2.1. Overall Design of Speaker-Based Haptic Rendering Device

Our haptic rendering system uses a loudspeaker to effect displacement of the mobile component of a 1-DOF haptic renderer, taking advantage of the low friction and inertia exhibited by this inexpensive commercial device.

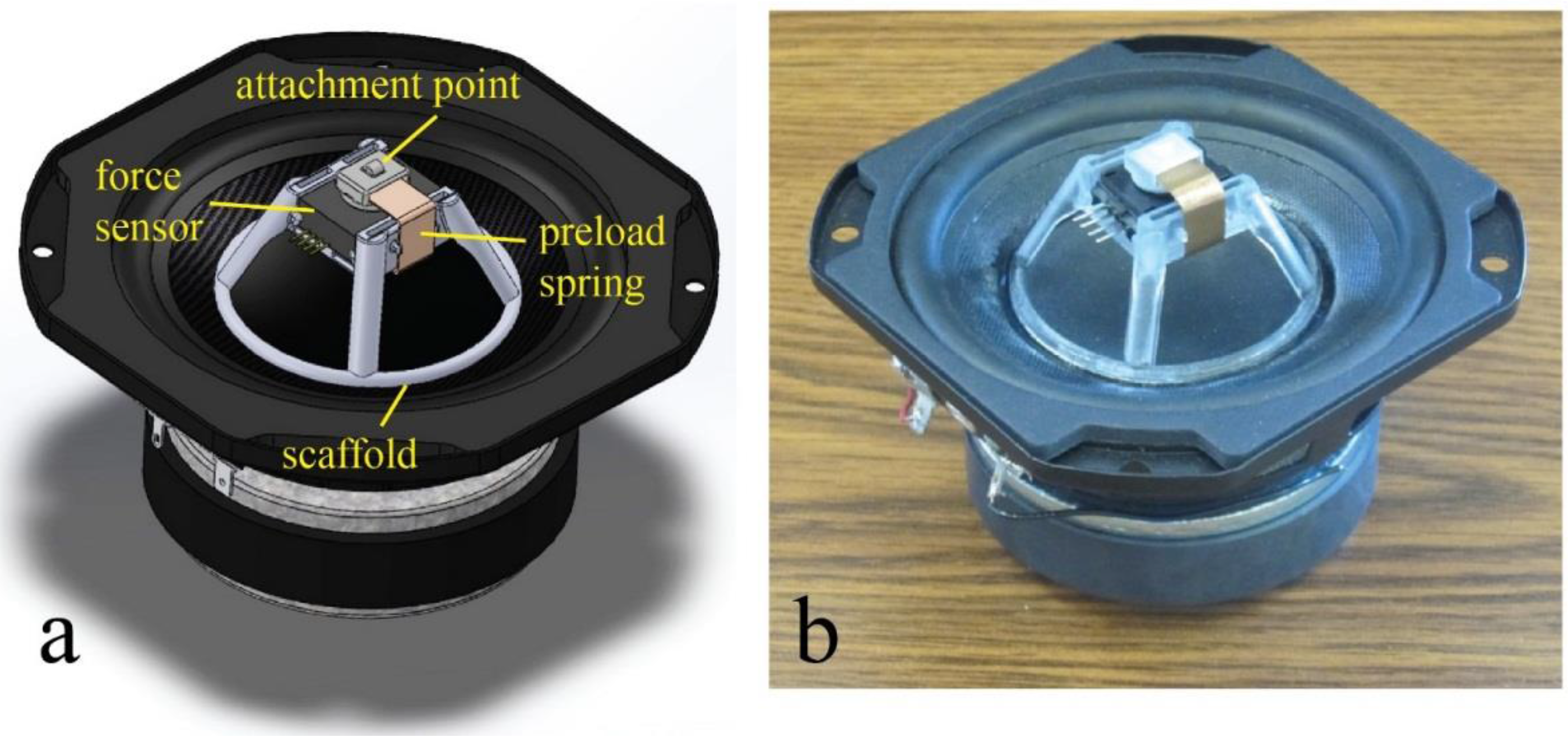

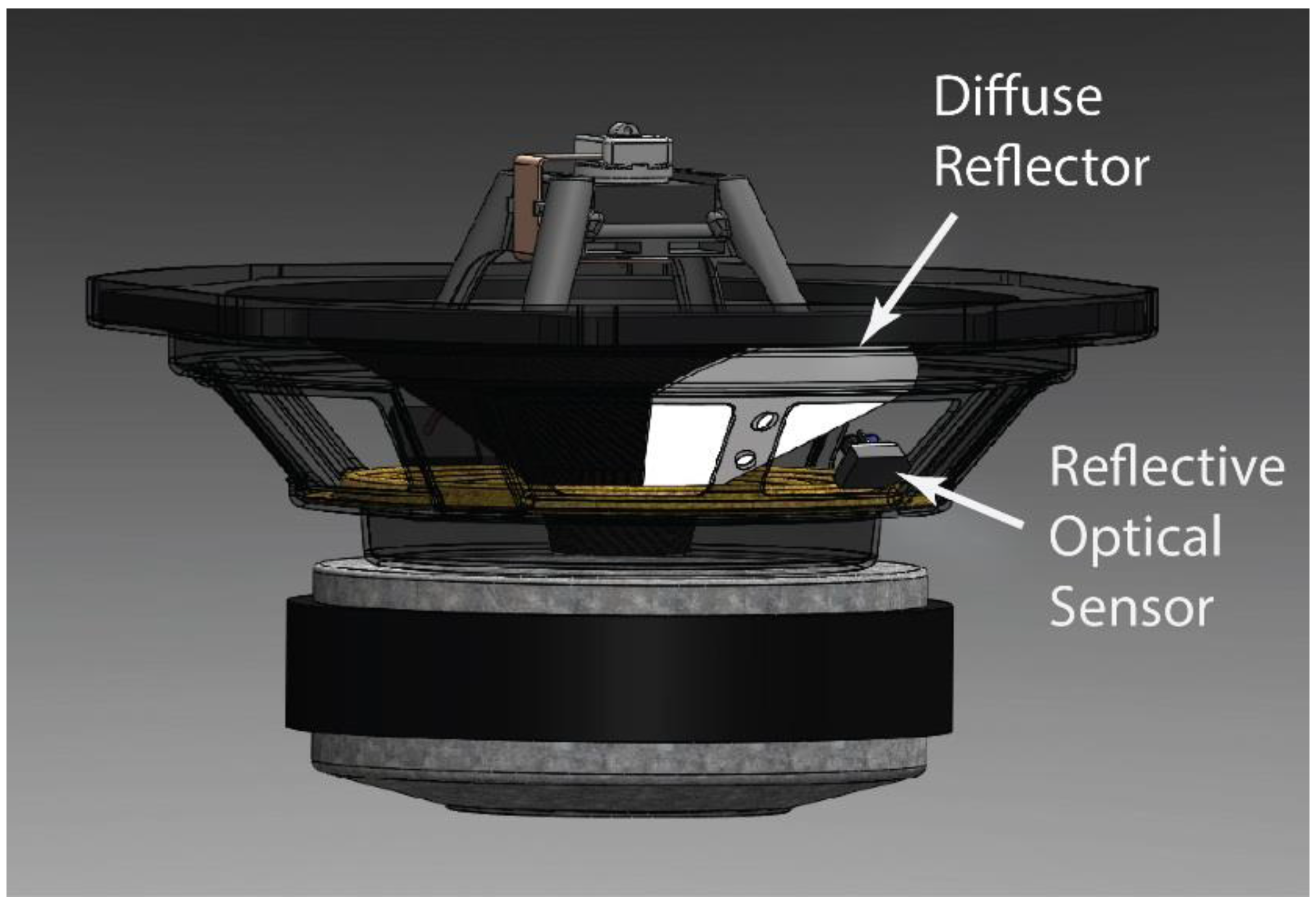

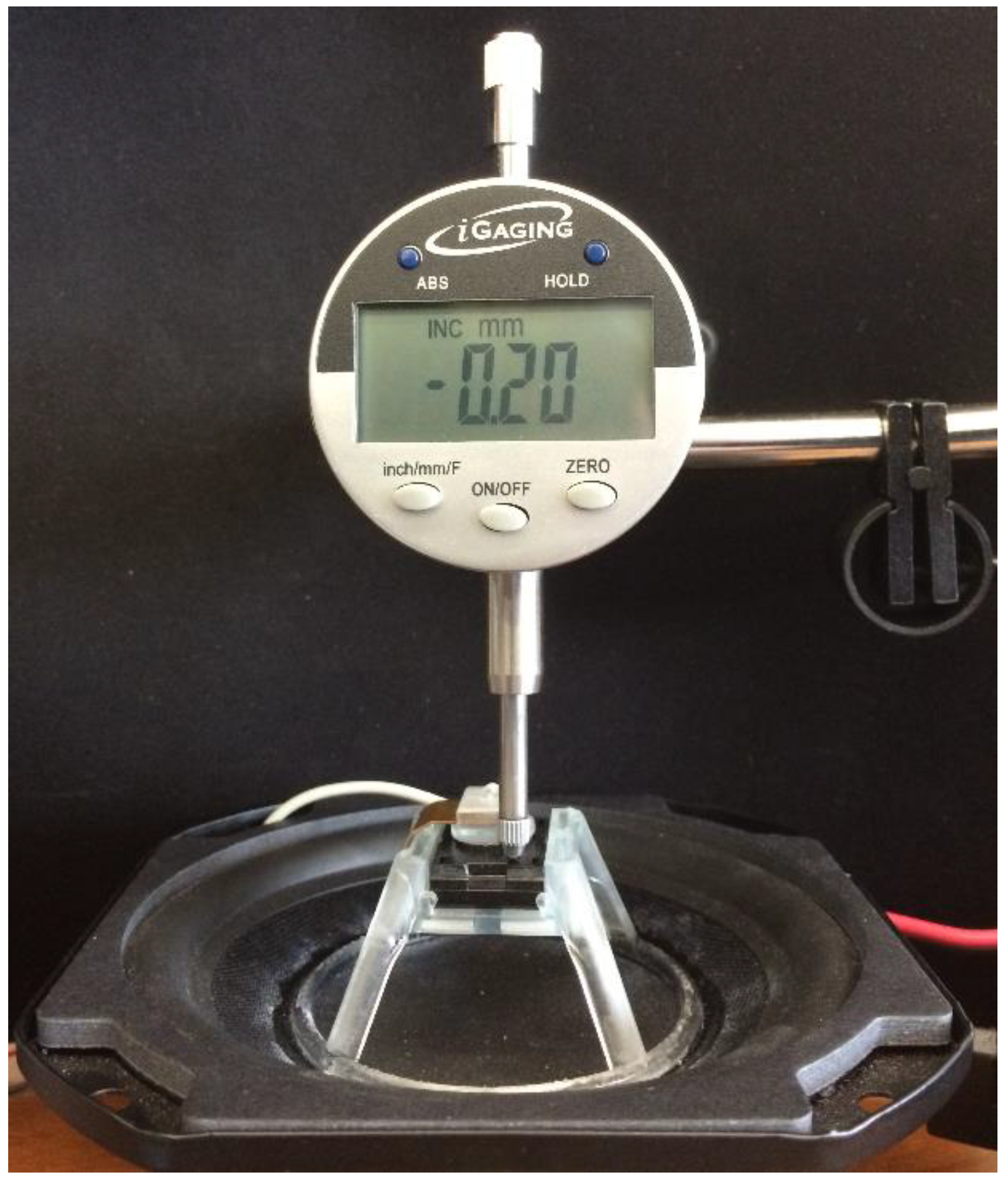

Figure 1 shows the design (SolidWorks) of our initial prototype as well as a photograph of the actual device. A custom plastic scaffold, produced using stereolithography, is attached to the central ring of the speaker cone to move up and down as a unit. The scaffold is made stiff and lightweight by use of hollow beams, supporting an attachment point for user interaction. Here, users will attach mock needles, scalpels,

etc., enabling interaction with simulated tissues during psychophysics experiments.

The paper cone of the speaker can be made to move up or down with its attached scaffold by introducing a directional current in the speaker’s voice coil, which is mounted over a permanent magnet mounted to the metal frame of the speaker. The suspension of the cone is stabilized by a spider, a centering spring and damper whose compliance returns the cone to the middle of its displacement range at rest. We have chosen an 80-Watt 5-inch loudspeaker (Faital Pro 5FE120) designed for midrange to bass frequencies, and capable of delivering 10 N of sustained force (as determined below). Its maximum displacement range is approximately 1 cm in each direction from the rest point. During normal operation in the audio range of 20 Hz to 20 KHz, the displacement is far less, allowing the compliance of the spider to be assumed linear. This linearity is important in audio systems to avoid distortion. Our application, however, while benefiting from the ability of the speaker to react at such frequencies, also employs frequencies all the way