An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication

Abstract

1. Introduction

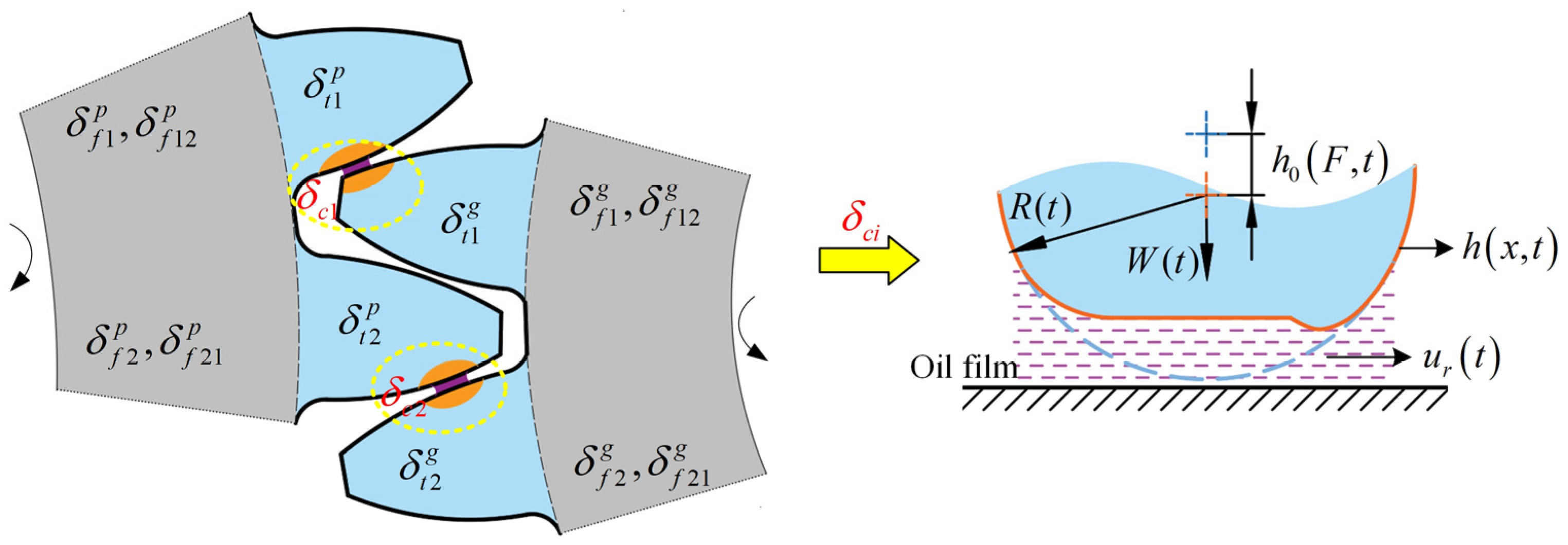

2. Transient Thermal EHL Equations

3. Load Distribution Model in Thermal EHL Contact

3.1. Deformation Components

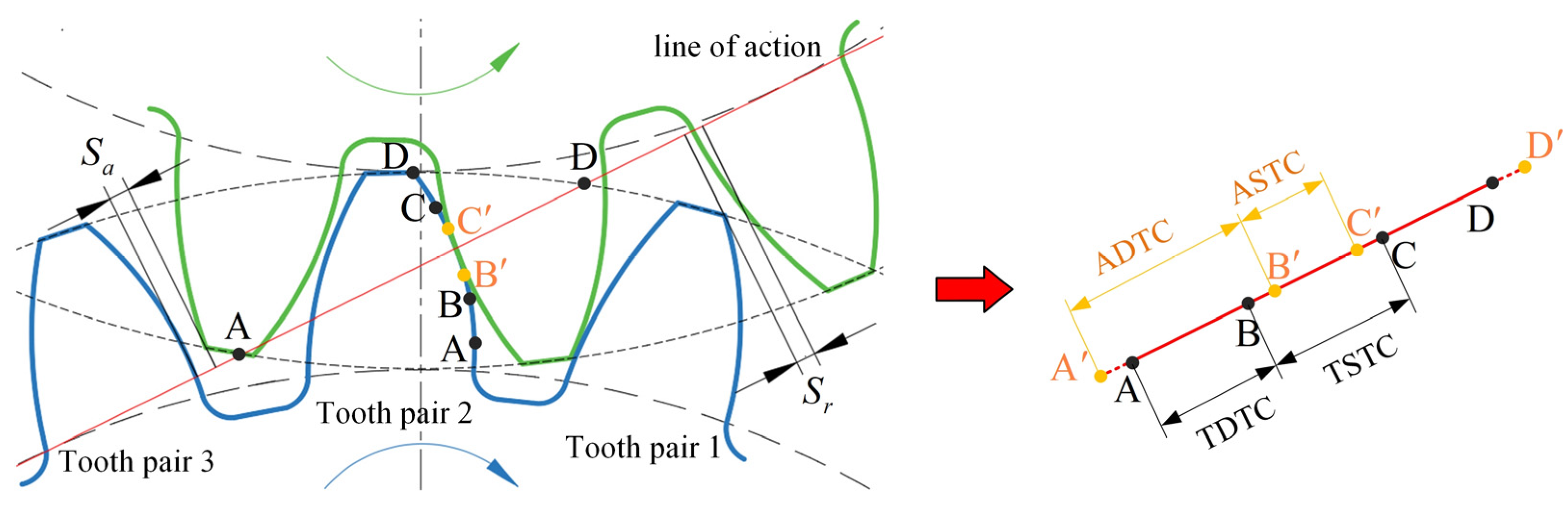

3.2. Extended Tooth Contact

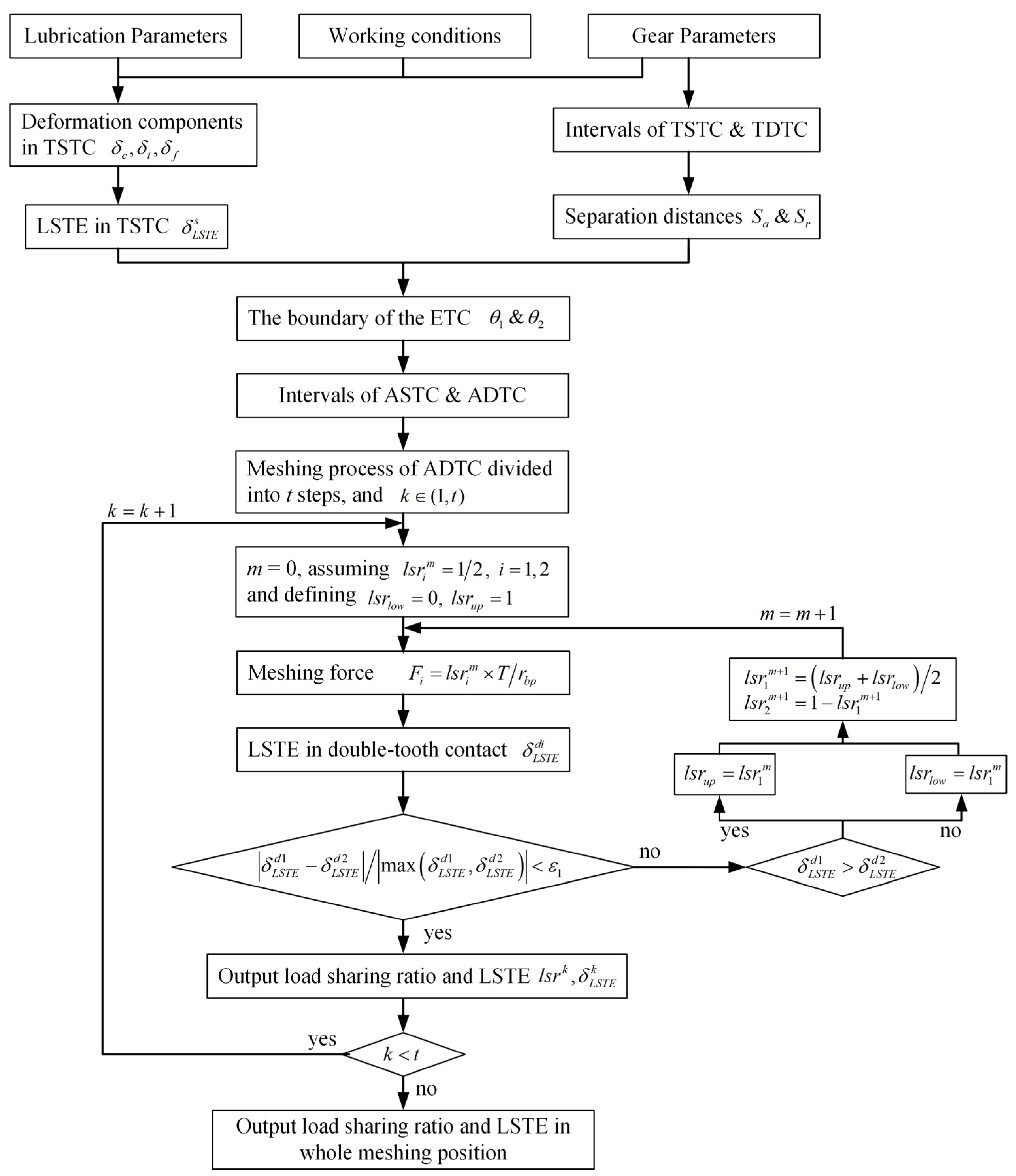

3.3. Load Distribution in Double Tooth Contact

3.4. Iterative Solution Procedure

4. Results and Discussion

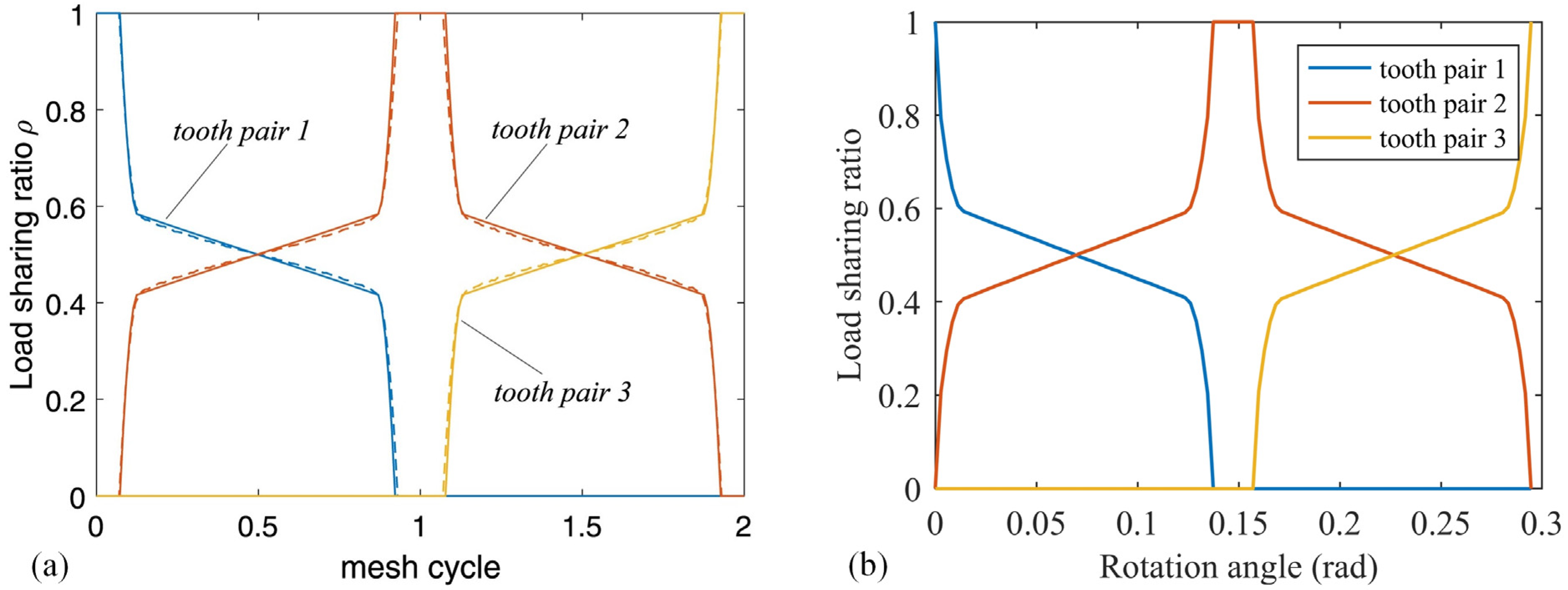

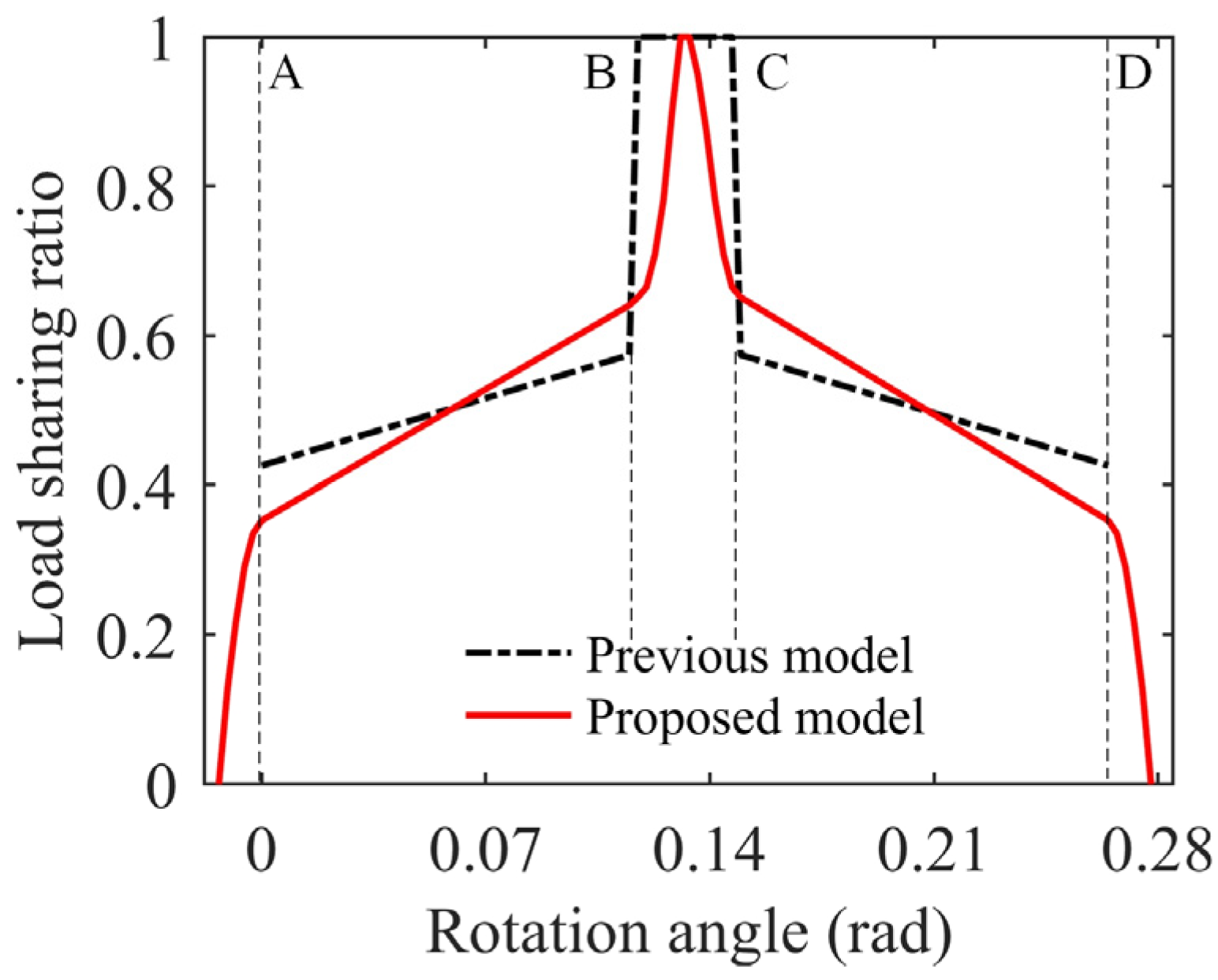

