Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Greases

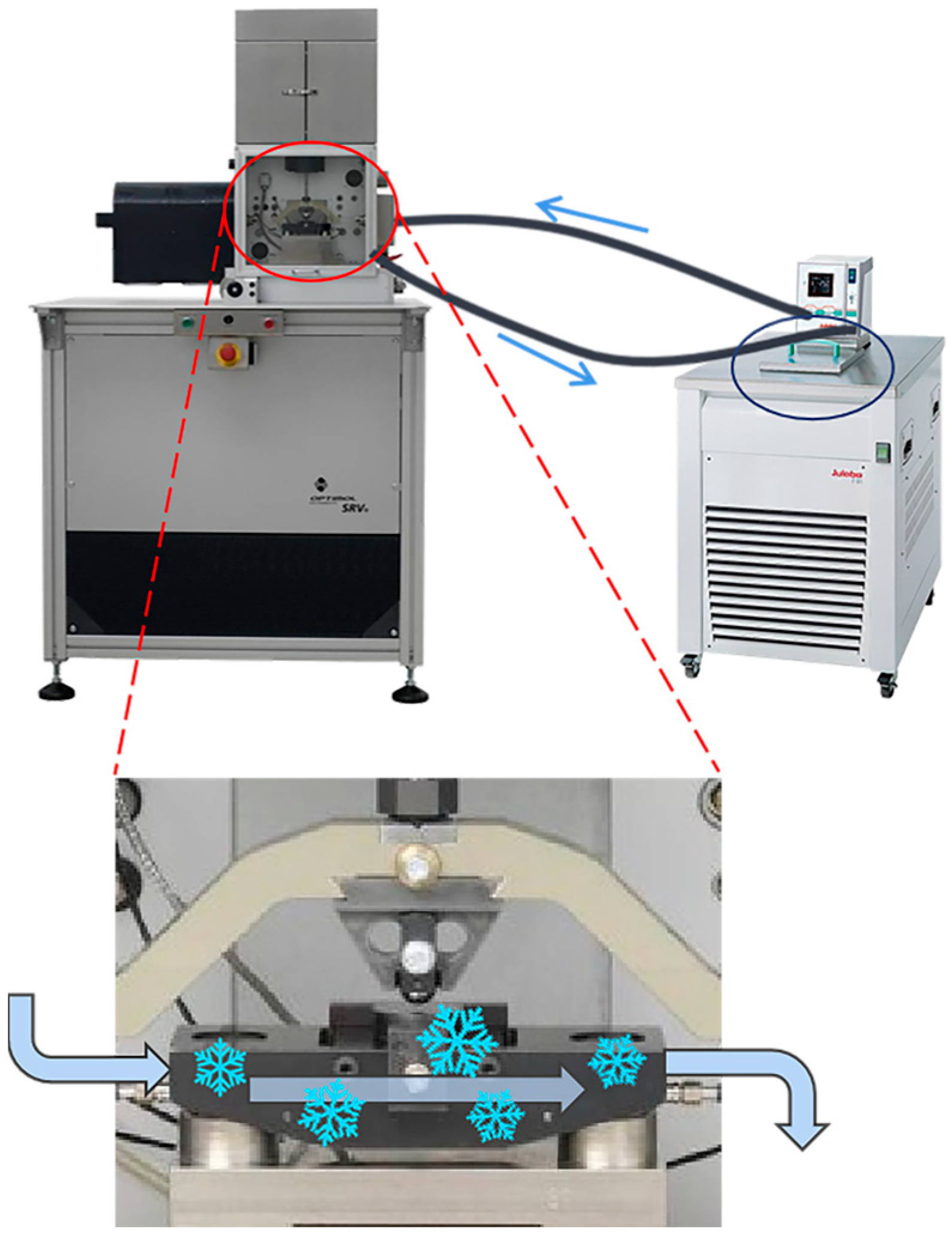

2.3. Characterization of Tribology

2.4. Characterization of Rheology

3. Results

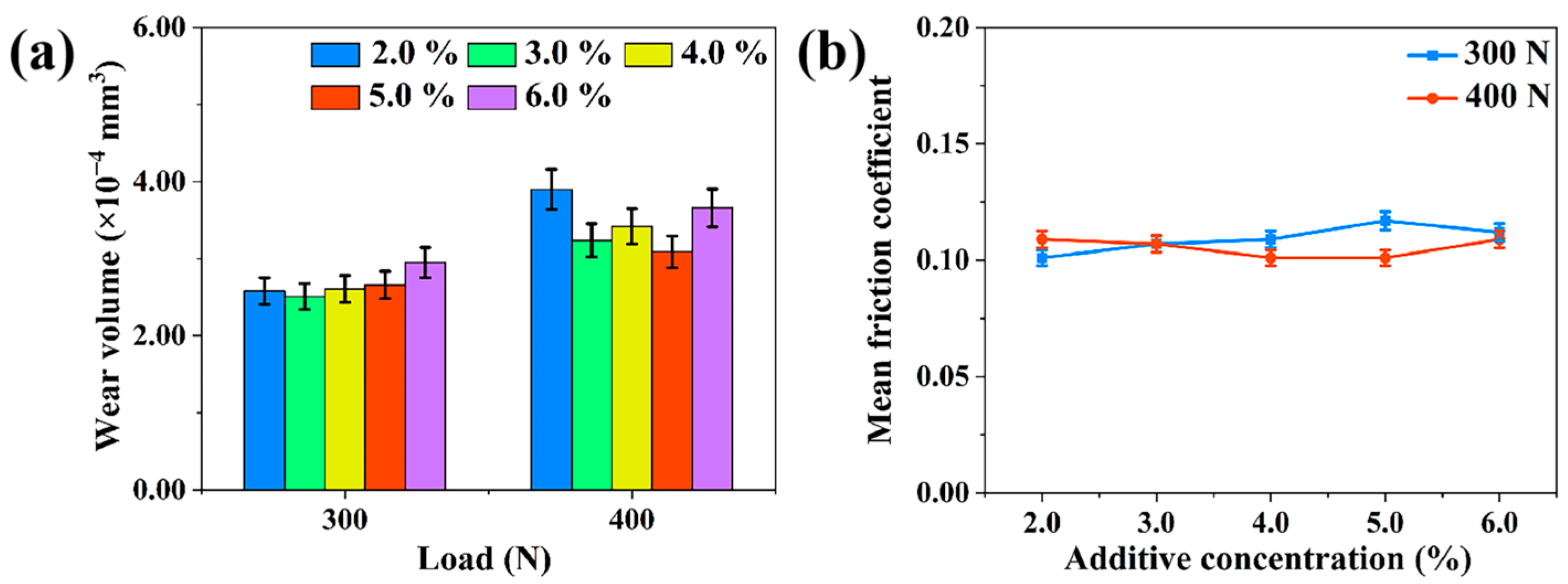

