Experimental Evidence of the Speed Variation Effect on SVM Accuracy for Diagnostics of Ball Bearings

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Experimental Campaign

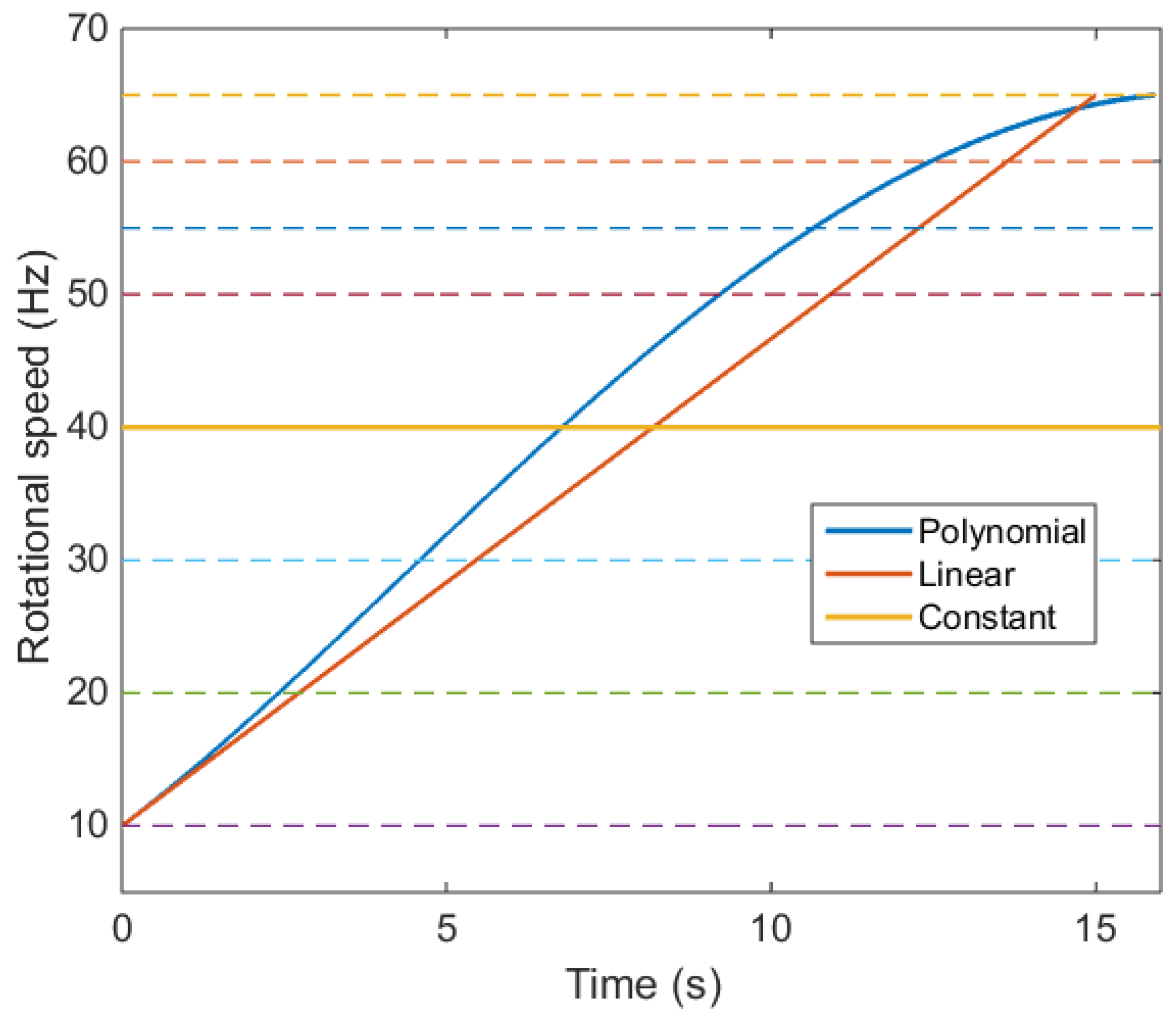

- Constant speed motion. Tested speeds: 10, 20, 30, 40, 50, 55, 60, 65 Hz. All the tests lasted 15 s.

- Linear increasing speed motion. From 10 to 65 Hz in 15 s, corresponding to a constant acceleration of 1320 deg/s2 (3.667 Hz/s2);

- Fifth-grade polynomial motion profile. From 10 to 65 Hz in 15 s. The polynomial equation iswith , the coefficients are:for initial conditions of position 0 deg, velocity 0 deg/s, and an acceleration 0 deg/s2.

