Recent Advances in Additive Manufacturing: A Review of Current Developments and Future Directions

Abstract

1. Introduction

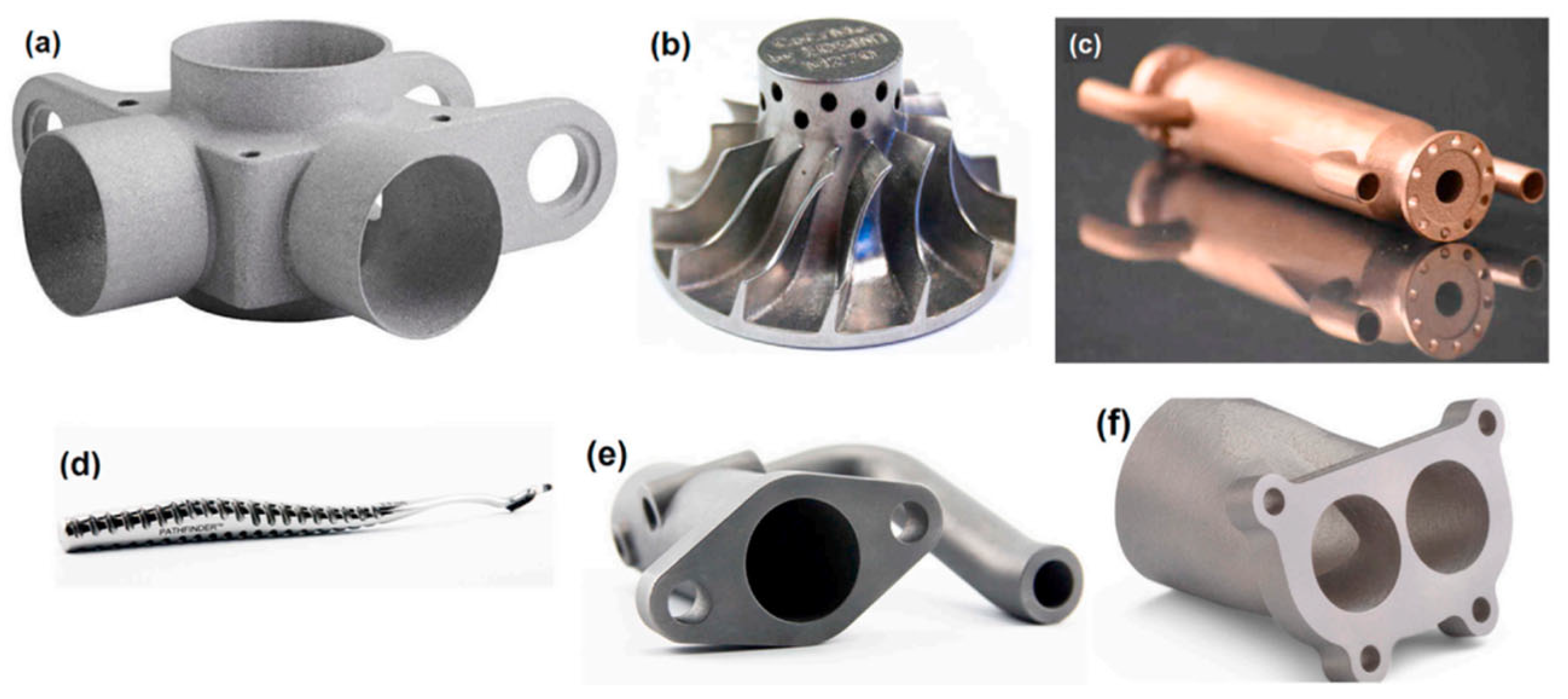

2. Current Developments in Additive Manufacturing

2.1. Overview of Existing AM Technologies

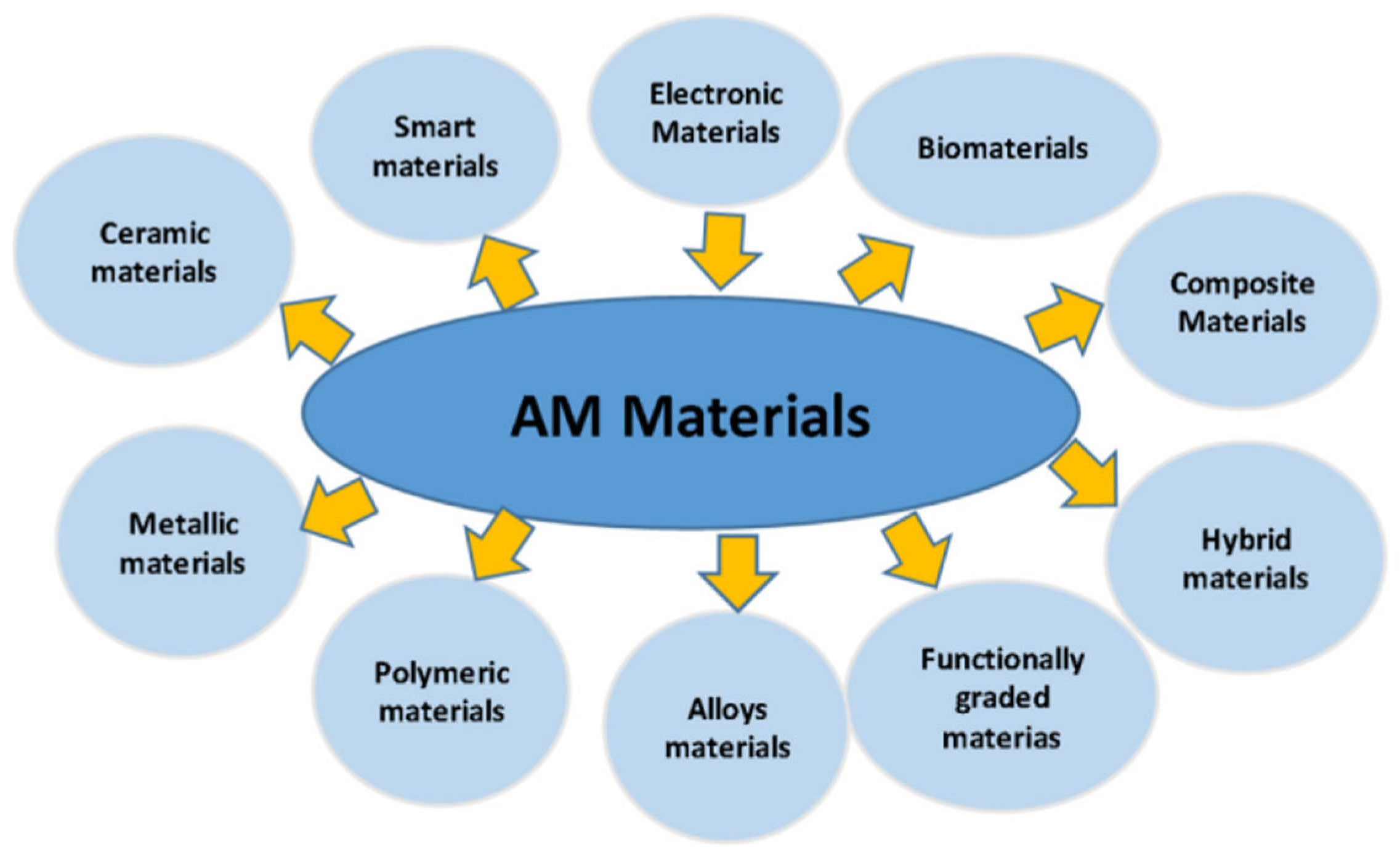

2.2. Materials Used Within AM Technologies

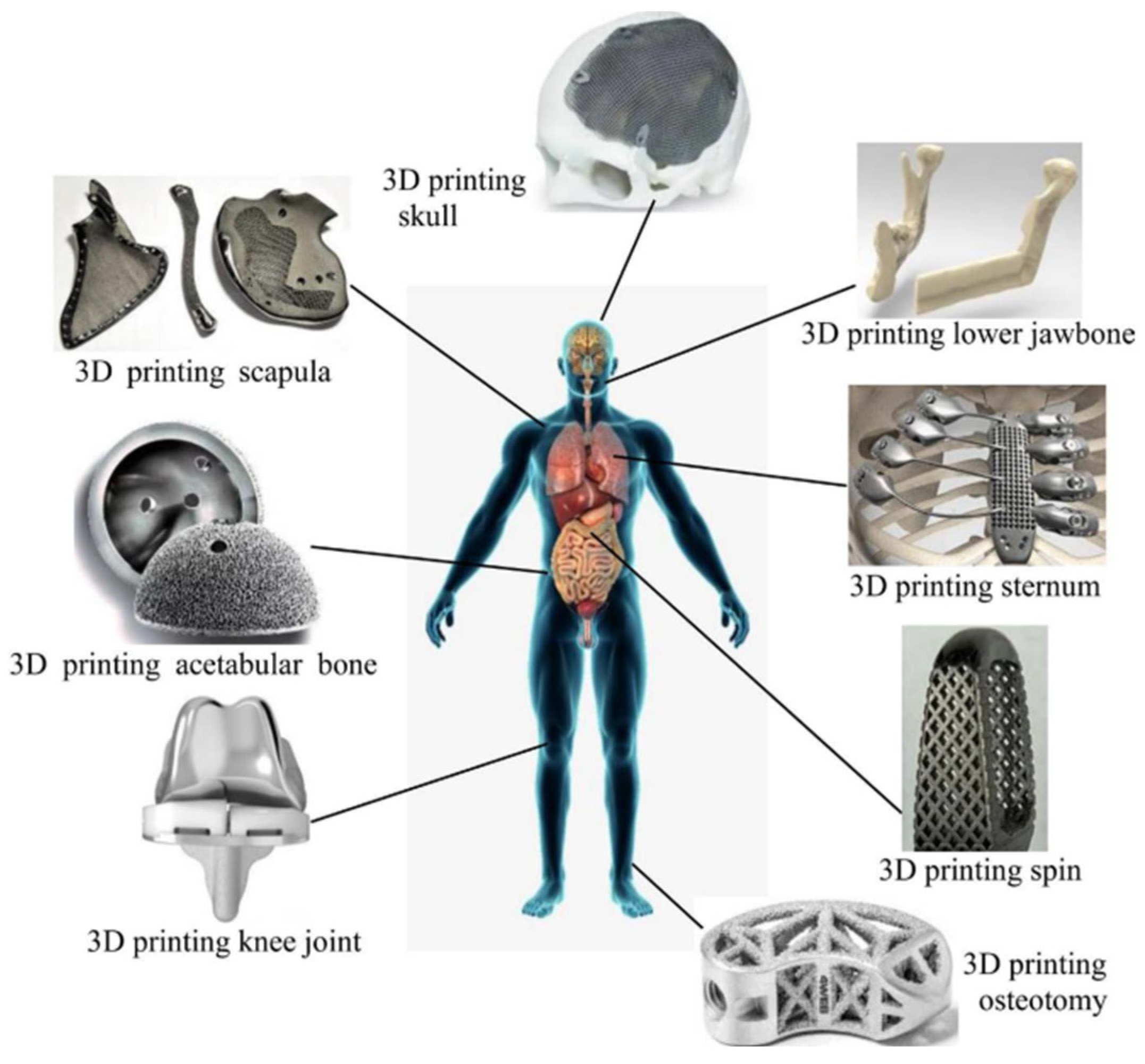

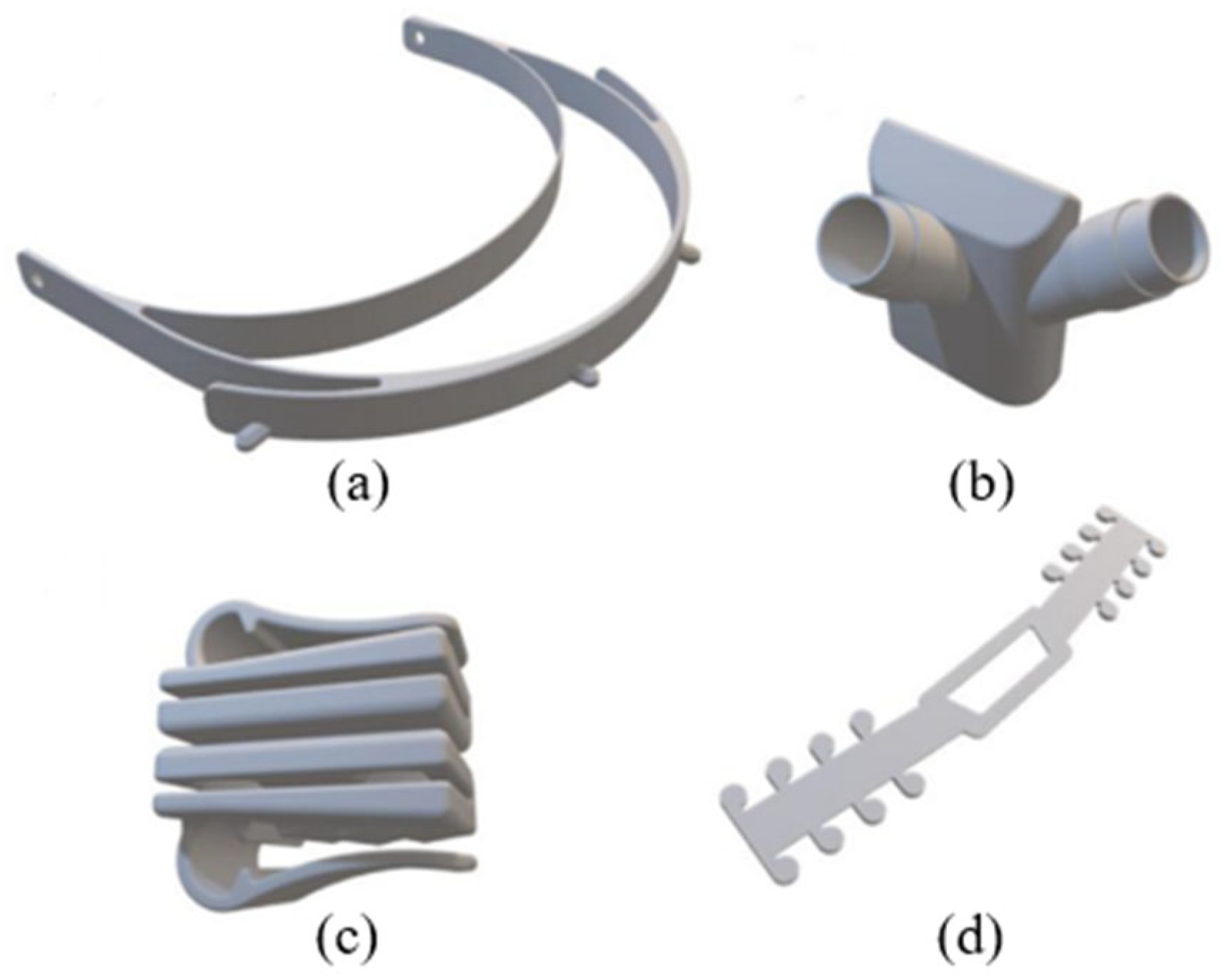

2.3. Applications in Various Industries

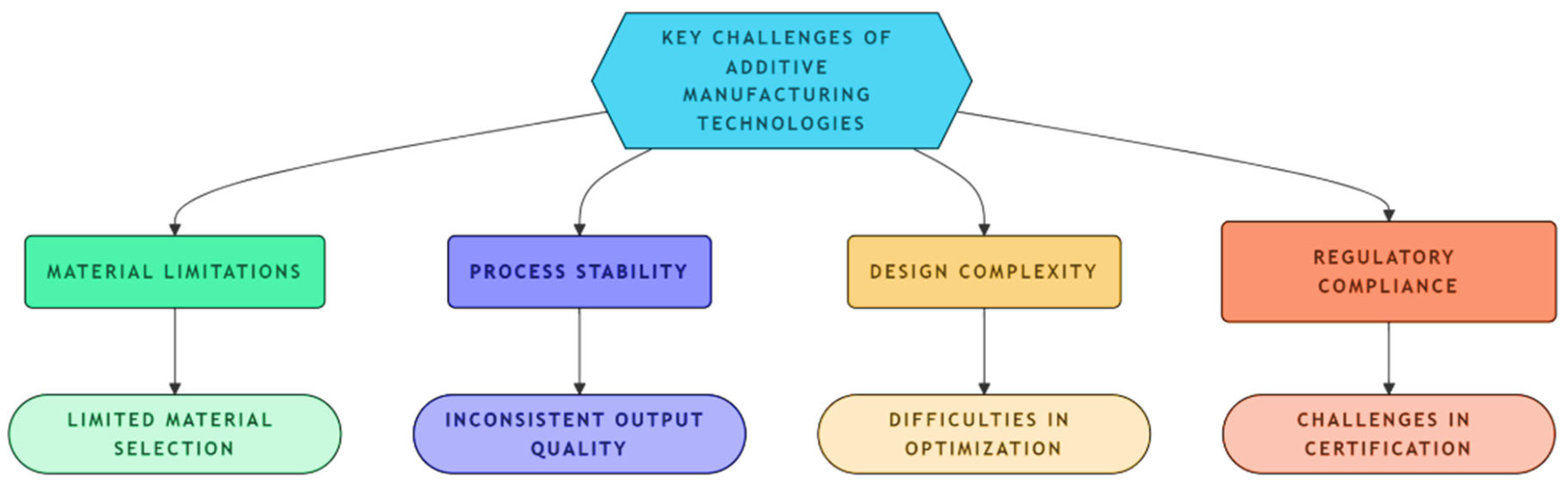

3. Challenges of Additive Manufacturing

3.1. General Challenges

3.2. Technical Challenges of Additive Manufacturing

3.3. Operational and Organizational Challenges of Additive Manufacturing

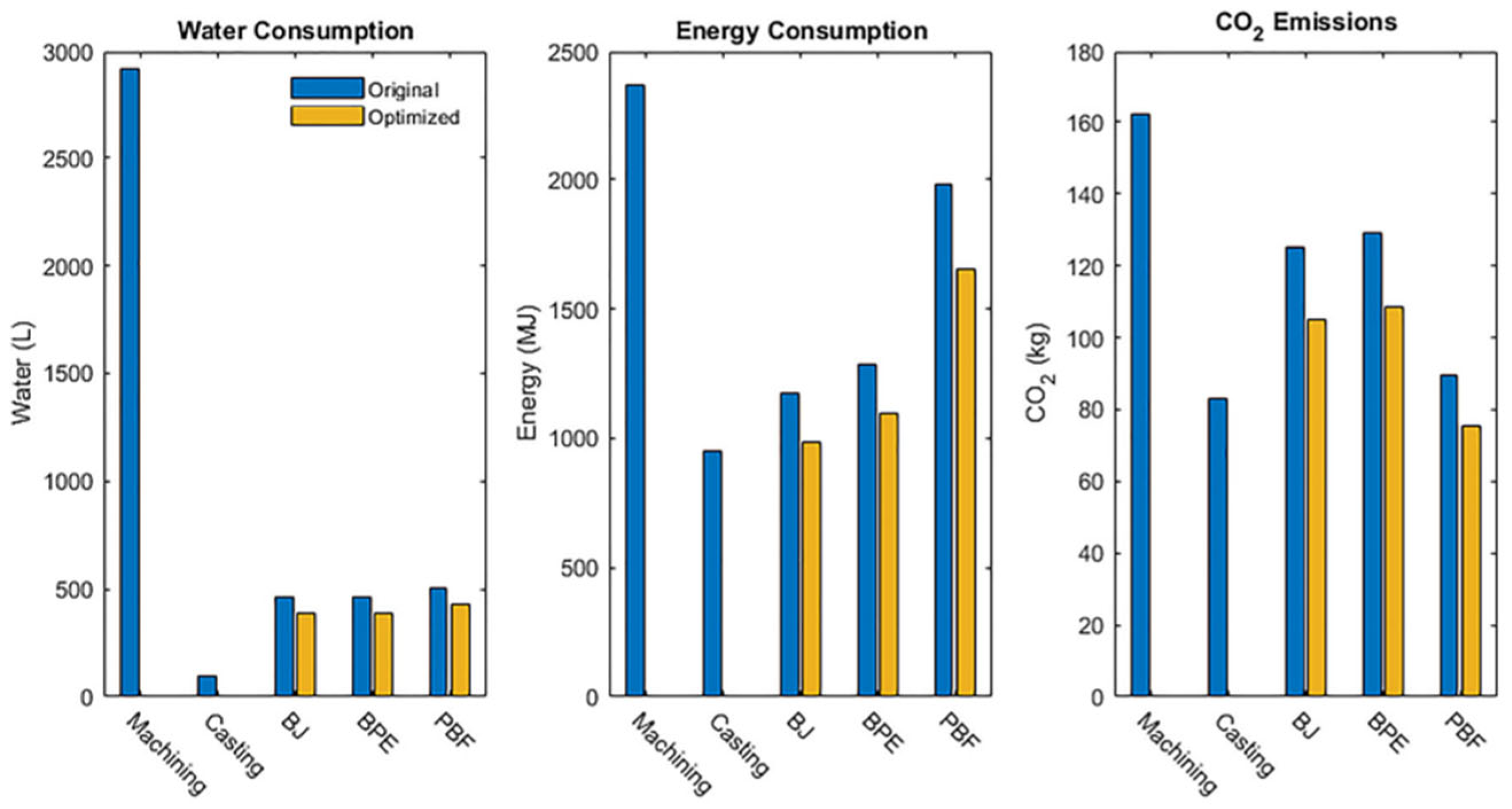

3.4. Environmental Challenges of Additive Manufacturing

4. Future Directions

4.1. Emerging Technologies

4.2. Four-Dimensional Printing

4.3. Trends in Materials Science for AM Applications

4.4. Potential Impacts on Supply Chain and Production Models

4.5. Scalability

4.6. Future Research Directions

5. Conclusions

- -

- Additive manufacturing enables the design and production of complex, customized parts, adapted to specific needs respecting environmental, healthcare and social conditions.

- -

- By building layer by layer, additive manufacturing reduces raw material waste, which is often greater in traditional processes.

- -

- Additive manufacturing can solve the problem of stocking raw materials or spare parts by manufacturing on demand and on site, without the need for long, costly supply chains.

- -

- The cost of equipment, production time and limited choice of materials remain challenges for the wider adoption of this technology.

- -

- Additive manufacturing continues to progress, paving the way for new applications and products, particularly to produce more smart, functional, sustained products in many fields such medicine, aeronautics, automotive and consumer goods.

- -

- Research and development are needed to improve the performance, accessibility, scalability and cost-effectiveness of additive manufacturing.

- -

- AM technologies should focus on the implementation of sustainable and recyclable Bio-based materials, the development of multi-material and functional printing for more complex and integrated solutions, and the incorporation of intelligent functionality into printed structures.

- -

- 4D printing represents a promising step in the innovation of self-adaptive systems for more smart printed structures that meet healthcare and environmental requirements.

- -

- The standardization of AM technologies and the development of industry-wide certifications will encourage wider adoption of scalable AM solutions.

- -

- The study of hybrid techniques used in 3D printing is a promising topic which should enable the process to be developed further and made more flexible.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skrodzka, M.; Cieślak, A.; Łabowska, M.B.; Detyna, J.; Michalak, I. Bio-based additive manufacturing: An overview. In Additive Manufacturing Materials and Technology; Elsevier: Amsterdam, The Netherlands, 2024; pp. 291–316. [Google Scholar] [CrossRef]

- Krishnanand; Taufik, M. Surface roughness investigation of 3D printed parts via in-situ pellet-filament co-extrusion process. Mater. Manuf. Process. 2025, 40, 1029–1048. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Agrawal, P. Additive manufacturing of metal matrix composites. Mater. Des. 2025, 252, 113609. [Google Scholar] [CrossRef]

- Dubey, D.; Singh, S.P.; Behera, B.K. A review on recent advancements in additive manufacturing techniques. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Arefin, N.; Moni, H.-E.; Espinosa, D.; Cong, W.; Zeng, M. Multi-material additive manufacturing of energy storage and conversion devices: Recent progress and future prospects. Appl. Phys. Rev. 2025, 12, 011330. [Google Scholar] [CrossRef]

- Ma, L.; Yu, S.; Xu, X.; Amadi, S.M.; Zhang, J.; Wang, Z. Application of artificial intelligence in 3D printing physical organ models. Mater. Today Bio 2023, 23, 100792. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with artificial intelligence in additive manufacturing: A systematic review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Goh, G.D.; Wong, K.K.; Tan, N.; Seet, H.L.; Nai, M.L.S. Large-format additive manufacturing of polymers: A review of fabrication processes, materials, and design. Virtual Phys. Prototyp. 2024, 19, e2336160. [Google Scholar] [CrossRef]

- Orth, A.; Webber, D.; Zhang, Y.; Sampson, K.L.; de Haan, H.W.; Lacelle, T.; Lam, R.; Solis, D.; Dayanandan, S.; Waddell, T.; et al. Deconvolution volumetric additive manufacturing. Nat. Commun. 2023, 14, 14412. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Y.; Ruan, K.; Guo, H.; He, M.; Shi, X.; Guo, Y.; Kong, J.; Gu, J. Advances in 3D printing for polymer composites: A review. InfoMat 2024, 6, e12568. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Seisekulova, A.; Talamona, D.; Perveen, A. The Post-Processing of Additive Manufactured Polymeric and Metallic Parts. J. Manuf. Mater. Process. 2022, 6, 116. [Google Scholar] [CrossRef]

