STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards

Abstract

1. Introduction

- 1.

- Indirect or interconnected. The STEP-NC machining data are interpreted to generate toolpaths and program the operations. The G-code must be converted using a post-processor (interpreter) in the CNC to undertake the paths [13]. Thus, this machine code becomes completely invisible when used;

- 2.

- Interpreted or with embedded CAM. The axis movement command is executed directly from the STEP-NC file. However, the milling toolpaths cannot be modified during execution [13];

- 3.

- Adaptive or intelligent. The CNC controller evaluates the process data online during process execution. The results obtained are used to optimize the real-time manufacturing parameters. To adapt itself to the requirements, the controller decides whether modifications are needed in the toolpath or whether more operations should be added to the work plan [14].

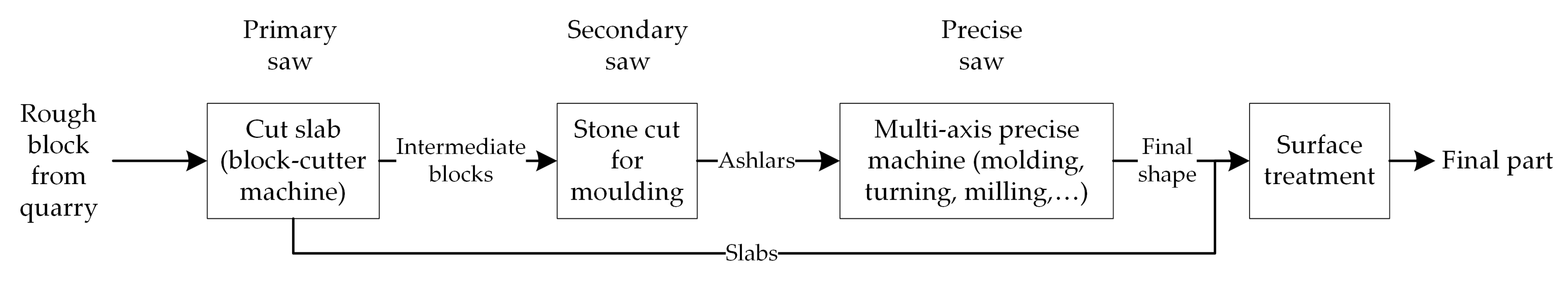

2. Automation in the Stone-Processing Sector

2.1. Stone-Processing Equipment

2.2. Automation Requirements for Stone-Processing Machines

3. New Standards for Machining Processes Automation: Work Specification and Toolpath Control

3.1. STEP-NC: Feature-Based Machining Specifications

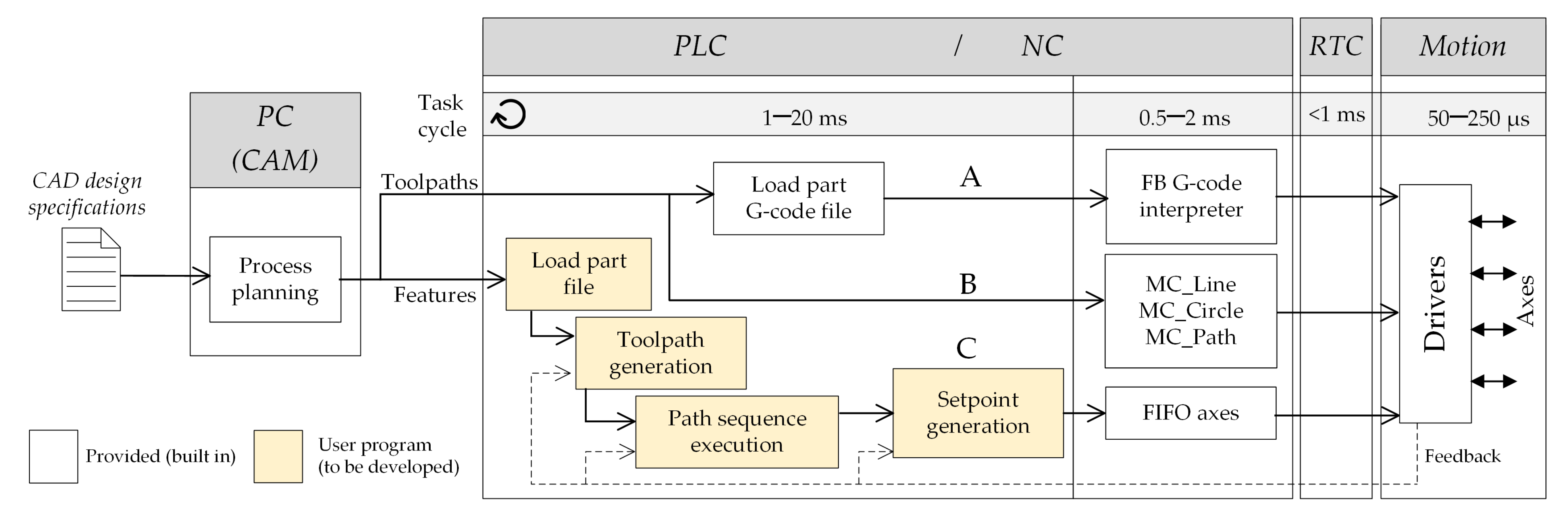

3.2. Industrial Automation Standards for Motion Control and Resources for Interpolated Toolpath Automation in Industrial Numerical Controllers

