yield a general trend of contact performance and behaviors. In this case, simulation must be used to acquire precise information about what actually occurs at the roughness scale. The field of EHL numerical simulation has met with great success when used in many problems, for example, the development of efficient simulation algorithms for the precise study of film thickness and deformation calculations. The available EHL and ML models are based on assumptions that are not valid when roughness features (asperities) make contact, resulting in an inaccurate calculation of pressure and external load-carrying capacity. In this study, a new model for predicting the pressure distribution in asperity contact has been proposed and verified using CFD simulation.

Several studies are reported in the literature focusing on surface roughness effects on the functionality and lifespan of lubricated contact, and this topic is currently a priority in tribology industries [

1,

2,

3,

4]. A thorough assessment of the history of numerical simulation of the ML is well documented in the literature [

5,

6,

7,

8]. To numerically simulate the rough lubricated contacts, stochastic and deterministic models have been used in past. Patir and Cheng [

9] developed a famous stochastic average flow model for rough lubricated surfaces, where the traditional Reynolds equation has been modified by including both pressure and shear flow factors that will be the functions of surface roughness characteristics. In the average flow model, a separate deterministic sub-model is required for determining the flow factors, which will provide a general effect exhibited by surface roughness when using the average flow model. However, this model is unable to give specific details regarding the elevated pressure areas where roughness peaks of the opposite surface contact with each other [

10,

11,

12,

13]. Later, deterministic models were introduced for robust design calculations, whereby local variation in tribological parameters can be predicted. The deterministic ML study begins with the simulation of simple irregularities in the form of sinusoidal roughness [

14], and progresses to the digital real rough surface simulation [

15]. Zhu et al. [

16] proposed a unified numerical approach for Mixed Lubrication in 1999. They suggested that the Reynolds equation can be used in both hydrodynamic and contact regions. To avoid the need for information related to the fluid–solid interaction border position and related boundary conditions, the pressure flow terms in the Reynolds equation can be removed when the film thickness is zero. This approach can simplify numerical calculations and avoid the potential errors caused by inaccurate boundary conditions. Later, a similar model was also applied for the mixed elasto-hydrodynamic simulation of hypoid gears [

17,

18].

There have been various challenges in numerically simulating the ML and asperity contact problem. The most fundamental problem is the boundary conditions (BC), which have been resolved by introducing the LCICs conditions [

11] and are applicable for surfaces where the ε = dh/dL ratio is far less, and velocity changes in the film thickness direction can be ignored. However, the model has limitations, since it can only be applied to a limited range of mesh sizes. In the case of multiple solid blocks, a fine mesh will be required, and this algorithm is ineffective in providing accurate solutions. Similarly, Deolalikar et al. [

19] adopted the no-flow BC by treating the fluid and solid contact zones separately. Many authors have used this method to some extent [

20,

21]. The other problems are that we need a high degree of discretization to capture the local physical reality, which will further require high computational power. The calculation of micro-deformation, thermal, non-Newtonian and transient effects complicates the problem in terms of calculation time and effort required.

The MG (multigrid) technique has been an important part of numerically solving problems related to lubricated contacts for decades, ever since Lubrecht et al. [

22] first used it in 1986 in their EHL solution. Later, Venner [

23] significantly enhanced the relaxation method by utilizing the multigrid approach for isothermal EHL problems. Liu, Wang et al. [

24] investigated the impacts of various differential schemes on EHL calculations using the semi-system approach [

25]. Various differential schemes have no effect when sufficient film thickness is achieved to keep the contacting surfaces apart. However, for ultra-thin film thickness, e.g., below 10–20 nm, the influence becomes more significant because truncation errors are large for higher-order discretization (2C) in the case of sharp gradients [

24] whereas truncation errors are low for low-order discretization schemes (1B). Hence, the literature provides evidence that the first-order backward scheme (1B) solves the problem more accurately compared to the second-order central (2C) schemes [

11,

24].

This paper’s main goal is to numerically simulate the impact of asperity contact operating under ML conditions. In order to make multiple asperities, the solution grid should be fine enough to capture the geometrical configuration of the gap between the contact accurately. Liu, Wang et al. have used the LCICs boundary conditions for a single block of the square and cylindrical cross-section with a mesh size of 128 × 128 nodes [

11]. For multiple solid contacts, however, the method is limited because of computational efficiency and accuracy requirements, since multiple asperities would need to be represented with a fine grid to get the local pressure distribution. The fine grid has a low residual reduction rate compared to the coarse grid, and with the increasing number of unknowns (n), the asymptotic convergence speed slows [

