Abstract

Surface friction in metal forming processes can be reduced by creating lubricant reservoirs at the interface between surfaces in contact, and a laser texturing process can be employed to produce the micro-dimples that act as the reservoirs on the surfaces. However, the role of the laser texturing parameters in the friction reduction of tool steel surfaces has still received very little attention. Therefore, this study aims to reduce the friction of the AISI D2 tool steel surface on which a nanosecond pulse laser was applied to create an array of micro-lubricant pockets for trapping lubricant. The effects of laser power, irradiation duration, and spacing distance between pockets on the pocket diameter, size of the heat-affected zone, surface friction, and wettability were investigated in this work. The average laser power in the range from 5 to 10 W and laser irradiation duration of 0.02 to 0.10 s were applied. The results showed that the increase in laser power and irradiation duration enlarged the pocket diameter and heat-affected zone. The largest pocket diameter of 40 µm was achievable by using 10 W laser power together with 0.10 s irradiation time. The pin-on-disc method was employed to determine the friction coefficient of the tool steel, where JIS SPFC 980Y advanced high-strength steel was used as a disc. The friction coefficient of laser-textured with different spacing distances of 150, 200, and 250 µm versus untextured surfaces was compared and found to vary depending on the applied normal load. The laser-textured surface having a pocket spacing distance of 150 µm and pocket density of 5.6%, offered the lowest friction coefficient of 0.097 on average for all tested loads, whereas the average friction coefficient of the untextured surface was 0.117. In addition, the wettability of textured surfaces was insignificantly changed compared to that of untextured ones, so the micro-lubricant pockets did not cause oleophobicity affecting the performance of lubrication. Well-defined micro-pockets using the most appropriate laser parameters, i.e., 10 W laser power with 0.10 s irradiation duration and 150 µm spacing distance, successfully reduced the sliding friction of contacting couples between the laser-textured tool steel and advanced high-strength steel surfaces. The low surface friction induced by the laser-fabricated micro-lubricant pockets has been feasible for the forming tool and die applications where the energy consumed in their operations can be minimized.

1. Introduction

An effective approach for improving energy efficiency or reducing the fuel consumption of automobiles is to reduce their total weight. This is a major challenge in manufacturing which pushes the design and production limits of lightweight components. High-strength steels generally offer a high potential for the reduction of automobile weight due to their high specific strength [1]. However, their formability is very poor as the forming of such metals requires high forces and machine power. Importantly, this shortens the tool’s life and consumes high contact pressure in the forming process. Galling or severe scratch, which is a type of adhesive wear, is a major problem in the forming of advanced high-strength steel sheets (AHSS) [2]. This problem can be remedied by selecting a proper die material that is of low surface friction, such as carbides, ceramics, and cermets. Another approach is to make the lubricant retained on the die surface throughout the forming operation. Various ceramic dies have been applied in the deep drawing of various sheet materials since friction and surface damage can be substantially reduced. Deep drawability in a dry condition can be attained both for mild steel, and pure copper sheets with silicon nitride and silicon carbide dies, and the drawing load for stainless steel sheets is significantly reduced when using an alumina die [3]. Electro-conductive ceramic dies can be employed in the deep dry drawing of cold rolled mild steel (SPCC) sheets. The zirconia-based electro-conductive ceramic die operating without lubricant has an equivalent deep drawability to the conventional cold work tool steel die with lubricant [4]. In the case of cermets, a TiCN-based cermet die can improve the formability of stainless steel drawn cups [5]. The tribological performance of Ti(C, N)-based cermets with different graphite contents is investigated, and the cermets containing graphite can significantly improve the tribological properties [6].

Coatings deposited on the forming tools are usually used to minimize tool wear and prolong tool life. The low friction coefficient and high hardness of coatings are important factors for limiting adhesive wear and enhancing the anti-galling performance of the tool surface [7,8,9,10]. Although the hard coats can enhance the surface properties and prolong the service life of forming dies, lubricant is usually employed to further reduce the friction taking place in the forming process.

The lubrication of interfacial surfaces during the sheet metal forming process is essential for reducing friction and preventing the adhesion of work material to the forming tools. The micro-plasto-hydrodynamic lubrication is apparent when the lubricant is entrapped, pressurized, and subsequently extracted from pockets on the structured work surface [11]. Mizuno and Okamoto [12] investigated the effects of lubricant viscosity, pressure, and sliding velocity on lubricating conditions. The work surface, which has micro pockets for trapping the lubricant, is preferred to reduce friction during the forming process. By using high-viscosity lubricants under high pressure and high sliding speed, the thickness of boundary films is found to increase with the amount of trapped lubricant in the pockets at the interface. Steinhoff et al. [13] also found that the work surface having lubricant pockets facilitates the lubrication in forming processes substantially. Bech et al. [14] observed the entrapment and escape of liquid lubricant in the metal forming, and they found that the escape of lubricant from the pockets in the strip drawing importantly affects the drawing load. The use of high contact pressure can also lead to the breakdown of lubricant film and result in the galling accordingly.

