Pareto Front Optimization for Spiral-Grooved High-Speed Thrust Bearings: Comparison Between Analytical and Numerical Models †

Abstract

1. Introduction

2. Materials and Methods

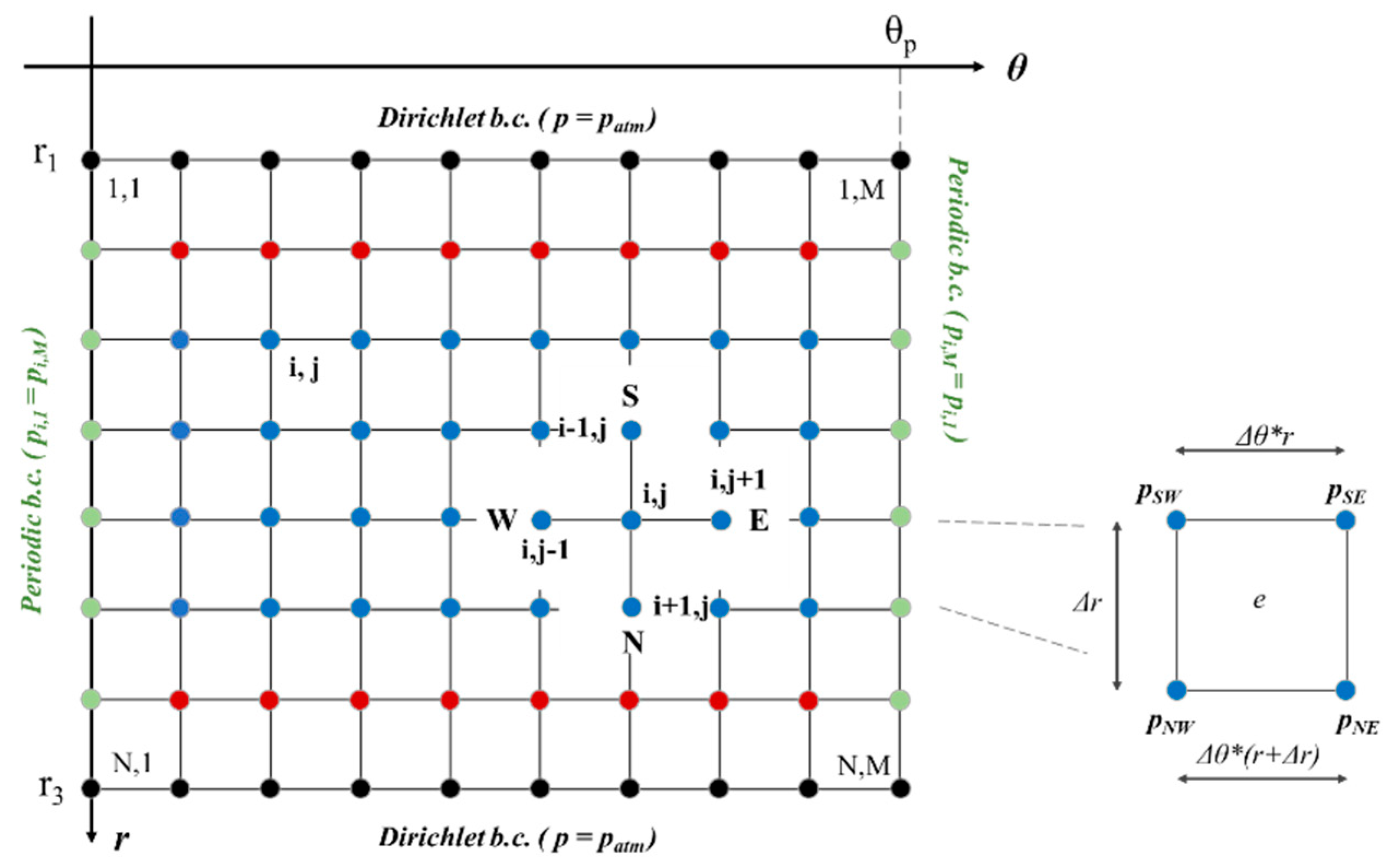

2.1. Finite Difference Model

2.2. Analytical Model

2.3. Optimization Algorithm

3. Results

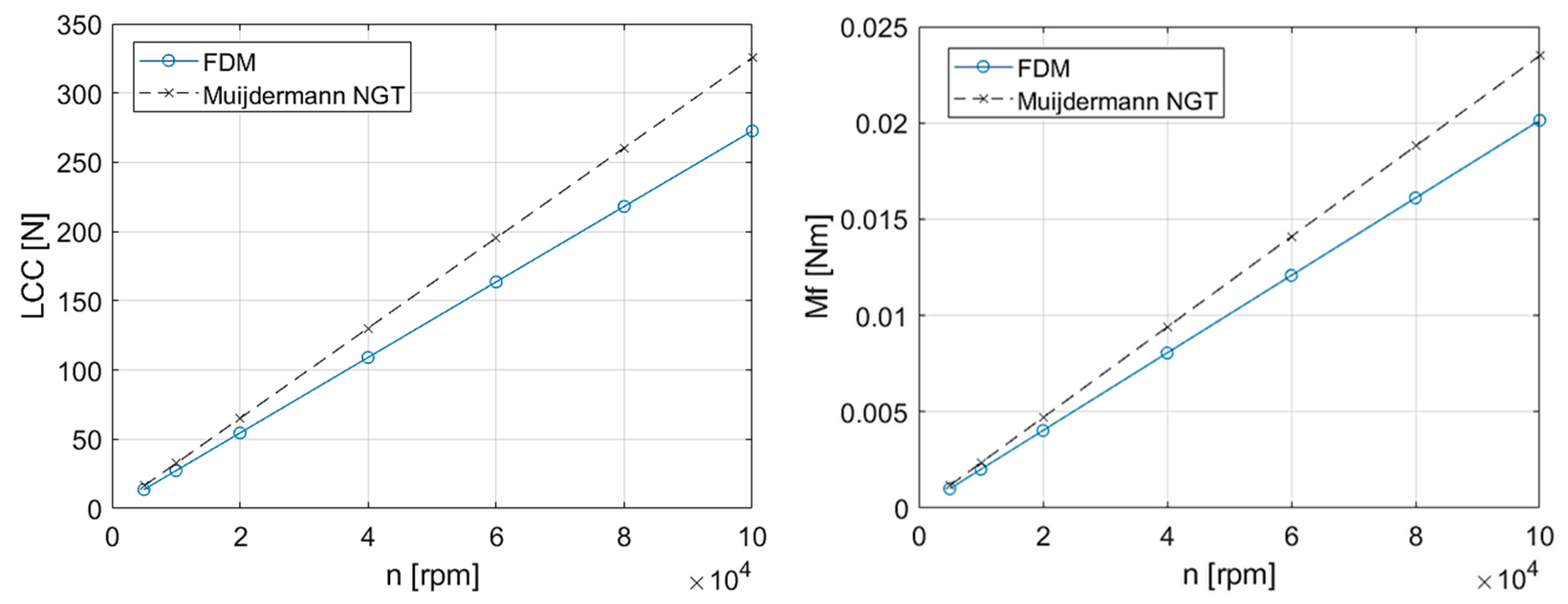

3.1. Validation of the FD Model

3.2. Convergence Analysis

3.3. Comparison of Numerical vs. Analytical

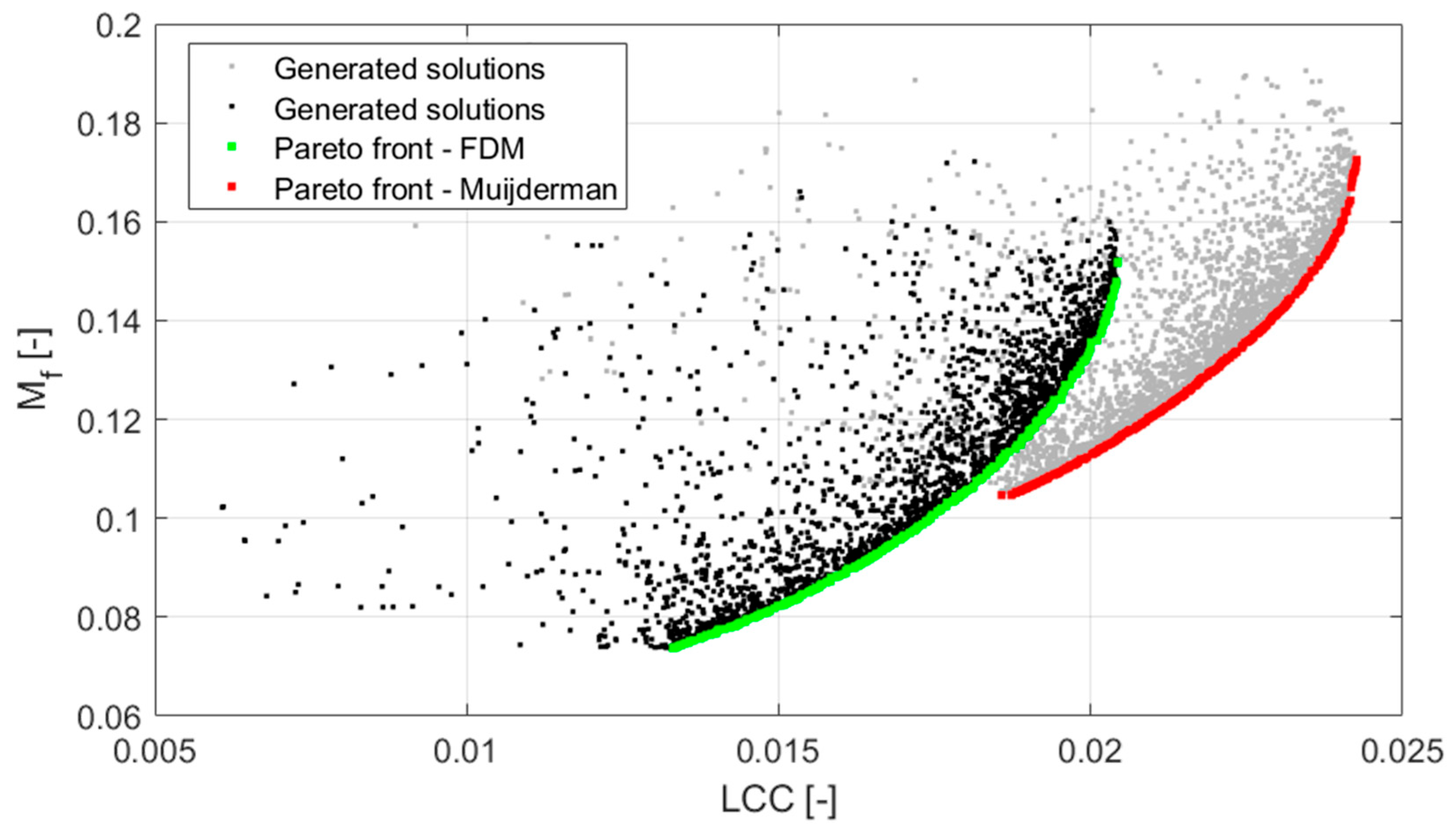

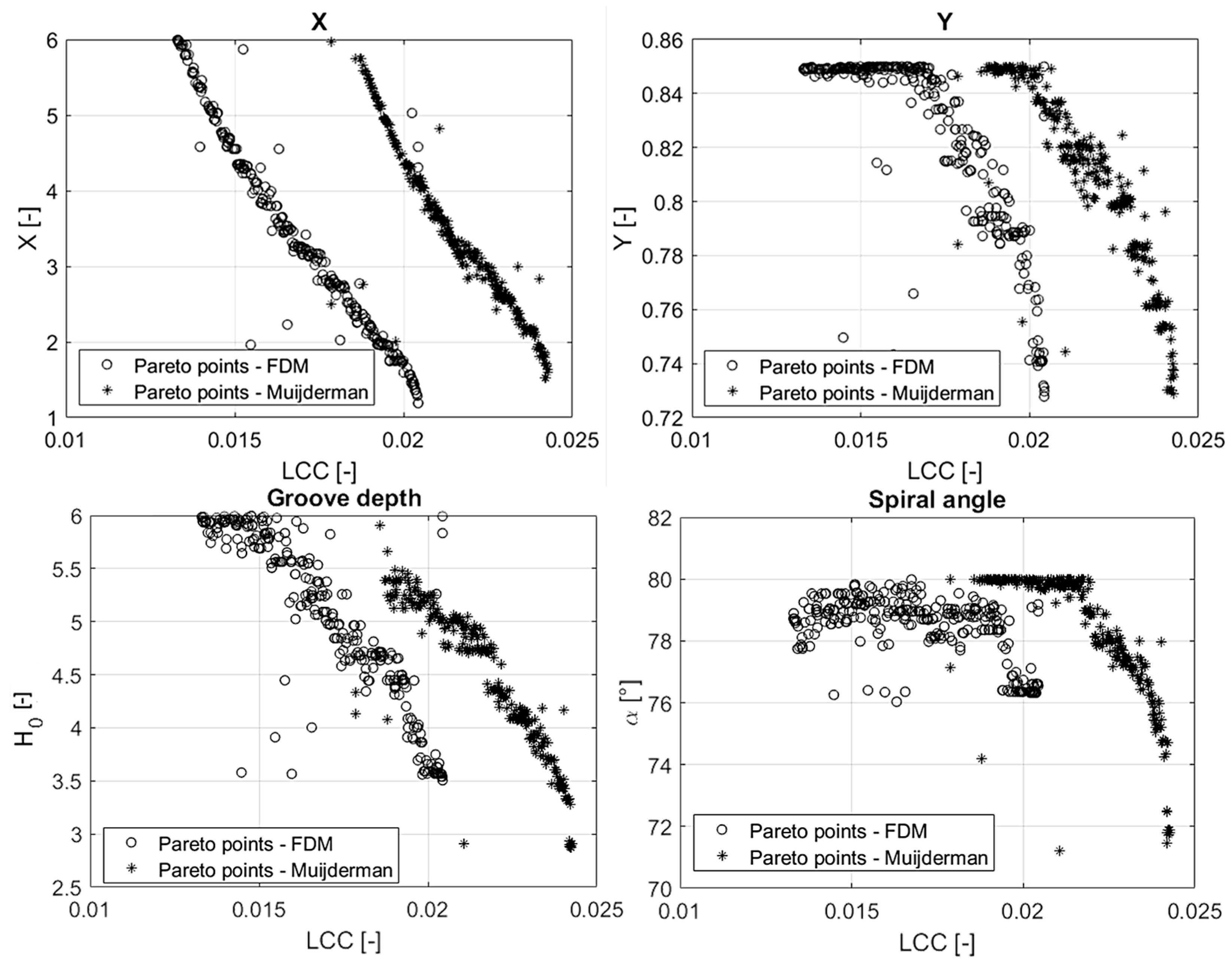

3.4. Multi-Objective Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| NGT | Narrow groove theory |

| SGTB | Spiral-grooved thrust bearing |

| LCC | Load-carrying capacity |

Symbols

| [m] | Circumferential length of a groove at radius r | |

| [m] | Circumferential length of a ridge at radius r | |

| [m] | Air gap height | |

| [m] | Groove depth | |

| [m] | Air Gap height reference parameter | |

| [m] | Air gap height in the grooved region | |

| [m] | Air gap height in the ungrooved region | |

