Study on the Influence of Different Dropper Models in Pantograph–Catenary System on Dropper Load Simulation

Abstract

1. Introduction

2. FEM-Based Pantograph–Catenary Interaction Model with Different Dropper Models

2.1. Modeling of the FEM-Based Catenary Model

2.1.1. Modeling of the Contact and Messenger Wire, Catenary Suspension, and Registration Arm

2.1.2. Modeling of the Dropper

2.2. Modeling of the Pantograph and Pantograph–Catenary Interaction

2.3. The FEM-Based Pantograph–Catenary Interaction Model

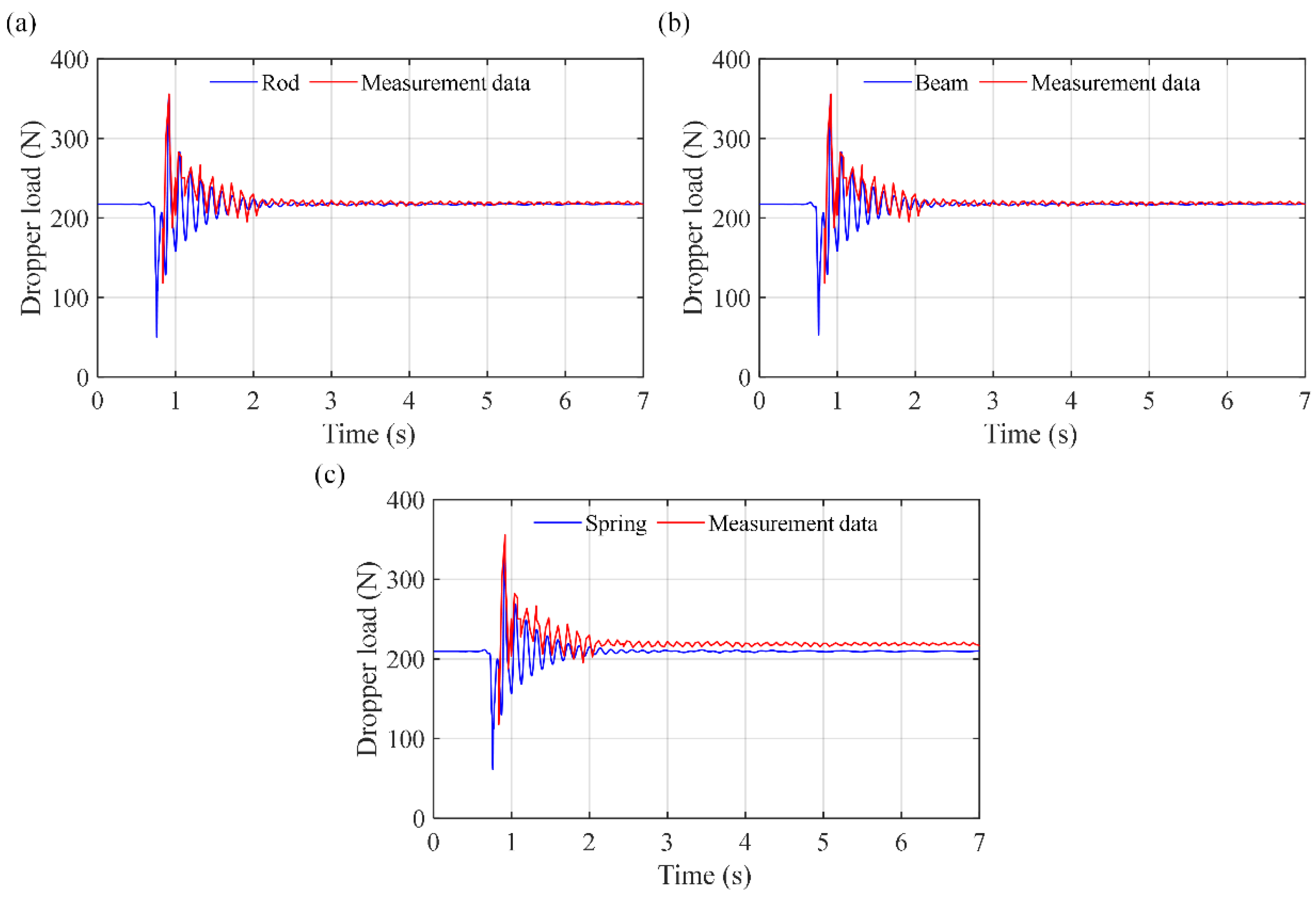

3. Validation

4. Study on the Influence of Different Dropper Models on Dropper Dynamic Loads

