Abstract

Vegetable oils have been used as metalworking fluids (MWFs) for many years, particularly in small-scale metalworking operations and in industries where environmental regulations are strict. Before the development of modern MWFs, vegetable oils were one of the most common lubricants used for metalworking tools. The use of vegetable oils can be traced back to ancient civilizations such as Egypt, Greece, and Rome, where olive oil was commonly used to lubricate metal tools and weapons. Today, vegetable oils are used as MWFs in a variety of applications. They are often combined with additives or nanoparticles to enhance their performance, such as improving the lubricity, cooling properties, and stability of the oil, as well as reducing friction and wear on the cutting tool. Additives, such as antioxidants, anti-wear agents, and extreme pressure (EP) additives, can be used to improve the performance of vegetable oils as cutting fluids. Compared to standard MWFs, vegetable oils are generally more biodegradable and environmentally friendly, and can be more cost-effective. However, MWFs may offer superior performance in certain areas, such as lubrication and cooling. Ultimately, the choice of MWFs will depend on the specific requirements of the metalworking operation and the balance between performance, cost, and environmental considerations. As the demand for sustainability and environmental responsibility continues, the use of vegetable oils as MWFs is likely to become even more popular in the future. Overall, vegetable oils offer a viable and potentially attractive alternative to standard MWFs in certain applications. This review highlights both conventional and most recent advances in vegetal oils frequently used as lubricant fluids in manufacturing processes.

1. Introduction

Lubricants play a crucial role in various industrial processes, including metalworking and machining. However, the widespread use of petroleum-based lubricants has been linked to negative environmental impacts, including groundwater contamination and air pollution. Metalworking fluids (MWFs) are a type of lubricant that are widely used in machining operations, and the majority of these fluids are mineral oil-based. Despite their benefits in enhancing productivity and manufacturing quality, MWFs pose significant environmental and health hazards, therefore, researchers and tribologists are exploring alternatives to petroleum-based MWFs, including vegetable-based lubricants [1].

Vegetable-based lubricants are gaining attention as an ecofriendly alternative to petroleum-based lubricants due to their renewability, biodegradability, and lower toxicity [2]. Many researchers are exploring the use of various vegetable oils as potential candidates for metalworking fluids. For instance, Pereira et al., investigated the use of canola oil-based cutting fluids with the addition of alumina nanoparticles for machining stainless steel samples. Their study found that the addition of nanoparticles improved the lubricity of the canola oil-based fluid, resulting in reduced tool wear and improved surface finish [3].

Another study from Marichelvam et al., investigated the use of soybean oil-based cutting fluid with an environmentally friendly additive for machining of aluminum alloys. The study found that the soybean oil-based fluid with the additive provided better cooling and lubrication compared to conventional mineral oil-based fluids, resulting in improved surface finish and reduced tool wear [4].

Moreover, researchers have explored the use of waste vegetable oil as a potential feedstock for bio-based lubricants. Kurre and Yadav examined the potential of waste cooking oil as a feedstock for the production of bio-based lubricants, and they discovered that the waste cooking oil-based lubricant showed good lubrication properties and could be a potential candidate for industrial applications [5].

In addition to vegetable oils, researchers have also explored the use of bio-based esters as potential candidates for metalworking fluids. A study published in 2018 investigated the use of bio-based esters derived from renewable sources such as palm oil and rapeseed oil as metalworking fluids, founding out that the bio-based esters showed good lubrication properties and had the potential to replace petroleum-based MWFs [6].

The development of ecofriendly alternatives to petroleum and mineral-based lubricants is an area of active research. Vegetable-based lubricants, including those derived from waste vegetable oil and bio-based esters, have shown promise as potential candidates for metalworking fluids. Future research in this area could lead to the development of more sustainable and environmentally friendly lubricants for industrial applications.

One of the main openings in the available research about vegetable oils used for metalworking fluids is the lack of a comprehensive understanding of the underlying mechanisms of lubrication, which makes it difficult to predict and optimize the performance of vegetable oil-based lubricants. While there has been a significant amount of research done on the tribological properties of vegetable oils and their derivatives, there are still many unanswered questions about the specific mechanisms involved in the lubrication process. In addition, there is a need for more research on the long-term durability and stability of vegetable oil-based lubricants under a variety of operating conditions, including high temperatures and pressures. This will be critical in order to develop lubricants that can compete with petroleum-based products in terms of performance and durability. Finally, there is also a need for more research on the environmental impacts of vegetable oil-based lubricants, including their biodegradability and toxicity to aquatic organisms. Overall, there is still much work to be done in order to fully realize the potential of vegetable oils as a sustainable and environmentally-friendly alternative to petroleum-based lubricants.

2. Lubricants

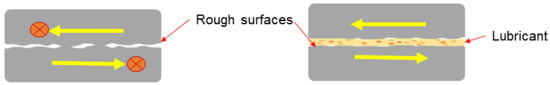

A lubricant is a substance that is used to reduce friction and wear between two sliding surfaces, playing an essential role in maintaining the health and longevity of machines and equipments [7]. It forms a thin layer of protection between the two surfaces, reducing friction and wear (Figure 1), protecting against corrosion and rust, and helping to dissipate heat. Lubricants are used in a wide variety of applications, including automotive engines, hydraulic systems, industrial machinery, and marine equipment [8].

Figure 1.

Schematic diagram representing the role of lubricants in reducing friction and wear. The image on the left demonstrates two rough surfaces with high friction, creating sliding resistance. The image on the right demonstrates how adding lubricant creates a thin film that produces more accessible sliding conditions [7].

There are several different types of lubricants, each one with unique properties and applications. The most common types of lubricants include mineral oil, synthetic oil, and grease. Mineral oil is a petroleum-based lubricant that is commonly used in engines, hydraulic systems, and gearboxes. It is relatively inexpensive and widely available. However, it can break down over time and can be susceptible to oxidation [9]. Synthetic oil is made from chemical compounds and is designed to be more stable and longer-lasting than mineral oil. It can perform well in extreme temperatures and high-pressure applications [10]. Synthetic oil is commonly used in industrial equipment, turbines, and aircraft engines. Grease is a semi-solid lubricant that is composed of a base oil and a thickening agent. It is used in areas where a liquid lubricant may not be practical, such as in bearings or open gears. Grease is often used in automotive and marine applications [11]. Other types of lubricants include biodegradable lubricants, which are designed to be environmentally friendly, and food-grade lubricants, which are used in the food industry.

Lubricants have several properties that must be considered when selecting the right lubricant for a particular application, that include viscosity, pour point, flash point, and oxidation stability [12]. Viscosity is the measure of a lubricant’s resistance to flow. A high viscosity lubricant will be thicker and provide more protection against wear and tear. However, it may also cause more friction and generate more heat. A low viscosity lubricant will flow more easily and generate less heat, but it may not provide as much protection against wear [13]. Pour point is the temperature at which a lubricant will begin to solidify. A high pour point lubricant may not be suitable for colder temperatures, as it may become too thick and fail to provide adequate lubrication [14]. Flash point is the temperature at which a lubricant will ignite when exposed to a flame. This property is important for safety considerations and can help prevent accidents [15]. Oxidation stability is the lubricant’s ability to resist chemical reactions with oxygen over time. A lubricant with good oxidation stability will last longer and protect against wear and tear better [16].

A wide variety of lubricants are available, each with its own unique properties and applications. Selecting the right lubricant for a particular application is essential to ensure the longevity and efficiency of an equipment. Several factors should be considered when selecting a lubricant, including the type of equipment being used, the operating conditions, the load and speed of the equipment, and the type of surface materials in contact. Regular maintenance, including inspection and cleaning of the lubricant system, is also essential for optimal performance [17]. Lubricants can also have a significant impact on the environment, and it is essential to consider their environmental impact when selecting a lubricant. Biodegradable lubricants, which are designed to break down in the environment, are available and should be used in areas where environmental impact is a concern. In addition, proper disposal of used lubricants is essential to prevent environmental damage [11].

3. Metalworking Fluids

MWFs (Metalworking Fluids) are liquids or gels used in various metalworking processes such as cutting, grinding, milling, and drilling to lubricate and cool the tool and workpiece, remove debris, improve the surface finish or act as bacterial controls [18].

The worldwide demand for MWFs over the past 20 years has been steadily increasing [19]. This can be attributed to the growth of the manufacturing sector, particularly in developing countries, as well as the increasing use of high-speed and high-performance machinery. According to a report by Grand View Research, the global MWFs market size was valued at $9.5 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 4.4% from 2020 to 2027 [20]. The report identifies Asia Pacific as the largest market for MWFs, driven by the growth of the manufacturing sector in countries such as China and India.