down to direct current (DC), permitting us to move the cone to any desired displacement and hold it there. Our unorthodox application thus results in greater displacements than normally used for a speaker, requiring consideration of the non-linearity of its compliance. This, and other considerations, require us to know the actual displacement of the speaker at any given time, as will be discussed below.

In determining the useful range of displacements generated by DC currents in the coil, it is important to consider the maximum power rating of the speaker. For our speaker, this is reported by the manufacturer to be 80 W, which, given 5.4 Ω electrical resistance at DC, would seem to imply a maximum DC voltage of 21 V, since DC power equals V2/R. We have found, however, that the safe maximum DC voltage is signficantly less, approximately 10 V. This discrepancy is due to the fact that the manufacturer’s reported maximum power is for audio frequencies, at which much of the energy put into the coil is dissipated as sound instead of heat in the coil. At DC, all of the energy is dissipated as heat, and so the voltage must be less to avoid melting the coil.

We have included a force sensor (Honeywell FS-01) mounted between the attachment point and the scaffold, with a preload spring allowing measurement of push and pull forces exerted by the user at the attachment point (see

Figure 1). The sensor has a total range of 6.7 N with precision of approximately ±0.03 N and accuracy of approximately ±0.07 N. We could theoretically compute the externally applied force without a sensor, based on the displacement of the speaker and the force delivered by the voice coil, as is done with the Maglev system described above. However, we choose to include the sensor because it provides an independent measurement with greater accuracy and speed than could be provided by such calculations.

2.2. Measuring Displacement with Inductance