- Adu-Amankwa, K.; Corney, J.; Rentizelas, A.; Wodehouse, A. Intellectual Property Management Challenges of Additive Manufacturing in Replacement Part Supply Chains. IFAC-PapersOnLine 2022, 55, 1527–1532. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for sustainable additive manufacturing: A review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Calignano, F.; Mercurio, V. An overview of the impact of additive manufacturing on supply chain, reshoring, and sustainability. Clean. Logist. Supply Chain 2023, 7, 100103. [Google Scholar] [CrossRef]

- Etayo-Escanilla, M.; Campillo, N.; Ávila-Fernández, P.; Baena, J.M.; Chato-Astrain, J.; Campos, F.; Sánchez-Porras, D.; García-García, Ó.D.; Carriel, V. Comparison of Printable Biomaterials for Use in Neural Tissue Engineering: An In Vitro Characterization and In Vivo Biocompatibility Assessment. Polymers 2024, 16, 1426. [Google Scholar] [CrossRef]

- Agócs, C.; Hanon, M.M.; Zsidai, L. A comprehensive review of Fused Deposition Modeling (FDM) method using PLA, ABS, and PET-G polymers. Gradus 2024, 11, 1–12. [Google Scholar] [CrossRef]

- Minh, P.S.; Huynh, D.S.T.; Tran, A.S. Metal 3D Printing by Fused Deposition Modeling (FDM) with Metal Powder Filament Materials. Defect Diffus. Forum 2022, 417, 61–65. [Google Scholar] [CrossRef]

- Winarso, R.; Anggoro, P.; Ismail, R.; Jamari, J.; Bayuseno, A. Application of fused deposition modeling (FDM) on bone scaffold manufacturing process: A review. Heliyon 2022, 8, e11701. [Google Scholar] [CrossRef]

- Mani, M.; Karthikeyan, A.; Kalaiselvan, K.; Muthusamy, P.; Muruganandhan, P. Optimization of FDM 3-D printer process parameters for surface roughness and mechanical properties using PLA material. Mater. Today Proc. 2022, 66, 1926–1931. [Google Scholar] [CrossRef]

- Gholipour, F.; Shabgard, M.R.; Baraheni, M. Experimental study and optimizing the FDM process using war strategy optimization technique to enhance mechanical properties and surface quality of the PLA thermoplastic. J. Thermoplast. Compos. Mater. 2024, 38, 2617–2644. [Google Scholar] [CrossRef]

- Sola, A.; Rosa, R.; Ferrari, A.M. Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment? Polymers 2024, 16, 1986. [Google Scholar] [CrossRef] [PubMed]

- Olawumi, M.A.; Oladapo, B.I.; Olugbade, T.O. Evaluating the impact of recycling on polymer of 3D printing for energy and material sustainability. Resour. Conserv. Recycl. 2024, 209, 107769. [Google Scholar] [CrossRef]

- Krishnanand; Singh, V.; Mittal, V.; Branwal, A.K.; Sharma, K.; Taufik, M. Extrusion strategies in fused deposition additive manufacturing: A review. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 238, 988–1012. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, H.; Lopez-Pola, T.; Fernandez-Rubio, P.; Fernandez-Rodriguez, P. Analysis of Volatile Organic Compound Emissions in 3D Printing: Implications for Indoor Air Quality. Buildings 2024, 14, 3343. [Google Scholar] [CrossRef]

- Ali Saqib, M.A.; Abbas, S.M.; Tanaka, H. Sustainability and innovation in 3D printing: Outlook and trends. Clean Technol. Recycl. 2024, 4, 1–21. [Google Scholar] [CrossRef]

- Kalyan, B.P.; Kumar, L. 3D Printing: Applications in Tissue Engineering, Medical Devices, and Drug Delivery. Aaps Pharmscitech 2022, 23, 92. [Google Scholar] [CrossRef]

- Yüceer, Ö.M.; Öztürk, E.K.; Çiçek, E.S.; Aktaş, N.; Güngör, M.B. Three-Dimensional-Printed Photopolymer Resin Materials: A Narrative Review on Their Production Techniques and Applications in Dentistry. Polymers 2025, 17, 316. [Google Scholar] [CrossRef] [PubMed]

- Kadauw, A.A.A. Neural Network Optimization of Mechanical Properties of ABS-like Photopolymer Utilizing Stereolithography (SLA) 3D Printing. J. Manuf. Mater. Process. 2025, 9, 116. [Google Scholar] [CrossRef]

- Guttridge, C.; Shannon, A.; O’SUllivan, A.; O’SUllivan, K.J.; O’SUllivan, L.W. Biocompatible 3D printing resins for medical applications: A review of marketed intended use, biocompatibility certification, and post-processing guidance. Ann. 3D Print. Med. 2022, 5, 100044. [Google Scholar] [CrossRef]

- Gao, W.; Guo, Y.; Cui, J.; Liang, C.; Lu, Z.; Feng, S.; Sun, Y.; Xia, Q.; Zhang, B. Dual-curing polymer systems for photo-curing 3D printing. Addit. Manuf. 2024, 85, 104142. [Google Scholar] [CrossRef]

- Kalat, M.N.; Ziai, Y.; Dziedzic, K.; Gradys, A.; Urbański, L.; Zaszczyńska, A.; Lantada, A.D.; Kowalewski, Z. Experimental evaluation of build orientation effects on the microstructure, thermal, mechanical, and shape memory properties of SLA 3D-printed epoxy resin. Eur. Polym. J. 2025, 228, 113829. [Google Scholar] [CrossRef]

- Husna, A.; Ashrafi, S.; Tomal, A.A.; Tuli, N.T.; Bin Rashid, A. Recent advancements in stereolithography (SLA) and their optimization of process parameters for sustainable manufacturing. Hybrid Adv. 2024, 7, 100307. [Google Scholar] [CrossRef]

- Singh, S.; Kaur, D.; Singh, M.; Balu, R.; Mehta, A.; Vasudev, H. Challenges and issues in manufacturing of components using polymer-based selective laser sintering (SLS): A review. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 1–24. [Google Scholar] [CrossRef]

- Mahamud, Z.H.; Khan, R.; Amin, J.M.; Islam, M.S. AI For Defect Detection in Additive Manufacturing: Applications In Renewable Energy And Biomedical Engineering. Strat. Data Manag. Innov. 2025, 2, 01–20. [Google Scholar] [CrossRef]

- Żur-Pińska, J.; Gładysz, M.Z.; Ubels, D.; Siebring, J.; Włodarczyk-Biegun, M.K. Smart and sustainable: Exploring the future of PHAs biopolymers for 3D printing in tissue engineering. Sustain. Mater. Technol. 2023, 38, e00750. [Google Scholar] [CrossRef]

