1. Introduction

Motion control studies have gained significant attention, particularly in autonomous vehicles, including robotics and unmanned systems. Tracked vehicles are often characterized by their use of continuous tracks instead of wheels and are widely employed in scenarios involving rough or uneven terrains. However, this paper specifically focuses on the trajectory tracking problem under firm ground conditions, which is also crucial for achieving autonomy in unmanned tracked vehicles (

Figure 1). While these vehicles are capable of handling diverse terrains, firm ground presents challenges such as managing high-slip conditions and ensuring accurate trajectory prediction. Our study aims to address these challenges by developing a robust predictive model tailored to firm ground scenarios, enhancing both stability and navigation precision. Various methods have been explored to address these issues, yet a robust predictive model is necessary to enhance navigation accuracy and stability. The trajectory tracking problem is commonly the basis for autonomy and it is handled with many different methods. These approaches can be categorized under following groups:

- i.

Classical control methods such as PID control [

1];

- ii.

Kinematic methods such as pure pursuit and Stanley control [

2,

3,

4];

- iii.

Intelligent and learning based methods such as neural network-based control [

5];

- iv.

Optimization based methods such as model predictive control.

Figure 1.

Illustration of an unmanned tracked vehicle platform [

6].

Figure 1.

Illustration of an unmanned tracked vehicle platform [

6].

In tracked vehicle dynamics, methods such as classical PID control offer simplicity but often fail to manage the complex nonlinearities in dynamic systems. Kinematic approaches such as pure pursuit provide basic geometrical path tracking but struggle under conditions with significant slip. Intelligent control methods such as neural networks have potential for adaptability, yet their robustness is still questionable due to limitation with training dataset. Model predictive control (MPC) is effective for handling constraints but becomes computationally challenging when dealing with high-slip scenarios and due to detailed contact mechanics specific to tracked vehicles. These existing methods, while valuable, often do not fully address the challenges at higher speeds, underscoring the need for robust and computationally fast predictive models.

As an optimization-based approach, MPC provides a structured optimal control problem solving technique while conveniently handling the system constraints of linear or non-linear systems. For the trajectory following problem, the MPC approach is extensively used especially in wheeled vehicles. Prediction models for wheeled vehicles show variety, from kinematic single-track models to dynamic two-track models. In high-slip conditions, kinematic single-track models become insufficient for catching the dynamics of actual plant. Therefore, one-track or two-track dynamic models are used introducing the slip of the tires [

7,

8,

9].

Dynamic modelling of tracked vehicles has been widely investigated in the literature, where ride and handling studies are generally covered separately. For ride dynamics, suspension dynamics, track–ground contact relationships, and track wrapping algorithms are mostly studied for both hard and soft soil terrain conditions [

10,

11,

12,

13]. In handling studies of these vehicles, accurate modelling constitutes a much more complex phenomenon compared to wheeled vehicles, due to slip occurring through the large contact areas of track pads during skid steer maneuver. Kinematic and dynamic approaches are used in the modelling of these vehicles. In kinematic models, the simplest method includes calculating the instantaneous center of velocity using the track velocities of the vehicle, with slip effects being disregarded [

14] (

Figure 2a). Additionally, a further improved method for kinematic model is the sliding model, where the instantaneous center is shifted forward due to sliding track characteristics [

15,

16] (

Figure 2b).

In MPC-based trajectory following applications for tracked vehicles, kinematic models are most common due to their simplicity and low computational cost. Zhou et al. [

14] employed a torque-driven linearized kinematic model neglecting slip, achieving acceptable results at low speeds with a lightweight test robot using only

X,

Y, and yaw as controlled states. An EKF-enhanced kinematic model in [

17] estimated road and steering resistance, improving lateral tracking by 24% over the basic model in 10–20 km/h off-road tests. In [

15], a sliding kinematic model based on the instantaneous turning center was applied to minimize heading deviations for large turning radii. The same authors [

16] later updated slip parameters from measured states and applied MPC to the sliding model, outperforming pure pursuit, classical MPC without slip, and the Levenberg–Marquardt method.

When considering the load concentration of the tracks on firm ground, tracked vehicle models can be designed similarly to wheeled vehicle models for slippage calculations under road wheels. A good example for this approach is given in [

18], where track force is represented by magic formula as in wheeled vehicles.

Apart from these studies, recent ones have explored diverse trajectory-tracking strategies to enhance the control and efficiency of unmanned vehicles. Reference [

19] proposed a polytopic model-based robust MPC for autonomous wheeled vehicles, reducing complexity by using fewer Takagi–Sugeno vertices and adding an

H∞ compensation controller for uncertainty and disturbance rejection, validated in Carsim/Simulink. In their extended study [

20], they introduced an event-triggered system (ETS) to reduce the communication load while maintaining path-tracking accuracy, validated through hardware-in-the-loop tests. This illustrates the importance of computational efficiency in predictive controllers. Other studies include adaptive MPC for wheel–track hybrid vehicles to address nonlinear and coupled dynamics [

21], quartic polynomial planning plus MPC for crawler pavers [

22], energy-efficient off-road path planning using a modified A* algorithm [

23], online learning and model updating via recursive least squares and Kalman filtering [

24], and decoupled adaptive motion control for leader–follower tracked vehicles to maintain precise speed and curvature tracking [

25]. These studies collectively highlight the innovative approaches in trajectory tracking, focusing on predictive control strategies to improve the performance and reliability of automated and unmanned vehicle systems across different environments and tasks.

Despite all these studies, there remains a gap in developing robust predictive models for tracked vehicles that can integrate adaptive capabilities and improve decision-making processes under varying environmental conditions. Additionally, most of the studies, especially involving robotic platforms, present low velocities limited to 20 km/h, and the performances of the prediction models are not commonly captured beyond these limits.

To address this gap, we propose a simplified slip-based prediction model for MPC that achieves a practical balance between accuracy and computational efficiency. Unlike purely kinematic methods, which lose accuracy under high-slip conditions, and full dynamic models, which are too computationally demanding for real-time use, the core novelty of this study lies in simplifying the exponential shear displacement formulation (Equation (29)). In the proposed method, the complex integral operation is replaced with an equivalent multiplication of resultant slip velocities and effective contact time [

26]. A further analysis shows that particular group of parameters, including the exponential shear displacement function, become insensitive at higher track speeds and slip values. These terms are, therefore, substituted with a constant factor (

), which yields a mathematically simpler yet bounded error representation of slip dynamics. This innovation not only reduces the computational load but also makes the linearization of the nonlinear model at each MPC step more straightforward and less demanding in the calculation. Building on this principle, the study introduces a torque-driven, slip-based two-track vehicle model that computes slip velocities and contact forces under each wheel, enabling nonlinear MPC to be feasible for real-time trajectory tracking of tracked vehicles operating at higher speeds on firm terrain.

The controller is applied on a plant model, which is taken from [

27], and which has extended features through the application of shear displacement theory and built upon the improvements of [

28,

29,

30]. With mentioned modifications, the results of the proposed nonlinear prediction model are compared with the kinematic prediction model in [

14], in different scenarios such as (i) cornering maneuvers with increasing speed and (ii) spiral maneuvers with constant speed. Furthermore, a reference trajectory of the created complex test track is used to investigate the performance of the proposed model.

The analyses are conducted in a simulation environment tailored for unmanned driving conditions; however, the controller’s accuracy is validated by replicating the test results from a series of controlled experiments carried out on a five-wheeled tracked vehicle platform, operated in manned mode. These experiments are designed to evaluate the controller’s performance in various scenarios, including low-speed cornering and high-speed maneuvers on an asphalt track, as well as stabilized test parkour. The verification studies involve data from GPS tracking and speed and torque measurements from the sprocket driving shafts, ensuring the controller’s effectiveness and reliability. The postprocessing of these measurements and all methodologies applied in this study is conducted in MATLAB—Simulink R2021b software environments.

The current article comprises eight subsections, including

Section 1, which has provided an introduction for the study. In

Section 2, the plant model is explained. In

Section 3, details of the kinematic-based prediction model are explained. In

Section 4, the fundamentals of the proposed nonlinear prediction model are introduced. Additionally, the main contribution of the article is explained here by emphasizing the conducted simplifications in the shear displacement model. In

Section 5, the MPC formulation for trajectory tracking problem is described. Results of trajectory following studies are compared in

Section 6 for the kinematic-based and proposed slip-based prediction model. In

Section 7, the verification studies are discussed, where the collected test data are utilized. Both the vehicle’s measured states and the measurements from the sprocket driving shaft are employed to verify the controller’s output. Finally, the outcomes of the study are summarized in

Section 8.

2. Tracked Vehicle Plant Model

The plant model for this study is taken from [

27]. The model provides improvements for the transient calculation methods onto past contributions to skid steering tracked vehicle applications. The plant model includes the following features:

(i) Concentrated vertical load under road wheels;

(ii) Discretized cells for track pads under road wheels;

(iii) Shear displacement-based force development;

(iv) Vertical load changes due to longitudinal, lateral acceleration, track pretension, and applied sprocket torques.

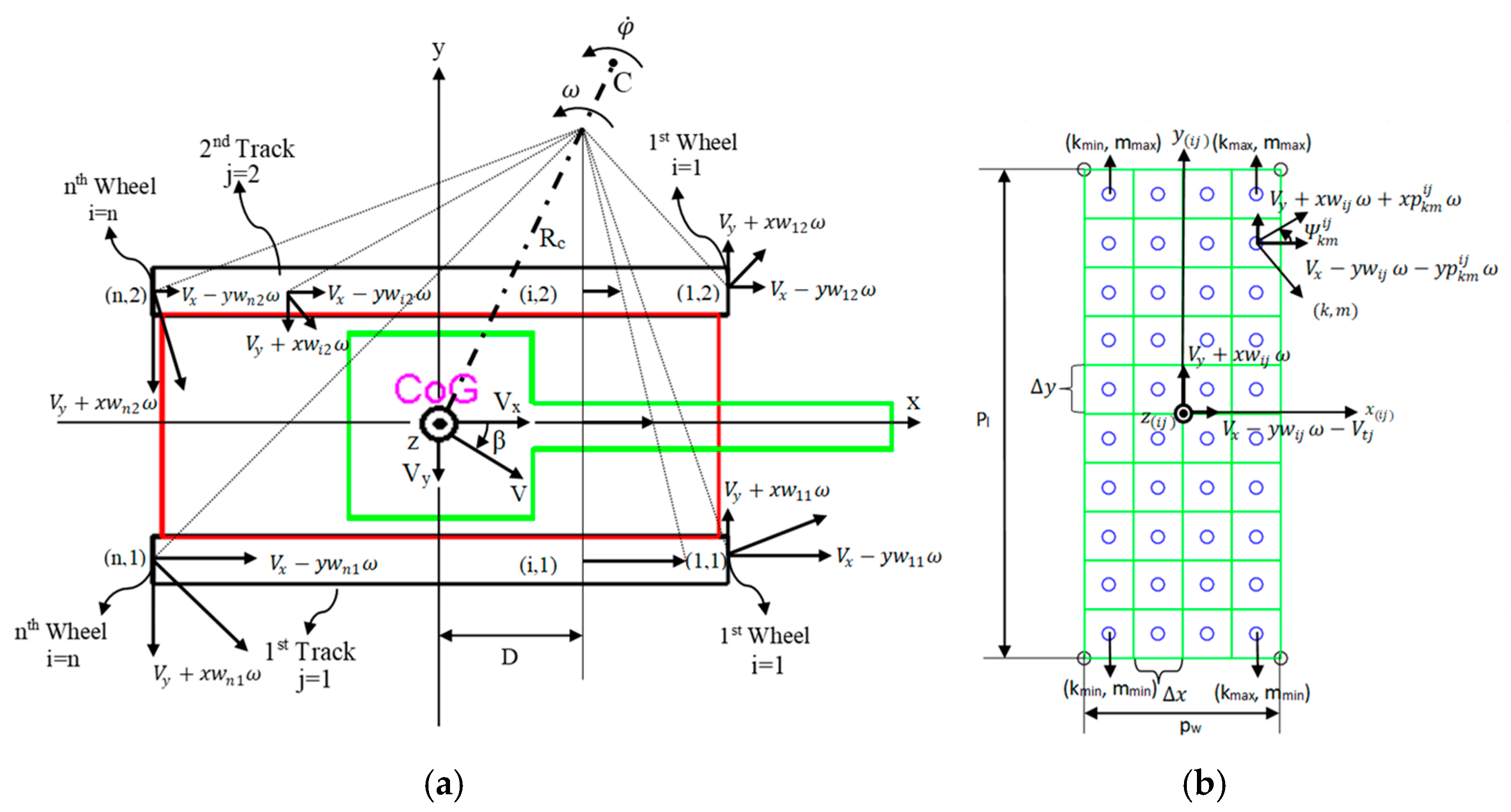

In the model, track pads are discretized to smaller portions and kinematic calculations are performed for each portion (

Figure 3b). First, longitudinal, lateral, and resultant slip velocities of each discretized cells are calculated with Equations (1)–(3), where

,

, and

are the longitudinal, lateral, and resultant slip velocities, respectively;

and

represent the position of each wheel center in vehicle coordinates;

and

are the positions of the discretized cells in wheel center coordinates;

is the velocity of each track.

