Electric Machine Design Tool for Permanent Magnet Synchronous Machines and Induction Machines

Abstract

:1. Introduction

2. State of the Art

2.1. Machine Topology

2.2. Loss Types of Electric Machines

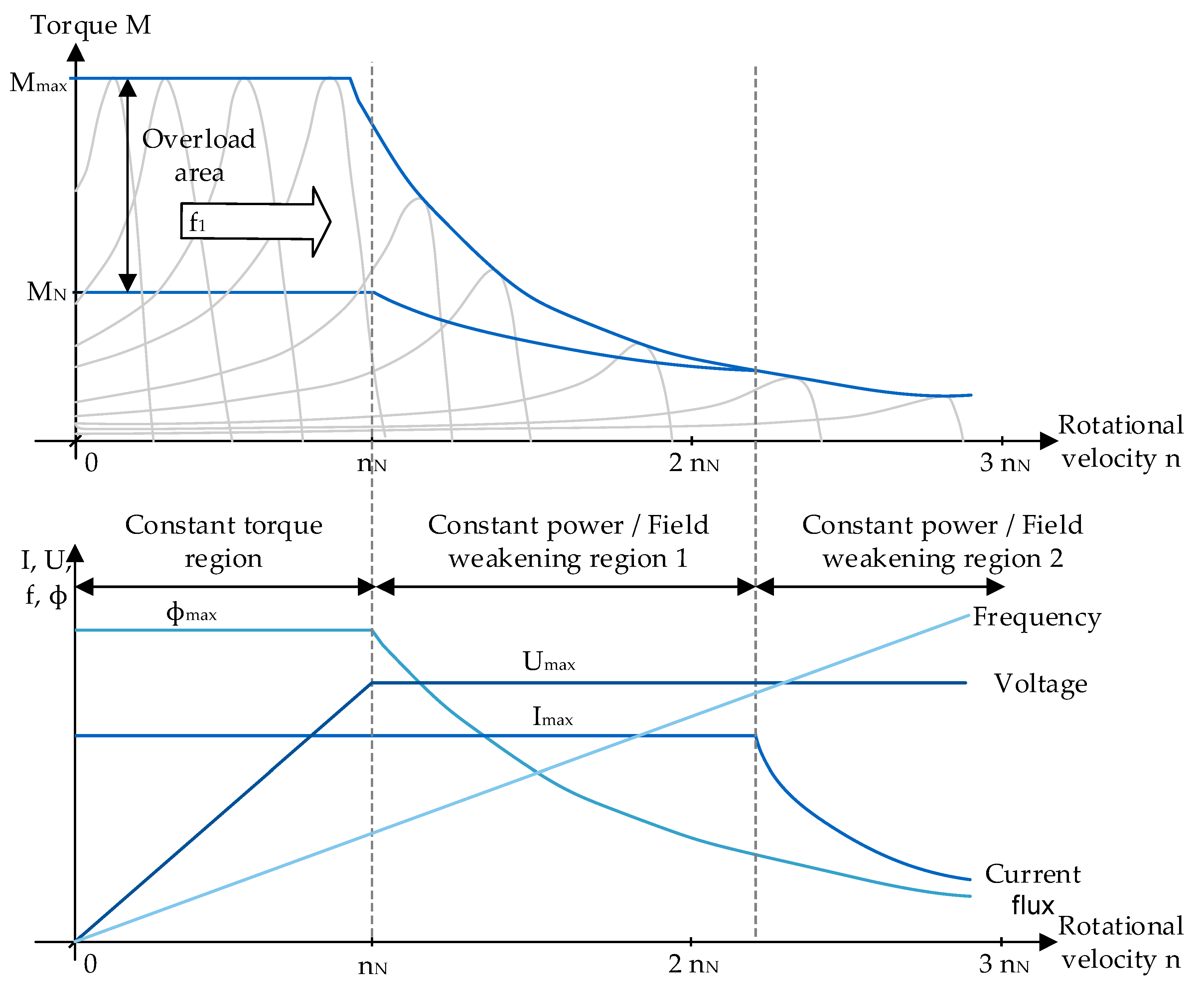

2.3. Efficiency Diagrams

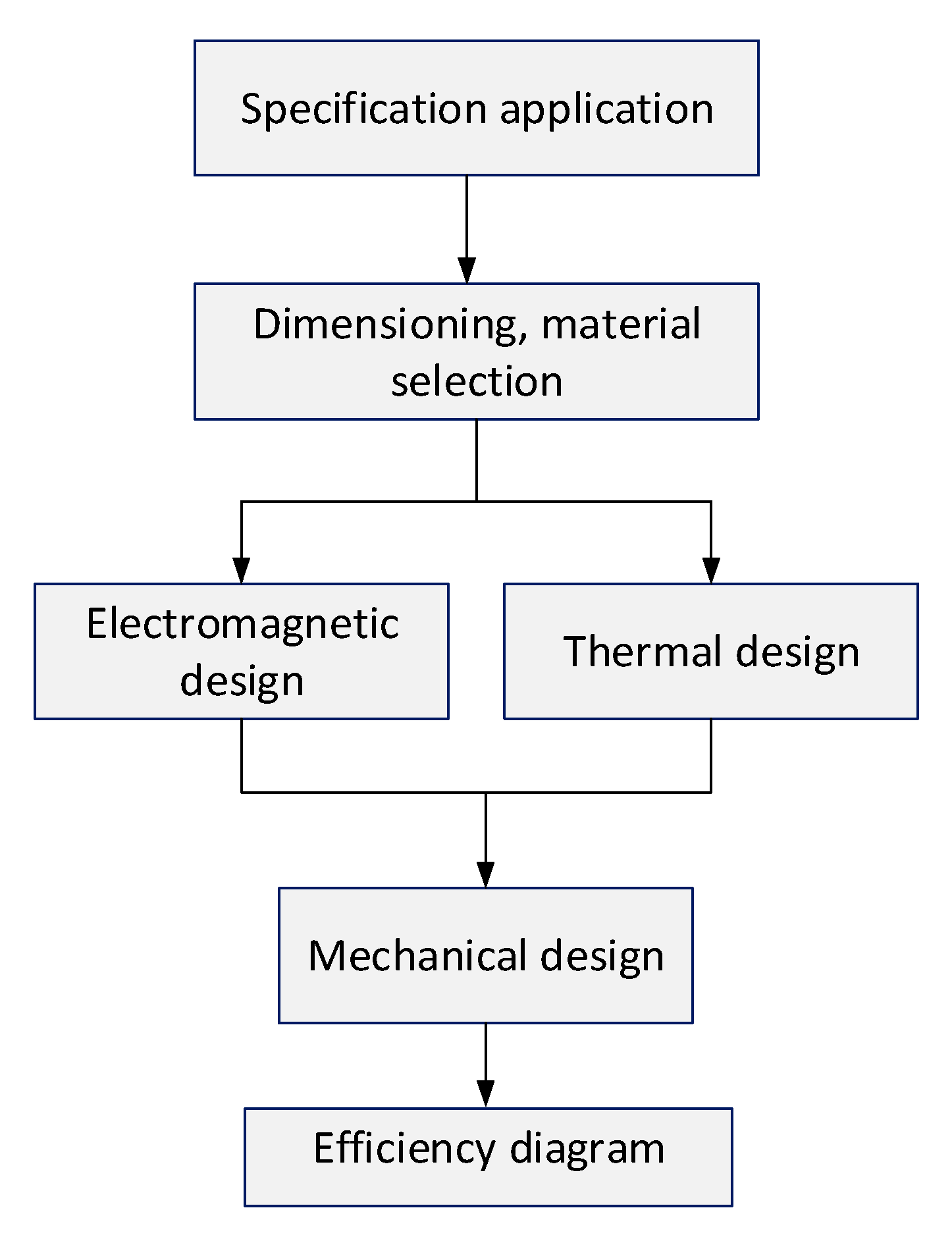

2.4. Conventional Machine Design

3. Methodology and Model Structure

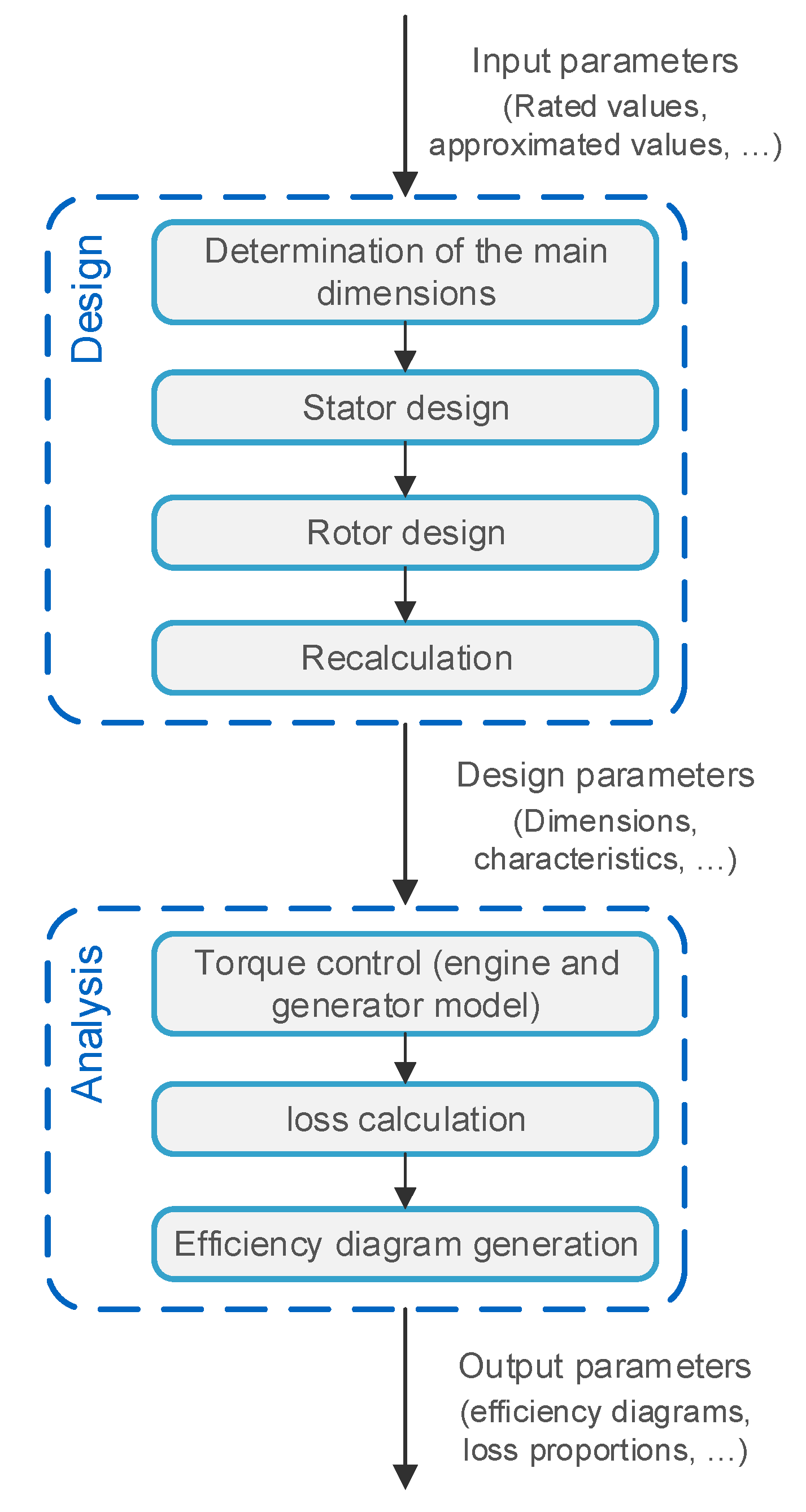

3.1. Overall Model Structure

3.2. Comparison of the Simulation Process of PMSM and IM

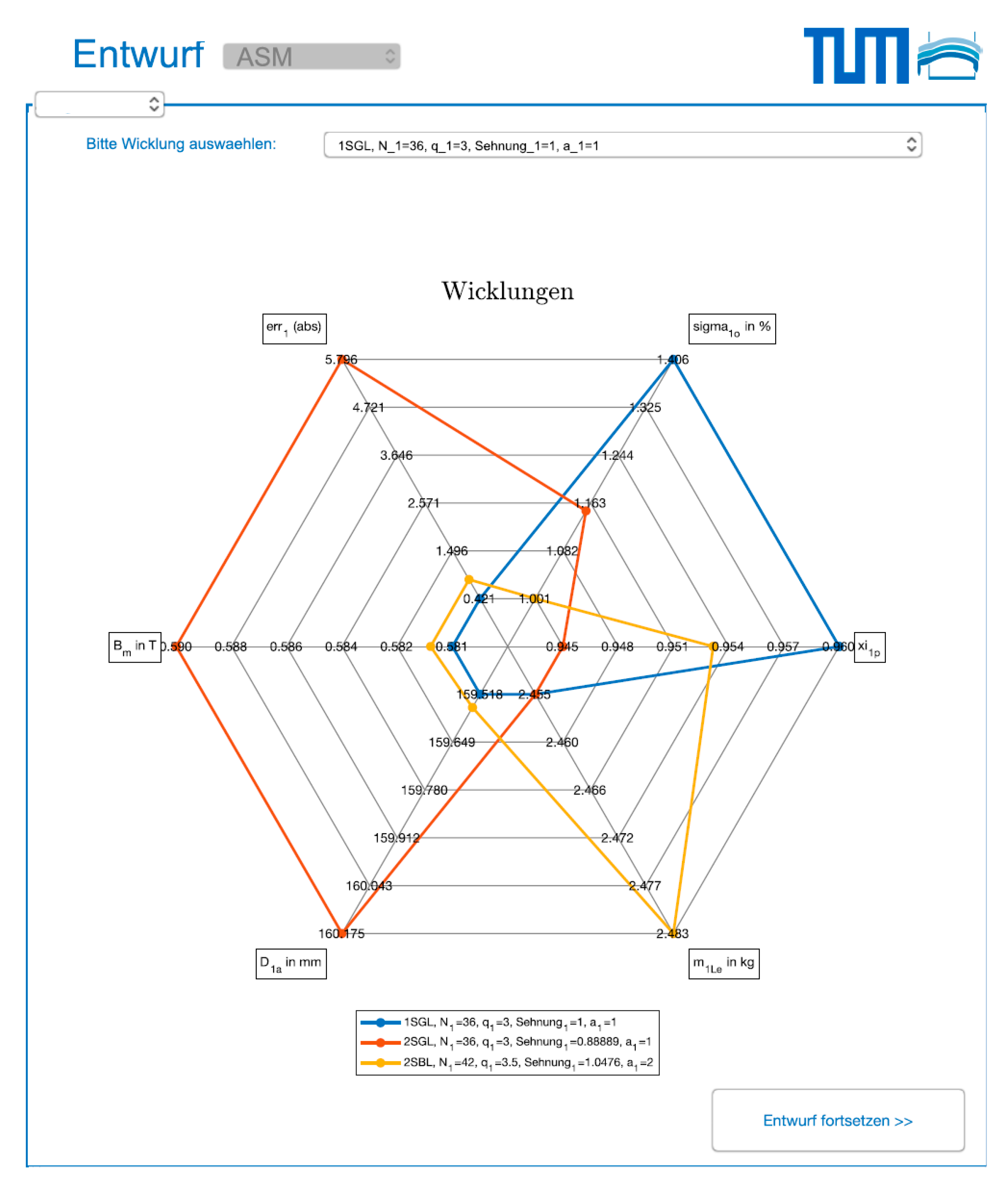

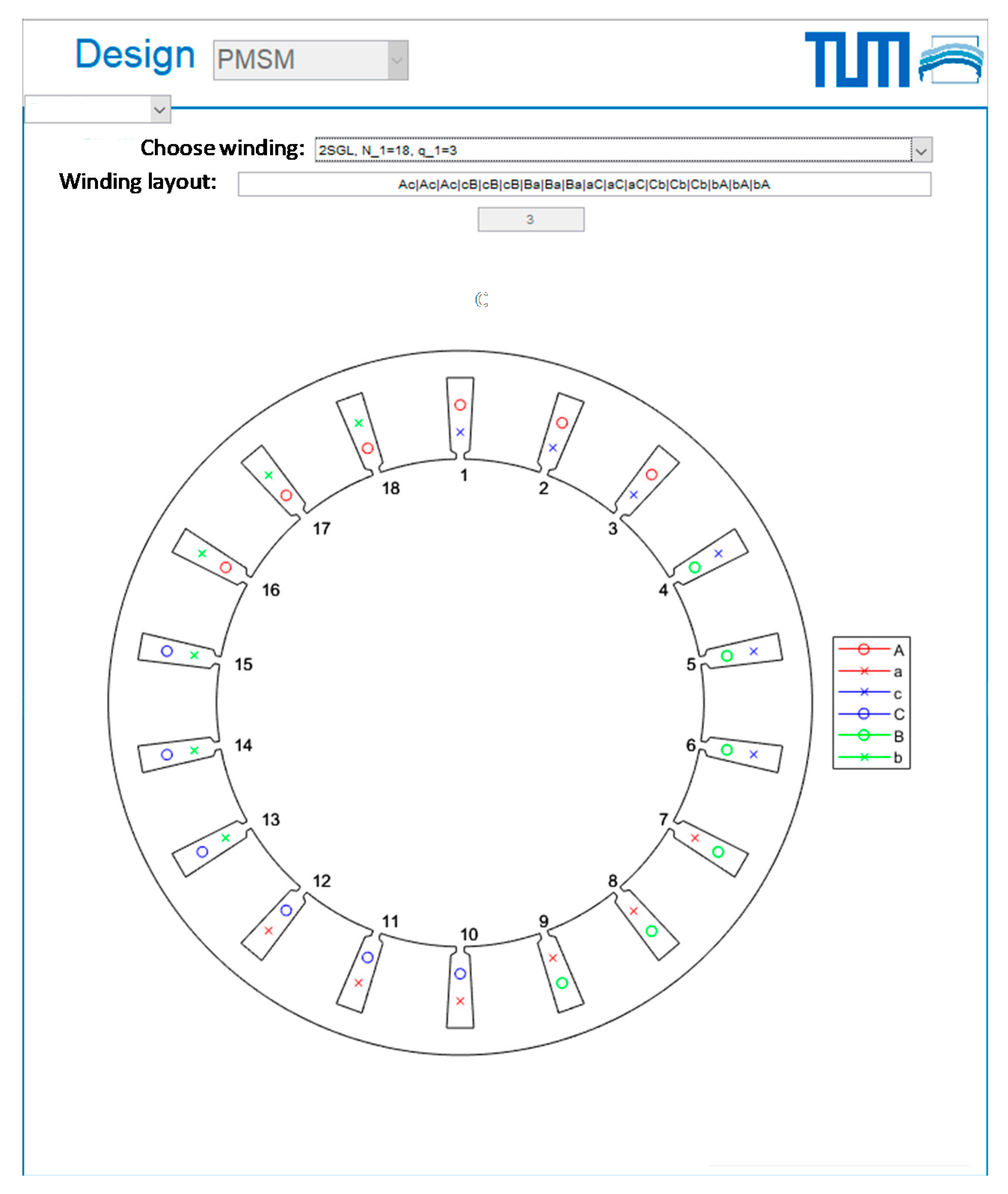

3.2.1. Design

3.2.2. Analysis

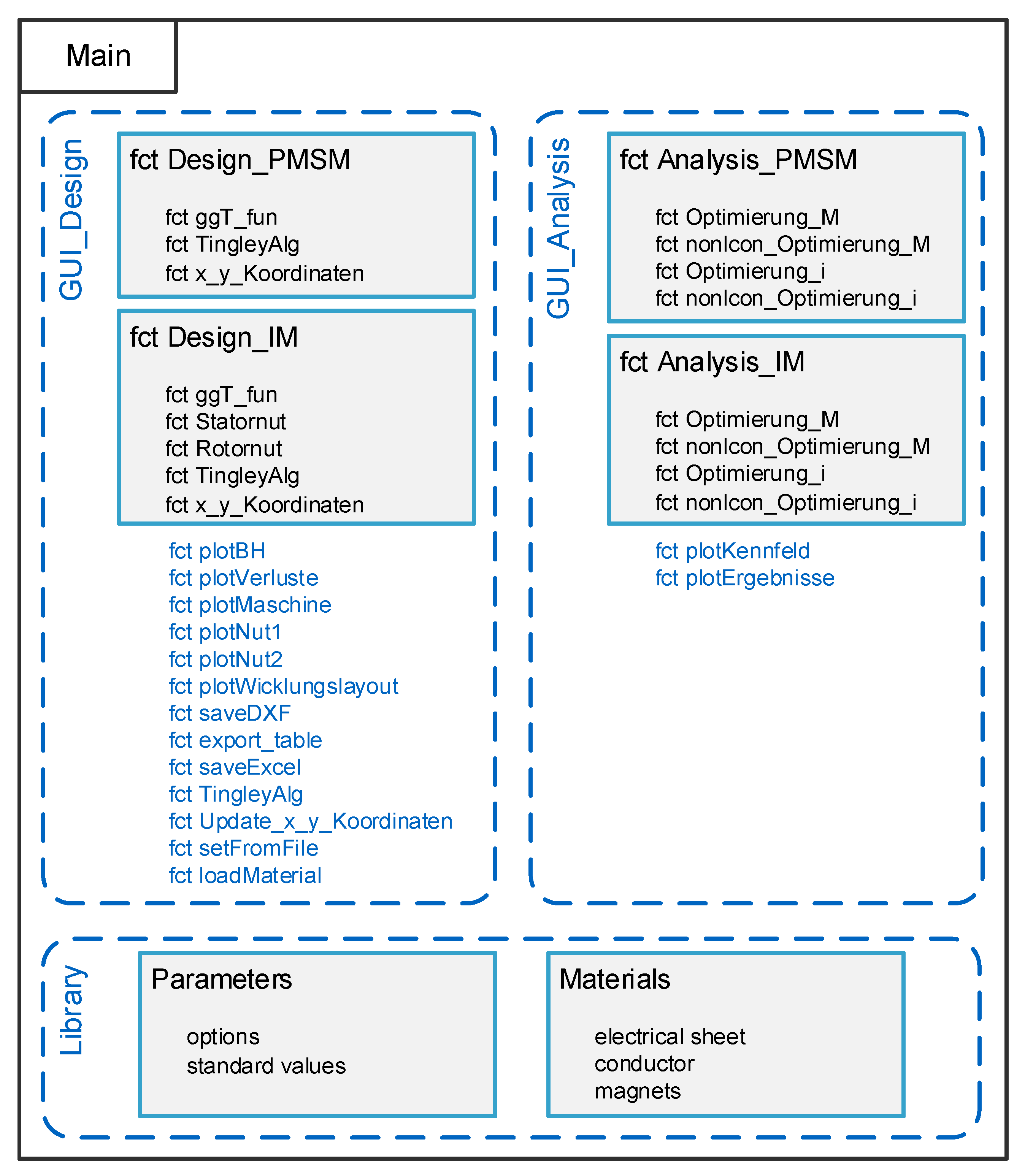

3.3. Model Structure and Functions

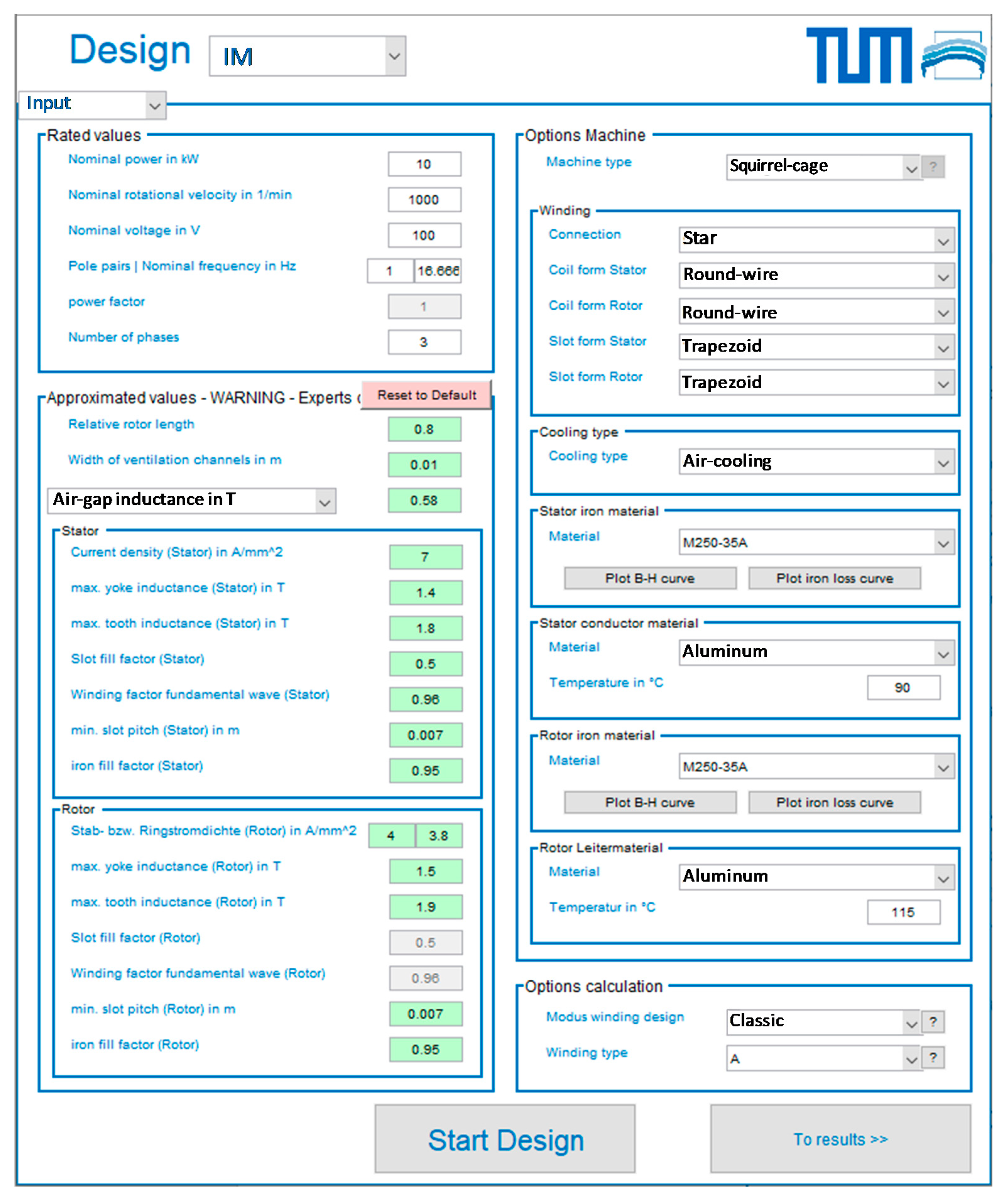

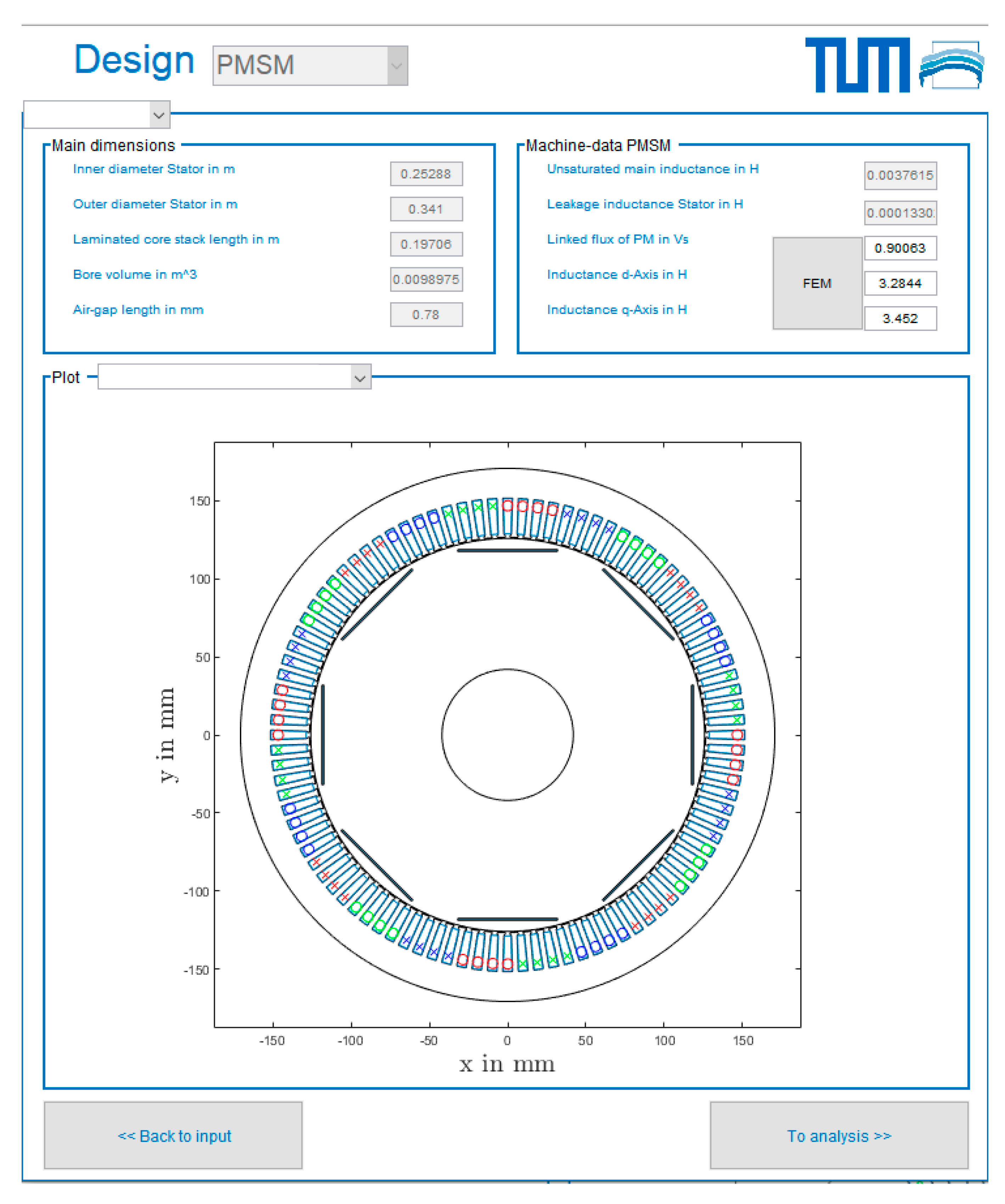

3.4. Graphical User Interface for Design

3.5. Graphical User Interface for Analysis

4. Validation and Discussion of Results

