Effect of Ceramic Particles on Ni-Based Alloy Coating Fabricated via Laser Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

3.1. Phases

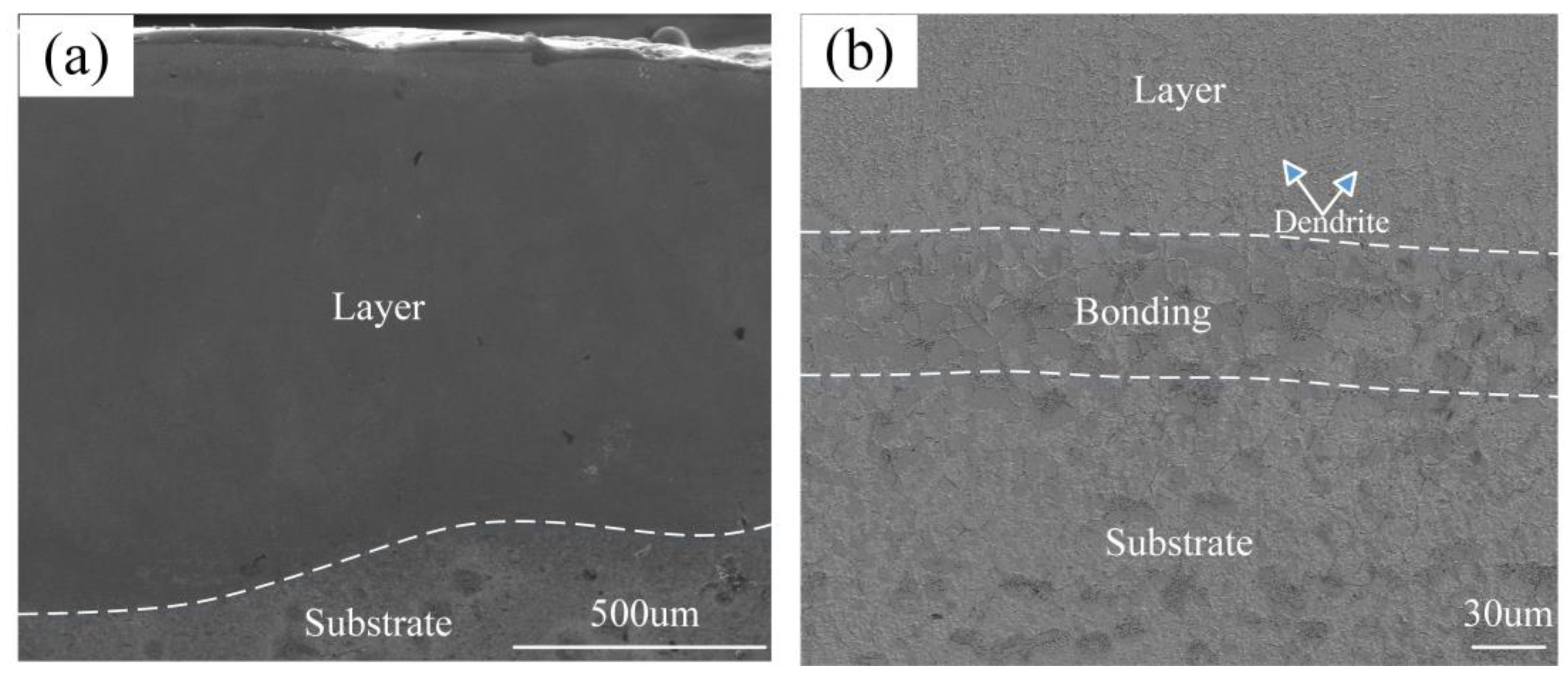

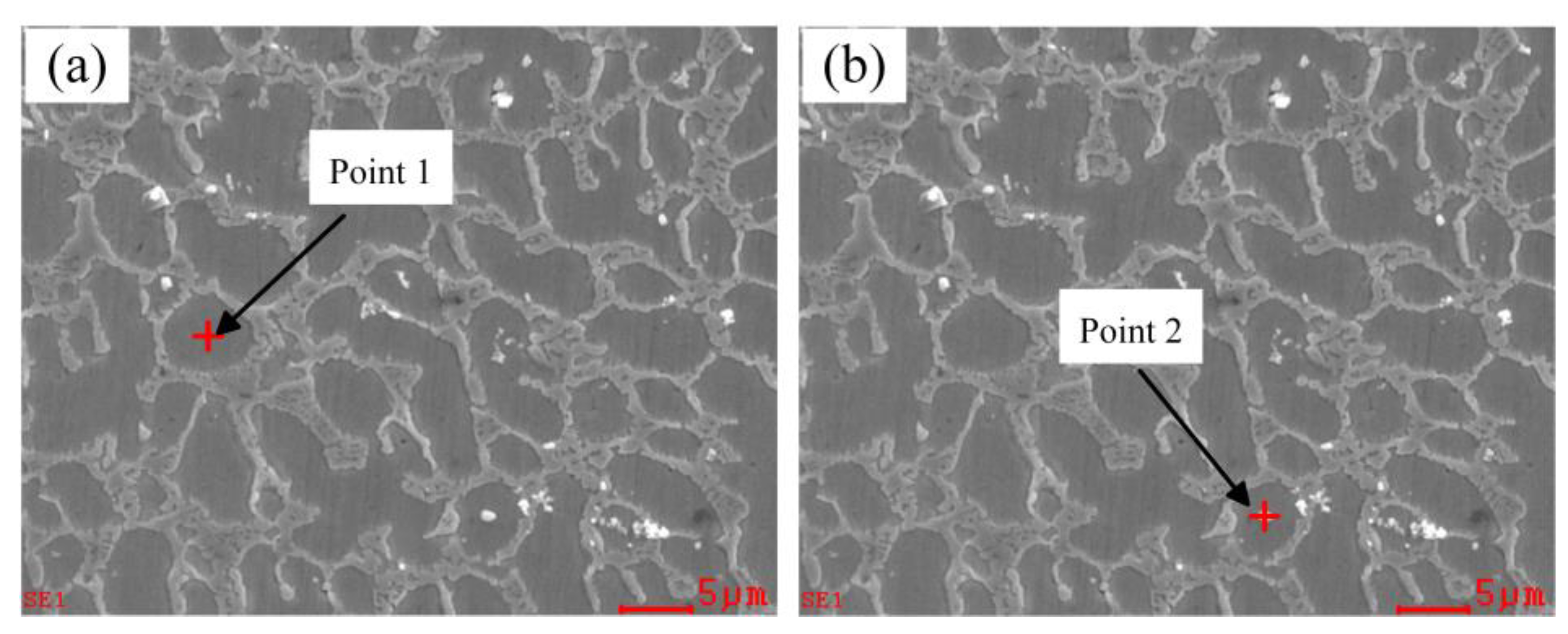

3.2. Microstructure

3.3. Microhardness

3.4. Friction and Wear Resistance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2021, 134, 106619. [Google Scholar] [CrossRef]

- Yuan, W.; Li, R.; Chen, Z. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Gao, Y.L.; Lu, P.Y.; Bai, S.C.; Qin, B.L.; Zhang, D.D. Influence of laser power on microstructure and properties of Al-Si+Y2O3 coating. Coatings 2023, 13, 1289. [Google Scholar] [CrossRef]

- Rukanskis, M.; Padgurskas, J.; Sabalius, A. Friction and wear of electrospark coatings made of molybdenum, bronze, and combined (Ti+Al+C) composition on steel 45 in a lubricant medium. J. Frict. Wear 2021, 42, 56–62. [Google Scholar] [CrossRef]

- Li, J.; Cao, Z.; Liu, L. Effect of microstructure on hardness and wear properties of 45 steel after induction hardening. Steel Res. Int. 2021, 92, 2000540. [Google Scholar] [CrossRef]

- Ma, W.L.; Zhao, J.; Wang, F.B. Effect of textured surface on friction and wear properties of 45 steel. Tribology 2022, 43, 314–324. [Google Scholar] [CrossRef]

- Li, W.Y.; Ma, T.J.; Yang, S.Q. Effect of friction time on flash shape and axial shortening of linear friction welded 45 steel. Mater. Lett. 2008, 62, 293–296. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.Y.; Li, G.H.; Tang, L. Friction and wear behavior of Ni-based alloy coatings with different amount of WC-TiC ceramic particles. J. Mater. Sci. 2023, 58, 1116–1126. [Google Scholar] [CrossRef]