By integrating the slip velocity along the contact timing of track pads, the slip displacement of each cell can be calculated for both longitudinal and lateral directions. The combination of these displacements gives the overall shear displacement of the cells, as shown in Equation (4), where

corresponds to resultant shear displacement. The integration time bound

represents the contact duration of each cell with the ground, which changes with respect to the velocity of the track. Applying the equation used in [

31], the shear stress of each track pad cell is calculated in Equation (5), where

is the vertical load on each wheel, A is the track pad area,

is the friction coefficient, and

is the shear deformation modulus.

Components of shear forces are summed for each track pad cell in order to calculate total forces under each road wheel in longitudinal (

) and lateral (

directions. Additionally, moments created by longitudinal and lateral forces (

,

respectively) are calculated. Finally, equations of motion are calculated in Equations (6)–(8), where

is longitudinal acceleration;

is lateral acceleration;

and

are rolling resistance forces of the right and left tracks, respectively;

and

are the lateral distances of the tracks to the CG of the right and left tracks, respectively.

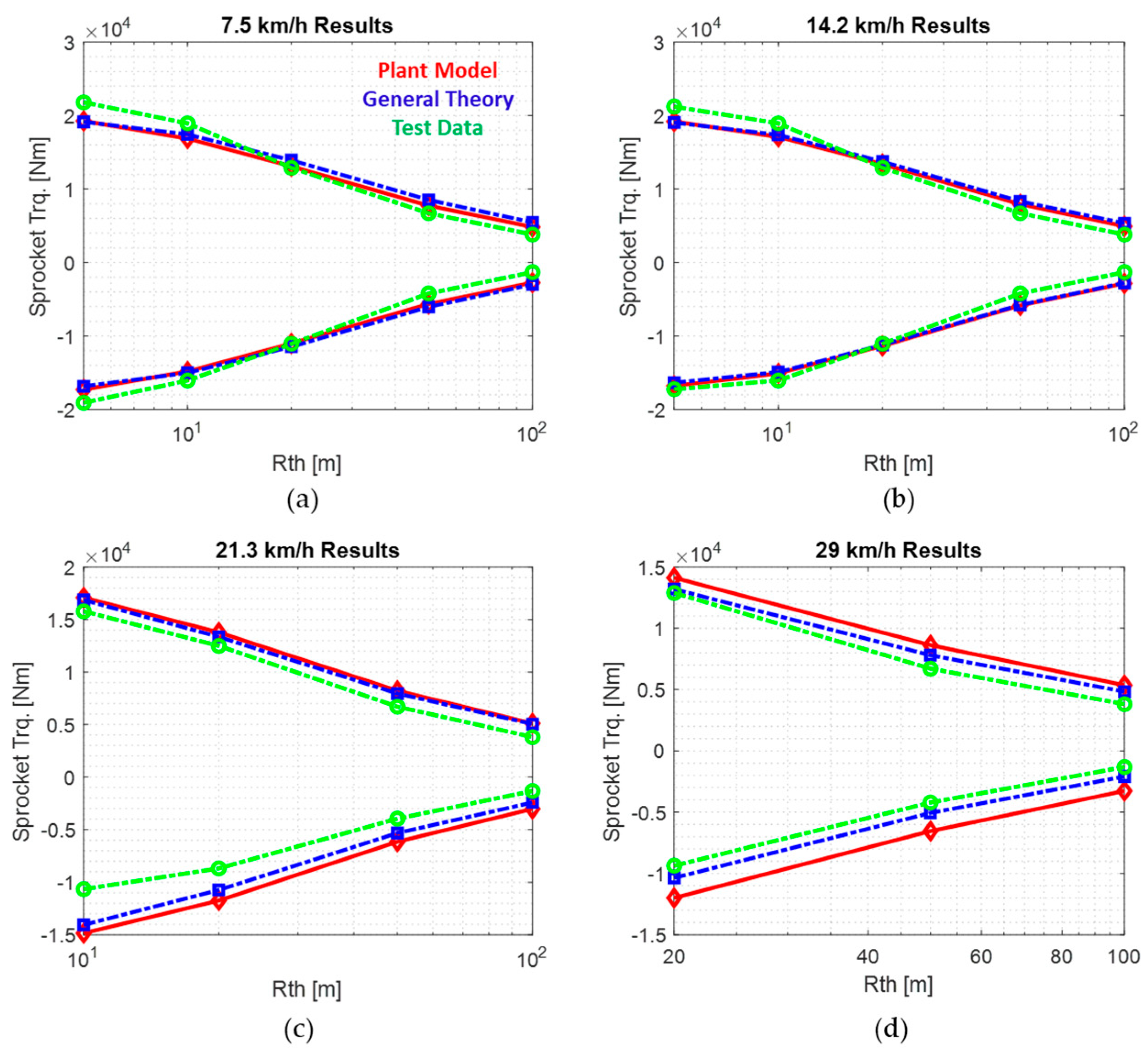

To demonstrate the fidelity of the plant model, sprocket torque results for various turning radii and speeds are compared against the well-known general theory for skid steering presented by Wong et al. [

31] and test data in [

32,

33] obtained from a 25.5 ton tracked vehicle. The comparison, presented in

Figure 4, with its numerical data provided in

Appendix A, shows that the plant model produces results closely matching the test data, particularly at speeds below 21.3 km/h, with deviations increasing at higher speeds. Nevertheless, the model successfully captures the overall trends and serves as a strong example of a transient tracked vehicle modeling approach that applies state-of-the-art contact force calculations based on the shear displacement method. It should be noted that the general theory results are presented here using the “concentrated load under each road wheel” assumption, one of the approaches investigated by Wong, which is likewise adopted in the plant model.

Building upon the plant model outlined in this section, which covers the essential dynamics of the tracked vehicle, we now advance to the development of predictive models crucial for trajectory tracking. In

Section 3, we introduce the kinematic prediction model, offering a simplified approach to forecasting vehicle motion based on geometric and velocity parameters. Subsequently,

Section 4 describes the slip-based prediction model, which incorporates the effects of wheel–terrain interactions to enhance predictive accuracy. These models serve as foundational components within the model predictive control framework, which is further explained in

Section 5.

3. Kinematic-Based Model as a Foundation for MPC Prediction

In this section, we introduce a kinematic vehicle model as outlined in [

14]. This model is used to assess its performance in comparison to the slip-based model described in

Section 4. Both models operate as nonlinear prediction tools within the model predictive control framework, enabling predictions of vehicle motion to facilitate the trajectory following control of the plant model described in

Section 2. The integration of these models within the MPC formulation is further detailed in

Section 5.

The layout of the model is presented in

Figure 2a. The positions in longitudinal and lateral coordinates (

) and the yaw angle (

) of the vehicle are the main states of the model, where the velocities of the outer and inner tracks (

,

) are the main inputs of the system initially. Nonlinear equations for vehicle motion can be written with the following nonholonomic form, where

refers to the thread of the vehicle.

To extend the given definition and apply the sprocket torques as inputs of the system, tracked vehicle force equations and kinematic relationships can be used. Dynamics at the sprocket level can be defined as in Equation (10), where,

defines the required traction force (Equation (11)), which comprises resistance due to (i) longitudinal motion

, and (ii) the so-called turning resistance moment—

, while the rest of the components belong to (iii) translational and (iv) rotational inertial forces (

and

, respectively).

The turning resistance moment (

) [

31], steering resistance force (

), and effective lateral friction coefficient (

[

34] definitions are given in Equations (12) and (13).

Combining Equations (10) and (11), sprocket level equations take the following form:

Combined kinematic equations of motion of the tracked vehicle are obtained as in Equations (15)–(19):

where

and

in Equations (17) and (18) comprise terms related to inertial effects, such as the inertia of driveline

and yaw inertia of the vehicle

, as shown in Equations (20) and (21).

In concluding the vehicle model introduced in this section, this approach provides a foundational basis for the vehicle motion obtained by applying the kinematic laws. To facilitate its application within the MPC framework, we linearize the nonlinear state matrices by their Jacobians. This linearization process yields discretized state representations, essential for predicting future states over the defined prediction horizon. These specific procedures will be explained thoroughly in

Section 5.

4. Development of a Simplified Slip-Based Model as a Foundation for MPC Prediction

This section introduces the core research contribution of this study—a simplified slip-based nonlinear prediction model specifically designed for model predictive control of tracked vehicles. Traditional shear displacement models often involve computationally intensive integrals, making them less practical for real-time applications. The proposed model addresses this challenge by implementing further simplifications, enhancing computational efficiency while maintaining effective tracking performance. The simplified model is verified later through a comparison with the full nonlinear shear-displacement-based plant model. As a remainder, this section, as well as

Section 3, establish the fundamentals of the prediction models. Next, these models are utilized in the MPC framework as the derivations that will be explained in

Section 5.

Differing from kinematic models, the proposed model includes the contact force generation characteristics of track pads. Assuming that the vertical load under track pads is concentrated under road wheels, calculations can be performed based on point contact force generation as in wheeled vehicle applications. Therefore, slip velocities are calculated for each road wheel location with kinematic relations. Shear forces developed by the pads are estimated for longitudinal and lateral directions. Finally, equations of motion based on these forces are constructed.

As described in Equations (4) and (5), calculating shear forces in tracked vehicles typically involves integrating the slip velocity over the contact time, a process that can be computationally intensive and challenging to linearize. To address this, our study applies simplifications in track force estimation to develop a more efficient prediction model. As stated in [

28], shear displacement can be approximated with the multiplication of combined slip and average contact times, as in Equation (22), where

defines the shear displacement under each road wheel,

defines the resultant slip velocity, and

is the average contact time under road wheels. Notice that this equation is a simplified version, where

is calculated by dividing the contact length (

under road wheels by the track velocity, as in Equation (23). Here,

is the vectoral distance of the i

th road wheel to the CG. Therefore,

defines the distance of the road wheel to first road wheel.

The slip ratio under each wheel can be expressed with Equations (24)–(26).

Utilizing Equations (24)–(26), components of the forces in longitudinal and lateral directions can be defined as in Equations (27) and (28), where

is the resultant force (Equation (29)), which refers to the well-known shear displacement approach [

31].

The last term in Equation (29) is the exponential function, and by combining Equations (22) and (23), the following definition is obtained:

Combining Equations (27)–(30), the force equations become Equations (31) and (32).

