1. Introduction

Laser Powder Bed Fusion (LPBF) is an advanced metal additive manufacturing (MAM) technology that has been adopted in various technological sectors and industries due to its versatility and precision in the manufacturing of components with arbitrarily intricate shapes. The main advantages of LPBF lie in its ability to fabricate near fully dense metal components with excellent mechanical properties when utilizing optimized process parameters, as well as to create lightweight, topology-optimized structures with minimal material waste, enabling a high degree of design freedom, rapid prototyping and cost advantages compared to traditional manufacturing methods [

1,

2,

3,

4]. This leading manufacturing process has gained great interest and is widely employed in industries where geometrical complexity and customizability are critical requirements, namely aerospace [

5,

6], automotive [

7,

8], and biomedical engineering [

9].

However, LPBF is inherently complex and sensitive to a variety of process, material, and environmental parameters that subsequently influence melt pool dynamics and final part quality. This often results in defect formation such as porosity, lack of fusion, balling, cracks, and part distortions. Therefore, recent research efforts have focused on adjusting these process parameters based on data derived from process monitoring. At the same time, the relationship between process parameters and process signatures, such as melt pool size and temperature, is further investigated and exploited to serve as valid indicators of the process state.

Numerous methodological approaches have been proposed in the literature for optimizing the LPBF process, addressing both monitoring and control areas. In terms of monitoring, single-sensor and multi-sensor systems have been developed to reliably and efficiently capture critical process signatures. In terms of control, different strategies have been studied, integrating open-loop and closed-loop frameworks. Moreover, the previous literature reviews [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] on in situ monitoring and control in LPBF have contributed to establishing a knowledge base. However, the current literature tends to focus on single-sensor monitoring applications, such as melt pool imaging, thermal cameras, or photodiode [

10,

11,

12,

13,

15,

19], while multi-sensor and sensor fusion approaches remain limited [

12,

14,

20]. Similarly, although several studies address control in LPBF, their scope and depth remain limited, often presented as complementary to the extensive literature on monitoring, while [

11,

18] provide a more control-focused perspective. Thus, a notable gap has been identified in the systematic review of the advances in multi-sensor fusion approaches and the detailed analysis of the current progress in control techniques. The benefit of using multiple sensors in general, is also backed by the fact that as per Andler et al. [

21], fusing information from multimodal data sources can provide insights that would be unattainable from the individual sources. This review aims to address the gap in multi-sensor fusion monitoring in LPBF, which arises as a more holistic and precise approach to defect detection, and gather the state-of-the-art in process control methods as well. Hence, an integrated perspective that provides a comprehensive overview of the current advanced techniques in LPBF process monitoring and control is presented, emphasizing the respective advantages, implementation challenges, and impact on process quality. The objective is to identify emerging trends and possible research limitations and gaps in the current state-of-the-art, and subsequently, to suggest possible future directions. Consequently, detailed descriptions regarding the various methodologies are not provided in the paper and any interested reader is referred to the original source paper for in-depth explanations.

This review is structured to provide a clear and comprehensive overview of recent advancements in LPBF monitoring and control.

Section 2 presents the fundamentals of the LPBF process, describing the working principle, explaining the relevant technical aspects of the process and highlighting the key process parameters, signatures, and quality metrics.

Section 3 outlines the research methodology followed for the investigation, selection, and classification of the relevant publications available, specifying the keywords and main criteria for the publications’ inclusion.

Section 4 analyzes the research findings on the state-of-the-art in multi-sensor integration and data fusion strategies in LPBF monitoring. Subsequently,

Section 5 reviews current advancements in LPBF control, categorizing the findings into physics-informed, Machine Learning (ML)-assisted, and hybrid approaches. Finally,

Section 6 provides a conclusions overview, while identifying key research challenges and outlining future work in the development of efficient and robust methodologies in LPBF monitoring and control. A list of the abbreviations used throughout the paper has been compiled and can be found before the list of references, for the reader’s convenience.

2. LPBF Process Fundamentals

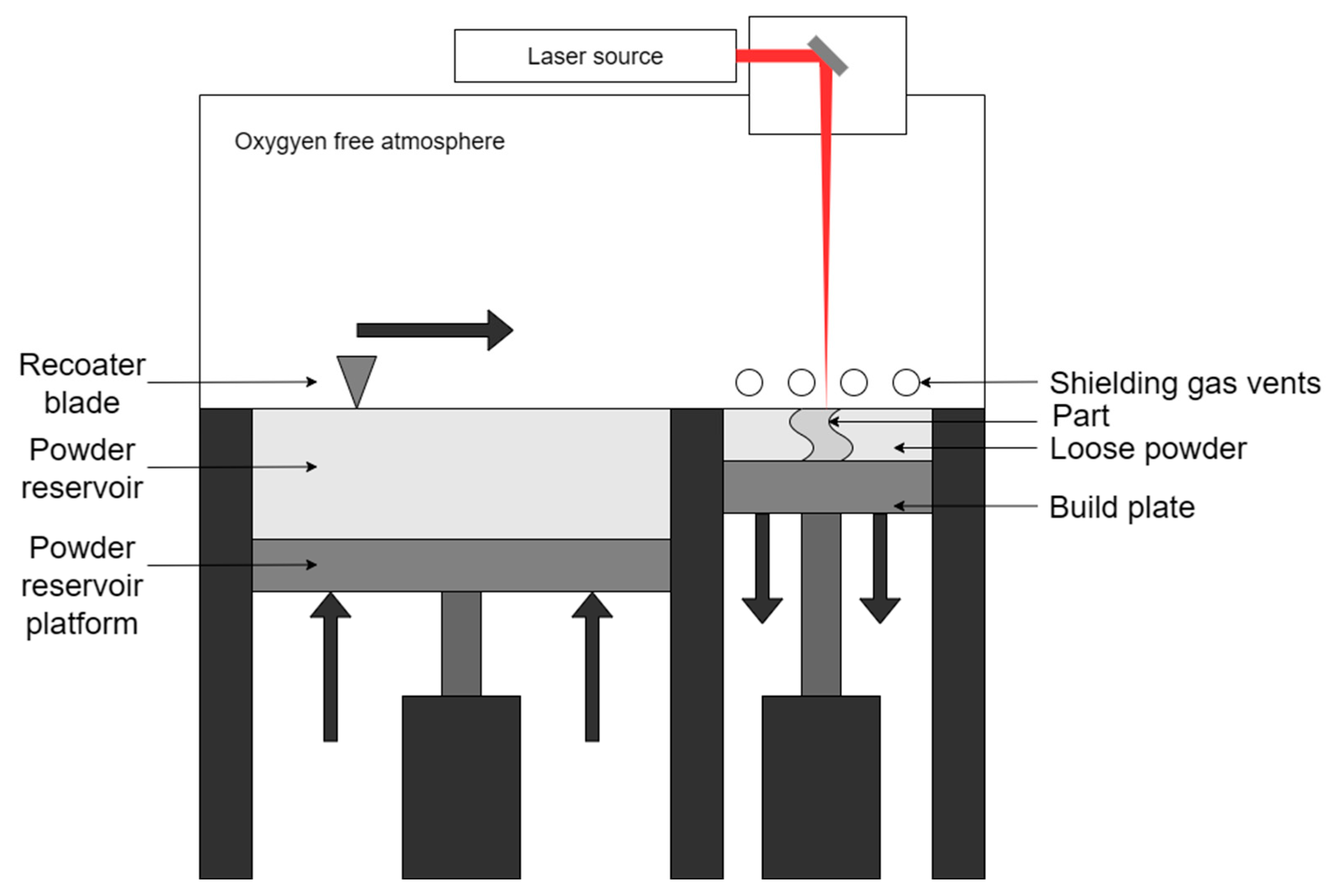

LPBF builds parts directly from digital models, by selectively melting powder layer by layer (

Figure 1) [

12,

13,

14,

15,

18,

19].

The parameters of the LPBF process can be categorized into three types. Firstly, process-related parameters include the layer height, hatch spacing (defined as the distance between the centerlines of adjacent laser scan tracks), laser power, laser speed, laser spot size, laser focusing depth, absorptivity (dependent on the powder’s characteristics and laser wavelength), laser power distribution within the beam, and powder spreading parameters [

22,

23,

24]. In addition, a derived parameter, namely volumetric energy density, is calculated from the aforementioned inputs. Secondly, material-related parameters include the powder material, its particle shape and size distribution, which as per Sun et al. play a crucial role in absorptivity, with good sphericity leading to the highest absorptivity for their test case [

25]. Finally, environmental variables include the oxygen content in the build chamber, and the type and flow rate of the shielding gas over the build area.

Moreover, during the process, various physical phenomena occur as the laser deposits energy into the powder and generates a moving melt pool. This produces emissions [

13] that are either optical, such as light within the visible spectrum from the formation of the melt pool and part, as well as infrared (IR) from the reflection of the laser source and thermal radiation from the heated part and melt pool, or acoustic, also generated from the absorption of the laser into the powder. More specifically, the melt pool can be characterized by its dimensions and temperature, while other macroscopic signatures of the process include the plume of the melt pool, the heat accumulation around it due to the energy deposited in the part by the laser, and powder spatter. As a result of the unpredictable nature of the process and the steep temperature gradients involved, a number of possible defects [

11] may occur. These include general dimensional errors due to warping, surface defects, cracking, porosity, or undesirable material properties related to microstructure and residual stresses. In terms of quality classification, the majority of publications use porosity as the primary quality descriptor when assessing the effectiveness of process optimization. However, part quality is also defined by dimensional accuracy, load-bearing capability, and surface finish where applicable.

Figure 2 presents an overview of the main LPBF process parameters and process signatures, along with quality metrics [

26] of the final part, which are used to define process performance.

3. Research Methodology

The presented study comprises a review of the recent progress in the field of LPBF advanced monitoring and optimization, focusing on data fusion techniques and feedback control methodologies. Specifically, papers published between 2020 and the end of May 2025–corresponding to the period during which this review was conducted–were systematically searched, collected, and classified to provide a concise and representative overview of the current state-of-the-art in multi-sensor fusion monitoring and control methods for the LPBF process.

To identify the relevant literature for this review, first a search was conducted using Google Scholar:

https://scholar.google.com/ (last accessed on 30 May 2025) utilizing different combinations of specific keywords, including “Selective laser melting” (SLM), “Laser powder bed fusion”, “Multi-sensor fusion”, “In Situ Monitoring”, “Process Monitoring”, “Defect Detection”, “Quality Control”, “Process control”, “Closed-loop control”, “Open-loop control”, “Feedback control” and “Feedback loop”. In addition, the AI-assisted tool Elicit:

https://elicit.org (last accessed on 30 May 2025) was employed to detect related publications applying research questions incorporating the aforementioned keywords. Indicative questions formed and applied to Elicit research assistant are the following:

What are the current advancements in LPBF process monitoring?