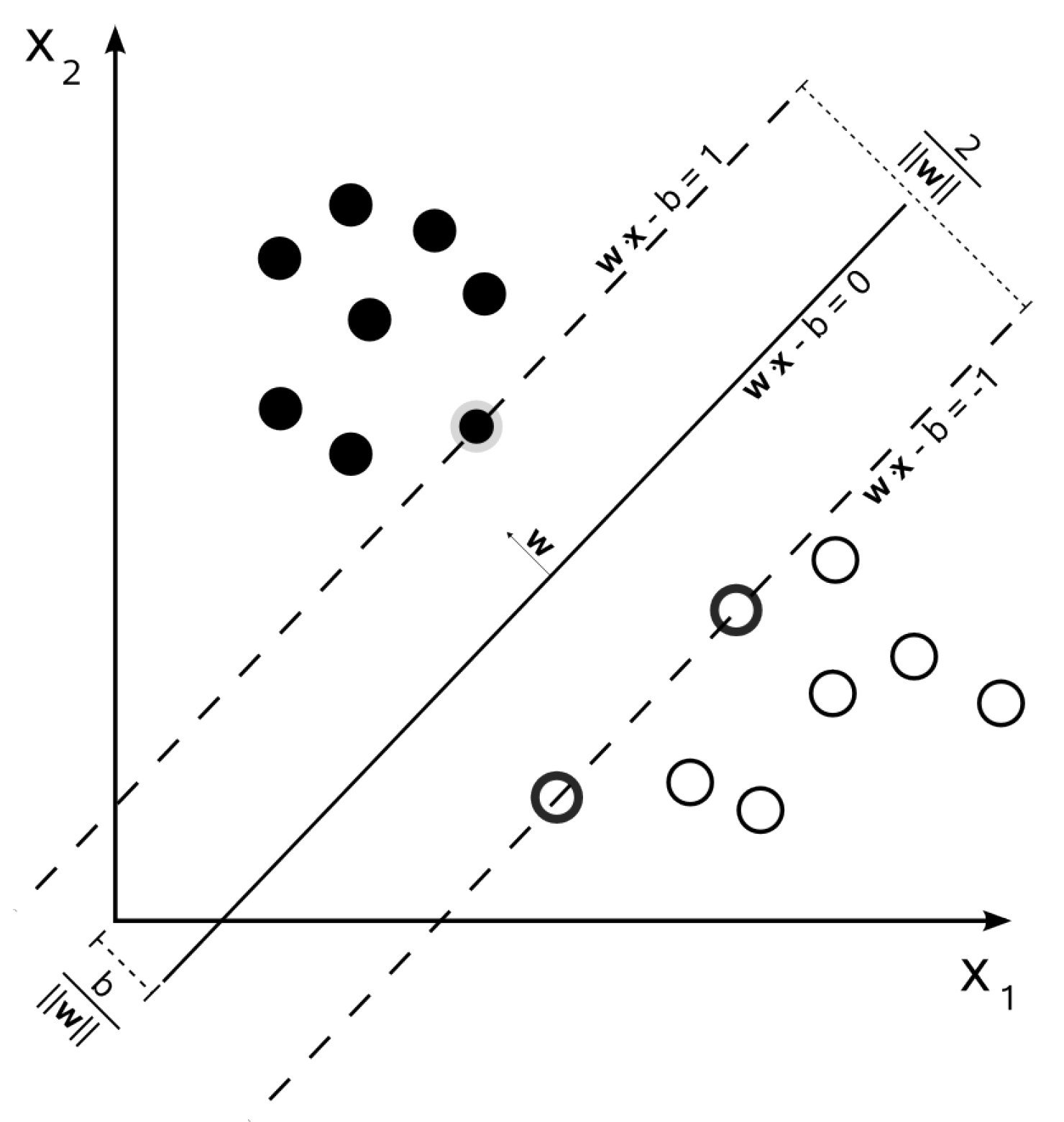

2.3. Machine Learning

3. Results

- Influence of motion profile on the SVM output;

- Influence of discretization of the speed range in the training step;

- Influence of the length of the signal in the training step;

- Influence of feature arrays in the training step;

- Influence of feature domain in the training step.