4.1. Model Verification

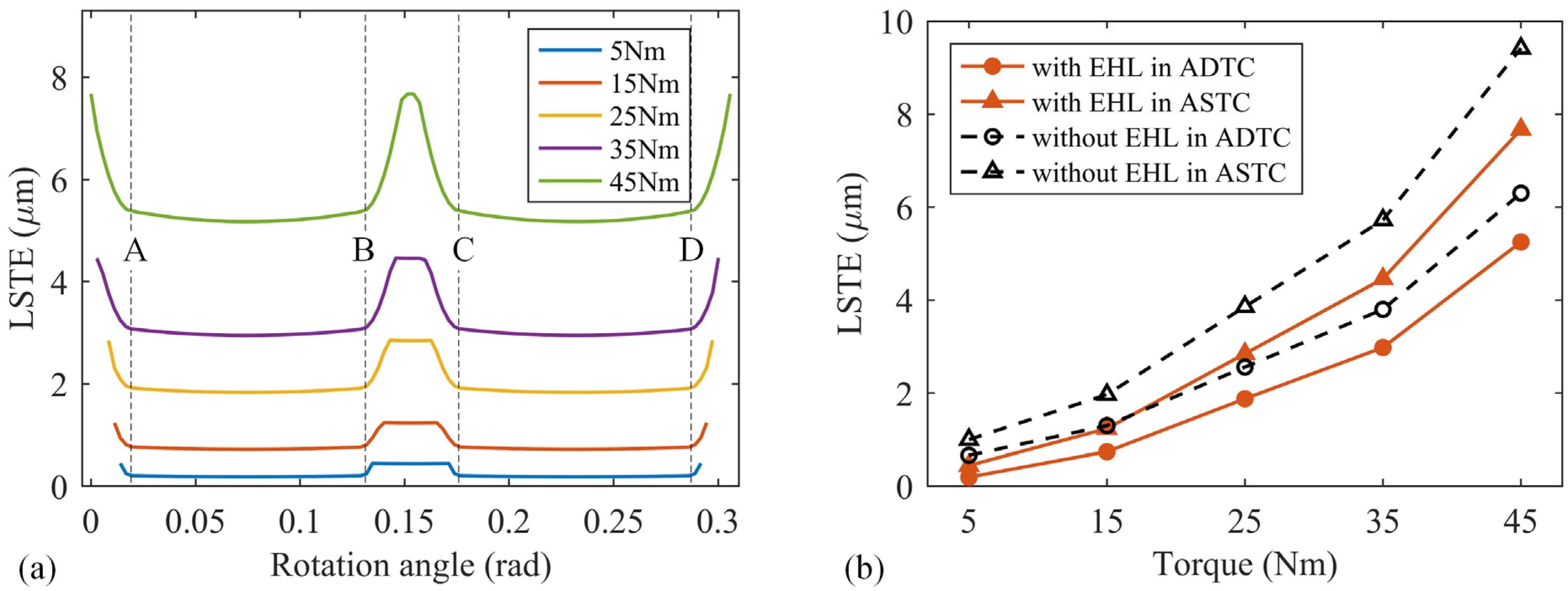

4.2. Effect of Torque on Load Distribution and LSTE

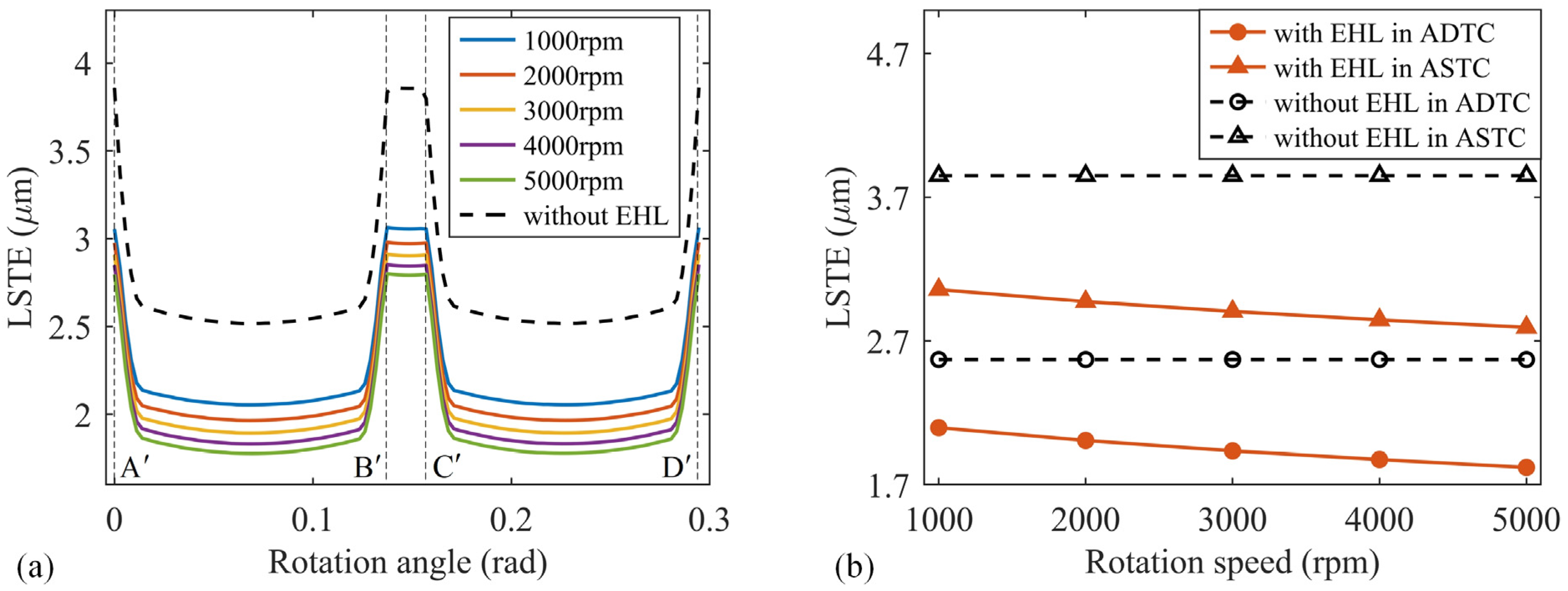

4.3. Effect of Rotation Speed on LSTE

4.4. Influence of EHL Load Distribution Model on Lubrication Behavior

5. Conclusions

- The load sharing ratio predicted by the proposed model for dry contact gear drive is consistent with the FEM simulation results presented in previous research, which proves the correctness and universality of the proposed analytical model;

