A Review of Biochar from Biomass and Its Interaction with Microbes: Enhancing Soil Quality and Crop Yield in Brassica Cultivation

Abstract

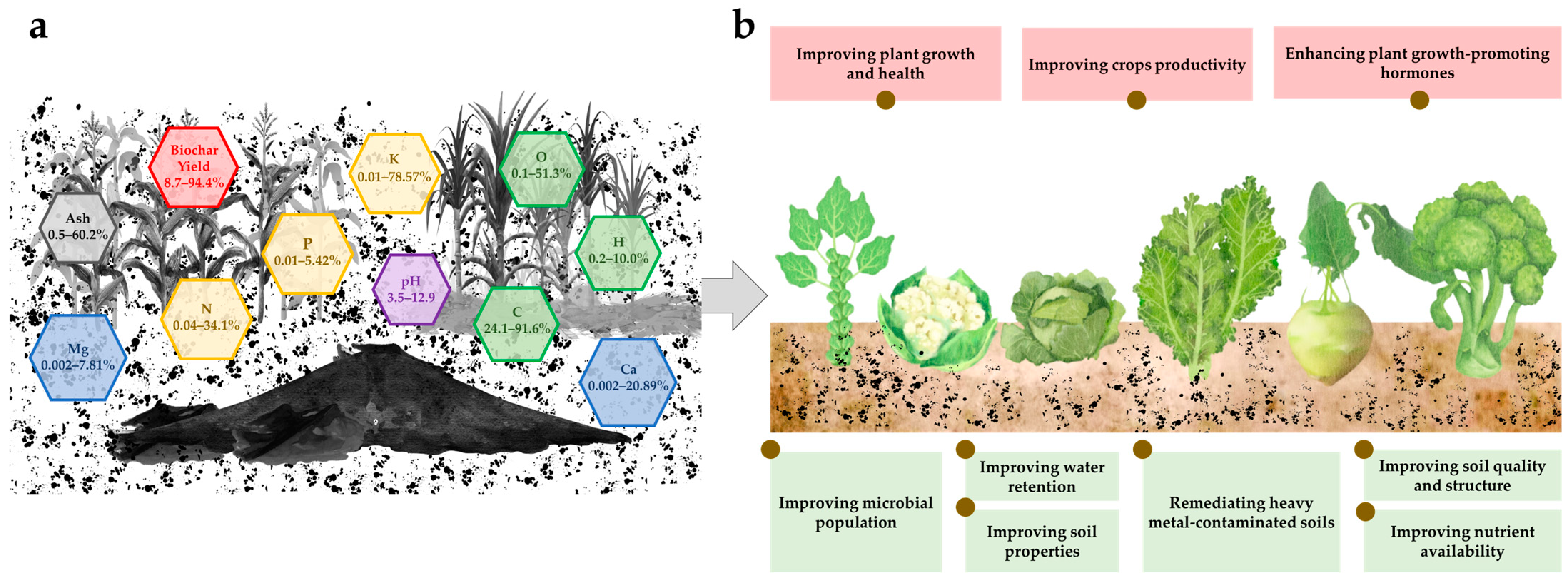

1. Introduction

2. Production and Properties of Biochar from Biomass

2.1. Biochar Production Methods and Parameters

| Process | Temperature (°C) | Residence Time | Heating Rate (°C/s) | Yields % | ||

|---|---|---|---|---|---|---|

| Biochar | Bio-Oil | Syngas | ||||

| Slow pyrolysis | 300–700 | hour–days | <1 | 35 | 30 | 35 |

| Intermediate pyrolysis | 500–650 | 10–20 s | 1.0–10 | 25 | 50 | 25 |

| Fast pyrolysis | 300–1250 | 0.5–20 s | 10–200 | 12 | 75 | 13 |

| Flash pyrolysis | 800–1300 | <0.5 s | >1000 | 20 | 50 | 30 |

| Gasification | 700–1500 | 10–20 s | 10–300 | 10 | 5 | 85 |

| HTC | 180–300 | 1–16 h | – | 50–80 | 5–20 | 2–5 |

| Torrefaction | 200–300 | <30 min | <50 | 80 | 0 | 20 |

2.2. Types and Sources of Biomass Used for Biochar Production

| Biochar Materials | Pyrolysis Temp (°C) | pH | Elemental Composition (%, Mass Based) | Ash (%) | Yield (%) | References | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O | P | K | Ca | Mg | ||||||

| Almond (Prunus dulcis) shell | 300–800 | 6.9–11.7 | 24.1–89.4 | 1.0–6.0 | 0.5–1.0 | 11.8–42.0 | 0.02–0.21 | 0.16–4.89 | 0.37–6.01 | 0.01–0.42 | 3.4–12.8 | 25.4–65.1 | [44,45,46,47] |

| Apple tree (Malus domestica) | 300–800 | 7.0–10.3 | 62.2–84.8 | 0.6–5.7 | 0.3–3.2 | 5.8–23.7 | 0.21–1.49 | 0.57–1.14 | 12.90–20.89 | 3.01–5.64 | 6.7–10.1 | 28.5–47.9 | [48,49,50] |

| Bambara groundnut (Vigna subterranea) shell | 450–750 | - | 48.4–81.0 | 2.5–5.1 | 0.4–2.0 | 15.4–45.9 | 5.50 | 1.43–78.57 | 0.20–3.05 | 0.07–1.56 | 16.1–19.7 | 45.7 | [51,52,53] |

| Bamboo (Bambusa) | 250–800 | 5.2–10.3 | 38.3–88.4 | 0.9–4.7 | 0.2–2.6 | 5.7–38.5 | 0.24–2.15 | 0.30–0.52 | 0.22–0.34 | 0.14–0.23 | 3.0–4.7 | 17.4–73.2 | [20,54,55,56,57] |

| Beech wood (Fagus sylvatica) chips | 300–700 | 5.18–7.8 | 70.0–88.0 | 1.5–4.2 | 1.4 | 15.0 | - | - | - | - | 1.2–9.8 | 22.0–31.7 | [58,59] |

| Brazilian pepperwood (Schinus terebinthifolia) | 300–600 | 6.6–9.7 | 59.3–77.0 | 2.2–5.2 | 0.1–34.1 | 0.3–17.7 | 0.03–0.09 | 0.10–0.29 | 0.73–2.59 | 0.12–0.29 | - | 28.9–51.5 | [54] |

| Buckwheat (Fagopyrum esculentum) husk | 350–650 | 9.2–10.0 | 70.1–83.9 | 1.8–4.4 | 0.9–1.0 | 13.3–24.4 | - | - | - | - | 4.0–33.1 | 28.5–46.3 | [60] |

| Canola (Brassica napus) hull | 350–850 | - | 46.5–55.3 | 3.8–5.1 | 0.8–2.6 | 5.8–18.9 | - | - | - | - | 16.1–40.7 | - | [61] |

| Canola (B. napus) meal | 350–850 | - | 51.1–60.7 | 3.9–5.2 | 1.5–3.8 | 11.0–20.9 | - | - | - | - | 12.1–31.4 | - | [61] |

| Canola (B. napus) stalk | 250–650 | 7.2–11.0 | 41.7–61.9 | 1.9–5.0 | 0.9–1.1 | 34.2–37.4 | 1.39–4.25 | - | - | - | 8.7–70.8 | [62] | |

| Canola (B. napus) straw | 300–700 | 6.4–10.8 | 54.9–65.7 | 3.2–3.5 | 0.04–1.3 | – | 0.16–0.48 | - | - | - | 10.7–28.6 | 9.2–24.4 | [63,64] |

| Coconut flesh waste | 350–600 | 72.7–83.3 | 1.5–10.0 | 2.2–3.0 | 11.0–13.9 | 4.6–8.2 | [65] | ||||||

| Coffee (Coffea sp.) ground | 500–550 | 6.9–10.1 | 68.0 | 4.0 | 3.6–3.7 | 18.0 | 0.44 | 1.79 | - | - | 6.2 | - | [20,66] |

| Coffee (Coffea sp.) husk | 350–750 | 9.7–9.9 | 60.5–66.0 | 1.6–3.9 | - | 9.8–19.5 | - | - | - | - | 12.9–19.6 | 43.5 | [67] |

| Conocarpus (Conocarpus erectus) tree | 200–800 | 7.4–12.9 | 64.2–85.0 | 0.6–4.0 | 0.7–0.9 | 4.9–26.6 | 0.84–1.34 | 0.38–1.15 | 43.4–67.5 | 3.43–7.81 | 4.5–8.6 | - | [13] |

| Corn (Zea mays) cob | 250–700 | 8.6–9.9 | 43.3–87.2 | 2.1–5.1 | 0.4–0.9 | 9.0–51.3 | 0.11–0.31 | 0.78–3.01 | 0.02–0.11 | 0.06–0.32 | 6.1–13.3 | 18.9–27.1 | [20,68,69,70,71,72,73] |

| Corn (Z. mays) stalk | 400–600 | 8.5–10.5 | 44.7–72.4 | 1.5–5.8 | 0.5–2.3 | 2.2–19.9 | 0.33 | 1.52 | - | - | 11.6–2.3 | 28.3–38.3 | [74,75,76] |