In terms of product type, soluble oil-based MWFs are the most commonly used, followed by synthetic and semi-synthetic MWFs. The use of biodegradable MWFs is also on the rise due to increasing environmental concerns [21]. However, the MWFs industry has faced some challenges over the past 20 years, including stricter environmental regulations and increasing concerns over the health and safety of workers exposed to MWFs [19]. These factors have led to the development of new formulations that are more environmentally friendly and less harmful to human health.

3.1. Classification of Metalworking Fluids

MWFs are formulated with a variety of chemicals such as lubricants, surfactants, corrosion inhibitors, biocides, and pH adjusters. The type and concentration of these chemicals determine the properties of MWFs such as viscosity, pH, foaming tendency, and biological stability [22,23,24].

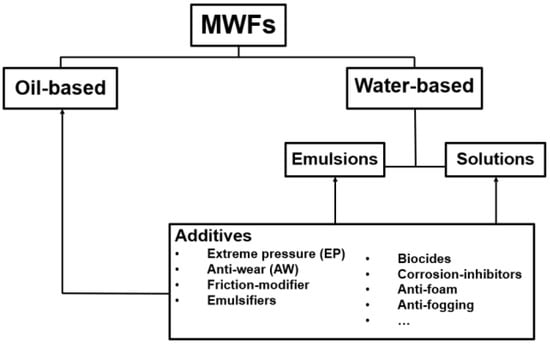

The classification of MWFs has been based on different criteria, such as formulation (oil-based, water-based), manufacturing process (cutting fluid, grinding oil, forming oil, etc.), or quantity (flooding, MQL, etc.) [25]. The DIN 51385 classification of MWFs is determined by their composition, with oil-based or water-based being the more common classification, where specific properties are achieved by adding specific chemical substances (additives) [26]. Figure 2 shows the classification of MWFs according to DIN 51385 and includes some typical classes of additives.

Figure 2.

Classification of the MWF types according to DIN 51385 [25].

It is also to be noticed that water-based MWFs are typically composed of 85–95% water and 5–15% additives, while oil-based MWFs have a higher percentage of lubricants and additives, usually between 80–95% [27].

MWFs can be further classified into three main categories based on their composition [28,29,30]:

- Straight oils: In addition to being known as mineral oils, these fluids are made from petroleum or synthetic base oils and do not contain any emulsifiers or additives. They provide excellent lubrication and heat dissipation but tend to accumulate on the workpiece, resulting in poor surface finish and machine cleanliness. They are suitable for low-speed and heavy-duty operations and for materials that are prone to rust or corrosion;

- Soluble oils: In addition to being known as emulsifiable oils, these fluids contain a mixture of mineral oil, emulsifiers, and other additives such as rust inhibitors, biocides, or surfactants. They form stable emulsions when mixed with water and provide good lubrication, cooling, and cleaning properties. They are suitable for high-speed and light-to-medium-duty operations and for materials that are not prone to rust or corrosion;

- Synthetic fluids: These fluids are made from synthetic base oils and contain various additives such as esters, glycols, or polyalphaolefins. They provide excellent lubrication, cooling, and cleaning properties and are more stable and less prone to bacterial growth than straight or soluble oils. They are suitable for high-speed and high-precision operations and for materials that require superior surface finish and dimensional accuracy.

In addition to the three main categories, there are also other types of MWFs such as semi-synthetic fluids, which are a blend of mineral and synthetic oils, and dry lubricants, which are powders or pastes applied directly to the metal surface. The choice of MWFs depends on the specific metalworking operation, the material being processed, and the performance and health criteria desired [31].

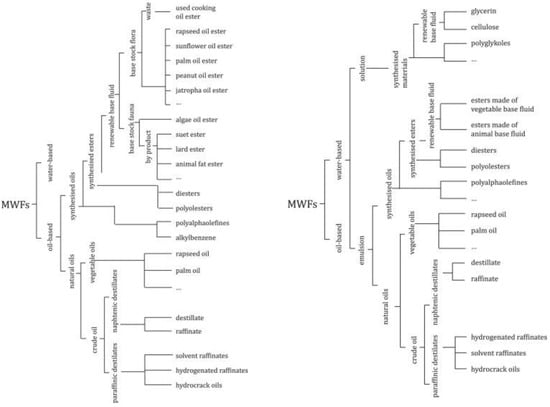

There has been a significant variety of raw materials used as base fluids for metalworking fluids. Figure 3 displays potential sources of base fluids for oil-based and water-based MWFs, respectively. Both categories comprise natural and synthesized oils, including those based on mineral oil or renewable materials. The most common renewable base fluids utilized thus far are synthesized esters [32,33], which are obtained from an alcohol and a vegetable or animal triglyceride such as palm oil, rapeseed oil, or animal fat. Synthetic esters are viewed as a promising alternative to traditional base fluids because they offer high quality, customized properties, non-toxicity, and excellent biodegradability. Esters are particularly relevant for oil-based MWFs as demonstrated by the large number and proportion of options. Synthesized esters are also important for water-based MWFs, but a greater range of suitable fluids is available. Examples of such fluids include MWF solutions based on glycerol, biopolymers, and gelatin, as well as ionic liquids and re-refined MWFs. Alternative additives such as nanoparticles, sulphurized fatty acids, and ionic liquids are also being introduced.

Figure 3.

Types of oil and water-based MWFs [25].

3.2. Functions and Application

MWFs serve multiple functions in metalworking operations, but their main objective is lubrication, in order to reduce friction and wear between the tool and workpiece, which prolongs the tool life and improves the surface finish of the workpiece. Other function of grand importance is the cooling effect of MWFs, where they dissipate heat generated during metalworking, which prevents the workpiece from overheating and warping, and reduces the risk of thermal cracks and dimensional inaccuracies [28,29,34].

Cleaning is another task for MWFs, as they flush away the debris and chips generated during metalworking, which prevents them from re-adhering to the workpiece and tool and helps maintain the cutting performance. MWFs also contain corrosion inhibitors that protect the tool and workpiece from rust and oxidation, which can compromise their integrity and quality [25]. MWFs can harbor bacteria and fungi, which can cause odors, skin irritation, and health hazards. Biocides are added to MWFs to control the growth of microorganisms and maintain the hygiene of the working environment, acting as biocidal agents [35].

MWFs can be applied to the metal surface in various ways, including flood cooling, misting, spraying, or jetting. Flood cooling involves immersing the workpiece in a pool of MWFs, while misting and spraying involve spraying the MWFs in the form of fine droplets or mist onto the workpiece [36,37]. Jetting involves directing a high-pressure stream of MWFs onto the cutting tool or workpiece [38].

Lacalle et al., addressed that, in the high-speed milling process of wrought aluminum alloys, built-up edge formation is a common problem, and lubrication and cooling are critical factors to address this issue. Two techniques are typically employed to combat this problem: emulsion of oil in water and spray of oil micro-drops in air. However, emulsion coolant is found to be ineffective in high-speed milling because it cannot reach the inner zones of the tool teeth. In contrast, minimum quantity lubrication (MQL) is found to be a more efficient technique that cools the tool and workpiece, lubricates, and removes chips. This was assessed through computational simulation and experimental evidence. Additionally, the study found that nozzle position relative to the feed direction is critical in achieving the optimum effect of the MQL flow. Finally, the use of MQL flow reduced the consumption of cutting oil by approximately 95%, leading to lower machining costs, with consumption levels lower than 0.06 cm3/min or 3.6 cm3 per machining hour in experimental tests [39].

The effect of lubricoolant in the turning operation at high cutting speeds is a crucial aspect that needs to be considered. While a mechanistic model for cutting forces in turning has been proposed by Fernández-Abia et al., there are still some limitations in the processing of materials, particularly austenitic stainless steels. The behavior of these materials during machining is not well understood, which is significant when considering the continuous increment of cutting speeds in technological development. Although the specific force coefficients for AISI 303 austenitic stainless steel have been obtained using the proposed model at high cutting speeds, the effects of lubricoolant on these coefficients remain to be studied. The lubricoolant effects could change significantly at high cutting speeds, and this would need to be taken into account for accurate cutting force prediction. Further research is required to improve the mechanistic model for cutting forces in turning and to incorporate the effects of lubricoolant in high-speed machining of austenitic stainless steels [40].

