Effect of Microstructure of TiN /TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films

Abstract

1. Introduction

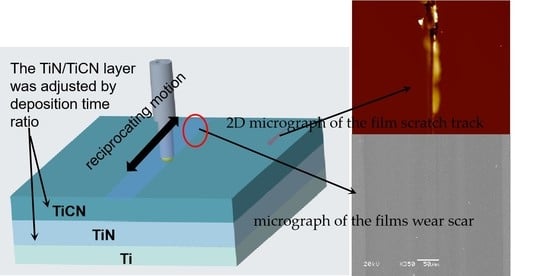

2. Materials and Methods

2.1. Specimens Preparation

2.2. Films Characterization

2.3. Properties

3. Results

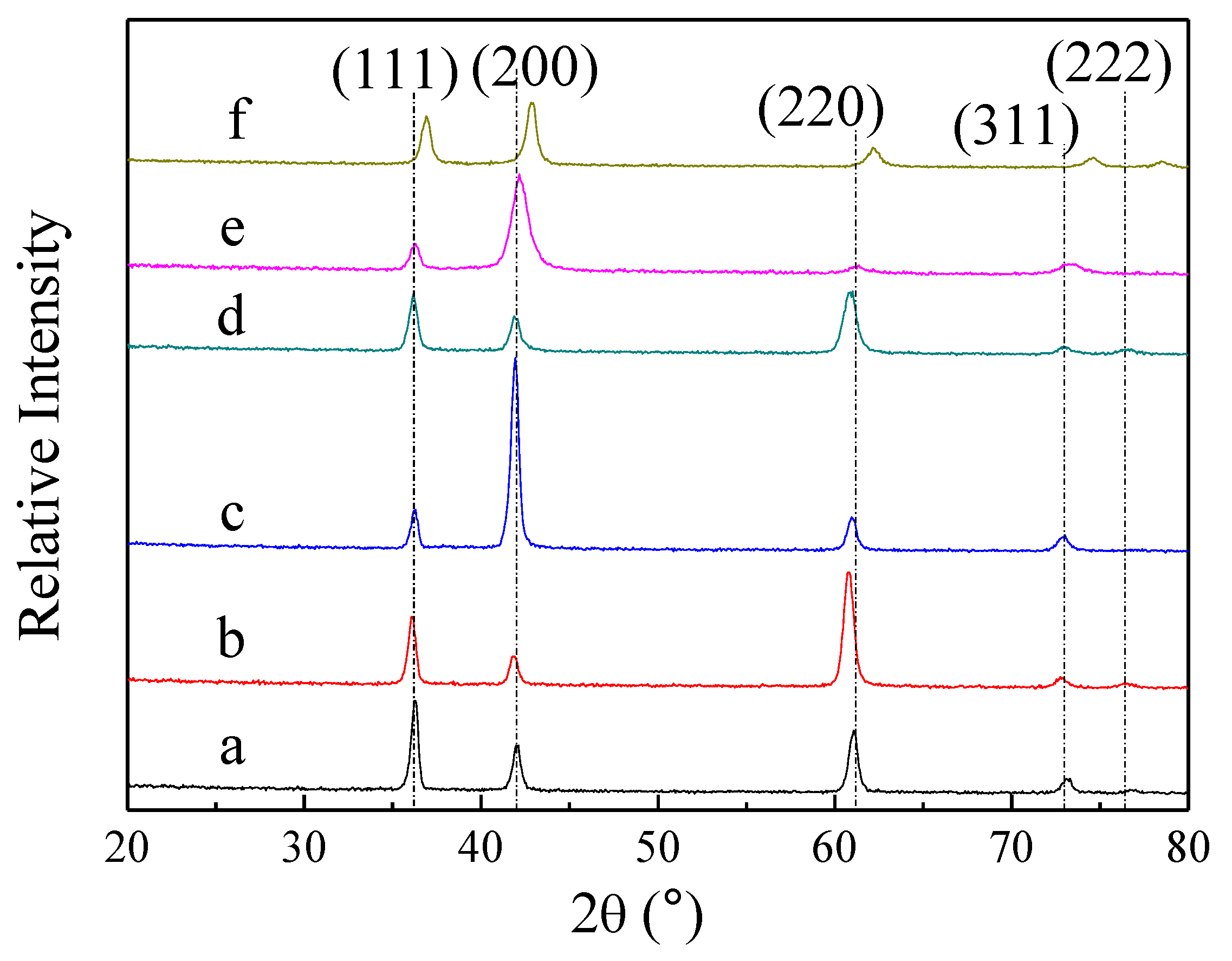