3.1. Influence of Motion Profile

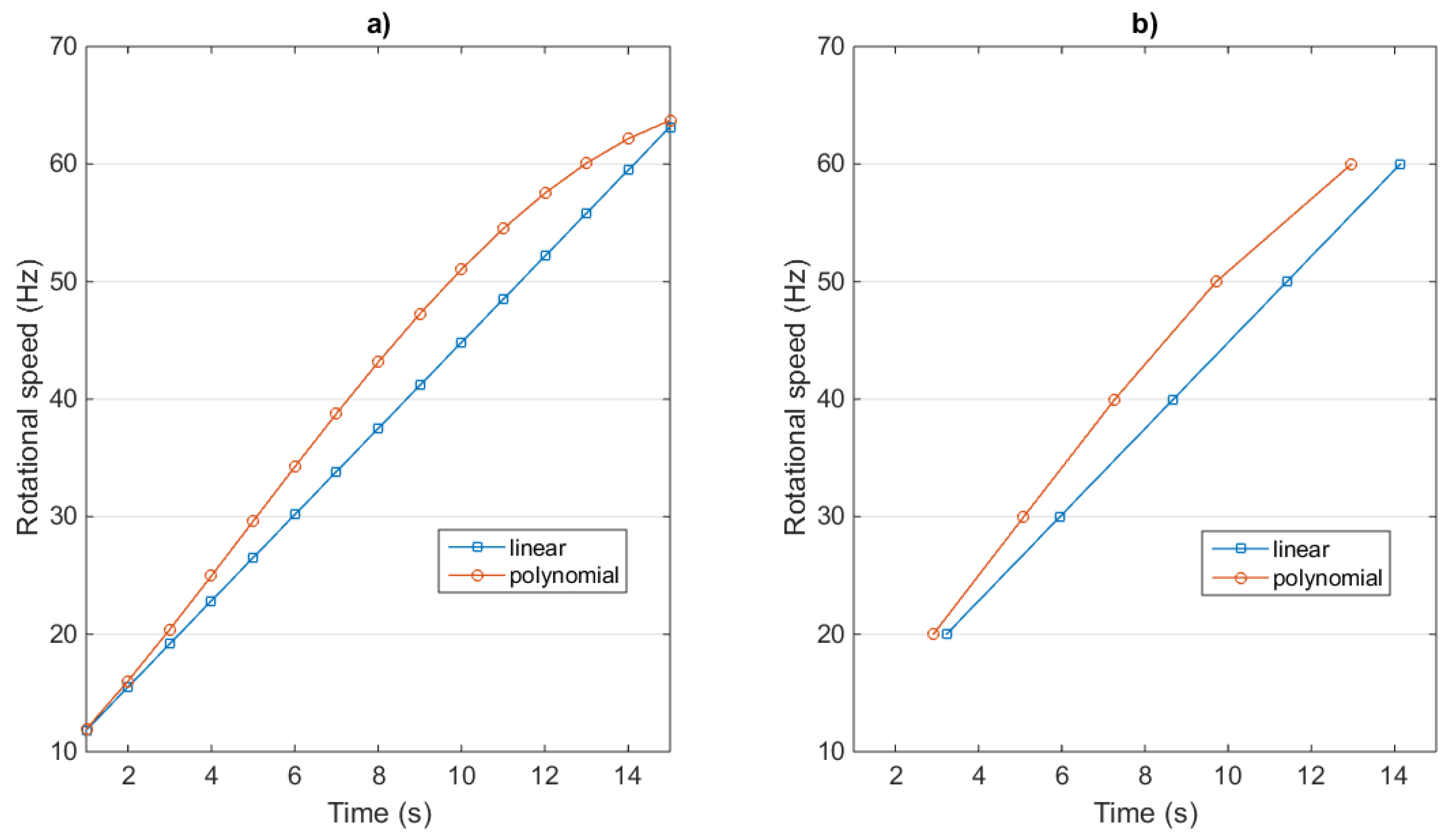

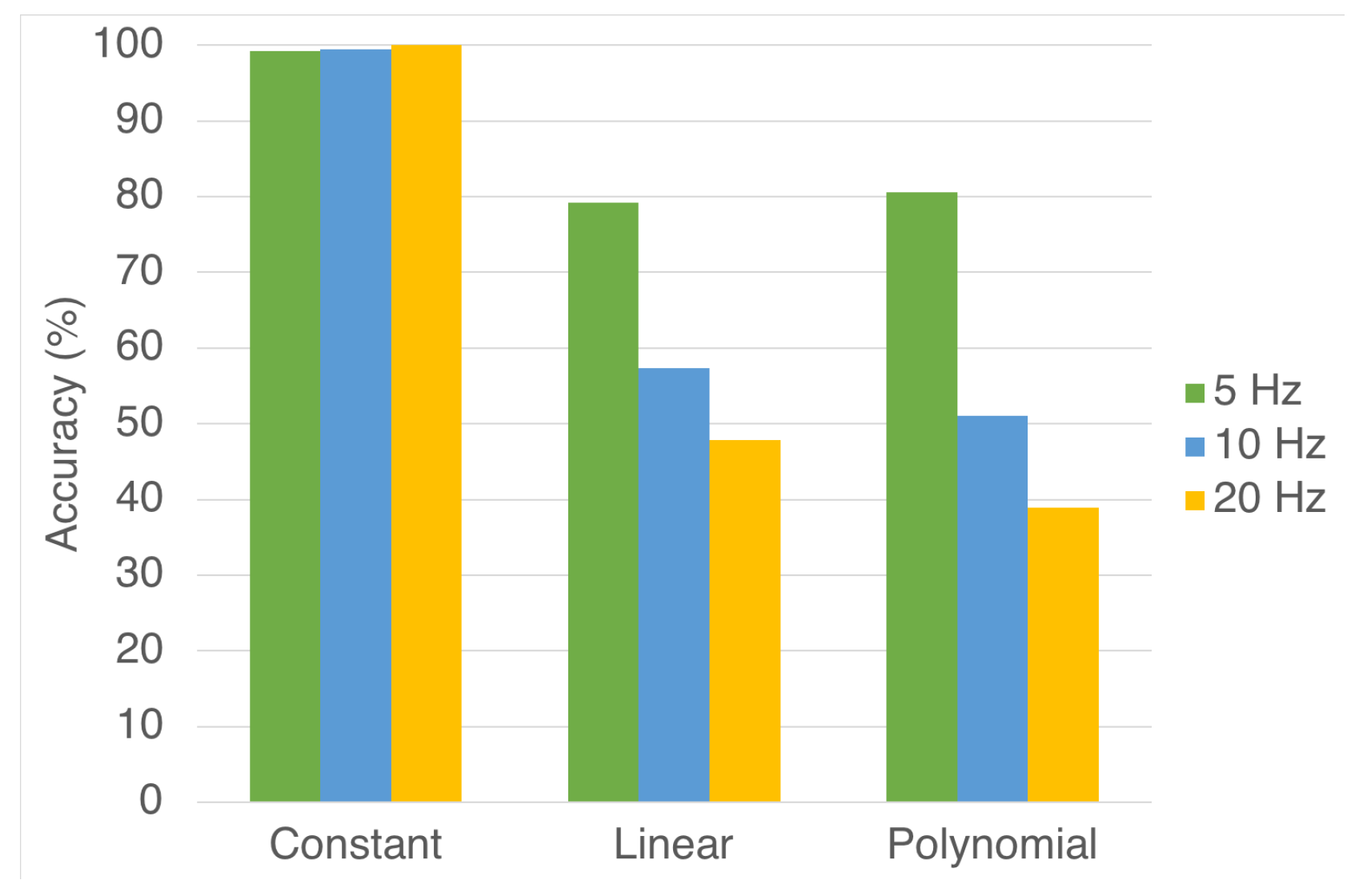

3.2. Influence of Discretization of the Speed Range

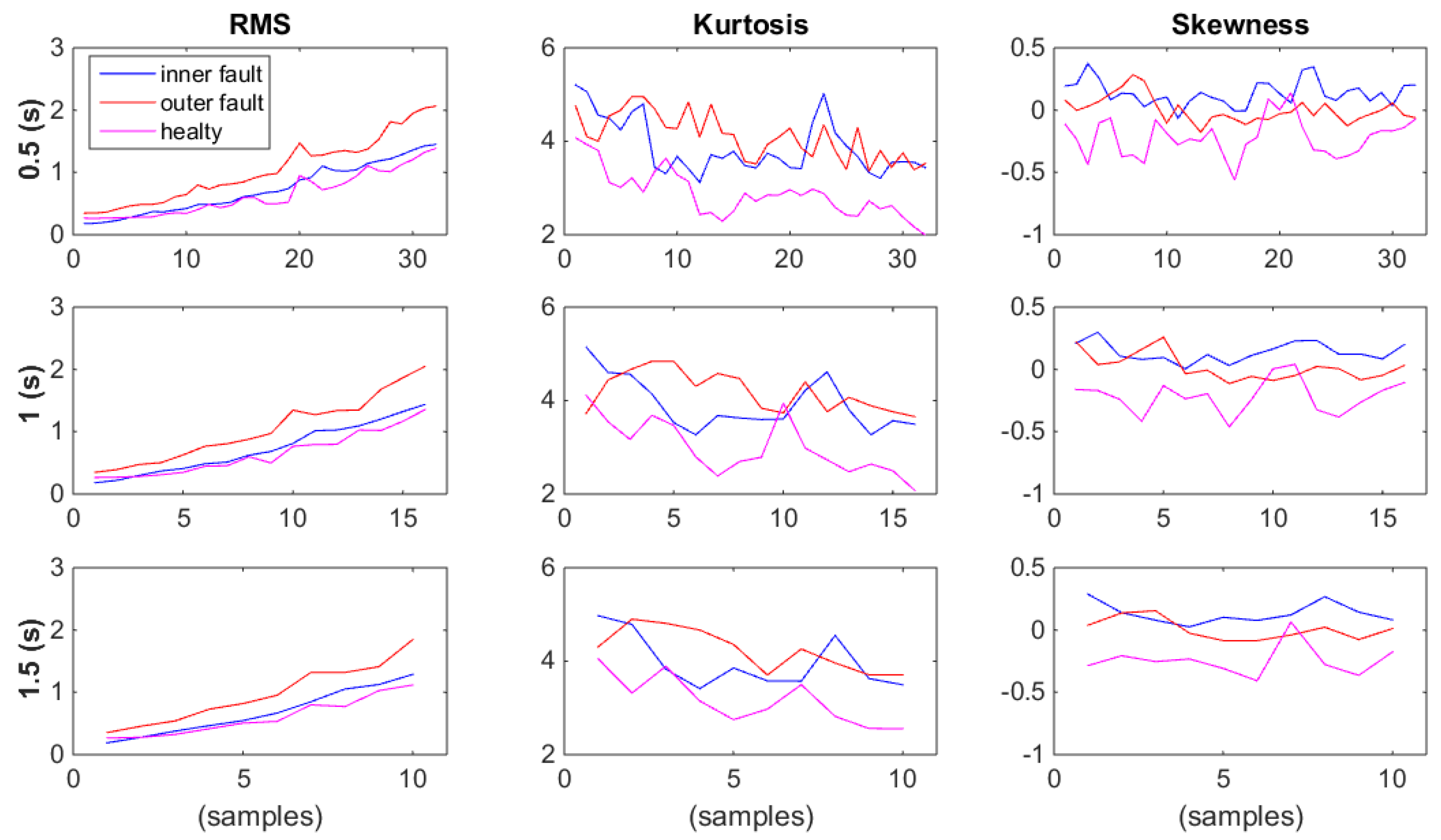

3.3. Influence of the Length of the Signal

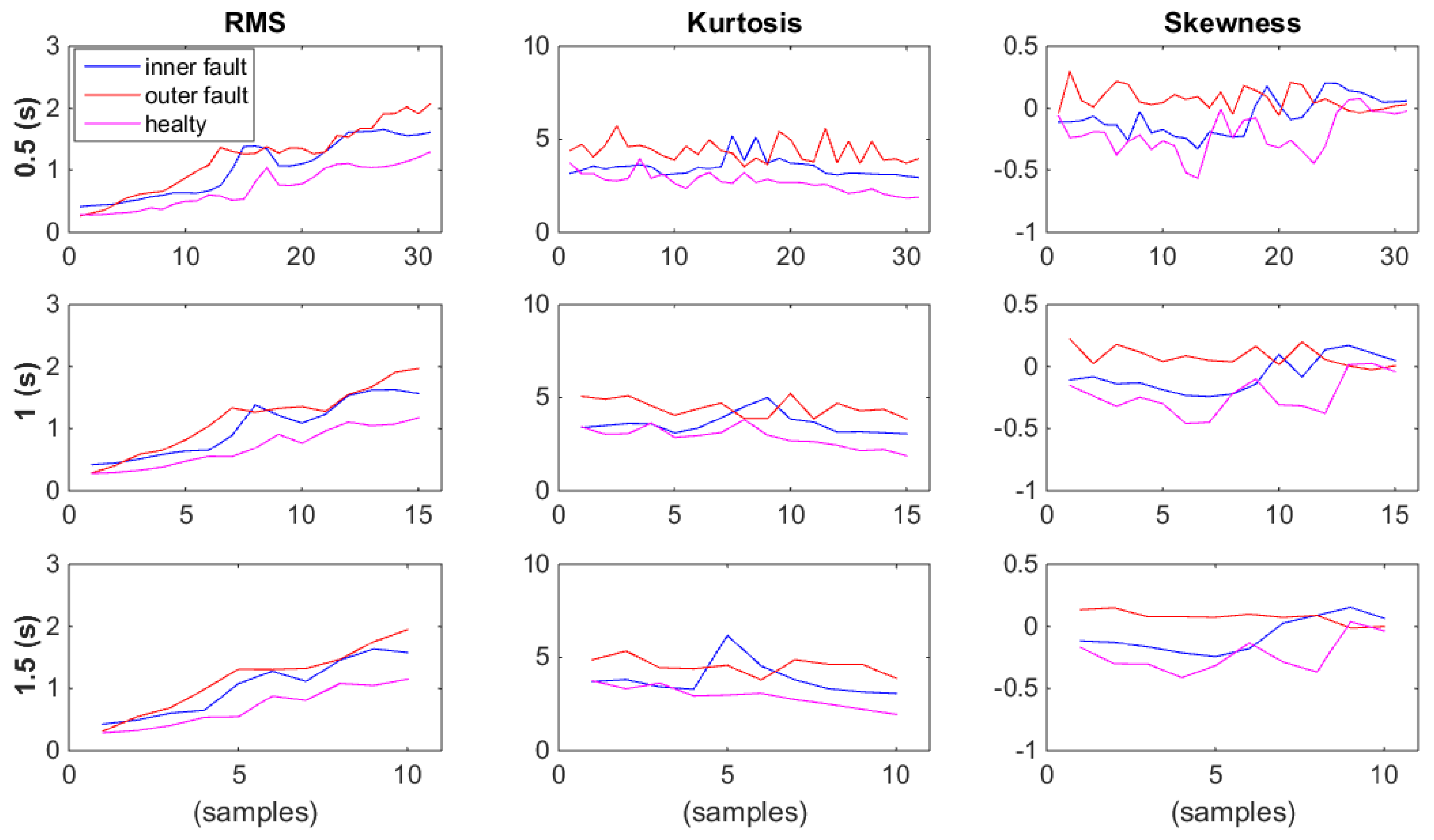

3.4. Influence of Feature Array in Training Step

3.5. Influence of Features Domain

- Time domain: RMS, skewness, and kurtosis.

- Frequency domain: frequency RMS, spectral skewness, and spectral kurtosis.

- Time and frequency domains: RMS, skewness, kurtosis, spectral skewness, and spectral kurtosis.

4. Conclusions

- The training data must span the speed range in detail, at least 5 Hz steps.

- Despite the speed range discretization step, there is a limit to the accuracy that depends on the motion profile and cannot be exceeded.