The performance of MWFs depends on several factors, including their composition, concentration, pH, viscosity, flow rate, pressure, and temperature. The optimal performance of MWFs can be achieved by selecting the right type and formulation of MWFs, maintaining their concentration and pH within the recommended range, controlling their temperature and flow rate, and ensuring their cleanliness and compatibility with the metalworking system [41].

3.3. Additives

An additive is a substance or chemical compound that is added to another material to enhance or modify its properties [42]. Metalworking fluids often contain various additives or nanoparticles to improve their overall performance, by enhancing their lubricating and cooling properties, reducing friction and wear, and protecting against corrosion and other forms of degradation [16,43,44]. The selection of the additives and nanoparticles to be used in MWFs depends on the specific application and the performance requirements. Some commonly used additives and nanoparticles include [45]:

- Extreme pressure additives: These additives contain compounds such as sulphur, phosphorus, and chlorine that provide extra protection against wear and tear under high-pressure conditions;

- Anti-wear additives: Contain compounds such as zinc and molybdenum that provide additional protection against wear and tear;

- Corrosion inhibitors: These additives help to protect against corrosion of the metal surfaces being worked on by the MWFs;

- Biocides: These additives help to prevent the growth of microorganisms such as bacteria and fungi in the MWFs;

- Emulsifiers: These additives help to keep the oil and water components of the MWFs mixed together;

- Nanoparticles: Nanoparticles such as titanium oxide and aluminum oxide are sometimes added to MWFs to improve their lubricating and cooling properties. These nanoparticles can also help to reduce friction and wear and provide better surface finish.

- Polymers: Polymers such as polyethylene glycol (PEG) and polyalphaolefin (PAO) are sometimes added to MWFs to enhance their lubricating properties.

Emulsifiers, biocides and corrosion inhibitors are especially for water-based MWFs, whereas surface active additives and stabilizing substances are applied in all MWFs [46]. The most common additives are summarized in Table 1.

Table 1.

Compilation of additives used in MWFs during the last decades, associated examples and their function according to [42].

3.4. Selection and Maintenance of MWFs

The selection and maintenance of MWFs should be based on the specific metalworking operation, the material being processed, and the performance and health criteria desired. The major factors to consider when choosing and using MWFs are compatibility, concentration, pH, filtration, recycling and disposal [47].

The MWF should be compatible with the material being processed, the tool and equipment used, and other fluids in the system. Incompatible fluids can cause foaming, corrosion, or bacterial growth. The concentration of MWFs should be adjusted to the optimal level to balance the lubrication, cooling, and cleaning functions. Over-concentration can cause foaming, skin irritation, and waste, while under-concentration can lead to poor performance and bacterial growth. The pH of MWFs should be within the recommended range to avoid skin irritation, corrosion, or bacterial growth. Acidic fluids can cause corrosion, while alkaline fluids can cause skin irritation and bacterial growth. MWFs should be filtered regularly to remove debris, chips, and bacterial contaminants. Dirty fluids can cause poor surface finish, tool wear, and health hazards [48,49].

MWFs can be recycled and reused to reduce waste and cost [50,51]. However, the recycled fluid should be tested and treated for bacterial growth, pH, and concentration before being reused. They should always be disposed of properly according to local regulations and standards, as some MWFs may be classified as hazardous waste and require special handling and disposal methods [52].

3.5. Health and Environmental Effects of MWFs

The use of MWFs can have both beneficial and detrimental effects on the health and environment [27]. Some of the most potential risks and mitigation measures associated with MWFs are skin and respiratory irritation, microbial contamination, environmental pollution and occupational exposure limits [53].

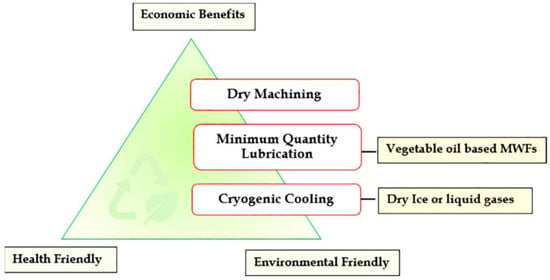

In terms of skin and respiratory irritation, some MWFs contain alkaline ingredients or biocides that can cause skin irritation, dermatitis, or asthma if exposed to them for a prolonged period. Workers should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators, and follow good hygiene practices to minimize the risk of exposure [18,54]. MWFs can also provide a favorable environment for the growth of bacteria and fungi, which can produce odors, cause infections, or reduce their effectiveness. The concentration of biocides in MWFs should be monitored and adjusted to ensure their efficacy and safety, and regular maintenance and cleaning of MWF systems should be conducted to prevent bacterial build-up [55]. To achieve sustainable machining operations, improvements are needed, such as the development of new materials and application methods, as well as new technologies for the disposal of MWFs [56]. The development of ecofriendly MWFs will enable the use of cutting-edge technology, making processes more sustainable and safer for workers and the environment. Opportunities for sustainable machining are shown in Figure 4, which can be used to address issues related to mineral oil-based MWFs. Achieving precise dimensions of the workpiece is crucial from both a quality and economic standpoint [57,58]. Therefore, machining operators should identify conditions that result in precise dimensions for most of the working materials use [59,60,61].

Figure 4.

The opportunities for performing sustainable machining [27].

One potential solution for green and sustainable machining of difficult-to-machine materials is the use of minimum quantity lubrication (MQL), which can replace traditional flood-assisted cooling [62]. The use of vegetable oil-based solutions is also a promising approach to improving machinability [63]. MQL uses oil-based mist, compressed air convection, and oil mist evaporation to reduce friction at the cutting interface, thus controlling heat generation during machining. However, MQL is limited by its low cooling properties, which can be improved by better temperature control during the machining process to reduce tool wear rates [64]. Several advanced MQL approaches are currently available, including minimum quantity cooling lubrication (MQCL), hybrid MQL+ CO2 lubrication, solid-lubricant-assisted MQL, MQL with nano-fluids, oil on water droplet MQL, and electrostatic minimum quantity lubrication (EMQL) [65,66,67,68,69,70]. While MQCL has gained popularity in the industry, its performance is highly dependent on specific MQL parameters such as droplet size, air flow, and nozzle distance from the cutting zone [71,72].

O. Pereira et al., proposed the use of a combination of cryogenic cooling and minimum quantity of lubrication (MQL) techniques, which were compared with other near-to-dry coolant alternatives. The results indicated that the combined technique improves tool life by over 50% and enables an increase in cutting speed by more than 30% compared to dry machining. Additionally, cutting forces and surface integrity were maintained or even improved in comparison with conventional techniques. From an environmental perspective, a life cycle assessment was conducted to compare the different alternatives proposed. The study reveals that the combination of cryogenic and MQL techniques strikes a balance between technical and environmental concerns, while stand-alone systems do not provide a complete solution. Cooling without lubrication or vice versa is insufficient when machining these materials [73]. On another research, the author proposed a new cooling-lubrication system which combines CO2 cryogenic and MQL technologies, where two nozzle adapters were proposed with different CO2 outlets, being the developed nozzles Plug & Play and directly applicable to commercial MQL systems. The behaviors of nozzle adapters were simulated by CFD (Computational Fluid Dynamics) and the optimal nozzle adapter was tested by milling Inconel 718 ®. In these milling tests, the tool life was measured, and different main cooling-lubrication techniques were used (dry, wet, CO2 stand alone, MQL stand alone and CO2 + MQL. The results showed that wet machining was the alternative which had the better performance. Nevertheless, and being the main objective to minimize or remove mineral oil emulsions to achieve an ecologic process more profitable, MQL + CO2 machining was the alternative which presented the best results, reaching values over 90% in comparison with wet machining but being more environmentally friendly [66].

MWFs can be released into the environment through wastewater, spills, or air emissions, and can have adverse effects on aquatic life, soil, and air quality [74]. To mitigate the environmental impact of MWFs, they should be properly disposed of or recycled, and their concentration and composition should be monitored to comply with environmental regulations. Some chemicals used in MWFs such as formaldehyde, boric acid, or nitrosamines have been identified as potential carcinogens or reproductive toxins, and their exposure limits have been set by regulatory agencies such as OSHA (Occupational Safety and Health Administration), NIOSH (National Institute for Occupational Safety and Health), or IARC (International Agency for Research on Cancer). Employers should follow the guidelines and standards established by these agencies to ensure the health and safety of their workers [75].