| Corn (Z. mays) stover | 300–500 | 7.3–9.8 | 45.5–78.1 | 2.1–5.4 | 0.3–1.5 | 6.2–42.0 | - | 0.01–0.44 | 0.002–0.33 | 0.002– 0.23 | 5.7–32.8 | 17.0–66.0 | [68,77,78] |

| Corn (Z. mays) straw | 300–700 | 7.9–11.4 | 35.9–85.9 | 1.5–5.0 | 0.04–2.4 | 1.9–31.6 | 0.25–2.51 | 0.02–4.57 | 0.003–0.52 | 0.003–0.79 | 3.2–60.2 | 24.9–43.6 | [63,79,80,81,82] |

| Cotton (Gossypium sp.) seed hull | 200–800 | 3.5–10.1 | 51.9–91.0 | 0.6–6.0 | 0.6–1.9 | 5.9–40.5 | - | - | - | - | 3.1–9.2 | 24.2–83.4 | [83] |

| Cotton (Gossypium sp.) stalk | 550 | 9.6–10.3 | 64.3–71.9 | 3.4–4.8 | 1.1–1.9 | 11.0–43.9 | 0.13 | 0.7 | 0.2 | 0.3 | 8.8–19.1 | - | [75,84] |

| Cotton (Gossypium sp.) straw | 300–600 | 8.4 | 74.8–84.6 | 2.3 | 0.6–1.2 | 12.7–21.2 | 0.19 | 2.56–4.08 | 0.27–1.17 | 0.40 | 2.9 | 30.5 | [80,81] |

| Date palm (Phoenix dactylifera) | 300–800 | 8.3–11.5 | 58.0–74.6 | 0.9–4.1 | 0.3–0.5 | 2.3–20.8 | - | 2.18–2.71 | 4.85–8.08 | 1.53–2.02 | 14.4–21.4 | - | [85] |

| Eucalyptus (Eucalyptus sp.) | 350–750 | 5.9–10.0 | 67.4–90.9 | 1.5–5.4 | 0.4–0.6 | 5.6–19.5 | - | - | - | - | 0.7–1.1 | 28.2–42.5 | [67,86,87] |

| Hemp (Cannabis sativa) stalks | 400–1000 | 73.8–89.1 | 0.2–3.8 | 0.6–1.3 | 0.1–14.9 | - | - | - | - | 6.5–11.3 | - | [88] | |

| Hickory (Carya sp.) wood | 450–600 | 8.0–9.4 | 81.8–84.0 | 2.2–3.2 | 0.1–0.7 | 11.1–14.0 | 0.02–0.04 | 0.24–0.34 | 0.59–0.92 | 0.13–0.18 | - | - | [89] |

| Larch (Larix kaempferi) wood | 600 | - | 91.2 | 2.0 | 0.1 | 2.9 | - | 0.04 | 0.05 | 0.01 | [90] | ||

| Mulberry (Morus alba) wood | 350–650 | 10.2–11.1 | 67.9–80.1 | 1.6–4.5 | 1.6–2.2 | 16.6–25.2 | - | - | - | - | 7.5–9.8 | 22.8–37.5 | [60] |

| Oak (Quercus sp.) wood | 400–800 | 6.4–9.7 | 70.5–89.0 | 0.7–3.6 | 0.3–0.7 | 3.3–21.5 | 0.10 | 0.20–0.90 | 0.31–2.7 | 0.08–0.20 | 2.9–13.4 | - | [48,90,91] |

| Oil palm (Elaeis guineensis) mesocarp fiber | 250–600 | - | 47.1–67.0 | 1.9–5.0 | 1.1–1.4 | 15.4–42.2 | - | - | - | - | 14.6 | - | [70,92] |

| Oil palm (E. guineensis) empty fruit bunches | 250–600 | - | 47.1–67.3 | 1.9–6.0 | <0.1–1.7 | 18.1–46.0 | - | - | - | - | 5.3–13.9 | - | [70,92,93] |

| Oil palm (E. guineensis) bark | 400 | 7.1 | 68.9 | 5.3 | 0.9 | 20.8 | - | - | - | - | - | - | [86] |

| Oil palm (E. guineensis) kernel shell | 250–600 | - | 51.9–68.8 | 2.0–5.7 | 0.5–0.8 | 12.9–38.5 | - | - | - | - | 15.6 | - | [70,92] |

| Oil palm (E. guineensis) frond | 600 | - | 69.9 | 1.7 | - | 11.0 | - | - | - | - | 17.6 | - | [92] |

| Oil palm (E. guineensis) trunk | 600 | - | 66.3 | 1.6 | - | 18.2 | - | - | - | - | 13.9 | - | [92] |

| Peanut (Arachis hypogaea) hull | 300–600 | 6.6–9.1 | 59.3–77.0 | 2.2–5.2 | 0.1–0.3 | 17.2–34.1 | 0.03–0.09 | 0.10–0.25 | 0.73–1.81 | 0.12–0.29 | - | 28.9–51.5 | [54] |

| Peanut (A. hypogaea) shell | 198–700 | 7.8–11.1 | 53.5–84.0 | 0.9–6.1 | 0.7–2.7 | 3.3–33.3 | 0.19–0.26 | 0.93–2.21 | 0.56–2.49 | 0.23–0.41 | 1.2–24.4 | 21.9–45.7 | [45,69,79,89,94,95,96] |

| Peanut (A. hypogaea) straw | 300–700 | 6.3–11.2 | 43.6–53.7 | - | 1.5–3.5 | - | 0.46–1.16 | - | - | - | 16.6–34.9 | 20.1–38.5 | [63] |

| Pear (Pyrus communis) tree waste | 300–600 | 8.9–10.1 | 66.7–75.1 | 3.5–5.7 | 2.9–3.2 | 18.3–24.6 | 2.00–1.72 | - | - | - | - | - | [49] |

| Pecan (Carya illinoinensis) shell | 350–700 | 4.9–7.2 | 64.5–91.2 | 1.5 –5.3 | 0.3–0.6 | 1.6–27.6 | 0.03–0.05 | - | - | - | 1.8–5.2 | - | [94,97] |

| Persimmon (Diospyros virginiana) tree | 300–600 | 8.1–9.9 | 67.6–76.9 | 2.9–5.5 | 2.7–3.1 | 17.4–24.0 | 0.77–1.63 | - | - | - | - | - | [49] |

| Pigeon pea (Cajanus cajan) stalk | 400–600 | 7.9–10.1 | 76.17–84.87 | 2.3–4.5 | 0.2–0.4 | 11.7–19.2 | - | - | - | - | 3.1–4.8 | - | [57] |

| Pine (Pinus sp.) bark | 350–750 | 7.8–9.9 | 67.6–86.3 | 1.2–3.7 | - | 19.1–28.7 | - | - | - | - | 7.9–14.5 | 38.9–59.6 | [67] |

| Pine (Pinus sp.) needle | 100–700 | - | 50.87–93.7 | 0.6–6.2 | 0.67 –4.1 | 2.1–42.3 | 0.11 | 0.14 | 0.68 | 0.11 | 0.9–18.7 | 17.7–30.0 | [89,95,98,99] |

| Pine (Pinus sp.) nutshell | 600 | - | 89.0 | 2.2 | 0.4 | 6.7 | - | 0.30 | 0.02 | 0.01 | 1.8 | - | [100] |

| Pine (Pinus sp.) woodchip | 150–900 | 5.8–11.4 | 49.2–91.5 | 0.5–6.2 | 0.1–0.6 | 5.0–43.6 | 0.02–0.35 | 0.17–0.82 | 0.33–9.23 | 0.06–0.26 | 1.0–15.4 | 14.8–79.8 | [44,56,93,99,101,102,103,104] |

| Pine (Pinus sp.) sawdust | 600–1600 | - | 88.9 | 2.5 | 0.1 | 4.1 | - | 0.16 | 0.28 | 0.03 | 4.5 | 13.0–17.0 | [99,100] |

| Pistachio (Pistacia vera) shell | 250–650 | 4.7–8.8 | 54.2–89.0 | 1.3–5.9 | 0.05–0.7 | 2.7–37.3 | - | - | - | - | 1.5–4.8 | 31.6 | [96,97] |

| Platanus orientalis | 550 | 8.0–9.0 | 67.7–79.7 | 3.7–5.8 | 0.6–1.5 | 9.7 19.3 | - | - | - | - | 3.6–13.2 | - | [75] |

| Poplar (Populus sp.) wood | 300–800 | 8.1–8.2 | 43.8–81.1 | 1.5–3.9 | 0.4–2.8 | 12.3–51.1 | 0.06–0.20 | 0.66–0.92 | 0.96–1.22 | 0.13–0.16 | 32.9 | 20.0–56.0 | [102,105] |

| Rape (B. napus) stalk | 550 | 9.5–9.7 | 64.1–70.1 | 4.1–7.0 | 0.6–2.0 | 7.9–14.7 | - | - | - | - | 10.1–19.5 | - | [75] |

| Rapeseed (B. napus) straw | 300–800 | - | 55.4–65.0 | 1.3– 5.6 | 3.3 –3.9 | 30.1–36.3 | - | - | - | - | 27.8–45.1 | 21.0–38.0 | [105] |

