Humidity Influence on Aero-Engine Control Plan Inflection Point and Performance

Abstract

1. Introduction

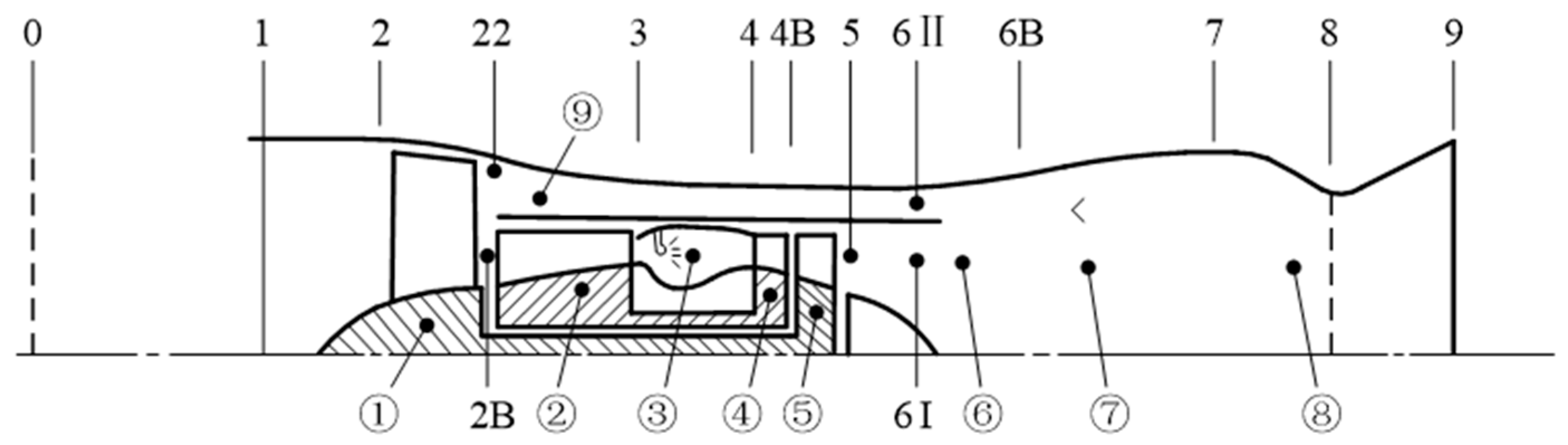

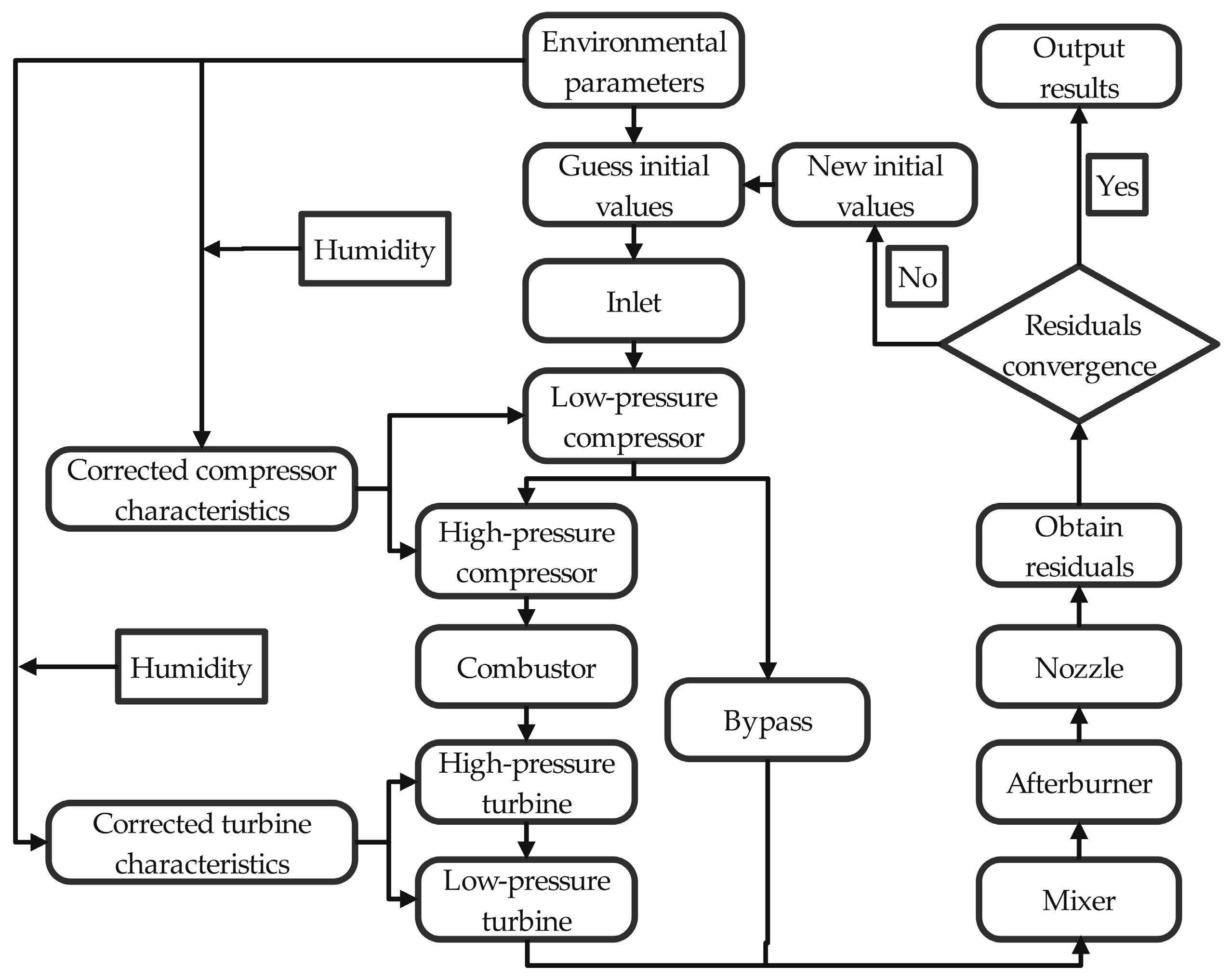

2. Numerical Model

2.1. Humidity

2.2. Component-Level Model

2.3. Model Validation

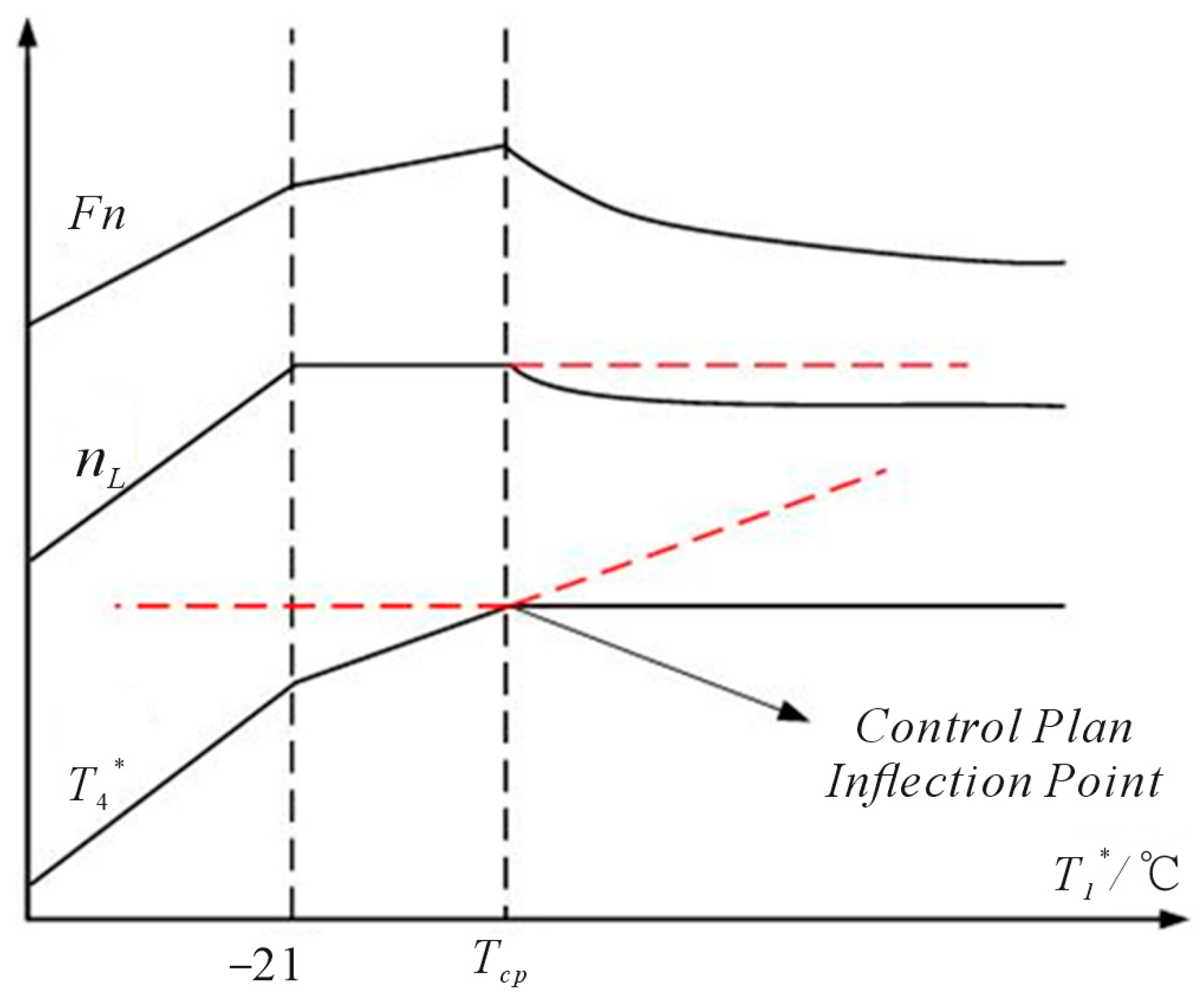

2.4. Control Plan Inflection Point Temperature

3. Ambient Humidity Correction Model

Numerical Model for Humidity Correction

4. Results of Analysis

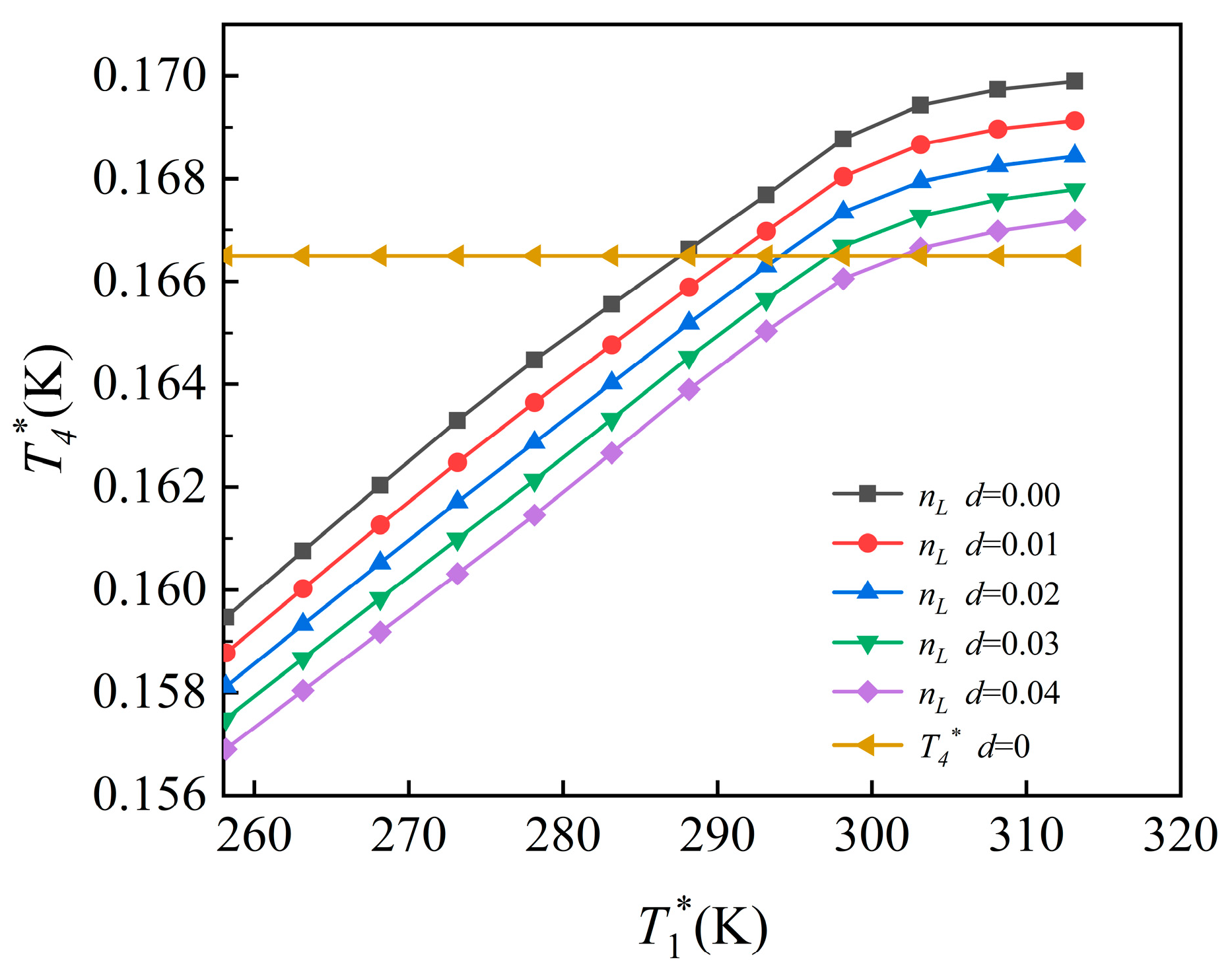

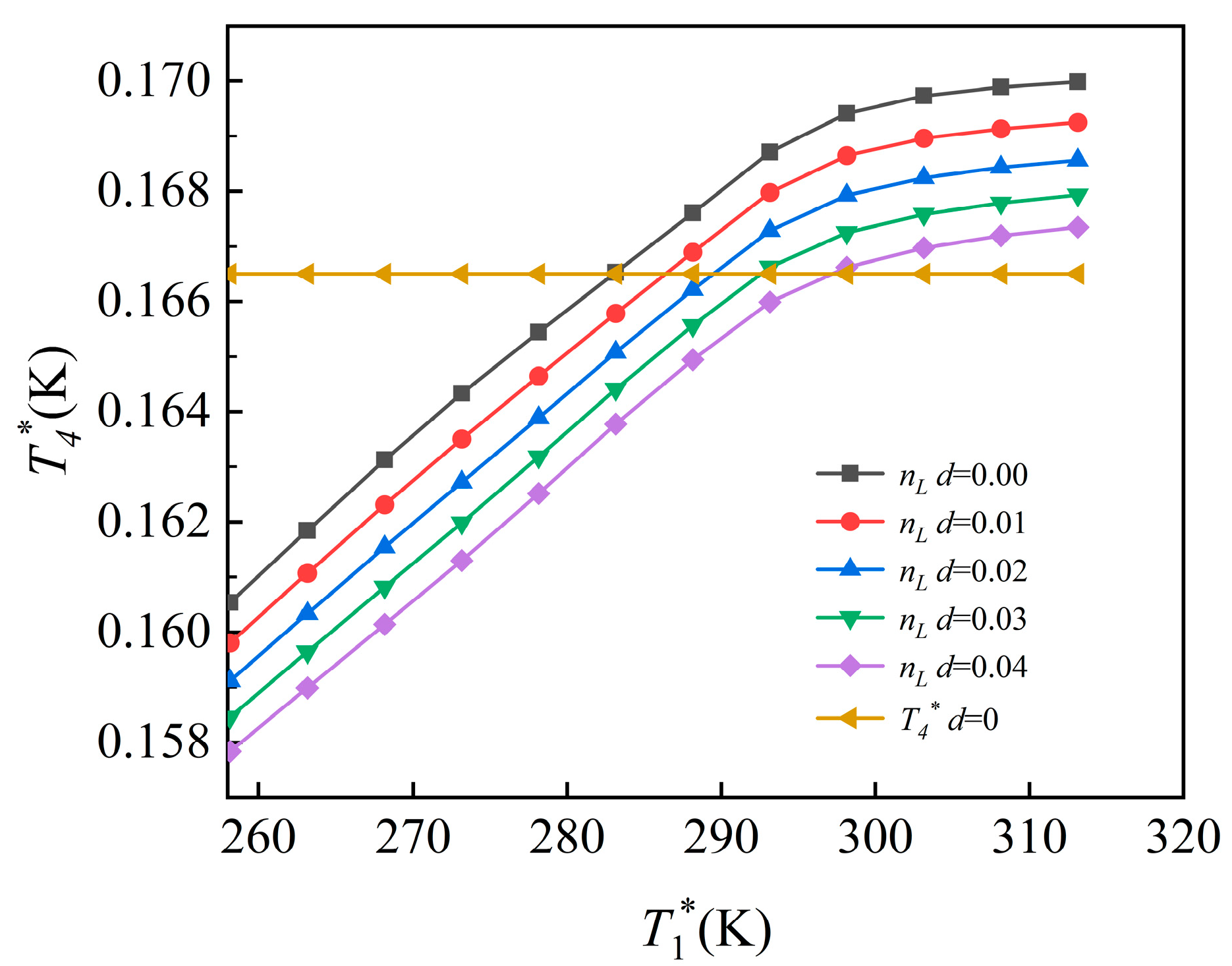

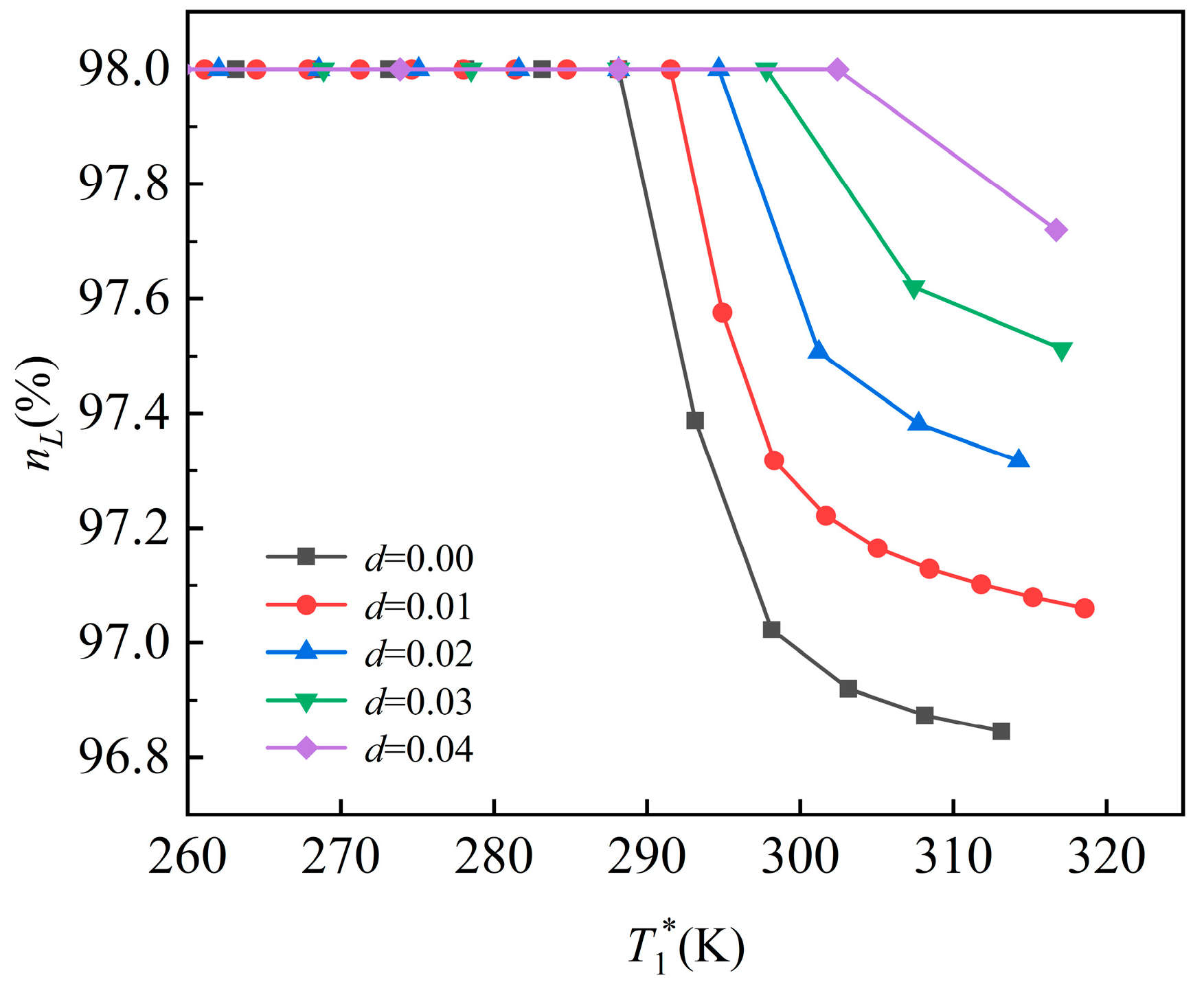

4.1. Influence of Ambient Humidity on Engine Control Plan

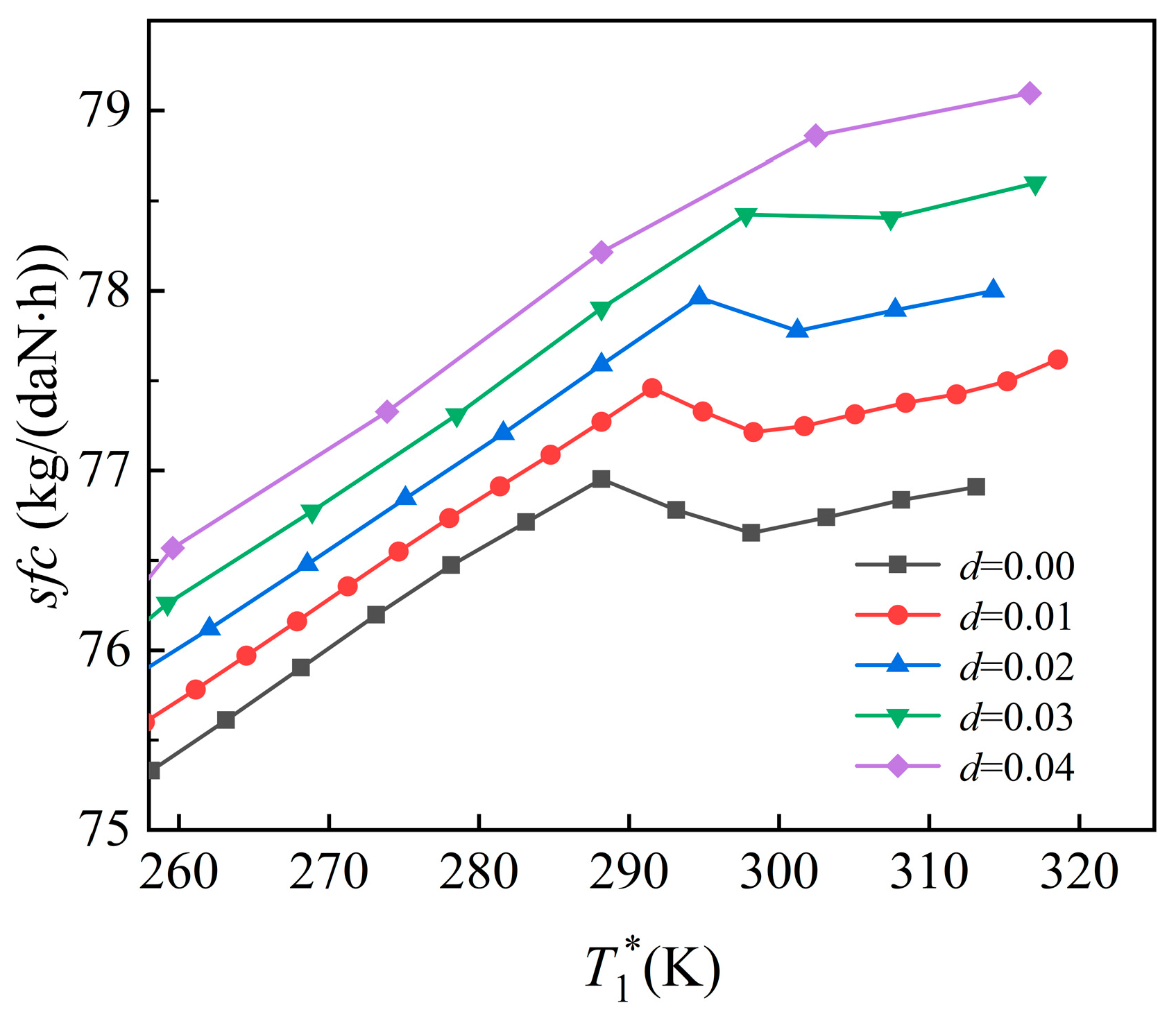

4.2. Influence of Control Plan Inflection Point Variations on Aero-Engine Performance

