Mechanical and Tribological Behaviors of U75VG Rail Flash−Butt Welded Joint

Abstract

1. Introduction

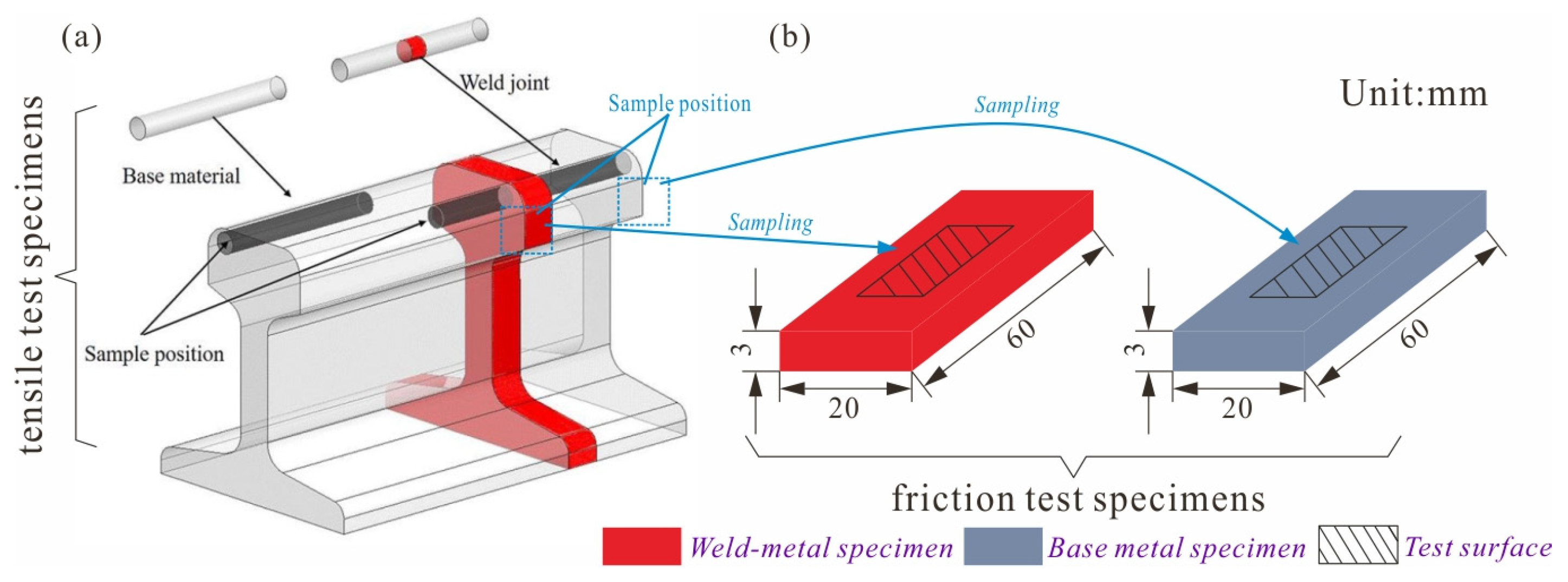

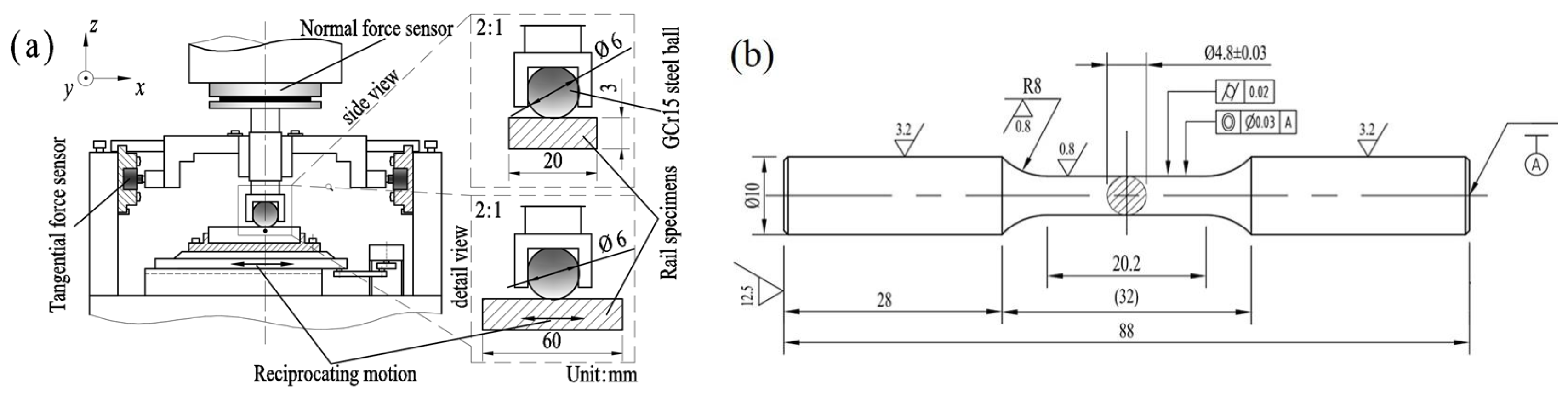

2. Experimental Details

2.1. Experimental Materials

2.2. Experimental Method

3. Results

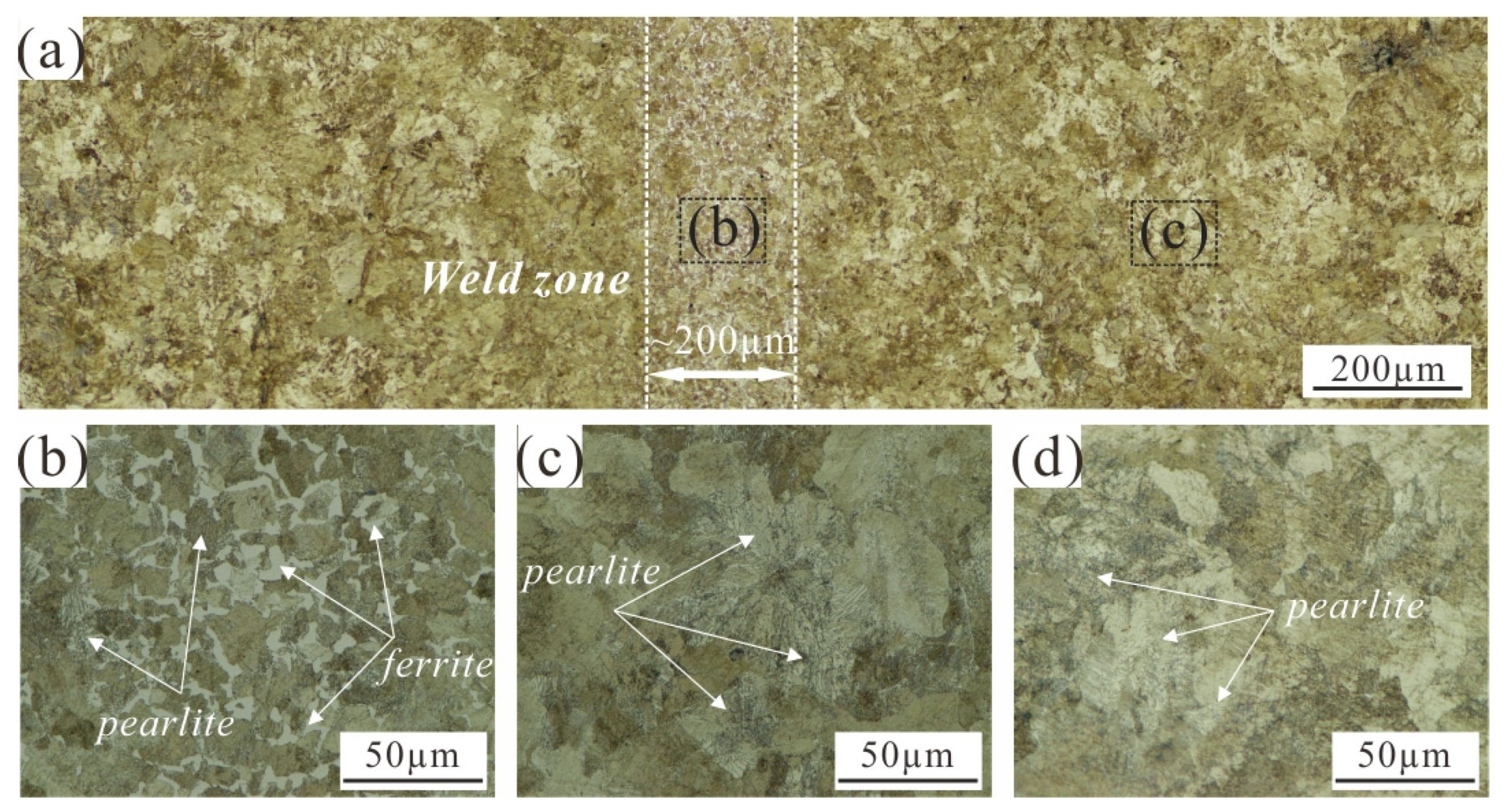

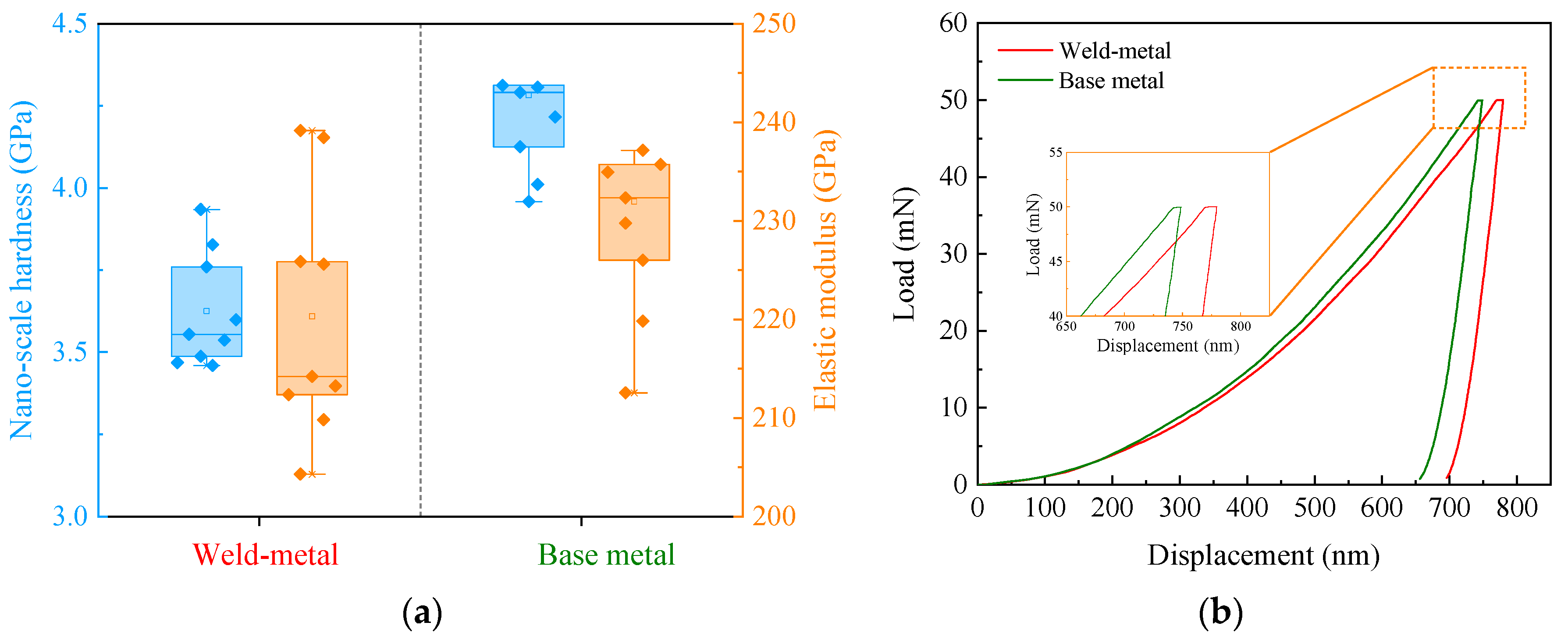

3.1. Microstructure and Mechanical Characteristic

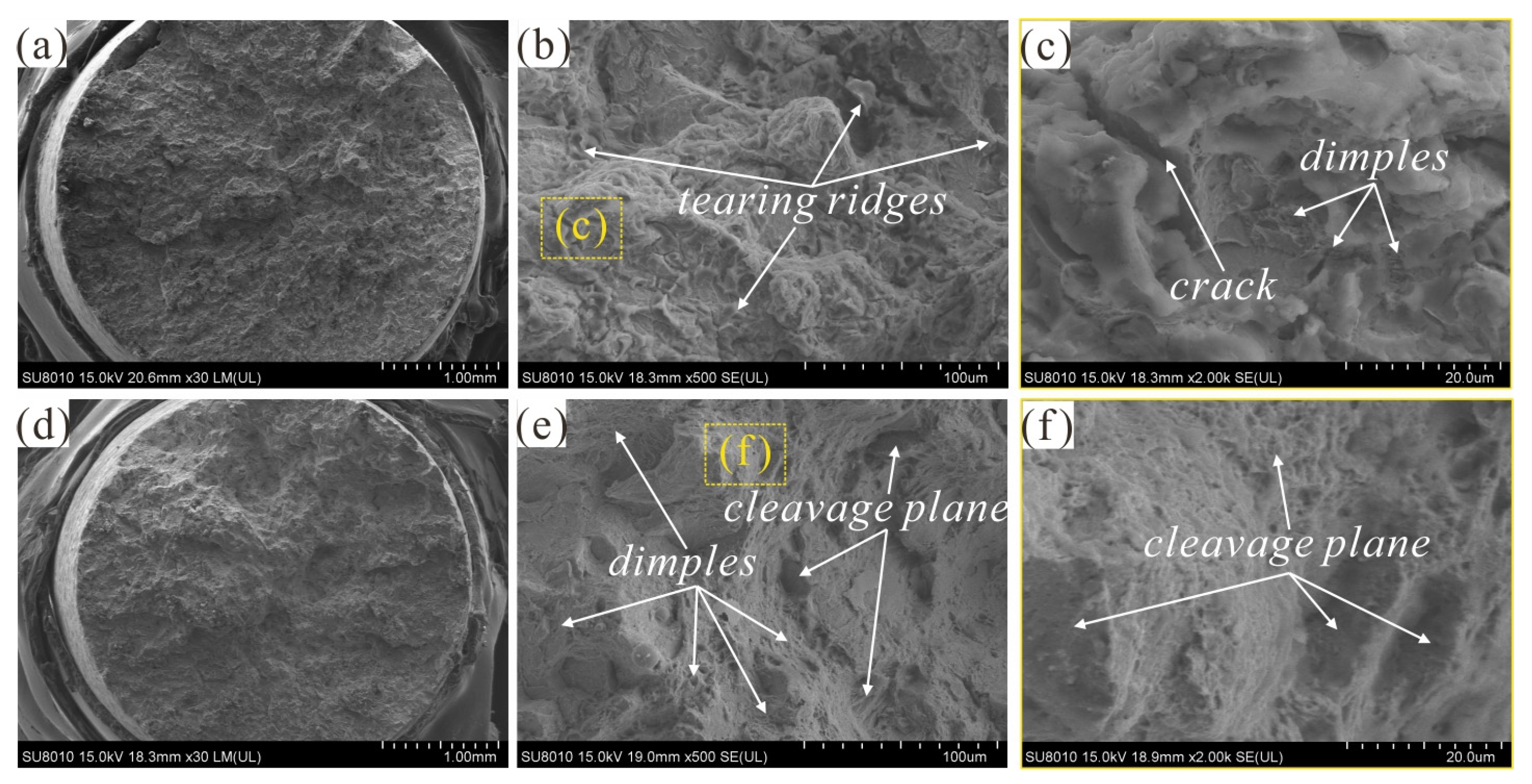

3.2. Fracture Morphology

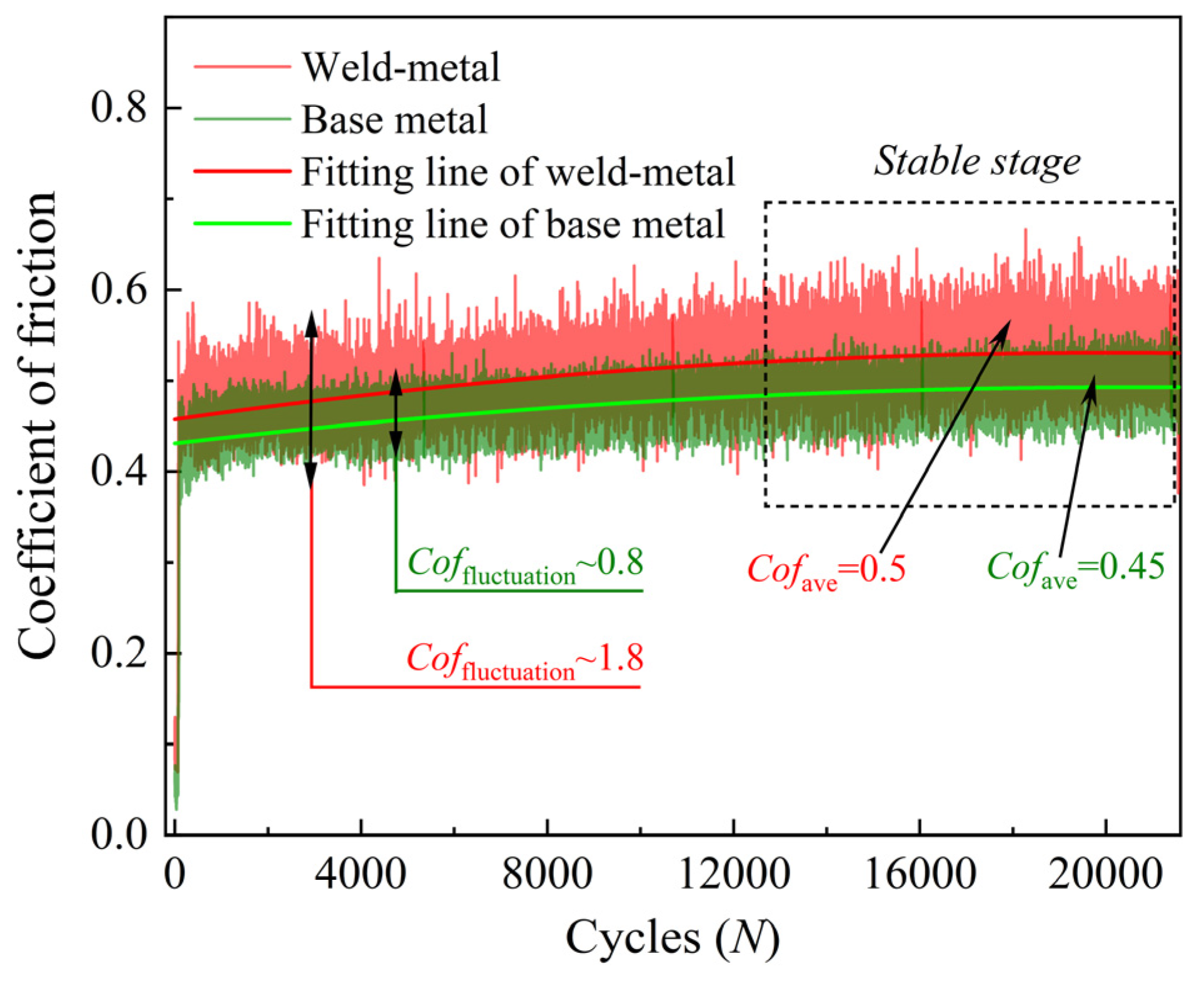

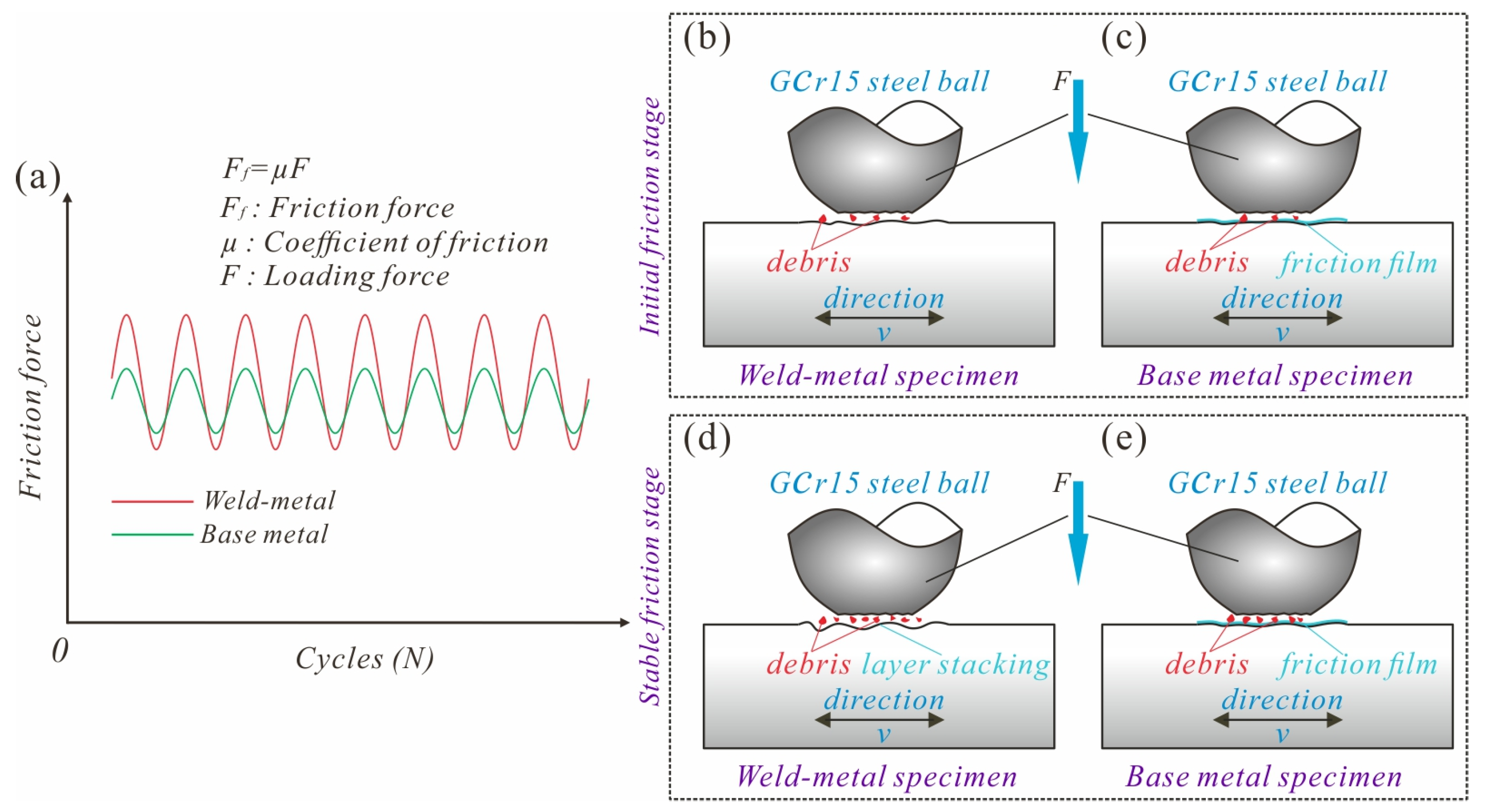

3.3. Coefficient of Friction

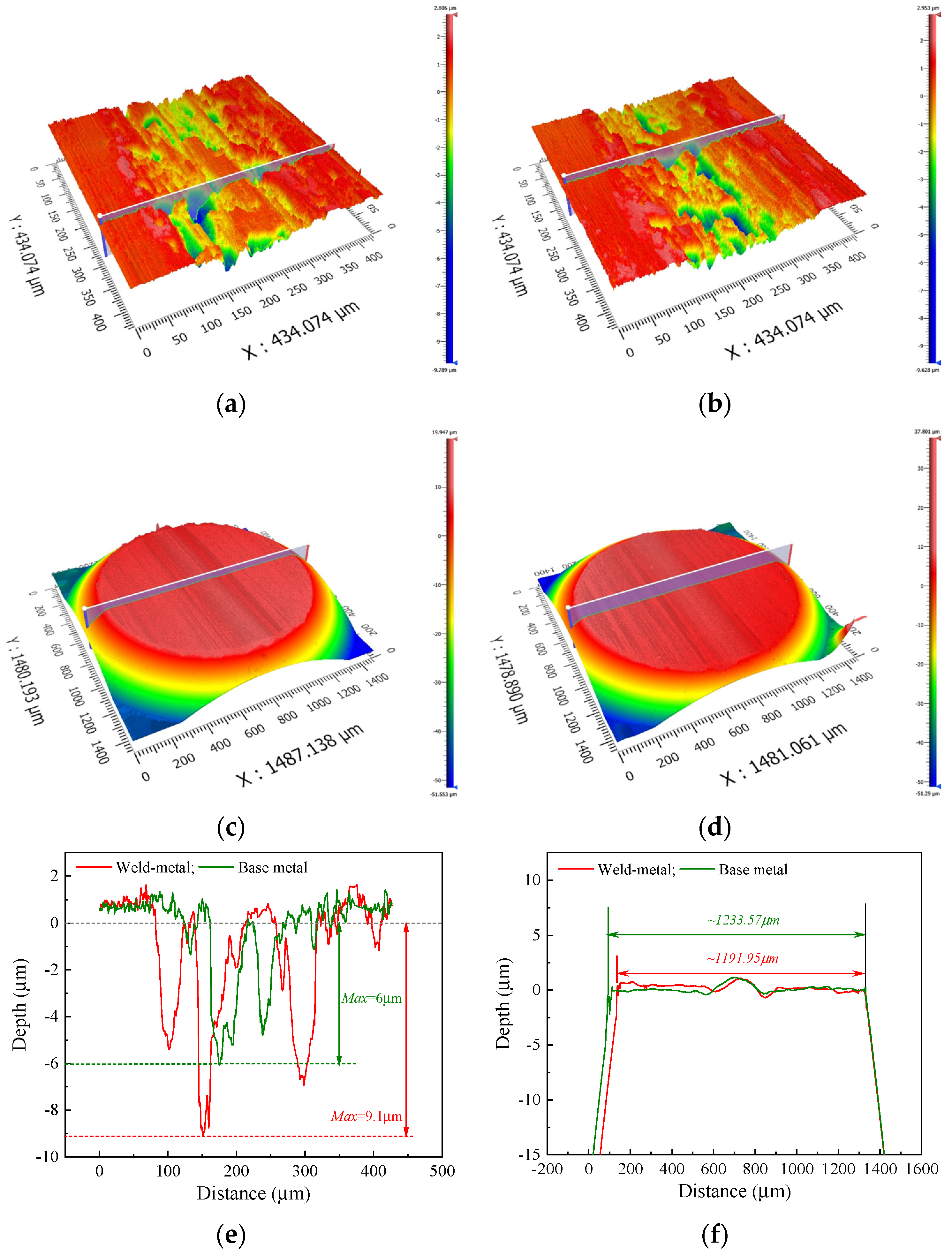

3.4. Surface Damage Morphology

4. Discussion

5. Conclusions

- (1)