| Rice (Oryza sativa) husk | 350–800 | 5.1–9.6 | 38.8–47.8 | 0.3–5.1 | 0.2–0.8 | 2.7–40.4 | - | - | - | - | 14.5 | 65.4–94.4 | [48,69] |

| Rice (O. sativa) straw | 250–900 | 6.8–11.1 | 29.2–88.7 | 0.3–5.1 | 0.1–1.9 | 2.6–26.4 | 0.01–5.42 | 1.56–4.80 | 0.49–13.3 | 0.81–1.13 | 10.7–52.0 | 8.8–50.1 | [48,62,63,81,100,101,102,103,104,105,106,107,108,109,110,111] |

| Salix babylonica | 550 | - | 66.0–77.2 | 2.2–4.9 | 0.4–1.7 | 10.7–22.1 | - | - | - | - | 6.4–10.0 | - | [75] |

| Shea nut (Vitellaria paradoxa) shell | 600 | - | 61.3 | 4.7 | 0.7 | 32.3 | 0.08 | 0.78 | 0.23 | 0.14 | - | 43.6 | [53] |

| Soybean (Glycine max) straw | 300–700 | 7.7–11.1 | 54.1–62.6 | - | 0.1–3.6 | - | 0.27–0.72 | - | - | - | - | - | [63] |

| Soybean (G. max) stover | 300–700 | 7.3–11.3 | 68.8–82.0 | 1.3–4.3 | 1.3–1.9 | 15.5–25.0 | - | - | - | - | 10.4–17.2 | 21.6–37.0 | [95] |

| Sugarcane bagasse (Saccharum officinarum) | 300–750 | 5.0–9.7 | 57.0–90.5 | 1.4–5.2 | 0.3–1.6 | 4.3–26.7 | 0.05–0.42 | 0.15–1.85 | 0.10–0.91 | 0.11–0.21 | 2.0–23.6 | 26.9–41.5 | [59,67,73,76,80,82,89,112,113,114] |

| Sunflower (Helianthus annuus) husk | 550 | 10.3 | 78.0 | 3.4 | 0.6 | 12.0 | - | - | - | - | 5.6 | - | [65] |

| Sweet sorghum (Sorghum bicolor) stalk | 600 | - | 74.9 | 2.9 | 0.5 | 21.0 | 0.60 | 0.16 | 0.14 | 0.35 | - | 27.1 | [53] |

| Teak (Tectona grandis) sawdust | 400–700 | - | 71.7–81.6 | 2.1–4.0 | 1.2–1.4 | 14.9–23.2 | - | - | - | - | 7.5–12.2 | 26.5–37.4 | [115] |

| Walnut (Juglans sp.) shell | 250–800 | 6.0–9.9 | 24.1–91.6 | 1.4–5.7 | 0.5–0.9 | 1.7–35.0 | 0.20 | 0.16 | 6.01 | 0.42 | 1.1–10.1 | 22.7–40.5 | [45,46,58,96] |

| Wheat (Triticum aestivum) stalk | 550 | 9.3–9.5 | 53.0–58.8 | 4.2–5.0 | 0.9–1.2 | 7.6–14.2 | - | - | - | - | 21.5–33.1 | - | [75] |

| Wheat (T. aestivum) straw | 300–800 | 7.2–9.4 | 38.5–78.6 | 1.2–4.6 | 0.2–2.3 | 14.6–34.5 | 0.10–0.34 | 0.59–3.60 | 0.11–2.08 | 0.21–0.69 | 8.1–46.0 | 22.8–33.4 | [35,65,79,80,84,93,100,109,116] |

| Willow (Salix sp.) wood chip | 450–650 | 7.3–9.8 | 78.4–84.8 | 1.1–2.0 | 0.8–1.0 | - | - | 0.57 | - | 0.23 | 4.3–5.4 | - | [117,118] |

2.3. Properties of Biochar from Biomass

3. Biochar and Microbial Interactions for Enhancing Brassica Crop Productivity

4. Environmental and Economic Benefits of Biochar Application

5. Potential and Limitations

| Impact | Biochar a | Microorganisms b |

|---|---|---|

| Potential |

|

Plants increased their tolerance to salt stress, drought stress, and heavy metal (Zn, Cd, Cu, Fe, Pb) stress;

Enterobacter cloacae protected against Fusarium wilt (Fusarium oxysporum) in Spinacia oleracea; Streptomyces sp. protected against root-lesion nematode (Pratylenchus penetrans) in Medicago sativa; Fusarium equiseti and Glomus mosseae protected against anthracnose (Colletotrichum orbiculare) and damping off (Rhizoctonia solani) in Cucumis sativus;

|

| Limitations |

|

|

6. Future Perspectives and Interesting Driving Issues

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Card, S.D.; Hume, D.E.; Roodi, D.; McGill, C.R.; Millner, J.P.; Johnson, R.D. Beneficial endophytic microorganisms of Brassica–A review. Biol. Control 2015, 90, 102–112. [Google Scholar] [CrossRef]

- The Food and Agriculture Organization (FAO). Available online: https://www.fao.org/faostat/en/#home (accessed on 4 November 2024).

- Subramanian, P.; Kim, S.H.; Hahn, B.S. Brassica biodiversity conservation: Prevailing constraints and future avenues for sustainable distribution of plant genetic resources. Front. Plant Sci. 2023, 14, 1220134. [Google Scholar] [CrossRef] [PubMed]

- Ayadi, J.; Debouba, M.; Rahmani, R.; Bouajila, J. Brassica genus seeds: A review on phytochemical screening and pharmacological properties. Molecules 2022, 27, 6008. [Google Scholar] [CrossRef]

- Le, T.N.; Chiu, C.H.; Hsieh, P.C. Bioactive compounds and bioactivities of Brassica oleracea L. var. italica sprouts and microgreens: An updated overview from a nutraceutical perspective. Plants 2020, 9, 946. [Google Scholar] [CrossRef]

- Friedt, W.; Tu, J.; Fu, T. Academic and economic importance of Brassica napus Rapeseed. In The Brassica napus Genome. Compendium of Plant Genomes; Liu, S., Snowdon, R., Chalhoub, B., Eds.; Springer: Cham, Switzerland, 2018; pp. 1–20. ISBN 978-3-319-43694-4. [Google Scholar]

- Zandberg, J.D.; Fernandez, C.T.; Danilevicz, M.F.; Thomas, W.J.; Edwards, D.; Batley, J. The global assessment of oilseed Brassica crop species yield, yield stability and the underlying genetics. Plants 2022, 11, 2740. [Google Scholar] [CrossRef]

- Bolan, S.; Sharma, S.; Mukherjee, S.; Kumar, M.; Rao, C.S.; Nataraj, K.C.; Singh, G.; Vinu, A.; Bhowmik, A.; Sharma, H.; et al. Biochar modulating soil biological health: A review. Sci. Total Environ. 2023, 914, 169585. [Google Scholar] [CrossRef] [PubMed]

- Amalina, F.; Abd Razak, A.S.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Biochar production techniques utilizing biomass waste-derived materials and environmental applications–A review. J. Hazard. Mater. Adv. 2022, 7, 100134. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Khan, S.; Irshad, S.; Mehmood, K.; Hasnain, Z.; Nawaz, M.; Rais, A.; Gul, S.; Wahid, M.A.; Hashem, A.; Abd_Allah, E.F.; et al. Biochar production and characteristics, its impacts on soil health, crop production, and yield enhancement: A review. Plants 2024, 13, 166. [Google Scholar] [CrossRef] [PubMed]

- Rehrah, D.; Reddy, M.R.; Novak, J.M.; Bansode, R.R.; Schimmel, K.A.; Yu, J.; Watts, D.W.; Ahmedna, M. Production and characterization of biochars from agricultural by-products for use in soil quality enhancement. J. Anal. Appl. Pyrolysis. 2014, 108, 301–309. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Hussain, Q.; Usman, A.R.; Ahmad, M.; Abduljabbar, A.; Sallam, A.S.; Ok, Y.S. Impact of biochar properties on soil conditions and agricultural sustainability: A review. Land Degrad. Dev. 2018, 29, 2124–2161. [Google Scholar] [CrossRef]

- Qambrani, N.A.; Rahman, M.M.; Won, S.; Shim, S.; Ra, C. Biochar properties and eco-friendly applications for climate change mitigation, waste management, and wastewater treatment: A review. Renew. Sustain. Energy Rev. 2017, 79, 255–273. [Google Scholar] [CrossRef]

- Haddad, N.; Al Tawaha, A.R.; Alassaf, R.; Alkhoury, W.; Abusalem, M.; Al-Sharif, R. Sustainable agriculture in jordan–a review for the potential of biochar from agricultural waste for soil and crop improvement. J. Ecol. Eng. 2024, 25, 190–202. [Google Scholar] [CrossRef]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar role in the sustainability of agriculture and environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Hnini, M.; Rabeh, K.; Oubohssaine, M. Interactions between beneficial soil microorganisms (PGPR and AMF) and host plants for environmental restoration: A systematic review. Plant Stress 2024, 100391. [Google Scholar] [CrossRef]

- Qi, W.Y.; Chen, H.; Wang, Z.; Xing, S.F.; Song, C.; Yan, Z.; Wang, S.G. Biochar-immobilized Bacillus megaterium enhances Cd immobilization in soil and promotes Brassica chinensis growth. J. Hazard. Mater. 2023, 458, 131921. [Google Scholar] [CrossRef] [PubMed]