3.1. Influence of Additive Concentrations on the Tribological Properties of PP Grease

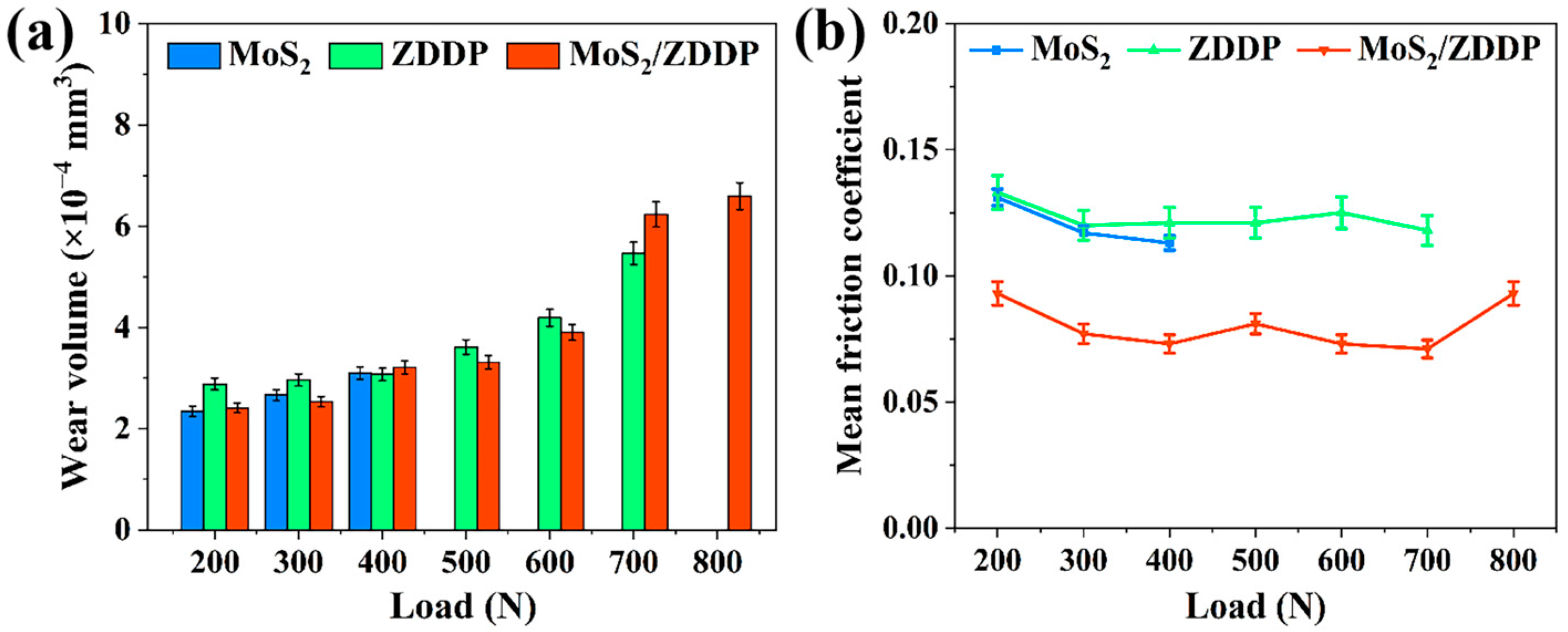

3.2. Influence of Combined Additives on the Tribological Properties of PP Grease at Different Temperatures