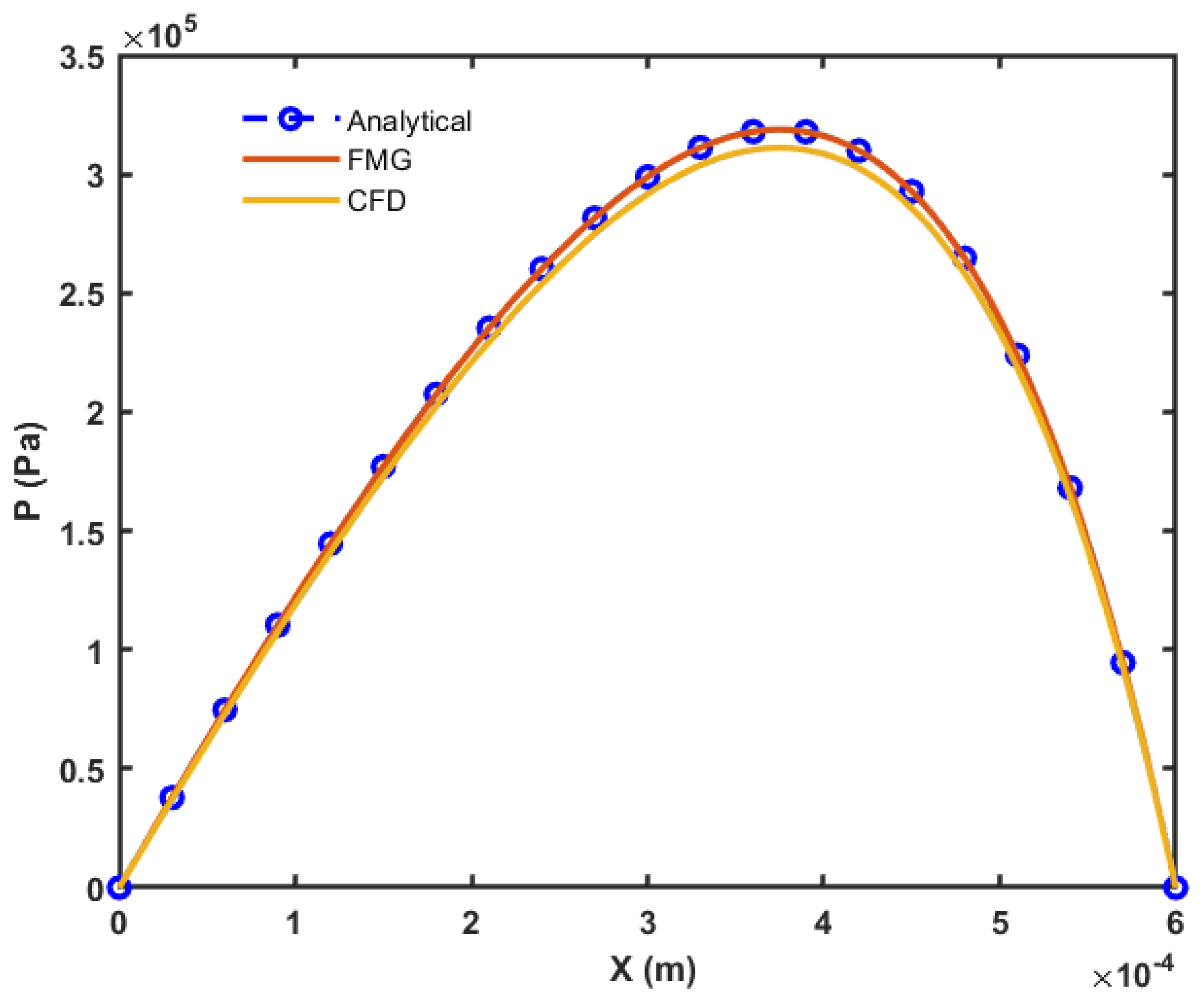

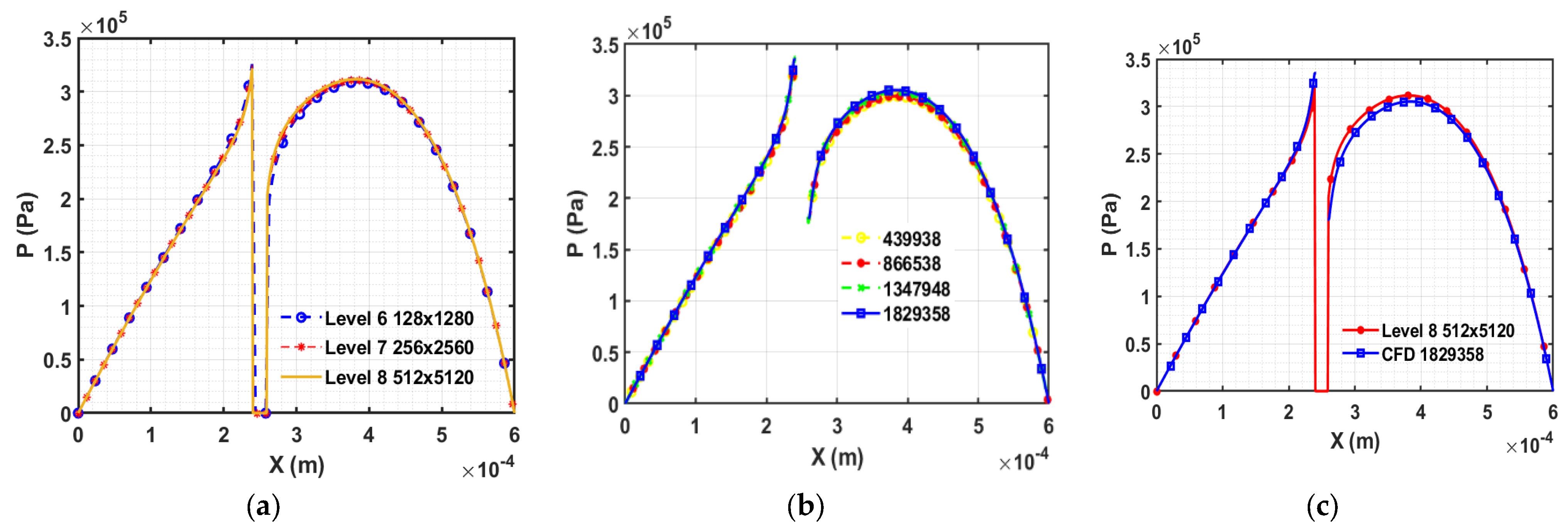

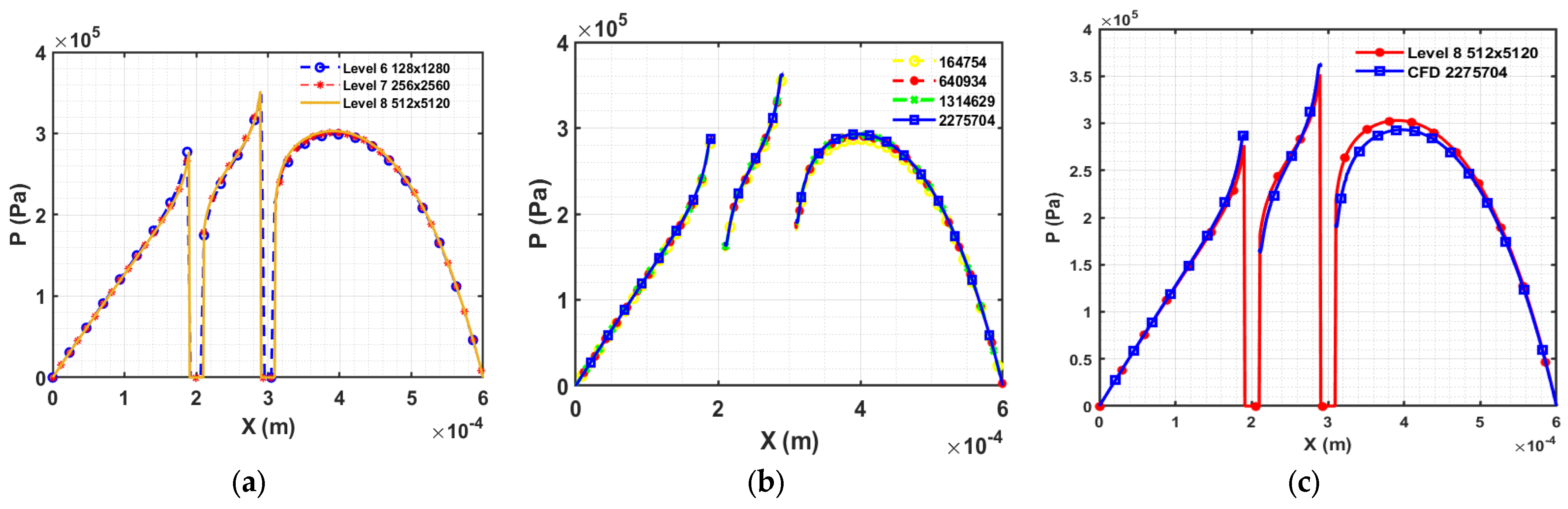

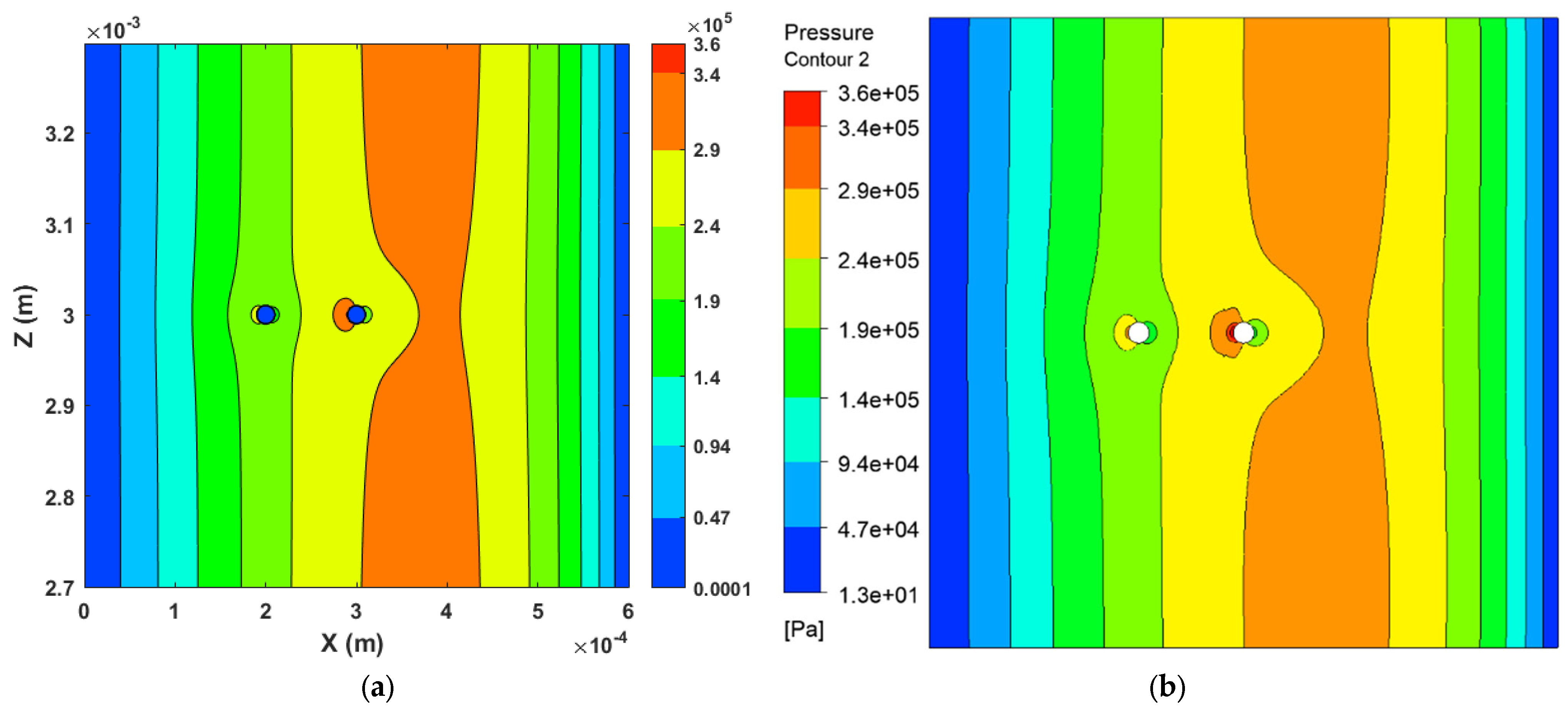

23]. In this paper, to predict the pressure distribution in multiple asperity contact, a full multigrid (FMG) method has been implemented, and the produced results have been verified using the CFD simulation. The shear flow term of the Reynolds equation has been solved by using the 1B differential scheme to improve the accuracy, and it has also been demonstrated that the conventionally used 2C differential scheme cannot accurately estimate the hydrodynamic effect of asperity contact that may occur under ML conditions.

