1. Introduction

A polar crane is a large-scale special lifting equipment operated at the top of a containment vessel; it is mainly used for heavy equipment lifting and fuel replacing. Taking the lifting process of reactor pressure vessel upper heads as an example, the hook block needs to be slowly lowered and accurately aligned with the center of the reactor pressure vessel, which places a high demand for precision lifting on the polar crane.

Reliable manufacturing processes and reasonable structural design methods are the basis for precise lifting of a polar crane. Literature [

1] took the physical structure of the rope-sheave system of the polar crane into account and proposed a systematic method for analyzing the dynamics of the system based on the virtual power principle. Literature [

2] presented a quasi-static method to analyze the equilibrium path and trajectory deflections for the load of the polar crane, which is of great significance for improving the structural layout of the lifting system. Literature [

3] proposed a static balanced approach to analyzing the straightness deviation of the hook block during the lifting process. Literature [

4] analyzed the influence of bridge deformation on the locating accuracy under different working conditions by the finite element method. Literature [

5] presented an effective control method for the welding deformation of corbel by improving the welding process and welding sequence. Literature [

6] analyzed the rigid-flexible coupling model of a polar crane based on the ANSYS and ADAMS co-simulation analysis method. The results obtained have important reference values in analyzing the influence of structural flexibility on locating accuracy.

Related studies did not consider the impact of the operation process on lifting accuracy. In the field of traditional hoisting machinery, a series of control technologies is relatively mature and provides an important reference for the polar crane. In the aspect of swing suppression control, Literature [

7] aimed for a double pendulum structure of overhead cranes and proposed a trajectory tracking and swing suppression control method based on sliding mode control theory. Literature [

8] proposed a multivariable generalized predictive control method for an overhead crane based on the particle swarm optimization algorithm and achieved good control performance. Literature [

9] designed a linear quadratic regulator based on Takagi–Sugeno fuzzy modeling and particle swarm optimization algorithm for anti-swing and positioning control of the overhead crane. In terms of crane trajectory planning, aimed at the problem of payload residual swing caused by inertial force, Literature [

10] designed the acceleration curve of the trolley based on the energy control method. Literature [

11] proposed an energy optimal model of the overhead crane according to energy consumption, operation time, and safety. To deal with the problem of parameter uncertainty in the trajectory planning, Literature [

12] proposed an uncertain estimation and optimization scheme which provides guidance for uncertain analysis and online controller design of overhead cranes. Literature [

13] proposed a new control system based on the state feedback control method to deliver high-performance trajectory tracking with minimum load swings in high-speed motions. In the field of the offshore ship-mounted crane, Literature [

14] designed a neural network-based adaptive controller to solve the payload swing caused by sea waves. Literature [

15] proposed a novel event-triggered fuzzy robust fault-tolerant control approach to overcome actuator fault and external disturbance of offshore ship-mounted crane. Literature [

16] designed an observer-based nonlinear feedback control to achieve simultaneous accurate jib/trolley positioning and fast payload swing suppression against complex unknown external disturbances.

A polar crane is a nonlinear control system with multiple inputs, multiple outputs, and strong coupling. Moreover, due to the movement of the trolley, a polar crane is often in a state of center of gravity shift during rotation. As an effective nonlinear control method, active disturbance rejection control (ADRC) has the advantages of simple, feasible, and strong robustness, and for the coupling system, the cross-coupling disturbance can be estimated and compensated by the ESO. Therefore, compared with the traditional decoupling control method, ADRC has significant advantages [

17,

18,

19] and can be an important method to solve the control problem of the polar crane.

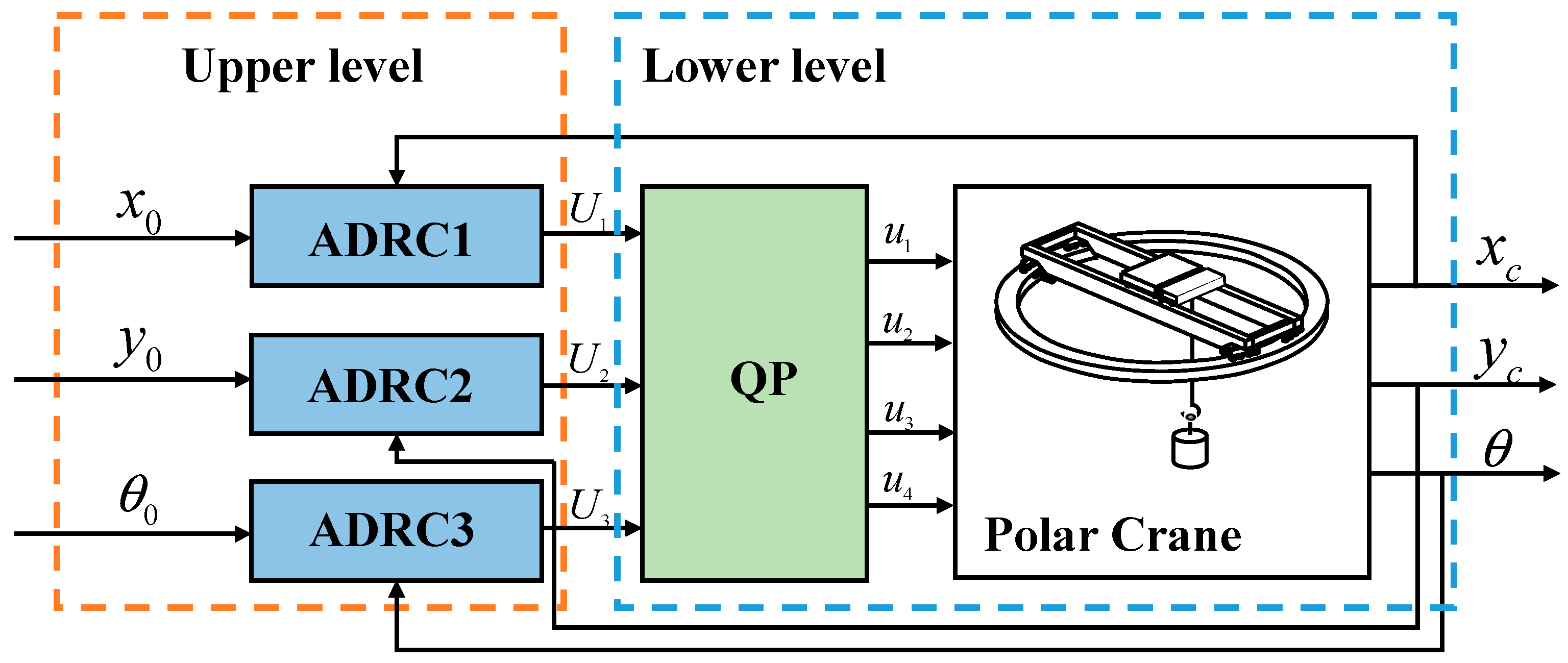

As stated previously, most studies in the field of precise lifting of a polar crane have only focused on the lifting mechanism design and analysis, but the problem of location deviation during crane operation has been ignored. To address this problem, a novel locating control scheme for the polar crane is proposed in this paper. The main contributions of this paper are summarized as follows:

- (1)

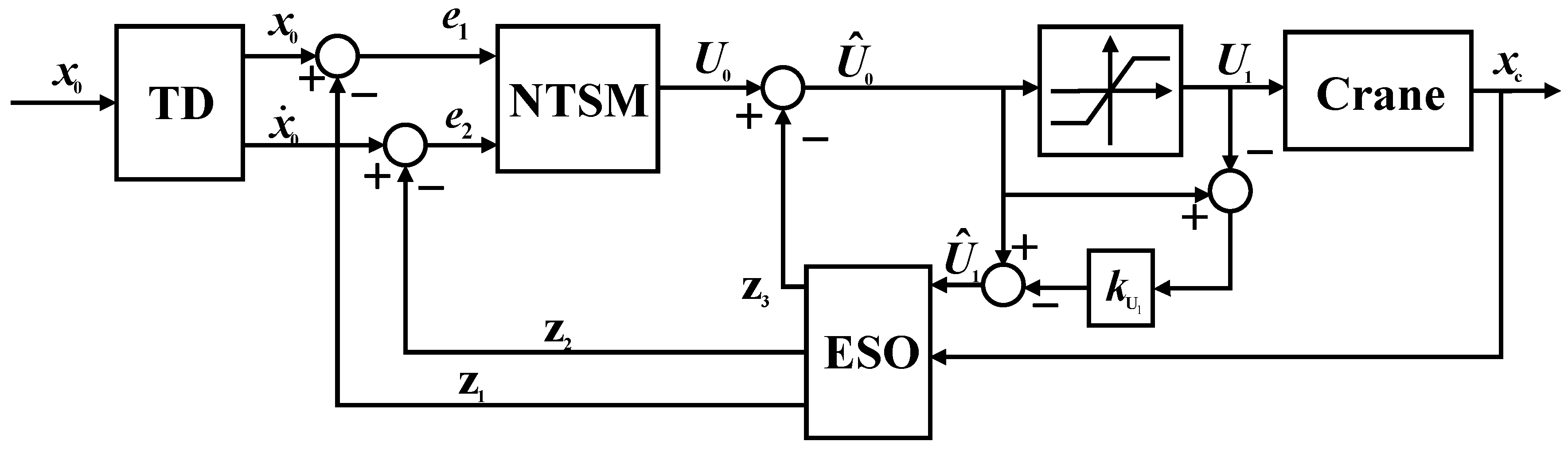

An nonsingular terminal sliding mode (NTSM)-ADRC-based decoupling method is first proposed to effectively address the cross-coupling disturbance for the polar crane system and to greatly improve the robustness and adaptability of the crane system.

- (2)

To properly address the problem of redundant actuation, a quadratic programming (QP) optimization model is designed, in which the contact force of the horizontal guide device is introduced to reduce the trajectory deviation of the bridge truck.

- (3)

The proposed NTSM-ADRC-QP control scheme has good performance in locating control under the conditions of center of gravity shift and external disturbance.

The paper is organized as follows: The nonholonomic constraint dynamic model of the polar crane and model validation are introduced in

Section 2.

Section 3 illustrates the overall structure of the NTSM-ADRC-based decoupling control method, the stability analysis, and the quadratic programming algorithm for the polar crane. Numerical simulations and analyses are provided in

Section 4 for the proposed control scheme. Finally,

Section 5 concludes the main works of this paper.

