Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites

Abstract

1. Introduction

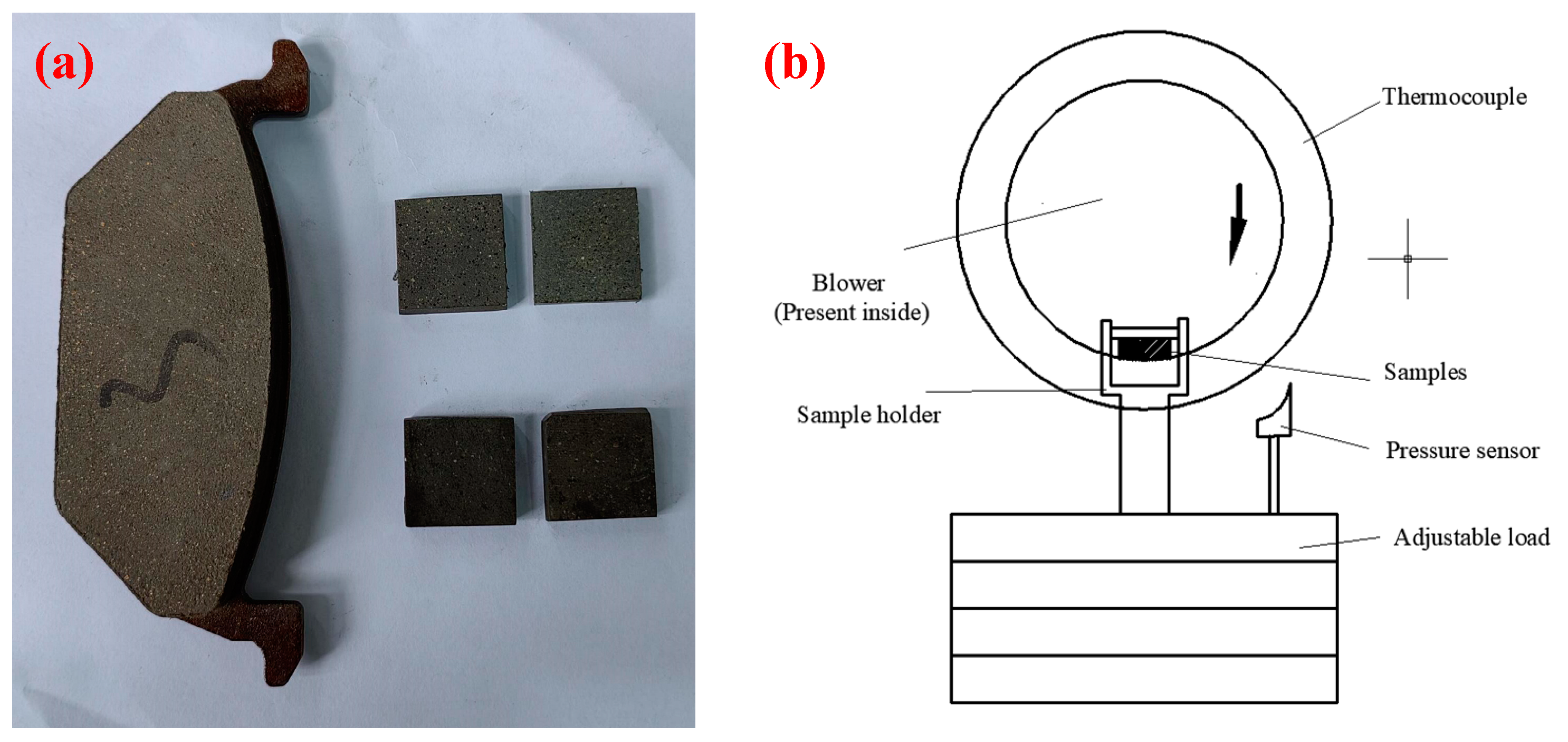

2. Experimental Details

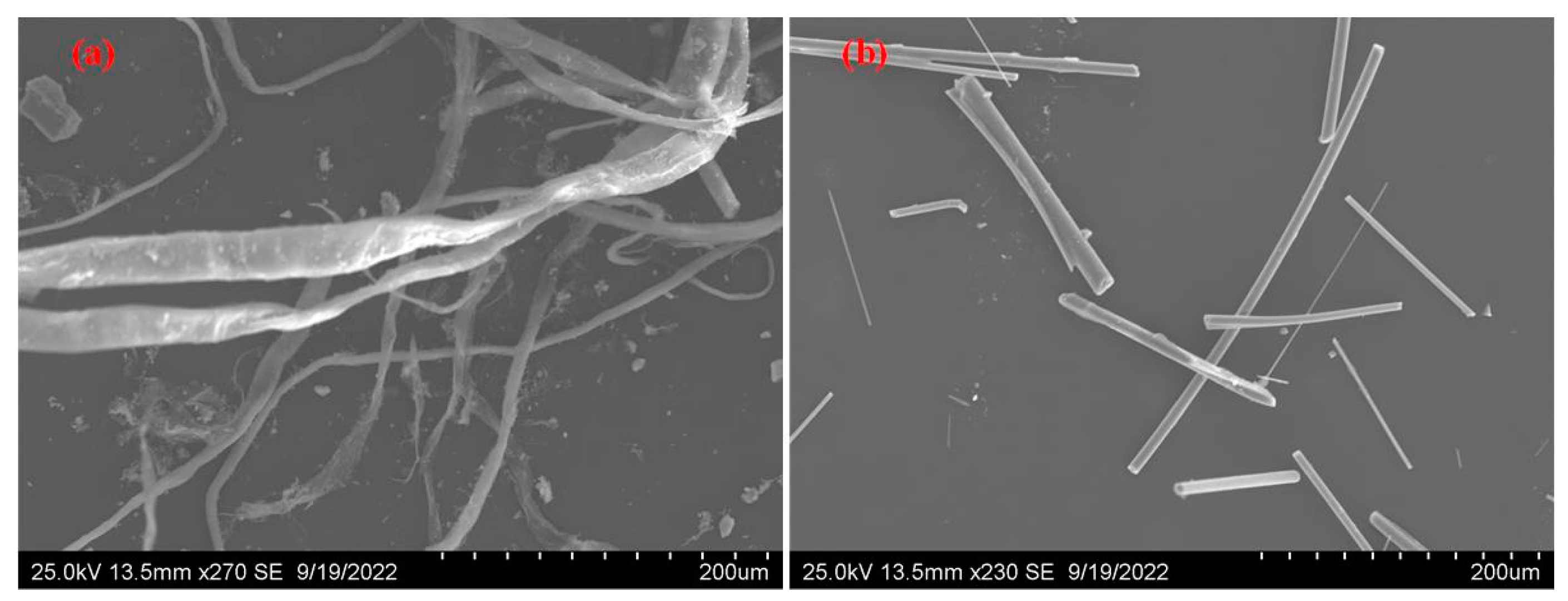