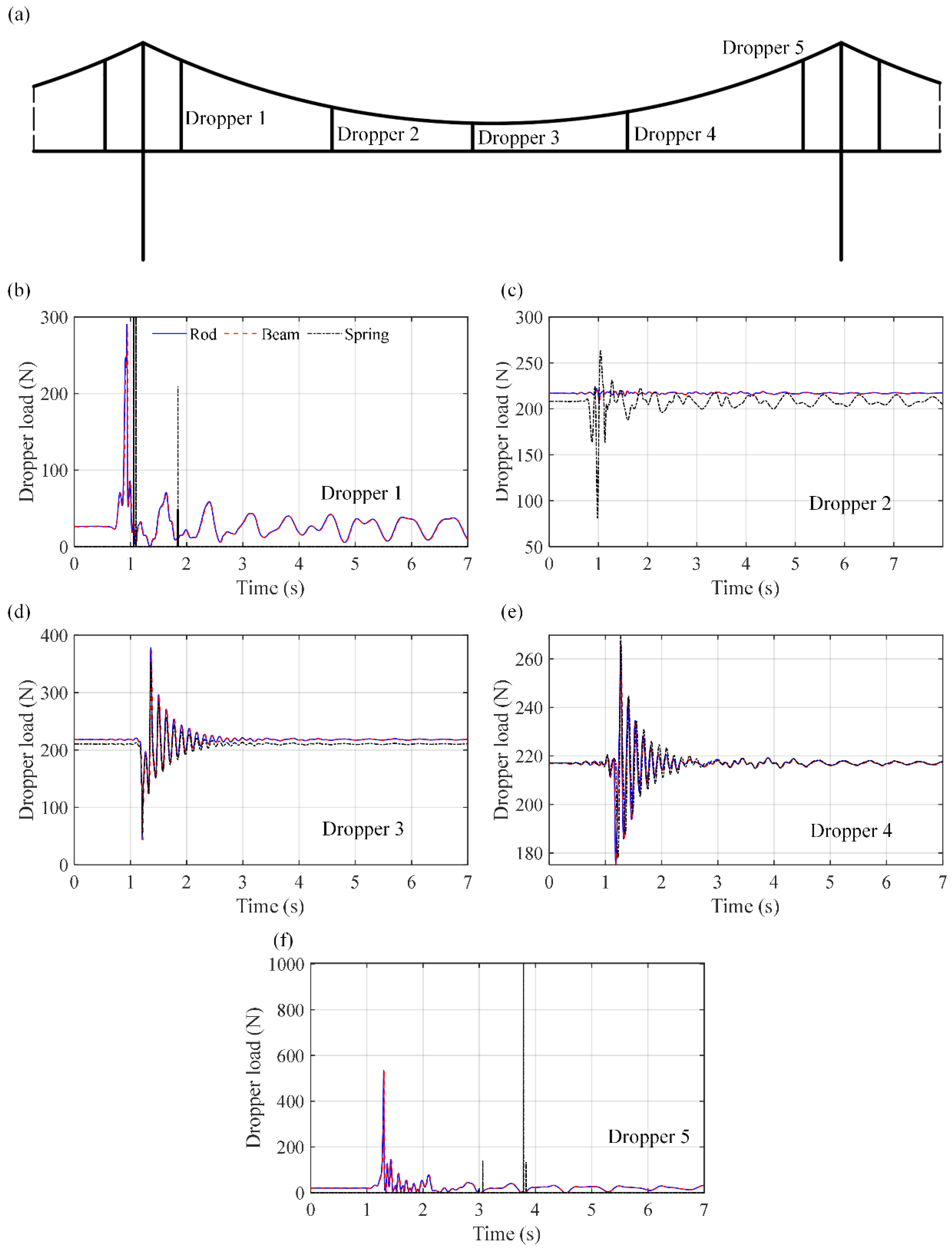

4.1. Influence of Different Dropper Models on Dropper Dynamic Loads at Different Droppers

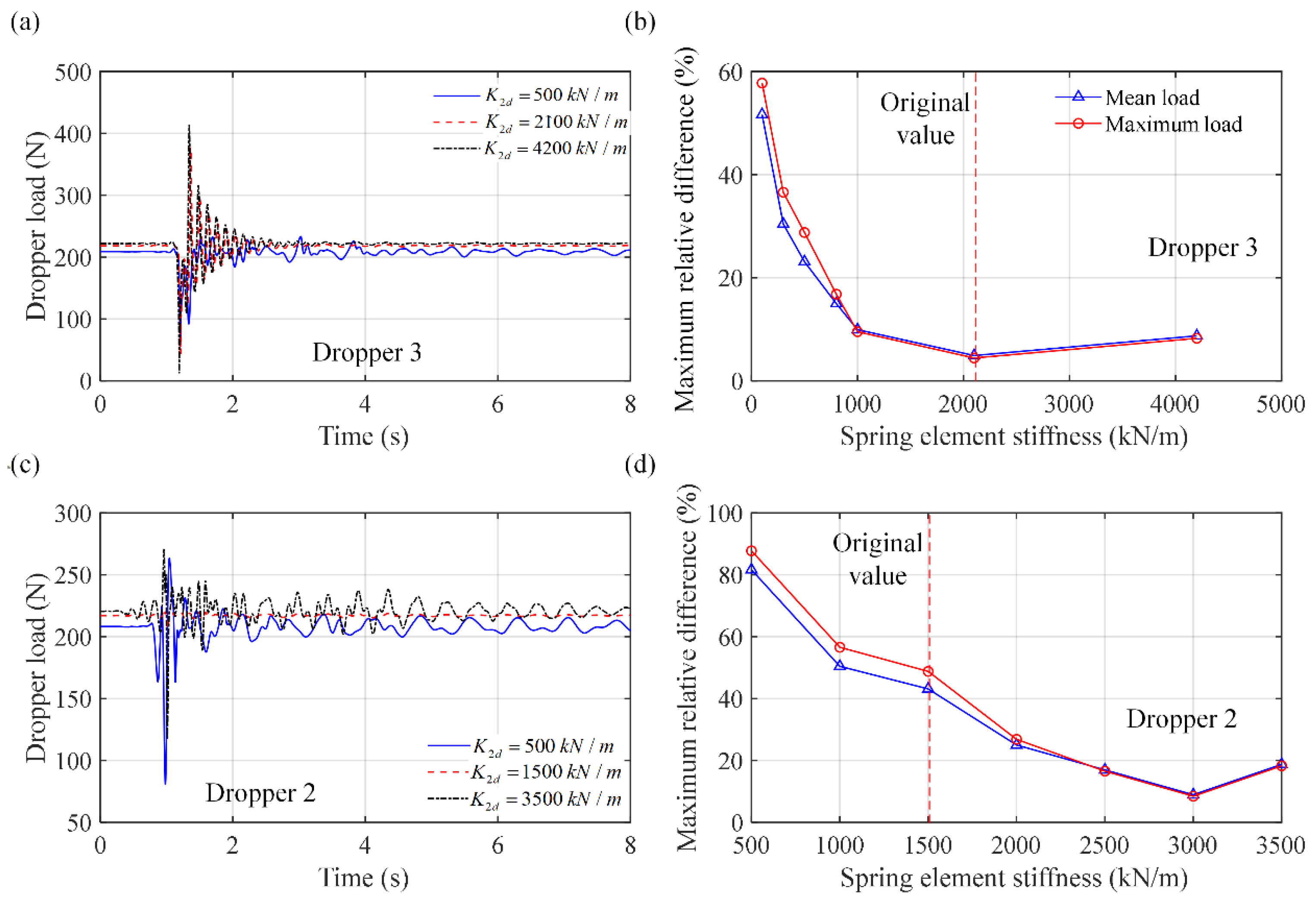

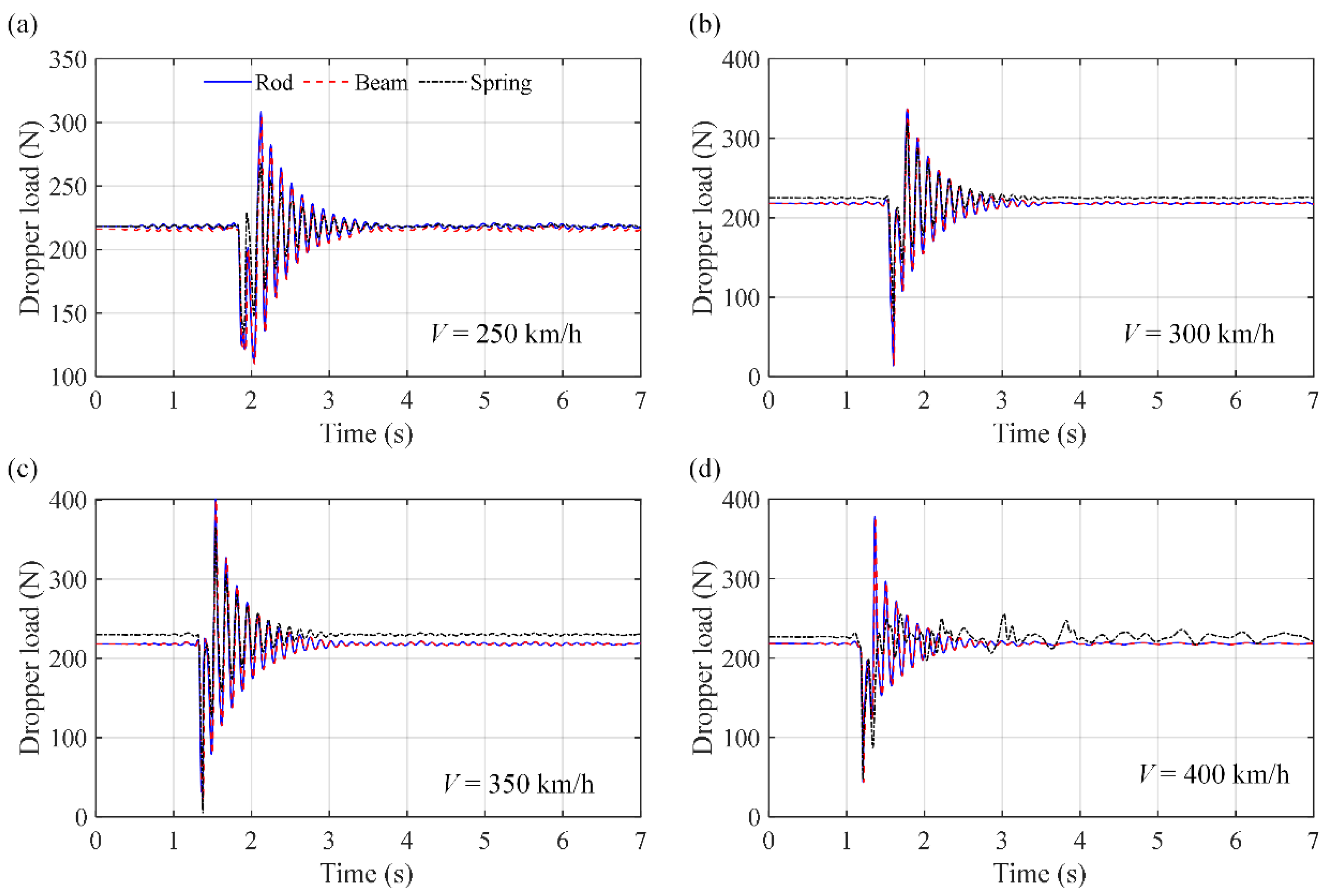

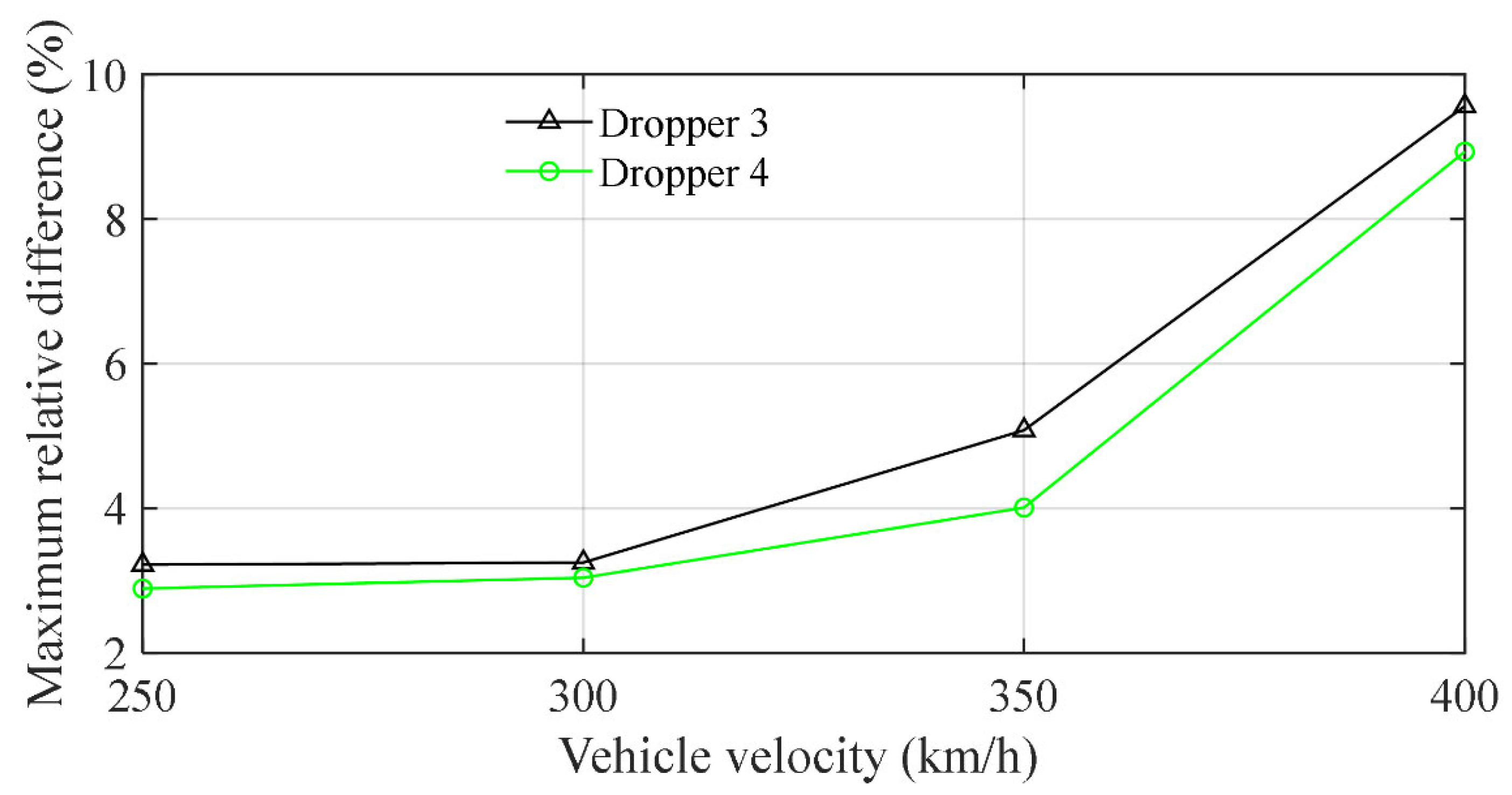

4.2. Influence of the Stiffness and Operation Speed on the Dropper Models’ Accuracy

4.3. Influence of Dropper Models on Calculation Efficiency

5. Conclusions

- The bilinear spring model can only be used for generalized pantograph–catenary interaction dynamic analysis. While the pantograph–catenary interaction model with the bilinear spring dropper model can obtain