The Thermal Error Estimation of the Machine Tool Spindle Based on Machine Learning

Abstract

:1. Introduction

2. Methodology

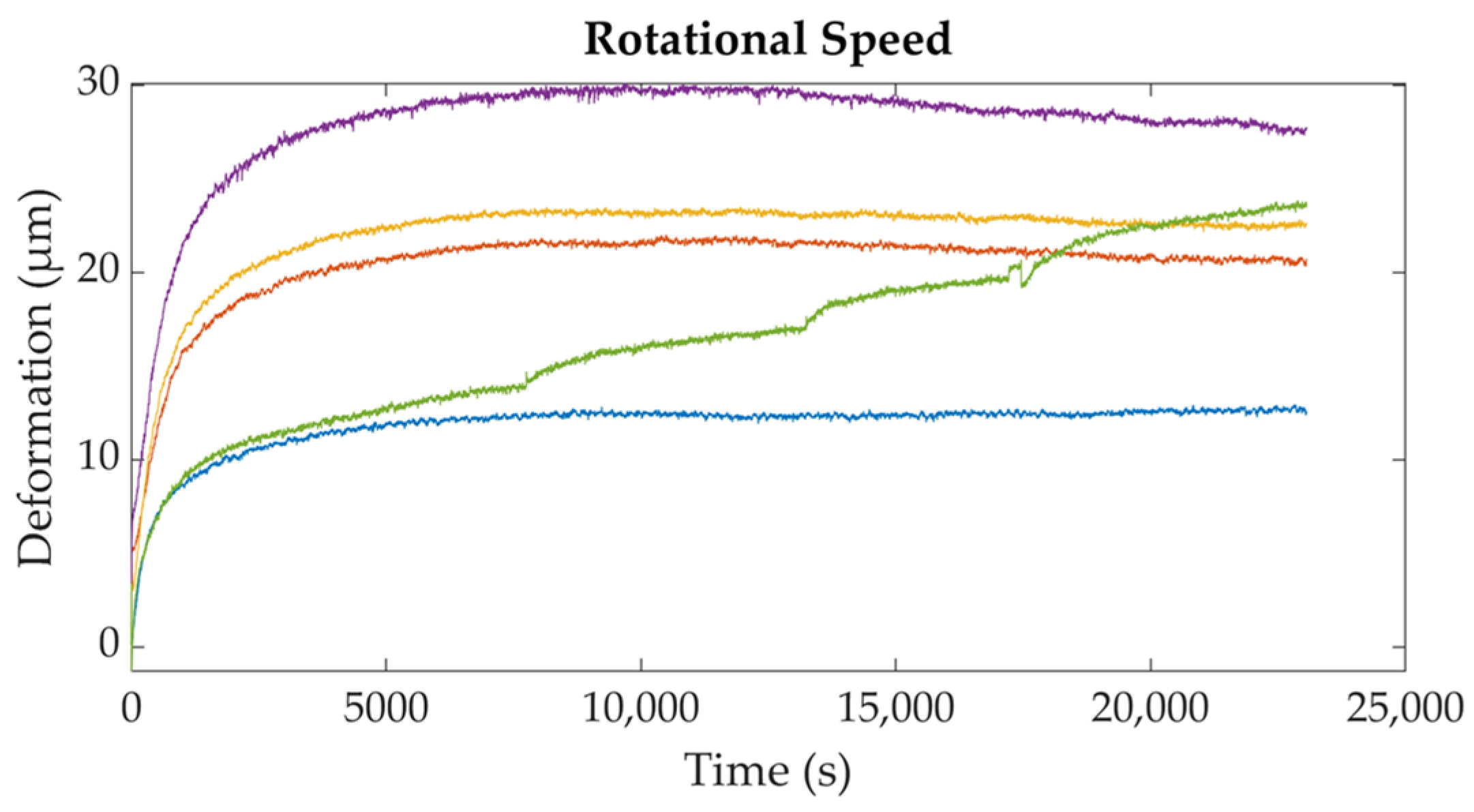

2.1. Spindle Running-in Setup

2.2. Feature Temperature Measurement

2.3. Thermal Error Measurement

2.4. Training Data and Validation Data

2.5. Thermal Error Modeling by Machine Learning

2.5.1. Gaussian Process Regression (GPR)

- Use the “Import Data” to import the training data sets and the testing data sets;