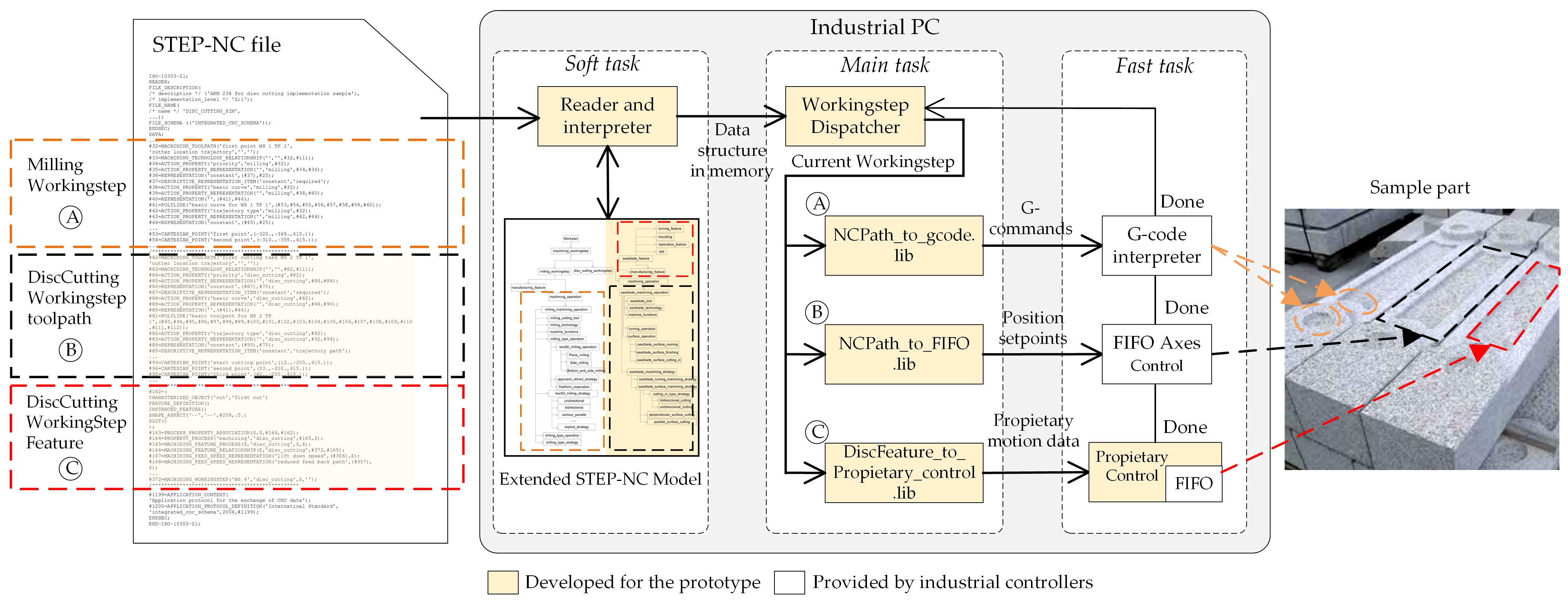

4. Feature-Based Mixed-Technology Automation Proposal for Stone-Processing Machines

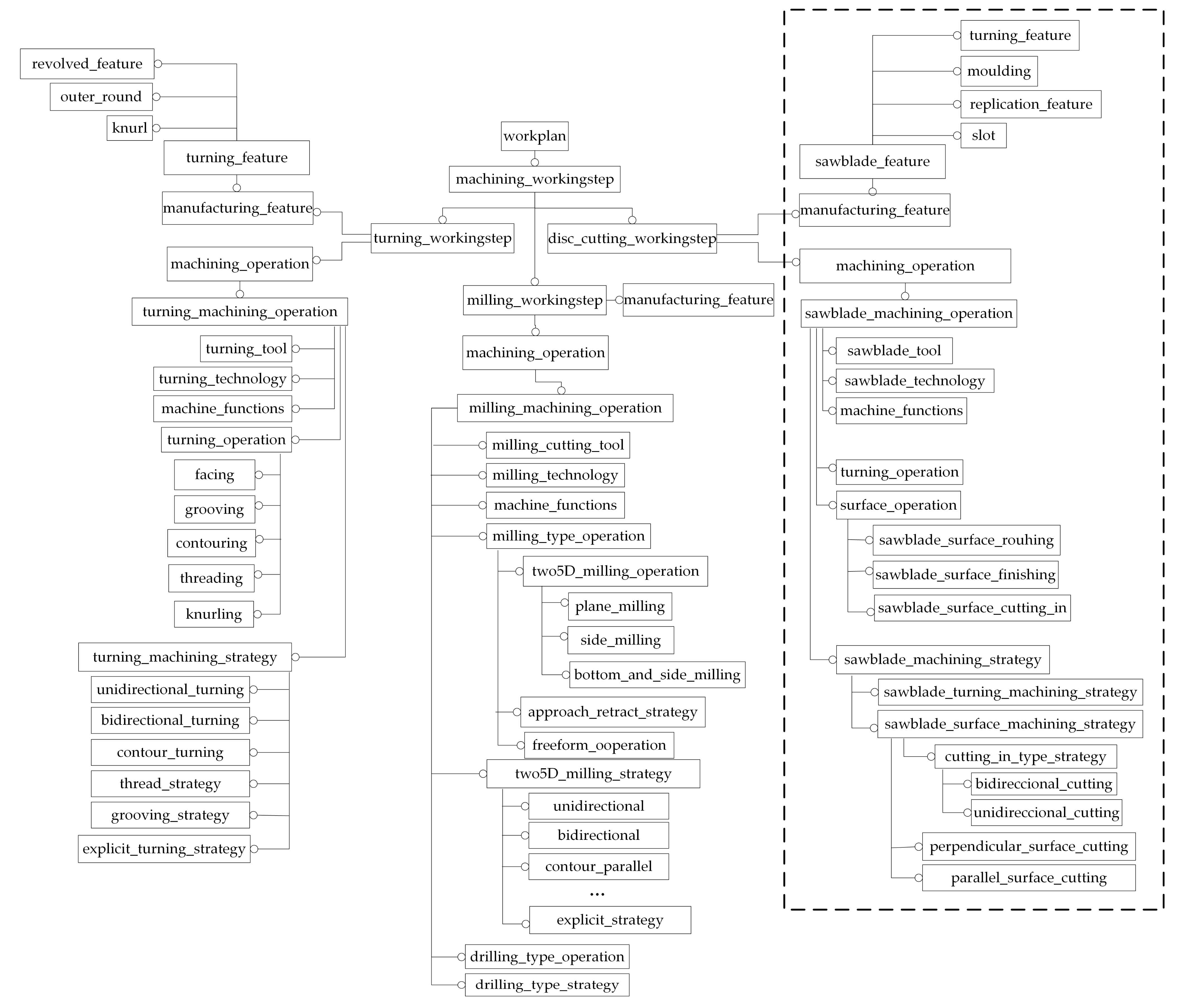

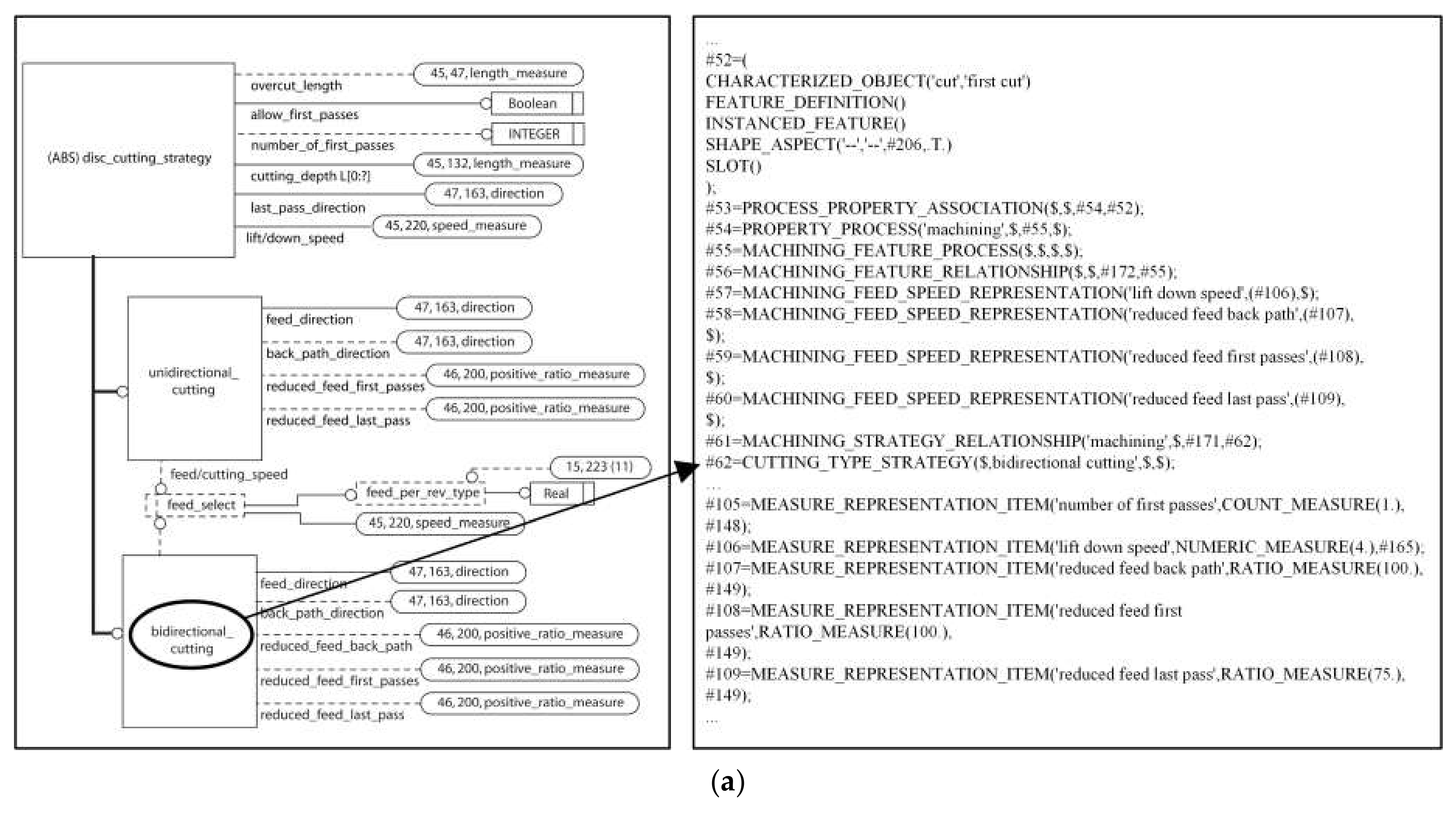

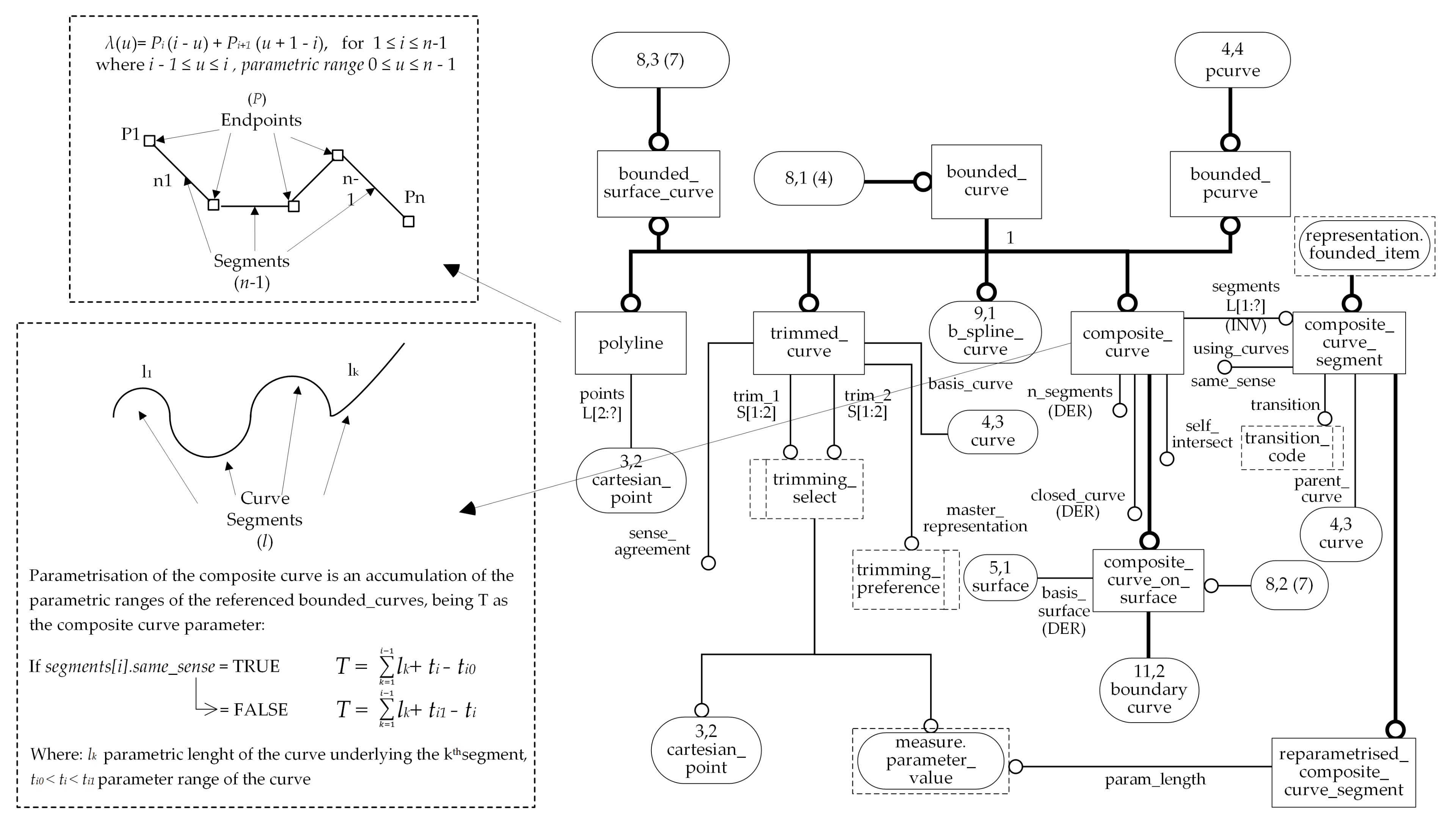

4.1. STEP-NC Model Extension for Stone Processing

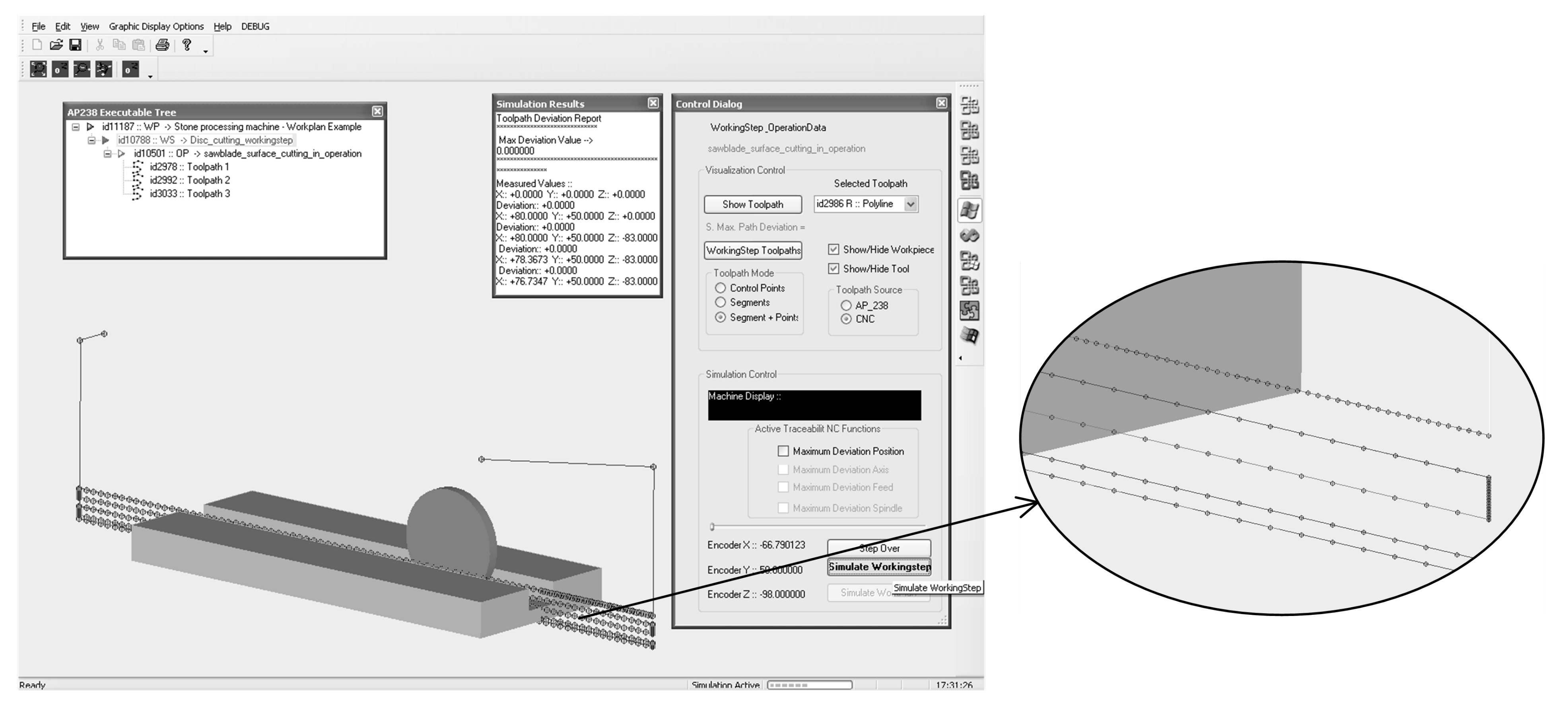

4.2. STEP-NC Prototype for Stone-Processing Automation: Simulation Implementation