Metalworking fluid are a significant contributor to the effluents that are disposed of into the environment, as stated in a study cited as [76]. The volume of MWF waste has been estimated to be over 20 billion liters, according to research by Cheng et al. [48]. To address this issue, environmental regulatory bodies are urging companies to adopt or develop new methods of controlling and discharging industrial MWFs to mitigate their adverse effects on the environment and natural habitats. Thus, there is a need for ecofriendly MWFs to achieve sustainability in machining processes [77]. Vegetable oil-based MWFs have demonstrated superior performance compared to mineral oil-based MWFs, as they generate a more effective lubricant layer between the tool and workpiece, created by the saturated fatty acids present in vegetable oil. [78,79,80]. Furthermore, the presence of triglycerides in vegetable oil provides better lubricant properties, as demonstrated by Lawal et al. [60]. These vegetable oil-based MWFs increased tool life by up to 177% and reduced thrust force by up to 7% in drilling operations on AISI 316L steel [80].

4. Vegetable Oils

4.1. Past History

Vegetable oils have been used as lubricants for many years. In fact, before the development of modern cutting fluids, vegetable oils were one of the most common lubricants used for metalworking tools [81]. The use of vegetable oils as MWFs can be traced back to ancient civilizations such as Egypt, Greece, and Rome, where olive oil was commonly used to lubricate metal tools and weapons [82].

During the industrial revolution in the 18th and 19th centuries, the demand for metalworking increased significantly, and the use of cutting fluids became more widespread. At that time, mineral oils, which were readily available and had higher lubricating properties than vegetable oils, were commonly used as cutting fluids. However, vegetable oils continued to be used as cutting fluids in some applications, particularly in areas where environmental concerns were important [82,83].

In the mid-20th century, synthetic cutting fluids began to gain popularity, as they offered superior lubricating properties and longer lifespans than vegetable oils or mineral oils. However, the environmental and health concerns associated with synthetic cutting fluids have led to renewed interest in vegetable oils as cutting fluids in recent years [84].

Today, vegetable oils are used as Metalworking fluids in a variety of applications, particularly in industries where environmental regulations are strict, such as the food industry. They are also commonly used in small-scale metalworking operations, such as hobbyist workshops or artisanal metalworking. As the push for sustainability and environmental responsibility continues, the use of vegetable oils as cutting fluids is likely to become even more popular in the future [85,86].

4.2. Chemical Structure

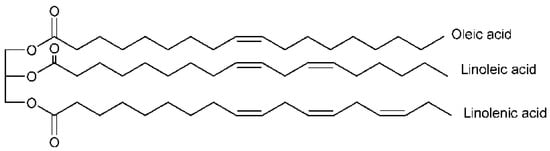

The structure and lube properties of vegetable oils are determined by their triglyceride composition, which consists of a glycerol molecule that is esterified with three fatty acid molecules, which can be either saturated or unsaturated, and can have different chain lengths. The type of fatty acid present in the triglyceride determines the physical and chemical properties of the oil [87,88].

The fatty acid molecules can be either saturated or unsaturated, and they can have different chain lengths. Saturated fatty acids have no double bonds between their carbon atoms, which means they are saturated with hydrogen atoms. They have a straight chain structure, which makes them more closely packed together and results in a solid or semisolid texture at room temperature [89,90]. Examples of saturated fatty acids found in vegetable oils include palmitic acid and stearic acid [91]. Unsaturated fatty acids, on the other hand, have one or more double bonds between their carbon atoms, which creates a kink in their chain structure. This kink prevents the fatty acid molecules from packing closely together, resulting in a liquid texture at room temperature. Unsaturated fatty acids are further classified as either monounsaturated or polyunsaturated, depending on the number of double bonds in their chain. Monounsaturated fatty acids have one double bond in their chain, and they include oleic acid, which is found in olive oil, and palmitoleic acid, which is found in macadamia nut oil. Polyunsaturated fatty acids have two or more double bonds in their chain, and they include linoleic acid and linolenic acid, which are essential fatty acids that cannot be synthesized by the body and must be obtained through the diet [92]. These fatty acids are found in high concentrations in oils such as corn oil, soybean oil, and sunflower oil. Table 2 shows the fatty acids structure of various vegetable oils.

Table 2.

Fatty acid structure of various vegetable oils [93].

The chemical and physical characteristics of vegetable oils depend largely on the composition of unsaturated fatty acids, which is influenced by factors like the climate of cultivation and genetic modification of the crops. The fatty acids in vegetable oils are predominantly long and straight-chained, with unconjugated double bonds, and are mostly cis-configured (Figure 5). However, certain fatty acids like ricinoleic and vernolic acids have hydroxyl and epoxy functional groups, respectively. vegetable oils like soybean, sunflower, palm, and linseed oil have high levels of oleic, linoleic, and linolenic acids [94,95]. Castor oil and vernonia oil, on the other hand, are rich in ricinoleic and vernolic acids respectively. The percentage of unsaturation in vegetable oils is a key factor in their suitability for use as environmentally acceptable lubricants. Edible oils like coconut, olive, soybean, and palm are commonly used for bio lubricant formulations, while non-edible oils like neem, castor, and jatropha are relatively inexpensive and thus, preferred for biofuel/bio lubricant production [87,96,97,98]. It has been reported that the triglyceride structure provides desirable properties for boundary lubrication. As a result of their long and polar fatty acid chains, triglycerides are thought to provide effective boundary lubrication due to their high-strength lubricant films that interact strongly with metallic surfaces, reducing friction as well as wear [93,99]. In terms of lubricity, fatty acids are believed to be key substances due to their polarity, which produces oriented molecular films and contributes oiliness along with antiwear properties [93,100,101].

Figure 5.

General structure of triglyceride esters of edible vegetable oils [87].

Vegetable oils, such as soybean, rapeseed, and sunflower oil, can be effective as MWFs due to their lubricating properties, as they contain fatty acids that provide a protective film to the tool surface and help to reduce friction between the tool and the workpiece [79]. Additionally, vegetable oils have a high flash point, which means they can withstand high temperatures without igniting or forming harmful vapors.

One advantage of using vegetable oils as cutting fluids is that they are biodegradable and non-toxic, making them a more environmentally friendly option compared to traditional cutting fluids, which often contain hazardous chemicals. Vegetable oils are also readily available and cost effective. However, there are also some limitations, as vegetable oils can have a shorter lifespan than synthetic MWFs and may require more frequent replacement. They can also cause issues with rust and corrosion on certain metals if not used properly. Table 3 depicts the rheological properties of different vegetable oils.

Table 3.

Physico-chemical properties of vegetable oils [93].

4.3. Additives

Additives and nanoparticles are often used in vegetable oils to enhance their performance as metalworking fluids [102]. These additives can help to improve the lubricity, cooling properties, and stability of the oil, as well as reduce friction and wear on the cutting tool [103]. The choice of additive or nanoparticle can have a significant impact on the performance and stability of the metalworking fluid and depend on the specific application and requirements of the operation. Some of the most common additives and nanoparticles used in vegetable oils for metalworking are [104]:

- Antioxidants: Antioxidants are added to vegetable oils to prevent oxidation and extend the shelf life of the oil. They can also help to reduce the formation of harmful sludge and varnish on metalworking tools. Common antioxidants used in vegetable oils used as MWFs include phenols, amines, and sulfides;

- Antiwear agents: Antiwear agents are added to vegetable oils to reduce the wear and tear on metalworking tools. These agents can form a protective layer on the tool surface, reducing friction and preventing damage;

- Extreme pressure (EP) additives: EP additives are used to improve the lubricity and antiwear properties of vegetable oils, particularly under high pressure or high-temperature conditions. They can also help to reduce tool wear and extend the lifespan of the tool. Common EP agents used in vegetable oil-based MWFs include sulfur, phosphorus, and chlorine compounds;

- Nanoparticles: Nanoparticles such as graphene, carbon nanotubes, and alumina can be added to vegetable oils to improve their lubricating properties. These nanoparticles can form a protective layer on the tool surface, reducing friction and improving the wear resistance of the tool;

- Emulsifiers: Emulsifiers are used to help vegetable oils mix with water, which is necessary for some metalworking operations. Emulsifiers can also help to stabilize the oil-water mixture and prevent the oil from separating. Common emulsifiers used in vegetable oil-based MWFs include fatty acids, sorbitan esters, and alkylphenol ethoxylates;

- Biocides: Biocides are used to prevent the growth of bacteria and other microorganisms in the metalworking fluid. This can help to prevent the fluid from becoming contaminated and causing problems with the tool or workpiece. Common biocides used in vegetable oil-based MWFs include quaternary ammonium compounds, isothiazolones, and organic acids.

