1. Introduction

Thermo-elastohydrodynamic lubrication (TEHL) occurs in a variety of machine components, e.g., cam-follower contacts, bearing contacts, and gear contacts. Because of the relatively small contacts that are highly loaded, the film thickness is very small, whereas the hydrodynamic pressure can rise significantly, even up to 3 GPa. In case of significant slip and shear, the temperature may also rise significantly within the small contact. It is well known that there is a significant variation in the properties of the lubricant under these conditions. In the past 50 years, several constitutive equations have been developed to describe the dependency of lubricant properties on the governing conditions in TEHL contacts. These equations have been used in numerical modelling to evaluate pressure and temperature distributions, film thicknesses, and to calculate friction. It is well known that constitutive models for viscosity and density are crucial to obtain proper results from the numerical modelling of TEHL contacts.

In brief, there are three so-called equations of state developed by Dowson, Tait, and Murnaghan which link the density to the pressure. Dowson and Higginson obtained a compressibility model from curve-fitting data of mineral oils as a function of pressure up to about

for a given temperature [

1]. Note that Tait’s equation is an empirical model, whereas Murnaghan’s equation is derived from a linear theory of finite strain [

2].

Besides density, viscosity also plays an essential role in (T)EHL. There are mainly three mechanisms impacting the viscosity, i.e., piezo-viscous behaviour, temperature dependency, and shear thinning behaviour. Typically, the pressure and temperature effects are taken into account through a Newtonian viscosity model, whereas a non-Newtonian model is required when shear rates are high, e.g., when sliding occurs. The Roelands model is the most commonly used Newtonian viscosity model [

3]. This empirical correlation was reported to be valid at least up to

and between 20–50 °C for general mineral oils. Doolittle, on the other hand, developed a model based on free-volume theory for liquid viscosity and suggested using the free volume, related to density, as an input variable for viscosity calculation instead of using temperature and pressure directly [

4]. A free-volume model states that the relative volume of molecules present in a liquid affects the resistance to flow. Note that these models have been modified several times to be adopted for the TEHL problem [

5,

6,

7].

At high shear rates, liquid lubricants display a non-Newtonian behaviour, particularly shear thinning, implying that the viscosity decreases with increasing shear rate. Johnson and Tevaarwerk [

8] investigated the fluid shear behaviour in the EHL oil film and proposed the original form of the Eyring model. They found a broad agreement between the non-linear Maxwell model and Eyring theory when the pressure and temperature variation were taken into account. The Eyring model has often been used in classical EHL calculation. However, in some recent studies, the non-Newtonian Carreau shear thinning model has been preferred [

9,

10,

11]. It has been proven that the sinh law or Eyring model can predict the traction curve accurately according to the traction test of Conry et al. [

12]. Note that this study specifically investigated the traction curve for LVI260 oil. However, Bair reported different properties of LVI260, especially the viscosity and shear modulus [

7]. Furthermore, Bair et al. [

13] argued that the viscosity data should be fitted to the rheological flow curve (viscosity vs. shear rate) to predict both traction and film thickness accurately and not to the traction curve. Furthermore, the basics and assumptions behind these shear thinning models are reviewed by Spike and Jie [

14]. They stated that input parameters in the Eyring and Carreau models greatly affect the accuracy of these models; both models could predict accurately when their parameters were tuned. However, Bair et al. [

15] objected to this, pointing to some misrepresentations in the work of Spike and Jie.

Kumar and Khonsari [

16] compared the Eyring (sinh law) and power law-based Carreau models. They showed that the Carreau model could predict central film thickness more successfully in the EHL point contact. They also showed that the traction curve is more sensitive to the value of the pressure-viscosity coefficient. In a recent study, Tosic et al. [

17] employed the CFD-Boussinesq approach to investigate more in-depth the differences between the two sets of constitutive models mentioned earlier. They indicate that the choice of constitutive models becomes more crucial at higher loads. However, Tosic et al. applied a very low Eyring stress value for Squalane in their comparison, which can considerably influence the evaluation of the final TEHL solution.