- Choose the “Machine Learning and Deep Learning” variety in the App toolbar, and then use the “Regression Learner”;

- Choose a training data set, set the thermal error data to response, set the temperature data to predictors, and set “validation” to prevent the model from overfitting;

- Choose the Exponential of Gaussian Process Regression, one can use “Advanced” to adjust the training parameters;

- Click “Export Model”, input testing data set to the model to get a response, get mean error and accuracy by calculating the true value, and predicted value based on the testing data set.

2.5.2. Random Forests (RF)

3. Results

3.1. Thermal Error Model Based on Gaussian Process Regression

3.2. Thermal Error Model Based on Random Forest

3.3. Feature Temperature Points Selection by Pearson Correlation Coefficient (PCC)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bryan, J. International status of thermal error research. CIRP Ann. 1990, 39, 645–656. [Google Scholar] [CrossRef]

- Ramesh, R.; Mannan, M.A.; Poo, A.N. Error compensation in machine tools—A review: Part I: Geometric, cutting-force induced and fixture-dependent errors. Int. J. Mach. Tools Manuf. 2000, 40, 1235–1256. [Google Scholar] [CrossRef]

- Li, Y.; Yu, M.; Bai, Y.; Hou, Z.; Wu, W. A review of thermal error modeling methods for machine tools. Appl. Sci. 2021, 11, 5216. [Google Scholar] [CrossRef]

- Postlethwaite, S.R.; Allen, J.P.; Ford, D.G. Machine tool thermal error reduction—An appraisal. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1999, 213, 1–9. [Google Scholar] [CrossRef]

- Takabi, J.; Khonsari, M.M. Experimental testing and thermal analysis of ball bearings. Tribol. Int. 2013, 60, 93–103. [Google Scholar] [CrossRef]

- Kendoush, A.A. An approximate solution of the convective heat transfer from an isothermal rotating cylinder. Int. J. Heat Fluid Flow 1996, 17, 439–441. [Google Scholar] [CrossRef]

- Jędrzejewski, J.; Kaczmarek, J.; Kowal, Z.; Winiarski, Z. Numerical optimization of thermal behavior of machine tools. CIRP Ann. 1990, 39, 379–382. [Google Scholar] [CrossRef]

- Chen, D.; Bonis, M.; Zhang, F.; Dong, S. Thermal error of a hydrostatic spindle. Precis. Eng. 2011, 35, 512–520. [Google Scholar] [CrossRef]

- Feng, W.; Li, Z.; Gu, Q.; Yang, J. Thermally induced positioning error modelling and compensation based on thermal characteristic analysis. Int. J. Mach. Tools Manuf. 2015, 93, 26–36. [Google Scholar] [CrossRef]

- Venugopal, R.; Barash, M.; Shaw, M.C. Thermal effects on the accuracy of numerically controlled machine tools. CIRP Ann. 1986, 35, 255–258. [Google Scholar] [CrossRef]

- Mayr, J.; Ess, M.; Weikert, S.; Wegener, K.J.P.L. Compensation of Thermal Effects on Machine Tools Using a FDEM Simulation Approach. In Proceedings of the 9th Lamdamap Conference, Brunel University, Uxbridge, UK, 30 June–2 July 2009; ISBN 1861941188. Available online: https://www.iwf.mavt.ethz.ch/ConfiguratorJM/publications/Compensati_129500865499587/O1.5_Mayr.pdf (accessed on 9 July 2021).