2. Modeling Approach

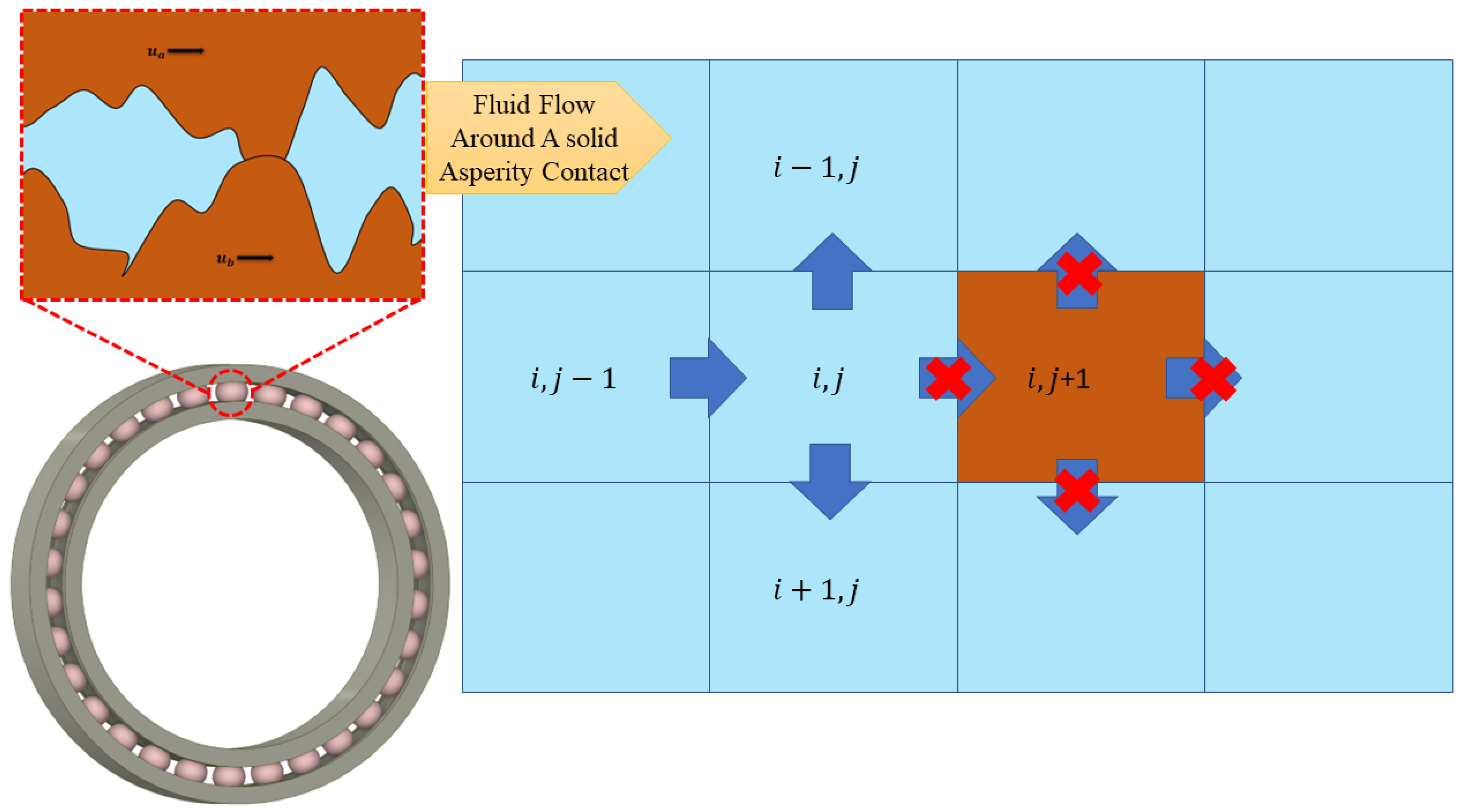

ML occurs when surfaces in contact are not perfectly smooth and are subjected to high loads and low speeds, such as in journal bearings and gears. It is a combination of hydrodynamic lubrication and boundary lubrication. To study this phenomenon, a hydrodynamic lubricated contact is simplified into a simple wedge problem.. To represent direct solid-to-solid contact in this simplified wedge, a rigid solid asperity that blocks the flow of lubricant is modeled. The effect of solid asperities blocking the lubricant flow at the interface of the converging wedge is numerically calculated without considering deformation. The traditional Reynolds equation alone cannot accurately solve this problem due to its unrealistic assumptions, so the LCIC’s boundary conditions [

3] have been adopted at the boundary of the fluid–solid interaction (

Figure 2, around the brown box). These conditions ensure that no physical flow can pass through the interface [

5]. Additionally, algorithms have been developed using the multigrid method to solve the multiple asperity contact problem efficiently and accurately. Hence, a novel and advanced deterministic model has been designed to numerically simulate the converging wedge film with solid asperity contact to determine the fluid pressure using the Reynolds equation. Below,

Figure 2 illustrates the phenomenon of fluid–solid interaction. It consists of blue boxes, representing fluid elements, and brown boxes, representing solid elements. The arrows in

Figure 2 depict the fluid flow, whereas the same arrows with a red cross represent the location of the no-flow boundary condition that has been enforced at the interface of the fluid–solid contact.

