A Multi-Criteria Decision Framework Considering Different Levels of Decision-Maker Involvement to Reconfigure Manufacturing Systems

Abstract

1. Introduction

2. Related Studies

- Changes in production volume: This is known as a scalability problem and is related to demand fluctuations and variations in the required production amount [13].

- Changes in functionality: This is known as a convertibility problem and is related to the introduction, upgrading, or modification of new products or process capabilities or functionalities [14].

- Changes in requirements: This is related to a modification of the technical specifications of a product. In this case, the aim is to find the configuration that best encounters the required specifications [15].

- Changes in resource availability or reliability: This refers to the operating status of the production resources and equipment. Examples of such changes are breakdowns or failures in machines [13].

- The different types of changes have motivated researchers to tackle them from different perspectives:

- System engineering: From this perspective, researchers have focused on finding configurations that best encounter the required customer specifications [15].

- Planning: From this perspective, researchers have focused on determining, in advance, the sequence of configurations that best cope with the predicted changes over numerous time periods [11].

- Monitoring and control: From this perspective (i.e., at run-time or production execution), researchers have considered a reconfiguration as a possible solution enabling the use of the flexibility of the system to manage disturbances, disruptions, and risks. It is worth mentioning that only very few authors have tackled the configuration from this perspective [16].

2.1. Multi-Criteria Decision Making for RMS

2.2. Weighting Schemes

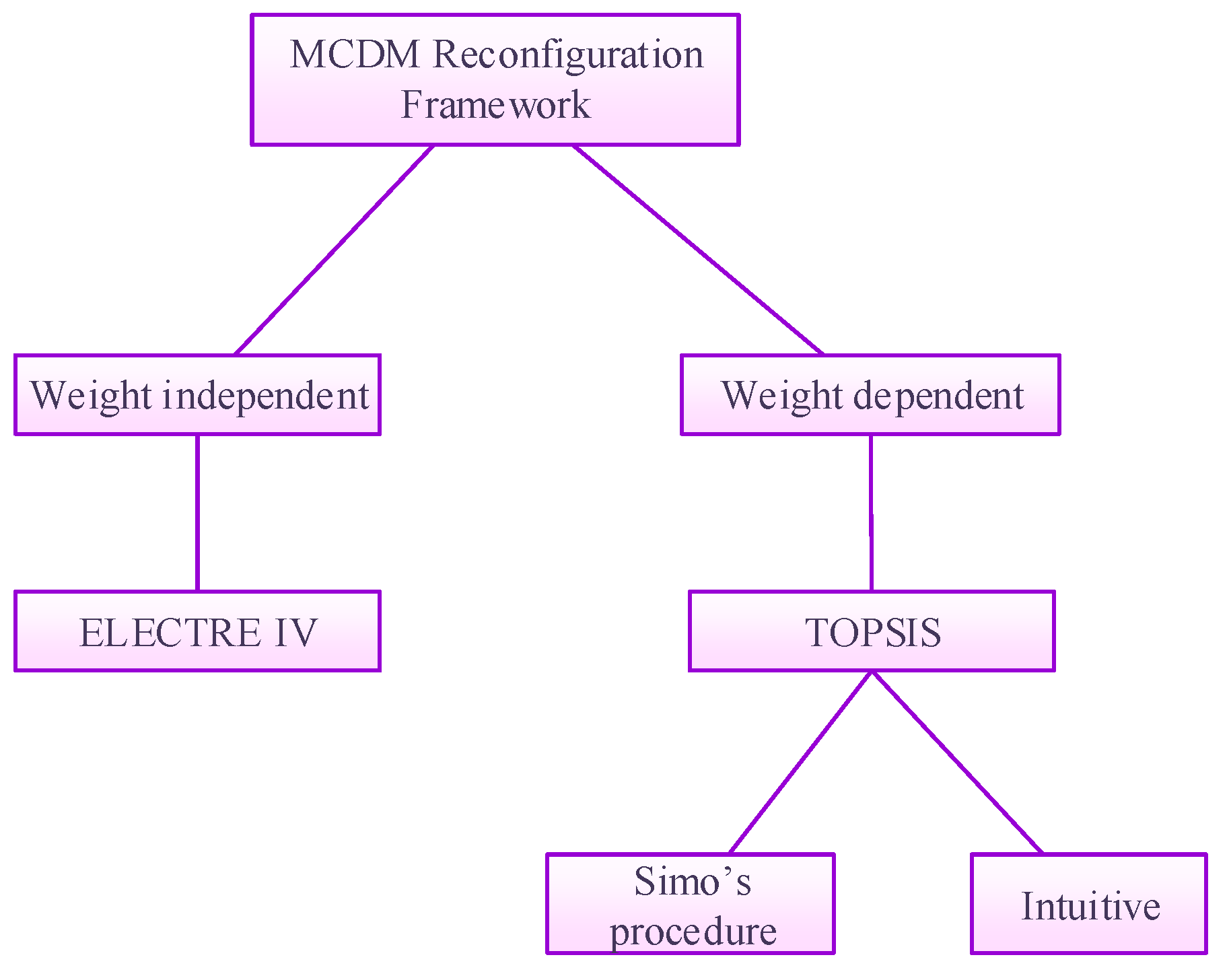

3. MCDM Reconfiguration Framework

- intuitive weighting through direct DM involvement;

- indirect weighting through a revised SIMOS procedure weighting; and

- DM (DM) independent weighting.

