Nine-Probe Third-Order Matrix System for Precise Flatness Error Detection

Abstract

1. Introduction

2. System Design and Algorithm Development

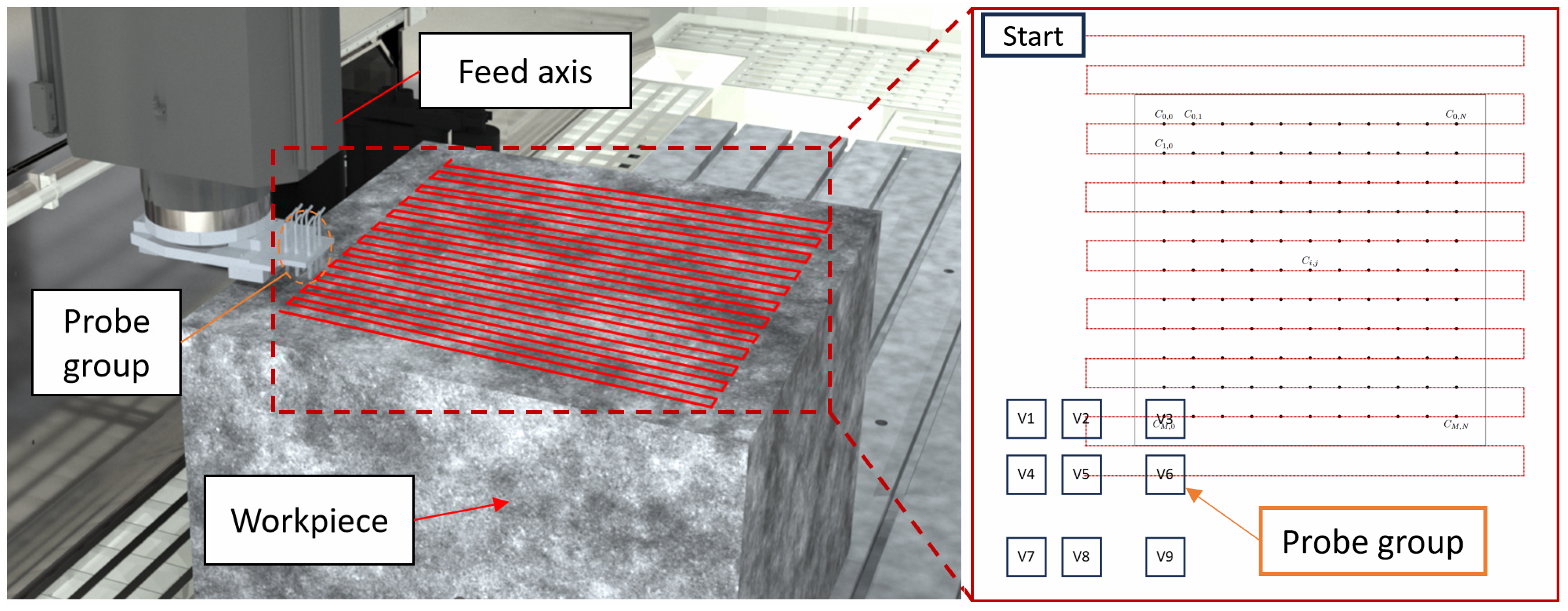

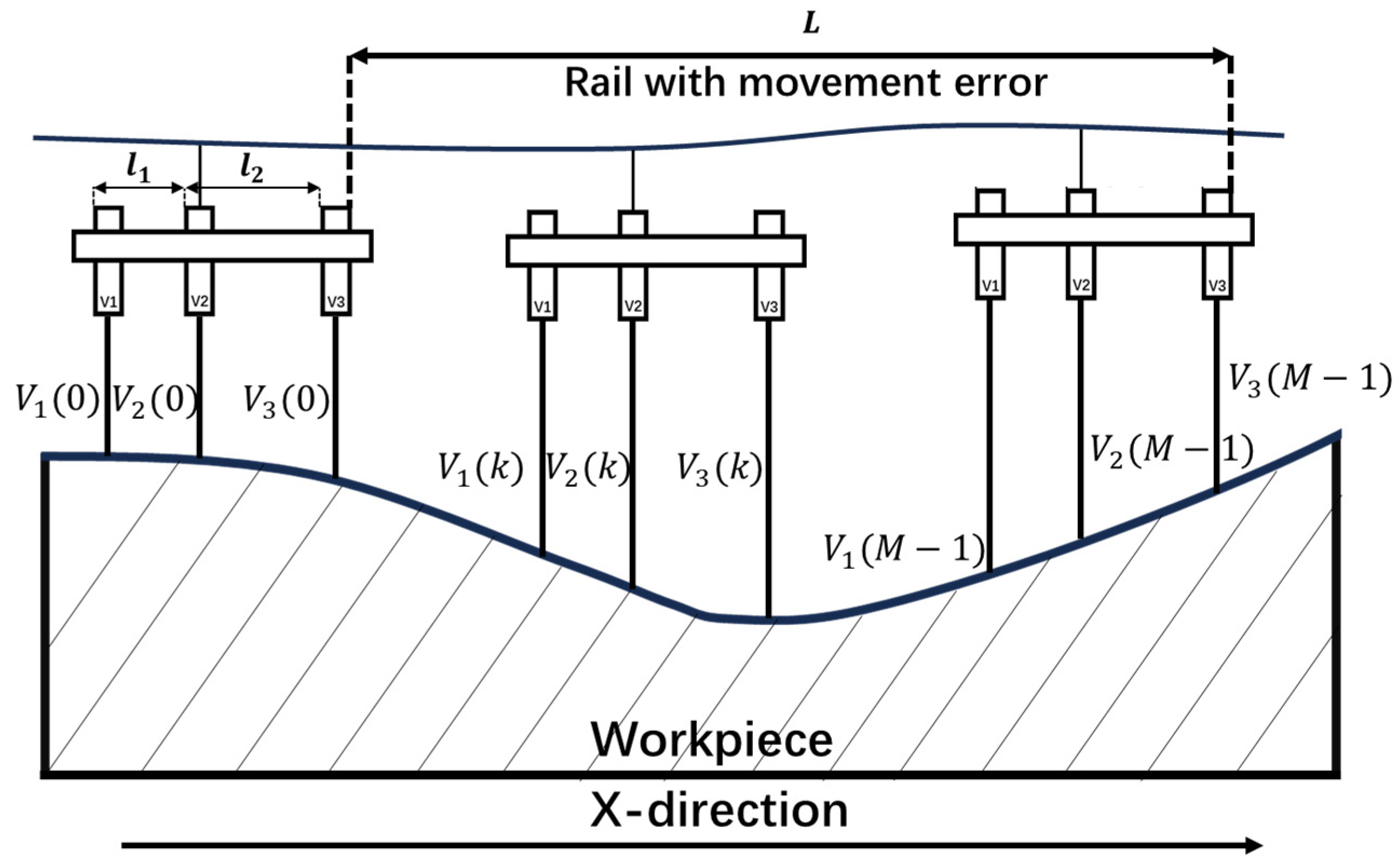

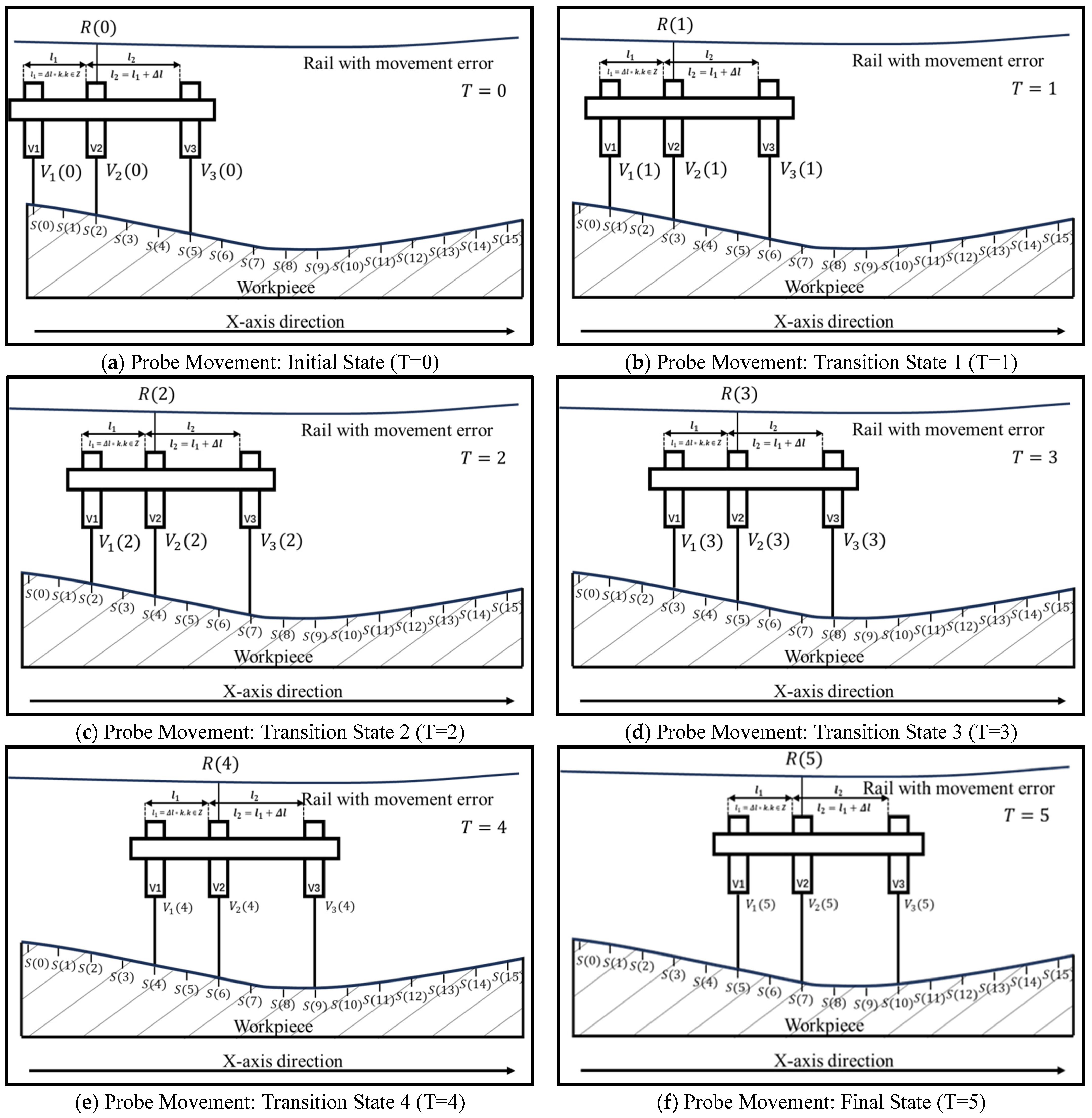

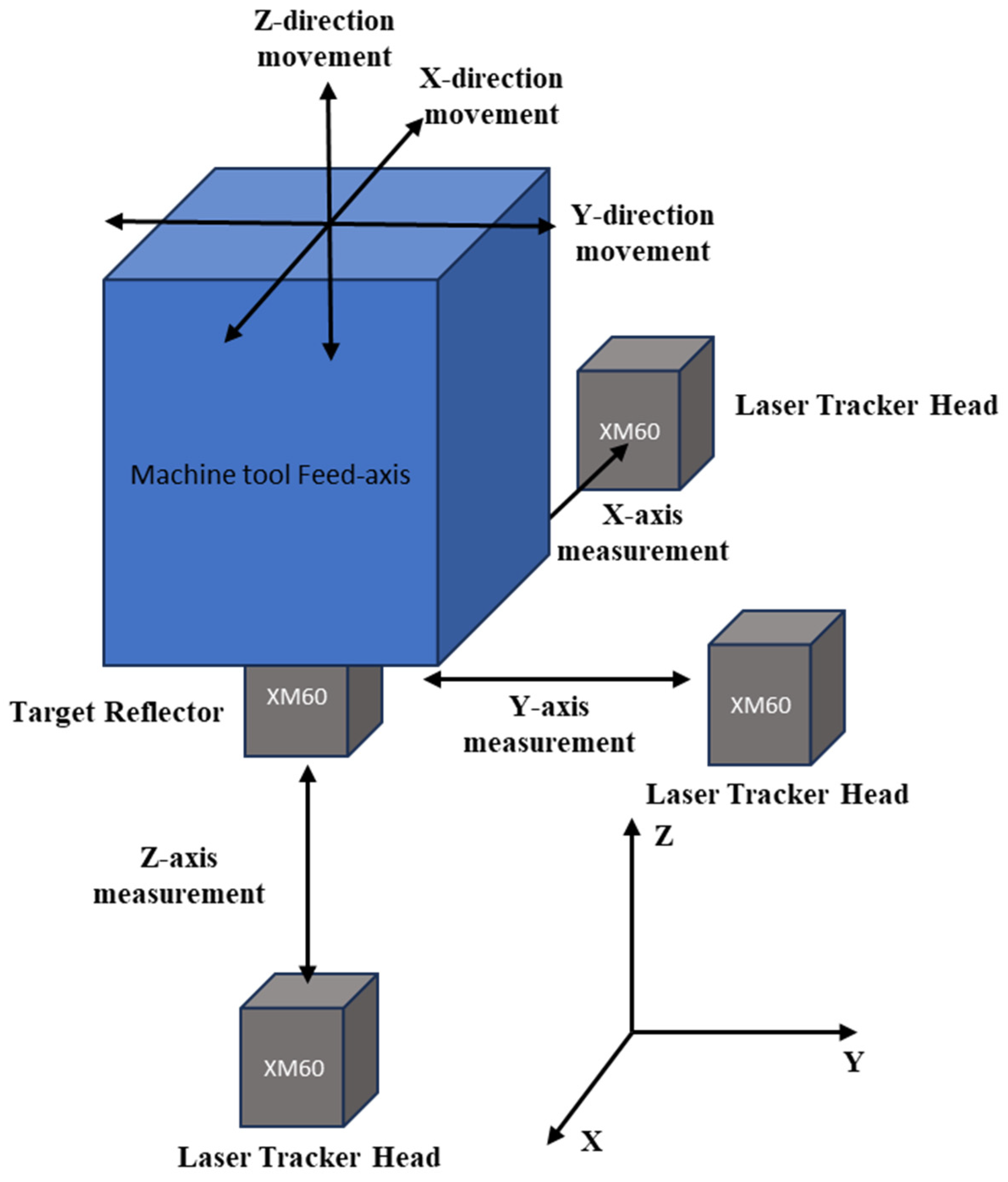