To simplify the problem, it has been assumed that the solid pressure is greater than the pressure generated in the fluid film. Hence, it allows the solid asperities to make contact with the bottom surface. Therefore, the model is a simplified version of ML that does not consider the solid contact pressure. The Reynolds equation in the traditional solution process is discretized using high-order schemes such as 2C to discretize each term of the equation. However, in this study, to numerically simulate the problem of asperity contact, the Reynolds equation 1B finite difference discretization method has been utilized for the Couette Flow (CF) terms, which produced more accurate results compared to the 2C scheme. FDM-generated pressure has been compared with the CFD model in verifying the results. CFD uses Navier–Stokes equations to solve the model using the Finite Volume Method (FVM) [

26]. To deal with cavitation during the flow simulation, a multiphase mixture model has been used, where the mass transfer between the two phases is governed by the Schnerr and Sauer cavitation model [

27]. When the pressure of any liquid reduces to a level below its saturation pressure (Ps = 13 Pa), the liquid will start to enter into a vapor phase.

3. CFD Model Setup

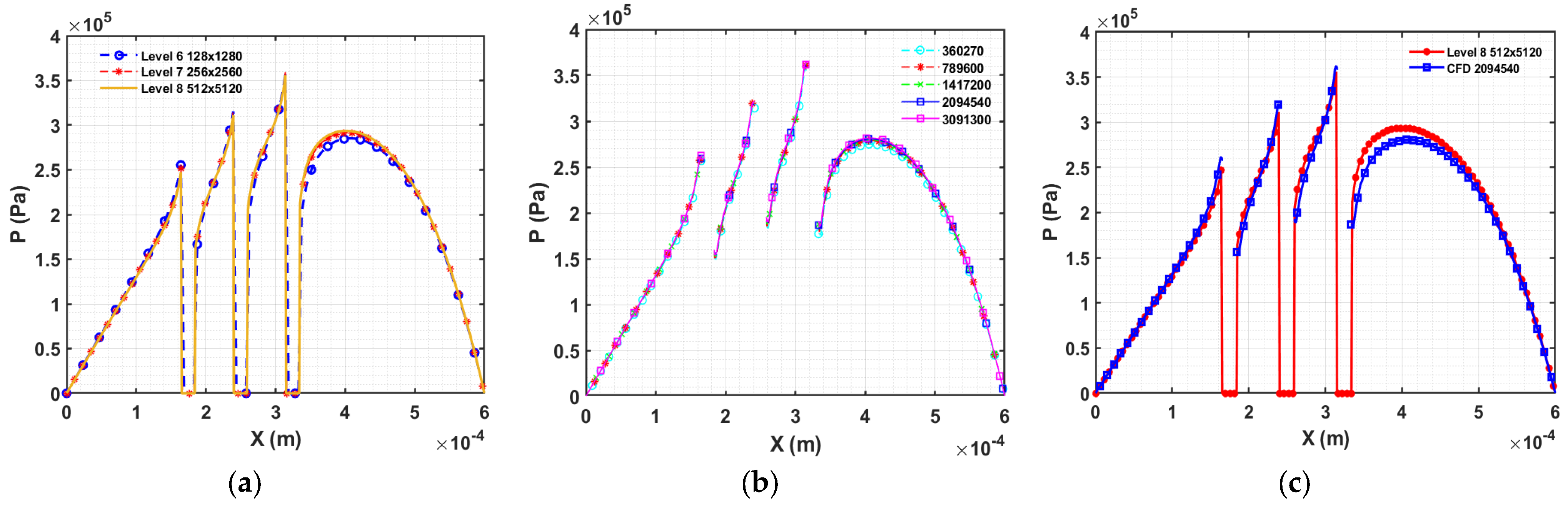

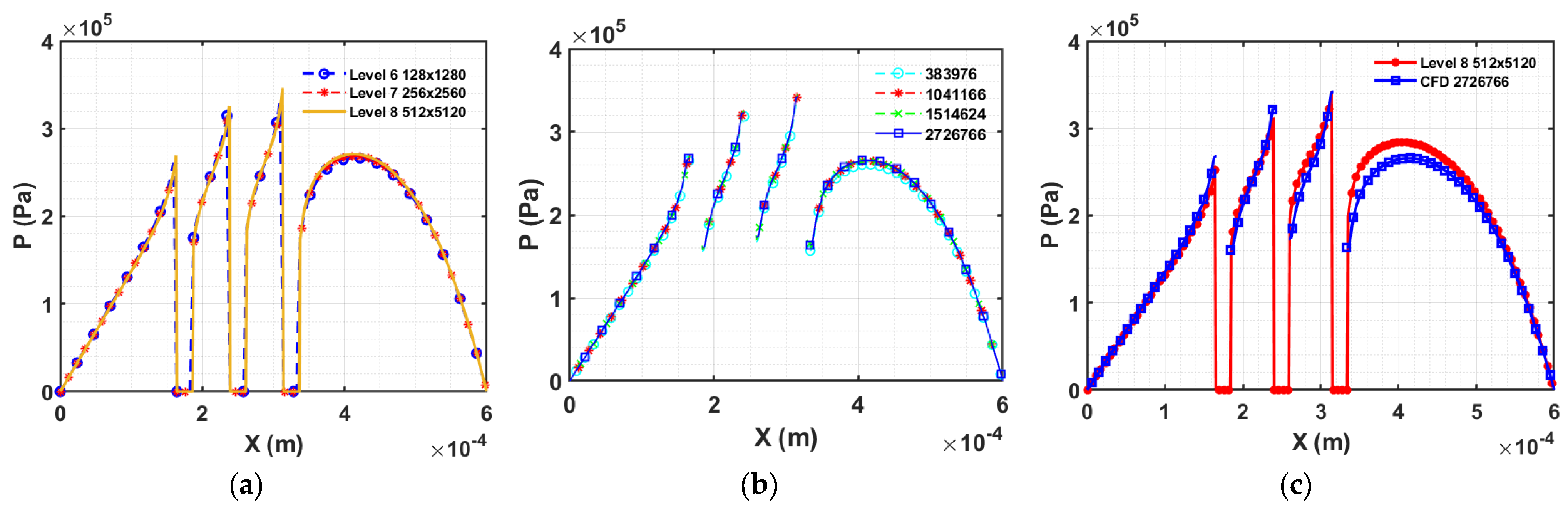

The design modeler application of the ANSYS software has been used to construct the 3D model of converging wedge film thickness with variously shaped contacting solid asperities. In all the CFD models used in this study, it has been assumed that the upper and lower contact surfaces are smooth with no-slip boundary conditions, and to represent fluid–solid interaction (see

Figure 3), solid asperities have been designed at the middle of the fluid domain. According to previous research [

28,

29], it is generally advised to use structural quadrilateral meshes instead of unstructured triangular meshes in fluid simulation using CFD, because they provide better stability, accuracy, and convergence. Therefore, in our CFD models, we have employed a quadrilateral mesh type, which was created using ICEM CFD software (ANSYS 2022). This software uses a multiblock structured mesh approach that generates a grid from the block, which is further subdivided into smaller blocks. The structured mesh developed using this software generally has well-defined elements, and can be used for complex geometries with varying boundary conditions. This meshing software is based on the FVM for generating mesh, and it also offers advanced mesh editing tools for adjusting mesh properties and resolving issues such as skewness and aspect ratio. The mesh sensitivity analysis has been conducted for each model and a range of elements has been utilized for the sensitivity testing of the CFD models varying between 1 × 10

5 and 1 × 10

8. However, the specific number of elements used for each model is displayed in the figures of the corresponding CFD sensitivity analysis. The CFD solution has been obtained using double precision, a pressure-based model where flow is considered laminar. The momentum and continuity equations have been solved using the Semi-Implicit Method for Pressure Linked Equations (SIMPLE) algorithmic approach. Pressure inlet and outlet boundary conditions have been applied during the CFD simulation.

Table 1 lists the various parameters that have been used to model the problem [