Bio-based additives are becoming increasingly popular in metalworking fluids due to their lower environmental impact and improved sustainability compared to traditional petroleum-based additives. These additives are derived from renewable resources such as vegetable oils, plant extracts, and other bio-based materials, and can be used to improve the performance of metalworking fluids in a variety of ways, including as corrosion inhibitors, lubricants, emulsifiers, wetting agents, and humectants. Table 4 lists some common bio-based additives that can be used in vegetable oil-based metalworking fluids, along with their sources and functions. It’s important to note that the specific properties and functions of each additive can vary depending on factors such as the source of the oil and the processing methods used [105,106,107].

Table 4.

Bio-based additives that can be used in vegetable oil-based metalworking fluids.

4.4. Nanoparticles

Nanoparticles are extremely small particles that have at least one dimension in the range of 1–100 nanometer. Because of their small size, nanoparticles can exhibit unique properties that are not observed in larger particles of the same material, for example, they may have a larger surface area-to-volume ratio, increased reactivity and thermal conductivity, unique optical, electrical, and magnetic properties [122,123,124].

In recent years, there has been growing interest in using nanoparticles as additives in MWFs to improve their performance in industrial applications, in terms of their lubricity, thermal stability, wear resistance, and other properties, which can lead to improved machining performance, longer tool life, and reduced maintenance costs [125]. However, there are also concerns about the potential health and environmental impacts of using nanoparticles in MWFs. Some studies have suggested that nanoparticles may pose health risks to workers who are exposed to them, particularly through inhalation [126,127]. Additionally, the potential environmental impacts of releasing nanoparticles into the environment are not yet fully understood. As a result, there is ongoing research into the safety and environmental impacts of using nanoparticles in MWFs, as well as efforts to develop safe and effective methods for using nanoparticles in these applications. Despite these challenges, the use of nanoparticles in cutting fluids and MWFs is expected to continue to grow as researchers and industry professionals seek new ways to improve the performance of these important industrial fluids [128,129].

Some of the most commonly studied nanoparticles for use in vegetable oil-based fluids include carbon-based nanoparticles, such as graphene and carbon nanotubes: These nanoparticles have been shown to improve the lubricity and wear resistance of vegetable oil-based fluids, which can lead to improved machining performance [7,125]. Metal-based nanoparticles, such as silver and copper have also been analyzed, since these nanoparticles have antimicrobial properties and can be used to inhibit the growth of bacteria and other microorganisms in MWFs [130]. Ceramic-based nanoparticles, such as alumina and silica, have also demonstrated to improve the thermal stability and anti-wear properties of vegetable oil-based fluids, which can lead to improved performance in high-temperature machining applications [84,131,132]. Other studies include magnetic nanoparticles, such as iron oxide, which can be used to create magnetorheological (MR) fluids, which can change their viscosity and other properties in response to an applied magnetic field. MR fluids have potential applications in precision machining and other high-precision industrial processes [131,133].

There are also some bio-based nanoparticles that have been investigated for use as additives in vegetable oil-based MWFs. Bio-based nanoparticles are those that are derived from natural sources such as plants, animals, or microorganisms, and may offer a more sustainable and environmentally friendly alternative to conventional nanoparticles [5,134,135]. Some examples of bio-based nanoparticles that have been studied for use as additives in cutting fluids and MWFs include chitosan nanoparticles (have been shown to improve the lubricity and anti-wear properties of vegetable oil-based fluids), cellulose nanoparticles (have been shown to improve the thermal stability and lubricity of vegetable oil-based fluids), silk nanoparticles (have been investigated due to the fact of their excellent lubrication properties and biocompatibility) and nanocellulose (has been shown to improve the lubricity, thermal stability, and anti-wear properties of vegetable oil-based fluids) [136,137,138].

4.5. Chemical Modification

Vegetable oils are not likely to be used directly as base stocks or lubricant additives because they have lower thermo-oxidative stability, higher viscosity, and lower volatility compared to traditional petroleum-based oils. As a result, they burn incompletely and form deposits in fuel injectors due to their high viscosity and low volatility. Before vegetable oils can be used as biofuels or biolubricants, they must be chemically modified. This can be achieved through reactions at the carboxyl groups of fatty acids, esters, or triglycerides, or reactions at the olefinic functionalities of the fatty acid chain. The most important initial step in producing biofuels and lubricants from vegetable oils is transesterification, which produces fatty acid alkyl esters and glycerol. Transesterified vegetable oils have been used as biofuels and biolubricants in several researches [87,139,140,141,142].

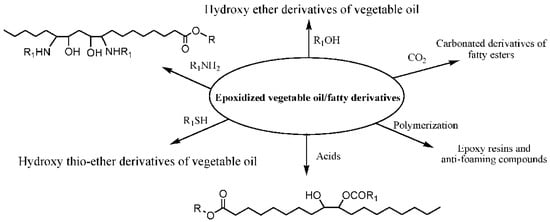

Fatty acids produced by transesterification can be further converted into their derivatives using one or multistep strategies involving numerous reactions to produce various types of lubricants and additives based on industrial needs. Glycerol obtained from triglyceride esters can also be converted into water-based lubricant additives along with other essential chemicals. Functionalization of the olefin functional groups of unsaturated fatty esters or free fatty acids of vegetable oils can be performed by various reactions such as epoxidization, carbonation, maleation, acrylation, hydroxylation, hydroformylation, reduction, thiol-ene addition, and polymerization. These reactions can produce plasticizers, polyurethanes, adhesives, paints, coatings, and environmentally friendly additives for lubricants [143,144,145,146].

As mentioned before, one of the most common modifications of vegetable oils is transesterification, which involves the exchange of fatty acid chains in the triglyceride molecule with an alcohol. This process leads to the formation of esters and glycerol. Transesterification can be catalyzed by acids, bases, or enzymes, and is commonly used to produce biodiesel from vegetable oils. However, it can also be used to modify vegetable oils for use as lubricants [121,139,147].

Another modification method is epoxidation, which involves the addition of an epoxide group to the unsaturated fatty acid chains in the triglyceride molecule. Epoxidized vegetable oils have improved oxidative stability and can be used as stabilizers for polymers, as well as plasticizers, solvents, and lubricants. The opening of the epoxy rings of vegetable oils/fatty derivatives to produce different value-added compounds that have an application in the formulation of biolubricants are shown in Figure 6 [148,149].

Figure 6.

Epoxidized vegetable oil/fatty derivatives as a starting material to prepare different biolubricants/additives for lubricants [87].

Oxidative cleavage is another method that can be used to modify vegetable oils. This process involves the breaking of the unsaturated fatty acid chains in the triglyceride molecule by reaction with ozone, hydrogen peroxide or other oxidants. The resulting products can be used as surfactants, emulsifiers, or lubricants [150,151].

Hydrogenation is another method of modification, which involves the addition of hydrogen atoms to the unsaturated fatty acid chains in the triglyceride molecule. This process converts unsaturated fatty acids to saturated fatty acids, which improves the oxidative stability and melting point of the vegetable oil. Hydrogenated vegetable oils are commonly used as solid fats in food products, but they can also be used as lubricants [152,153].

Other modification methods include esterification, interesterification, and polymerization [154,155,156]. These methods can be used to modify the physical and chemical properties of vegetable oils for use as lubricants, including improving viscosity, thermal stability, and wear resistance, while also reducing environmental impacts compared to traditional mineral oil-based fluids.

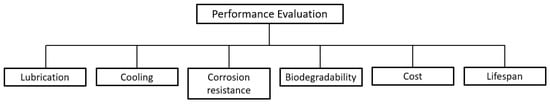

5. Performance of Vegetable Oils against Standard Lubricants

The performance of vegetable oils used as MWFs can be compared against standard MWFs in several key areas, including lubrication, cooling, corrosion resistance, biodegradability, cost, and lifespan, as it is shown in Figure 7. While MWFs may offer superior performance in certain areas, vegetable oils can be a viable alternative in certain applications, particularly where environmental concerns are important. Ultimately, the choice of the MWF will depend on the specific requirements of the metalworking operation and the balance between performance, cost, and environmental considerations.

Figure 7.

Key areas tested for the performance evaluation of vegetable oils used as standard MWFs.