2.1. Materials and Composite Preparation

2.2. Characterization of Physical and Mechanical Properties

2.3. Friction and Wear Testing

3. Results and Discussion

3.1. Physical and Mechanical Characterization

3.2. Friction and Wear Properties during Fade–Recovery Cycles

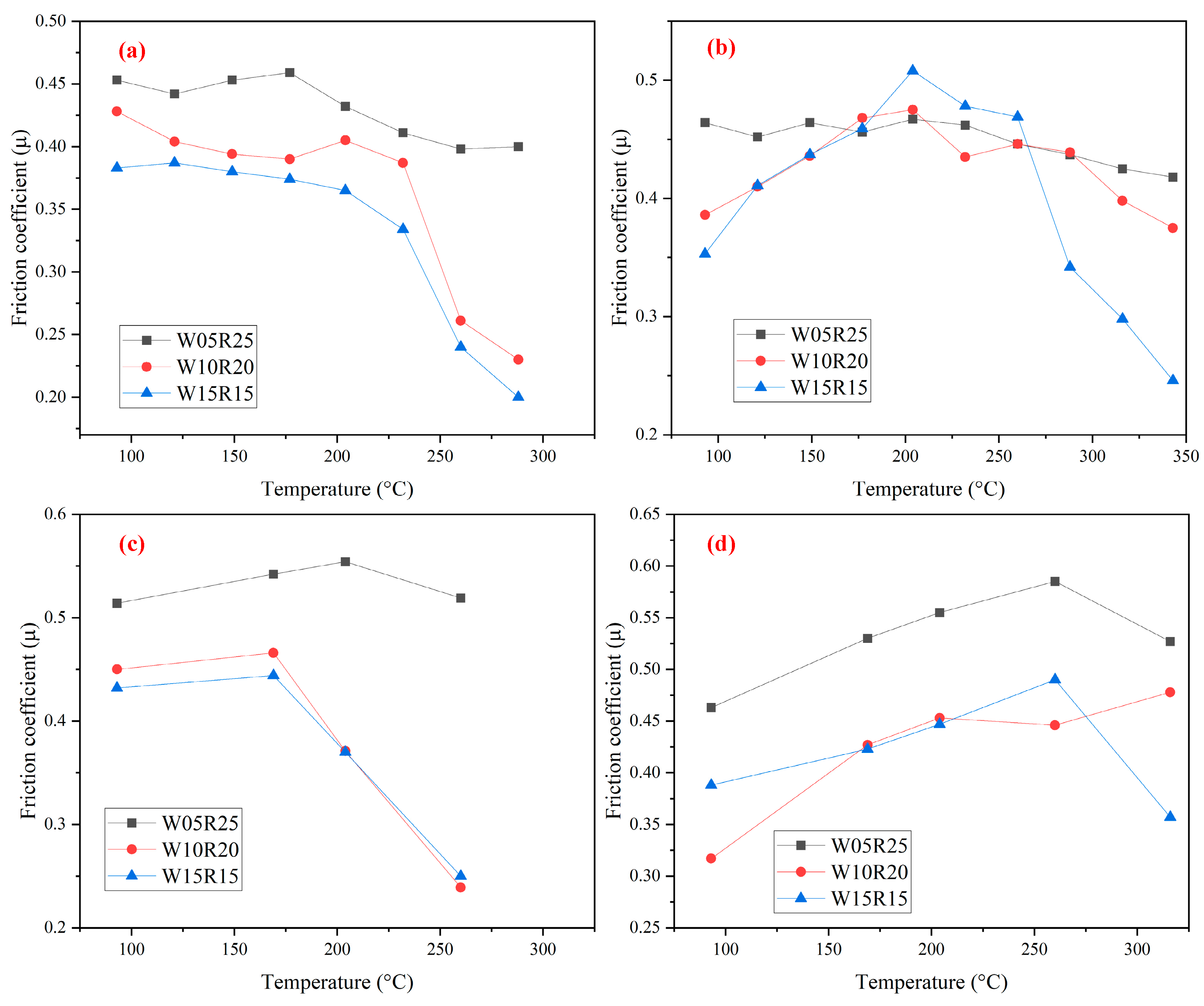

3.2.1. Friction Performance of the Composites

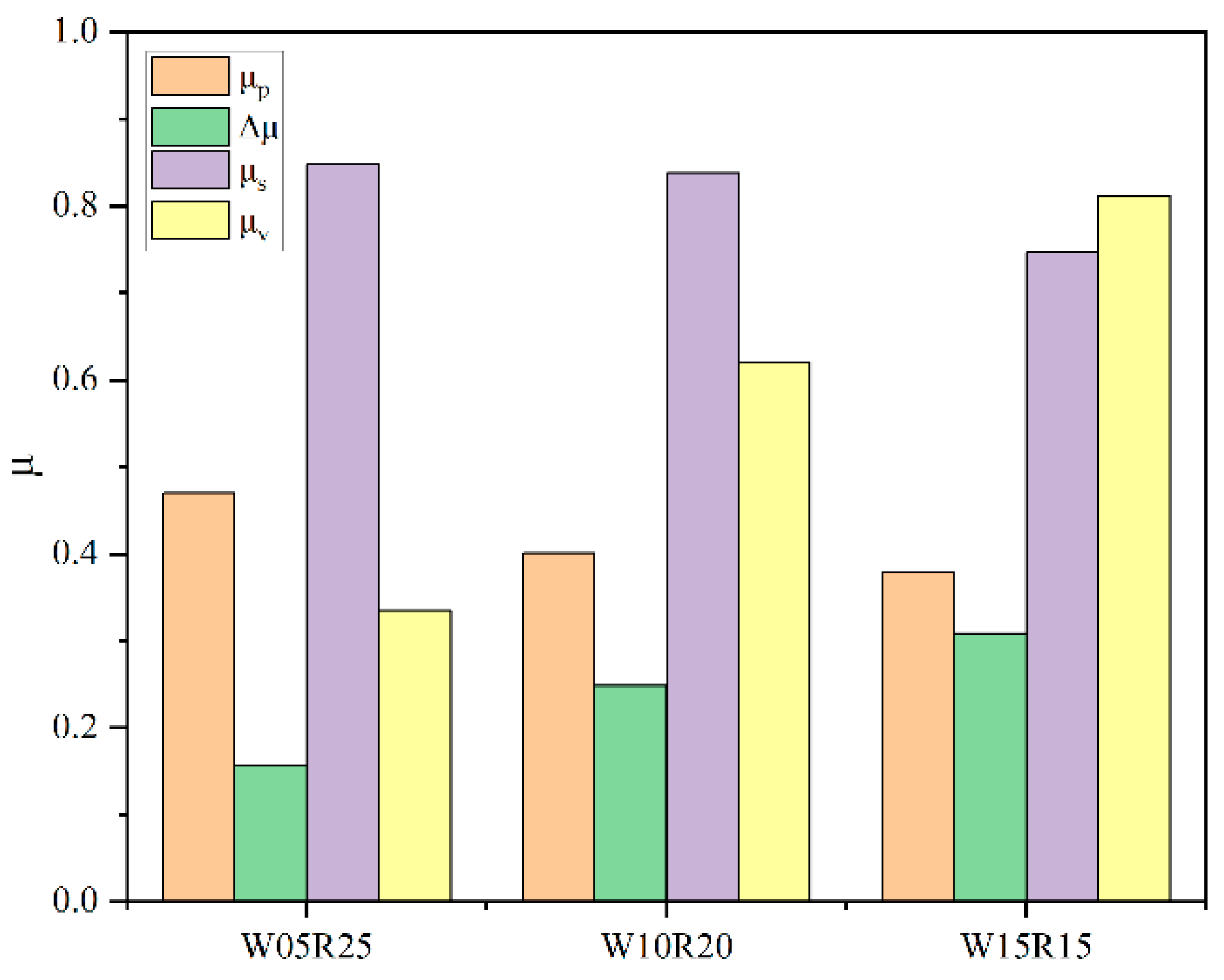

3.2.2. , Δμ, , Performance of the Composites