- Tripti Kumar, A.; Maleva, M.; Borisova, G.; Rajkumar, M. Amaranthus biochar-based microbial cell composites for alleviation of drought and cadmium stress: A novel bioremediation approach. Plants 2023, 12, 1973. [Google Scholar] [CrossRef] [PubMed]

- Jatuwong, K.; Aiduang, W.; Kiatsiriroat, T.; Kamopas, W.; Lumyong, S. Effects of biochar and arbuscular mycorrhizal fungi on soil health in Chinese kale (Brassica oleracea var. alboglabra L.) cultivation. Microbiol. Res. 2024, 15, 404–421. [Google Scholar] [CrossRef]

- Brigham, C. Biopolymers: Biodegradable alternatives to traditional plastics. In Green Chemistry; Elsevier: Amsterdam, The Netherlands, 2018; pp. 753–770. [Google Scholar]

- Collard, F.X.; Blin, J. A review on pyrolysis of biomass constituents: Mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Vanholme, R.; Demedts, B.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin biosynthesis and structure. Plant Physiol. 2010, 153, 895–905. [Google Scholar] [CrossRef]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Visser, E.D.; Seroka, N.S.; Khotseng, L. Recent advances in biochar: Synthesis techniques, properties, applications, and hydrogen production. Processes 2024, 12, 1111. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353. [Google Scholar]

- Pahnila, M.; Koskela, A.; Sulasalmi, P.; Fabritius, T. A review of pyrolysis technologies and the effect of process parameters on biocarbon properties. Energies 2023, 16, 6936. [Google Scholar] [CrossRef]

- Piloni, R.V.; Brunetti, V.; Urcelay, R.C.; Daga, I.C.; Moyano, E.L. Chemical properties of biosilica and bio-oil derived from fast pyrolysis of Melosira varians. J. Anal. Appl. Pyrolysis. 2017, 127, 402–410. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, P.; Liu, S.; Peng, P.; Min, M.; Cheng, Y.; Anderson, E.; Zhou, N.; Fan, L.; Liu, C.; et al. Effects of feedstock characteristics on microwave-assisted pyrolysis–a review. Bioresour. Technol. 2017, 230, 143–151. [Google Scholar] [CrossRef] [PubMed]

- Yorgun, S.; Yıldız, D. Slow pyrolysis of paulownia wood: Effects of pyrolysis parameters on product yields and bio-oil characterization. J. Anal. Appl. Pyrolysis. 2015, 114, 68–78. [Google Scholar] [CrossRef]

- Papari, S.; Hawboldt, K. A review on the pyrolysis of woody biomass to bio-oil: Focus on kinetic models. Renew. Sustain. Energy Rev. 2015, 52, 1580–1595. [Google Scholar] [CrossRef]

- Chen, P.; Xie, Q.; Addy, M.; Zhou, W.; Liu, Y.; Wang, Y.; Cheng, Y.; Li, K.; Ruan, R. Utilization of municipal solid and liquid wastes for bioenergy and bioproducts production. Bioresour. Technol. 2016, 215, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Pittman Jr, C.U.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Dang, T.; Mosley, L.M.; Fitzpatrick, R.; Marschner, P. Organic materials differ in ability to remove protons, iron and aluminium from acid sulfate soil drainage water. Water Air Soil Poll. 2015, 226. [Google Scholar] [CrossRef]

- Yadav, S.P.S.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar application: A sustainable approach to improve soil health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar]

- Riseh, R.S.; Vazvani, M.G.; Hassanisaadi, M.; Thakur, V.K. Agricultural wastes: A practical and potential source for the isolation and preparation of cellulose and application in agriculture and different industries. Ind. Crop. Prod. 2024, 208, 117904. [Google Scholar] [CrossRef]

- Adhikari, S.; Nam, H.; Chakraborty, J.P. Conversion of solid wastes to fuels and chemicals through pyrolysis. Waste Biorefin. 2018, 239–263. [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Adejumo, I.O.; Adebiyi, O.A. Agricultural solid wastes: Causes, effects, and effective management. In Strategies of Sustainable Solid Waste Management; Saleh, H.M., Ed.; Intech Open: London, UK, 2020. [Google Scholar]

- Voccia, D.; Lamastra, L. Unpacking the carbon balance: Biochar production from forest residues and its impact on sustainability. Energies 2024, 17, 4582. [Google Scholar] [CrossRef]

- Al Masud, M.A.; Shin, W.S.; Sarker, A.; Septian, A.; Das, K.; Deepo, D.M.; Iqbal, M.A.; Islam, A.R.M.T.; Malafaia, G. A critical review of sustainable application of biochar for green remediation: Research uncertainty and future directions. Sci. Total Environ. 2023, 166813. [Google Scholar] [CrossRef] [PubMed]

- Ibitoye, S.E.; Loha, C.; Mahamood, R.M.; Jen, T.C.; Alam, M.; Sarkar, I.; Das, P.; Akinlabi, E.T. An overview of biochar production techniques and application in iron and steel industries. Bioresour. Bioprocess. 2024, 11, 65. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Calero, J.M.; Barrón, V.; Torrent, J.; del Campillo, M.C.; Gallardo, A.; Villar, R. Effects of biochars produced from different feedstocks on soil properties and sunflower growth. J. Plant Nutr. Soil Sci. 2014, 177, 16–25. [Google Scholar] [CrossRef]

- Fetjah, D.; Ainlhout, L.F.E.; Ihssane, B.; Houari, A.; Idardare, Z.; Bouqbis, L. Biological, physico-chemical and morphological analyses of four biochars derived from agricultural waste. J. Ecol. Eng. 2021, 22, 36–46. [Google Scholar] [CrossRef]

- McCaffrey, Z.; Torres, L.F.; Chiou, B.S.; Hart-Cooper, W.; McMahan, C.; Orts, W.J. Almond and Walnut Shell Activated Carbon for Methylene Blue Adsorption. ACS Sustain. Chem. Eng. 2024, 1, 1421–1431. [Google Scholar] [CrossRef]

- Zabaleta, R.; Sánchez, E.; Fabani, P.; Mazza, G.; Rodriguez, R. Almond shell biochar: Characterization and application in soilless cultivation of Eruca sativa. Biomass Convers. Biorefin. 2024, 14, 18183–18200. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Park, J.H.; Ok, Y.S.; Kim, S.H.; Kang, S.W.; Cho, J.S.; Heo, J.S.; Delaune, R.D.; Seo, D.C. Characteristics of biochars derived from fruit tree pruning wastes and their effects on lead adsorption. J. Korean Soc. Appl. Biol. Chem. 2015, 58, 751–760. [Google Scholar] [CrossRef]

- Zhao, S.X.; Ta, N.; Wang, X.D. Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef]

- Mohammed, I.Y.; Abakr, Y.A.; Hui, J.N.X.; Alaba, P.A.; Morris, K.I.; Ibrahim, M.D. Recovery of clean energy precursors from Bambara groundnut waste via pyrolysis: Kinetics, products distribution and optimisation using response surface methodology. J. Clean. Prod. 2017, 164, 1430–1445. [Google Scholar] [CrossRef]

- Musa, M.; Alhassan, J.; Yakub, M.I.; Abdalla, A.Y.; Kabir, K.F.; Suzana, Y.; Festo, M.; Ibraheem, A.; Sean, M.; Soh Aik, C.; et al. The influence of Bambara groundnut shells biochar on the early growth of sweet corn variety in the sub-humid tropics. Direct Res. J. Agric. Food Sci. 2021, 9, 198–205. [Google Scholar]

- Ibrahim, M.D.; Abakr, Y.A.; Gan, S.; Thangalazhy-Gopakumar, S. Physicochemical analysis and intermediate pyrolysis of bambara groundnut shell (BGS), sweet sorghum stalk (SSS), and shea nutshell (SNS). Environ. Technol. 2024, 45, 1870–1883. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Gao, B.; Zhang, M.; Inyang, M.; Zimmerman, A.R. Effect of biochar amendment on sorption and leaching of nitrate, ammonium, and phosphate in a sandy soil. Chemosphere 2012, 89, 1467–1471. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Yang, H.; Li, K.; Chen, X.; Chen, H. Investigation on biomass nitrogen-enriched pyrolysis: Influence of temperature. Bioresour. Technol. 2018, 249, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Masís-Meléndez, F.; Segura-Chavarría, D.; García-González, C.A.; Quesada-Kimsey, J.; Villagra-Mendoza, K. Variability of physical and chemical properties of TLUD stove derived biochars. Appl. Sci. 2020, 10, 507. [Google Scholar] [CrossRef]

- Sahoo, S.S.; Vijay, V.K.; Chandra, R.; Kumar, H. Production and characterization of biochar produced from slow pyrolysis of pigeon pea stalk and bamboo. Clean. Eng. Technol. 2021, 3, 100101. [Google Scholar] [CrossRef]

- Wystalska, K.; Kwarciak-Kozłowska, A. The effect of biodegradable waste pyrolysis temperatures on selected biochar properties. Materials 2021, 14, 1644. [Google Scholar] [CrossRef] [PubMed]