2. Crane Description, Modeling, and Simulation

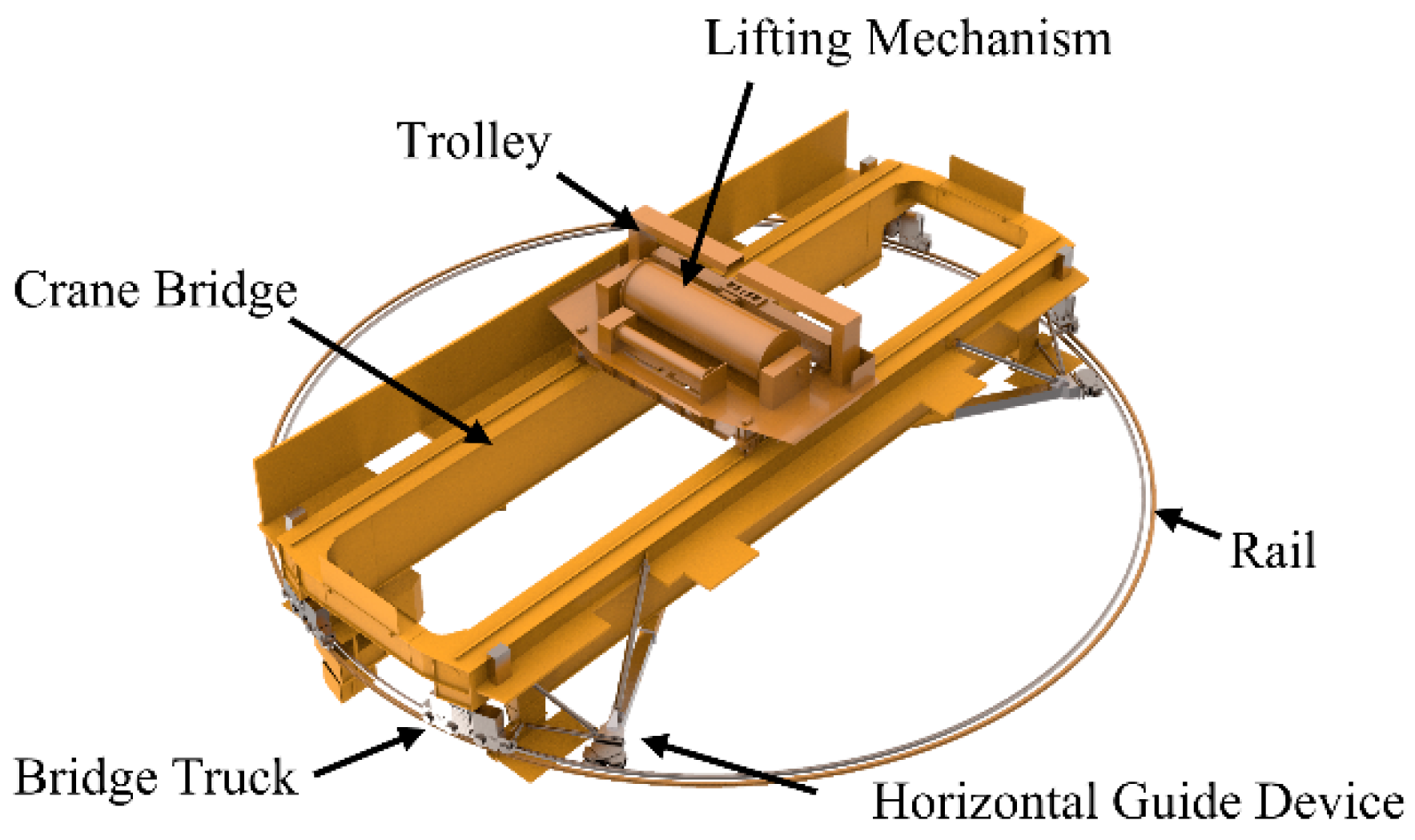

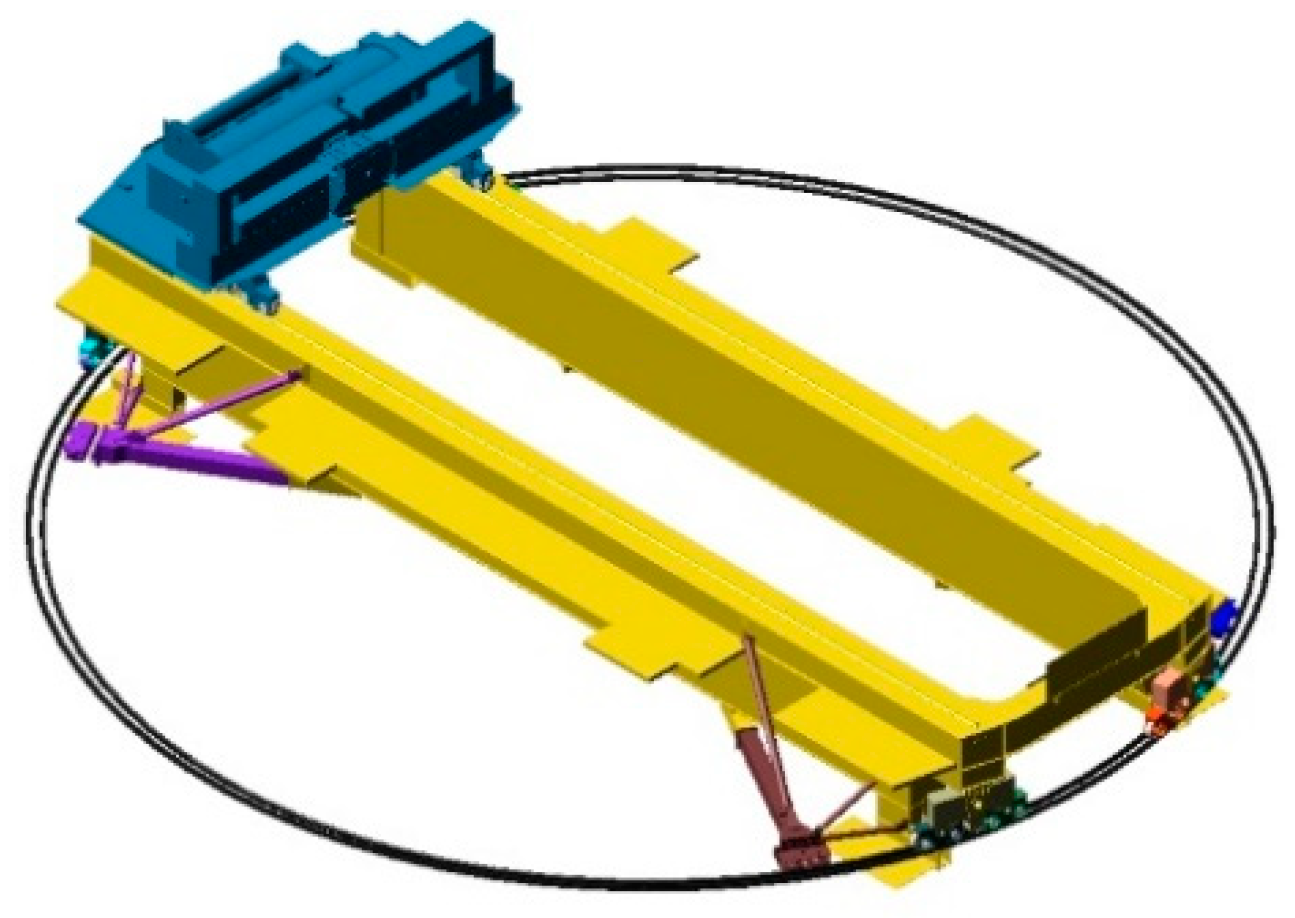

A polar crane is installed on the top of the containment vessel. As shown in

Figure 1, the main structures include a crane bridge, a bridge truck, a trolley, a lifting mechanism, a horizontal guide device, and an electrical system.

The bridge truck is used to drive the crane rotating on the rail, and the trolley is installed on the crane bridge; thus, it can move on the crane bridge. Based on the cooperative movement between the trolley and the bridge truck, the lifting mechanism can cover all areas of the reactor building. In addition, horizontal guide devices are installed to ensure the crane operates safely.