| Algorithm 1: Setpoint generation |

| Input: A list of segments of a bounded_curve (Sbc) and CNC deviation data (CNCdv) |

| Output: A list of points to use in a FIFO axes control (Lout) |

| First vertex point, Fv; |

| Last vertex point, Lv; |

| Spatial norm, Sn; |

| Uniform abscissa distribution of points on the bounded_curve, Up; |

| Projected point, Pp; |

| 1 foreachsegment in Sbc do |

| 2 Fv, Lv ← Take the first vertex point and the last vertex point of the current segment |

| 3 Sn ← Calculus of the spatial norm from both vertex points (Fv, Lv) |

| 4 Up ← Computes a uniform abscissa distribution of points from Sn |

| 5 foreach point in Up do |

| 6 Update point with CNCdv |

| 7 Pp ← Project the point and its parameter on the current segment of thebounded_curve |

| 8 Add Pp to Lout |

| 9 end foreach |

| 10 end foreach |

4.3. STEP-NC Prototype for Stone-Processing Automation: Industrial Controller Implementation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO 6983-1:2009 Automation Systems and Integration—Numerical Control of Machines—Program Format and Definitions of Address Words—Part 1: Data Format for Positioning, Line Motion and Contouring Control Systems; ISO: Geneva, Switzerland, 2009.

