1. Introduction

Global commitments to carbon-neutral growth, coupled with tightening resource constraints, are accelerating the transition from linear “make-use-dispose” production to closed-loop value creation. As a strategy for restoring end-of-life (EOL) products to their original performance, remanufacturing plays a pivotal role in this transition. It preserves the embodied energy of initial manufacture, reduces raw-material demand by up to 85%, and can shrink life-cycle greenhouse-gas emissions by 50% or more [

1]. Market projections show the European remanufacturing sector alone surpassing €100 billion by 2030 [

2], and the Chinese government has outlined a target to reach a remanufacturing industry output value of 200 billion RMB during the 14th Five-Year Plan period [

3]. Therefore, governments have increasingly considered remanufacturing as a lever for high-quality employment and industrial resilience. To fully exploit these benefits, sophisticated planning systems are essential to effectively address the variability, uncertainty, and multi-stage characteristics of remanufacturing processes.

A typical remanufacturing chain comprises five tightly coupled stages: disassembly, inspection, reprocessing, reassembly, and final testing [

4,

5]. Unlike conventional manufacturing, each returned core may follow a bespoke route, driven by its unique quality state and customer requirements. Scheduling, therefore, becomes the “control centre” of the remanufacturing shop: it must allocate heterogeneous resources, synchronise serial and parallel flows, respect precedence constraints, and react to stochastic arrivals and machine disruptions, under cost-, energy-, and carbon-reduction targets. In distributed or cloud-based ecosystems, the challenge intensifies: tasks, resources, and data can be geographically dispersed and virtually orchestrated, demanding new optimisation paradigms [

6].

Although academic output has grown steadily, with more than 190 publications between 2005 and 2025, the knowledge base remains fragmented. Prior reviews focus on isolated topics and seldom contrast centralised versus distributed architectures [

7,

8,

9]. Energy- and carbon-aware objectives, quality uncertainty, and large-scale industrial instances are under-explored, while no study has combined bibliometric mapping with an in-depth methodological synthesis. To close these gaps, the contributions of this study are listed as follows:

Map the intellectual landscape by analysing 20 years of publications, unveiling thematic clusters and temporal trends;

Formalise the scheduling problem and highlight how stochastic core quality, multi-phase precedence, and sustainability targets differentiate it from conventional manufacturing;

Link processes and technologies to the constraints they impose on scheduling;

Compare modelling and solution methods for both centralised shop-floor systems and emerging cloud-based, distributed ecosystems;

Identify unresolved challenges in dynamic, collaborative, large-scale, carbon-aware, and digital-twin-driven scheduling, outlining a future research agenda.

The rest of the paper is structured as follows.

Section 2 presents the bibliometric landscape of remanufacturing scheduling.

Section 3 formalises the scheduling problem and distinguishes key system features.

Section 4 reviews enabling processes and technologies that shape scheduling constraints.

Section 5 and

Section 6 synthesise modelling frameworks and algorithms for centralised and decentralised remanufacturing systems, respectively.

Section 7 synthesises research gaps and future directions, and

Section 8 concludes the study.

2. Bibliometric Landscape of Remanufacturing Scheduling

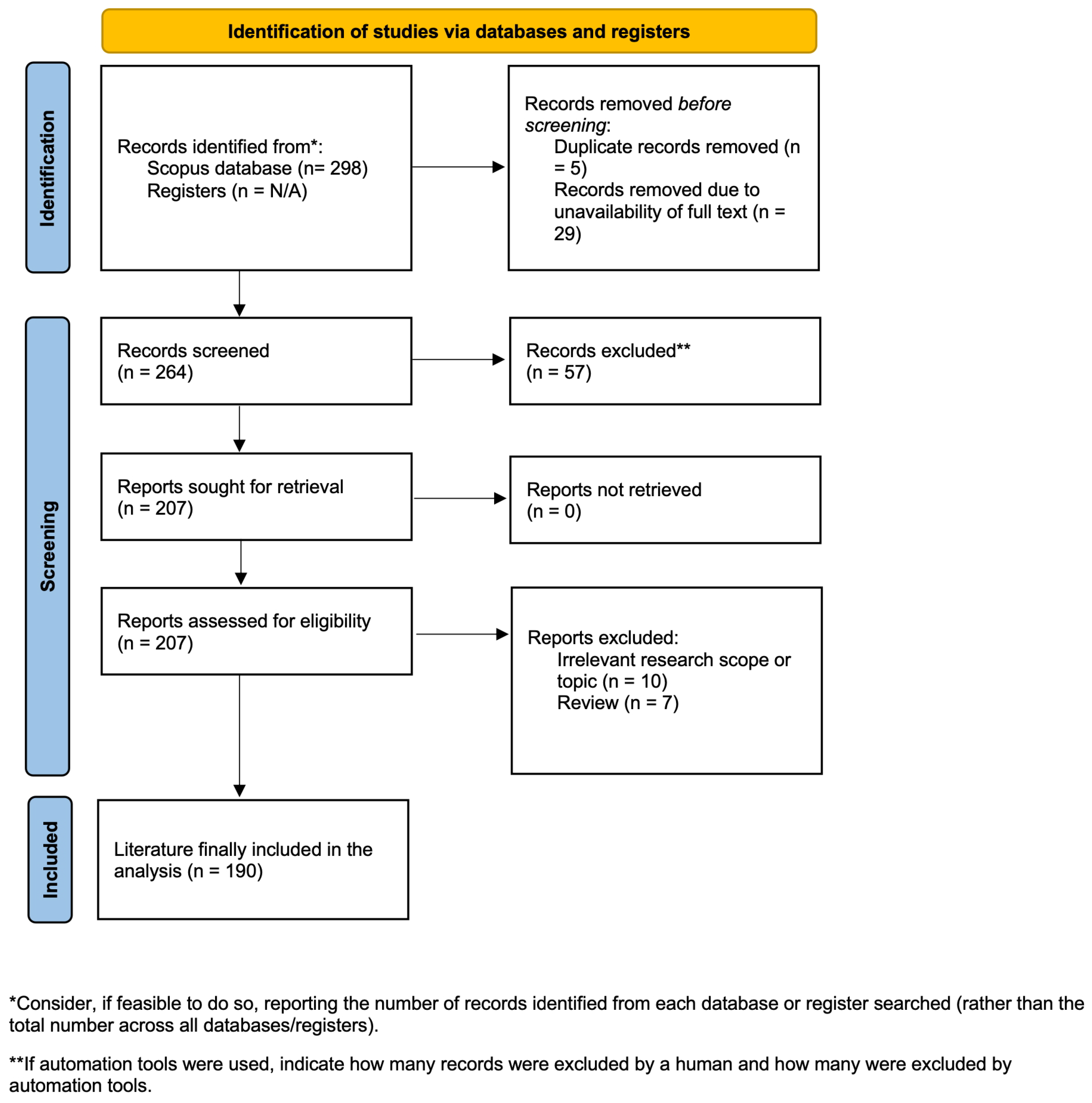

The motivation of this paper is to provide an up-to-date review of the development of remanufacturing scheduling. A combined-review method was employed, covering data acquisition, bibliometric analysis, and a systematic review. The overview of the proposed research method is shown in

Figure 1. Scopus is applied to collect data, complemented with a manual screening of the literature to ensure the inclusion of high-quality and pertinent documents. The bibliometric analysis is then conducted using a software tool, VOSviewer, to show the publication analysis, keyword co-occurrence analysis, and overlay visualisation analysis. These analyses provide insights into the research topics, future trends, application areas, and knowledge domains within the field of remanufacturing scheduling, thereby offering a comprehensive overview of the current state and potential directions of research in remanufacturing scheduling.

2.1. Data Collection and Search Protocol

A comprehensive bibliometric search was carried out in Scopus on 15 February 2025. For this review, the Scopus database was selected as the literature database; comparative studies show Scopus indexes a broader range of engineering and operations-management journals than Web of Science (WoS) [

10]. Many breakthrough algorithms in remanufacturing scheduling first appear in conference series such as Procedia CIRP and IEEE ICIT, which are comprehensively covered by Scopus but only partially by WoS. The Boolean expression (“remanufactur*”) AND (“schedul*”) was applied to titles, abstracts, and indexed keywords from 2005 to 2025, returning 298 records. And the full format of querying keywords was selected as (“remanufacturing” or “end-of-life” or “life cycle”) and (“scheduling” or “optimization”). The screening process is shown in

Figure 2: During the initial screening phase, two independent investigators screened the retrieved records and used the “Remove Duplicates” function of Excel to remove duplicate records. During the content screening phase, the two investigators continued to independently evaluate the title and abstract of each record to determine whether it met the inclusion criteria, excluding those that involved maintenance or logistics without an explicit scheduling component. For records with disagreements, consensus was reached through discussion, and a third expert was consulted when necessary. After the above steps, 190 publications (145 journal articles and 45 conference papers) remained for analysis. The data were processed with VOSviewer 1.6.20. Co-occurrence networks were generated on the basis of keywords, using full counting and a minimum threshold of four occurrences; link strength was measured as the total number of shared occurrences between keyword pairs. In this process, duplicate keywords or keywords with the same meaning were further checked and removed by two independent investigators before the data were imported into VOSviewer to ensure the accuracy of the analysis.

2.2. Publication Output and Source Profile

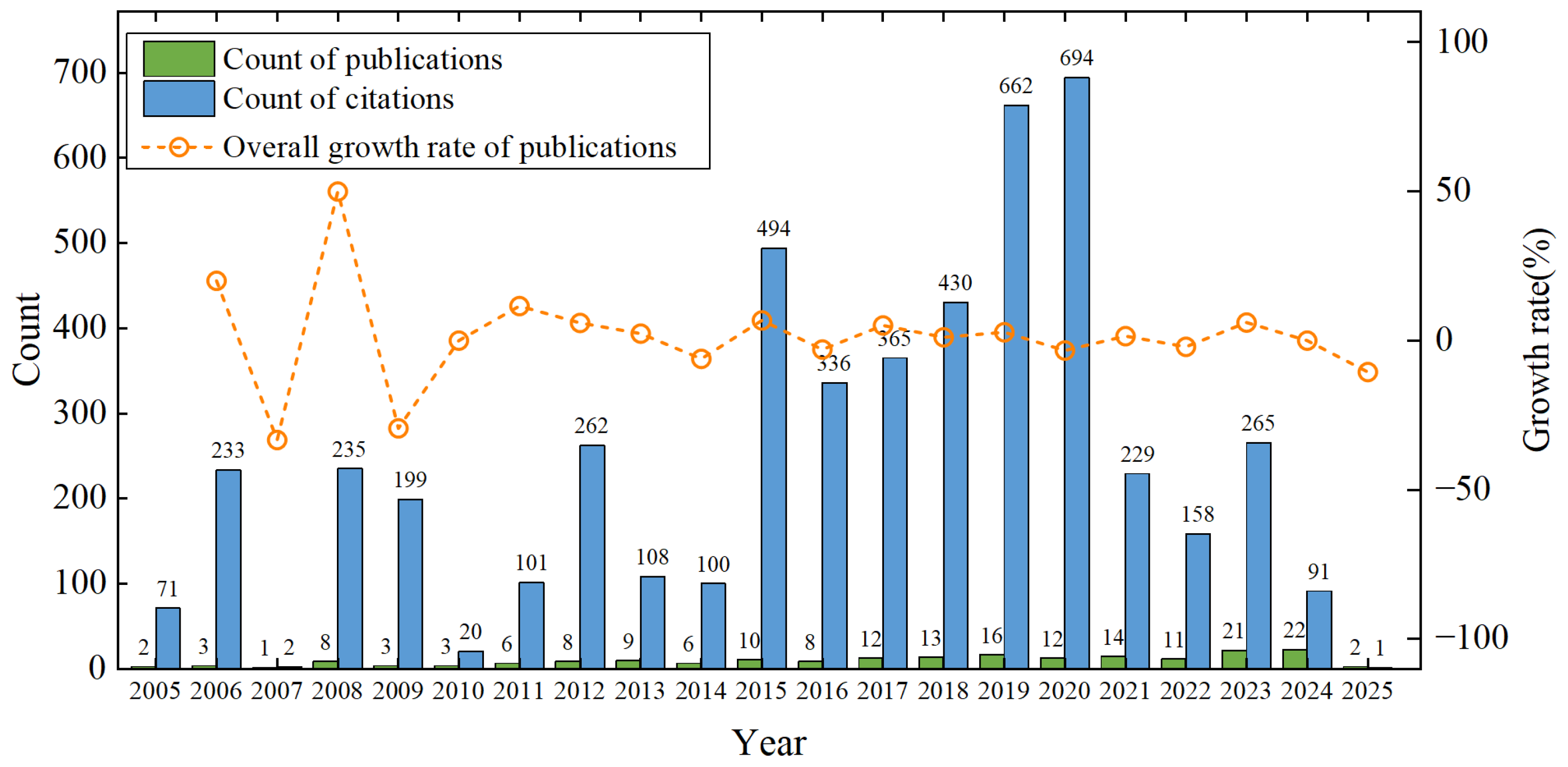

Figure 3 shows a marked upward trajectory in annual output: from only two papers in 2005, the field expanded to 22 papers in 2024, corresponding to an average annual growth rate of approximately 10.5%. The citation count shows a steady upward trajectory, accelerating markedly after 2015 and peaking in 2020. Research is concentrated in a small group of operations management and sustainability journals. The Journal of Cleaner Production, the International Journal of Production Research, and Computers & Industrial Engineering each published nine articles across the period, while a further 20 journals, including the European Journal of Operational Research, the Journal of Manufacturing Systems, and Resources, Conservation and Recycling, which account for the next 60% of journal publications (

Table 1). The presence of 45 conference papers, most of them in IEEE or ASME proceedings, indicates a growing interest in the cyber–physical implementation of scheduling models.