What is the state-of-the-art in defect detection for SLM?

What are the state-of-the-art techniques for in situ monitoring in LPBF?

What multi-sensor fusion methods are used for quality control in SLM?

What control strategies have been studied for improving LPBF-ed part quality?

What are the current advancements in LPBF open-loop and close-loop control?

Elicit was used to identify publications from the last five years that address multi-sensor monitoring and control in the LPBF process. Then, the resulting publications were manually reviewed and evaluated for inclusion and further analysis, based on relevance and quality. For both Google Scholar and Elicit searches, non-English publications were excluded, while the main inclusion criteria, based on screening of titles and abstracts were as follows:

The paper addresses the LPBF/SLM process.

The paper presents a method or overview involving multi-sensor monitoring and/or process control.

The paper was published from 2020 onwards.

The research procedure mentioned above resulted in a final list of 62 relevant publications from 2020 to 2025, of which 28 address multi-sensor monitoring of LPBF process, 30 study process control, while 4 examine both topics.

Figure 3 presents an overview graph of the listed publications from 2020 to 2025.

As can be observed, the last five years have shown a steady increase in academic interest for the development of robust monitoring and control methodologies for the LPBF process. Notably, the number of relevant publications in 2024 nearly quadrupled compared to 2020. Moreover, by the middle of 2025, seven articles have already been published on these topics, reflecting sustained interest in this research area.

4. Sensor Fusion-Based Approaches in LPBF Monitoring

In this section, the literature is examined in depth. First, review papers on the topic are surveyed to frame the field’s broad challenges, particularly why single sensor approaches are inadequate for LPBF’s rapid, multiphysics dynamics. Second, research articles are analyzed to demonstrate how successive studies expand sensing suites and ML pipelines, each incrementally improving defect detection accuracy. Finally, dominant sensor choices and fusion strategies are quantified, revealing the remaining obstacles and providing practical takeaways and directions for future research.

Process monitoring is a very important approach for evaluating the process state during execution and, generally, it is common practice in manufacturing. Typically, it involves the collection of measurements/data, which are subsequently processed and compared to reference and/or benchmark values so as to conclude whether the process operates as expected or some rectifying action has to be applied. However, it remains an emerging technology in the context of LPBF, primarily due to the multitude of challenges associated with the process’s fast and complex physical dynamics. To this end, there have been many attempts to innovate in this space, with multiple configurations and signal processing methods being developed, ultimately concluding that multi-sensor fusion is required to capture the LPBF process in sufficient detail. This section summarizes the findings of recent review studies, whereas individual articles that have contributed to the state-of-the-art are examined in

Section 4.1 and

Section 4.2, focusing on part quality monitoring and process monitoring, respectively.

Peng et al. [

15] review and categorize the detection methods used to monitor the LPBF process, detailing the signal types they capture and the defects they reveal. They stress the challenge of handling the vast data streams in real time, both to keep pace with LPBF’s rapid dynamics and to enable real-time process adjustment and control, and they advocate multi-sensor fusion to improve defect-detection accuracy. This, they note, drives yet larger data volumes and reflects the industry’s shift from single to multi-sensor setups.

Zhang et al. [

27] also expand on the problems arising from the need to process data in real time, but in the context of feedback control and ML applications. The review goes over the process of applying ML to LPBF and shows that historically, defect detection techniques focus on single defect types, potentially missing additional important part information and providing inadequate data for process monitoring and automation.

Fan et al. [

28] provide an in-depth overview of the state of general AM monitoring and autonomous techniques as well as production planning. They identify a gap in integrated process control–owing to the fragmented use of ML in the production pipeline and the lack of a higher-level controller–and propose a multi-layer system framework to oversee the process using multi-sensor fusion for streamlined operation.

Chen et al. [

12] also emphasize the need for multi-sensor fusion but focus on LPBF and Laser-Directed Energy Deposition (LDED) instead. They analyze sensors by cost, sensitivity, noise rejection, and ease of installation. Acoustic sensors, which are discussed in detail, excel in defect detection and low cost but lack noise rejection. The review finally points out the lack of standardization of current monitoring techniques and calls for the implementation of new multi-sensor monitoring systems, with capabilities beyond simply stopping the process upon fault detection.

Similarly, Kong et al. [

14] suggest that there is a lack of a generalized fusion model and unified theory, owing to practical problems in the current data fusion designs. Their review describes multi-sensor measurement and data fusion technology and its applications in precision monitoring of different manufacturing systems, as well as summarizes different levels of data fusion, including data-layer fusion, feature-layer fusion, and decision-level fusion.

Zu et al. [

17] provide a comprehensive review of the signal types emitted during Laser Additive Manufacturing (LAM) processes and their relation to specific defects, then catalog process monitoring and feedback control algorithms, as well as their applications. They give special focus to online high speed X-ray imaging for its ability to provide insights into mechanisms such as defect evolution, spatter impact, and pore dynamics. Their review, like others, also emphasizes the need for integrating multiple sensor and signal types in online monitoring, since relying on a single sensor type is inherently limited in its ability to detect the full range of possible defects that can occur during the LPBF process.

4.1. Part Quality Monitoring

To begin, Gaikwad et al. [

29] use a Sequential Decision-Analysis Neural Network (SeDANN) to fuse pyrometer and camera signals in order to predict part quality, which is defined by a post print height map measurement. The effect of varying common LPBF process parameters is studied for single print tracks, while the neural network is tested against black-box neural networks such as Convolutional Neural Networks (CNN), which are outperformed by it. The type of neural network used is also easily expandable to fuse more sensor inputs, with the authors suggesting the addition of an acoustic sensor, as well as the possibility for the model to be applied to general MAM.

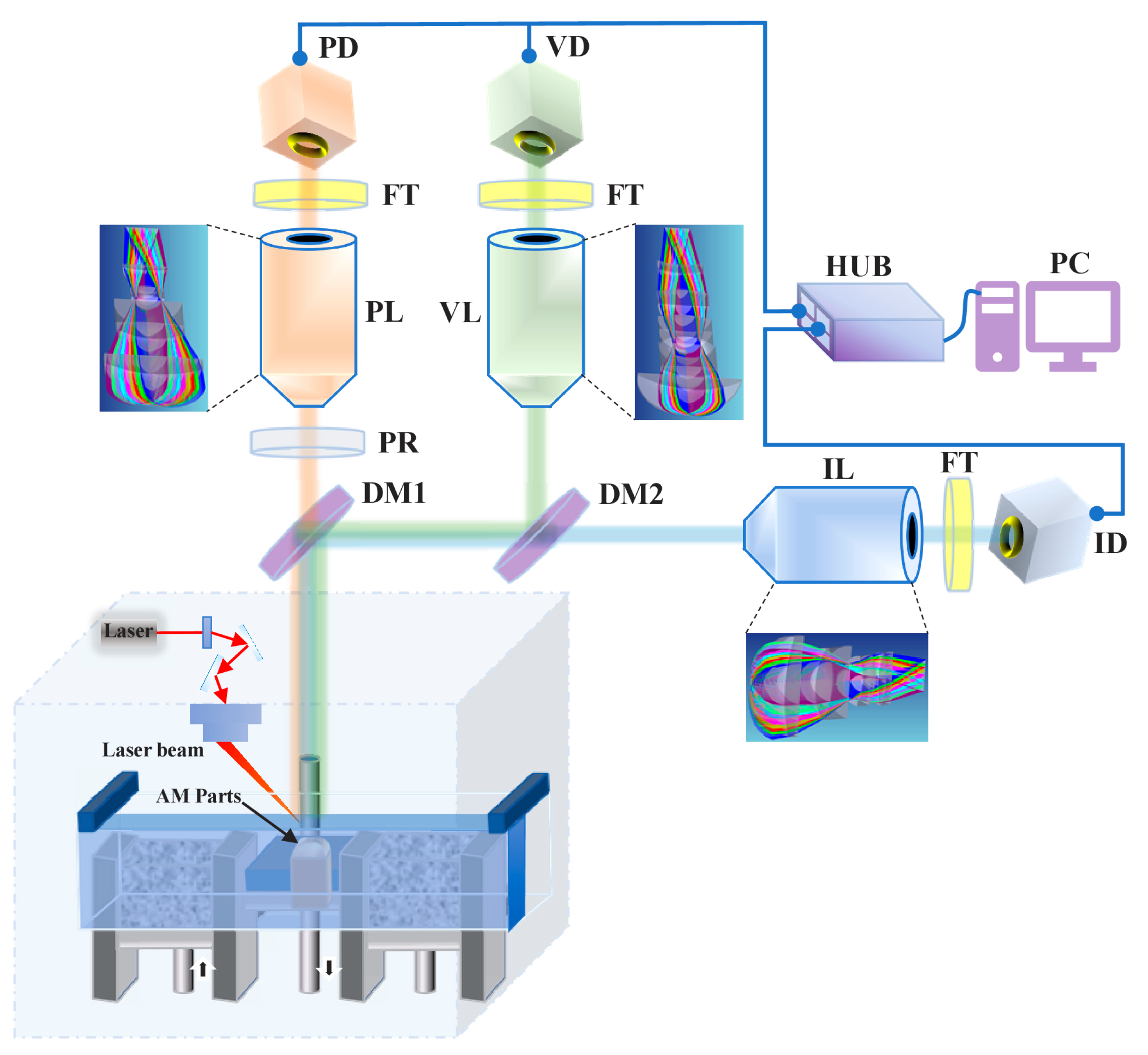

Building on the premise that single-channel data is rarely sufficient, Peng et al. [

30,

31] published two articles concerning the design and development of a multi sensor defect monitoring system shown in

Figure 4. The system uses a fusion of visible light, IR, and a polarization imaging channel in a co-axial configuration, designed and optimized via Monte Carlo analysis, which proves capable of high quality, in situ defect image extraction. The authors reasoned that single sensor monitoring provides insufficient levels of information in order to accurately monitor the LPBF process.

Li et al. [

32] present a model which integrates layer-wise imaging data and acoustic signals using a unified CNN framework to detect defects during printing. Image processing and signal-to-image conversion are used to merge the multi-source heterogeneous sensor data, with the result being higher classification accuracy (92.33% over 63.27%) and earlier fault detection compared to single sensor applications.