accurate pantograph–catenary contact force results, the dropper dynamic loads from the bilinear spring model are different from those from the measurement data, and their maximum relative difference can reach 8.7%. When considering different droppers in one span, this maximum relative difference can even reach 45% compared to the rod element model. In addition, the original stiffness of the bilinear spring model can also result in inaccurate results. Therefore, the bilinear spring model can not be used for dropper dynamic analysis.

- Both the beam and rod dropper models can accurately simulate the dropper loads in the present FEM-based pantograph–catenary system for different droppers, and their maximum relative difference compared to the measurement data is no more than 3.6% in different models. But the calculation efficiency of the pantograph–catenary system with the rod element model is higher than that of the beam element model, where its CPU time is only half that of the beam element model. Therefore, to accurately and efficiently present the dropper dynamic loads of the catenary system under pantograph–catenary interactions, it is suggested to use the rod model in the pantograph–catenary system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, Y.; Xiao, S.; Lu, L.; Yang, B.; Zhu, T.; Yang, G. Fatigue failure of integral droppers of high-speed railway catenary under impact load. Eng. Fail. Anal. 2022, 134, 106086. [Google Scholar] [CrossRef]

- Liu, G.; Ding, N.; Zhou, J.; Xu, N.; Guo, W. Fracture failure of dropper wires in the Power Supply System of a subway line. J. Fail. Anal. Prev. 2021, 21, 370–375. [Google Scholar] [CrossRef]

- Liu, L.; Ding, N.; Xu, N.; Guo, W.; Shi, J.; Li, N.; Zhang, L.; Meng, B.; Zairi, F. Failure analysis and optimization of a suspended structure in the power supply system of the subway. Eng. Fail. Anal. 2020, 115, 104619. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Peng, J.-F.; Tan, D.-Q.; Xu, Z.-B.; Liu, J.-H.; Mo, J.-L.; Zhu, M.-H. Failure analysis and optimization of integral droppers used in high speed railway catenary system. Eng. Fail. Anal. 2018, 91, 496–506. [Google Scholar] [CrossRef]

- Lee, G.-c.; Lee, T.-h.; Lee, J.-w. Mechanical loads of dropper for high speed electric railway. J. Korean Soc. Railw. 2011, 14, 222–227. [Google Scholar] [CrossRef]

- Pan, L.; Chen, L.; Zhang, H.; Xing, T.; Yang, C.; Dong, G. Study on numerical simulation method and dynamic force of dropper of a catenary system. Adv. Mech. Eng. 2023, 15, 16878132221143027. [Google Scholar] [CrossRef]

