Characterization of Counter-Surface Substrates for a Laboratory Abrasion Tester (LAT100) Compared with Asphalt and Concrete to Predict Car Tire Performance

Abstract

:1. Introduction

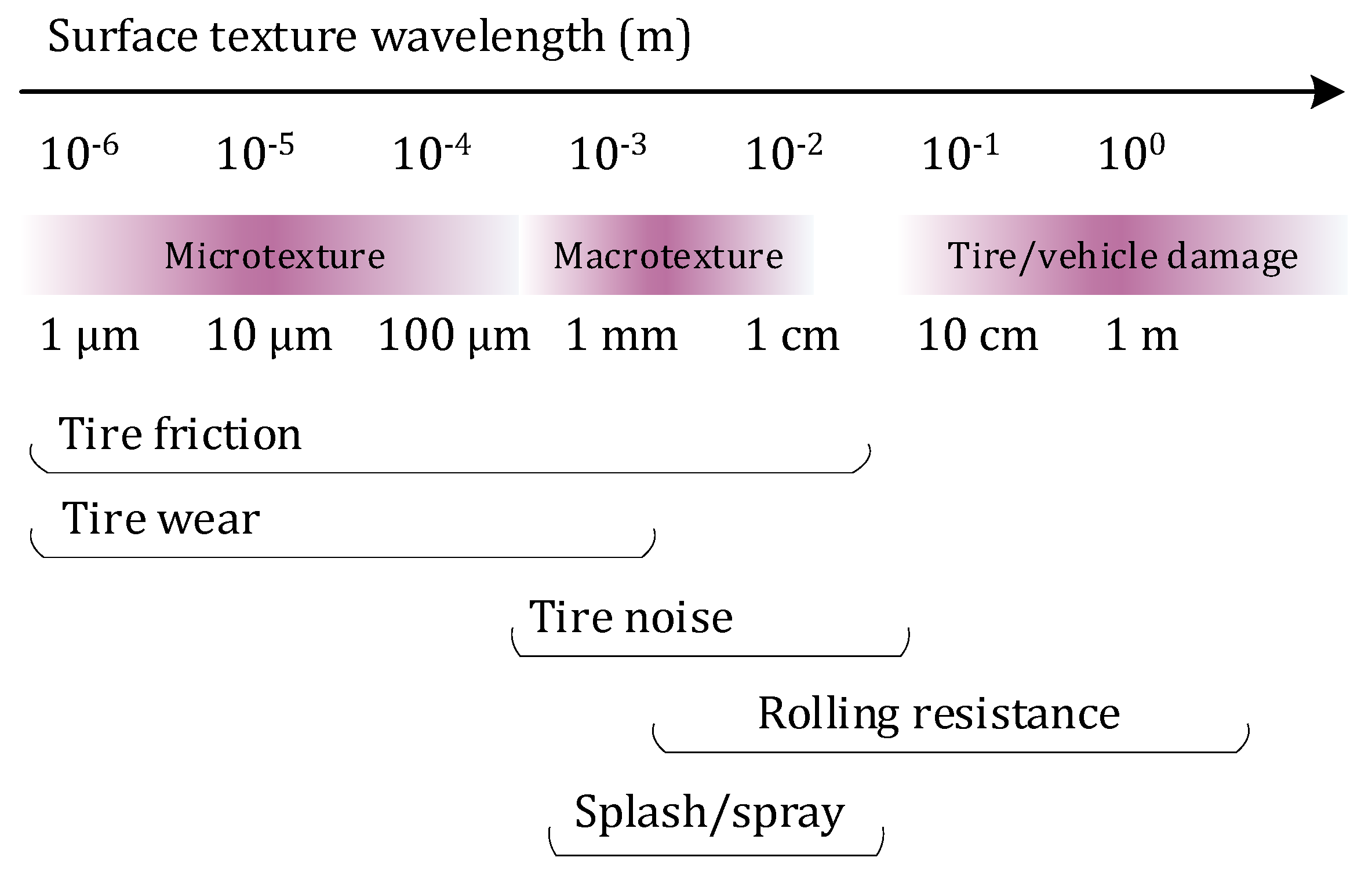

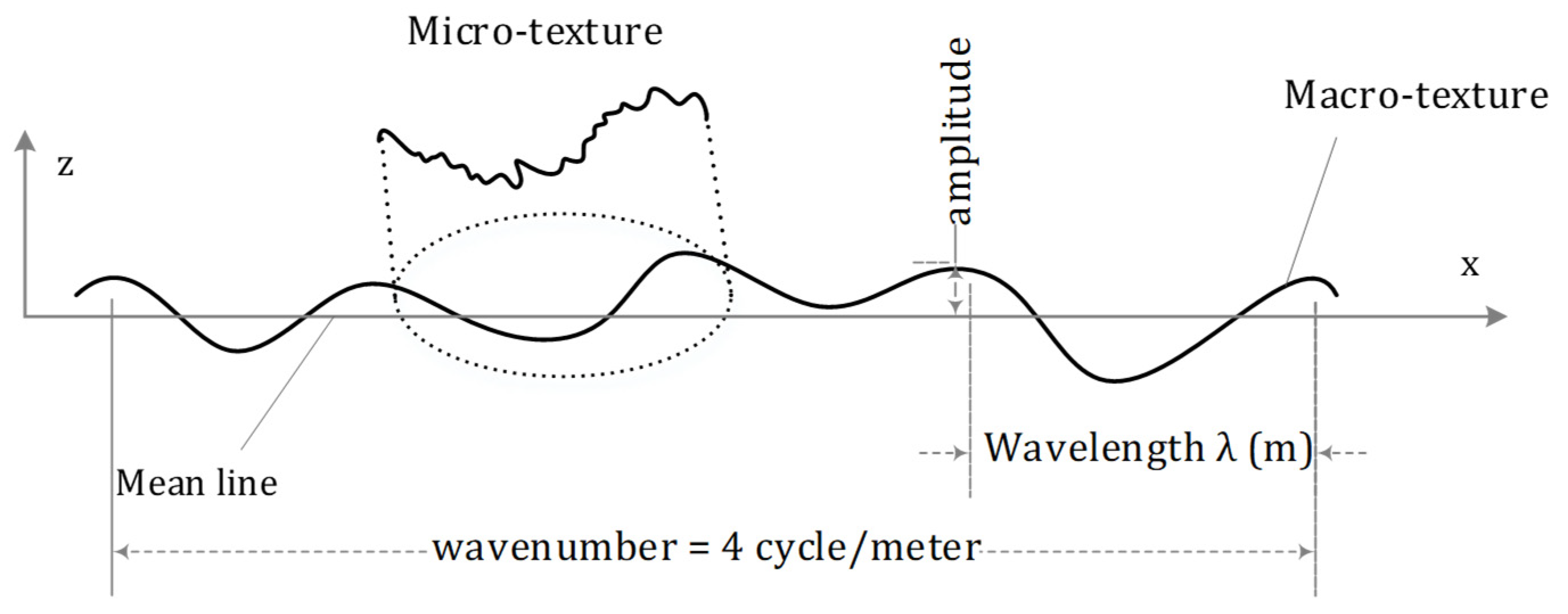

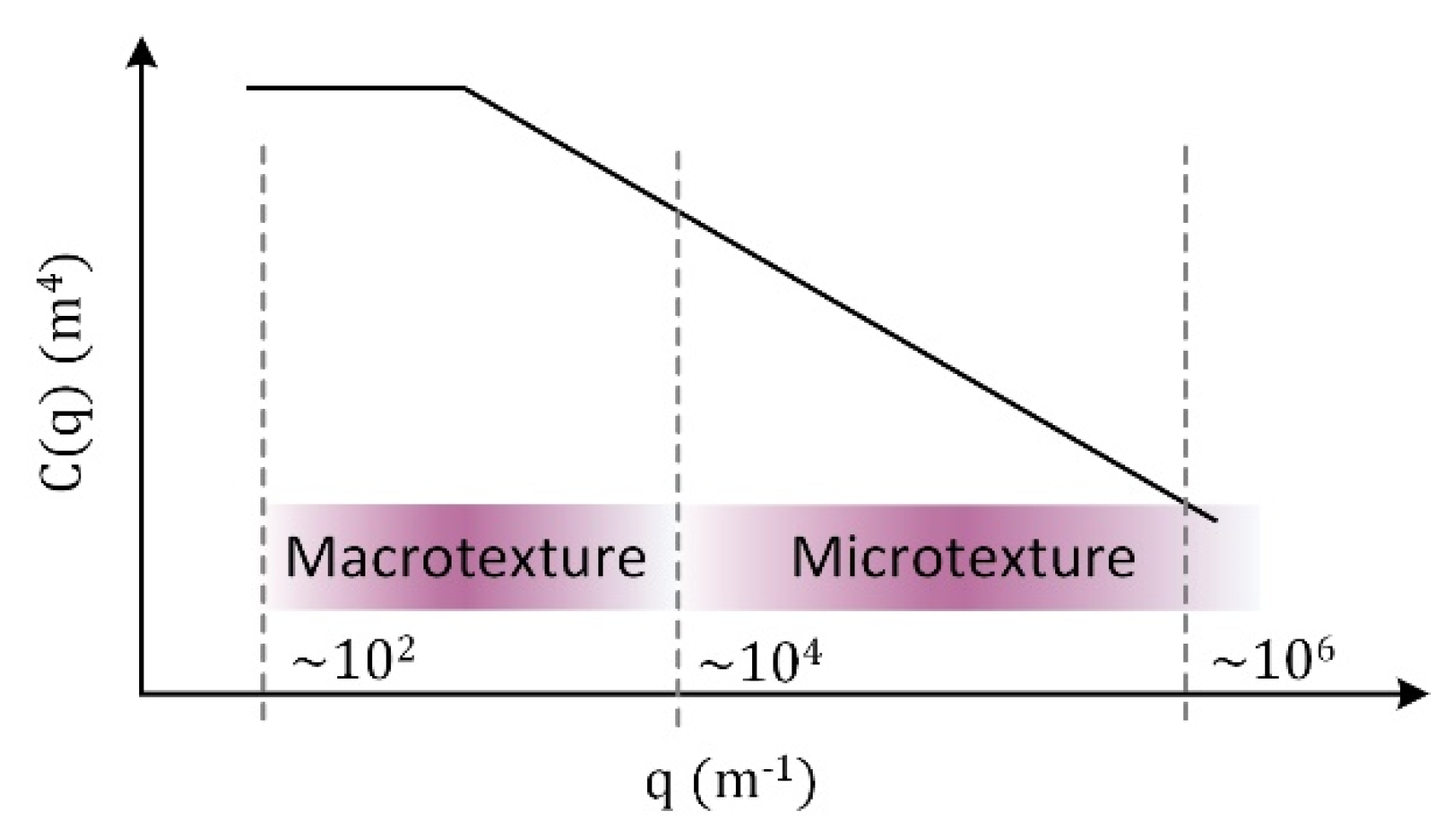

1.1. Classification of Road Surface Texture