3.2.3. Fade and Recovery Performance of the Composites

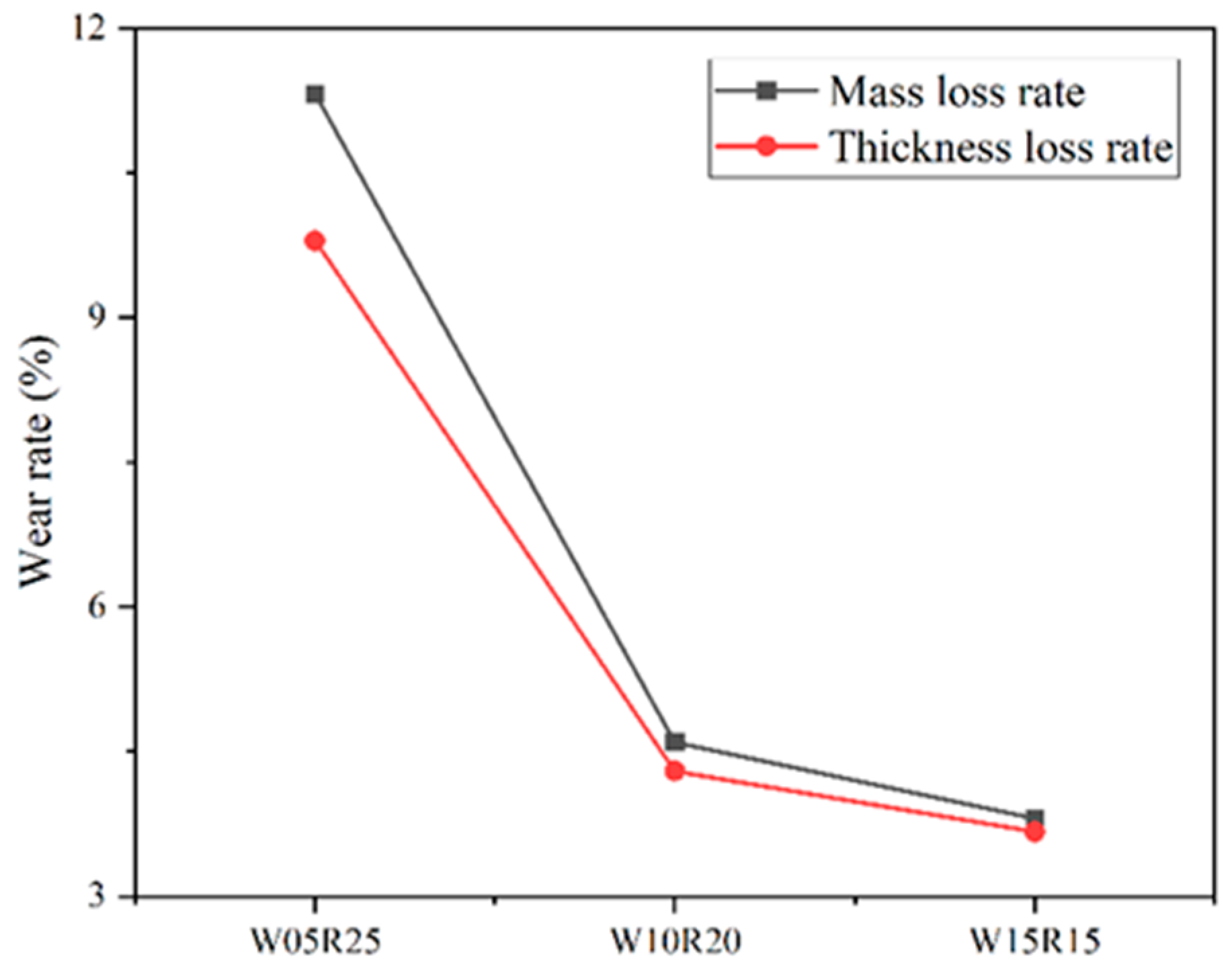

3.2.4. Wear Performance of the Composites

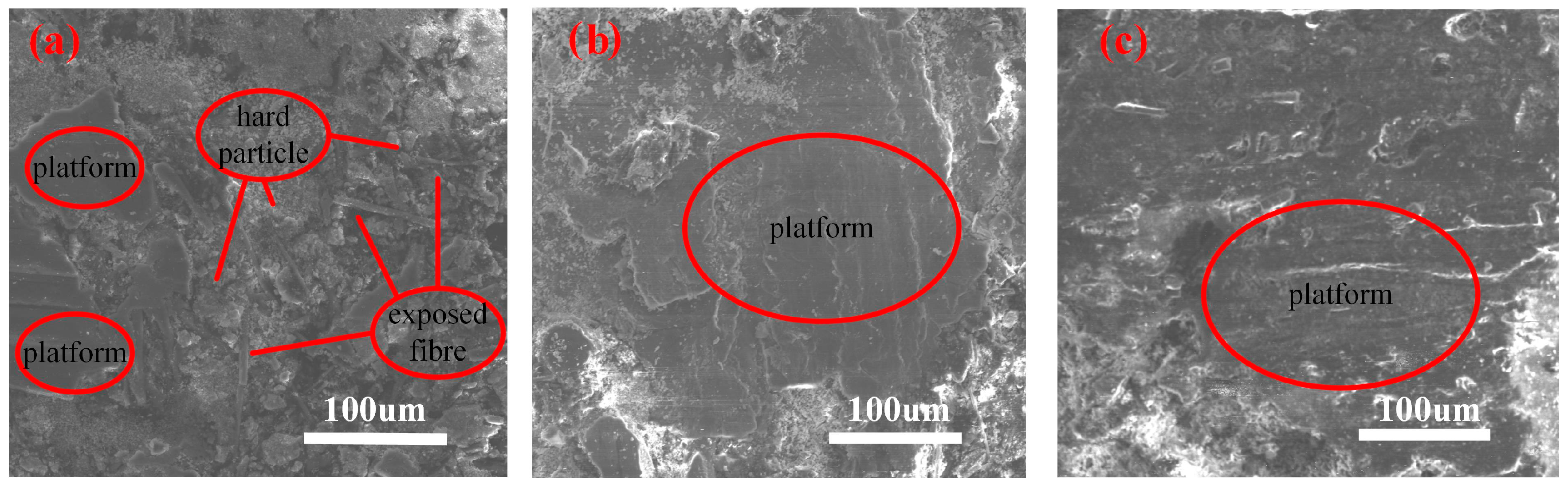

3.2.5. Wear Mechanism

4. Conclusions

- (1)

- Density, hardness, and shear strength are higher in samples that contain higher contents of rockwool fiber than wood fiber. Water absorption increases with the increase in wood fiber content.