As a first approximation, the displacement of a speaker at steady state is proportional to the current in its voice-coil, and thus displacement might be predictable from that current. However, for a number of reasons, we require independent measurement of speaker displacement. As noted, we are moving the cone further than in normal audio applications, operating it in the range of non-linear compliance. A further nonlinearity is introduced as the voice-coil moves relative to the permanent magnet, because the force produced by a given current changes as more or less of the voice coil is positioned over the permanent magnet. Both of these nonlinearities could be compensated for by calibration. However, in our application the user will apply additional forces to the attachment point, so displacement can no longer be predicted from coil current alone. Thus we need an independent measurement of displacement.

Various technologies are available to measure displacement, including those based on resistance, capacitance, inductance, reluctance, optical encoding, reflected and transmitted light intensity, and coherent light. Some of these require physical contact, which would increase the mass of the moving component, while others do not. Each has advantages and disadvantages in terms of accuracy, range, complexity, expense, etc.

We choose instead to make use of information provided by the speaker itself, namely, changes in the electrical inductance of the voice coil as it moves over the permanent magnet. Electrical inductance is a component of electrical impedance, whose magnitude can be measured by injecting a sinusoidal voltage and monitoring the resulting sinusoidal current at the same frequency. The impedance of a speaker, as a function of frequency, is due to a number of sources, both electrical and mechanical. If we understand these sources, we can isolate the coil’s electrical inductance from its total electrical and mechanical impedance.

