A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture

Abstract

1. Introduction

2. Materials and Methods

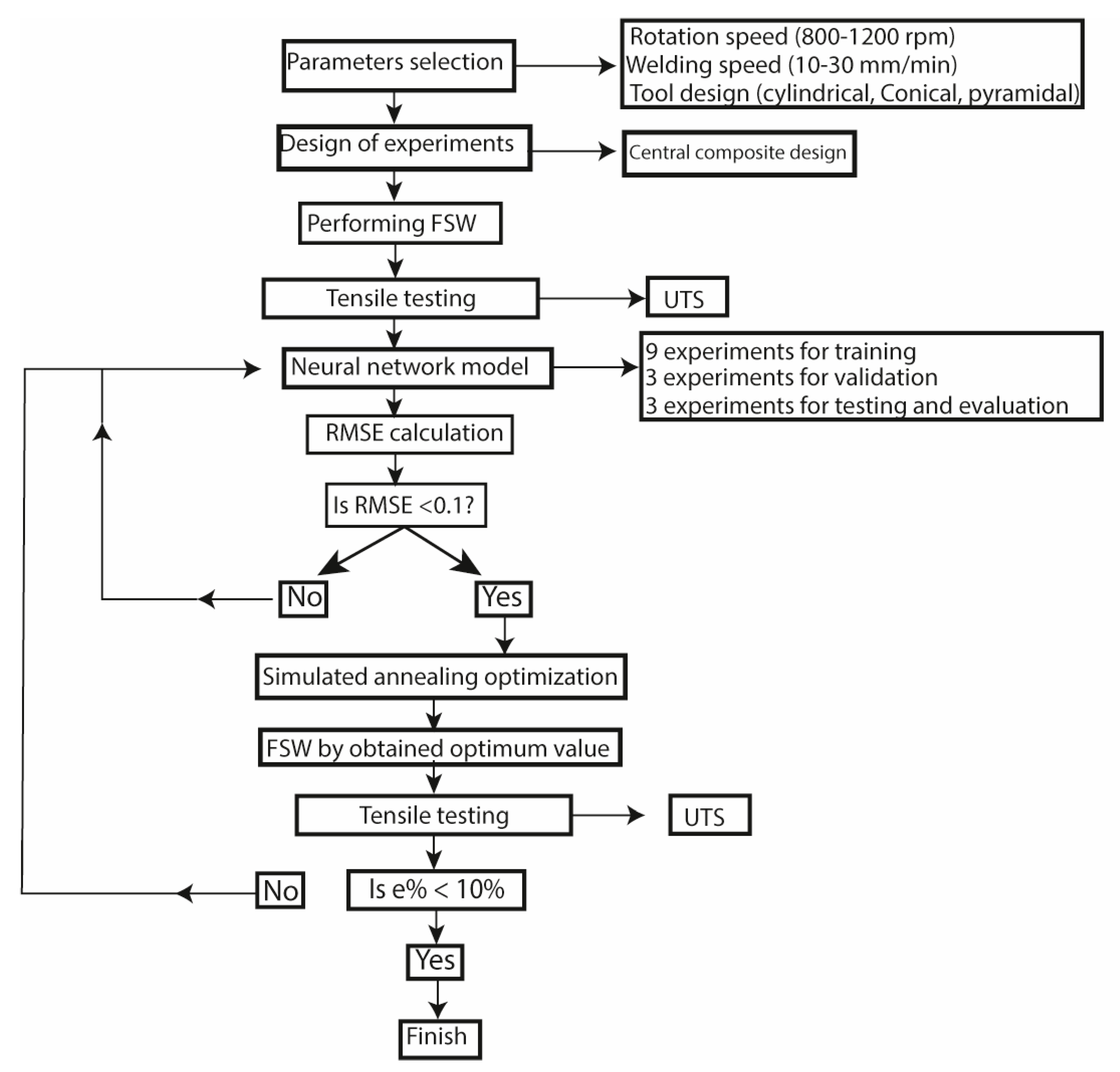

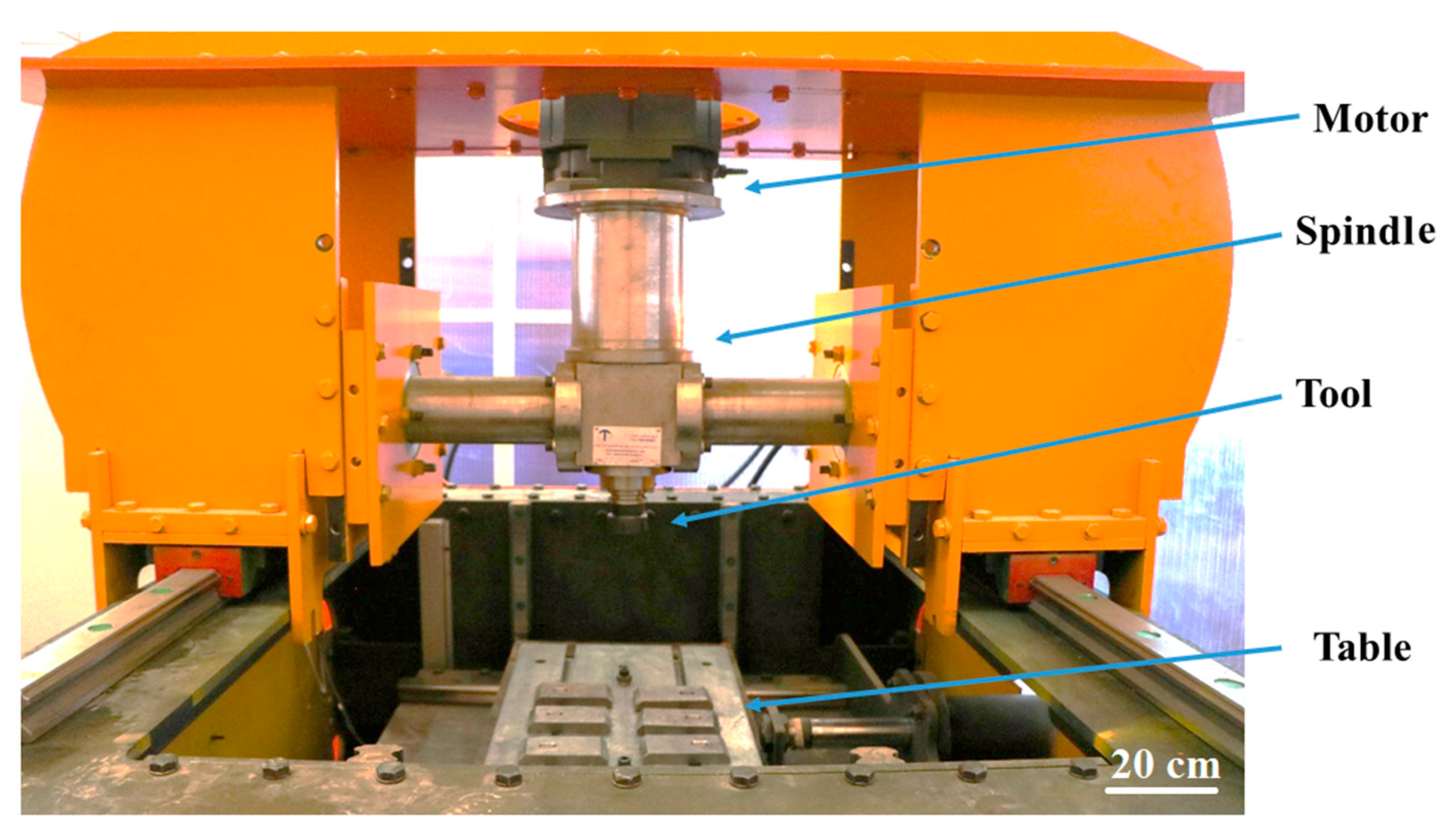

2.1. Experimental Procedure

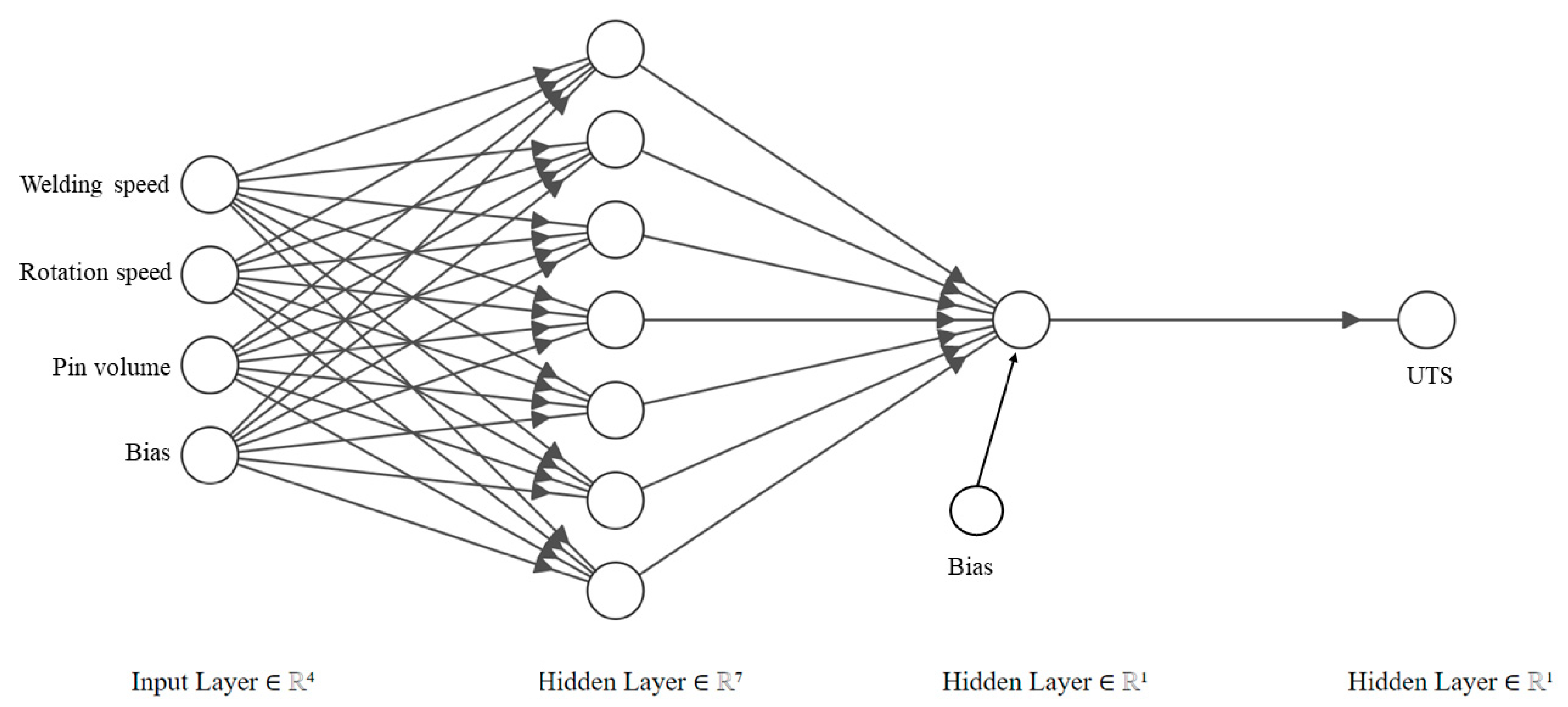

2.2. Artificial Neural Network Model

2.3. Simulated Annealing Algorithm