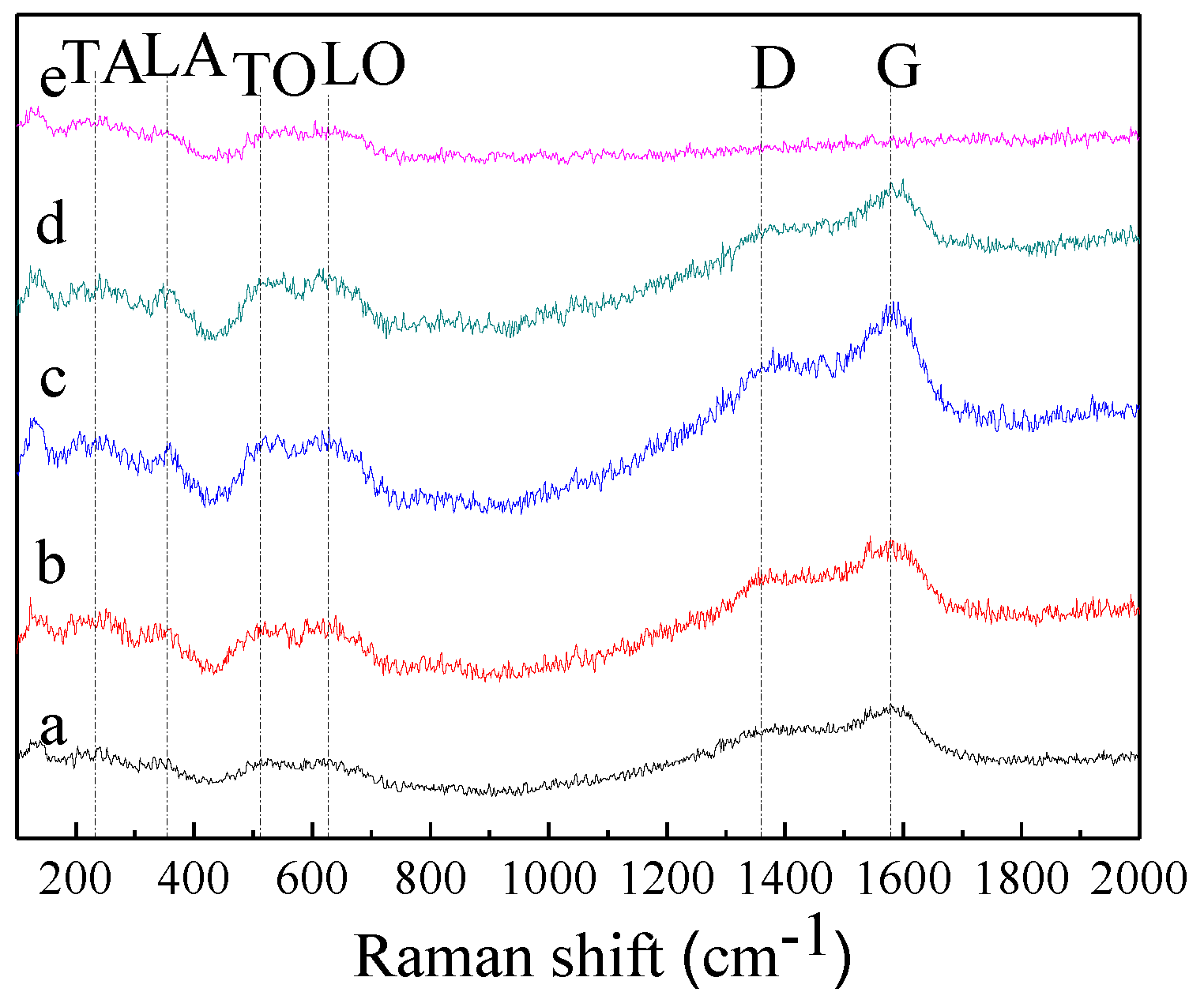

3.1. Composition and Microstructure

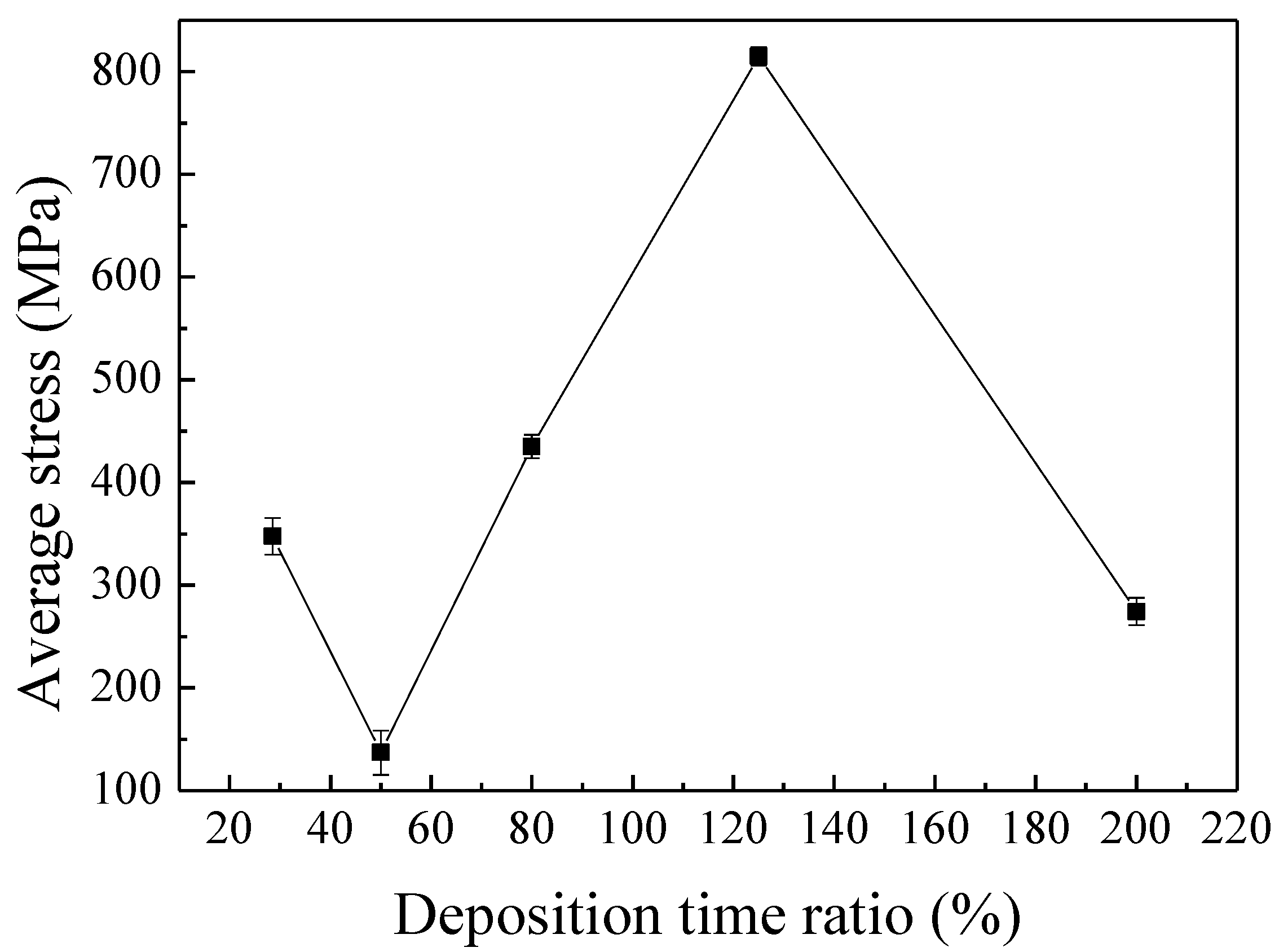

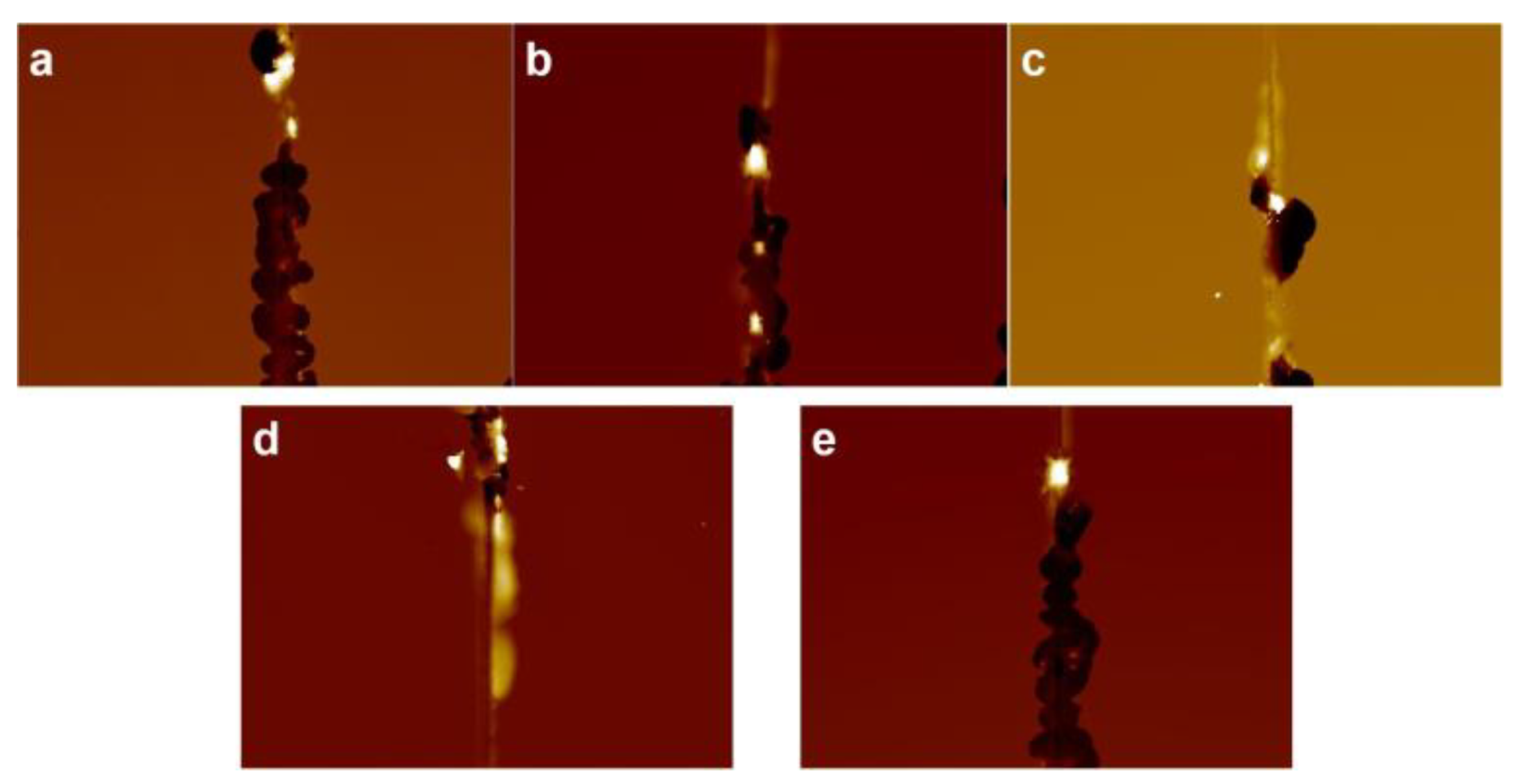

3.2. Stress and Scratch Test

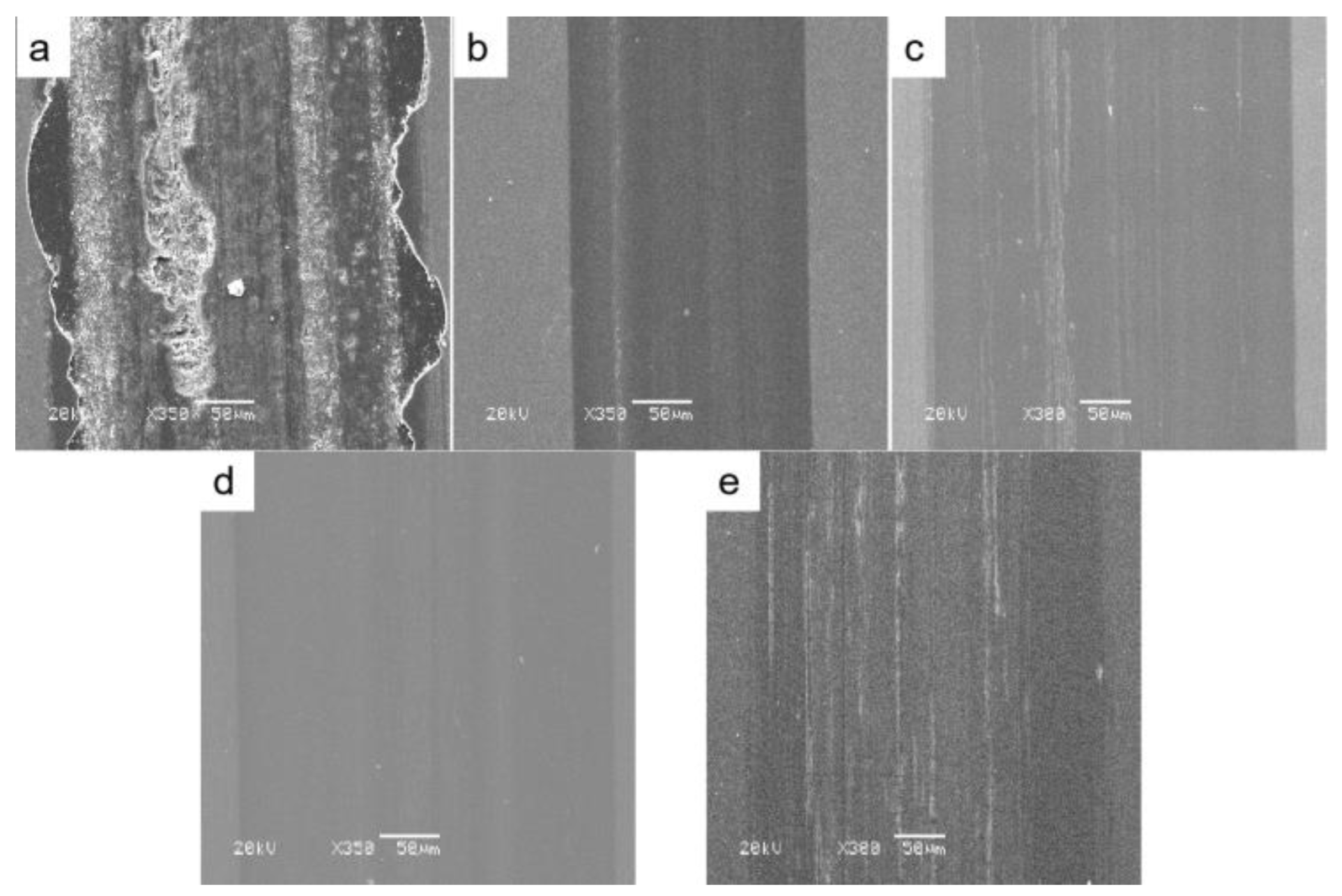

3.3. Tribological Properties

4. Conclusions

- The composition and bonding structure of the films only slightly changed, while crystalline structure was of significant variation with the deposition time ratio. The film deposited under deposition time ratio of 50% had an obvious change in the preferred orientation from (111) to (220).

- The adhesion strength and internal stresses were closely related to the deposition time ratio. The film deposited under deposition time ratio of 50% had an optimal value of adhesion strength. However, the stress curve firstly declined, then increased, and finally declined.

- The COF of the films was divided into the three stages: initial stage, lubricant stage, and invalid stage. The COF curve included the stages when the films were deposited under deposition time ratios of 50% and 125%. Among the films, the COF was about 0.139 in the steady stage.

- The films deposited under deposition time ratio of 50% was of lower wear rate than the other samples, which was 1.163 × 10−6 mm3·m−1·N−1. Moreover, the width of its wear scar was shorter.