Although the combination of Dowson, Roelands, and Eyring models was typically used in classical EHL calculations, the combination of Tait, Doolittle, and Carreau models has recently received more attention. Despite the fact that all of these models claim to be accurate, there is still some debate about their accuracy and the fundamental differences between them [

14,

15]. Although several studies have mainly focused on the differences in the prediction of viscosity, mean shear stress, and traction curve [

18,

19,

20,

21], the actual sensitivity of TEHL solutions and derived parameters to the chosen constitutive models for the same lubricant have not been investigated in-depth and will be the focus of this paper.

The classical Reynolds approach has been extensively used to investigate the importance of using reliable rheological models [

22,

23,

24]. This approach has been proven to be accurate and efficient for EHL contact under isothermal conditions. Nevertheless, the Reynolds approach, albeit a modified version, is also used for non-isothermal EHL calculations and requires coupling with an energy equation to calculate thermal transport along and across the lubricant film and in the solids. An additional complication is that the Reynolds equation requires integration over the film thickness of the lubricant properties, which are temperature-dependent. Alternatively, one can solve the complete set of conservation equations, i.e., mass, momentum, and energy, using CFD in combination with constitutive equations to describe the dependency of lubricant properties to state variables and shear rate, avoiding the use of complicated integral of the properties across the film thickness. It goes without saying that CFD involves much more computing time and resources but with the gain of offering potentially more in-depth insight into local physical phenomena [

25].