- The accuracy is not sensible to the length of the signal on which the feature array is computed (this is valid for the specific feature array discussed in this paper).

- A proper choice of the feature array can decrease the effect of the variation of the motion profile.

- In non-stationary conditions, time-domain features are preferable to frequency-domain features in the diagnostics of ball-bearings.

Author Contributions

Funding

Conflicts of Interest

References

- Jardine, A.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- El-Thalji, I.; Jantunen, E. A summary of fault modelling and predictive health monitoring of rolling element bearings. Mech. Syst. Signal Process. 2015, 60–61, 252–272. [Google Scholar] [CrossRef]

- Taylor, J.I.; Kirkland, D.W. The Bearing Analysis Handbook: A Practical Guide for Solving Vibration Problems in Bearings; Vibration Consultants: New York, NY, USA, 2004. [Google Scholar]

- Randall, R.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Antoni, J. The spectral kurtosis: A useful tool for characterising nonstationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Antoni, J.; Randall, R. The spectral kurtosis: Application to the vibratory surveillance and diagnostics of rotating machines. Mech. Syst. Signal Process. 2006, 20, 308–331. [Google Scholar] [CrossRef]

- Peng, Z.; Chu, F. Application of the wavelet transform in the condition monitoring and fault diagnostics: A review with bibliograpy. Mech. Syst. Signal Process. 2004, 18, 199–221. [Google Scholar] [CrossRef]

- Donoho, D.; Johnstone, I. Ideal spatial adaptation by wavelet shrinkage. Biometrika 1994, 81, 425–455. [Google Scholar] [CrossRef]

- Antoni, J.; Randall, R. Differential diagnosis of gear and bearing faults. J. Vib. Acoust. 2002, 124, 165–171. [Google Scholar] [CrossRef]

- Antoni, J.; Randall, R. A stochastic model for simulation and diagnostics of rolling element bearings with localized faults. J. Vib. Acoust. 2002, 125, 282–289. [Google Scholar] [CrossRef]

- Chaturvedi, G.H.; Thomas, D.W. Adaptive noise cancelling and condition monitoring. J. Sound Vib. 1981, 76, 391–405. [Google Scholar] [CrossRef]

- McFadden, F. A revised model for the extraction of periodic waveforms by time domain averaging. Mech. Syst. Signal Process. 1987, 1, 83–95. [Google Scholar] [CrossRef]