4.2.1. Performance Analysis Under Ground Test Conditions

4.2.2. Performance Analysis Under Take-Off Condition

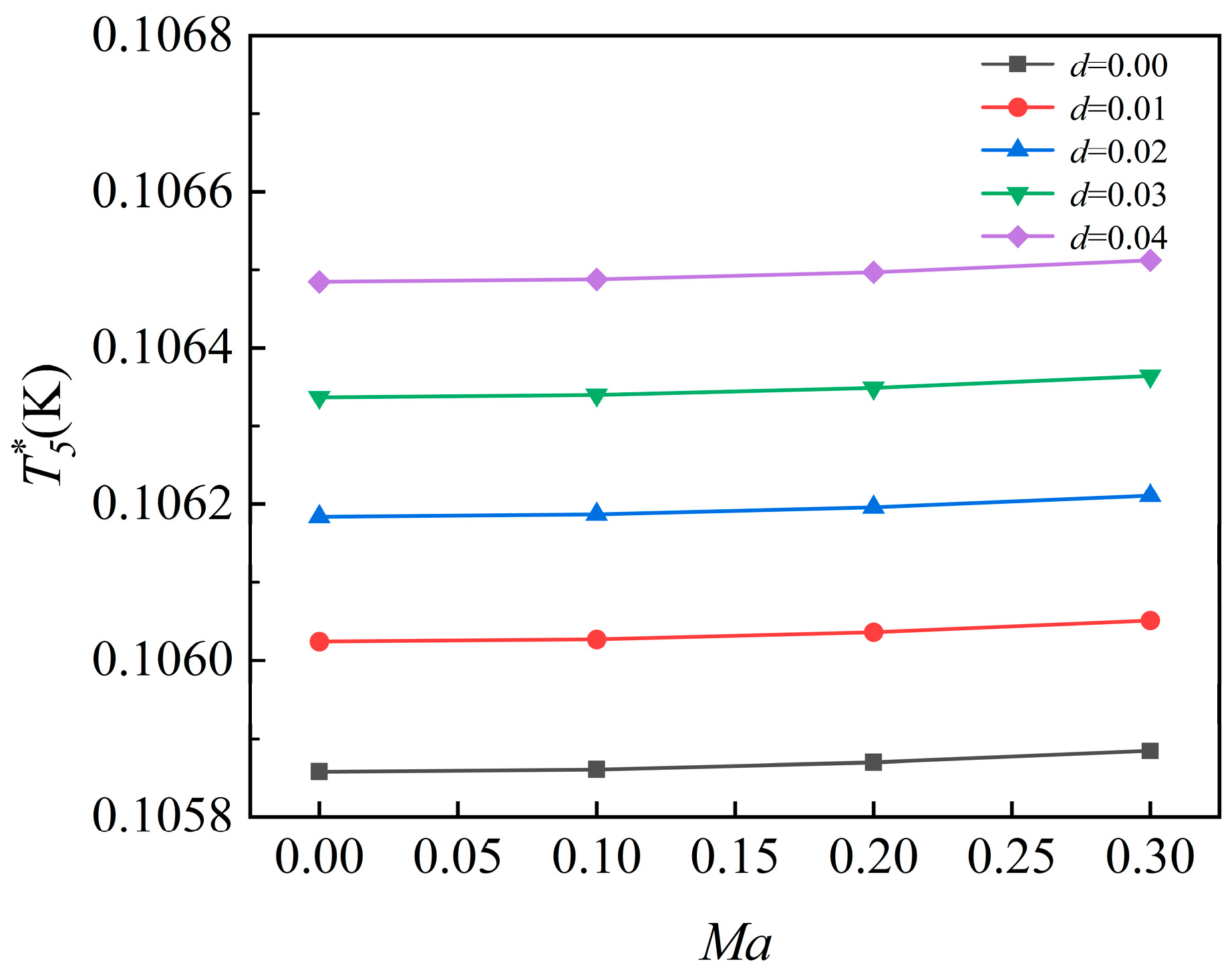

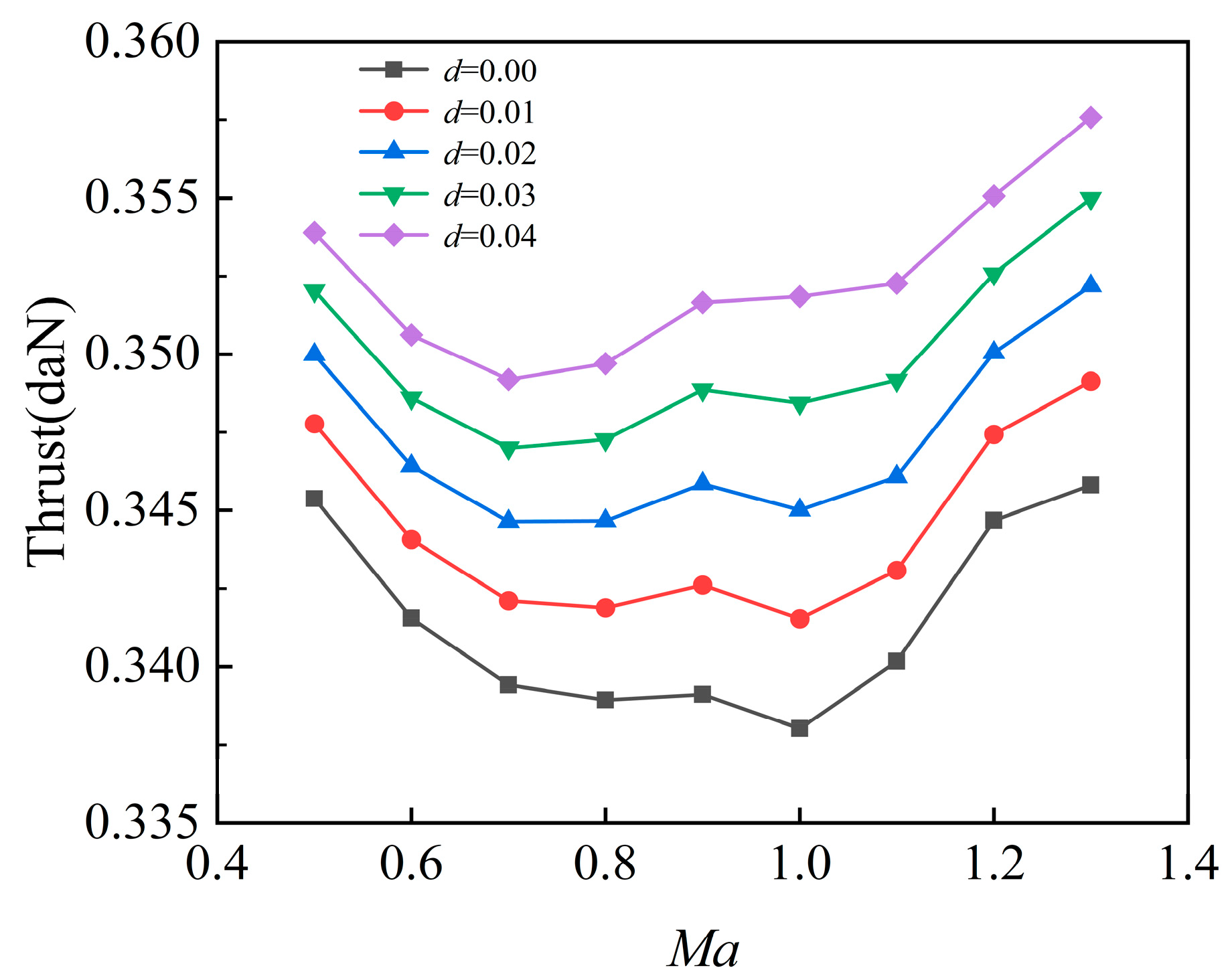

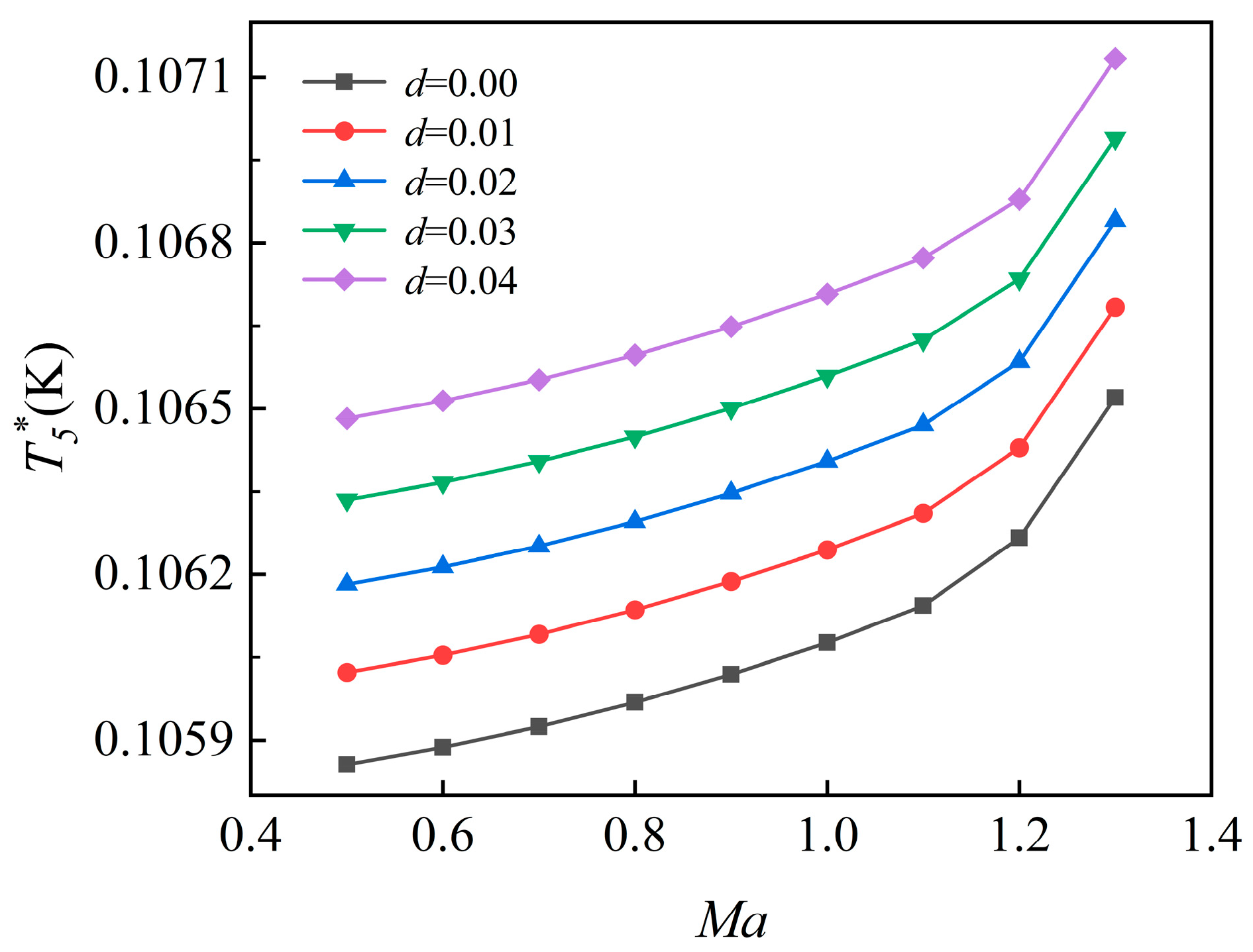

4.2.3. Performance Analysis Under Cruising Condition

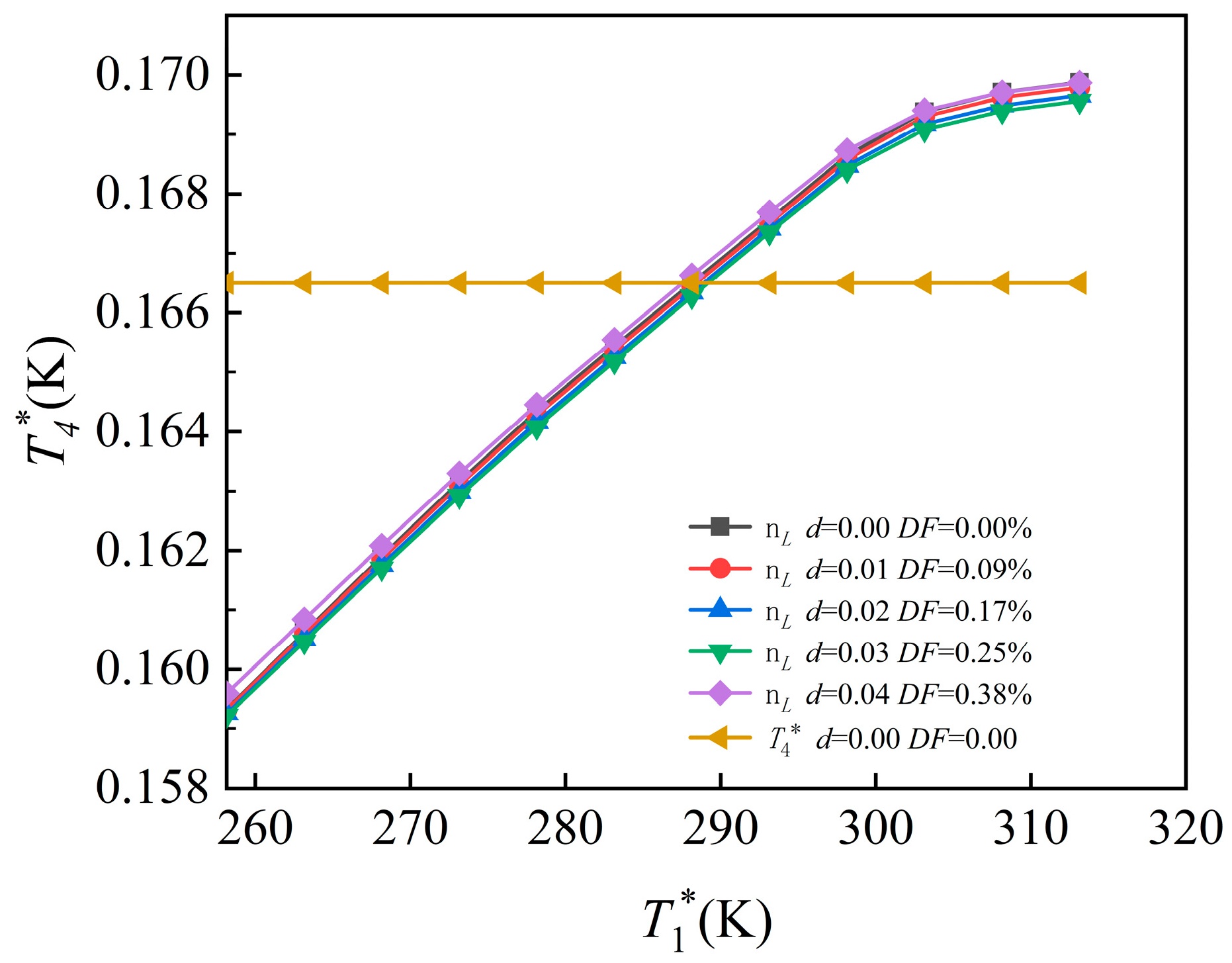

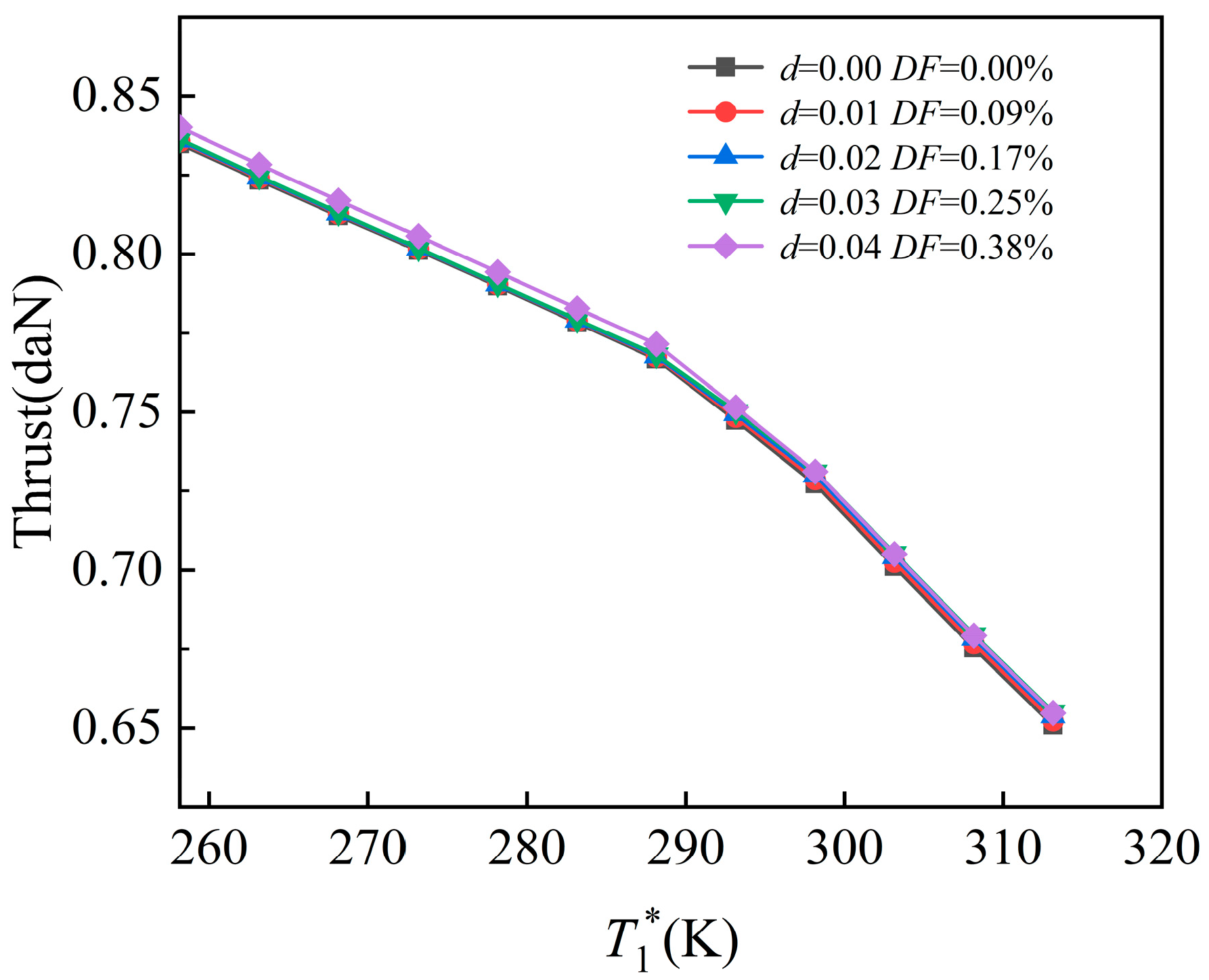

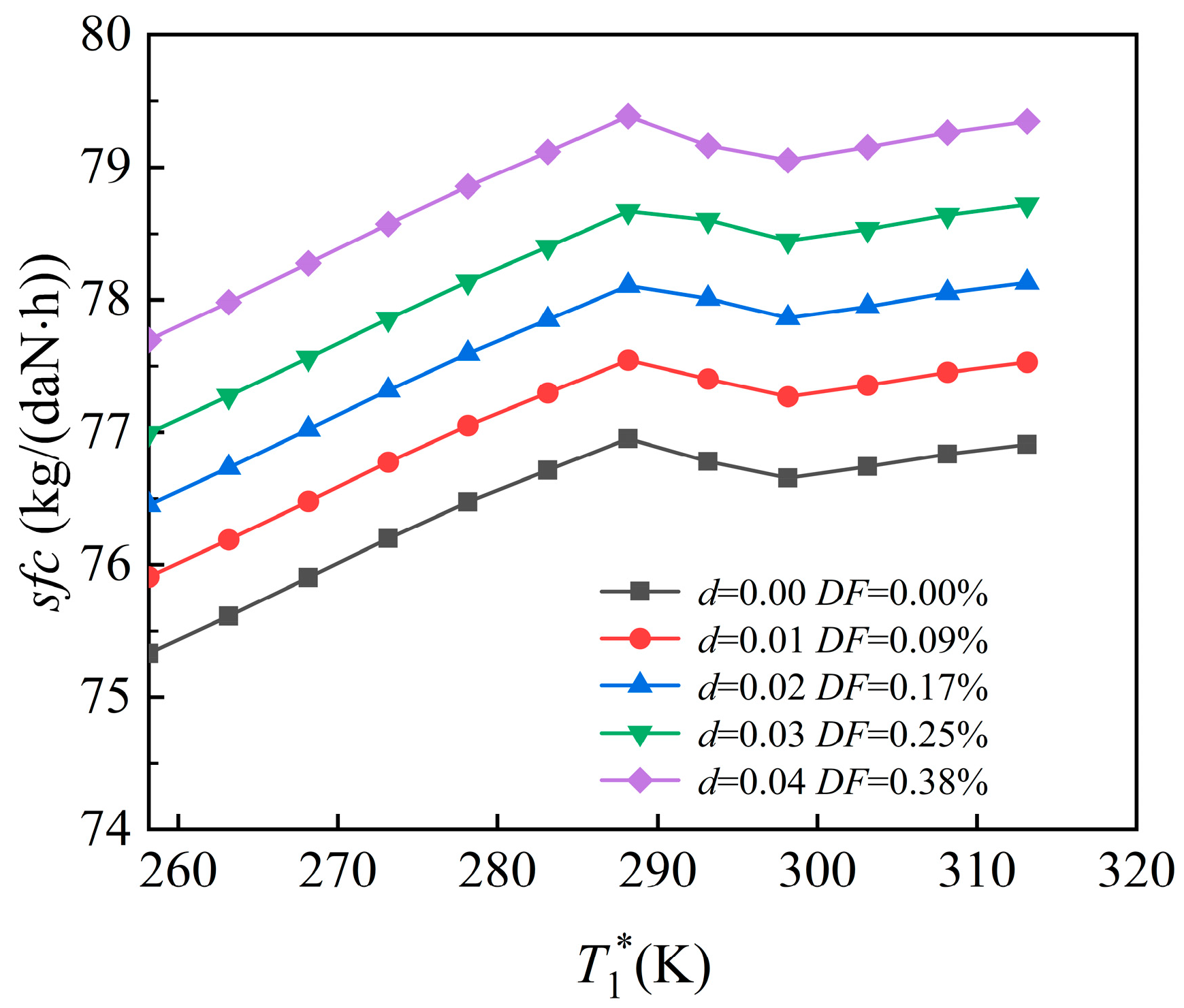

4.3. Coupled Effects of Humidity and Component Performance Degradation on Aero-Engine Performance

5. Conclusions

- (1)

- As ambient humidity increases, the control plan inflection point shifts rightward, with the degree of displacement increasing proportionally. At h = 0 km and Ma = 0, the inflection temperature is 288.15 K when d = 0, while humidity levels of 0.01 and 0.04 delay the control transition by 3.38 K and 14.28 K, respectively. At h = 0 km and Ma = 0.2, the inflection temperature is 283.03 K when d = 0, while humidity levels of 0.01 and 0.04 delay the control transition by 3.35 K and 14.17 K, respectively. At h = 5 km and Ma = 0.8, the inflection temperature is 255.31 K when d = 0, while humidity levels of 0.01 and 0.04 delay the control transition by 3.14 K and 14.31 K, respectively.

- (2)

- Under ground test conditions, thrust increases post-inflection point shift, with an average gain of 0.53%. Under take-off conditions, thrust gains decline with increasing humidity, and higher thrust is observed under lower humidity. Under cruising conditions, trends are consistent with take-off behavior.

- (3)

- Under the coupled effects of humidity and degradation, the inflection point remains near 288.15 K. Compared to the undegraded, zero-humidity baseline, thrust variation is minimal. However, sfc increases with both rising humidity and degradation, averaging a 0.79% growth.

- (4)

- The sfc increase rate is higher when both humidity and component degradation are considered than when humidity alone is considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bird, J.; Grabe, W. Humidity Effects on Gas Turbine Performance. In Proceedings of the ASME 1991 International Gas Turbine and Aeroengine Congress and Exposition, Orlando, FL, USA, 3–6 June 1991. [Google Scholar] [CrossRef]