- Lo, Y.-C.; Hu, Y.-C.; Chang, P.-Z. Parameter estimation of the thermal network model of a machine tool spindle by self-made Bluetooth temperature sensor module. Sensors 2018, 18, 656. [Google Scholar] [CrossRef] [Green Version]

- Huang, D.; Hong, J.; Zhang, J.; Wu, D.; Li, C. Thermal resistance network for solving temperature field in spindle system. J. Xi’an Jiaotong Univ. 2012, 46, 63–66. [Google Scholar]

- Liu, Z.; Pan, M.; Zhang, A.; Zhao, Y.; Yang, Y.; Ma, C. Thermal characteristic analysis of high-speed motorized spindle system based on thermal contact resistance and thermal-conduction resistance. Int. J. Adv. Manuf. Technol. 2015, 76, 1913–1926. [Google Scholar] [CrossRef]

- Wu, C.-H. Thermal Deformation Prediction of a Machine Tool Spindle by Thermal Network Model. Master’s Thesis, National Taiwan University, Taipei, Taiwan, 1 July 2019. [Google Scholar]

- Yan, J.; Yang, J.G. Application of synthetic grey correlation theory on thermal point optimization for machine tool thermal error compensation. Int. J. Adv. Manuf. Technol. 2009, 43, 1124–1132. [Google Scholar] [CrossRef]

- Lo, C.-H.; Yuan, J.; Ni, J. Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. Int. J. Mach. Tools Manuf. 1999, 39, 1383–1396. [Google Scholar] [CrossRef]

- Yuan, J.; Ni, J. The real-time error compensation technique for CNC machining systems. Mechatronics 1998, 8, 359–380. [Google Scholar] [CrossRef]

- Han, J.; Wang, L.; Cheng, N.; Wang, H. Thermal error modeling of machine tool based on fuzzy c-means cluster analysis. In Proceedings of the 2011 International Conference on Electronic & Mechanical Engineering and Information Technology, Harbin, China, 12–14 August 2011. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, J.; Ji, S.; Liang, F. The selection of temperature-sensitivity points based on K-harmonic means clustering and thermal positioning error modeling of machine tools. Int. J. Adv. Manuf. Technol. 2019, 100, 2333–2348. [Google Scholar] [CrossRef]

- Krulewich, D.A. Temperature integration model and measurement point selection for thermally induced machine tool errors. Mechatronics 1998, 8, 395–412. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W. Axial thermal error compensation method for the spindle of a precision horizontal machining center. In Proceedings of the 2012 IEEE International Conference on Mechatronics and Automation, Chengdu, China, 5–8 August 2012. [Google Scholar] [CrossRef]

- Ruijun, L.; Wenhua, Y.; Zhang, H.H.; Qifan, Y. The thermal error optimization models for CNC machine tools. The International J. Adv. Manuf. Technol. 2012, 63, 1167–1176. [Google Scholar] [CrossRef]

- Yang, H.; Ni, J. Dynamic modeling for machine tool thermal error compensation. J. Manuf. Sci. Eng. 2003, 125, 245–254. [Google Scholar] [CrossRef]

- Creighton, E.; Honegger, A.; Tulsian, A.; Mukhopadhyay, D. Analysis of thermal errors in a high-speed micro-milling spindle. Int. J. Mach. Tools Manuf. 2010, 50, 386–393. [Google Scholar] [CrossRef]

- Chen, J.S. Thermal Error Modeling for Volumetric Error Compensation. ASME Winter Annu. Meet. 1992, PED-55, 113–125. [Google Scholar]

- Li, S.; Zhang, Y.; Zhang, G. A study of pre-compensation for thermal errors of NC machine tools. Int. J. Mach. Tools Manuf. 1997, 37, 1715–1719. [Google Scholar] [CrossRef]

- Pahk, H.; Lee, S.W. Thermal error measurement and real time compensation system for the CNC machine tools incorporating the spindle thermal error and the feed axis thermal error. Int. J. Adv. Manuf. Technol. 2002, 20, 487–494. [Google Scholar] [CrossRef]

- Shi, H.; Jiang, C.; Yan, Z.; Tao, T.; Mei, X. Bayesian neural network–based thermal error modeling of feed drive system of CNC machine tool. Int. J. Adv. Manuf. Technol. 2020, 108, 3031–3044. [Google Scholar] [CrossRef]

- Haitao, Z.; Jianguo, Y.; Jinhua, S. Simulation of thermal behavior of a CNC machine tool spindle. Int. J. Mach. Tools Manuf. 2007, 47, 1003–1010. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Kao, M.-C.; Chang, C.-P. Investigation on the spindle thermal displacement and its compensation of precision cutter grinders. Measurement 2011, 44, 1183–1187. [Google Scholar] [CrossRef]