2.1. Dynamic Model of the Polar Crane

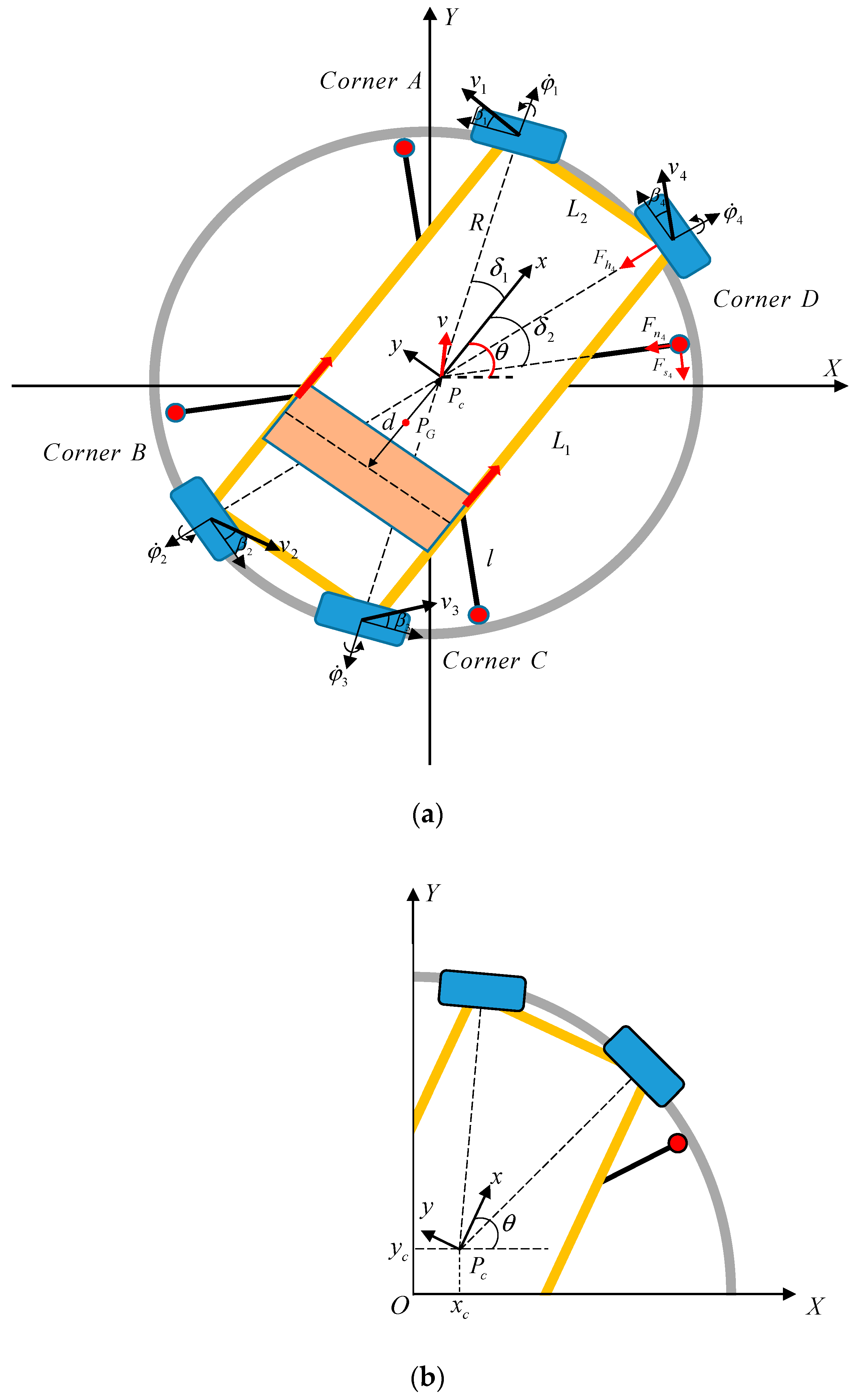

In

Figure 2, a graphical representation of the polar crane is shown. It could be seen that

is a global coordinate frame attached to the center of the rail,

is a local coordinate frame attached to the polar crane,

is the geometric center of the crane, and

is the center of mass of the crane.

Under the condition of planer movement, the configuration of the polar crane can be described by seven generalized coordinates. Among them, three variables describe the position and orientation of the crane, and four variables describe the motion states of the driving wheels:

where

are the coordinates of the geometric center

in the global coordinate frame;

is the rotation angle of the polar crane; and

,

,

, and

are the angular displacements of the driving wheels installed in the bridge truck.

Moreover, the corresponding system parameters are illustrated in

Table 1.

According to

Figure 2, the relationship between the geometric center

and the center of mass

can be depicted as follows:

where

are the coordinates of the center of mass

in the global coordinate frame.

Assuming a pure rolling condition for the driving wheels, the following constraint equations can be derived:

The matrix form of the constraints in Equation (2) can be rewritten as follows:

where

The Lagrange–Rouse equation is used to derive the dynamic equations of the polar crane, since the planer movement of the crane, the total kinetic energy

, can be written as follows:

where

is the rotary inertia of the driving wheel and

is the equivalent rotary inertia of the crane bridge and trolley around the center of mass

. Note that

will change in response to the variation of the parameter

.

The Lagrange–Rouse equation of motion for the polar crane system is governed by the following [

20]:

where

is the element of

,

is the generalized force,

is the Lagrange multiplier, and

is the element of

.

Substituting the derivative of Equations (1) and (5) into Equation (6), the dynamic equations can be expressed by the generalized coordinates:

where

,

, and

are the generalized forces corresponding to the generalized coordinates

,

, and

, respectively, and

,

,

, and

are the control torques of the driving wheels.

For the convenience of expression, the dynamic equations in Equation (7) can be rewritten in a matrix form:

where

is the mass/inertia matrix of the crane system;

denotes Coriolis and centripetal forces;

is the vector of generalized forces;

is the matrix of system constraints, which was obtained earlier; and

is the vector of Lagrange multipliers.

2.2. Generalized Force Analysis of the Crane System

2.2.1. Dynamic Analysis of the Bridge Truck

During crane operation, in addition to the control torques, the driving wheels of the bridge truck are also subject to lateral forces. Furthermore, the vertical load is the necessary condition for generation of the lateral force, and the vertical loads can be expressed as follows:

where

is the altitude distance between the center of mass of the crane and the rail plane.

Besides that, the lateral force is also related to the side-slip angle of the driving wheel, and the side-slip angle of each wheel can be expressed as follows:

Based on the empirical model, the lateral forces can be expressed as follows [

21]:

where

,

, and

are coefficients determined by wheel test data.

Therefore, the lateral force can be written as a vector form:

where

2.2.2. Dynamic Analysis of the Horizontal Guide Device

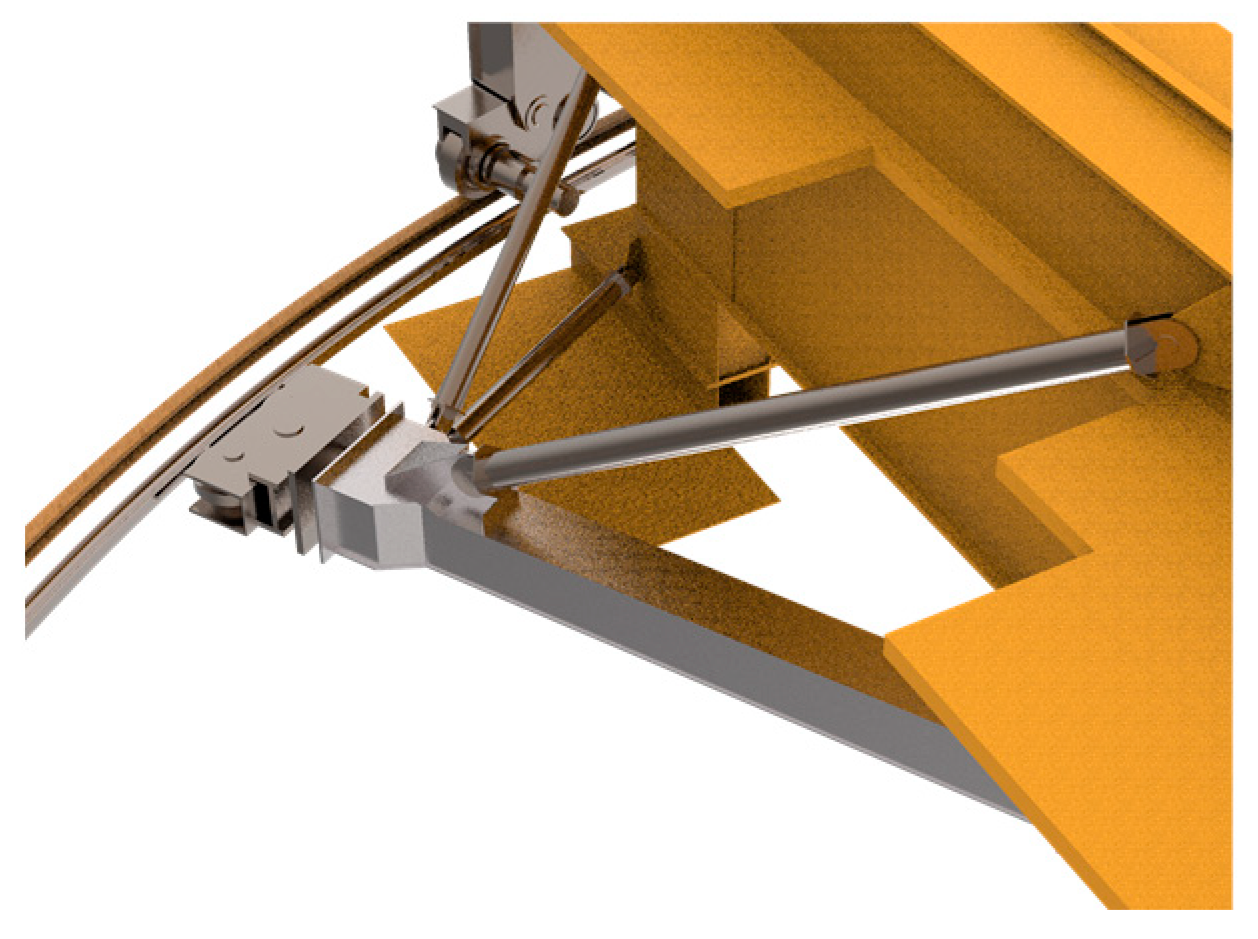

As shown in

Figure 3, horizontal guide devices are installed at every corner of the crane bridge, which are mainly composed of a horizontal guide outrigger, an oblique rod, a horizontal rod, and horizontal guide wheels. Furthermore, the horizontal guide wheels are connected to the outrigger by disc springs.

For ease of calculation, invasion between the horizontal guide wheel and the rail is allowed, so that the invasion distance can be used instead of the compression of the disc spring.