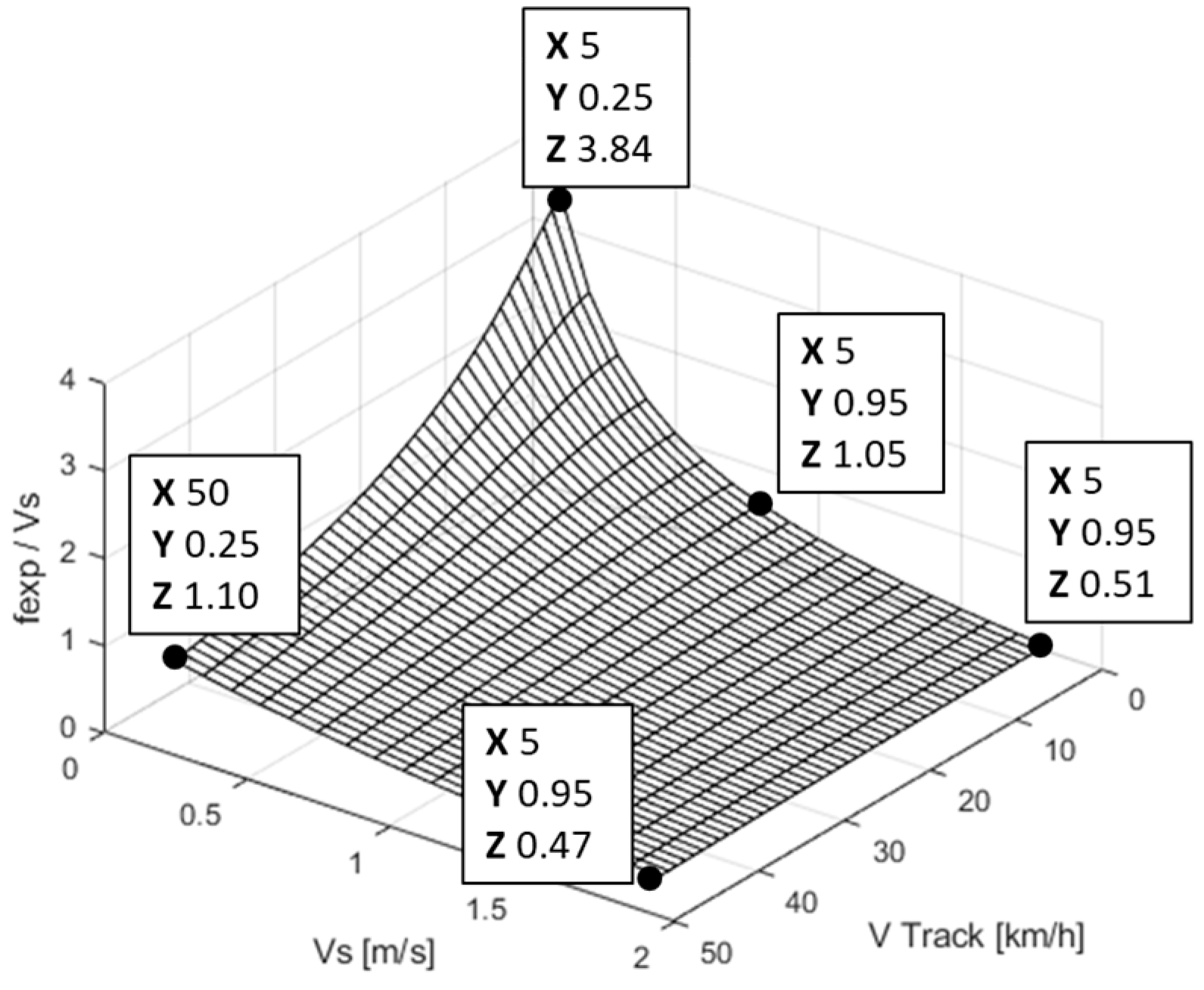

Analyzing the effect of change of

and the

in change of

, the surface in

Figure 5 is obtained for the mid road wheel. The increases in

and

parameters lead

to operate on an almost planar surface and become insensitive to their increase. This feature can be used in the simplification of the prediction model. Instead of an exact calculation of this factor, a constant value can be applied, so that the calculation effort in track forces decreases. Therefore, calculations of longitudinal and lateral forces can be approximated with Equations (33) and (34). Finally, the layout of the proposed model can be constructed as in

Figure 6. The method used to calculate the vertical load under each wheel is explained in

Appendix B.

The longitudinal slip velocities under the i

th road wheel on the right side and left sides of the vehicle are calculated using Equations (35) and (36).

Moments created by longitudinal forces on the right and left sides are then calculated according to Equations (37) and (38), where

and

are the transmitted longitudinal forces under the i

th wheel on the right and left sides, respectively.

The lateral slip velocities under the i

th road wheel on the right side and left side of the vehicle are calculated using Equation (39).

Moments created by lateral forces on the right and left sides are then calculated according to Equations (40) and (41), where

and

are transmitted lateral forces under the i

th wheel on the right and

left sides, respectively.

Using the force and moment calculations, state calculations for the longitudinal and lateral velocities of the vehicle in body coordinates and yaw velocity are conducted with Equations (42)–(44).

Velocities of the vehicle in global coordinates are calculated by applying appropriate transformations, as shown in Equations (45)–(47). The integration of these parameters over time provides the calculation of position states (

,

and

) given in Equation (51).

Finally, states for sprocket speeds are calculated by differential equations given in Equations (48) and (49).

The states and inputs of the nonlinear model are summarized in Equations (50)–(52).

In the MPC structure, and are designed as manipulated variables, whereas resistance forces are fed to the system as calculated inputs. The reference trajectory is fed to the system in terms of its longitudinal and lateral positions and yaw angle, as in the kinematic-based prediction model: .

In this section, we develop a simplified slip-based model. This model incorporates slip dynamics, addressing the limitations of the kinematic model. The next section provides a procedure for how these models are utilized to predict future vehicle states, formulate control objectives, and implement constraints to achieve optimal trajectory tracking performance.

5. MPC Problem Formulation

In this section, we detail the model predictive control (MPC) formulation, utilizing both the kinematic model from

Section 3 and the slip-based model from

Section 4 as prediction models for trajectory tracking. The nonlinear prediction models used in this study (kinematic and slip-based) are linearized at each controller sampling instant (Ts = 0.05 s) about the current measured states and latest control inputs. This yields the updated Jacobian matrices

and

of the system dynamics with respect to states and inputs in Equations (62)–(65). These continuous-time Jacobians are then discretized using the Euler method (Equations (66)–(68)) to produce the local linear prediction model in discrete-time state–space form. Based on this model, the MPC cost function is formulated to penalize deviations from the reference trajectory and excessive control changes over a prediction horizon N = 20 (1 s look-ahead) and a control horizon M = 2 (0.1 s control window). The resulting QP problem is solved using MATLAB’s fmincon function; only the first control action of the optimized sequence is applied to the plant before the horizon is shifted forward and the procedure repeated. An analysis for computational efficiency is introduced later in

Section 6.2, with a sensitivity analysis of these specific MPC parameters providing the timing headroom for the calculation of each step-in solution of the MPC problem over a specific scenario. To facilitate the MPC design,

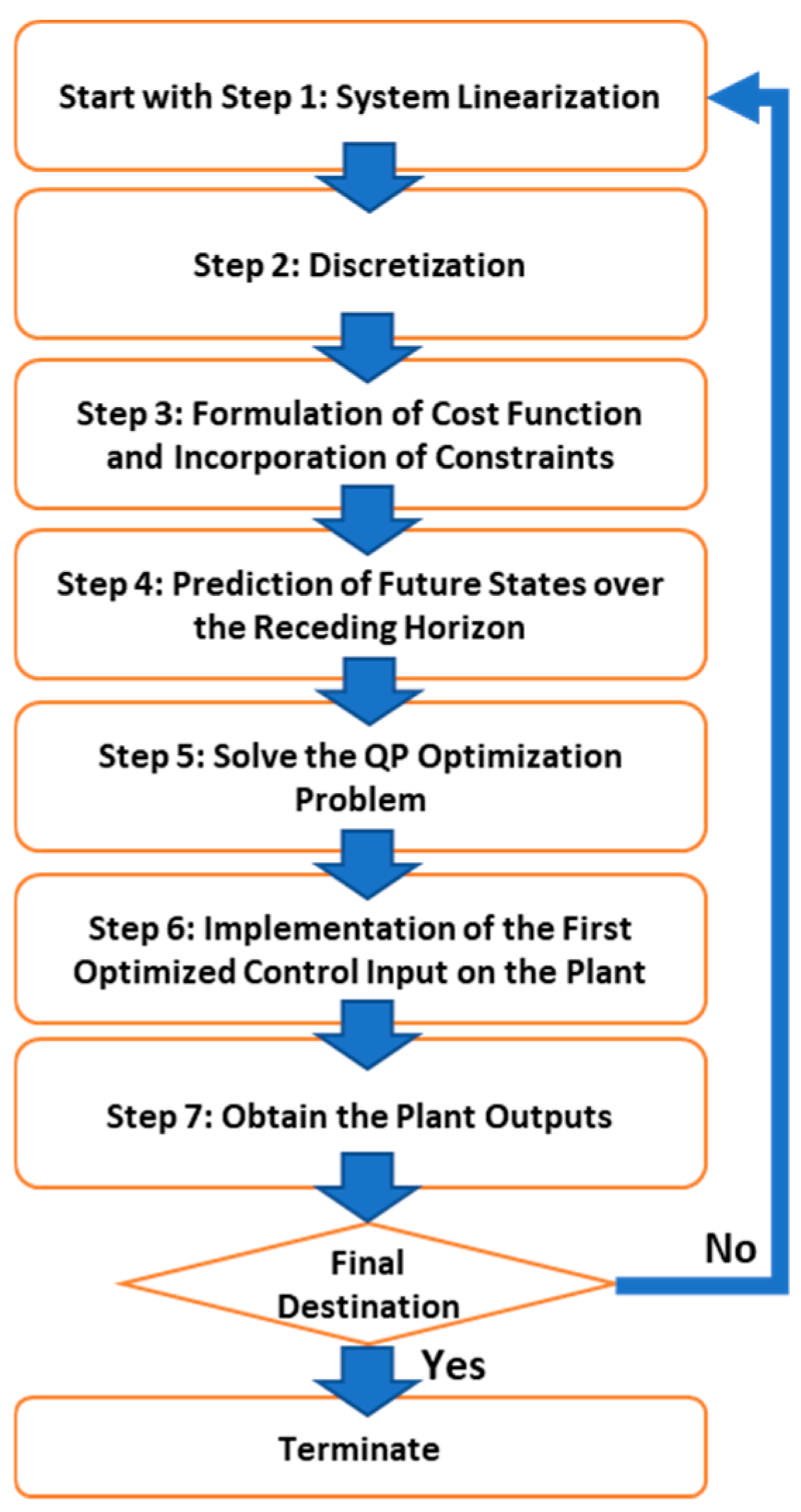

Figure 7 presents a flowchart of this process, showing the mentioned process sequence.

To start with the derivation, generalized discrete state space calculations can be given with the following equations, where k is the stage number of the problem:

States for the vehicle, which follow the trajectory perfectly, are calculated by the function given in Equation (55). The inputs of this function are the reference state vector (Equation (56)) and the reference manipulated vector

(Equation (57)).

Actual states of the vehicle are calculated by Equation (58).

Nonlinear state equations are linearized with Taylor series expansion, as in Equation (59).

Subtracting Equations (58) and (59), Equations (60) and (61) can be obtained.

and

are Jacobian matrices with respect to (

and

, respectively (Equations (62) and (63)).

Using the state matrices in Equations (17) and (18), Jacobian matrices of the kinematic-based nonlinear model (

Section 3) are computed by taking the partial derivatives of the system dynamics with respect to the state vector

x in Equation (16) and the input vector

u in Equation (19). The same linearization procedure is applied to the slip-based prediction model, where the Jacobians are computed from the nonlinear state Equations (42)–(49) with respect to states given in Equation (51) and the input vector in Equation (52). The resulting continuous-time Jacobians

and

define the local linear approximation of the nonlinear dynamics at a given operating point. Based on these calculations, the explicit form of

is given in Equation (64), while

is expressed in Equation (65) for the slip-based prediction model. The detailed, term-by-term partial derivatives used to construct these matrices are provided in

Appendix C, enabling direct traceability from the nonlinear state equations to the elements of

and

.

where

,

, and

represent the sum of vertical loads on the left side, right side, and both sides, respectively;

are vertical loads for the i

th road wheels of the right and left sides, respectively. Next, discretized forms of the linearized new state equations are then obtained with Equations (66)–(68).

Prediction states for the horizon length of N and control horizon M are calculated as Equations (69)–(73).

Finally, the output of the linearized equations is found with appropriate output matrices as in Equation (74). Here,

is zero, since the output function recalls only [x, y,

] outputs, which are independent from the inputs.

A generic MPC formulation is given in Equation (77), where

is the output,

is the reference signal, and u is the control input;

and

are the weights between the output error and the control variables.

The quadratic problem of MPC can be defined with Equations (78)–(80), where

is the Hessian matrix and

is the linear component of the objective function problem.

The constraints for input sprocket torques following conditions in Equations (81) and (82) are then applied, where

and

are the maximum and minimum sprocket torques, respectively.