- Kseniya, S.; Mikhail, T.; Maksim, G.; Alexander, G.; Alina, K.; Natalia, R.; Azamat, K.; Maxim, R.; Igor, C.; Valery, M. Surface modification of polyamide by SWCNTs for application in SLS 3D printing. Compos. Part A Appl. Sci. Manuf. 2025, 193, 108829. [Google Scholar] [CrossRef]

- Nobre, L.; Barros, D.; Bessa, J.; Cunha, F.; Machado, M.; Mendonça, J.P.; Luís, J.; Oliveira, M.; Machado, P.; Fernandes, C.; et al. Enhancing mechanical performance in SLS-printed PA12-slate composites through amino-silane treatment of mineral waste. Int. J. Adv. Manuf. Technol. 2024, 134, 2979–2992. [Google Scholar] [CrossRef]

- Karanwad, T.; Banerjee, S. Tuning of laser energy density impacts the sinterability of tableting materials and its 3D-printed structures. Mater. Manuf. Process. 2024, 39, 2124–2138. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.; Xu, M. Advances in selective laser sintering of polymers. Int. J. Extreme Manuf. 2022, 4, 042002. [Google Scholar] [CrossRef]

- Gueche, Y.A.; Sanchez-Ballester, N.M.; Bataille, B.; Aubert, A.; Leclercq, L.; Rossi, J.-C.; Soulairol, I. Selective Laser Sintering of Solid Oral Dosage Forms with Copovidone and Paracetamol Using a CO2 Laser. Pharmaceutics 2022, 13, 160. [Google Scholar] [CrossRef]

- Lin, W.-C.; Tang, J.-F.; Cheng, C.-C.; Kuo, C.-C.; Hung, W.-H. Development of low-shrinkage eco-friendly composite materials for the DLP 3D printing technique. Mater. Adv. 2025, 6, 1889–1898. [Google Scholar] [CrossRef]

- Dai, J.; Luo, K.; Spintzyk, S.; Unkovskiy, A.; Li, P.; Xu, S.; Fernandez, P.K. Post-processing of DLP-printed denture base polymer: Impact of a protective coating on the surface characteristics, flexural properties, cytotoxicity, and microbial adhesion. Dent. Mater. 2022, 38, 2062–2072. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, Q.; Slita, A.; Backman, O.; Gounani, Z.; Rosqvist, E.; Peltonen, J.; Willför, S.; Xu, C.; Rosenholm, J.M.; et al. Digital light processing (DLP) 3D-fabricated antimicrobial hydrogel with a sustainable resin of methacrylated woody polysaccharides and hybrid silver-lignin nanospheres. Green Chem. 2022, 24, 2129–2145. [Google Scholar] [CrossRef]

- Jiang, T.; Yan, B.; Jiang, M.; Xu, B.; Xu, Y.; Yu, Y.; Ma, T.; Wang, H. Enhanced Adhesion—Efficient Demolding Integration DLP 3D Printing Device. Appl. Sci. 2022, 12, 7373. [Google Scholar] [CrossRef]

- Brooks, A.K.; Yadavalli, V.K. Post-Print Processing to Minimize Cytotoxicity of 3D-Printed Photopolymer Resins for Biomedical Applications. J. Appl. Polym. Sci. 2025, 142, e56545. [Google Scholar] [CrossRef]

- Nejedlá, Z.; Poustka, D.; Herma, R.; Liegertová, M.; Štofik, M.; Smejkal, J.; Šícha, V.; Kaule, P.; Malý, J. Class II biocompatible E-Shell 300 3D printing material causes severe developmental toxicity in Danio rerio embryos and reduced cell proliferation in vitro—Implications for 3D printed microfluidics. RSC Adv. 2021, 11, 16252–16267. [Google Scholar] [CrossRef] [PubMed]

- Menzel, R.; Budde, D.; Maier, T.; Pahl, I.; Raddatz, L.; Lausch, R.; Zumbrum, M.; Hauk, A. Parylene C Coating Efficacy Studies: Enhancing Biocompatibility of 3D Printed Polyurethane Parts for Biopharmaceutical and CGT Applications. ACS Appl. Bio Mater. 2024, 7, 5369–5381. [Google Scholar] [CrossRef] [PubMed]

- Sekmen, K.; Rehbein, T.; Johlitz, M.; Lion, A.; Constantinescu, A. Thermal analysis and shrinkage characterization of the photopolymers for DLP additive manufacturing processes. Contin. Mech. Thermodyn. 2024, 36, 351–368. [Google Scholar] [CrossRef]

- Gao, B.; Zhao, H.; Peng, L.; Sun, Z. A Review of Research Progress in Selective Laser Melting (SLM). Micromachines 2023, 14, 57. [Google Scholar] [CrossRef]

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging Features and the SLM/DMLS Residual Stresses Problem: Review and Future Research Need. Technologies 2017, 5, 15. [Google Scholar] [CrossRef]

- Jayasankar, D.C.; Gnaase, S.; Kaiser, M.A.; Lehnert, D.; Tröster, T. Advancements in Hybrid Additive Manufacturing: Integrating SLM and LMD for High-Performance Applications. Metals 2024, 14, 772. [Google Scholar] [CrossRef]

- Joralmon, D.; Tang, T.; Jayant, L.; Yoo, M.; Li, X. Recent advances and prospects in selective laser sintering (sls) and melting (slm) and multiphoton lithography for 3d printing. R. Soc. Chem. 2024, 2, 185–217. [Google Scholar] [CrossRef]

- Banothu, D.; Kumar, P.; Reddy, R. Advancements in 3D printing for metal bio-implants: A comprehensive bibliometric and scientometric analysis. J. Mech. Contin. Math. Sci. 2024, 19, 9–28. [Google Scholar] [CrossRef]

- Ahmadi, M.; Tabary, S.B.; Rahmatabadi, D.; Ebrahimi, M.; Abrinia, K.; Hashemi, R. Review of selective laser melting of magnesium alloys: Advantages, microstructure and mechanical characterizations, defects, challenges, and applications. J. Mater. Res. Technol. 2022, 19, 1537–1562. [Google Scholar] [CrossRef]

- Gao, B.; Shi, J.; Qin, M.; Peng, L.; Sun, Z. Progress in the study of quality and mechanical properties of selective laser melting molded parts. Curr. Mater. Sci. 2024, 18, 51–79. [Google Scholar] [CrossRef]

- Limbasiya, N.; Jain, A.; Soni, H.; Wankhede, V.; Krolczyk, G.; Sahlot, P. A comprehensive review on the effect of process parameters and post-process treatments on microstructure and mechanical properties of selective laser melting of AlSi10Mg. J. Mater. Res. Technol. 2022, 21, 1141–1176. [Google Scholar] [CrossRef]

- Agyapong, J.; Mateos, D.; Czekanski, A.; Boakye-Yiadom, S. Investigation of effects of process parameters on microstructure and fracture toughness of SLM CoCrFeMnNi. J. Alloys Compd. 2024, 987, 173998. [Google Scholar] [CrossRef]

- Foudzi, F.M.; Hung, L.Y.; Jamhari, F.I.; Buhairi, M.A.; Sulong, A.B.; Muhamad, N.; Radzuan, N.A.M.; Aziz, I.; Tan, K.S. Physical and hardness performance at different surfaces for titanium alloy (Ti6Al4V) printed using selective laser melting process (SLM). J. Kejuruter. 2024, 36, 1217–1226. [Google Scholar] [CrossRef]

- Dejene, N.D.; Lemu, H.G. Current Status and Challenges of Powder Bed Fusion-Based Metal Additive Manufacturing: Literature Review. Metals 2023, 13, 424. [Google Scholar] [CrossRef]

- Foudzi, F.M.; Buhairi, M.A.; Jamhari, F.I. Effect of SLM Processing Parameters and Energy Density on Physical and Mechanical Properties at Different Surfaces. In Proceedings of the 7th International Conference and Exhibition on Sustainable Energy and Advanced Materials (ICE-SEAM 2021), Melaka, Malaysia, 23 November 2021; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Forcellese, P.; Mancia, T.; Mignanelli, C.; Simoncini, M.; Verdini, T. Effect of Printing Orientation Angle and Heat Treatment on the Mechanical Properties and Microstructure of Binder-Jetting-Printed Parts in 17-4 PH Stainless Steel. Metals 2024, 14, 1220. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, A.; Li, G.; Hu, Q.; Ye, C.; Shen, M.; Xiao, Y.; Liu, S.; Ji, D. Improving the properties of binder jetted ceramics via nanoparticle dispersion infiltration. Ceram. Int. 2022, 48, 33580–33587. [Google Scholar] [CrossRef]

- Choi, J.-H.; Kwon, M.; Hwang, K.-T.; Kim, J.-H.; Choi, J.-H.; Kim, U.-S.; Han, K.-S. Mechanical reinforcement of complex shaped ceramic filter fabricated using binder jetting process with photocurable composite ink. J. Mater. Res. Technol. 2025, 35, 5514–5520. [Google Scholar] [CrossRef]

- Heng, Y.; Mao, Y.; Feng, K.; Zheng, J.; Xie, Y.; Wei, Q. Enhanced green density of binder jetted tungsten heavy alloys with an inorganic metal salt binder. J. Mater. Res. Technol. 2025, 35, 2226–2241. [Google Scholar] [CrossRef]

- Janzen, K.; Rieß, T.; Emmelmann, C. Investigation on curing strategies for metal binder jetting with Ti-6Al-4V. Addit. Manuf. Lett. 2025, 13, 100272. [Google Scholar] [CrossRef]

- Tan, M.; Dharani, D.; Dong, X.; Maiorana, C.; Chaudhuri, B.; Nagapudi, K.; Chang, S.-Y.; Ma, A.W. Pilot-scale binder jet 3D printing of sustained release solid dosage forms. Int. J. Pharm. 2023, 631, 122540. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Zhang, R.; Tai, Z.; Liu, Z.; Lu, B. Non-heat source forming technology of binder jetting metal powder and its post-treatment process. Int. J. Adv. Manuf. Technol. 2024, 132, 2077–2089. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, Y.; Li, J.; Wang, Y.; Meng, D.; Zhang, H.; Dai, J. Research and implementation of large-area sintering technology based on image-shaped laser. Rapid Prototyp. J. 2024, 30, 811–821. [Google Scholar] [CrossRef]

- Senthooran, V.; Weng, Z.; Wu, L. Enhancing Mechanical and Thermal Properties of 3D-Printed Samples Using Mica-Epoxy Acrylate Resin Composites—Via Digital Light Processing (DLP). Polymers 2024, 16, 1148. [Google Scholar] [CrossRef]

- Tuteski, O.; Kochov, A. SLA-based injection molding tool inserts: Challenges, innovations, and future prospects. Adv. Technol. Mater. 2024, 49, 29–36. [Google Scholar] [CrossRef]

- Abdelkhalek, S. Binder jetting additive manufacturing comparative study. J. Phys. 2023, 2616, 012002. [Google Scholar] [CrossRef]

- Fang, X.; Zu, Y.; Ma, Q.; Hu, J. State of the art of metal powder bonded binder jetting printing technology. Discov. Mater. 2023, 3, 15. [Google Scholar] [CrossRef]

- Cocchi, L.; Mariani, M.; Graziosi, S.; Viganò, R.; Lecis, N. Design challenges in leveraging binder jetting technology to innovate the medical instrument field. Proc. Des. Soc. 2024, 4, 1737–1746. [Google Scholar] [CrossRef]

- Balasankar, A.; Anbazhakan, K.; Arul, V.; Mutharaian, V.N.; Sriram, G.; Aruchamy, K.; Oh, T.H.; Ramasundaram, S. Recent Advances in the Production of Pharmaceuticals Using Selective Laser Sintering. Biomimetics 2023, 8, 330. [Google Scholar] [CrossRef] [PubMed]

- Mamo, H.B.; Adamiak, M.; Kunwar, A. 3D printed biomedical devices and their applications: A review on state-of-the-art technologies, existing challenges, and future perspectives. J. Mech. Behav. Biomed. Mater. 2023, 143, 105930. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive manufacturing by digital light processing: A review. Prog. Addit. Manuf. 2022, 8, 331–351. [Google Scholar] [CrossRef]

- Guo, X.; Moudgil, B.M. Role of Powder Properties and Flowability in Polymer Selective Laser Sintering—A Review. KONA Powder Part. J. 2024, 41, 26–41. [Google Scholar] [CrossRef]

- Simchi, A.; Petzolfdt, F.; Hartwig, T.; Hein, S.B.; Reineke, L.; Barthel, B.; Hosseini, D. Binder jetting additive manufacturing of complex-shaped parts with minimum sintering anisotropy. In Proceedings of the World Powder Metallurgy 2022 Congress & Exhibition, Lyon, France, 9–13 October 2022. [Google Scholar] [CrossRef]

- Swetha, S.; Sahiti, T.J.; Priya, G.S.; Harshitha, K.; Anil, A. Review on digital light processing (DLP) and effect of printing parameters on quality of print. Interactions 2024, 245, 178. [Google Scholar] [CrossRef]

- Ravi, P.; Patel, P. Stereolithography (sla) in pharmaceuticals. In Additive Manufacturing in Pharmaceuticals; Springer Nature: Singapore, 2023; pp. 97–123. [Google Scholar] [CrossRef]

- Pandey, P.; Krishnanand; Nayak, A.; Taufik, M. Development of mathematical model for surface roughness estimation in material jetting 3D printed parts. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 239, 2038–2049. [Google Scholar] [CrossRef]

- Chen, K.J.; Elkaseer, A.; Scholz, S.G.; Hagenmeyer, V. On the correlation between pre-processing workflow and dimensional accuracy of 3D printed parts in high-precision Material Jetting. Addit. Manuf. 2024, 91, 104335. [Google Scholar] [CrossRef]

- Daneshdoost, N.; Peloquin, J.; Gall, K. Structure-performance relationships of multi-material jetting polymeric composites designed at the voxel scale: Distribution and composition effects. J. Manuf. Process. 2024, 131, 2118–2132. [Google Scholar] [CrossRef]

- Chen, T.; Jiang, H.; Zhang, R.; He, F.; Han, N.; Wang, Z.; Jia, J. Leveraging printability and biocompatibility in materials for printing implantable vessel scaffolds. Mater. Today Bio 2024, 29, 101366. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material jetting for advanced applications: A state-of-the-art review, gaps and future directions. Addit. Manuf. 2022, 60, 103270. [Google Scholar] [CrossRef]

- Montemurro, M.; Alaimo, G.; Panettieri, E.; Catapano, A.; Carraturo, M.; Auricchio, F. Design of Multi-Material Structures Using Material Jetting Technology: Topology Optimisation, Numerical Analysis and Experiments. Compos. Struct. 2023, 330, 117838. [Google Scholar] [CrossRef]

- Baniasadi, H.; Abidnejad, R.; Fazeli, M.; Lipponen, J.; Niskanen, J.; Kontturi, E.; Seppälä, J.; Rojas, O.J. Innovations in hydrogel-based manufacturing: A comprehensive review of direct ink writing technique for biomedical applications. Adv. Colloid Interface Sci. 2024, 324, 103095. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, e2108855. [Google Scholar] [CrossRef]

- Ko, K.W.; Lee, T.; Jeong, J.; Lee, Y.; Kim, I.; Seo, J.; Park, Y.; Kim, J.; Park, S. Hydrogel Ink for 3D Printing with High and Widely Tunable Mechanical Properties via the Salting-Out Effect. Adv. Mater. Technol. 2024, 9, 2400157. [Google Scholar] [CrossRef]

- Kaliampakou, C.; Lagopati, N.; Charitidis, C.A. Direct Ink Writing of Alginate–Gelatin Hydrogel: An Optimization of Ink Property Design and Printing Process Efficacy. Appl. Sci. 2023, 13, 8261. [Google Scholar] [CrossRef]

- Chen, J.X.M.; Chen, T.; Zhang, Y.; Fang, W.; Li, W.E.; Li, T.; Popovic, M.R.; Naguib, H.E. Conductive Bio-based Hydrogel for Wearable Electrodes via Direct Ink Writing on Skin. Adv. Funct. Mater. 2024, 34, 2403721. [Google Scholar] [CrossRef]