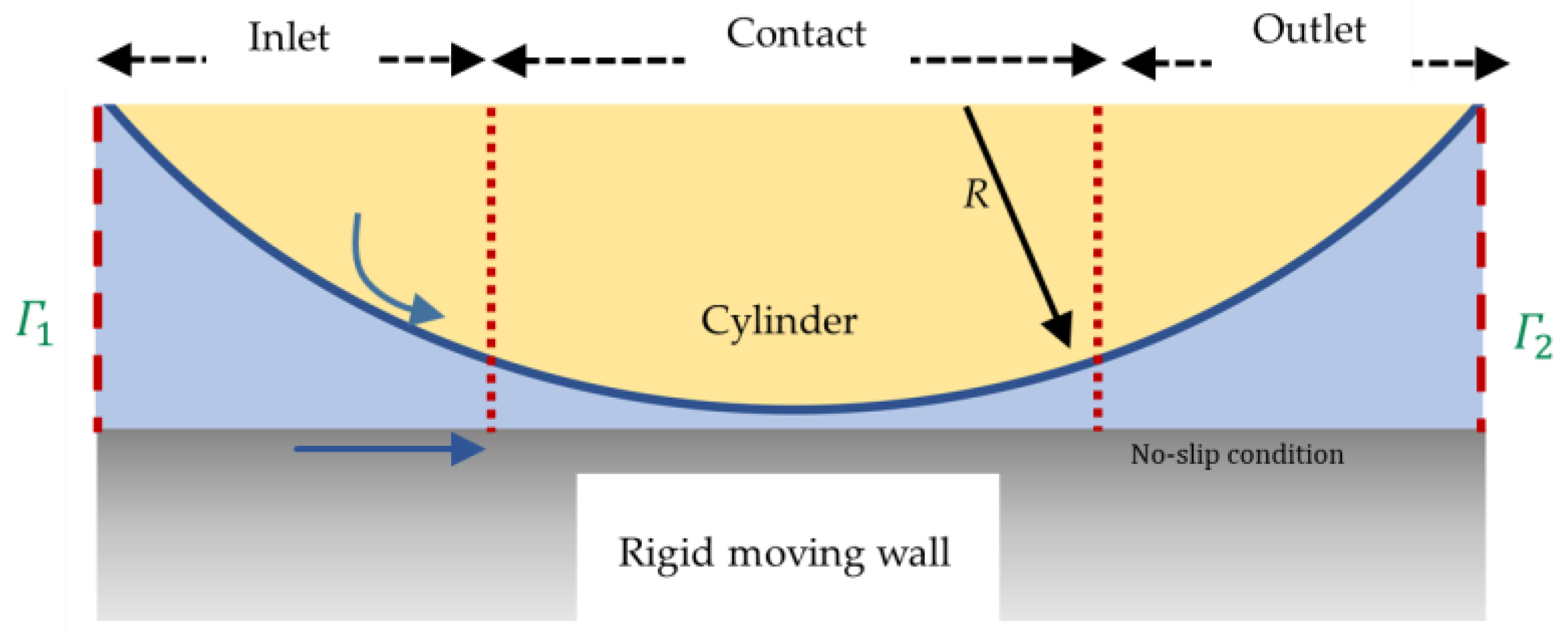

Almqvist and Larsson [

26], in their pioneering work, opted to solve the Navier–Stokes equations instead of the Reynolds equation to simulate TEHL contacts. They used a single-phase CFD model, which involved solving equations for mass and momentum conservation, as well as an energy equation. They successfully simulated TEHL contact with a maximum contact pressure of

. Hartinger et al. [

27] were one of the first to model a 2D line TEHL contact using CFD. They have found a significant pressure gradient across the lubricant film in sliding conditions, which is mainly due to the viscosity gradient induced by the temperature gradient across the film thickness. A thermal validation of this model for 3D point TEHL contact was presented later [

28]. Hajishafiee et al. [

29] extended Hartinger’s model to include a linear elastic structural model for the solid body as well as a robust and two-way FSI coupling model, which is more appropriate for high loads. Scurria et al. [

30] compared the Reynolds equation and the full Navier–Stokes equation for EHL contact under isothermal conditions for Newtonian lubricants. They observed that the inertia term influenced the accuracy of the Reynolds solution, especially at low loads and relatively high speeds of rotation.

In this paper, the authors aim to compare the film thickness, lubricant temperature, and traction curve of the aforementioned two groups of well-known constitutive models, commonly used together, under different operating conditions. Thereto the CFD-FSI approach is used to avoid effects of film thickness averaging of lubricant properties. The first group includes the Dowson model for the density and the Roelands and Eyring models for viscosity. The second group includes the Tait model for density combined with the Doolittle and Carreau models for viscosity. A homogeneous equilibrium model (HEM) is used to describe cavitation, and the above-mentioned advanced constitutive models are implemented and applied. Moreover, a linear elastic solver in combination with a temperature equation is employed to describe deformation and heat conduction through the solid materials. The numerical results will fundamentally be evaluated to provide a clear picture for comparing these models. Moreover, the deviations between predicted contact variables, e.g., film thickness, temperature, coefficient of friction, etc., will be quantified for these well-known lubricant constitutive equations under a wide range of operating conditions.

3. Constitutive Modelling of the Lubricant

As a lubricant, Squalane (SQL) is used in this study because its constitutive behaviour has been reported in a wide range of pressure, temperature, and shear rate. The density and viscosity of SQL have been measured in different laboratories and are available in the literature [

4,

37,

38] with maximum uncertainties of

. In the following sections, we discuss the existing models used in the literature for modelling the rheological behaviour of SQL.

The current study targets to evaluate the effects of two groups of constitutive models, which are commonly used, on different variables of interest in the TEHL contact. The first group—further denoted as TDC—consists of

Tait equation of state [

7]

Doolittle Newtonian viscosity model (P, T dependency) [

20]

Carreau shear thinning model (shear rate dependency) [

7]

And the second group—denoted as DRE—includes:

Dowson equation of state [

1]

Roelands–Houpert Newtonian viscosity model (P, T dependency) [

27,

29]

Eyring shear thinning model (shear rate dependency) [

28]

The chosen constitutive models have been widely used by different research groups, and our choice to include them in our study was based on their prevalence in the literature. The first group of equations is presented in

Table 3, and the second group is listed in

Table 4. More details about these models can be found in the provided references. All fine-tuned parameters related to these models have been found in the literature, which will be explained later. Note that in these equations,

and

are density, dynamic viscosity of Newtonian fluid, and dynamic viscosity of the non-Newtonian fluid, respectively.