Change of input torques are limited with the following constraints:

Therefore, the MPC problem is solved subject to the inequalities:

The objective of the problem is to find the optimized control sequence and apply the first control value to the system

. Repeating this sequence until the end of the calculation finalizes the MPC procedure.

7. Test Verification for the Controller Performance

This section includes a verification of the plant model used in the study and the proposed MPC controller. Since the plant model is driven by the torque outputs of the MPC, test scenarios are focused on measurements of the vehicle trajectory and the sprocket states. Therefore, the vehicle was instrumented with different measurement devices during the tests, such as with GPS (Racelogic VBOX IISX, VBOX Automotive, Buckingham, UK), IMU (SBG Ellipse-D, SBG Systems, Carrières-sur-Seine, France), Kvaser (Kvaser AB, Mölndal, Sweden), and encoder instruments for speed measurements of the sprocket driving shafts and a strain gauge-type measurement setup for torque measurements on the sprocket driving shafts. In

Figure 18 the instrumentation package for measurements on the sprocket driving shaft is presented. The asphalt test track used in the conducted experiments is demonstrated in

Figure 19.

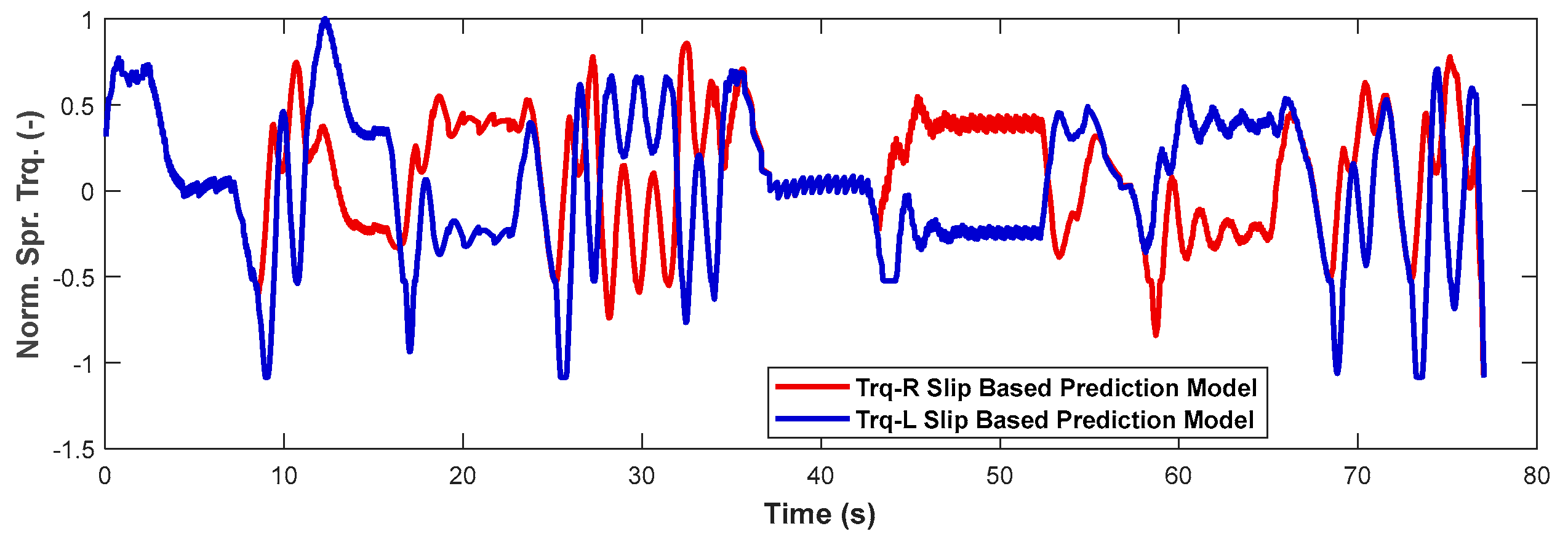

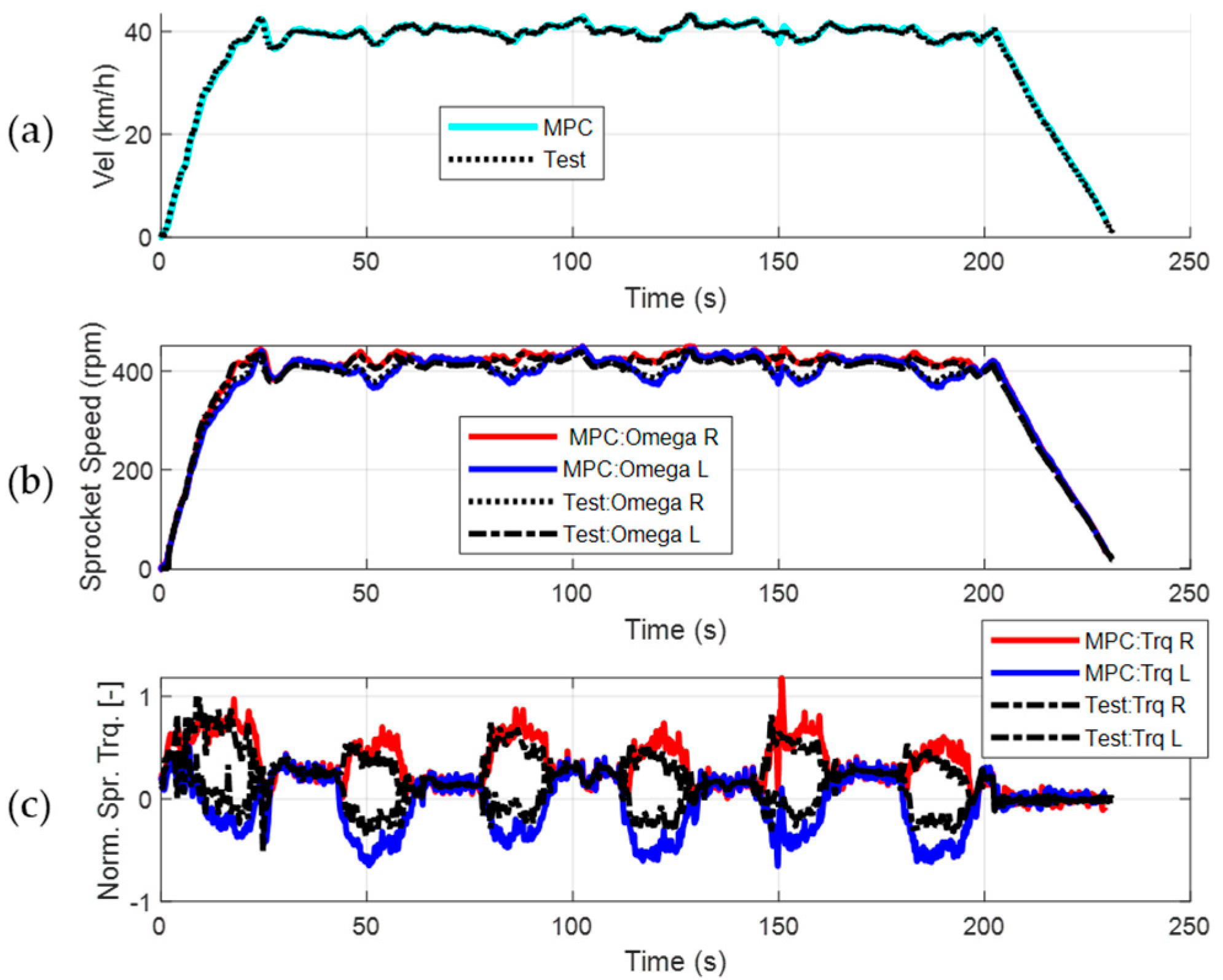

Tests were conducted in three categories: (1) low-speed cornering maneuvers on the asphalt test track; (2) touring on the asphalt with higher speeds on the test track; (3) touring on a stabilized test parkour. The main aim of these tests was to observe the performance of the vehicle at low and high speeds and use the results for a comparison with the MPC controller outputs. The obtained GPS data from the tests were converted to Cartesian coordinates and fed to the MPC controller in the simulation environment as the reference trajectory to reproduce the results of the tests.

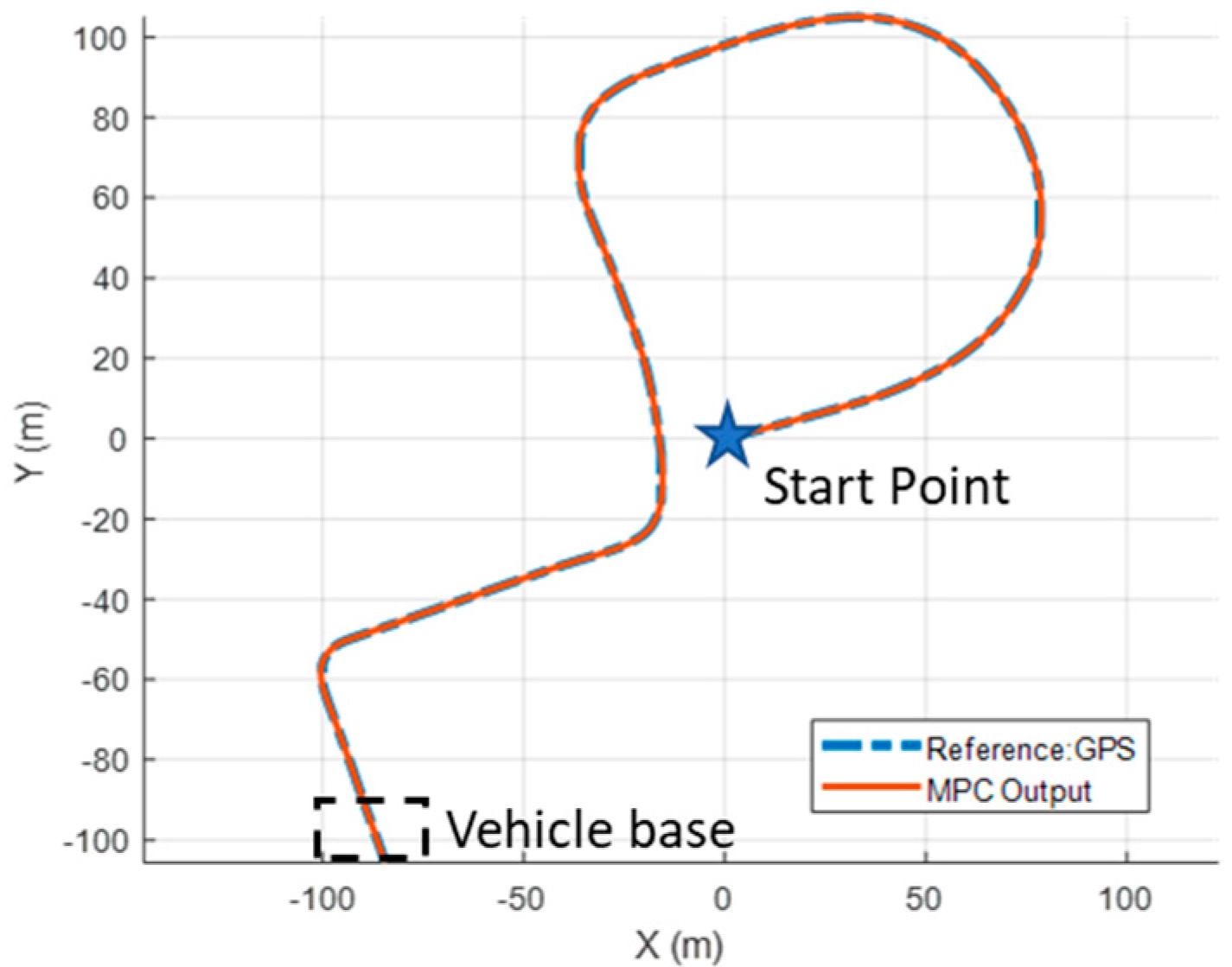

In the first scenario, the vehicle moves to its parking base at about 15 km/h of steady velocity. The GPS coordinates and results of the controlled plant model are presented in