- (2)

- Rockwool fiber can improve the coefficient of friction, reduce fluctuation, and enhance friction stability; wood fiber has a significant impact on wear resistance. Meanwhile, the fade performance worsens with the addition of a high content of wood fiber.

- (3)

- The worn surface of the W05R25 sample showed typical wear characteristics (exposed fibers, small discontinuous platforms, wear debris, and peeling pits); however, in high-content wood fiber samples, large continuous contact platforms appeared.

- (4)

- The brake friction material with 5% wood fiber and 25% rockwool fiber has the highest stable friction performance (0.847), the highest %R (112.3), the lowest %F (15.3), and the lowest friction variation performance (0.344), which is considered to be the optimal formulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, N.; Yin, Z. The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites. Lubricants 2022, 10, 220. [Google Scholar] [CrossRef]

- Amirjan, M. Microstructure, wear and friction behavior of nanocomposite materials with natural ingredients. Tribol. Int. 2019, 131, 184–190. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Shojaei, A.; Dordanihaghighi, S.; Jafarpour, E.; Mohammadi, S.; Arjmand, M. Effects of hybrid carbon-aramid fiber on performance of non-asbestos organic brake friction composites. Wear 2020, 452–453, 203280. [Google Scholar] [CrossRef]

- Aranganathan, N.; Mahale, V.; Bijwe, J. Effects of aramid fiber concentration on the friction and wear characteristics of non-asbestos organic friction composites using standardized braking tests. Wear 2016, 354-355, 69–77. [Google Scholar] [CrossRef]

- Kumar, N.; Mehta, V.; Kumar, S.; Grewal, J.S.; Ali, S. Bamboo natural fiber and PAN fiber used as a reinforced brake friction material: Developed asbestos-free brake pads. Polym. Compos. 2022, 43, 2888–2895. [Google Scholar] [CrossRef]

- Irawan, A.P.; Fitriyana, D.F.; Tezara, C.; Siregar, J.P.; Laksmidewi, D.; Baskara, G.D.; Abdullah, M.Z.; Junid, R.; Hadi, A.E.; Hamdan, M.H.M.; et al. Overview of the Important Factors Influencing the Performance of Eco-Friendly Brake Pads. Polymers 2022, 14, 1180. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S.; Kumar, S.; Ali, S.; Kumar, N. A novel Himachal’s Bagar (Sabai) grass fiber used as a brake friction material in brake polymer composite and compared to standard brake friction material. Polym. Compos. 2022, 43, 215–224. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, S.; Grewal, J.S.; Mehta, V.; Ali, S. Comparative study of Abaca fiber and Kevlar fibers based brake friction composites. Polym. Compos. 2021, 43, 730–740. [Google Scholar] [CrossRef]

- Monreal, P.; Oroz, J.; Gutiérrez, K.; Ambroj, I.C. Natural Latxa Sheep Wool as an Environmentally Friendly Substitute for Specific Organic Fibers in Railway Friction Materials: A Preliminary Approach. Tribol. Trans. 2021, 64, 851–863. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, A.; Patnaik, A.; Chauhan, R.; Ali, S. Influence of wollastonite shape and amount on tribo-performance of non-asbestos organic brake friction composites. Wear 2017, 386–387, 157–164. [Google Scholar] [CrossRef]

- Cui, G.; Liu, H.; Shi, R.; Li, S.; Han, J. Dry-braking properties of resin based friction materials by different fibres. Lubr. Sci. 2019, 32, 21–29. [Google Scholar] [CrossRef]

- Hua, Y.; Li, F.; Hu, N.; Fu, S.-Y. Frictional characteristics of graphene oxide-modified continuous glass fiber reinforced epoxy composite. Compos. Sci. Technol. 2022, 223. [Google Scholar] [CrossRef]

- Struchkova, T.S.; Vasilev, A.P.; Okhlopkova, A.A.; Danilova, S.N.; Alekseev, A.G. Mechanical and Tribological Properties of Polytetrafluoroethylene Composites Modified by Carbon Fibers and Zeolite. Lubricants 2021, 10, 4. [Google Scholar] [CrossRef]

- Monreal-Pérez, P.; González, J.; Iraizoz, A.; Bilbao, U.; Clavería, I. Effect of the steel fiber length on the friction performance and wear mechanism of railway brake shoes. Tribol. Int. 2022, 172. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.; Basch, R.; Fash, J. The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Hirayama, T.; Khalafallah, D. An investigation into the tribological properties of wood flour reinforced poly-propylene composites. Mater. Res. Express 2019, 7, 015313. [Google Scholar] [CrossRef]