| [-] | Dimensionless air gap | |

| [-] | Dimensionless grooved depth | |

| [-] | Dimensionless air gap height within the grooves | |

| [-] | Number of grooves | |

| [N] | Reference load capacity | |

| [N] | Bearing load capacity | |

| [N] | Load capacity of the analytical model by Muijderman | |

| [-] | Dimensionless load capacity | |

| [-] | Number of nodes along the radial direction | |

| [-] | Number of nodes along the circumferential direction | |

| [N] | Friction torque of the analytical model by Muijderman | |

| [N] | Friction torque of the grooved region | |

| [N] | Friction torque of the ungrooved region | |

| [Nm] | Bearing friction torque | |

| [Nm] | Reference friction torque | |

| [-] | Dimensionless friction torque | |

| [Nm] | Reference friction torque | |

| [Pa] | Reference pressure parameter | |

| [-] | Dimensionless pressure | |

| [m] | Radial coordinate | |

| [m] | Radial coordinate reference parameter | |

| [m] | Inner radius of the thrust bearing | |

| [m] | Radius at the interface between grooved and ungrooved bearing surface | |

| [m] | Outer radius of the bearing | |

| [-] | Groove-to-ridge ratio | |

| [-] | Grooved-to-ungrooved ratio in the radial direction of the bearing | |

| [N] | Load capacity of the grooved region | |

| [N] | Load capacity of the ungrooved region | |

| α | [rad] | Spiral angle |

| [m2] | Area of the e-th element of the grid | |

| [rad] | Grid spacing along the circumferential direction | |

| [m] | Grid spacing along the radial direction | |

| [rad] | Angular coordinate | |

| [rad] | Periodicity angle | |

| [Pa s] | Fluid dynamic viscosity | |

| [kg/m3] | Fluid density | |

| [Pa] | Shear stress acting on the moving thrust surface | |

| [rad/s] | Angular speed |

References

- Schiffmann, J.; Favrat, D. Integrated design and optimization of gas bearing supported rotors. J. Mech. Des. 2010, 132, 051007. [Google Scholar] [CrossRef]

- Schiffmann, J. Integrated Design and Multi-Objective Optimization of a Single Stage Heat-Pump Turbocompressor. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013; Volume 55898, p. V03BT03A031. [Google Scholar]