Lasers are a promising tool for rapidly and accurately fabricating micro-scale pockets or textures on the surface of various materials. Geiger et al. [15] use an excimer laser for texturing the surface of the TiN-coated punch used in the cold forging process. The laser-textured surface can entrap the lubricant during the forming process, thus reducing friction and increasing tool life. Wakuda et al. [16] found that the frictional properties of silicon nitride ceramic tool are improved by creating micro-scale pockets on its surface, and the friction coefficient of a textured surface is lower than that of untextured one when the suitable size and density of pockets are applied. The pocket shape, however, does not affect the reduction of the friction coefficient [16]. Vilhena et al. [17,18] use an Nd: YAG laser for producing pockets on 100Cr6 bearing steel surface, and they found that the dimensions and quality of pockets are subject to the laser processing parameters. The textured surface has a detrimental effect on the friction for the point contact, whereas the friction is substantially reduced in the case of flat contact. The tribological behavior of textured surfaces also depends on the depth of pockets. An increase in the pocket depth provides a positive effect toward the reduction of surface friction as it can entrap more amount of lubricant. Apart from lasers, Basnyat et al. [19] created micrometer-sized pocket patterns on TiAlCN hard coatings by using a reactive ion etching technique and filled with solid lubricants. The friction of the textured surface is significantly reduced because the pockets act as reservoirs for supplying the solid lubricants to the interface. Li et al. [20] investigated the friction of textured nickel-based composite surfaces filled with molybdenum disulfide (MoS2) powder at high temperatures in a dry sliding condition. The friction coefficient of the surface is low, and the pockets can trap wear particles and raise the effective lubricating temperature of the solid lubricant. Meng et al. [21] investigated the influence of rectangular pockets with a flat bottom on the friction of parallel surfaces under different sliding conditions. Abe et al. [22] improved the adhesive wear resistance in the ironing of stainless steel cups by utilizing a TiCN-based cermet die having fine lubricant pockets. The pockets are prepared by shot-peening followed by a polishing process. The friction is reduced by the squeezing of liquid lubricant from the pockets into the die-cup interface during the process. Schneider et al. [23] found that the pocket pattern, density, and aspect ratio, which is a depth-to-diameter ratio, influence the reduction of friction. The pockets arranged in a hexagonal pattern with a pocket density of 10% and an aspect ratio of 0.1 provide the maximum reduction of friction. Shimizu et al. [24] revealed the underlying mechanism and relationship between the geometrical parameters of dimple surface textures and lubrication properties during the ironing process of the stainless steel sheet. The influence of the lubricant reservoir on the load-carrying capacity of the lubricant during the ironing operation is found to depend on the pocket size. The lowest punch force is obtained when using the pocket diameter of 50 µm together with a high-viscosity lubricant. Lasers have been utilized for texturing Ti6Al4V titanium alloy surfaces with different morphologies, i.e., lines, crosshatching, and dimples. The lowest steady-state coefficient of friction is obtained for the dimpled surface [25]. Gaikwad et al. [26] further noted that the increase in dimple density decreases the friction and wear of the laser-textured Ti6Al4V surface. Although metal surfaces can be textured to improve their tribological properties by using ion etching and shot-peening techniques, lasers are still mostly used for texturing or creating micro-features on the surface due to their fine-scale, repeatable, highly-automated, rapid, and non-contact processing in addition to their viability for ablating most materials [27]. Hence, the laser surface texturing process has attracted both industrial and academic interests in producing tailor-made morphology and improving the tribological properties of tool and die surfaces toward metal-forming applications. However, the tool and die utilized for forming advanced high-strength steel under a high load typically result in adhesive wear. The friction reduction of contacting couples between the tool steel and advanced high-strength steel surfaces is anticipated by creating a particular morphology with the aid of the laser texturing process. Since there has been very little discussion on the effect of laser texturing parameters on the size of micro-scale pockets for lubrication, this present work attempts to gain a better insight into the texturing process and reveal the capability of the laser-textured surfaces to reduce friction.

In this study, micro-scale pockets for trapping lubricant and wear debris were made on the AISI D2 tool steel surface by using a nanosecond pulse laser. The effects of average laser power and laser irradiation duration on the pocket diameter and size of the heat-affected zone were investigated. In addition, the influences of the spacing distance between adjacent pockets on the surface friction and wettability were examined through the pin-on-disc test and contact angle measurement. The understanding of these issues could provide an essential guideline for reducing the friction of metal surfaces by means of the laser-fabricated micro-lubricant pockets.

2. Experimental Procedures

2.1. Materials

AISI D2 tool steel (DIN 1.2379 or grade SKD11, JIS G4404 according to Japanese Industrial Standards) was employed as samples for laser texturing and as pins for a friction test. The raw material of bulk metal was machined into square samples (2 pieces) with dimensions of 30 mm × 30 mm × 10 mm and cylindrical pins (40 pieces) with a diameter of 6 mm and a length of 30 mm. The end of the pins was tapered to the flat with a diameter of 3 mm. The samples and pins were heat treated in a vacuum heat treatment furnace at a hardening temperature of 1050 °C with a holding time of 90 min and then quenched in nitrogen at a pressure of 280 kPa. The samples were subsequently tempered for two cycles at a temperature of 500 °C for 90 min and cooled in nitrogen gas at a pressure of 80 kPa to room temperature. A hardness of 63 ± 2 HRC measured by a microhardness tester (MMT-X series from Matsuzawa Co. Ltd., Akita, Japan) was obtained in this study. The work surface was initially prepared by grinding and polishing processes to obtain a flat and smooth surface with the arithmetic average roughness, Ra of 0.08 ± 0.01 µm. The surface roughness measurement was performed by a 2D stylus method using an 8 mm measured length with a 0.8 mm cut-off. The Young’s modulus, tensile strength and 0.2% offset yield strength of AISI D2 are 208 GPa, 1736 MPa and 1532 MPa, respectively [28,29]. AISI D2 tool steel contains the chemical composition (wt.%) of 1.4~1.6C, max.0.4Si, max.0.6Mn, max.0.03P, max.0.03S, 11~13Cr, 0.8~1.2Mo and 0.2~0.5V [30].

2.2. Laser Surface Texturing Process

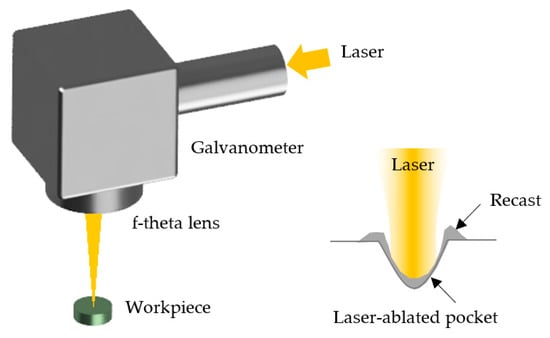

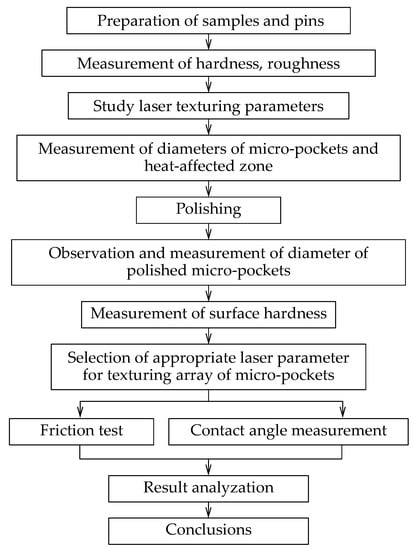

A nanosecond pulse laser was used to create an array of micro-scale pockets on the steel surface in this study. The laser emitted a wavelength of 1064 nm and provided the laser pulse duration and repetition rate of 100 ns and 100 kHz, respectively. A galvanometer equipped with a 100-mm f-theta lens was employed for scanning and focusing the laser beam on the workpiece surface. The laser beam distribution was Gaussian, and the focused beam diameter at 1/e2 intensity was 37.66 µm. The workpiece surface was cleaned with methanol prior to the laser texturing process. The process was carried out under the ambient air without using any assist gas, as shown in Figure 1. Each pocket was produced by irradiating the focused laser beam on the work surface, where the metal melted and vaporized through the ablation mechanism [31]. The flow chart of the experimental procedure is shown in Figure 2.