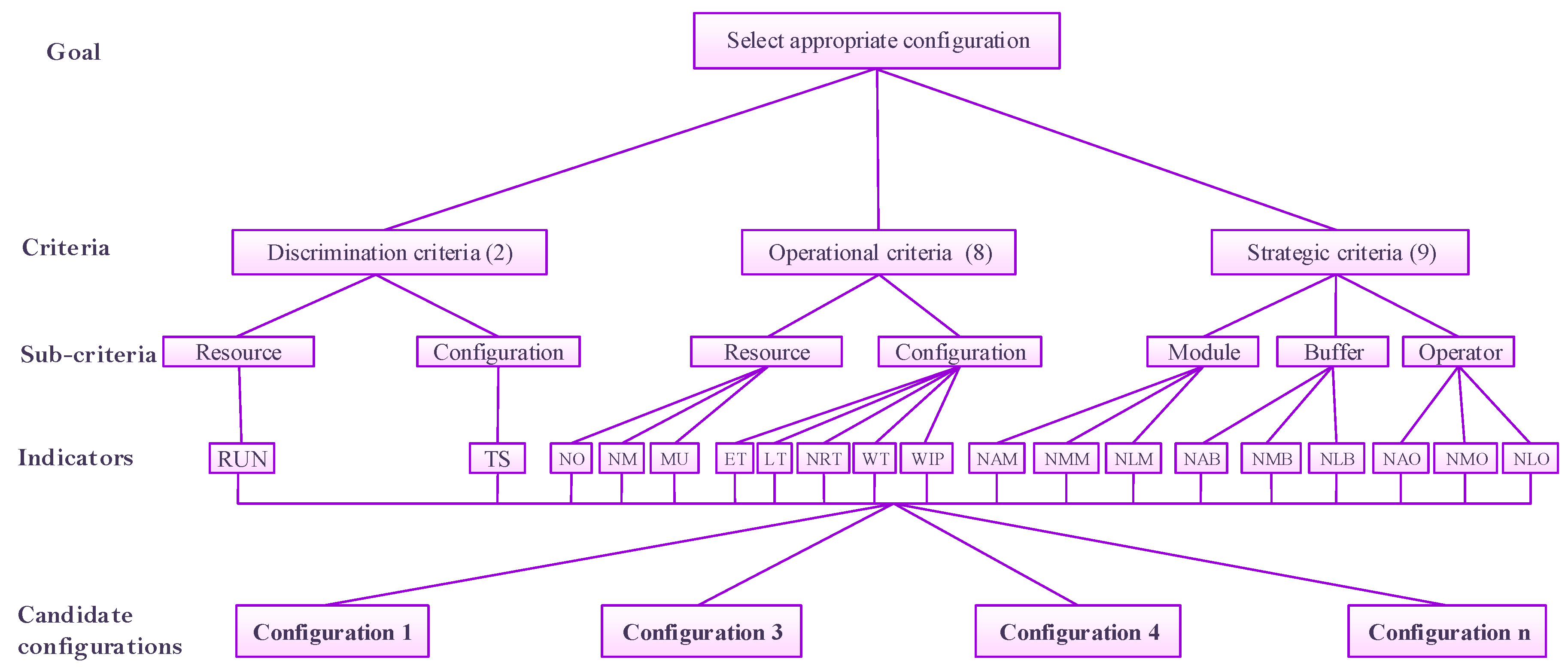

- Discrimination criteria are used to evaluate the ability of the configurations to meet the new production requirements, which includes the resource unavailability (RUN) and throughput satisfaction (TS).

- Operational criteria are used to evaluate the dynamic behavior and performance of the candidate configurations, which are composed of two types, namely configuration and resources indicators. The configuration indicators measure the ability of a configuration to meet the current requirements, and resource indicators measure the performance of individual modules. Table 1 illustrates these indicators.

- Strategic criteria are used to evaluate the effort (i.e., cost or time) needed to move from the current configuration to a new candidate configuration (i.e., a reconfiguration process). This effort is assessed as a function of the number of removed/added/relocated buffers, machines, and operators. Table 2 shows these indicators.

4. TOPSIS Procedure

4.1. Intuitive Weighting

4.2. Revised SIMOS Procedure

4.2.1. Collecting the Information

- 1-

- The name and a brief description of each criterion are written on a card. Hence, there will be named cards, where represents the number of criteria (in this case, criteria). These cards should not contain any information that can influence the preferences of the DM.

- 2-

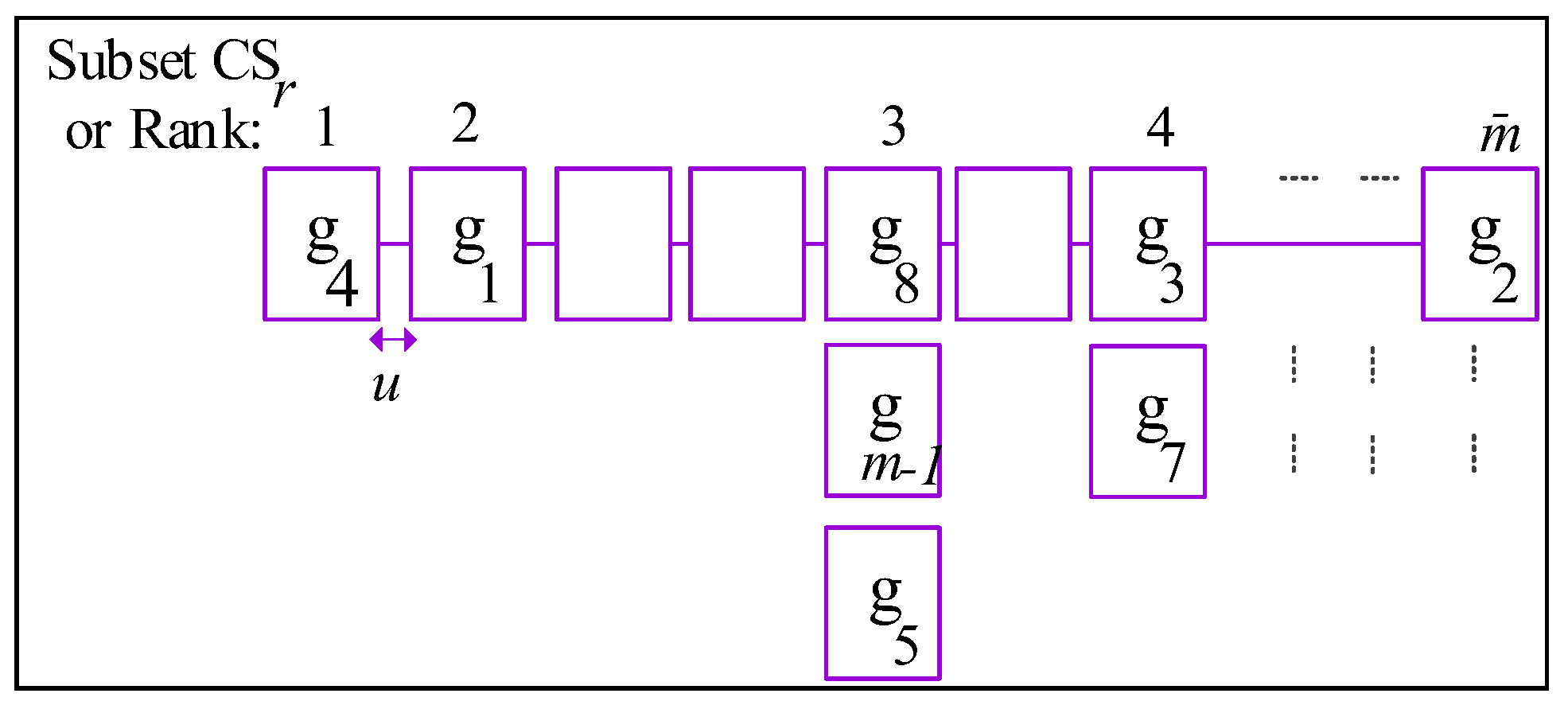

- The named cards are given to the DM without any specific arrangement for placement in descending order, starting from the least important cards on the left-hand side and ending with the most important card on the right-hand side (). If the DM believes that two criteria have the same importance, the DM can group them into a subset. In the end, there will be a ranking of the subsets of the criteria ; here, represents the number of subsets and . As depicted in Figure 3, can be composed of a single criterion, , where rank consists of criterion , or can be composed of two or more criteria, i.e., , which consists of two criteria and .