5.1. Lubrication

An article published by Zareh-desari and Davoodi [104] investigated the use of vegetable oil-based nano-lubricants in metal forming processes as an environmentally friendly alternative to traditional lubricants. The authors conduct experiments to evaluate the lubrication performance of these nano-lubricants and compare their performance to that of traditional lubricants. The results show that the nano-lubricants provide better lubrication performance and reduce the wear and tear on the metal forming tools. Additionally, the use of vegetable oil-based lubricants can reduce the environmental impact of the metal forming process by reducing the amount of waste generated and lowering the energy consumption required for the process. Overall, the article suggests that the use of vegetable oil-based nano-lubricants could be a promising solution for improving the environmental sustainability of metal forming processes.

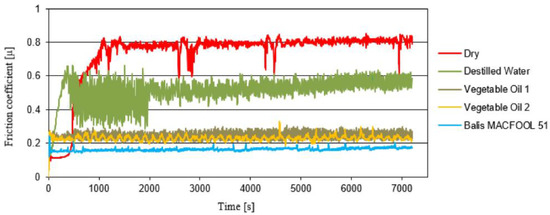

Another article entitled “Analysis of a Vegetable Oil Performance in a Milling Process by MQL Lubrication” [157] evaluated the performance of a vegetable oil as a lubricant in a milling process using Minimum Quantity Lubrication (MQL) technique. The authors evaluated the effects of different operating conditions, such as cutting speed, feed rate, and lubricant flow rate, on the performance of the vegetable-oil-based lubricant. The results of the study showed that the vegetable oil-based lubricant had a positive impact on the performance of the milling process, reducing the cutting forces and the temperature of the tool. The study also found that the optimal operating conditions for using the vegetable oil-based lubricant varied depending on the specific cutting conditions, suggesting that vegetable oil-based lubricants have the potential to be an effective and environmentally friendly alternative to traditional lubricants in metalworking processes. Figure 8 demonstrates the tribological tests, evaluating the friction coefficient during sliding, performed under dry conditions, with distilled water, with a standard MWFs and with two vegetable oils derived from effluents of olive oil, without any additives added. In terms of stability of the friction coefficient values during sliding, both the vegetables oils and the industrial cutting fluid showed relatively smooth friction coefficient evolution curves when compared to the sliding contacts in presence of distilled water or under dry condition.

Figure 8.

Comparison of the evolution of the friction coefficient during sliding in tribological tests (alumina ball against stainless steel; W = 5 N; v = 0.5 m/s) [157].

In a study published by Kazeem et al. [84], was investigated the use of canola oil-based cutting fluids with the addition of nanoparticles for machining of stainless steel. The study found that the addition of alumina nanoparticles to the canola oil-based fluid improved its lubricity, resulting in reduced tool wear and improved surface finish.

Another study published in 2019 [158] evaluated the performance of vegetable oils at three different concentrations as sustainable cutting fluids in turning of AISI 1045 steel. The results showed that despite the better thermal and tribological properties of the mineral-based cutting fluids, the vegetable-based emulsion had an overall better performance in relation to the wettability angle and machining force and provided comparable performance to traditional cutting fluids in terms of cutting force, tool wear, and surface roughness.

5.2. Cooling

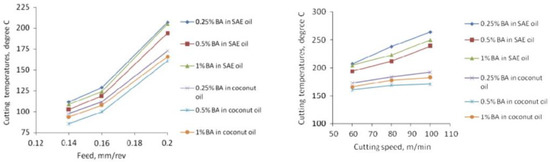

An article published by Mosiewicki and Aranguren [159] described an experimental study that investigates the performance of nanoboric acid suspensions in two different cutting fluids (SAE-40 and coconut oil) during turning of AISI 1040 steel. The study aimed to evaluate the effects of the nanoboric acid suspensions on cutting forces, surface roughness, and tool wear. The experimental results show that the addition of nanoboric acid suspensions to the cutting fluids reduces the cutting forces and surface roughness and improves the tool life. The authors attribute these improvements to the lubricating and cooling effects of the nanoboric acid particles.

In the section of cutting temperatures, the authors report on the effect of nanoboric acid suspensions on the cutting temperature during turning of AISI 1040 steel. The cutting temperature was measured using a K-type thermocouple inserted into a hole drilled in the cutting tool. The experimental results, which can be seen in Figure 9, show that the addition of nanoboric acid suspensions to the cutting fluids reduces the cutting temperature. For example, when using coconut oil as the cutting fluid, the cutting temperature was reduced by 21.4% when adding 0.3% nanoboric acid concentration compared to the base oil without any additive. The authors suggest that the reduction in cutting temperature could be attributed to the improved thermal conductivity and heat transfer properties of the nanoboric acid particles in the cutting fluid. They also note that the reduction in cutting temperature can help to improve the tool life and reduce the risk of thermal damage to the workpiece, providing further evidence of the potential benefits of using nanoboric acid suspensions as cutting fluid additives.

Figure 9.

Variation of cutting temperatures with feed (speed = 60 m/min, d.o.c = 1 mm, time = 15 min) (left), and Variation of cutting temperatures with cutting speed (feed = 0.2 mm/rev, d.o.c = 1 mm, time = 15 min) (right) [159].

In a study entitled “Performance of Vegetable Oils as a Cooling Medium in Comparison to a Standard Mineral Oil” [160], three oils-a standard mineral oil that has been in use for many years, and two new biodegradable vegetable oils (partially hydrogenated and winterized crude expelled soybean oils) were evaluated. The testing was conducted using a modified ISO 9950 procedure, with an agitation rate of 0.3 m/s, and an austenitic steel probe (X 6 CrNi 18 10 alloy) instead of INCONEL 600. Additional unalloyed hardenable steel probes (Ck 45) were used to show the metallurgical transformation in martensite, local differences, and dependencies on the rewetting time and the metallurgical steel condition. The cooling behavior of immersion quenching was primarily influenced by the sequence of cooling phases and different heat transfer rates. Heat transfer on the specimen surface was mainly determined by the rewetting conditions, which depended on the cooling characteristics of the quenching medium, bath temperatures, and agitation rates. The two soybean oils investigated did not show any significant differences in cooling behavior. The rewetting conditions on the sample surface and the cooling rates were similar, and the cooling characteristics of vegetable oils were faster than those of mineral oil. Although the tests were conducted under laboratory conditions, the study established the potential of vegetable oils as alternatives to mineral oils for industrial heat-treating processes.

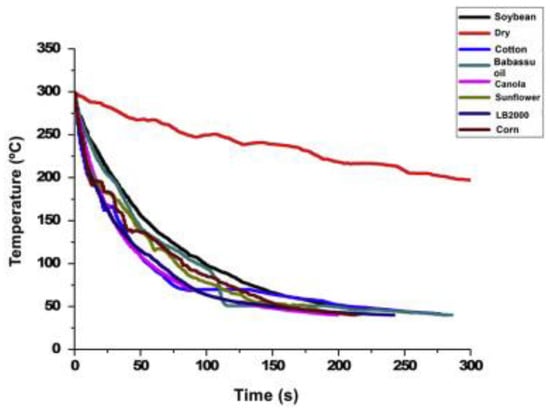

A. Junior et al. [161] published in 2016, the use of vegetable oils as lubricants and coolants during the milling of AISI 1045 steel. The study focused on the potential of vegetable oils to improve the sustainability of manufacturing processes by reducing the environmental impact and improving the health and safety of workers. The experimental results show that the vegetable oils exhibit good lubrication and cooling performance during the milling process, with some oils performing better than others. The authors also report that the use of vegetable oils as lubricants and coolants can reduce the amount of hazardous waste generated, as well as the risk of skin irritation and other health problems associated with the use of mineral oils. The cooling ability of cutting fluids was evaluated applying a calorimetric test, to determine the cooling ability of each vegetable oil used as a cutting fluid (cottonseed, babassu nut, canola, sunflower, corn and soybean oils and the commercial oil LB 2000), considering the dynamic behavior during the measurement, approaching the conditions encountered in practice (i.e., during machining). The cooling curves obtained can be seen in Figure 10.

Figure 10.

Cooling curves for the sample, with MQL application of vegetable oil-based fluids [161].

The cooling rates of the cutting fluids decreased in the following order: LB 2000 (the commercial oil), cottonseed, canola, corn, sunflower, soybean and babassu nut oil, being the test under dry conditions where the workpiece cooled more slowly. It was also observed that when the temperature of the workpiece sample is high, the order of decreasing cooling ability of the cutting fluids changes to cottonseed, canola, LB 2000, corn, sunflower, soybean and babassu nut oil.