Figure 1.

Schematic of laser texturing process.

Figure 2.

Flow chart of the experimental procedure.

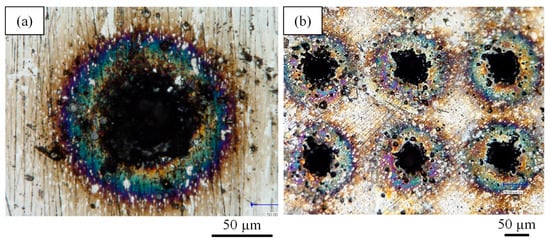

Average laser power and laser irradiation duration were taken into account in this study as they are the main parameters contributing to the heat input toward the workpiece. After some preliminary tests, a remarkable pocket can be obtained when the laser power of equal or greater than 5 W and the laser irradiation duration of equal or longer than 0.02 s were utilized. Regarding the trial tests, six levels of average laser power and five levels of laser irradiation duration were considered. The experiment was conducted in accordance with the full-factorial scheme, where the total number of experiments was 30 tests. Laser texturing conditions used for making the micro-lubricant pockets are given in Table 1. Each condition was arranged in a single row with 20 pockets. The spacing distance between pockets and rows was 200 µm. The average laser power of 5 to 10 W and laser irradiation duration of 0.02 to 0.10 s were applied in the experiment. After texturing the surface, the samples were ultrasonically cleaned with methanol and then dried in hot air. The diameter of the micro-lubricant pocket and size of the heat-affected zone (HAZ) were observed and measured by using a 3D laser confocal microscope (OLS5000 from Olympus Corp., Tokyo, Japan), as shown in Figure 3a. Regarding Figure 3, the size of HAZ can roughly be defined by the burn mark or heat tint appearing around the laser-ablated pocket. The workpieces were then ground to remove burn marks, recast structure, and spatters deposited on the edge of pockets by 1000 and 1200-grit emery papers and later polished by 0.3 and 0.1 µm Al2O3 slurry. The polished samples were observed by a scanning electron microscope (AURIGA FE-SEM/FIB/EDX from Carl Zeiss NTS GmbH, Oberkochen, Germany), and the pocket diameter was measured again by the optical microscope. The hardness at the surface of post-polished pockets was characterized by a dynamic ultra-micro hardness tester (DUH-211S from SHIMADZU Corp., Kyoto, Japan) with a Berkovich indenter measured every 10 µm interval from the distance of 5 µm to 75 µm next to the pocket’s edges with a 50 mN load. A laser texturing condition was selected for creating an array of micro-lubricant pockets with different spacing distances between the adjacent pockets on the AISI D2 tool steel surface. The friction and wettability of the sample surface were quantified by the pin-on-disc test and contact angle measurement. An example of the array of micro-lubricant pockets obtained after the laser texturing process is shown in Figure 3b.

Table 1.

Laser texturing conditions examined in this study.

Figure 3.

Micrograph of (a) single pocket and (b) array of pockets after the laser texturing process with the average laser power of 10 W and laser irradiation duration of 0.10 s.

2.3. Friction Test

The aim of having micro-lubricant pockets on the work surface is to generate hydrodynamic pressure, which enables the lubricant retention and trapping of wear debris. Hydrodynamic pressure is a key factor for reducing surface friction, and it is attained by creating micro-scale pockets on the surface with a pocket density of 5% [32]. The pocket density (Darea) is a function of pocket diameter (d) and spacing distance between adjacent pockets (s), and it is calculated by using [20]:

The laser texturing condition causing the pocket diameter of 40 µm was selected to texture the sample surface for the friction test in this study. In order to alter the pocket density, three different spacing distances, i.e., 150, 200, and 250 µm, were applied in the surface texturing of the samples. These spacing distances are equivalent to the pocket density of 5.6%, 3.1%, and 2.0%, respectively. Besides the 5% density recommended in [32], the lower densities were intentionally considered in this study as the process of making them caused less heat accumulation in the work material and shorter processing time than the texturing with 5% pocket density.

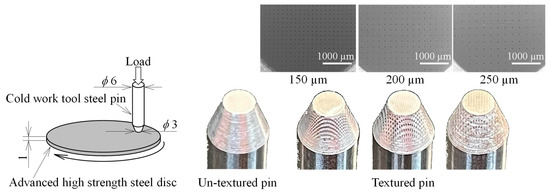

The untextured and laser-textured surfaces were subjected to the friction test regarding the pin-on-disc type (TRB from Anton Parr GmbH, Graz, Austria). The tests imitated the sliding movement between a forming tool against a sheet material in a deep drawing process under a normal load. The contacting couples were an AISI D2 tool steel pin and a JIS SPFC 980Y advanced high-strength steel disc representing the forming die and formed part materials, respectively. Although the typical pin-on-disc test uses the hemispherical-end pin with a point contact to induce Hertzian contact pressure [33], the flat-end pin providing a planar contact was instead employed in this study to enable the investigations of the lubricating effect and roles of micro-lubricant pockets toward the reduction of friction. The AISI D2 flat-end pin was 3 mm in diameter, and its planar contact area was 7.07 mm2. The pin was hardened to 63 ± 2 HRC and subsequently finished by grinding and polishing processes to achieve the arithmetic average roughness, Ra of 0.08 ± 0.01 µm. For the laser-textured samples, an array of micro-lubricant pockets was made on the entire flat-end surface of pins with different spacing distances, as noted earlier. The disc was a 1.0 mm thick JIS SPFC 980Y advanced high-strength steel having the Vickers hardness of 236 ± 5.5 HV and Ra of 0.75 ± 0.05 µm. The disc sample was of an elastic modulus of 206 GPa, a tensile strength of 1002 MPa, a yield strength of 712 MPa, and an elongation of 16% [10]. The chemical composition of JIS SPFC 980Y characterized by an optical emission spectrometer (MAXx LMF05 from SPECTRO Analytical Instruments GmbH, Kleve, Germany) with five analysis points is given in Table 2.

Table 2.

Chemical composition of JIS SPFC 980Y advanced high-strength steels (in wt.%).

The pin-on-disc test was carried out at room temperature under a lubricated sliding condition. A liquid lubricant of highly chlorinated extreme pressure oil blended with fatty additives, namely Castrol ILOFORM TDN 81 with a kinematic viscosity of 157.0–180.0 cSt at 40 °C, was applied in the test. The setting of the pin-on-disc test is shown in Figure 4. The stationary pin slid against the rotating disc at a constant sliding speed of 0.1 m/s. This speed simulated the speed of the press machine used in a deep drawing process. During the tests, the coefficient of friction was recorded as a function of sliding distance. The average coefficient of friction was taken at which the test reached its steady state. Three levels of normal load applied in the friction test were 2, 5, and 8 N, and the contact pressures caused by these loads were 0.283, 0.707, and 1.132 MPa, respectively. The conditions for the friction test are summarized in Table 3. Each testing condition was repeated three times, and the average was calculated as the final reading.