30].

4. FDM Model

Equation (1) shows the dimensionless Reynolds equation:

where

,

,

hydrodynamic pressure,

film thickness,

direction of flow, and

lateral axis to the flow direction. Here, the left-hand side (LHS) terms are known as the Poiseuille terms, and the right-hand side (RHS) term is called the wedge term. In wedge terms, H (film thickness) can be defined analytically. Equation (2) shows the dimensionless film thickness used for the converging simple wedge geometry.

The Reynolds equation has been discretized using the 2C discretization scheme, as shown in Equation (3):

The higher-order discretization scheme (e.g., 2C) provides close to exact results for thick fluid films. Hence, both the Poiseuille terms and wedge terms have been discretized using 2C discretization. However, for ultra-thin fluid films or where a large gradient of film thickness exists, using the 1B scheme for the wedge term provides a more accurate solution than the 2C scheme, because truncation errors are significant with higher-order schemes in the case of sharp gradients [

24]. Lui et al. has suggested using the 1B scheme for the RHS of the Reynolds equation [

11]. Hence, following the recommendations of Ref. [

11], Equation (1) can also be discretized as Equation (4), where the Couette flow or wedge flow term has been discretized using the 1B scheme.

Below, Equation (5) shows the different terms of the Reynolds equation in the form of flow continuity, as suggested by Liu et al. [

31], where P refers to the Poiseuille flow terms and C refers to Couette flow terms. Equation (4) can also be presented considering the right-hand side function

when applying the FMG approach.

The above Equation (5) shows the discretized Reynolds equation in the form of flow continuity, as suggested by Liu et al. [

11].

5. Relaxation

While solving the Reynolds equation, negative pressure has been kept equal to zero, because the Reynolds equation is not valid in the cavitation region. The problem has been solved on a unit square domain Γ = [0, 1] × [0, 1]. In this paper, the model is assumed to have smooth contacting surfaces producing a converging wedge-shaped film thickness where the inclined upper wall is stationary with the moving lower surface at 1 m/s velocity. The inlet height is 10 μm, the outlet height is 6 μm, and the length of the converging wedge is 600 μm. At the boundaries, the pressure is assumed to be zero, and any predicted negative pressure during iteration is also considered zero. Furthermore, the residuals are only calculated for positive pressure regions; hence, cavitated regions should have zero residuals. To define the interface boundary condition between the fluid and solid, it has been assumed that the external load is larger than the hydrodynamic pressure generated in the lubricated contact, and the fluid will flow around the solid asperity contact. On the other hand, if the fluid pressure is higher than the external load, the fluid will lift the solid asperity contact and begin flowing in without making any solid contact. Hence, to mathematically define the solid contact, we must ensure that the fluid–solid interface does not allow any physical flow to pass through it. As a result, the no-flow restriction has been incorporated into the Reynolds equation with zero film thickness. For more information on the application of LCICs, readers are referred to reference [

11].