- Hu, Y.-C.; Chen, P.-J.; Chang, P.-Z. Thermal-feature system identification for a machine tool spindle. Sensors 2019, 19, 1209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lei, M.; Jiang, G.; Yang, J.; Mei, X.; Xia, P.; Zhao, L. Thermal error modeling with dirty and small training sample for the motorized spindle of a precision boring machine. Int. J. Adv. Manuf. Technol. 2017, 93, 571–586. [Google Scholar] [CrossRef]

- Towards Data Science. Available online: https://towardsdatascience.com/an-intuitive-guide-to-gaussian-processes-ec2f0b45c71d (accessed on 5 August 2021).

- Rasmussen, C.E. Gaussian Processes in Machine Learning. In Advanced Lectures on Machine Learning; Lecture Notes in Computer Science; Bousquet, O., von Luxburg, U., Rätsch, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 63–71. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Nagar, J.; Sharma, S.; Kotiyal, V. A Gaussian process regression approach to predict the k-barrier coverage probability for intrusion detection in wireless sensor networks. Expert Syst. Appl. 2021, 172, 114603. [Google Scholar] [CrossRef]

- Biau, G.; Scornet, E. A Random Forest Guided Tour. Test 2016, 25, 197–227. [Google Scholar] [CrossRef] [Green Version]

- Louppe, G. Understanding Random Forest—From Theory to Practice. Ph.D. Thesis, University of Liège, Liège, Belgium, 28 July 2014. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, J.; Wu, H. Application of ACO-BPN to thermal error modeling of NC machine tool. Int. J. Adv. Manuf. Technol. 2010, 50, 667–675. [Google Scholar] [CrossRef]

- Dexian, Z.; Xiaolian, L.; Hanming, S.; Ri-Yao, C. Identification of position of key thermal susceptible points for thermal error compensation of machine tool by neural network. In Proceedings of the International Conference on Intelligent Manufacturing, Wuhan, China, 28 August 1995. [Google Scholar] [CrossRef]

- Gramacy, R.B. Surrogates: Gaussian Process Modeling, Design and Optimization for the Applied Sciences, 1st ed.; CRC Press: Lake Wanaka, New Zealand, 2020; pp. 143–222. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Breiman, L.; Friedman, J.; Stone, C.J.; Olshen, R.A. Classification and Regression Trees, 1st ed.; CRC press: Boca Raton, FL, USA, 1984. [Google Scholar]

| Specification of the Temperature Sensor Probe | Specification of the Laser Displacement Meter | ||

|---|---|---|---|

| Sensor type | PT1000 (A class) | Sensor type | Keyence LK-055 |

| Accuracy (°C) | ±(0.15 ± 0.002|t|) | Reference distance (mm) | 50 |

| Measurement range (°C) | −50 to 300 | Measurement range (mm) | ±10 |

| Excited current limit (mA) | ≤5 | Light source | Red semiconductor laser |

| Thermal response (s) | ≤0.3 @ air | Wave length (nm) | 655 |

| Package material | Stainless steel 304 | Light spot diameter (μm) | 50 × 2000 |