2.3. Thematic Structure of the Field

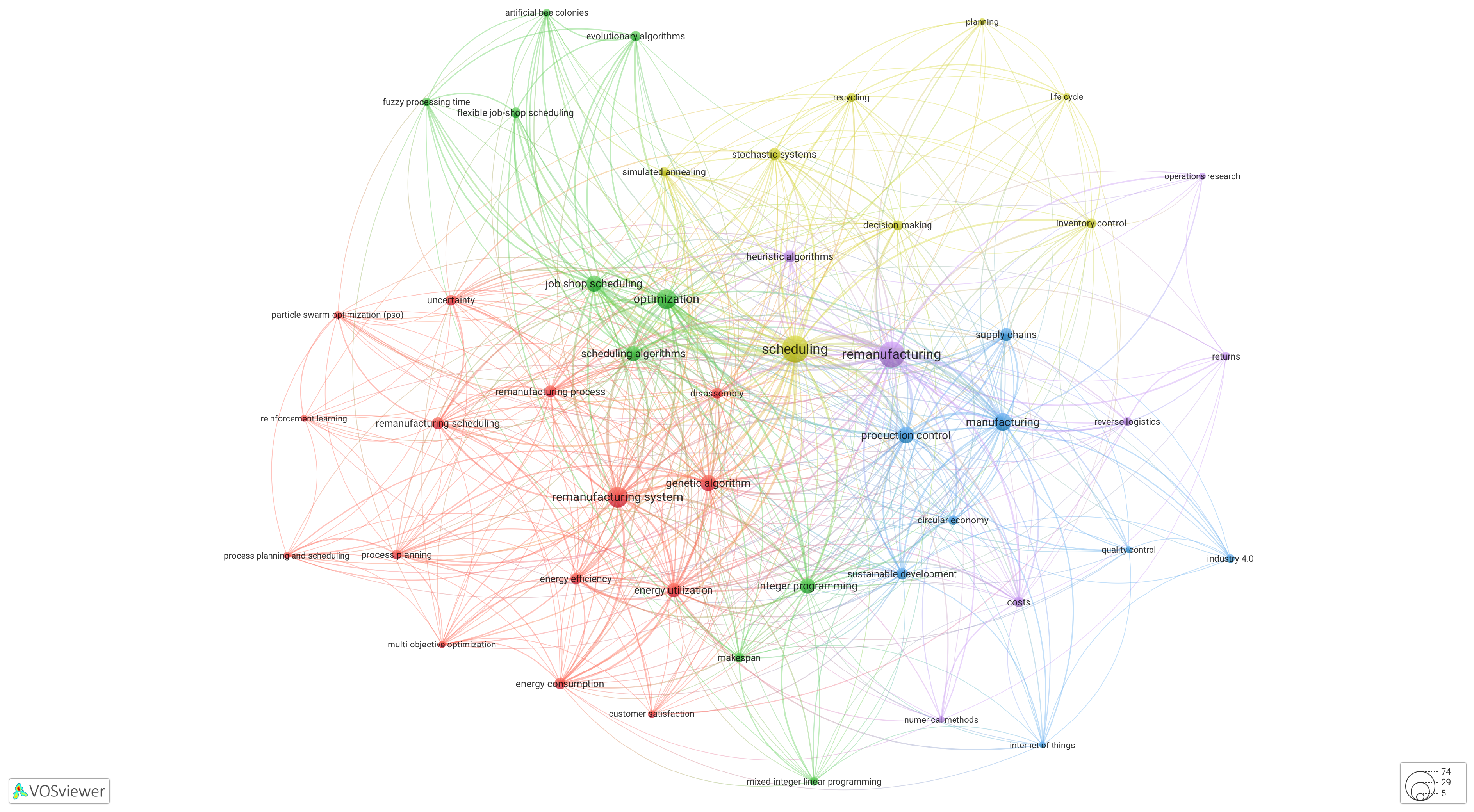

The co-occurrence map in

Figure 4 organises 48 high-frequency co-occurring keywords into five colour-coded clusters. The clustering resolution is set to 1.0, and the minimum-occurrence threshold is set to 4. These settings ensure that only keywords appearing at least 4 times in the dataset are included in the analysis, revealing the intellectual architecture of remanufacturing scheduling research over the past two decades. Serving as the main topic of the network, a dense red cluster anchors the field, it is dominated by the terms remanufacturing, scheduling, remanufacturing system, multi-objective optimization, and process planning, and it is linked by the highest cumulative link strength. Publications in this core strand concentrate on formulating shop-floor scheduling models, typically mixed-integer programmes or classical meta-heuristics, that integrate disassembly, reprocessing, and reassembly within a single facility and frequently pursue multi-objective optimisation of makespan, cost, and, to a lesser extent, energy. The red cluster also contains reinforcement learning, particle swarm optimisation, genetic algorithms, uncertainty, and remanufacturing scheduling. Its composition signals an emergent line of inquiry that blends data-driven or nature-inspired search techniques with stochastic modelling to cope with the quality variability and real-time disturbances characteristic of remanufacturing operations.

Radiating from remanufacturing scheduling are four more specialised clusters. To the upper right, a yellow cluster connects inventory control, recycling, stochastic systems, and life cycle. This cluster emphasises the importance of inventory control and recycling processes in the decision-making and scheduling of remanufacturing. Directly upon the red cluster lies a compact green cluster built around flexible job-shop scheduling and fuzzy processing time. Studies here address low-volume, high-variety contexts in which operations may be routed through alternative machines and processing times are imprecise; the cluster’s relative isolation underlines the methodological specificity of flexible job-shop research.

On the right-hand side, a purple cluster connects reverse logistics, numerical methods, operation research, returns, and costs. This strand shifts the analytical lens beyond the factory gate, embedding scheduling decisions within wider closed-loop supply chain considerations such as take-back systems, inventory positioning, and transport lead times. Finally, a blue cluster occupies the map centre, linking circular economy, production control, sustainable development, and supply chains. Although less densely connected, its presence indicates a growing tendency to situate scheduling research within broader sustainability and stakeholder-value narratives.

A visual inspection of the network shows several thematic groups that are clearly distinct yet still interconnected. At the main research topic, the red cluster functions as the methodological hub, while the surrounding clusters contribute algorithmic innovations, broaden the application contexts, and introduce sustainability motivations. Overall, the pattern depicts a field that is moving beyond deterministic, shop-floor-focused models toward intelligent, uncertainty-aware scheduling frameworks that integrate supply chain logistics and are evaluated against circular-economy goals.

2.4. Temporal Evolution of Research Topics

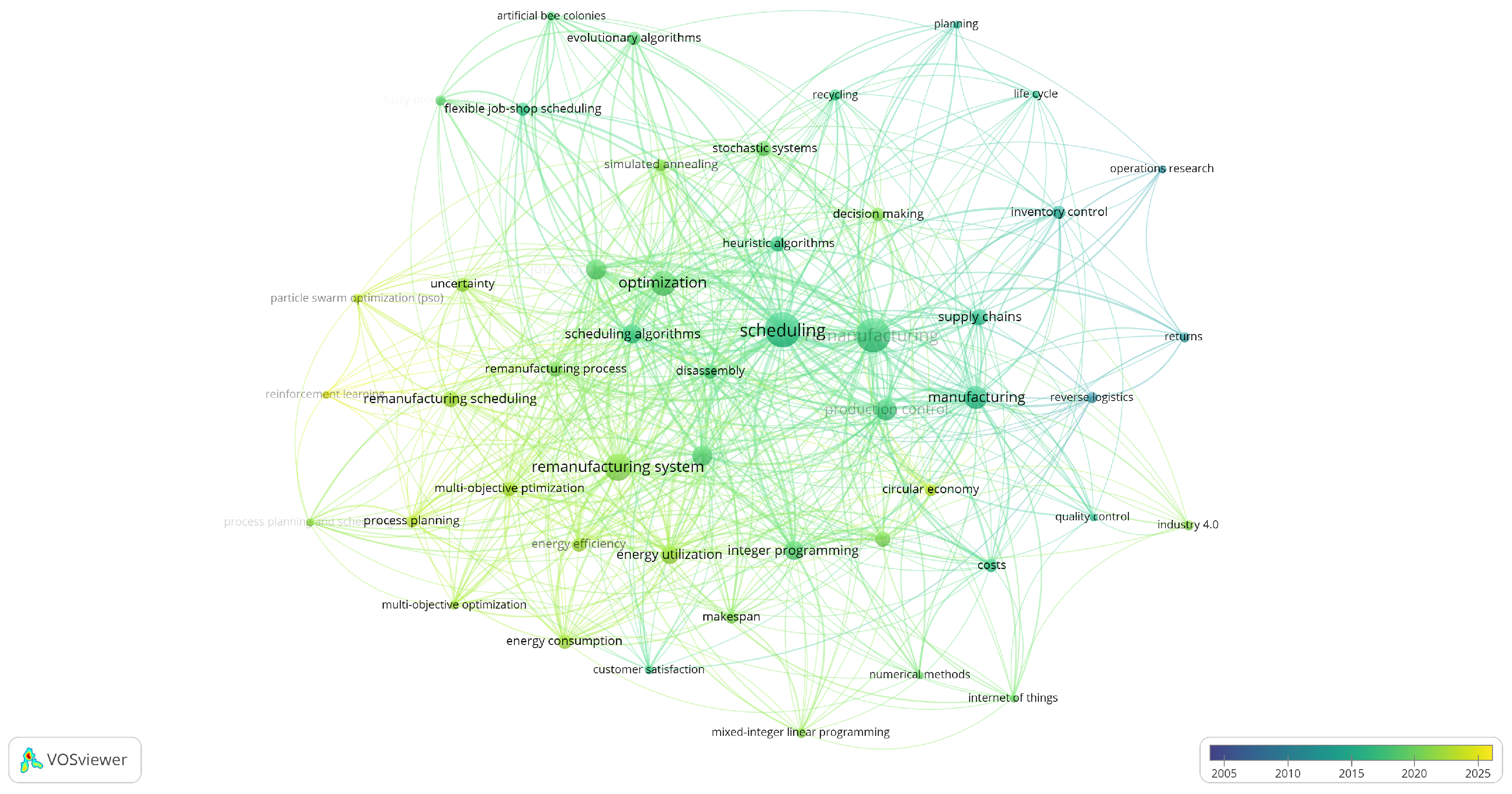

The network of keyword-age overlay visualization is shown in

Figure 5, derived from the average publication year of every term in the co-occurrence network, which reveals a four-stage trajectory for remanufacturing scheduling scholarship over the period of 2005–2025.

2.4.1. Stage 1: Foundational Modelling (2005–2013)

Early research concentrated on translating classical flow-shop and job-shop formulations to remanufacturing environments, solved via exact methods [

12], while treating reverse logistics as an exogenous, static supply source whose uncertain returns were reduced to fixed average rates through deterministic integer programming, turning them into predictable inputs, rather than stochastic variables coupled with real-time shop-floor decisions. Key terms (e.g., integer programming, makespan, and production control) reflect a deterministic, single-objective approach, with no explicit consideration of sustainability or digitalisation.

2.4.2. Stage 2: Heuristic Enrichment and First Sustainability Signals (2014–2018)

From 2013 onward, metaheuristic search [

13] enters the scene: genetic algorithms and simulated annealing become common approaches, and the first scattered mentions of sustainable development appear. This phase thus marks a methodological broadening, away from pure integer models, while simultaneously planting the seeds of an environmental agenda.

2.4.3. Stage 3: Flexibility and Multi-Objective Optimisation (2018–2022)

Driven by Industry 4.0, researchers begin to redefine the shop floor as a flexible job-shop with alternative routings and competing criteria. Terms such as flexible job-shop scheduling [

14], multi-objective optimisation [

15], and energy utilisation [

16] move toward the semantic core of the field; publication counts accelerate sharply, confirming that these years constitute a quantitative and thematic inflexion point.

2.4.4. Stage 4: Data-Driven, Uncertainty-Aware Decision Making (2022–2025)

The most recent literature emphasises uncertainty, process planning, energy consumption, and reinforcement learning. Their late average dates (2022–2023) and rapidly rising link strengths indicate a decisive shift toward real-time, dynamic optimisation. The spotlight on uncertainty reflects the recognition that core quality, disassembly yields, and machine availability fluctuate stochastically and must, therefore, be modelled explicitly to ensure schedule robustness [

17]. The growing prominence of integrated process planning suggests an effort to collapse off-line route design and on-line dispatching into a single integrated problem, improving resource utilisation and responsiveness [

4]. Finally, the arrival of reinforcement learning signals the adoption of algorithms that learn optimal scheduling policies through continuous interaction with the production environment; recent studies report significant gains in large-scale or flexible job-shop contexts [

18,

19].

In summary, the bibliometric analysis reveals a clear shift of remanufacturing scheduling from deterministic, shop-centric optimisation to a research agenda focused on stochastic modelling, AI-driven control, and sustainability metrics. This evolution provides the foundation for the methodological reviews discussed in the remainder of this paper. Specifically, the meta-heuristics reported in

Figure 4, such as particle swarm optimisation (PSO) and genetic algorithm (GA), are well-established population-based techniques belonging to computational intelligence (CI), a recognised subfield of artificial intelligence (AI). In addition, the emerging trend of reinforcement learning (RL) is explicitly rooted in machine learning (ML) and, therefore, firmly situated within the broader AI domain. With respect to “stochastic”, the keyword cluster encompasses stochastic systems and fuzzy processing times, reflecting the growing interest in handling uncertainty and variability in remanufacturing scheduling environment. Regarding “carbon”, the term denotes carbon-emission consumption as an optimisation objective. This indicator is typically integrated with other criteria such as makespan and total energy consumption to construct multi-objective optimisation problems in remanufacturing scheduling for sustainable development. The bibliometric analysis has unveiled the evolving landscape of remanufacturing scheduling, highlighting the increasing integration of advanced techniques and sustainability considerations. This sets the foundation for a detailed exploration of the problem definition and distinctive scheduling features that characterise this complex field.