Focusing specifically on image data, Peng et al. [

33] propose a multi-sensor image fusion method for defect detection, combining visible and IR imaging. The dual-camera system simultaneously captures visible and IR light intensity, then a multi-sensor image fusion method based on finite discrete shearlet transform (FDST), multi-scale sequential toggle operator (MSSTO), and an improved pulse-coupled neural networks (PCNN) framework is used to fuse information in the visible and IR spectrums to detect defects accurately. This fusion strategy also improves image contrast and information richness, display of image edge contour and texture information, and effectively retains and fuses the main information in the source image, which is of great significance for defect detection and processing parameter optimization in PBF processes.

Moving away from imaging techniques, Li et al. [

34] present an off-axis setup combining a microphone and a photodiode to record process signatures, which are transformed from 1-D signals into 2-D images and fed to a CNN so that features from both modalities are jointly extracted and fused. Using three quality labels derived from density and porosity post-print measurements, the fused representation outperformed all single-sensor and other baseline models by at least 5%, achieving an average classification accuracy of 99.08%.

Leveraging dual-wavelength imaging, Gaikwad et al. [

35] developed a system using two coaxial high-speed (HS) cameras at different IR wavelengths, resulting in the capability to thermally image by comparing the two outputs. Physics-informed features from the melt pool images are extracted and used in neural net training. When tested on builds with deliberately varied laser defocus (yielding a spectrum of porosity and warpage severities verified by X-ray Computed Tomography (CT) and metallography), the fused model outperforms any single-sensor baseline, remaining agnostic to part geometry. It is also concluded that faster, basic ML algorithms–Support Vector Machine (SVM) and Multi-layer Perceptron (MLP)–in combination with the feature extraction, perform equally to black box deep learning using raw data with a CNN.

Recognizing that data imbalance can undermine classifier training, Li et al. [

36] address this issue, which is often a challenge when it comes to in situ defect monitoring for LPBF. They achieve this by pairing acoustic emission (AE) and coaxial photodiode sensors with a deep learning pipeline that first augments minority defect classes via generative oversampling and then fuses the two signal streams for classification. Their fused model exceeds 93% accuracy while running in roughly 0.19 ms per layer, showing that balanced data combined with multi-modal features can deliver real-time, robust quality flags during LPBF builds.

In order to further mitigate class imbalance, Li et al. [

37] employ a Wasserstein Generative Adversarial Network (WGAN). Microphone and photodiode signals are converted to 2D grayscale images, then fused with camera-captured layer-wise images to train the network for classifying part porosity. Experiments are conducted under varying degrees of class imbalance: the network is trained on time-domain, frequency-domain, and augmented (synthetically generated) data. The results show that the method maintains high prediction accuracy despite class imbalance, and the authors identify optimal network architectures and training strategies for different imbalance ratios.

With an emphasis on real-time deployment, Wu et al. [

38] develop a real-time quality-monitoring scheme that streams three complementary melt-pool signals, HS visible video, coaxial photodiode emission and airborne acoustics, with their layout presented in

Figure 5, then converts each 1D trace into 2D grayscale images so that an enhanced LeNet-5 CNN can extract localized features. Data was labeled using porosity measurements and used to train the network, decision-level fusion via the weighted Dempster-Shafer evidence theory lifts the triple-sensor classifier to 98%, 93%, and 100% accuracy on high-, medium- and low-quality samples, respectively, outperforming all single- or dual-sensor baselines. It is also determined that the HS camera is the most significant input in single- and multi-sensor tests.

Cao et al. [

39] propose “Trans-Cross,” a Transformer architecture with a dedicated cross-attention block that simultaneously ingests 10 kHz coaxial photodiode and microphone signals. After an Aquila-optimized variational-mode-decomposition (AO-VMD) denoises each signal, the network fuses the complementary features and classifies both process-parameter fluctuations and resulting part-quality states, which are defined by measuring porosity with optical microscopy. The triple-stage Convolution, Cross-Attention and Self-Attention pipeline pushes accuracy to 97.4% for parameter-shift detection and 99.7% for porosity-based quality grading, beating single-sensor and ResNet/1-D-CNN baselines even when input windows or training data are severely reduced, thus underscoring the merit of Transformer-level multimodal fusion for real-time LPBF monitoring.

Broadening both spectral and spatial coverage, Bevans et al. [

40] fuse three thermo-optical streams–near-infra-red (NIR) tomography, 150 fps spatter imaging, and layer-wise optical powder-bed photos–into spectral-graph “process signatures” that lightweight classifiers use to flag defects across parts of varied geometry. This data was used as inputs for ML models, such K-Nearest Neighbor (KNN), SVM, and shallow neural networks. The heterogeneous model identifies micro-porosity, layer warpage, and scan-path errors with F-scores > 93%, demonstrating reliable shape-agnostic, multiscale flaw detection.

4.2. Process Monitoring

Dongsen et al. [

41] developed an in situ LPBF monitoring system that uses heterogeneous signals from acoustic and imaging sensors, providing better classification accuracy (78.13%) than when they are not used in tandem (72.57% and 75.50%, respectively). The system is capable of determining the state of melt tracks, from under- to over-heating.

Pushing the envelope further, Pandiyan et al. [

42] introduce a deep-learning framework, using a heterogeneous sensing system consisting of back reflection, visible and IR light as well as AE sensors, in order to classify lack of fusion, conduction mode, and keyholes. High-speed synchrotron X-ray imaging is used to validate the correlation between defects and process parameters. CNN and Long-Short-Term Memory (LSTM) networks are then combined to perform the classification, allowing the model to adapt to diverse temporal signal lengths. It is also established that back reflection and AE sensors carry the majority of useful information used by the networks to obtain a result.

In a similar manner, Tempelman et al. [

43] couple inline pyrometry with AE sensing to flag localized keyhole-pore formation. The two data streams were time-synchronized with the scan path, and HS X-ray radiography was used to identify keyhole pore locations. Feature-level fusion of thermal and acoustic signatures significantly outperformed single-sensor classifiers in detecting pore events, while the method proves equally effective for detecting pores of varying size.

Zhang et al. [

44] then combine co-axial two-wavelength pyrometry temperature maps to off-axis HS morphology imagery, yielding a layer-wise, part-referenced record of every melt-pool event. The data is filtered using a CNN, classifying the imagery into various melt pool states as well as the absence of one, and fed into an LSTM neural network, enabling accurate forecasts of post-build surface topography.

Leveraging machine data outputs in combination with sensing, Zou et al. [

45] propose a CNC-synchronized, optical-emission monitoring setup, with two photodiodes supplemented by co-axial HS imaging, to track the melt-pool. Intensity- and frequency-domain features from the multi-sensor traces as well as feature extraction using the HS camera are fused then statistically analyzed, resulting in the detection of transition, keyhole and balling melting states, flagging spatter- and delamination-prone zones with >95% accuracy and reduction in false alarms when compared with single-sensor methods.

Gorgannejad et al. [

46] propose synchronizing off-axis and coaxial NIR photodiodes with airborne acoustic-emission sensing, combined with HS synchrotron X-ray imaging for subsurface defect monitoring to provide temporal registration of pore formation. The signal segments were featurized using power spectral density (PSD) and highly comparative time series analysis (HCTSA) while the predictive performance was evaluated for SVM, KNN, and Gaussian Naïve Bayes (GNB). The two featurization strategies yielded comparable performances and highlighted the superior effectiveness of the microphone over photodiode sensors and the off-axis photodiode over a coaxial geometry. HCTSA also revealed that the degree of randomness in the acoustic, the stability metric of the off-axis photodiode, and the spectral content of the coaxial photodiode signal was the most crucial for the detection of keyhole pores.

Likewise, Zou et al. [

47] devised a melt-pool monitoring method by time-synchronizing coaxial photodiode optical-emission traces with frame-based melt-pool images, and fusing the resulting spectral- and geometry-level features inside a lightweight random-forest model. Tested on stainless-steel cubes that deliberately include randomized process faults, the multi-signal pipeline increases the F1-score for defect detection by ~10 percentage points relative to either sensor alone, illustrating how inexpensive photodiode data become far more informative once coupled to vision-derived morphology in a unified feature space.

McKinney et al. [

48] trained a Contrastive Language-Image Pre-training (CLIP) dual-encoder to embed five synchronous data streams, high-resolution vision, airborne audio, bidirectional galvo-position traces, and laser-power read-outs, into a common latent space. The learned embeddings achieve 100% cross-modal retrieval on the held-out 5% validation set, and Uniform Manifold Approximation and Projection (UMAP) visualization reveals well-separated clusters that correspond exactly to the parts on each build plate, automatically highlighting those printed with lowered power or increased speed.

Peng et al. [

49] present a purpose-built dual-channel visible/IR imaging rig, which is tuned to pick up thermally driven micro-instabilities, pores, cracks and spheroidized zones, at micro-/nano-scale resolutions. Careful optical design allows the system to image defects reliably from a 380–450 mm working distance, then fuse the two spectral streams in a backend vision pipeline, while simulation and tolerance analyses show the setup can capture and classify instabilities that defeat single-sensor approaches.

Targeting subtle parameter drifts, Cao et al. [

50] target subtle but quality-critical micro-shifts in LPBF process parameters, fusing three synchronous in situ channels, coaxial photodiode emissions, airborne acoustic traces, and HS melt-pool video. An ellipse-adjustment routine first segments melt-pool images to isolate motion features, which are concatenated with frequency-filtered acoustic and optical-intensity descriptors and fed to lightweight ML classifiers. The fused model is tested with small intentional parameter changes and recognizes ≤5% laser-power or scan-speed drifts with 99.9% accuracy, outperforming any single sensor and illustrating how motion-aware vision augments low-cost point diagnostics for early-warning process control.

Finally, Zhou et al. [

51] fused a coaxial photodiode that logs optical-emission intensity and an in-chamber microphone capturing 50 kHz acoustic traces in order to monitor the energy input state in real time. After temporally aligning the signals and binning them into three porosity-based classes, they feed both streams into a Hierarchical Features Fusion (HFF) network, a ConvNeXt-derived Hybrid Feature-Pyramid Network that merges multi-scale features before classification. The network distinguishes low, nominal, and high energy states with 99.45% accuracy in just 0.33 ms per layer, outperforming single-sensor and conventional fusion baselines and demonstrating millisecond-level viability for possible closed-loop control.

4.3. Discussion in LPBF Sensor Fusion Monitoring

Considering the above studies, a clear trend can be observed: as LPBF researchers fuse multiple sensor types and signals, spanning vision, thermal, and acoustic modalities, and couple them with different neural network types they are able to achieve better performance compared to single sensor approaches. In

Table 1, the publications mentioned above are summarized, with sensor types, fusion methods, and monitored characteristics presented in an easily readable format.