- Antoni, J.; Randall, R. Unsupervised noise cancellation for vibration signals: Part I—Evaluation of adaptive algorithms. Mech. Syst. Signal Process. 2004, 18, 89–101. [Google Scholar] [CrossRef]

- Antoni, J.; Randall, R. Unsupervised noise cancellation for vibration signals: Part II—A novel frequency-domain algorithm. Mech. Syst. Signal Process. 2004, 18, 103–117. [Google Scholar] [CrossRef]

- Potter, R. A new order tracking method for rotating machinery. Sound Vib. 1990, 24, 30–34. [Google Scholar]

- Cocconcelli, M.; Bassi, L.; Secchi, C.; Fantuzzi, C.; Rubini, R. An algorithm to diagnose ball bearing faults in servomotors running arbitrary motion profiles. Mech. Syst. Signal Process. 2012, 27, 667–682. [Google Scholar] [CrossRef]

- Cocconcelli, M.; Zimroz, R.; Rubini, R.; Bartelmus, W. STFT based approach for ball bearing fault detection in a varying speed motor. In Condition Monitoring of Machinery in Non-Stationary Operation; Fakhfakh, T., Bartelmus, W., Chaari, F., Zimroz, R., Haddar, M., Eds.; Springer: New York, NY, USA, 2012; pp. 41–50. [Google Scholar]

- Worden, K.; Staszewski, W.; Hensman, J. Natural computing for mechanical systems research: A tutorial overview. Mech. Syst. Signal Process. 2011, 25, 4–11. [Google Scholar] [CrossRef]

- Jack, L.; Nandi, A. Fault detection using Support Vector Machines and Artificial Neural Networks, augmented by Genetic Algorithms. Mech. Syst. Signal Process. 2002, 16, 373–390. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Zhu, Y. Intelligent fault diagnosis of rolling element bearing based on SVMs and fractal dimension. Mech. Syst. Signal Process. 2007, 21, 2012–2024. [Google Scholar] [CrossRef]

- Konar, P.; Chattopadhyay, P. Bearing fault detection of induction motor using wavelet and Support Vector Machines (SVMs). Appl. Soft Comput. 2011, 11, 4203–4211. [Google Scholar] [CrossRef]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer: New York, NY, USA, 1995. [Google Scholar]

- Widodo, A.; Yang, B. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Lui, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar]

- Cerrada, M.; Sanchez, R.; Li, C.; Pacheco, F.; Cabrera, D.; de Oliveira, J.; Vasquez, R. A review on data-driven fault severity assessment in rolling bearing. Mech. Syst. Signal Process. 2018, 99, 169–196. [Google Scholar] [CrossRef]

- Zhou, S.; Qian, S.; Chang, W.; Xiao, Y.; Chen, Y. A novel bearing multi-fault diagnosis approach based on Weighted Permutation Entropy and an Improved SVM Ensemble Classifier. Sensors 2018, 18, 1934. [Google Scholar] [CrossRef] [PubMed]

- Santos, P.; Villa, L.F.; Reñones, A.; Bustillo, A.; Maudes, J. An SVM-Based Solution for Fault Detection in Wind Turbines. Sensors 2015, 15, 5627–5648. [Google Scholar] [CrossRef] [PubMed]

- Biagiotti, L.; Melchiorri, C. Trajectory Planning for Automatic Machines and Robots; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Wikipedia Contributors. Support Vector Machine—Wikipedia, The Free Encyclopedia. 2018. Available online: https://en.wikipedia.org/wiki/Support_vector_machine (accessed on 29 August 2018).

- Cristianini, N.; Shawe-Taylor, J. An Introduction to Support Vector Machines and Other Kernel-Based Learning Methods; Cambridge University Press: New York, NY, USA, 2000. [Google Scholar]

- Crammer, K.; Singer, Y. On the Algorithmic Implementation of Multiclass Kernel-based Vector Machines. J. Mach. Learn. Res. 2001, 2, 265–292. [Google Scholar]

- Scholkopf, B.; Burges, C.; Smola, A. Advances in Kernel Methods: Support Vector Learning; MIT Press: Cambridge, MA, USA, 1999. [Google Scholar]

- Caesarendra, W.; Tjahjowidodo, T. A Review of Feature Extraction Methods in Vibration-Based Condition Monitoring and Its Application for Degradation Trend Estimation of Low-Speed Slew Bearing. Machines 2017, 5, 21. [Google Scholar] [CrossRef]

- Wang, Y.; Xian, J.; Markert, R.; Liang, M. Spectral kurtosis for fault detection, diagnosis and prognostics of rotating machines: A review with applications. Mech. Syst. Signal Process. 2016, 66, 679–698. [Google Scholar] [CrossRef]