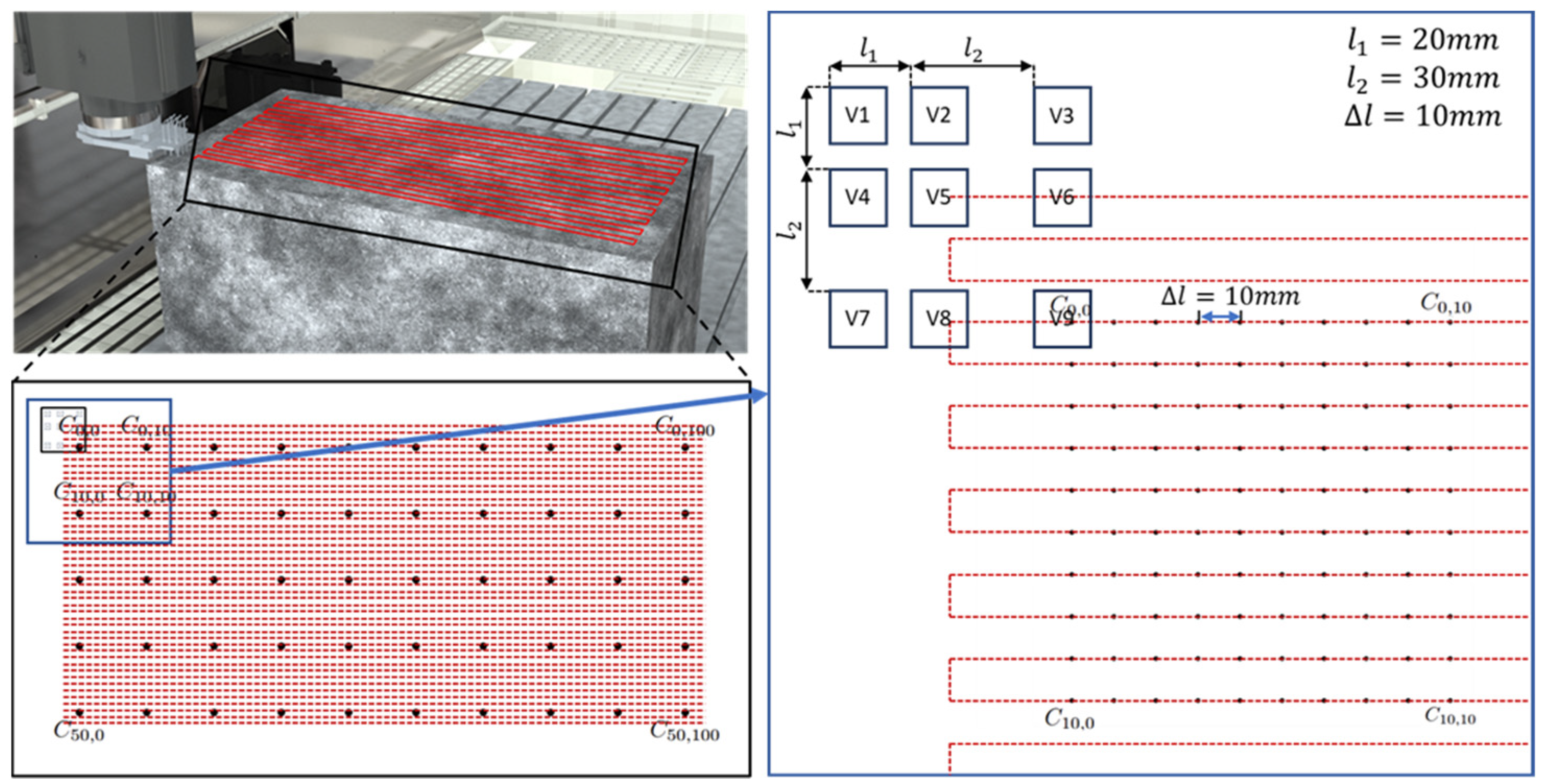

2.1. System Configuration and Measurement Principle

- Probe linearity: Each high-precision capacitive probe (HD series) has a linear error ≤ 0.1% of full scale, confirmed via calibration with a Renishaw XL-80 laser interferometer;

- Simultaneous sampling: The nine probes achieve synchronous data acquisition with a time deviation ≤ 1 ms, guaranteed by the CNC system’s 60 Hz real-time sampling module;

- Probe position accuracy: The 3 × 3 probe matrix is calibrated via a coordinate measuring machine (CMM, accuracy ±2 μm), ensuring the distance between adjacent probes has a position error ≤ 5 μm.