3. Results and Discussion

4. Conclusions

- ▪

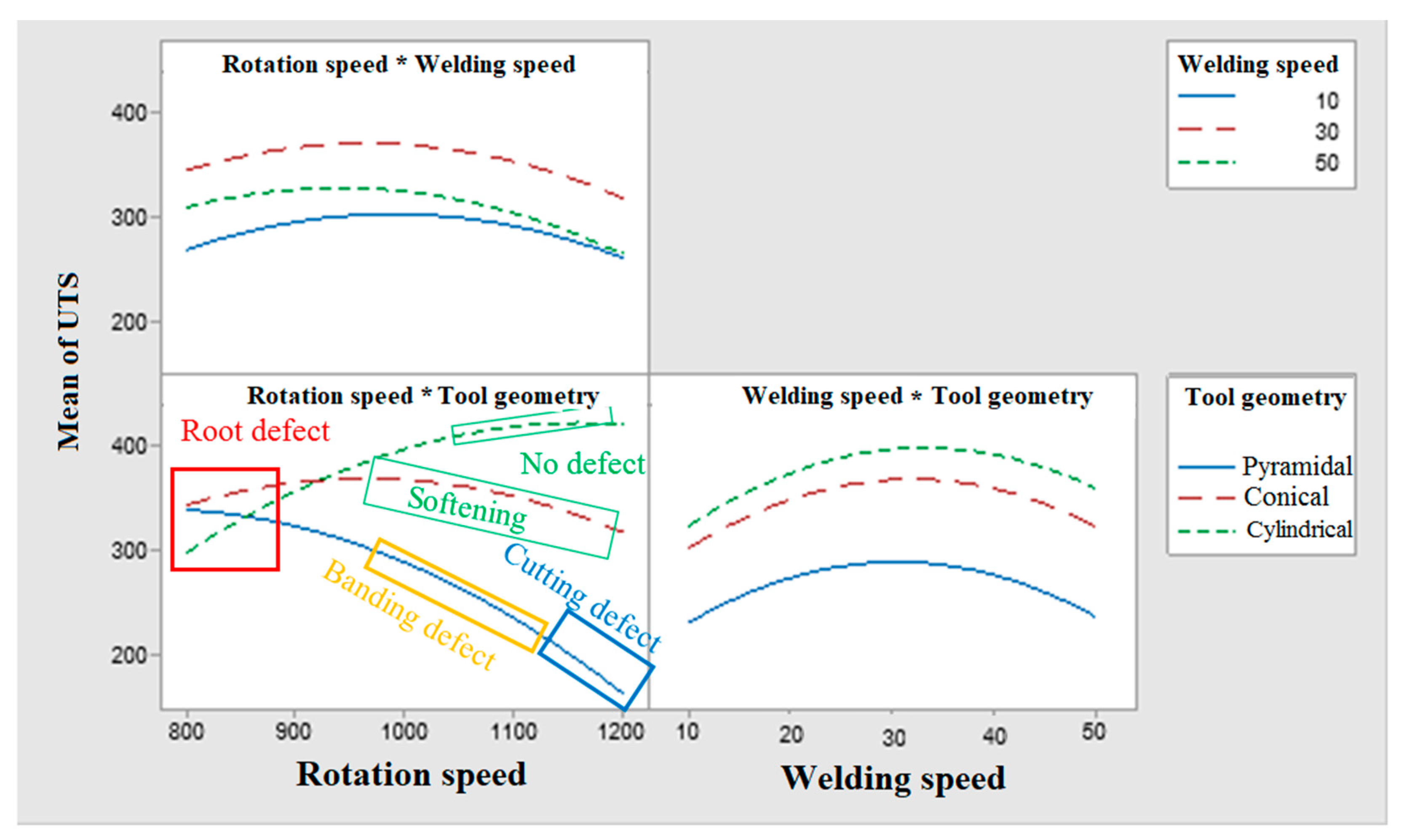

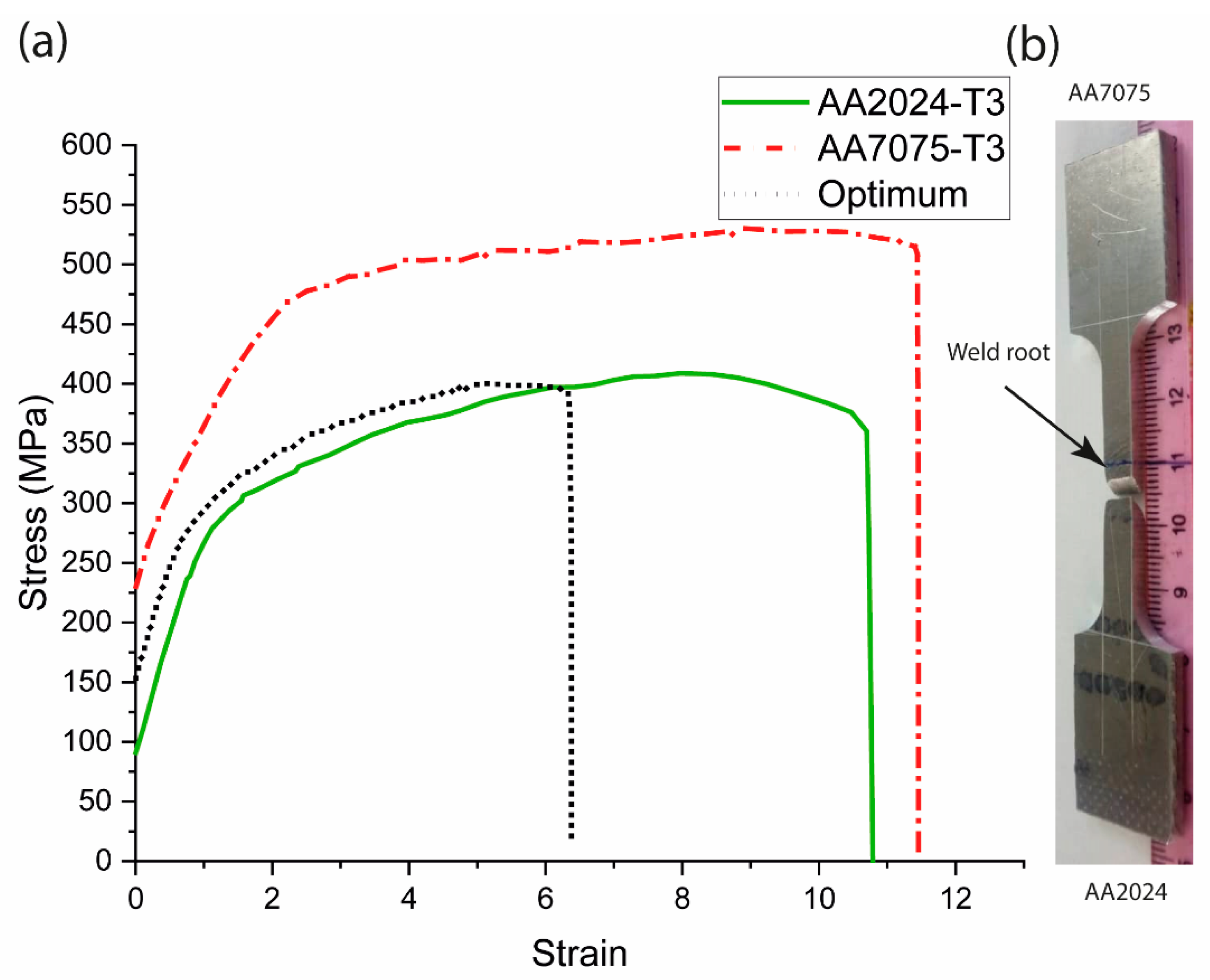

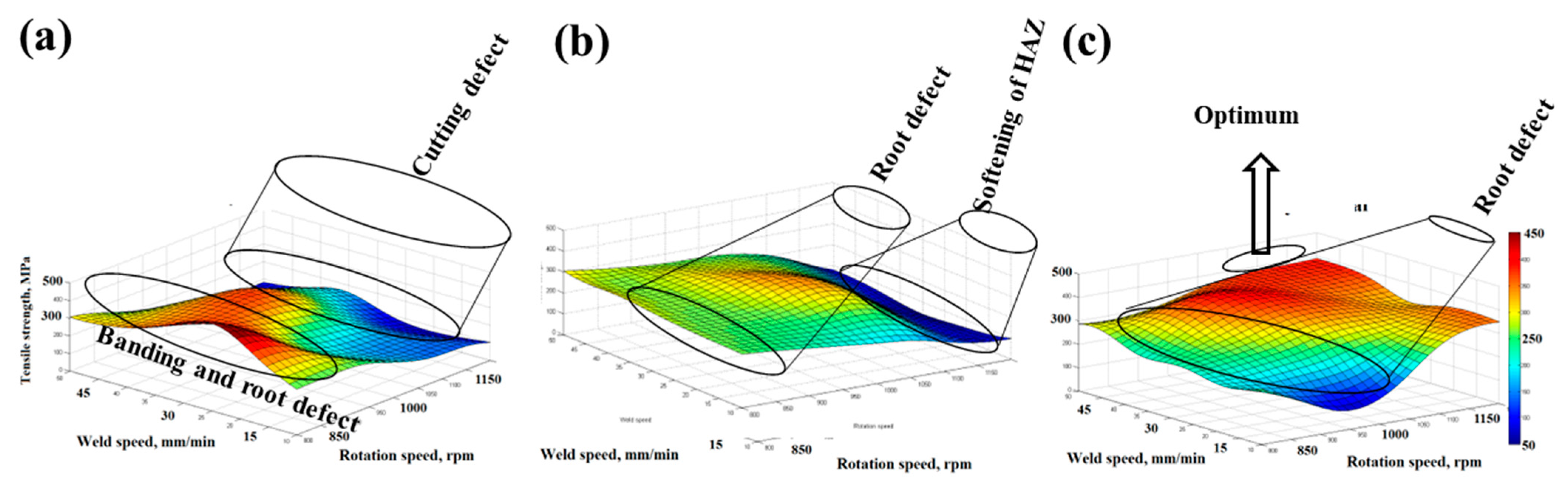

- ANN was successfully used to understand the effect of welding parameters and tool geometry on the ultimate tensile strengths of the welds. The