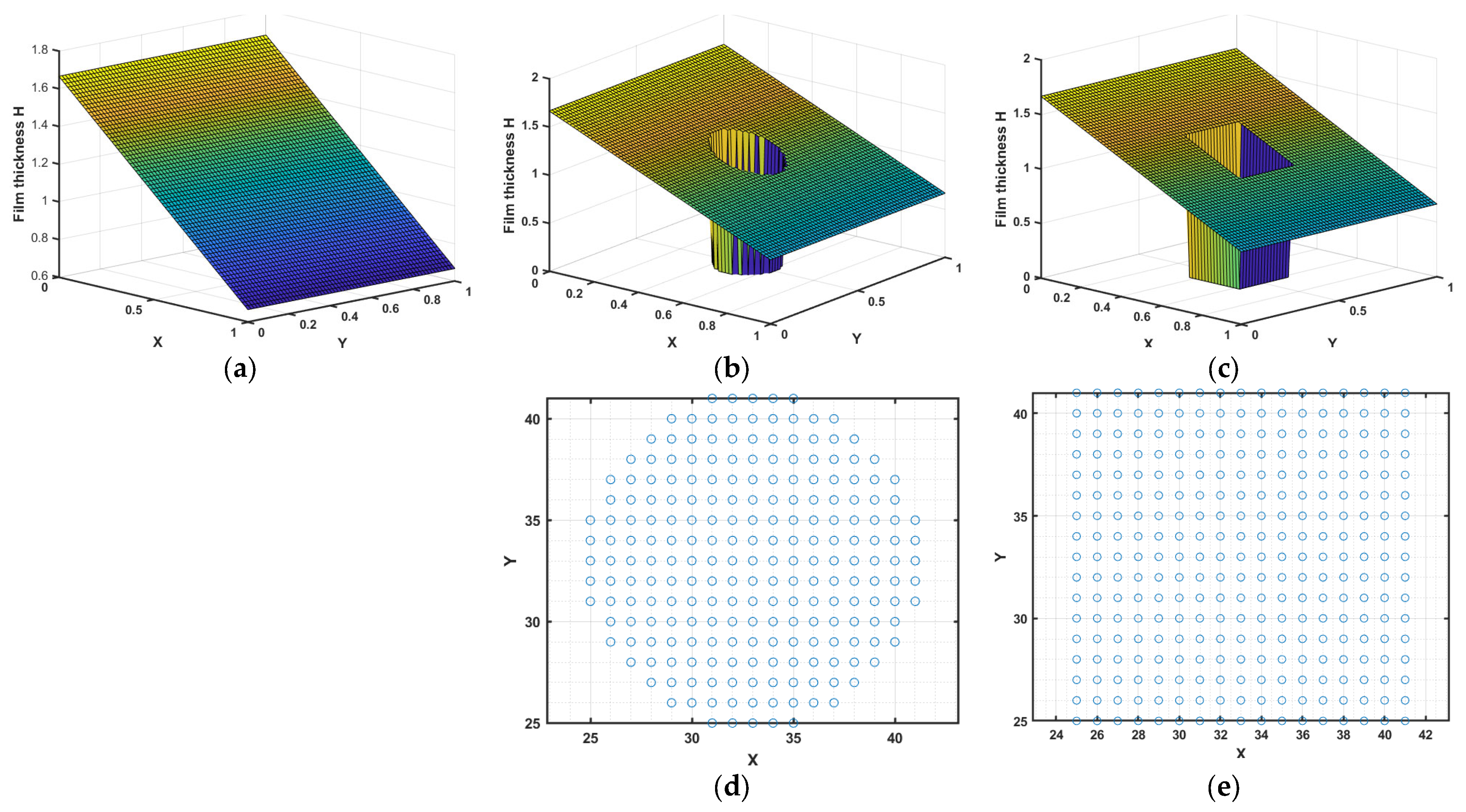

Figure 3 shows the three types of film thickness, considering the inlet height is 1 mm and outlet height is 4 mm, and the length and width of the converging wedge is 30 mm. At the boundaries, the pressure is assumed to be zero, and any predicted negative pressure during iteration is also considered zero. Furthermore, the residuals are only calculated for positive pressure regions; hence, cavitated regions should have zero residuals.

Figure 3a depicts the simple wedge film thickness, whereas

Figure 3b displays the wedge with a single cylindrical asperity contact problem.

Figure 3c illustrates the wedge with a single square asperity contact problem. In addition,

Figure 3d,e demonstrate the cross-sectional area of the cylinder and square solid asperity, and corresponding elements that make contact with the lower wall, where the film thickness is zero.