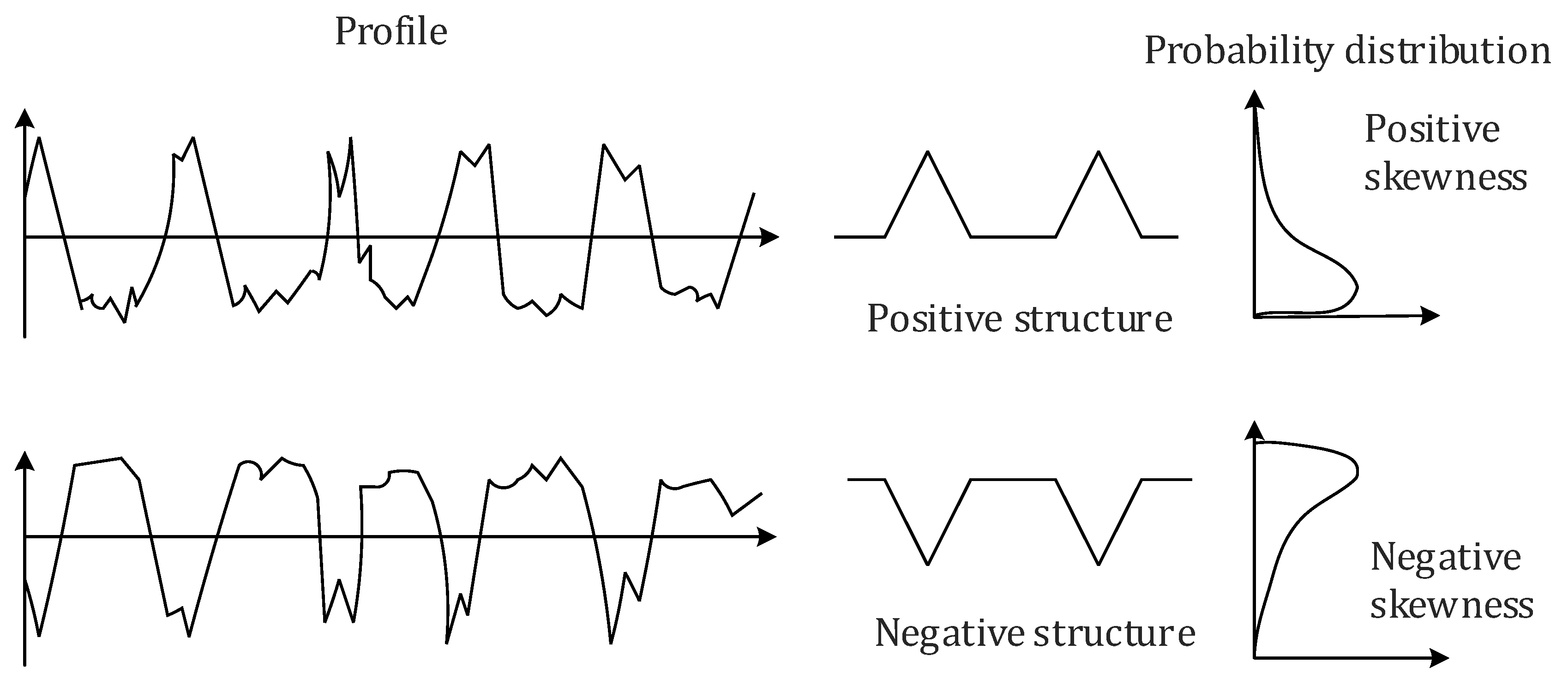

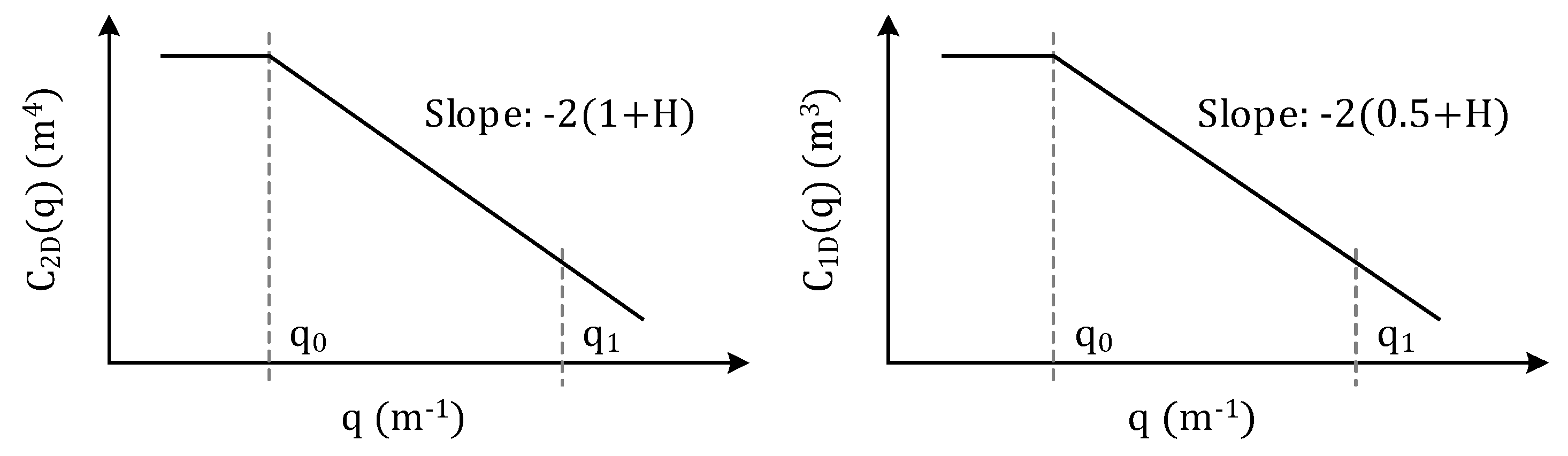

1.2. Characterization of Texture

2. Experimental

- Road samples: asphalt and concrete;

- Sandpaper grade P120;

- LAT100 counter-surface discs 60, 180, 320, and 180B;

- A comparably smooth surface, such as an A4 paper sheet.