- Thawari, N.; Gullipalli, C.; Katiyar, J.K. Effect of multi-layer laser cladding of Stellite 6 and Inconel 718 materials on clad geometry, microstructure evolution and mechanical properties. Mater. Today Commun. 2021, 28, 102604. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Guo, D.; Yang, M.; Sun, H.; Wang, Z.; Hui, X.; Wu, Y. Microstructures, corrosion resistance and wear resistance of high-entropy alloys coatings with various compositions prepared by laser cladding: A review. Coatings 2022, 12, 1023. [Google Scholar] [CrossRef]

- Kim, R.E.; Kim, E.S.; Karthik, G.M.; Gu, G.H.; Ahn, S.Y.; Park, H.; Moon, J.; Kim, H.S. Heterostructured alloys with enhanced strength-ductility synergy through laser-cladding. Scr. Mater. 2022, 215, 114732. [Google Scholar] [CrossRef]

- Ouyang, W.; Xu, Z.; Chao, Y.; Liu, Y.; Luo, W.; Jiao, J.; Sheng, L.; Zhang, W. Effect of electrostatic field on microstructure and mechanical properties of the 316L stainless steel modified layer fabricated by laser cladding. Mater. Charact. 2022, 191, 112123. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Z.; Pang, M. Effect of WC content on laser cladding Ni-based coating on the surface of stainless steel. Mater. Today Commun. 2022, 31, 103357. [Google Scholar] [CrossRef]

- Ocelík, V.; Oliveira, U.; Boer, M. Thick Co-based coating on cast iron by side laser cladding: Analysis of processing conditions and coating properties. Surf. Coat. Technol. 2007, 201, 5875–5883. [Google Scholar] [CrossRef]

- Fu, Z.K.; Ding, H.H.; Wang, W.J. Investigation on microstructure and wear characteristic of laser cladding Fe-based alloy on wheel/rail materials. Wear 2015, 330, 592–599. [Google Scholar] [CrossRef]

- Shan, B.; Chen, J.; Chen, S.; Ma, M.; Ni, L.; Shang, F.; Zhou, L. Laser cladding of Fe-based corrosion and wear-resistant alloy: Genetic design, microstructure, and properties. Surf. Coat. Technol. 2022, 433, 128117. [Google Scholar] [CrossRef]

- Gao, Z.; Geng, H.; Qiao, Z.; Sun, B.; Gao, Z.; Zhang, C. In situ TiBX/TiXNiY/TiC reinforced Ni60 composites by laser cladding and its effect on the tribological properties. Ceram. Int. 2023, 49, 6409–6418. [Google Scholar] [CrossRef]

- Qi, K.; Yang, Y. Microstructure, wear, and corrosion resistance of Nb-modified magnetic field-assisted Co-based laser cladding layers. Surf. Coat. Technol. 2022, 434, 128195. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, R.; Bai, Q.; Chen, Z.; Yan, X. Aging strengthening treatment of laser cladding Co-based alloy coating. Mater. Lett. 2022, 313, 131746. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y.; Tan, X.J.; Liang, G.; Zhang, Q.M. Microstructure and high temperature tribological behavior of laser cladding Ni60A alloys coatings on 45 steel substrate. Trans. Nonferrous Met. Soc. China 2015, 25, 1525–1532. [Google Scholar] [CrossRef]

- Zhu, L.D.; Wang, S.H.; Pan, H.C.; Yuan, C.T.; Chen, X.S. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology. J. Manuf. Process. 2020, 49, 344–354. [Google Scholar] [CrossRef]

- Liu, Q.S.; Liu, X.B.; Wang, G.; Liu, Y.F.; Meng, Y.; Zhang, S.H. Effect of Cu content on microstructure evolution and tribological behaviors of Ni60 composite coatings on 45# steel by laser cladding. Opt. Laser Technol. 2022, 156, 108549. [Google Scholar] [CrossRef]

- Sun, S.Y.; Wang, J.L.; Xu, J.H.; Cheng, X.Y.; Jing, C.H.; Chen, Z.D.; Ru, H.L.; Liu, Y.Y.; Jiao, J.K. Preparing WC-Ni coatings with laser cladding technology: A review. Mater. Today Commun. 2023, 37, 106939. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Q.; Yu, Z.; Wang, H.; Zhang, T. Influence of Y2O3 addition on the microstructure of TiC reinforced Ti-based composite coating prepared by laser cladding. Mater. Charact. 2022, 189, 111962. [Google Scholar] [CrossRef]

