A Comprehensive Review of Flow-Induced Vibration and Fatigue Failure in the Moving Components of Control Valves

Abstract

1. Introduction

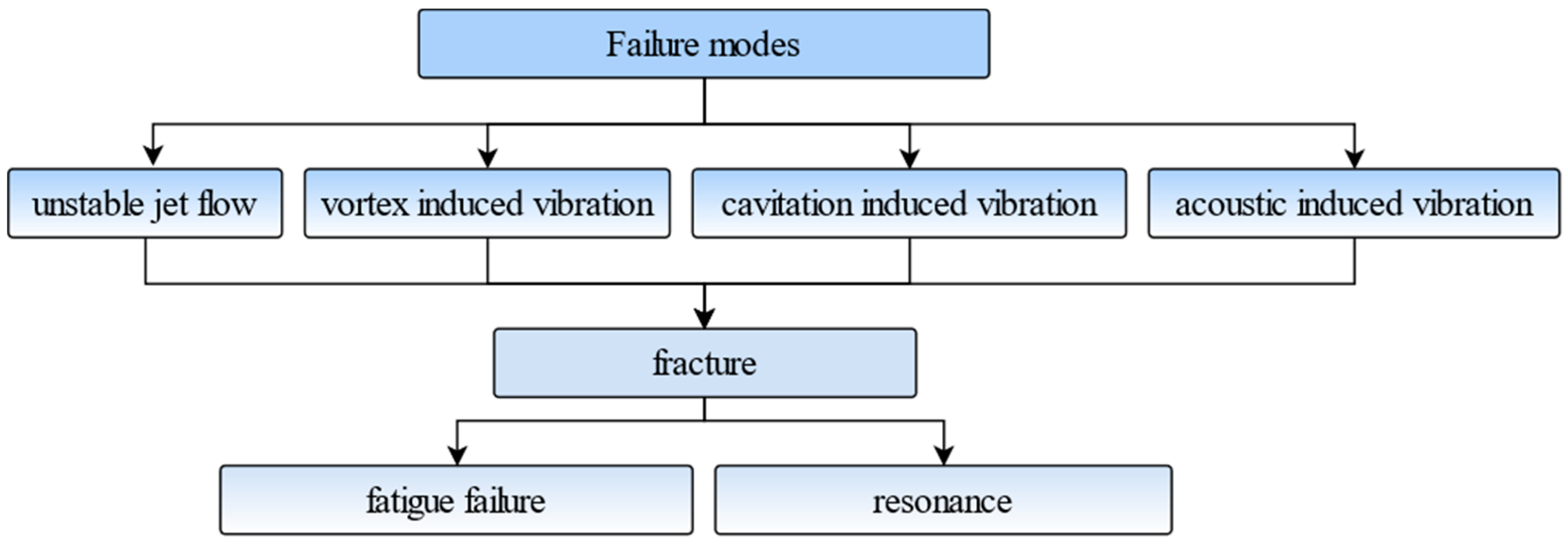

2. Modes and Mechanisms of Failure Due to Flow-Induced Vibration in Control Valves

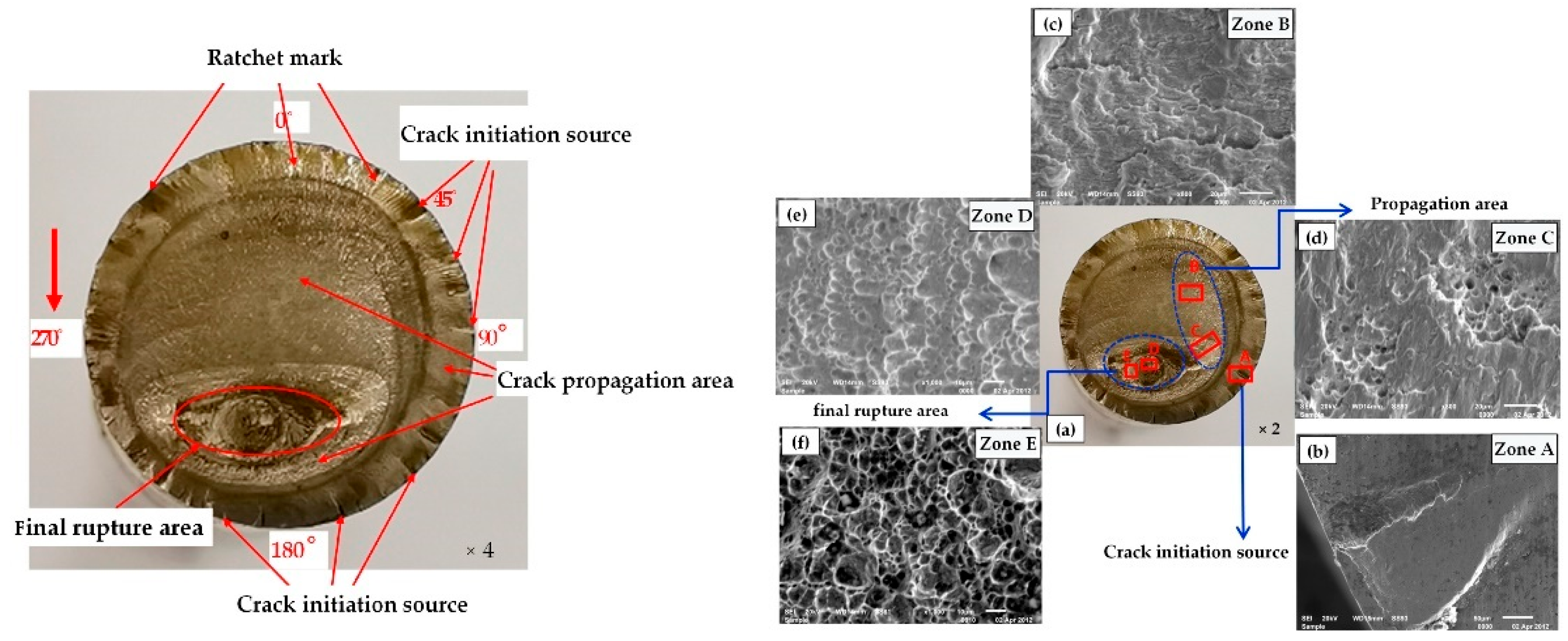

3. Failure Phenomenon of Flow-Induced Vibration Fatigue Fracture of Control Valves

4. Failure Factors

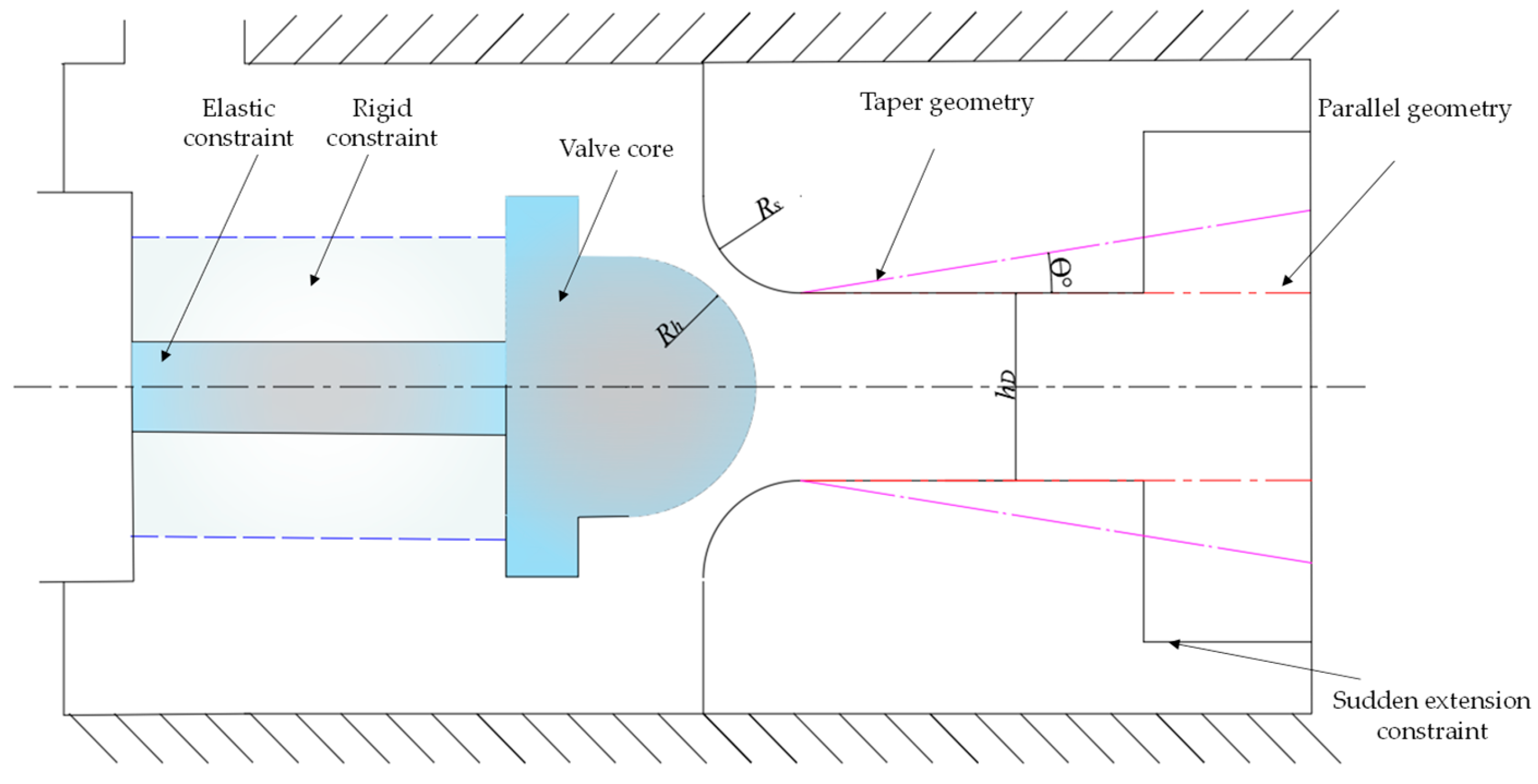

4.1. Unstable Jet Flow-Induced Vibration

4.2. Vortex-Induced Vibration

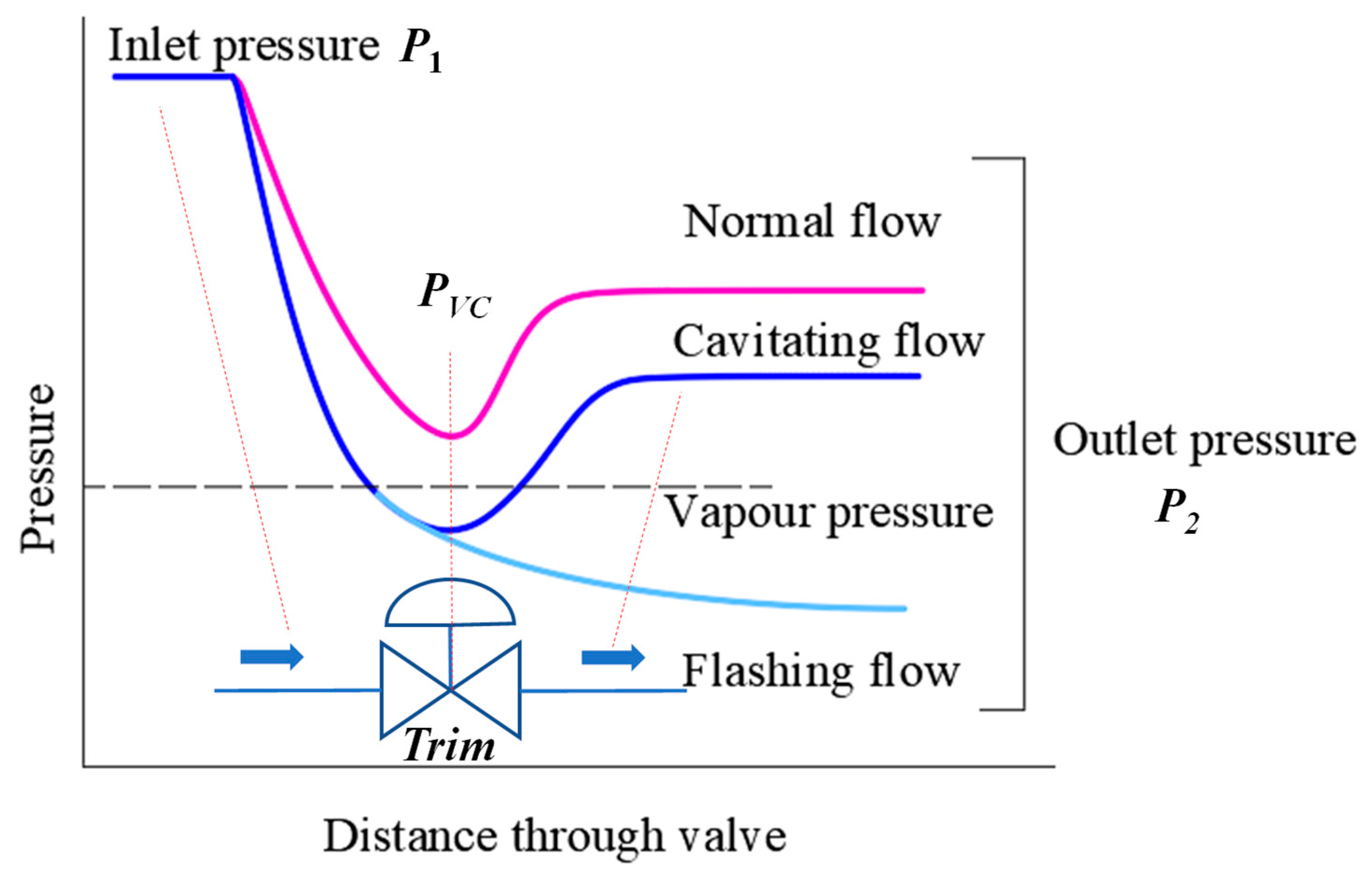

4.3. Cavitation-Induced Vibration

4.4. Flow-Excited Acoustic Resonance

5. Anti-Vibration Measures

- Change the structural dynamics characteristics of the valve stem moving component: Changing the material of the valve plug–valve stem moving component, increasing the diameter of the valve stem, optimizing the connection method between the valve stem and the valve plug, and adjusting the restraint method of the valve stem can effectively change the natural frequency and vibration shape of its structure. This helps prevent the natural frequency of the valve plug assembly from resonating with the