optimum condition was obtained by the SA method which corresponded to the experimental result successfully.

- ▪

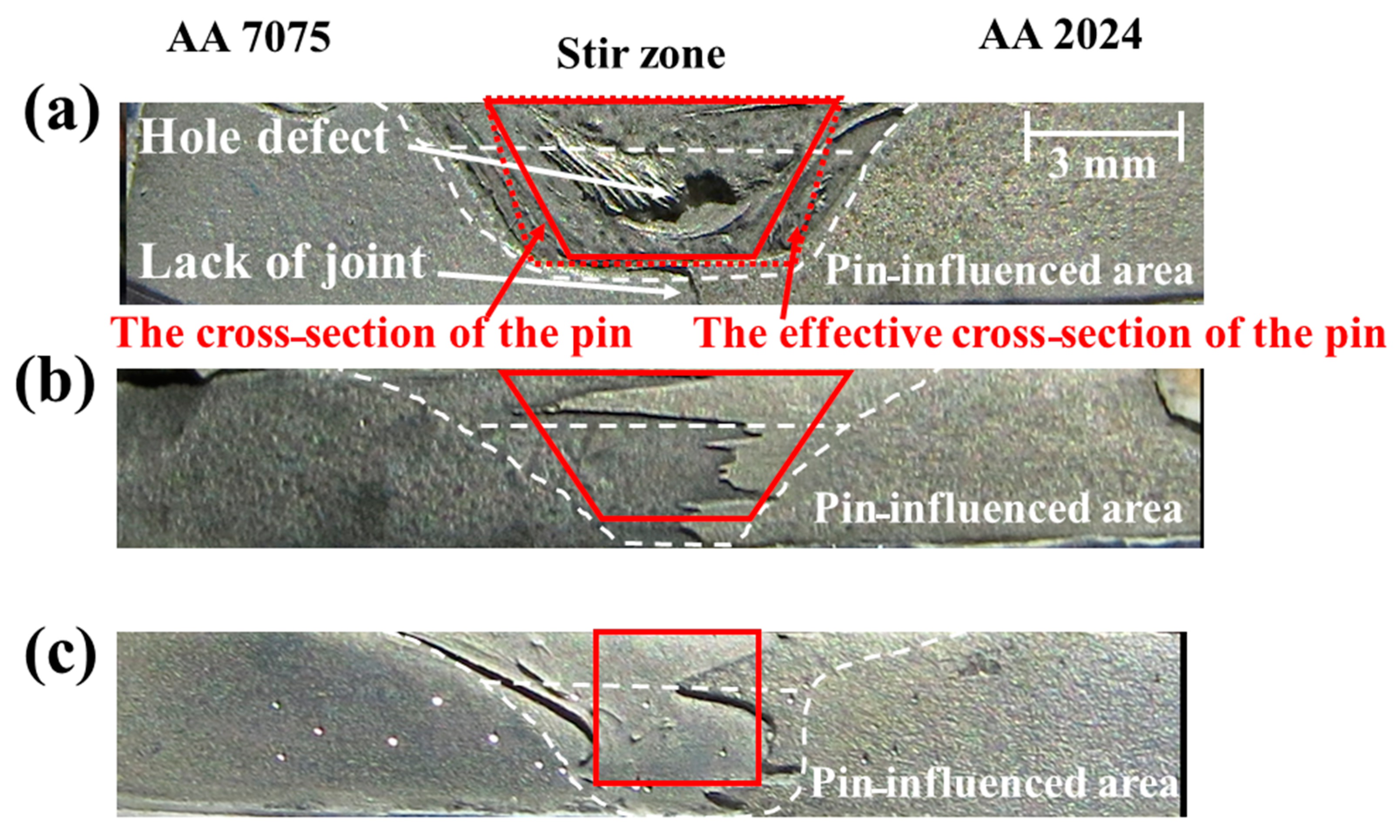

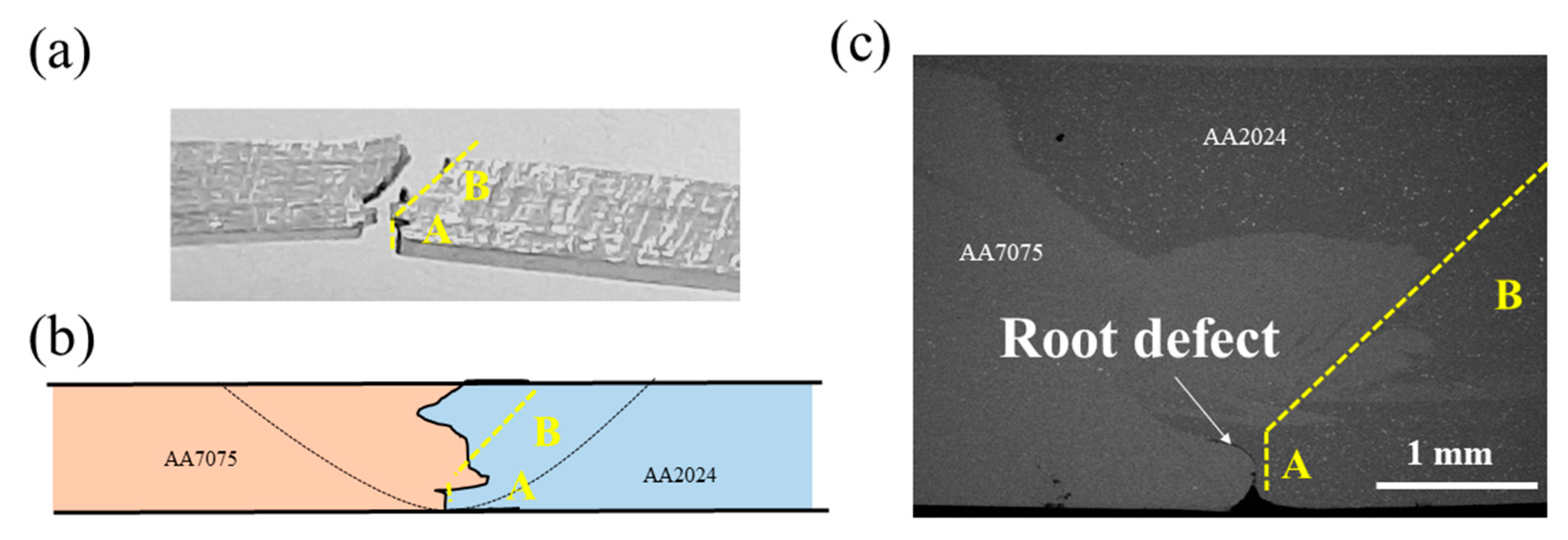

- All the joints possessed a root defect at a low rotation speed of the joint due to a lack of material flow under the pin.