- Huang, S.; Wong, E.; Göksel, B.; Qian, J.; Vleugels, J. Direct Ink Writing of Open and Dense NbC-Ni Matrix Cermet Structures; EPMA Publications: Chantilly, France, 2022. [Google Scholar] [CrossRef]

- Somers, N.; Jean, F.; Lasgorceix, M.; Preux, N.; Delmotte, C.; Boilet, L.; Petit, F.; Leriche, A. Fabrication of doped β-tricalcium phosphate bioceramics by Direct Ink Writing for bone repair applications. J. Eur. Ceram. Soc. 2022, 43, 629–638. [Google Scholar] [CrossRef]

- Álvarez, F.; Cifuentes, A.; Serrano, I.; Franco, L.; Fargas, G.; Fenollosa, F.; Uceda, R.; Llanes, L.; Tardivat, C.; Llorca, J.; et al. Optimization of the sintering thermal treatment and the ceramic ink used in Direct Ink Writing of α-Al2O3: Characterization and catalytic application. J. Eur. Ceram. Soc. 2022, 42, 2921–2930. [Google Scholar] [CrossRef]

- Navas, J.L.; Suen, C.Y.; Liu, Z.; Mostrales, D.C.; Yeung, K.L. 3D Cell Culture on Hierarchical Porous Soft Aerogel Structures Printed by DIW Process from Dual Network Gel Ink. Adv. Mater. Technol. 2024, 10, 2401235. [Google Scholar] [CrossRef]

- Pinargote, N.W.S.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef]

- Dong, H.; Li, X.; Xu, K.; Zang, Z.; Liu, X.; Zhang, Z.; Xiao, W.; Li, Y. A Review on Solid-State-Based Additive Friction Stir Deposition. Aerospace 2022, 9, 565. [Google Scholar] [CrossRef]

- Yasa, E.; Poyraz, O.; Molyneux, A.; Sharman, A.; Bilgin, G.M.; Hughes, J. Systematic Review on Additive Friction Stir Deposition: Materials, Processes, Monitoring and Modelling. Inventions 2024, 9, 116. [Google Scholar] [CrossRef]

- Dong, X.; Zhou, M.; Geng, Y.; Han, Y.; Lei, Z.; Chen, G.; Shi, Q. Recent advances in additive friction stir deposition: A critical review. Materials 2024, 17, 5205. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Samaei, A.; Xue, T.; Xie, X.; Guo, S.; Cao, J.; MacDonald, E.; Gan, Z. Additive friction stir deposition of metallic materials: Process, structure and properties. Mater. Des. 2023, 234, 112356. [Google Scholar] [CrossRef]

- Gor, M.; Barnett, M.; Fabijanic, D.; Bhattacharjee, P.P. Additive friction stir deposition of super duplex stainless steel: Microstructure and mechanical properties. Addit. Manuf. Lett. 2024, 9, 100204. [Google Scholar] [CrossRef]

- Yoder, J.K.; Erb, D.J.; Henderson, R.; Yu, H.Z. Closed-loop temperature controlled solid-state additive manufacturing of Ti-6Al-4V with forging standard out-of-plane tensile properties. J. Mech. Work. Technol. 2023, 322, 118201. [Google Scholar] [CrossRef]

- Cahalan, L.P.; Williams, M.B.; Brewer, L.N.; McDonnell, M.M.; Kelly, M.R.; Lalonde, A.D.; Allison, P.G.; Jordon, J.B. Parametric Investigation of Parallel Deposition Passes on the Microstructure and Mechanical Properties of 7075 Aluminum Alloy Processed with Additive Friction Stir Deposition. Appl. Sci. 2024, 14, 457. [Google Scholar] [CrossRef]

- Hassan, A.; Awang, M.; Pedapati, S.R.; Altaf, K.; Marode, R.V.; Ahmed, S.W. Experimental investigation on tool pin profile for defect-free multi-layered laminates using friction stir additive manufacturing. Results Eng. 2023, 20, 101516. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, R.; Wang, L.; Liu, M.; Li, S. Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals 2024, 14, 581. [Google Scholar] [CrossRef]

- Yakubov, V.; Ostergaard, H.; Hughes, J.; Yasa, E.; Karpenko, M.; Proust, G.; Paradowska, A.M. Evolution of material properties and residual stress with increasing number of passes in aluminium structure printed via additive friction stir deposition. Materials 2024, 17, 3457. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Hybrid Additive Manufacturing. In Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Alfattani, R. Hybrid Manufacturing Systems: Integrating Additive and Subtractive Techniques for Precision and Versatility. Int. J. Adv. Manuf. Technol. 2024. [Google Scholar] [CrossRef]

- Jiménez, A.; Bidare, P.; Hassanin, H.; Tarlochan, F.; Dimov, S.; Essa, K. Powder-based laser hybrid additive manufacturing of metals: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 63–96. [Google Scholar] [CrossRef]

- Hamran, N.N.N.; Ghani, J.A.; Ramli, R.; Mahmood, W.M.F.W. Hybrid Machining: A Review on Recent Progress. In Intelligent Manufacturing and Mechatronics; iM3F 2023; Aziz, A.R., Ismail, Z., Iqbal, A.K.M.A., Ahmed, I., Eds.; Springer Proceedings in Materials; Springer: Singapore, 2024; Volume 40. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. Current trends and research opportunities in hybrid additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 623–648. [Google Scholar] [CrossRef]

- Nyamuchiwa, K.; Palad, R.; Panlican, J.; Tian, Y.; Aranas, C., Jr. Recent Progress in Hybrid Additive Manufacturing of Metallic Materials. Appl. Sci. 2023, 13, 8383. [Google Scholar] [CrossRef]

- Xu, J.; Xie, Y.; Yu, X.; Zhang, Y.; Luo, Y.; Yu, S.; Huang, J.; Fan, D. Titanium alloy functionally gradient materials fabricated by in-situ laser-arc hybrid additive manufacturing. J. Mater. Res. Technol. 2025, 36, 2760–2771. [Google Scholar] [CrossRef]

- Wang, J.; Feng, L.; Xu, J.; Zha, X.; Cui, Y.; Li, K.; Xie, T. Optimal process parameter combinations search for desired deposited layer geometry in laser-arc hybrid additive manufacturing based on multi-pass overlapping deposited layer contour prediction model and improved NSGA-II algorithm. Opt. Laser Technol. 2025, 187, 112700. [Google Scholar] [CrossRef]

- Gao, H.; Zhu, Y.; Wang, T.; Li, R.; Yao, X.; Cheng, X. Heterogeneous solid-state phase transition behavior during different annealing treatments of the hybrid additive manufactured gradient dual-phase titanium alloy. Mater. Sci. Eng. A 2025, 931, 148200. [Google Scholar] [CrossRef]

- Cordero, M.Z.; Toshev, R.; Helo, P. Hybrid Additive Manufacturing for Assembly and Postprocessing Solutions. Procedia Comput. Sci. 2025, 253, 104–113. [Google Scholar] [CrossRef]

- Fan, W.; Hu, G.; Chen, Y.; Du, Y.; Peng, Y.; Wang, Y.; Li, Y.; Tan, H.; Zhang, F.; Lin, X. Effect of interface morphology on tensile response of Ti6Al4V alloy fabricated by laser hybrid additive manufacturing: Experiments & simulations. J. Mater. Res. Technol. 2025, 35, 2771–2780. [Google Scholar] [CrossRef]

- Deng, Q.; Miao, Y.; Yang, Z.; Zhao, Y.; Liu, J.; Li, H.; Wu, B. Orientation, dendrites and precipitates in Hastelloy C276 alloy fabricated by laser and arc hybrid additive manufacturing. J. Mater. Res. Technol. 2025, 35, 3129–3143. [Google Scholar] [CrossRef]

- Ge, C.; Shen, Z.; Liu, D.; Dong, G.; Niu, F.; Wu, D.; Ma, G. Mechanism of mechanical properties enhancement in laser- arc hybrid additive manufacturing of Mg-Gd-Y-Zr alloy based on nano precipitated phase. J. Magnes. Alloy. 2025. [Google Scholar] [CrossRef]

- Brown, N.C.; Mueller, J. Hybrid Formative-Additive Manufacturing. Adv. Mater. 2025, 37, e2417609. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, Z.; Deng, S.; Zhang, Y.; Bernard, A. Base shape generation and optimization for multi-axis hybrid additive manufacturing. Mater. Sci. Addit. Manuf. 2023, 2, 2103. [Google Scholar] [CrossRef]

- Sheikh, T.; Behdinan, K. Fused Deposition Modelling of Thermoplastic Polymer Nanocomposites: A Critical Review. C 2024, 10, 29. [Google Scholar] [CrossRef]

- Sheikh, T.; Behdinan, K. Geometric void-multiscale model for evaluating the effect of bead width and layer height on voids in FDM parts. Rapid Prototyp. J. 2023, 29, 1565–1579. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, S.; Mei, H.; Chen, Z. 3D printing of complex-shaped polymer-derived ceramics with enhanced structural retention. Mater. Manuf. Process. 2022, 37, 1267–1279. [Google Scholar] [CrossRef]

- Xu, D.; Yang, W.; Cao, P. In situ multi-metal alloying in laser-based additive manufacturing: A concise review. Compos. Part B Eng. 2025, 299, 112443. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, F.; Zhang, G.; Ji, W.; Su, Y.; Liu, H.; Chen, S. Microstructure and mechanical properties of aluminum alloys fabricated by a novel laser- liquid metal flow additive manufacturing. J. Mater. Res. Technol. 2025, 35, 3474–3485. [Google Scholar] [CrossRef]

- Bernalte, E.; Augusto, K.K.L.; Crapnell, R.D.; Andrews, H.G.; Fatibello-Filho, O.; Banks, C.E. Eco-friendly integration of gold nanoparticles into additive manufacturing filaments: Advancing conductivity and electrochemical performance. RSC Appl. Interfaces 2024, 2, 439–450. [Google Scholar] [CrossRef]

- Saraswat, R.; Shagun; Dhir, A.; Balan, A.S.S.; Powar, S.; Doddamani, M. Synthesis and application of sustainable vegetable oil-based polymers in 3D printing. RSC Sustain. 2024, 2, 1708–1737. [Google Scholar] [CrossRef]

- Saran, O.S.; Reddy, A.P.; Chaturya, L.; Kumar, M.P. 3D printing of composite materials: A short review. Mater. Today Proc. 2022, 64, 615–619. [Google Scholar] [CrossRef]

- Dede, D.Ö.; Zeller, D.K.; Demirel, M.; Al-Johani, H.; Schimmel, M.; Çakmak, G.; Yilmaz, B.; Donmez, M.B. Effect of manufacturing trinomial and preparation design on the fabrication and fit accuracy of additively and subtractively manufactured resin-based overlay restorations. J. Dent. 2025, 157, 105687. [Google Scholar] [CrossRef]

- Patel, G.; Minko, T. Miscibility, phase behavior, and mechanical properties of copovidone/HPMC ASLF and copovidone/Eudragit EPO polymer blends for hot-melt extrusion and 3D printing applications. Int. J. Pharm. 2025, 670, 125124. [Google Scholar] [CrossRef]

- Ahmad, M.; Javaid, M.; Haleem, A. Enhancing biocompatible metal alloy fabrication for bio implants through laser-based additive manufacturing (LBAM). Biomed. Anal. 2024, 1, 73–85. [Google Scholar] [CrossRef]

- Ukwaththa, J.; Herath, S.; Meddage, D. A review of machine learning (ML) and explainable artificial intelligence (XAI) methods in additive manufacturing (3D Printing). Mater. Today Commun. 2024, 41, 110294. [Google Scholar] [CrossRef]

- Yu, K.Y.; Kim, H.; Lee, I.H. Multi-material additive manufacturing process design of sensor embedded soft gripper. Sensors Actuators A Phys. 2025, 386, 116322. [Google Scholar] [CrossRef]

- Park, S.J.; Ju, H.G.; Hong, S.; Son, Y.; Ahn, I.H. New possibilities in polymer binder jetting additive manufacturing via infiltration and warm isostatic pressing. Mater. Des. 2023, 231, 112045. [Google Scholar] [CrossRef]

- Clemens, F.; Sarraf, F.; Borzì, A.; Neels, A.; Hadian, A. Material extrusion additive manufacturing of advanced ceramics: Towards the production of large components. J. Eur. Ceram. Soc. 2023, 43, 2752–2760. [Google Scholar] [CrossRef]

- Ahmad, S.; Hashmi, A.W.; Singh, J.; Arora, K.; Tian, Y.; Iqbal, F.; Al-Dossari, M.; Khan, M.I. Innovations in additive manufacturing of shape memory alloys: Alloys, microstructures, treatments, applications. J. Mater. Res. Technol. 2024, 32, 4136–4197. [Google Scholar] [CrossRef]

- Piepoli, A.; Lagrasta, F.P.; Pellegrino, R.; Pontrandolfo, P. Recycled vs. Virgin Materials in Additive Manufacturing: Assessing the Risk Mitigation Potential in Uncertain Supply Scenarios. Procedia Comput. Sci. 2025, 253, 2605–2614. [Google Scholar] [CrossRef]

- Mobarak, H.; Abid, A.S.; Munna, S.; Dutta, M.; Rimon, I.H. Additive manufacturing in biomedical: Applications, challenges, and prospects. Hybrid Adv. 2025, 10, 100467. [Google Scholar] [CrossRef]

- Kumar, M.B.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A review of various materials for additive manufacturing: Recent trends and processing issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Raja, S.; Praveenkumar, V.; Rusho, M.A.; Yishak, S. Optimizing additive manufacturing parameters for graphene-reinforced PETG impeller production: A fuzzy AHP-TOPSIS approach. Results Eng. 2024, 24, 103018. [Google Scholar] [CrossRef]

- Liesenfeld, J.; Jablonski, J.J.; da Silva, J.R.F.; Buenos, A.A.; Scheuer, C.J. Impact of annealing on the characteristics of 3D-printed graphene-reinforced PLA composite. J. Manuf. Process. 2024, 128, 133–157. [Google Scholar] [CrossRef]

- Maleki, H.; Asadi, P.; Sedghi, A.; Choupani, N.; Moghanian, A.; Elamy, M.I. (Alumina and graphene)/PLA nanocomposites manufactured by digital light processing 3D printer. J. Mater. Res. Technol. 2024, 32, 3120–3134. [Google Scholar] [CrossRef]

- Apicella, A.; Scarfato, P.; Incarnato, L. Study on 3D printability of PLA/PBAT/PHBV biodegradable blends for packaging applications. Polym. Test. 2025, 145, 108748. [Google Scholar] [CrossRef]

- Ali, S.; Deiab, I.; Pervaiz, S. Optimizing the properties of PHBV/PBAT blend for additive manufacturing. Procedia CIRP 2025, 131, 7–12. [Google Scholar] [CrossRef]

- Li, Y.; Sun, G.; Wang, Z.; Sun, H.; Deng, Y.; Yuan, X.; Li, X.; Wang, H. Ceramic particles induce microstructure modification to achieve excellent strength-ductility combination of additive manufactured AlSi10Mg alloy. Mater. Sci. Eng. A 2025, 932, 148259. [Google Scholar] [CrossRef]

- Pawlowski, P.; Stanczak, M.; Broniszewska-Wojdat, P.; Blanc, L.; Fras, T.; Rusinek, A. Energy-absorption capacity of additively manufactured AlSi10Mg cellular structures subjected to a blast-induced dynamic compression–experimental and numerical study. Int. J. Impact Eng. 2025, 198, 105216. [Google Scholar] [CrossRef]

- Ramesh, R.; Gairola, S.; Jayaganthan, R.; Kamaraj, M. Effects of post-processing on the microstructural evolution and mechanical behaviour of an additively manufactured AlSi10Mg alloy. J. Mater. Res. Technol. 2025, 34, 2802–2813. [Google Scholar] [CrossRef]

- Deng, K.; Khan, H.U.; Park, S.; Sung, D.H.; Fu, K. Additive manufacturing of continuous carbon fiber/epoxy composites with structured core-shell towpreg: Methods, characterization, and mechanics. Compos. Part B Eng. 2025, 291, 112001. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M.; Ghobakhloo, M.; Mordas, G.; Skotnicová, K. Additive manufacturing of continuous carbon fiber reinforced polymer composites using materials extrusion process. Mechanical properties, process parameters, fracture analysis, challenges, and future prospect. A review. Adv. Compos. Hybrid Mater. 2024, 7, 202. [Google Scholar] [CrossRef]