2.2. Error Separation Algorithm Formulation

3. Experimental System Development and Uncertainty Evaluation

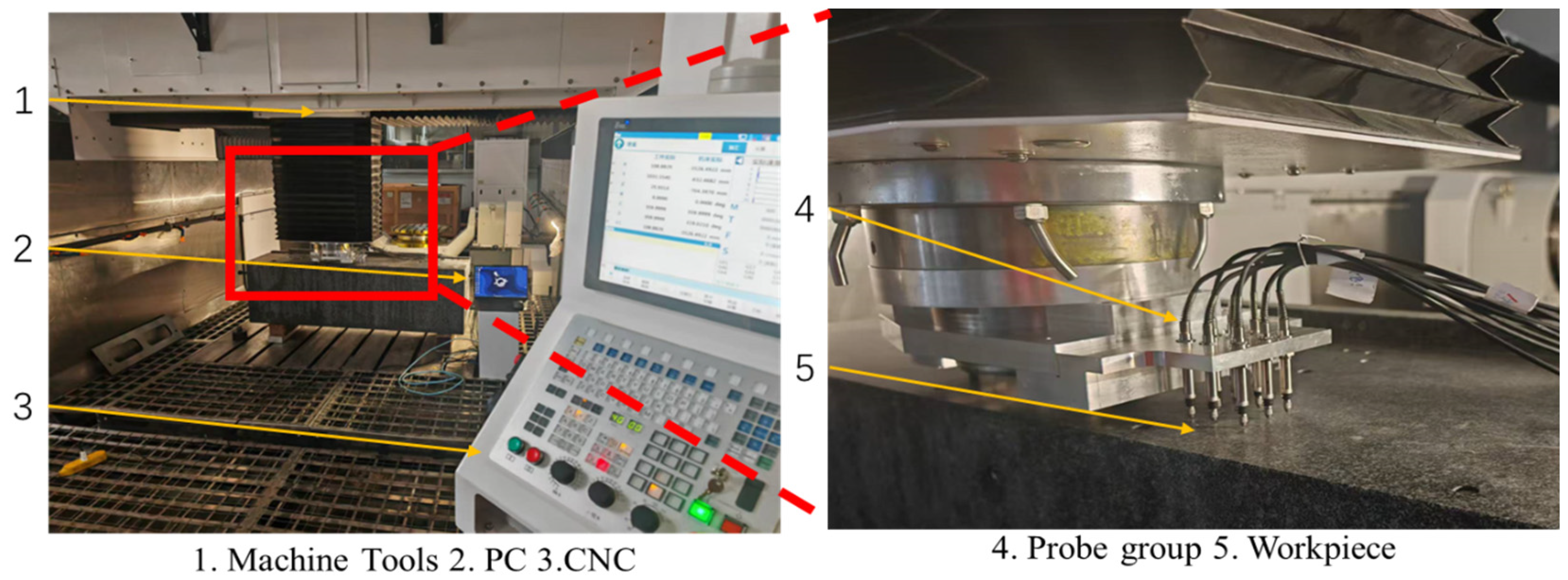

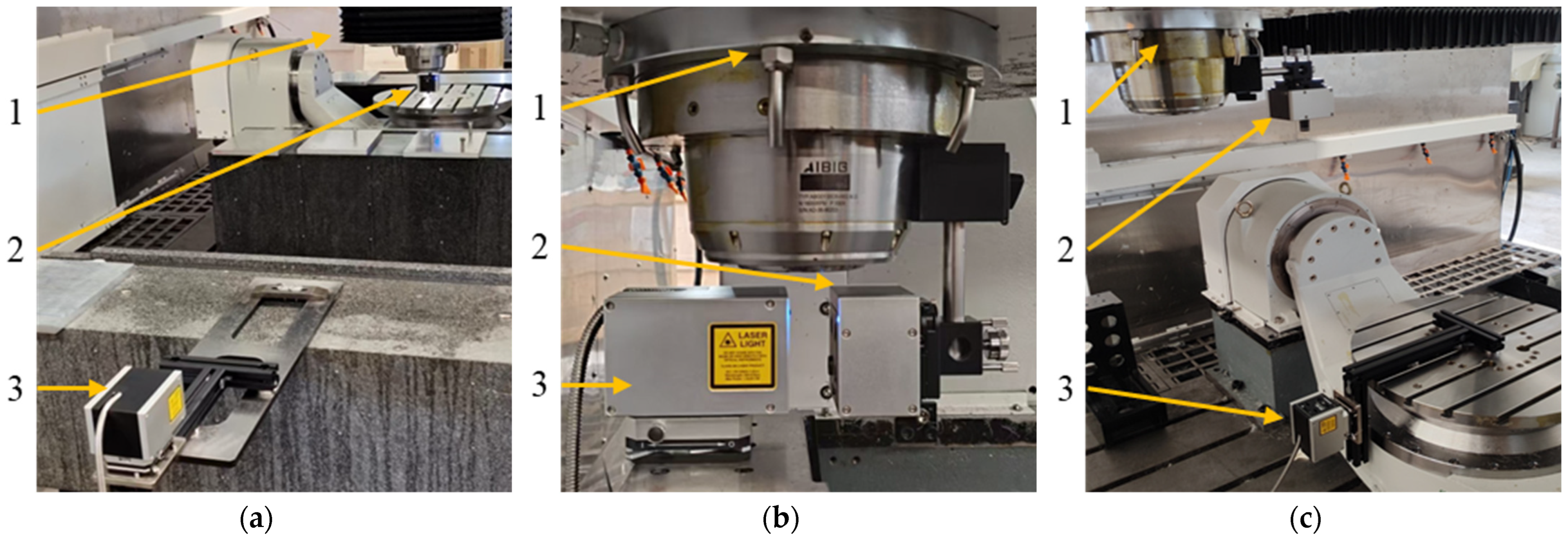

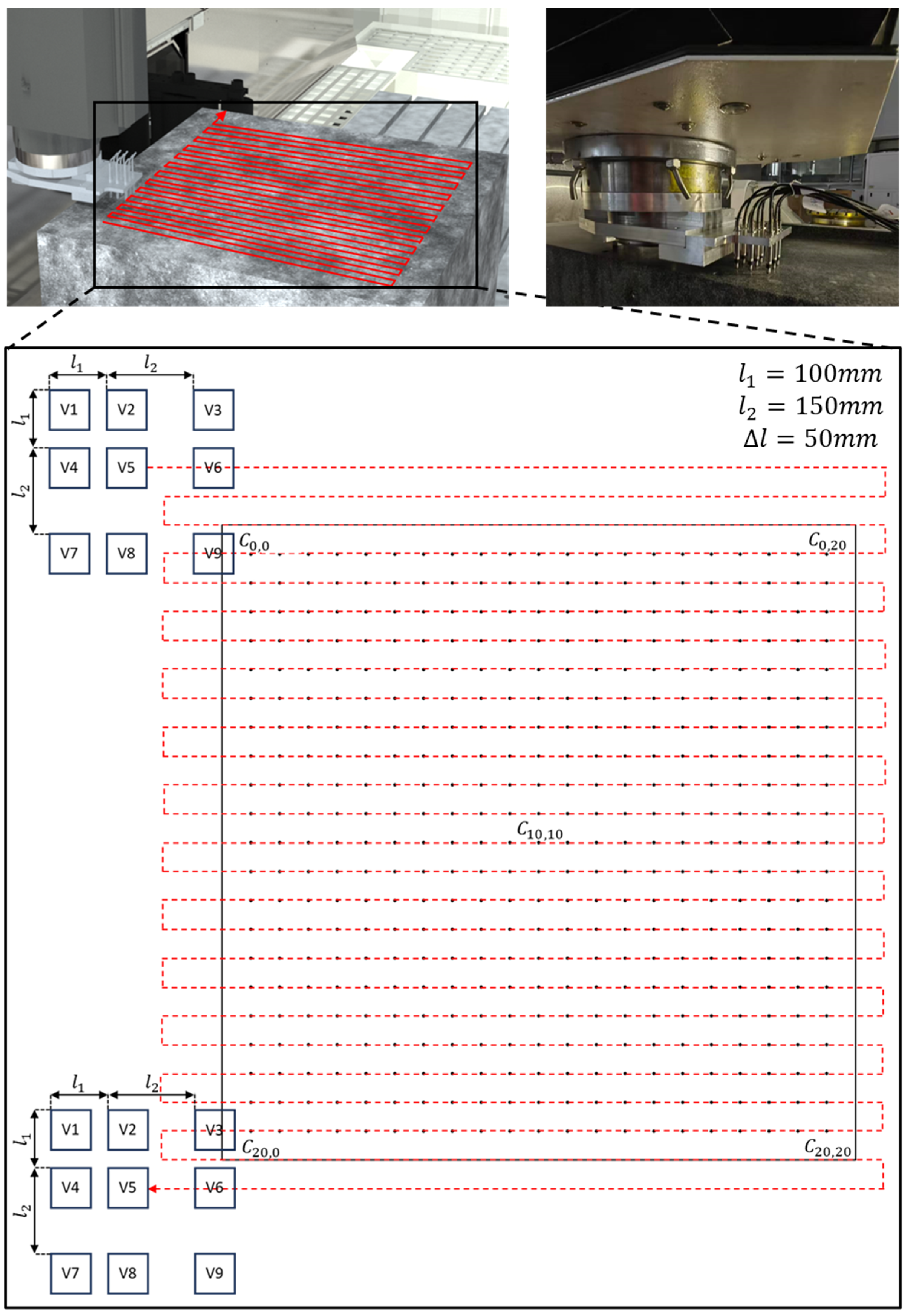

3.1. Experimental Setup Design and Integration

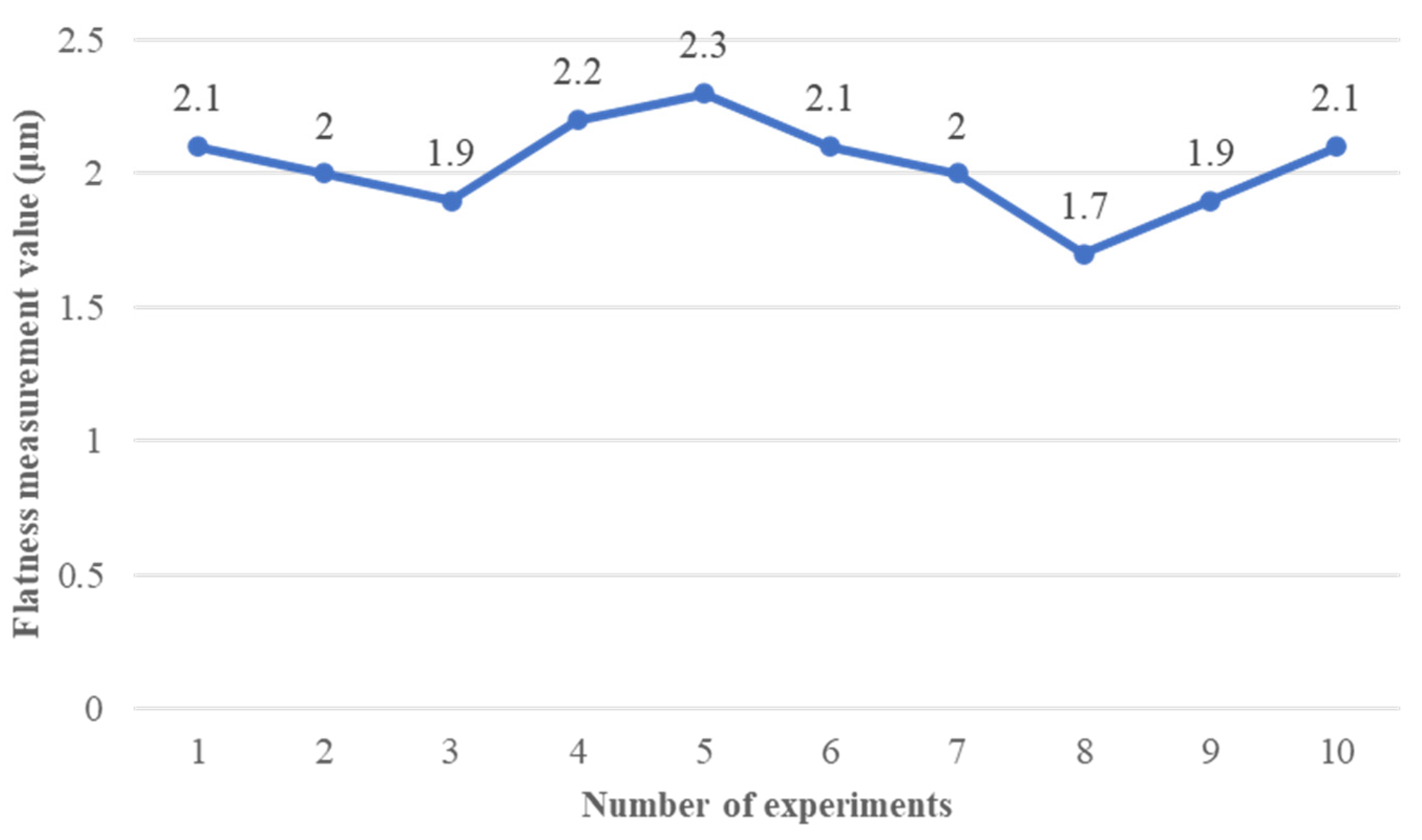

3.2. Machine Tool Accuracy and Repeatability Testing

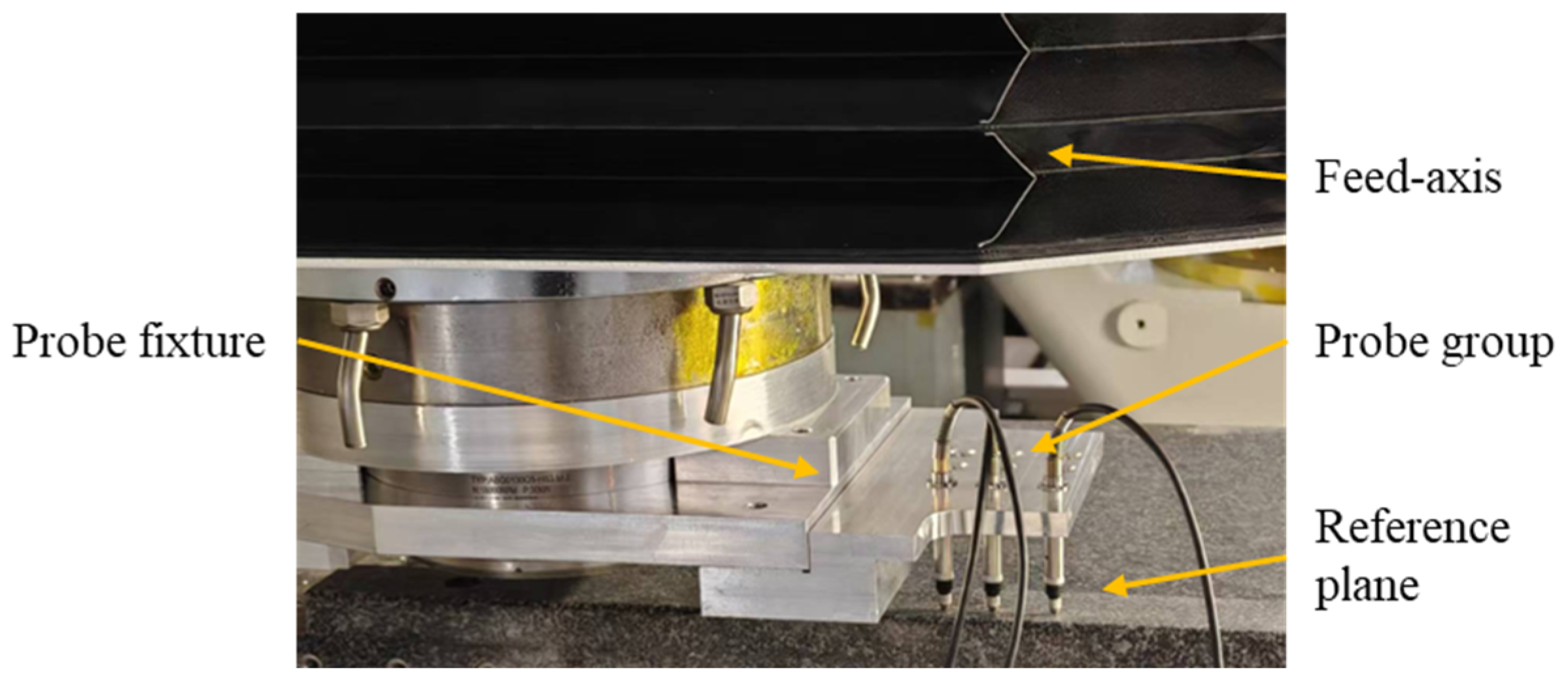

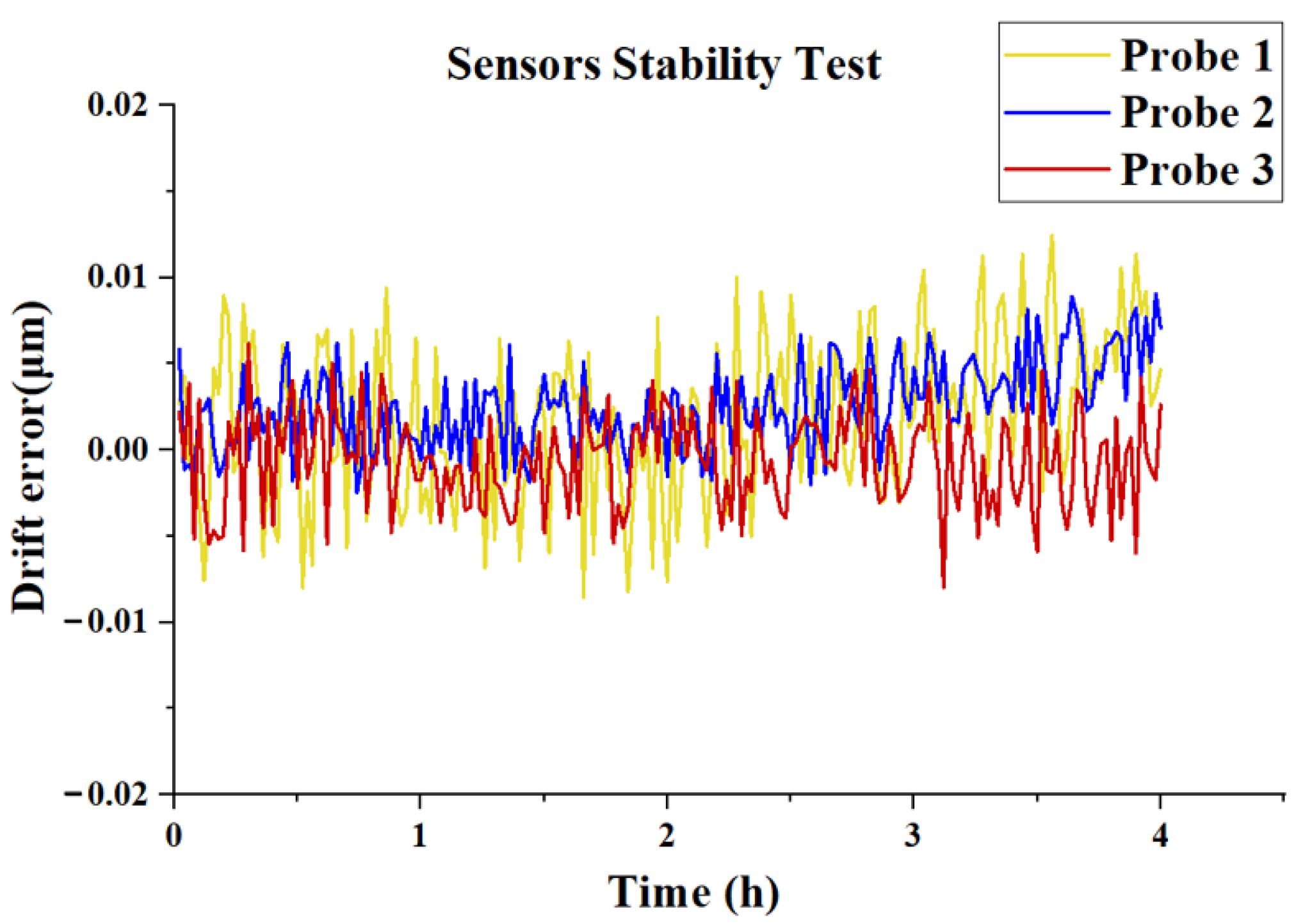

3.3. Probe Group Uncertainty Tests

3.4. Experiment System Measurement Uncertainty Tests

4. Experimental Verification of Measurement System Performance

4.1. Experiment Design

4.2. Experiment Results

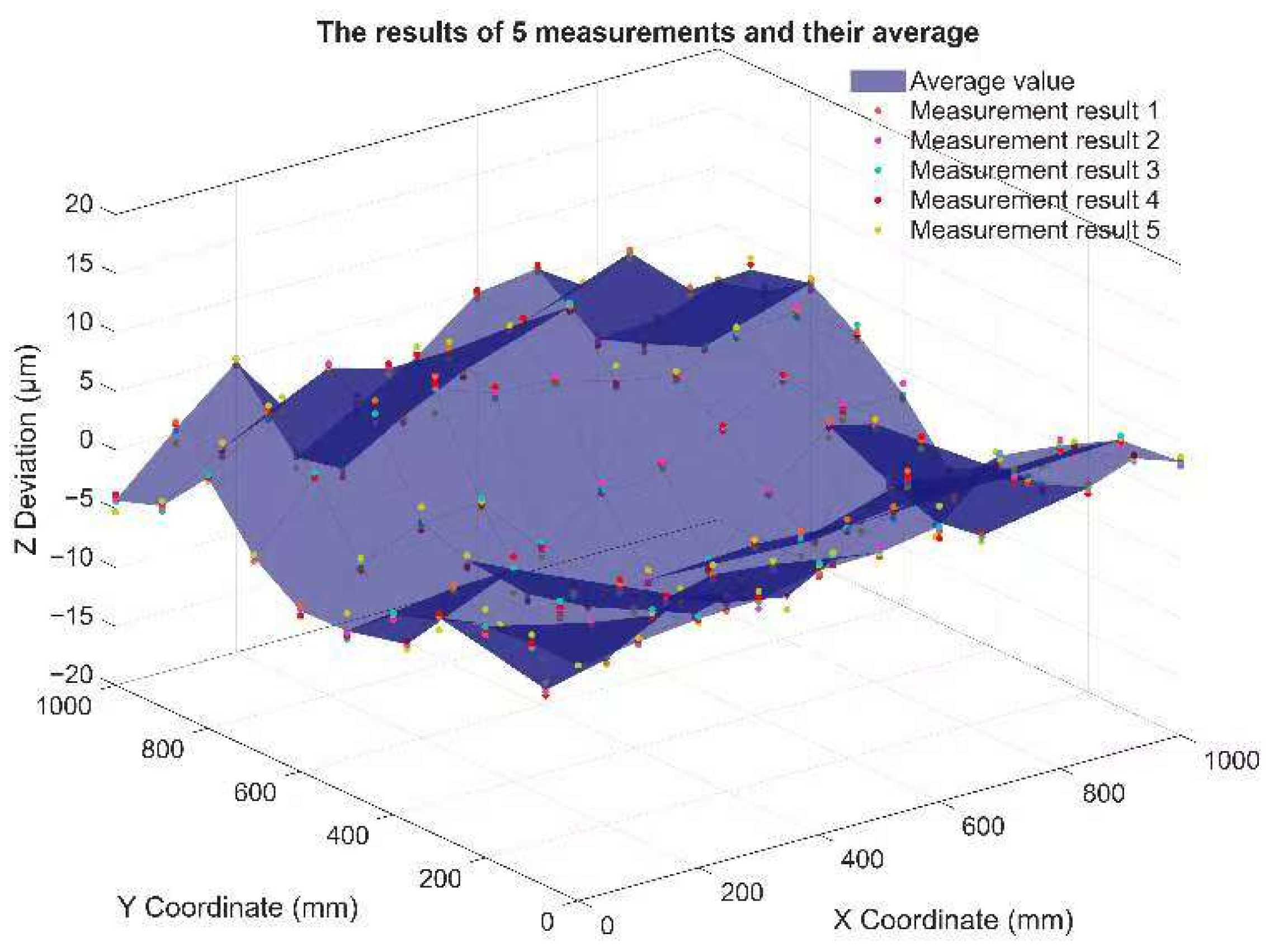

4.2.1. Nine Probe Method Measurement Results

4.2.2. Electronic Level Method Measurement Results

4.2.3. Comparative Analysis of Measurement Outcomes

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dichev, D.; Diakov, D.; Zhelezarov, Y.; Nikolova, H.; Kupriyanov, O.; Dicheva, R. Accuracy Evaluation of Flat Surfaces Measurements in Conditions of External Influences. Machines 2021, 9, 156. [Google Scholar] [CrossRef]

- Huang, S.; Pang, Y.; Xia, H. Data Preprocessing for Flatness Measurements of Large Precision Workpieces. J. Phys. Conf. Ser. 2024, 2770, 012014. [Google Scholar] [CrossRef]

- Shu, H.; Zou, C.; Chen, J.; Wang, S. Research on Micro/Nano Surface Flatness Evaluation Method Based on Improved Particle Swarm Optimization Algorithm. Front. Bioeng. Biotechnol. 2021, 9, 775455. [Google Scholar] [CrossRef]