4.1. Validation of Main Dimensions

4.1.1. Calculation Example Müller

4.1.2. Audi E-Tron

4.1.3. Renault Twizy

4.1.4. Tesla Model S

4.2. Validation of Electromagnetic Parameters

4.3. Validation of Loss Calculation for Model

5. Conclusions and Summary

Open Source

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wallentowitz, H.; Freialdenhoven, A.; Olschewski, I. Strategien zur Elektrifizierung des Antriebstranges. Technologien, Märkte und Implikationen; Vieweg + Teubner: Wiesbaden, Germany, 2010. [Google Scholar]

- Juraschek, S.; Buchner, A.; Schinnerl, B. Die Elektrische Antriebstechnologie der BMW Group; International Vienna Motor Symposium; VDI-Verlag: Berlin, Germany, 2018; Volume 2. [Google Scholar]

- Mahmoudi, A.; Soong, W.L.; Pellegrino, G.; Armando, E. Efficiency Maps of Electrical Machines. In Proceedings of the Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015. [Google Scholar]

- Wacker, P. Effizienzsteigerung im Antriebsstrang von Elektrofahrzeugen mittels aktiver Batteriepackverschaltung. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2018. [Google Scholar]

- Horlbeck, L. Auslegung elektrischer Maschinen für automobile Antriebsstränge unter Berücksichtigung des Überlastpotentials. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2018. [Google Scholar]

- Fischer, R. Elektrotechnik für Maschinenbauer; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2016. [Google Scholar] [CrossRef]

- Schnettler, A.; Kampker, A.; Vallée, D. Elektromobilität: Grundlagen Einer Zukunftstechnologie; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Futschik, H.D.; Achleitner, A.; Döllner, G.; Burgers, C.; Friedrich, J.K.H.; Mohrdieck, C.H.; Schulze, H.; Wöhr, M.; Antony, P.; Urstöger, M. Formen und neue Konzepte. In Vieweg Handbuch Kraftfahrzeugtechnik; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2013. [Google Scholar]