- Schiffmann, J. Integrated design and multi-objective optimization of a single stage heat-pump turbocompressor. J. Turbomach. 2015, 137, 071002. [Google Scholar] [CrossRef]

- Wagner, P.H.; Wuillemin, Z.; Diethelm, S.; Schiffmann, J. Modeling and designing of a radial anode off-gas recirculation fan for solid oxide fuel cell systems. J. Electrochem. Energy Convers. Storage 2017, 14, 011005. [Google Scholar] [CrossRef]

- Whipple, R.T. Theory of the Spiral Grooved Thrust Bearing with Liquid or Gas Lubricant; Great Britain Atomic Energy Research Establishment: Harwell, UK, 1951. [Google Scholar]

- Muijderman, E.A. Spiral Groove Bearings; Springer: Berlin/Heidelberg, Germany, 1966. [Google Scholar]

- On the Spiral Grooved, Self Acting, Gas Bearing. Available online: https://apps.dtic.mil/sti/citations/AD0433660 (accessed on 11 March 2024).

- Vohr, J.H.; Chow, C.Y. Characteristics of Herringbone-Grooved, Gas-Lubricated Journal Bearings. J. Basic Eng. 1965, 87, 568–576. [Google Scholar] [CrossRef]

- Huang, X.; Xu, G.; Jiang, S. Static characteristics of water-lubricated hydrodynamic spiral-groove journal and thrust bearings for motorized spindle. J. Tribol. 2023, 145, 124501. [Google Scholar] [CrossRef]

- Waumans, T.; Mattheijssens, J.; Meuws, D.; Vleugels, P.; Peirs, J.; Al-Bender, F.; Reynaerts, D. Design and testing of aerodynamic thrust bearings for micro turbomachinery applications. In Proceedings of the 7th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications, Freiburg, Germany, 27–29 November 2007; pp. 257–260. [Google Scholar]

- Hashimoto, H.; Ochiai, M. Theoretical analysis and optimum design of high speed gas film thrust bearings (static and dynamic characteristic analysis with experimental verifications). J. Adv. Mech. Des. Syst. Manuf. 2007, 1, 102–112. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, G.; Bi, C. Air Bearing Spindle Motor for Hard Disk Drives. Tribol. Trans. 2005, 48, 468–473. [Google Scholar] [CrossRef]