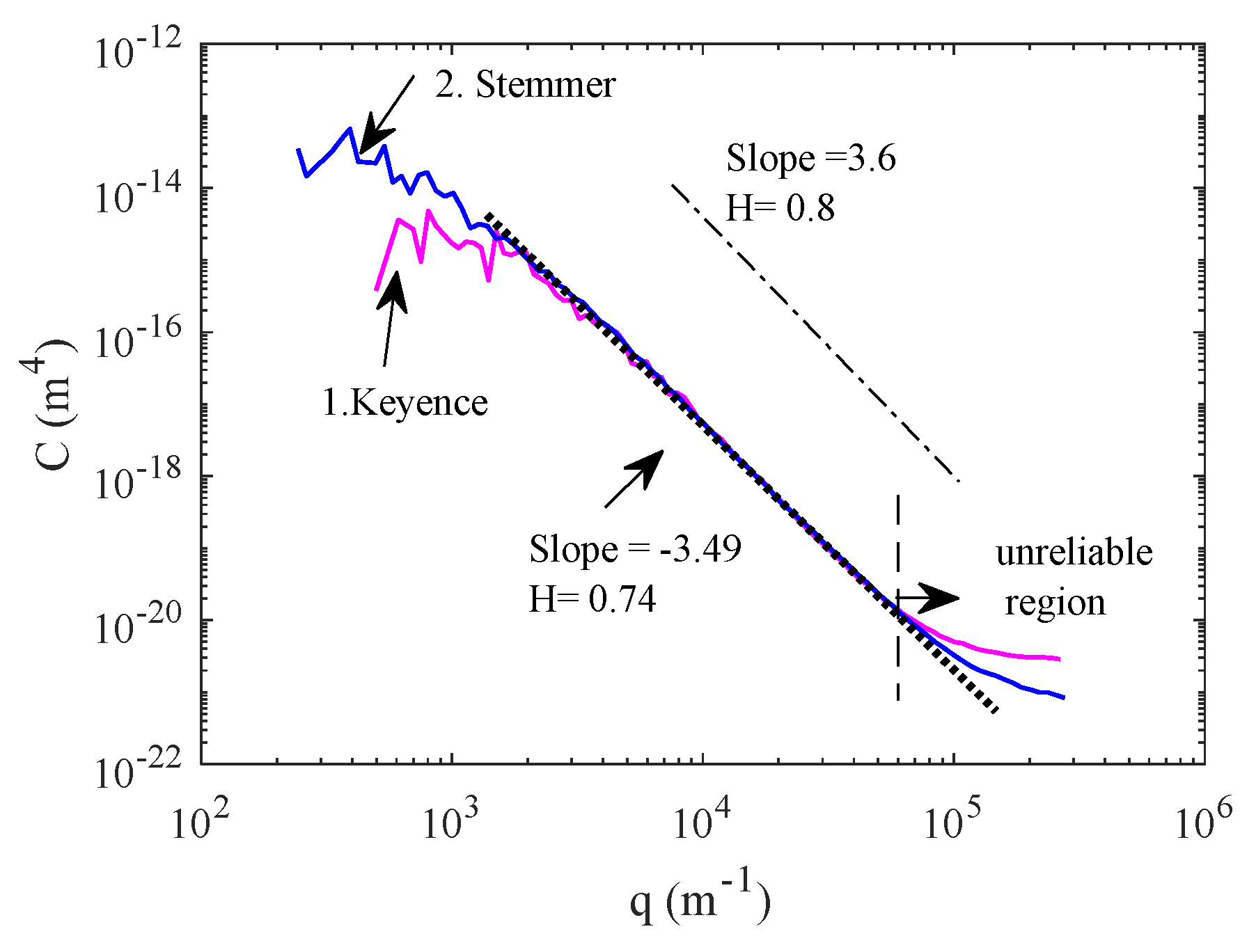

- A Keyence confocal laser scanning microscopy VK 970 for the indoor testing. A maximum scanning area of 2 cm2 can be acquired by stitching and combining multiple measurements into one image. Three lens magnifications of 10×, 50×, and 100× at different resolutions were employed.

- A Stemmer imaging laser scanner with a Micro-Epsilon optoNCDT2300 triangulation laser sensor with a maximum height range of 20 mm. The XY-stage has a range of 100 mm × 100 mm and a maximum resolution of 10 µm/pixel. This device was utilized to assess the macro texture.