- Peterson, S.C.; Chandrasekaran, S.R.; Sharma, B.K. Birchwood biochar as partial carbon black replacement in styrene–butadiene rubber composites. J. Elastomers Plast. 2015, 48, 305–316. [Google Scholar] [CrossRef]

- Zama, E.F.; Zhu, Y.G.; Reid, B.J.; Sun, G.X. The role of biochar properties in influencing the sorption and desorption of Pb (II), Cd (II) and As (III) in aqueous solution. J. Clean. Prod. 2017, 148, 127–136. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Physico-chemistry of biochars produced through steam gasification and hydro-thermal gasification of canola hull and canola meal pellets. Biomass Bioenergy 2019, 120, 458–470. [Google Scholar] [CrossRef]

- Yang, C.; Liu, J.; Lu, S. Pyrolysis temperature affects pore characteristics of rice straw and canola stalk biochars and biochar-amended soils. Geoderma 2021, 397, 115097. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, R.K.; Zhang, H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, H.; Chang, E.; Zhao, Z.; Wang, R.; Xu, R.; Jiang, J. Alleviation of aluminum phytotoxicity by canola straw biochars varied with their cultivating soils through an investigation of wheat seedling root elongation. Chemosphere 2019, 218, 907–914. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.M.; Shariff, A.; Abdullah, N.; Aziz, N.M. Temperature effect on biochar properties from slow pyrolysis of coconut flesh waste. Mal. J. Fund. Appl. Sci. 2019, 15, 153–158. [Google Scholar] [CrossRef]

- Bednik, M.; Medyńska-Juraszek, A.; Ćwieląg-Piasecka, I. Effect of six different feedstocks on biochar’s properties and expected stability. Agronomy 2022, 12, 1525. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; Melo, I.C.N.D.; Melo, L.C.; Magriotis, Z.M.; Sánchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef] [PubMed]

- Mullen, C.A.; Boateng, A.A.; Goldberg, N.M.; Lima, I.M.; Laird, D.A.; Hicks, K.B. Bio-oil and bio-char production from corn cobs and stover by fast pyrolysis. Biomass Bioenergy 2010, 34, 67–74. [Google Scholar] [CrossRef]

- Obia, A.; Mulder, J.; Martinsen, V.; Cornelissen, G.; Børresen, T. In situ effects of biochar on aggregation, water retention and porosity in light-textured tropical soils. Soil Tillage Res. 2016, 155, 35–44. [Google Scholar] [CrossRef]

- Pahla, G.; Mamvura, T.A.; Ntuli, F.; Muzenda, E. Energy densification of animal waste lignocellulose biomass and raw biomass. S. Afr. J. Chem. Eng. 2017, 24, 168–175. [Google Scholar] [CrossRef]

- Rattanaphaiboon, P.; Homdoung, N.; Tippayawong, N. Production and characterization of corncob biochar for agricultural use. In AIP Conference Proceedings, Proceedings of the 3rd International Conference on Energy and Power, ICEP2021, Chiang Mai, Thailand, 18–20 November 2021; AIP Publishing: Melville, NY, USA, 2022; pp. 020034-1–020034-6. [Google Scholar]

- Pinky, N.S.; Mobarak, M.B.; Mustafi, S.; Rahman, M.Z.; Nahar, A.; Saha, T.; Bahadur, N.M. Facile preparation of micro-porous biochar from Bangladeshi sprouted agricultural waste (corncob) via in-house built heating chamber for cationic dye removal. Arab. J. Chem. 2023, 16, 105080. [Google Scholar] [CrossRef]

- Hayat, Z.; Baig, S.A.; Shams, D.F.; Javed, H.A.; Xu, X.; Danish, M. Insights into the effects of pyrolysis parameters on biochar synthesis from green wastes and its As (III) removal efficiency. Int. J. Environ. Sci. Technol. 2024, 21, 895–908. [Google Scholar] [CrossRef]

- Rombolà, A.G.; Marisi, G.; Torri, C.; Fabbri, D.; Buscaroli, A.; Ghidotti, M.; Hornung, A. Relationships between chemical characteristics and phytotoxicity of biochar from poultry litter pyrolysis. J. Agric. Food Chem. 2015, 63, 6660–6667. [Google Scholar] [CrossRef]

- Yang, F.; Lee, X.; Wang, B. Characterization of biochars produced from seven biomasses grown in three different climate zones. Chin. J. Geochem. 2015, 34, 592–600. [Google Scholar] [CrossRef]

- Qadir, M.F.; Naveed, M.; Khan, K.S.; Mumtaz, T.; Raza, T.; Mohy-Ud-Din, W.; Mustafa, A. Divergent responses of phosphorus solubilizing bacteria with P-laden biochar for enhancing nutrient recovery, growth, and yield of canola (Brassica napus L.). Chemosphere 2024, 353, 141565. [Google Scholar] [CrossRef]

- Chen, X.; Kuhn, E.; Jennings, E.W.; Nelson, R.; Tao, L.; Zhang, M.; Tucker, M.P. DMR (deacetylation and mechanical refining) processing of corn stover achieves high monomeric sugar concentrations (230 g L−1) during enzymatic hydrolysis and high ethanol concentrations (>10% v/v) during fermentation without hydrolysate purification or concentration. Energy Environ. Sci. 2016, 9, 1237–1245. [Google Scholar]

- Rafiq, M.K.; Bachmann, R.T.; Rafiq, M.T.; Shang, Z.; Joseph, S.; Long, R. Influence of pyrolysis temperature on physico-chemical properties of corn stover (Zea mays L.) biochar and feasibility for carbon capture and energy balance. PLoS ONE 2016, 11, e0156894. [Google Scholar] [CrossRef] [PubMed]

- Gai, X.; Wang, H.; Liu, J.; Zhai, L.; Liu, S.; Ren, T.; Liu, H. Effects of feedstock and pyrolysis temperature on biochar adsorption of ammonium and nitrate. PLoS ONE 2014, 9, e113888. [Google Scholar] [CrossRef]

- Sun, J.; Lian, F.; Liu, Z.; Zhu, L.; Song, Z. Biochars derived from various crop straws: Characterization and Cd(II) removal potential. Ecotoxicol. Environ. Saf. 2014, 106, 226–231. [Google Scholar] [CrossRef] [PubMed]

- Lian, F.; Sun, B.; Chen, X.; Zhu, L.; Liu, Z.; Xing, B. Effect of humic acid (HA) on sulfonamide sorption by biochars. Environ. Pollut. 2015, 204, 306–312. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Xu, C.; Chen, Z.; Zhang, S. Properties of biomass-derived biochars: Combined effects of operating conditions and biomass types. Bioresour. Technol. 2015, 192, 83–89. [Google Scholar] [CrossRef] [PubMed]

- Uchimiya, M.; Wartelle, L.H.; Klasson, K.T.; Fortier, C.A.; Lima, I.M. Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J. Agric. Food Chem. 2011, 59, 2501–2510. [Google Scholar] [CrossRef]

- Liu, L.; Liu, G.; Zhou, J.; Wang, J.; Jin, R.; Wang, A. Improved bioreduction of nitrobenzene by black carbon/biochar derived from crop residues. RSC Adv. 2016, 6, 84388–84396. [Google Scholar] [CrossRef]

- Usman, A.R.A.; Abduljabbar, A.; Vithanage, M.; Ok, Y.S.; Ahmad, M.; Ahmad, M.; Elfaki, J.; Abdulazeem, S.S.; Al-Wabel, M.I. Biochar production from date palm waste: Charring temperature induced changes in composition and surface chemistry. J. Anal. Appl. Pyrolysis. 2015, 115, 392–400. [Google Scholar] [CrossRef]

- Sun, L.; Wan, S.; Luo, W. Biochars prepared from anaerobic digestion residue, palm bark, and eucalyptus for adsorption of cationic methylene blue dye: Characterization, equilibrium, and kinetic studies. Bioresour. Technol. 2013, 140, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Singh, B.; Singh, B.P.; Krull, E. Biochar carbon stability in four contrasting soils. Eur. J. Soil Sci. 2014, 65, 60–71. [Google Scholar] [CrossRef]

- Marrot, L.; Candelier, K.; Valette, J.; Lanvin, C.; Horvat, B.; Legan, L.; DeVallance, D.B. Valorization of hemp stalk waste through thermochemical conversion for energy and electrical applications. Waste Biomass Valori. 2022, 1–19. [Google Scholar] [CrossRef]

- Wu, H.; Che, X.; Ding, Z.; Hu, X.; Creamer, A.E.; Chen, H.; Gao, B. Release of soluble elements from biochars derived from various bio mass feedstocks. Environ. Sci. Pollut. Res. 2016, 23, 1905–1915. [Google Scholar] [CrossRef]

- Ban, S.E.; Lee, E.J.; Lim, D.J.; Kim, I.S.; Lee, J.W. Evaluation of sulfuric acid-pretreated biomass-derived biochar characteristics and its diazinon adsorption mechanism. Bioresour. Technol. 2022, 348, 126828. [Google Scholar] [CrossRef]

- Takaya, C.A.; Fletcher, L.A.; Singh, S.; Anyikude, K.U.; Ross, A.B. Phosphate and ammonium sorption capacity of biochar and hydrochar from different wastes. Chemosphere 2016, 145, 518–527. [Google Scholar] [CrossRef] [PubMed]