- Mazzanti, V.; Fortini, A.; Malagutti, L.; Ronconi, G.; Mollica, F. Tribological Behavior of a Rubber-Toughened Wood Polymer Composite. Polymers 2021, 13, 2055. [Google Scholar] [CrossRef]

- Du, G.; Liu, A. The flexural and tribological properties of UHMWPE composite filled with plasma surface-treated wood fibers. Surf. Interface Anal. 2017, 49, 1142–1146. [Google Scholar] [CrossRef]

- Amirthan, G.; Balasubramanian, M. Reciprocating sliding wear studies on Si/SiC ceramic composites. Wear 2011, 271, 1039–1049. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Lv, X.; Yu, J.; Zhuang, J.; Tong, J. Mineral fibre reinforced friction composites, Effect of Rockwoo fibre on mechanical and tribological behavior. Mater. Res. Express 2018, 5, 095308. [Google Scholar] [CrossRef]

- Stephen Bernard, S.; Jayakumari, L.S. Effect of rockwool and steel fiber on the friction performance of brake lining materials. Matéria 2016, 21, 656–665. [Google Scholar] [CrossRef]

- Makni, F.; Cristol, A.-L.; Desplanques, Y.; Elleuch, R. Friction Performance Improvement of Phenolic/Rockwool Fibre Composites: Influence of Fibre Morphology and Distribution. Materials 2022, 15, 5381. [Google Scholar] [CrossRef] [PubMed]

- Aranganathan, N.; Bijwe, J. Development of copper-free eco-friendly brake-friction material using novel ingredients. Wear 2016, 352–353, 79–91. [Google Scholar] [CrossRef]

- Bagheri Kazem Abadi, S.; Khavandi, A.; Kharazi, Y. Effects of mixing the steel and carbon fibers on the friction and wear properties of a PMC friction material. Appl. Compos. Mater. 2010, 17, 151–158. [Google Scholar] [CrossRef]

- Kumar, S.; Mer, K.K.S.; Gangil, B.; Patel, V.K. Synergy of rice-husk filler on physico-mechanical and tribological properties of hybrid Bauhinia-vahlii/sisal fiber reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 2070–2082. [Google Scholar] [CrossRef]

- Song, W.; Park, J.; Choi, J.; Lee, J.J.; Jang, H. Effects of reinforcing fibers on airborne particle emissions from brake pads. Wear 2021, 484–485, 203996. [Google Scholar] [CrossRef]

- Öztürk, B.; Arslan, F.; Öztürk, S. Hot wear properties of ceramic and basalt fiber reinforced hybrid friction materials. Tribol. Int. 2007, 40, 37–48. [Google Scholar] [CrossRef]

- Bismarck, A.; Aranberri-Askargorta, I.; Springer, J.; Lampke, T.; Wielage, B.; Stamboulis, A.; Shenderovich, I.; Limbach, H.-H. Surface characterization of flax, hemp and cellulose fibers; Surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Wang, L.; Tong, J.; Zhuang, J.; Jia, H. Performance assessment of hybrid fibers reinforced friction composites under dry sliding conditions. Tribol. Int. 2018, 119, 262–269. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.; Retegi, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of short flax fibre bundle/polypropylene composites: Influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos. Sci. Technol. 2005, 65, 1582–1592. [Google Scholar] [CrossRef]

- Xin, X.; Xu, C.G.; Qing, L.F. Friction properties of sisal fibre reinforced resin brake composites. Wear 2007, 262, 736–741. [Google Scholar] [CrossRef]

- Qi, S.; Fu, Z.; Yun, R.; Jiang, S.; Zheng, X.; Lu, Y.; Matejka, V.; Kukutschova, J.; Peknikova, V.; Prikasky, M. Effects of walnut shells on friction and wear performance of eco-friendly brake friction composites. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 511–520. [Google Scholar] [CrossRef]

- Ali, S.; Kumar, N.; Grewal, J.S.G.; Thakur, V.; Chau, K.W.; Kumar, M. Coconut waste fiber used as brake pad reinforcement polymer composite and compared to standard Kevlar-based brake pads to produce an asbestos free brake friction material. Polym. Compos. 2022, 43, 1518–1525. [Google Scholar] [CrossRef]

