A Multi-Layer Triboelectric Material Deep Groove Ball Bearing Triboelectric Nanogenerator: Speed and Skidding Monitoring

Abstract

1. Introduction

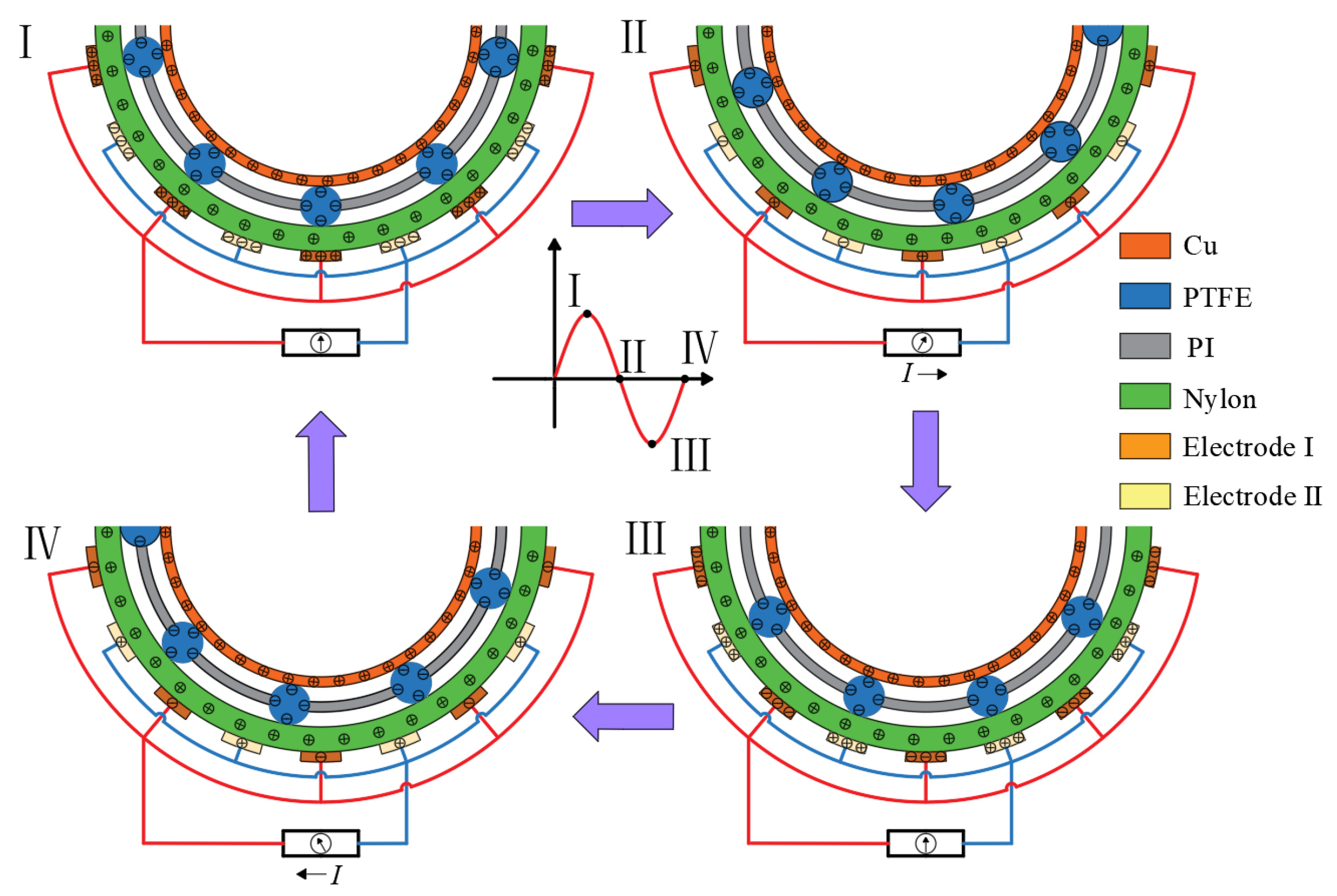

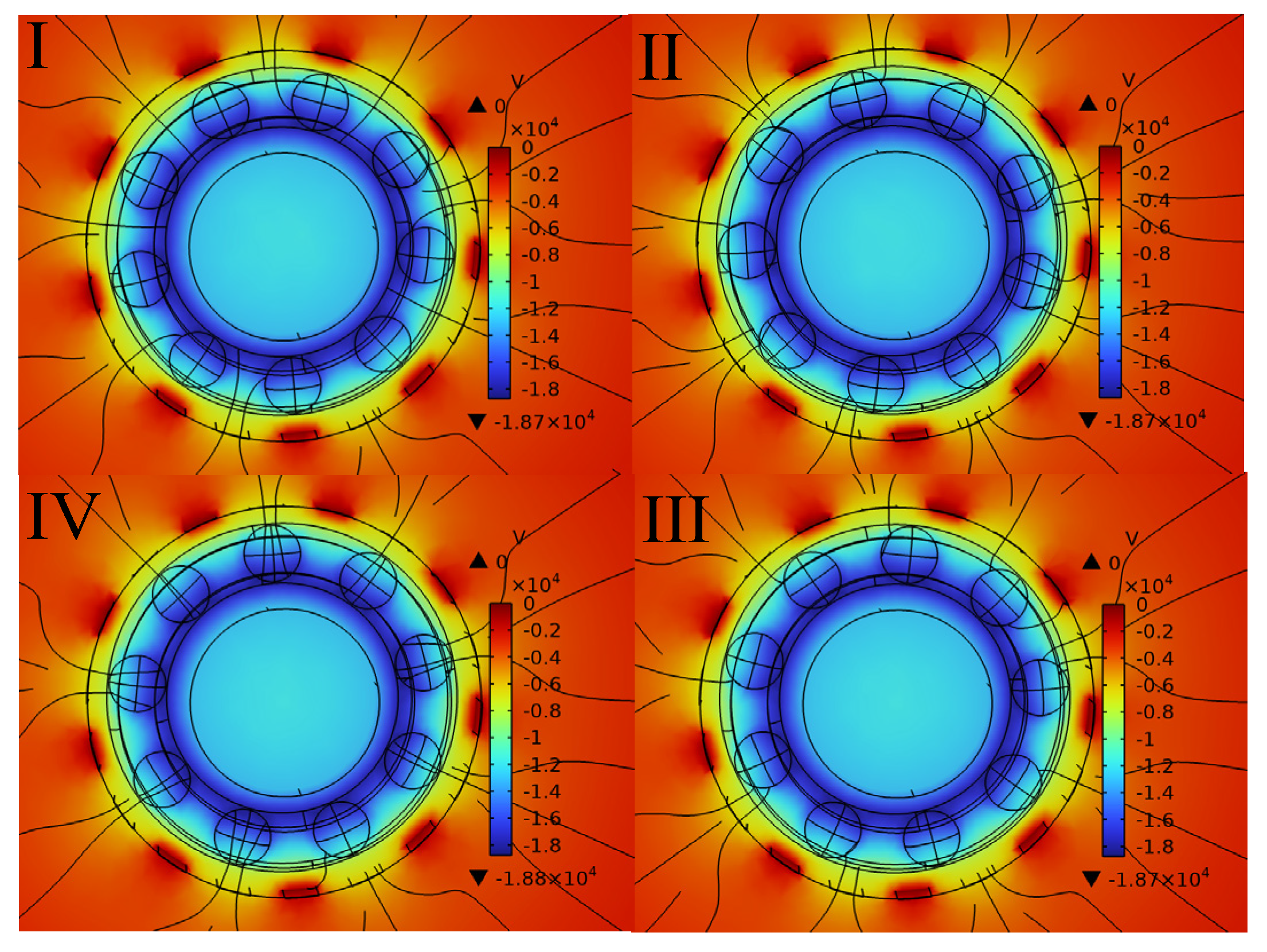

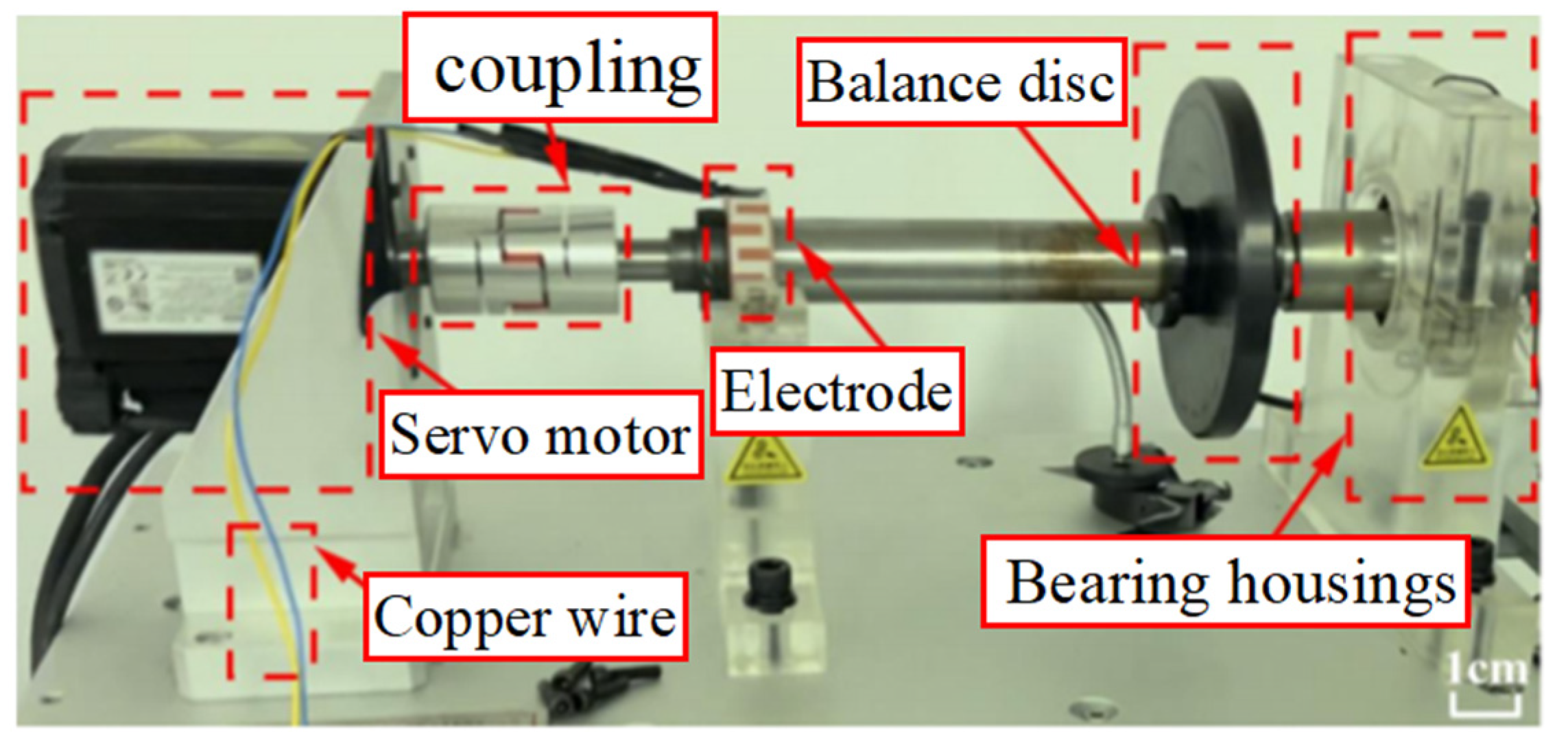