Figure 4.

Pin-on-disc test (unit in mm) and an array of micro-lubricant pockets made on the surface of the flat-end pin.

Table 3.

Friction test conditions.

2.4. Contact Angle Measurement

The wettability of untextured and textured surfaces was quantified through the contact angle measurement of oil and water droplets. The contact angle can indicate the level of surface polarity or surface-free energy that attracts or repels liquid to or from the surface. When the angle of oil or water droplet is greater than 90°, the surface becomes oleophobic or hydrophobic, respectively, and it is unlikely wetted by the liquids. On the other hand, the surface is oleophilic or hydrophilic when the angle is less than 90°. The wettability of metal surfaces can be altered after being textured by laser due to the changes in surface roughness and chemical composition [34]. However, the change in surface wettability to be more oleophobic is undesirable for lubrication as the lubricant cannot wet and retain on the surface. Therefore, the pockets made on the AISI D2 surface should not induce oleophobicity compared to the untextured sample. In this study, the contact angle measurement was carried out by using a contact angle device (OCA 15EC from DataPhysics Instruments GmbH, Filderstadt, Germany) with a sessile drop technique using a 0.5 microliter droplet of oil (Castrol ILOFORM TDN 81) or distilled water. The measurement of each sample was performed three times, and the average angle was calculated.

3. Results and Discussion

3.1. Laser-Fabricated Micro-Lubricant Pockets

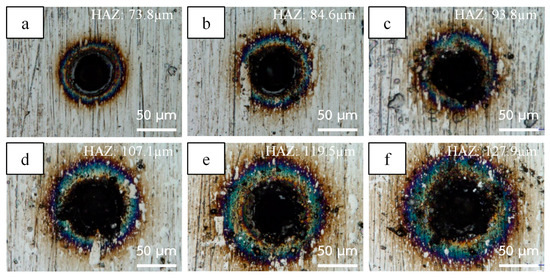

The experiments were performed with regard to the processing conditions given in Table 1. The micro-lubricant pockets caused by using the different laser powers with the irradiation duration of 0.10 s are shown in Figure 5. According to the figure, the pocket diameter was found to increase with the laser power. Since the pocket was fabricated through the laser ablation mechanism, the material irradiated by the laser was rapidly melted and vaporized from the work surface to form a micro-pocket. Some material elements were not completely vaporized but remained in liquid status on the pocket surface during the ablation. The liquid metal was flowed and ejected outwardly from the pocket’s center by the Marangoni effect and recoil pressure. The ejected liquid metal thereby landed on the workpiece surface around the pocket’s edge and then solidified as a recast structure or spatter. The amount of recast is proportional to the laser power applied in the texturing process, as presented in Figure 5. When using high laser power, the heat energy induced by the laser is also high. This leads to a greater thermal gradient and a larger heat-affected zone (HAZ), as well as spatter deposition occurring around the pocket.

Figure 5.

Micro-lubricant pockets obtained after the laser texturing process with the laser irradiation duration of 0.10 s and an average laser power of (a) 5 W, (b) 6 W, (c) 7 W, (d) 8 W, (e) 9 W, and (f) 10 W.

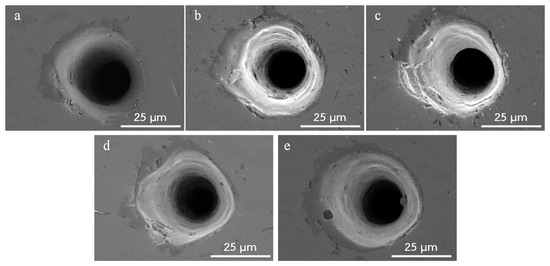

The micro-lubricant pockets obtained by utilizing the different laser irradiation durations with the average laser power of 10 W are illustrated in Figure 6. The sizes of pocket and HAZ also increased with the irradiation duration, but the effects were less compared to those of laser power. By considering Figure 5b and Figure 6c, these pockets were induced by the same energy of 0.6 J. Nevertheless, a smaller pocket with less HAZ and spatters was attained by using 6 W laser power together with 0.10 s irradiation duration (Figure 5b) rather than using 10 W power with 0.06 s duration (Figure 6c). Though the use of low laser power was able to produce the micro-lubricant pocket with small HAZ and fewer spatters, the spatters were still unable to be eliminated from the laser-textured surface. These spatters and recast structures being in a form of metal oxides can dislodge from the surface and seriously cause abrasion wear to the mating surfaces. This is thus not acceptable for the surface specifically prepared for improving the tribological properties. Such recast depositions were subsequently removed by the polishing process prior to the friction test in this study. In addition to the potential abrasion induced by the recast dislodgement, the processing time is another important indicator from the manufacturing point of view. Regarding the case of 0.6 J energy, if the average laser power of 6 W is used instead of 10 W, the processing time will be increased by 67%. This substantially affects the total time consumed in the texturing of large tool/die surfaces.

Figure 6.

Micro-lubricant pockets obtained after the laser texturing process with the average laser power of 10 W and a laser irradiation duration of (a) 0.02 s, (b) 0.04 s, (c) 0.06 s, (d) 0.08 s, and (e) 0.10 s.