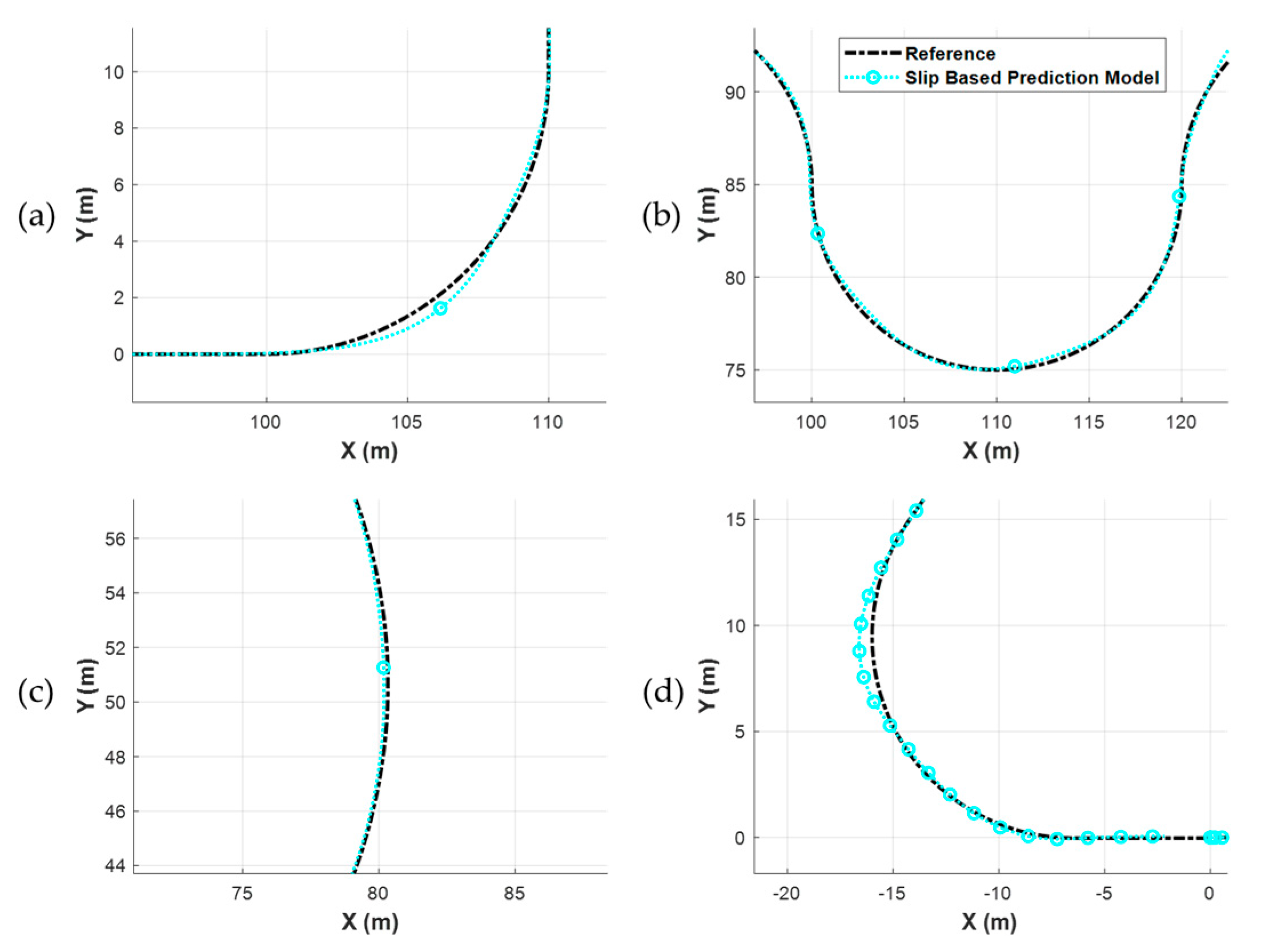

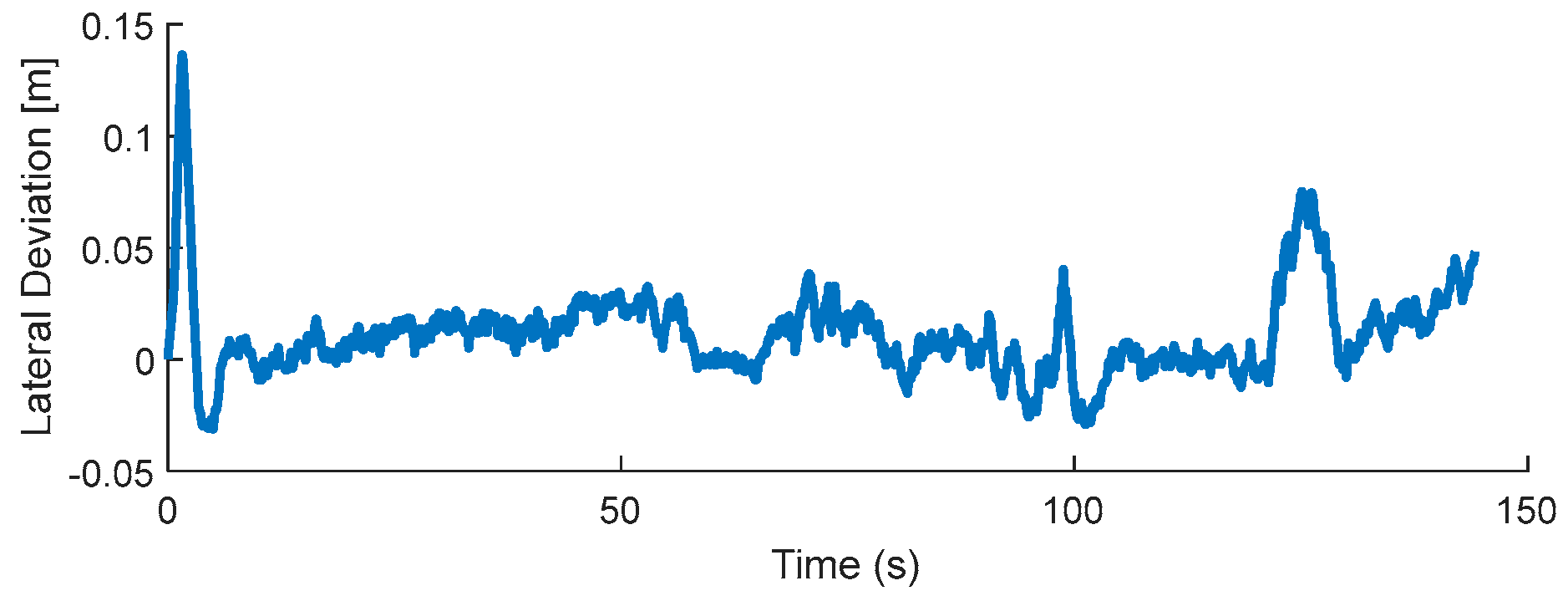

Figure 20, showing the close alignment of the test coordinates with the simulation outputs.

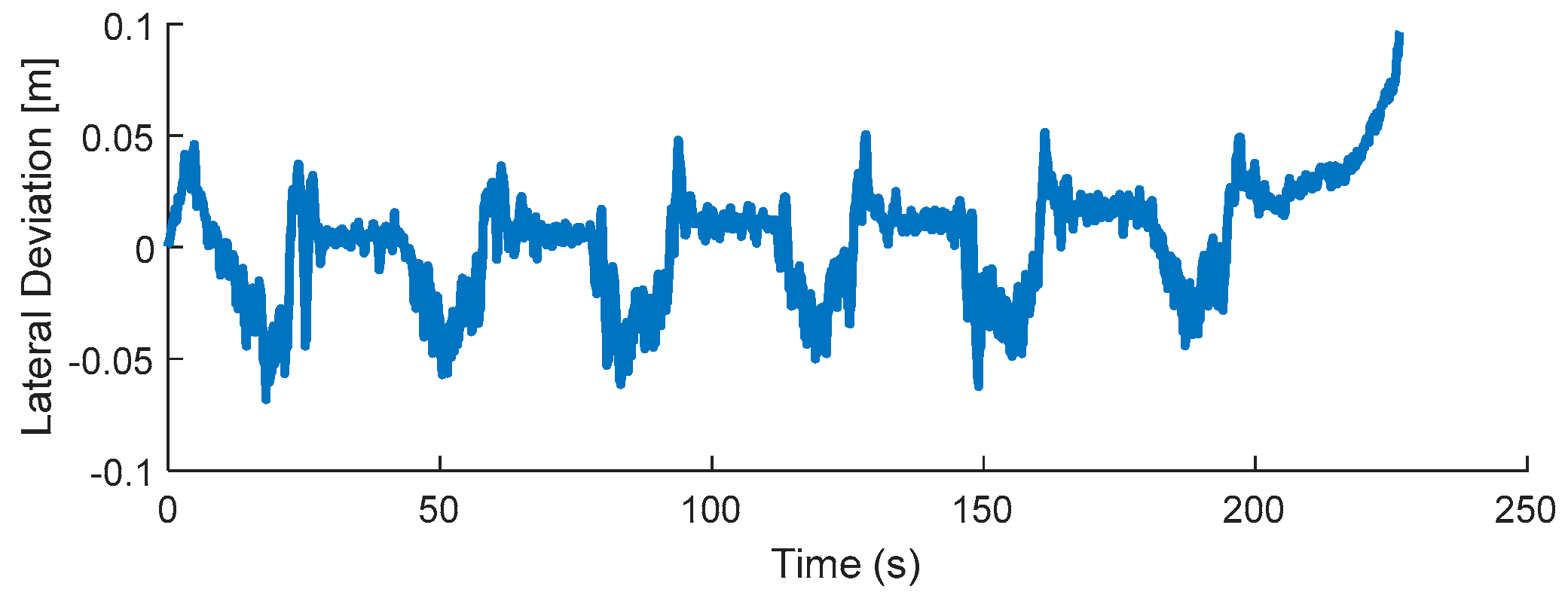

Figure 21 verifies this fact by showing that the RMS error for the lateral deviation is 0.022 m.