fluid excitation frequency. At the same time, the rigidity of the valve stem is improved and the valve stem’s ability to resist deformation is enhanced, thereby reducing the risk of valve stem breakage caused by flow-induced vibration.

- Optimize the valve stem structure to avoid local high stress: Optimizing the structure of the valve stem and valve plug, especially smooth transition processing in the connection transition area, can effectively avoid stress concentration. In addition, changing the shape of the valve plug and designing more reasonable flow channels can disperse and reduce local high stress areas.

- Add damping: Increasing structural damping can significantly improve the system’s ability to absorb vibrations. Damping can be improved by introducing springs, using soft sealing structures, and using packing materials with high friction to attenuate flow-induced vibrations.

- Change the fluid flow characteristics: The fluid flow characteristics within the control valve can be changed by changing the shape of the orifice or using a different type of valve plug. For example, the use of multi-stage pressure-reducing sleeve control valves can reduce cavitation. The impact force caused by bubble collapse during cavitation is absorbed by the fluid, thereby reducing the vibration caused by cavitation.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anilkumar, A.; Kartik, V. Eigen and temporal characteristics of multi-frequency parametrically-excited rotor-oscillator systems. J. Sound Vib. 2021, 493, 115824. [Google Scholar] [CrossRef]

- Chen, F.; Liu, H.; Zhang, S. Time-adaptive loosely coupled analysis on fluid-thermal-structural behaviors of hypersonic wing structures under sustained aeroheating. Aerosp. Sci. Technol. 2018, 78, 620–636. [Google Scholar] [CrossRef]

- Chizfahm, A.; Yazdi, E.A.; Eghtesad, M. Dynamic modeling of vortex induced vibration wind turbines. Renew. Energy 2018, 121, 632–643. [Google Scholar] [CrossRef]

- Guo, F.; Lyu, Y.; Duan, Z.; Fan, Z.; Li, W.; Chen, F. Analysis of Regulating Valve Stem Fracture in a Petrochemical Plant. Processes 2023, 11, 1106. [Google Scholar] [CrossRef]

- El Bouzidi, S.; Hassan, M.; Ziada, S. Experimental characterisation of the self-excited vibrations of spring-loaded valves. J. Fluids Struct. 2018, 76, 558–572. [Google Scholar] [CrossRef]