- Ben Said, L.; Karray, S.; Zghal, W.; Hentati, H.; Ayadi, B.; Chabir, A.; Alhadri, M. Investigation of Short Carbon Fiber-Reinforced Polylactic Acid Composites Blades for Horizontal Axis Wind Turbines: Mechanical Strength and Energy Efficiency of Fused Filament Fabrication-Printed Blades. J. Compos. Sci. 2025, 9, 118. [Google Scholar] [CrossRef]

- Baharlou, E.; Ma, J. Effect of raster orientation on large-scale robotic 3D printing of short carbon fiber-reinforced PLA composites. Addit. Manuf. Lett. 2025, 13, 100276. [Google Scholar] [CrossRef]

- Bouhamed, A.; Dammak, M.; Hagui, H.; Jrad, H. Multiscale mechanical characterization of 3D-printed PLA composites with carbon fiber reinforcement: Effect of raster angle and layer thickness. Int. J. Adv. Manuf. Technol. 2025, 137, 4805–4824. [Google Scholar] [CrossRef]

- Ammar, S.; Ben Fraj, B.; Hentati, H.; Saouab, A.; Ben Amar, M.; Haddar, M. Mechanical performances of printed carbon fiber-reinforced PLA and PETG composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 1488–1499. [Google Scholar] [CrossRef]

- Su, G.; Zhang, Y.; Jin, C.; Zhang, Q.; Lu, J.; Liu, Z.; Wang, Q.; Zhang, X.; Ma, J. 3D printed zirconia used as dental materials: A critical review. J. Biol. Eng. 2023, 17, 78. [Google Scholar] [CrossRef]

- Yoo, L.-G.; Pang, N.-S.; Kim, S.-H.; Jung, B.-Y. Mechanical properties of additively manufactured zirconia with alumina air abrasion surface treatment. Sci. Rep. 2023, 13, 9153. [Google Scholar] [CrossRef]

- Guan, Z.; Yang, X.; Liu, P.; Xu, X.; Li, Y.; Yang, X. Additive manufacturing of zirconia ceramic by fused filament fabrication. Ceram. Int. 2023, 49, 27742–27749. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D.J. Additive manufacturing of NiTi shape memory alloy and its industrial applications. Heliyon 2024, 10, e23369. [Google Scholar] [CrossRef]

- Cohen, Y.; Burkhardt, C.; Vogel, L.; Baum, A.; Mitteramskogler, G.; Shilo, D.; Faran, E. Sinter-Based Additive Manufacturing of Ni–Ti Shape Memory Alloy. Shape Mem. Superelasticity 2023, 9, 492–503. [Google Scholar] [CrossRef]

- Sahraei, A.; Mirsalehi, S.E. An investigation on application of friction stir additive manufacturing (FSAM) for the production of AA6061/TiC-graphene hybrid nanocomposite in the shape of multi-layer cylindrical part. J. Mater. Res. Technol. 2024, 30, 6737–6752. [Google Scholar] [CrossRef]

- Abbasi-Nahr, M.; Mirhosseini, S.S. Additive manufacturing of AA5083/TiN-Diamond hybrid nanocomposite parts via additive friction stir deposition: Metallurgical structure, mechanical, tribological, and electrochemical properties. J. Mater. Res. Technol. 2024, 30, 8187–8208. [Google Scholar] [CrossRef]

- Abbasi–Nahr, M.; Mirsalehi, S.E. Additive friction stir deposition of AA5083/MoS2-diamond hybrid nanocomposites: Investigating their metallurgical, mechanical, tribological, and electrochemical characteristics, and process-structure-property relationships. J. Alloys Compd. 2025, 1013, 178553. [Google Scholar] [CrossRef]

- De Faria, L.V.; Caldas, N.M.; Villafuerte, L.M.; Nascimento, S.F.D.; Quattrociocchi, D.G.; Lima, T.d.M.; Rocha, D.P.; Semaan, F.S.; Pacheco, W.F.; Matos, R.C.; et al. Graphite/Aluminum oxide/polylactic acid composite material: A valuable strategy for additively manufacturing cheap and improved electrochemical platforms for sensing sulfamethoxazole in honey samples. Electrochim. Acta 2024, 495, 144480. [Google Scholar] [CrossRef]

- Yang, W.; Yang, H.; Yang, K.; Wang, X.; Hu, C.; Lin, X. Microstructure evolution and mechanical properties of large-size AZ31 magnesium alloy block fabricated by wire arc additive manufacturing. J. Magnes. Alloy. 2025, 13, 1187–1202. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, H.; Wang, X.; Zhang, S.; Luan, P.; Hu, X.; Xu, C. Processing, microstructure, and mechanical behavior of AZ31 magnesium alloy fabricated by electron beam additive manufacturing. J. Alloys Compd. 2023, 938, 168567. [Google Scholar] [CrossRef]

- Mallek, H.; Mellouli, H.; Allouch, M.; Wali, M.; Dammak, F. Energy absorption of 3D-printed PETG and PETG/CF sandwich structures with cellular cores subjected to low-velocity impact: Experimental and numerical analysis. Eng. Struct. 2025, 327, 119653. [Google Scholar] [CrossRef]

- Mellouli, H.; Mallek, H.; Allouch, M.; Tlili, H.; Wali, M.; Dammak, F. Structural optimization of additively manufactured PETG/CF honeycomb sandwich structures for lightweight applications. Prog. Addit. Manuf. 2024, 10, 5447–5463. [Google Scholar] [CrossRef]

- Allouch, M.; Ben Fraj, B.; Dhouioui, M.; Kesssentini, A.; Hentati, H.; Wali, M.; Ferhi, M. Mechanical, microstructural and numerical investigations of 3D printed carbon fiber reinforced PEEK. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 238, 2131–2139. [Google Scholar] [CrossRef]

- Saracyakupoglu, T. The Qualification of the Additively Manufactured Parts in the Aviation Industry. Am. J. Aerosp. Eng. 2019, 6, 1. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Veniali, F. Laser polishing: A review of a constantly growing technology in the surface finishing of components made by additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 1433–1472. [Google Scholar] [CrossRef]

- Tregenza, O.; Hutasoit, N.; Palanisamy, S.; Hulston, C. Air-based cold spray: An advanced additive manufacturing technique for functional and structural applications. Int. J. Adv. Manuf. Technol. 2025, 136, 4677–4714. [Google Scholar] [CrossRef]

- Yang, J.; Li, B.; Liu, J.; Tu, Z.; Wu, X. Application of Additive Manufacturing in the Automobile Industry: A Mini Review. Processes 2024, 12, 1101. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Chunhua, S.; Guangqing, S. Application and Development of 3D Printing in Medical Field. Mod. Mech. Eng. 2020, 10, 25–33. [Google Scholar] [CrossRef]

- Colorado, H.A.; Mendoza, D.E.; Lin, H.-T.; Gutierrez-Velasquez, E. Additive manufacturing against the COVID-19 pandemic: A technological model for the adaptability and networking. J. Mater. Res. Technol. 2022, 16, 1150–1164. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Azam, A. Medical additive manufacturing in the battle against the COVID-19 pandemic. In Medical Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2024; pp. 21–60. [Google Scholar] [CrossRef]

- Kumar, J.R.; Mayandi, K.; Gnanaraj, S.J.P.; Chandrasekar, K.; Ramalingam, P.S. A critical review of an additive manufacturing role in COVID-19 epidemic. Mater. Today Proc. 2022, 68, 1521–1527. [Google Scholar] [CrossRef] [PubMed]

- DïlEk, E.; Yildirim, M.I.; Uzun, M. Additive manufacturing (3D printing) in technical fashion industry applications. Tekst-Ind. 2021, 69, 4–15. [Google Scholar] [CrossRef]

- Al-Nabi, S.M.A.; Ibrahim, W.O.; Saad, M.E.-R.M.M.A. Additive Manufacturing in Metal Jewelry Industry: Analytical Study. Int. Des. J. 2023, 13, 141–150. [Google Scholar] [CrossRef]

- Lacava, H.; Cherrington, N.; Corrado, A.; Bigdellou, S.; Chen, Q. A Preliminary Study of 3D Printing Home Designs for Improving Efficiency and Sustainability of Indigenous Housing in Canada. Sustainability 2024, 16, 5781. [Google Scholar] [CrossRef]

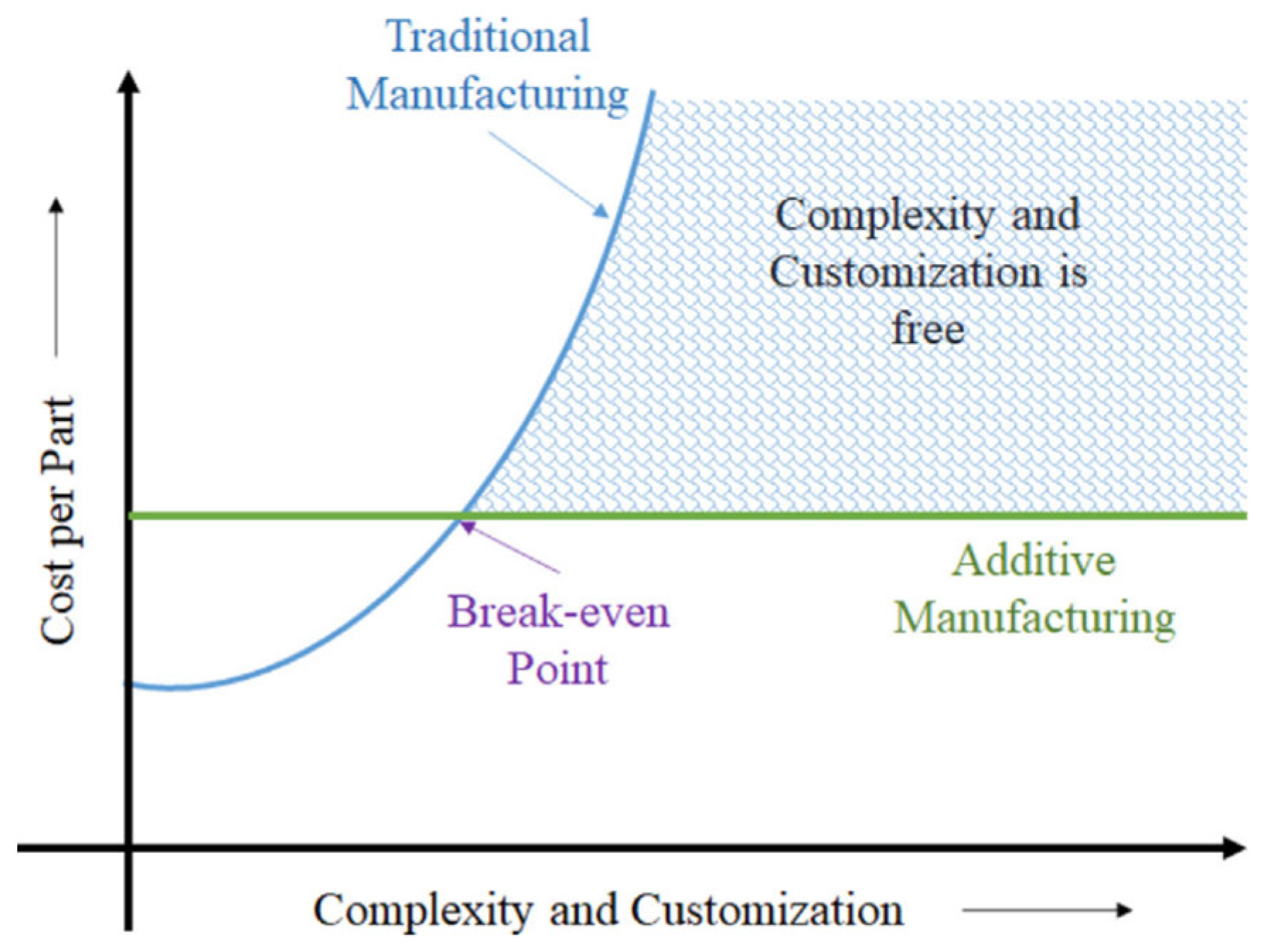

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Mecheter, A.; Tarlochan, F.; Kucukvar, M. A Review of Conventional versus Additive Manufacturing for Metals: Life-Cycle Environmental and Economic Analysis. Sustainability 2023, 15, 12299. [Google Scholar] [CrossRef]

- Gupta, A.K.; Krishnanand; Taufik, M. The effect of process parameters in material extrusion processes on the part surface quality: A review. Mater. Today Proc. 2022, 50, 1234–1242. [Google Scholar] [CrossRef]

- Godec, D.; Pilipović, A.; Breški, T.; Ureña, J.; Jordá, O.; Martínez, M.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Leoben, M.; Blasco, J.R.; et al. Introduction to Additive Manufacturing. In A Guide to Additive Manufacturing. Springer Tracts in Additive Manufacturing; Godec, D., Gonzalez-Gutierrez, J., Nordin, A., Pei, E., Ureña Alcázar, J., Eds.; Springer Tracts in Additive Manufacturing; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Weflen, E. Hybrid Additive and Subtractive Manufacturing of Large-Scale and Multi-Material Parts; Iowa State University: Armes, IA, SUA, 2023. [Google Scholar]

- Alghamdy, M.; Ahmad, R.; Alsayyed, B. Material Selection Methodology for Additive Manufacturing Applications. Procedia CIRP 2019, 84, 486–490. [Google Scholar] [CrossRef]

- DeBoer, B.; Nguyen, N.; Diba, F.; Hosseini, A. Additive, subtractive, and formative manufacturing of metal components: A life cycle assessment comparison. Int. J. Adv. Manuf. Technol. 2021, 115, 413–432. [Google Scholar] [CrossRef]

- Hassan, M.; Mohanty, A.K.; Wang, T.; Dhakal, H.N.; Misra, M. Current Status and Future Outlook of 4D Printing of Polymers and Composites-A Prospective. Compos. Part C Open Access 2025, 17, 100602. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, D.; Liu, J.; Xu, S.; Qiu, F.; Hu, L.; Liu, Y.; Ke, C.; Ruan, C. 4D printing polymeric biomaterials for adaptive tissue regeneration. Bioact. Mater. 2025, 48, 370–399. [Google Scholar] [CrossRef]

- Prakash, A.; Malviya, R.; Sridhar, S.B.; Shareef, J. 4D printing in dynamic and adaptive bone implants: Progress in bone tissue engineering. Bioprinting 2024, 44, e00373. [Google Scholar] [CrossRef]

- Damiati, L.A.; Alsudir, S.A.; Mohammed, R.Y.; Majrashi, M.A.; Albrahim, S.H.; Algethami, A.; Alghamdi, F.O.; Alamari, H.A.; Alzaydi, M.M. 4D printing in skin tissue engineering: A revolutionary approach to enhance wound healing and combat infections. Bioprinting 2025, 45, e00386. [Google Scholar] [CrossRef]

- Niazy, D.; Ashraf, M.; Bodaghi, M.; Zolfagharian, A. Resilient city perspective: 4D printing in art, architecture and construction. Mater. Today Sustain. 2024, 26, 100708. [Google Scholar] [CrossRef]

- Alam, F.; Ubaid, J.; Butt, H.; El-Atab, N. Swift 4D printing of thermoresponsive shape-memory polymers using vat photopolymerization. NPG Asia Mater. 2023, 15, 65. [Google Scholar] [CrossRef]

- Spiegel, C.A.; Hackner, M.; Bothe, V.P.; Spatz, J.P.; Blasco, E. 4D Printing of Shape Memory Polymers: From Macro to Micro. Adv. Funct. Mater. 2022, 32, 2110580. [Google Scholar] [CrossRef]

- Kumar, S.S.; Akmal, J.S.; Salmi, M. 4D printing of shape memory polymer with continuous carbon fiber. Prog. Addit. Manuf. 2024, 9, 1985–1995. [Google Scholar] [CrossRef]