2. Structure and Operating Mechanism of DGTG

3. Results and Discussion

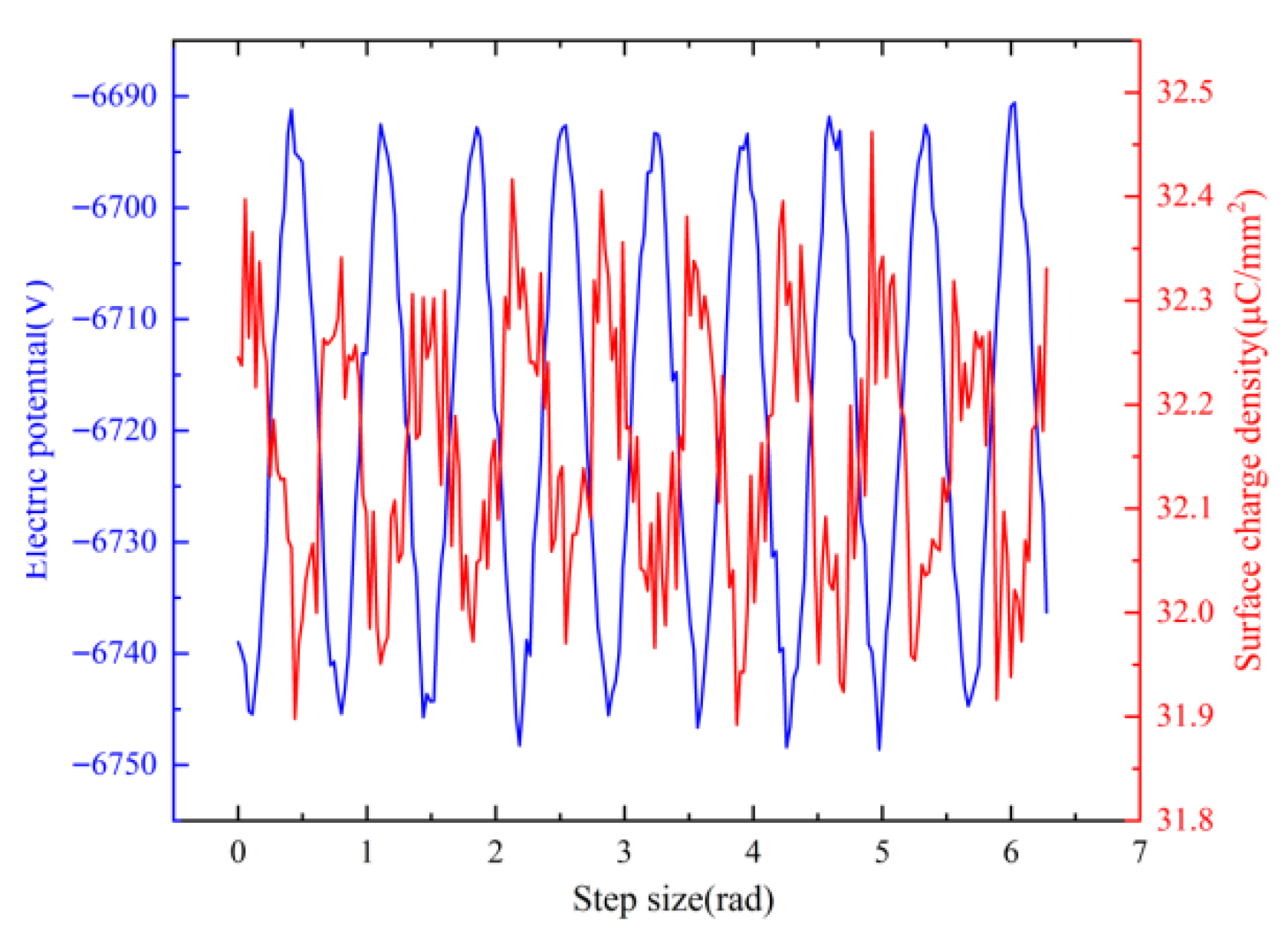

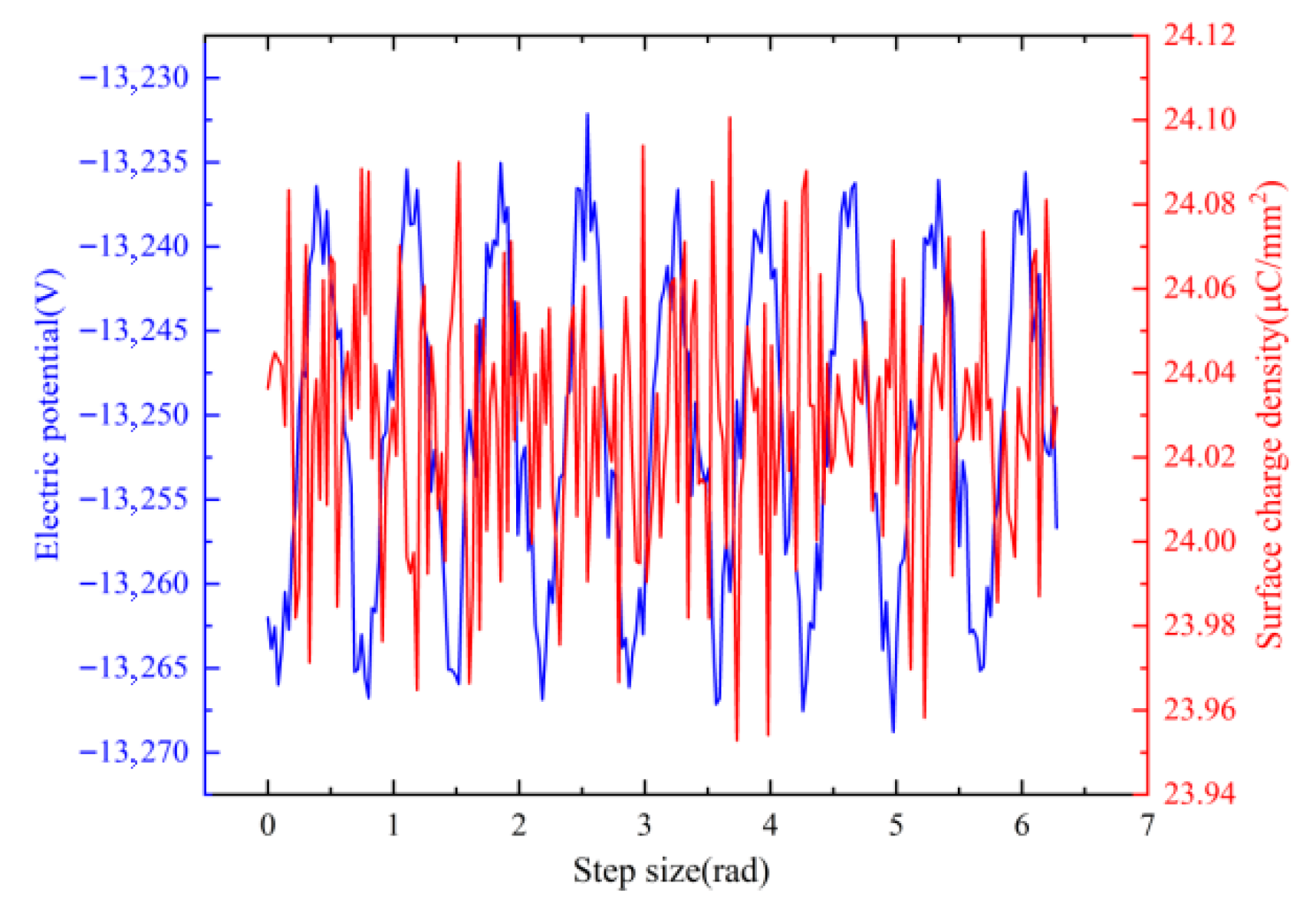

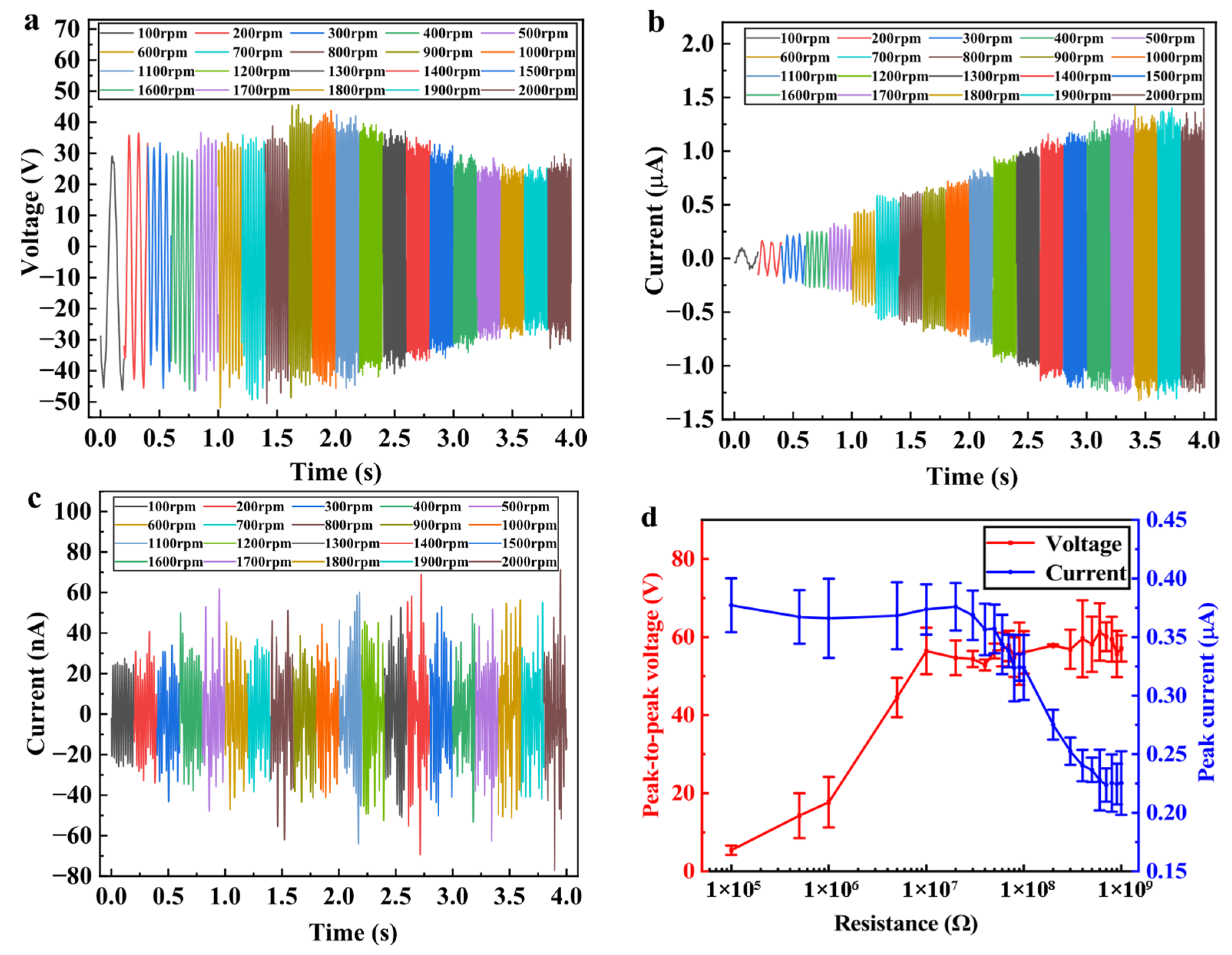

3.1. Output Performance of the DGTG

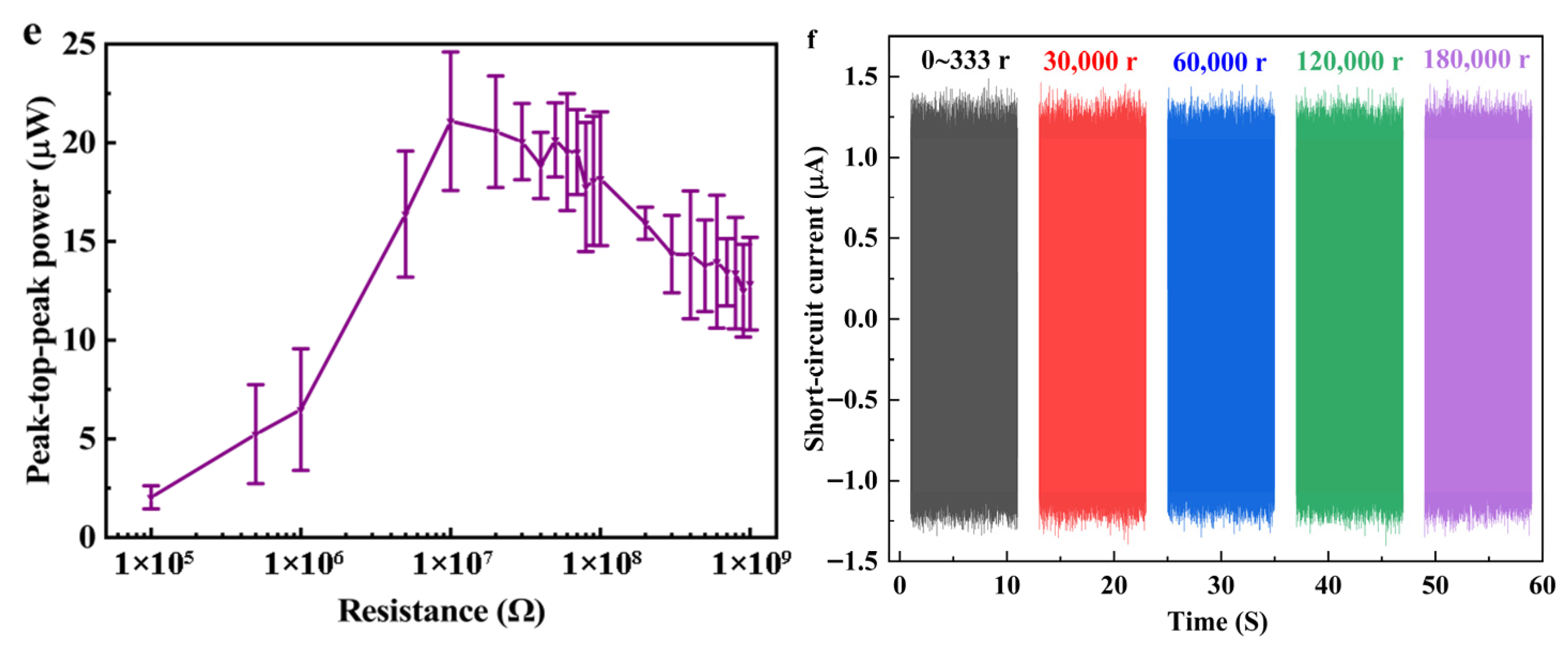