Author Contributions

Funding

Conflicts of Interest

References

- Mekgwe, G.N.; Akinribide, O.J.; Akinwamide, S.O.; Olubambi, P.A. Fabrication of graphite reinforced TiCxNy by spark plasma sintering technique: A comparative assessment of microstructural integrity and nanoindentation properties. Vacuum 2021, 187, 110144. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Effect of duplex nanostructured TiAlSiN/TiSiN/TiAlN-TiAlN and TiAlN-TiAlSiN/TiSiN/TiAlN coatings on the hard turning performance of Al2O3-TiCN ceramic cutting tools. Wear 2019, 418–419, 226–240. [Google Scholar] [CrossRef]

- Polcar, T.; Novak, R.; Siroky, P. The tribological characteristics of TiCN coating at elevated temperatures. Wear 2006, 260, 40–49. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B. Influence of CH4 fraction on the composition, structure, and internal stress of the TiCN coatings deposited by LAFAD technique. Vacuum 2010, 85, 89–94. [Google Scholar] [CrossRef]

- Yang, Y.L.; Yan, W.; Zhang, D.; Song, G.Z.; Zheng, Y.R. In Situ-Fabrication of TiCN Ceramic Coating on Titanium Alloy by Laser Cladding Technology. Key Eng. Mater. 2010, 434–435, 485–488. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, D.; Yan, W.; Zheng, Y. Microstructure and wear properties of TiCN/Ti coatings on titanium alloy by laser cladding. Opt. Lasers Eng. 2010, 48, 119–124. [Google Scholar] [CrossRef]

- Yang, Y.; Yao, W.; Zhang, H. Phase constituents and mechanical properties of laser in-situ synthesized TiCN/TiN composite coating on Ti-6Al-4V. Surf. Coat. Technol. 2010, 205, 620–624. [Google Scholar] [CrossRef]

- Caicedo, J.C.; Amaya, C.; Yate, L.; Gómez, M.E.; Zambrano, G.; Alvarado-Rivera, J.; Muñoz-Saldaña, J.; Prieto, P. TiCN/TiNbCN multilayer coatings with enhanced mechanical properties. Appl. Surf. Sci. 2010, 256, 5898–5904. [Google Scholar] [CrossRef]

- Agudelo, L.C.; Ospina, R.; Castillo, H.A.; Devia, A. Synthesis of Ti/TiN/TiCN coatings grown in graded form by sputtering dc. Phys. Scripta. 2008, T131, 014006. [Google Scholar] [CrossRef]

- Guruvenket, S.; Li, D.; Klemberg-Sapieha, J.E.; Martinu, L.; Szpunar, J. Mechanical and tribological properties of duplex treated TiN, nc-TiN/a-SiNx and nc-TiCN/a-SiCN coatings deposited on 410 low alloy stainless steel. Surf. Coat. Technol. 2009, 203, 2905–2911. [Google Scholar] [CrossRef]

- Klemberg-Sapieha, J.E.; Jedrzejowski, P.; Martinu, L. Mechanical and optical characteristics of superhard nanocomposite TiN/a-Si3N4 and TiCN/a-SiCN coatings produced by PECVD. J. Superhard Mater. 2007, 29, 147–152. [Google Scholar] [CrossRef]

- Balaceanu, M.; Braic, M.; Braic, V.; Pavelescu, G. Properties of arc plasma deposited TiCN/ZrCN superlattice coatings. Surf. Coat. Technol. 2005, 200, 1084–1087. [Google Scholar] [CrossRef]

- Sun, H.; Billard, A.; Luo, H.; Zheng, W.; Zheng, X.; Dai, M.; Lin, S.; Shi, Q.; Sanchette, F. Influence of carbon content on the mechanical properties of TiCN–Cu nanocomposite coatings prepared by multi-arc ion plating. Vacuum 2021, 187, 110139. [Google Scholar] [CrossRef]

- Wang, Q.; Jin, X.; Zhou, F. Comparison of mechanical and tribological properties of CrBN coatings modified by Ni or Cu incorporation. Friction 2022, 10, 516–529. [Google Scholar] [CrossRef]

- Rebelodefigueiredo, M.; Neidhardt, J.; Kaindl, R.; Reiter, A.; Tessadri, R.; Mitterer, C. Formation mechanisms of low-friction tribo-layers on arc-evaporated TiC1−xNx hard coatings. Wear 2008, 265, 525–532. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Zhao, H.; Xian, L.; Fan, H.; Li, Z.; Du, H. Study on the growth and wear behavior of the TiAlN-based composite coating deposited on TiCN-based cermets with different binder phase. Wear 2020, 460–461, 203460. [Google Scholar] [CrossRef]