- ▪

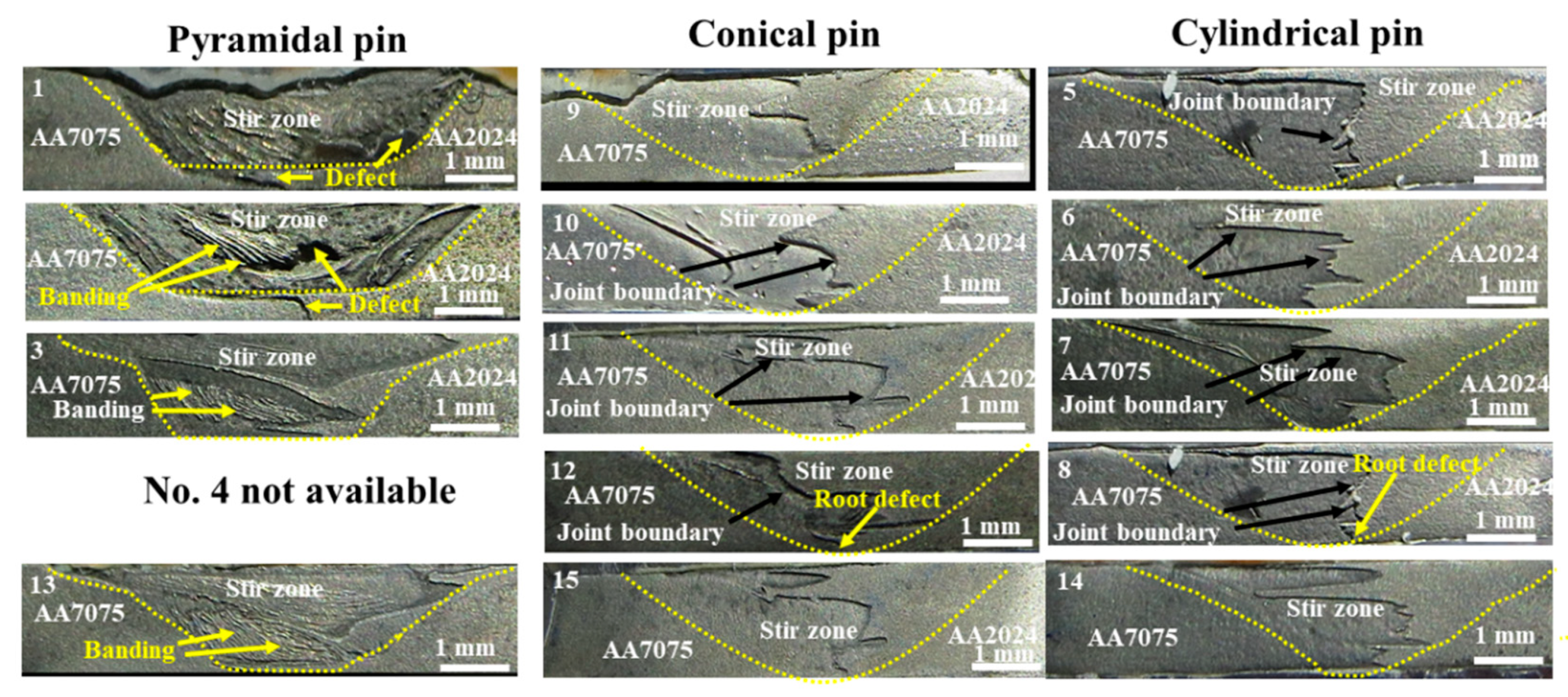

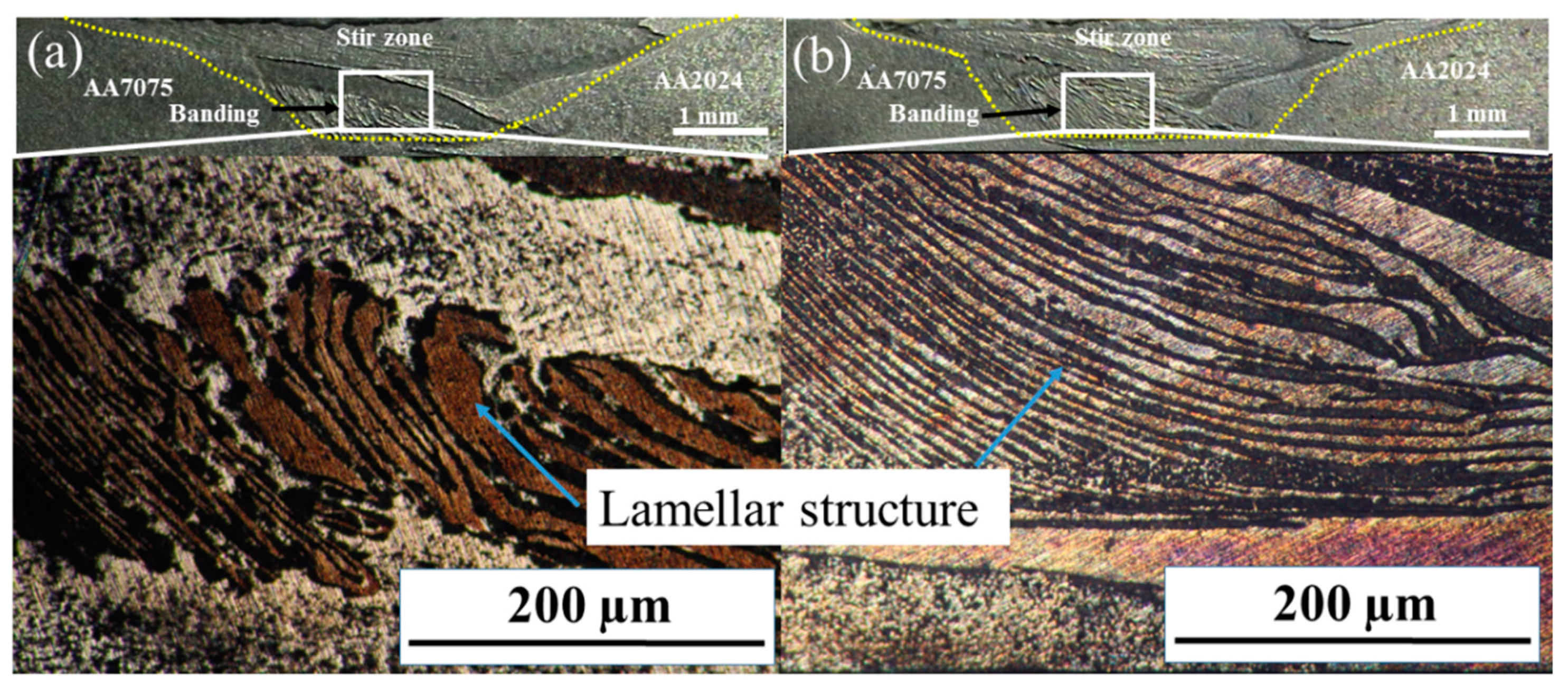

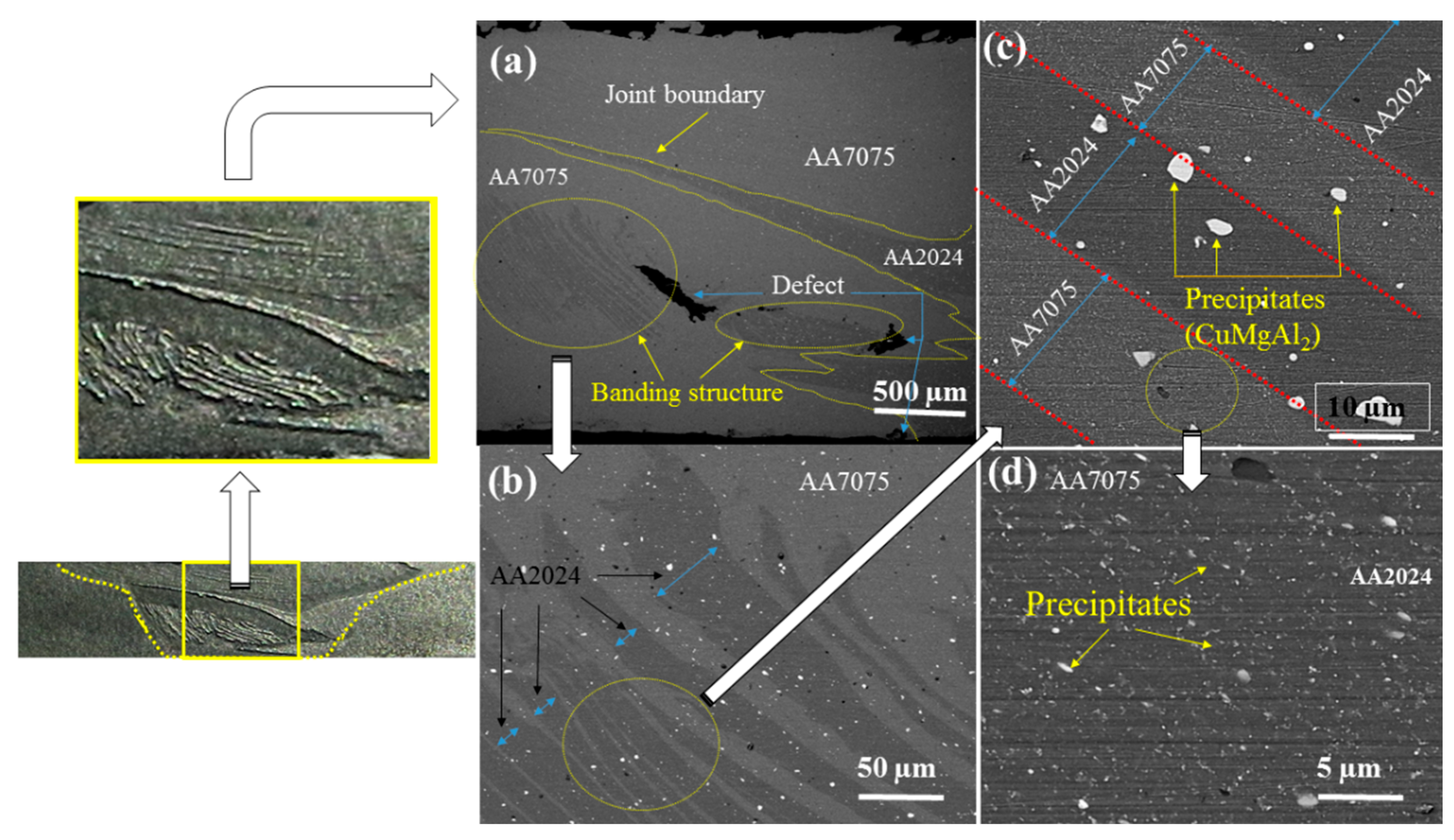

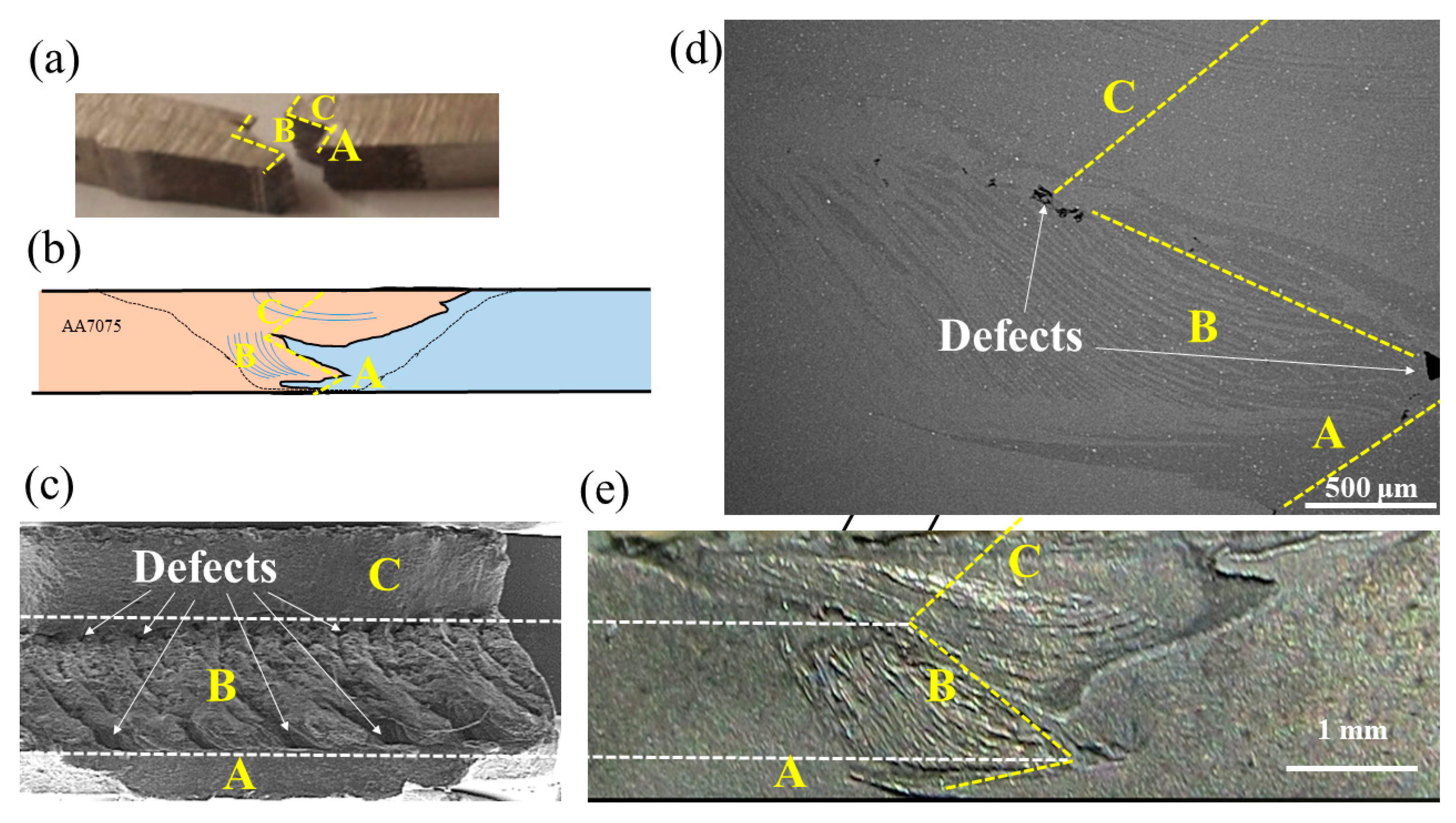

- The joints made by the pyramidal pin possessed the lowest joint strengths due to the various welding defects at different tool rotation speeds: at 1200 rpm the lack of plastic flow, at 1000 rpm the banding structure, and at 800 rpm the root defect.