3. Problem Definition and Distinctive Scheduling Features

Remanufacturing scheduling is defined as the allocation of heterogeneous resources to the sequence of tasks required to restore EoL products to a “like-new” condition. The problem differs fundamentally from its conventional manufacturing in three respects: (i) the quality and quantity of incoming cores are stochastic, rather than deterministic; (ii) a full product may traverse disassembly, inspection, reprocessing, reassembly, and final testing, yielding multi-level precedence relations; and (iii) value is created not only via throughput and cost reduction but also through material recovery and carbon abatement. To formalise subsequent discussions, this study first distinguished two system archetypes and then outlined the prevailing constraints and objective functions, concluding with a comparison to traditional manufacturing scheduling.

3.1. System Typology

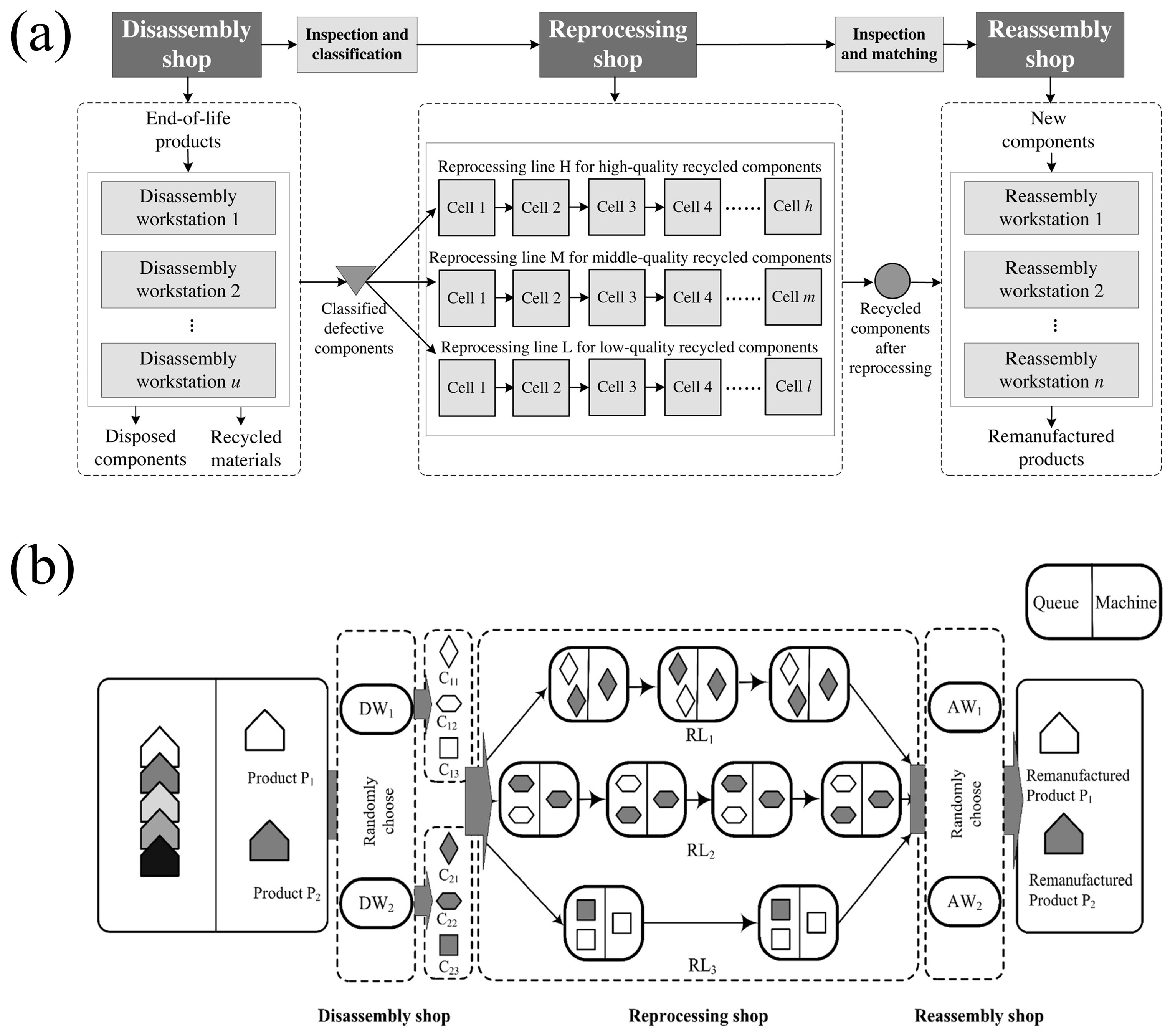

In a centralised setting, all macroscopic phases are co-located within a single facility. A typical centralised remanufacturing system consists of three stages: a disassembly shop, a reprocessing shop, and a reassembly shop [

20]. Disassembly, reprocessing, and reassembly operations share common physical resources; transportation delays between stages are, therefore, negligible, yet resource contention is acute. A crucial principle to adhere to is that the remanufacturing tasks across these three stages must be executed in a prioritised sequence [

21,

22]. Given the heterogeneity of reprocessing requirements, centralised remanufacturing systems fall into two configurations: (i) flow-shop remanufacturing systems suited to high-volume, low-variety returns, and (ii) job-shop remanufacturing systems designed for low-volume, high-variety returns [

14]. Uncertainty manifests primarily as variable processing times, stochastic machine failures, and the heterogeneous quality of incoming cores, which influences route selection and processing requirements [

23].

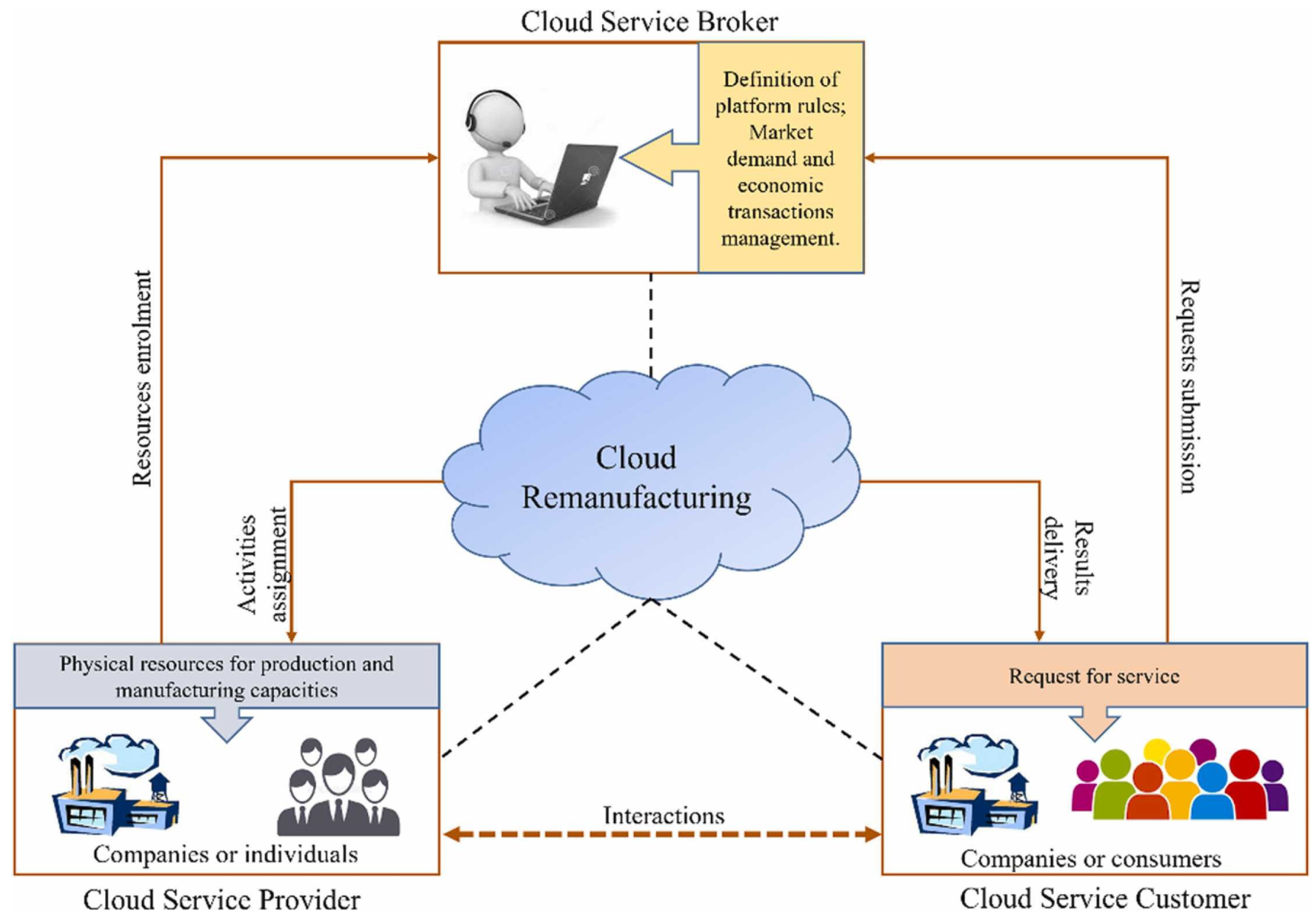

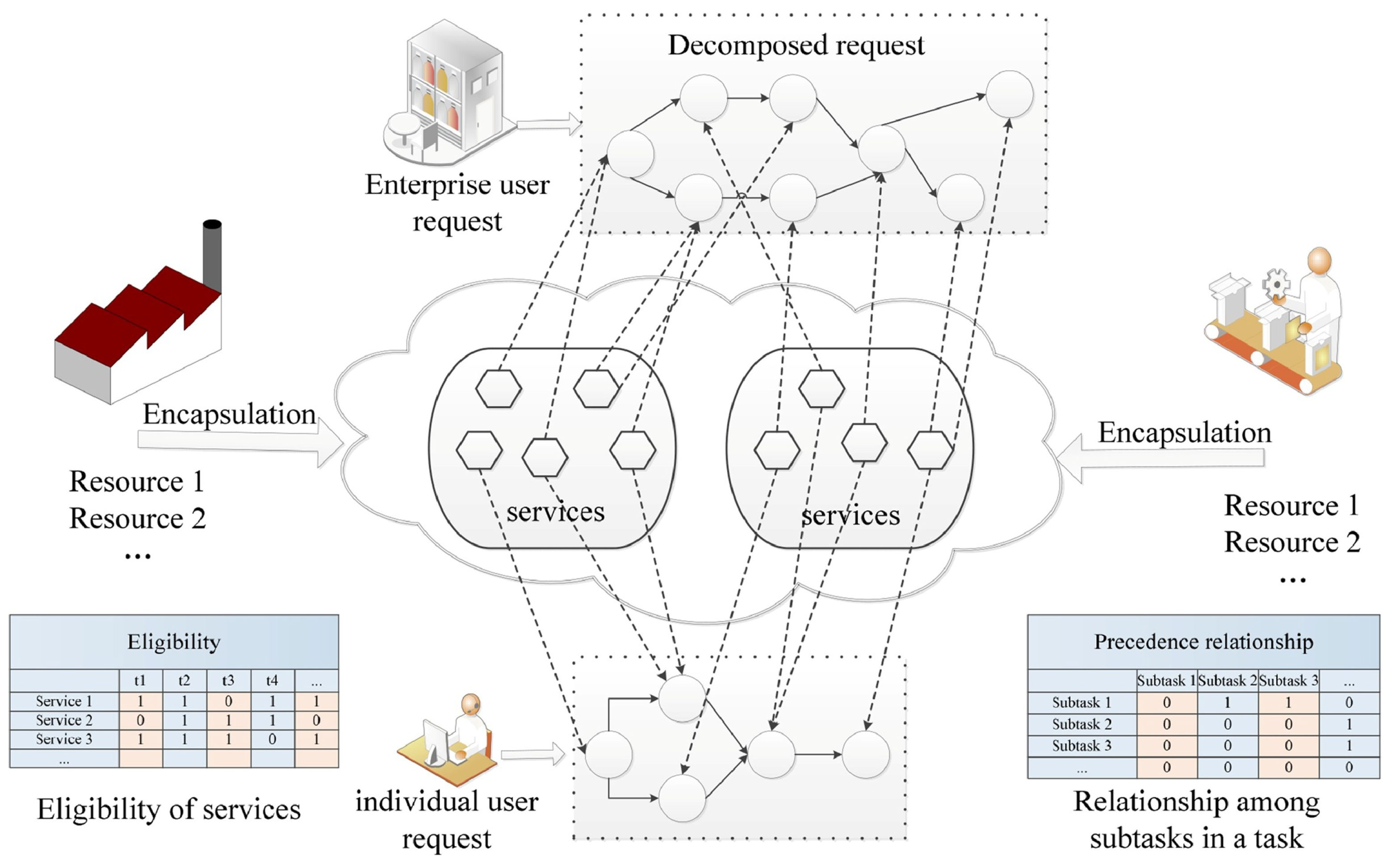

Distributed or cloud-enabled systems virtualise remanufacturing resources across geographically dispersed service providers. Tasks (or task fragments) are published to a cloud platform that orchestrates service composition, resource reservation, and data exchange.

Figure 6 illustrates a typical cloud-remanufacturing architecture [

6], where physical capacities owned by multiple companies or individuals are virtualised and exposed as services through a central platform. Customers submit repair or refurbishment requests, which are matched by the cloud service broker to suitable providers according to platform policies, current market demand, and negotiated service-level agreements. The broker then decomposes each request into elementary activities, reserves the required resources, and coordinates data exchange until results are returned to the customer.