3. Results and Discussion

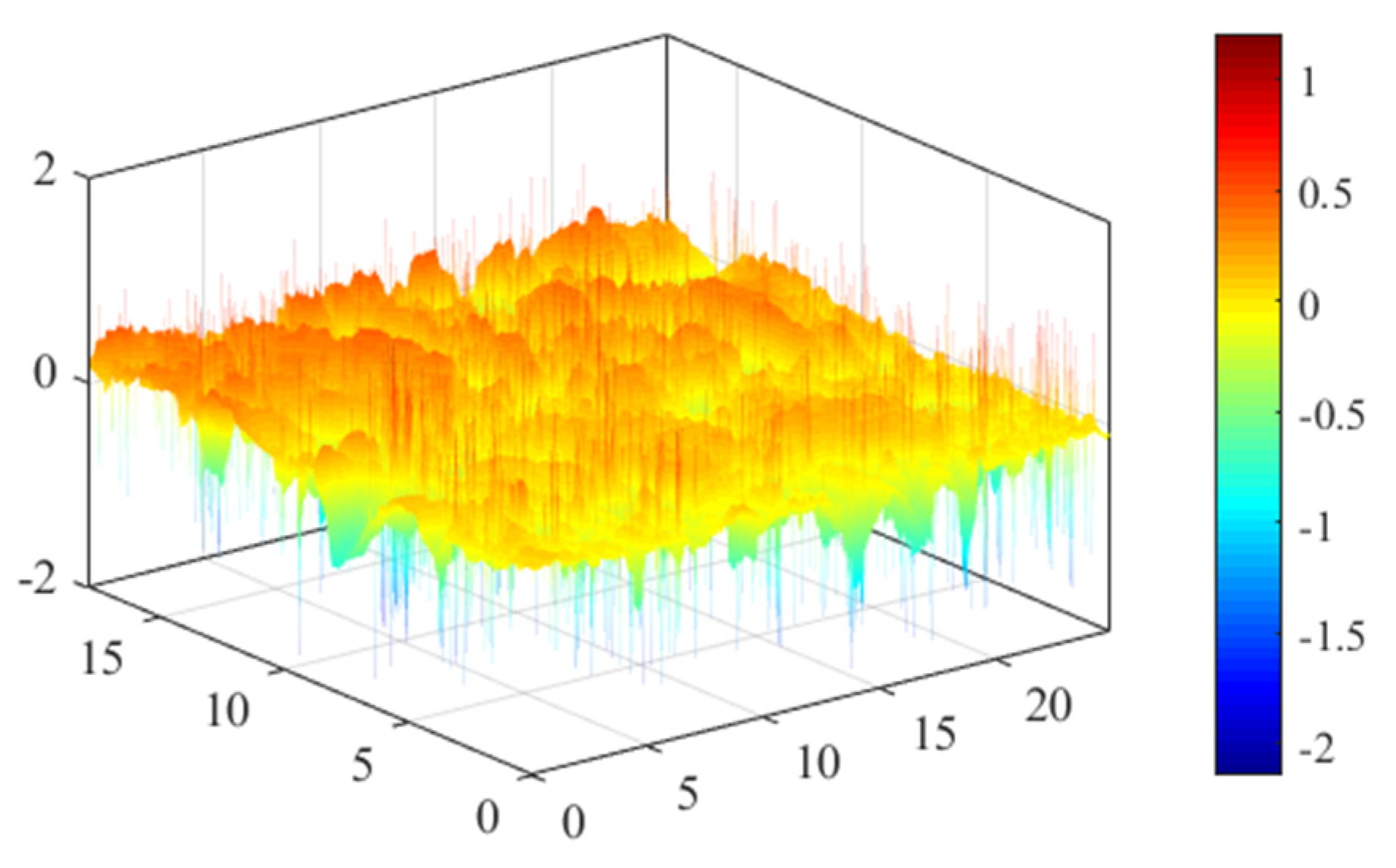

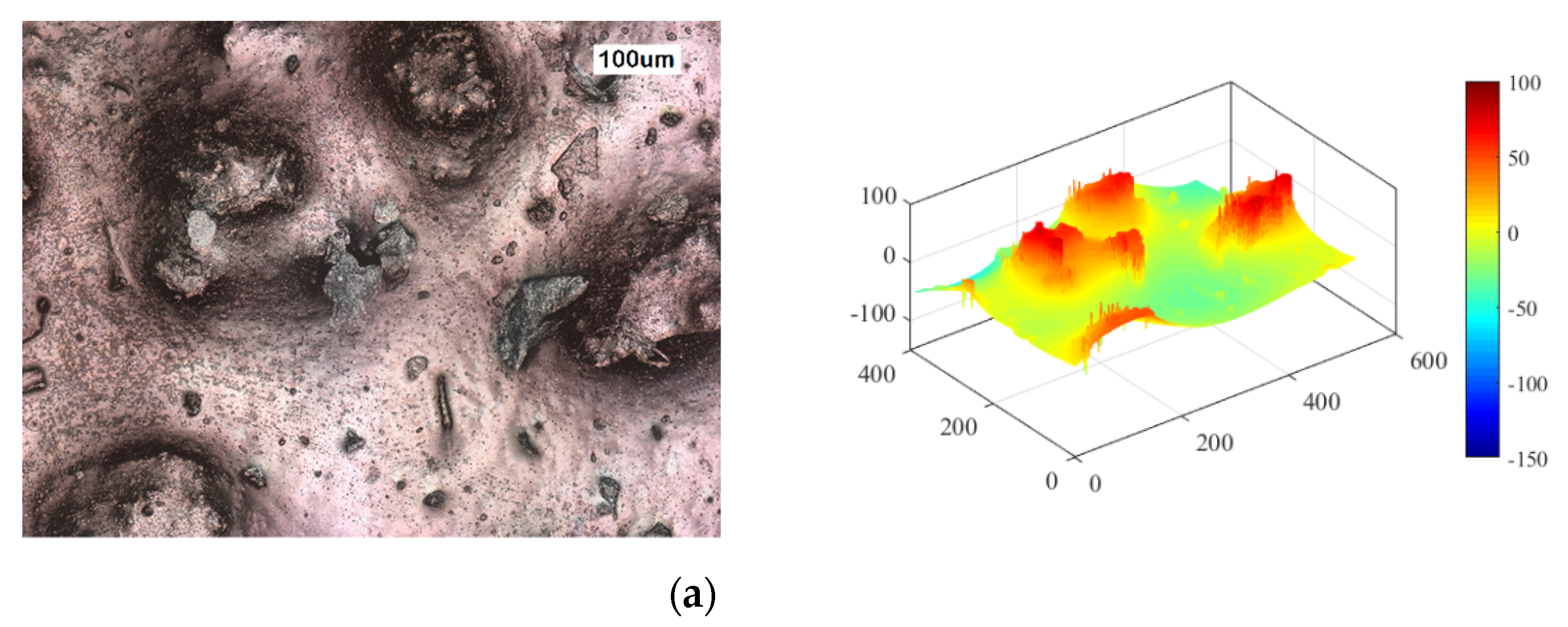

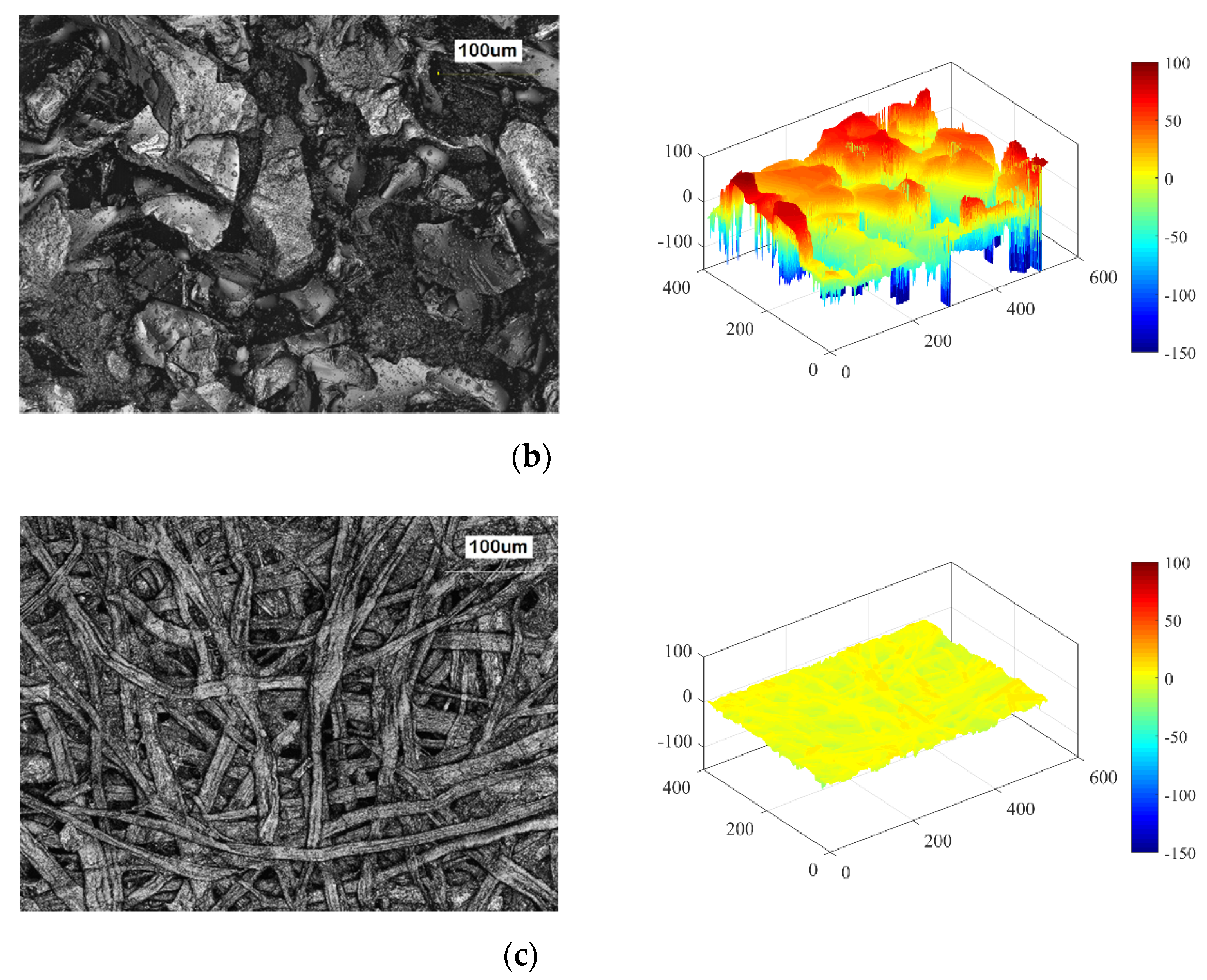

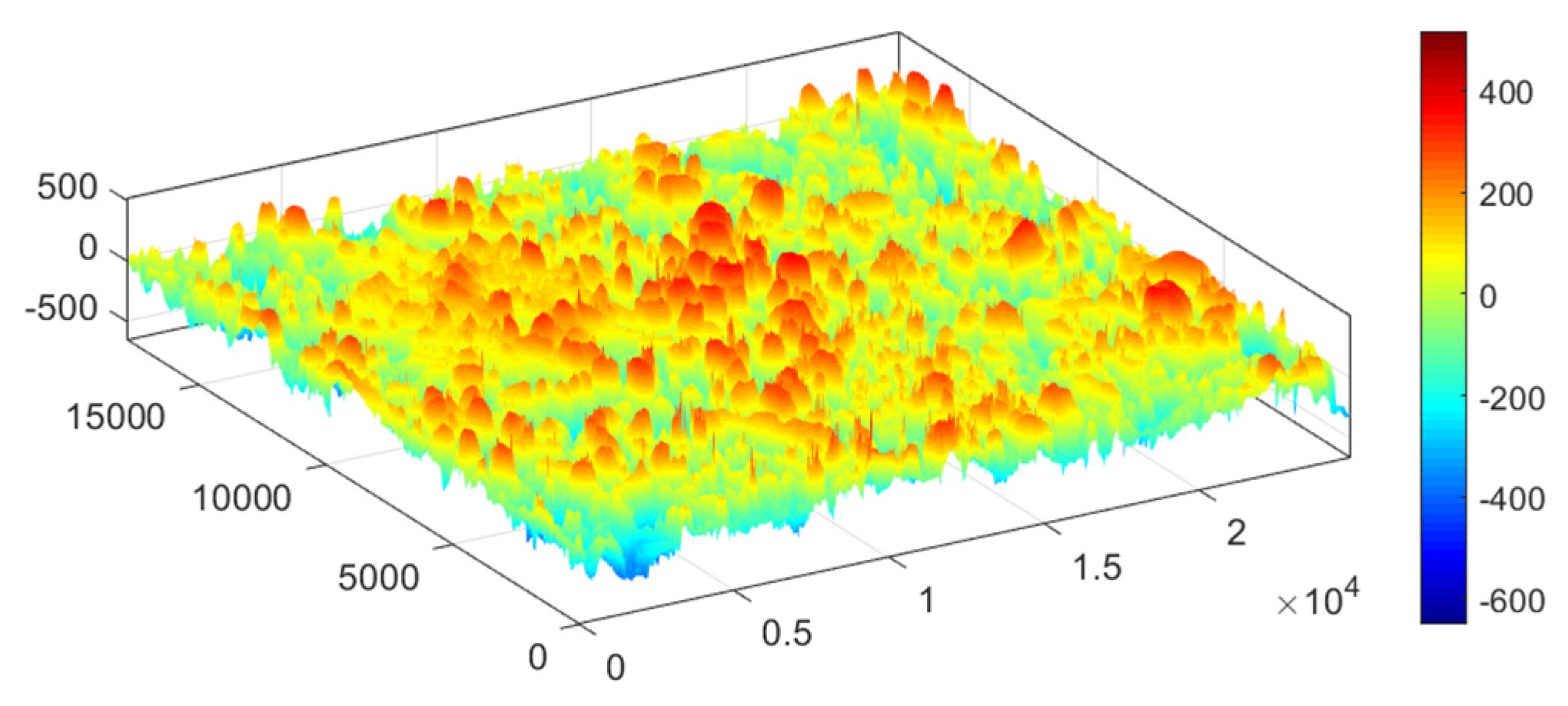

3.1. Macro-Texture Characterization

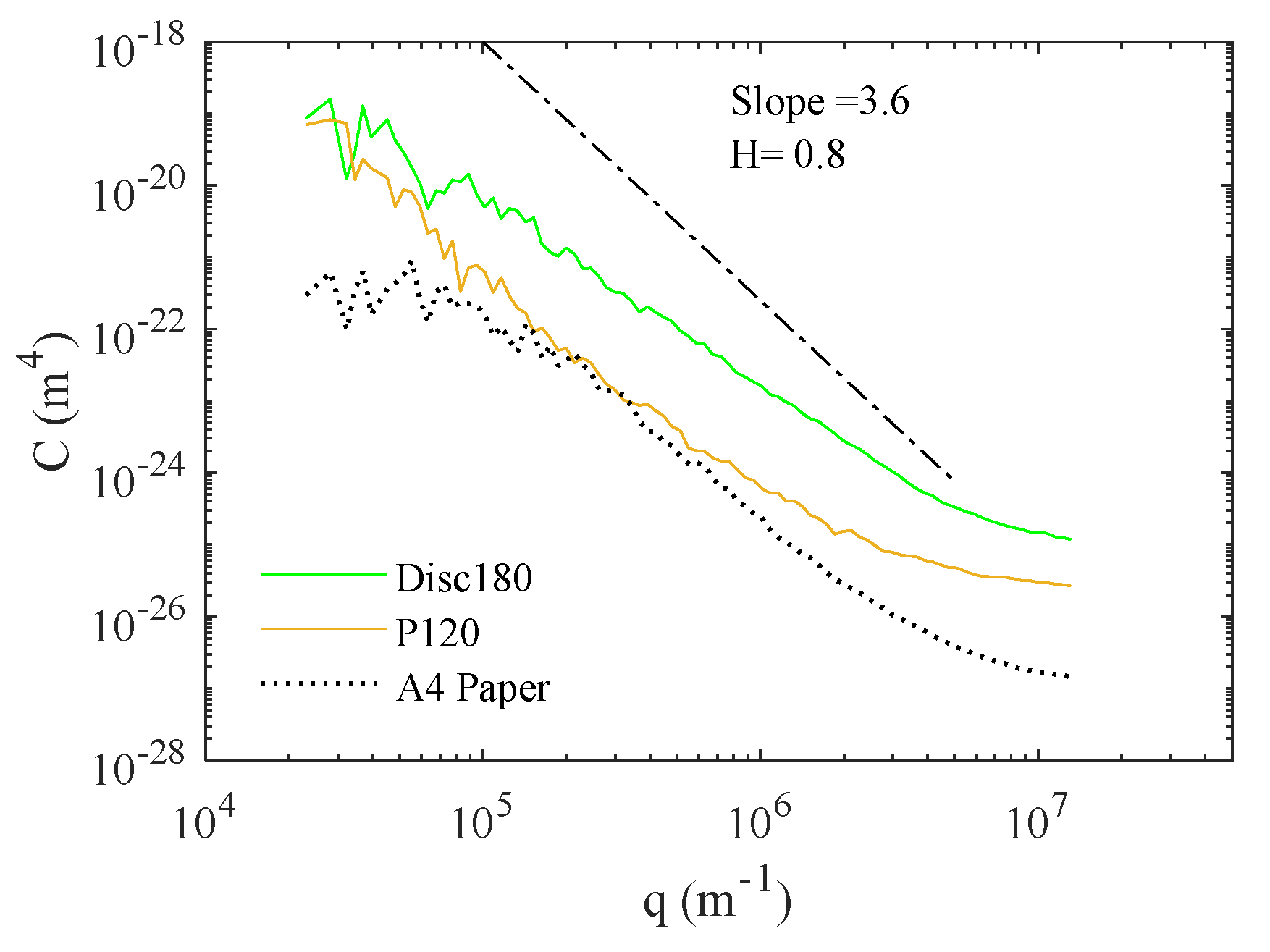