- Ruiz-Gonzalez, R.; Gomez-Gil, J.; Gomez-Gil, F.; Martínez-Martínez, V. An SVM-Based Classifier for Estimating the State of Various Rotating Components in Agro-Industrial Machinery with a Vibration Signal Acquired from a Single Point on the Machine Chassis. Sensors 2014, 14, 20713–20735. [Google Scholar] [CrossRef] [PubMed]

- Poyhonen, S.; Negrea, M.; Arkkio, A.; Hyotyniemi, H.; Koivo, H. Fault Diagnostics of an Electrical Machine with Multiple Support Vector Classifiers. In Proceedings of the 2002 IEEE International Symposium on Intelligent Control, Vancouver, BC, Canada, 27–30 October 2002; pp. 373–378. [Google Scholar]

- The MathWorks, Inc. Statistics and Machine Learning Toolbox. User’s Guide; The MathWorks, Inc.: Natick, MA, USA, 2018. [Google Scholar]

- Weisstein, E.W. Parseval’s Theorem. 2018. Available online: http://mathworld.wolfram.com/ParsevalsTheorem.html (accessed on 14 October 2018).

| Deep Groove Ball Bearing (6204) | |

|---|---|

| Pitch diameter (mm) | 33.5 |

| Ball diameter (mm) | 7.94 |

| Rotational frequency (Hz) | 55 |

| Outer race fault frequency (Hz) | 167.9 |

| Inner race fault frequency (Hz) | 272.1 |

| Speed Range (Hz) | Samples | Motion Profile | Accuracy | |

|---|---|---|---|---|

| Training | [10, 20, 30, 40, 50, 60] | 432 | Constant | — |

| Test | [10, 20, 30, 40, 50, 60] | 108 | Constant | 99.5% |

| [10–60] (Figure 5a) | 96 | Linear | 57.3% | |

| 90 | Polynomial | 51.1% | ||

| [20, 30, 40, 50, 60] (Figure 5b) | 36 | Linear | 75% | |

| 36 | Polynomial | 69.4% |

| Δ(Hz) | Speed Range (Hz) | Constant Speed | Linear Speed | Polynomial Speed |

|---|---|---|---|---|

| 5 | [50–65] | 99.3% | 79.2% | 80.6% |

| 10 | [10–60] | 99.5% | 57.3% | 51.1% |

| 20 | [10–50] | 100% | 47.9% | 38.9% |

| T(s) | Constant Speed | Linear Speed | Polynomial Speed |

|---|---|---|---|

| 0.5 | 99.1% | 64.1% | 68.3% |

| 1 | 100% | 66.7% | 66.7% |

| 1.5 | 99% | 61.7% | 71.7% |

| Feature Array | Constant Speed | Linear Speed | Polynomial Speed |

|---|---|---|---|

| RMS, kurtosis, skewness | 100% | 66.7% | 66.7% |

| Kurtosis, skewness | 92.7% | 64.6% | 58.9% |

| RMS, kurtosis | 96.2% | 60.42% | 65.56% |

| RMS, skewness | 95.8% | 63.54% | 62.22% |

| Features Domain | Constant Speed | Linear Speed | Polynomial Speed |

|---|---|---|---|

| Time domain | 99.5% | 57.3% | 51.1% |

| Frequency domain | 99.5% | 53.13% | 37.78% |

| Time and frequency domains | 100% | 41.67% | 35.56% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavalaglio Camargo Molano, J.; Rubini, R.; Cocconcelli, M. Experimental Evidence of the Speed Variation Effect on SVM Accuracy for Diagnostics of Ball Bearings. Machines 2018, 6, 48. https://doi.org/10.3390/machines6040048

Cavalaglio Camargo Molano J, Rubini R, Cocconcelli M. Experimental Evidence of the Speed Variation Effect on SVM Accuracy for Diagnostics of Ball Bearings. Machines. 2018; 6(4):48. https://doi.org/10.3390/machines6040048

Chicago/Turabian StyleCavalaglio Camargo Molano, Jacopo, Riccardo Rubini, and Marco Cocconcelli. 2018. "Experimental Evidence of the Speed Variation Effect on SVM Accuracy for Diagnostics of Ball Bearings" Machines 6, no. 4: 48. https://doi.org/10.3390/machines6040048

APA StyleCavalaglio Camargo Molano, J., Rubini, R., & Cocconcelli, M. (2018). Experimental Evidence of the Speed Variation Effect on SVM Accuracy for Diagnostics of Ball Bearings. Machines, 6(4), 48. https://doi.org/10.3390/machines6040048