- Gardan, J.; Makke, A.; Recho, N. A Method to Improve the Fracture Toughness Using 3D Printing by Extrusion Deposition. Procedia Struct. Integr. 2016, 2, 144–151. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Raagul, S.; Avs, Y.; Sriniketh, K.; Bcsc, S. Compact, Handheld Dosa Bot Design. In Proceedings of the 2018 2nd International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 11–12 May 2018; pp. 147–151. [Google Scholar]

- Ivan, M.; Ernek, M.; Miklovicova, E. TwinCAT Control of CNC Machine over CoE. In Proceedings of the 2019 22nd International Conference on Process Control (PC19), Strbske Pleso, Slovakia, 11–14 June 2019; pp. 91–96. [Google Scholar]

- S SIMOTION G-Code Interpreter—ID: 109477030—Industry Support Siemens. Available online: https://support.industry.siemens.com/cs/document/109477030/simotion-g-code-interpreter?dti=0&pnid=14515&lc=en-US (accessed on 23 October 2021).

- Lu, X.; Zhou, Y.F.; Xing, X.L.; Shao, L.Y.; Yang, Q.X.; Gao, S.Y. Open-Source Wire and Arc Additive Manufacturing System: Formability, Microstructures, and Mechanical Properties. Int. J. Adv. Manuf. Technol. 2017, 93, 2145–2154. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, H.; Hu, Q.; Liu, D.; Lammer, H. Research and Implementation of a Non-Supporting 3D Printing Method Based on 5-Axis Dynamic Slice Algorithm. Robot. Comput.-Integr. Manuf. 2019, 57, 496–505. [Google Scholar] [CrossRef]

- Xu, X.W.; Newman, S.T. Making CNC Machine Tools More Open, Interoperable and Intelligent—A Review of the Technologies. Comput. Ind. 2006, 57, 141–152. [Google Scholar] [CrossRef]

- Xu, X.W. Realization of STEP-NC Enabled Machining. Robot. Comput.-Integr. Manuf. 2006, 22, 144–153. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Hardwick, M.; Zhao, Y.F.; Proctor, F.M.; Nassehi, A.; Xu, X.; Venkatesh, S.; Odendahl, D.; Xu, L.; Hedlind, M.; Lundgren, M.; et al. A Roadmap for STEP-NC-Enabled Interoperable Manufacturing. Int. J. Adv. Manuf. Technol. 2013, 68, 1023–1037. [Google Scholar] [CrossRef]

- Rauch, M.; Laguionie, R.; Hascoet, J.-Y.; Suh, S.-H. An Advanced STEP-NC Controller for Intelligent Machining Processes. Robot. Comput.-Integr. Manuf. 2012, 28, 375–384. [Google Scholar] [CrossRef]

- Rauch, M.; Laguionie, R.; Hascoet, J.-Y. Achieving a STEP-NC Enabled Advanced NC Programming Environment. In Advanced Design and Manufacturing Based on STEP; Xu, X., Nee, A.Y.C., Eds.; Springer Series in Advanced Manufacturing; Springer: London, UK, 2009; pp. 197–214. ISBN 978-1-84882-738-7. [Google Scholar]

- Lan, H.; Liu, R.; Zhang, C. A Multi-Agent-Based Intelligent STEP-NC Controller for CNC Machine Tools. Int. J. Prod. Res. 2008, 46, 3887–3907. [Google Scholar] [CrossRef]

- Xiao, W.; Zheng, L.; Huan, J.; Lei, P. A Complete CAD/CAM/CNC Solution for STEP-Compliant Manufacturing. Robot. Comput.-Integr. Manuf. 2015, 31, 1–10. [Google Scholar] [CrossRef]

- Latif, K.; Adam, A.; Yusof, Y.; Kadir, A.Z.A. A Review of G Code, STEP, STEP-NC, and Open Architecture Control Technologies Based Embedded CNC Systems. Int. J. Adv. Manuf. Technol. 2021, 114, 2549–2566. [Google Scholar] [CrossRef]

- Slavkovic, N.; Zivanovic, S.; Milutinovic, D. An Indirect Method of Industrial Robot Programming for Machining Tasks Based on STEP-NC. Int. J. Comput. Integr. Manuf. 2019, 32, 43–57. [Google Scholar] [CrossRef]

- Alvares, A.J.; Rodriguez, E.; Riano Jaimes, C.I.; Toquica, J.S.; Ferreira, J.C.E. STEP-NC Architectures for Industrial Robotic Machining: Review, Implementation and Validation. IEEE Access 2020, 8, 152592–152610. [Google Scholar] [CrossRef]

- PLCopen. Creating Reusable, Hardware Independent Motion Control Applications via IEC 61131-3 and PLCopen Function Blocks; PLCopen: Zaltbommel, The Netherlands, 2018. [Google Scholar]

- Wang, C.Y.; Clausen, R. Computer Simulation of Stone Frame Sawing Process Using Diamond Blades. Int. J. Mach. Tools Manuf. 2003, 43, 559–572. [Google Scholar] [CrossRef]