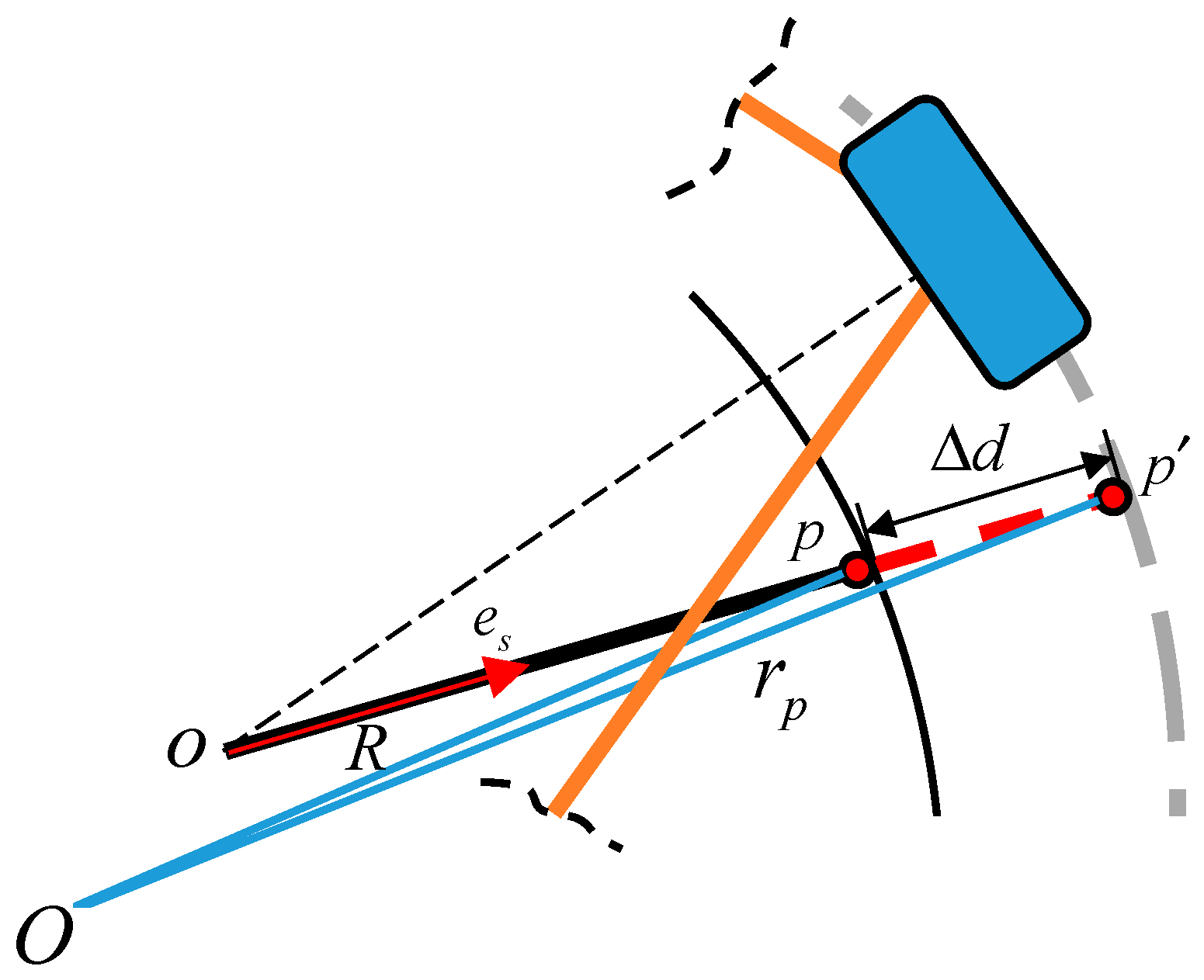

Figure 4 shows the kinematic relationship of the horizontal guide device, where

is the contact point of the horizontal guide wheel and the rail,

is the invasion point,

is the unit vector along the horizontal guide outrigger,

is the invasion distance, and

is the radius of the rail.

Referring to [

22], the kinematic relationship can be expressed as follows:

From Equation (13), the invasion distance can be obtained as follows:

where

and

.

Therefore, the contact forces of the horizontal guide wheels can be written as follows:

where

is the magnitude of the contact force, which can be confirmed based on the relationship between invasion distance

and stiffness coefficient of the disc spring and where

is the unit vector of each horizontal guide outrigger.

From the above analysis, the contact forces can be written in a vector form:

where

Moreover, the frictional force between the horizontal guide wheel and the rail can be expressed as follows:

where

is the rolling friction coefficient between the horizontal guide wheel and the rail and

is the tangential velocity of the horizontal guide wheel.

Similarly, the frictional forces can be written in a vector form as follows:

where

2.3. Simulation and Verification of the Crane System

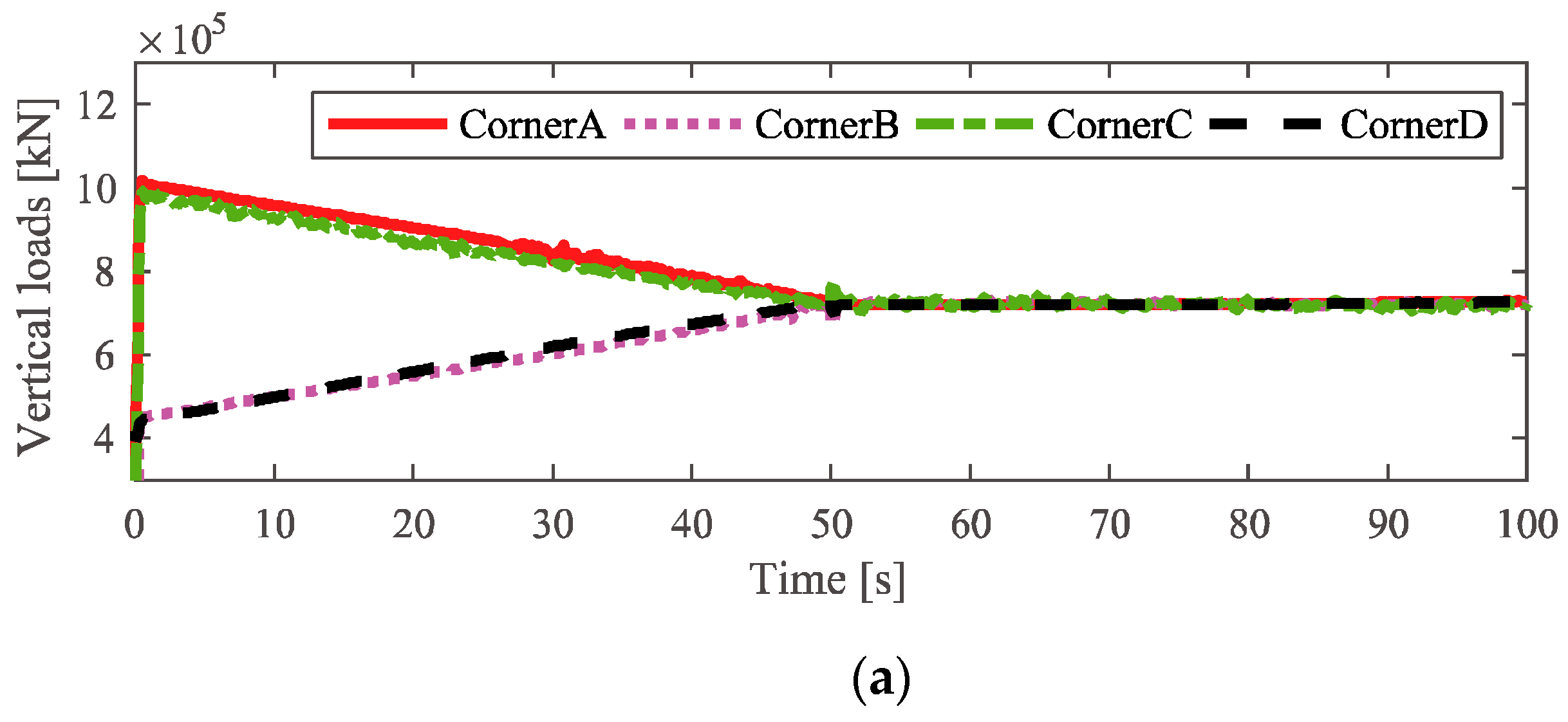

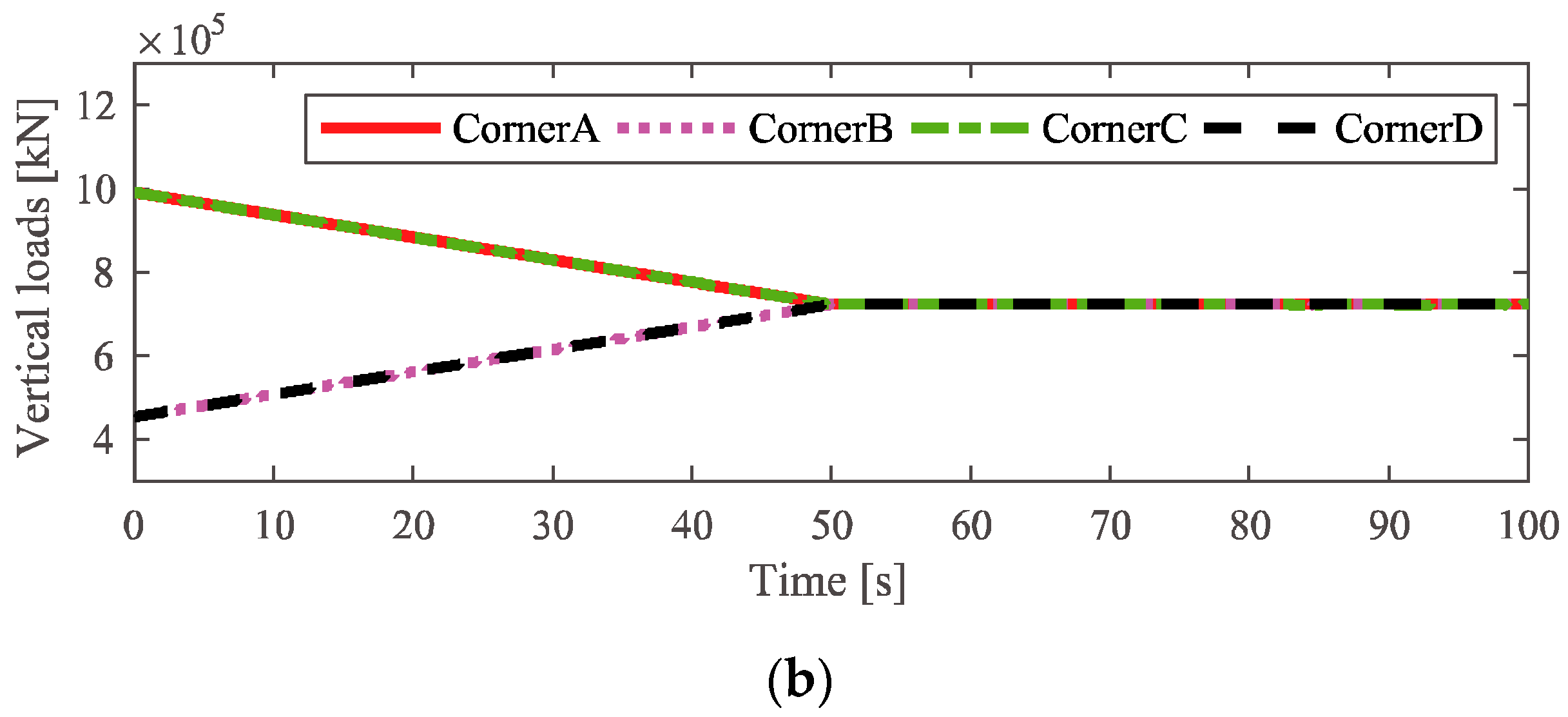

To verify the crane system depicted by the aforementioned equations, the simulation results of the crane system in MATLAB are compared with the results obtained from the crane system modeled in ADAMS software.