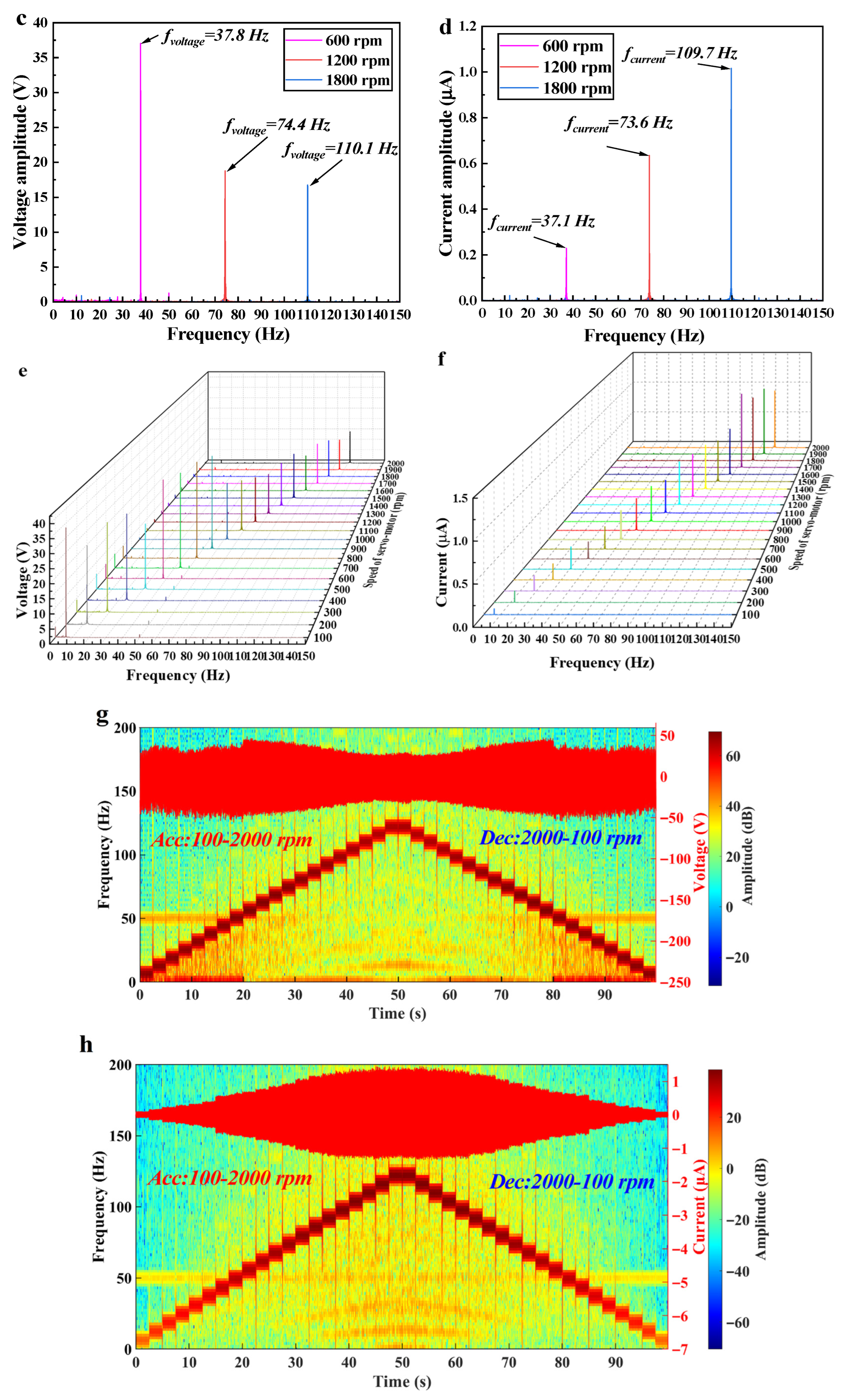

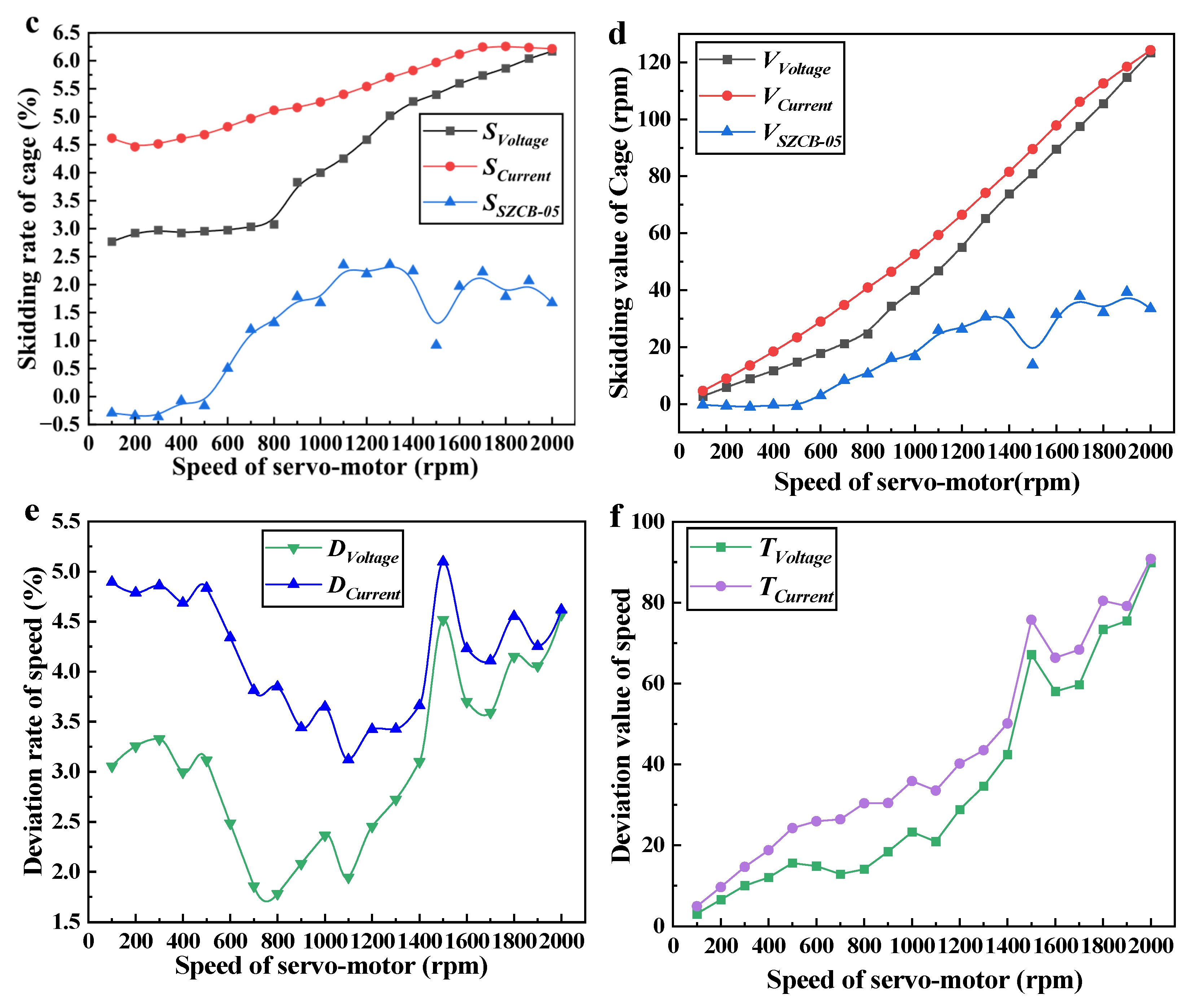

3.2. Analysis of Time–Frequency Characteristics

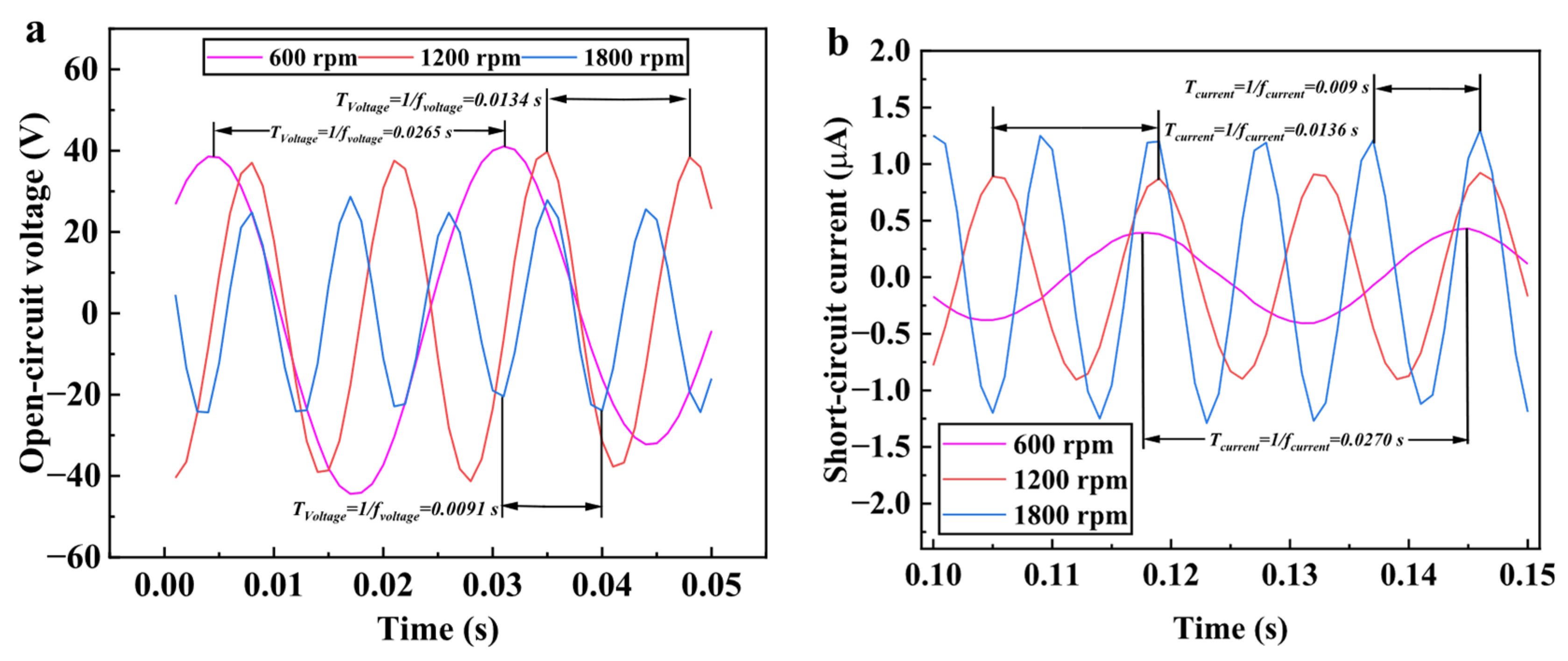

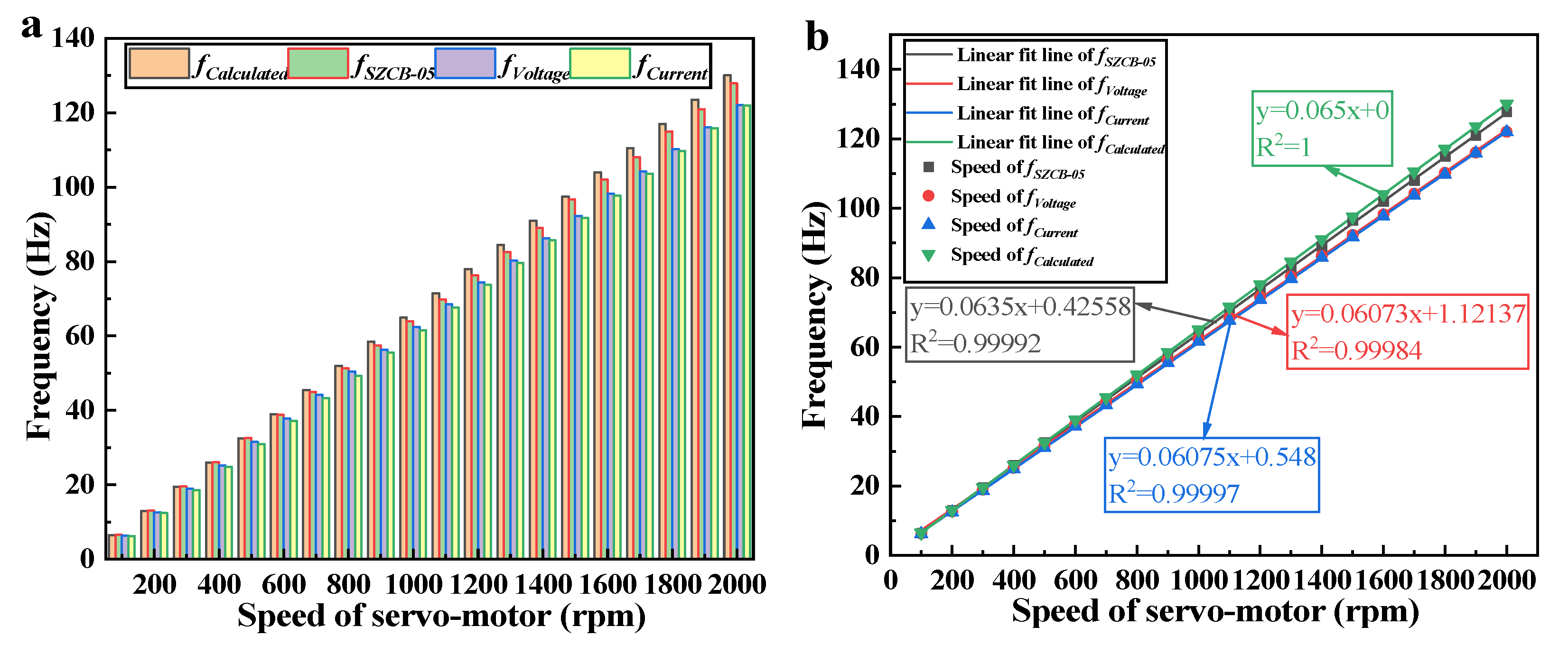

3.3. Analysis of Skidding Monitoring Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TENG | Triboelectric nanogenerator |

| DGTG | Deep groove ball triboelectric nanogenerator |

| PTFE | Polytetrafluoroethylene |

| RMS | Root mean square |

References

- Wang, K.; Huang, Y.; Luo, H. TFASOT for bearing damage feature extraction and enhancement under complex working conditions. Meas. Sci. Technol. 2024, 35, 096121. [Google Scholar] [CrossRef]

- Marsick, A.; André, H.; Khelf, I.; Leclère, Q.; Antoni, J. Restoring cyclostationarity of rolling element bearing signals from the instantaneous phase of their envelope. Mech. Syst. Signal Process. 2023, 193, 110264. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Liang, H.; Zhang, H.; Wang, W. The cage instability of angular contact ball bearing under high speed conditions. Mech. Mach. Theory 2024, 197, 105646. [Google Scholar] [CrossRef]