Within this setting, scheduling is a two-dimensional problem. In addition to establishing the temporal sequence of disassembly, reprocessing, and reassembly operations, the scheduler must select an optimal spatial allocation across geographically dispersed providers. Traditional precedence and component-matching constraints remain in force, but new considerations emerge: inter-site transit times, heterogeneous pricing schemes, contractual quality clauses, and network latency for real-time data transfer [

24,

25,

26]. Because provider capabilities and inspection standards vary widely, quality uncertainty propagates through the system, making dynamic, quality-aware task reassignment an essential feature of any practical scheduling algorithm.

3.2. Typical Constraints and Objective Functions

Across both archetypes, four classes of constraints can be identified. (i) Precedence constraints enforce the overall sequence of disassembly, inspection, reprocessing, reassembly, and testing, along with the technological order of sub-operations within each phase. (ii) Component-matching constraints ensure that reassembly begins only when every required part has cleared inspection or reprocessing [

14]. (iii) Resource-capacity constraints stipulate that a machine or service can process at most one task at a time (or, in the distributed case, up to its declared capacity). (iv) Quality-conformance constraints require that each component’s post-processing quality exceeds a target level before it can move to the next phase [

27].

Across the 190-paper corpus, objective functions coalesce into four broad themes (as shown in

Table 2). Time-performance metrics, including makespan, total flow time, or aggregate tardiness, appear in 78 studies, making them the single most frequent criterion, especially in early work that adapted classic flow-shop and job-shop formulations to remanufacturing settings. Economic objectives are addressed in 56 papers; these models minimise a composite cost that typically spans disassembly, re-processing, transportation and inventory holding. Beginning in 2017, a surge of interest in sustainability introduced energy and carbon indicators, now present in 43 papers that quantify electricity use or carbon emissions at the machine or system level. Finally, 22 papers incorporate service-quality terms, including due-date compliance, customer satisfaction, or the reliability of the remanufactured product, reflecting the industry’s shift toward service contracts and cloud brokerage. Since 2017, authors have increasingly combined these metrics in multi-objective formulations that search for Pareto-optimal trade-offs among time, cost, and energy; 65 papers (34% of the corpus) adopt such an approach. The trend confirms that contemporary research views remanufacturing scheduling as a multi-criteria decision problem, rather than a single-target optimisation task.

3.3. Comprehensive Analysis Method

In this systematic review, due to the lack of unified benchmarks and datasets in the field of remanufacturing scheduling, the data formats and contents reported in the studies varied greatly. This resulted in the inability to effectively perform data transformation or impute missing summary statistics, which limited the ability to conduct quantitative synthesis. Therefore, a qualitative synthesis approach was adopted to summarise the research results through descriptive analysis and explore the trade-offs between different methods in single or multiple optimisation objectives (such as makespan, cost, and energy consumption). In addition, due to the differences in data formats, data transformation or imputation of missing summary statistics was not possible, which further limited the ability to conduct a quantitative synthesis. Nevertheless, by recording the intervention characteristics and outcomes of each study in detail, the transparency and traceability of the research results were ensured to minimise the risk of bias.

3.4. Key Differences from Traditional Manufacturing Scheduling

Relative to new-product manufacturing, remanufacturing scheduling introduces three additional layers of complexity. First, input variability is inherent [

17,

23,

38]: the processing route and time for each task depend on the inspected condition of its core and, hence, must be decided concurrently with scheduling, rather than assumed upfront. Second, reverse-flow coupling links forward production activities to reverse-logistics and disassembly outputs, generating a many-to-one mapping between tasks and final assemblies that is absent in virgin production lines [

46]. Third, sustainability objectives elevate energy consumption, material recovery, and carbon footprint to first-class optimisation criteria, alongside the classic measures of throughput and cost [

42,

47]. These distinctive features necessitate integrated models that combine process planning, quality assessment, and real-time control.

4. Remanufacturing Processes and Enabling Technologies

Remanufacturing restores an EOL product to at least its original performance by guiding it through five tightly linked macroscopic phases: disassembly, inspection, reprocessing, reassembly and final testing. Each phase introduces unique constraints, decision variables, and feedback signals to the scheduling layer.

Figure 7 summarises their bilateral interactions: schedules determine the temporal order and resource allocation of phase-level tasks, while the data generated inside each phase recursively reshape subsequent schedules.

4.1. Disassembly Technologies

The disassembly shop separates the returned core into modules or individual parts, aiming to recover as much residual value as possible. Manual operations dominated early lines, but today, hybrid human-robot cells equipped with force-torque sensors and vision guidance are increasingly common [

48]. Related research focuses on automatic fixture recognition [

49], collision-free path planning [

48], and a real-time balance of multi-station disassembly lines [

50]. The problem is, therefore, a miniature scheduling task in its own right, often cast as a disassembly sequencing or line-balancing optimisation [

51,

52]. If the global scheduler overlooks the internal sequencing logic, it may result in downstream bottlenecks due to part mixes that violate component-matching rules or due-date requirements.

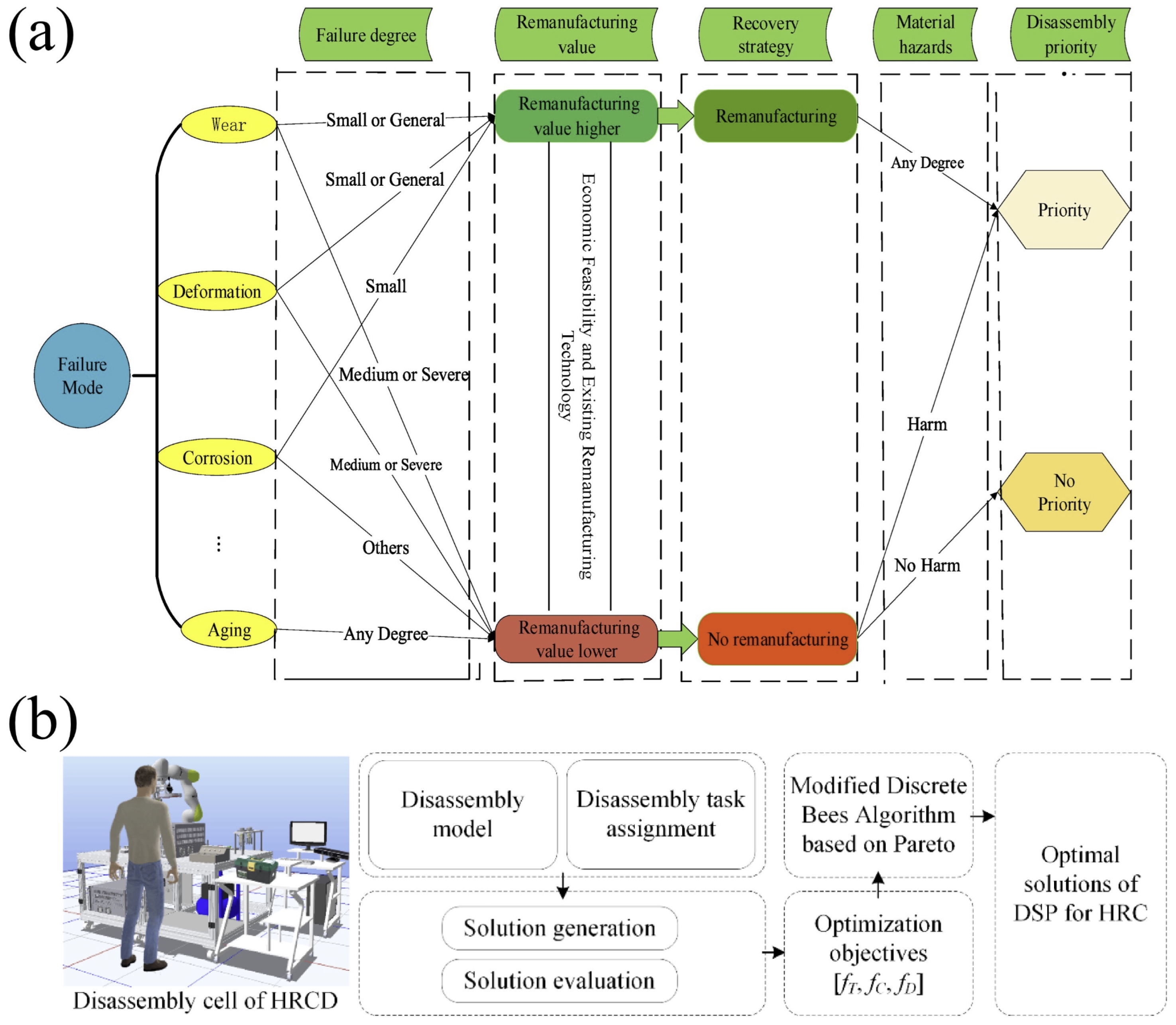

Contemporary research on disassembly line balancing incorporates multiple objectives beyond cycle time, including tooling cost, ergonomic risk, and hazardous material exposure. As illustrated in

Figure 8a, Meng et al. [

51] studied the disassembly line balance problem for remanufacturing systems with the consideration of several different types of failures and material hazards, and they adopted the multi-objective non-dominated sorting genetic algorithm (NSGA) II to obtain the optimised disassembly task sequences. According to

Figure 8b, Xu et al. also [

53] proposed a discrete bees algorithm for disassembly sequence planning in the remanufacturing environment, which considers human–robot collaboration. Errington et al. [

54] developed an economic model to support the decision-making processes in the robotic disassembly tasks. Different recovery options, including reuse, remanufacturing, recycling, and disposal, can be reasonably selected according to the calculated economic outputs.

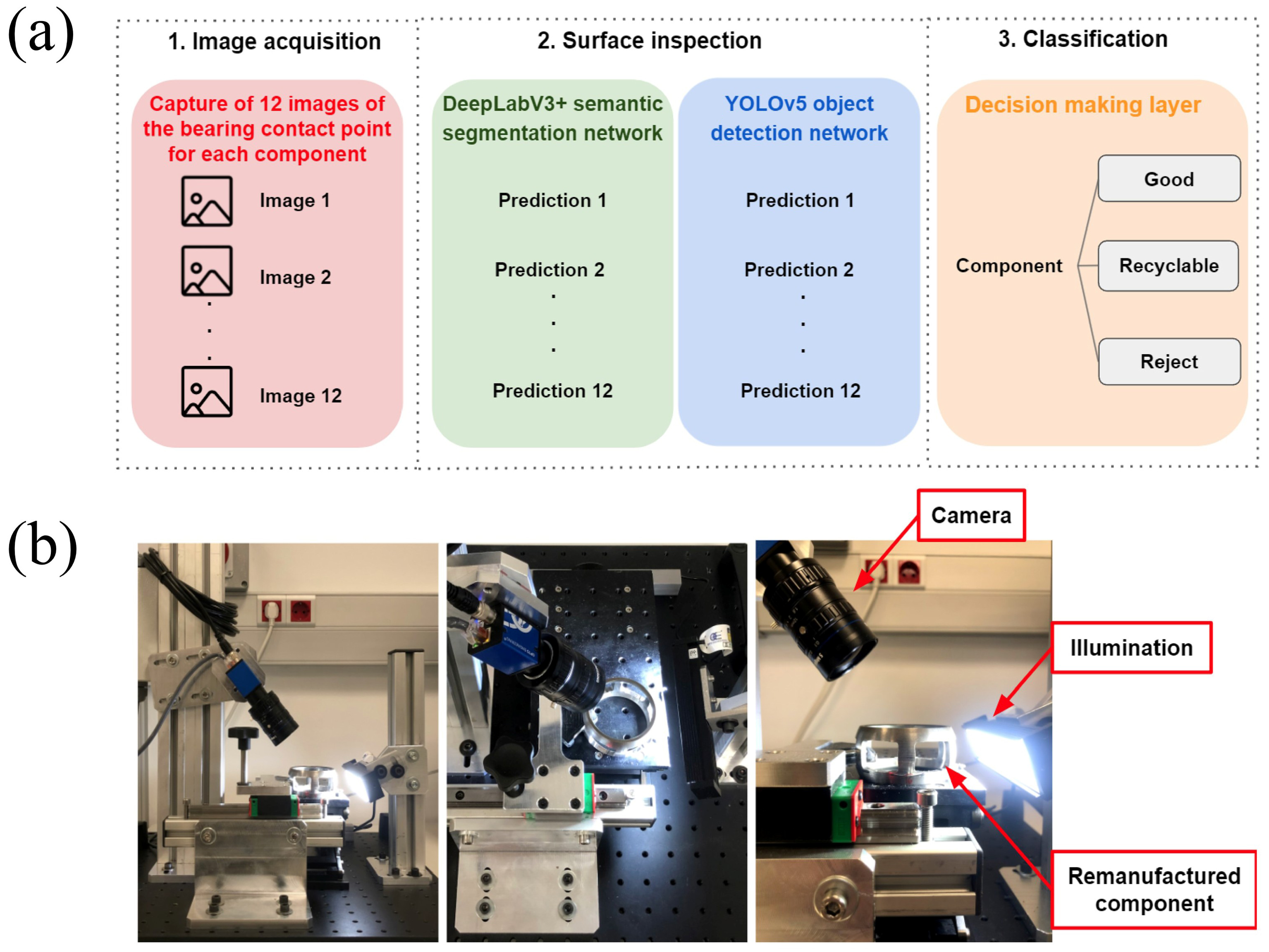

4.2. Inspection and Quality Assessment

Immediately after disassembly, each component is classified into reuse, repair, or discard categories. Traditional template matching and statistical sampling are being replaced with high-resolution X-ray CT, laser profilometry, and hyperspectral imaging linked to machine learning classifiers [

55]. For example, Imam et al. [

56] devised a vision-based robotic laser-cladding repair cell that integrates deep learning damage localisation with 3D scanning, enabling the autonomous restoration of fixed bends and reducing repair time by more than 63%. Hao et al. [

57] developed an adaptive failure-feature identification and mixed case-based reasoning/rule-based reasoning process-planning framework that couples hybrid additive-subtractive tool-path generation, allowing multi-defect turbine blades to be remanufactured efficiently and cost-effectively. Saiz et al. [

58] designed an automated inspection and classification system (

Figure 9) for remanufacturing automotive components, utilising the deep learning model which combined DeepLabV3+ and YOLOv5. Through the ensemble learning of the combined model, it achieves the efficient detection and classification of surface wear on automotive parts, achieving an accuracy of 93.33% and significantly improving inspection performance.