- Chantanumat, Y.; Phetwarotai, W.; Sangthong, S.; Palamanit, A.; Abu Bakar, M.S.; Cheirsilp, B.; Phusunti, N. Characterization of bio-oil and biochar from slow pyrolysis of oil palm plantation and palm oil mill wastes. Biomass Convers. Biorefin. 2023, 13, 13813–13825. [Google Scholar] [CrossRef]

- Nanda, S.; Mohanty, P.; Pant, K.K.; Naik, S.; Kozinski, J.A.; Dalai, A.K. Characterization of North American lignocellulosic biomass and biochars in terms of their candidacy for alternate renewable fuels. Bioenergy Res. 2012, 6, 663–677. [Google Scholar] [CrossRef]

- Novak, J.M.; Lima, I.; Xing, B.; Gaskin, J.W.; Steiner, C.; Das, K.C.; Ahmedna, M.; Rehrah, D.; Watts, D.W.; Busscher, W.J.; et al. Characterization of designer biochar produced at different temperatures and their effects on a loamy sand. Ann. Environ. Sci. 2009, 3, 195–206. [Google Scholar]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef] [PubMed]

- Jeníček, L.; Tunklová, B.; Malaťák, J.; Velebil, J.; Malaťáková, J.; Neškudla, M.; Hnilička, F. The impact of nutshell biochar on the environment as an alternative fuel or as a soil amendment. Materials 2023, 16, 2074. [Google Scholar] [CrossRef]

- Konsolakis, M.; Kaklidis, N.; Marnellos, G.E.; Zaharaki, D.; Komnitsas, K. Assessment of biochar as feedstock in a direct carbon solid oxide fuel cell. RSC Adv. 2015, 5, 73399–73409. [Google Scholar] [CrossRef]

- Jeon, C.; Solis, K.L.; An, H.R.; Hong, Y.; Igalavithana, A.D.; Ok, Y.S. Sustainable removal of Hg (II) by sulfur-modified pine-needle biochar. J. Hazard. Mater. 2020, 388, 122048. [Google Scholar] [CrossRef]

- Sharma, A.K.; Ghodke, P.K.; Goyal, N.; Bobde, P.; Kwon, E.E.; Lin, K.Y.A.; Chen, W.H. A critical review on biochar production from pine wastes, upgradation techniques, environmental sustainability, and challenges. Bioresour. Technol. 2023, 387, 129632. [Google Scholar] [CrossRef] [PubMed]

- Ponomarev, K.; Pervushina, A.; Korotaeva, K.; Yurtaev, A.; Petukhov, A.; Tabakaev, R.; Shanenkov, I. Influence of biochar amendment obtained from organic wastes typical for Western Siberia on morphometric characteristics of plants and soil properties. Biomass Convers. Biorefin. 2023, 14, 28849–28860. [Google Scholar] [CrossRef]

- Brennan, A.; Jimenez, E.M.; Puschenreiter, M.; Alburquerque, J.A.; Switzer, C. Effects of biochar amendment on root traits and contaminant availability of maize plants in a copper and arsenic impacted soil. Plant Soil 2014, 379, 351–360. [Google Scholar] [CrossRef]

- Marks, E.A.N.; Mattana, S.; Alcañiz, J.M.; Domene, X. Biochars provoke diverse soil mesofauna reproductive responses in laboratory bioassays. Eur. J. Soil Biol. 2014, 60, 104–111. [Google Scholar] [CrossRef]

- Kupryianchyk, D.; Hale, S.; Zimmerman, A.R.; Harvey, O.; Rutherford, D.; Abiven, S.; Knicker, H.; Schmidt, H.P.; Rumpel, C.; Cornelissen, G. Sorption of hydrophobic organic compounds to a diverse suite of carbonaceous materials with emphasis on biochar. Chemosphere 2016, 144, 879–887. [Google Scholar] [CrossRef] [PubMed]

- Novak, J.; Sigua, G.; Watts, D.; Cantrell, K.; Shumaker, P.; Szogi, A.; Johnson, M.G.; Spokas, K. Biochars impact on water infiltration and water quality through a compacted subsoil layer. Chemosphere 2016, 142, 160–167. [Google Scholar] [CrossRef] [PubMed]

- Gheorghe-Bulmau, C.; Volceanov, A.; Stanciulescu, I.; Ionescu, G.; Marculescu, C.; Radoiu, M. Production and properties assessment of biochars from rapeseed and poplar waste biomass for environmental applications in Romania. Environ. Geochem. Health. 2022, 44, 1683–1696. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Zhang, P.; Zhao, L.; Sun, H. Sorption and degradation of carbaryl in soils amended with biochars: Influence of biochar type and content. Environ. Sci. Pollut. Res. 2015, 23, 2724–2734. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Gao, B.; Yao, Y.; Fang, J.; Zhang, M.; Zhou, Y.; Chen, H.; Yang, L. Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties. Chem. Eng. J. 2014, 240, 574–578. [Google Scholar] [CrossRef]

- Wu, W.; Yang, M.; Feng, Q.; McGrouther, K.; Wang, H.; Lu, H.; Chen, Y. Chemical characterization of rice straw-derived biochar for soil amendment. Biomass Bioenergy 2012, 47, 268–276. [Google Scholar] [CrossRef]

- Naeem, M.A.; Khalid, M.; Arshad, M.; Ahmad, R. Yield and nutrient composition of biochar produced from different feedstocks at varying pyrolytic temperatures. Pak. J. Agric. Sci. 2014, 51, 75–82. [Google Scholar]

- Yoo, G.; Kim, Y.J.; Lee, Y.O.; Ding, W. Investigation of green-house gas emissions from the soil amended with rice straw biochar. KSCE J. Civ. Eng. 2016, 20, 2197–2207. [Google Scholar] [CrossRef]

- Cen, K.; Zhang, J.; Ma, Z.; Chen, D.; Zhou, J.; Ma, H. Investigation of the relevance between biomass pyrolysis polygeneration and washing pretreatment under different severities: Water, dilute acid solution and aqueous phase bio-oil. Bioresour. Technol. 2019, 278, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Carrier, M.; Hardie, A.G.; Uras, Ü.; Görgens, J.; Knoetze, J.H. Production of char from vacuum pyrolysis of South-African sugar cane bagasse and its characterization as activated carbon and biochar. J. Anal. Appl. Pyrolysis. 2012, 96, 24–32. [Google Scholar] [CrossRef]

- Uras, Ü.; Carrier, M.; Hardie, A.G.; Knoetze, J.H. Physico-chemical characterization of biochars from vacuum pyrolysis of South African agricultural wastes for application as soil amendments. J. Anal. Appl. Pyrolysis 2012, 98, 207–213. [Google Scholar] [CrossRef]

- White, P.M.; Potter, T.L.; Lima, I.M. Sugarcane and pinewood biochar effects on activity and aerobic soil dissipation of metribuzin and pendimethalin. Ind. Crop. Prod. 2015, 74, 737–744. [Google Scholar] [CrossRef]

- Gupta, S.K. Brassicas. In Breeding Oilseed Crops for Sustainable Production; Gupta, S.K., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 33–53. ISBN 978-0-12-801309-0. [Google Scholar]

- Aon, M.; Aslam, Z.; Hussain, S.; Bashir, M.A.; Shaaban, M.; Masood, S.; Iqbal, S.; Khalid, M.; Rehim, A.; Mosa, W.F.A.; et al. Wheat straw biochar produced at a low temperature enhanced maize growth and yield by influencing soil properties of typic calciargid. Sustainability 2023, 15, 9488. [Google Scholar] [CrossRef]

- Prendergast-Miller, M.T.; Duvall, M.; Sohi, S.P. Biochar-root interactions are mediated by biochar nutrient content and impacts on soil nutrient availability. Eur. J. Soil Sci. 2014, 65, 173–185. [Google Scholar] [CrossRef]

- Nelissen, V.; Saha, B.K.; Ruysschaert, G.; Boeckx, P. Effect of different biochar and fertilizer types on N2O and NO emissions. Soil Biol. Biochem. 2014, 70, 244–255. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 2015, 176, 288–291. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.K.; Strezov, V.; Chan, K.Y.; Ziolkowski, A.; Nelson, P.F. Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J. Environ. Manag. 2011, 92, 223–228. [Google Scholar] [CrossRef]

- Kabir, E.; Kim, K.H.; Kwon, E.E. Biochar as a tool for the improvement of soil and environment. Front. Environ. Sci. 2023, 11, 1324533. [Google Scholar] [CrossRef]

- Luan, J.; Fu, Y.; Tang, W.; Yang, F.; Li, X.; Yu, Z. Impact of interaction between biochar and soil microorganisms on growth of Chinese cabbage by increasing soil fertility. Appl. Sci. 2023, 13, 12545. [Google Scholar] [CrossRef]

- Devereux, R.C.; Sturrock, C.J.; Mooney, S.J. The effects of biochar on soil physical properties and winter wheat growth. Earth Environ. Sci. Trans. 2012, 103, 13–18. [Google Scholar] [CrossRef]

- Basso, A.S.; Miguez, F.E.; Laird, D.A.; Horton, R.; Westgate, M. Assessing potential of biochar for increasing water-holding capacity of sandy soils. Gcb Bioenergy 2013, 5, 132–143. [Google Scholar] [CrossRef]