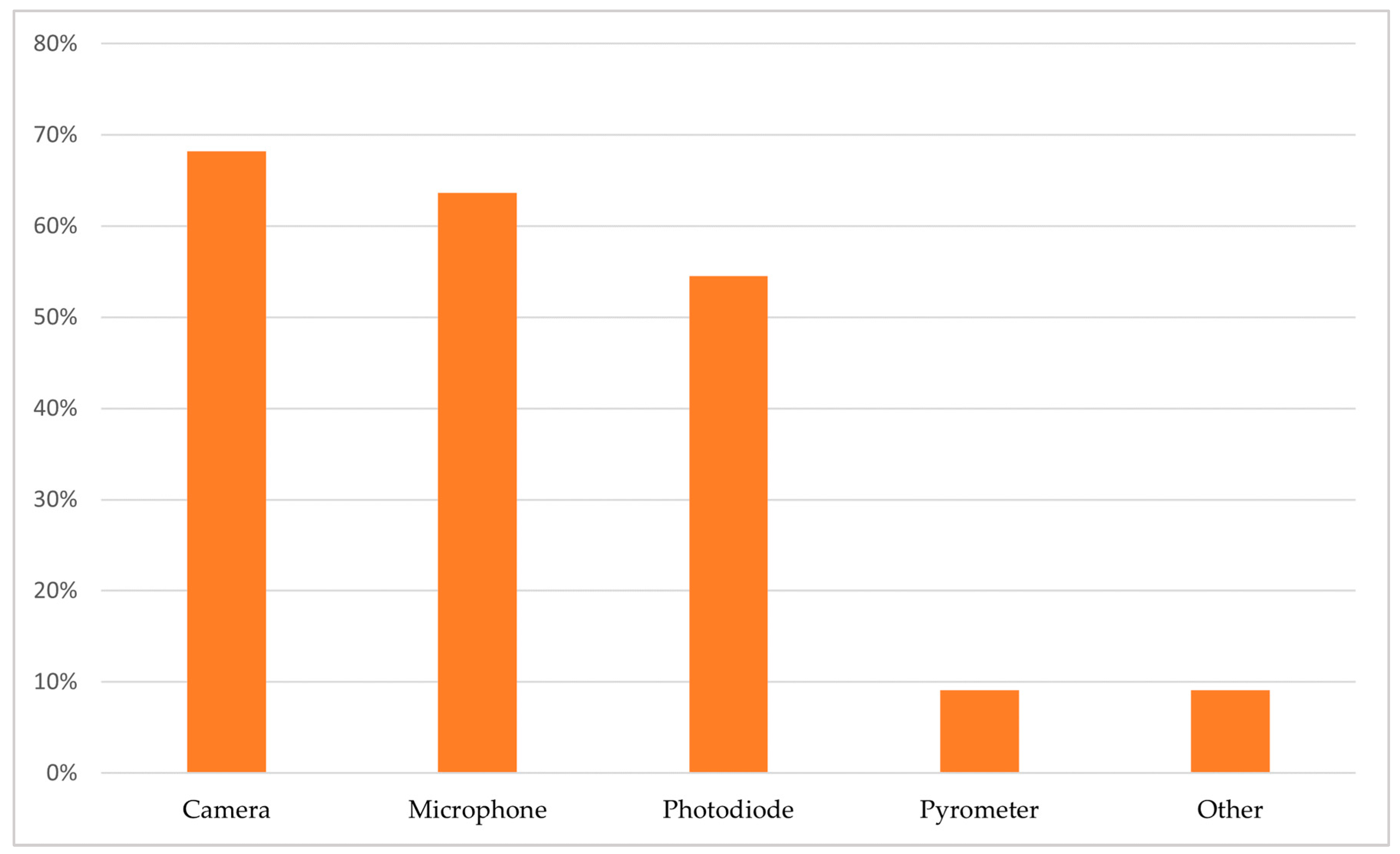

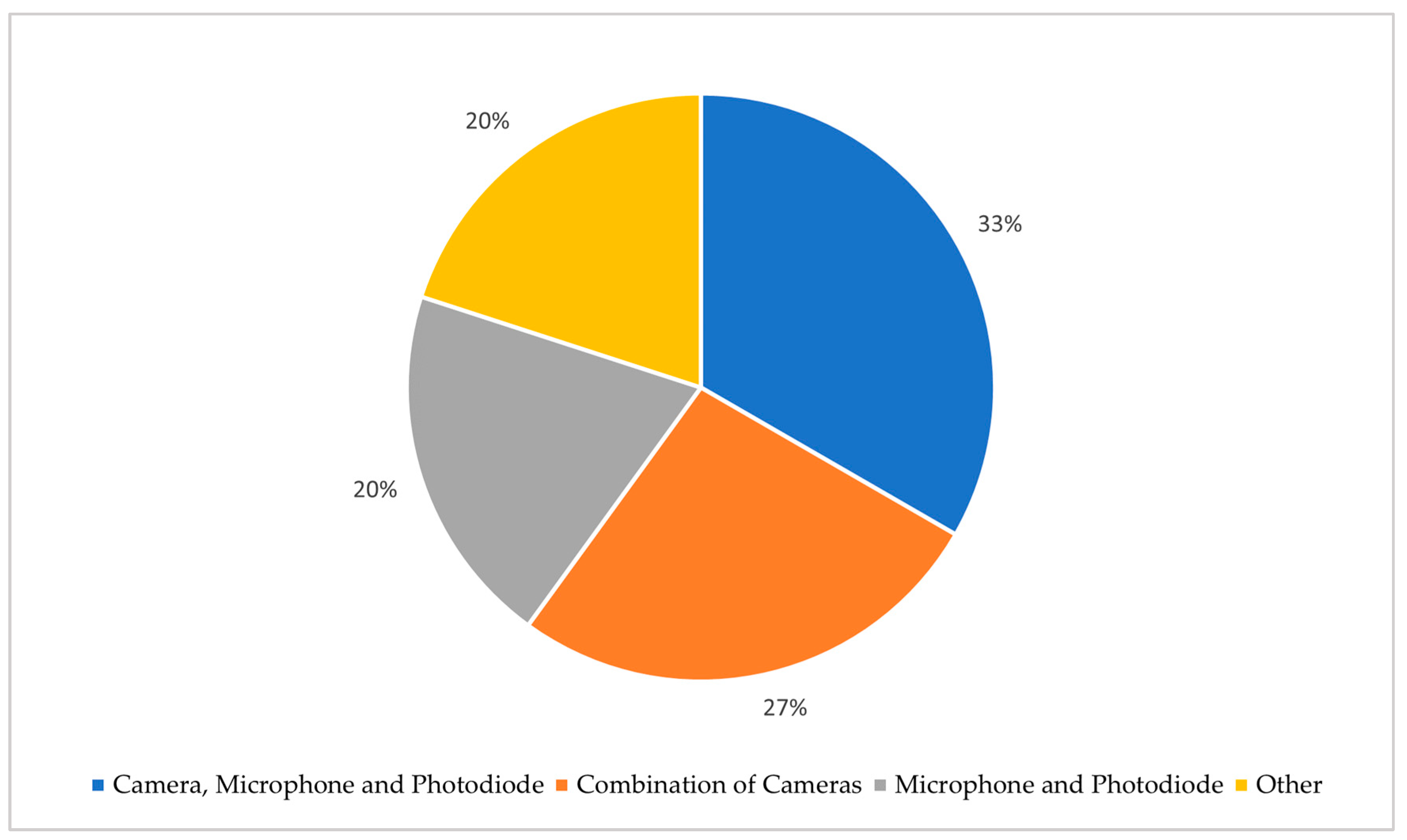

From the data presented in

Figure 6,

Figure 7 and

Figure 8 the trends of sensor fusion are visible, notably in sensor type and monitored characteristics of the process. In

Figure 6, the occurrence of sensors or sensor combinations in the surveyed literature is presented. In this figure, the percentages of each column are derived from the amount of literature where the sensor type attributed to the column is used alongside others in a multi-sensor monitoring method. For example, the usage of any type of camera in almost 70% of the methods proposed in the literature makes it apparent that camera-based data streams (visible, IR, HS, etc.) are the go-to modality and are often used as part of a sensor fusion scheme. Microphones and photodiodes are also popular, achieving only slightly lower usage metrics than cameras. Conversely, pyrometers are scarcely found in the literature, along with signals included in the “other” category, consisting of machine outputs and laser galvanometer position signals. This trend suggests a convergence on vision plus acoustics/optics as the default sensor stack. When it comes to the monitored characteristic,

Figure 7 shows porosity prediction is still the most frequently reported approach, followed by keyhole detection and melt pool/state monitoring. It is worth noting that a large portion of the literature does not opt to obtain data directly related to the quality of the part or possible defects, instead capturing data such as deviation from the selected process parameters, or the energy input state of the process. In

Figure 8, the usage rates of exact setups for monitoring porosity, melt pool/melt state and keyholing are shown. The setups consisting of a microphone, photodiode, and camera are the most common, with the same setup but with the omission of the camera also following closely. The usage of different types of cameras together is also notable, since it signifies the importance of camera positioning as well as its type when it comes to collecting varied data. Concerning the fusion methods, CNN pipelines are still the most frequently reported approach. However, the appearance of GAN, CLIP, and CNN + LSTM hybrids in the last three years signals a shift toward richer temporal or generative representations as datasets grow.

Overall, the surveyed literature consistently confirms that individual sensing modalities–whether optical, thermal, acoustic, or photodiode–capture only a subset of the complex, rapidly evolving physical phenomena in LPBF. This limitation suggests that single-sensor systems may be approaching a performance ceiling in terms of defect detection and false-alarm suppression. As for fusion architectures, effective monitoring solutions increasingly employ hierarchical fusion frameworks:

Data-level fusion merges raw, time-synchronous signals but imposes significant bandwidth and storage demands.

Feature-level fusion concatenates engineered or learned descriptors, striking the most favorable compromise between computational cost and predictive performance.

Decision-level fusion combines sensor-specific classifiers through ensemble or evidential methods, offering low-latency inference albeit with reduced sensitivity to subtle inter-modal correlations.