- The length of the weld metal is about 200μm and has a large amount of ferrite, while the base metal is lamellar pearlite and no obvious ferrite was observed, leading to a significantly higher nano−scale hardness value. Simultaneously, the high proportion of ferrite in the weld metal results in higher plasticity than that of the base metal.

- (2)

- The yielding and strength of the welded specimen are 385 MPa and 1090 MPa, respectively, which are about 24.51% and 7.63% lower than that of the base metal specimen. More dimples and tearing ridges can be detected on the fracture morphology of the all−weld−metal specimen, while the fracture morphology of the base metal specimen is filled with shallow dimples and cleavage planes.

- (3)

- The all−weld−metal specimen has a relatively higher COF, and its fluctuation amplitude is 1.25 times higher than that of the base metal specimen, which was due to the rougher worn surface. In the stable stage, the average COF of the all−weld−metal and base metal specimens are 0.5 and 0.45, respectively.

- (4)

- The introduction of flash−butt welding will change the wear mechanism of the U75VG rail from adhesive wear and oxidation to fatigue wear and slight oxidation, leading to slighter wear damage. Therefore, the worn surface of the weld metal is uneven; there are obvious cracks and serious delamination characteristics, and the ploughing is narrow and deep, while the worn surface of the base metal is relatively flat and no obvious peeling pits are observed, and there are obvious friction films and many adhesions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farhangi, H.; Mousavizadeh, S.M. Horizontal split−web fractures of flash butt welded rails. In Proceedings of the 8th International Fracture Conference; Yildiz Technical University: Istanbul, Turkey, 2007. [Google Scholar]

- Porcaro, R.R.; Faria, G.L.; Godefroid, L.B.; Apolonio, G.R.; Candido, L.C.; Pinto, E.S. Microstructure and mechanical properties of a flash butt welded pearlitic rail. J. Mater. Process. Technol. 2019, 270, 20–27. [Google Scholar] [CrossRef]