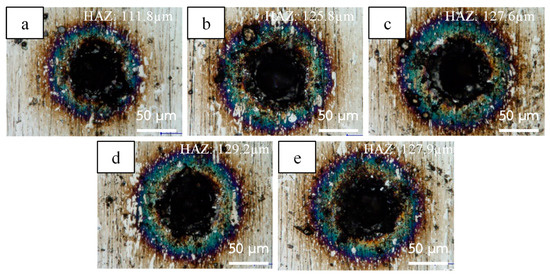

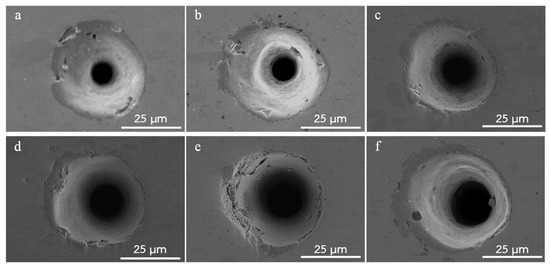

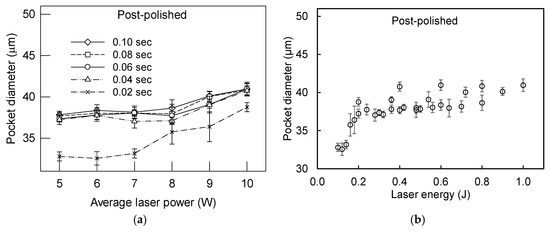

The measured diameters of micro-lubricant pocket and HAZ are plotted in Figure 7, showing the insignificant change of the diameters when using the laser irradiation duration equal to or greater than 0.04 s. The irradiation duration of 0.02 s was too short to induce a substantial ablation, particularly when applied with low laser power. At a duration of equal to or greater than 0.04 s, a plasma plume might stably be formed above the laser-irradiated region, and it, in turn, absorbs the incident laser intensity through the inverse bremsstrahlung absorption. This thus attenuates the laser intensity reaching the work surface for further ablation and enlarging the pocket diameter as well as the HAZ size. The largest pocket diameter of 50 µm on average was obtained by using 10 W laser power with 0.10 s irradiation duration.

Figure 7.

(a) Micro-lubricant pocket diameter and (b) heat-affected zone diameter caused by the different processing conditions.

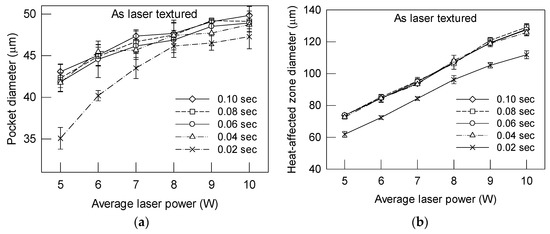

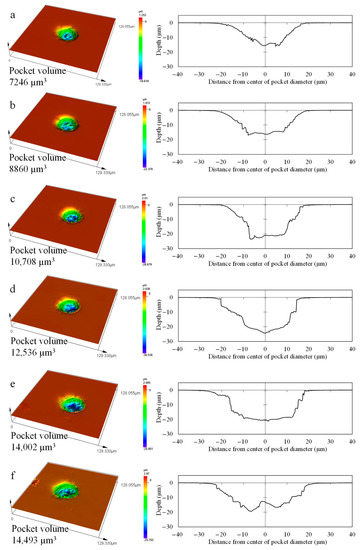

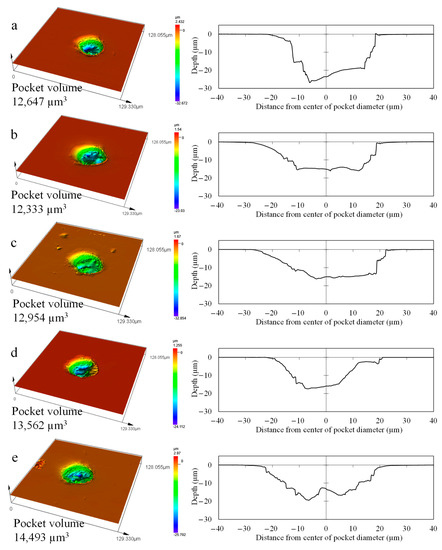

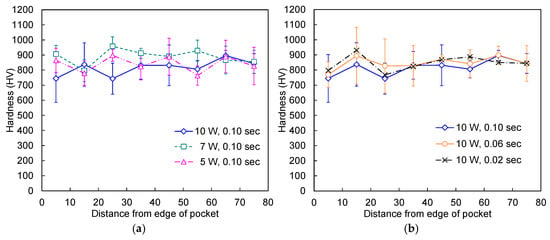

The laser-textured surfaces were polished in order to remove the burn marks and recast deposition. The micro-lubricant pockets obtained after being polished are shown in Figure 8 and Figure 9. The burn marks and recast formed around the pocket were removed. The morphology and cross-sectional profile of micro-lubricant pockets are shown in Figure 10 and Figure 11. There was no bulge of recasts remaining at the edge of pockets. This essentially provides a positive effect on lubrication [35]. The diameter and depth of pockets varied from 32 µm to 40 µm and from 15 µm to 25 µm, respectively, depending on the laser processing condition. The diameter of pockets is plotted in Figure 12a, showing the size of 5–10 μm or 20% smaller than that obtained before the work surface was polished (Figure 7a). This is due to the removal of recasts protruding at the edge of pockets that reveals the actual diameter of the pockets underneath the recast layer. Using the irradiation duration of 0.02 s still caused a smaller pocket than the others. The largest pocket having an average volume of 14,493 μm3, was created by using 10 W laser power with 0.10 s laser irradiation duration. The pocket volume basically defines the capability of the textured surface for retaining lubricant and trapping wear debris when applied for metal forming processes. The hardness profile on the surface of post-polished micro-lubricant pockets obtained by utilizing the different average laser powers and laser irradiation durations are shown in Figure 13. Retempering may occur during the laser texturing process. For the 0.10 s irradiation duration, the average surface hardness of 10 W, 7 W and 5 W laser powers were 744, 906 and 864 HV, respectively, and the average surface hardness of base metal was 843 HV. Using 10 W laser power led to the reduction of hardness near the pocket’s edge, at which a high tempering temperature was induced by the laser, whereas using 7 W or 5 W laser power caused a lower tempering temperature, and the retempered hardness was found to be almost same as the hardness of the base metal.

Figure 8.

SEM micrograph of polished samples caused by using the laser irradiation duration of 0.10 s and the average laser power of (a) 5 W, (b) 6 W, (c) 7 W, (d) 8 W, (e) 9 W, and (f) 10 W.

Figure 9.

SEM micrograph of polished samples caused by using the average laser power of 10 W and the laser irradiation duration of (a) 0.02 s, (b) 0.04 s, (c) 0.06 s, (d) 0.08 s, and (e) 0.10 s.

Figure 10.

Surface topography and 2D profiles of micro-lubricant pockets obtained after polishing with the laser irradiation duration of 0.10 s and the average laser powers of (a) 5 W, (b) 6 W, (c) 7 W, (d) 8 W, (e) 9 W, and (f) 10 W.

Figure 11.

Surface topography and 2D profiles of micro-lubricant pockets obtained after polishing with the average laser power of 10 W and the laser irradiation duration of (a) 0.02 s, (b) 0.04 s, (c) 0.06 s, (d) 0.08 s, and (e) 0.10 s.

Figure 12.

Diameter of post-polished micro-lubricant pockets obtained (a) under the different laser powers and irradiation durations and (b) laser energy.

Figure 13.

Hardness on the surface of post-polished micro-lubricant pockets obtained (a) under the different laser powers and (b) irradiation durations.