Advances in fusion hardware have also been matched by the progression of data-driven models. Where early studies relied on SVMs and shallow convolutional networks, mid-period work adopted CNN-LSTM hybrids and graph-based evidence frameworks for real-time inference, while the most recent contributions leverage transformer architectures and contrastive dual-encoders, enabling latent-space alignment of heterogeneous streams and paving the way for closed-loop process control. Additionally, the importance of low-cost point sensors within fusion frameworks is apparent, where despite their simplicity, back-reflection photodiodes and acoustic sensors repeatedly emerge as dominant contributors to fused feature spaces when combined with imaging data, frequently surpassing HS cameras in cost–benefit terms. As for where the current implementations are lacking, significant gaps are identified in the form of severe class imbalance, difficulty in achieving a high acquisition rate of in situ data and lack of standardization. Recent studies attempt to close these gaps through physics-informed feature extraction, generative adversarial oversampling, and deployment of light-weight models on embedded GPUs or FPGAs; nevertheless, standardized datasets and benchmarking protocols are still lacking. Future research directions could include the following:

Development of geometry-agnostic quality metrics suitable for real-time parameter correction.

Formal guidelines for sensor placement, calibration, and data sharing to facilitate reproducibility.

Computationally efficient transformer or graph neural-network implementations capable of processing high data rate multi-sensor streams at the edge.

5. Control Strategies in LPBF

Control of LPBF has attracted great interest within the scientific community in recent years, resulting in a growing number of published approaches and several noteworthy review efforts addressing the current trends and challenges in the field. This Section outlines the main conclusions drawn from the existing literature reviews on LBPF, while

Section 5.1,

Section 5.2 and

Section 5.3 discuss recent advances in physics-informed, ML-assisted and hybrid physics-informed/ML-assisted control approaches, respectively. Physics-informed control strategies utilize fundamental process models, such as heat transfer and melt pool dynamics, to guide process dynamics, ML-assisted techniques exploit data-driven predictive models trained on process monitoring data to adjust control parameters, and hybrid approaches integrate both for improved control.

The evolution of control strategies in SLM has been reviewed by Al-Saadi et al. [

18] and Murtaza et al. [

16]. Al-Saadi et al. highlight the lack of suitable physics-based, control-oriented models and the absence of sufficiently fast control systems capable of responding to process disturbances in real time, while data-driven alternatives are still in early stages of development. Furthermore, they express a concern that most research focuses on simple geometries, overlooking the process complexities involved in fabricating highly intricate parts–one of AM’s key strengths. They also stress the need to further address core control principles such as stability, uncertainty, and robustness, and they suggest the incorporation of thermal history and track formation dynamics to manage more effective control strategies. Murtaza et al. [

16] present a comparative overview of the three categories of monitoring and control configurations in SLM–closed-loop feedback control, open-loop feedback control, and passive monitoring–assessed in terms of effectiveness, complexity and cost factors. They conclude that closed-loop feedback control is the most reliable technique, albeit the most complex and expensive.

Focusing on data-driven advancements, Wang et al. [

10] and Zhang et al. [

27] provide comprehensive reviews of ML applications in LPBF, both highlighting as key limitations the large volume of sensing data and poor generalization performance across different materials and machines. For offline optimization, Wang et al. [

10] point out the difficulty of assessing the joint effects of multiple process parameters using traditional statistical methods. Consequently, most studies either limit themselves to a few parameters or fuse several inputs into single “signal” variables. Thus, the potential of ML to effectively combine parameter effects and extrapolate process maps beyond experimental data is emphasized. Regarding online control, the review notes the limited number of studies due to the complexity of process dynamics and distinguishes between in situ feedback (adjusting parameters before printing the next layer based on previous-layer data) and in-process feedback (real-time control of process signatures). Zhang et al. [

27] offer a complementary classification of control approaches, categorizing them as either layer-scale or part-scale feedback systems, while they suggest Internet of Things (IoT), digital twins, cloud computing, and more comprehensive physics-based modeling as promising solutions to address existing generalization and computational challenges.

Archaryagie et al. [

20] have focused on the powder spreading process of LPBF, reviewing literature on the present adaptive control approaches for powder recoating parameters. Although many studies have explored the influence of recoater speed, powder dosage, and layer height on powder bed quality in LPBF, there is a significant gap in adaptive control strategies that react to detected anomalies before the subsequent powder layer is deposited. Moreover, it is concluded that although digital twin frameworks and ML–based monitoring have exhibited encouraging results, further development is required to manage predictive, real-time adjustment of recoating parameters to enhance powder layer uniformity and optimize LPBF process performance and stability.

Broader perspectives on MAM, including LPBF, are presented in reviews [

11,

12,

13,

17,

19], where control strategies across multiple AM modalities are analyzed. Gunasegaram et al. [

11] have conducted a detailed review on ML-assisted in situ adaptive strategies for MAM processes, distinguishing between defect avoidance, mitigation, and repair. They argue that while ML-assisted offline optimization and online monitoring have exhibited substantial progress, ML-assisted in situ control is an emerging area of research, and autonomous, adaptive control frameworks are required to be established to manage robust, reliable process control. Furthermore, the authors highlight the observed tendency to reinforcement learning (RL) approaches or inverse ML models for making rapid, situation-aware control decisions, though they also clarify that the majority of the existing studies concern LDED where lower scanning speeds facilitate closed-loop control. Similarly in [

12], where closed-loop feedback control and in-process defect correction strategies in LAM systems are reviewed, the primary focus is on the LDED process, as only two closed-loop approaches related to LPBF are studied–one using a custom PID controller and the other employing a rule-based control algorithm to adjust the laser power–while no methodology for in-process defect correction addressing LPBF is presented.

Lin et al. [

13] introduce four control subsystems–laser-power, powder-spreading, powder-preheating and temperature control–particularly emphasizing the critical role of powder-spreading control. Moreover, the main trends in MAM process control are identified, including the focus of literature works on empirical rather than physics-based models, the selection of melt pool monitoring as process signature due to its strong influence on building quality, as well as the widespread use of improved PID algorithms for melt pool temperature control. Chai et al. [

19] in their extensive review on MAM, again draw the conclusion that although ML has shown promise in defect diagnosis and process monitoring for LPBF, its integration into closed-loop control remains limited due to high data acquisition costs, computational demands, and immature end-to-end learning frameworks. In addition, it is highlighted that current research primarily focuses on single-variable control–namely the laser power and the scanning mode–and external quality metrics, such as dimensional accuracy. Future progress will require real-time, multi-variable control systems utilizing advanced sensing, such as AE, and ML-assisted techniques that link process parameters to geometric fidelity. In [

17], Zu et al. analyze two main categories of feedback control adopted in LAM–Statistical Process Control (SPC) for basic, reactive process adjustments applications and ML–driven feedback as a more automated alternative–where they emphasize the need for advancements in sensor speed, data fusion, digital twins, and computational infrastructure for wider adoption of autonomous ML-based feedback control.

In their review, Fan et al. [

28] observe that AM process control strategies remain non-unified, lacking integrated control. They argue that although ML-driven solution adoption promotes computational efficiency compared to traditional physics-based simulations, the amount of training datasets required remains a limitation. To overcome this, they advocate for hierarchical, AI-driven systems–from real-time sensing to high-level decision-making–to execute adaptive interventions holistically and optimize the LPBF process. Finally, Kumar et al. [

52] provide a general overview of ML integration in AM processes, detailing ML as a useful tool across the lifecycle of the manufactured parts, including design and topological optimization, defect detection, quality prediction, as well as indicative applications of intelligent process control in LPBF utilizing closed-loop algorithms.

5.1. Physics-Informed Control

Physics-informed control strategies in LPBF integrate thermal models, sensor feedback, and traditional control theory to regulate specific process signatures, such as melt pool geometry and inter-layer temperature (ILT), by adjusting key process parameters. The conjunction of physical model of heat transfer dynamics with real-time monitoring enables the effective alleviation of instabilities during the process and improves overall quality of manufactured parts.

Wang et al. [

53] developed a closed-loop control system to adjust laser power based on captured melt pool emissions. A light-dependent resistor (LDR) was utilized on a customized LPBF platform to monitor powder bed thermal emissions, and two Arduino microcontrollers were employed to run the developed PID control and data acquisition programs. Experimental printings implementing the feedback control were performed on a customized smart LPBF testbed that exhibits high printing quality, enabling in situ sensing and control. Microscopic imaging and high spatial resolution 3D scanning of the printed parts indicated that both the average and the standard deviation of the dimensional error improved when adaptive laser-power control was applied, compared to the constant power cases. The authors also highlight the low-cost and computer-independent operation of the proposed controller. Similarly, Hussain et al. [