- El Bouzidi, S.; Hassan, M.; Ziada, S. Self-excited vibrations of spring-loaded valves operating at small pressure drops. J. Fluids Struct. 2018, 83, 72–90. [Google Scholar] [CrossRef]

- Duan, Y.; Revell, A.; Sinha, J.; Hahn, W. A computational fluid dynamics (CFD) analysis of fluid excitations on the spindle in a high-pressure valve. Int. J. Press. Vessel. Pip. 2019, 175, 103922. [Google Scholar] [CrossRef]

- Wang, H.M.; Hu, F.; Kong, X.S.; Chen, S. Pressure fluctuation of steam on the disc in a triple eccentric butterfly valve. SN Appl. Sci. 2020, 2, 1193. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Han, C.; Ma, X.; Wu, F. Analysis on flow induced vibration of main steam bypass valve in a nuclear power plant. J. Phys. Conf. Ser. 2021, 1985, 012027. [Google Scholar] [CrossRef]

- Liu, S.; Huang, X.; Feng, Z.; Jiang, X.; Wang, B.; Wu, W. Study on Flow-Induced Vibration of Self-Regulation Check Valve During Opening. Press. Vessel. Pip. Conf. 2021, 85352, V005T007A012. [Google Scholar]

- Sun, X.; Li, X.; Zheng, Z.; Huang, D. Fluid–structure interaction analysis of a high-pressure regulating valve of a 600-MW ultra-supercritical steam turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2015, 229, 270–279. [Google Scholar] [CrossRef]

- Wei, A.-B.; Gao, R.; Zhang, W.; Wang, S.-H.; Zhou, R.; Zhang, X.-B. Computational fluid dynamics analysis on flow-induced vibration of a cryogenic poppet valve in consideration of cavitation effect. J. Zhejiang Univ.-Sci. A 2022, 23, 83–100. [Google Scholar] [CrossRef]

- Yonezawa, K.; Ogawa, R.; Ogi, K.; Takino, T.; Tsujimoto, Y.; Endo, T.; Tezuka, K.; Morita, R.; Inada, F. Flow-induced vibration of a steam control valve. J. Fluids Struct. 2012, 35, 76–88. [Google Scholar] [CrossRef]

- Zeid, A.; Shouman, M. Flow-induced vibration on the control valve with a different concave plug shape using FSI simulation. Shock Vib. 2019, 2019, 8724089. [Google Scholar] [CrossRef]

- Widell, K.-E. Governing valve vibrations in a large steam turbine. In Practical Experiences With Flow-Induced Vibrations; Springer: Berline/Heidelberg, Germany, 1980; pp. 320–322. [Google Scholar] [CrossRef]

- Nakano, M.; Outa, E.; Tajima, K. Noise and vibration related to the patterns of supersonic annular flow in a pressure reducing gas valve. J. Fluids Eng. 1988, 110, 55–61. [Google Scholar] [CrossRef]

- Ziada, S.; Bühlmann, E.; Bolleter, U. Flow impingement as an excitation source in control valves. J. Fluids Struct. 1989, 3, 529–549. [Google Scholar] [CrossRef]

- Pluviose, M. Stabilization of flow through steam-turbine control valves. J. Eng. Gas Turbines Power. 1989, 111, 642–646. [Google Scholar] [CrossRef]

- Michaud, S.; Ziada, S.; Pastorel, H. Acoustic fatigue of a steam dump pipe system excited by valve noise. J. Press. Vessel Technol. 2001, 123, 461–468. [Google Scholar] [CrossRef]

- Hardin, J.; Kushner, F.; Koester, S. Elimination of Flow-Induced Instability from Steam Turbine Control Valves; Texas A&M University: College Station, TX, USA, 2003. [Google Scholar]

- Stastny, M.; Bednar, L.; Tajc, L.; Kolar, P.; Martinu, P.; Matas, R. Pulsating flows in the inlet of a nuclear steam turbine. In Proceedings of the 5th European Conference on Turbomachinery, Fluid Dynamics and Thermodynamics, Prague, Czech Republic, 18–21 March 2003; pp. 17–22. [Google Scholar]

- Zhang, D.; Engeda, A.; Hardin, J.R.; Aungier, R.H. Experimental study of steam turbine control valves. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 493–507. [Google Scholar] [CrossRef]

- Zhang, D.; Engeda, A. Vent uri valves for steam turbines and improved design considerations. Proc. Inst. Mech. Eng. Part A J. Power Energy 2003, 217, 219–230. [Google Scholar] [CrossRef]

- Morita, R.; Inada, F.; Mori, M.; Tezuka, K.; Tsujimoto, Y. CFD calculation and experiments of unsteady flow on control valve. Heat Transf. Summer Conf. 2004, 46911, 51–58. [Google Scholar]

- Morita, R.; Inada, F.; Mori, M.; Tezuka, K.; Tsujimoto, Y. Flow induced vibration of a steam control valve in middle-opening condition. ASME Press. Vessel. Pip. Conf. 2005, 41898, 485–490. [Google Scholar]

- Morita, R.; Inada, F.; Mori, M.; Tezuka, K.; Tsujimoto, Y. CFD simulations and experiments of flow fluctuations around a steam control valve. J. Fluids Eng. 2007, 129, 48–54. [Google Scholar] [CrossRef]

- Yonezawa, K.; Toyohira, Y.; Nagashima, T.; Tsujimoto, Y.; Tezuka, K.; Mori, M.; Morita, R.; Inada, F. An experimental study of unsteady transonic flow in a steam control valve with simple model. J. Environ. Eng. 2010, 5, 134–143. [Google Scholar] [CrossRef]

- Zanazzi, G.; Schaefer, O.; Sell, M.; Ridoutt, C. Unsteady CFD simulation of control valve in throttling conditions and comparison with experiments. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; p. V05BT25A019. [Google Scholar]