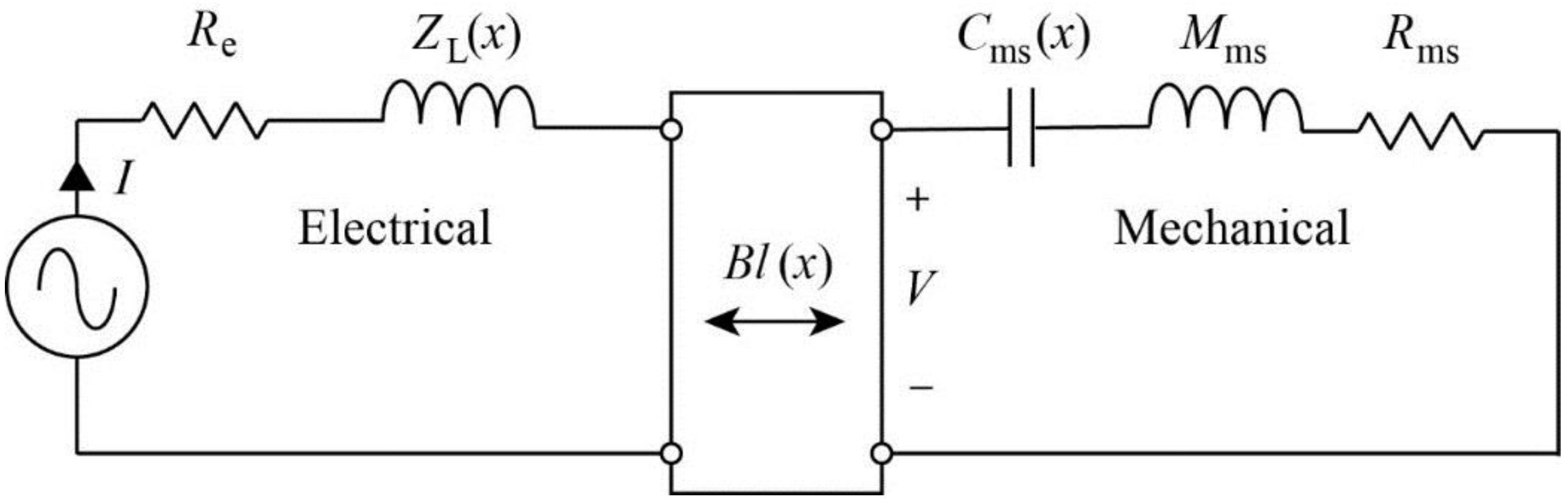

Electromechanical systems are often understood in terms of

lumped parameter models. Figure 2 shows a simplified lumped parameter model for a speaker adapted from [

8], with terms defined in

Table 1. The left and right halves of the diagram depict, respectively, the electrical and mechanical properties of the speaker. Notice that electrical symbols are used on both sides, representing, on the right side, their analogous mechanical properties,

i.e., inductance represents mass, resistance represents friction or damping, and capacitance represents compliance. The mass of the moving portion (cone + voice-coil + scaffold,

etc.) is represented by “inductance”

Mms. The air resistance of the cone and damping in the spider is shown as

Rms. The mechanical compliance is represented by “capacitance”

Cms(

x), and is a function of displacement

x because, as noted above, it is nonlinear at the extremes of displacement. On the electrical side of the model, we have the DC resistance

Re and the electrical impedance due to inductance

ZL(

x), which changes with displacement and thus should allow us to make a measurement of displacement, if we can isolate it from the other elements in the model.

The transduction between the electrical and mechanical halves of the lumped parameter model is represented by the electro-dynamical force factor Bl(x), accounting for energy transfer in both directions. Electrical current in the voice coil I causes the mechanical force that moves the speaker, represented on the mechanical side by “voltage” V. Energy is also transferred in the other direction, with mechanical motion of the coil resulting in an opposing electrical voltage in the voice coil. Thus mechanical properties of the speaker (such as its mechanical resonance) show up as part of its electrical impedance.