- Hashimoto, H.; Namba, T. Optimization of groove geometry for a thrust air bearing according to various objective functions. J. Tribol. 2009, 131, 041704. [Google Scholar] [CrossRef]

- Hashimoto, H.; Ochiai, M. Optimization of groove geometry for thrust air bearing to maximize bearing stiffness. J. Tribol. 2008, 130, 031101. [Google Scholar] [CrossRef]

- Fesanghary, M.; Khonsari, M.M. On the optimum groove shapes for load-carrying capacity enhancement in parallel flat surface bearings: Theory and experiment. Tribol. Int. 2013, 67, 254–262. [Google Scholar] [CrossRef]

- Yu, Y.; Pu, G.; Jiang, T.; Jiang, K. A dragonfly wing inspired biomimetic aerodynamic thrust bearing for increased load capacity. Int. J. Mech. Sci. 2020, 176, 105550. [Google Scholar] [CrossRef]

- Muijderman, E.A. Spiral groove bearings. Ind. Lubr. Tribol. 1965, 17, 12–17. [Google Scholar] [CrossRef]

- Gu, L.; Guenat, E.; Schiffmann, J. A review of grooved dynamic gas bearings. Appl. Mech. Rev. 2020, 72, 010802. [Google Scholar] [CrossRef]

- Colombo, F.; Goti, E.; Lentini, L.; Raparelli, T. Investigation on the Static Characteristics of a Dynamic Gas Thrust Bearing with Spiral Grooves for a Small-Scale High-Speed Application. In Proceedings of the ITS-IFToMM 2024, Salerno, Italy, 6–8 May 2024; Ciulli, E., Ruggiero, A., Eds.; Mechanisms and Machine Science. Springer Nature: Cham, Switzerland, 2024; Volume 160, pp. 180–190. [Google Scholar] [CrossRef]

- Colombo, F.; Goti, E.; Lentini, L. Spiral Groove Thrust Bearing Modeling with Finite Difference Method. In Advances in Italian Mechanism Science; Quaglia, G., Boschetti, G., Carbone, G., Eds.; Mechanisms and Machine Science; Springer Nature: Cham, Switzerland, 2024; Volume 163, pp. 498–507. ISBN 978-3-031-64552-5. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, S.; Lin, X. Static and dynamic characteristics of high-speed water-lubricated spiral-groove thrust bearing considering cavitating and centrifugal effects. Tribol. Int. 2020, 145, 106159. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| 0.498 | |

| 16.45 mm | |

| 33 mm | |

| K | 12 |

| ω | 70 krpm |

| To be optimized | |

| To be optimized | |

| To be optimized | |

| α | To be optimized |

| Parameter | Value |

|---|---|

| 0.5 to 0.85 | |

| 1 to 6 | |

| 2.5 to 7 | |

| α | 60° to 80° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colombo, F.; Goti, E.; Lentini, L. Pareto Front Optimization for Spiral-Grooved High-Speed Thrust Bearings: Comparison Between Analytical and Numerical Models. Machines 2025, 13, 832. https://doi.org/10.3390/machines13090832

Colombo F, Goti E, Lentini L. Pareto Front Optimization for Spiral-Grooved High-Speed Thrust Bearings: Comparison Between Analytical and Numerical Models. Machines. 2025; 13(9):832. https://doi.org/10.3390/machines13090832

Chicago/Turabian StyleColombo, Federico, Edoardo Goti, and Luigi Lentini. 2025. "Pareto Front Optimization for Spiral-Grooved High-Speed Thrust Bearings: Comparison Between Analytical and Numerical Models" Machines 13, no. 9: 832. https://doi.org/10.3390/machines13090832

APA StyleColombo, F., Goti, E., & Lentini, L. (2025). Pareto Front Optimization for Spiral-Grooved High-Speed Thrust Bearings: Comparison Between Analytical and Numerical Models. Machines, 13(9), 832. https://doi.org/10.3390/machines13090832