- Li, Y.; Wang, K.; Fu, H.; Guo, X.; Lin, J. Microstructure and wear resistance of in-situ TiC reinforced AlCoCrFeNi-based coatings by laser cladding. Appl. Surf. Sci. 2022, 585, 152703. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; Lu, B.; Tan, N.; Cai, L.; Yong, Q. Effect of WC content on microstructure and properties of high-speed laser cladding Ni-based coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- Li, Y.T.; Fu, H.G.; Ma, T.J.; Wang, K.M.; Yang, X.J.; Lin, J. Microstructure and wear resistance of AlCoCrFeNi-WC/TiC composite coating by laser cladding. Mater. Charact. 2022, 194, 112479. [Google Scholar] [CrossRef]

- Xiao, Q.; Sun, W.L.; Yang, K.X.; Xing, X.F.; Chen, Z.H.; Zhou, H.N.; Lu, J. Wear mechanisms and micro-evaluation on WC particles investigation of WC-Fe composite coatings fabricated by laser cladding. Surf. Coat. Technol. 2021, 420, 127341. [Google Scholar] [CrossRef]

- Chen, C.L.; Feng, A.X.; Wei, Y.C.; Wang, Y.; Pan, X.M.; Song, X.Y. Role of nano WC particles addition on the corrosion behavior of laser cladding WC/Ni coatings. Mater. Lett. 2023, 337, 133939. [Google Scholar] [CrossRef]

- Jie, M.; Gao, Y.L. Study on hardness and wear resistance of laser cladding Al-Si coating. Appl. Laser. 2015, 35, 629–633. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | S | P | Fe |

|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.42–0.5 | 0.5–0.8 | 0.17–0.37 | ≤0.035 | ≤0.035 | Bal. |

| Element | C | Si | B | Fe | Cr | WC | TiC | Ni |

|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.65 | 4.2 | 4.6 | 6.3 | 17.5 | 10 | 10 | Bal. |

| Element | Fe | Ni | C | Si | Cr | W |

|---|---|---|---|---|---|---|

| Point 1 | 67.0 | 14.8 | 1.7 | 1.3 | 9.7 | 5.5 |

| Point 2 | 41.6 | 5.2 | 19.3 | 0.5 | 28.5 | 4.9 |

| Element | Fe | Ni | C | Si | Cr | W |

|---|---|---|---|---|---|---|

| Point 3 | 50.2 | 5.3 | 2.7 | 0.3 | 29.0 | 12.5 |

| Point 4 | 46.7 | 9.6 | 12.2 | 0.3 | 21.5 | 9.7 |

| Element | Fe | Ni | C | Si | Cr | W |

|---|---|---|---|---|---|---|

| Point 5 | 27.3 | 4.6 | 11.9 | 6.1 | 9.6 | 40.5 |

| Point 6 | 29.6 | 4.8 | 25.5 | 16.7 | 18.4 | 5.0 |

| Item | Ball Radius (mm) | Length (mm) | Width (mm) |

|---|---|---|---|

| Ni-based coating | 6.5 | 5.23 | 1.35 |

| Substrate | 6.5 | 5.58 | 2.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, Y.; Wang, L.; Jin, Y.; Wang, Z.; Shi, X. Effect of Ceramic Particles on Ni-Based Alloy Coating Fabricated via Laser Technology. Lubricants 2023, 11, 483. https://doi.org/10.3390/lubricants11110483

Zhang Y, Wang Y, Wang L, Jin Y, Wang Z, Shi X. Effect of Ceramic Particles on Ni-Based Alloy Coating Fabricated via Laser Technology. Lubricants. 2023; 11(11):483. https://doi.org/10.3390/lubricants11110483

Chicago/Turabian StyleZhang, Yanhua, Yinan Wang, Li Wang, Ying Jin, Zhaofeng Wang, and Xiaoling Shi. 2023. "Effect of Ceramic Particles on Ni-Based Alloy Coating Fabricated via Laser Technology" Lubricants 11, no. 11: 483. https://doi.org/10.3390/lubricants11110483

APA StyleZhang, Y., Wang, Y., Wang, L., Jin, Y., Wang, Z., & Shi, X. (2023). Effect of Ceramic Particles on Ni-Based Alloy Coating Fabricated via Laser Technology. Lubricants, 11(11), 483. https://doi.org/10.3390/lubricants11110483