- The load sharing ratio, LSTE and contact ratio of the gear pair vary significantly with the applied torque due to the effect of extended tooth contact. The influence of thermal EHL contact is more obvious for the lightly loaded case;

- With the changes in rotation speed, the LSTE shows evident variation due to the sensitivity of oil film thickness to speed. The influence of thermal EHL contact at high rotation speed is more pronounced;

- There is a significant coupling effect between the load distribution and thermal EHL solution. Therefore, the thermal EHL solution should be calculated iteratively in the load distribution model for the EHL contact gear pairs. Similarly, the accurate analysis of transient thermal EHL behavior for gear transmission requires a matching load distribution model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Gear Pair A | Gear Pair B | ||

|---|---|---|---|---|

| Pinion | Gear | Pinion | Gear | |

| Tooth number | 40 | 40 | 42 | 86 |

| Modules (mm) | 1 | 1 | 2.5 | 2.5 |

| Tooth width (mm) | 20 | 20 | 30 | 30 |

| Pressure angle (°) | 20 | 20 | 20 | 20 |

| Elastic modulus (GPa) | 206.8 | 206.8 | 210 | 210 |

| Poisson’s ratio | 0.3 | 0.3 | 0.3 | 0.3 |

| Tip clearance coefficient | 0.25 | 0.25 | 0.25 | 0.25 |

| Addendum coefficient | 1 | 1 | 1 | 1 |

| Torque on pinion (Nm) | 5–45 | - | 100 | - |

| Rotation speed of pinion (rpm) | 1000–5000 | - | 2000 | - |

| Characteristic shear stress (MPa) | 10 | 10 | ||

| Ambient density of lubricant (kg/m3) | 870 | 870 | ||

| Ambient viscosity of lubricant () | 0.03 | 0.06 | ||

| Ambient temperature (K) | 313 | 313 | ||

| Specific heat of lubricant (J/(kg K)) | 2000 | 2000 | ||

| Thermal conductivity of lubricant (W/(m·K)) | 0.14 | 0.14 | ||

References

- Dowson, D.; Higginson, G.R. A Numerical Solution to the Elasto-Hydrodynamic Problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- Larsson, R. Transient non-Newtonian elastohydrodynamic lubrication analysis of an involute spur gear. Wear 1997, 207, 67–73. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Li, H.Q.; Tong, J.W.; Yang, P.R. Transient thermoelastohydrodynamic lubrication analysis of an involute spur gear. Tribol. Int. 2004, 37, 773–782. [Google Scholar] [CrossRef]