Laser energy applied in the texturing process was calculated by multiplying the average laser power by the irradiation duration. The influence of laser energy on the diameter of micro-lubricant pockets is presented in Figure 12b. The diameter sharply increased with the energy when the ablation was subjected to an energy of less than 0.2 J. A slight increase in diameter was subsequently apparent when using the energy of equal to or greater than 0.2 J. This critical level of energy can be defined as a threshold at which the ablation of AISI D2 is substantially conducive to the formation of a micro-lubricant pocket as per the given laser beam diameter (37.66 µm). Since Shimizu et al. [24] suggest a pocket diameter of 50 µm to induce a decent hydrodynamic pressure for promoting the lubrication, and Kasem et al. [36] found the pocket diameters of 25 µm and 30 µm led to a significant reduction in the coefficient of friction compared to the pocket diameter of 100 µm, the energy of 1.0 J caused by using the 10 W laser power and 0.10 s irradiation duration was able to produce the post-polished pocket diameter of about 40 µm. This condition was further employed to prepare an array of micro-lubricant pockets on the AISI D2 surface for the friction and wettability tests.

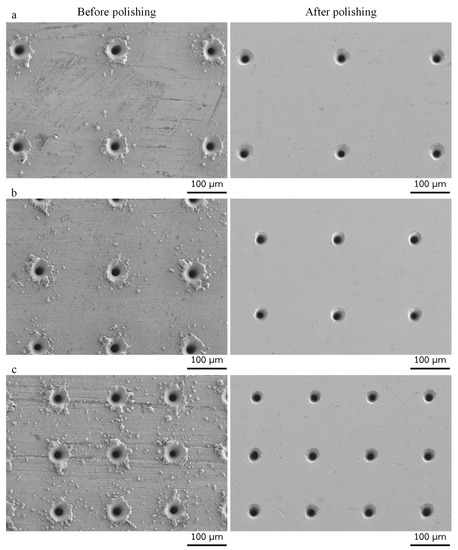

An array of micro-lubricant pockets was made on the entire surface of the flat-end pin for the pin-on-disc test. The three spacing distances, i.e., 150, 200, and 250 µm, as listed in Table 3, were applied in the texturing of the AISI D2 surface whose micrographs are shown in Figure 14. According to Figure 14, the laser-induced recast and spatters deposited on the work surface were totally removed by the polishing process. Such post-processing is necessary to avoid the abrasion wear caused by the dislodgement of recast and spatters. In addition, the bulge of the recast around the pocket can deteriorate the lubrication condition, in which the thickness of the lubricant film is reduced, and the surface friction is increased accordingly [17]. The larger the distance between the adjacent pockets, the lower the pocket density is made on the surface. Regarding Equation (1), the spacing distance of 150 µm is equivalent to 5.6% pocket density.

Figure 14.

SEM micrographs of micro-lubricant pockets produced by using 10 W laser power and 0.10 s irradiation duration with the spacing distance of (a) 250 µm, (b) 200 µm, and (c) 150 µm.

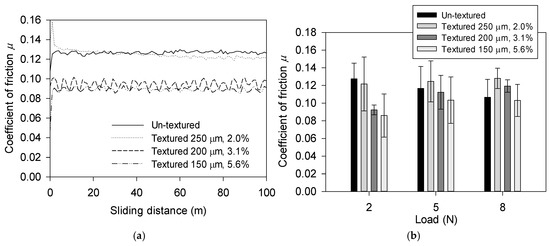

3.2. Effect of Pocket Density on Friction

The friction test of untextured and laser-textured AISI D2 pins sliding against JIS SPFC 980Y advanced high-strength steel disc was carried out under the three normal loads of 2, 5, and 8 N. These caused the contact pressure of 0.283, 0.707, and 1.132 MPa, respectively. The coefficient of friction was recorded as a function of a sliding distance of up to 100 m. The wear of pins was negligible for all tests, so the wear rate was disregarded in this study. The results of untextured and textured pins having pocket density of 2.0%, 3.1%, and 5.6% (250, 200, and 150 µm spacing distance) at the normal load of 2 N are shown in Figure 15a. The coefficients of friction for all surfaces increased rapidly at the initial stage of sliding. The friction coefficient of untextured and textured surfaces became steady after a few meters of sliding distance except for the sample with the pocket density of 2.0% that had a sharply increased and then decreased coefficient at the early stage. This may be due to the roughness of the new friction pair that is high at the initial running and then results in the peak. According to Figure 15a, the untextured and textured surfaces having a pocket density of 2.0% are of high friction coefficient than that of the other two textured surfaces. The pocket density of 2.0% is perhaps too low to enhance the lubricating effect as the large contact area hinders the hydrodynamics of lubrication and provides less amount of retained lubricant in a unit surface area. A significant reduction of friction coefficient was obtained from the textured surfaces having pocket densities of 3.1% and 5.6%. Adding more pockets per unit area contributes to the trapping and feeding of lubricant into the sliding interface, thus reducing friction. However, there was a small fluctuation of friction in the steady state when testing the 3.1% and 5.6% pocket density surfaces. This is a result of a stick-slip sliding effect that is a consequence of escaping trapped lubricant into the contacting surface. The friction coefficient of the two surfaces was about the same, which varied between 0.09 and 0.1. With regard to the findings, the pocket density of 3.1% was also viable for reducing the friction coefficient of the AISI D2 surface, although a pocket density of greater than 5% is suggested [16,32].

Figure 15.

Coefficient of friction (a) plotted against the sliding distance under the normal load of 2 N and (b) plotted against the three applied normal loads.