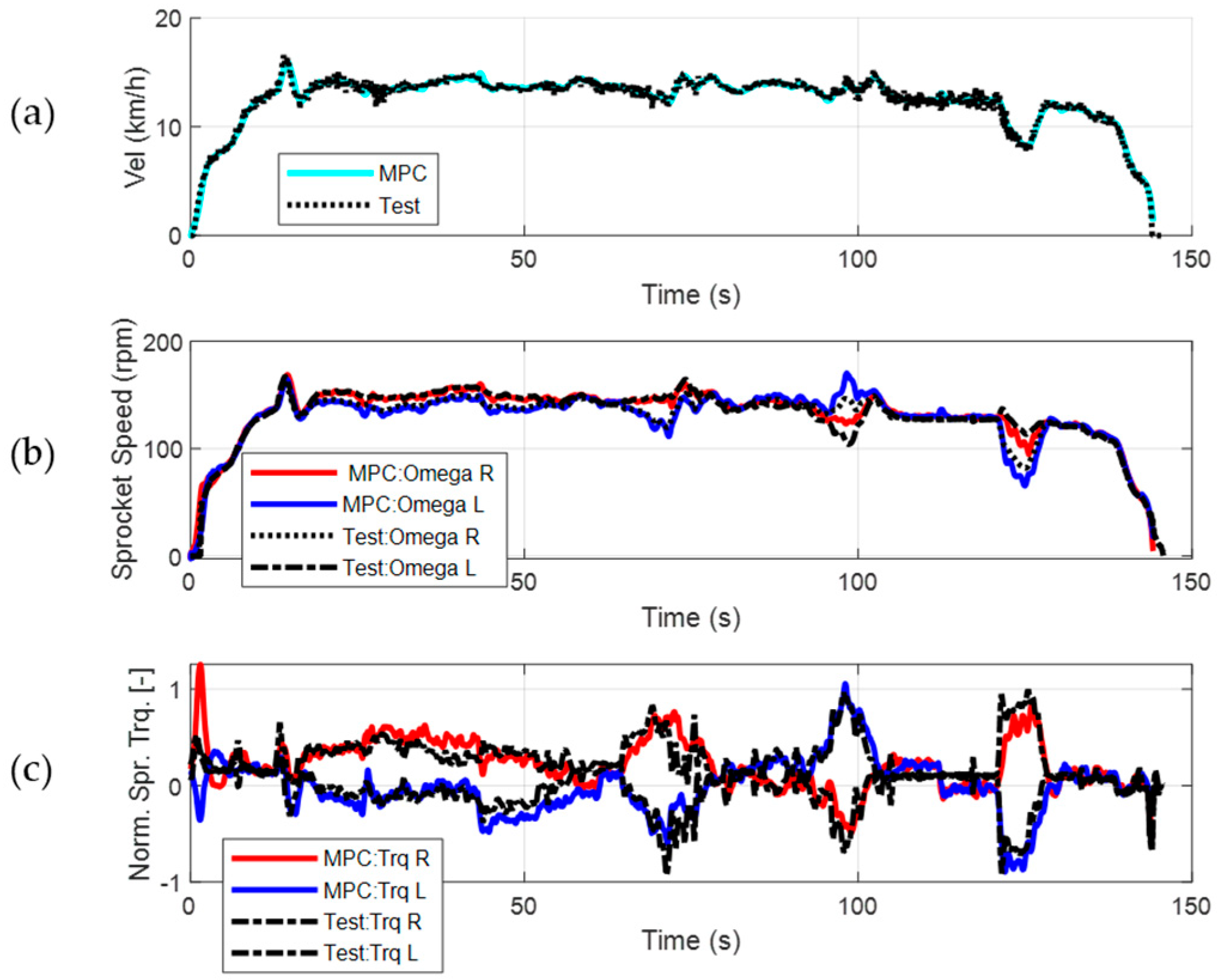

Figure 22 presents the comparison of the test data and the reproduced test in terms of the velocity profile, speed, and torques at the sprocket. The RMS differences between the reproduced simulation data and the test data for velocity, sprocket speeds, and torques are as follows: 0.3 km/h, 5.3 rpm for the right sprocket, 5.1 rpm for the left sprocket, 0.11 normalized torque for the right sprocket, and 0.12 normalized torque for the left sprocket. Normalization is conducted with respect to the absolute maximum torque value of the test data and the RMS errors correspond to 11% and 12% of this value, which are within the acceptable range, while the torque signals of the simulation results show similar trends to the measurements.

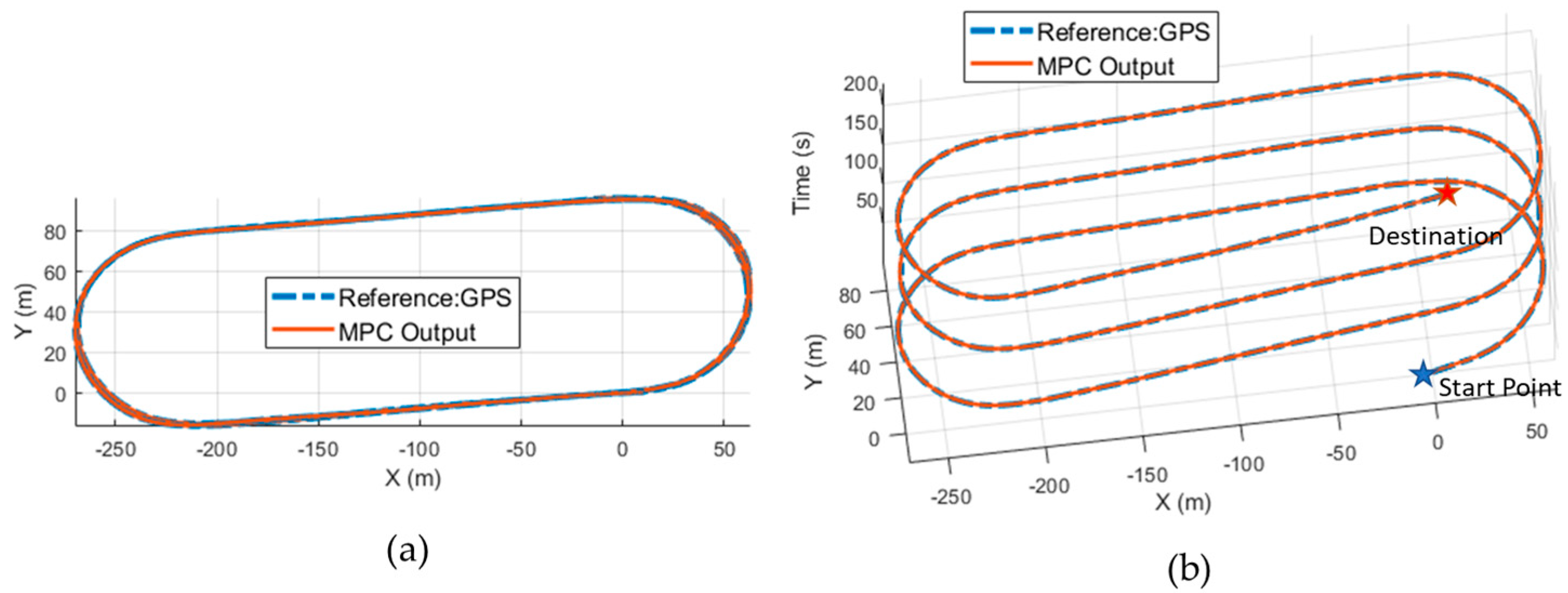

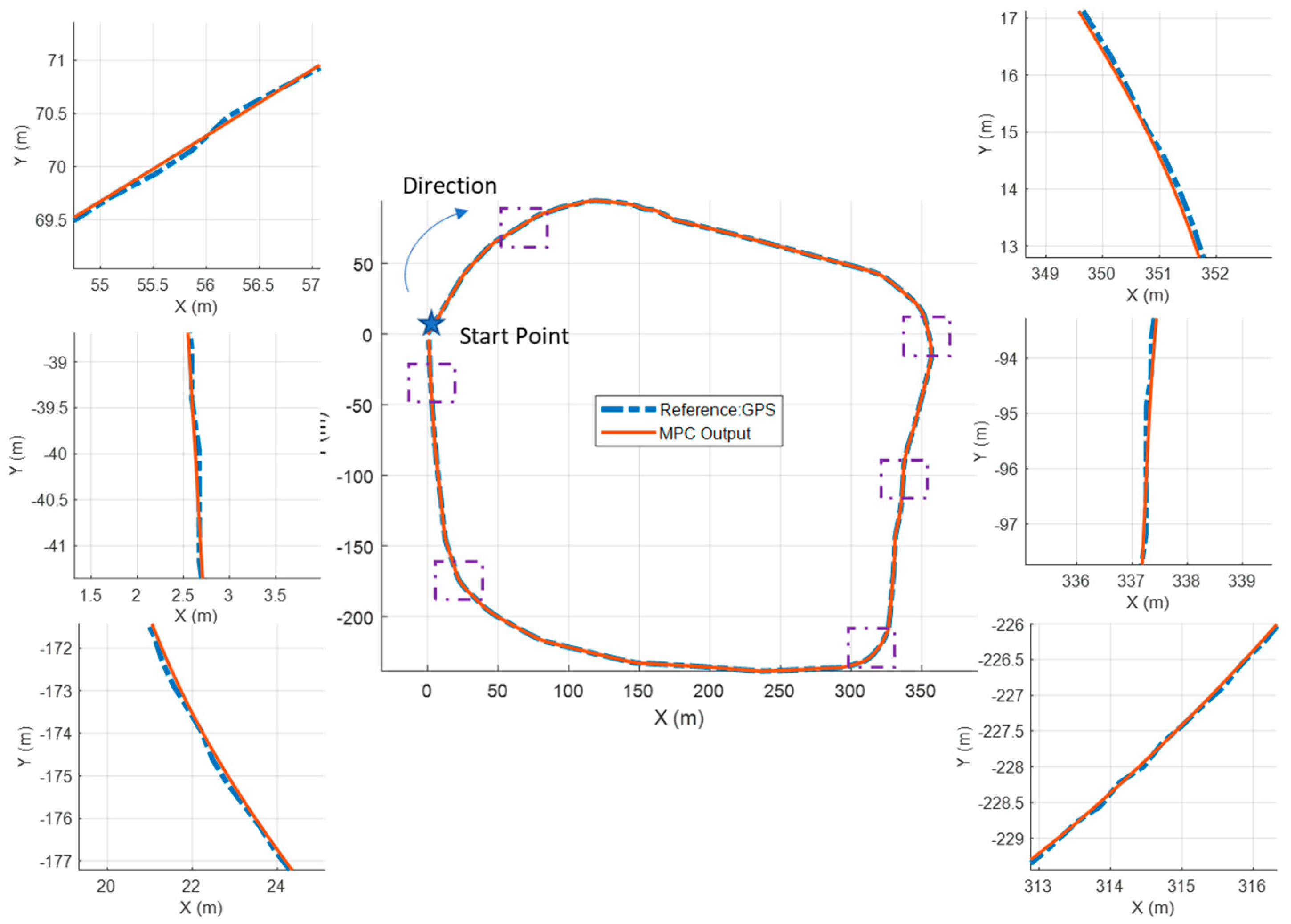

In the second scenario, the vehicle tours around the track with steady velocity of about 40 km/h. In