- Saleh, A.A.; Amer, M.; Nada, N. Investigation of Error Sources in Absolute Flatness Measurement Using Fizeau Interferometer. Opt. Eng. 2024, 63, 101502. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, C.; Liang, X.; Qiu, Z.; Zhang, X.; Lian, C.; Li, J.; Ji, J.; Shan, P.; Lyu, X.; et al. Genetic Algorithms and Machine Learning Enhanced Laser Displacement Sensor Point Cloud Augmentation for Low-Cost, Large-Scale Flatness Measurements. IEEE Sens. J. 2023, 23, 22189. [Google Scholar] [CrossRef]

- Zhou, L.; Zheng, N.; Li, J.; Yuan, Z.; Wang, J.; Fang, F.; Xu, Q. Splicing Measurement and Compensation of Straightness Errors for Ultra-Precision Guideways. Micromachines 2023, 14, 1670. [Google Scholar] [CrossRef]

- Miko, B. Assessment of Flatness Error by Regression Analysis. Measurement 2022, 188, 110542. [Google Scholar] [CrossRef]

- Yang, D.; Zou, J. Precision Analysis of Flatness Measurement Using Laser Tracker. Sensors 2023, 23, 7890. [Google Scholar] [CrossRef]

- Dichev, D.; Diakov, D.; Zhelezarov, I.; Valkov, S.; Ormanova, M.; Dicheva, R.; Kupriyanov, O. A Method for Correction of Dynamic Errors When Measuring Flat Surfaces. Sensors 2024, 24, 5154. [Google Scholar] [CrossRef]

- Mathews, R.; No, T.; Honeycutt, A.; Tyler, C.; Smith, S. Rapid Commissioning of Large Machine Tools Using Finite Element-Based Correction of Geometric Errors. Precis. Eng. 2024, 78, 101–112. [Google Scholar] [CrossRef]