- Cho, Y.H. Numerical simulation of the dynamic responses of railway overhead contact lines to a moving pantograph, considering a nonlinear dropper. J. Sound Vib. 2008, 315, 433–454. [Google Scholar] [CrossRef]

- Cho, Y.H.; Lee, K.; Park, Y.; Kang, B.; Kim, K.-n. Influence of contact wire pre-sag on the dynamics of pantograph–railway catenary. Int. J. Mech. Sci. 2010, 52, 1471–1490. [Google Scholar] [CrossRef]

- Song, Y.; Antunes, P.; Pombo, J.; Liu, Z. A methodology to study high-speed pantograph-catenary interaction with realistic contact wire irregularities. Mech. Mach. Theory 2020, 152, 103940. [Google Scholar] [CrossRef]

- Zhang, W.; Mei, G.; Zeng, J. A study of pantograph/catenary system dynamics with influence of presag and irregularity of contact wire. Veh. Syst. Dyn. 2002, 37, 593–604. [Google Scholar] [CrossRef]

- Pombo, J.; Ambrósio, J.; Pereira, M.; Rauter, F.; Collina, A.; Facchinetti, A. Influence of the aerodynamic forces on the pantograph–catenary system for high-speed trains. Veh. Syst. Dyn. 2009, 47, 1327–1347. [Google Scholar] [CrossRef]

- Bucca, G.; Collina, A. A procedure for the wear prediction of collector strip and contact wire in pantograph–catenary system. Wear 2009, 266, 46–59. [Google Scholar] [CrossRef]

- Liu, Z.; Jönsson, P.-A.; Stichel, S.; Rønnquist, A. Implications of the operation of multiple pantographs on the soft catenary systems in Sweden. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2016, 230, 971–983. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z.; Wang, R. A spatial coupling model to study dynamic performance of pantograph-catenary with vehicle-track excitation. Mech. Syst. Signal Process. 2021, 151, 107336. [Google Scholar] [CrossRef]

- Antunes, P.; Ambrósio, J.; Pombo, J.; Facchinetti, A. A new methodology to study the pantograph–catenary dynamics in curved railway tracks. Veh. Syst. Dyn. 2020, 58, 425–452. [Google Scholar] [CrossRef]

- Nåvik, P.; Rønnquist, A.; Stichel, S. Variation in predicting pantograph–catenary interaction contact forces, numerical simulations and field measurements. Veh. Syst. Dyn. 2017, 55, 1265–1282. [Google Scholar] [CrossRef]

- Song, Y.; Rønnquist, A.; Jiang, T.; Nåvik, P. Identification of short-wavelength contact wire irregularities in electrified railway pantograph–catenary system. Mech. Mach. Theory 2021, 162, 104338. [Google Scholar] [CrossRef]

- Song, Y.; Wang, H.; Frøseth, G.; Nåvik, P.; Liu, Z.; Rønnquist, A. Surrogate modelling of railway pantograph-catenary interaction using deep long-short-term-memory neural networks. Mech. Mach. Theory 2023, 187, 105386. [Google Scholar] [CrossRef]

- Chu, W.; Wang, H.; Song, Y.; Liu, Z. FENet: A Physics-Informed Dynamics Prediction Model of Pantograph-Catenary Systems in Electric Railway. IET Intell. Transp. Syst. 2025, 19, e70059. [Google Scholar] [CrossRef]

- Song, Y.; Ouyang, H.; Liu, Z.; Mei, G.; Wang, H.; Lu, X. Active control of contact force for high-speed railway pantograph-catenary based on multi-body pantograph model. Mech. Mach. Theory 2017, 115, 35–59. [Google Scholar] [CrossRef]

- Wang, X.; Song, Y.; Lu, B.; Wang, H.; Liu, Z. Assessment of current collection performance of rail pantograph-catenary considering long suspension bridges. IEEE Trans. Instrum. Meas. 2025, 74, 7500714. [Google Scholar] [CrossRef]