To this end, by using the modeled polar crane in ADAMS software, as shown in

Figure 5, the crane system is simulated in a typical working condition, in which the movement states of the crane can be expressed as follows:

where an equal angular velocity

is applied to the driving wheels of the bridge truck and the trolley starts to move from the end of crane bridge (

) at

and then stops at the center of crane bridge (

). The vertical loads of the driving wheels during crane operation are shown in

Figure 6.

As it can be seen in the illustrations, although the vertical loads of the driving wheels obtained by using the proposed model and ADAMS are almost the same, there are still some slight differences; the main reasons for this are the differences in the wheel–rail contact conditions and structure simplification of the proposed theoretical model.

4. Simulation Results and Discussion

In order to verify the effectiveness of the NTSM-ADRC-QP control scheme proposed in this paper, MATLAB/Simulink software is used for the simulations. The detailed dynamics parameters of the simulation model are shown in

Table 2. Considering the structural characteristics of the system, there are two typical working conditions of the polar crane implemented to verify the performance of the proposed control scheme and compared with the ADRC-QP method simultaneously.

The parameters of the ESO in the control scheme are as follows:

where the parameters of the ESO in the ADRC-QP control scheme are set to be consistent with those in the NTSM-ADRC-QP control scheme and the parameters of the sliding mode surfaces in each channel are as follows:

In addition, considering the safety of the crane rotation, the virtual control item is limited to .

4.1. Simulation Analysis of the Autonomous Operating of the Bridge Truck

In this section, in order to verify the locating performance of the proposed control scheme, we consider a typical working condition of the polar crane, in which the bridge truck rotates at a constant velocity.

The reference attitude of the polar crane can be expressed as follows:

The initial attitude of the polar crane can be depicted as follows:

The distance between the trolley and the geometric center

is as follows:

To verify the robustness of the system, here, we applied the following external disturbances of the driving wheels:

and

The locating performances of the polar crane in this working condition are illustrated in

Figure 9, while the corresponding simulation results of the horizontal guide device and the driving wheel are shown in

Figure 10,

Figure 11 and

Figure 12.

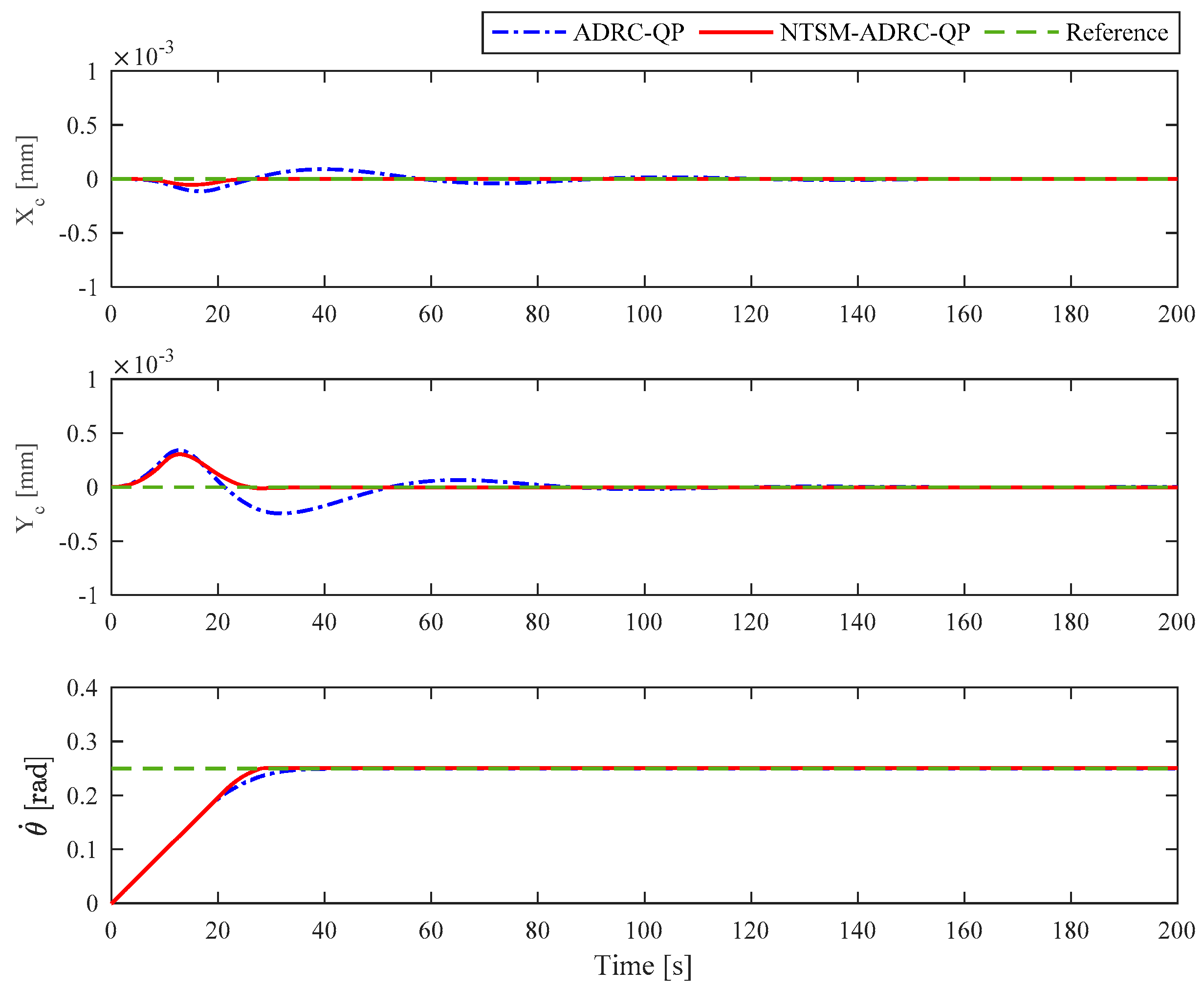

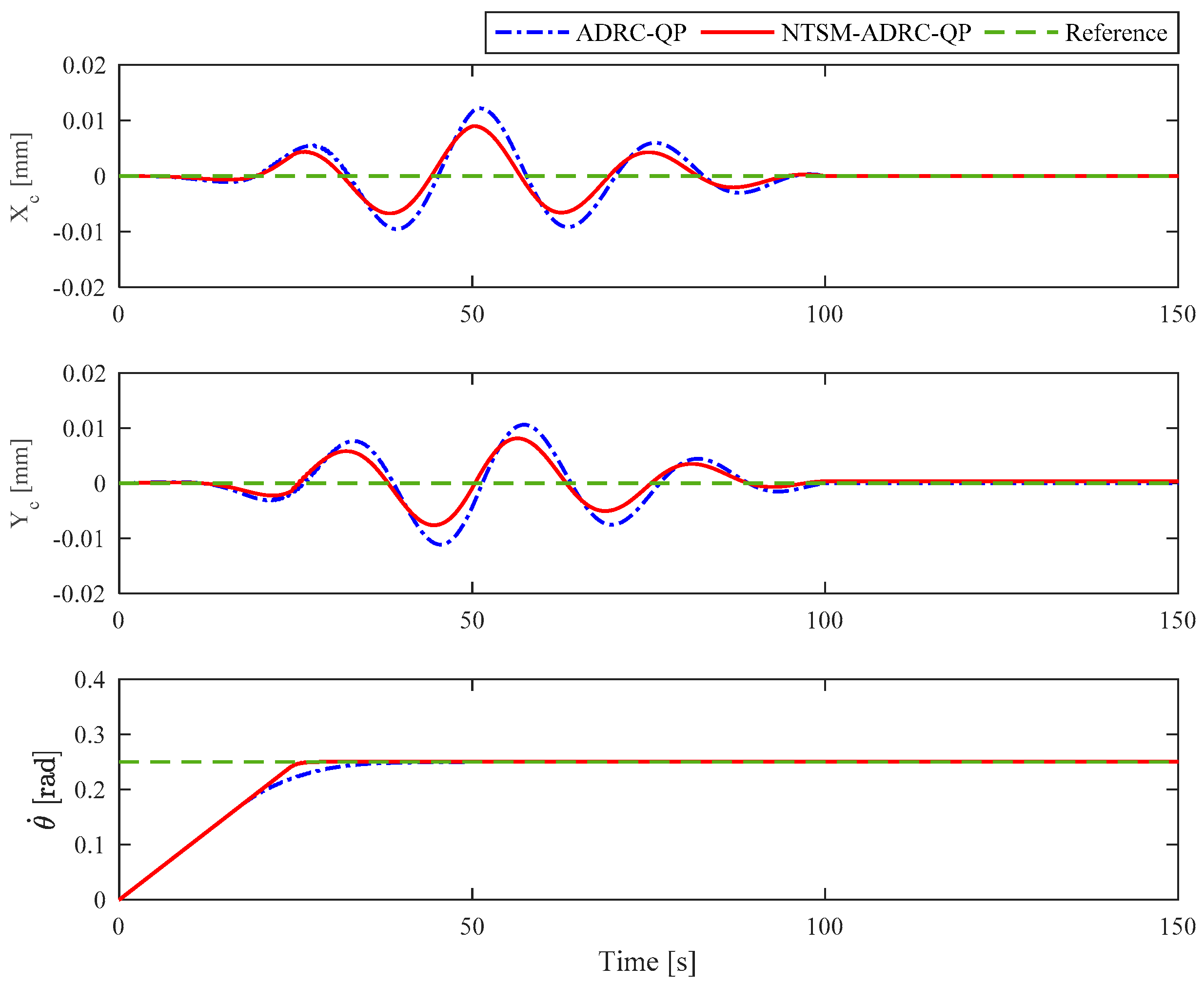

The locating performances of the two controllers are given in

Figure 9. From

Figure 9, it can be seen that the two controllers proposed in this paper are both able to ensure the locating accuracy very well, but in contrast, the convergence speed and robustness of the NTSM-ADRC-QP are obviously superior to the ADRC-QP.