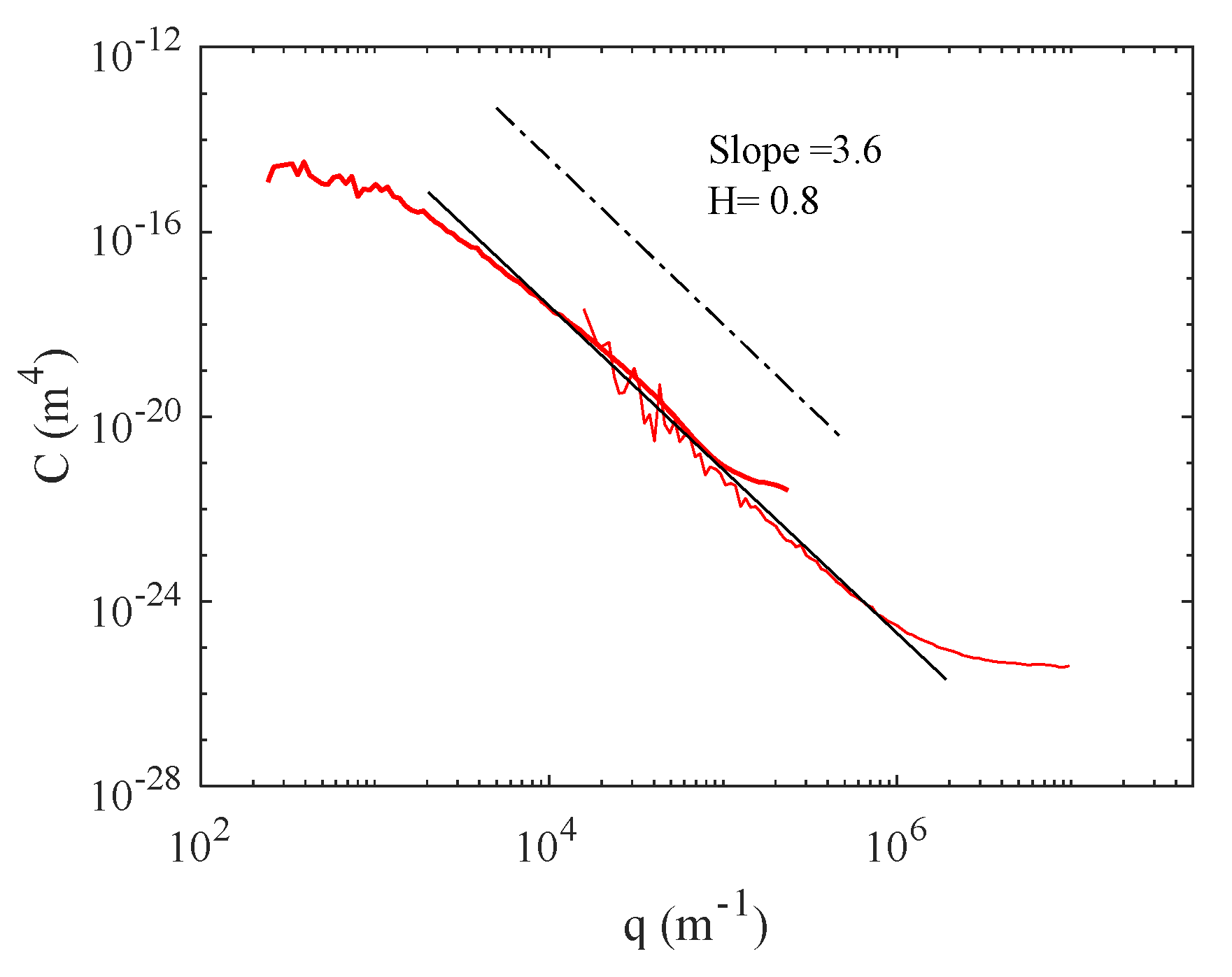

3.2. Micro-Texture Characterization

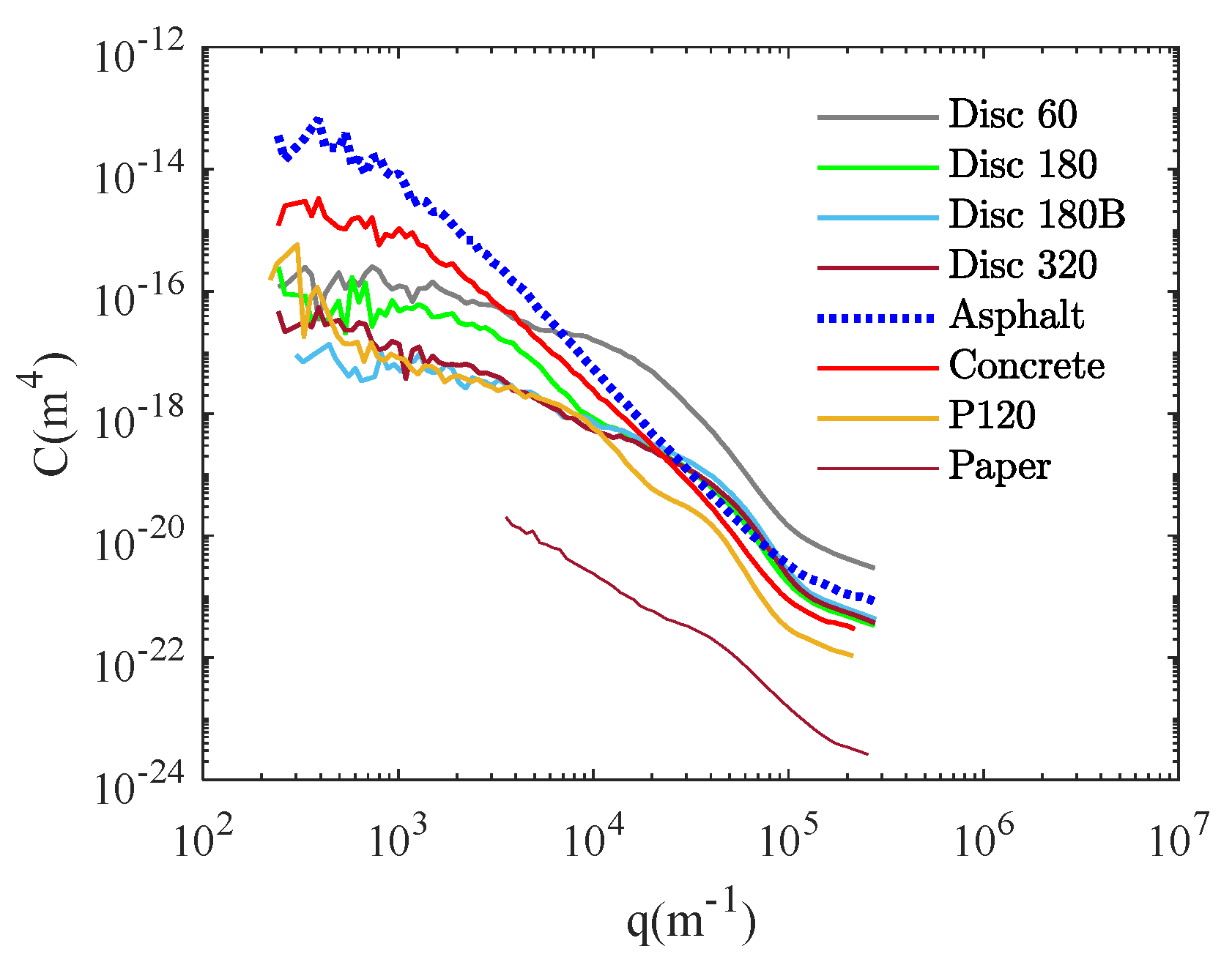

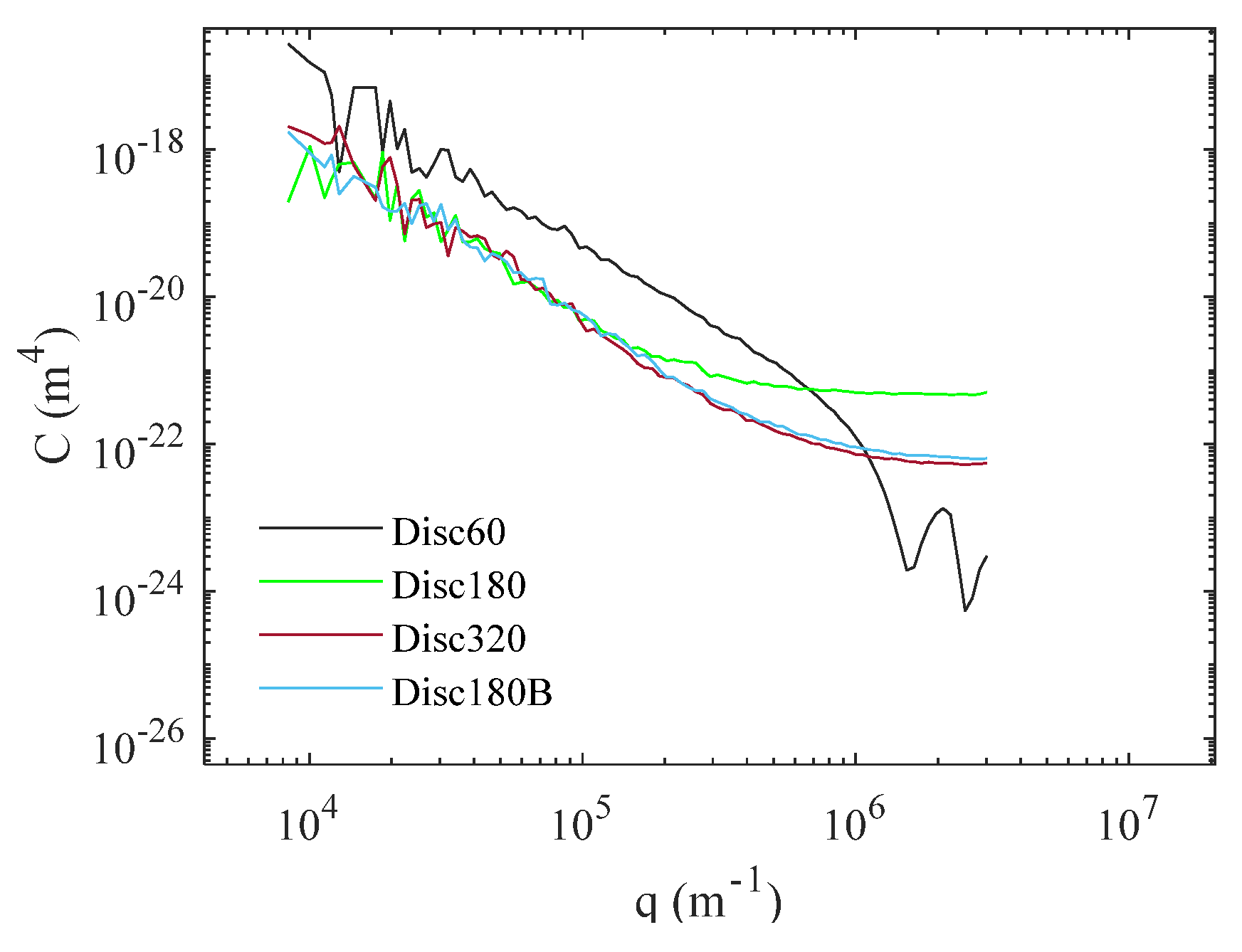

3.3. Combined Macro and Micro Characterization: Overall Picture

4. Conclusions

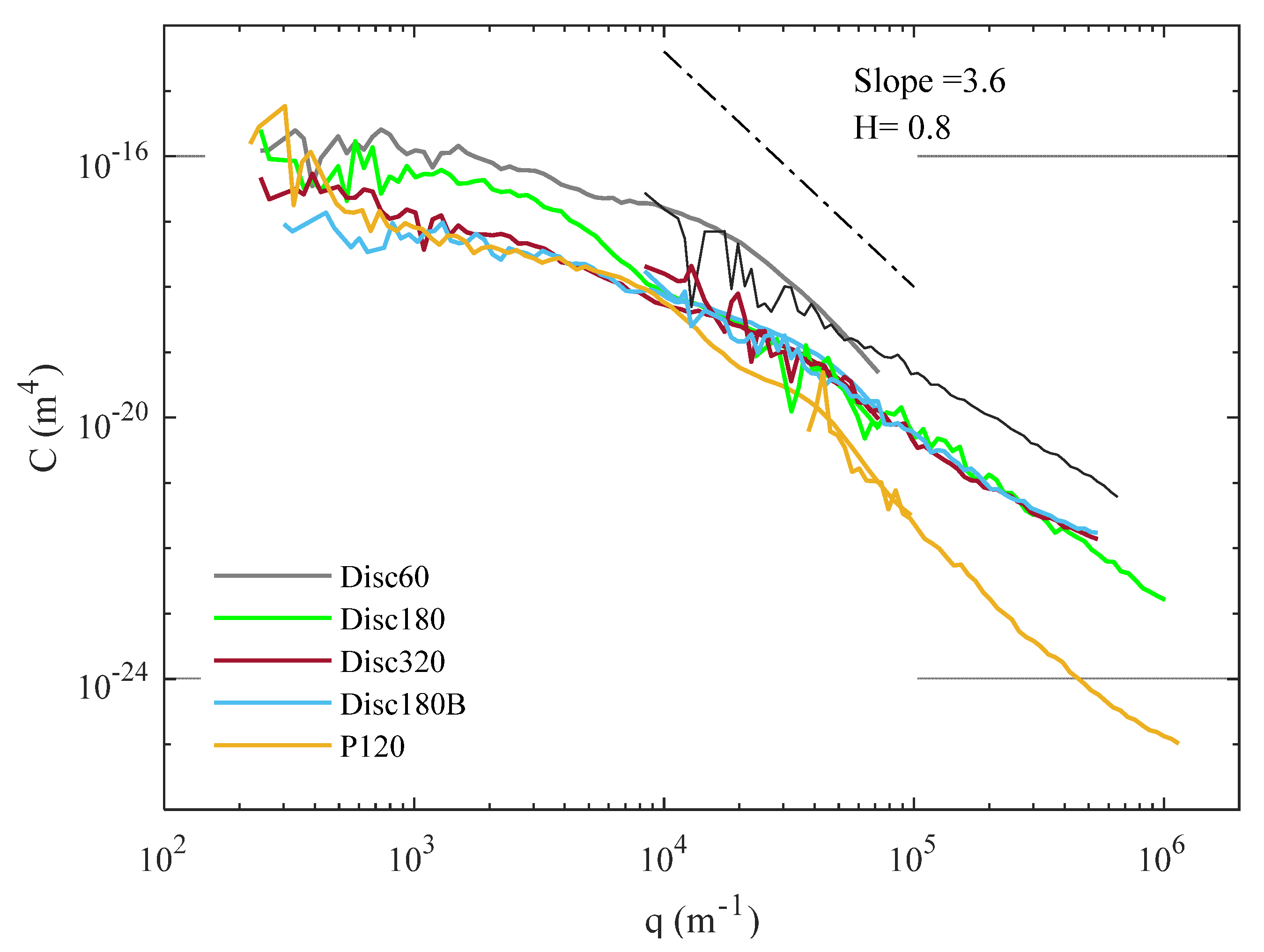

- There is a shift upwards for LAT100 disc 60, which suggests the asperities with the same wavenumbers in comparison with other discs have larger amplitudes representing the micro texture of that surface.

- LAT100 disc 320 shows smaller amplitudes for macro texture compared to disc 180 and asphalt; however, the micro texture is in the same range as for discs 180 and 180B.

- The extra flattening for disc 180B affects only the macro texture and the structure or the shape of the asperities compared to disc 180. The micro texture is the same.