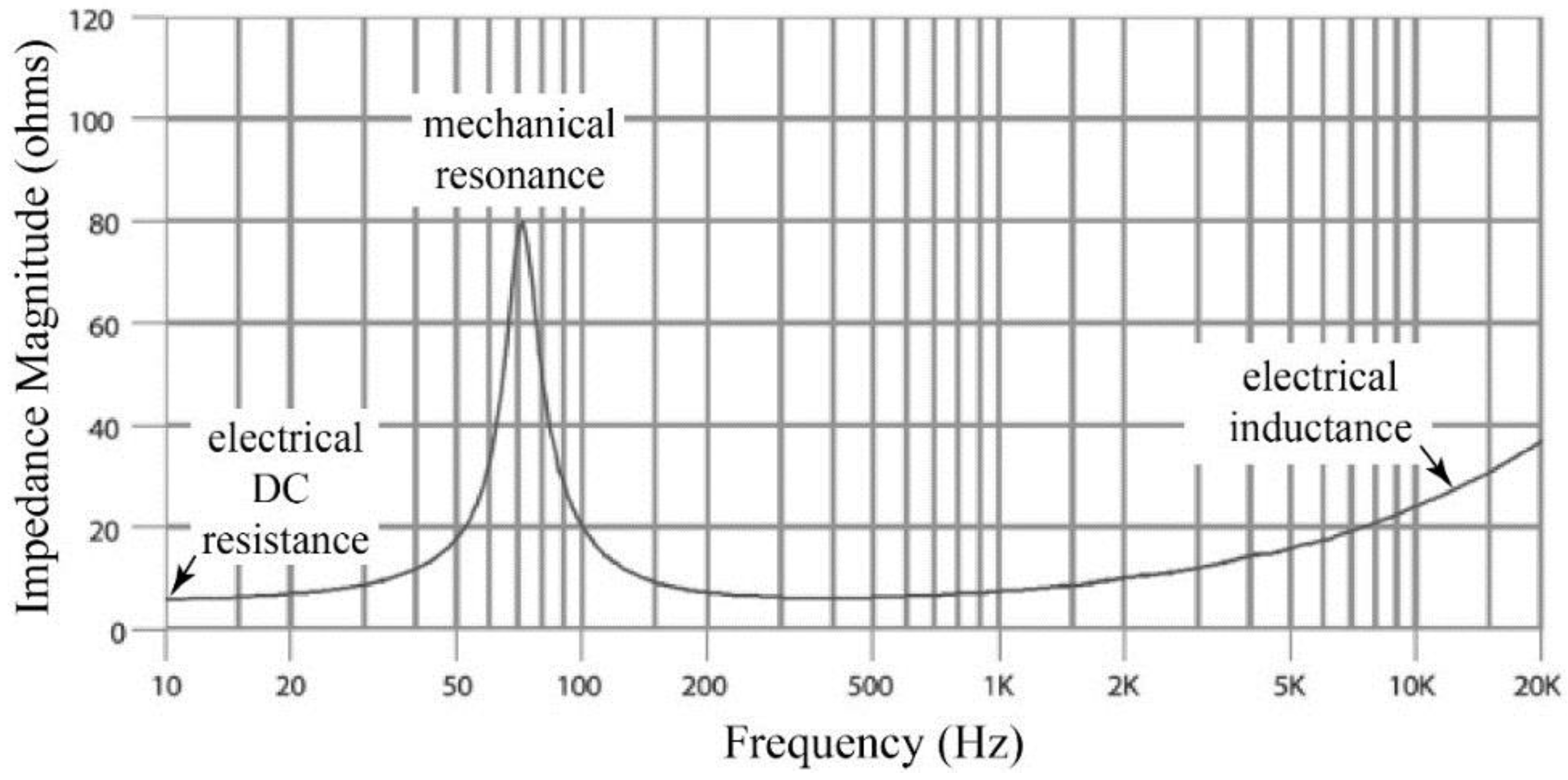

The electrical impedance as a function of frequency for our particular speaker is shown in

Figure 3. Impedance is a complex quantity, and the graph displays only its magnitude. The impedance extends from the electrical DC resistance

Re (not shown at 0 Hz due to logarithmic scale), up through mechanical resonance at approximately 60 Hz. The mechanical resonance is due to a minimum in the mechanical impedance at that frequency, with the mass and compliance establishing a resonant system. This

minimum mechanical impedance is translated into a

maximum electrical impedance by

Bl(

x), which, as may be recalled, converts electrical

current into mechanical “

voltage,” thus replacing the definition of impedance with its reciprocal.

At higher frequencies,

Figure 3 shows a slowly increasing value due primarily to inductance of the voice coil. As already noted,

ZL(

x) changes as the voice coil moves over the ferromagnetic material in the permanent magnet, and it is this value we will use for computing displacement. It also changes as a function of frequency, increasing because of the fundamental nature of inductance:

where

is frequency in radians per second and

L is the inductance.

To measure ZL(x), we introduce a sinusoidal voltage at a frequency well above mechanical resonance, and in fact, above the audio range entirely, so as not to create an audible signal. For reasons discussed below, we have chosen that frequency to be 30 KHz.