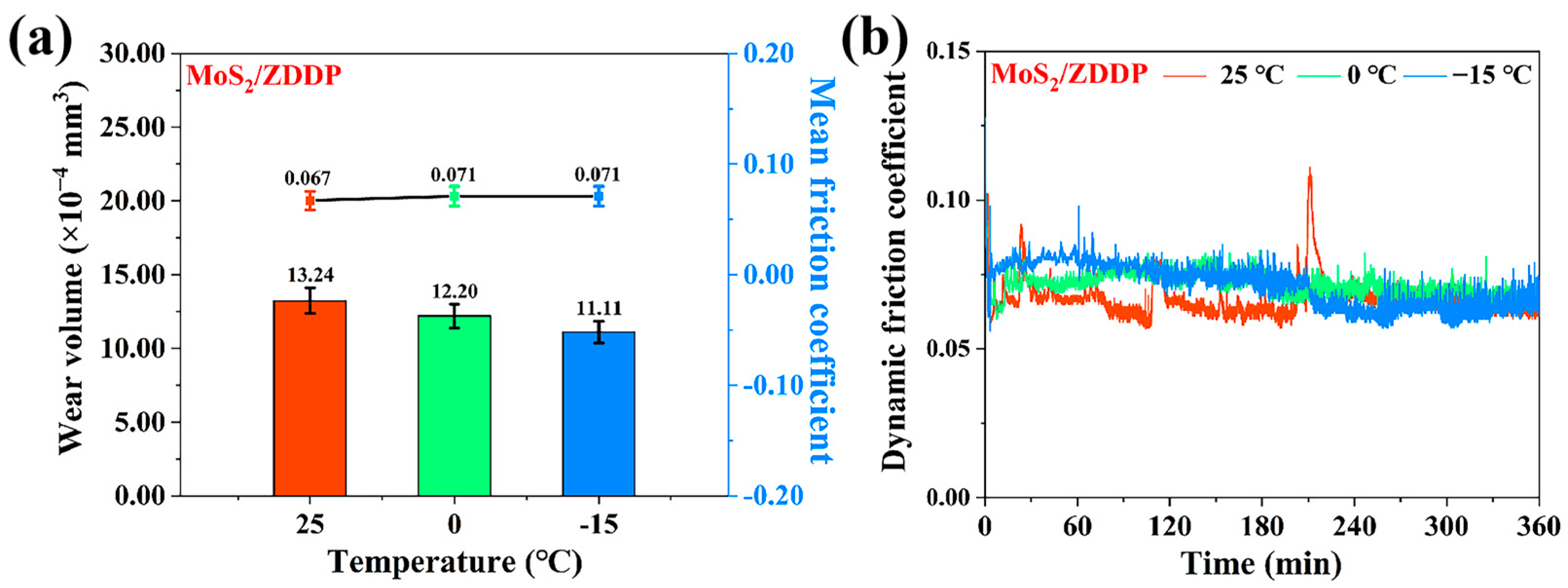

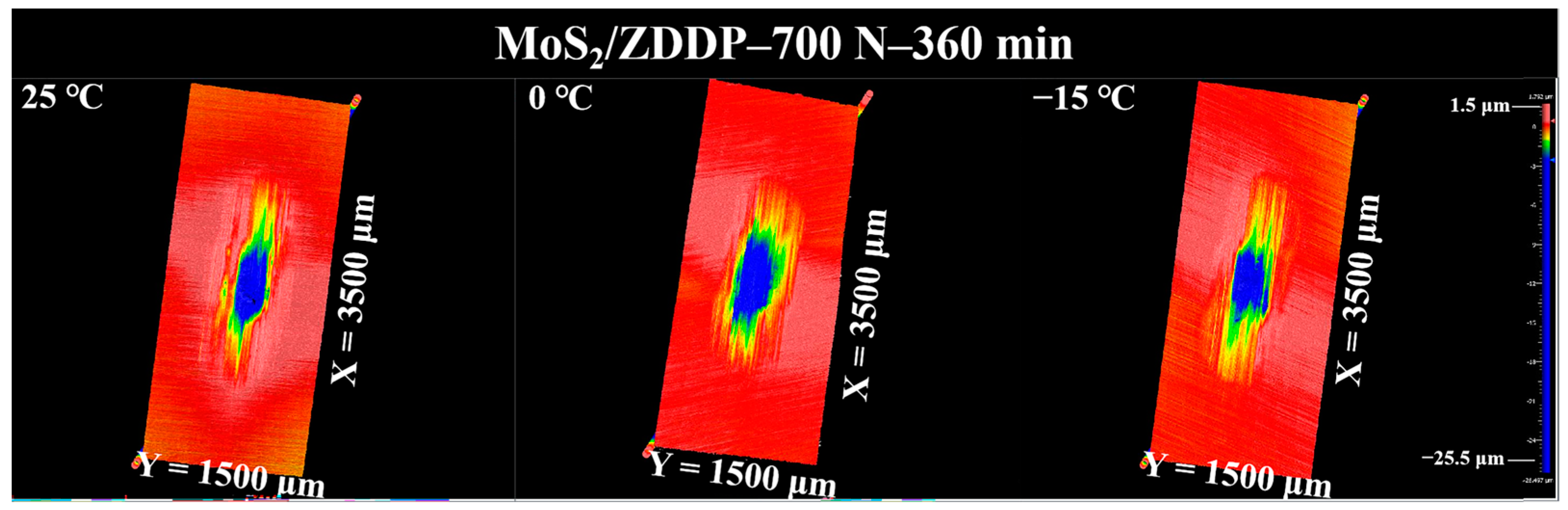

3.3. Influence of Combined Additives on the Tribological Properties of PP Grease at Different Temperatures for Long-Time Tests