4.3. Reprocessing Technologies

Reprocessing is a series of remanufacturing processes that can restore the appearance, reliability, and service performance of the disassembled components with various types of defects. In this section, the research progress of three representative reprocessing processes will be presented: (a) cleaning; (b) additive/subtractive repair; and (c) surface modification.

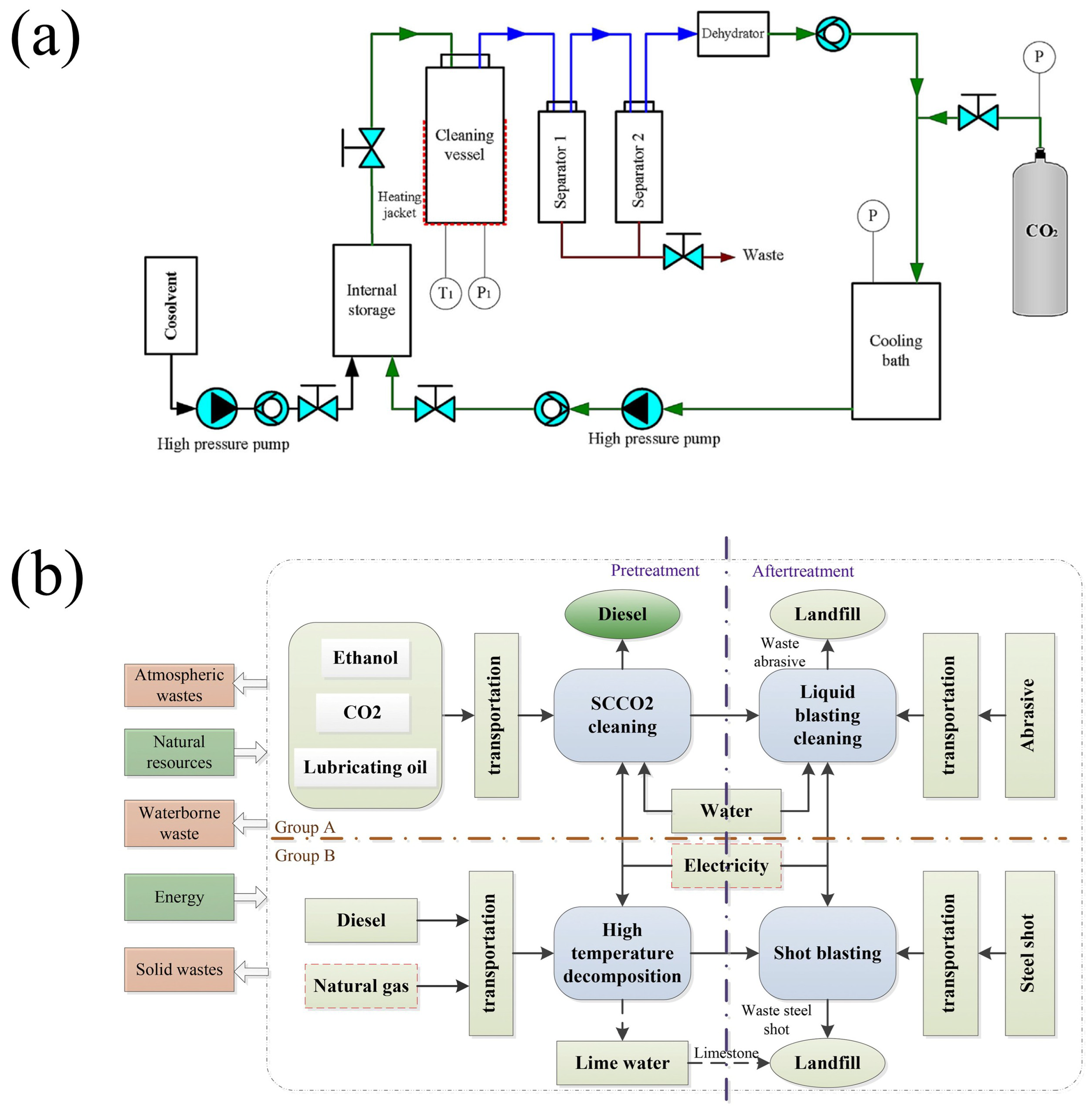

4.3.1. Cleaning

Cleaning is a critical first step in reprocessing because residual oil, grease, corrosion products, and particulates can compromise every downstream operation. Li et al. [

59] demonstrated an environmentally benign route in which super-critical carbon dioxide (SCCO

2) dissolves lubricant films on returned aluminium engine parts, achieving equivalent cleanliness to alkaline baths without solvent disposal (

Figure 10a). Using life-cycle assessment, Peng et al. [

60] compared SCCO

2 and liquid-blasting against two conventional options—high-temperature pyrolysis and shot-blasting (

Figure 10b). Their results place high-temperature decomposition as the most polluting option, followed by SCCO

2, with shot-blasting and liquid-blasting showing the lowest overall impacts. Taken together, these studies indicate that advanced, low-solvent cleaning technologies can substantially reduce the environmental footprint of remanufacturing while delivering the required surface quality.

4.3.2. Additive/Subtractive Repair

Additive manufacturing (AM) has moved beyond rapid prototyping and is now the principal advanced route for restoring high-value cores. Kanishka and Acherjee [

61] reported that laser direct energy deposition (LDED) processes account for almost half (49%) of all AM-based remanufacturing studies; the next most common routes are wire-arc additive manufacturing and additive-subtract hybrid manufacturing. Within LDED, laser cladding is used most frequently because it delivers fast cycle times, low material consumption, reduced labour input, and superior mechanical, as well as corrosion, performance. Liu et al. [

62] evaluated the environmental effects of remanufacturing cast iron cylinder head blocks processed via laser cladding, demonstrating that laser cladding can obviously reduce a negative environmental impact, as shown in

Figure 11a. Zhu et al. [

63] carried out research on remanufacturing methods based on a laser cladding technique for 45 steel gear, and the test results indicate that the remanufactured tooth can essentially regain its look before breaking. As shown in

Figure 11b, Kanazawa et al. [

64] proposed a laser hardening process based on a laser cladding technique to remanufacture carburised steels, and they found that the proposed method can restore the surface performance of the damaged gears effectively. Li et al. [

65] repaired ductile cast iron by filling simulated defects with a Ni-Cu alloy via laser cladding. Among the groove geometries studied, a circular groove combined with cross-hatch cladding produced the lowest residual stresses; the rebuilt zone achieved an ultimate tensile strength of 502 MPa, matching that of the virgin substrate.

Recent research has increasingly turned to hybrid additive–subtractive systems for remanufacturing, as they harness the unique strengths of each technique while compensating for their individual limitations. In practice, machining and grinding already support additive repair in pre- and post-processing; what distinguishes hybrid technology is the integration of both processes on a single, multi-axis platform. This one-setup arrangement eliminates refixturing, preserves geometric references, and shortens the overall lead time, making it particularly attractive for high-precision remanufacturing applications. Jone et al. [

66] demonstrated a hybrid manufacturing cell that fuses laser cladding, five-axis machining, and in-process 3-D scanning, enabling the agile, low-waste refurbishment of turbine blades. To localise repair zones automatically, Li et al. [

67] generalised the workflow by integrating scanning, model reconstruction, fine registration, and adaptive process selection for arbitrary worn components. Hascoët et al. [

68] partially automated the repair loop: defects were first milled into controlled cavities and then refilled via laser metal deposition under optical feedback. Expanding the concept, Newman et al. [

69] and Zhu et al. [

70] coupled fused-filament fabrication, CNC machining and on-board inspection to transform obsolete or recycled parts into redesigned components with enhanced features. Le et al. [

71] introduced feature-based hybrid manufacturing process-planning algorithms and later showed that the hybrid strategy outperforms recycling, casting, and standalone machining in life-cycle impact assessments. Liu et al. [

72] proposed a level-set-driven design-for-remanufacturing method that upgrades broken parts through topology-aware hybrid AM-SM operations.

While hybrid additive-subtractive technology greatly enhances remanufacturing flexibility, it also recasts scheduling as a coupled add-cut sequencing problem. Decisions about where to deposit material and when to switch to machining must respect thermal dwell times, tool-change windows, and shared-spindle constraints–dependencies. While standard flow-shop or job-shop models with their assumption of independent stations cannot capture these features. Addressing this gap, Zheng et al. [

32] reformulated hybrid process planning as a precedence-constrained sequencing optimisation, embedding a detailed cost model into a branch-and-bound framework. Their cost-driven scheduler simultaneously selects additive and subtractive features, orders them to satisfy geometric and thermal precedence, and outputs a global plan that minimises total remanufacturing cost while meeting accuracy requirements.

4.4. Reassembly Technologies

Reassembly is the final gate in the remanufacturing chain, governing both the utilisation rate of recovered components and the total cost of the operation. Wang et al. [

41] modelled reassembly as a component-oriented Markov decision process (MDP); when applied to diesel-engine cores, their policy raised overall system throughput by 40%. Extending the concept, Oh and Behdad [

73] formulated a graph-based optimisation that links reassembly with just-in-time procurement. The model introduces two actionable parameters—disposal point and reassembly threshold—allowing managers to decide whether to scrap, reorder, or rebuild a component on the fly (

Figure 12). Collectively, these studies show that embedding stochastic control and inventory logic into the reassembly stage can convert what was once a deterministic “bolt-up” step into a dynamic lever for cost and capacity optimisation in remanufacturing scheduling.

4.5. Final Testing Technologies

Final-stage testing is indispensable for ensuring that remanufactured products achieve OEM-level performance. Kernbaum et al. [

74] evaluated multiple diagnostic techniques for electronic equipment—most notably signature analysis—and proposed an initial virtual testing platform for printed-circuit boards. Zhang et al. [

75] presented a comprehensive review of metal magnetic memory (MMM) testing, demonstrating its international use in predicting the remaining life of remanufacturing cores and detecting fatigue cracks. They further called for a deeper investigation into the micro-physical mechanisms of MMM to sharpen manufacturability assessments for remanufacturing cores.

5. Centralised Remanufacturing Systems

5.1. Process Planning for Centralised Remanufacturing Systems

Remanufacturing process planning involves formulating the process route and scheduling parameters, which directly impact the carbon emissions, makespan, and cost of remanufacturing. Therefore, developing efficient and high-quality process planning is crucial for enhancing the economic and environmental benefits of the remanufacturing industry. Unlike mass-production planning, remanufacturing must contend with the variable quality of end-of-life (EOL) products. This variability introduces significant challenges in production planning and control activities, including the uncertain quality and quantity of the recycled components and the uncertain damage degree of the disassembled components.

To address these uncertainty challenges, researchers have developed various process planning methods for remanufacturing. The first type of process planning method is based on the reliability and failure rate. For instance, Jiang et al. [

5] connected remanufactured product reliability with end-of-life failure-rate distributions, while Wang et al. [

76] combined damage-characterisation models with an improved genetic–neural hybrid (IGA-ANN) to guide process planning (

Figure 13a). These methods aim to ensure that the remanufactured products meet the required reliability standards and reduce the risk of future failures in the long term.

The second type of process planning method is based on knowledge reuse; case-based reasoning (CBR) is a common technique applied in this type. Li et al. [

77] proposed an integrated remanufacturing process planning method based on blockchain and CBR, enabling the rapid acquisition of suitable process plans. Wu and Liu [

78] proposed an innovative method for fine-grained process retrieval and reuse based on the component models, which enhances the efficiency of the assembly stage in remanufacturing. Jiang et al. [

79] developed a hybrid method combining rough sets and CBR for remanufacturing process planning, which improved the efficiency of generating process plans. He et al. [

80] further refined this approach using an ontological framework to encode and reuse prior planning knowledge (

Figure 13b). Hu et al. [

81] extracted and organised remanufacturing disassembly process knowledge from historical data resources and combined it with rule-based reasoning to automatically generate optimal disassembly sequences and solutions. These methods leverage existing knowledge and experience to reduce the time and effort required for process planning in remanufacturing.

The third type of process planning method is based on feature extraction. Le et al. [

71] manually derived and applied remanufacturing-specific rules to extract features from hybrid additive-subtractive sequence CAD models (

Figure 13c). They also proposed an automatic level-set function method, which was experimentally verified. Zheng and Ahmad [

82] developed a cost-driven process planning method for hybrid additive–subtractive remanufacturing. They introduced an automated feature extraction method for additive and subtractive features, transforming the process planning task into a cost-optimisation problem. These methods focus on accurately extracting features from product models to guide process planning and improve the efficiency of remanufacturing.

In summary, the existing research on process planning in remanufacturing has explored various approaches, including reliability and failure rate-based methods, knowledge reuse-based methods, and feature extraction-based methods. Each type of method has its own advantages and contributes to improving the efficiency, quality, and sustainability of remanufacturing processes.

Figure 13.

Process planning for remanufacturing: (

a) optimisation framework considering fault feature for remanufacturing process planning [

76]; (

b) integrated remanufacturing process planning generation system [

80]; and (

c) process planning designing framework of incorporating for additive and subtractive manufacturing technologies [

71].

Figure 13.

Process planning for remanufacturing: (

a) optimisation framework considering fault feature for remanufacturing process planning [

76]; (

b) integrated remanufacturing process planning generation system [

80]; and (

c) process planning designing framework of incorporating for additive and subtractive manufacturing technologies [

71].