- 3-

- Until now, any two consecutive subsets and have an identical distance between them equal to the scale unit (Figure 3). To help the DM conceive the importance of any two subsets of the criteria, the DM is requested to recognize the distance between them by inserting one or more blank cards. Each inserted blank card is intended to give an extra unit distance between their weights. For instance, in Figure 3, and have a distance equal to , which means the latter is -times more important than the former.

- 4-

- In the end, the DM will be requested to say how much the difference in importance is between the subset on the right-hand side , (the most important) in comparison with the subset on the left-hand side (the least important). In other words, the DM will be asked whether the difference of importance between these two subsets is two-fold, three-fold, or more. This importance value is the Z-ration that determines the absolute value of each player in the evaluation scale.

4.2.2. Algorithm

4.2.3. Rounding and Minimization of Distortion

- List : This is achieved by ranking the pairs of in increasing values of .

- List : This is achieved by ranking the pairs of in increasing values of .

- Set and consider as the number of criteria in set .

- (a)

- In the case of , is formed with the summation of the criteria of and , which represents the last criterion belonging to and not . Thus, list is constructed by the first criterion belonging to and not .

- (b)

- In the case of , is formed with the summation criterion belonging to and not , and , which represents the first criterion belonging to and not Thus, list is constructed by , the last criterion belonging to and not .

4.3. TOPSIS Algorithm

- Step 1:

- Determine the evaluation matrix of which is as follows:where represent the performance of indicator j (the third section) in configuration i, assessed based on the new production requirements triggered by a disturbance.

- Step 2:

- Deduce, the normalized matrix of which is as follows:

- Step 3:

- Calculate the weighted normalized matrix of which is the following:

- Step 4:

- Let , which is related to the set of indicators that have a positive impact, where these indicators are .Let be related to the set of indicators that have a negative impact, where these indicators areCalculate the row vector of the positive ideal solutions and the row vector of the negative ideal solutions as follows:where and are the best and worst values of criterion j recorded over all configurations.

- Step 5:

- For each configuration i, calculate distance from the positive ideal solutions and distance from the negative ideal solutions:

- Step 6:

- Calculate , the relative closeness to the ideal solution.

- Step 7:

- Order the configurations based on their relative closeness in ascending order.

- Step 8:

- Choose the first configuration.

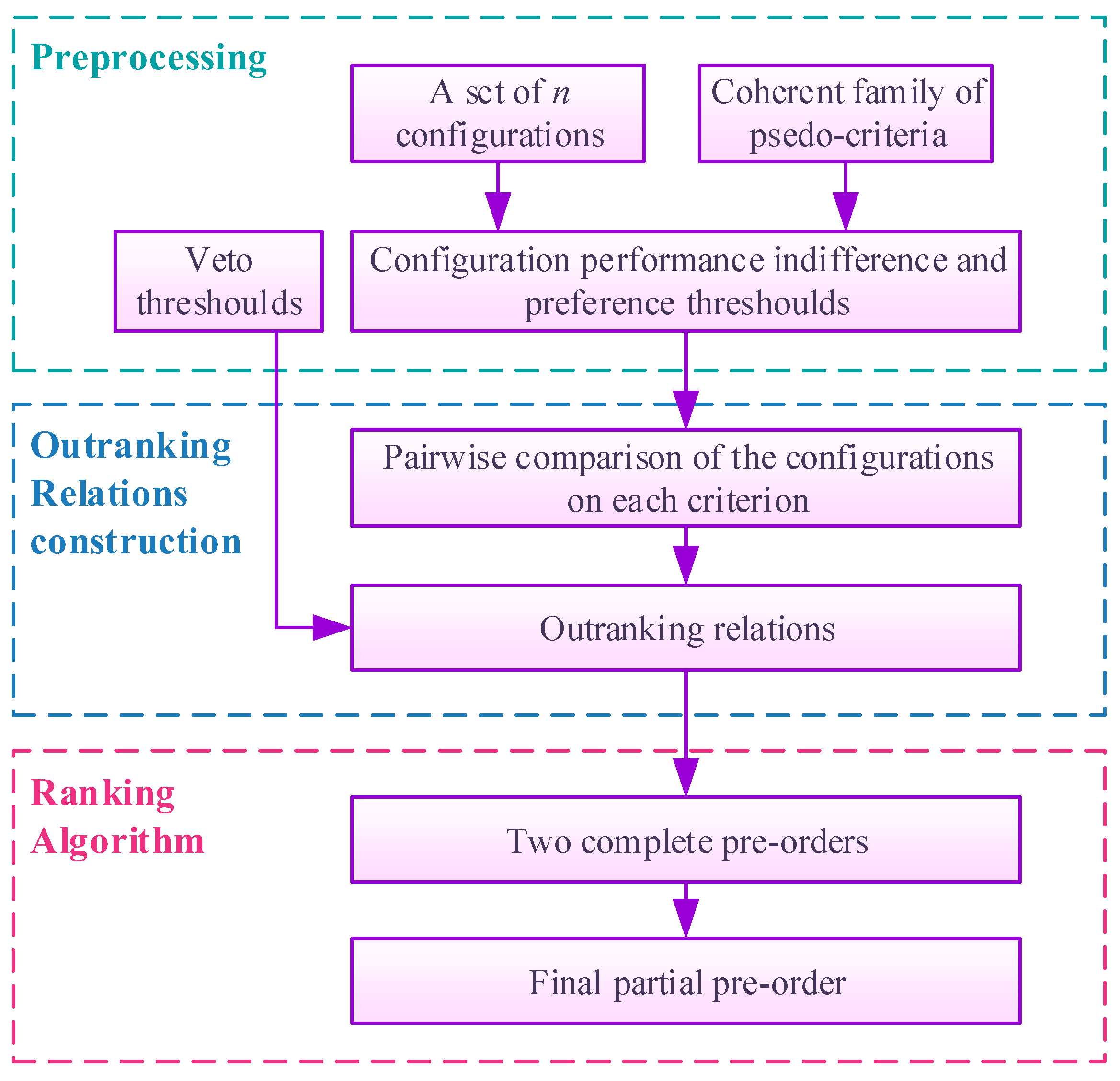

5. ELECTRE IV Procedure

- as a set of n candidate configurations,

- as a set of m criteria, where , and

- as the performance of the configuration according to the criterion .