- Yin, C.; Lei, W.; Wang, S.; Xie, G.; Qiu, D. Biochar and arbuscular mycorrhizal fungi promote rapid-cycling Brassica napus growth under cadmium stress. Sci. Total Environ. 2024, 953, 176034. [Google Scholar] [CrossRef]

- Wei, T.; Li, X.; Li, H.; Gao, H.; Guo, J.; Li, Y.; Ren, X.; Hua, L.; Jia, H. The potential effectiveness of mixed bacteria-loaded biochar/activated carbon to remediate Cd, Pb co-contaminated soil and improve the performance of pakchoi plants. J. Hazard. Mater. 2022, 435, 129006. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.X.; Ding, K.; Yang, X.R.; Wadaan, M.A.; Hozzein, W.N.; Peñuelas, J.; Zhu, Y.G. Straw biochar increases the abundance of inorganic phosphate solubilizing bacterial community for better rape (Brassica napus) growth and phosphate uptake. Sci. Total Environ. 2019, 647, 1113–1120. [Google Scholar] [CrossRef]

- Širić, I.; Eid, E.M.; Taher, M.A.; El-Morsy, M.H.; Osman, H.E.; Kumar, P.; Adelodun, B.; Fayssal, S.A.; Mioč, B.; Andabaka, Z.; et al. Combined use of spent mushroom substrate biochar and PGPR improves growth, yield, and biochemical response of cauliflower (Brassica oleracea var. botrytis): A preliminary study on greenhouse cultivation. Horticulturae 2022, 8, 830. [Google Scholar] [CrossRef]

- Sabir, A.; Naveed, M.; Bashir, M.A.; Hussain, A.; Mustafa, A.; Zahir, Z.A.; Kamran, M.; Ditta, A.; Núñez-Delgado, A.; Saeed, Q.; et al. Cadmium mediated phytotoxic impacts in Brassica napus: Managing growth, physiological and oxidative disturbances through combined use of biochar and Enterobacter sp. MN17. J. Environ. Manag. 2020, 265, 110522. [Google Scholar] [CrossRef] [PubMed]

- Lalay, G.; Ullah, S.; Shah, S.; Jamal, A.; Saeed, M.F.; Mihoub, A.; Zia, A.; Ahmed, I.; Seleiman, M.F.; Mancinelli, R.; et al. Combined effect of biochar and plant growth-promoting Rhizbacteria on physiological responses of canola (Brassica napus L.) subjected to drought stress. J. Plant Growth Regul. 2024, 43, 1814–1832. [Google Scholar] [CrossRef]

- Cheng, C.; Luo, W.; Wang, Q.; He, L.; Sheng, X. Combined biochar and metal-immobilizing bacteria reduces edible tissue metal uptake in vegetables by increasing amorphous Fe oxides and abundance of Fe-and Mn-oxidising Leptothrix species. Ecotoxicol. Environ. Saf. 2020, 206, 111189. [Google Scholar] [CrossRef]

- Ghassemi-Golezani, K.; Abdoli, S. Alleviation of salt stress in rapeseed (Brassica napus L.) plants by biochar-based rhizobacteria: New insights into the mechanisms regulating nutrient uptake, antioxidant activity, root growth and productivity. Arch. Agron. Soil Sci. 2023, 69, 1548–1565. [Google Scholar] [CrossRef]

- Sun, X.; Wang, S.; Tian, J.; Xiang, X.; Zheng, H.; Liu, H.; Fang, Z.; Tian, Z.; Liu, L.; Zhu, Y.; et al. Synergistic interplay between ABA-generating bacteria and biochar in the reduction of heavy metal accumulation in radish, pakchoi, and tomato. Environ. Pollut. 2023, 333, 122084. [Google Scholar] [CrossRef] [PubMed]

- Losacco, D.; Tumolo, M.; Cotugno, P.; Leone, N.; Massarelli, C.; Convertini, S.; Tursi, A.; Uricchio, V.F.; Ancona, V. Use of biochar to improve the sustainable crop production of cauliflower (Brassica oleracea L.). Plants 2022, 11, 1182. [Google Scholar] [CrossRef] [PubMed]

- Carter, S.; Shackley, S.; Sohi, S.; Suy, T.B.; Haefele, S. The impact of biochar application on soil properties and plant growth of pot grown lettuce (Lactuca sativa) and cabbage (Brassica chinensis). Agronomy 2013, 3, 404–418. [Google Scholar] [CrossRef]

- Sun, H.; Jeyakumar, P.; Xiao, H.; Li, X.; Liu, J.; Yu, M.; Rana, P.B.J.; Shi, W. Biochar can increase Chinese cabbage (Brassica oleracea L.) yield, decrease nitrogen and phosphorus leaching losses in intensive vegetable soil. Phyton 2022, 91, 197. [Google Scholar] [CrossRef]

- Shoudho, K.N.; Khan, T.H.; Ara, U.R.; Khan, M.R.; Shawon, Z.B.Z.; Hoque, M.E. Biochar in global carbon cycle: Towards sustainable development goals. Curr. Res. Green Sustain. Chem. 2024, 8, 100409. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for environmental management: An introduction. In Biochar for Environmental Management; Routledge: London, UK, 2015; pp. 1–13. [Google Scholar]

- Zhang, C.; Lin, Y.; Tian, X.; Xu, Q.; Chen, Z.; Lin, W. Tobacco bacterial wilt suppression with biochar soil addition associates to improved soil physiochemical properties and increased rhizosphere bacteria abundance. App. Soil Ecol. 2017, 112, 90–96. [Google Scholar] [CrossRef]

- El-Naggar, A.; Lee, S.S.; Awad, Y.M.; Yang, X.; Ryu, C.; Rizwan, M.; Rinklebe, J.; Tsang, D.C.W.; Ok, Y.S. Influence of soil properties and feedstocks on biochar potential for carbon mineralization and improvement of infertile soils. Geoderma 2018, 332, 100–108. [Google Scholar] [CrossRef]

- Schnitkey, G.; Paulson, N.; Swanson, K.; Baltz, J. Fertilizer prices, rates, and costs for 2023. Farmdoc Dly. 2022, 12, 148. [Google Scholar]

- Zhang, P.; Duan, W.; Peng, H.; Pan, B.; Xing, B. Functional biochar and its balanced design. ACS Environ. Au 2021, 2, 115–127. [Google Scholar] [CrossRef]

- Hu, W.; Di, Q.; Liang, T.; Liu, J.; Zhang, J. Effects of spent mushroom substrate biochar on growth of oyster mushroom (Pleurotus ostreatus). Environ. Technol. Innov. 2022, 28, 102729. [Google Scholar] [CrossRef]

- Pandian, K.; Vijayakumar, S.; Mustaffa, M.R.A.F.; Subramanian, P.; Chitraputhirapillai, S. Biochar–a sustainable soil conditioner for improving soil health, crop production and environment under changing climate: A review. Front. Soil Sci. 2024, 4, 1376159. [Google Scholar] [CrossRef]

- Kumari, K.; Kumar, R.; Bordoloi, N.; Minkina, T.; Keswani, C.; Bauddh, K. Unravelling the recent developments in the production technology and efficient applications of biochar for agro-ecosystems. Agriculture 2023, 13, 512. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Wei, Q.; Liu, L.; Gu, X.; Gou, J.; Wang, M. Chemical fertilizer reduction combined with biochar application ameliorates the biological property and fertilizer utilization of pod pepper. Agron. 2023, 13, 1616. [Google Scholar] [CrossRef]

- Waheed, A.; Xu, H.; Qiao, X.; Aili, A.; Yiremaikebayi, Y.; Haitao, D.; Muhammad, M. Biochar in sustainable agriculture and Climate Mitigation: Mechanisms, challenges, and applications in the circular bioeconomy. Biomass BioEnergy 2025, 193, 107531. [Google Scholar] [CrossRef]

- Sharma, P. Biochar application for sustainable soil erosion control: A review of current research and future perspectives. Front. Environ. Sci. 2024, 12, 1373287. [Google Scholar] [CrossRef]

- Premalatha, R.P.; Poorna Bindu, J.; Nivetha, E.; Malarvizhi, P.; Manorama, K.; Parameswari, E.; Davamani, V. A review on biochar’s effect on soil properties and crop growth. Front. Energy Res. 2023, 11, 1092637. [Google Scholar] [CrossRef]

- Nepal, J.; Ahmad, W.; Munsif, F.; Khan, A.; Zou, Z. Advances and prospects of biochar in improving soil fertility, biochemical quality, and environmental applications. Front. Environ. Sci. 2023, 11, 1114752. [Google Scholar] [CrossRef]

- Antoszewski, M.; Mierek-Adamska, A.; Dąbrowska, G.B. The importance of microorganisms for sustainable agriculture—A review. Metabolites 2022, 12, 1100. [Google Scholar] [CrossRef]

- Samac, D.A.; Kinkel, L.L. Suppression of the root-lesion nematode (Pratylenchus penetrans) in alfalfa (Medicago sativa) by Strepto myces spp. Plant Soil 2001, 235, 35–44. [Google Scholar] [CrossRef]