- Zhu, B.; Mardel, J.; Kelly, G.L. An investigation of tribological properties of CN and TiCN coatings. J. Mater. Eng. Perform. 2004, 13, 481–487. [Google Scholar] [CrossRef][Green Version]

- Wei, C.H.; Lin, J.F.; Jiang, T.H.; Ai, C.F. Tribological characteristics of titanium nitride and titanium carbonitride multilayer films: Part I. The effect of coating sequence on material and mechanical properties. Thin Solid Films 2001, 381, 94–103. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Hao, J.Y.; Liu, X.Q.; Gong, Q.Y.; Liu, W.M. TiN/TiCN Multilayer Films Modified by Argon Plasma Treatment. Appl. Surf. Sci. 2013, 280, 764–771. [Google Scholar] [CrossRef]

- Meng, J.; Lu, J.; Wang, J.; Yang, S. Tribological behavior of TiCN-based cermets at elevated temperatures. Materi. Sci. Eng. A 2006, 418, 68–76. [Google Scholar] [CrossRef]

- Morant, C.; Prieto, P.; Forn, A.; Picas, J.A.; Elizalde, E.; Sanz, J.M. Hardness enchancement by CN/TiCN/TiN multilayer films. Surf. Coat. Technol. 2004, 180–181, 512–518. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Ren, X.D.; Hao, H.Y.; Li, A.; Liu, W.M. Carbon nanohoops as attractive toughening and lubricant agents in TiN porous films. Appl. Surf. Sci. 2017, 393, 60–66. [Google Scholar] [CrossRef]

- Alisir, S.H.; Evrensel, D. Investigation into Coating Structure and Wear Environment Effects on Tribological Properties of Pistn Ring Coated with Monolayer TiAlN and Multilayer TiN/TiAlN. J. Mater. Eng. Perform. 2022, 31, 1654–1666. [Google Scholar] [CrossRef]

- Wróblewski, P.; Rogólski, R. Experimental Analysis of the Influence of the Application of TiN, TiAlN, CrN and DLC1 Coatings on the Friction Losses in an Aviation Internal Combustion Engine Intended for the Propulsion of Ultralight Aircraft. Materials 2021, 14, 6839. [Google Scholar] [CrossRef]

- Ruan, H.T.; Wang, Z.Y.; Wang, L.; Sun, L.L.; Peng, H.; Ke, P.L.; Wang, A.Y. Designed Ti/TiN sub-layers suppressing the crack and erosion of TiAlN coatings. Surf. Coat. Technol. 2022, 438, 128419. [Google Scholar] [CrossRef]

- Wróblewski, P.; Koszalka, G. An Experimental Study on Frictional Losses of Coated Piston Rings with Symmetric and Asymmetric Geometry. SAE Int. J. Engines 2021, 14, 85386. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H. Tribological behavior and wear mechanisms of Ti-C: H/TiC/TiCN/TiN/Ti coatings when sliding against steel, bronze and aluminum alloy rods. J. Mater. Sci. 2001, 36, 189–199. [Google Scholar] [CrossRef]

- Talib, R.J.; Toff, M.R.M.; Ariff, H.M. Wear mechanism of TiN, TiAlN and TiCN coated drills during drilling of carbon steel. J. Phys. Sci. 2007, 18, 75–85. [Google Scholar]

- Sun, C.Q.; Fu, Y.Q.; Yan, B.B.; Hsieh, J.H.; Lau, S.P.; Sun, X.W.; Tay, B.K. Improving diamond–metal adhesion with graded TiCN interlayers. J. Appl. Phys. 2002, 91, 2051–2054. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Ebner, R.; Bakker, R.J. Chemistry and microstructure of PLD (Ti,Al)CxN1-x coatings deposited at room temperature. Appl. Phys. A 2004, 79, 1469–1471. [Google Scholar] [CrossRef]

- Peters, A.M.; Nastasi, M. Effect of carrier gas on the deposition of titanium carbo-nitride coatings by a novel organo-metallic plasma immersion ion processing technique. Vacuum 2002, 67, 169–175. [Google Scholar] [CrossRef]