- Tönshoff, H.K.; Hillmann-Apmann, H.; Asche, J. Diamond Tools in Stone and Civil Engineering Industry: Cutting Principles, Wear and Applications. Diam. Relat. Mater. 2002, 11, 736–741. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, R.; Hu, T. On the Futuristic Machine Control in a STEP-Compliant Manufacturing Scenario. Int. J. Comput. Integr. Manuf. 2006, 19, 508–515. [Google Scholar] [CrossRef]

- Brook, B. Principles of Diamond Tool Technology for Sawing Rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 41–58. [Google Scholar] [CrossRef]

- Mikaeil, R.; Mokhtarian, M.; Shaffiee Haghshenas, S.; Careddu, N.; Alipour, A. Assessing the System Vibration of Circular Sawing Machine in Carbonate Rock Sawing Process Using Experimental Study and Machine Learning. Geotech. Geol. Eng. 2021, 1–17. [Google Scholar] [CrossRef]

- Danjou, C.; Le Duigou, J.; Eynard, B. Closed-Loop Manufacturing Process Based on STEP-NC. Int. J. Interact. Des. Manuf. 2017, 11, 233–245. [Google Scholar] [CrossRef]

- ISO 14649:2003 Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers; ISO: Geneva, Switzerland, 2003.

- ISO 10303-238:2020 Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 238: Application Protocol: Model Based Integrated Manufacturing; ISO: Geneva, Switzerland, 2020.

- Kumar, S.; Newman, S.T.; Nassehi, A.; Vichare, P.; Tiwari, M.K. An Information Model for Process Control on Machine Tools. In Advances in Intelligent and Soft Computing, Proceedings of the 6th CIRP-Sponsored International Conference on Digital Enterprise Technology; Huang, G.Q., Mak, K.L., Maropoulos, P.G., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 66, pp. 1565–1582. ISBN 978-3-642-10429-9. [Google Scholar]

- Gómez-Hernández, J.-F.; Davia-Aracil, M.; Sanchez-Romero, J.-L.; Jimeno-Morenilla, A. An Approach to Implement STEP-NC in the Footwear Industry. Comput. Ind. 2021, 125, 103384. [Google Scholar] [CrossRef]

- Nassehi, A.; Newman, S.T.; Xu, X.W.; Rosso, R.S.U. Toward Interoperable CNC Manufacturing. Int. J. Comput. Integr. Manuf. 2008, 21, 222–230. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-Integrated Software Platform for Robotic Construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Correa, F. Robot-Oriented Design for Production in the Context of Building Information Modeling. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction and Mining, Auburn, AL, USA, 21 July 2016; pp. 853–861. [Google Scholar]

- Pellegrinelli, S.; Terkaj, W.; Urgo, M. A Concept for a Pallet Configuration Approach Using Zero-Point Clamping Systems. Procedia CIRP 2016, 41, 123–128. [Google Scholar] [CrossRef][Green Version]

- Hamid, M.; Tolba, O.; El Antably, A. BIM Semantics for Digital Fabrication: A Knowledge-Based Approach. Autom. Constr. 2018, 91, 62–82. [Google Scholar] [CrossRef]

- Siemens AG. Library Kinematics Control; Siemens AG: Munich, Germany, 2021. [Google Scholar]

- MC_MovePath—Beckhoff Automation GmbH & Co. KG. Available online: https://infosys.beckhoff.com/english.php?content=../content/1033/tf5410_tc3_collision_avoidance/8893267467.html&id= (accessed on 23 October 2021).

- LENZE. Motion Function Libraries; Reference manual PLC Designer; Lenze Automation GmbH: Stuttgart, Germany, 2019. [Google Scholar]

- MC_MovePath—ISG Industrielle Steuerungstechnik GmbH. Available online: https://www.isg-stuttgart.de/kernel-html5/en-GB/190234507.html (accessed on 23 October 2021).

- Yaskawa Electric Corporation. MotionWorks; Toolbox Introduction: Kitakyushu, Japan; Yaskawa Electric Corporation: Kitakyushu, Japan, 2017. [Google Scholar]

- REX Controls. Function Blocks of REXYGEN; REX Controls s.r.o.: Pilsen, Czech Republic, 2021. [Google Scholar]

- OMRON Corporation. NJ/NX-Series Motion Control Instructions Reference Manual; OMRON Corporation: Kyoto, Japan, 2019; p. 768. [Google Scholar]

- Beckhoff Automation GmbH & Co. KG. TwinCAT 3|NC FIFO AXES; Beckhoff Automation GmbH & Co. KG: Verl, Germany, 2021. [Google Scholar]

- Liu, L.; Yao, Y.; Li, J. Development of a Novel Component-Based Open CNC Software System. Int. J. Adv. Manuf. Technol. 2020, 108, 3547–3562. [Google Scholar] [CrossRef]

- Zhang, X.; Nassehi, A.; Safaieh, M.; Newman, S.T. Process Comprehension for Shopfloor Manufacturing Knowledge Reuse. Int. J. Prod. Res. 2013, 51, 7405–7419. [Google Scholar] [CrossRef]

- Sun, P.; Liu, Q.; Ding, J.; Pi, S. Open CNC System Design for Multiple Intelligent Functions Based on TwinCAT and NET Framework. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 910–915. [Google Scholar]