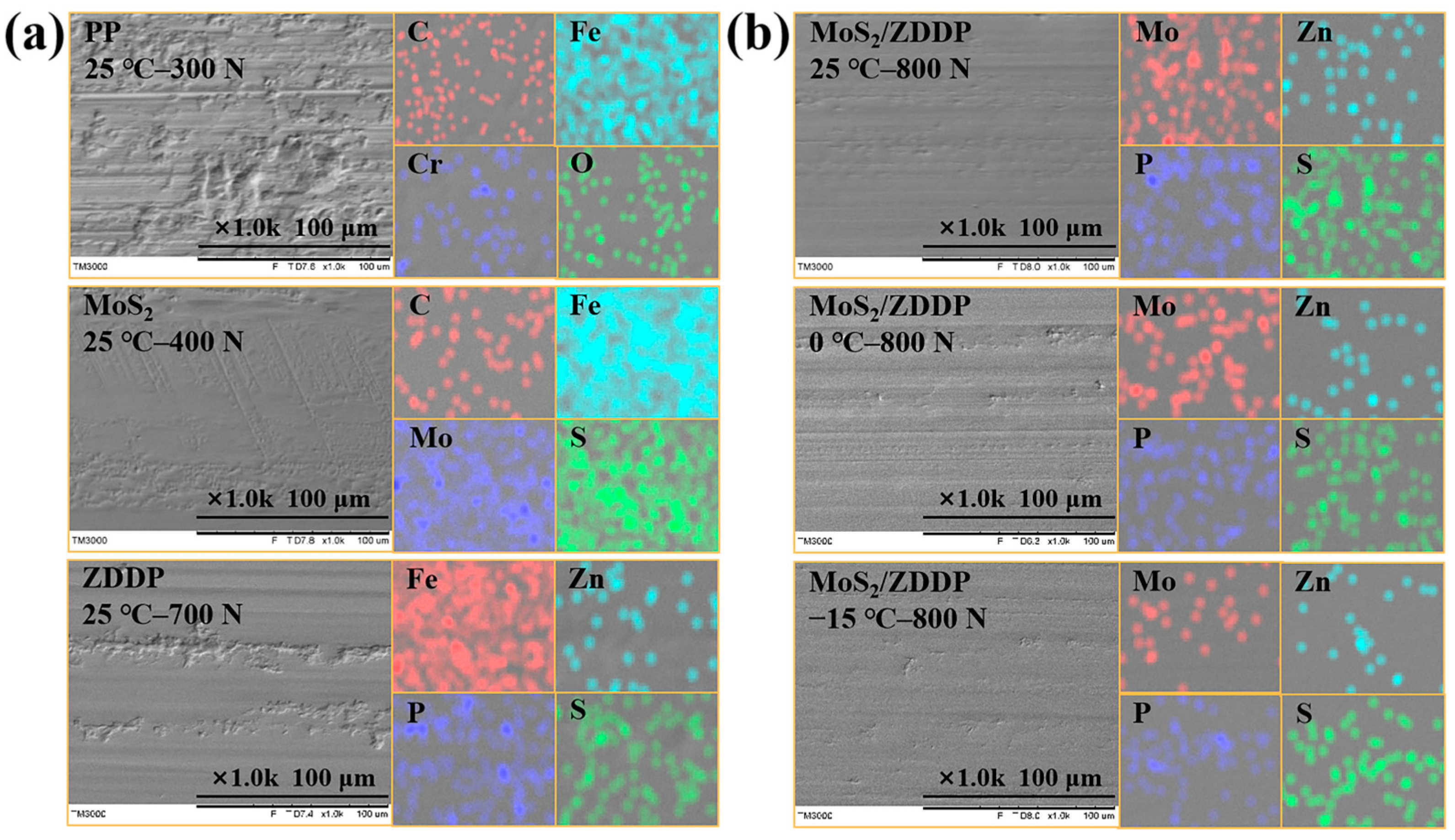

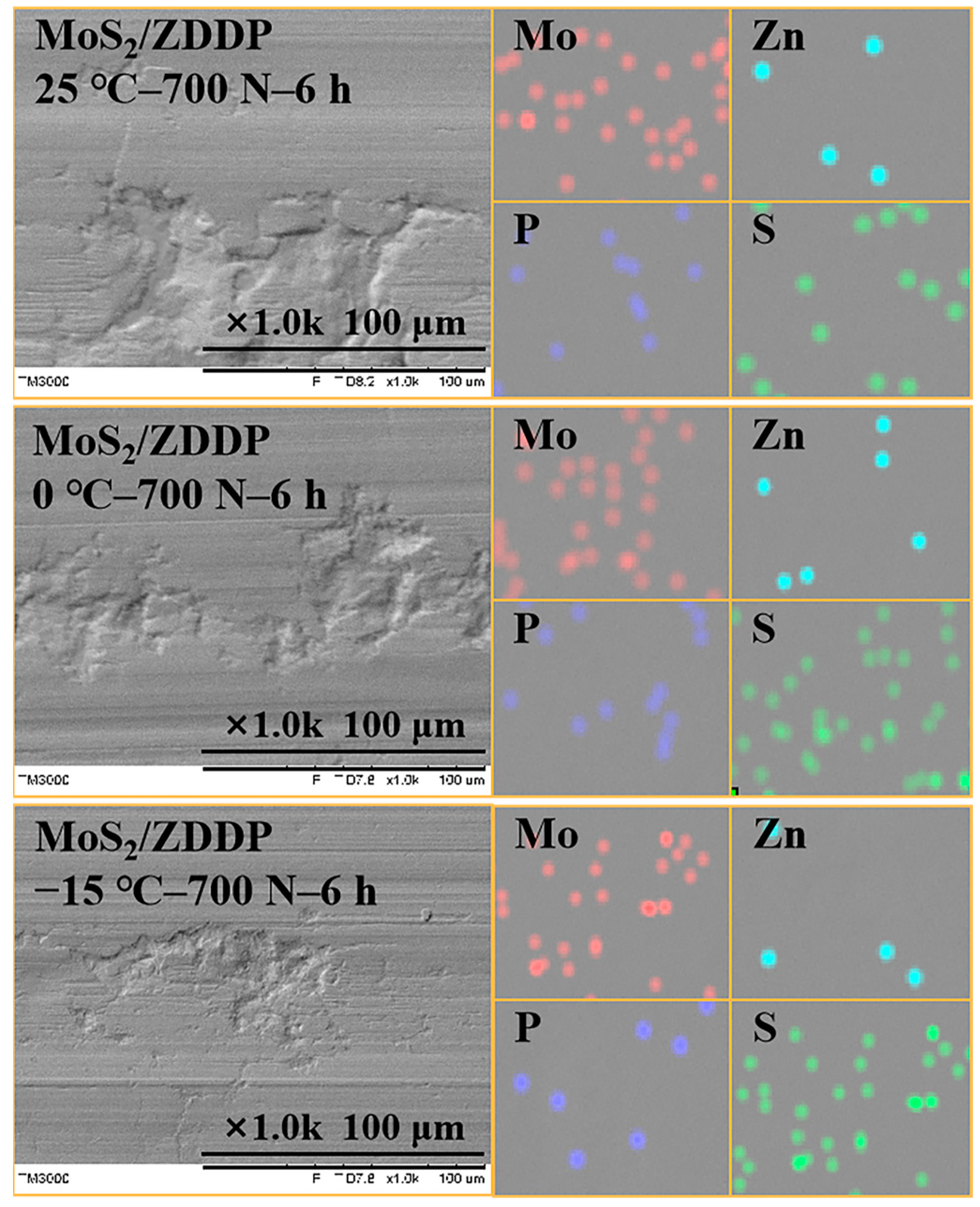

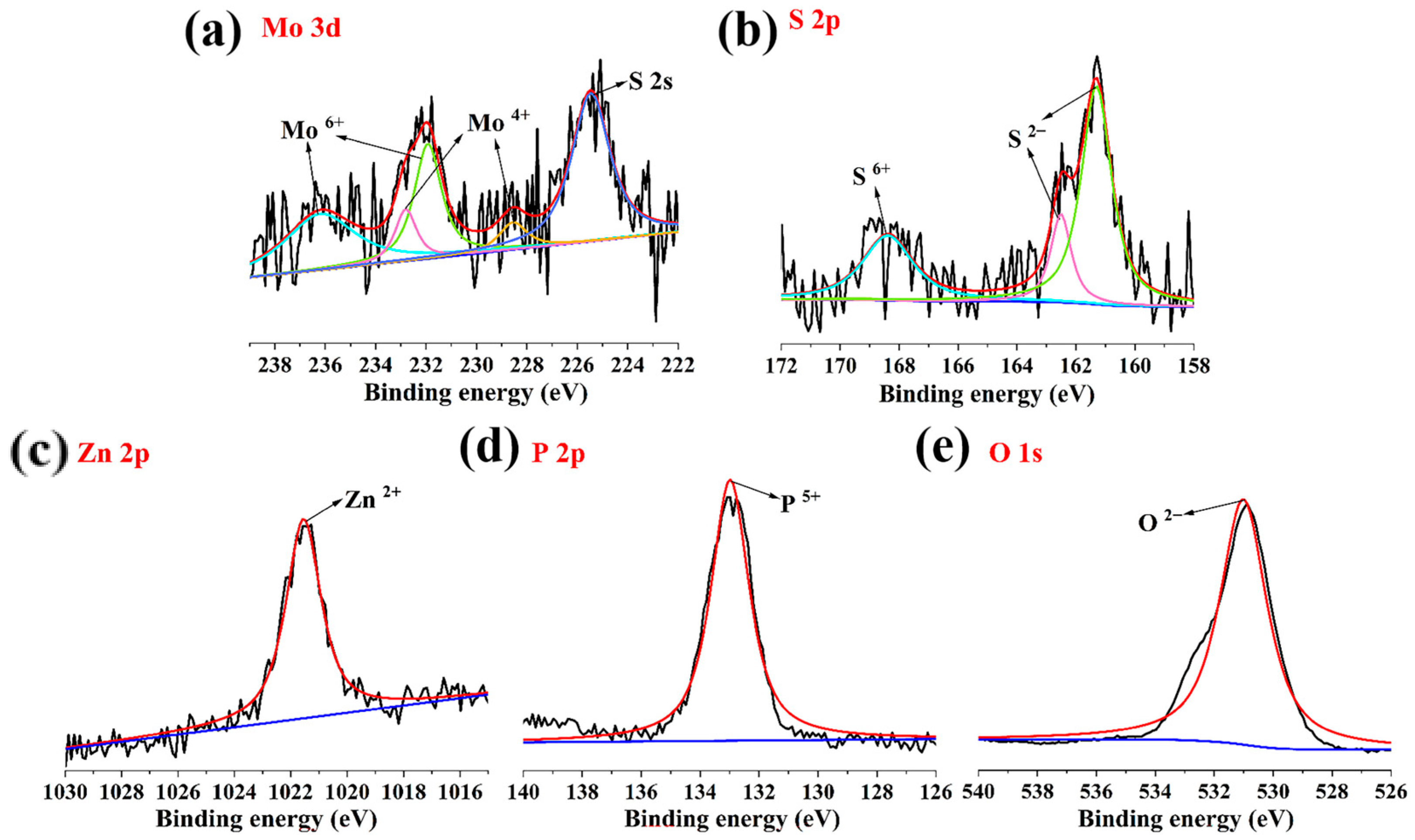

3.4. Surface Morphologies and Elemental Analysis of Wear Scars

3.5. Rheological Properties of PP Grease with Additives at Different Temperatures

4. Discussion

5. Conclusions

- (1)

- Based on the results of the tribological experiments, the optimal concentration for MoS2 was 5.0 wt.%, and 1.5 wt.% for ZDDP in the PP grease system.