- Su, H.; Ye, R.; Cheng, F.; Cui, C.; Yu, Q. A Straightness Error Compensation System for Topography Measurement Based on Thin Film Interferometry. Photonics 2021, 8, 149. [Google Scholar] [CrossRef]

- Lai, T.; Liu, J.; Chen, F.; Li, Z.; Guan, C.; Xu, C.; Hu, H.; Dai, Y.; Chen, S.; Dai, Z. Allocation of Geometrical Errors for Developing Precision Measurement Machine. J. Manuf. Mater. Process. 2024, 8, 124. [Google Scholar] [CrossRef]

- Kiyono, S.; Gao, W. Profile Measurement of Machined Surface with a New Differential Method. Precis. Eng. 1994, 16, 212–218. [Google Scholar] [CrossRef]

- Chai, N.; Yin, Z.; Yao, J. High Accuracy Profile Measurement with a New Virtual Multi-Probe Scanning System. IEEE Access 2020, 8, 158727–158734. [Google Scholar] [CrossRef]

- Gao, W.; Yokoyama, J.; Kojima, H.; Kim, S.-W. Precision Measurement of Cylinder Straightness Using a Scanning Multi-Probe System. Int. J. Mach. Tools Manuf. 2007, 47, 1053–1058. [Google Scholar] [CrossRef]

- Li, F.; Li, H.; Kim, M.-K.; Lo, K.-C. Laser Scanning Based Surface Flatness Measurement Using Flat Mirrors for Enhancing Scan Coverage Range. Remote Sens. 2021, 13, 714. [Google Scholar] [CrossRef]

- Xiao, S.; Wu, J.; Lai, N.; Lin, R.; Qiao, M.; Wang, Z.; Luo, W.; Fu, Y.; Liang, P.; Zhou, P.; et al. Research on Flatness Measurement of Large-Size Parts Based on 3-D Machine Vision. IEEE Trans. Instrum. Meas. 2023, 72, 3514812. [Google Scholar] [CrossRef]