The average friction coefficient of each sample is plotted in Figure 15b, showing the change of friction under the different normal loads. The untextured surface exhibited a decreasing trend of friction when increasing the applied load. The coefficient of 0.128 was obtained under the normal load of 2 N. It is anticipated that the 2 N load may be too low to flatten the surface asperities of the disc, and the contact points of sharp asperities then contribute to high contact pressure and adhesion, thus resulting in a high friction coefficient. When applying a higher normal load, the protrusions of the contact surface are gradually flattened, and the surface roughness decreases accordingly. This thereby leads to the reduction of friction coefficient. As for the results, the friction coefficient of the textured surface with the pocket density of 2% had no significant difference under the three applied loads, and the coefficient was about 0.12. On the other hand, the textured surfaces having a pocket density of 3.1% and 5.6% were of lower friction coefficient than the surface with a 2% pocket density. The pocket array with a smaller spacing distance considerably facilitates the trapping and feeding of lubricant into the interface and also enables the formation and maintenance of lubricant film on the contact surface. However, the friction coefficient was found to increase with the increased normal load. The thinning of lubricant film under a higher load is anticipated to increase the friction of the interface to which the micro-lubricant pockets are not capable of retention and supplying an adequate amount of lubricant. This is typical behavior for the friction conditions transiting from the mixed lubrication to the boundary lubrication modes [16]. The use of proper lubricant viscosity is another issue to be considered for strengthening the hydrodynamic pressure and maintaining the lubricant film at the interface under a certain contact speed [37]. The roles of micro-lubricant pockets in the enhancement of the hydrodynamic effect and their interactions with the lubricant properties are challenging topics in this field of study. According to the results, the laser-textured surface with a pocket density of 5.6% offered an average friction coefficient of 0.097 which was the lowest coefficient among the tested conditions. This could be a promising method for reducing the surface friction of AISI D2 as well as other tool steels used in metal forming applications. Moreover, further theoretical analysis is necessary for investigating the underlying lubrication mechanism of micro-lubricant pockets in future work. In the development of a novel bearing, the experimental and numerical study of hydrodynamic lubrication of the liquid film can provide new ideas and ways for the design of the bearing [38]. Through computational fluid dynamics (CFD) simulations, the characteristics and behaviors of lubricant flow with textured surfaces may be comprehensively assessed.

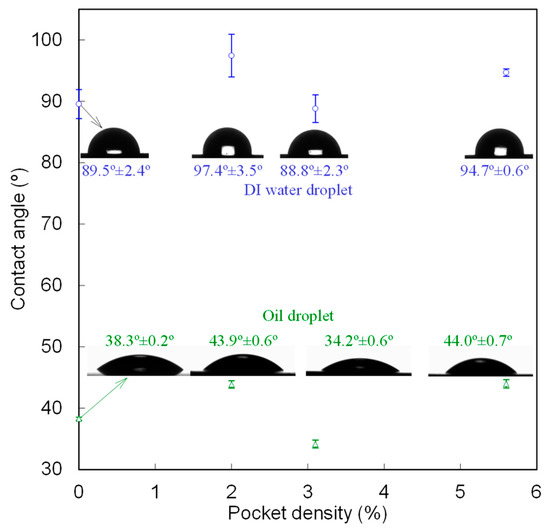

3.3. Effect of Pocket Density on Surface Wettability

Besides surface friction, wettability is another surface property that affects the retention of lubricant on the surface. The reduction of friction would not be possible if the surface was poorly wetted by the lubricant or became more oleophobic or hydrophobic after being textured by laser. The wettability of untextured and textured surfaces was thus quantified in this study through the contact angle measurement to ensure the functionality of the improved surface for lubrication. Basically, the surface having a low contact angle or high wettability is desired as the applied lubricant can spread well and adhere to the entire contact surface. Figure 16 shows the average contact angle of oil and distilled water dropped on the untextured (0% pocket density) and textured surfaces. The contact angle of the textured surfaces was slightly changed compared to the untextured surface. The contact angle of oil and water droplets on the untextured surface was 38.3 ± 0.2° and 89.5 ± 2.4°, whereas it was 44.0 ± 0.7° and 94.7 ± 0.6°, respectively, for the textured surface with the 5.6% pocket density. The oil droplet was found to spread on the surfaces more than the water one, and the angle was much lower than 90°. According to the results, the surface wettability was little altered after laser texturing the micro-lubricant pockets on the AISI D2 surface. The small contact angle of the oil droplet explicitly indicated the oleophilicity of the metal surface for being wetted by the lubricant, thus leading to the reduction of friction.

Figure 16.

The average contact angle of untextured and textured surfaces with different pocket densities.

4. Conclusions

The role of the laser texturing process in creating the micro-lubricant pocket has been comprehensively revealed in this paper, and the laser-textured surface with a suitable pocket density has offered a lower coefficient of friction than the flat surface. A nanosecond pulse laser was employed in this study for texturing the AISI D2 cold work tool steel surface. The effects of average laser power and laser irradiation duration on the diameter of the micro-lubricant pocket and heat-affected zone were examined. Surface friction and wettability were also investigated and discussed in relation to pocket density. The following conclusions were drawn from the results obtained in this study:

- The pocket diameter increased with the increase in average laser power and irradiation duration. The largest pocket diameter was 40 µm which was a result of using 10 W laser power together with 0.10 s irradiation time. The pocket depth and volume obtained were about 20 μm and 14,493 μm3, respectively.

- The laser energy of 0.2 J was a threshold for ablating the micro-lubricant pocket whose diameter corresponded to the laser beam diameter. By using energy greater than this level, the pocket diameter was slightly enlarged.

- The friction coefficient of the textured surface with the pocket density of 5.6% was 0.097 on average, which was lower than that of the surface with a lower pocket density as well as the untextured surface. In addition, the wettability of textured surfaces remained unchanged after the laser texturing process. This implies a significant contribution of the laser-fabricated micro-lubricant pockets toward the friction reduction of AISI D2 surface and plausibly of other tool steels employed in metal-forming applications.

- Using the suitable laser parameters, which were 10 W laser power with 0.10 s irradiation duration and 150 µm spacing distance, successfully reduced the sliding friction of contacting couples between the laser-textured tool steel and advanced high-strength steel surfaces.

Author Contributions

Conceptualization, W.D. and V.S.; methodology, W.D. and V.S.; formal analysis, W.D. and V.S; investigation, W.D. and V.S.; writing—original draft preparation, W.D.; writing—review and editing, W.D. and V.S.; supervision, V.S.; project administration, W.D.; funding acquisition, W.D. and V.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Rajamangala University of Technology Isan, grant number NKR2564INC005 and Thailand Science Research and Innovation (TSRI) Basic Research Fund: Fiscal year 2023 under project number FRB660073/0164 (Program: Advanced Materials and Manufacturing for Applications in New S-curve Industries).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to express their appreciation to Nipon Taweejun at Thai Tohken Thermo Co., Ltd. and Surin Maneesri, the Rajamangala University of Technology Isan, for their technical assistance. Tool and Die Technology Center, the Rajamangala University of Technology. Suvarnabhumi is kindly acknowledged for carrying out the friction test.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of lightweight components by metal forming. CIRP Ann. Manuf. Technol. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Kim, H.; Sung, J.; Goodwin, F.E.; Altan, T. Investigation of galling in forming galvanized advanced high strength steels (AHSSs) using the twist compression test (TCT). J. Mater. Process. Technol. 2008, 205, 459–468. [Google Scholar] [CrossRef]

- Kataoka, S.; Murakawa, M.; Aizawa, T.; Ike, H. Tribology of dry deep-drawing of various metal sheets with use of ceramics tools. Surf. Coat. Technol. 2004, 177–178, 582–590. [Google Scholar] [CrossRef]