5.1. Outranking Relation Constructions

5.1.1. Thresholds

- Indifference threshold refers to the largest difference in the performance between any two configurations and compatible with the situation in which there is no difference.

- Preference threshold refers to the smallest difference in performance between any two configurations and in which the DM undoubtedly prefers an alternative that has the best performance.

- Veto threshold is the smallest difference in performance between any two configurations and according to which the DM is not in favor of the idea that the worst between the two configurations under consideration on a specific criterion may be overall regarded as equivalent to the better one, even when the performance of the worst is better under all other criteria.

- The calculation of the direct indifference threshold is .

- The calculation of the inverse indifference threshold is .

- The direct indifference threshold will be calculated as .

- The inverse indifference threshold will be calculated as .

- Case 1: Increasing the preferences for the performance (↑) and direct thresholds (→).

- Case 2: Decreasing the preferences for the performance (↓) and direct thresholds (→).

- Case 3: Increasing the preferences for the performance (↑) and inverse thresholds (←).

- Case 4: Decreasing the preferences for the performance (↓) and inverse thresholds (←).

- In Case 1, the coefficient is .

- In Cases 2 and 3, the coefficient is .

- In Case 4, the coefficient is .

- The following relation should be satisfied for each criterion: .

- To avoid an incoherence, the following conditions should be satisfied:

5.1.2. Preferences and Indifferences

5.1.3. Pairwise Binary Relations

5.1.4. Outranking Relations

| Quasi-dominance | ; |

| Canonic-dominance | ; |

| Pseudo-dominance | ; |

| Sub-dominance | ; |

| Veto-dominance | . |

5.1.5. Fuzzy Outranking Matrix

| Fuzzy outranking matrix = | . | . | (24) | ||||

| 1 | |||||||

| 1 | |||||||

| . | . | 1 | |||||

| . | 1 | ||||||

| 1 |

5.1.6. Distillation Threshold

- In the first step, only the strongest dominance threshold among those that have been asserted will be considered.

- In the second step, the two strongest dominance thresholds will be considered.

- : determines the number of configurations that outranks:

- : (determines the number of configurations that outrank :

- : ( determines the relative rank of configuration in set :

5.2. Ranking Algorithm

5.2.1. Distillation

5.2.2. Ascending and Descending Pre-Ordering Algorithms.5.2.3. Final Ranking

| Step-1: | |

| Step-2: | |

| Step-3: | |

| Step-4: | Among the arcs of the fuzzy outranking relations that have credibility lower than , select the one with the maximum value: Notice that |

| Step-5: | Calculate the of all configurations belonging to . |

| Step-6: | Obtain the minimum or maximum : , or . |

| Step-7: | Build the subset: , or |

| Step-8: | ifor or then, go to step 9 else, do , = or = , go to step 4 |

| Step-9: | do = or = if or then , go to step 2 else, END of distillation. |

- Configuration is considered better than if in at least one of the distillations, is better than , and in the other distillation, is at least as well ranked as .

- Configuration is judged as indifferent to if the two configurations belong to the same equivalence class in the two pre-orders.

- Configuration and are incomparable if is better ranked than in the ascending distillation and is better ranked than in the descending distillation, or vice-versa.

6. Case Study

6.1. Presentation of the Case Study

6.1.1. Simulation-Based Evaluation of Configurations

6.1.2. Disturbance Occurrence

6.2. TOPSIS Selection

6.2.1. Intuitive Weighting

| RUN | TS | NO | NM | MU | ET | LT | NRT | WT | WIP | NAM | NMM | NLM | NAB | NMB | NLB | NAO | NMO | NLO | ||

| E= | 1 | 1 | 4 | 4 | 0.79 | 2 | 0 | 44 | 1.39 | 13.80 | 1 | 0 | 0 | 4 | 0 | 0 | 1 | 0 | 0 | Config D |

| 0 | 1 | 3 | 3 | 0.62 | 0 | 0 | 16 | 1.1 | 8.9 | 1 | 1 | 0 | 3 | 0 | 1 | 1 | 1 | 0 | Config C | |

| 1 | 1 | 4 | 4 | 0.72 | 1 | 0 | 32 | 1.89 | 21.05 | 2 | 1 | 0 | 0 | 0 | 0 | 2 | 1 | 0 | Config B |

6.2.2. Improved SIMOS Weighting

6.3. ELECTRE IV Selection

| Fuzzy outranking matrix = | ||||

| 1 | 0 | 0 | ||

| 0 | 1 | 0 | ||

| 0.2 | 0 | 1 |

6.3.1. Descending Pre-Order

| crispy outranking matrix = | ||||

| 0 | 0 | 0 | ||

| 0 | 0 | 0 | ||

| 1 | 0 | 0 |

| Power, weakness, and qualification | = | ||||

| Power | 1 | 0 | 0 | ||

| Weakness | 0 | 0 | 1 | ||

| Qualification | 1 | 0 | -1 |

6.3.2. Ascending Pre-Order

| crispy outranking matrix = | ||||

| 0 | 0 | 0 | ||

| 0 | 0 | 0 | ||

| 1 | 0 | 0 |

| Power, weakness, and qualification | = | ||||

| Power | 1 | 0 | 0 | ||

| Weakness | 0 | 0 | 1 | ||

| Qualification | 1 | 0 | -1 |

6.3.3. Final Ranking

6.4. Results and Discussion

- In a sense, the fact that the intuitive and SIMOS weighting provides identical rankings demonstrates a justification of the intuitive weighting procedure. In fact, SIMOS weighting is a type of detailed and documented intuitive weighting. However, such a result is not systematic. It may be useful to consider a sensitivity analysis to assess the impact of the weight variation and an assignment in the reconfiguration decision.