5.2. Shop Floor Scheduling for Centralised Remanufacturing Systems

Regarding remanufacturing scheduling, prior studies classify systems by reprocessing-shop configuration into two types: flow-shop-based RMS (FSRMS) and job-shop-based RMS (JSRMS). In high-volume/low-variety (HVLV) environments, EOL products follow a single, standardised process route, making a flow-shop layout most appropriate [

83]. Conversely, in low-volume/high-variety (LVHV) settings, fewer EOL products demand multiple, diverse routing options; here, a job-shop configuration better accommodates the flexibility required to handle complex process paths [

84,

85].

The FSRMS has attracted significant attention due to its relatively simple structure and high efficiency. Kim et al. [

86] developed an integer-programming model for an RMS with parallel flow reprocessing shops and proposed heuristics to minimise total flow time. Building on this, Shi et al. [

87] applied a flower-pollination algorithm to a multi-objective RMS scheduling problem—comprising parallel disassembly shops, flow-shop reprocessing lines, and parallel reassembly shops (

Figure 14a). More recently, Wang et al. [

20] introduced an invasive-weed-optimisation algorithm to simultaneously reduce makespan and energy consumption in a similar FSRMS configuration (

Figure 14b). By contrast, early work on job-shop-based RMS (JSRMS) was conducted by Guide et al., who first proposed a drum-buffer-rope scheduling method for remanufacturing [

88] and subsequently enhanced it with priority dispatching rules [

89]. In 2018, Yu and Lee [

14] became the first to optimise the complete RMS scheduling problem, which includes parallel disassembly/reassembly shops and a job-shop reprocessing shop, their study showed that an integrated algorithm outperformed decomposed approaches.

With the shift towards green manufacturing, the importance of energy efficiency in remanufacturing scheduling is becoming increasingly prominent. Optimised production schedules must balance throughput and energy conservation to deliver both economic and social benefits. To improve scheduling efficiency and curb energy use, many researchers have addressed multi-objective problems using exact algorithms. For example, Wei et al. [

90] devised an integrated energy-aware approach for FJSP that optimises makespan and energy cost by varying machining speeds. Rakovitis et al. [

91] formulated a novel mixed-integer programme with an event-based time representation to minimise energy expenses in FJSP. However, exact methods struggle as the problem size grows. To tackle larger instances, Mokhtari and Hasani [

15] employed a variable meta-heuristic algorithm, effectively solving the multi-objective FJSP. Ebrahimi et al. [

28] combined ant colony optimisation with simulated annealing to jointly reduce energy costs and total tardiness. Recently, energy-efficient scheduling in remanufacturing has attracted growing academic interest. Zhao et al. [

39] cut energy consumption in engine remanufacturing by modelling a fuzzy job-shop schedule and adapting a basic genetic algorithm. Giglio et al. [

35] addressed a hybrid energy-aware lot-sizing and scheduling problem for manufacturing/remanufacturing systems using an effective heuristic. More recently, Zhang et al. [

42] examined energy-efficient remanufacturing scheduling with a flexible job-shop reprocessing shop, proposing an improved grey wolf optimiser, which guided by a global criterion to minimise both total energy use and completion time.

5.3. Dynamic Scheduling for Centralised Remanufacturing Systems

In dynamic environments, remanufacturing scheduling needs to be able to respond in real time to various uncertain factors. Many studies are dedicated to developing remanufacturing scheduling methods that can cope with uncertainties. For example, Wen et al. [

92] addressed uncertainty by optimising a remanufacturing scheduling system model constrained by two random variables. Gao et al. [

93] used an empirical strategy to solve the scheduling problem of remanufacturing systems with uncertain reprocessing time. Fu et al. [

43] used a stochastic simulation model to address the uncertainty in the remanufacturing scheduling systems. Guo et al. [

45] proposed multi-objective scheduling of remanufacturing systems considering time window constraints and outsourcing options. In order to more effectively handle uncertainty, some studies have adopted fuzzy theory to provide more intuitive solutions. Shi et al. [

94] characterised and solved the dual uncertainty in the remanufacturing scheduling problem using dual fuzzy variables. Wang et al. [

95] developed a multi-objective linear fuzzy function to address the uncertainty of demand and recycling in remanufacturing scheduling.

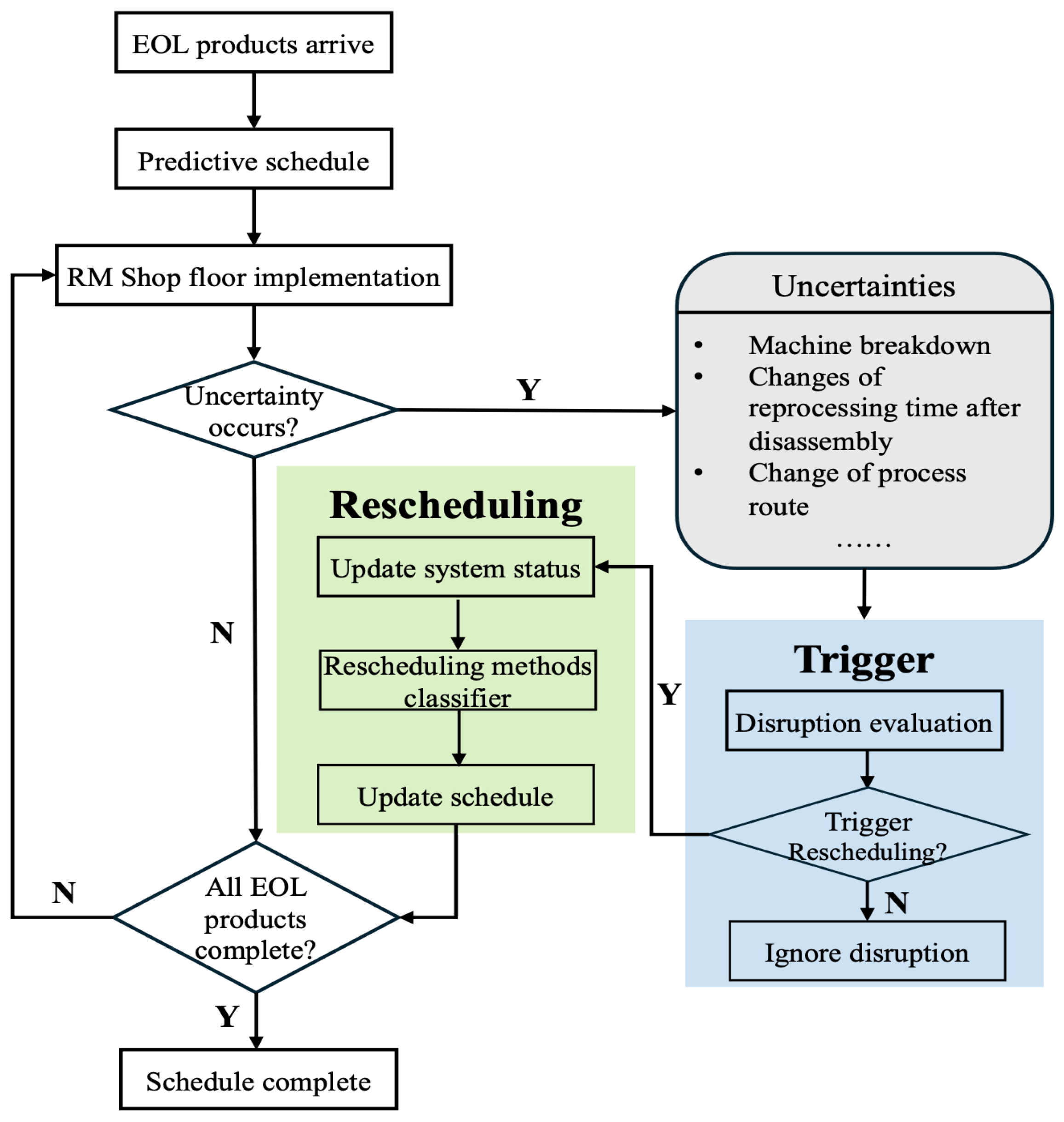

At present, there is relatively little research on solving dynamic scheduling in remanufacturing, and only a few studies have truly achieved the dynamic adjustment of scheduling plans. For example, Zheng et al. [

96] proposed a self-adaptive rescheduling strategy based on a Conditional Generative Adversarial Network (CGAN) and Improved Reaction Framework (IRF) for aircraft component remanufacturing systems in dynamic environments (

Figure 15). This method can respond in real time to dynamic changes such as equipment failures, demand fluctuations, etc. and improve the robustness and flexibility of the system by adaptively adjusting the scheduling plan. The dynamic scheduling problem incorporates dynamic factors or unexpected events such as machine breakdown and new order arrival in the production environment. For the dynamic flexible job-shop scheduling problem, different reinforcement-learning-based solutions have been proposed. Wu et al. [

97] developed a DRL method based on proximal policy optimisation (PPO) and hybrid prioritised experience replay. Using a feasible solution matrix as state representation, paired priority dispatching rules as the action space, and a reward function based on machine idle time, this method can significantly reduce rescheduling time in a dynamic environment with uncertain processing time and improve learning efficiency and policy convergence. Wan et al. [

98] introduced a diffusion based transformer (DIFFormer) for encoding operations and machine nodes to capture complex node dependencies. By applying a heterogeneous graph for state space, using operation-machine pairs as the action space, and training with the Twin Delayed Deep Deterministic policy gradient (TD3) algorithm, their method achieved better optimisation quality and efficiency than traditional dispatching rules on dynamic instances. More recently, Yazdanparast et al. [

99] proposed a novel framework for remanufacturing scheduling in collaborative customisation, addressing the challenges of dynamic scheduling and inter-department coordination through a multi-agent deep Q-network approach. This method aims to enhance real-time decision-making and improve the alignment between the delivered product and the customised product by establishing communication between the assembly, cleaning-repair, and assembly departments.

5.4. Integrated Process Planning and Scheduling for Centralised Remanufacturing Systems

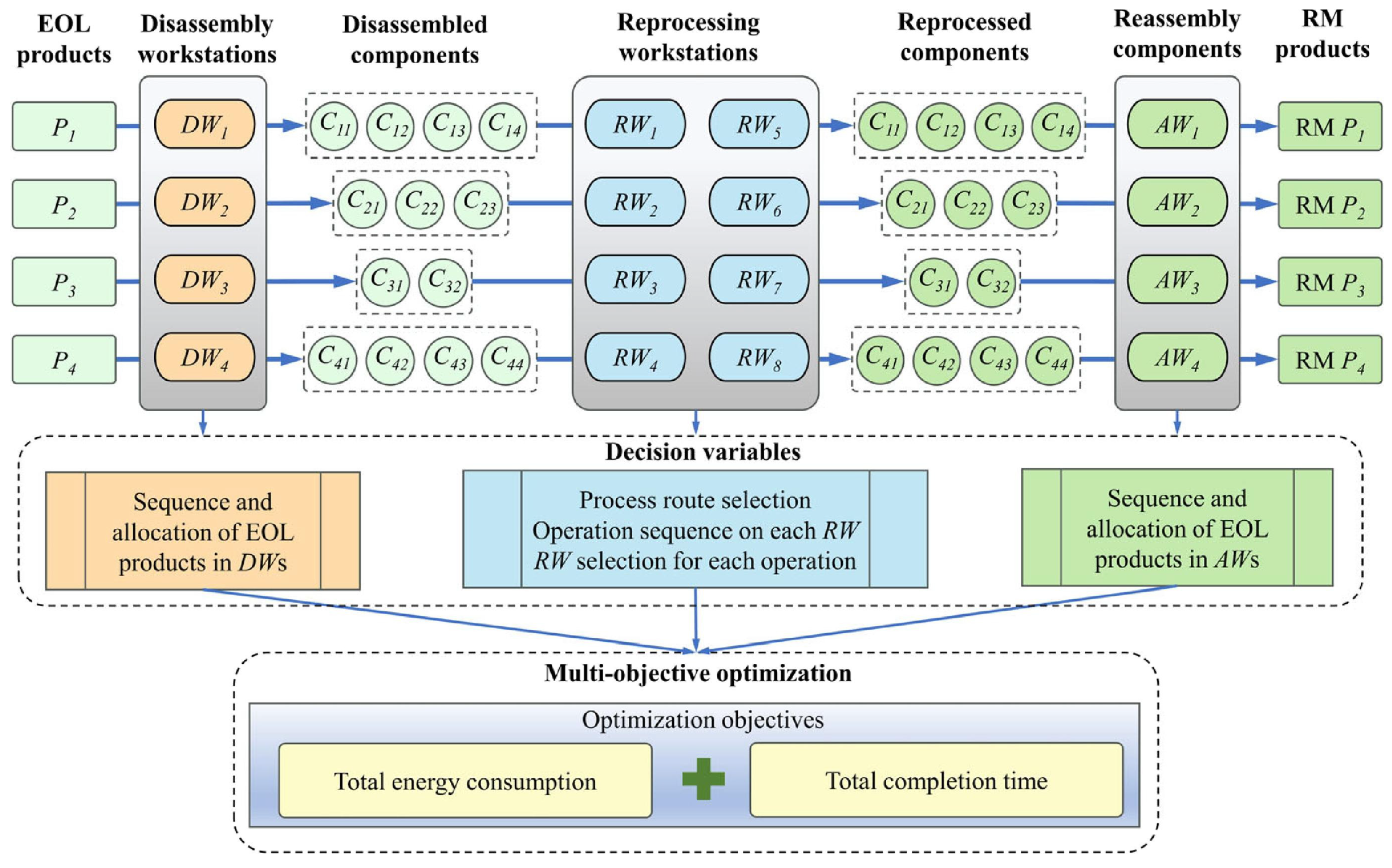

The integrated process planning and scheduling (IPPS) problem in remanufacturing simultaneously determines process routes and workstation allocation. This problem is inherently more complex than the classical job-shop scheduling problem (JSP). Zhang et al. [

13] were the first to address IPPS in remanufacturing, developing a simulation-based, multi-objective genetic-algorithm framework. More recently, Gong et al. [

30] proposed a mathematical model for IPPS in RMSs and solved it via a multi-layer evolutionary algorithm. However, neither study incorporated disassembly or reassembly stages, limiting their applicability in real-world settings. To bridge this gap, Zhang et al. [

4] formulated a single-objective IPPS model for an RMS featuring parallel disassembly/reassembly workstations and a flexible job-shop reprocessing shop, and they tackled it using a modified artificial bee colony algorithm. Building on this, Zhang et al. [

100] extended the approach to a multi-objective, energy-efficient IPPS framework (

Figure 16), aiming to minimise both total energy consumption (TEC) and the total completion time (TCT) by optimising three key decision variables.