Moreover, at a pressure in the order of

, the thermal properties are not constant; hence, Equations (33)–(36) include pressure and temperature influences on heat conductivity and heat capacity of the lubricant [

22,

38]. The thermal properties models are listed in

Table 5.

The fine-tuned parameters for TDC models are suggested in [

5,

39,

40] and listed in

Table 6, and the constants in DRE models are provided in

Table 7 for SQL. Note that these parameters are listed for an inlet temperature of 313.15 K. The dynamic viscosity of liquid at ambient pressure for different temperatures can also be found in [

5], and the pressure–viscosity and temperature–viscosity coefficient can be extracted from the data available in [

41]. It is worth noting that the Eyring stress was chosen based on the curve fitting to the experimental data. The authors have properly fitted the experimental data of reference [

42] by using Eyring stress of 5.5 MPa, which is consistent with previous studies as noted in reference [

14]. In practice, the DRE model set is almost exclusively used in conjunction with direct measurements of EHL parameters, such as traction curves and optical film thickness measurements, rather than calibrating it to measurements obtained from high-pressure viscometers and rheometers. The TDC model set, on the other hand, is almost exclusively used in combination with high-pressure rheometer data. Typically, laboratories which have high-pressure viscometers available do not use DRE models to correlate their data.

However, to assess the intrinsic accuracy and its impact on TEHL parameters, the authors believe both constitutive model sets should be properly calibrated to the same experimental datasets. Here, we opted to use publicly available high-pressure rheometer data for calibration because we believe it is a more rigorous approach to match the material properties directly to the measurements than to determine the constitutive properties by matching secondary variables (e.g., traction curves, film thicknesses) via inverse engineering approaches. The latter inevitably rely on intermediate models (e.g., CFD-FSI, Reynolds–Boussinesq). However, we note that the selected approach assumes the availability and reliability of high-pressure rheometer data for Squalane, which are unfortunately not always available for the majority of commercial lubricants.

We should emphasize that these parameters have been chosen according to the numerical studies that used SQL with previously mentioned models. For example, the Dowson EoS with generalized constants has been used, while these constants could be calibrated for SQL. The authors have used common models with suggested constants from the literature to show the deviation and sensitivity of the TEHL solution to the selected models; therefore, no calibration has been performed.

Furthermore, the fine-tuned parameters for thermal properties are provided in

Table 8. Note that the same thermal properties models have been used for comparison between DRE and TDC groups. In addition, the steel material with the properties listed in

Table 9 was used in this study.

The relative volume has also been plotted for Tait and Dowson equations of state in

Figure 2. The data is limited to

pressure, whereas the deviation becomes larger at higher pressure, which can be considered the difference in the extrapolation of data using Tait and Dowson equations. In the Dowson EoS, the temperature dependence has been accounted for by multiplying a linear lubricant temperature function with the original model, such that the density of the lubricant can be expressed as the product of two separate density functions:

. Although this shows correct behaviour at ambient pressure, the influence of temperature at higher pressure has not been taken into account properly. A better fit could be obtained if the constants in Equation (27) depend on temperature. However, such an approach is typically not followed in the literature. Hence, this motivates our choice to use the proposed constants of Dowson as commonly used in the literature.