- (2)

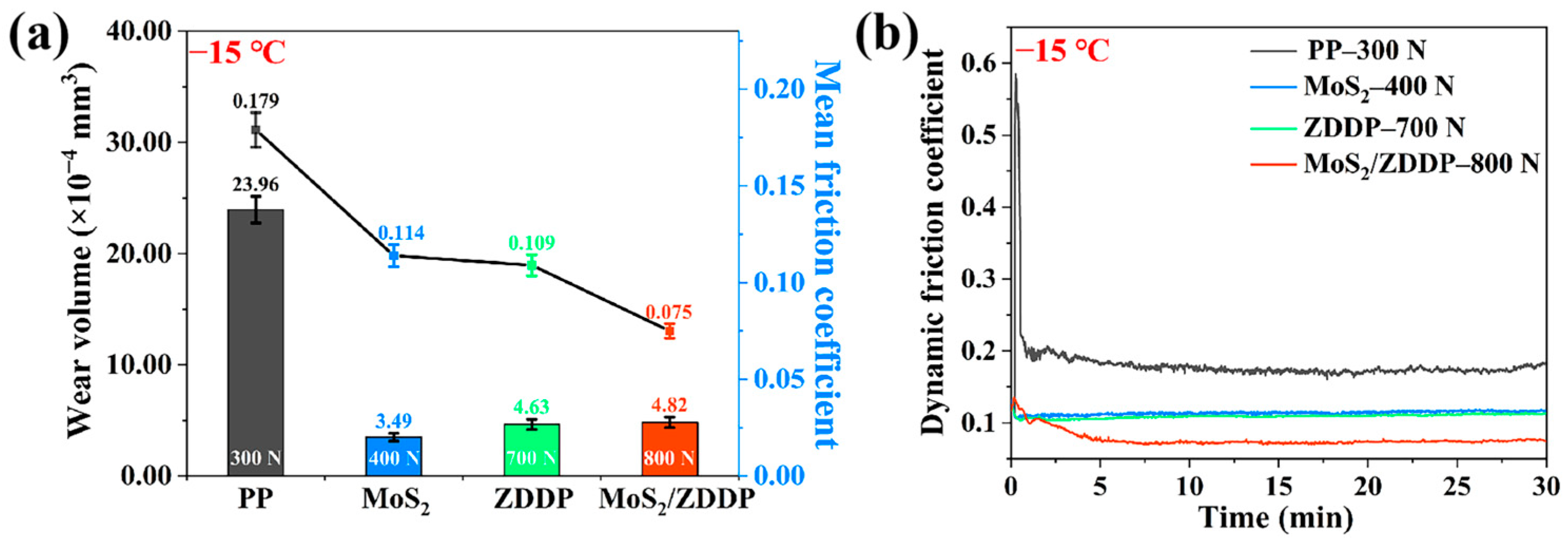

- Compared with PP grease and PP grease with MoS2 or ZDDP as an additive at a temperature of −15 °C, there was an outstanding synergistic effect for the MoS2/ZDDP additives. The carrying load of the MoS2/ZDDP grease reached 800 N, 3.67 times that of the pure PP grease. Under the highest applied load, the antiwear and friction reduction properties of the MoS2/ZDDP grease were the best among the four grease samples. The dynamic friction coefficient of the MoS2/ZDDP grease cloud maintained a stable state at an applied load of 800 N.

- (3)

- The effect of temperature on the tribological performance of PP grease with MoS2/ZDDP additives was realized at temperatures ranging from 25 °C to −15 °C. The wear volumes of the MoS2/ZDDP grease at 0 and −15 °C were lower than that at 25 °C under the higher load. The temperatures and applied loads had little impact on the friction coefficient. The dynamic friction coefficient curves showed that the friction coefficient was stable at lower temperatures, especially with the higher load and longer friction time.

- (4)

- Under the low-temperature and high-applied-load friction process, the active components of the additives reached the metal surfaces effectively in the polymer grease system: the polymer system did not interfere with the function of the additives. Protective tribofilms originating from the MoS2 and ZDDP were formed by absorption and chemical reactions. The solid additive MoS2 not only penetrated into the steel surfaces to form a solid film, but also adhered to the surface tribochemical layer formed by the organic additive ZDDP. MoS2 and ZDDP played a synergistic role in severe working conditions.

- (5)

- The viscoelastic and thixotropic rheological results showed that the additives of MoS2, ZDDP and MoS2/ZDDP did not affect the gel structure, viscoelasticity or flow characteristics of the base PP grease. The grease containing additives had a good viscosity recovery rate and ductility at low temperatures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leckner, J.; Westbroek, R. Polypropylene a new thickener technology for energy efficient lubrication. NLGI Spokesm. 2017, 81, 34–56. [Google Scholar]

- Morway, A.J.; Seelbach, C.W.; Lippincott, S.B. Polypropylene Grease. U.S. Patent 2,917,458, 15 December 1959. [Google Scholar]

- Polishuk, A.T.; Johnson, H.L. Grease Compositions Containing Atactic Polypropylene. U.S. Patent 3,290,244, 6 December 1966. [Google Scholar]

- Bill, M. Grease. U.S. Patent 3,392,119, 9 July 1968. [Google Scholar]

- Dodson, S.C.; Newman, R.H. Grease Composition. U.S. Patent 3,850,828, 26 November 1974. [Google Scholar]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Gonçalves, D.; Graça, B.; Campos, A.V.; Seabra, J.; Leckner, J.; Westbroek, R. Formulation, rheology and thermal ageing of polymer greases—Part I: Influence of the thickener content. Tribol. Int. 2015, 87, 160–170. [Google Scholar]

- Meijer, D.; Lankamp, H. Polymer thickened lubricating grease. U.S. Patent 5,874,391, 23 Febuary 1999. [Google Scholar]

- Muller, D.; Matta, C.; Thijssen, R.; bin Yusof, M.N.; van Eijk, M.C.P.; Chatra, S. Novel polymer grease microstructure and its proposed lubrication mechanism in rolling/sliding contacts. Tribol. Int. 2017, 110, 278–290. [Google Scholar]