- Janzen, V.P.; Smith, B.A.; Luloff, B.V.; Pozsgai, J.; Dietrich, A.R.; Bouvier, J.M.; Errett, A.J.; Kitko, G.T.; Roberts, T.C. Acoustic noise reduction in large-diameter steam-line gate valves. ASME Press. Vessel. Pip. Conf. 2007, 42827, 513–522. [Google Scholar]

- Zaryankin, A.; Arianov, S.; Paramonov, A.; Gotovtsev, A.; Storozhuk, S. A new control valve with a push rod for intermediate-pressure cylinders of steam turbines. Therm. Eng. 2007, 54, 879–885. [Google Scholar] [CrossRef]

- Liu, G.; Wang, S.; Guo, H.; Mao, J.; Feng, Z.; Xiang, X. Investigation on flow characteristics and stability of control valves for steam turbines. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; pp. 811–820. [Google Scholar]

- Tecza, J.; Chochua, G.; Moll, R. Analysis of fluid-structure interaction in a steam turbine throttle valve. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; pp. 2329–2338. [Google Scholar]

- Clari, M.B.; Polklas, T.; Joos, F. Three-dimensional flow separations in the diffuser of a steam turbine control valve. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; pp. 2327–2334. [Google Scholar]

- Lindqvist, H. CFD simulation on flow induced vibrations in high pressure control and emergency stop turbine valve. In Proceedings of the NURETH-14: 14. International Topical Meeting on Nuclear Reactor Thermalhydraulics, Toronto, ON, Canada, 25–30 September 2011. [Google Scholar]

- Engeda, A. Performance study and instability analysis of steam turbine control valve. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; pp. 651–661. [Google Scholar]

- Hajšman, M.; Kovandová, D.; Matas, R. Some aspects of numerical simulation of control valves for steam turbines. EPJ Web Conf. 2012, 25, 01052. [Google Scholar] [CrossRef]

- Matas, R.; Straka, F.; Hoznedl, M. Numerical simulation of flow and determination of aerodynamic forces in the balanced control valve. EPJ Web Conf. 2013, 45, 01062. [Google Scholar] [CrossRef]

- Barannyk, O.; Oshkai, P. Investigation of diametral acoustic modes in a model of a steam control gate valve. J. Press. Vessel Technol. 2014, 136, 061302. [Google Scholar] [CrossRef]

- Bianchini, C.; Da Soghe, R.; Cosi, L.; Imparato, E. Numerical analysis of the unsteady loads on a steam turbine double seat control valve. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A048. [Google Scholar]

- Bianchini, C.; Da Soghe, R.; Imparato, E.; Cosi, L. Aeroacoustic analysis of a steam turbine double seat control valve. In Proceedings of the 11th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics ETC11, Madrid, Spain, 23–27 March 2015. [Google Scholar]

- Brüggemann, P.; Vinnemeier, P.; Balkowski, I.; Büscher, C.; Stapper, P.; Zimmer, G.; Wirsum, M. A new emergency stop and control valves design: Part 1—Experimental verification with scaled models. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A001. [Google Scholar]

- Musch, C.; Deister, F.; Zimmer, G.; Balkowski, I.; Brüggemann, P.; Haslinger, W. A new emergency stop and control valve design: Part 2—Validation of numerical model and transient flow physics. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A002. [Google Scholar]

- Chakrabarti, S.; Potdar, Y.; Baik, S.; Welch, D.; Forte, G. Forced Response Analysis of Steam Turbine Inlet Flow Control Valves. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V07BT35A023. [Google Scholar]

- Domnick, C.; Benra, F.; Dohmen, H.; Musch, C. Numerical investigation on under expanded wall jet separation in a steam turbine valve diffuser. In Proceedings of the International Symposium on Rotating Machinery ISROMAC-15, Honolulu, HI, USA, 24–28 February 2014. [Google Scholar]

- Domnick, C.B.; Benra, F.-K.; Brillert, D.; Dohmen, H.J.; Musch, C. Numerical investigation on the time-variant flow field and dynamic forces acting in steam turbine inlet valves. J. Eng. Gas Turbines Power 2015, 137, 081601. [Google Scholar] [CrossRef]

- Domnick, C.B.; Benra, F.-K.; Brillert, D.; Dohmen, H.J.; Musch, C. Improving the design of steam turbine inlet valves by numerical methods for enhanced part load operation. In Proceedings of the 11th European Conference on Turbomachinery Fluid dynamics & Thermodynamics, Madrid, Spain, 23–27 March 2015. [Google Scholar]

- Domnick, C.; Benra, F.; Brillert, D.; Dohmen, H.; Musch, C. Numerical Investigation of the Fluid and Structure Dynamics of a Steam Turbine Inlet Valve at Different Operation Conditions. In Proceedings of the VKI Workshop on Safety and Control Valves, Von Kármán Institute, Sint Genesius Rhode, Belgium, 8–9 April 2015. [Google Scholar]

- Domnick, C.B.; Benra, F.-K.; Brillert, D.; Dohmen, H.J.; Musch, C. Numerical investigation on the vibration of steam turbine inlet valves and the feedback to the dynamic flow field. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; p. V008T026A004. [Google Scholar]

- Domnick, C.B.; Benra, F.-K.; Brillert, D.; Musch, C. Modification of a steam valve diffuser for enhanced full load and part load operation using numerical methods. Period. Polytech. Mech. Eng. 2016, 60, 185–192. [Google Scholar] [CrossRef]

- Domnick, C.B.; Benra, F.-K.; Brillert, D.; Dohmen, H.J.; Musch, C. Investigation on flow-induced vibrations of a steam turbine inlet valve considering fluid–structure interaction effects. J. Eng. Gas Turbines Power 2017, 139, 022507. [Google Scholar] [CrossRef]