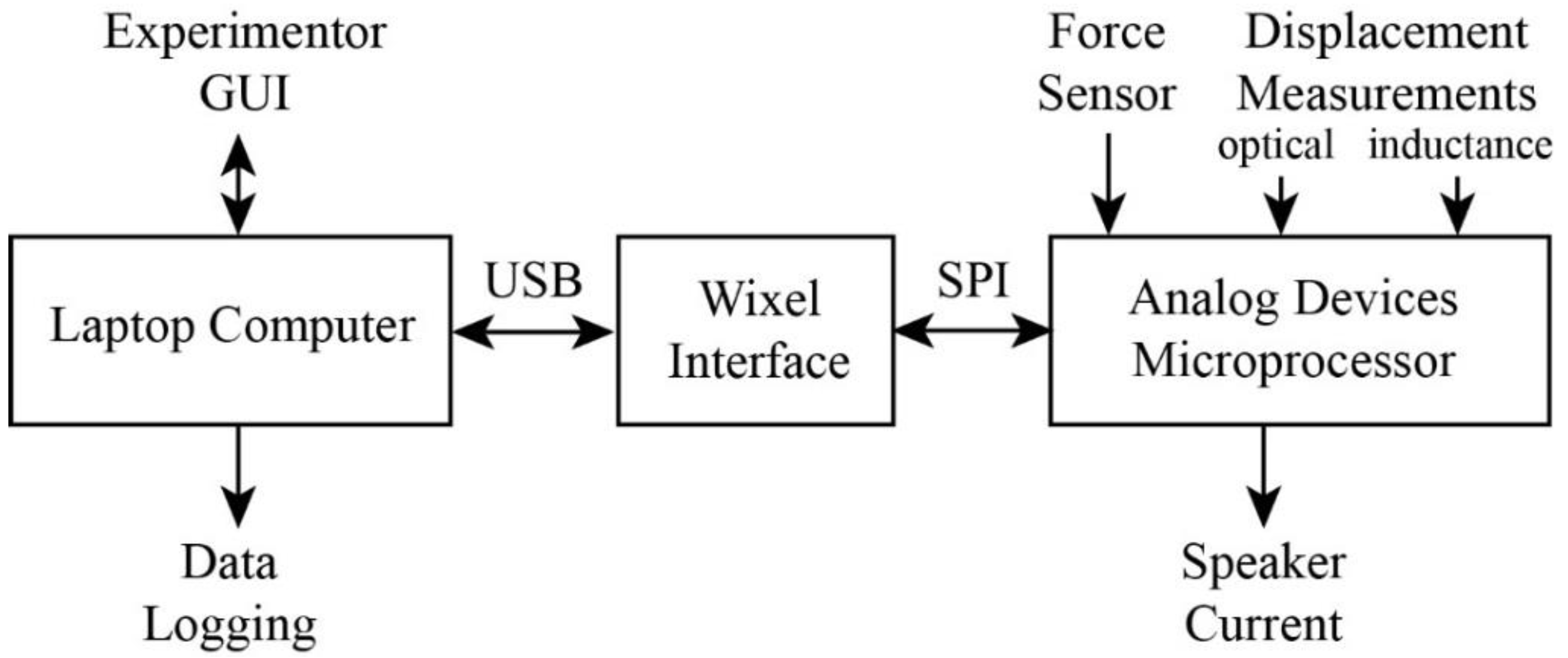

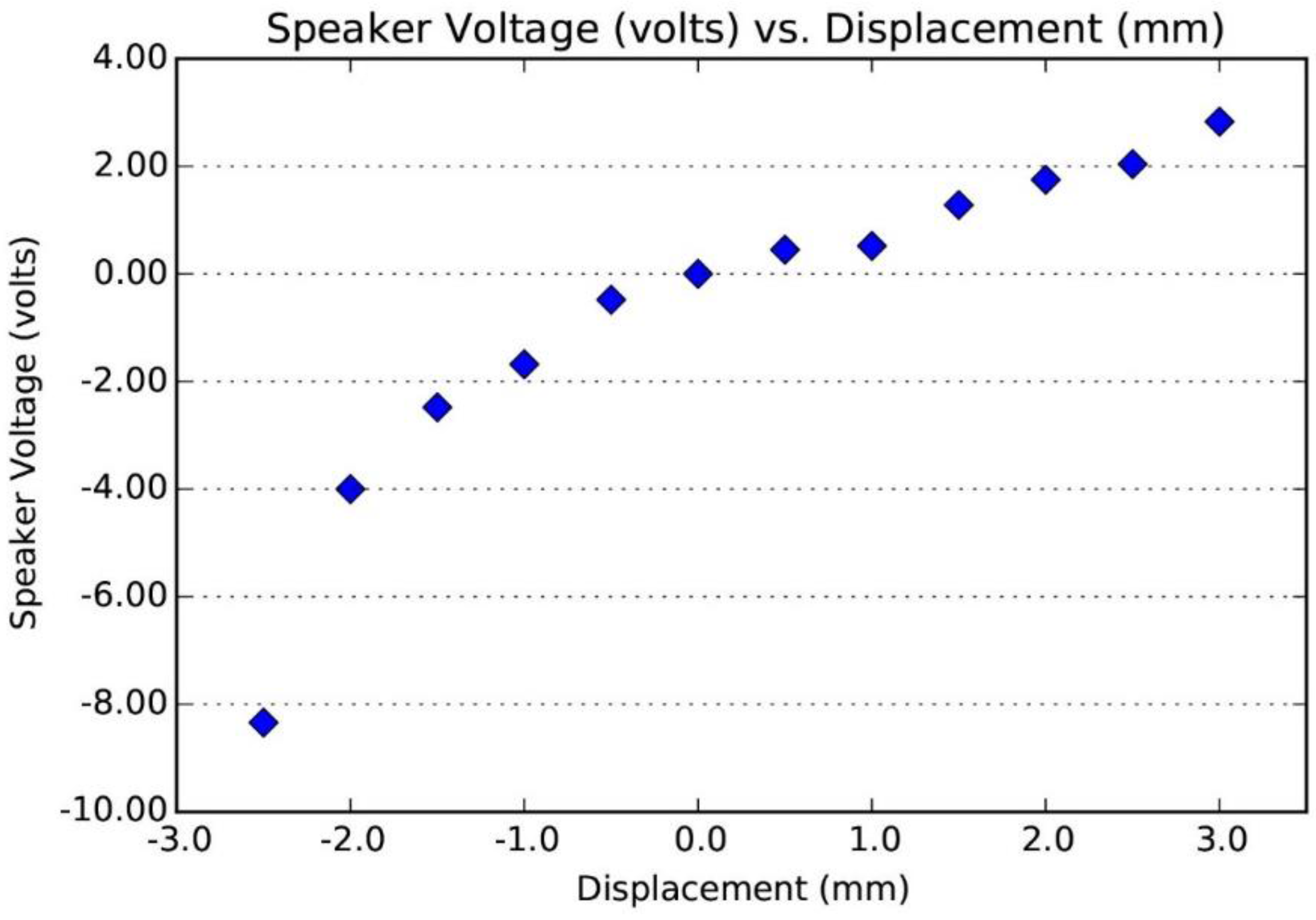

Figure 4 shows the configuration of our system to measure the impedance

ZL(

x) due to inductance. A high-power linear push-pull amplifier (PA74A, Apex Microtechnology) was used to move the speaker with low-frequency (including DC) current, as well as to introduce the 30 KHz signal, with the two signals being added before the amplifier. Since the amplifier is essentially a voltage source, changes in