- Farschtschi, A. Elektromaschinen in Theorie und Praxis: Aufbau, Wirkungsweisen, Anwendungen, Auswahl- und Auslegungskriterien, 2nd ed.; VDE-Verlag: Berlin, Germany, 2007. [Google Scholar]

- Schröder, D. Elektrische Antriebe-Grundlagen: Mit durchgerechneten Übungs- und Prüfungsaufgaben; Springer Vieweg: Berlin, Germany, 2017. [Google Scholar]

- Binder, A. Elektrische Maschinen und Antriebe; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Babiel, G. Elektrische Antriebe in der Fahrzeugtechnik; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014. [Google Scholar] [CrossRef]

- Kampker, A. Elektromobilproduktion; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Kremser, A. Elektrische Maschinen und Antriebe; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2004. [Google Scholar] [CrossRef]

- Teigelkötter, J. Energieeffiziente elektrische Antriebe: Grundlagen, Leistungsleektronik, Betriebsverhalten und Regelung von Drehstrommotoren; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2013. [Google Scholar]

- Pyrhonen, J.; Jokinen, T.; Hrabovcova, V. Design of Rotating Electrical Machine; Wiley: Chichester, UK, 2014. [Google Scholar]

- Müller, G.; Ponick, B. Grundlagen Elektrischer Maschinen and Berechnung elektrischer Maschinen, 10th ed.; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Woehl-Bruhn, H. Synchronmaschine mit Eingebetteten Magneten und Neuartiger Variabler Erregung für Hybridantriebe; Cuvillier Verlag: Göttingen, Germany, 2010; ISBN-13: 978-3869552774. [Google Scholar]

- Finken, T. Fahrzyklusgerechte Auslegung von permanentmagneterregten Synchronmaschinen für Hybrid- und Elektrofahrzeuge. Ph.D. Thesis, Technical University of Aachen, Aachen, Germany, 2011. [Google Scholar]

- Hofmann, P. Hybridfahrzeuge; Springer: Vienna, Austria, 2014. [Google Scholar] [CrossRef]

- Giersch, H.-U.; Harthus, H.; Vogelsang, N. Elektrotechnik für Fachschulen: Elektrische Maschinen; Vieweg+Teubner Verlag: Wiesbaden, Germany. [CrossRef]

- Meyer, W. Technologie Elektrischer Maschinen; Hieronymus: Munich, Germany, 2018. [Google Scholar]

- Krings, A.; Soulard, J. Overview and Comparison of Iron Loss Models for Electrical Machines. J. Electr. Eng. 2010, 10, 162–169. [Google Scholar]

- Neuschl, Z. Rechnerunterstützte experimentelle Verfahren zur Bestimmung der lastunabhängigen Eisenverluste in permanentmagnetisch erregten elektrischen Maschinen mit additionalem Axialfluss. Ph.D. Thesis, Technical University of Cottbus, Cottbus, Germany, 2007. [Google Scholar]

- Spring, E. Elektrische Maschinen; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

- Fuest, K.; Döring, P. Elektrische Maschinen und Antriebe; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2000. [Google Scholar] [CrossRef]