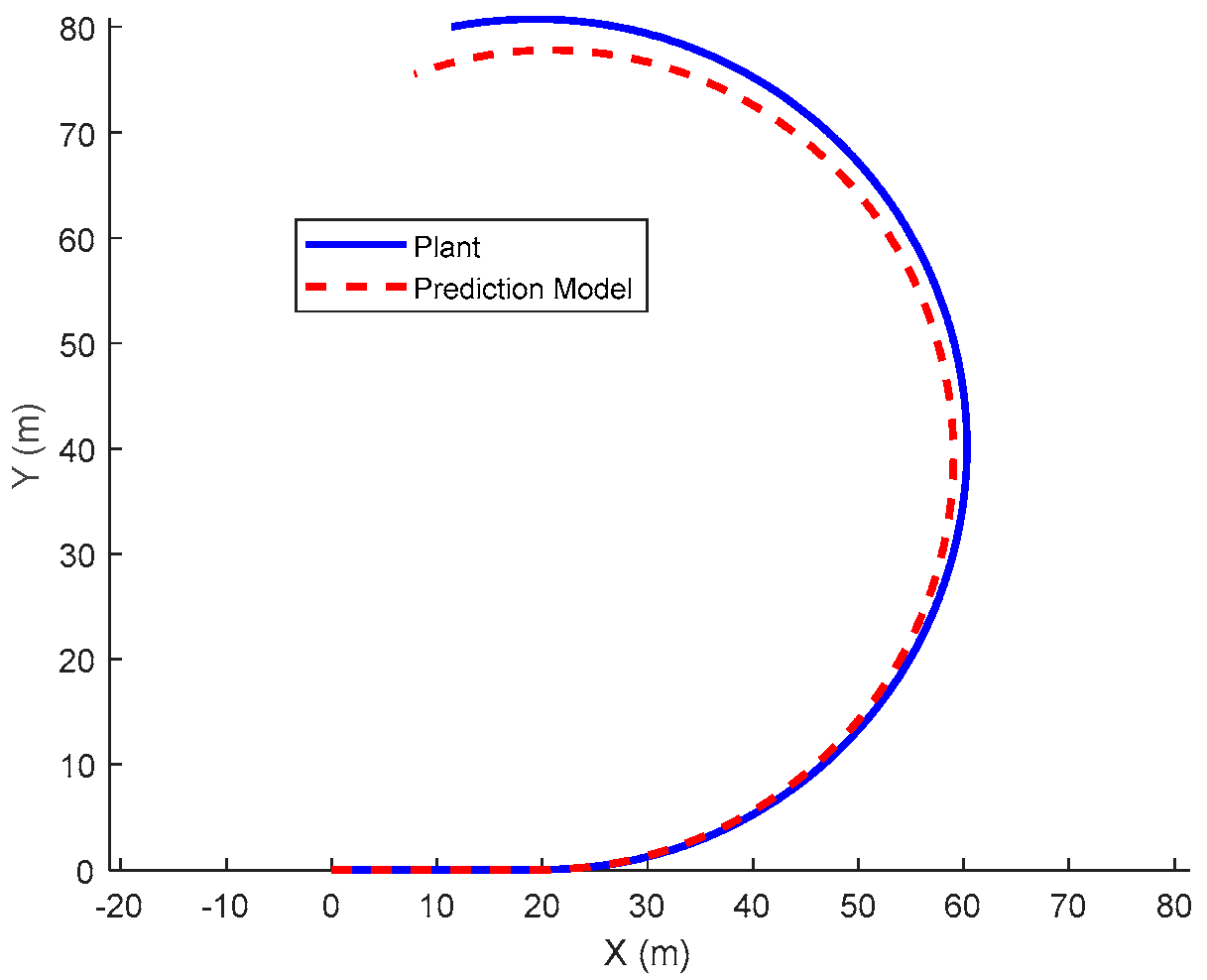

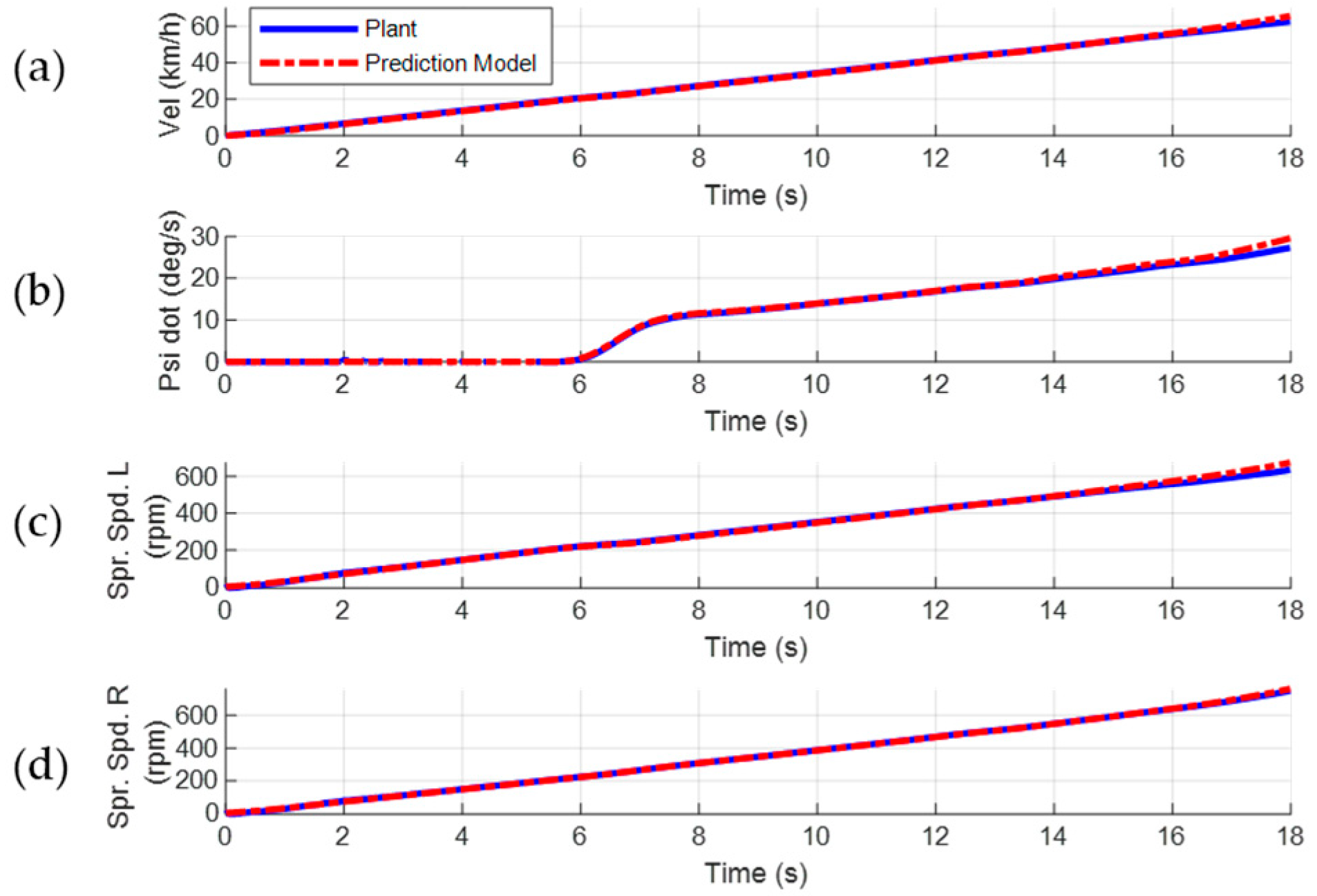

Figure 23, the trajectories of the GPS data and reproduced test data with the MPC controller are presented.

Figure 23a provides a top-down view, whereas

Figure 23b illustrates the trajectory in the time domain as the third dimension, showing close alignment of test coordinates with the simulation outputs.

Figure 24 verifies this fact by presenting the RMS error for the lateral deviation, which is 0.025 m.

Figure 25 presents the comparison of the test data and the reproduced test in terms of velocity profiles, speeds, and torques at the sprocket. The RMS differences between reproduced simulation data and the test data for velocities, sprocket speeds, and torques are as follows: 0.4 km/h, 8.7 rpm for the right sprocket, 9.7 rpm for the left sprocket, 0.11 normalized torque for the right sprocket, and 0.18 normalized torque for the left sprocket. Normalization is conducted with respect to the absolute maximum torque value of the test data, and the RMS errors correspond to 11% and 18% of this value for the right and left sides, respectively. As a result, in both Test Scenario 1 and Test Scenario 2, the replicated simulation results show good alignment with the test results. The relatively high error in the left sprocket (inner side at corners) points out the necessity for improvement, especially at higher velocities, in future work.

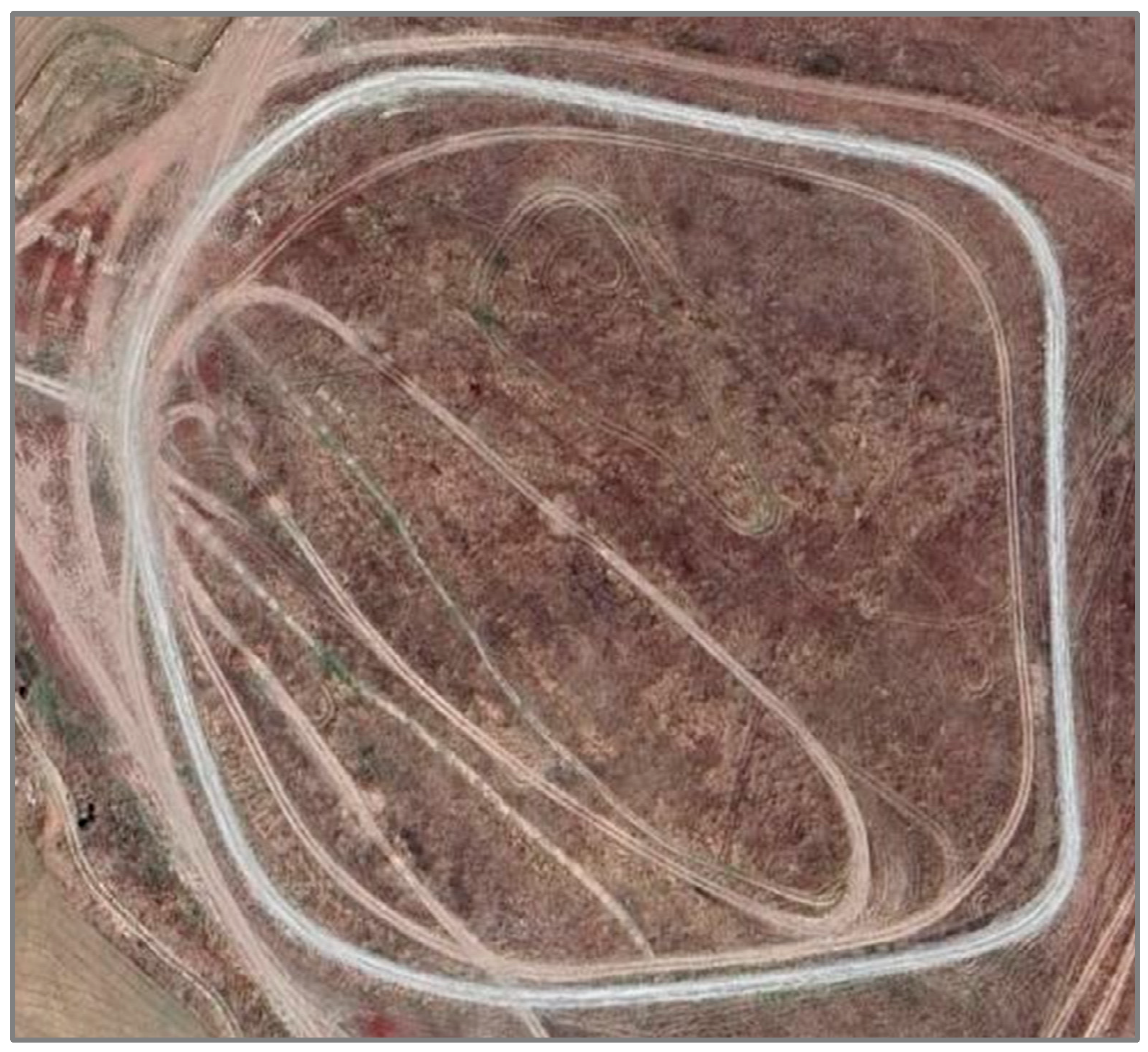

Apart from the tests performed on the asphalt track, GPS data obtained from experiments conducted on a stabilized dirt road surface were also used to replicate these scenarios within the simulation environment, following the same procedure as for the asphalt track tests. These stabilized road experiments were carried out at a different time from the asphalt track trials; therefore, torque measurement sensors on the sprocket driving shafts were not available during these runs. Differing from the asphalt road, friction coefficient was applied as 0.7 to represent the loose surface of the test parkour. The mentioned parkour used in these experiments is demonstrated in

Figure 26. The results of replicated simulations are presented in

Figure 27 and

Figure 28.

According to the results, the RMS differences between reproduced simulation data and the test data for velocities and sprocket speeds are as follows: 0.9 km/h, 13 rpm for the right sprocket and 14 rpm for the left sprocket. The RMS of the lateral deviation is about 0.028 m. These results also approve the applicability of this method in the replicated simulation environment and demonstrate that the controller delivers satisfactory performance.

Table 6 summarizes the results of all previously presented tests, as well as additional trials conducted to assess the robustness of the proposed control method on firm ground. For the repeated trials, the RMS lateral deviation values on asphalt road scenarios ranged between 0.020 m and 0.035 m, with a coefficient of variation (CV) of approximately 21%. For stabilized road scenarios, the RMS lateral deviation values ranged between 0.028 m and 0.045 m, with a CV of approximately 33%, reflecting the greater variability expected under more irregular terrain conditions. The largest lateral deviation was observed in the stabilized parkour test (Scenario 4-2 in

Table 6), with a value of 0.045 m. This deviation was mainly due to road surface irregularities, errors in converting GPS position data to Cartesian coordinates, and variations in the friction coefficient under stabilized road conditions, all of which make accurate replication in the simulation environment more challenging. It should be noted that the CV for stabilized road conditions was calculated from only two trials; therefore, it should be interpreted as an indicative measure rather than a statistically robust metric. Nevertheless, the measured ranges and CV values confirm the repeatability of the scenarios, the robustness of the controller in achieving its intended functionality, and the feasibility of applying it, particularly on firm ground surfaces.

8. Discussion and Conclusion

In this study, a slip-based prediction model was developed to enhance the trajectory tracking of unmanned tracked vehicles on firm road conditions by integrating it into a nonlinear model predictive control (NMPC) framework. The core novelty lies in the simplification of the exponential shear displacement formulation, yielding a bounded error but computationally efficient model of slip dynamics. The proposed approach, therefore, achieves a practical balance between accuracy and computational cost, confirming its suitability for high-speed operations in firm terrain conditions.