- Zhang, G.; Wetzel, B.; Wang, Q. Tribological behavior of PEEK-based materials under mixed and boundary lubrication conditions. Tribol. Int. 2015, 88, 153–161. [Google Scholar]

- Zhao, J.; Gao, T.; Dang, J.; Cao, W.; Wang, Z.; Li, S.; Shi, Y. Using green, economical, efficient two-dimensional (2D) talc nanosheets as lubricant additives under harsh conditions. Nanomaterials 2022, 12, 1666. [Google Scholar] [CrossRef]

- Nan, F.; Yin, Y. Improving of the tribological properties of attapulgite base grease with graphene. Lubr. Sci. 2021, 33, 380–393. [Google Scholar]

- Jin, B.; Zhao, J.; Chen, G.; He, Y.; Huang, Y.; Luo, J. In situ synthesis of Mn3O4/graphene nanocomposite and its application as a lubrication additive at high temperatures. Appl. Surf. Sci. 2021, 546, 149019. [Google Scholar]

- Spikes, H. The history and mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar]

- Freuler, H.C. Modified lubricating oil. U.S. Patent 2,364,283, 5 December 1944. [Google Scholar]

- Freuler, H.C. Modified lubricating oil. U.S. Patent 2,364,284, 5 December 1944. [Google Scholar]

- Nicholls, M.A.; Do, T.; Norton, P.R.; Kasrai, M.; Bancroft, G.M. Review of the lubrication of metallic surfaces by zinc dialkyl-dithiophosphates. Tribol. Int. 2005, 38, 15–39. [Google Scholar]

- Sato, K.; Watanabe, S.; Sasaki, S. High Friction Mechanism of ZDDP Tribofilm Based on in situ AFM Observation of Nano-Friction and Adhesion Properties. Tribol. Lett. 2022, 70, 94. [Google Scholar]

- Zhang, J.; Ueda, M.; Campen, S.; Spikes, H. Boundary friction of ZDDP tribofilms. Tribol. Lett. 2021, 69, 8. [Google Scholar] [CrossRef]

- Dawczyk, J.; Morgan, N.; Russo, J.; Spikes, H. Film thickness and friction of ZDDP tribofilms. Tribol. Lett. 2019, 67, 34. [Google Scholar] [CrossRef]

- Taylor, L.J.; Spikes, H. Friction-enhancing properties of ZDDP antiwear additive: Part I—Friction and morphology of ZDDP reaction films. Tribol. Trans. 2003, 46, 303–309. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Liu, Y.; Yang, L.; Chen, L. 2D nano-materials beyond graphene: From synthesis to tribological studies. Appl. Nanosci. 2020, 10, 3353–3388. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid lubrication with MoS2: A review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Roberts, E.W. Thin solid lubricant films in space. Tribol. Int. 1990, 23, 95–104. [Google Scholar] [CrossRef]

- Tomala, A.; Vengudusamy, B.; Rodríguez Ripoll, M.; Naveira Suarez, A.; Remškar, M.; Rosentsveig, R. Interaction between selected MoS2 nanoparticles and ZDDP tribofilms. Tribol. Lett. 2015, 59, 26. [Google Scholar] [CrossRef]

- Yadgarov, L.; Stroppa, D.G.; Rosentsveig, R.; Ron, R.; Enyashin, A.N.; Houben, L.; Tenne, R. Investigation of rhenium-doped MoS2 nanoparticles with fullerene-like structure. Z. Anorg. Allg. Chem. 2012, 638, 2610–2616. [Google Scholar] [CrossRef]

- Dixena, R.K.; Sayanna, E.; Badoni, R.P. A study on tribological behaviours of ZDDP in polymer thickened lubricating greases. Lubr. Sci. 2016, 28, 177–186. [Google Scholar] [CrossRef]

- Shu, J.; Harris, K.; Munavirov, B.; Westbroek, R.; Leckner, J.; Glavatskih, S. Tribology of polypropylene and Li-complex greases with ZDDP and MoDTC additives. Tribol. Int. 2018, 118, 189–195. [Google Scholar] [CrossRef]

- Jacobson, E.B. Polymer Thickened Lubricant; Axel Christiernsson: Gothenburg, Sweden, 2007. [Google Scholar]

- Goncalves, D.; Graça, B.; Campos, A.V.; Seabra, J. Film thickness and friction behaviour of thermally aged lubricating greases. Tribol. Int. 2016, 100, 231–241. [Google Scholar] [CrossRef]

- Hu, E.; Xu, Y.; Hu, K.; Hu, X. Tribological properties of 3 types of MoS2 additives in different base greases. Lubr. Sci. 2017, 29, 541–555. [Google Scholar] [CrossRef]

- Wu, H.; Johnson, B.; Wang, L.; Dong, G.; Yang, S.; Zhang, J. High-efficiency preparation of oil-dispersible MoS2 nanosheets with superior anti-wear property in ultralow concentration. J. Nanoparticle Res. 2017, 19, 339. [Google Scholar] [CrossRef]

- Qu, J.; Barnhill, W.C.; Luo, H.; Meyer III, H.M.; Leonard, D.N.; Landauer, A.K.; Kheireddin, B.; Gao, H.; Papke, B.L.; Dai, S. Synergistic effects between phosphonium-alkylphosphate ionic liquids and zinc dialkyldithiophosphate (ZDDP) as lubricant additives. Adv. Mater. 2015, 27, 4767–4774. [Google Scholar] [CrossRef] [PubMed]