6. Decentralised Remanufacturing Systems

6.1. Development of Decentralised Remanufacturing Systems

Over the past decade, the Fourth Industrial Revolution has entered a phase of rapid acceleration, with IoT and cloud computing introduced to enhance the intelligence and sustainability of manufacturing enterprises. In remanufacturing, scholars have begun exploring these technologies with notable efforts. Ullah and Sarkar [

101] proposed an IoT-enabled return channel to improve recycling rates, while Zhang et al. [

102] implemented IoT for rapid production scheduling of remanufactured automobile engines, employing intelligent identification and the end-to-end monitoring of disassembly components. Pan and Lin [

103] further advanced risk management by integrating IoT data with neural-network-based risk assessment models.

In cloud computing, Wang et al. were the first to conceptualise a cloud-based remanufacturing system [

40] and subsequently designed a cloud production platform to address data exchange and resource-management challenges in remanufacturing environments [

104]. Du et al. developed a method for dynamically discovering and fulfilling remanufacturing service demands [

105]. Although early work on combining RMS with IoT and cloud computing exists, the field of cloud remanufacturing remains in its infancy. Caterino et al. [

6] introduced the concept of cloud remanufacturing, delineating its platform characteristics, its associated technologies, and a corresponding mathematical model (see

Figure 17).

6.2. Scheduling for Decentralised Remanufacturing Systems

In the cloud manufacturing/remanufacturing system, the linked suppliers and customers can provide their core competencies as remanufacturing resources and capabilities and obtain services according to requested criteria, respectively. However, as a growing number of service suppliers and customers are involved in the cloud manufacturing/remanufacturing platform, the complexity of resource allocation and task arrangement increases significantly.

For cloud-based systems, a robust management mechanism must coordinate service composition and decomposition, discovery, matching, and, crucially, resource scheduling—with the latter enabling shared manufacturing resources across geographically distributed edges. Resource scheduling lies at the heart of this paradigm. For example, Liu et al. [

106] showed that prioritising workloads when assigning tasks can significantly enhance platform performance (

Figure 18). Li et al. [

107] developed a two-level scheduling model to tackle heterogeneous task allocation, while Hu et al. [

108] applied a chaos-optimisation algorithm to examine the impacts of workload, efficiency, resource availability, and IoT coordination on scheduling. Recognising user needs, these approaches also integrate service-related metrics, such as service efficiency and capacity, into the scheduling criteria. Wan et al. [

109] further validated a hierarchical scheduling framework through extensive case studies. Although cloud manufacturing has advanced rapidly, analogous research on cloud remanufacturing scheduling remains limited, owing to the intrinsic complexity of remanufacturing systems.

Early work in cloud remanufacturing scheduling was initiated by Caterino et al. [

6], who applied Tabu Search and the Bees algorithm to the problem. Zhang et al. [

25] then formulated a mixed-integer model for a cloud-based remanufacturing system, where EoL components of discrete quality grades are reused, reprocessed on alternative lines, or replaced—and introduced a Nonlinear Grey Wolf Optimiser with a crisscross update strategy to minimise makespan and cost, achieving superior convergence on real-world data. Building on this, Zhang et al. [

26] proposed an integrated, multi-phase framework (

Figure 19) covering inspection, disassembly, reprocessing, reassembly, and final testing. They solved the resulting large-scale, bi-objective problem using Improved Whale Optimisation algorithm, enhanced with self-adaptive weighting and quadratic interpolation, outperforming traditional heuristics in both convergence speed and solution accuracy.

7. Discussion and Future Trends

Scheduling remains the primary lever for boosting both production efficiency and managerial effectiveness in RMSs. Accordingly, a substantial body of work has explored scheduling problems in both centralised and decentralised contexts. Despite this progress, several pressing challenges endure, pointing to fertile directions for future research. These challenges and the resulting research opportunities are discussed in the subsections that follow.

In the field of remanufacturing scheduling, existing optimisation methods are divided into four categories: mixed-integer linear programming (MILP), the heuristics method, the meta-heuristics method, and the deep reinforcement learning method. These four types of methods exhibit different characteristics in terms of solution quality, robustness to uncertainty, and computational expense. Although MILP can provide high-quality solutions by exploring all potential solutions to achieve global optimality, it requires a large amount of computational expense and leads difficulty in optimising large-scale or highly dynamic problems. The heuristic method quickly provides solutions by reducing the search space through empirical rules, making it suitable for real-time applications; however, it may sacrifice the quality of the solution and produce suboptimal results. The meta-heuristics method achieves balance by combining heuristic elements with more systematic searching strategies, improving the solution quality while maintaining reasonable computational efficiency, and it is particularly effective in dealing with complex multi-objective problems. DRL, serving as an emerging method that utilises machine learning to adapt to a dynamic remanufacturing scheduling environment and uncertainties, has shown promise in improving robustness and computational efficiency, although the quality of solutions may vary, depending on the specific training and problem situation.

7.1. Ongoing Challenges and Future Directions

7.1.1. Dynamic Scheduling

Dynamic scheduling faces many challenges in remanufacturing systems. Compared with traditional manufacturing systems, centralised and distributed remanufacturing scheduling systems are more flexible, complex, and uncertain. This leads to the emergence of various random dynamic events, such as the insertion and cancellation of remanufacturing tasks, service failures, and uncertain reprocessing time and cost [

110,

111,

112,

113,

114,

115]. The emergence of these events makes the solution of the dynamic remanufacturing scheduling problem particularly important, and it has attracted many researchers to develop new meta-heuristic algorithms to address this challenge. In addition to meta-heuristic algorithms, deep reinforcement learning technology has also been proven to handle these complexities and uncertainties by learning optimal policies through interaction with the environment. Meanwhile, the responsive capability of DRL gives the potential to solve dynamic remanufacturing scheduling problems [

116,

117,

118,

119,

120,

121,

122,

123,

124]. However, although deep reinforcement learning has shown great potential in this field, it still faces some challenges in practical applications. For example, how to achieve effective learning and decision-making under complex constraints, and how to maintain the stability and efficiency of the algorithm in a large-scale dynamic environment are issues that need further research.

7.1.2. Collaborative Scheduling

Collaborative scheduling is the difficulty for scheduling in cloud remanufacturing systems, consisting of both the coordination of cloud and local tasks, as well as the integrated management of cloud computing and remanufacturing resources [

125,

126,

127,

128,

129,

130]. The collaborative scheduling of these tasks and resources needs to revolve around dynamic resource occupancy, and the uncertainty of tasks, such as task arrival patterns, task cancellations, emergency orders, etc., can lead to frequent changes in collaborative schedules. Effective scheduling methods are required to handle this situation, involving movement-based dynamic adjustment methods, methods for analysing the influence chain between tasks, and methods for assessing the tolerance for dynamic disruptions. Another difficulty with the cloud remanufacturing platform is the collaborative scheduling of the production and computer resources.

7.1.3. Large-Scale Scheduling

Large-scale scheduling is also significant for remanufacturing scheduling in terms of efficiency [

131,

132,

133,

134,

135,

136]. Highly efficient algorithms and procedures are needed to increase efficiency. Different heuristic and meta-heuristic techniques are now being used to optimise the efficiency problem. In a real remanufacturing environment, extensive remanufacturing jobs, tasks, and services may be involved. However, in existed research, the number of jobs, tasks, and services is often in the tens or hundreds. Because of this, the majority of the current algorithms would fall short in handling large-scale problems. In this situation, new methodologies and algorithms must be created. For example, it is necessary to use parallel methods. In addition to improving the optimisation algorithms, new strategies such as service categorisation and filtering also need to be taken into account. In actuality, improving scheduling efficiency may be achieved through preparatory service screening and filtering, in accordance with service needs.

7.1.4. Carbon Tracking and Sustainable Scheduling

With increasing environmental regulations and corporate sustainability goals, carbon tracking and sustainable scheduling have become important in remanufacturing systems. Integrating carbon footprint calculations into scheduling models can help optimise energy consumption and reduce emissions [

137,

138,

139,

140]. This requires the development of new methods that can balance production efficiency with environmental impact, such as the application of machine learning to predict and mitigate carbon emissions in real time. Machine learning techniques can be used to track and model the carbon footprint by automatically analysing data on greenhouse gas emissions and energy consumption. This includes automatic data collection, an analysis of large volumes of data, modelling and forecasting, and the optimisation of processes to reduce greenhouse gas emissions. This integration of carbon tracking and scheduling models is crucial, as it allows for a more holistic approach to managing the environmental impact of remanufacturing processes.

7.1.5. Digital-Twins Driven Scheduling

Digital twins (DTs) technology offers a promising approach to enhancing scheduling accuracy and efficiency in remanufacturing systems [

141,

142,

143,

144,

145]. By creating virtual replicas of physical systems, DTs can provide real-time data and predictive analytics to support dynamic scheduling decisions. However, several challenges remain. For example, DTs rely heavily on high-quality input data to accurately replicate physical systems and processes. Poor data quality can lead to inaccurate models and predictions, and they might compromise the effectiveness of DTs technology in real-time applications. Integrating DTs with existing manufacturing systems and processes can be complex and resource-intensive, often requiring significant investment in advanced technologies, software, and expertise to ensure seamless operation. Scalability remains a major concern, particularly when using low-cost sensors and other budget-friendly technologies. Ensuring that these solutions can scale to accommodate larger and more complex systems without performance degradation is a critical challenge. Klein and Furmans [

146] proposed a flexible, digital-twin driven object transfer system implemented in a remanufacturing demonstration environment to address the high uncertainty in remanufacturing processes, demonstrating its effectiveness through an extensive experimental study involving calibration, large-scale virtual experiments, and final validation on 37 unique starter motor cores. Techniques such as AR and adaptive online simulation models require significant computational power, which can hinder their deployment in resource-constrained environments. Future research should focus on developing robust data acquisition and processing techniques, as well as scalable and efficient computational frameworks, to fully leverage the potential of DTs in remanufacturing scheduling.

8. Conclusions

This review has consolidated two decades of remanufacturing scheduling research into a coherent narrative. Annual output has risen by roughly 14% since 2005, while the intellectual centre of gravity has moved from deterministic, single-plant optimisation toward data-rich, uncertainty-aware frameworks that blend shop-floor control with closed-loop supply chain and sustainability objectives. By formalising the problem, we showed how stochastic core quality, multi-phase precedence, and carbon-reduction targets create distinctive precedence, capacity, and quality-conformance constraints in both centralised and cloud-enabled systems. A scan of enabling technologies (human-machine disassembly, machine vision inspection, hybrid addition and subtraction repair, and digital final testing) is narrowing the gap between execution and planning with increasingly refined data. Classic mixed-integer and meta-heuristic methods still suffice for small, static settings, but large-scale, dynamic environments favour reinforcement learning, decomposition hybrids, and integrated process planning and scheduling models, underscoring the strategic importance of advanced, sustainability-oriented schedulers for realising the economic and environmental promise of remanufacturing.

In this systematic review, due to the lack of unified benchmarks and datasets in the field of remanufacturing scheduling, the data formats and contents reported in the studies varied greatly. This resulted in the inability to effectively perform data transformation or impute missing summary statistics, which limited the ability to conduct quantitative synthesis. In addition, this systematic analysis is also limited by its exclusive focus on peer-reviewed journal articles, deliberately omitting conference proceedings that often contain early-stage innovations and practitioner-led case studies. This narrow perspective may underestimate the advancement of cutting-edge algorithms and emerging application areas that have not yet matured into journal formats. Therefore, future research should expand the evidence base, including conference papers, industry whitepapers, and standard documents, establish quantitative benchmarks, stress test algorithms on real-world, large-scale instances, and explore blockchain secure data sharing, digital twin architecture, and reinforcement learning agents capable of real-time adaptive control. Bridging the current divide between scholarly models and shop-floor realities will be vital for delivering truly dynamic, collaborative, and carbon-aware scheduling in the next generation of remanufacturing systems.

Author Contributions

Y.Z.: methodology, software, investigation, funding acquisition, and writing—review and editing. W.Z.: methodology, investigation, and writing—original draft. R.W.: software, investigation, and writing—review and editing. R.A.: conceptualisation, supervision, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research work is supported by the Fundamental Research Funds for the Central Universities, CHD (300102254501-202413), the Natural Science Foundation of Jiangsu Province (BK20240453), and the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (23KJB460032).