- Jiang, H.; Chung, C.; Dunn, M.L.; Yu, K. 4D printing of liquid crystal elastomer composites with continuous fiber reinforcement. Nat. Commun. 2024, 15, 2110580. [Google Scholar] [CrossRef] [PubMed]

- Javed, M.; Corazao, T.; Saed, M.O.; Ambulo, C.P.; Li, Y.; Kessler, M.R.; Ware, T.H. Programmable Shape Change in Semicrystalline Liquid Crystal Elastomers. ACS Appl. Mater. Interfaces 2022, 14, 35087–35096. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Hou, Y.; An, R.; Qi, H.J.; Zhou, K. 4D Printing of Reprogrammable Liquid Crystal Elastomers with Synergistic Photochromism and Photoactuation. Adv. Mater. 2024, 36, e2303969. [Google Scholar] [CrossRef]

- Abdullah, T.; Okay, O. 4D Printing of Body Temperature-Responsive Hydrogels Based on Poly(acrylic acid) with Shape-Memory and Self-Healing Abilities. ACS Appl. Bio Mater. 2023, 6, 703–711. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Li, H.; Meng, F.; Xu, Z.; Hao, L.; Yao, Y.; Zhu, H.; Wang, C.; Wu, J.; Bian, S.; et al. 4D printed hydrogel scaffold with swelling-stiffening properties and programmable deformation for minimally invasive implantation. Nat. Commun. 2024, 15, 1587. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Y.; Yang, Y. 4D printed shape memory alloy binary bits for unconventional information processing. Virtual Phys. Prototyp. 2024, 19, 1587. [Google Scholar] [CrossRef]

- Long, F.; Xu, G.; Wang, J.; Ren, Y.; Cheng, Y. Variable Stiffness Conductive Composites by 4D Printing Dual Materials Alternately. Micromachines 2022, 13, 1343. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Xiao, X.; Liu, T.; Zhang, C.; Gu, M.; Qi, X. 4D Printing of Electrically Activated Reversible Deformation Composite Actuators. Adv. Mater. Technol. 2025, 10, 2401345. [Google Scholar] [CrossRef]

- Shin, E.J.; Son, J.H.; Lee, H.S.; Lee, S. Manufacturing of Conductive Filaments for 3D/4D Printing through In Situ Polymerization of Biobased Thermoplastic Polyurethane/Multiwall Carbon Nanotube Composites. ACS Appl. Polym. Mater. 2024, 6, 1751–1762. [Google Scholar] [CrossRef]

- Wang, R.; Yuan, C.; Cheng, J.; He, X.; Ye, H.; Jian, B.; Li, H.; Bai, J.; Ge, Q. Direct 4D printing of ceramics driven by hydrogel dehydration. Nat. Commun. 2024, 15, 758. [Google Scholar] [CrossRef]

- Wang, F.; Liu, C.; Yang, H.; Wang, H.; Zhang, H.; Zeng, X.; Wang, C.; Zhang, W.; Lv, W.; Zhu, P.; et al. 4D printing of ceramic structures. Addit. Manuf. 2023, 63, 103411. [Google Scholar] [CrossRef]

- Zheng, H.; Fang, M.; Long, F.; Jing, H.; Wang, B.; Fan, X.; Guo, J.; Cheng, Y.; Sun, A. 4D printing of programmable liquid–vapor phase change composites for multi-responsive flexible actuators. J. Mater. Chem. A 2025, 13, 18473–18483. [Google Scholar] [CrossRef]

- Mehta, P.; Sahlot, P. Application of phase change materials in 4D printing: A review. Mater. Today Proc. 2021, 47, 4746–4752. [Google Scholar] [CrossRef]

- Pradeep, N.; Sastry, C.C.; Brandão, L.; Meennakshi, B. 3D Printing of Shrimp Derived Chitosan with HAp as a Bio-Composite Scaffold. Mater. Manuf. Process. 2021, 37, 1257–1266. [Google Scholar] [CrossRef]

- Begum, S.A.; Krishnan, P.S.G.; Kanny, K. Bio-based Polymers: A Review on Processing and 3D Printing. Polym. Sci. Ser. A 2023, 65, 421–446. [Google Scholar] [CrossRef]

- Thakur, D.; Bareen, M.A.; Gupta, A.; Saha, S.; Sahu, J.K. Frontiers in 3D printing for biobased food packaging. Food Sci. Biotechnol. 2024, 34, 2381–2401. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, K.Q.; Vuillaume, P.Y.; Hu, L.; López-Beceiro, J.; Cousin, P.; Elkoun, S.; Robert, M. Recycled, Bio-Based, and Blended Composite Materials for 3D Printing Filament: Pros and Cons—A Review. Mater. Sci. Appl. 2023, 14, 148–185. [Google Scholar] [CrossRef]

- Gobena, S.T.; Woldeyohannes, A.D. Comparative review on the application of smart material in additive manufacturing: 3D and 4D printing. Discov. Appl. Sci. 2024, 6, 353. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. From Static to Dynamic: Smart Materials Pioneering Additive Manufacturing in Regenerative Medicine. Int. J. Mol. Sci. 2023, 24, 15748. [Google Scholar] [CrossRef]

- Pinho, A.C.; Piedade, A.P. Stimuli-Responsive Smart Materials for Additive Manufacturing. In Nanotechnology-Based Additive Manufacturing; Deshmukh, K., Pasha, S.K.K., Sadasivuni, K.K., Eds.; Wiley: Hoboken, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Islam, A.; Hasan, J.; Hossain, K.R. Intelligent materials in 3D printing:A journey from additive manufacturing to 4D printing. J. Adv. Manuf. Sci. Technol. 2024, 4, 2024016. [Google Scholar] [CrossRef]

- Mishra, S.K.; P. R, S.; Sajin Jose, S.S.; Upadhyay, R.K. Wire arc additive manufacturing: Materials, processes and its constraints. Mater. Manuf. Process. 2025, 40, 723–740. [Google Scholar] [CrossRef]

- Raspall, F.; Araya, S.; Pazols, M.; Valenzuela, E.; Castillo, M.; Benavides, P. Wire Arc Additive Manufacturing for Widespread Architectural Application: A Review Informed by Large-Scale Prototypes. Buildings 2025, 15, 906. [Google Scholar] [CrossRef]

- Moschinger, M.; Vauderwange, T.; Enzinger, N. Plasma wire arc additive manufacturing and its influence on high-carbon steel substrate properties. Weld. World 2024, 68, 1999–2011. [Google Scholar] [CrossRef]

- Queguineur, A.; Asadi, R.; Ostolaza, M.; Valente, E.H.; Nadimpalli, V.K.; Mohanty, G.; Hascoët, J.-Y.; Ituarte, I.F. Wire arc additive manufacturing of thin and thick walls made of duplex stainless steel. Int. J. Adv. Manuf. Technol. 2023, 127, 381–400. [Google Scholar] [CrossRef]

| Technology | Principle | Advantages | Limitations | Key Challenges in the Future |

|---|---|---|---|---|

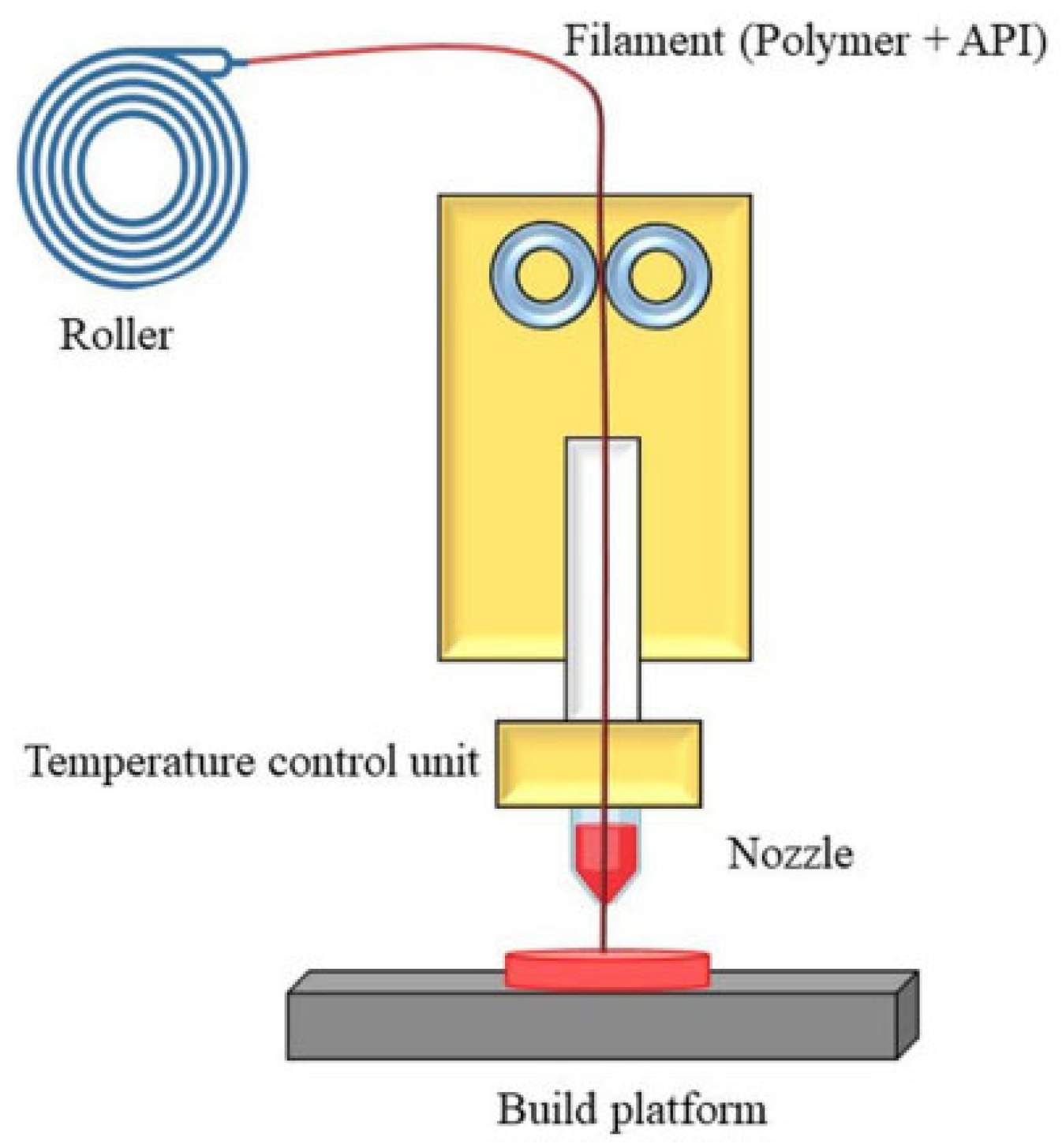

| FDM | Melts and extrudes thermoplastic filament layer by layer | Wide range of materials; Effective cost; User-friendly; Accessible | Lower productivity, especially for complex designs; Limited resolution; Material warping | Test several composite materials based on thermoplastics; Improve print speed and surface quality; Develop printers for high scale products |

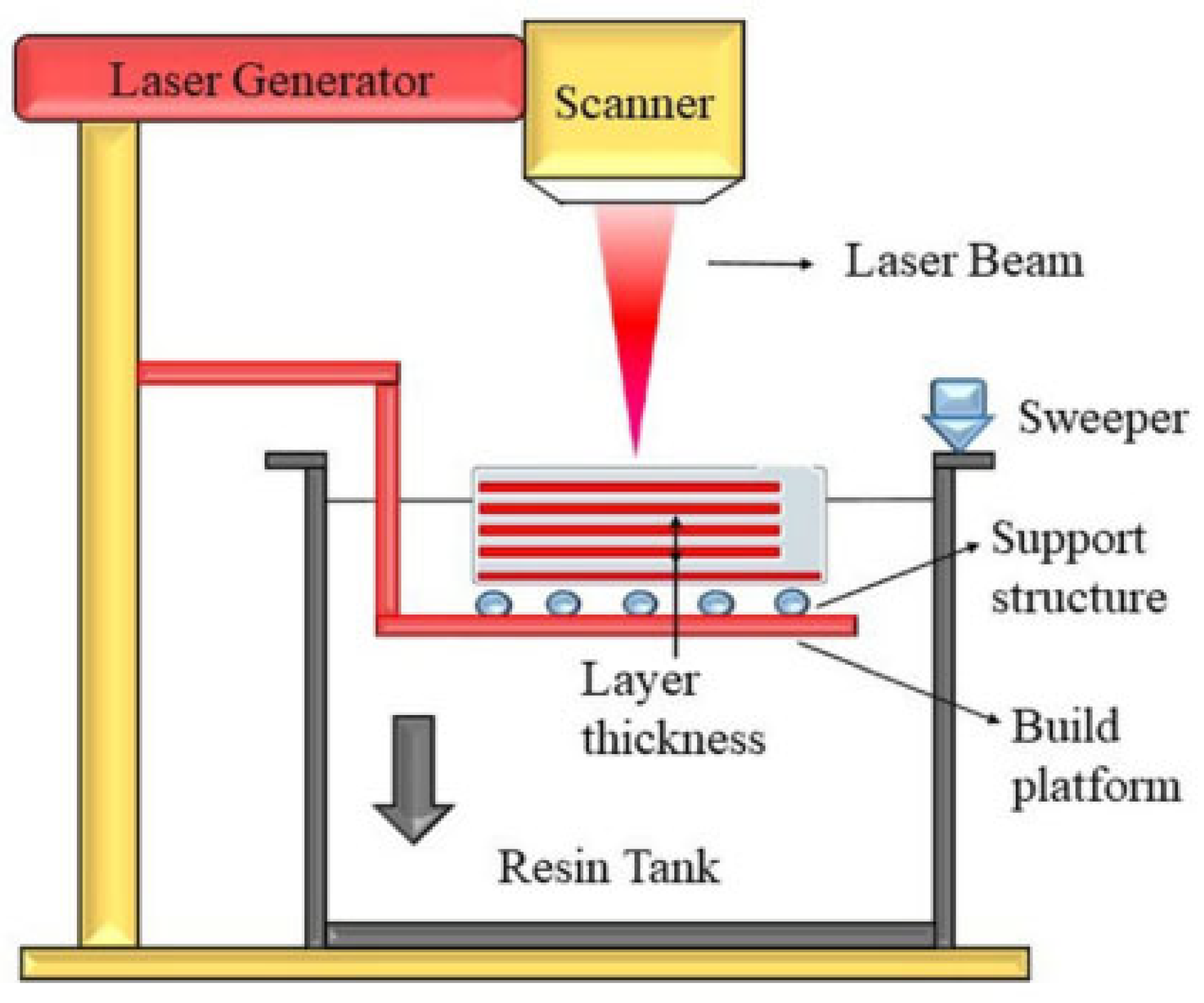

| SLA | Cures liquid photopolymer resin using UV light layer by layer | High precision and detail; Good surface finish; Wide range of materials | Higher post-processing time; High resin cost; Limited build size | Enhance the material choice and sustainability; Reduce post-processing times; Test applications in bigger scales |