- Tsuda, K.; Kosaka, Y.; Tsuge, S.; Kub, Y.; Horin, O. Evaluation of the endophyte Enterobacter cloacae SM10 isolated from spinach roots for biological control against Fusarium wilt of spinach. J. Gen. Plant Pathol. 2001, 67, 78–84. [Google Scholar] [CrossRef]

- Kavitha, B.; Reddy, P.V.L.; Kim, B.; Lee, S.S.; Pandey, S.K.; Kim, K.H. Benefits and limitations of biochar amendment in agricultural soils: A review. J. Environ. Manag. 2018, 227, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, H.; Kashyap, V.H.; Mishra, A.; Bordoloi, S.; Singh, P.K.; Joshi, N.C. Biochar-based fertilizers and their applications in plant growth promotion and protection. 3 Biotech 2022, 12, 136. [Google Scholar] [CrossRef]

- Das, S.K.; Choudhury, B.U.; Hazarika, S.; Mishra, V.K.; Laha, R. Long-term effect of organic fertilizer and biochar on soil carbon fractions and sequestration in maize-black gram system. Biomass Convers. Biorefin. 2023, 1–14. [Google Scholar] [CrossRef]

- Bo, X.; Zhang, Z.; Wang, J.; Guo, S.; Li, Z.; Lin, H.; Huang, Y.; Han, Z.; Kuzyakov, Y.; Zou, J. Benefits and limitations of biochar for climate-smart agriculture: A review and case study from China. Biochar 2023, 5, 77. [Google Scholar] [CrossRef]

- de Araujo Avila, G.M.; Gabardo, G.; Clock, D.C.; de Lima Junior, O.S. Use of efficient microorganisms in agriculture. Res., Soc. Dev. 2021, 10, e40610817515. [Google Scholar] [CrossRef]

- O’Callaghan, M.; Ballard, R.A.; Wright, D. Soil microbial inoculants for sustainable agriculture: Limitations and opportunities. Soil Use Manag. 2022, 38, 1340–1369. [Google Scholar] [CrossRef]

- Nadeem, S.M.; Naveed, M.; Ayyub, M.; Khan, M.Y.; Ahmad, M.; Zahir, Z.A. Potential, limitations and future prospects of Pseudomonas spp. for sustainable agriculture and environment: A Review. Soil Environ. 2016, 35, 106–145. [Google Scholar]

- Wang, L.; O’Connor, D.; Rinklebe, J.; Ok, Y.S.; Tsang, D.C.; Shen, Z.; Hou, D. Biochar aging: Mechanisms, physicochemical changes, assessment, and implications for field applications. Environ. Sci. Technol. 2020, 54, 14797–14814. [Google Scholar] [CrossRef] [PubMed]

- Devi, P.; Saroha, A.K. Risk analysis of pyrolysed biochar made from paper mill effluent treatment plant sludge for bioavailability and eco-toxicity of heavy metals. Bioresour. Technol. 2014, 162, 308–315. [Google Scholar] [CrossRef]

- Li, C.B.; Zhang, J.Q.; Chen, X.; Zhang, J.G.; Zhai, X.; Lin, A.F. Effect of biochar application on soil health and its potential risks to flue-cured tobacco production. Chin. Tob. Sci. 2018, 39, 91–97. [Google Scholar]

- Qin, Y.X.; Li, G.; Gao, Y.; Zhang, L.; Ok, Y.S.; An, T. Persistent free radicals in carbon-based materials on transformation of refractory organic contaminants (ROCs) in water: A critical review. Water Res. 2018, 137, 130–143. [Google Scholar] [CrossRef]

- Buss, W.; Hilber, I.; Graham, M.C.; Mašek, O. Composition of PAHs in biochar and implications for biochar production. ACS Sustain. Chem. Eng. 2022, 10, 6755–6765. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, J.; Tang, G.; Bao, D.; Wang, T.; Kong, D. Impacts and mechanisms of biochar on soil microorganisms. Plant Soil Environ. 2023, 69, 45–54. [Google Scholar] [CrossRef]

- Sigmund, G.; Huber, D.; Bucheli, T.D.; Baumann, M.; Borth, N.; Guebitz, G.M.; Hofmann, T. Cytotoxicity of biochar: A workplace safety concern? Environ. Sci. Technol. Lett. 2017, 4, 362–366. [Google Scholar] [CrossRef]

- Wang, C.; Luo, D.; Zhang, X.; Huang, R.; Cao, Y.; Liu, G.; Zhange, Y.; Wang, H. Biochar-based slow-release of fertilizers for sustainable agriculture: A mini review. Environ. Sci. Ecotechnol. 2022, 10, 100167. [Google Scholar] [CrossRef]

- Guo, M. The 3R principles for applying biochar to improve soil health. Soil Syst. 2020, 4, 9. [Google Scholar] [CrossRef]

- Mohammadi, A. Overview of the benefits and challenges associated with pelletizing biochar. Processes 2021, 9, 1591. [Google Scholar] [CrossRef]

- Suriyawong, P.; Chuetor, S.; Samae, H.; Piriyakarnsakul, S.; Amin, M.; Furuuchi, M.; Hata, M.; Inerb, M.; Phairuang, W.; Phairuang, W. Airborne particulate matter from biomass burning in Thailand: Recent issues, challenges, and options. Heliyon 2023, 9, e14261. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Zhang, Y.; Fang, J.; Ma, Z.; Li, C.; Yan, M.; Qiao, N.; Liu, Y.; Bian, M. Reduction and reuse of forestry and agricultural bio-waste through innovative green utilization approaches: A review. Forests 2024, 15, 1372. [Google Scholar] [CrossRef]

- Atmosphere Monitoring Service. Tropical Fire Season in The Northern Hemisphere: How Did 2020 Compare to Previous Years? Available online: https://atmosphere.copernicus.eu/tropical-fire-season-northern-hemisphere-how-did-2020-compare-previous-years (accessed on 20 January 2025).

| Biochar Materials | Microbes | Species | Brassica Crops | Synergistic Impact | Sources |

|---|---|---|---|---|---|

| Bamboo (Bambusa sp.) | Fungi | AMF | Brassica oleracea var. alboglabra |

| [20] |

| Fungi | AMF | B. napus |

| [125] | |

| Corncob (Z. mays) | Bacteria | Ochrobactrum sp. Bacillus mucilaginosus | B. rapa |

| [122] |

| Amaranthus | Bacteria | Serratia sp. Pseudomonas sp. | B. napus |

| [19] |

| Bacteria | Enterobacter asburiae, Enterobacter tabaci, and Klebsiella variicola in a 1:3:3 proportion | B. chinensis |

| [126] | |

| Rice (O. sativa) straw Rice (O. sativa) husks Soybean (G. max) straw Peanut (A. hypogaea) shells Corn (Z. mays) cobs Wood | Bacteria | Arthrobacter defluvii Burkholderia cepacia Bacillus megaterium Pseudomonas frederiksbergensis Rhodanobacter sp. Streptomyces prasinopilosus Variovorax paradoxus | B. napus |

| [127] |

| Sugarcane bagasse (S. officinarum) | Bacteria | Enterococcus gallinarum | B. napus |

| [74] |

| Spent mushroom substrate | Bacteria | Bacillus subtilis Pseudomonas fluorescence | B. oleracea var. botrytis |

| [128] |

| Maize straw (Z. mays) | Bacteria | Bacillus megaterium | B. chinensis |

| [18] |

| Paper and pulp waste | Bacteria | Enterobacter sp. | B. napus |

| [129] |

| Waste wood of Morus alba | Bacteria | Pseudomonas sp. | B. napus |

| [130] |

| Rice (O. sativa) husks | Bacteria | Bacillus megaterium Serratia liquefaciens | B. campertris ssp. Chinensis var. Four-season |

| [131] |

| Peach (Prunus persica) residues | Bacteria | Pseudomonas putida Azotobacter chroococcum | B. napus |

| [132] |

| Bacteria | Azospirillum brasilense | B. chinensis |

| [133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jatuwong, K.; Aiduang, W.; Kiatsiriroat, T.; Kamopas, W.; Lumyong, S. A Review of Biochar from Biomass and Its Interaction with Microbes: Enhancing Soil Quality and Crop Yield in Brassica Cultivation. Life 2025, 15, 284. https://doi.org/10.3390/life15020284

Jatuwong K, Aiduang W, Kiatsiriroat T, Kamopas W, Lumyong S. A Review of Biochar from Biomass and Its Interaction with Microbes: Enhancing Soil Quality and Crop Yield in Brassica Cultivation. Life. 2025; 15(2):284. https://doi.org/10.3390/life15020284

Chicago/Turabian StyleJatuwong, Kritsana, Worawoot Aiduang, Tanongkiat Kiatsiriroat, Wassana Kamopas, and Saisamorn Lumyong. 2025. "A Review of Biochar from Biomass and Its Interaction with Microbes: Enhancing Soil Quality and Crop Yield in Brassica Cultivation" Life 15, no. 2: 284. https://doi.org/10.3390/life15020284

APA StyleJatuwong, K., Aiduang, W., Kiatsiriroat, T., Kamopas, W., & Lumyong, S. (2025). A Review of Biochar from Biomass and Its Interaction with Microbes: Enhancing Soil Quality and Crop Yield in Brassica Cultivation. Life, 15(2), 284. https://doi.org/10.3390/life15020284