- Wang, H.; Tang, X.; Song, B.; Wang, X. A Novel Architecture of the Embedded Computer Numerical Control System Based on PLCopen Standard. Proc. Inst. Mech. Eng. B. J. Eng. Manuf. 2014, 228, 595–605. [Google Scholar] [CrossRef]

- Wang, H.; Xu, X.; Tedford, J.D. An Adaptable CNC System Based on STEP-NC and Function Blocks. Int. J. Prod. Res. 2007, 45, 3809–3829. [Google Scholar] [CrossRef]

- Harbs, E.; Negri, G.H.; Jarentchuk, G.; Hasegawa, A.Y.; Rosso, R.S.U., Jr.; da Silva Hounsell, M.; Lafratta, F.H.; Ferreira, J.C. CNC-C2: An ISO14649 and IEC61499 Compliant Controller. Int. J. Comput. Integr. Manuf. 2021, 34, 621–640. [Google Scholar] [CrossRef]

- Hu, P.; Han, Z.; Fu, Y.; Fu, H. Implementation of Real-Time Machining Process Control Based on Fuzzy Logic in a New STEP-NC Compatible System. Math. Probl. Eng. 2016, 2016, 9814973. [Google Scholar] [CrossRef]

- ISO 10303-10:2004 Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 10: General Process Data; ISO: Geneva, Switzerland, 2004.

- ISO 10303-224:2006 Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 224: Application Protocol: Mechanical Product Definition for Process Planning Using Machining Features; ISO: Geneva, Switzerland, 2006.

- IEC 61131-3:2013 Programmable Controllers—Part 3: Programming Languages; IEC: Geneva, Switzerland, 2013.

- Adamson, G.; Wang, L.; Moore, P. Feature-Based Function Block Control Framework for Manufacturing Equipment in Cloud Environments. Int. J. Prod. Res. 2019, 57, 3954–3974. [Google Scholar] [CrossRef]

| Manufacturer | Implementation | G-code | UD 1 Path | Data Preparation | Runtime Adaptation | Additional Information |

|---|---|---|---|---|---|---|

| Siemens [35] | MC_MovePath | Yes | Yes | Propietary external tool (G-code) MC_PathSelect (user path) | Tool and radius offset | Feedback of the remaining distance to the next toolpath and current running trajectory. Insertion of actions, waits, and planned events during trajectory execution. |

| Beckhoff [36] | MC_MovePath | No | Yes | MC_MoveLinear (circular) AbsPreparation for each toolpath | No | Insertion of planned intermediate jobs during the execution of the trajectory. “Done” signal at the end of the specified set of paths. |

| Lenze SE [37] | MC_MovePath | Yes | No | MC_PathRef (FromFile) | No | Current running line and its number if previously specified in the G-code by the “N” code. |

| ISG Industrielle Steuerungstechnik [38] | MC_MovePath | Yes | No | MCV_GrpPathPrepare | No | Insertion of planned intermediate jobs during the execution of the trajectory. Feedback of the execution of the paths through the block “MVC_ReadActualPathInfo”: current line number, % distance completed, and deviation from the axis position from the continuation position. |

| Yaskawa [39] | MC_MovePath | Yes | Yes | Read_Gcode_File (G-code) CP_PathGenerator (user path) | Tool offset | Remote path via UDP (minimum delay of 50 ms). Events and jobs. Feedback of lines currently processed, executed, and the difference between processed and executed total lines. It allows the movement of six axes and one extruder. |

| Rexygen MC [40] | MC_MovePath | No | Yes | Creation of the path by using a drawing tool | No | Single-path oriented. Spatial trajectory generation using the NURBS algorithm. |

| Omron [41] | MC_SyncMoveAbsolute/Velocity | No | Yes | Generation of motion profiles | Yes | Cyclically using the specified target position or velocity for the axis selected. |

| Beckhoff [42] | FIFO Axes | No | Yes | Generation of motion profiles | Yes | Synchronous motion of all axes specified in the FIFO table. Main PLC task sends an array of points in each PLC cycle specifying the synchronous FIFO time. Linear interpolation between neighboring points in the FIFO task to obtain the acceleration and velocity values of the control loops of the motion control task (SAF cycle). FIFO cycle can be faster than NC cycle. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garrido, J.; Silva, D.; Sáez, J. STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards. Machines 2021, 9, 327. https://doi.org/10.3390/machines9120327

Garrido J, Silva D, Sáez J. STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards. Machines. 2021; 9(12):327. https://doi.org/10.3390/machines9120327

Chicago/Turabian StyleGarrido, Julio, Diego Silva, and Juan Sáez. 2021. "STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards" Machines 9, no. 12: 327. https://doi.org/10.3390/machines9120327

APA StyleGarrido, J., Silva, D., & Sáez, J. (2021). STEP-NC-Compliant Implementation to Support Mixed-Control Technologies Applied to Stone-Processing Machines Based on Industrial Automation Standards. Machines, 9(12), 327. https://doi.org/10.3390/machines9120327