Figure 9 shows the rotation velocity of the polar crane, and the results show that the proposed control scheme can achieve the stable uniform rotation and the accurate locating simultaneously.

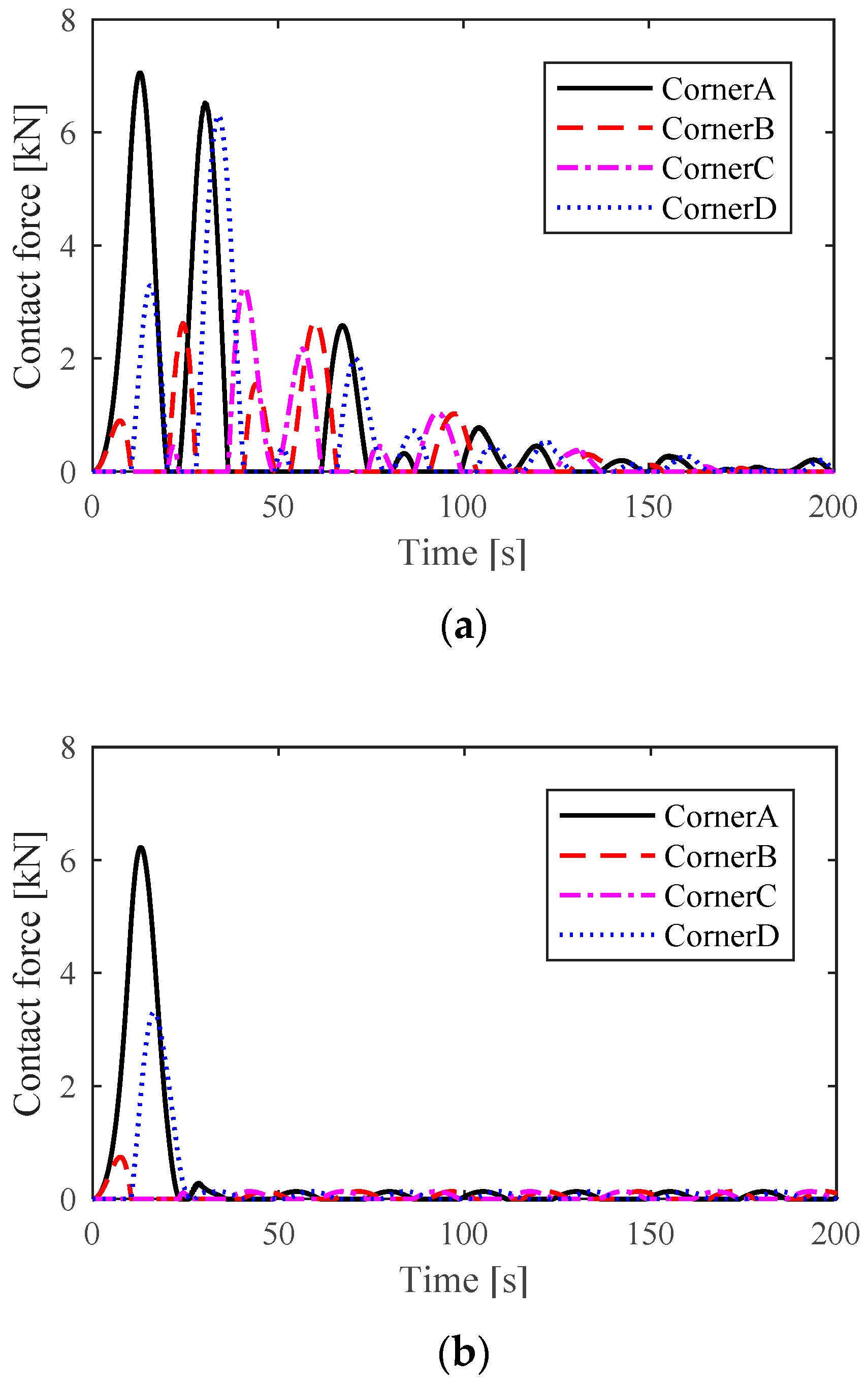

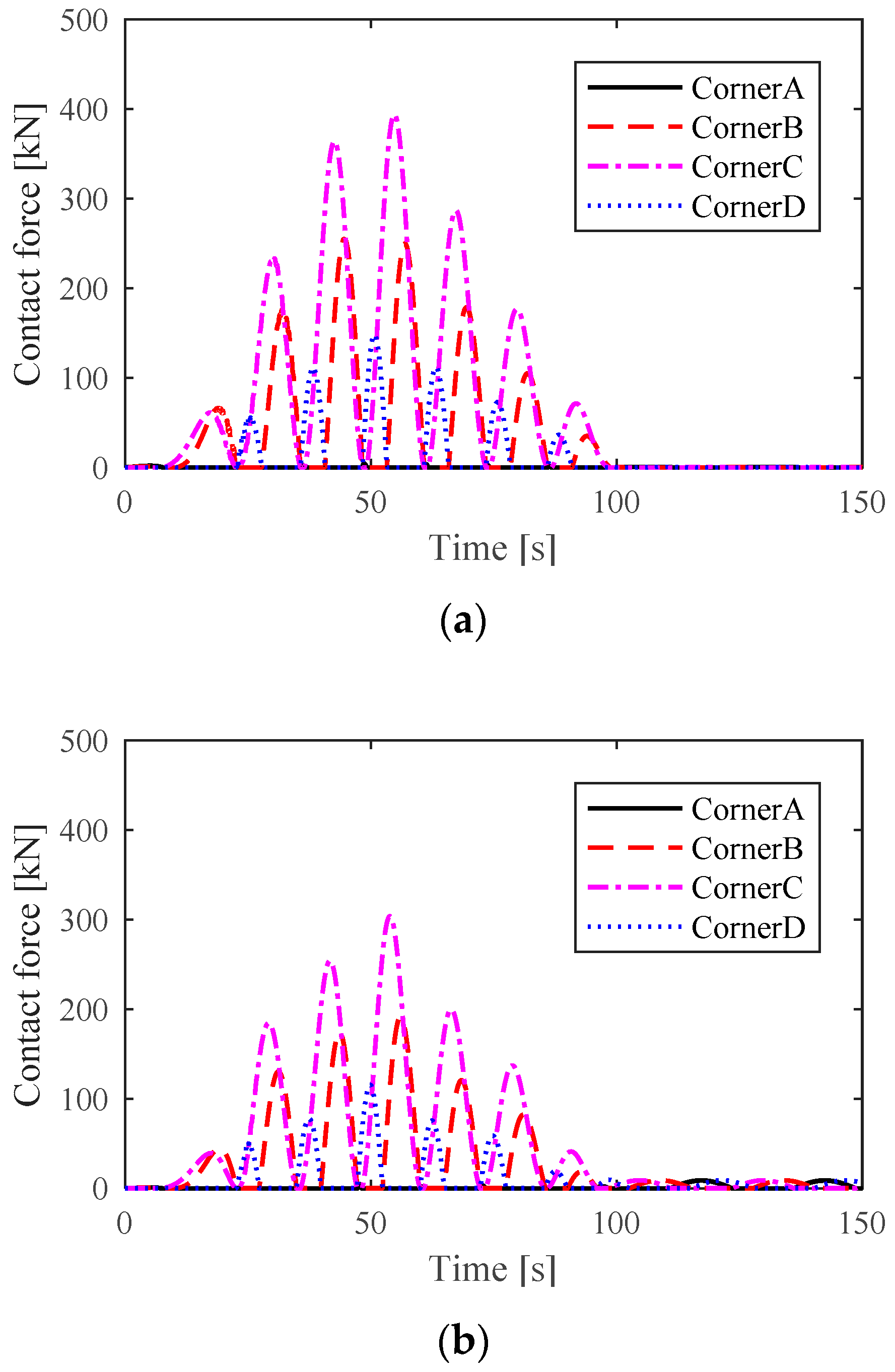

Figure 10 shows the contact forces of the horizontal guide devices; we can see that, compared with ADRC-QP, the contact forces of NTSM-ADRC-QP are obviously decreased. The main reason is that, as the location deviation decreases, the amount of compression between the horizontal guide wheel and the rail is accordingly decreased.