- Peng, C.; Yang, C.; Xue, J.; Gong, Y.; Zhang, W. An adaptive variable-length cable element method for form-finding analysis of railway catenaries in an absolute nodal coordinate formulation. Eur. J. Mech.-A/Solids 2022, 93, 104545. [Google Scholar] [CrossRef]

- Facchinetti, A.; Gasparetto, L.; Bruni, S. Real-time catenary models for the hardware-in-the-loop simulation of the pantograph–catenary interaction. Veh. Syst. Dyn. 2013, 51, 499–516. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Z.; Stichel, S.; Zhu, W.; Lei, J.; Yao, Y. A comparative study on the influence of typical track failures on high-speed pantograph-catenary interaction dynamics. Veh. Syst. Dyn. 2024, 62, 2883–2911. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, W.; Fan, W.; Yang, C.; Zhang, W. A new three-dimensional moving Timoshenko beam element for moving load problem analysis. J. Vib. Acoust. 2020, 142, 031001. [Google Scholar] [CrossRef]

- Larson, M.G.; Bengzon, F. The Finite Element Method: Theory, Implementation, and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 10. [Google Scholar]

- Yang, C.; Xu, Y.; Zhu, W.; Fan, W.; Zhang, W.; Mei, G. A three-dimensional modal theory-based Timoshenko finite length beam model for train-track dynamic analysis. J. Sound Vib. 2020, 479, 115363. [Google Scholar] [CrossRef]

- Tan, P.; Li, X.; Wu, Z.; Ding, J.; Ma, J.; Chen, Y.; Fang, Y.; Ning, Y. Multialgorithm fusion image processing for high speed railway dropper failure–defect detection. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 4466–4478. [Google Scholar] [CrossRef]

- Yao, Y.; Yang, Z.; Wang, J.; Zhang, W. Analysis of contact force and uplift of pantograph–catenary system in overlap section based on numerical simulations and experimental tests. Veh. Syst. Dyn. 2023, 61, 2492–2515. [Google Scholar] [CrossRef]

- Yao, Y.; Zou, D.; Zhou, N.; Mei, G.; Wang, J.; Zhang, W. A study on the mechanism of vehicle body vibration affecting the dynamic interaction in the pantograph–catenary system. Veh. Syst. Dyn. 2021, 59, 1335–1354. [Google Scholar] [CrossRef]

| Dropper Models | |||

|---|---|---|---|

| Rod | Beam | ||

| Model CPU time (s) | V = 250 km/h | 1434 | 2533 |

| V = 300 km/h | 1452 | 2538 | |

| V = 350 km/h | 1444 | 2545 | |

| V = 400 km/h | 1467 | 2724 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Chen, L.; Xu, Y.; Dong, B.; Guo, X.; Zhu, W. Study on the Influence of Different Dropper Models in Pantograph–Catenary System on Dropper Load Simulation. Machines 2025, 13, 874. https://doi.org/10.3390/machines13090874

Pan L, Chen L, Xu Y, Dong B, Guo X, Zhu W. Study on the Influence of Different Dropper Models in Pantograph–Catenary System on Dropper Load Simulation. Machines. 2025; 13(9):874. https://doi.org/10.3390/machines13090874

Chicago/Turabian StylePan, Like, Liming Chen, Yan Xu, Bo Dong, Xiaoli Guo, and Weidong Zhu. 2025. "Study on the Influence of Different Dropper Models in Pantograph–Catenary System on Dropper Load Simulation" Machines 13, no. 9: 874. https://doi.org/10.3390/machines13090874

APA StylePan, L., Chen, L., Xu, Y., Dong, B., Guo, X., & Zhu, W. (2025). Study on the Influence of Different Dropper Models in Pantograph–Catenary System on Dropper Load Simulation. Machines, 13(9), 874. https://doi.org/10.3390/machines13090874