- Apostolidis, A.; Stamoulis, K. A Health Monitoring Modelling Case Study: Humidity Effects on Engine Deterioration Prediction. MATEC Web Conf. 2021, 349, 03011. [Google Scholar] [CrossRef]

- Gardiner, A.W. Atmospheric Humidity and Engine Performance. SAE Trans. 1929, 24, 267–272. [Google Scholar] [CrossRef]

- Naeem, M.; Singh, R.; Probert, D. Implications of Engine Deterioration for Operational Effectiveness of a Military Aircraft. Appl. Energy 1998, 60, 115–152. [Google Scholar] [CrossRef]

- Rhee, J.; Im, J.; Kim, J.; Song, S.J. Humidity Effects on the Aerodynamic Performance of a Transonic Compressor Cascade. Int. J. Heat Mass Transf. 2019, 140, 743–751. [Google Scholar] [CrossRef]

- Yamamoto, S.; Araki, K.; Moriguchi, S.; Miyazawa, H.; Furusawa, T.; Yonezawa, K.; Umezawa, S.; Ohmori, S.; Suzuki, T. Effects of Wetness and Humidity on Transonic Compressor of Gas Turbine. Int. J. Heat Mass Transf. 2021, 178, 121649. [Google Scholar] [CrossRef]

- Yu, D.; Zhao, H.X.Z.; Xu, Z.; Sui, Y.; Liu, J. An Approximate Non-Linear Model for Aeroengine Control. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2011, 225, 1366–1381. [Google Scholar] [CrossRef]

- Chen, J.; Hu, Z.; Wang, J. Aero-Engine Real-Time Models and Their Applications. Math. Probl. Eng. 2021, 2021, 1–17. [Google Scholar] [CrossRef]

- Martínez, F.R.; Martínez, A.R.; Velazquez, M.T.; Diez, P.Q.; Eslava, G.T.; Francis, J.A. Evaluation of the Gas Turbine Inlet Temperature with Relation to the Excess Air. Energy Power Eng. 2011, 34, 517–524. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Yan, Z.; Li, R.; Tian, A.; Xu, X.; Zhang, H. Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin. Processes 2023, 11, 1768. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Xi, F.; Wei, B.; Duan, D.; Cai, Z.; Si, S. Data Driven Comprehensive Performance Evaluation of Aeroengines: A Network Dynamic Approach. Engineering 2025, 46, 292–305. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, W.; Yuan, X.; Wang, Y.; Shen, Z.; Wang, F. Research on the Impact of the Sand and Dust Ingestion Test on the Overall Performance of Turboshaft Engines. Aerospace 2025, 12, 146. [Google Scholar] [CrossRef]