- Domnick, C.B.; Brillert, D.; Musch, C.; Benra, F.-K. Clarifying the physics of flow separations in steam turbine inlet valves at part load operation and improved design considerations. J. Fluids Eng. 2017, 139, 081105. [Google Scholar] [CrossRef]

- Schramm, A.; Müller, T.; Polklas, T.; Brunn, O.; Mailach, R. Unsteady Flow in Extraction Modules of Industrial Steam Turbines. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A009. [Google Scholar]

- Zeng, L.-F.; Liu, G.-W.; Mao, J.-R.; Wang, S.-S.; Zhang, C.; Yu, X.; Zhang, J.-J.; Xu, Y.-T. Research on the coupling mechanism between alternating flow pattern and valve stem system of steam turbine control valve. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V01BT27A049. [Google Scholar]

- Zanazzi, G.; Rice, T.; Sell, M.; Ridoutt, C. Experimental and numerical investigation into the aerodynamics of a novel steam turbine valve and its field application. J. Eng. Gas Turbines Power 2014, 136, 091601. [Google Scholar] [CrossRef]

- Bianchini, C.; Da Soghe, R.; Cosi, L.; Imparato, E. Aeroacoustic computational analysis of a steam turbine trip valve. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; p. V008T026A014. [Google Scholar]

- Bolin, C.; Engeda, A. Analysis of flow-induced instability in a redesigned steam control valve. Appl. Therm. Eng. 2015, 83, 40–47. [Google Scholar] [CrossRef]

- Zeng, L.; Liu, G.; Mao, J.; Yuan, Q.; Wang, S.; Wei, L.; Wang, Z. A novel numerical simulation method to verify turbulence models for predicting flow patterns in control valves. J. Fluid Sci. Technol. 2015, 10, JFST0007. [Google Scholar] [CrossRef]

- Zeß, J.-P.; Polklas, T.; Joos, F. Experimental Investigation of the Flow in a Control Valve of an Industrial Steam Turbine. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016; p. V008T026A028. [Google Scholar]

- Wang, P.; Liu, Y. Influence of a circular strainer on unsteady flow behavior in steam turbine control valves. Appl. Therm. Eng. 2017, 115, 463–476. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Y. Unsteady flow behavior of a steam turbine control valve in the choked condition: Field measurement, detached eddy simulation and acoustic modal analysis. Appl. Therm. Eng. 2017, 117, 725–739. [Google Scholar] [CrossRef]

- Jin, H.; Zheng, Z.; Ou, G.; Zhang, L.; Rao, J.; Shu, G.; Wang, C. Failure analysis of a high pressure differential regulating valve in coal liquefaction. Eng. Fail. Anal. 2015, 55, 115–130. [Google Scholar] [CrossRef]

- Zhou, C.L.; Yan, A.J.; Wei, X.; Fan, Z.D.; Zhu, L. Fracture Failure Analysis of a High-Pressure Bypass Valve Stem. J. Fail. Anal. Prev. 2023, 23, 1038–1045. [Google Scholar] [CrossRef]

- Yi, J.; Hu, H.; Zheng, Y.; Zhang, Y. Experimental and computational failure analysis of a high pressure regulating valve in a chemical plant. Eng. Fail. Anal. 2016, 70, 188–199. [Google Scholar] [CrossRef]

- Kwon, O.G.; Han, M.S. Failure analysis of the exhaust valve stem from a Waukesha P9390 GSI gas engine. Eng. Fail. Anal. 2004, 11, 439–447. [Google Scholar] [CrossRef]

- Okutsu, R.; Kuramochi, S.; Outa, E.; Machiyama, T. Noise and Vibration Induced by Throttling of High Pressure Compressible Fluid: Part 1-Characteristics of Noise and Vibration Generated by Cage-guided Control Valve. Bull. JSME 1985, 28, 837–845. [Google Scholar] [CrossRef]

- Yonezawa, K.; Nakajima, T.; Toyohira, Y.; Tsujimoto, Y.; Morita, R.; Tezuka, K.; Mori, M. A two-dimensional study of scale effects of flow oscillation in a steam control valve. Nippon. Kikai Gakkai Ronbunshu B Hen 2006, 72, 2172–2177. [Google Scholar] [CrossRef][Green Version]

- Terachi, Y.; Yonezawa, K.; Tsujimoto, Y.; Yokota, K.; Tezuka, K.; Mori, M.; Morita, R. A study of flow induced vibration in a steam control valve. Nippon Kikai Gakkai Ronbunshu B Hen 2004, 70, 371–379. [Google Scholar] [CrossRef][Green Version]

- Yonezawa, K.; Toyohira, Y.; Ichida, Y.; Ogawa, R.; Tsujimoto, Y.; Tezuka, K.; Mori, M.; Morita, R.; Inada, F. A Study of Transonic Flow Fluctuation in Steam Control Valve and Pressure Fluctuation in Downstream Pipe. Trans. Jpn. Soc. Mech. Eng. Ser. B 2008, 74, 286–294. [Google Scholar] [CrossRef]

- Yonezawa, K.; Ogawa, R.; Ogi, K.; Takino, T.; Tsujimoto, Y.; Endo, T.; Tezuka, K.; Morita, R.; Inada, F. Flow-induced vibration of valve head of steam control valve. Nippon Kikai Gakkai Ronbunshu B Hen 2011, 77, 1098–1110. [Google Scholar] [CrossRef]

- Zaryankin, A.; Zroichikov, N.; Paramonov, A.; Noskov, V.; Grigor’ev, E.Y. Pressure pulsations in the turbine steam-admission path and their influence on the vibration state of the turbine control valves. Therm. Eng. 2012, 59, 106–112. [Google Scholar] [CrossRef]