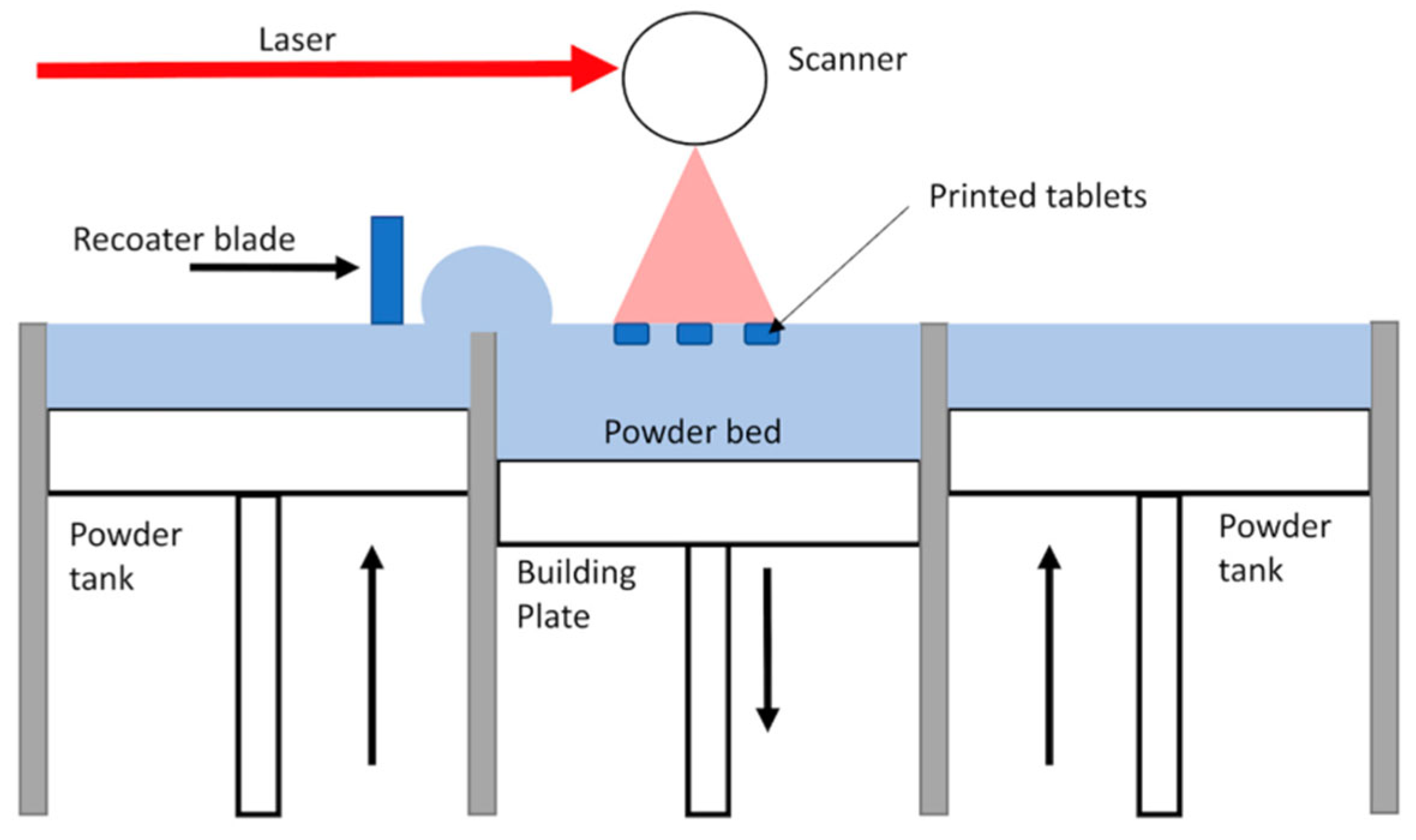

| SLS | Uses a laser to selectively fuse powdered materials layer by layer | Strong and functional parts; Complex geometries; Without the need of supporting structures | High equipment cost; Limited material options; Low surface finish; Low resolution | Test wider range of materials and integrate composites; Reduce costs and improve scalability; Optimize the surface finish and precision of printed products |

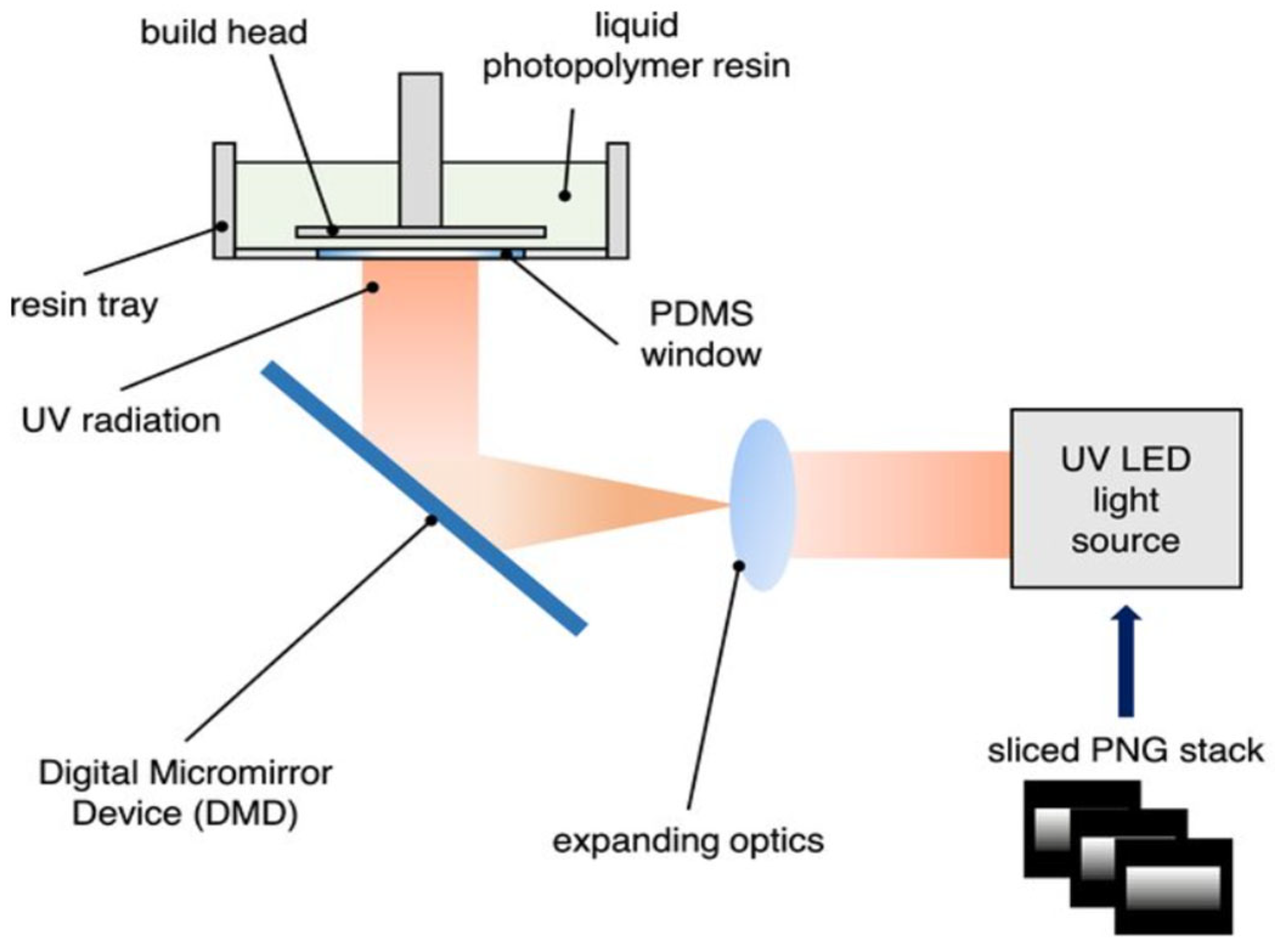

| DLP | Uses a digital light projector to cure resin layer by layer | High quality of prints; Fast printing speeds; Good for prototyping | Small range of materials; Requires post-processing; Resin can be hazardous | Develop safer materials; Innovate eco-friendly or bio-based resins; Test composite resins; Test wider range of printing materials |

| SLM/DLMS | Relies on the projection or modulation of a light pattern to selectively harden, sinter, or melt the material as a sequence of thin layers is deposited | Enables complex geometries; High strength-to-weight ratios; Allows complete fusion of powders to create strong parts | Challenges in optimizing process parameters; Ensuring part quality, and expanding material compatibility; Gaps in controlling defects such as porosity, residual stresses, and anisotropic mechanical properties, which limits the reliability and scalability of SLM/DLMS parts | Require additional work to compensate for high residual stress and limit the occurrence of distortion; Several studies highlighted non-linear relationships between energy density and mechanical outcomes, emphasizing the need for optimized parameter windows to avoid defects like keyhole formation or lack of fusion |

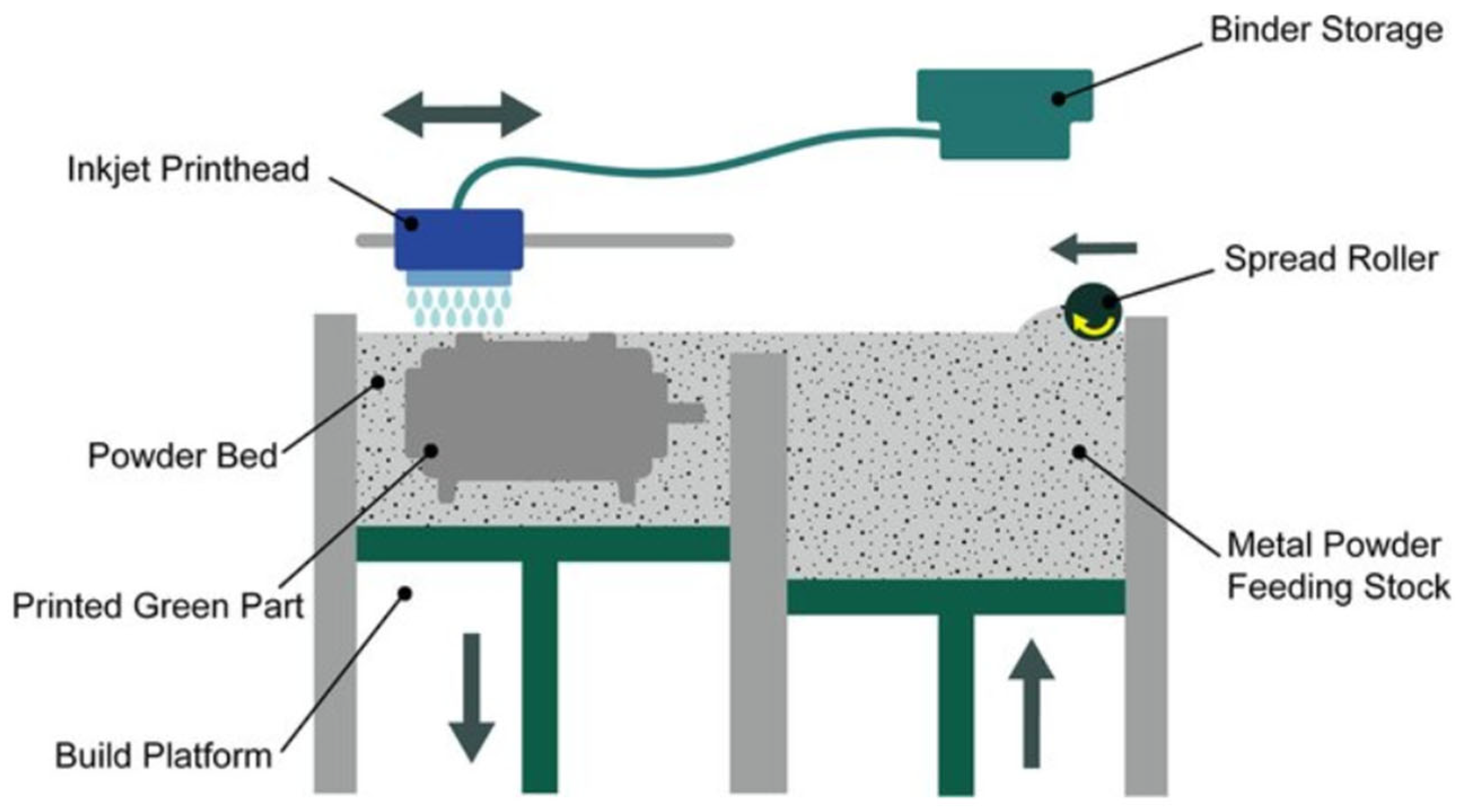

| Binder Jetting | Deposits a liquid binder onto layers of powder to form 3D objects | Fast printing speeds; Suitable for large parts; Minimal waste generation | Limited mechanical properties; Requires post-processing (e.g., sintering); Low surface finish | Expand material options; Improve part strength and durability; Optimization to improve the surface finish |

| Material Jetting | Sprays droplets of liquid material which are cured layer by layer | Multi-material capabilities; High resolution and surface quality | Requires extensive post-processing depending on designs; High material costs | Improve compatibility and range of substances; Develop more affordable materials |

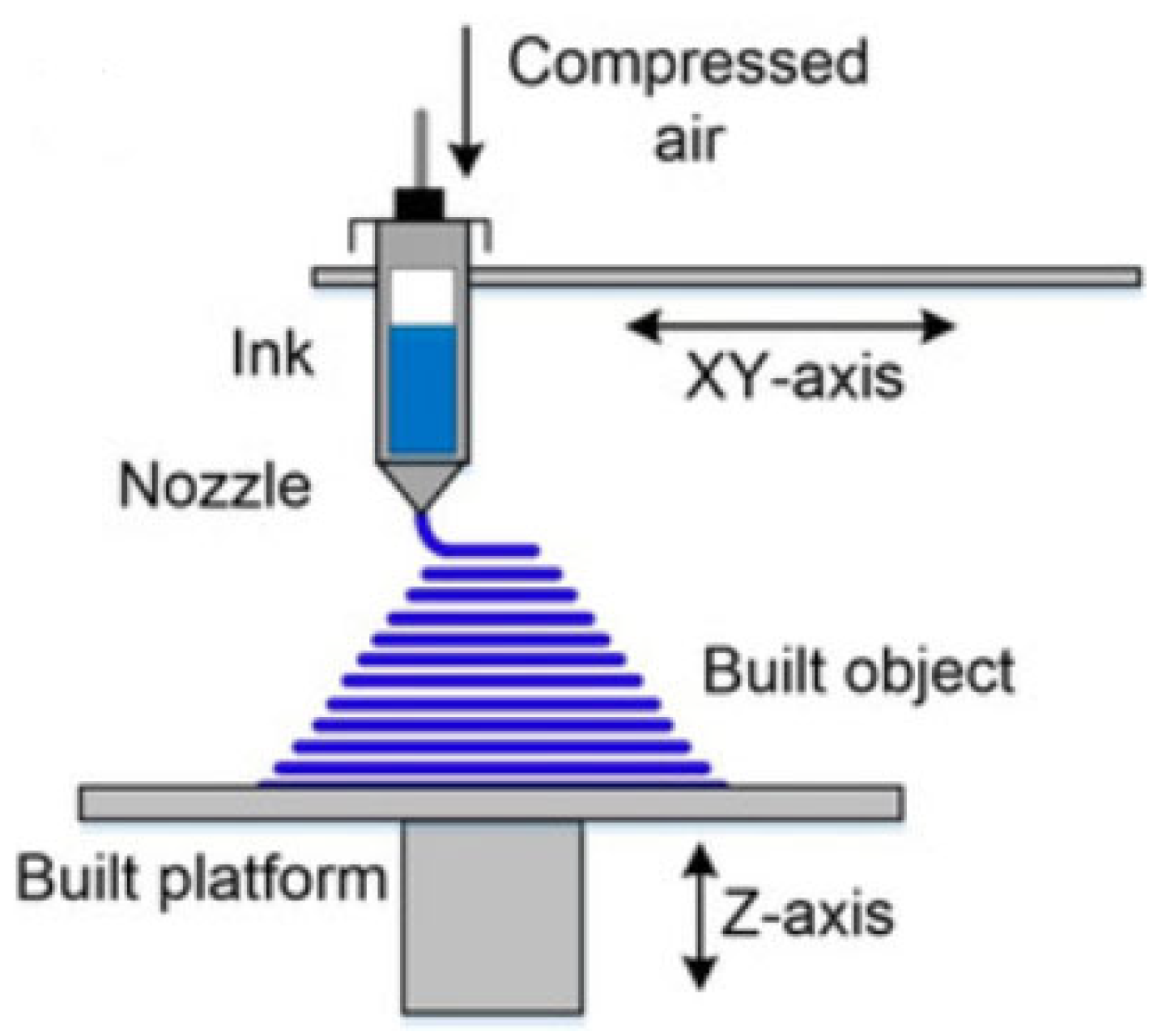

| DIW | Uses a viscous, shear-thinning ink with a yield stress, pushed through a nozzle by pneumatic, screw, or piston-driven pressure to deposit continuous strands layer by layer | Technique emerged as the most versatile 3D printing method for the broadest range of materials; Creating complex three-dimensional structures with tailored shapes, sizes, and functionalities | Complexity of ink formulation and printing processes, particularly for functional conductive hydrogels; The need for post-processing treatments such as sintering for ceramics; Limited long-term stability data for bio-printed structures; Scalability of advanced formulations for commercial production | Ink rheology design and predictability; controlling micro- to macro-scale architecture within a single print to realize graded porosity, aligned fiber networks, or multi-material interfaces; Achieving high-resolution features without sacrificing build speed or causing nozzle clogging; developing low-temperature, energy-efficient, and scalable post-processing routes compatible with heat-sensitive components and biological materials; Designing green, bio-based, or recyclable inks with comparable performance; Reducing hazardous solvents and improving long-term stability |