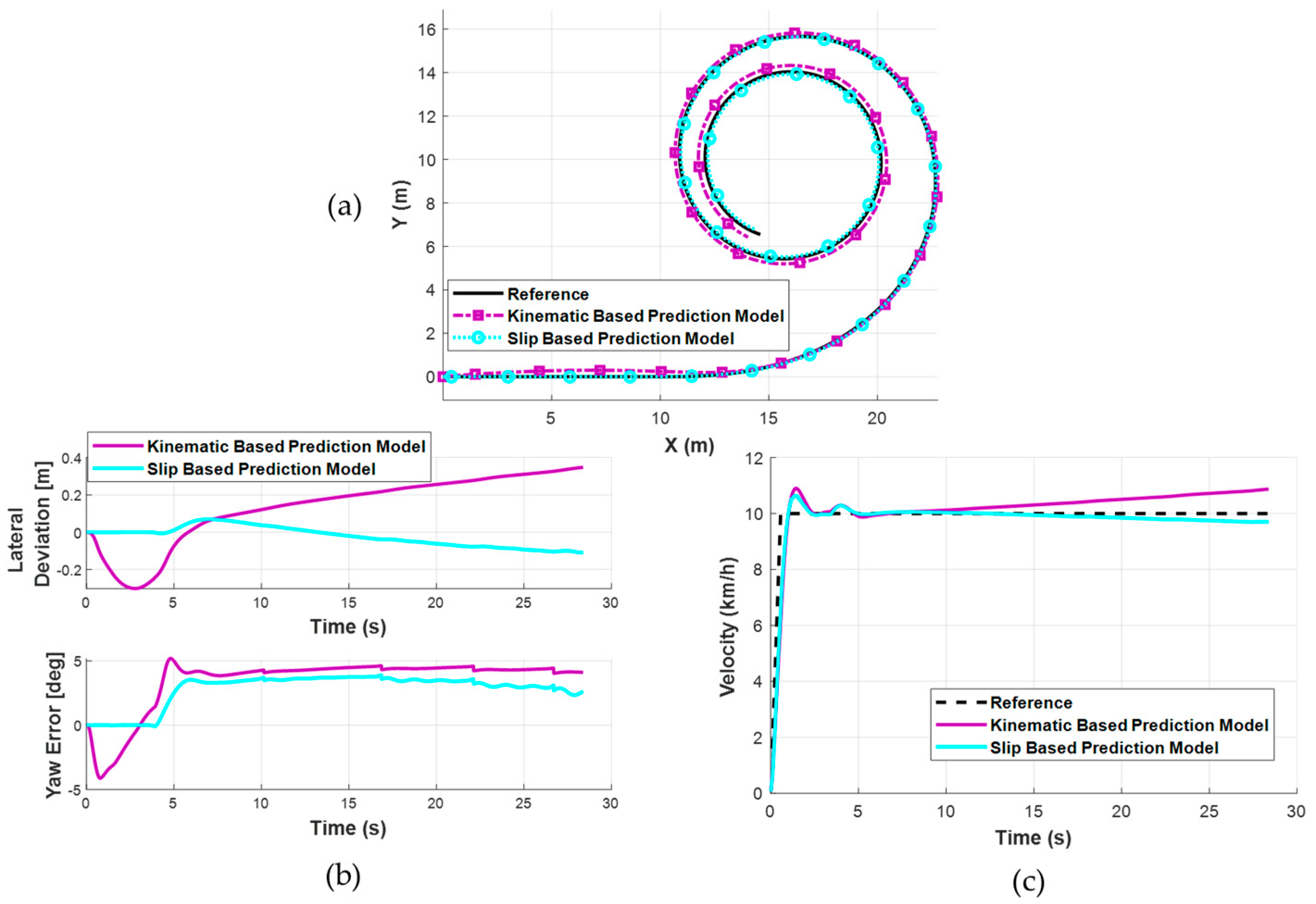

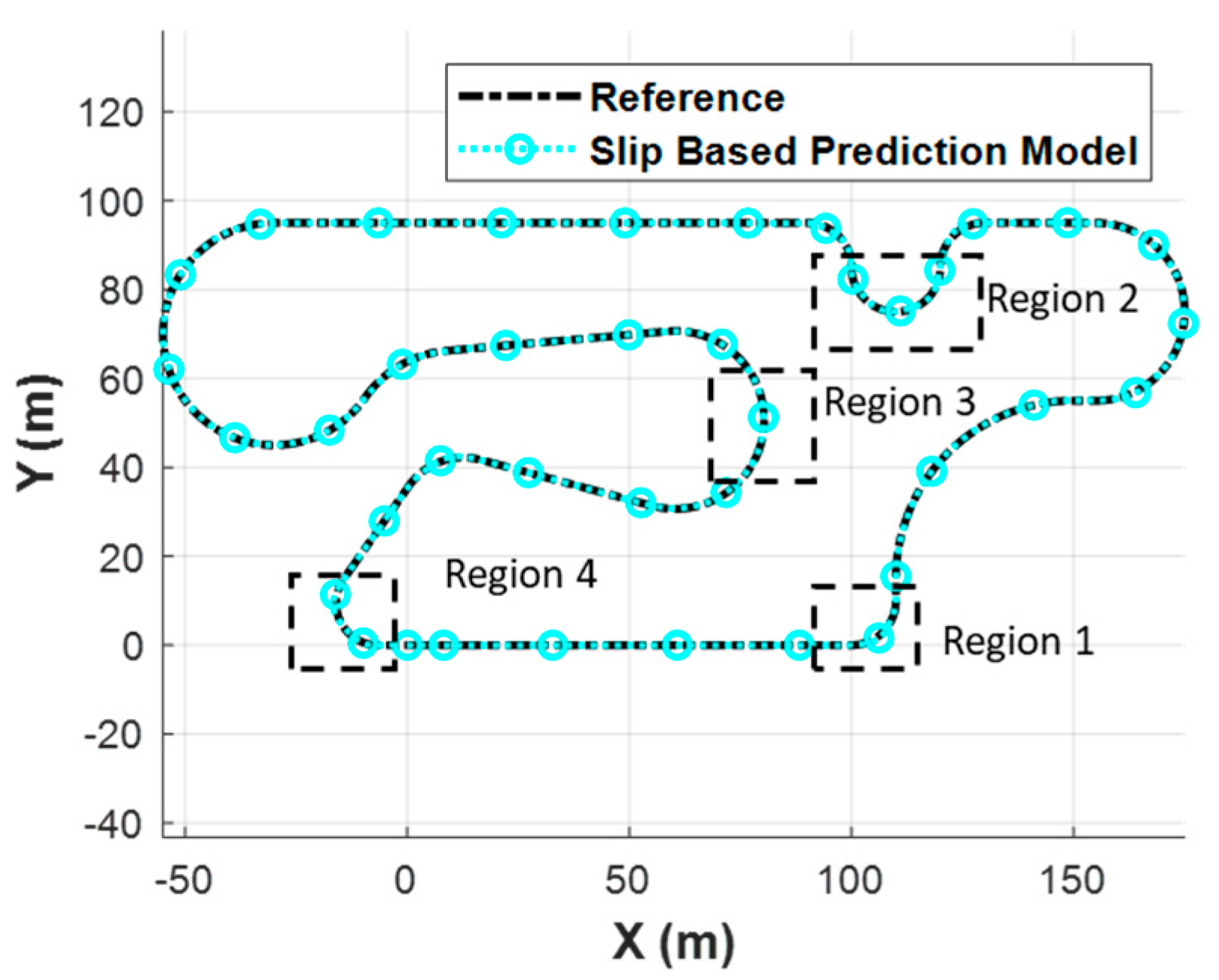

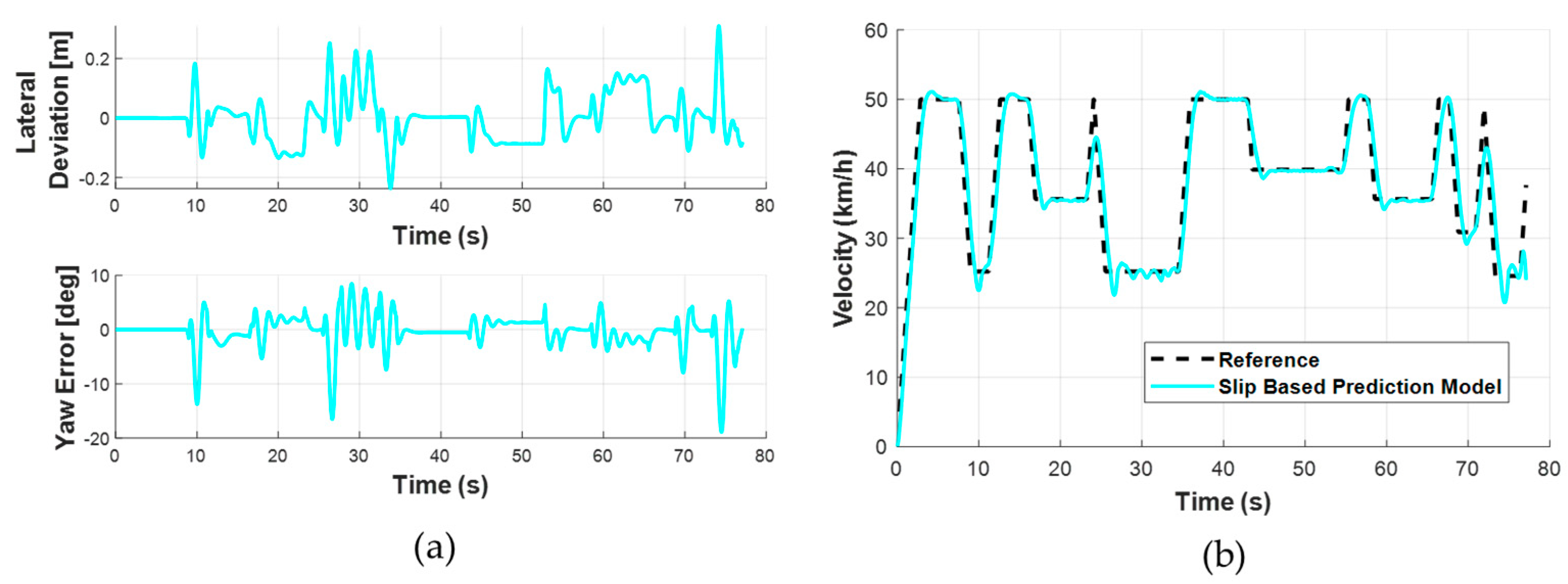

Comparative analyses demonstrated that the proposed slip-based controller outperformed the kinematic-based model, particularly in high-speed cornering and spiral maneuver scenarios. The slip-based model consistently maintained lateral deviation below 0.06 m RMS in comparative cases, whereas the kinematic model departed from the trajectory at increasing speeds. For a complex trajectory at up to 50 km/h, the lateral deviation remained below 0.08 m RMS, further confirming the robustness of the approach.

Sensitivity analyses were performed to assess the model’s robustness under varying conditions. The results indicated that the model maintains its high performance across different scenarios. Accuracy analyses further highlighted the model’s trend-wise similar performance against the plant model in trajectory tracking tasks. Computational efficiency evaluations indicated that with N = 20 and M = 2, the MPC used about 78% of the available sampling time, demonstrating feasibility for high-performance machines but highlighting the need for tuning in real-time embedded applications.

Validation was carried out through simulation replications using field test data from a five-wheeled tracked vehicle platform on asphalt and stabilized road conditions. The controller reproduced the vehicle’s trajectory, with lateral errors under 0.05 m RMS, and showed good agreement for sprocket speeds and torque trends, with torque estimation errors of up to 18% in asphalt test track conditions. These results confirm the effectiveness and reliability of the proposed framework for firm ground operations.

The improvements presented in this study have promising implications for real-world applications. By incorporating detailed slip dynamics into the prediction model, our approach enhances the reliability of trajectory tracking in unmanned tracked vehicles on firm ground. This advancement is crucial for applications such as unmanned heavy robotic applications and construction vehicles, where precise navigation and control are essential. The model’s ability to maintain low lateral deviations suggests its potential to improve operational efficiency and safety in these sectors.

While our model demonstrates promising results, certain limitations still require further investigation. To extend the usability of the model to more challenging environments such as uneven or deformable terrain, several factors must be addressed. The track–terrain contact mechanics will vary significantly, altering slip generation and distribution outcomes, particularly on irregular or low-cohesion surfaces. In the proposed formulation, track–terrain interaction is expressed in the shear displacement equations through the shear deformation modulus This parameter directly influences the exponential term in the force calculation; hence, it determines the effective range of the constant factor used in the simplified force calculations. Variations in shear deformation modulus under different terrain properties will, therefore, require either dedicated tuning of or preferably an adaptive parameter-updating scheme to maintain the model’s accuracy. As a possible future extension, learning-based estimation techniques could be integrated with the base prediction model to identify online, enabling the MPC to adapt in real time to changing surface conditions. Addressing these areas will bridge the gap between simulation results and practical applications.