Another study conducted by Zhang et al. [162] investigated the performance of a soybean oil-based cutting fluid with the addition of an environmentally friendly additive for machining of aluminum alloys. The study found that the soybean oil-based fluid with the additive provided better cooling and lubrication compared to conventional mineral oil-based fluids, resulting in improved surface finish and reduced tool wear.

A study published in 2021 [163] investigated the use of a soybean oil-based cutting fluid with the addition of zinc oxide nanoparticles for turning of stainless steel. The study found that the soybean oil-based fluid with the nanoparticles provided improved cooling and lubrication, resulting in reduced cutting forces and improved surface finish.

Padmini et al. [164], investigated the use of a castor oil-based cutting fluid with the addition of nano-clay particles for milling of aluminum alloys. The study found that the castor oil-based fluid with the nanoparticles provided improved cooling and lubrication, resulting in reduced cutting forces and improved surface finish.

A study published by Lawal et al. [60] studied the performance of a vegetable oil-based MWF with the addition of a bio-based surfactant for drilling of titanium alloys. The study noticed that the vegetable oil-based fluid with the surfactant provided improved cooling and lubrication, resulting in reduced tool wear and improved hole quality.

5.3. Corrosion Resistance

The use of vegetable oils as potential alternatives to mineral oils in lubricant applications can be challenging, due to their susceptibility to oxidation and corrosive action [165]. Vegetable oils contain unsaturated fatty acids, which are prone to oxidation in the presence of oxygen, heat, and metal catalysts. The oxidation process can result in the formation of corrosive by-products such as organic acids and peroxides, which can cause corrosion and wear of metal surfaces [84]. To address these challenges, researchers have explored various strategies to improve the oxidative stability and anti-corrosion properties of vegetable oils used in lubricants. These strategies include the use of antioxidants and corrosion inhibitors, modification of the fatty acid composition, and blending with other oils or additives [33,166].

F. Grigoriev and I. Kavaiova [167], performed corrosiveness and oxidative stability tests of vegetable oils. It was shown that linseed and rapeseed oils have high levels of corrosiveness and oxidative stability, related to the predominance of its polymerization processes over hydrolysis processes. It was established that the basic mechanism of the corrosive action of oils on copper is the reaction with the metal of oil oxidation products with atmospheric oxygen.

A conference paper entitled Corrosion Inhibition of Carbon Steel by Non-Edible Vegetable Oils used as Cutting Fluids in Minimum Quantity Lubrication (MQL) [168], investigated the corrosion inhibition performance of neem seed oil (NSO) and jatropha seed oil (JSO) on carbon steel in a 0.5 M H2SO4 environment, which is common in oil refineries and sulfur plants. The study employed open-circuit potential (OCP) measurement, potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS) techniques to investigate the corrosion performance of NSO and JSO. The concentration of each oil sample was varied from 0.01 to 0.04 g/mL. The results showed that both NSO and JSO had high corrosion inhibition efficiencies on the exposed area of the metal in 0.5 M H2SO4, reaching a maximum of 99.96% and approximately 100% for JSO and NSO respectively. The inhibition action of the oil samples was attributed to the adsorption of the phytochemicals contained in the oil on the surface of the metal. The pH of the oil samples was tested and compared to ISO and GB standards for metalworking fluids and the pH of each oil sample admixed with H2SO4 acid was also determined. The JSO showed low inhibition efficiencies at 0.01 g/mL for PP and EIS techniques, and the affirmation of this poor performance is supported by the more negative OCP obtained at this concentration. The results obtained confirmed the agreement of PP and EIS techniques. Overall, the study concludes that NSO and JSO are good corrosion inhibitors on the metal sample in H2SO4 environment.

On another study [169], the researchers investigated the effectiveness of jojoba oil as a “green inhibitor” for preventing the corrosion of C38 carbon steel in 1 M HCl solution. The inhibitor efficiency was evaluated using both electrochemical and measurement methods. The results showed that the use of jojoba oil caused a decrease in corrosion current density, indicating a reduction in the corrosion rate of the steel. The effectiveness of the inhibitor increased with increasing concentration of the jojoba oil, with the highest efficiency observed at a concentration of 3 g/L. The researchers also found that the jojoba oil acted as a mixed inhibitor in the HCl medium, and the highest efficiency was observed in the 1 M HCl solution. Additionally, the jojoba oil was found to adsorb onto the surface of the steel, with a higher adsorption rate for H ions than Cl ions, leaving fewer sites available for corrosion to occur.

Trzepieciński [170] compared the performance of a rapeseed oil-based cutting fluid to a petroleum-based fluid in the turning of carbon steel. The study found that the rapeseed oil-based fluid provided similar or slightly worse performance in terms of tool life, cutting forces, and surface finish compared to the petroleum-based fluid. In most of the conditions analyzed, the addition of boric acid into vegetable oils lead to an increase in the lubrication efficiency by up to 15% compared to pure oils. The effectiveness of lubrication by olive and rapeseed oils in decreasing the frictional resistances depended on the nominal pressure applied.

Ozcelik et al. [171] compared the performance of a sunflower oil-based MWF to a conventional petroleum-based MWF in the grinding of steel. The performances of three vegetable-based cutting fluids developed from crude sunflower oil, refined sunflower oil, refined canola oil and commercial semi-synthetic cutting fluid were compared in terms of tool wear, thrust force and surface roughness during drilling of AISI 304 austenitic stainless steel with HSSE tool. Experimental results show that canola-based cutting fluid gives the best performance due to its higher lubricant properties with respect to other cutting fluids at the constant cutting conditions (spindle speed of 750 rpm and feed rate of 0.1 mm/rev). The study also found that the sunflower oil-based fluid provided similar or slightly worse performance in terms of surface roughness, grinding force, and material removal rate compared to the petroleum-based fluid.

Rahim and Sasahara [172] carried out a drilling experiment to evaluate the efficiency of palm oil and compare it with minimal quantity lubrication technique using synthetic ester, flood coolant and air blow with respect to cutting temperature, cutting force, torque and tool life. The experimental results showed that the application of palm oil under minimal quantity lubrication condition as the cutting fluid was more efficient process as it improves the machining performances.

5.4. Biodegradability

In a study entitled “Biodegradation of vegetable oils: A review” [173], the authors assumed that, despite vegetable oils have been mainly used in food applications, with the rise in crude oil prices and the increasing demand for renewable and environmentally friendly industrial fluids, vegetable oils have gained attention as a viable alternative. Biodegradability is an important factor in assessing the ecofriendliness of substances, and vegetable oils have been shown to biodegrade more easily compared to mineral-based oils. Despite this advantage, researchers are still faced with the challenge of finding ways to improve the working efficiency of vegetable oils, particularly in terms of their poor oxidative stability and high pour points, in a safe and cost-effective manner.

Another study issued by Erhan and Asadauskas [174], compared lubricants derived from petroleum to vegetable-based lubricants, and concluded that they are more biodegradable, but they often lack in other technical characteristics. The quality of the basestock, which makes up more than 80% of the lubricant, is crucial and must meet certain performance criteria such as cleanliness, viscosity, volatility, oxidative, and hydrolytic stability, deposit-forming tendencies, solvency, and compatibility with elastomers and other system components. For vegetable-based lubricants, the most critical issues are their poor oxidative stability and low-temperature performance. Research has shown that vegetable oils are about ten times less stable than mineral oils or synthetic biodegradable basestocks such as isoalkyl adipates or poly alphaolefins, as demonstrated by the thin film oxidation test. Additionally, low-temperature performance, such as pour points and cold storage, is also problematic for vegetable oils. These issues cannot be fully remedied by lubricant additives, so chemical modification of vegetable oils is necessary to eliminate oxidation-susceptible sites and disrupt crystal formation at low temperatures.

5.5. Cost

Generally, vegetable oils tend to be more expensive than mineral-based lubricants, but their prices can vary depending on factors such as the type of vegetable oil and the region where it is produced. Additionally, the cost-effectiveness of using vegetable oils as lubricants may depend on the specific application and the overall cost-benefit analysis of using renewable and biodegradable alternatives [171,175].