| Protection level | IP 65 | Linearity | ±0.02% |

| Repeatability (μm) | 0.025 | ||

| Sampling time (μs) | 20 | ||

| Package material | Al | ||

| Protection level | IP 67 | ||

| Data Group | Data Set | Speed (rpm) |

|---|---|---|

| Training group | T5000,1, T5000,2, T5000,3 | 5000 |

| T6000,1, T6000,2, T6000,3 | 6000 | |

| T7000,1, T7000,2, T7000,3 | 7000 | |

| T8000,1, T8000,2, T8000,3 | 8000 | |

| Tvar,1, Tvar,2, Tvar,3 | 5000→6000→7000→8000 | |

| Validation group | V5000,1, V5000,2, V5000,3 | 5000 |

| V6000,1, V6000,2, V6000,3 | 6000 | |

| V7000,1, V7000,2, V7000,3 | 7000 | |

| V8000,1, V8000,2, V8000,3 | 8000 | |

| Vvar,1, Vvar,2, Vvar,3 | 5000→6000→7000→8000 |

| No. F. Pt. 1 | ME2 (μm) | RMSE3 (μm) | R2 * | Accuracy |

|---|---|---|---|---|

| 2 | 1.6423 | 1.7481 | 0.9884 | 88.92% |

| 3 | 1.6128 | 1.6860 | 0.9888 | 89.09% |

| 4 | 1.5960 | 1.7098 | 0.9888 | 89.19% |

| 5 | 1.5595 | 1.6805 | 0.9889 | 89.45% |

| 6 | 1.5769 | 1.6759 | 0.9894 | 89.38% |

| 7 | 1.5458 | 1.6557 | 0.9899 | 89.57% |

| 8 | 1.5374 | 1.6734 | 0.9906 | 89.64% |

| 9 | 1.5145 | 1.6539 | 0.9905 | 89.71% |

| 10 | 1.5160 | 1.6573 | 0.9910 | 89.62% |

| No. F. Pt. 1 | ME 2 (μm) | RMSE 3 (μm) | R2 * | Accuracy |

|---|---|---|---|---|

| 2 | 1.5728 | 1.6633 | 0.9914 | 89.41% |

| 3 | 1.5730 | 1.6656 | 0.9909 | 89.41% |

| 4 | 1.5273 | 1.6402 | 0.9905 | 90.49% |

| 5 | 1.5167 | 1.6474 | 0.9901 | 89.61% |

| 6 | 1.5125 | 1.6417 | 0.9902 | 89.62% |

| 7 | 1.5140 | 1.6495 | 0.9898 | 89.61% |

| 8 | 1.5129 | 1.6482 | 0.9899 | 89.62% |

| 9 | 1.5130 | 1.6490 | 0.9898 | 89.62% |

| 10 | 1.5181 | 1.6506 | 0.9898 | 89.60% |

| Paper | M. L. Model * | F. Pt. Selection * | No. F. Pt. * | ME * | RMSE * | R2 * | Accuracy * |

|---|---|---|---|---|---|---|---|

| This paper | RF ** | PCC *** | 4 | 1.5273 | 1.6402 | 0.9905 | 90.49% |

| GPR ** | PCC | 4 | 1.5960 | 1.7098 | 0.9888 | 89.19% | |

| [16] | DCM ** | IGM *** | 4 | 3.62 | - | - | - |

| [17] | Mallows’ Cp | CC *** | 4 | - | - | 0.982 | 89% |

| [19] | MLR ** | FCM *** | 4 | 1.8 | - | - | - |

| [20] | MLR | KHM *** | 3 | - | 6.9690 | 0.9356 | 90.86% |

| [21] | GI ** | - | 9 | - | 2.4928 | - | 93% |

| [22] | LS ** | SRCC *** | 11 | - | - | - | 85% |

| [23] | RBF ** | CC | 5 | - | 2.4 | - | 75% |

| [29] | BNN ** | FCM | 3 | 1.741 | 1.998 | 0.807 | 74.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, Y.-C.; Wang, P.-H.; Hu, Y.-C. The Thermal Error Estimation of the Machine Tool Spindle Based on Machine Learning. Machines 2021, 9, 184. https://doi.org/10.3390/machines9090184

Chiu Y-C, Wang P-H, Hu Y-C. The Thermal Error Estimation of the Machine Tool Spindle Based on Machine Learning. Machines. 2021; 9(9):184. https://doi.org/10.3390/machines9090184

Chicago/Turabian StyleChiu, Yu-Cheng, Po-Hsun Wang, and Yuh-Chung Hu. 2021. "The Thermal Error Estimation of the Machine Tool Spindle Based on Machine Learning" Machines 9, no. 9: 184. https://doi.org/10.3390/machines9090184

APA StyleChiu, Y.-C., Wang, P.-H., & Hu, Y.-C. (2021). The Thermal Error Estimation of the Machine Tool Spindle Based on Machine Learning. Machines, 9(9), 184. https://doi.org/10.3390/machines9090184