- Bolte, E. Elektrische Maschinen; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Semidey, S.A.; Duan, Y.; Mayor, J.R.; Harley, R.G.; Habetler, T.G. Optimal Electromagnetic-Thermo-Mechanical Integrated Design Candidate Search and Selection for Surface-Mount Permanent-Magnet Machines Considering Load Profiles. IEEE Trans. Ind. Appl. 2011. [CrossRef]

- Hombitzer, M.; Franck, D.; von Pfingsten, G.; Hameyer, K. Permanentmagneterregter Traktionsantrieb für ein Elektrofahrzeug: Bauraum, Wirkungsgrad und Kosten-das Auslegungsdreieck, Haus der Technik Fachbuch. In Elektrische Antriebstechnologie für Hybrid- und Elektrofahrzeuge; Expert Verlag: Aachen, Germany, 2014. [Google Scholar]

- Kalt, S.; Erhard, J.; Lienkamp, M. Holistic Analysis of Potential Stator Designs using Parameter Permutation. In Proceedings of the Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar]

- Kalt, S.; Erhard, J.; Danquah, B.; Lienkamp, M. Electric Machine Design Tool for Permanent Magnet Synchronous Machines. In Proceedings of the Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar]

- Kalt, S.; Erhard, J.; Lienkamp, M. Optimized Stator Design Method using Machine Parameter Permutation. Forschung im Ingenieurswesen 2019, 83, 853–861. [Google Scholar] [CrossRef]

- Vaerst, G. Magnetisierungskurven VACOFLUX 50 und VACOFLUX 48. J. Erhard, Interviewmaterial. 2019. [Google Scholar]

- Emetor, A.B. Electric Motor Winding Calculator. Available online: https://www.emetor.com/windings/ (accessed on 30 May 2019).

- Staton, D.; James, G. Open Source Electric Motor Models for Commercial EV & Hybrid Traction Motors. 2018. Available online: https://www.coilwindingexpo.com/berlin/__media/pages/Tutorial-1-D--Staton-&-J--Goss-MDL.PDF (accessed on 30 May 2018).

- Technische Daten BMW i3. Available online: https://www.press.bmwgroup.com/deutschland/article/attachment/T0273661DE/392973 (accessed on 30 September 2018).

- Ozpineci, B. Oak Ridge National Laboratory Annual Progress Report for the Power Electronics and Electric Motors Program-2016. Available online: https://info.ornl.gov/sites/publications/Files/Pub71072.pdf (accessed on 30 September 2018).

- A2MAC1 EURL. A2MAC1 Automotive Benchmarking. 2019. Available online: https://www.a2mac1.com/ (accessed on 30 May 2019).

- Miller, J.M. Electric Motor R&D, Oak Ridge National Laboratory. 2013. Available online: https://www.energy.gov/sites/prod/files/2014/03/f13/ape051_miller_2013_o.pdf (accessed on 23 March 2020).

- Ozpineci, B. Oak Ridge National Laboratory Annual Progress Report for the Power Electronics and Electric Motors Program-2014. Available online: https://info.ornl.gov/sites/publications/files/Pub52422.pdf (accessed on 30 May 2018).

- Jelden, H.; Lück, P.; Kruse, G.; Tousen, J. Der Elektrische Antriebsbaukasten von Volkswagen. MTZ 2014, 2, 14–21. [Google Scholar] [CrossRef]

- Brusa. Drive-Motor 400V. Available online: https://www.brusa.biz/en/products/drive/motor-400-v.html (accessed on 30 May 2019).

- Pint, S.; Ardey, N.; Mendl, G.; Fröhlich, G.; Straßer, R.; Laudenbach, T.; Doerr, J. The new full electric drivetrain from Audi. In Proceedings of the Internationales Wiener Motorensymposium, Vienna, Austria, 26–27 April 2018. [Google Scholar]

- Doerr, J.; Attensperger, T.; Wittmann, L.; Enzinger, T. Die neuen elektrischen Achsantriebe von Audi. MTZ-Motortechnische Zeitschrift 2018, 76, 16–27. [Google Scholar] [CrossRef]

- Tesla Inc. Technische Daten Tesla Model S. 2019. Available online: https://www.tesla.com/sites/default/files/model_s_owners_manual_north_america_en_us.pdf, (accessed on 30 May 2019).

- Schüppel, F.; Schlüter, M.; Gacnik, J. Design of battery electric vehicles in accordance with legal standards and manufacturers’ and customers’ requirements. In Der Antrieb von Morgen; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017. [Google Scholar] [CrossRef]

- Technische Daten Renault Twizy. 2019. Available online: https://www.cdn.renault.com/content/dam/Renault/AT/downloadcenter/twizy/PL_Twizy.pdf (accessed on 30 May 2019).

- MAHLE Letrika. AC conversion kit ASV 7102, Information from manufacturer, Interviewmaterial. 2015. [Google Scholar]

- Müller, G. Berechnungsbeispiel Induktionsmaschine. 2019. Available online: http://application.wiley-vch.de/books/sample/3527405259_beispiele.zip (accessed on 30 May 2019).

- Benedikt, D.; Alexander, K.; Tony, W.; Markus, L.; André, P. Modular Simulation Application for Designing and Analyzing Electric Vehicles. In Proceedings of the International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar]

| Strand A | Strand c | Strand B | |||||||

|---|---|---|---|---|---|---|---|---|---|

| + | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| − | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| + | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| − | 28 | 29 | 31 | 31 | 32 | 33 | 34 | 35 | 36 |

| Parameter | Symbol | Unit | |

|---|---|---|---|

| Options losses | copper losses | - | - |

| iron losses | - | - | |

| desired iron loss model | - | - | |

| mechanical losses | - | - | |

| additional losses | - | - | |

| Options calculations and simulation | generator model | - | - |

| max. rotational velocity | nmax | 1/min | |

| resolution rotational velocity | ticsn | - | |

| resolution torque | ticsM | - | |

| excitation max. voltage | u1,max | V | |

| excitation max. current | i1,max | A |

| Rated Values | |||

| nominal power | 3 kW | number of pole pairs | 2 |

| nominal rotational velocity | 1500 1/min | nominal frequency | 50 Hz |

| nominal voltage | 400 V | number of phases | 3 |

| Approximate values | |||

| relative rotor length | 1.45 | stator minimal slot pitch | 0.008 |

| width of ventilation channels | 0.01 m | stator iron fill factor | 0.95 |

| air-gap induction | 0.58 T | rotor rod current density | 4.2 A/mm2 |

| stator current density | 6.9 A/mm2 | rotor ring current density | 5.0 A/mm2 |

| stator maximum yoke inductance | 1.65 T | rotor maximum yoke inductance | 1.6 T |