- Fishbach, L.H.; Koenig, R.W. GENENG 2: A Program for Calculating Design and Off-Design Performance of Two- and Three-Spool Turbofans with as Many as Three Nozzles; NASA: Cleveland, OH, USA, 1972. [Google Scholar]

- Kurzke, J. Model Based Gas Turbine Parameter Corrections. In Proceedings of the 2003 ASME Turbo Expo: Power for Land, Sea, and Air, Atlanta, GA, USA, 16–19 June 2003. [Google Scholar] [CrossRef]

- Li, Y.G.; Pilidis, P.; Newby, M.A. An Adaptation Approach for Gas Turbine Design-Point Performance Simulation. J. Eng. Gas Turbines Power 2005, 128, 789–795. [Google Scholar] [CrossRef]

- Li, Y.G.; Abdul Ghafir, M.F.; Wang, L.; Singh, R.; Huang, K.; Feng, X.; Zhang, W. Improved Multiple Point Nonlinear Genetic Algorithm Based Performance Adaptation Using Least Square Method. J. Eng. Gas Turbines Power 2011, 134, 031701. [Google Scholar] [CrossRef]

- Pang, S.; Li, Q.; Zhang, H. An Exact Derivative Based Aero-Engine Modeling Method. IEEE Access 2018, 6, 34516–34526. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Jeng, Y.-L. Influences of Charge Air Humidity and Temperature on the Performance and Emission Characteristics of Diesel Engines. J. Ship. Res 1996, 40, 172–177. [Google Scholar] [CrossRef]

- Nikolaidis, T. Water Ingestion Effects on Gas Turbine Engine Performance. Doctor Thesis, Cranfield University, Bedfordshire, UK, 2008. Available online: http://hdl.handle.net/1826/3516 (accessed on 8 September 2025).

- Castiglione, T.; Perrone, D.; Strafella, L.; Ficarella, A.; Bova, S. Linear Model of a Turboshaft Aero-Engine Including Compo nents Degradation for Control-Oriented Applications. Energies 2023, 16, 2634. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, J.; Yu, Y. Effect of Performance Degradation on the Inflection Point of Engine Control Plan. J. Air Force Eng. Univ. (Nat. Sci.) 2022, 23, 70–78. [Google Scholar]

- Milojević, S.; Džunić, D.; Marić, D.; Skrúcaný, T.; Mitrović, S.; Pešić, R. Tribological Assessment of Aluminum Cylinder Material for Piston Compressors in Trucks and Buses Brake Systems. Teh. Vjesn.—Tech. Gaz. 2021, 28, 1268–1276. [Google Scholar] [CrossRef]

- Su, S.; Lian, X. Application of Genetic Algorithm in Nonlinear Mathematical Model of Aero Engine. J. Propul. Technol. 2004, 3, 237–240. [Google Scholar] [CrossRef]

- Luo, G.; Wang, R. The Numerical Simulation of Aero Gas Turbine Engine, 1st ed.; National Defense Industry Press: Beijing, China, 2006; pp. 71–74. [Google Scholar]

- Qian, F.; Song, W.; Luo, G. Calculation of integrated performance for aircraft/engines. J. Aerosp. Power 2013, 28, 1112–1118. [Google Scholar] [CrossRef]

- North Atlantic Treaty Organization. Recommended Practices for the Assessment of the Effects of Atmospheric Water Ingestion on the Performance and Operability of Gas Turbine Engines; North Atlantic Treaty Organization: Brussels, Belgium, 1995. [Google Scholar]

- Wang, Z. Aeroengine Degradation Evaluation Based on Thermodynamic Model and Neural Network. Master’s Thesis, Civil Aviation University of China, Tianjin, China, 2022. [Google Scholar]

| d | Ma | |||

|---|---|---|---|---|

| 0.0 | 0.1 | 0.2 | 0.3 | |

| 0.01 | 0.60 | 0.62 | 0.64 | 0.67 |

| 0.02 | 0.55 | 0.56 | 0.58 | 0.62 |

| 0.03 | 0.50 | 0.52 | 0.54 | 0.57 |

| 0.04 | 0.46 | 0.47 | 0.49 | 0.52 |

| d | Ma | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 | |

| 0.01 | 0.69 | 0.73 | 0.79 | 0.87 | 1.03 | 1.04 | 0.86 | 0.80 | 0.96 |

| 0.02 | 0.64 | 0.68 | 0.74 | 0.81 | 0.95 | 1.02 | 0.87 | 0.75 | 0.87 |

| 0.03 | 0.58 | 0.63 | 0.68 | 0.75 | 0.87 | 0.99 | 0.89 | 0.72 | 0.80 |

| 0.04 | 0.53 | 0.58 | 0.63 | 0.70 | 0.80 | 0.98 | 0.89 | 0.71 | 0.73 |

| d | DF/% | Temperature/K | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 258.15 | 268.15 | 278.15 | 288.15 | 298.15 | 303.15 | 308.15 | 313.15 | ||

| 0.01 | 0.09 | 0.09 | 0.08 | 0.07 | 0.09 | 0.19 | 0.21 | 0.21 | 0.22 |

| 0.02 | 0.17 | 0.04 | 0.02 | 0.005 | 0.03 | 0.19 | 0.22 | 0.22 | 0.23 |

| 0.03 | 0.25 | 0.05 | 0.04 | 0.02 | 0.04 | 0.17 | 0.19 | 0.19 | 0.19 |

| 0.04 | 0.38 | 0.44 | 0.45 | 0.46 | 0.45 | −0.004 | −0.05 | −0.05 | −0.05 |

| d | DF/% | Temperature/K | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 258.15 | 268.15 | 278.15 | 288.15 | 298.15 | 303.15 | 308.15 | 313.15 | ||

| 0.00 | 0.00 | 0.8348 | 0.8121 | 0.7898 | 0.7668 | 0.7272 | 0.7010 | 0.6753 | 0.6509 |

| 0.01 | 0.09 | 0.8356 | 0.8127 | 0.7904 | 0.7674 | 0.7286 | 0.7025 | 0.6768 | 0.6523 |

| 0.02 | 0.17 | 0.8359 | 0.8128 | 0.7904 | 0.7677 | 0.7300 | 0.7040 | 0.6783 | 0.6538 |

| 0.03 | 0.25 | 0.8363 | 0.8131 | 0.7906 | 0.7680 | 0.7312 | 0.7053 | 0.6796 | 0.6551 |

| 0.04 | 0.38 | 0.8401 | 0.8168 | 0.7942 | 0.7715 | 0.7311 | 0.7050 | 0.6792 | 0.6547 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Lin, W.; Yu, Y. Humidity Influence on Aero-Engine Control Plan Inflection Point and Performance. Machines 2025, 13, 860. https://doi.org/10.3390/machines13090860

Yu J, Lin W, Yu Y. Humidity Influence on Aero-Engine Control Plan Inflection Point and Performance. Machines. 2025; 13(9):860. https://doi.org/10.3390/machines13090860

Chicago/Turabian StyleYu, Jinlu, Wujun Lin, and Yang Yu. 2025. "Humidity Influence on Aero-Engine Control Plan Inflection Point and Performance" Machines 13, no. 9: 860. https://doi.org/10.3390/machines13090860

APA StyleYu, J., Lin, W., & Yu, Y. (2025). Humidity Influence on Aero-Engine Control Plan Inflection Point and Performance. Machines, 13(9), 860. https://doi.org/10.3390/machines13090860