- Intuitive criteria weighting and DM preferences. The criteria weights are set up to favor the discrimination criteria first, followed by the operational and strategic criteria in order. Within each category, the criteria weights are assigned equally (the TOPSIS section) for the sake of simplification. However, the weights within each category are not necessarily equal. For example, in the strategic criteria category, the effort/cost required to add or move modules is not equal to the effort/cost required to add or move operators. The revised SIMOS method overcomes this issue and assigns different weights for each criterion in the same category.

- Estimation of theratio during SIMOS procedure. Standardizing this ratio in each manufacturing sector is worth investigating. Such standardization can be achieved in several ways, such as by surveying field experts.

- ELECTRE IV and threshold parameters. Some parameters have to be set up to make a clear decision regarding an indifference, preference, or veto relation. Because a configuration ranking and selection are highly sensitive to such parameters, a more rational and systematic approach should be considered to set them up, based for example on learning [38], [39], or on simulation–optimization [34] techniques.

7. Conclusions and Future Research

Author Contributions

Funding

Conflicts of Interest

References

- Bougrine, A.; Darmoul, S.; Hajri-gabouj, S. TOPSIS based multi-criteria reconfiguration of manufacturing systems considering operational and ergonomic indicators. In Proceedings of the 1st International Conference on Advanced Systems and Electric Technologies, IC_ASET, Hammamet, Tunisia, 14–17 January 2017. [Google Scholar]

- ElMaraghy, H.A. Changing and Evolving Products and Systems—Models and Enablers. In Changeable and Reconfigurable Manufacturing Systems; Elmaraghy, H., Ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Xia, T.; Dong, Y.; Xiao, L.; Du, S.; Pan, E.; Xi, L. Recent advances in prognostics and health management for advanced manufacturing paradigms. Reliab. Eng. Syst. Saf. 2018, 178, 255–268. [Google Scholar] [CrossRef]

- Maganha, I.; Silva, C.; Ferreira, L.M.D.F. Understanding reconfigurability of manufacturing systems: An empirical analysis. J. Manuf. Syst. 2018, 48, 120–130. [Google Scholar] [CrossRef]

- Koren, Y. Reconfigurable Manufacturing Systems. CIRP Ann. Manuf. Technol. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- Figueira, J.; Greco, S.; Ehrgott, M. Multiple Criteria Decision Analysis : State of the Art Surveys; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems : Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Xu, Z.; Xi, F.; Liu, L.; Chen, L. A method for design of modular reconfigurable machine tools. Machines 2017, 5, 16. [Google Scholar] [CrossRef]

- Andersen, A.-L.; Brunoe, T.D.; Nielsen, K.; Rösiö, C. Towards a generic design method for reconfigurable manufacturing systems: Analysis and synthesis of current design methods and evaluation of supportive tools. J. Manuf. Syst. 2017, 42, 179–195. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, S.; Asjad, M.; Gupta, P. Reconfigurable manufacturing systems: journey and the road ahead. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 1849–1857. [Google Scholar] [CrossRef]

- Gyulai, D.; Vén, Z.; Pfeiffer, A.; Váncza, J.; Monostori, L. Matching demand and system structure in reconfigurable assembly systems. Procedia CIRP 2012, 3, 579–584. [Google Scholar] [CrossRef]

- Heilala, J.; Voho, P. Modular reconfigurable flexible final assembly systems. Assem. Autom. 2001, 21, 20–30. [Google Scholar] [CrossRef]

- Ratchev, S.; Lohse, N. Data modelling for web enabled design of modular precision assembly devices. Assem. Autom. 2004, 24, 63–70. [Google Scholar] [CrossRef]

- Landherr, M.; Westkämper, E. Integrated product and assembly configuration using systematic modularization and flexible integration. In Proceedings of the Variety Management in Manufacturing. Proceedings of the 47th CIRP Conference on Manufacturing Systems, Windsor, Ontario, Canada, 28–30 April 2014. [Google Scholar]

- Koren, Y.; Shpitalni, M. Design of reconfigurable manufacturing systems. J. Manuf. Syst. 2010, 29, 130–141. [Google Scholar] [CrossRef]

- Ribeiro, T.; Gonçalves, G. Formal methods for reconfigurable assembly systems. In Proceedings of the 15th IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Bilbao, Spain, 13–16 September 2010. [Google Scholar]

- Cheikh, S.B.; Hajri-gabouj, S.; Darmoul, S. Manufacturing configuration selection under arduous working conditions : A multi-criteria decision approach. In Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 8–10 March 2016. [Google Scholar]

- Abdi, M.R. Layout configuration selection for reconfigurable manufacturing systems using the fuzzy AHP. Int. J. Manuf. Technol. Manag. 2009, 17, 149–165. [Google Scholar] [CrossRef]

- Abdi, M.R.; Labib, A.W. Performance evaluation of reconfigurable manufacturing systems via holonic architecture and the analytic network process. Int. J. Prod. Res. 2011, 49, 1319–1335. [Google Scholar] [CrossRef]

- Tsai, T.N. Selection of the optimal configuration for a flexible surface mount assembly system based on the interrelationships among the flexibility elements. Comput. Ind. Eng. 2014, 67, 146–159. [Google Scholar] [CrossRef]

- Ateekh-Ur, R.; Babu, A.S. The evaluation of manufacturing systems using concordance and disconcordance properties. Int. J. Serv. Oper. Manag. 2009, 5, 326–349. [Google Scholar]

- Ateekh-Ur, R. Manufacturing Configuration Selection using Multi-Criteria Decision Tool. Int. J. Adv. Manuf. Technol. 2013, 65, 625–639. [Google Scholar]

- Ateekh-Ur, R.; Babu, A.S. Evaluation of reconfigured manufacturing systems : an AHP framework. Int. J. Product. Qual. Manag. 2009, 4, 228–246. [Google Scholar]

- Bensmaine, A.; Dahane, M.; Benyoucef, L. Process plan generation in reconfigurable manufacturing systems using AMOSA and TOPSIS. In Proceedings of the IFAC Proceedings Volumes (IFAC-PapersOnline), Bucharest, Romania, 23–25 May 2012. [Google Scholar]

- Abdi, M.R.; Labib, A.W. A design strategy for reconfigurable manufacturing systems (RMSs) using analytical hierarchical process (AHP): A case study. Int. J. Prod. Res. 2003, 41, 2273–2299. [Google Scholar] [CrossRef]

- Lohse, N.; Hirani, H.; Ratchev, S. Equipment ontology for modular reconfigurable assembly systems. Flex. Serv. Manuf. J. 2006, 17, 301–314. [Google Scholar]