- ▪

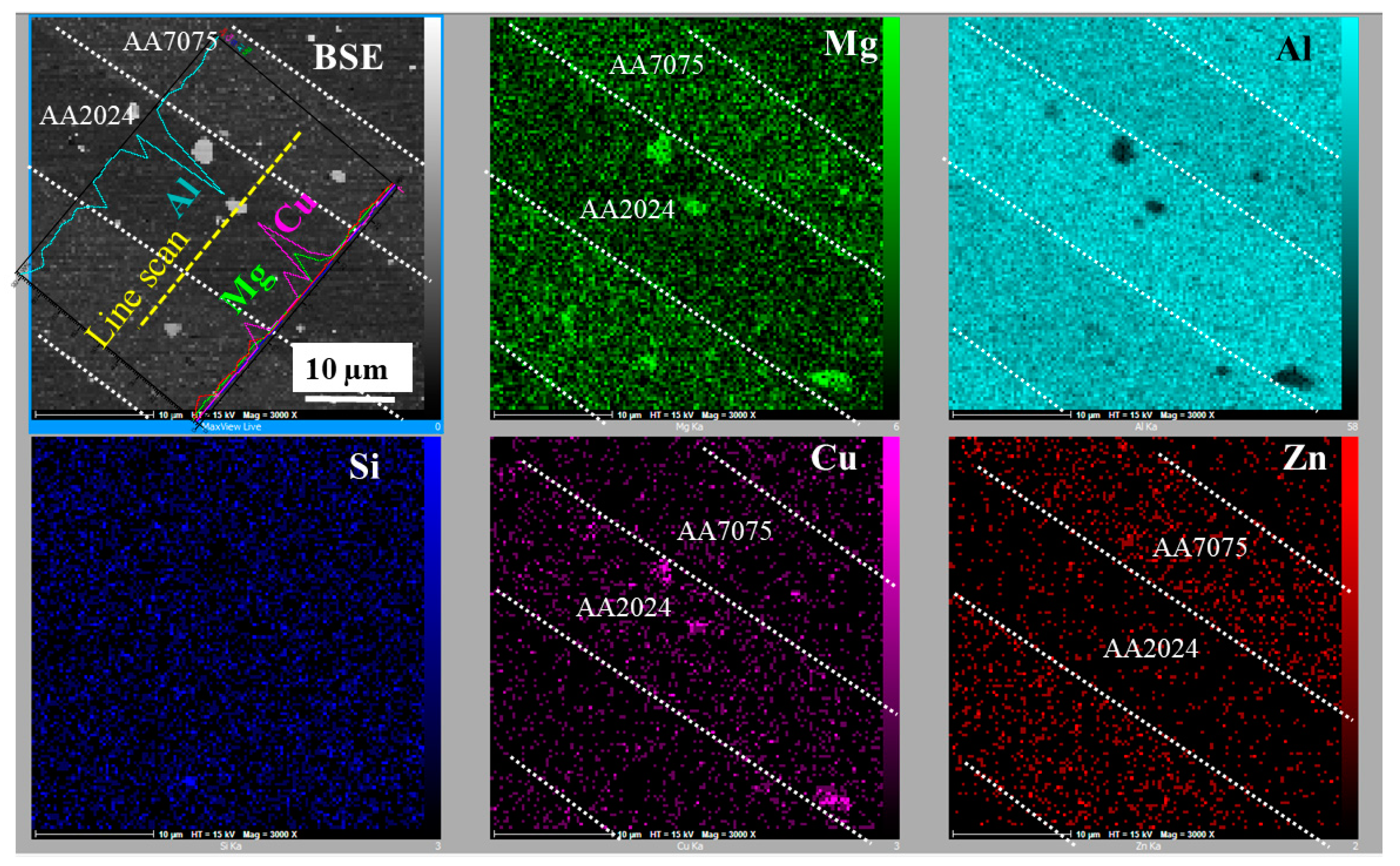

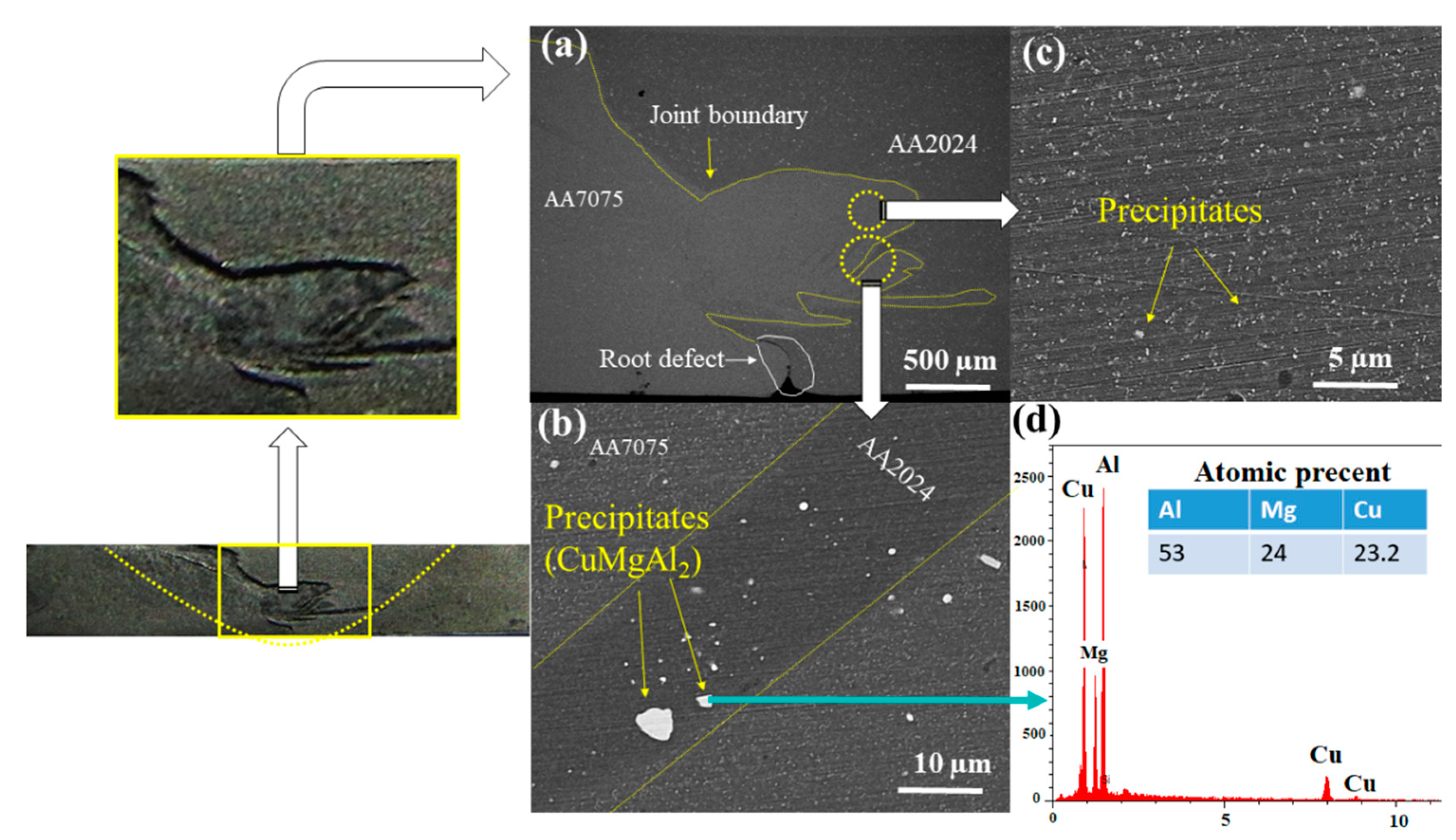

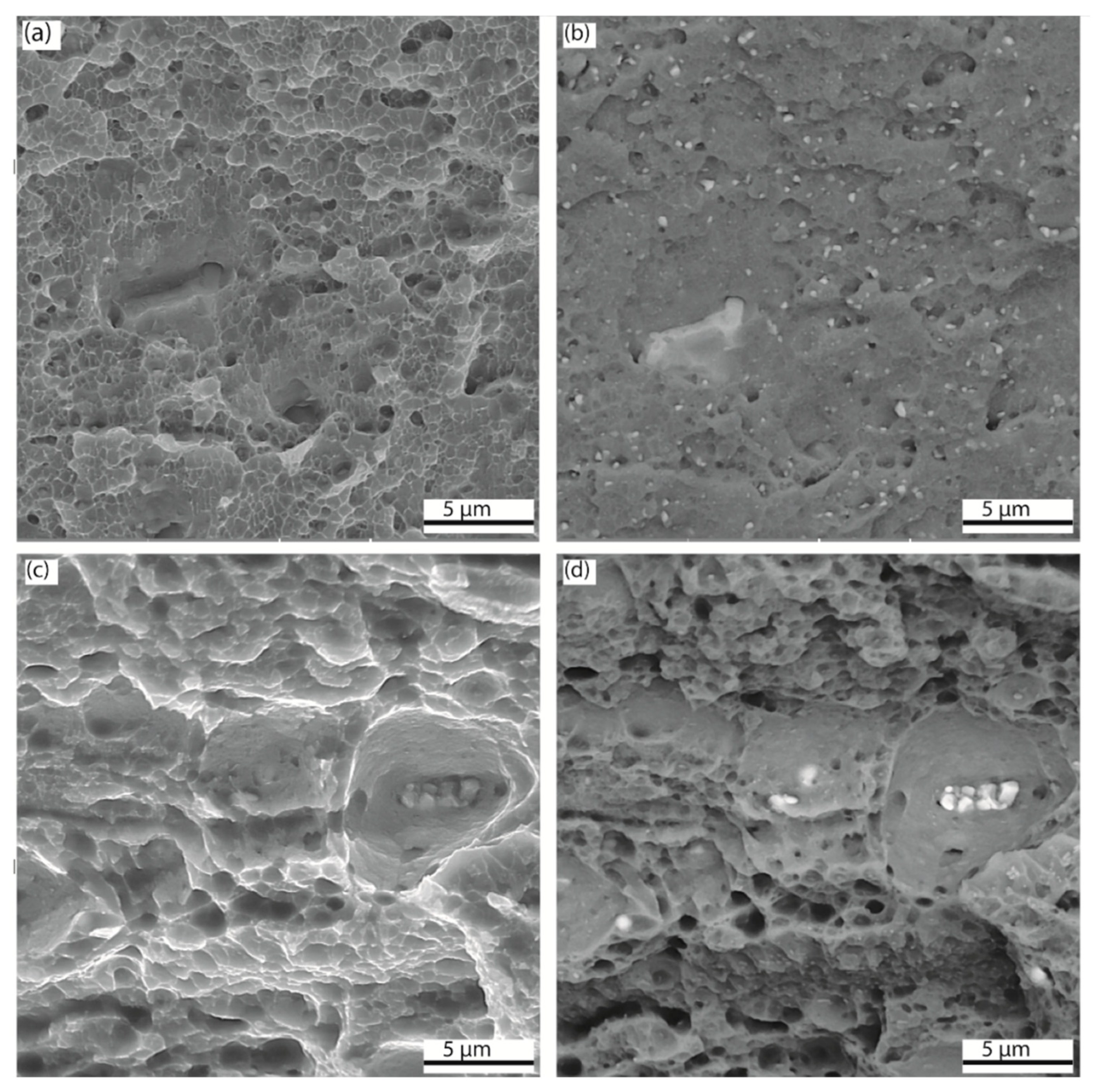

- The joints made by the conical pin were free of defects at higher rotation speeds but still had a low tensile strength. This was attributed to the softening caused by the precipitates coarsening in the stir zone due to a high temperature during welding.

- ▪

- The UTS of the welded specimens had little sensitivity to the welding speed.

- ▪

- The optimum joint strength was obtained using the cylindrical tool at high rotation speed where the root defect disappeared due to sufficient material flow. This tool, having a low volume, did not cause a high temperature during welding and, therefore, softening was minimized.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beygi, R.; Mehrizi, M.Z.; Akhavan-Safar, A.; Safaei, S.; Loureiro, A.; da Silva, L.F.M. Design of friction stir welding for butt joining of aluminum to steel of dissimilar thickness: Heat treatment and fracture behavior. Int. J. Adv. Manuf. Technol. 2021, 112, 1951–1964. [Google Scholar] [CrossRef]

- Çam, G.; İpekoğlu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Nonnenmann, T.; Beygi, R.; Carbas, R.J.; da Silva, L.F.; Öchsner, A. Synergetic effect of adhesive bonding and welding on fracture load in hybrid joints. J. Adv. Join. Process. 2022, 6, 100122. [Google Scholar] [CrossRef]

- Beygi, R.; Kazeminezhad, M.; Mehrizi, M.Z.; Eisaabadi, B.G.; Loureiro, A. Friction stir butt welding of Al-Cu bilayer laminated composites: Analysis of force, torque, and temperature. Int. J. Adv. Manuf. Technol. 2017, 88, 393–400. [Google Scholar] [CrossRef]

- Küçükömeroğlu, T.; Aktarer, S.M.; Ipekoğlu, G.; Çam, G. Microstructure and mechanical properties of friction-stir welded St52 steel joints. Int. J. Miner. Met. Mater. 2018, 25, 1457–1464. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.; Barbosa, A.; Marques, E.; da Silva, L. A comprehensive analysis of a pseudo-brittle fracture at the interface of intermetallic of η and steel in aluminum/steel joints made by FSW: Microstructure and fracture behavior. Mater. Sci. Eng. A 2021, 824, 141812. [Google Scholar] [CrossRef]