- Elmelegy, A.; Zahwi, S. Comparative Study of Error Determination of Machine Tools. Int. J. Adv. Manuf. Technol. 2023, 127, 4329–4341. [Google Scholar] [CrossRef]

- Hwang, J.; Park, C.-H.; Gao, W.; Kim, S.-W. A Three-Probe System for Measuring the Parallelism and Straightness of a Pair of Rails for Ultra-Precision Guideways. Int. J. Mach. Tools Manuf. 2007, 47, 1053–1058. [Google Scholar] [CrossRef]

- Stauffenberg, J.; Ortlepp, I.; Belkner, J.; Dontsov, D.; Langlotz, E.; Hesse, S.; Rangelow, I.; Manske, E. Measurement Precision of a Planar Nanopositioning Machine with a Range of Motion of Ø100 mm. Appl. Sci. 2022, 12, 7843. [Google Scholar] [CrossRef]

- Yang, P.; Takamura, T.; Takahashi, S.; Takamasu, K.; Sato, O.; Osawa, S.; Takatsuji, T. Development of high-precision micro-coordinate measuring machine: Multi-probe measurement system for measuring yaw and straightness motion error of XY linear stage. Precis. Eng. 2011, 35, 424–430. [Google Scholar] [CrossRef]

- Manske, E.; Fröhlich, T.; Füßl, R.; Ortlepp, I.; Mastylo, R.; Blumröder, U.; Dontsov, D.; Kühnel, M.; Köchert, P. Progress of nanopositioning and nanomeasuring machines for cross-scale measurement with subnanometre precision. Meas. Sci. Technol. 2020, 31, 085005. [Google Scholar] [CrossRef]

- ISO 230-1:2012; Test Code for Machine Tools—Part 1: Geometric Accuracy of Machines Operating Under no-Load or Quasi-Static Conditions. ISO: Geneva, Switzerland, 2012.