ZL(

x) result in changes in the 30 KHz voltage across the transformer primary in series with the speaker. An air-core transformer was used to avoid non-linearity due to saturation in a ferromagnetic core. The transformer was constructed from two coils (Jantzen Audio 0.50 mH Crossover Coil) mounted adjacent and coaxially. The 30 KHz voltage in the secondary was processed by a peak detector to yield voltage

Vout. The peak detector produced a

greater voltage when the inductance of the speaker was

reduced, because the speaker coil and the transformer primary formed a voltage divider across the linear amplifier output.

To achieve a maximum change in

Vout with

ZL(

x), we matched the impedance of the transformer primary

ZT with that of the voice coil at rest,

ZL(0), approximately 0.50 mH. Let us denote the amplitude of the 30 KHz sinusoid at the amplifier output as

VS. Assuming that

Re is much less than |

ZL(

x)| at 30 KHz (which is supported by

Figure 3), and assuming that the DC resistance of the transformer primary is negligible (its wire gage is much thicker than the voice coil), and that the transformer and peak detector are both 100% efficient, then a reasonable approximation for

Vout is:

which changes monotonically with impedance

ZL(

x), and thus with displacement

x. Proper calibration of

Vout against an independent measurement of displacement should therefore permit determination of

x by inductance.

We have chosen 30 KHz, because at higher frequencies the circuit shown in

Figure 4 encounters an additional resistance

Reddy (not shown in

Figure 2) resulting from eddy currents in the ferromagnetic magnet of the speaker. At a high enough frequency,

Reddy dominates the coil inductance, and as shown in Equation (3), this reduces the sensitivity of

Vout to changes in

ZL(

x) and thus to changes in

x.