- Sandpaper P120 has a surface with a positive , while disc 180 has a negative one. It also has a higher exponent indicating a rougher surface than disc 180.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carrillo, C.; Bachmann, C. Can we get the road into the lab? Challenges in tire testing. In Science Meets Tires; Ika Institut für Kraftfahrzeuge and Rwth Aachen University: Aachen, Germany, 2018. [Google Scholar]

- Salehi, M.; Noordermeer, J.W.; Reuvekamp, L.A.; Dierkes, W.K.; Blume, A. Measuring rubber friction using a Laboratory Abrasion Tester (LAT100) to predict car tire dry ABS braking. Tribol. Int. 2019, 131, 191–199. [Google Scholar] [CrossRef]

- O’Neill, A.; Gruber, P.; Watts, J.F.; Prins, J. Predicting Tyre Behaviour on Different Road Surfaces; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Emami, A.; Khaleghian, S. Investigation of tribological behavior of Styrene-Butadiene Rubber compound on asphalt-like surfaces. Tribol. Int. 2019, 136, 487–495. [Google Scholar] [CrossRef]

- Ludwig, C. Influence of testing surface on tire lateral force characteristics. In Science Meets Tires; Ika Institut für Kraftfahrzeuge and Rwth Aachen University: Aachen, Germany, 2018. [Google Scholar]

- Kanafi, M.M.; Tuononen, A.J.; Dorogin, L.; Persson, B.N. Rubber friction on 3D-printed randomly rough surfaces at low and high sliding speeds. Wear 2017, 376–377, 1200–1206. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Junge, T.; Pastewka, L. Quantitative characterization of surface topography using spectral analysis. Surf. Topogr. Metrol. Prop. 2017, 5, 013001. [Google Scholar] [CrossRef]

- Persson, B.N.J. On the Fractal Dimension of Rough Surfaces. Tribol. Lett. 2014, 54, 99–106. [Google Scholar] [CrossRef]

- Bouzid, N.; Heimann, B. Micro Texture Characterization and Prognosis of the Maximum Traction between Grosch Wheel and Asphalt Surfaces under Wet Conditions. In Elastomere Friction: Theory, Experiment and Simulation; Besdo, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 201–220. [Google Scholar]

- Heinz, M.; Grosch, K.A. A Laboratory Method to Comprehensively Evaluate Abrasion, Traction and Rolling Resistance of Tire Tread Compounds. Rubber Chem. Technol. 2007, 80, 580–607. [Google Scholar] [CrossRef]

- Grosch, K.A. Goodyear Medalist Lecture. Rubber Friction and its Relation to Tire Traction. Rubber Chem. Technol. 2007, 80, 379–411. [Google Scholar] [CrossRef]

- Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Tolpekina, T.; Blume, A. A New Horizon for Evaluating Tire Grip Within a Laboratory Environment. Tribol. Lett. 2020, 68, 37. [Google Scholar] [CrossRef] [Green Version]

- Salehi, M.; Noordermeer, J.W.; Reuvekamp, L.A.; Blume, A. Parameter optimization for a laboratory friction tester to predict tire ABS braking distance using design of experiments. Mater. Des. 2020, 194, 108879. [Google Scholar] [CrossRef]

- Grosch, K.A. Correlation Between Road Wear of Tires and Computer Road Wear Simulation Using Laboratory Abrasion Data. Rubber Chem. Technol. 2004, 77, 791–814. [Google Scholar] [CrossRef]

- Grosch, K.A. A new way to evaluate traction-and wear properties of tire tread compounds. In Rubber Division; American Chemical Society: Cleveland, OH, USA, 1997. [Google Scholar]

- Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Blume, A. Understanding Test Modalities of Tire Grip and Laboratory-Road Correlations with Modeling. Tribol. Lett. 2021, 69, 116. [Google Scholar] [CrossRef]

- Flintsch, G.W.; McGhee, K.K.; de León Izeppi, E.; Najafi, S. The Little Book of Tire Pavement Friction, 1st ed.; Pavement Surface Properties Consortium, Virginia Tech: Blacksburg, VA, USA, 2012. [Google Scholar]

- Introduction, Section G.3000, in The Contact Patch, Transport Technology from the Ground Up. Available online: www.the-contact-patch.com/book/general (accessed on 3 January 2022).

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Processing Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Chang, W.-R. The effects of surface roughness and contaminants on the dynamic friction between porcelain tile and vulcanized rubber. Saf. Sci. 2002, 40, 577–591. [Google Scholar] [CrossRef]

- Nayak, P.R. Random Process Model of Rough Surfaces. J. Lubr. Technol. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Whitehouse, D.J. Surface roughness characterization. In Handbook of Surface Metrology; Institute of Physics Publishing: Bristol, UK; Philadelphia, PA, USA, 1994. [Google Scholar]

- Persson, B.; Albohr, O.; Tartaglino, U.; Volokitin, A.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 2004, 17, R1–R62. [Google Scholar] [CrossRef] [Green Version]

- Carr, J.R. Statistical self-affinity, fractal dimension, and geologic interpretation. Eng. Geol. 1997, 48, 269–282. [Google Scholar] [CrossRef]

- Krim, J.; Palasantzas, G. Experimental observations of self-affine scaling and kinetic roughening at sub-micron lengthscales. Int. J. Mod. Phys. B 1995, 9, 599–632. [Google Scholar] [CrossRef] [Green Version]

- Lorenz, B.; Persson, B.N.J.; Dieluweit, S.; Tada, T. Rubber friction: Comparison of theory with experiment. Eur. Phys. J. E 2011, 34, 129. [Google Scholar] [CrossRef]

- Carbone, G.; Lorenz, B.; Persson, B.; Wohlers, A. Contact mechanics and rubber friction for randomly rough surfaces with anisotropic statistical properties. Eur. Phys. J. E 2009, 29, 275–284. [Google Scholar] [CrossRef]

- Heinz, M. A Universal Method to Predict Wet Traction Behaviour of Tyre Tread Compounds in the Laboratory. J. Rubber Res. 2010, 13, 91–102. [Google Scholar]

- Salehi, M.; Noordermeer, J.W.; Reuvekamp, L.A.E.M.; Dierkes, W.K.; Blume, A. Vorhersagen für das Bremsverhalten von Reifen durch Bestimmung der Gummireibung. Gummi Fasern Kunstst. 2019, 72, 24–33. [Google Scholar]

- Tiwari, A.; Miyashita, N.; Espallargas, N.; Persson, B.N.J. Rubber friction: The contribution from the area of real contact. J. Chem. Phys. 2018, 148, 224701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Persson, J.S.; Tiwari, A.; Valbahs, E.; Tolpekina, T.V.; Persson, B.N.J. On the Use of Silicon Rubber Replica for Surface Topography Studies. Tribol. Lett. 2018, 66, 140. [Google Scholar] [CrossRef]

| Disc Designation | 60 | 180 | 320 | 180B |

|---|---|---|---|---|

| Disc code | EKW 60 SHARP | EKW 180 SHARP | EKW 320 | EKW 180 BLUNT |

| Average particle size (μm) | 225 | 60 | 32 |  |

| Corundum sieve analysis (μm) | 0% > 425 | 0% > 125 | Max. of 52 * | |

| Max. 30% > 300 | Max. 15% > 90 | |||

| Min. 40% > 250 | Min. 40% > 63 | Min. of 19 * | ||

| Min. 65% > 212 | Min. 65% > 53 |

| Surface | Sa (μm) | Sq (μm) | Ssq (μm) |

|---|---|---|---|

| Disc 60 | 146 | 175 | −0.44 |

| Disc 180 | 47 | 65 | −1.37 |

| Disc 320 | 39 | 48 | −0.33 |

| Disc 180B | 35 | 44 | −0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Blume, A. Characterization of Counter-Surface Substrates for a Laboratory Abrasion Tester (LAT100) Compared with Asphalt and Concrete to Predict Car Tire Performance. Lubricants 2022, 10, 8. https://doi.org/10.3390/lubricants10010008

Salehi M, Noordermeer JWM, Reuvekamp LAEM, Blume A. Characterization of Counter-Surface Substrates for a Laboratory Abrasion Tester (LAT100) Compared with Asphalt and Concrete to Predict Car Tire Performance. Lubricants. 2022; 10(1):8. https://doi.org/10.3390/lubricants10010008

Chicago/Turabian StyleSalehi, Marzieh, Jacques W. M. Noordermeer, Louis A. E. M. Reuvekamp, and Anke Blume. 2022. "Characterization of Counter-Surface Substrates for a Laboratory Abrasion Tester (LAT100) Compared with Asphalt and Concrete to Predict Car Tire Performance" Lubricants 10, no. 1: 8. https://doi.org/10.3390/lubricants10010008

APA StyleSalehi, M., Noordermeer, J. W. M., Reuvekamp, L. A. E. M., & Blume, A. (2022). Characterization of Counter-Surface Substrates for a Laboratory Abrasion Tester (LAT100) Compared with Asphalt and Concrete to Predict Car Tire Performance. Lubricants, 10(1), 8. https://doi.org/10.3390/lubricants10010008