- Su, T.; Song, G.; Zheng, D.; Ju, C.; Zhao, Q. Facile synthesis of protic ionic liquids hybrid for improving antiwear and anticorrosion properties of water-glycol. Tribol. Int. 2021, 153, 106660. [Google Scholar] [CrossRef]

- Tannous, J.; de Bouchet, B.M.I.; Le-Mogne, T.; Charles, P.; Martin, J.M. Contribution of gas phase lubrication in understanding tribochemistry of organosulphur compounds. Tribol. Mater. Surf. Interfaces 2007, 1, 98–104. [Google Scholar] [CrossRef]

- Tannous, J.; Dassenoy, F.; Lahouij, I.; Le-Mogne, T.; Vacher, B.; Bruhács, A.; Tremel, W. Understanding the tribochemical mechanisms of IF-MoS2 nanoparticles under boundary lubrication. Tribol. Lett. 2011, 41, 55–64. [Google Scholar] [CrossRef]

- Zhang, Z.; Yamaguchi, E.; Kasrai, M.; Bancroft, G. Tribofilms generated from ZDDP and DDP on steel surfaces: Part 1, growth, wear and morphology. Tribol. Lett. 2005, 19, 211–220. [Google Scholar] [CrossRef]

- Hyun, K.; Kim, S.H.; Ahn, K.H.; Lee, S.J. Large amplitude oscillatory shear as a way to classify the complex fluids. J. Non-Newton. Fluid Mech. 2002, 107, 51–65. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Romero, A.; Valencia, C.; Franco, J.M. Formulation and processing of virgin and recycled polyolefin/oil blends for the development of lubricating greases. J. Ind. Eng. Chem. 2013, 19, 580–588. [Google Scholar] [CrossRef]

- Sánchez, M.C.; Franco, J.M.; Valencia, C.; Gallegos, C.; Urquiola, F.; Urchegui, R. Atomic force microscopy and thermo-rheological characterisation of lubricating greases. Tribol. Lett. 2011, 41, 463–470. [Google Scholar] [CrossRef]

- Xu, N.; Li, W.; Zhang, M.; Zhao, G.; Wang, X. New insight to the tribology-structure interrelationship of lubricating grease by a rheological method. RSC Adv. 2015, 5, 54202–54210. [Google Scholar] [CrossRef]

- Dunckle, C.G.; Aggleton, M.; Glassman, J.; Taborek, P. Friction of molybdenum disulfide–titanium films under cryogenic vacuum conditions. Tribol. Int. 2011, 44, 1819–1826. [Google Scholar] [CrossRef]

- Babuska, T.F.; Pitenis, A.A.; Jones, M.R.; Nation, B.L.; Sawyer, W.G.; Argibay, N. Temperature-dependent friction and wear behavior of PTFE and MoS2. Tribol. Lett. 2016, 63, 15. [Google Scholar] [CrossRef]

- Colbert, R.S.; Sawyer, W.G. Thermal dependence of the wear of molybdenum disulphide coatings. Wear 2010, 269, 719–723. [Google Scholar] [CrossRef]

- Zhao, X.; Phillpot, S.R.; Sawyer, W.G.; Sinnott, S.B.; Perry, S.S. Transition from thermal to athermal friction under cryogenic conditions. Phys. Rev. Lett. 2009, 102, 186102. [Google Scholar] [CrossRef]

- Curry, J.F.; Babuska, T.F.; Brumbach, M.T.; Argibay, N. Temperature-Dependent Friction and Wear of MoS2/Sb2O3/Au Nanocomposites. Tribol. Lett. 2016, 64, 18. [Google Scholar] [CrossRef]

- Hamilton, M.A.; Alvarez, L.A.; Mauntler, N.A.; Argibay, N.; Colbert, R.; Burris, D.L.; Muratore, C.; Voevodin, A.A.; Perry, S.S.; Sawyer, W.G. A possible link between macroscopic wear and temperature dependent friction behaviors of MoS2 coatings. Tribol. Lett. 2008, 32, 91–98. [Google Scholar] [CrossRef]

- Barry, H.F.; Binkelman, J.P. MoS2 Lubrication of Various Metals. Lubr. Eng. 1966, 22, 139–145. [Google Scholar]

- Cen, H.; Morina, A.; Neville, A.; Pasaribu, R.; Nedelcu, I. Effect of water on ZDDP anti-wear performance and related tribochemistry in lubricated steel/steel pure sliding contacts. Tribol. Int. 2012, 56, 47–57. [Google Scholar] [CrossRef]

- Needelman, W.; LaVallee, G. Forms of water in oil and their control. In Proceedings of the Noria Lubrication Excellence Conference, Columbus, OH, USA, 16–18 May 2006. [Google Scholar]

- Lancaster, J.K. A review of the influence of environmental humidity and water on friction, lubrication and wear. Tribol. Int. 1990, 23, 371–389. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Tian, C.; Hao, L.; Xu, H.; Dong, J. Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures. Lubricants 2023, 11, 464. https://doi.org/10.3390/lubricants11110464

Zhao X, Tian C, Hao L, Xu H, Dong J. Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures. Lubricants. 2023; 11(11):464. https://doi.org/10.3390/lubricants11110464

Chicago/Turabian StyleZhao, Xinrui, Chengguang Tian, Lei Hao, Hong Xu, and Jinxiang Dong. 2023. "Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures" Lubricants 11, no. 11: 464. https://doi.org/10.3390/lubricants11110464

APA StyleZhao, X., Tian, C., Hao, L., Xu, H., & Dong, J. (2023). Tribology and Rheology of Polypropylene Grease with MoS2 and ZDDP Additives at Low Temperatures. Lubricants, 11(11), 464. https://doi.org/10.3390/lubricants11110464