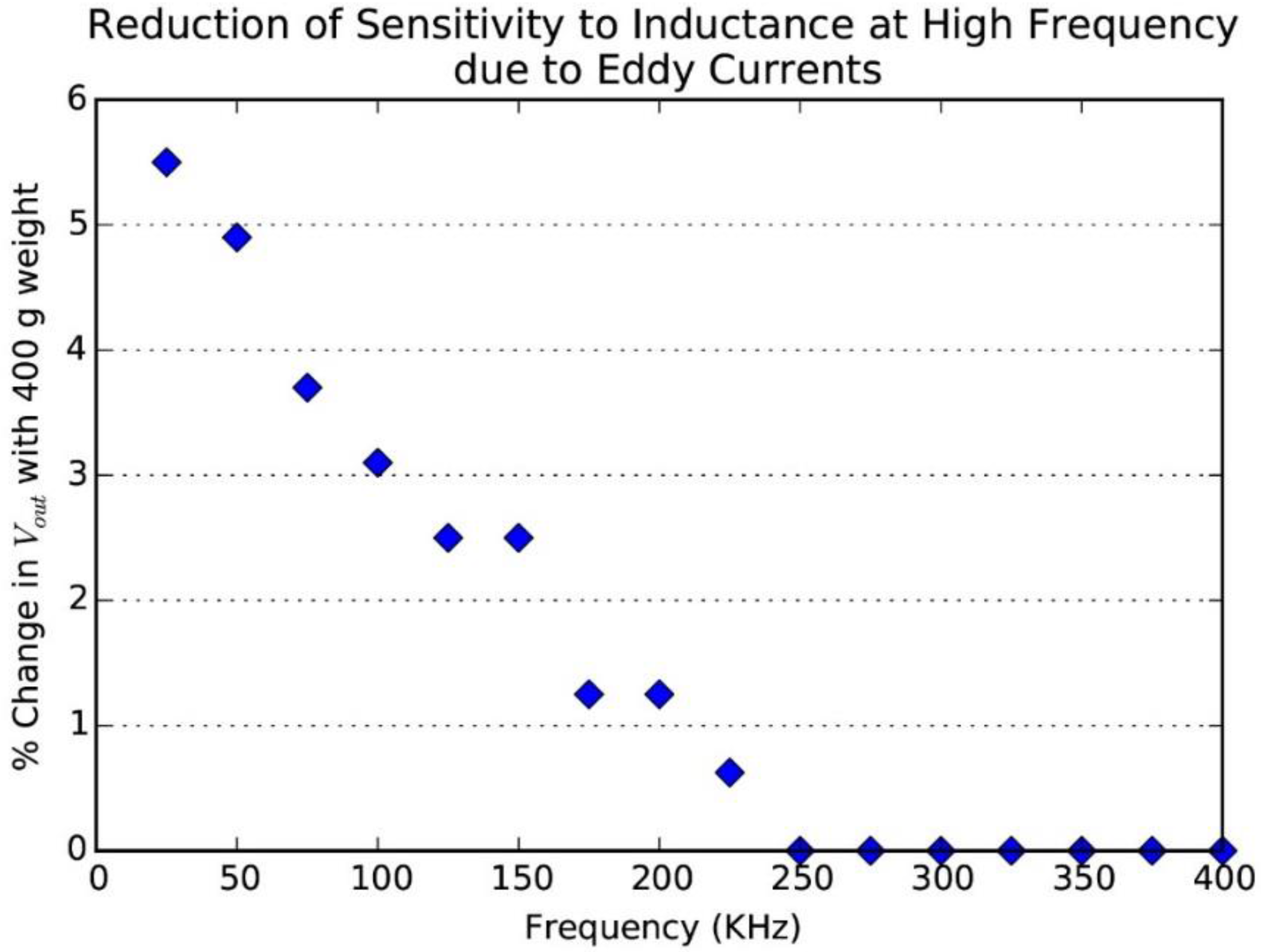

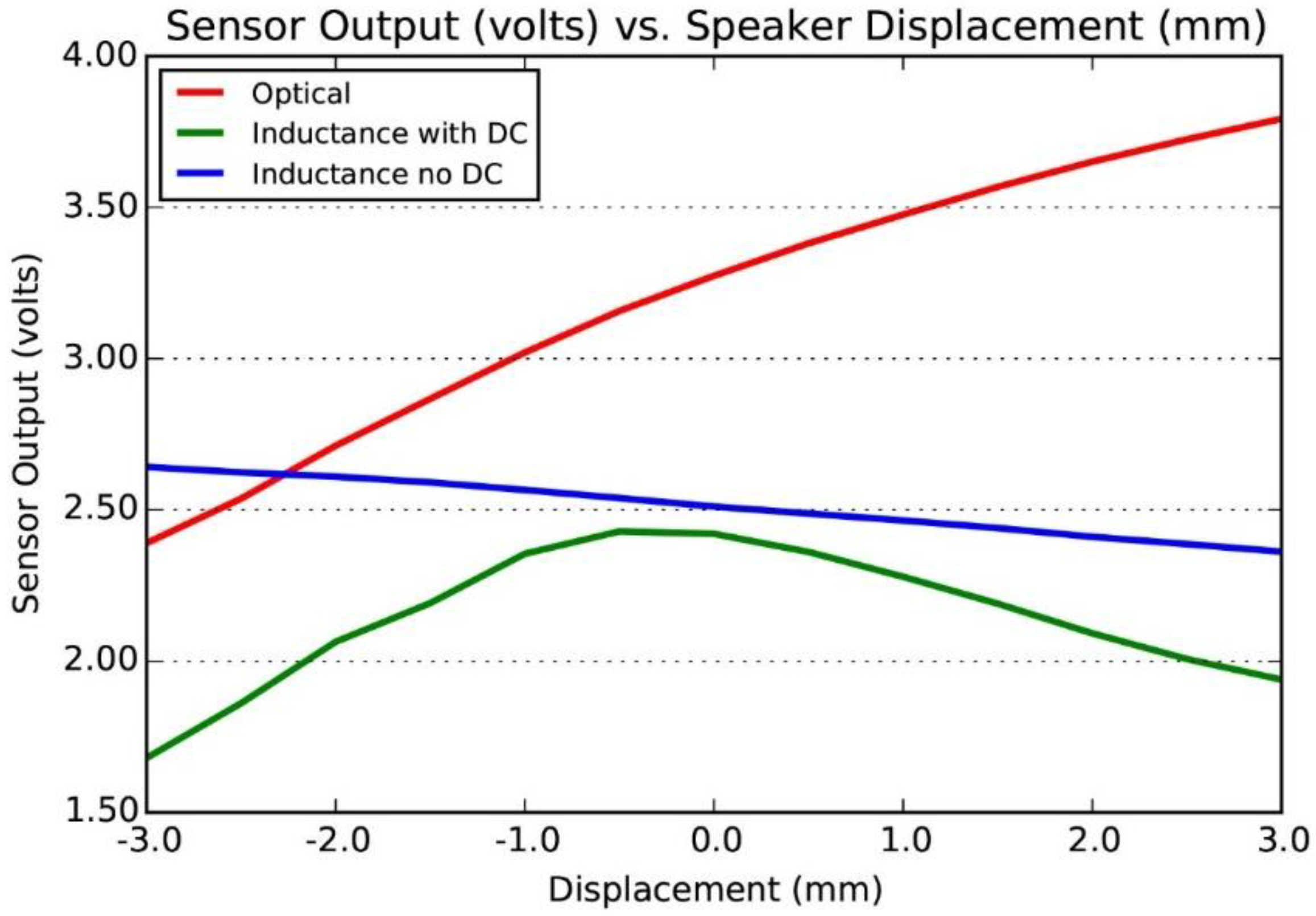

We explored the effect of

Reddy by recording

Vout before and after placing a 400 g weight on the scaffold to cause a consistent displacement. This displacement changed

Vout by a percentage that depended on the frequency of the sinusoidal voltage.

Figure 5 shows the resulting data. Above the upper limit of the audio frequencies (20 KHz), the percentage decreases monotonically to zero because of increasing

Reddy.

These results led us to choose a frequency just above the audio range at 30 KHz to measure the coil inductance.