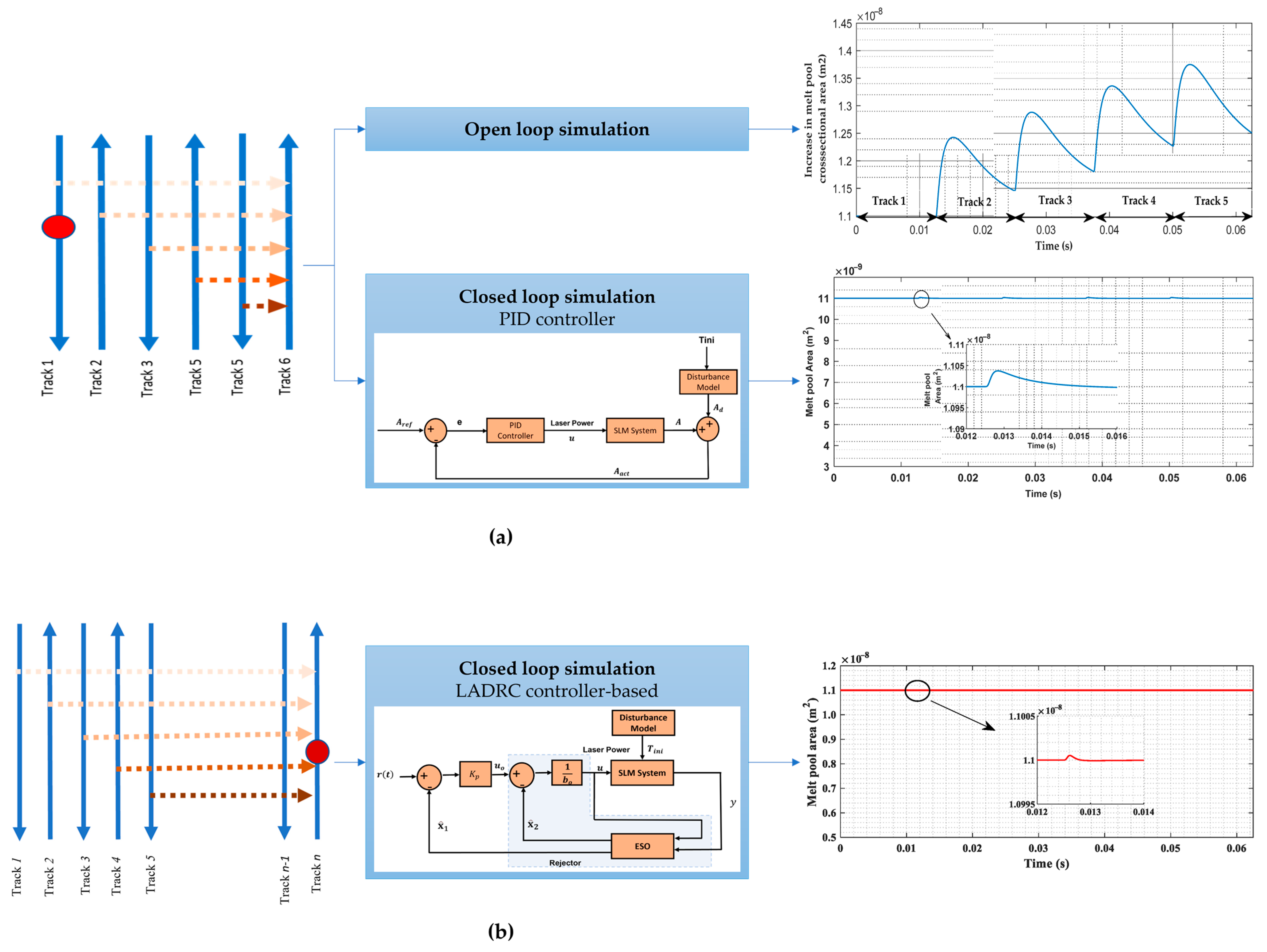

54] designed a PID feedback control strategy based on thermal model of the melt-pool area dynamics derived from energy balance and the effect of heat from adjacent scan tracks. They carried out both open-loop simulations to observe how disturbing heat from previous tracks affects melt-pool size, and closed-loop simulations to test the PID controller’s response across multiple tracks with different disturbance scenarios,

Figure 9a. Simulation results demonstrate that the proposed PID controller effectively stabilized the melt pool cross section area by dynamically adjusting laser power across scan tracks, while the authors also suggest further validation either through in situ melt pool measurements or by comparing single-layer builds produced with and without melt pool area regulation via laser power adjustment.

Building upon the previous work, Hussain et al. [

55] proposed a linear Active Disturbance Rejection Control (LADRC) strategy that integrates a dynamic model of the melt pool cross-sectional area, derived from energy balance including disturbances caused by residual heat from previously scanned tracks. By utilizing real-time disturbance estimation, the laser power is adjusted to regulate melt pool area,

Figure 9b. Simulation results demonstrate that the proposed approach effectively attains the control objective, while simpler to implement and easier to tune compared to a PID controller. Furthermore, the authors recommend that incorporating a nonlinear observer and controller, combined with a high-fidelity model of uncertain nonlinear melt pool dynamics, could further advance disturbance rejection capability.

Focusing on temperature and defect control, Kavas et al. [

56] demonstrated a closed-loop control strategy that receives feedback from an off-axis thermal camera, and stabilizes ILT by regulating laser power. The effective ILT stabilization of the proposed controller was verified through an experimental procedure, that included the LPBF manufacturing of parts with different overhang angles for assessing the controller robustness to geometry-induced thermal variability. However, it is stressed that modulating only the laser power parameter pushes the controller out of the stable process regime due to temperature measurement errors and model inaccuracies, thereby incorporation of waiting time is suggested to encounter this challenge. Complementing this, Vasileska et al. [

57] proposed a layer-wise closed-loop control strategy on an open LPBF platform realizing melt pool monitoring with NIR images utilizing a co-axial Complementary Metal-Oxide-Semiconductor (CMOS) camera and image processing. Based on the captured melt pool size at each layer, the laser duty cycle of the following layer is adjusted, targeting to minimize geometrical deviations in overhang regions. Furthermore, the authors state that although the presented layer-wise control strategy is slower than real-time control, it effectively manages to hinder the progression of sagging and surface collapse defects on overhang regions beginning with the second printing layer.

Advancing spatial thermal control, Wang et al. [

58] introduced a layer-to-layer control-oriented thermal model performing voxel-level monitoring and applying Spatial Iterative Learning Control (SILC) law to regulate melt pool area across layers. A dedicated analysis was carried out to verify the model’s output controllability in both temporal and spatial (voxel) domains, while experimental verification, conducting geometry-invariant layers and layer-varying geometry cases, indicated that the Iterative Learning Control (ILC) successfully adjusted melt pool temperature even in challenging areas where heat accumulation results in increased melt pool size. Furthermore, the developed model enables the monitoring of spatial-driven physics and the creation of spatial controllers that can manage thermal effects without temporal delays, thus has been proposed by the authors for use in voxel-level monitoring and characterization techniques. Furthermore, Liao-McPherson et al. [

59] developed a layer-wise thermal control strategy for SLM based on a comprehensive multi-layer, graph-based thermal model that captures cumulative heat buildup and inter-layer dynamics. A structured model reduction methodology was implemented to derive a reduced-order model (ROM) while quantifying its approximation error relative to the full multi-layer model. Utilizing this ROM, a linear-quadratic regulator (LQR) state feedback controller was designed to regulate temperature gradients across layers by adjusting laser power. Simulation studies demonstrated that the in-layer controller effectively prevents heat accumulation and maintains target temperature profiles, while the ROM-based controller exhibited high closed-loop performance despite its reduced complexity.

Nath et al. [

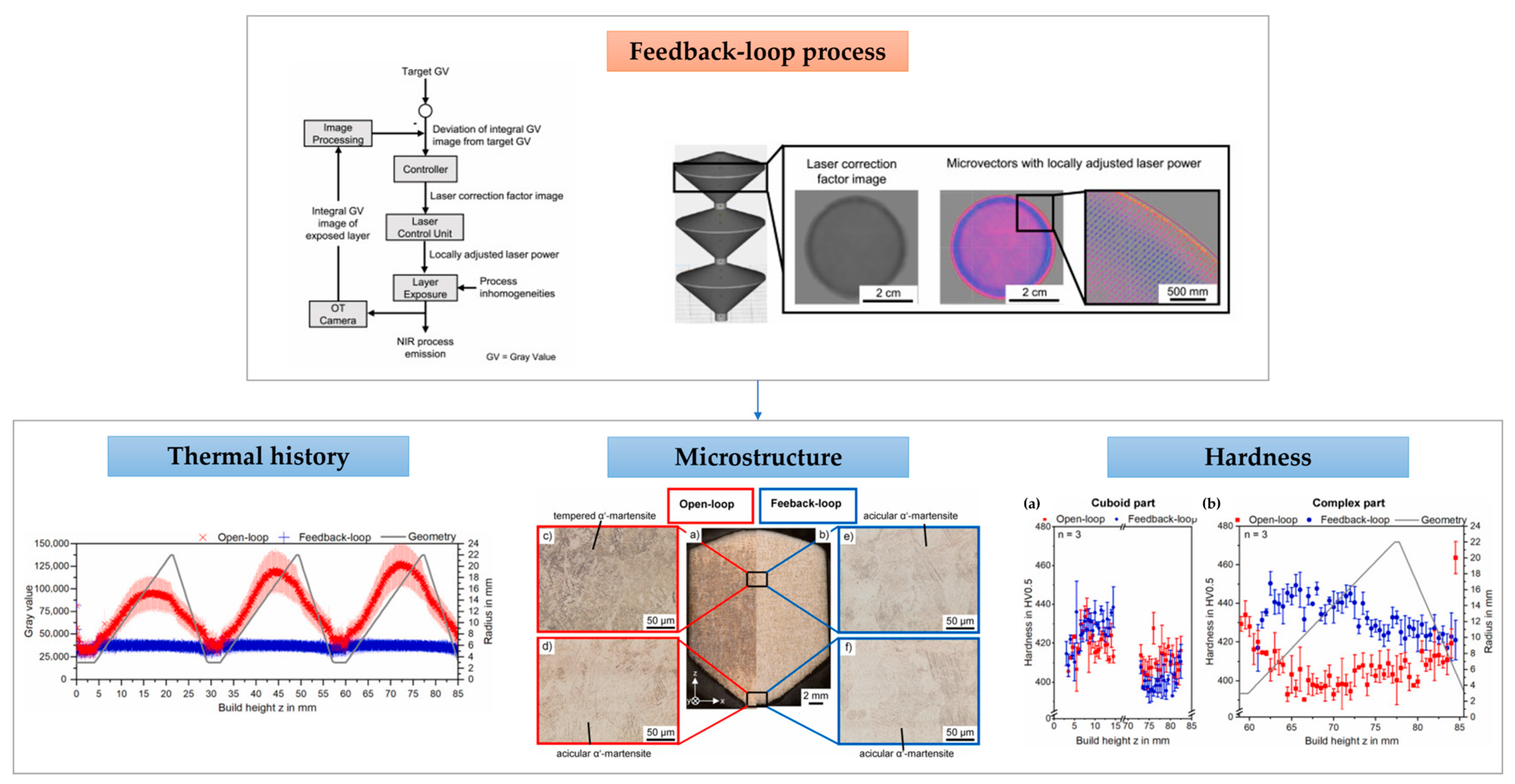

60] propose a Bayesian predictive porosity control framework, integrating a physics-based model with real-time surface temperature monitoring. At each layer, the current porosity level is defined, as well as the predicted porosity of the subsequent layers based on the captured thermal data fed to the model. Depending on the predicted porosity value, the system either adjusts laser parameters, continues as is, or terminates the build. While the method demonstrated strong predictive capabilities contributing to improved porosity levels, it was only validated using synthetic data, and the need for actual experimental data before implementing it on a real AM system is highlighted. Nahr et al. [

61] introduced a Smart Fusion feedback-loop control methodology that dynamically adjusts laser-power in real-time by comparing gray values obtained from optical tomography measurements during LPBF to a target profile, aiming to maintain a consistent thermal history throughout the LPBF process. The developed approach was tested on both cuboid and complex geometry parts prone to heat accumulation, using open-loop and Smart Fusion feedback-loop control methods available in a commercial printer. Experimental comparison with open-loop control revealed superior results in terms of microstructure uniformity, hardness, and thermal consistency, as illustrated in

Figure 10.