- Liu, K.; Wang, D.; Chen, B.; Shi, X.; Feng, Y.; Li, W. Vibration characteristics investigation of a single/dual rotor-bearing-casing system with local bearing defects. Mech. Syst. Signal Process. 2024, 225, 112227. [Google Scholar] [CrossRef]

- Xu, M.; Wang, M.; He, D.; Ding, X.; Shao, Y.; Gu, F. Skidding behavior of lubricated rolling element bearings under the influence of oil film and radial clearances. Tribol. Int. 2024, 194, 109500. [Google Scholar] [CrossRef]

- Gao, S.; Chatterton, S.; Pennacchi, P.; Han, Q.; Chu, F. Skidding and cage whirling of angular contact ball bearings: Kinematic-hertzian contact-thermal-elasto-hydrodynamic model with thermal expansion and experimental validation. Mech. Syst. Signal Process. 2022, 166, 108427. [Google Scholar] [CrossRef]

- Shi, J.; Yu, Y.; Jiang, X.; Li, C.; Shen, C.; Huang, W.; Zhu, Z. Dynamic modeling considering time-varying contact pairs and parameterized defects of deep groove ball bearings for its vibration characteristic analysis. Nonlinear Dyn. 2024, 112, 17781–17809. [Google Scholar] [CrossRef]

- Xu, M.; Han, Y.; Sun, X.; Shao, Y.; Gu, F.; Ball, A.D. Vibration characteristics and condition monitoring of internal radial clearance within a ball bearing in a gear-shaft-bearing system. Mech. Syst. Signal Process. 2022, 165, 108280. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Qing, T.; Zhang, Y.; Liang, H.; Zhang, S. The effect of lubricant temperature on dynamic behavior in angular contact ball bearings. Mech. Mach. Theory 2019, 149, 103832. [Google Scholar] [CrossRef]

- Aretusini, S.; Cascajero, A.; Cornelio, C.; Echevarria, X.; Spagnuolo, E.; Tapetado, A.; Vazquez, C.; Di Toro, G.; Cocco, M. Mechanical Energy Dissipation During Seismic Dynamic Weakening in Calcite-Bearing Faults. J. Geophys. Res. Solid Earth 2024, 129, e2024JB028927. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, W.; Yin, H.; Shang, Y. Progressive damage analysis of three-dimensional braided composites under flexural load by micro-CT and acoustic emission. Compos. Struct. 2019, 226, 111196. [Google Scholar] [CrossRef]

- Dai, P.; Liang, X.; Wang, J.; Wang, F.; Niu, L. The acoustic-vibration characteristics of cylindrical roller bearings with raceway failures: Simulation and experiment. Measurement 2024, 234, 114918. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Q.; Wang, S.; Ma, T.; Gao, S.; Kong, Y.; Han, Q.; Chu, F. Hybrid triboelectric-variable reluctance generator assisted wireless intelligent condition monitoring of aero-engine main bearings. Nano Energy 2025, 136, 110721. [Google Scholar] [CrossRef]

- Gao, S.; Han, Q.; Jiang, Z.; Zhang, X.; Pennacchi, P.; Chu, F. Triboelectric based high-precision self-powering cage skidding sensor and application on main bearing of jet engine. Nano Energy 2022, 99, 107387. [Google Scholar] [CrossRef]

- Gao, S.; Ma, T.; Zhou, N.; Feng, J.; Pu, H.; Luo, J.; Pennacchi, P.; Chu, F.; Han, Q. Extremely compact and lightweight triboelectric nanogenerator for spacecraft flywheel system health monitoring. Nano Energy 2024, 122, 109330. [Google Scholar] [CrossRef]

- Fan, F.; Tian, Z.; Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Song, M.; Chung, J.; Chung, S.; Cha, K.; Heo, D.; Kim, S.; Hwang, P.; Kim, D.; Koo, B.; Hong, K.; et al. Semisolid-lubricant-based ball-bearing triboelectric nanogenerator for current amplification, enhanced mechanical lifespan, and thermal stabilization. Nano Energy 2021, 93, 106816. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, Y.; Yu, M.; Yu, D.; Lv, J.; Yin, J.; Liu, J.; Wu, R. Triboelectric sensor for planetary gear fault diagnosis using data enhancement and CNN. Nano Energy 2022, 103, 107804. [Google Scholar] [CrossRef]

- Ruan, S.; Gao, S.; Feng, J.; Kong, Y.; Han, Q.; Chu, F. Intelligent triboelectric V-belts with condition monitoring capability. Mech. Syst. Signal Process. 2024, 209, 111132. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, R.; Wu, F.; Luo, J.; Pu, H.; Chu, F.; Han, Q. Rotating single-electrode triboelectric V-belts with skidding and wear monitoring capabilities. Tribol. Int. 2024, 193, 109404. [Google Scholar] [CrossRef]

- Jin, T.; Sun, Z.; Li, L.; Zhang, Q.; Zhu, M.; Zhang, Z.; Yuan, G.; Chen, T.; Tian, Y.; Hou, X.; et al. Triboelectric nanogenerator sensors for soft robotics aiming at digital twin applications. Nat. Commun. 2020, 11, 5381. [Google Scholar] [CrossRef]

- Xie, M.; Zhu, M.; Yang, Z.; Okada, S.; Kawamura, S. Flexible self-powered multifunctional sensor for stiffness-tunable soft robotic gripper by multimaterial 3D printing. Nano Energy 2021, 79, 105438. [Google Scholar] [CrossRef]

- Liu, D.; Gao, Y.; Zhou, L.; Wang, J.; Wang, Z. Recent advances in high-performance triboelectric nanogenerators. Nano Res. 2023, 16, 11698–11717. [Google Scholar] [CrossRef]

- Li, Z.; Yu, A.; Zhang, Q.; Zhai, J. Recent advances in fabricating high-performance triboelectric nanogenerators via modulating surface charge density. Int. J. Extrem. Manuf. 2024, 6, 052003. [Google Scholar] [CrossRef]

- Cao, X.; Xiong, Y.; Sun, J.; Xie, X.; Sun, Q.; Wang, Z. Multidiscipline Applications of Triboelectric Nanogenerators for the Intelligent Era of Internet of Things. Nano-Micro Lett. 2022, 15, 14. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Deng, H.; Shi, S.; Tian, S.; Wu, H.; Tang, J.; Zhang, C.; Zhang, X.; Zha, J.; et al. Advanced Dielectric Materials for Triboelectric Nanogenerators: Principles, Methods and Applications. Adv. Mater. 2024, 36, e2314380. [Google Scholar] [CrossRef]

- Fang, L.; Zheng, Q.; Hou, W.; Zheng, L.; Li, H. A self-powered vibration sensor based on the coupling of triboelectric nanogenerator and electromagnetic generator. Nano Energy 2022, 97, 107164. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Gao, Q.; Yuan, Z.; He, S.; Yu, X.; Wang, L.; Cheng, T. Self-powered triboelectric mechanical motion sensor for simultaneous monitoring of linear-rotary multi-motion. Nano Energy 2023, 108, 108239. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhu, L.; Wang, Z.; Zhang, X.; Li, Q.; Han, Q.; Yang, Z.; Qin, Z. Hybrid triboelectric-piezoelectric nanogenerator assisted intelligent condition monitoring for aero-engine pipeline system. Chem. Eng. J. 2025, 519, 165121. [Google Scholar] [CrossRef]