| stator maximum tooth inductance | 1.65 T | rotor maximum tooth inductance | 1.65 T |

| stator slot fill factor | 0.4 | rotor minimal slot pitch | 0.007 m |

| winding factor fundamental wave | 0.96 | rotor iron fill factor | 0.95 |

| Options | |||

| machine type | squirrel cage | iron material stator | M800-50A |

| connection | delta | conductor material stator | copper |

| coil form stator | round wire | temperature conductor stator | 95 °C |

| coil form rotor | round wire | iron material rotor | M800-50A |

| slot form stator | trapezoid | conductor material rotor | aluminum |

| slot form rotor | trapezoid | temperature conductor rotor | 115 °C |

| cooling type | air | winding layout option | manual |

| Results | |||

| Literature values | Calculation model | Relative deviation | |

| stator outer diameter | 160.0 mm | 159.3 mm | −0.44% |

| stator inner diameter | 99.0 mm | 99.3 mm | 0.30% |

| rotor outer diameter | 98.3 mm | 98.7 mm | 0.41% |

| rotor inner diameter | 35.0 mm | 36.1 mm | 3.14% |

| laminated core stack length | 112.3 mm | 112.4 mm | 0.09% |

| air-gap length | 0.35 mm | 0.33 mm | −5.71% |

| bore volume | 864.5 cm3 | 870.5 cm3 | +0.69% |

| Rated values | |||

| nominal power | 40 kW | number of pole pairs | 2 |

| nominal rotational velocity | 5000 1/min | nominal frequency | 166.67 Hz |

| nominal voltage | 360 V | number of phases | 3 |

| Approximated values | |||

| relative rotor length | 1.0 | stator minimal slot pitch | 0.007 |

| width of ventilation channels | 0.01 m | stator iron fill factor | 0.95 |

| air-gap induction | 0.58 T | rotor rod current density | 4.0 A/mm2 |

| stator current density | 7 A/mm2 | rotor ring current density | 3.8 A/mm2 |

| stator maximum yoke inductance | 1.5 T | rotor maximum yoke inductance | 1.8 T |

| stator maximum tooth inductance | 1.8 T | rotor maximum tooth inductance | 2.0 T |

| stator slot fill factor | 0.5 | rotor minimal slot pitch | 0.007 m |

| winding factor fundamental wave | 0.96 | rotor iron fill factor | 0.95 |

| Options | |||

| machine type | squirrel cage | iron material stator | VACOFLUX |

| connection | star | conductor material stator | copper |

| coil form stator | round wire | temperature conductor stator | 90 °C |

| coil form rotor | round wire | iron material rotor | VACOFLUX |

| slot form stator | trapezoid | conductor material rotor | aluminum |

| slot form rotor | trapezoid | temperature conductor rotor | 115 °C |

| cooling type | liquid | winding layout option | manual |

| Results | |||

| Reference machine | Calculation model | Relative deviation | |

| stator outer diameter | 245.0 mm | 244.5 mm | −0.20% |

| stator inner diameter | 157.2 mm | 154.5 mm | −1.72% |

| rotor outer diameter | 156.0 mm | 153.2 mm | −1.79% |

| rotor inner diameter | 70.0 mm | 66.8 mm | −4.57% |

| laminated core stack length | 120.0 mm | 120.1 mm | 0.08% |

| air-gap length | 0.6 mm | 0.6 mm | 0.00% |

| bore volume | 2329.0 cm3 | 2250.3 cm3 | −3.38% |

| Results | |||

|---|---|---|---|

| Reference Machine | Calculation Model | Relative Deviation | |

| stator outer diameter | 200.0 mm | 198.2 mm | −0.9% |

| stator inner diameter | - | 124.7 mm | - |

| rotor outer diameter | 124.0 mm | 123.8 mm | −0.16% |

| rotor inner diameter | - | 53.3 mm | - |

| laminated core stack length | 120.0 mm | 116.7 mm | −2.75% |

| air-gap length | - | 0.4 mm | - |

| bore volume | 1449.2 cm3 | 1425.3 cm3 | −1.65% |

| Results | |||

|---|---|---|---|

| Reference Machine | Calculation Model | Relative Deviation | |

| stator outer diameter | 254.0 mm | 255.6 mm | 0.63% |

| stator inner diameter | 157.0 mm | 157.1 mm | 0.06% |

| rotor outer diameter | 155.8 mm | 155.7 mm | −0.16% |

| rotor inner diameter | 50.0 mm | 54.5 mm | 9.0% |

| laminated core stack length | 152.6 mm | 152.8 mm | 0.13% |

| air-gap length | 0.6 mm | 0.7 mm | 16.67% |

| bore volume | 2954.2 cm3 | 2961.9 cm3 | 0.26% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalt, S.; Erhard, J.; Lienkamp, M. Electric Machine Design Tool for Permanent Magnet Synchronous Machines and Induction Machines. Machines 2020, 8, 15. https://doi.org/10.3390/machines8010015

Kalt S, Erhard J, Lienkamp M. Electric Machine Design Tool for Permanent Magnet Synchronous Machines and Induction Machines. Machines. 2020; 8(1):15. https://doi.org/10.3390/machines8010015

Chicago/Turabian StyleKalt, Svenja, Jonathan Erhard, and Markus Lienkamp. 2020. "Electric Machine Design Tool for Permanent Magnet Synchronous Machines and Induction Machines" Machines 8, no. 1: 15. https://doi.org/10.3390/machines8010015

APA StyleKalt, S., Erhard, J., & Lienkamp, M. (2020). Electric Machine Design Tool for Permanent Magnet Synchronous Machines and Induction Machines. Machines, 8(1), 15. https://doi.org/10.3390/machines8010015