- Sirovich, L. Turbulence and the Dynamics of Coherent Structures. 1. Coherent Structures. Q. Appl. Math. 1987, 45, 561–571. [Google Scholar] [CrossRef]

- Barbieri, R.; Barbieri, N. Finite element acoustic simulation based shape optimization of a muffler. Appl. Acoust. 2006, 67, 346–357. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Liu, Y.Z. Wall-pressure fluctuations of separated and reattaching flow over blunt plate with chord-to-thickness ratio. Exp. Therm. Fluid Sci. 2012, 42, 125–135. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, W.W.; Wu, Z.Y.; Kim, H.D.; Lin, Z. Effect of the opening degree on evolution of cryogenic cavitation through a butterfly valve. Energy 2023, 283, 128543. [Google Scholar] [CrossRef]

- Wang, H.; Kong, X.; Liu, H. Vibration characteristics analysis for a tri-eccentric butterfly valve. J. Vib. Shock 2018, 37, 202–212. [Google Scholar]

- Hasan, A.; Matsuo, S.; Setoguchi, T.; Kim, H. Transonic moist air flow around a symmetric disc butterfly valve with non-equilibrium condensation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 2165–2179. [Google Scholar] [CrossRef]

- Xu, D.; Ge, C.; Li, Y.; Liu, Y. Evaluation the possibility of vortex-induced resonance for a multistage pressure reducing valve. PLoS ONE 2022, 17, e0266414. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, W.; Wang, W.; Xu, X.; Zhu, L. Simulation for VIV of high pressure drop labyrinth-sleeve combined regulating valves. J. Vib. Shock 2020, 39, 95–103. [Google Scholar]

- Li, S.; Kang, Y.; Meng, L.; Pan, W.; Zhang, W.; Liu, T. Flow-induced noise of a high pressure drop control valve. J. Vib. Shock 2020, 39, 116–121. [Google Scholar]

- Qiu, C.; Jiang, C.-H.; Zhang, H.; Wu, J.-Y.; Jin, Z.-J. Pressure drop and cavitation analysis on sleeve regulating valve. Processes 2019, 7, 829. [Google Scholar] [CrossRef]

- Au-Yang, M.K. Flow-induced vibration of power and process plant components: A practical workbook. Appl. Mech. Rev. 2002, 55, B64. [Google Scholar] [CrossRef]

- Moussou, P.; Papaconstantinou, T.; Cohen, J. Scaling the Vibrations of Water Pipes: Application to Industrial Case Studies. ASME Press. Vessel. Pip. Conf. 2006, 47888, 389–396. [Google Scholar]

- Yang, B.-S.; Hwang, W.-W.; Ko, M.-H.; Lee, S.-J. Cavitation detection of butterfly valve using support vector machines. J. Sound Vib. 2005, 287, 25–43. [Google Scholar] [CrossRef]

- Yuzawa, S.; Okutsu, R.; Hashizume, T.; Outa, E. Cavitation erosion features in industrial control valves at an inlet pressure of 20 MPa. JSME Int. J. Ser. B Fluids Therm. Eng. 1998, 41, 1105–1113. [Google Scholar] [CrossRef]

- Yuzawa, S.; Okutsu, R.; Hashizume, T.; Outa, E. Development of Cavitation Erosion on a Contoured Plug in High Pressure Control Valves. Nihon Kikai Gakkai Ronbunshu B Hen/Trans. Jpn. Soc. Mech. Eng. Part B 2002, 68, 1697–1705. [Google Scholar] [CrossRef][Green Version]

- Yi, D.; Lu, L.; Zou, J.; Fu, X. Interactions between poppet vibration and cavitation in relief valve. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1447–1461. [Google Scholar] [CrossRef]

- Inoue, F.; Oto, E.; Tajima, K.; Machiyama, T. An Experimental Study on Control Valve Cavitation (2nd Report, String Bubble Cavitation in Contoured-plug Valve). Trans. Jpn. Soc. Mech. Eng. 1991, 57, 7–15. [Google Scholar] [CrossRef]

- Inoue, F. An Experimenttal Study on Control Valve Cavitation (3rd Report, Vortex Shedding and Cavitation Inception on a Contoured Plug). Trans. JSME 1993, 59, 131–138. [Google Scholar] [CrossRef]

- Kumagai, K.; Ryu, S.; Ota, M.; Maeno, K. Investigation of poppet valve vibration with cavitation. Int. J. Fluid Power 2016, 17, 15–24. [Google Scholar] [CrossRef]

- Fumihiro, I.; Eisuke, O.; Kiyohiro, T.; Tadahiro, M. An Experimental Study on Control Valve Cavitation: 1st Report, Diagnostics of Cavitation Vibration at High Pressure Reduction and at Low Valve Opening. JSME Int. J. Bull. JSME 1987, 30, 1501. [Google Scholar]

- Yang, Q.; Aung, N.Z.; Li, S. Confirmation on the effectiveness of rectangle-shaped flapper in reducing cavitation in flapper–nozzle pilot valve. Energy Convers. Manag. 2015, 98, 184–198. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Lu, K.; Chen, Z. Cavitation reduction of a flapper-nozzle pilot valve using continuous microjets. Int. J. Heat Mass Transf. 2019, 133, 1099–1109. [Google Scholar] [CrossRef]

- Watanabe, M.; Nishino, K.; Kitajima, Y.; Yonekura, K.; Hagiwara, T. Flow-induced vibration of a control valve in a cavitating flow. ASME Press. Vessel. Pip. Conf. 2009, 43673, 239–246. [Google Scholar]