- Sun, Y.; Zeng, W.D.; Zhao, Y.Q.; Zhang, X.M.; Shu, Y.; Zhou, Y.G. Modeling constitutive relationship of Ti40 alloy using artificial neural network. Mater. Des. 2011, 32, 1537–1541. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Beygi, R.; Delzendehrooy, F.; da Silva, L. Fracture energy assessment of adhesives–Part I: Is GIC an adhesive property? A neural network analysis. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1461–1476. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Beygi, R.; Akhavan-Safar, A.; da Silva, L. Fracture energy assessment of adhesives Part II: Is GIIc an adhesive material property?(A neural network analysis). J. Adv. Join. Process. 2021, 3, 100049. [Google Scholar] [CrossRef]

- Beygi, R.; Mehrizi, M.Z.; Verdera, D.; Loureiro, A. Influence of tool geometry on material flow and mechanical properties of friction stir welded Al-Cu bimetals. J. Mater. Process. Technol. 2018, 255, 739–748. [Google Scholar] [CrossRef]

- Kumar, K.S.A.; Murigendrappa, S.M.; Kumar, H. A Bottom-Up Optimization Approach for Friction Stir Welding Parameters of Dissimilar AA2024-T351 and AA7075-T651 Alloys. J. Mater. Eng. Perform. 2017, 26, 3347–3367. [Google Scholar] [CrossRef]

- Amirafshar, A.; Pouraliakbar, H. Effect of tool pin design on the microstructural evolutions and tribological characteristics of friction stir processed structural steel. Measurement 2015, 68, 111–116. [Google Scholar] [CrossRef]

- Babu, K.K.; Panneerselvam, K.; Sathiya, P.; Haq, A.N.; Sundarrajan, S.; Mastanaiah, P.; Murthy, C.V.S. Parameter optimization of friction stir welding of cryorolled AA2219 alloy using artificial neural network modeling with genetic algorithm. Int. J. Adv. Manuf. Technol. 2018, 94, 3117–3129. [Google Scholar] [CrossRef]

- D’Orazio, A.; Forcellese, A.; Simoncini, M. Prediction of the vertical force during FSW of AZ31 magnesium alloy sheets using an artificial neural network-based model. Neural Comput. Appl. 2019, 31, 7211–7226. [Google Scholar] [CrossRef]