A review written by Srivastava and Sahai [176], says that the increasing demand for renewable, environmentally friendly lubricants has led to the utilization of bio-based materials such as natural oils and fats. Vegetable oils are an attractive option for ecofriendly lubricants due to their excellent lubricity, viscosity-temperature characteristics, biodegradability, and low volatility. As India is an agriculture-based economy, there is great potential for producing vegetable oil-based lubricants that offer ecological compatibility and technical performance. However, to achieve specific performance requirements, vegetable oils may require chemical modification or blending with additives to meet the specifications for particular end-use applications. The article also stats that the high cost of oilseed is a major obstacle to the development of biolubricants, which are generally 1.5 to 5 times more expensive than mineral oils. However, the unpredictability of mineral oil prices and increasing global trade imbalances have made the use of renewable raw materials increasingly important. To minimize the higher economic cost, an economical and environmental balance must be struck, taking into account the advantages and hidden cost savings of biolubricants such as lower maintenance, manpower, storage, and disposal costs. Standardization for the classification of raw materials, stable pricing and supply of seed oils, and a long-term policy on industrial crops are also needed for widespread adoption of vegetable-based biolubricants, which currently have a market share of only 3 to 4% of total lubricant and hydraulic fluid use.

G. Karmakar et al. [87] published an article that focuses on the use of chemically modified vegetable oils as base fluids and additives to prepare cost-effective and environmentally friendly lubricant compositions. Being one of the emerging areas of industrial research, the chemical modification of vegetable oils to produce alternatives to petroleum-based materials. This is driven by the environmental impact of petroleum products and the shortage of petroleum resources. Chemical modification of vegetable oils can yield biolubricants, bioplasticizers, biofuels, non-isocyanate polyurethanes, biocomposites, and other value-added chemicals. Vegetable oils or their derivatives can be used as base fluids to formulate environmentally friendly lubricants. Chemically modified vegetable oils have enhanced multifunctional performance and biodegradability, making them attractive as sustainable additives. The authors also stated that, although biolubricants produced from vegetable oils are more costly than mineral lubricants, they are a promising alternative to synthetic and mineral oil-based lubricants because of their specific functional attributes such as high viscosity index, good lubricity, superior anticorrosion properties, high flash point, high biodegradability, and low aquatic toxicity.

Table 5 provides information on the market prices of different vegetable oils used in machining operations, which range from USD 1178.75 to 4441.54 per metric ton. Among all the oils, palm oil is the least expensive. The cost of metal cutting fluids ranges between 16 and 30% and is significant from both economic and technical perspectives, covering the entire product life cycle from procurement to disposal. Despite their high purchase cost, vegetable oils are more cost effective than mineral oils in this context. Investing in vegetable oils will yield profitable outcomes, taking into account the costs of maintenance, recycling, disposal, and stringent environmental regulations. In addition, large-scale cultivation of vegetable oil-based plants, trees, or crops would help to reduce the long-term purchase price [84].

Table 5.

Basic physicochemical qualities, cost, availability, and applications of selected cutting fluid [84,166].

5.6. Lifespan

The lifespan of vegetable oils as MWFs compared to standard lubricants can vary depending on the specific application and operating conditions. In general, vegetable oils have been found to have lower oxidative stability than mineral-based oils, which can lead to shorter lifespans and increased maintenance requirements. However, with proper formulation and additives, vegetable oils can have comparable or even superior lifespans to standard lubricants. Some studies have also shown that vegetable oils have lower friction and wear rates than mineral-based oils, which can potentially lead to longer equipment lifespan. Overall, the lifespan of vegetable oils as lubricants is a complex issue that requires consideration of multiple factors, including the specific application, operating conditions, and formulation of the lubricant [60,177].

Agarwal and Dhar [178] compared the long-term durability performance of a 10% blend of Karanja oil with mineral diesel (K10) against mineral diesel, two identical direct injection compression ignition (DICI) engines underwent a long-term endurance test. The test spanned over 512 h of engine operation, and analyzed carbon deposits, wear of vital engine components, and the effect of the new fuel on lubricating oil. The results showed that wear of the liner, piston, piston rings, valves, gudgeon pin, crank pin, bearings, and other components of the K10 fueled engine was comparable to that of the mineral diesel fueled engine. Moreover, the lubricating oil of the K10 engine contained lower levels of iron, lead, chromium, and zinc metal debris than the diesel fueled engine. However, the aluminum content in the lubricating oil of the K10 engine was slightly higher than that of the diesel fueled engine. In conclusion, Karanja oil has the potential to be a partial substitute for mineral diesel in DICI engines without substantial hardware modifications.

Singh et al. [179], highlighted the potential of non-edible vegetable oils for the production of biolubricants and discussed their properties, benefits, and applications. The study also provides an overview of the global lubricant market and future opportunities. Non-edible vegetable oil-based biolubricants offer several advantages, including enhanced lubricity, high viscosity, good anti-wear properties, high viscosity index, longer equipment service life, high load carrying capacity, low evaporation rate, and minimal emission of metal traces into the atmosphere. These characteristics indicate that non-edible vegetable oil-based biolubricants have the potential to offer a longer lifespan than traditional lubricants.

5.7. Overall Performance

The performance evaluation based on several studies, showed that, in general, on the lubrication area, both vegetable oils and standard MWFs can provide lubrication to metalworking tools, reducing friction and wear on the tool, however, standard MWFs may have a higher lubricating ability than vegetable oils, particularly when using synthetic MWFs. Both vegetable oils and standard MWFs can provide cooling to metalworking tools, but standard MWFs are typically more effective at cooling than vegetable oils, particularly in high-speed or high-temperature applications. Both vegetable oils and standard MWFs can provide some level of corrosion resistance to metalworking tools, but standard MWFs may be more effective at preventing rust and corrosion on certain metals. Vegetable oils are generally more biodegradable and environmentally friendly than standard MWFs, which may contain hazardous chemicals and pollutants, but are also often more cost-effective than standard MWFs, particularly synthetic MWFs, which can be quite expensive. In terms of the lifespan, standard MWFs may have a longer lifespan than vegetable oils, particularly synthetic MWFs, which can be used for longer periods of time without needing to be replaced.

The performance of vegetable oils as MWFs can vary depending on a variety of factors, including the type of oil used, the application, and the conditions under which the fluid is used. The addition of additives and nanoparticles can also significantly affect the performance of vegetable oil-based fluids. Vegetable oils as potential base stocks for lubricants and MWFs, have some advantages and disadvantages as depicted in Table 6 over mineral oils’ properties. The difficulties listed under disadvantages section are usually solved by proper modification of the base oil.

Table 6.

Advantages and disadvantages of vegetable oils as lubricants [93].

The studies mentioned, suggest that vegetable oil-based cutting fluids and MWFs with the addition of additives and nanoparticles can provide improved performance compared to conventional fluids. However, as with any new fluid or additive, it is important to carefully evaluate its performance for a specific application before implementing it on a larger scale. It is important to note that the performance of vegetable oil-based cutting fluids and MWFs can vary depending on the specific application and the conditions under which the fluid is used. While some studies have reported improved performance with the addition of additives and nanoparticles, other studies have reported mixed or inconclusive results. Therefore, it is important to conduct careful evaluation and testing to determine the optimal fluid and additives for a given application.

6. Conclusions

Metalworking fluids (MWFs) play an essential role in the machining and metalworking industry. The primary function of these fluids is to reduce friction and wear, cool and lubricate the cutting tool, and remove chips and other debris from the cutting zone. For many years, the most common fluids used for these purposes were mineral oil-based fluids, but in recent years, there has been a growing interest in the use of vegetable oils as an alternative. Vegetable oils are an attractive option for several reasons. Firstly, they are renewable, biodegradable, and have low toxicity compared to conventional petroleum-based fluids. Secondly, they are relatively low-cost and widely available, which makes them a sustainable option for many applications. Thirdly, vegetable oils contain natural lubricants and antioxidants that can improve their performance as MWFs.

One of the main challenges with using vegetable oils as MWFs is that they can have poor stability and low resistance to oxidation. This can lead to the formation of deposits and sludge, which can clog up the cutting tool and reduce performance. To overcome these challenges, researchers have been exploring different methods to modify the chemical and physical properties of vegetable oils, such as hydrogenation, esterification, and blending with other oils. These modifications can improve the stability, lubricity, and anti-wear properties of vegetable oils, making them more suitable for use as MWFs. Additives and nanoparticles can also be added to the vegetable oil to improve its performance. Vegetable oils can also be more sensitive to temperature changes than conventional fluids, which can affect their performance. Additionally, vegetable oil-based fluids can be more prone to microbial growth, which can lead to the formation of bacteria and fungi that can damage the cutting tool and reduce performance.