- Jung, H.; Friedman, B.; Hwang, W.; Copping, A.; Branch, R.; Deng, D. Self-powered arctic satellite communication system by harvesting wave energy using a triboelectric nanogenerator. Nano Energy 2023, 114, 108633. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, D.; Ji, X.; Xu, Z.; Zhang, H.; Mao, R.; Liu, W.; Wang, J.; Sun, Y. Rotational contact triboelectric nanogenerator driven by water flows inspired by waterwheels and their applications for lead ion removal. Nano Energy 2024, 128, 109800. [Google Scholar] [CrossRef]

- Yin, M.; Yu, Y.; Wang, Y.; Wang, Z.; Lu, X.; Cheng, T.; Wang, Z. Multi-plate structured triboelectric nanogenerator based on cycloidal displacement for harvesting hydroenergy. Extrem. Mech. Lett. 2019, 33, 100576. [Google Scholar] [CrossRef]

- Zhao, D.; Li, H.; Yu, Y.; Wang, Y.; Wang, J.; Gao, Q.; Wang, Z.; Wen, J.; Cheng, T. A current-enhanced triboelectric nanogenerator with crossed rollers for harvesting wave energy. Nano Energy 2023, 117, 108885. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, J.; Wang, Z.; Yu, X.; Zhang, Y.; Zhu, J.; Wang, Z.; Cheng, T. Double-blade structured triboelectric–electromagnetic hybrid generator with aerodynamic enhancement for breeze energy harvesting. Appl. Energy 2022, 326, 119970. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, S.; Wang, Y.; Wu, D.; Xiang, G.; Yang, S.; Zhang, J.; Dai, S.; Xu, M.; Xiang, X. Study on dynamics and power generation performance coupling of galloping-based triboelectric nanogenerator for harvesting broadband wind energy. Nano Energy 2024, 130, 110126. [Google Scholar] [CrossRef]

- Mu, S.; Li, S.; Zhao, H.; Wang, Z.; Xiao, X.; Xiao, X.; Lin, Z.; Song, Z.; Tang, H.; Xu, Q.; et al. A platypus-inspired electro-mechanosensory finger for remote control and tactile sensing. Nano Energy 2023, 116, 108790. [Google Scholar] [CrossRef]

- Liu, J.; Xu, P.; Zheng, J.; Liu, X.; Wang, X.; Wang, S.; Guan, T.; Xie, G.; Xu, M. Whisker-inspired and self-powered triboelectric sensor for underwater obstacle detection and collision avoidance. Nano Energy 2022, 101, 107633. [Google Scholar] [CrossRef]

- Wang, S.; Xu, P.; Wang, X.; Zheng, J.; Liu, X.; Liu, J.; Chen, T.; Wang, H.; Xie, G.; Tao, J.; et al. Underwater bionic whisker sensor based on triboelectric nanogenerator for passive vortex perception. Nano Energy 2022, 97, 107210. [Google Scholar] [CrossRef]

- Choi, D.; Sung, T.; Kwon, J. A self-powered smart roller-bearing based on a triboelectric nanogenerator for measurement of rotation movement. Adv. Mater. Technol. 2018, 3, 1800219. [Google Scholar] [CrossRef]

- Xin, Y.; Du, T.; Liu, T.; Sun, P.; Zhu, M.; Zheng, L.; Du, H.; Zou, Y.; Xu, M. Triboelectric nanogenerator embedded cylindrical roller bearing for rotational energy harvesting and self-powered fault diagnosis. Sens. Actuators A Phys. 2023, 362, 114664. [Google Scholar] [CrossRef]

- Yan, J.; Tang, Z.; Zhang, C.; Long, Y.; Li, J.; Sheng, Y. Study of wind energy harvesting based on rolling bearing type triboelectric nanogenerator. Energy Rep. 2024, 12, 3690–3699. [Google Scholar] [CrossRef]

- Han, Q.; Ding, Z.; Qin, Z.; Wang, T.; Xu, X.; Chu, F. A triboelectric rolling ball bearing with self-powering and self-sensing capabilities. Nano Energy 2020, 67, 104277. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, Y.; Wu, R.; Yin, J.; Yu, D.; Liu, J.; Cheng, T. A high-speed and long-life triboelectric sensor with charge supplement for monitoring the speed and skidding of rolling bearing. Nano Energy 2022, 92, 106747. [Google Scholar] [CrossRef]

- Jiang, Z.; Gao, S.; Kong, Y.; Pennacchi, P.; Chu, F.; Han, Q. Ultra-compact triboelectric bearing based on a ribbon cage with applications for fault diagnosis of rotating machinery. Nano Energy 2022, 99, 107263. [Google Scholar] [CrossRef]

- Gao, S.; Han, Q.; Zhang, X.; Pennacchi, P.; Chu, F. Ultra-high-speed hybrid ceramic triboelectric bearing with real-time dynamic instability monitoring. Nano Energy 2022, 103, 107759. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, L.; Li, S.; Liu, D.; Li, Y.; Gao, Y.; Liu, Y.; Dai, Y.; Wang, J.; Wang, Z. Selection rules of triboelectric materials for direct-current triboelectric nanogenerator. Nat. Commun. 2021, 12, 4686. [Google Scholar] [CrossRef]

- He, W.; Liu, W.; Chen, J.; Wang, Z.; Liu, Y.; Pu, X.; Yang, H.; Tang, Q.; Yang, H.; Guo, H.; et al. Boosting output performance of sliding mode triboelectric nanogenerator by charge space-accumulation effect. Nat. Commun. 2020, 11, 4277. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Wang, L.; Wang, Z.; Wang, F. A Multi-Layer Triboelectric Material Deep Groove Ball Bearing Triboelectric Nanogenerator: Speed and Skidding Monitoring. Machines 2025, 13, 875. https://doi.org/10.3390/machines13090875

Zhou Z, Wang L, Wang Z, Wang F. A Multi-Layer Triboelectric Material Deep Groove Ball Bearing Triboelectric Nanogenerator: Speed and Skidding Monitoring. Machines. 2025; 13(9):875. https://doi.org/10.3390/machines13090875

Chicago/Turabian StyleZhou, Zibao, Long Wang, Zihao Wang, and Fengtao Wang. 2025. "A Multi-Layer Triboelectric Material Deep Groove Ball Bearing Triboelectric Nanogenerator: Speed and Skidding Monitoring" Machines 13, no. 9: 875. https://doi.org/10.3390/machines13090875

APA StyleZhou, Z., Wang, L., Wang, Z., & Wang, F. (2025). A Multi-Layer Triboelectric Material Deep Groove Ball Bearing Triboelectric Nanogenerator: Speed and Skidding Monitoring. Machines, 13(9), 875. https://doi.org/10.3390/machines13090875