- Tansel, I.N.; Demetgul, M.; Okuyucu, H.; Yapici, A. Optimizations of friction stir welding of aluminum alloy by using genetically optimized neural network. Int. J. Adv. Manuf. Technol. 2010, 48, 95–101. [Google Scholar] [CrossRef]

- Dehabadi, V.M.; Ghorbanpour, S.; Azimi, G. Application of artificial neural network to predict Vickers microhardness of AA6061 friction stir welded sheets. J. Central South Univ. 2016, 23, 2146–2155. [Google Scholar] [CrossRef]

- Palanivel, R.; Laubscher, R.F.; Dinaharan, I.; Murugan, N. Tensile strength prediction of dissimilar friction stir-welded AA6351–AA5083 using artificial neural network technique. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 1647–1657. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Khalkhali, A.; Akbari, M.; Asadi, P. Investigation of friction stir welding tool parameters using FEM and neural network. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 229, 209–217. [Google Scholar] [CrossRef]

- Manvatkar, V.D.; Arora, A.; De, A.; Debroy, T. Neural network models of peak temperature, torque, traverse force, bending stress and maximum shear stress during friction stir welding. Sci. Technol. Weld. Join. 2012, 17, 460–466. [Google Scholar] [CrossRef]

- Kamalvand, E.; Jabbari, A.; Sheykholeslami, M.R.; Mazdak, S.; Beygi, R.; Mohammadi, S. Effect of friction stir welding parameters on the deep drawing of tailor-welded blanks (TWBs). CIRP J. Manuf. Sci. Technol. 2021, 33, 91–99. [Google Scholar] [CrossRef]

- Sudhakaran, R.; Murugan, V.V.; Sivasakthivel, P.S.; Balaji, M. Prediction and optimization of depth of penetration for stainless steel gas tungsten arc welded plates using artificial neural networks and simulated annealing algorithm. Neural Comput. Appl. 2013, 22, 637–649. [Google Scholar] [CrossRef]

- Padmanaban, R.; Balusamy, V.; Saikrishna, V.; Niranthar, K.G. Simulated Annealing Based Parameter Optimization for Friction Stir Welding of Dissimilar Aluminum Alloys. Procedia Eng. 2014, 97, 864–870. [Google Scholar] [CrossRef]

- Joseph, J.; Muthukumaran, S. Optimization of pulsed current GTAW process parameters for sintered hot forged AISI 4135 P/M steel welds by simulated annealing and genetic algorithm. J. Mech. Sci. Technol. 2016, 30, 145–155. [Google Scholar] [CrossRef]

- Torabi, A.; Kolahan, F. Optimizing pulsed Nd:YAG laser beam welding process parameters to attain maximum ultimate tensile strength for thin AISI316L sheet using response surface methodology and simulated annealing algorithm. Opt. Laser Technol. 2018, 103, 300–310. [Google Scholar] [CrossRef]

- Vijayavel, P.; Balasubramanian, V. Effect of pin profile volume ratio on microstructure and tensile properties of friction stir processed aluminum based metal matrix composites. J. Alloys Compd. 2017, 729, 828–842. [Google Scholar] [CrossRef]

- Liu, F.C.; Hovanski, Y.; Miles, M.P.; Sorensen, C.D.; Nelson, T.W. A review of friction stir welding of steels: Tool, material flow, microstructure, and properties. J. Mater. Sci. Technol. 2018, 34, 39–57. [Google Scholar] [CrossRef]

- Manuel, N.; Silva, C.; da Costa, J.M.D.; Loureiro, A. Friction stir welding of T-joints in dissimilar materials: Influence of tool geometry and materials properties. Mater. Res. Express 2019, 6, 106528. [Google Scholar] [CrossRef]

- Li, B.; Zhang, S.; Fang, Y. Effect of edge hone radius on plowing-induced plastic deformation in hard milling: Analytical modeling and experimental validation. Int. J. Adv. Manuf. Technol. 2019, 105, 3017–3029. [Google Scholar] [CrossRef]

- Lu, X.; Jia, Z.; Wang, H.; Feng, Y.; Liang, S.Y. The effect of cutting parameters on micro-hardness and the prediction of Vickers hardness based on a response surface methodology for micro-milling Inconel 718. Measurement 2019, 140, 56–62. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B 2008, 148, 82–87. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, G.; Cao, Y.; Zhu, Y.; Liu, Q. On the microstructure and mechanical properties of similar and dissimilar AA7075 and AA2024 friction stir welding joints: Effect of rotational speed. J. Manuf. Process. 2019, 37, 470–487. [Google Scholar] [CrossRef]

- Bertrand, R.; Robe, H.; Texier, D.; Zedan, Y.; Feulvarch, E.; Bocher, P. Analysis of AA2XXX/AA7XXX friction stir welds. J. Mater. Process. Technol. 2019, 271, 312–324. [Google Scholar] [CrossRef]

- Ibrahim, M.; Samuel, A.; Alkahtani, S.; Samuel, F. A novel solution heat treatment of 7075-type alloy. In Light Metals 2013; Springer: Berlin/Heidelberg, Germany, 2016; pp. 383–390. [Google Scholar] [CrossRef]

- Liang, M.; Chen, L.; Zhao, G.; Guo, Y. Effects of solution treatment on the microstructure and mechanical properties of naturally aged EN AW 2024 Al alloy sheet. J. Alloys Compd. 2020, 824, 153943. [Google Scholar] [CrossRef]