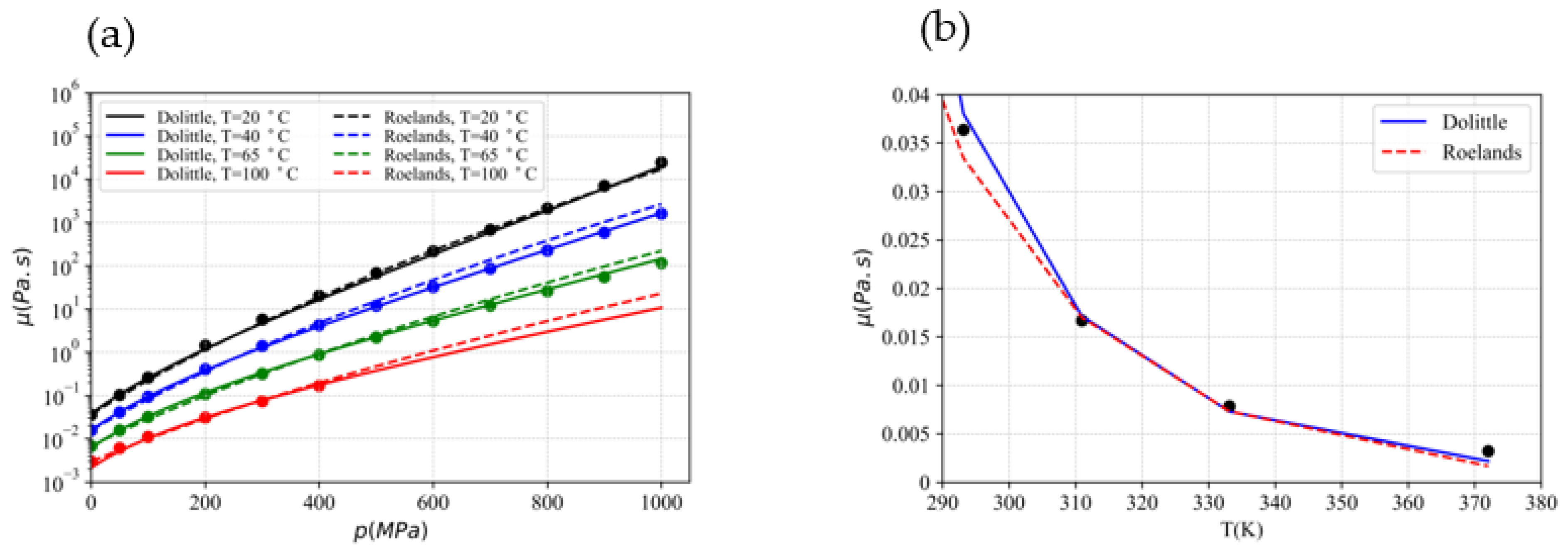

The viscosity is plotted against the pressure for four different temperatures at a zero shear rate in

Figure 3a. The point data are experimental data presented in [

5,

43] for Squalane. A deviation between the predicted Newtonian viscosity by the Roelands–Houpert and Doolittle models can be identified as the pressure and temperature increase. This deviation can be related to the pressure and temperature dependencies of viscosity,

and

(please see Equations (28)–(31)). Note that

and

are assumed constants and their values have been tuned for each temperature according to the available measured coefficient in [

41] to obtain the best-fit curve. It is worth noting that, according to experimental measurement,

decreases with an increase in temperature and pressure, whereas

is decreased with temperature and increases with pressure.

Typically,

and

β are determined according to the temperature of the lubricant at the inlet. However, the lubricant temperature can go significantly higher than the inlet value, implying that the fixed values of

α and

β are not consistent anymore in the contact. As a result, considering constant values for the pressure and temperature dependency of viscosity can affect the accuracy of the Roelands Newtonian model. For example, assuming an inlet temperature of

, using a constant value for

according to this temperature leads to a lower viscosity value for lubricant temperature above

than what is presented in

Figure 3a.

It is worth emphasizing once again that the authors follow the common approach in the literature, in which and are constant and selected based on the inlet condition, whereas the authors are aware that these parameters should be temperature- and pressure- dependent.