- Maier-Speredelozzi, V.; Hu, S.J. Selecting manufacturing system configurations based on performance using AHP. Tech. Pap. Soc. Manuf. Eng. MS 2002, 1–8. [Google Scholar]

- Cheikh, S.B.; Hajri-Gabouj, S.; Darmoul, S. Reconfiguring Manufacturing Systems using an Analytic Hierarchy Process with strategic and operational indicators. In Proceedings of the IEOM 2015-5th International Conference on Industrial Engineering and Operations Management, Dubai, UAE, 3–5 March 2015. [Google Scholar]

- Mabkhot, M.M.; Amri, S.K.; Darmoul, S.; Samhan, A.M.A.; Elkosantini, S. An ontology based multi-criteria decision support system to reconfigure manufacturing systems. IISE Trans. 2020, 18–42. [Google Scholar] [CrossRef]

- Hwang, K.; Ching-Lai, Y. Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Behzadian, M.; Otaghsara, S.K.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Simos, J. L’_evaluation environnementale: Un processus cognitif n_egoci_e, Lausanne. 1990. Available online: https://www.hindawi.com/journals/amse/2019/2505183/ (accessed on 20 February 2020).

- Simos, J. Evaluer l’impact sur l’environnement: Une approche originale par l’analyse multicritère et la négociation. Presses Polytechniques et Universitaires Romandes. 1990. Available online: https://www.lalibrairie.com/livres/evaluer-l-impact-sur-l-environnement--une-approche-originale-par-l-analyse-multicritere-et-la-negociation_0-801866_9782880741853.html?ctx=d0042dc4b2616657ed372ca2d760076b (accessed on 20 February 2020).

- Figueira, J.; Roy, B. Determining the weights of criteria in the ELECTRE type methods with a revised Simos’ procedure. Eur. J. Oper. Res. 2002, 139, 317–326. [Google Scholar] [CrossRef]

- Siskos, E.; Tsotsolas, N. Elicitation of criteria importance weights through the Simos method: A robustness concern. Eur. J. Oper. Res. 2015, 246, 543–553. [Google Scholar] [CrossRef]

- Shanian A, Milani AS, Carson C, Abeyaratne RC. A new application of ELECTRE III and revised Simos’ procedure for group material selection under weighting uncertainty. Knowledge-Based Syst. 2008, 21, 709–720. [Google Scholar] [CrossRef]

- Govindan, K.; Jepsen, M.B. ELECTRE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2016, 250, 1–29. [Google Scholar] [CrossRef]

- Roy, B. Comparing Actions and Developing Criteria. In Multicriteria Methodology for Decision Aiding; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Saracoglu, B.O. An Experimental Research Study on the Solution of a Private Small Hydropower Plant Investments Selection Problem by ELECTRE III/IV, Shannon’ s Entropy, and Saaty ’ s Subjective Criteria Weighting. Adv. Decis. Sci. 2015, 2015, 470–512. [Google Scholar] [CrossRef]

- Roy, B.; Bouyssou, D. Aide Multicritère à la Décision : Méthodes et Cas; Economica: France, Paris, 1993. [Google Scholar]

- Roy, B.; Hugonnard, J.C. Ranking of suburban line extension projects on the Paris metro system by a multicriteria method. Transp. Res. Part A Gen. 1982, 16, 301–312. [Google Scholar] [CrossRef]

- Bayar, N.; Hajri-Gabouj, S.; Darmoul, S. Knowledge-based disturbance propagation in manufacturing systems: A case study. In Proceedings of the 2nd International Conference on Advanced Systems and Electrical Technologies, IC_ASET’2018, Hammamet, Tunisia, 22–25 March 2018. [Google Scholar]

| Configuration Indicators. | Resource Indicators | ||||

|---|---|---|---|---|---|

| Criterion | Notation | Criterion | Notation | Criterion | Notation |

| Earliness | ET | Work in Process | WIP | Module Utilization | MU |

| Lateness | LT | Nearest to Required Throughput | NRT | No of Modules | NM |

| Waiting Time | WT | No operators | NLO | ||

| Criterion | Notation | Criterion | Notation | Criterion | Notation |

|---|---|---|---|---|---|

| No. of Additional Machines | NAM | No. of Additional Buffers | NAB | No. of Additional Operators | NAO |

| No. of Removed Machines | NMM | No. of Removed Buffers | NMB | No. of Removed Operators | NMO |

| No. of Relocated Machines | NLM | No. of Relocated Buffers | NLB | No. of Relocated Operators | NLO |

| Criteria | Discrimination Criteria | Operational Criteria | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Indicators | LT | ET | |||||||||||

| Value of wj | 0.3 | 0.3 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |||

| Criteria | Strategic Criteria | ||||||||||||

| Indicators | NAM | NMM | NLM | NAB | NMB | NLB | NAO | NMO | NLO | ||||

| Value of wj | 0.0111 | 0.0111 | 0.0111 | 0.0111 | 0.0111 | 0.0111 | 0.0111 | 0.0111 | 0.0111 | ||||