- ISO 230-2:2014; Test Code for Machine Tools—Part 2: Determination of Accuracy and Repeatability of Positioning of Numerically Controlled Axes. ISO: Geneva, Switzerland, 2014.

- GB/T 20428-2006; Granite Surface Plates. China Machinery Industry Federation: Beijing, China, 2006. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=371394233DD71C7948B402F26D38D001 (accessed on 7 September 2025).

- GB/T 11337-2004; Measurement of Departures from Flatness. China Machinery Industry Federation: Beijing, China, 2004. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=3EB9458F0BBAC9DE0C78CD60776E1D3F (accessed on 7 September 2025).

- ISO 12781-2:2011; Geometrical Product Specifications (GPS)—Flatness, Part 2: Specification Operators. ISO: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/53625.html (accessed on 7 September 2025).

- ISO 10360-5:2020; Geometrical Product Specifications (GPS)—Acceptance and Reverification Tests for Coordinate Measuring Systems (CMS), Part 5: Coordinate Measuring Machines (CMMs) Using Single and Multiple Stylus Contacting Probing Systems Using Discrete Point and/or Scanning Measuring Mode. ISO: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/73431.html (accessed on 7 September 2025).

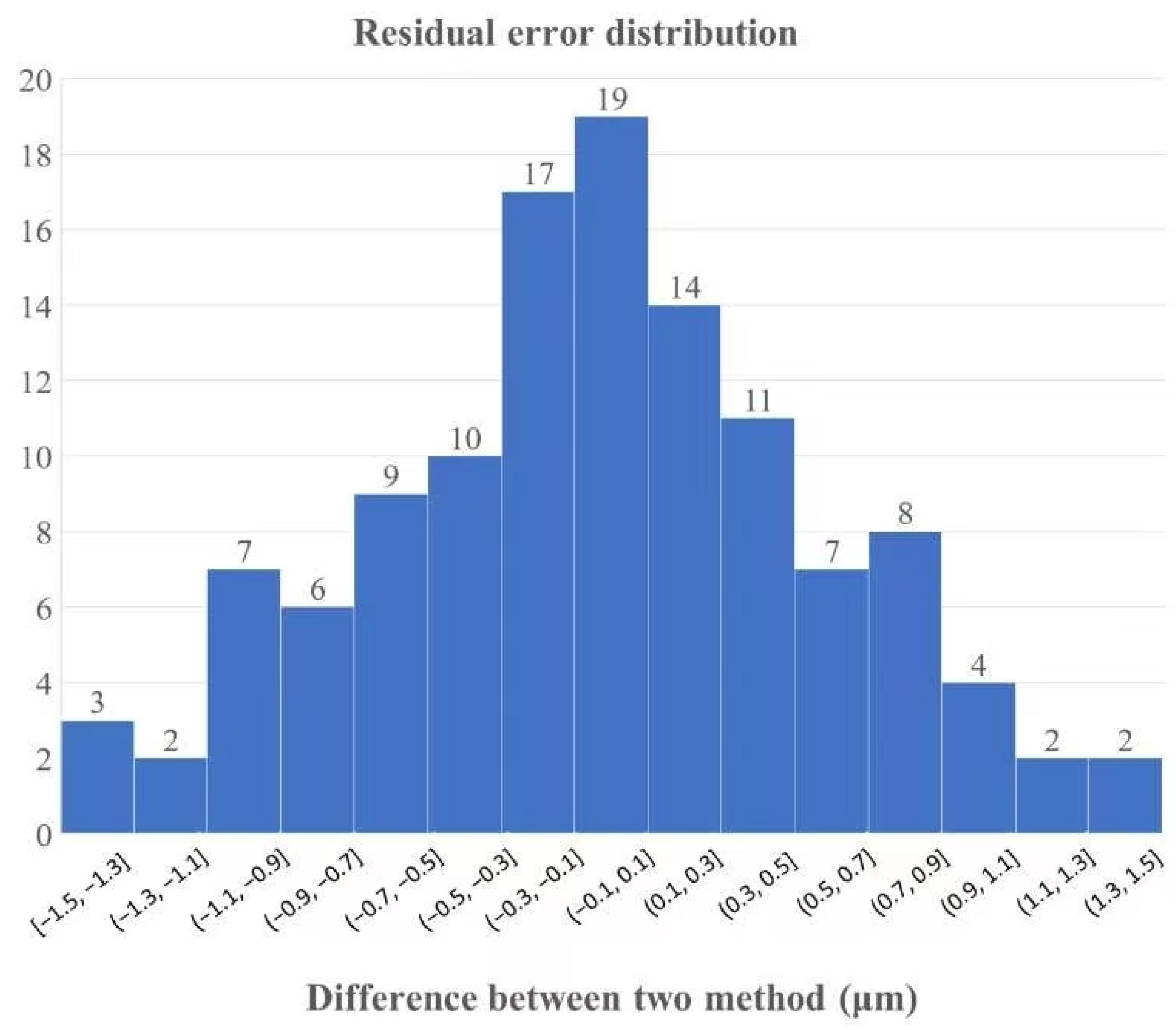

| Maximum Positive Error | Maximum Negative Error | Average Error | Standard Deviation | P-V Error |

|---|---|---|---|---|

| 1.39 µm | −1.44 µm | −0.07537 µm | 0.7170 | 2.83 µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Chen, J.; Peng, Z.; Ye, H.; Huang, Y.; Liu, X. Nine-Probe Third-Order Matrix System for Precise Flatness Error Detection. Machines 2025, 13, 856. https://doi.org/10.3390/machines13090856

Liu H, Chen J, Peng Z, Ye H, Huang Y, Liu X. Nine-Probe Third-Order Matrix System for Precise Flatness Error Detection. Machines. 2025; 13(9):856. https://doi.org/10.3390/machines13090856

Chicago/Turabian StyleLiu, Hua, Jihong Chen, Zexin Peng, Han Ye, Yubin Huang, and Xinyu Liu. 2025. "Nine-Probe Third-Order Matrix System for Precise Flatness Error Detection" Machines 13, no. 9: 856. https://doi.org/10.3390/machines13090856

APA StyleLiu, H., Chen, J., Peng, Z., Ye, H., Huang, Y., & Liu, X. (2025). Nine-Probe Third-Order Matrix System for Precise Flatness Error Detection. Machines, 13(9), 856. https://doi.org/10.3390/machines13090856