- Hassis, H.; Lauro, J.; Boyer, A.; Dueymes, E. Noise Caused by Cavitating Butterfly and Monovar Valves. Effects of Cavitation on Acoustic Sources; Numerical Simulation; Electricite de France (EDF): Paris, France, 1996. [Google Scholar]

- Hassis, H. Noise caused by cavitating butterfly and monovar valves. J. Sound Vib. 1999, 225, 515–526. [Google Scholar] [CrossRef]

- Sotoodeh, K. The mathematical analysis and review of noise in industrial valves. JMST Adv. 2022, 4, 45–55. [Google Scholar] [CrossRef]

- Merrick, R. Globe Valves-A New Standard. In Proceedings of the Valve World Conference, Asia, Suzhou, China, 23–24 September 2015. [Google Scholar]

- Sotoodeh, K. Cavitation in globe valves and solutions. Valve World Mag. 2016, 21, 32–36. [Google Scholar]

- Sotoodeh, K. Selecting a butterfly valve instead of a globe valve for fluid control in a utility service in the offshore industry (based on an industrial experience). Am. J. Mech. Eng. 2018, 6, 27–31. [Google Scholar] [CrossRef][Green Version]

- Solutions, E.A. Control Valve Handbook; Fisher Controls International: Marshalltown, IA, USA, 2017. [Google Scholar]

- Semrau, S.; Skoda, R.; Wustmann, W.; Habr, K. Experimental and numerical investigation of noise generation due to acoustic resonance in a cavitating valve. J. Sound Vib. 2019, 463, 114956. [Google Scholar] [CrossRef]

- Shioyama, T.; Asakura, D.; Kobayashi, T.; Iseki, T.; Hosaka, H. Coupling vibrations between pipe wall and internal higher-order acoustic wave caused by valve choking. Trans. Jpn. Soc. Mech. Eng. Part C 1995, 61, 3450–3455. [Google Scholar] [CrossRef]

| Valve Plug Shape | Valve Seat | Flow Direction | Identified Fluid Forcing | Reference |

|---|---|---|---|---|

| Contoured plug | Toric | Forward | Acoustic mode excited by mass flow fluctuations | [15] |

| Contoured plug | Toric | Reverse | Oblique shock, jet impingement, flow-excited acoustic resonance | [16] |

| Contoured plug | Toric | Reverse | Jet impingement, flow-excited acoustic resonance | [17] |

| Contoured plug | Toric with cut | Forward | Shock mixing processes, separation from plug mixing processes | [18] |

| Slotted plug | Sharp edge | Forward | Turbulent flow | [19] |

| Contoured plug | Toric | Forward | Separated flow, attached flow | [20] |

| Disc-type plug | Toric | Forward | Shock, separation flow, attached flow | [21] |

| Disc-type plug | Toric | Forward | Unsteady flow separation | [22,23] |

| Contoured plug | Toric | Forward | Unsteady flow separation from the plug, flow-excited acoustic resonance | [13,24,25,26,27,28] |

| Forward | Vortex shedding | [29] | ||

| Contoured plug | Toric | Forward | Unsteady flow | [30] |

| Contoured plug | Toric | Forward | Asymmetric inflow at high mass flow rates | [31] |

| Disc-type plug | Toric | Forward | Internal flow | [32] |

| Flat | Toric | Forward | Shock-induced wall jet separation | [33] |

| Contoured plug | Toric | Forward | Unstable flow separation, turbulent flow | [34] |

| Contoured plug | Toric | Forward | Flow separation at diffuser outlet | [35] |

| Contoured plug | Toric | Forward | Flow separation | [36] |

| Disc-type plug | Conical | Forward | Wall jet separation | [37] |

| Forward | Flow-excited acoustic resonance | [38] | ||

| Forward | Jet impingement | [39,40] | ||

| Disc-type plug | Toric | Forward | Acoustic modes, shear layer instability | [41,42] |

| Contoured plug | Toric | Forward | Flow-excited acoustic resonance | [43] |

| Contoured plug | Toric | Forward | Wall jet separation, flow-excited acoustic resonance, shear layer instability | [44,45,46,47,48,49,50,51] |

| Contoured plug | Toric | Forward | Unsteady flow jet detachment | [52] |

| Disc-type plug | Toric | Forward | Flow separation from hemispherical plug | [53] |

| Disc-type plug | Toric | Forward | Jet flow | [54] |

| Contoured plug | Toric | Forward | Acoustic-induced vibration | [55] |

| Disc-type plug | Toric | Forward | Flow separation | [56] |

| Contoured plug | Toric | Forward | Unsteady flow | [11] |

| Disc-type plug | Toric | Forward | Flow separation | [54,57] |

| Disc-type plug | Toric | Forward | Wall jet separation | [58] |

| Contoured plug | Toric | Forward | Flow-excited acoustic resonance | [59,60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Li, S.; Hou, J. A Comprehensive Review of Flow-Induced Vibration and Fatigue Failure in the Moving Components of Control Valves. Machines 2025, 13, 766. https://doi.org/10.3390/machines13090766

Yang L, Li S, Hou J. A Comprehensive Review of Flow-Induced Vibration and Fatigue Failure in the Moving Components of Control Valves. Machines. 2025; 13(9):766. https://doi.org/10.3390/machines13090766

Chicago/Turabian StyleYang, Lingxia, Shuxun Li, and Jianjun Hou. 2025. "A Comprehensive Review of Flow-Induced Vibration and Fatigue Failure in the Moving Components of Control Valves" Machines 13, no. 9: 766. https://doi.org/10.3390/machines13090766

APA StyleYang, L., Li, S., & Hou, J. (2025). A Comprehensive Review of Flow-Induced Vibration and Fatigue Failure in the Moving Components of Control Valves. Machines, 13(9), 766. https://doi.org/10.3390/machines13090766