- Shi, S.C.; Wang, W.C.; Ko, D.K. Influence of Inclusions on Mechanical Properties in Flash Butt Welding Joint of High−Strength Low−Alloy Steel. Metals 2022, 12, 242. [Google Scholar] [CrossRef]

- Skyttebol, A.; Josefson, B.L.; Ringsberg, J.W. Fatigue crack growth in a welded rail under the influence of residual stresses. Eng. Fract. Mech. 2005, 72, 271–285. [Google Scholar] [CrossRef]

- Stone, D.H.; Lwand, H.C.; Kristan, J.; Lehnhoff, G.R. Flash Butt Rail Weld Vertical Fractures. J. Fail. Anal. Prev. 2015, 15, 33–38. [Google Scholar] [CrossRef]

- Bauri, L.F.; Alves, L.H.D.; Pereira, H.B.; Tschiptschin, A.P.; Goldenstein, H. The role of welding parameters on the control of the microstructure and mechanical properties of rails welded using FBW. J. Mater. Res. Technol. 2020, 9, 8058–8073. [Google Scholar] [CrossRef]

- Kabo, E.; Ekberg, A.; Maglio, M. Rolling contact fatigue assessment of repair rail welds. Wear 2019, 436, 203030. [Google Scholar] [CrossRef]

- Zhao, X.H.; Fan, Y.J.; Liu, Y.; Wang, H.Y.; Dong, P. Evaluation of fatigue fracture mechanism in a flash butt welding joint of a U75V type steel for railroad applications. Eng. Fail. Anal. 2015, 55, 26–38. [Google Scholar] [CrossRef]

- Li, X.Y.; Ma, R.; Liu, X.; Lv, Q.B.; Wang, X.; Tian, Z. Effect of laser shock peening on fatigue properties of U75VG rail flash−butt welding joints. Opt. Laser Technol. 2022, 149, 107889. [Google Scholar] [CrossRef]