- Tamaoki, K.; Manabe, K.; Kataoka, S.; Aizawa, T. Electroconductive ceramic tooling for dry deep drawing. J. Mater. Process. Technol. 2010, 210, 48–53. [Google Scholar] [CrossRef]

- Abe, Y.; Fujita, T.; Mori, K.; Osakada, K.; Shiba, T.; Daodon, W. Improvement of formability in ironing of stainless steel drawn cups using low friction cermet dies. Procedia Eng. 2014, 81, 1896–1901. [Google Scholar] [CrossRef]

- Zhou, L.M.; Xiong, J.; Guo, Z.X.; Ye, J.L.; Liu, J.B. Tribological performances of Ti(C,N)-based cermets with different graphite contents in dry sliding condition. Int. J. Refract. Met. Hard Mater. 2017, 68, 113–120. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S.; Sandberg, O. Proper coating selection for improved galling performance of forming tool steel. Wear 2006, 261, 15–21. [Google Scholar] [CrossRef]

- Daodon, W.; Premanond, V.; Wongpisarn, W.; Niranatlumpong, P. Vanadium nitride and titanium nitride coatings for anti-galling behavior in ironing of aluminum alloy cups. Wear 2015, 342–343, 279–287. [Google Scholar] [CrossRef]

- Abe, Y.; Ohmi, T.; Mori, K.; Masuda, T. Improvement of formability in deep drawing of ultra-high strength steel sheets by coating of die. J. Mater. Process. Technol. 2014, 214, 1838–1843. [Google Scholar] [CrossRef]

- Sresomroeng, B.; Premanond, V.; Kaewtatip, P.; Khantachawana, A.; Kurosawa, A.; Koga, N. Performance of CrN radical nitrided tools on deep drawing of advanced high strength steel. Surf. Coat. Technol. 2011, 205, 4198–4204. [Google Scholar] [CrossRef]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally benign tribo-systems for metal forming. CIRP Ann. Manuf. Technol. 2010, 59, 760–780. [Google Scholar] [CrossRef]

- Mizuno, T.; Okamoto, M. Effects of lubricant viscosity at pressure and sliding velocity on lubricating conditions in the compression-friction test on sheet metals. Trans. ASME J. Lubr. Technol. 1982, 104, 53–59. [Google Scholar] [CrossRef]

- Steinhoff, K.; Rasp, W.; Pawelski, O. Development of deterministic- stochastic surface structures to improve the tribological conditions of sheet forming processes. J. Mater. Process. Technol. 1996, 60, 355–361. [Google Scholar] [CrossRef]

- Bech, J.; Bay, N.; Eriksen, M. Entrapment and escape of liquid lubricant in metal forming. Wear 1999, 232, 134–139. [Google Scholar] [CrossRef]

- Geiger, M.; Popp, U.; Engel, U. Excimer laser micro texturing of cold forging tool surfaces-influence on tool life. CIRP Ann. Manuf. Technol. 2002, 51, 231–234. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Podgornik, B.; Vižintin, J.; Možina, J. Influence of texturing parameters and contact conditions on tribological behaviour of laser textured surfaces. Meccanica 2011, 46, 567–575. [Google Scholar] [CrossRef]

- Basnyat, P.; Luster, B.; Muratore, C.; Voevodin, A.A.; Haasch, R.; Zakeri, R.; Kohli, P.; Aouadi, S.M. Surface texturing for adaptive solid lubrication. Surf. Coat. Technol. 2008, 203, 73–79. [Google Scholar] [CrossRef]

- Li, J.; Xiong, D.; Dai, J.; Huang, Z.; Tyagi, R. Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 2010, 43, 1193–1199. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, R.; Davis, T.; Cao, J.; Wang, Q.J.; Hua, D.; Liu, J. Study on effect of dimples on friction of parallel surfaces under different sliding conditions. Appl. Surf. Sci. 2010, 256, 2863–2875. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Hatashita, F.; Shiba, T.; Daodon, W.; Osakada, K. Improvement of seizure resistance in ironing of stainless steel cup with cermet die having fine lubricant pockets. J. Mater. Process. Technol. 2016, 234, 195–207. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef]

- Shimizu, T.; Kobayashi, H.; Vorholt, J.; Yang, M. Lubrication analysis of micro-dimple textured die surface by direct observation of contact interface in sheet metal forming. Metals 2019, 9, 917. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution. Tribol. Int. 2021, 160, 107049. [Google Scholar] [CrossRef]

- Gaikwad, A.; Vázquez-Martínez, J.M.; Salguero, J.; Iglesias, P. Tribological properties of Ti6Al4V titanium textured surfaces created by laser: Effect of dimple density. Lubricants 2022, 10, 138. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Wang, C.; Ding, F.; Tang, D.; Zheng, L.; Li, S.; Xie, Y. Modeling and simulation of the high-speed milling of hardened steel SKD11 (62 HRC) based on SHPB technology. Int. J. Mach. Tools Manuf. 2016, 108, 13–26. [Google Scholar] [CrossRef]

- Prabhu, S.; Vinayagam, B.K. Analysis of surface characteristics of AISI D2 tool steel material using electric discharge machining process with single-wall carbon nanotubes. Int. J. Mach. Mach. Mater. 2011, 10, 99–119. [Google Scholar] [CrossRef]

- JIS Handbook. Ferrous Materials & Metallurgy; Japanese Standards Association: Tokyo, Japan, 2018; p. 2672. [Google Scholar]

- Sun, S.; Brandt, M. Laser beam machining. In Nontraditional Machining Processes; Davim, J.P., Ed.; Springer: London, UK, 2013; pp. 35–96. [Google Scholar]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batcgelor, A.W. Engineering Tribology; Elsevier Butterworth-Hienemann: Maryland Heights, MO, USA, 2005. [Google Scholar]

- Tangwarodomnukun, V.; Kringram, S.; Zhu, H.; Qi, H.; Rujisamphan, N. Fabrication of superhydrophobic surface on AISI316L stainless steel using a nanosecond pulse laser. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2022, 236, 680–693. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Kasem, H.; Stav, O.; Grützmacher, P.; Gachot, C. Effect of low depth surface texturing on friction reduction in lubricated sliding contact. Lubricants 2018, 6, 62. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Yang, K. Theoretical and experimental study on the fluid-structure-acoustic coupling dynamics of a new water lubricated bearing. Tribol. Int. 2023, 177, 107982. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Wrona, S. The fluid-structure interaction lubrication performances of a novel bearing: Experimental and numerical study. Tribol. Int. 2023, 179, 108151. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).