Gao et al. [

62] proposed a hybrid control architecture combining feedforward and feedback strategies to improve thermal regulation and part quality. The feedforward component uses a finite element analysis (FEA) thermal model to predict temperature buildup, enabling proactive adjustment of laser power on a layer-wise basis, while the feedback component employs HS thermal sensing to adjust laser power in real time, compensating for local disturbances such as spatter. To evaluate the control strategy, test parts with both bulk and fine features were printed under four different conditions: no control, feedforward only, feedback only, and integrated control, showcasing the superior performance of the integrated feedforward-feedback system in terms of temperature profiles uniformity, dimensional accuracy, and porosity. Moreover, Al-Saadi et al. [

63] benchmark three common industrial control methodologies applied in SLM–PID, feedforward controller combined with PID and fuzzy logic–by adjusting laser power to regulate melt pool geometry across four printing tracks of 1 cm length. The simulation results indicated that the PID and the feedforward controller performed similarly except at the begging of each track where the feedforward controller slightly outperforms, while the fuzzy logic controller significantly enhances the system’s behavior owing to its ability to deal with nonlinear and hybrid characteristics present in the SLM process. Furthermore, the authors highlight the need to develop more advanced, adaptive control architectures, and evaluate their effectiveness with more complex part designs.

Huang et al. [

64] addressed synchronization challenges in EtherCAT-based SLM systems using a master-slave ILC strategy, designating the scanning system as the master. The effectiveness of the presented approach was assessed by comparing three control strategies, namely traditional distributed control, the proposed hybrid servo control, and the proposed hybrid learning control. The experimental results demonstrated that both the proposed strategies significantly reduced tracking errors compared to traditional distributed control, where the hybrid learning control achieving up to a 28% reduction in the scanning system tracking errors, a 20% reduction in contour errors, and an 87% reduction in tracking errors for the power system.

Table 2 presents an overview of the physics-informed control strategies studied in this section, summarizing their key features.

5.2. ML-Assisted Control

ML-assisted control strategies in LPBF leverage data-driven insights to account for complex process dynamics and enable effective adaptive parameter tuning. These strategies typically employ supervised learning or RL–often implemented via neural networks–combined with real-time sensor feedback to dynamically regulate key process parameters.

Ma et al. [

65] developed a layer-wise closed-loop control system utilizing a customized visual monitoring platform to perform online surface monitoring. SVM and CNN approaches were employed to establish the correlation between the captured images and melting qualities, while corrective actions on the laser power and scanning speed were determined for the following layer using fuzzy logic. The experimental results indicated that the CNN-based method enhanced with the convolutional block attention module (CBAM) attention mechanism achieves up to 98% accuracy in identifying melt quality. Additionally, fuzzy inference control (FIC) strategy with historical state consistency check mechanism (HSCCM) significantly enhances surface quality, mitigating severe surface issues that could lead to system failure; however, it cannot repair existing defects or prevent pores and holes formation.

Similarly focused on laser parameter optimization, Okolo et al. [

66] presented a vector-level ML control method on a commercial LPBF system equipped with AI-capable controllers, enabling dynamic adjustment of laser power and exposure time to optimize thermal history and ensure consistent solidification. A comprehensive evaluation, including microscopy observation, relative density measurements, and hardness testing, was conducted to assess the microstructure and build quality of the manufactured parts. The results demonstrated that microstructure uniformity, relative density consistency, and hardness were improved in the ML-optimized parts compared to the non-optimized counterparts, showcasing the effectiveness of AI-driven optimization. Along similar lines, Carter et al. [

67] studied the optimization of porosity utilizing a co-axial photodiode monitoring system to capture melt pool temperature, and a supervised ML algorithm to map offline the melt-pool features to the optimal laser power adjustments along the scan path. The results of the measurements with X-ray CT indicated that the developed ML-based control methodology achieved 12% average porosity size reduction and 65% pore size variability decrease compared to parts built with constant laser power.

Advancing beyond supervised methods, Vagenas et al. [

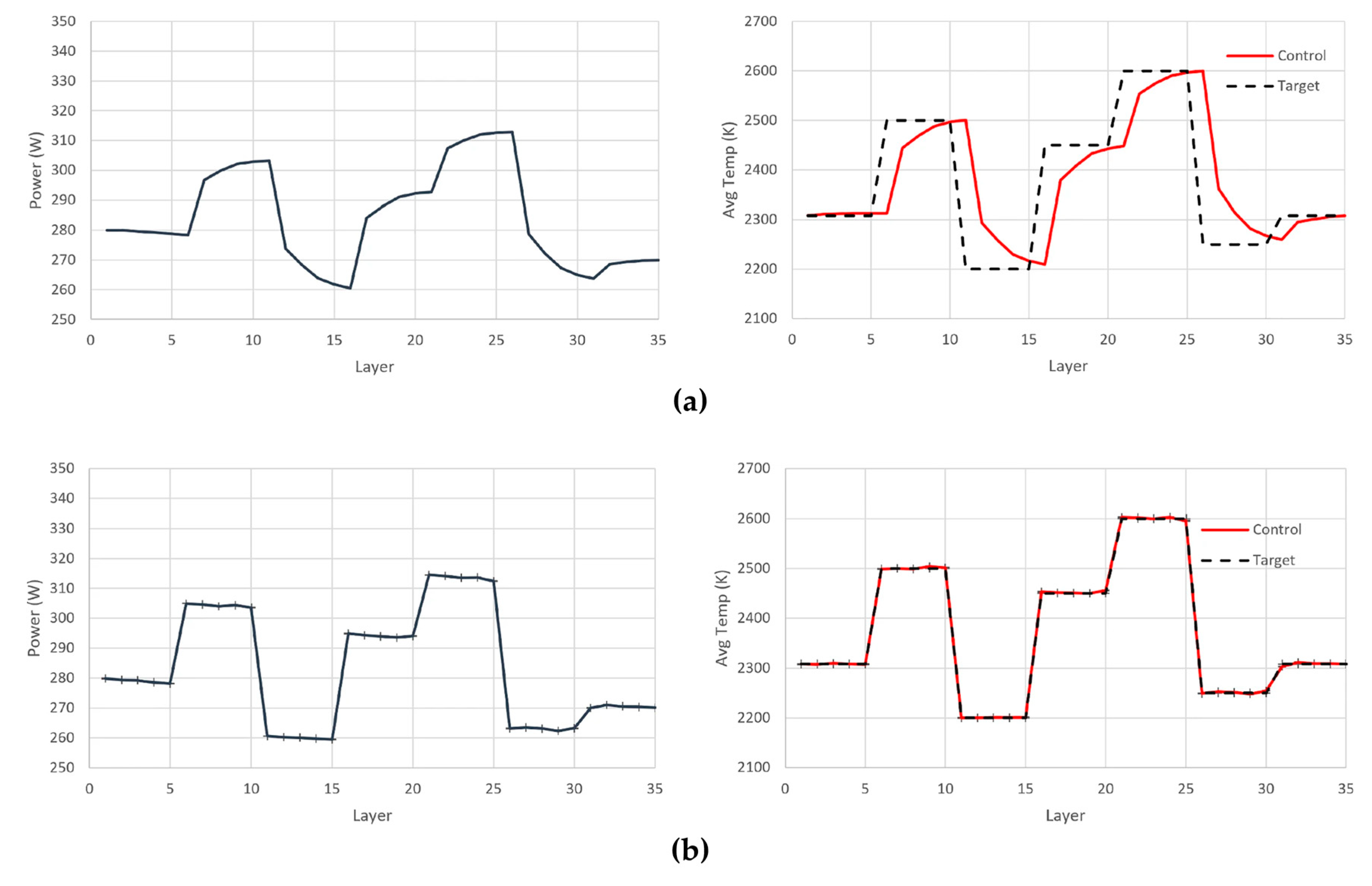

68] introduced a RL-based multi-layer process control system to address heat accumulation issues in LPBF. The RL controller successfully compensated for heat buildup over consecutive layers, while demonstrated improved control over temperature profiles during build layers compared to PID controllers (

Figure 11), especially in managing complex multi-layer thermal dynamics. The authors note, however, that further research is needed on convergence guarantees, constraint satisfaction, and control performance guarantees, to advance the trustworthiness of RL-based systems.

Table 3 presents an overview of the key features of the ML-assisted control approaches analyzed in this section.

5.3. Hybrid Physics-Informed and ML-Assisted Control

Hybrid physics-informed and ML-assisted control strategies combine the strengths of physics-based modeling and data-driven ML techniques to accomplish more accurate, adaptive, and robust process regulation. This synergy enables addressing complex disturbances and uncertainties that neither physics-based nor data-driven methods can deal with individually. In this section, recent advances employing RL, Gaussian Processes (GP), Bayesian optimization (BO), and hybrid modeling to optimize LPBF are reviewed.

A real-time, geometry-informed RL control strategy is proposed by Park et al. [

69], that combines in situ melt pool measurements with scan path geometry to dynamically control laser power signal and mitigate melt pool inhomogeneities. Trained safely via simulation using a data-driven model and experimentally validated on a physical LPBF system without further tuning, the presented approach significantly improved melt pool homogeneity in real time, achieving comparable performance to traditional feedforward and PID controllers in 20 times less computational time.