- Xu, J.M.; Wang, P.; Gao, Y.; Chen, J.Y.; Chen, R. Geometry evolution of rail weld irregularity and the effect on wheel−rail dynamic interaction in heavy haul railways. Eng. Fail. Anal. 2017, 81, 31–44. [Google Scholar] [CrossRef]

- Li, W.; Xiao, G.W.; Wen, Z.F.; Xiao, X.B.; Jin, X.S. Plastic deformation of curved rail at rail weld caused by train–track dynamic interaction. Wear 2011, 271, 311–318. [Google Scholar] [CrossRef]

- Fang, X.Y.; Zhang, H.N.; Ma, D.W.; Wu, Z.J.; Huang, W. Influence of welding residual stress on subsurface fatigue crack propagation of rail. Eng. Fract. Mech. 2022, 271, 108642. [Google Scholar] [CrossRef]

- Cai, W.; Wen, Z.F.; Jin, X.S.; Zhai, W.M. Dynamic stress analysis of rail joint with height difference defect using finite element method. Eng. Fail. Anal. 2007, 14, 1488–1499. [Google Scholar] [CrossRef]

- Zhao, J.Z.; Peng, X.; Fu, P.L.; Wang, Y.; Kang, G.Z.; Wang, P.; Kan, Q.H. Dynamic constitutive model of U75VG rail flash−butt welded joint and its application in wheel−rail transient rolling contact simulation. Eng. Fail. Anal. 2022, 134, 106078. [Google Scholar] [CrossRef]

- Sen, P.K.; Bhiwapurkar, M.; Harsha, S.P. A 3−D numerical simulation of fatigue crack growth in an alumino thermite welded UIC60 rail joint under different loading conditions. Mater. Today Proc. 2022, 59, 405–412. [Google Scholar] [CrossRef]

- Sen, P.K.; Bhiwapurkar, M.; Harsha, S.P. UIC60 rail alumino thermite weld’s semi elliptical head crack and stress intensity factor using ANSYS. Mater. Today Proc. 2022, 56, 3058–3064. [Google Scholar] [CrossRef]

- Pang, Y.; Grilli, N.; Su, H.; Liu, W.C.; Ma, J.; Yu, S.F. Experimental investigation on microstructures and mechanical properties of PG4 flash−butt rail welds. Eng. Fail. Anal. 2022, 141, 106650. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.Y.; Zhong, H.; Wang, W.J.; Meli, E.; Cui, X.L. Damage mechanism of a long−wavelength corrugated rail associated with rolling contact fatigue. Eng. Fail. Anal. 2022, 136, 106173. [Google Scholar] [CrossRef]

- Tawfik, D.; Mutton, P.J.; Chiu, W.K. Experimental and numerical investigations: Alleviating tensile residual stresses in flash−butt welds by localised rapid post−weld heat treatment. J. Mater. Process. Technol. 2008, 196, 279–291. [Google Scholar] [CrossRef]

- Ma, N.S.; Cai, Z.P.; Huang, H.; Deng, D.A.; Murakawa, H.; Pan, J.L. Investigation of welding residual stress in flash−butt joint of U71Mn rail steel by numerical simulation and experiment. Mater. Des. 2015, 88, 1296–1309. [Google Scholar] [CrossRef]

- Mansouri, H.; Monshi, A. Microstructure and residual stress variations in weld zone of flash−butt welded railroads. Sci. Technol. Weld. Join. 2004, 9, 237–245. [Google Scholar] [CrossRef]

- Su, Y.; Li, W.Y.; Wang, X.Y.; Ma, T.J.; Ma, L.; Dou, X.M. The sensitivity analysis of microstructure and mechanical properties to welding parameters for linear friction welded rail steel joints. Mater. Sci. Eng. A 2019, 764, 138251. [Google Scholar] [CrossRef]

- Su, H.; Li, J.; Lai, Q.; Pun, C.L.; Mutton, P.; Kan, Q.H.; Kang, G.Z.; Yan, W.Y. Ratcheting behaviour of flash butt welds in heat−treated hypereutectoid steel rails under uniaxial and biaxial cyclic loadings. Int. J. Mech. Sci. 2020, 176, 105539. [Google Scholar] [CrossRef]

- Çam, G.; Javaheri, V.; Heidarzadeh, A. Advances in FSW and FSSW of dissimilar Al−alloy plates. J. Adhes. Sci. Technol. 2022, 37, 162–194. [Google Scholar] [CrossRef]

- Çam, G. Prospects of producing aluminum parts by wire arc additive manufacturing (WAAM). Mater. Proc. 2022, 62, 77–85. [Google Scholar] [CrossRef]

- Luo, G.Y.; Cheng, M.P.; Liu, C.H.; Li, S.M.; Wang, X.G.; Song, L.J. Improving mechanical properties of quasi−continuous−wave laser beam welded 7075 aluminum alloy through microstructural refinement and homogenization of the fusion zone. Opt. Laser Technol. 2022, 153, 108221. [Google Scholar] [CrossRef]

- Liu, F.C.; Zhou, B.S.; Mao, Y.Q.; Huang, C.P.; Chen, Y.H.; Wang, Z.T. Microstructure and mechanical properties of laser welded joints between 2198/2060 Al–Li alloys. Mater. Sci. Technol. 2018, 34, 111–122. [Google Scholar] [CrossRef]