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RMS | Remanufacturing System |

| AM | Additive Manufacturing |

| ANN | Artificial Neural Network |

| AR | Augmented Reality |

| DRL | Deep Reinforcement Learning |

| DT | Digital Twin |

| EOL | End-of-Life |

| FJSP | Flexible Job-Shop Scheduling Problem |

| FSRMS | Flow-Shop Remanufacturing System |

| JSRMS | Job-Shop Remanufacturing System |

| HVLV | High-Volume, Low-Variety |

| LVHV | Low-Volume, High-Variety |

| IPPS | Integrated Process Planning and Scheduling |

| MDP | Markov Decision Process |

| MIP | Mixed-Integer Programming |

| TEC | Total Energy Consumption |

| TCT | Total Completion Time |

References

- Zhang, X.; Xu, L.; Zhang, H.; Jiang, Z.; Cai, W. Emergy based intelligent decision-making model for remanufacturing process scheme integrating economic and environmental factors. J. Clean. Prod. 2021, 291, 125247. [Google Scholar] [CrossRef]

- San-Francisco, A.; Sopelana, N.; Fernandez, J.M.; Otegi, J.R.; Minguez, R. Analysis about the incorporation of remanufacturing concept into life cycle assessment theories. J. Remanuf. 2020, 10, 127–139. [Google Scholar] [CrossRef]

- Luo, L.; Shan, R.; Xiang, J. The government intervention effectiveness in promoting remanufacturing: Subsidy or remanufacturing target? Socio-Econ. Plan. Sci. 2024, 92, 101829. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Ahmad, R. The integrated process planning and scheduling of flexible job-shop-type remanufacturing systems using improved artificial bee colony algorithm. J. Intell. Manuf. 2023, 34, 2963–2988. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhou, T.; Zhang, H.; Wang, Y.; Cao, H.; Tian, G. Reliability and cost optimization for remanufacturing process planning. J. Clean. Prod. 2016, 135, 1602–1610. [Google Scholar] [CrossRef]

- Caterino, M.; Fera, M.; Macchiaroli, R.; Pham, D.T. Cloud remanufacturing: Remanufacturing enhanced through cloud technologies. J. Manuf. Syst. 2022, 64, 133–148. [Google Scholar] [CrossRef]

- Lee, C.M.; Woo, W.S.; Roh, Y.H. Remanufacturing: Trends and issues. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 113–125. [Google Scholar] [CrossRef]

- Rizova, M.I.; Wong, T.; Ijomah, W. A systematic review of decision-making in remanufacturing. Comput. Ind. Eng. 2020, 147, 106681. [Google Scholar] [CrossRef]

- Gao, K.; Cao, Z.; Zhang, L.; Chen, Z.; Han, Y.; Pan, Q. A review on swarm intelligence and evolutionary algorithms for solving flexible job shop scheduling problems. IEEE/CAA J. Autom. Sin. 2019, 6, 904–916. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Teunter, R.; Kaparis, K.; Tang, O. Multi-product economic lot scheduling problem with separate production lines for manufacturing and remanufacturing. Eur. J. Oper. Res. 2008, 191, 1241–1253. [Google Scholar] [CrossRef]

- Zhang, R.; Ong, S.; Nee, A. A simulation-based genetic algorithm approach for remanufacturing process planning and scheduling. Appl. Soft Comput. 2015, 37, 521–532. [Google Scholar] [CrossRef]

- Yu, J.M.; Lee, D.H. Scheduling algorithms for job-shop-type remanufacturing systems with component matching requirement. Comput. Ind. Eng. 2018, 120, 266–278. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hasani, A. An energy-efficient multi-objective optimization for flexible job-shop scheduling problem. Comput. Chem. Eng. 2017, 104, 339–352. [Google Scholar] [CrossRef]

- Peng, S.; Li, T.; Zhao, J.; Guo, Y.; Lv, S.; Tan, G.Z.; Zhang, H. Petri net-based scheduling strategy and energy modeling for the cylinder block remanufacturing under uncertainty. Robot. Comput.-Integr. Manuf. 2019, 58, 208–219. [Google Scholar] [CrossRef]

- Liao, H.; Zhang, Q.; Shen, N.; Li, L. Stochastic analysis of quality uncertainty and optimal acquisition strategies for engine remanufacturing. J. Clean. Prod. 2020, 261, 121088. [Google Scholar] [CrossRef]

- Arulkumaran, K.; Deisenroth, M.P.; Brundage, M.; Bharath, A.A. Deep reinforcement learning: A brief survey. IEEE Signal Process. Mag. 2017, 34, 26–38. [Google Scholar] [CrossRef]

- Lei, K.; Guo, P.; Zhao, W.; Wang, Y.; Qian, L.; Meng, X.; Tang, L. A multi-action deep reinforcement learning framework for flexible Job-shop scheduling problem. Expert Syst. Appl. 2022, 205, 117796. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Yuan, G.; Pham, D.T. Energy-time tradeoffs for remanufacturing system scheduling using an invasive weed optimization algorithm. J. Intell. Manuf. 2023, 34, 1065–1083. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Zhang, T.; Jabarullah, N.H.; Li, F.; Fathollahi-Fard, A.M.; Wang, D.; Li, Z. Scheme selection of design for disassembly (DFD) based on sustainability: A novel hybrid of interval 2-tuple linguistic intuitionistic fuzzy numbers and regret theory. J. Clean. Prod. 2021, 281, 124724. [Google Scholar] [CrossRef]

- Yuan, G.; Yang, Y.; Tian, G.; Zhuang, Q. Comprehensive evaluation of disassembly performance based on the ultimate cross-efficiency and extension-gray correlation degree. J. Clean. Prod. 2020, 245, 118800. [Google Scholar] [CrossRef]

- Galbreth, M.R.; Blackburn, J.D. Optimal acquisition quantities in remanufacturing with condition uncertainty. Prod. Oper. Manag. 2010, 19, 61–69. [Google Scholar] [CrossRef]

- Guo, L.; Xu, Y.; He, W.; Cheng, Y. Optimization of complex part-machining services based on feature decomposition in cloud manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 1227–1244. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Ma, W.; Ahmad, R. Multi-task scheduling in cloud remanufacturing system integrating reuse, reprocessing, and replacement under quality uncertainty. J. Manuf. Syst. 2023, 68, 176–195. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Ma, Y.; Ahmad, R. A multi-phase integrated scheduling method for cloud remanufacturing systems. Adv. Eng. Inform. 2024, 62, 102802. [Google Scholar] [CrossRef]

- Cai, X.; Lai, M.; Li, X.; Li, Y.; Wu, X. Optimal acquisition and production policy in a hybrid manufacturing/remanufacturing system with core acquisition at different quality levels. Eur. J. Oper. Res. 2014, 233, 374–382. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Jeon, H.W.; Lee, S.; Wang, C. Minimizing total energy cost and tardiness penalty for a scheduling-layout problem in a flexible job shop system: A comparison of four metaheuristic algorithms. Comput. Ind. Eng. 2020, 141, 106295. [Google Scholar] [CrossRef]

- Beynaghi, A.; Moztarzadeh, F.; Shahmardan, A.; Alizadeh, R.; Salimi, J.; Mozafari, M. Makespan minimization for batching work and rework process on a single facility with an aging effect: A hybrid meta-heuristic algorithm for sustainable production management. J. Intell. Manuf. 2019, 30, 33–45. [Google Scholar] [CrossRef]

- Gong, G.; Deng, Q.; Chiong, R.; Gong, X.; Huang, H.; Han, W. Remanufacturing-oriented process planning and scheduling: Mathematical modelling and evolutionary optimisation. Int. J. Prod. Res. 2020, 58, 3781–3799. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, J.; Zhang, S.; Chen, M. Scenario-based robust remanufacturing scheduling problem using improved biogeography-based optimization algorithm. IEEE Trans. Syst. Man Cybern. Syst. 2022, 53, 3414–3427. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, J.; Ahmad, R. A cost-driven process planning method for hybrid additive-subtractive remanufacturing. J. Manuf. Syst. 2020, 55, 248–263. [Google Scholar] [CrossRef]

- Luglietti, R.; Magalini, F.; Taisch, M.; Cassina, J. Environmental Impact and Cost Evaluation in Remanufacturing Business Decision Support. In IFIP Advances in Information and Communication Technology; Springer: Berlin/Heidelberg, Germany, 2014; Volume 439, pp. 415–422. [Google Scholar] [CrossRef]

- Wang, W.; Mo, D.Y.; Wang, Y.; Tseng, M.M. Assessing the cost structure of component reuse in a product family for remanufacturing. J. Intell. Manuf. 2019, 30, 575–587. [Google Scholar] [CrossRef]

- Giglio, D.; Paolucci, M.; Roshani, A. Integrated lot sizing and energy-efficient job shop scheduling problem in manufacturing/remanufacturing systems. J. Clean. Prod. 2017, 148, 624–641. [Google Scholar] [CrossRef]

- Wang, W.; Tian, G.; Zhang, H.; Li, Z.; Zhang, L. A hybrid genetic algorithm with multiple decoding methods for energy-aware remanufacturing system scheduling problem. Robot. Comput.-Integr. Manuf. 2023, 81, 102509. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, C.; Mao, H.; Tian, G.; Jiang, Z.; Cai, W.; Wang, W. Integration of lean production and low-carbon optimization in remanufacturing assembly. Adv. Eng. Inform. 2024, 62, 102789. [Google Scholar] [CrossRef]

- Zhou, J.; Deng, Q.; Li, T. Optimal acquisition and remanufacturing policies considering the effect of quality uncertainty on carbon emissions. J. Clean. Prod. 2018, 186, 180–190. [Google Scholar] [CrossRef]

- Zhao, J.; Peng, S.; Li, T.; Lv, S.; Li, M.; Zhang, H. Energy-aware fuzzy job-shop scheduling for engine remanufacturing at the multi-machine level. Front. Mech. Eng. 2019, 14, 474–488. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. From Cloud manufacturing to Cloud remanufacturing: A Cloud-based approach for WEEE recovery. Manuf. Lett. 2014, 2, 91–95. [Google Scholar] [CrossRef]

- Wang, Y.; Mendis, G.P.; Peng, S.; Sutherland, J.W. Component-Oriented Reassembly in Remanufacturing Systems: Managing Uncertainty and Satisfying Customer Needs. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 021005. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Ahmad, R. An energy-efficient multi-objective scheduling for flexible job-shop-type remanufacturing system. J. Manuf. Syst. 2023, 66, 211–232. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, M.; Guo, X.; Qi, L. Stochastic multi-objective integrated disassembly-reprocessing-reassembly scheduling via fruit fly optimization algorithm. J. Clean. Prod. 2021, 278, 123364. [Google Scholar] [CrossRef]

- Guo, J.; Zou, J.; Du, B.; Wang, K. Integrated scheduling for remanufacturing system considering component commonality using improved multi-objective genetic algorithm. Comput. Ind. Eng. 2023, 182, 109419. [Google Scholar] [CrossRef]

- Guo, J.; Guo, W.; Du, B.; Zou, J.; Wang, K. A multi-objective integrated scheduling of remanufacturing system considering time window constrained outsourcing option. J. Clean. Prod. 2024, 468, 142916. [Google Scholar] [CrossRef]

- Shafiee Roudbari, E.; Fatemi Ghomi, S.M.T.; Sajadieh, M.S. Reverse logistics network design for product reuse, remanufacturing, recycling and refurbishing under uncertainty. J. Manuf. Syst. 2021, 60, 473–486. [Google Scholar] [CrossRef]

- Sharma, D.; Venkataraman, S.V. Strategic control of carbon emissions through taxation in a remanufacturing system. Comput. Ind. Eng. 2022, 174, 108797. [Google Scholar] [CrossRef]

- Hjorth, S.; Chrysostomou, D. Human–robot collaboration in industrial environments: A literature review on non-destructive disassembly. Robot. Comput.-Integr. Manuf. 2022, 73, 102208. [Google Scholar] [CrossRef]

- Mangold, S.; Steiner, C.; Friedmann, M.; Fleischer, J. Vision-based screw head detection for automated disassembly for remanufacturing. Procedia CIRP 2022, 105, 1–6. [Google Scholar] [CrossRef]

- Ong, S.K.; Chang, M.M.L.; Nee, A.Y. Product disassembly sequence planning: State-of-the-art, challenges, opportunities and future directions. Int. J. Prod. Res. 2021, 59, 3493–3508. [Google Scholar] [CrossRef]

- Meng, W.; Zhang, X. Optimization of remanufacturing disassembly line balance considering multiple failures and material hazards. Sustainability 2020, 12, 7318. [Google Scholar] [CrossRef]

- Tseng, Y.J.; Kao, H.T.; Huang, F.Y. Integrated assembly and disassembly sequence planning using a GA approach. Int. J. Prod. Res. 2010, 48, 5991–6013. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Q.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. Disassembly sequence planning using discrete Bees algorithm for human-robot collaboration in remanufacturing. Robot. Comput.-Integr. Manuf. 2020, 62, 101860. [Google Scholar] [CrossRef]

- Errington, M.; Childe, S.J. A business process model of inspection in remanufacturing. J. Remanuf. 2013, 3, 7. [Google Scholar] [CrossRef]

- Khan, A.; Mineo, C.; Dobie, G.; Macleod, C.; Pierce, G. Vision guided robotic inspection for parts in manufacturing and remanufacturing industry. J. Remanuf. 2021, 11, 49–70. [Google Scholar] [CrossRef]

- Imam, H.Z.; Al-Musaibeli, H.; Zheng, Y.; Martinez, P.; Ahmad, R. Vision-based spatial damage localization method for autonomous robotic laser cladding repair processes. Robot. Comput.-Integr. Manuf. 2023, 80, 102452. [Google Scholar] [CrossRef]

- Hao, C.; He, Y.; Li, Y.; Wang, Y.; Wang, Y.; Ma, W. An integrated restoration methodology based on adaptive failure feature identification. Robot. Comput.-Integr. Manuf. 2023, 81, 102512. [Google Scholar] [CrossRef]

- Saiz, F.A.; Alfaro, G.; Barandiaran, I. An inspection and classification system for automotive component remanufacturing industry based on ensemble learning. Information 2021, 12, 489. [Google Scholar] [CrossRef]

- Li, M.; Liu, W.; Short, T.; Qing, X.; Dong, Y.; He, Y.; Zhang, H.C. Pre-treatment of remanufacturing cleaning by use of supercritical CO2 in comparison with thermal cleaning. Clean Technol. Environ. Policy 2015, 17, 1563–1572. [Google Scholar] [CrossRef]