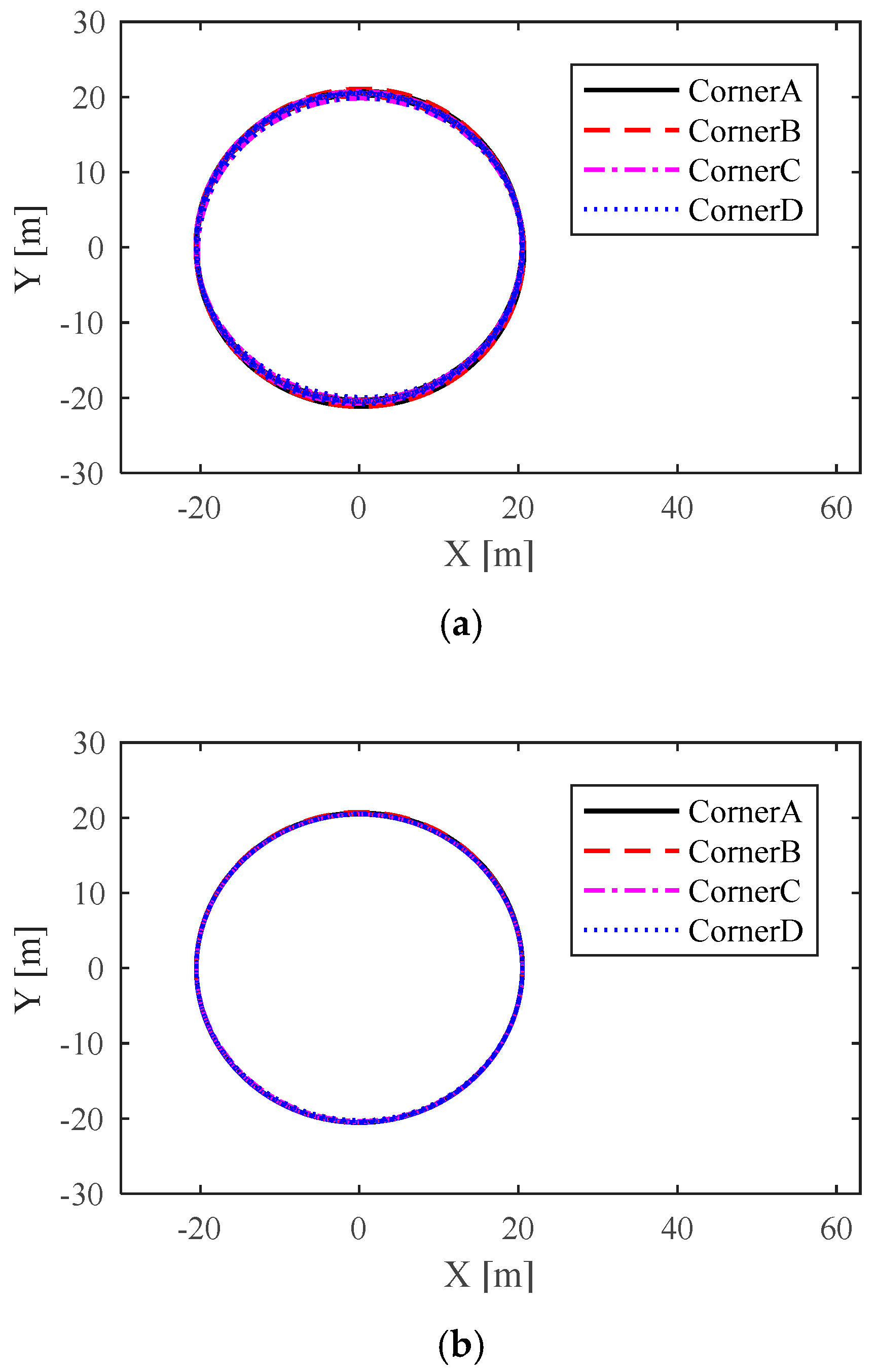

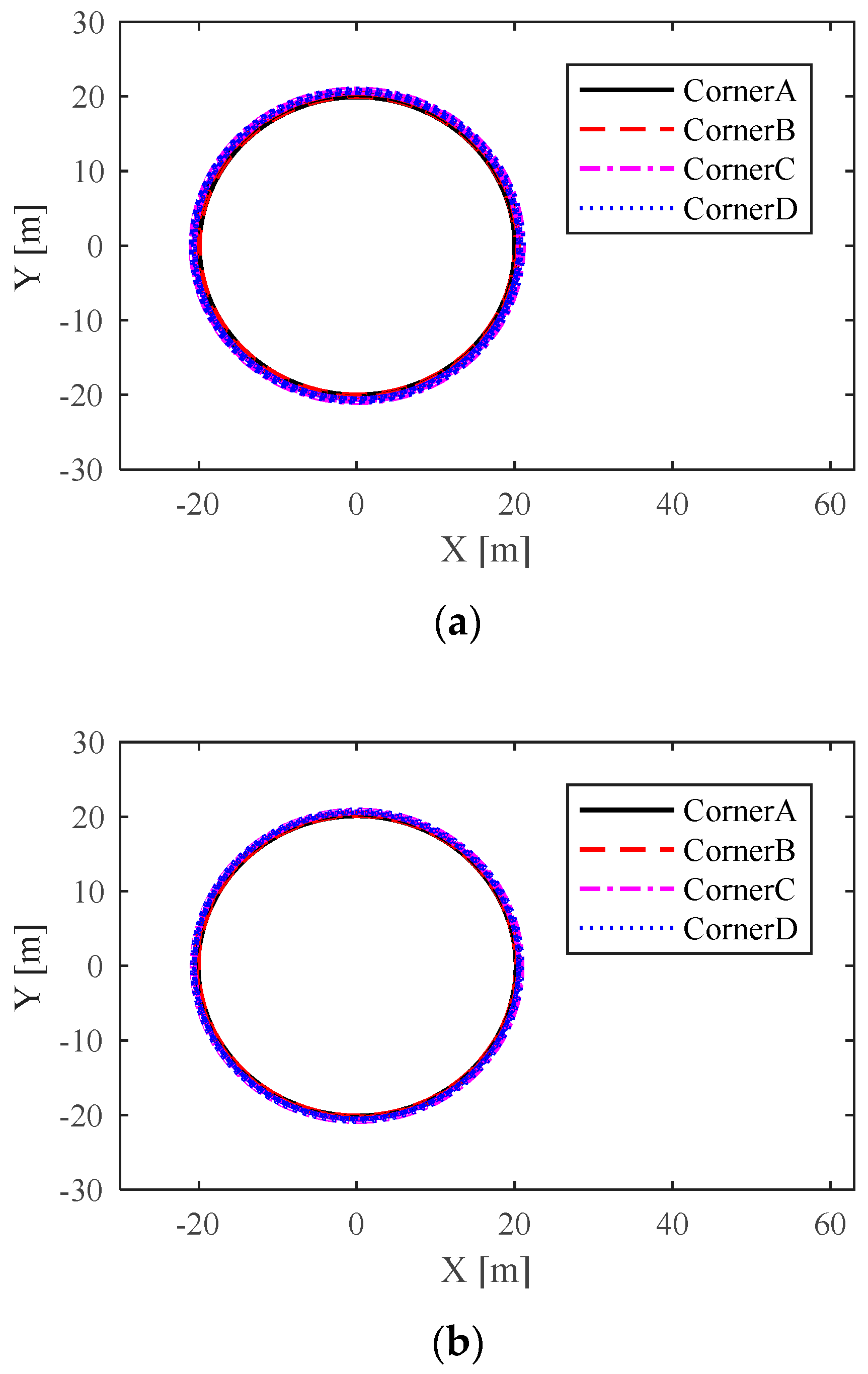

For direct observation, the moving trajectories of driving wheels at each corner are shown in

Figure 11; note that the trajectory deviation of the driving wheels are amplified in the same proportion. It can be seen that the moving trajectories of the driving wheels via the NTSM-ADRC-QP control scheme are almost the same as the rail route, which reflects the remarkable control accuracy of the proposed NTSM-ADRC-QP control scheme directly.