- Zhou, X.H.; Zhao, H.Y.; Liu, F.Y.; Yang, B.A.; Xu, B.X.; Chen, B.; Tan, C.W. Effects of beam oscillation modes on microstructure and mechanical properties of laser welded 2060 Al−Li alloy joints. Opt. Laser Technol. 2021, 144, 107389. [Google Scholar] [CrossRef]

- Ipekoğlu, G.; Çam, G. Formation of weld defects in cold metal transfer arc welded 7075−T6 plates and its effect on joint performance. IOP Conf. Ser. Mater. Sci. Eng. 2019, 629, 012007. [Google Scholar] [CrossRef]

- Çam, G.; Ventzke, V.; Dos Santos, J.F.; Koçak, M.; Jennequin, G.; Gonthier−Maurin, P. Characterisation of electron beam welded aluminium alloys. Mater. Sci. Technol. 1999, 4, 317–323. [Google Scholar] [CrossRef]

- Ancona, A.; Lugara, P.M.; Sorgente, D.; Tricarico, L. Mechanical characterization of CO2 laser beam butt welds of AA5083. J. Mater. Process. Technol. 2007, 191, 381–384. [Google Scholar] [CrossRef]

- EI−Batahgy, A.; Kutsuna, M. Laser Beam Welding of AA5052, AA5083, and AA6061 Aluminum Alloys. Adv. Mater. Sci. Eng. 2009, 2009, 974182. [Google Scholar] [CrossRef]

- Yang, Z.J.; Li, J.X.; Hou, S.S.; Cao, J.H.; Wang, G.L.; Lang, S.T.; Ding, P. Microstructural characteristics and mechanical properties of Ti–6Al–2Nb–2Zr–0.4B alloy welded joint using tungsten inert gas welding. J. Mater. Res. Technol. 2022, 21, 3129–3139. [Google Scholar] [CrossRef]

- Lewis, R.; Dwyer−Joyce, R.; Lewis, S.R.; Hardwick, C. Tribology of the Wheel−Rail Contact: The Effect of Third Body Materials. Int. J. Railw. Technol. 2012, 1, 167–194. [Google Scholar] [CrossRef]

- Chen, J.F.; Chu, J.Y.; Jiang, W.C.; Yao, B.; Zhou, F.; Wang, Z.B.; Zhao, P.C. Experimental and Numerical Simulation to Study the Reduction of Welding Residual Stress by Ultrasonic Impact Treatment. Materials 2020, 13, 837. [Google Scholar] [CrossRef] [PubMed]

- Hardwick, C.; Lewis, R.; Stock, R. The effects of friction management materials on rail with pre existing rcf surface damage. Wear 2017, 384, 50–60. [Google Scholar] [CrossRef]

- Li, X.; Dong, M.; Jiang, D.Y.; Li, S.F.; Shang, Y. The effect of surface roughness on normal restitution coefficient, adhesion force and friction coefficient of the particle−wall collision. Powder Technol. 2020, 362, 17–25. [Google Scholar] [CrossRef]

- Xiao, Y.L.; Cheng, Y.; Zhou, H.B.; Liang, W.H.; Shen, M.X.; Yao, P.P.; Zhao, H.P.; Xiong, G.Y. Evolution of contact surface characteristics and tribological properties of a copper−based sintered material during high−energy braking. Wear 2021, 488–489, 204163. [Google Scholar] [CrossRef]

- McColl, I.R.; Ding, J.; Leen, S.B. Finite element simulation and experimental validation of fretting wear. Wear 2004, 256, 1114–1127. [Google Scholar] [CrossRef]

| upset force/KN | 35 |

| upset length/mm | 10.5 |

| welding time/s | 85–95 |

| burning speed (mm/s) | 13.5–15.5 |

| clamping length/mm | 130–150 |

| weld width/mm | 20–25 |

| input heat/MJ | 8.6 |

| C | Si | Mn | S | P | V |

|---|---|---|---|---|---|

| 0.71~0.8 | 0.5~0.8 | 0.7~1.05 | ≤0.03 | ≤0.03 | 0.04~0.12 |

| C | Si | Mn | Cr | Mo | S/P | Ni + Cu |

|---|---|---|---|---|---|---|

| 0.95~1.05 | 0.15~0.35 | 0.25~0.45 | 1.45~1.65 | ≤0.1 | ≤0.025 | ≤0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, B.; Liu, S.; Li, Q.; Peng, J.; Shen, M. Mechanical and Tribological Behaviors of U75VG Rail Flash−Butt Welded Joint. Lubricants 2023, 11, 41. https://doi.org/10.3390/lubricants11020041

Rong B, Liu S, Li Q, Peng J, Shen M. Mechanical and Tribological Behaviors of U75VG Rail Flash−Butt Welded Joint. Lubricants. 2023; 11(2):41. https://doi.org/10.3390/lubricants11020041

Chicago/Turabian StyleRong, Bin, Shaopeng Liu, Qiuping Li, Jinfang Peng, and Mingxue Shen. 2023. "Mechanical and Tribological Behaviors of U75VG Rail Flash−Butt Welded Joint" Lubricants 11, no. 2: 41. https://doi.org/10.3390/lubricants11020041

APA StyleRong, B., Liu, S., Li, Q., Peng, J., & Shen, M. (2023). Mechanical and Tribological Behaviors of U75VG Rail Flash−Butt Welded Joint. Lubricants, 11(2), 41. https://doi.org/10.3390/lubricants11020041