- Zhou, C.; Xiao, Z.; Chen, S.; Han, X. Normal and tangential oil film stiffness of modified spur gear with non-Newtonian elastohydrodynamic lubrication. Tribol. Int. 2017, 109, 319–327. [Google Scholar] [CrossRef]

- Xiao, Z.; Li, Z.; Shi, X.; Zhou, C. Oil Film Damping Analysis in Non-Newtonian Transient Thermal Elastohydrodynamic Lubrication for Gear Transmission. J. Appl. Mech.-Trans. Asme 2018, 85, 035001. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhou, C.; Chen, S.; Li, Z. Effects of oil film stiffness and damping on spur gear dynamics. Nonlinear Dyn. 2019, 96, 145–159. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.J.; Zhu, C.C.; Parker, R.G. Effects of lubrication on gear performance: A review. Mech. Mach. Theory 2020, 145, 103701. [Google Scholar] [CrossRef]

- Zhou, W.G.; Zhu, R.P.; Liu, W.Z.; Shang, Y.W. An Improved Dynamic Transmission Error Model Applied on Coupling Analysis of Gear Dynamics and Elastohydrodynamic Lubrication. J. Tribol.-Trans. Asme 2022, 144, 051601. [Google Scholar] [CrossRef]

- Yang, X.K.; Tofighi-Niaki, E.; Zuo, M.J.; Tian, Z.G.; Safizadeh, M.S.; Qin, D.L. Analysis of spur gearbox dynamics considering tooth lubrication and tooth crack severity progression. Tribol. Int. 2023, 178, 108027. [Google Scholar] [CrossRef]

- Huangfu, Y.F.; Dong, X.J.; Chen, K.K.; Peng, Z.K. Coupling mechanism between systematic elastic deformation and gear surface damage. Int. J. Mech. Sci. 2023, 238, 107850. [Google Scholar] [CrossRef]

- Li, S.; Kahraman, A. A Transient Mixed Elastohydrodynamic Lubrication Model for Spur Gear Pairs. J. Tribol.-Trans. Asme 2010, 132, 011501. [Google Scholar] [CrossRef]

- Chen, M.; Xiong, X.; Zhuang, W. Design and Simulation of Meshing Performance of Modified Straight Bevel Gears. Metals 2021, 11, 33. [Google Scholar] [CrossRef]

- Sanchez, M.B.; Pleguezuelos, M.; Pedrero, J.I. Approximate equations for the meshing stiffness and the load sharing ratio of spur gears including hertzian effects. Mech. Mach. Theory 2017, 109, 231–249. [Google Scholar] [CrossRef]

- Marques, P.M.T.; Martins, R.C.; Seabra, J.H.O. Power loss and load distribution models including frictional effects for spur and helical gears. Mech. Mach. Theory 2016, 96, 1–25. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack. Mech. Mach. Theory 2013, 62, 63–74. [Google Scholar] [CrossRef]

- Xie, C.; Hua, L.; Han, X.; Lan, J.; Wan, X.; Xiong, X. Analytical formulas for gear body-induced tooth deflections of spur gears considering structure coupling effect. Int. J. Mech. Sci. 2018, 148, 174–190. [Google Scholar] [CrossRef]

- Xie, C.; Hua, L.; Lan, J.; Han, X.; Wan, X.; Xiong, X. Improved analytical models for mesh stiffness and load sharing ratio of spur gears considering structure coupling effect. Mech. Syst. Signal Process. 2018, 111, 331–347. [Google Scholar] [CrossRef]

- Lu, R.; Tang, W. Analytical calculation models for mesh stiffness and backlash of spur gears under temperature effects. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 4450–4462. [Google Scholar] [CrossRef]

- Tse, D.; Lin, H. Separation distance and static transmission error of involute spur gears. In Proceedings of the 28th Joint Propulsion Conference and Exhibit, Nashville, TN, USA, 6–8 July 1992; p. 3490. [Google Scholar]