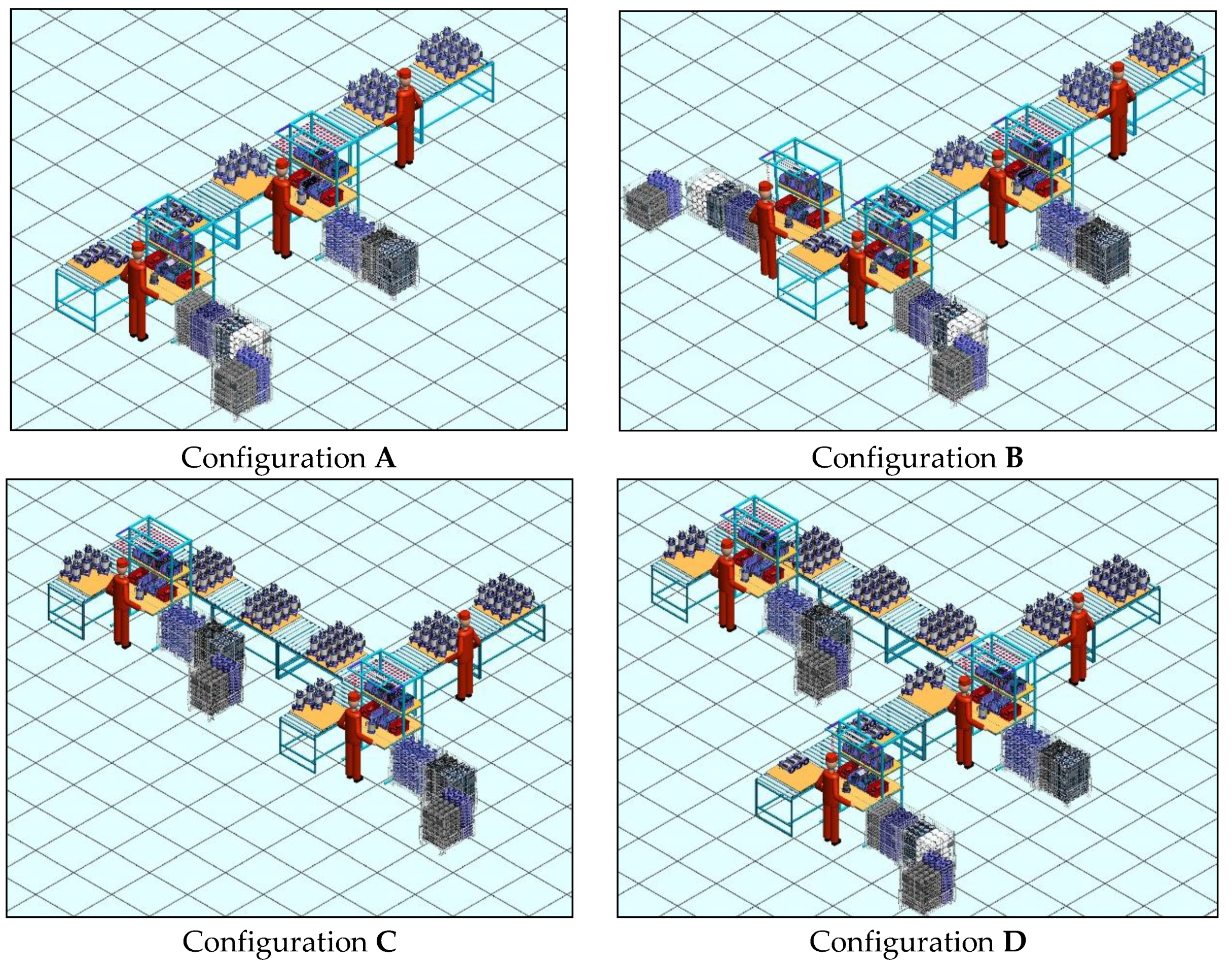

| Configuration | NO | NM | MU (%) | Th (Pcs/day) | WT (Hrs) | WIP (Pcs) |

|---|---|---|---|---|---|---|

| A | 3 | 3 | 0.67 | 60 | 1.40 | 11.12 |

| B | 4 | 4 | 0.72 | 96 | 1.89 | 21.05 |

| C | 3 | 3 | 0.62 | 80 | 1.10 | 8.90 |

| D | 4 | 4 | 0.79 | 108 | 1.39 | 13.80 |

| Modules | Service Times (minute) | ||

|---|---|---|---|

| Motor Assembly | Pump Assembly | Electro-Submersible Assembly | |

| Module-1 | NORM(7.01, 0.374) | LOGN(4.95, 0.559) | LOGN(12.51, 0.86) |

| Module-2 | 6.4 + GAMM(0.331,3.82) | 3.69 + GAMM(0.451, 4.12) | 12 + GAMM(0.331, 3.82) |