- Dreiling, I.; Stiens, D.; Chassé, T. Raman spectroscopy investigations of TiBxCyNz coatings deposited by low pressure chemical vapor deposition. Surf. Coat. Technol. 2010, 205, 1339–1344. [Google Scholar] [CrossRef]

- Detor, A.J.; Hodge, A.M.; Chason, E.; Wang, Y.M.; Xu, H.W.; Conyers, M.; Nikroo, A.; Hamza, A. Stress and microstructure evolution in thick sputtered films. Acta Mater. 2009, 57, 2055–2065. [Google Scholar] [CrossRef]

- Abadias, G. Stress and preferred orientation in nitride-based PVD coatings. Surf. Coat. Technol. 2008, 202, 2223–2235. [Google Scholar] [CrossRef]

- Shi, Y.L.; Peng, H.R.; Xie, Y.; Xie, G.W.; Zhao, C.; Li, S.Z. Plasma CVD of hard coatings Ti(CNO) using metallo-organic compound Ti(OC3H7)4. Surf. Coat. Technol. 2000, 132, 26–30. [Google Scholar]

- Stanishevsky, A.; Lappalainen, R. Tribological properties of composite Ti(N,O,C) coatings containing hard amorphous carbon layers. Surf. Coat Technol. 2000, 123, 101–105. [Google Scholar] [CrossRef]

- Bull, S.J.; Bhat, D.G.; Staia, M.H. Properties and performance of commercial TiCN coatings. Part 2: Tribological performance. Surf. Coat. Technol. 2003, 163–164, 507–514. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H. Sliding tribological behaviors of PVD CrN and AlCrN coatings against Si3N4 ceramic and pure titanium. Wear 2009, 267, 874–881. [Google Scholar] [CrossRef]

| Deposition Time Ratio | Thickness (μm) | Ti (at. %) | C (at. %) | N (at. %) | O (at. %) |

|---|---|---|---|---|---|

| 28.57 | 2.1 | 24.21 | 41.85 | 13.95 | 19.99 |

| 50.00 | 2.2 | 25.55 | 45.32 | 11.78 | 17.35 |

| 80.00 | 2.4 | 22.79 | 44.44 | 11.28 | 21.49 |

| 125.00 | 3.1 | 24.39 | 44.77 | 12.68 | 18.16 |

| 200.00 | 3.3 | 25.59 | 38.93 | 15.54 | 19.94 |

| Film | Critical Load, Lc (N) | Friction Coefficient at Lc, μc | Scratch Track Width at Lc, wc (mm) |

|---|---|---|---|

| a-28 | 17.9 ± 3.3 | 0.38 | 0.1795 |

| b-50 | 18.6 ± 1.5 | 0.40 | 0.1632 |

| c-80 | 17.0 ± 2.1 | 0.39 | 0.1702 |

| d-125 | 15.8 ± 0.8 | 0.38 | 0.2123 |

| e-200 | 12.0 ± 2.5 | 0.36 | 0.2145 |

| Samples | Deposition Time Ratio (%) | Wear Rate against Steel Balls (×10−6 mm3/N·m) |

|---|---|---|

| a-28 | 28.57 | 224.7 |

| b-50 | 50.00 | 1.163 |

| c-80 | 80.00 | 1.196 |

| d-125 | 125.00 | 2.668 |

| e-200 | 200.00 | 5.800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, Y.; Zhang, Q.; Liu, Y.; Deng, X.; Sun, H.; Mo, M. Effect of Microstructure of TiN /TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films. Lubricants 2023, 11, 21. https://doi.org/10.3390/lubricants11010021

Lyu Y, Zhang Q, Liu Y, Deng X, Sun H, Mo M. Effect of Microstructure of TiN /TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films. Lubricants. 2023; 11(1):21. https://doi.org/10.3390/lubricants11010021

Chicago/Turabian StyleLyu, Yanhong, Qiaoyu Zhang, Yang Liu, Xinrong Deng, Huilian Sun, and Min Mo. 2023. "Effect of Microstructure of TiN /TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films" Lubricants 11, no. 1: 21. https://doi.org/10.3390/lubricants11010021

APA StyleLyu, Y., Zhang, Q., Liu, Y., Deng, X., Sun, H., & Mo, M. (2023). Effect of Microstructure of TiN /TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films. Lubricants, 11(1), 21. https://doi.org/10.3390/lubricants11010021