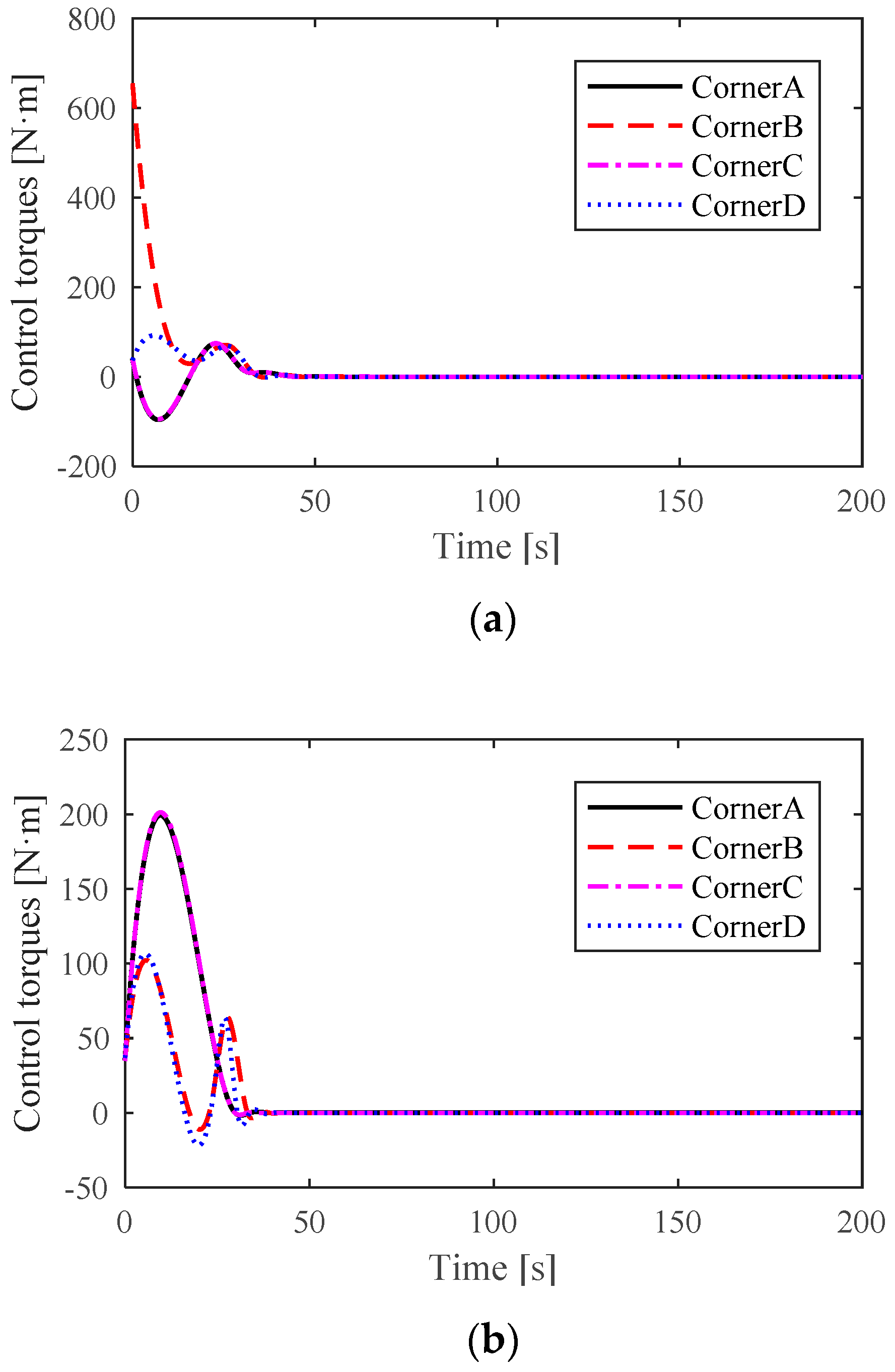

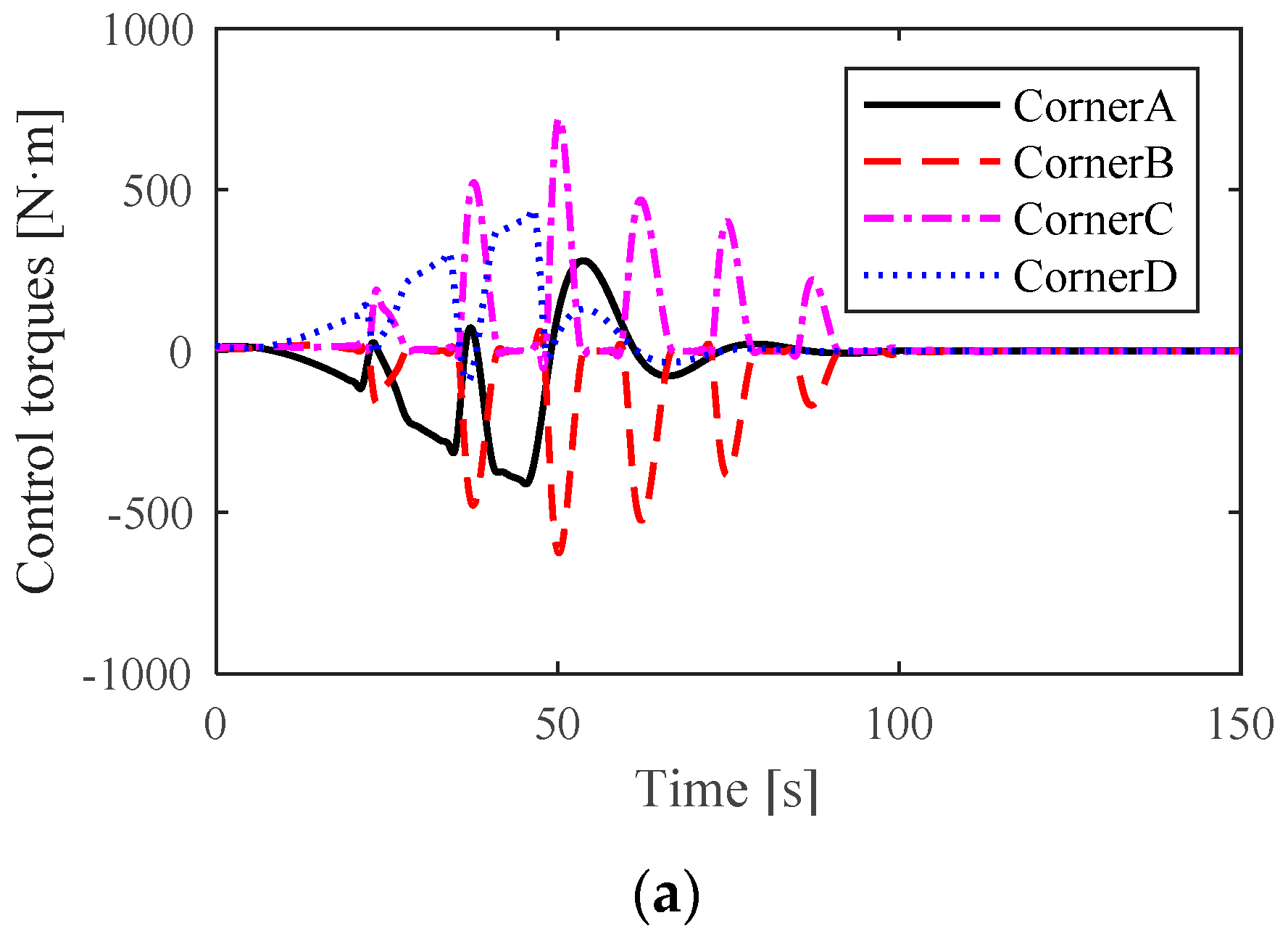

Figure 12 shows the distributed control torques of the driving wheels at each corner. It can be seen that the location deviation of the crane is close to zero before maintaining the uniform rotation, which reflects the robustness and effectiveness of the proposed control scheme. Furthermore, from the simulation results, note that the proposed quadratic program can effectively distribute the control torques and can thus improve the operational stability and control efficiency of the crane system.

4.2. Simulation Analysis of the Cooperative Operation

In this section, we focus on the effect of trolley movement on the crane locating performance, and the reference attitude and the initial attitude of the polar crane are set to be consistent with the above case; in this working condition, the distance between the trolley and the geometric center

is as follows:

Note that the center of mass and the rotary inertia of the crane will change in response to the variation of the parameter

. The simulation results are shown in

Figure 13,

Figure 14,

Figure 15 and

Figure 16.

From

Figure 13, it can be seen that the NTSM-ADRC-QP control scheme can still maintain fast convergence during crane operation, which reflects the better robustness of the designed control scheme. In addition, the simulation results further show that the movement of trolley has an important impact on crane location accuracy.

Figure 14 shows the contact forces of horizontal guide devices. We can see that the amplitude of the contact forces via the NTSM-ADRC-QP control scheme are decreased, which prove the robustness of the proposed control scheme on a side note.

Figure 15 shows the moving trajectories of the driving wheels at each corner. The simulation results are consistent with the results analyzed in

Figure 13 and

Figure 14. From the results, we can see that, under the center of mass and the rotary inertia changing, the moving trajectories of the driving wheels via NTSM-ADRC-QP are more precise.

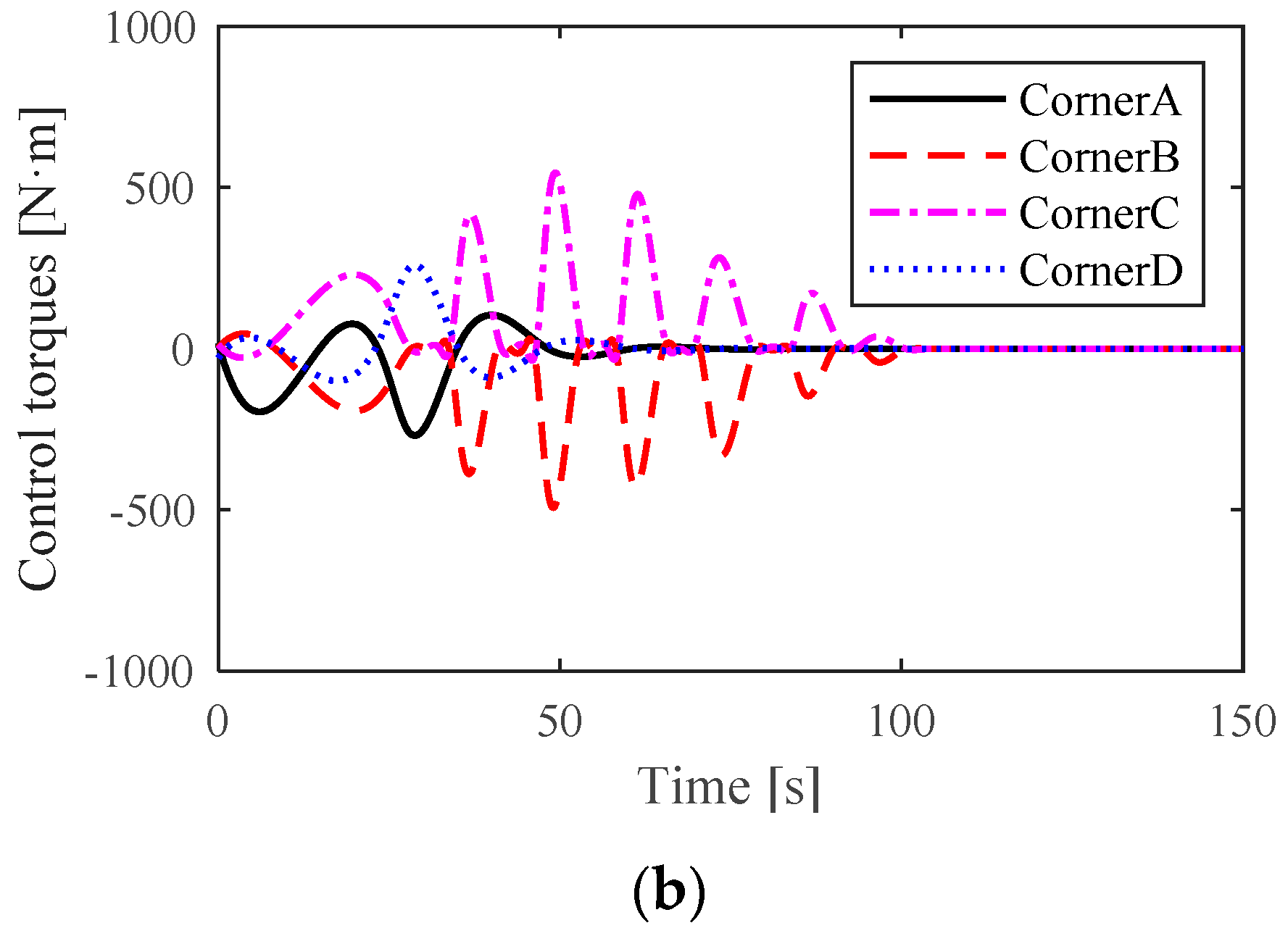

Figure 16 shows the distributed control torques of the driving wheels at each corner. In fact, based on the constraint relationships of the proposed quadratic programming algorithm, the variation in the location deviation will lead to variation in the control torques.

Figure 16 manifests the adjustment process of the crane location deviation under the condition of uniform rotation.

5. Conclusions

In this paper, a novel locating control scheme is presented to address the problem of precise location for a polar crane. Based on the Lagrange–Rouse equation, a nonholonomic constraint dynamic model of the polar crane is established, and the ADRC-based decoupling control method is proposed to solve cross-coupling disturbance of the crane system. To improve the locating accuracy and robustness, the NTSM is incorporated with ADRC, and the stability of the control scheme is proved by the Lyapunov function approach. Additionally, a control torque distribution method based on the quadratic programming algorithm is designed to deal with the redundant actuation of the bridge truck. Considering the center of gravity shift during crane operation, two typical working conditions are simulated to verify the effectiveness of the proposed control scheme. The simulation results show that the proposed control scheme can achieve effective dynamic control of precise locations on the basis of uniform rotation.

In future work, we will further consider factors such as creep characteristics of wheel–rail contact and response delay of the driving wheel to improve the performance and safety of the control scheme. Furthermore, we will add the scale model test to verify the effectiveness of the proposed control scheme.