| Module-3 | LOGN(6.5.22, 0.857) | NORM(5, 0.23) | LOGN(11.55, 0.343) |

| Module-4 | NORM(7.3, 0.005) | LOGN(5.2, 0.603) | LOGN(12.4, 0.902) |

| Inspection | UNIF(2, 25) | ||

| Configurations | Rank | |||

|---|---|---|---|---|

| D | 0.0005719 | 0.6740291 | 0.0008477 | 1 |

| B | 0.0011098 | 0.6855460 | 0.0016163 | 2 |

| C | 0.0465463 | 0.6313395 | 0.0686639 | 3 |

| Rank (Ascending) | Total | ||||

|---|---|---|---|---|---|

| 1 | NMO | 0 | 1 | 1 | 1.00 |

| 2 | NMB, NMM | 1 | 2 | 1.85 | 3.70 |

| 3 | NLO | 0 | 1 | 3.56 | 3.56 |

| 4 | NLB, NLM | 1 | 2 | 4.41 | 8.81 |

| 5 | NAO | 0 | 1 | 6.11 | 6.11 |

| 6 | NAB, NAM | 1 | 2 | 6.96 | 13.93 |

| 7 | NO | 1 | 2 | 8.67 | 8.67 |

| 8 | NM, MU | 1 | 2 | 10.37 | 20.74 |

| 9 | ET | 0 | 1 | 12.07 | 12.07 |

| 10 | WT, WIP | 1 | 2 | 12.93 | 25.85 |

| 11 | NRT | 1 | 2 | 14.63 | 14.63 |

| 12 | LT | 6 | 7 | 16.33 | 16.33 |

| 13 | TS | 0 | 1 | 22.30 | 22.30 |

| 14 | RUN | 0 | 1 | 23.15 | 23.15 |

| Sum | 19 | 13 | 27 | … | 180.85 |

| Rank | Criteria | N. | |||||

|---|---|---|---|---|---|---|---|

| 1 | NMO | 18 | 0.553 | 0.5 | 0.085 | 0.096 | 0.5 |

| 2 | NMB | 15 | 1.024 | 1.0 | 0.074 | 0.023 | 1.1 |

| 2 | NMM | 12 | 1.024 | 1.0 | 0.074 | 0.023 | 1.1 |

| 3 | NLO | 19 | 1.966 | 1.9 | 0.017 | 0.034 | 1.9 |

| 4 | NLB | 16 | 2.437 | 2.4 | 0.026 | 0.015 | 2.5 |

| 4 | NLM | 13 | 2.437 | 2.4 | 0.026 | 0.015 | 2.5 |

| 5 | NAO | 17 | 3.379 | 3.3 | 0.006 | 0.023 | 3.3 |

| 6 | NAB | 14 | 3.850 | 3.8 | 0.013 | 0.013 | 3.8 |

| 6 | NAM | 11 | 3.850 | 3.8 | 0.013 | 0.013 | 3.8 |

| 7 | NO | 3 | 4.792 | 4.7 | 0.002 | 0.019 | 4.7 |

| 8 | NM | 4 | 5.734 | 5.7 | 0.011 | 0.006 | 5.8 |

| 8 | MU | 5 | 5.734 | 5.7 | 0.011 | 0.006 | 5.8 |

| 9 | ET | 6 | 6.676 | 6.6 | 0.004 | 0.011 | 6.6 |

| 10 | WT | 9 | 7.147 | 7.1 | 0.007 | 0.007 | 7.2 |

| 10 | WIP | 10 | 7.147 | 7.1 | 0.007 | 0.007 | 7.2 |

| 11 | NRT | 8 | 8.089 | 8.0 | 0.001 | 0.011 | 8.0 |

| 12 | LT | 7 | 9.031 | 9.0 | 0.008 | 0.003 | 9.1 |

| 13 | TS | 2 | 12.328 | 12.3 | 0.006 | 0.002 | 12.4 |

| 14 | RUN | 1 | 12.800 | 12.7 | 0.00004 | 0.008 | 12.7 |

| SUM | 19 | … | 100 | 99 | … | … | 100.0 |

| N. Crit. | N. Crit. | N. Crit. | |||

|---|---|---|---|---|---|

| 1 | 0.00004 | 18 | 0.096 | 1 | √ |

| 8 | 0.001 | 19 | 0.034 | 8 | √ |

| 3 | 0.002 | 17 | 0.023 | 3 | √ |

| 6 | 0.004 | 15 | 0.023 | 6 | √ |

| 2 | 0.006 | 12 | 0.023 | 2 | |

| 17 | 0.006 | 3 | 0.019 | 17 | √ |

| 9 | 0.007 | 16 | 0.015 | 9 | |

| 10 | 0.007 | 13 | 0.015 | 10 | |

| 7 | 0.008 | 14 | 0.013 | 7 | |

| 4 | 0.011 | 11 | 0.013 | 4 | |

| 5 | 0.011 | 6 | 0.011 | 5 | |

| 14 | 0.013 | 8 | 0.011 | 14 | √ |

| 11 | 0.013 | 1 | 0.008 | 11 | √ |

| 19 | 0.017 | 9 | 0.007 | 19 | √ |

| 16 | 0.026 | 10 | 0.007 | 16 | |

| 13 | 0.026 | 4 | 0.006 | 13 | |

| 15 | 0.074 | 5 | 0.006 | 15 | |

| 12 | 0.074 | 7 | 0.003 | 12 | |

| 18 | 0.085 | 2 | 0.002 | 18 | √ |

| Criteria | Discrimination Criteria | Operational Criteria | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Indicators | LT | ET | |||||||||||

| Value of wj | 0.127 | 0.124 | 0.047 | 0.058 | 0.058 | 0.08 | 0.091 | 0.066 | 0.072 | 0.072 | |||

| Criteria | Strategic Criteria | ||||||||||||

| Indicators | NAM | NMM | NLM | NAB | NMB | NLB | NAO | NMO | NLO | ||||

| Value of wj | 0.038 | 0.011 | 0.025 | 0.038 | 0.011 | 0.025 | 0.033 | 0.005 | 0.019 | ||||

| Configurations | Rank | |||

|---|---|---|---|---|

| D | 0.0028598 | 0.6057285 | 0.0046992 | 1 |

| B | 0.0035781 | 0.6500052 | 0.0054746 | 2 |

| C | 0.0128308 | 0.6075778 | 0.0206812 | 3 |

| Criteria. | RUN | TS | NO | NAO | NMO | NLO | ||

|---|---|---|---|---|---|---|---|---|

| Direction of preferences | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ | ||

| Mode of definition | → | → | ← | → | → | → | ||

| Candidate Configurations | D = | 1 | 1 | 4 | 1 | 0 | 0 | |

| C = | 0 | 1 | 3 | 1 | 1 | 0 | ||

| B = | 1 | 1 | 4 | 2 | 1 | 0 | ||

| Indifferences | 0 | 0 | 0.1 | 0 | 0 | 0 | ||

| 0 | 0 | 2 | 2 | 2 | 5 | |||

| Preferences | 0 | 0 | 0.2 | 0 | 0 | 0 | ||

| 1 | 1 | 3 | 3 | 3 | 10 | |||

| Veto | 0 | 0 | 0.3 | 0 | 0 | 0 | ||

| 2 | 2 | 4 | 6 | 6 | 15 | |||

| Criteria | |||||||

|---|---|---|---|---|---|---|---|

| Binary relation of and |

| . | Binary Outranking Relations | Five Outranking Relations | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Total for | 0 | 2 | 6 | 9 | .. | .. | .. | .. | .. |

| Total for | 2 | 0 | 0 | 9 | .. | .. | √ | √ | √ |

| Configurations | Rank in Descending Pre-Order | Rank in Ascending Pre-Order | Rank in Final Pre-Order |

|---|---|---|---|

| D = | 1 | 2 | 1 |

| C = | 2 | 2 | 2 |

| B = | 2 | 1 | 3 |

| Configurations | Ranks | ||

|---|---|---|---|

| TOPSIS | ELECTRE IV | ||

| Intuitive Weighting | SIMOS Weighting | ||

| D | 1 | 1 | 1 |

| C | 3 | 3 | 2 |

| B | 2 | 2 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

M. Mabkhot, M.; Darmoul, S.; M. Al-Samhan, A.; Badwelan, A. A Multi-Criteria Decision Framework Considering Different Levels of Decision-Maker Involvement to Reconfigure Manufacturing Systems. Machines 2020, 8, 8. https://doi.org/10.3390/machines8010008

M. Mabkhot M, Darmoul S, M. Al-Samhan A, Badwelan A. A Multi-Criteria Decision Framework Considering Different Levels of Decision-Maker Involvement to Reconfigure Manufacturing Systems. Machines. 2020; 8(1):8. https://doi.org/10.3390/machines8010008

Chicago/Turabian StyleM. Mabkhot, Mohammed, Saber Darmoul, Ali M. Al-Samhan, and Ahmed Badwelan. 2020. "A Multi-Criteria Decision Framework Considering Different Levels of Decision-Maker Involvement to Reconfigure Manufacturing Systems" Machines 8, no. 1: 8. https://doi.org/10.3390/machines8010008

APA StyleM. Mabkhot, M., Darmoul, S., M. Al-Samhan, A., & Badwelan, A. (2020). A Multi-Criteria Decision Framework Considering Different Levels of Decision-Maker Involvement to Reconfigure Manufacturing Systems. Machines, 8(1), 8. https://doi.org/10.3390/machines8010008