Additionally, the temperature dependency of viscosity at atmospheric pressure is shown in

Figure 3b, in which both models have a slight deviation in comparison to experimental data. This plot contains a limited amount of data, whereas more data on a broader temperature range would be beneficial to evaluate the Doolittle versus Roelands models.

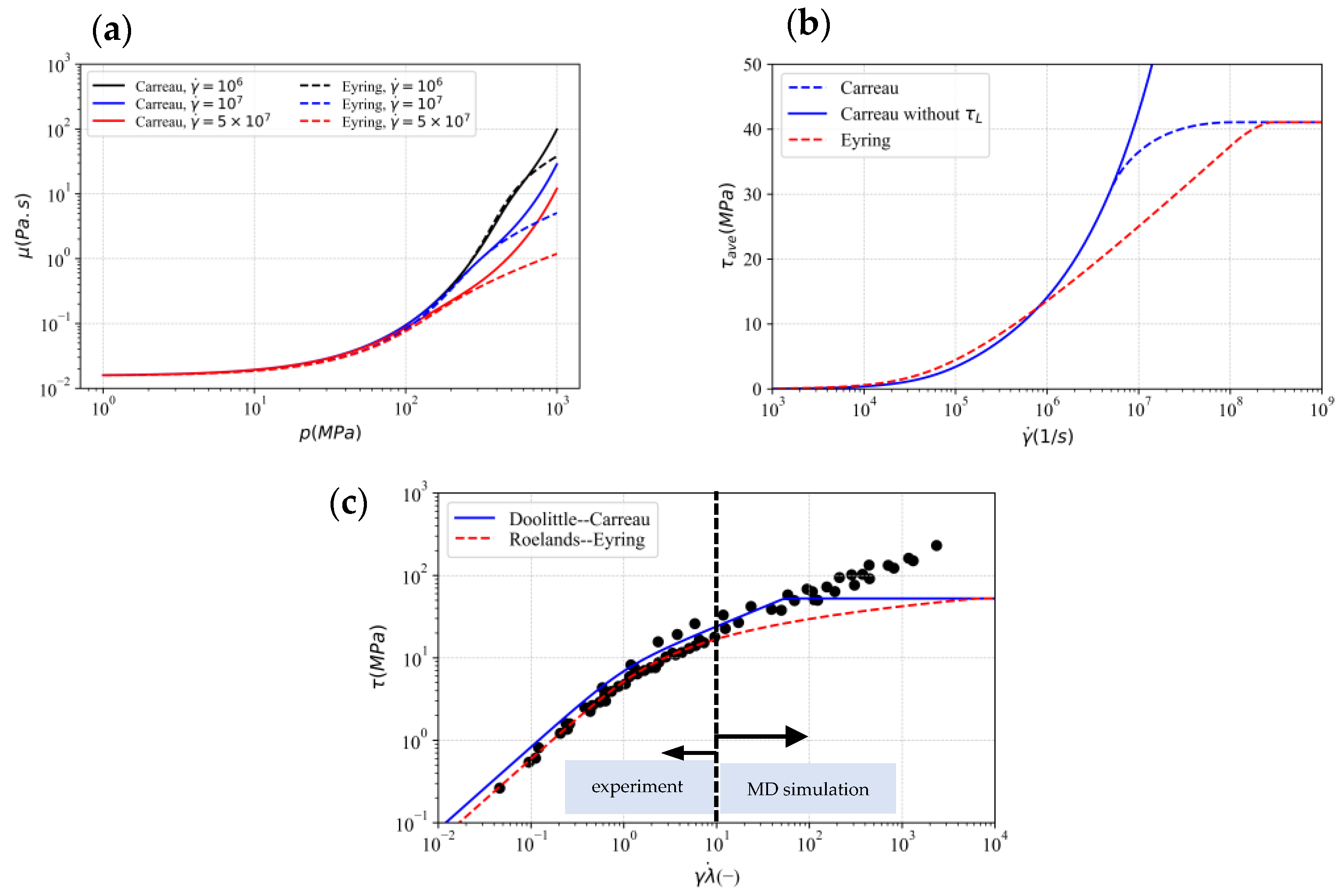

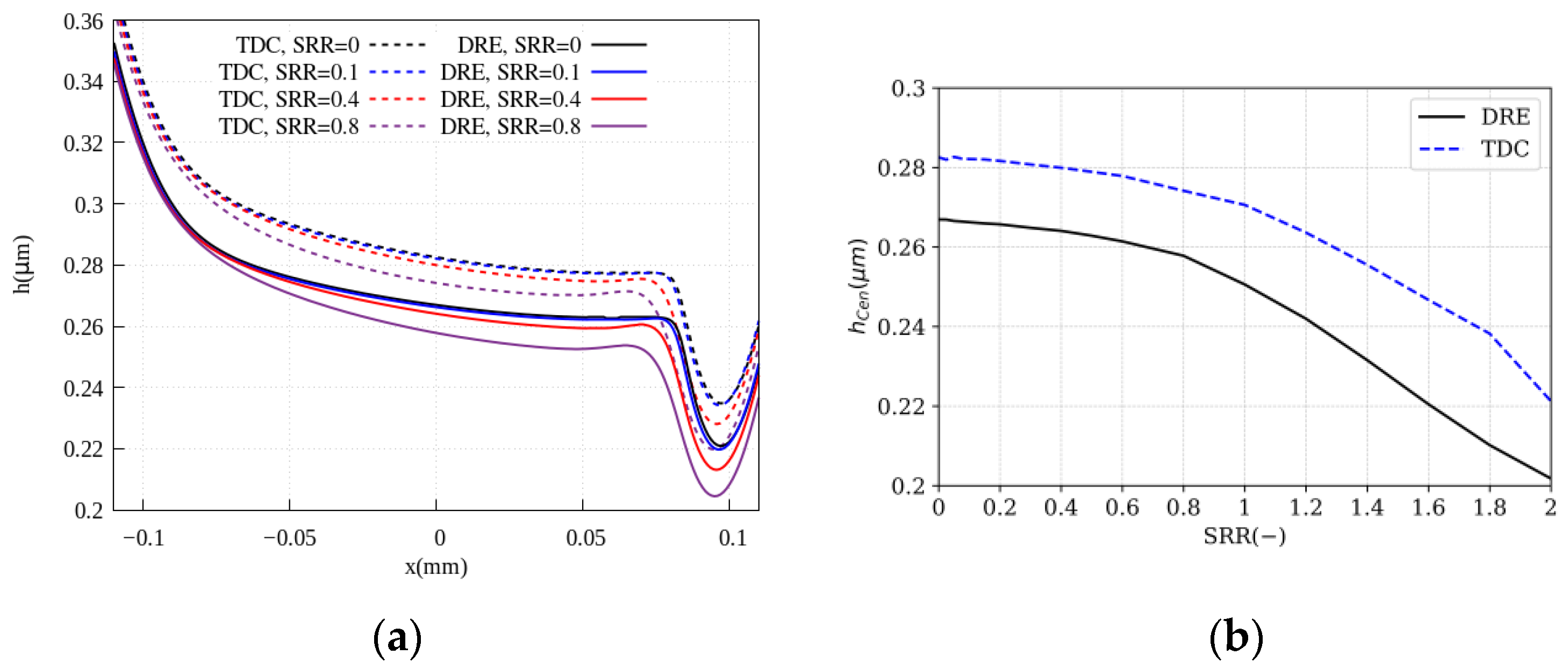

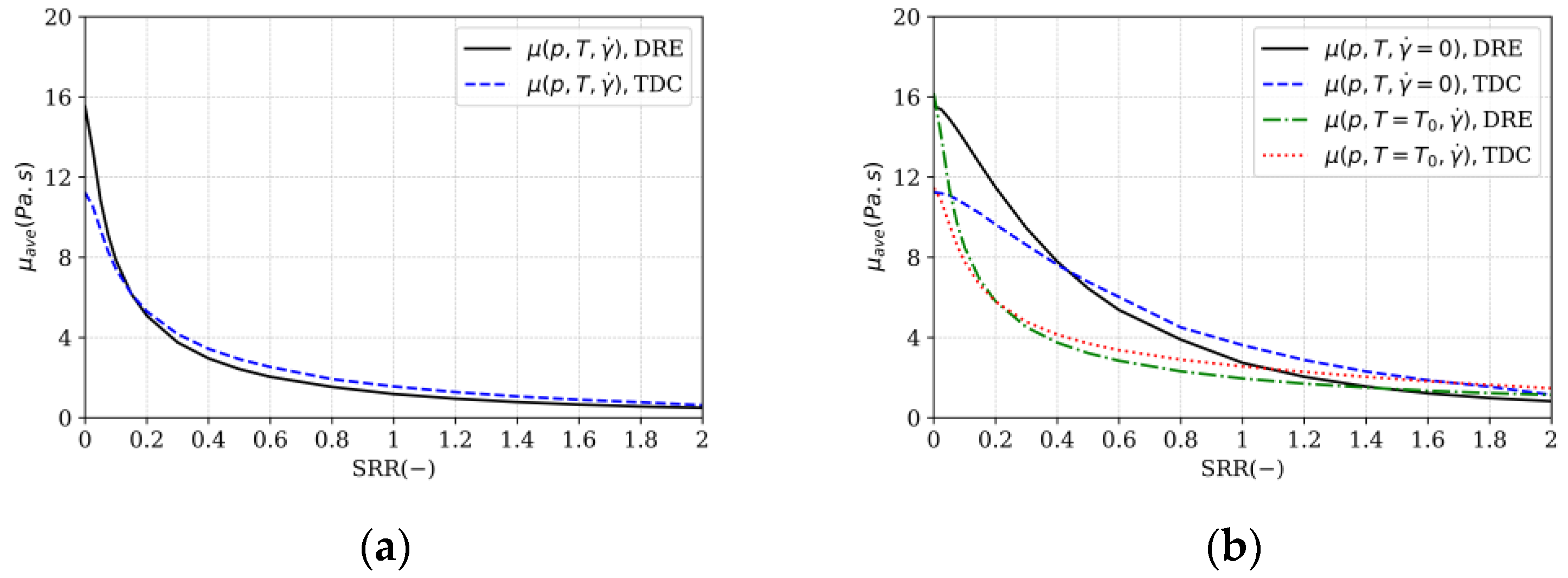

Finally, the shear dependency of viscosity models is illustrated in

Figure 4a. The viscosity at different shear rates is plotted against the pressure. In brief, the deviation between models becomes more significant as the pressure and shear rate increase, and the Carreau model predicts a higher viscosity value than Eyring.

Figure 4b displays the mean shear stress as a function of the shear rate for a maximum contact pressure of

and an inlet temperature of

. The mean shear stress profiles of the Eyring and Carreau models are clearly different at high shear rates. The mean shear stress, predicted by the Carreau model, requires limiting shear stress in order to prevent a continuous rise of the shear stress. Additionally, the limiting shear stress has been incorporated into the Eyring model. The master curve is also presented in

Figure 4c, indicating a deviation between Eyring and Carreau shear thinning models in the log–log scale. The point data for

are experimental data [

7], and the other part of data are extracted from non-equilibrium Molecular Dynamic (MD) simulations [

44,

45]. The MD results at high shear stress cannot be perfectly fitted by any of these models. Furthermore, MD simulation cannot describe the limiting shear stress. Even so, Carreau and Eyring can be compared with the master curve.