| AFSD | Feeding a consumable metal rod into a rotating, heated tool that traverses the build path, which causes plastic deformation, fracture, and interfacial bonding without melting the base material, and enabling layer-by-layer deposition | Low residual porosity; Reduced oxidation; Minimal warped distortion; Good surface integrity; Near-net-shape capability; Potential for in situ heat treatment and graded material properties | Relatively slow build rates; Equipment complexity; Limited deposition height per pass; Sensitivity to tool-path optimization; Challenges with post-build surface finish and dimensional accuracy | Optimizing AFSD for new materials; enhancing process efficiency; Expanding innovative applications; Enhance understanding of process-structure–property relationships across diverse alloys and composites, as well as the technological readiness for industrial adoption. |

| Hybrid AM | Combines additive manufacturing techniques such as directed energy deposition, or powder bed fusion with a secondary manufacturing process such as machining or welding | Enables the manufacture of near-net shapes followed by precise finishing; Reducing post-processing time; Could leverage the material efficiency of additive processes while taking advantage of the precision and dimensional accuracy of conventional processes; Improving feature resolution, surface quality, and the ability to work with a wider range of materials | Higher equipment and maintenance costs; Longer cycle times for hybrid workflows; Thermal management concerns; Process compatibility between deposition and removal steps; Material-property homogenization; Residual stresses; Anisotropy must be carefully managed; Process optimization often requires multidisciplinary modeling and robust process-monitoring strategies | Harmonizing disparate processes into a single consistent workflow; Real-time process monitoring and closed-loop control across modalities to ensure dimensional accuracy, surface finish, and thermal stability; Designing compatible material pairs with strong, durable interfaces; Managing thermal histories and diffusion across interfaces to avoid cracking, residual stresses, or delamination; Controlling heat input from different processes to minimize warpage, distortion, or phase changes |

| Technology | Main Findings | Process Parameters Range | Critics | References |

|---|---|---|---|---|

| FDM | In FDM process it is widely important to fine-tun the temperature, print speed, and layer height to achieve better print quality and performance particularly when using materials like PLA. | Build speed PLA/ABS/PET-G FDM: often in the range of ~20–80 mm/s. Metal-filled filaments or specialized materials: may require lower speeds, ~5–40 mm/s. Nozzle temperature (°C)

| The heavy focus on sustainability without equally analyzing the mechanical performances of bio-based materials in functional applications. Most investigations have focused on particular materials (mainly PLA) and particular printer setups, which may limit the applicability of their findings to other materials and printers. | [16,17,18,19,20,21,22,23,24,25,26,27] |

| SLA | Faster cure time is recorded using enhanced UV resins, better print precision and detailing. Recent studies highlighted remarkable improvements in photopolymer resin optimization, using procedures such as neural network approaches to enhance mechanical properties and bio-compatibility certifications. Which enabled the safer and more effective use of SLA-made products in healthcare applications. | Build speed Photopolymers: commonly 5–100 mm/s, with many studies clustering around 20–60 mm/s for balanced cure and build time. Layer height (µm to mm) SLA/Epoxy resins: 25–200 µm (0.025–0.2 mm), with common choices around 50–100 µm for good surface finish and dimensional accuracy. Nozzle/laser temperature Most photopolymer SLA/DLP uses a photoinitiation process rather than a heated nozzle; some dual-curing systems may involve modest temperatures during post-curing (room temp to ~60–80 °C for post-curing, depending on resin). Tensile strength (MPa) SLA epoxy resins: roughly 40–120 MPa depending on resin chemistry, curing, and orientation; biocompatible dental resins may be in the lower to mid-range (20–60 MPa) but can reach higher with optimized cure. Surface roughness (Ra, µm) Post-processing and layer height dominate: typical as-printed Ra ~1–5 µm for fine layers with smooth finishes; with larger layer heights, Ra can rise to ~10–25 µm or more. | While research identified challenges in post-processing, it may not give alternatives or innovative strategies to overcome these challenges. The critical dependence between SLA performances and the photopolymer resins proprieties. Many photopolymers suffer from issues such as lack of long-term stability, brittleness, and limited temperature resistance. Which can influence mechanical performance, durability, and sustainability of prints. | [28,29,30,31,32,33] |

| SLS | The last advances in this technique have marked a remarkable enhancement of the mechanical performance and applicability of polymer-based materials, especially in manufacturing composites and innovative oral dosage forms. Several investigations have demonstrated advancement in material formulations, such as the exploitation of the use of copovidone and paracetamol in SLS for pharmaceutical products and using amino-silane treatments to improve the mechanical properties of PA12-based composites. | Build speed (mm/s) Commonly 0.5–5 mm/s (depending on machine and part size). Laser energy density Typical ranges: 0.5–3.0 J/mm2 (depends on material, scan speed, layer thickness). Part bed temperature (°C) PA12 and similar powders: bed temperatures around 160–190 °C. Higher for tougher polymers. Tensile strength (MPa) PA12 parts: typically 30–50 MPa. Filled or reinforced polymers: higher, can approach 60–100 MPa in optimized cases. Surface roughness (Ra, μm) As-built SLS PA12: Ra often in the 5–15 μm range; with polishing or post-processing can be below 5 μm. | The need for precise experimental parameter identification and thermal modeling could complicate the SLS process, which leads to a challenge in achieving consistent accuracy of printed parts. In addition, dependence on high-quality powders and the risk of defects related to particle size distribution can limit the efficiency and scalability of SLS manufacturing. | [34,35,36,37,38,39,40,41] |

| DLP | Achievement of higher printing speeds which enables more efficient production in high-detailed applications. Expanded applications in dental technologies. Novel strategies have been presented for better efficiency in DLP systems. | Build speed (mm/s) photopolymers: commonly 5–50 mm/s. Tensile strength (MPa) typically 20–100 MPa, depending on resin (epoxies often higher; some dental/bio resins lower). Surface roughness (Ra, µm) As-printed: 1–20 µm depending on layer height, resin, and post-processing; post-processing can reduce Ra to below 1 µm in optimized cases. | Optimizing the printing speed and resolution need to focus on addressing how these modifications affect the mechanical performance and long-term durability of prints. | [42,43,44,45,46,47,48,49] |

| SLM/DLMS | Laser power, scan speed, hatch spacing, layer thickness, and scanning strategy critically influence density, porosity, residual stresses, microstructure, and mechanical performance. Non-uniform cooling and thermal gradients in SLM/DLMS lead to residual stresses that cause warping, cracking, and dimensional inaccuracies. Hot isostatic pressing (HIP), heat treatments, surface finishing, and machining are usually required to reach recommended density, strength, and fatigue performance. | Build/recoat speed (mm/s) and scan strategy Typical laser scan speeds for metals: roughly 0.5–5 mm/s. Laser energy density (J/mm2) Energy density often tuned around 60–180 J/mm2. Powder bed temperature or preheating Preheating for certain alloys (e.g., Ti, Al alloys) can be 100–600 °C depending on material and system. Surface roughness (Ra, µm) As-built SLM surfaces: Ra ~5–15 µm on key features; post-processing can reduce to sub-5 µm. | Conclusions about mechanical properties usually assume post-processing steps (HIP, heat treatment) that may not be available in all production settings, affecting real-world applicability. Many studies focus on technical feasibility without robust assessment of cycle time, cost, and scalability to production volumes. Fatigue, corrosion, and biocompatibility data are often limited to short-term tests, leaving uncertainties about long-term reliability. Many papers rely on simulations or energy density heuristics that do not fully account for complex thermal history, microstructure evolution, or residual stresses, leading to overconfident predictions. | [50,51,52,53,54,55,56,57,58,59,60,61] |

| Binder Jetting | The highlight of material versatility including applications in ceramics and metals. Highlight of new technologies to improve the mechanical properties of prints such as nanoparticle dispersion infiltration or post-heat treatments. Optimization of the process parameters for enhanced part density. | Print speed (mm/s) Typical practical speeds for fine features or dense parts: ~5–25 mm/s. High-throughput, coarse-feature builds: can approach 60–100 mm/s. Tensile strength Metals in binder-jetted parts can range from ~200–900 MPa after sintering. Surface finish and roughness Typically 5–20 µm on functional faces. | Insufficient analysis of limitations, such as challenges related to part strength, surface finish, and cost of materials and processing. Further exploration of long-term performance, scalability, and applicability across different industries. | [62,63,64,65,66,67,68] |

| Material Jetting | Careful optimization of pre-processing steps can lead to promising accuracy of prints. The composition and distribution of materials at the voxel-scale promisingly affect the structure–performance relationships, potentially improving the design flexibility of prints. Integrating a topology optimization and numerical analysis to predict experimental outcomes, can improve the intended results in Multi-Material Jetting. | Print speed (mm/s) Layer by layer: ~10 to 60 mm/s Typical practical speeds for fine features: 5 to 30 mm/s. Ultra-fine feature printing or very viscous inks, speeds often limited to 5–15 mm/s to maintain jetting stability and gap control. Surface roughness (Ra, µm) Commonly 1–10 µm for well-controlled resins and small features; rougher surfaces up to ~20–25 µm for larger features or higher viscosity resins. Dimensional accuracy Tolerances often in the range of ±0.1–0.3% for small to medium parts. Tensile strength (MPa) Roughly 20–80 MPa depending on resin chemistry and interfacial design; with favorable post-processing, higher values are possible. | The focus on pre-processing might not be sufficient to assess the impact of material properties on dimensional precision. It is needed to explore the practical implications of varying voxel compositions in terms of cost-effectiveness and manufacturing feasibility. Studies should consider long-term stability and degradation behavior of bio-compatible materials. | [82,83,84,85,86,87] |

| DIW | DIW is capable of processing a wide variety of scales and materials (hydrogels, ceramic-based composites, metals, and bio-based materials), offering geometric customization and adjustable mechanical properties. Control of ink formulation (viscosity, thixotropy, colloidal stability, rheology) and printing parameters (pressure, extrusion speed, temperature) is crucial for geometry, resolution, and precision. Hydrogels and bio-hybrids: tunable mechanical properties (rigidity, elasticity) can be obtained through combinations of alginate-gelatin, salting-out, and other matrix strategies. These properties are essential for biomedical applications. | Print speed (mm/s) Commonly 5–50 mm/s, with slower speeds for high-viscosity inks to ensure continuous extrusion. Surface roughness (Ra) Hydrogels and soft inks: ~1 to 10 µm for well-controlled filaments and fine features; roughness can be higher (10–50 µm) for coarse strands or larger features. Ceramic/particle-filled inks: ~5 to 20 µm for fine networks; 20–50 µm for more open or porous structures. Composite inks with pigments/fillers: ~5 to 30 µm depending on particle size and printing conditions. Tensile strength Hydrogels and soft polymer inks: roughly 0.1 to 10 MPa. Higher-strength variants with specialized chemistries and crosslinking can reach ~10–20 MPa. Semi-rigid polymer inks typically 10–70 MPa. With optimization (filler incorporation, crosslink density): 50–100 MPa is possible. | Correlation between ink composition and mechanical response: need to understand how each component and each printing condition influences viscoelastic behavior and long-term stability. Possible variability in ink preparation and printing parameters affecting the consistency of properties. Comprehensively characterize viscoelasticity and stability under relevant biological conditions. Optimize the salting-out process and alginate/gelatin ratios to achieve a targeted range of elastic modulus and other mechanical proprieties. | [88,89,90,91,92,93,94,95,96,97] |

| AFSD | The precise control of the thermal regime (heat input, rotation speed, feed rate) and the number of deposition passes is essential to achieve a homogeneous microstructure and consistent mechanical properties. The microstructure of AFSD parts is highly dependent on the number of passes, the tool profile, the feed rate, and the thermal parameters. The tool profile (pointed, cylindrical, multi-pin) and operating temperature control strongly influence microstructural integrity and the formation of internal residues. | Print speed (mm/s). small parts, high detail, build speed: roughly 5–20 mm/s, with slower speeds to maintain layer uniformity and proper fusion. Moderate-speed ~20–60 mm/s for balanced quality of prints. High-throughput AFSD builds (large parts, lower detail): ~60–150 mm/s or higher. Deposition/fusion energy Rough ranges: 0.5–5 J/cm2. Tensile strength ranging from 87.8 to 320 MPa. | The final microstructure is highly sensitive to deposition parameters: rotational speed, heat input, tool geometry (pin/profiles), number of passes, feed rate, and in some studies, closed-loop temperature control. Increasing the number of passes and optimizing heat input often improves hardness and strength but can induce residual stresses if not properly managed. Defects can arise if parameters are not optimized: improper tool profiles, heat input, and insufficient passes can still cause internal residues, microcracking, or non-uniform grain structure. | [98,99,100,101,102,103,104,105,106,107] |

| Hybrid AM | New innovations in hybrid AM techniques such as laser-arc methods, which lead to promising properties, microstructures, and performance of several composites and metallic materials. Importance of refining processing parameters to achieve better geometrical accuracy of prints. Many studies have focused on the optimization of mechanical proprieties (ductility, tensile strength) using controlled microstructural evolution. Applicability of hybrid AM techniques could cover many fields from aerospace materials to bio-inspired designs, suggesting its versatility and potential for future innovations. | Printing speed Ranging from extremely slow for fine details (e.g., 0.1 to 8 mm/s in a polymer extrusion example) to faster speeds on the order of dozens to hundreds of millimeters per second for metal deposition. Surface roughness For polymer hybrid manufacturing, values are as low as Ra = 1.94 μm. Hybrid processes show significant surface quality improvements of approximately 70% compared to conventional AM processes. Dimensional accuracy Hybrid systems report within ±0.5 μm. Material utilization rates exceed 95%. Tensile strength From below 100 MPa for some polymer composites to over 1000 MPa. | The need to test the durability and environmental use of materials produced by hybrid AM. There are key challenges to achieve a balance between different competing factors (e.g., depositional rates, thermal effects) which affect material performance, and lead to inconsistencies during processing. Issues related to the variability in material feedstock and the quality control. Many experimental setups are not easily scalable for industrial production. Hybrid AM could be costly due to sophisticated equipment and materials, which may not be economically viable for all applications, particularly for industries with tight margins. | [108,109,110,111,112,113,114,115,116,117,118,119,120,121,122] |

| Material | Description | Properties | Applications | AM Technique |

|---|---|---|---|---|

| Metals | Titanium, aluminum, stainless steel, | High strength, high toughness High durability | Automotive, aerospace, healthcare | Electron Beam Melting (EBM), Selective Laser Melting (SLM). |

| Polymers | PLA, ABS, PETG, Nylon, TPU, PVA | Low cost, easy to print, availability | Consumer products, prototyping | FDM, SLS, SLA |

| Ceramics | Alumina, Zirconia | High hardness, high toughness | Aerospace, healthcare | Binder Jetting, Precision Ceramics |

| Composites | Glass fiber, carbon fiber, | High stiffness high strength, | Automotive, Aerospace, sports equipment | FDM, CFF (Continuous Filament Fabrication) |

| Material | AM Technique | Main Findings | References |

|---|---|---|---|

| Graphene-reinforced Thermoplastic | FDM | Enhancement of the tensile strength and thermal conductivity up to 30%. | Raja et al. [143] Liesenfeld et al. [144] Maleki et al. [145] |

| PLA/PBAT/PHBV Bio-based Resin | FDM | Better biodegradability with maintained structural integrity. | Apicella et al. [146] Ali et al. [147] |

| AlSi10Mg aluminum Alloy | Selective Laser Melting (SLM) | Remarkable improvement in ductility and fatigue resistance. | Li et al. [148] Pawlowski et al. [149] Ramesh et al. [150] |