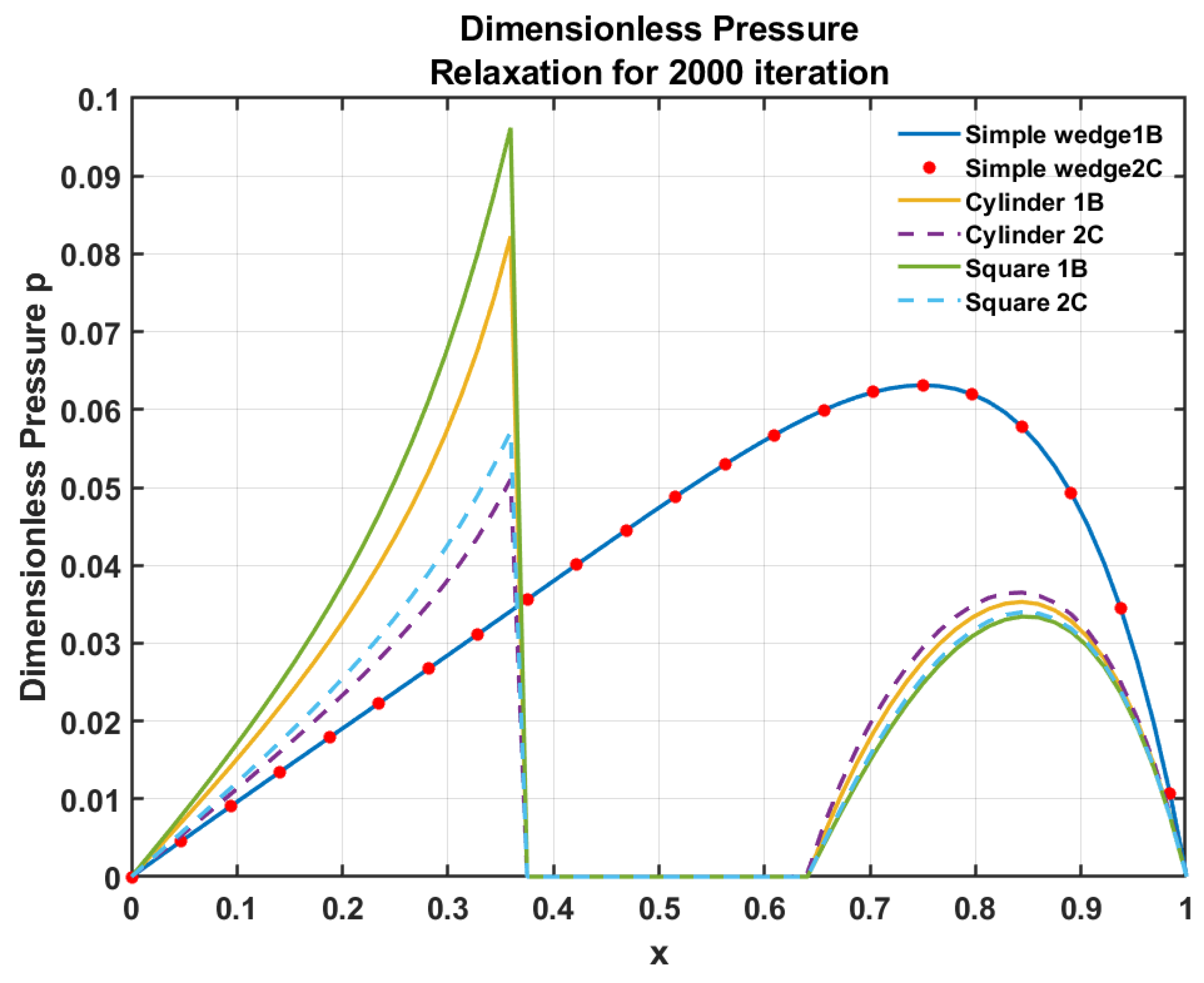

Figure 4 represents the pressure distribution calculated using Gauss–Seidel relaxation. Additionally, the LCIC boundary conditions have been adopted to calculate pressure when the fluid flow is blocked by the solid obstacle of the square and cylindrical cross-section [

11]. In

Figure 4, initially, the simple wedge problem (shown in

Figure 3a) has been solved using both 1B and 2C discretization schemes. The result shows (

Figure 4) that the discretization schemes (1B and 2C) do not affect pressure when the fluid film is uninterrupted. For instance, in the case of a converging simple wedge, both the discretization schemes produce an equal pressure profile. Secondly, an identical simple wedge problem with cylindrical (see

Figure 3b,d) and square (see

Figure 3c,e) asperity contacts in the middle of the domain has been solved using both 1B and 2C discretization schemes. In these cases, fluid flow is blocked using an 8 mm-long square and an 8 mm-diameter cylindrical asperity. The results in

Figure 4 show that different discretization schemes gives different results, especially in the case when fluid flow is interrupted by solid asperity. The 1B scheme accurately captures the increase in pressure when the fluid hits a solid asperity. However, 2C cannot accurately predict the pressure variation. Liu, Wang et al. have effectively explained why different discretization schemes give rise to different pressures [

2]. As the fluid flows towards the solid obstacle, the pressure increases sharply, and at this point, the fluid’s kinetic energy is converted into pressure energy.

Liu, Wang et al. have solved the same geometrical problem [

11], where cylindrical and square pillar blocks have been numerically simulated for many iterations to get the converged solution for a particular grid size (128 × 128 or 256 × 256). For greater grid sizes, the iteration will require a long time to calculate the accurate solution. Furthermore, if multiple asperity contacts are to be simulated, a fine grid must be used. Consequently, the convergence rate will be reduced, and an accurate solution will be less likely to be obtained within a short timeframe. Therefore, a new approach is needed that can simulate the asperity contact problem efficiently, accurately and in less time. A common technique to increase the overall efficiency of the process is the multigrid method. In the next section, we use the full multigrid method together with the LCIC’s boundary conditions around the solid object.

8. Conclusions

This paper describes a solid–fluid interaction model that simulates ML contacts under severe conditions. The model uses LCIC boundary conditions and the FMG method to solve the Reynolds equation via the finite difference method. Two different discretization schemes, 1B and 2C, are used to discretize the wedge term in the Reynolds equation. Numerical experiments are performed on circular cross-sections with single and multiple asperity contacts, and the fluid pressure distribution is compared with the 3D CFD simulation of laminar flow under the same working conditions.

The study reveals that the traditional Reynolds equation and the 2C scheme are unreliable when used in mixed lubrication scenarios where fluids and solids interact at the interface. The influence of different differential schemes is insignificant when the contacting surfaces are fully separated with sufficient lubricant film. However, a significant difference in the pressure distribution is observed when using the 1B versus the 2C scheme for discretizing the Couette flow term in the Reynolds equation when solid asperity contacts block the fluid flow. The proposed model offers reasonable computational efficiency on a standard personal computer to get detailed solutions related to solid asperity contact. Additionally, the developed novel multigrid algorithms significantly reduce the code execution time. Additionally, the robustness of the model has been validated by testing with single and multiple asperity contacts of circular cross-sections. The model can be easily extended to EHL, thermal and transient calculations, where the ratio is smaller than or equal to 0.01, and velocity changes in the film thickness direction can be ignored.