- Fu, Z.; Suo, B.; Yun, R.; Lu, Y.; Wang, H.; Qi, S.; Jiang, S.; Lu, Y.; Matejka, V. Development of eco-friendly brake friction composites containing flax fibers. J. Reinf. Plast. Compos. 2012, 31, 681–689. [Google Scholar] [CrossRef]

- Fu, Z.; Yun, R.; Qi, S.; Jiang, S.; Lu, Y. Friction performance and extension evaluation of jute fiberreinforced eco-friendly friction materials. J. Beijing Univ. Chem. Technol. 2012, 39, 55–59. [Google Scholar]

- Matějka, V.; Fu, Z.; Kukutschová, J.; Qi, S.; Jiang, S.; Zhang, X.; Yun, R.; Vaculík, M.; Heliová, M.; Lu, Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013, 51, 847–853. [Google Scholar] [CrossRef]

- Yap, Z.S.; Khalid, N.H.A.; Haron, Z.; Mohamed, A.; Tahir, M.M.; Hasyim, S.; Saggaff, A. Waste Mineral Wool and Its Opportunities—A Review. Materials 2021, 14, 5777. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Berglund, L.A. Structural and ecofriendly holocellulose materials from wood, Microscale fibers and nanoscale fibrils. Adv. Mater. 2021, 33, 2001118. [Google Scholar] [CrossRef] [PubMed]

- Chin, C.W.; Yousif, B.F. Potential of kenaf fibres as reinforcement for tribological applications. Wear 2009, 267, 1550–1557. [Google Scholar] [CrossRef]

- Gehlen, G.S.; Neis, P.D.; Barros, L.Y.; Poletto, J.C.; Ferreira, N.F.; Amico, S.C. Tribological performance of eco-friendly friction materials with rice husk. Wear 2022, 500, 204374. [Google Scholar] [CrossRef]

| Ingredients (%) | Functions | Samples | ||

|---|---|---|---|---|

| W05R25 | W10R20 | W15R15 | ||

| Phenolic resin | Binder | 10 | 10 | 10 |

| Rubber | 3 | 3 | 3 | |

| Wood fiber | Reinforced fiber | 5 | 10 | 15 |

| Rockwool | 25 | 20 | 15 | |

| Alumina | Abrasive | 5 | 5 | 5 |

| Graphite | Lubricant | 6 | 6 | 6 |

| Vermiculite | Filler | 5 | 5 | 5 |

| Barite | 41 | 41 | 41 | |

| Cycle | Speed (rpm) | Load (N) | Time | Temperature (°C) | Applications | Heater | |||

|---|---|---|---|---|---|---|---|---|---|

| On | Off | Min | Max | Change | |||||

| Burnish | 312 | 440 | 20 min | - | - | 93 | 1 | ||

| Baseline | 417 | 667 | 10 s | - | 82 | 104 | 20 | ||

| Fade-I | 417 | 667 | 10 min | - | 93 | 288 | 28 | 1 | on |

| Recovery-I | 417 | 667 | 10 s | - | 260 | 93 | 56 | 1 | |

| Wear | 417 | 667 | 20 s | 10 s | 193 | 204 | 100 | ||

| Fade-II | 417 | 667 | 10 min | - | 93 | 343 | 28 | 1 | on |

| Recovery-II | 417 | 667 | 10 s | - | 316 | 93 | 56 | 1 | |

| Baseline | 417 | 667 | 10 s | 20 s | 82 | 104 | 20 | ||

| Samples | Density (g/cm3) | Water Absorption (%) | Hardness (HRR) | Shear Strength (MPa) |

|---|---|---|---|---|

| W05R25 | 2.31 | 0.58% | 88.3 | 7.36 |

| W10R20 | 2.27 | 1.02% | 83.2 | 7.21 |

| W15R15 | 2.19 | 1.98% | 77.3 | 6.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Liu, H.; Huang, F. Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites. Lubricants 2023, 11, 27. https://doi.org/10.3390/lubricants11010027

Wang N, Liu H, Huang F. Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites. Lubricants. 2023; 11(1):27. https://doi.org/10.3390/lubricants11010027

Chicago/Turabian StyleWang, Nan, Hao Liu, and Fei Huang. 2023. "Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites" Lubricants 11, no. 1: 27. https://doi.org/10.3390/lubricants11010027

APA StyleWang, N., Liu, H., & Huang, F. (2023). Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites. Lubricants, 11(1), 27. https://doi.org/10.3390/lubricants11010027