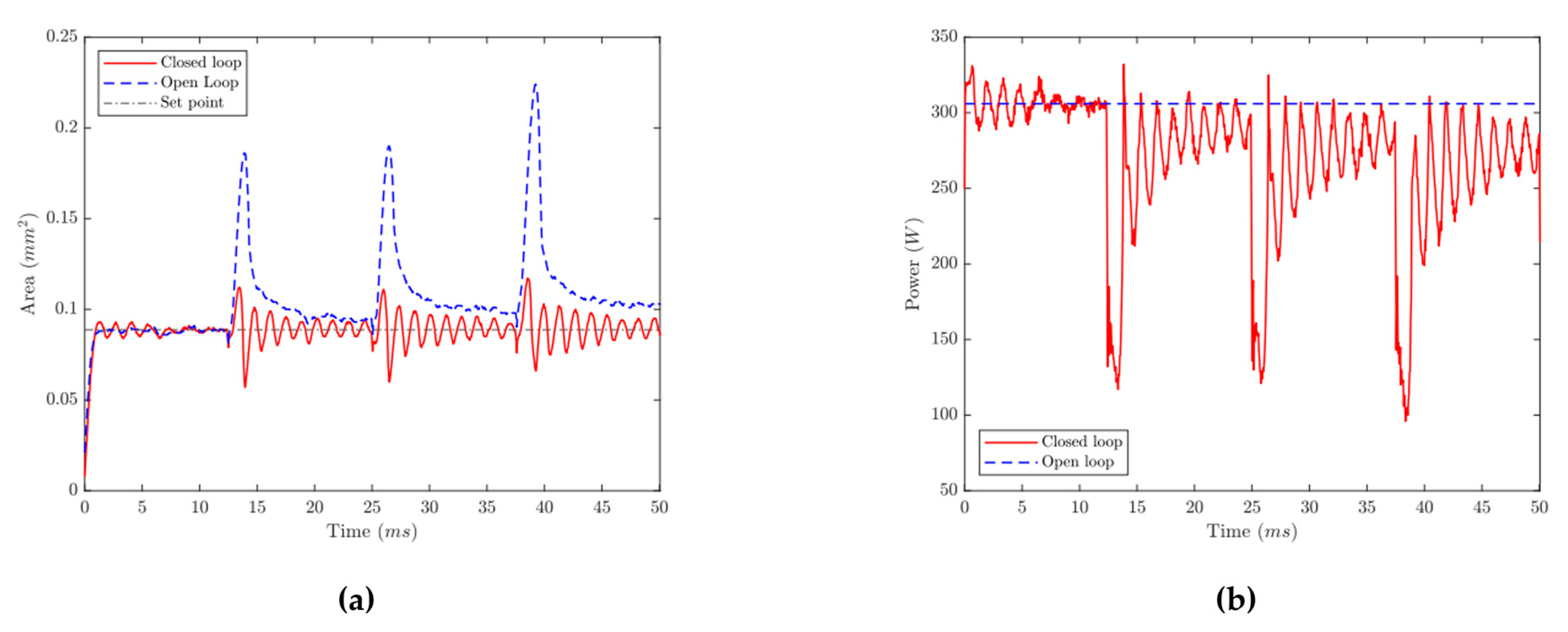

Similarly, Asadi et al. [

70] and Mondal et al. [

71] introduced hybrid physics-informed and ML-based modeling approaches for melt pool control. Asadi et al. [

70] presented a GP-based model integrated into a Model Predictive Control (MPC) to predict and dynamically control melt pool geometry in SLM, utilizing laser power as the control variable. High-fidelity Finite Element (FE) simulation, experimentally validated, was employed as training data for the GP model. As presented in

Figure 12, the developed closed-loop system effectively maintained melt pool stability and compensated for thermal disturbances outperforming the existing open-loop approach in comparative tests. Likewise, Mondal et al. [

71] proposed a hybrid modeling framework, integrating a physics-based analytical model and a GP surrogate to predict optimal process parameters and regulate the melt pool dimensions,

Figure 13. This combination provides the predictive accuracy of analytical models with the flexibility and uncertainty quantification of nonparametric ML, while results indicated that the use of surrogate-assisted modeling with GP and BO enable a powerful and efficient strategy for maintaining consistent melt pool geometry in LPBF, bridging the gap between computational efficiency and control-oriented accuracy for intelligent process adjustment.

Xi et al. [

72] investigated the effectiveness of PID and MPC strategies for regulating melt pool width and depth in LPBF process, utilizing an ML model that predicts melt pool geometry under process uncertainties from the powder absorptivity and laser spot size. Additionally, a Sampling-Based Dynamic Control Window (S-DCW) approach is proposed to enable real-time MPC decision-making, despite process uncertainties and computational constraints. Simulation results indicated that MPC outperforms PID in achieving control objectives, particularly when both melt pool width and depth are considered as control outputs, though requiring an accurate digital twin of the process.

Complementing these control approaches, Kavas et al. [

73] developed a BO-driven autotuning method for in-layer PI controllers, adjusting laser power based on pyrometer feedback. BO was applied to automatically tune the control gains KP and KI, in both online and offline tuning—where online tuning adapts the gains layer-by-layer during the build, and offline tuning pre-calibrates and keeps them fixed. The tuned controllers were experimentally tested on overheating-prone wedge geometries, and the printed parts were analyzed through microstructural assessment to evaluate build quality. Results exhibited that both online and offline BO-tuning effectively mitigated overheating compared to uncontrolled parts; however, lack-of-fusion porosities were observed, attributed to overly conservative laser power adjustments. The authors highlight that BO exhibits strong potential for automated controller tuning, paving the way for a more adaptive and robust control across LPBF systems without manual intervention.

Finally, an open-loop multi-data-driven model-based control (MMC) framework is presented by Huang et al. [

74] to enhance the accuracy and quality of overhang structures, employing data-driven models and real-time photodiode monitoring on a self-developed laboratory system. The presented work includes an energy density model for both solid substrates and overhang structures to optimize laser power, an IR correction model to address melt pool variation induced errors, and a reference voltage model for real time process monitoring. The MMC architecture effectively produced high-quality overhang structures, while reducing residual material by 49.9%.

An overview table with the key features of the hybrid physics-informed and ML-assisted control approaches studied in this section is provided below (

Table 4).

5.4. Discussion in LPBF Control

To clarify the recent developments in LPBF control,

Figure 14 provides a comparative overview of the reviewed control strategies.

Figure 14a,b display, respectively, the annual (2020–2025) and cumulative distributions of physics-informed, ML-assisted and hybrid approaches. As

Figure 14b shows, physics-informed strategies have dominated over the past five years, offering interpretable, thermos-physically grounded frameworks, while hybrid strategies integrating physics-based models with ML capabilities represent the second most studied type.

Figure 14a also reveals a marked uptick in purely ML-assisted studies during the last two years. Complementing these trends,

Figure 14c,d plot the percentage distribution of the primary process parameters adjusted and the control output across the reviewed approaches, respectively. Laser power is the most frequently tuned parameter in LPBF, likely due to its direct influence on melt-pool stability, energy input and overall part quality, while melt pool geometry is the most common control output, as it directly reflects thermal behavior and influences quality metrics, including microstructure and porosity.

Focusing individually on each of the studied control strategies, physics-informed control strategies demonstrate the potential of integrating thermal modeling, real-time sensing, and classical control theory to improve the stability and quality of LPBF processes. Most approaches focus on regulating melt pool geometry or ILT through closed-loop control mechanisms using PID, LQR, LADRC, or ILC. Their effectiveness has been validated in simulations and experimental setups, particularly in mitigating heat accumulation, improving dimensional accuracy, and stabilizing thermal profiles. However, significant gaps in the current physics-informed control strategies have been identified, including limited controller robustness under varying process conditions, lack of multi-parameter control, restricted adaptability to complex geometries or disturbances and challenges in parameter tuning, thus further progress necessitates enhancing model fidelity, and validating performance across diverse part designs and build conditions.

Furthermore, the application of ML to LPBF control has emerged as a promising approach in enhancing process adaptability, surface quality, and part consistency. Supervised learning approaches, including SVMs, CNNs, and fuzzy inference systems, have demonstrated high accuracy in defect detection and effective corrective action at the layer level. Moreover, ML-based parameter tuning has led to notable improvements in microstructure uniformity, porosity reduction, and mechanical properties. Additionally, RL has exhibited considerable potential in handling multi-layer thermal dynamics and complex control scenarios. Nevertheless, considerable gaps remain, including limited generalizability across different machines, materials, and geometries, as well as the inability to repair existing defects or fully prevent their formation, while high data requirements and real-time implementation capabilities also pose significant challenges. More specifically, generalizability is restricted by the fact that ML models are often trained and validated on specific machine setups, materials, and geometries degrading their performance when applied to different LPBF systems or part designs. Furthermore, the effective training of ML models typically demands large amounts of labeled in situ sensor data and post-build characterization, which can be time-consuming and expensive to acquire. Finally, real-time implementation is constrained by the computational intensity of advanced ML models that conflicts with the tight millisecond-level timelines required to effectively regulate the melt pool and prevent defect propagation.

Bridging the gap between purely physics-based and data-driven approaches, hybrid control strategies leverage the predictive accuracy and interpretability of physical modeling alongside the flexibility and adaptability of data-driven algorithms. Recent works show that combining GP, MPC, and BO enables dynamic and accurate control of melt pool geometry, even under thermal disturbances and process uncertainties. Moreover, RL approaches informed by geometry and simulation-trained models facilitate real-time adaptability with reduced computational costs. However, hybrid methods still exhibit an important gap in real-time deployment due to computational inefficiency, while additional challenges remain, including the need for high-fidelity digital twins and reliable training data. Nevertheless, they represent a powerful direction toward more intelligent, autonomous, and reliable LPBF control systems.

Finally, across the reviewed publications, it is worth mentioning that most control strategies in LPBF are implemented and validated through simulation, with a growing number of experimental studies conducted on custom LPBF platforms. Only a few approaches, such as Smart Fusion and AI-assisted control, have been tested on commercially available systems, marking an important step toward the adoption of advanced control methodologies in industrial LPBF systems. However, translating simulation-based strategies to practical implementation on commercial LPBF systems encounters several challenges. First, simplified assumptions may compromise model fidelity, failing to accurately reflect the real process dynamics, while unmodeled system disturbances, such as variations in powder properties or environmental conditions, may further degrade control effectiveness. Moreover, hardware limitations, including actuator response times, sensor integration constraints, and the restricted access typical of commercial LPBF systems, can restrain the achievable control precision and real-time implementation, highlighting the gap between simulated validation and practical implementation on commercial LPBF systems.

6. Conclusions

This review has distilled the most recent (2020–May 2025) surveys and primary studies to provide a structured overview of the field’s current state and trends. Firstly, LPBF monitoring is converging around vision-centric, multimodal stacks, visible/IR cameras augmented by low-cost photodiodes or microphones because no single sensor captures the process’s full complexity. Fusion has evolved from CNN-only pipelines to a diverse mix of graph, attention, and transformer architectures, with feature-level integration offering the best accuracy-to-cost balance. Despite gains, progress is capped by data volume and class imbalance, where physics-informed features, GAN oversampling, and lightweight edge models partly address these gaps. Closing these gaps will require the following:

Geometry-agnostic metrics;

Standardized sensor-deployment protocols;

Efficient network architectures capable of handling high-frequency and high-dimensional data for real-time inferencing.

As for real time control, physics-informed, ML-assisted, and Hybrid control approaches consistently underscore a need for the following:

Broader validation with more complex part designs and under realistic, multi-material conditions using commercially available LPBF systems;

Improved sensor integration and real-time data fusion;

Development of interpretable, generalizable ML frameworks;

Closed-loop architectures capable of adapting to multi-objective and multi-scale control challenges.

Intelligent, flexible, and reliable control systems are essential to achieving LPBF’s full potential in advancing industrial viability for manufacturing intricate metal components. Future research will benefit from cross-disciplinary efforts that bring together control theory, materials science, ML, and systems engineering. Finally, advancements in LPBF control are expected to be driven by the development of hybrid physics-informed and ML methodologies, further integration of digital twins, and the establishment of real-time adaptive control strategies.