| Aluminum Series | Chemical Composition (wt%) | UTS(MPa) | ||||

|---|---|---|---|---|---|---|

| Cu | Mg | Zn | Si | Al | ||

| AA2024 | 4.44 | 1.55 | 0.07 | 0.094 | 93.1 | 405.7 |

| AA7075 | 1.6 | 2.7 | 5.77 | 0.088 | 89.4 | 527.49 |

| Weld Parameters | Lower Limit | Upper Limit | ||||

|---|---|---|---|---|---|---|

| Welding speed (mm/min) | 10 | 50 | ||||

| Rotation speed (RPM) | 800 | 1200 | ||||

| Tool geometry | Cylindrical | Conical | Pyramidal | |||

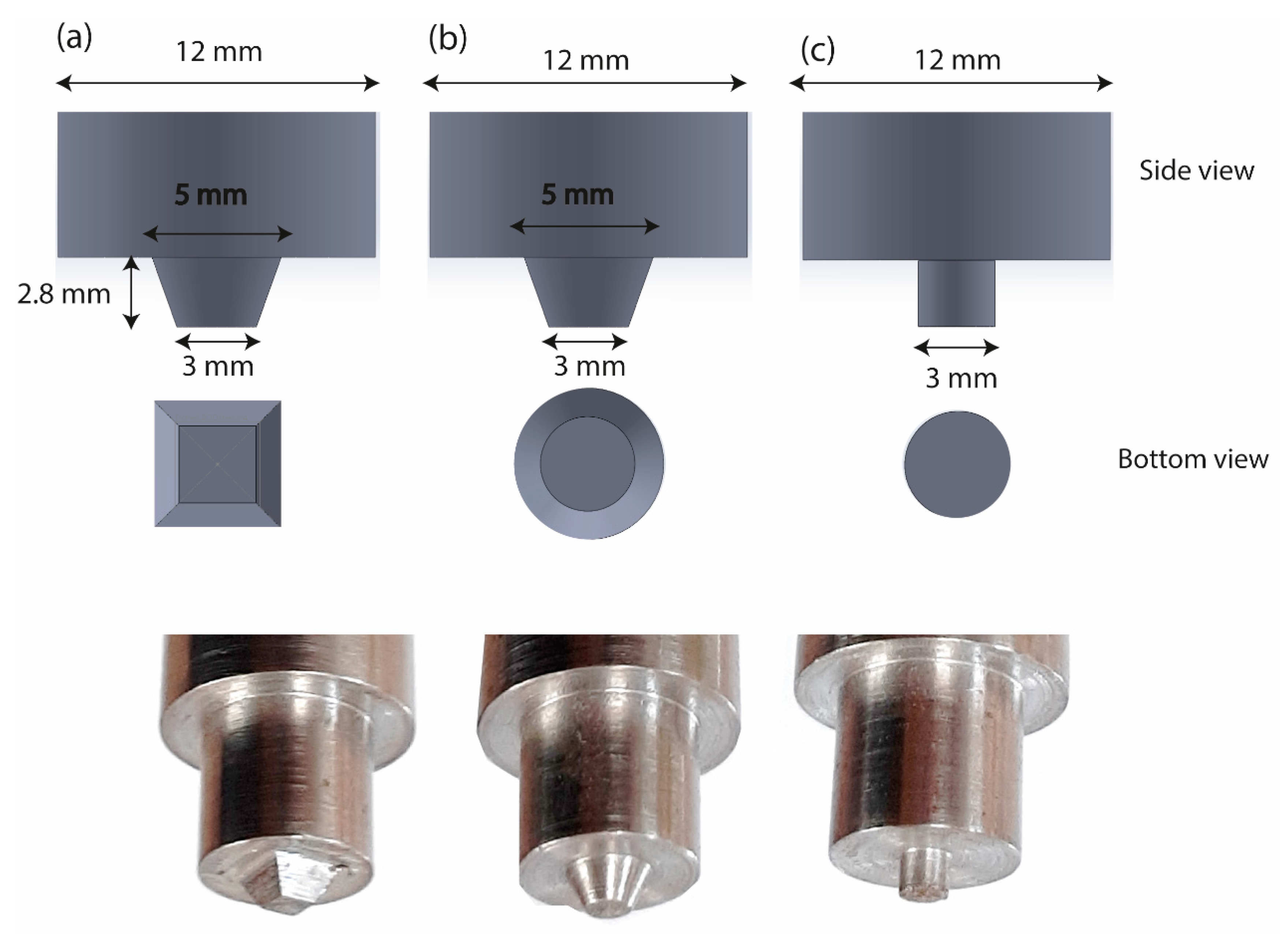

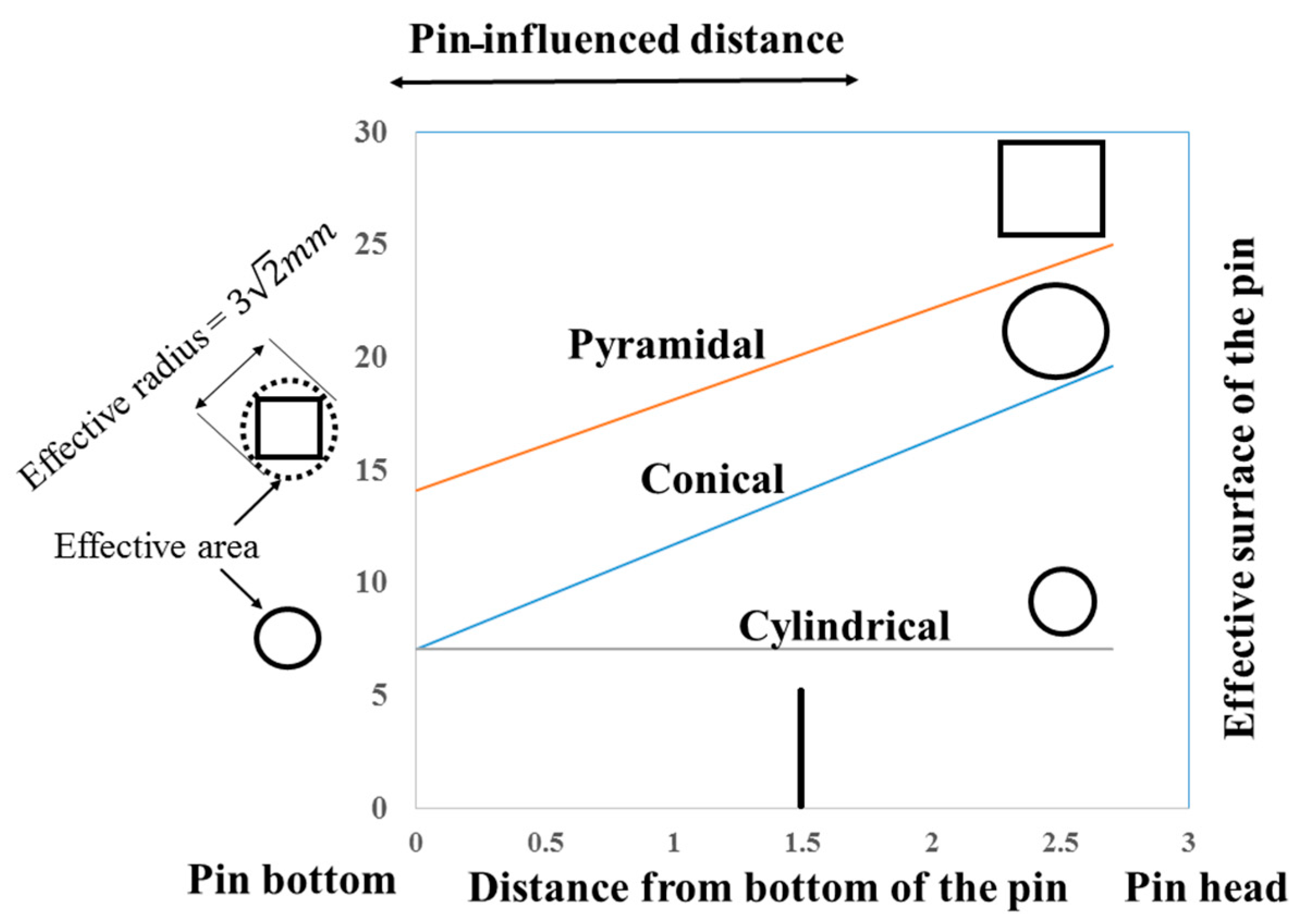

| Pin | Pyramidal | Conical | Circular |

|---|---|---|---|

| Effective volume (mm3) | 25 | 15 | 10 |

| Calculation of the volume |

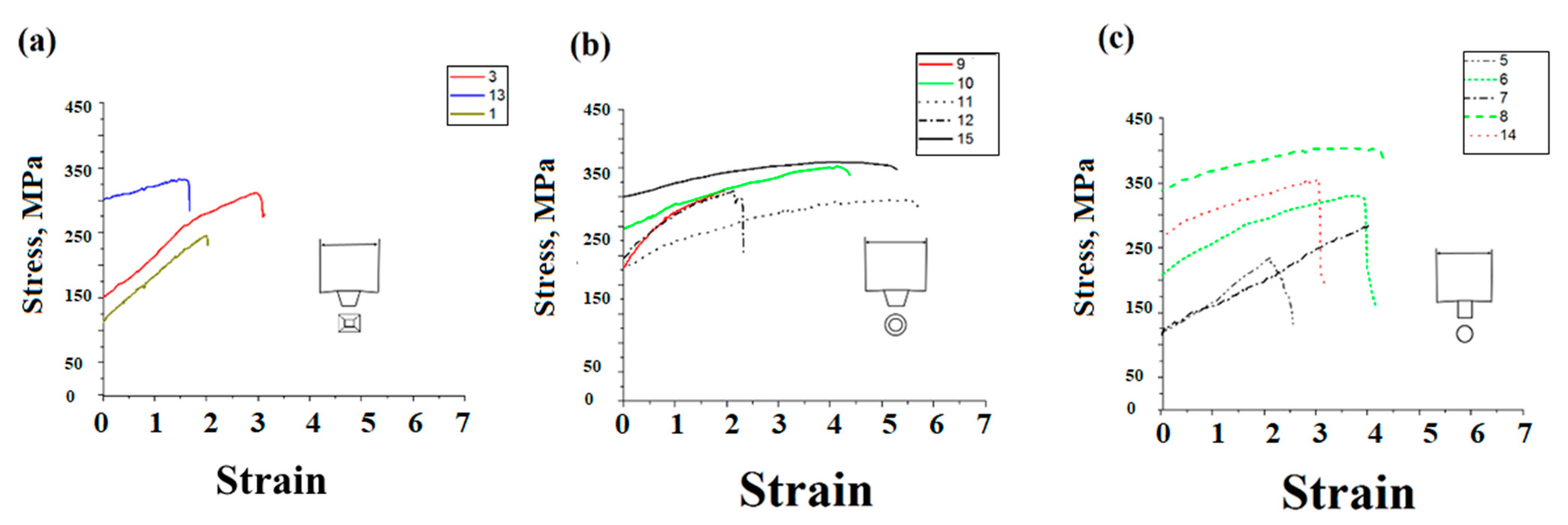

| Experiment Number | Data Set | Welding Speed (mm/min) | Tool Rotation Speed (rpm) | Tool | UTS (MPa) | Yield Strength (MPa) | Elongation | Defect Type |

|---|---|---|---|---|---|---|---|---|

| 1 | Training | 10 | 800 | Pyramidal | 257.35 | 35 | 1.96 | Root, Banding |

| 2 | Training | 10 | 1200 | Pyramidal | 100 | - | 0.25 | LOP * |

| 3 | Training | 50 | 800 | Pyramidal | 305.27 | 50 | 2.84 | Root, Banding |

| 4 | Training | 50 | 1200 | Pyramidal | 80 | - | 0.2 | LOP |

| 5 | Training | 10 | 800 | Cylindrical | 237.34 | 46 | 2.4 | Root |

| 6 | Training | 10 | 1200 | Cylindrical | 346.81 | 50 | 4.2 | - |

| 7 | Training | 50 | 800 | Cylindrical | 285 | 122 | 0.8 | Root |

| 8 | Training | 50 | 1200 | Cylindrical | 388.21 | 260 | 4.96 | - |

| 9 | Training | 30 | 800 | Conical | 313.15 | 180 | 1.4 | Root |

| 10 | Training | 30 | 1200 | Conical | 354.81 | 180 | 4.32 | - |

| 11 | Validation | 10 | 1000 | Conical | 320.57 | 175 | 7.4 | - |

| 12 | Validation | 50 | 1000 | Conical | 311.91 | 195 | 2.08 | - |

| 13 | Testing | 30 | 1000 | Pyramidal | 334.7 | 220 | 1.56 | Banding |

| 14 | Testing | 30 | 1000 | Cylindrical | 358 | 210 | 2.54 | Root |

| 15 | Testing | 30 | 1000 | Conical | 363.14 | 195 | 6.32 | - |

| Welding Speed | Tool Rotation | Effective Volume of the Pin | Predicted UTS | Experimental UTS |

|---|---|---|---|---|

| 50 mm/min | 1110 rpm | 10 mm3 | 420 MPa | 395 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beygi, R.; Zarezadeh Mehrizi, M.; Akhavan-Safar, A.; Mohammadi, S.; da Silva, L.F.M. A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture. Lubricants 2023, 11, 59. https://doi.org/10.3390/lubricants11020059

Beygi R, Zarezadeh Mehrizi M, Akhavan-Safar A, Mohammadi S, da Silva LFM. A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture. Lubricants. 2023; 11(2):59. https://doi.org/10.3390/lubricants11020059

Chicago/Turabian StyleBeygi, Reza, Majid Zarezadeh Mehrizi, Alireza Akhavan-Safar, Sajjad Mohammadi, and Lucas F. M. da Silva. 2023. "A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture" Lubricants 11, no. 2: 59. https://doi.org/10.3390/lubricants11020059

APA StyleBeygi, R., Zarezadeh Mehrizi, M., Akhavan-Safar, A., Mohammadi, S., & da Silva, L. F. M. (2023). A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture. Lubricants, 11(2), 59. https://doi.org/10.3390/lubricants11020059