- Ma, H.; Zeng, J.; Feng, R.; Pang, X.; Wen, B. An improved analytical method for mesh stiffness calculation of spur gears with tip relief. Mech. Mach. Theory 2016, 98, 64–80. [Google Scholar] [CrossRef]

- Chen, Z.; Ji, P. Study on wear in spur gears based on an improved load distribution model considering the effects of corner contact. Eng. Fail. Anal. 2020, 115, 104605. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Q.; Gui, L.; Fan, Z. Load distribution analysis considering corner contact effects to predict the mechanical efficiency of spur gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7546–7559. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, Y.; He, Z.; Xiao, Y.; Zhang, X. On the extended tooth contact and nonlinear dynamics for spur gears-An analytical model. Mech. Mach. Theory 2022, 175, 104958. [Google Scholar] [CrossRef]

- Roelands, C.J.A.; Vlugter, J.C.; Waterman, H.I. The Viscosity-Temperature-Pressure Relationship of Lubricating Oils and Its Correlation with Chemical Constitution. Asme J. Basic Eng. 1963, 85, 601. [Google Scholar] [CrossRef]

- Yang, P.; Wen, S. A Generalized Reynolds Equation for Non-Newtonian Thermal Elastohydrodynamic Lubrication. J. Tribol.-Trans. Asme 1990, 112, 631. [Google Scholar] [CrossRef]

- Qin, W.; Chao, J.; Duan, L. Study on stiffness of elastohydrodynamic line contact. Mech. Mach. Theory 2015, 86, 36–47. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R. Elastohydrodynamic Lubrication: The Fundamentals of Roller and Gear Lubrication; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Tian, X. Dynamic Simulation for System Response of Gearbox Including Localized Gear Faults; University of Alberta: Edmonton, AB, Canada, 2004. [Google Scholar]

- Sainsot, P.; Velex, P.; Duverger, O. Contribution of gear body to tooth deflections—A new bidimensional analytical formula. J. Mech. Des. 2004, 126, 748–752. [Google Scholar] [CrossRef]

- Xie, C.; Shu, X. A new mesh stiffness model for modified spur gears with coupling tooth and body flexibility effects. Appl. Math. Model. 2021, 91, 1194–1210. [Google Scholar] [CrossRef]

- Lin, H.; Wang, J.; Oswald, F.; Coy, J. Effect of extended tooth contact on the modeling of spur gear transmissions. In Proceedings of the 29th Joint Propulsion Conference and Exhibit, Monterey, CA, USA, 28–30 June 1993. [Google Scholar]

- Ma, H.; Pang, X.; Feng, R.; Zeng, J.; Wen, B. Improved time-varying mesh stiffness model of cracked spur gears. Eng. Fail. Anal. 2015, 55, 271–287. [Google Scholar] [CrossRef]

- Zhou, C.; Xiao, Z. Stiffness and damping models for the oil film in line contact elastohydrodynamic lubrication and applications in the gear drive. Appl. Math. Model. 2018, 61, 634–649. [Google Scholar] [CrossRef]

- Pei, J.; Han, X.; Tao, Y. An improved stiffness model for line contact elastohydrodynamic lubrication and its application in gear pairs. Ind. Lubr. Tribol. 2020, 72, 703–708. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, C.; Liu, H.; Gu, Z. Mesh stiffness and nonlinear dynamic response of a spur gear pair considering tribo-dynamic effect. Mech. Mach. Theory 2020, 153, 103989. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, R.; Tang, W.; Huang, Q.; Xie, J. An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication. Lubricants 2023, 11, 177. https://doi.org/10.3390/lubricants11040177

Lu R, Tang W, Huang Q, Xie J. An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication. Lubricants. 2023; 11(4):177. https://doi.org/10.3390/lubricants11040177

Chicago/Turabian StyleLu, Ruxin, Wencheng Tang, Qi Huang, and Junjie Xie. 2023. "An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication" Lubricants 11, no. 4: 177. https://doi.org/10.3390/lubricants11040177

APA StyleLu, R., Tang, W., Huang, Q., & Xie, J. (2023). An Improved Load Distribution Model for Gear Transmission in Thermal Elastohydrodynamic Lubrication. Lubricants, 11(4), 177. https://doi.org/10.3390/lubricants11040177