Electronic Artificial Intelligence and Digital Twins in Industry 5.0: A Systematic Review and Perspectives

Abstract

1. Introduction

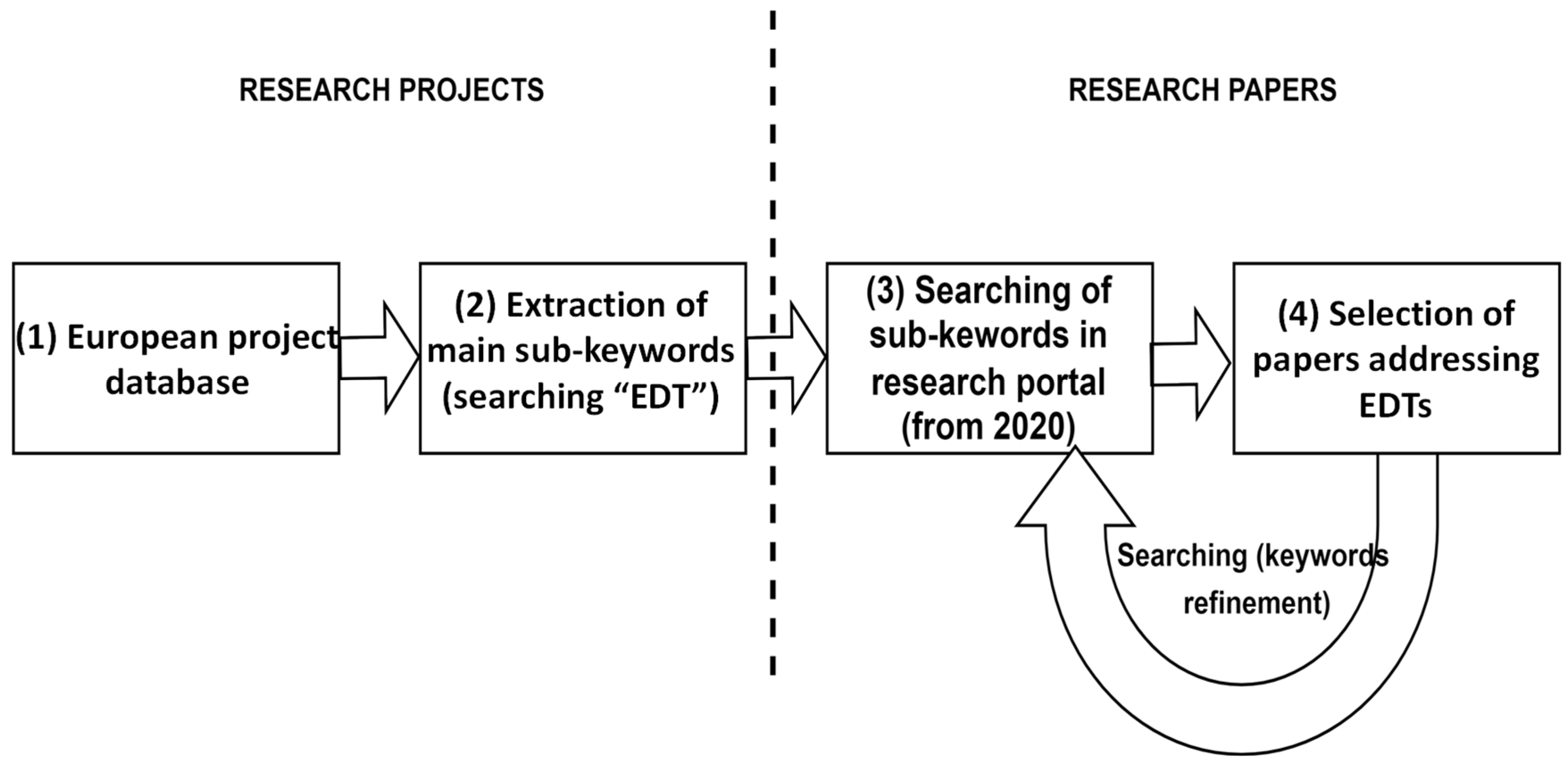

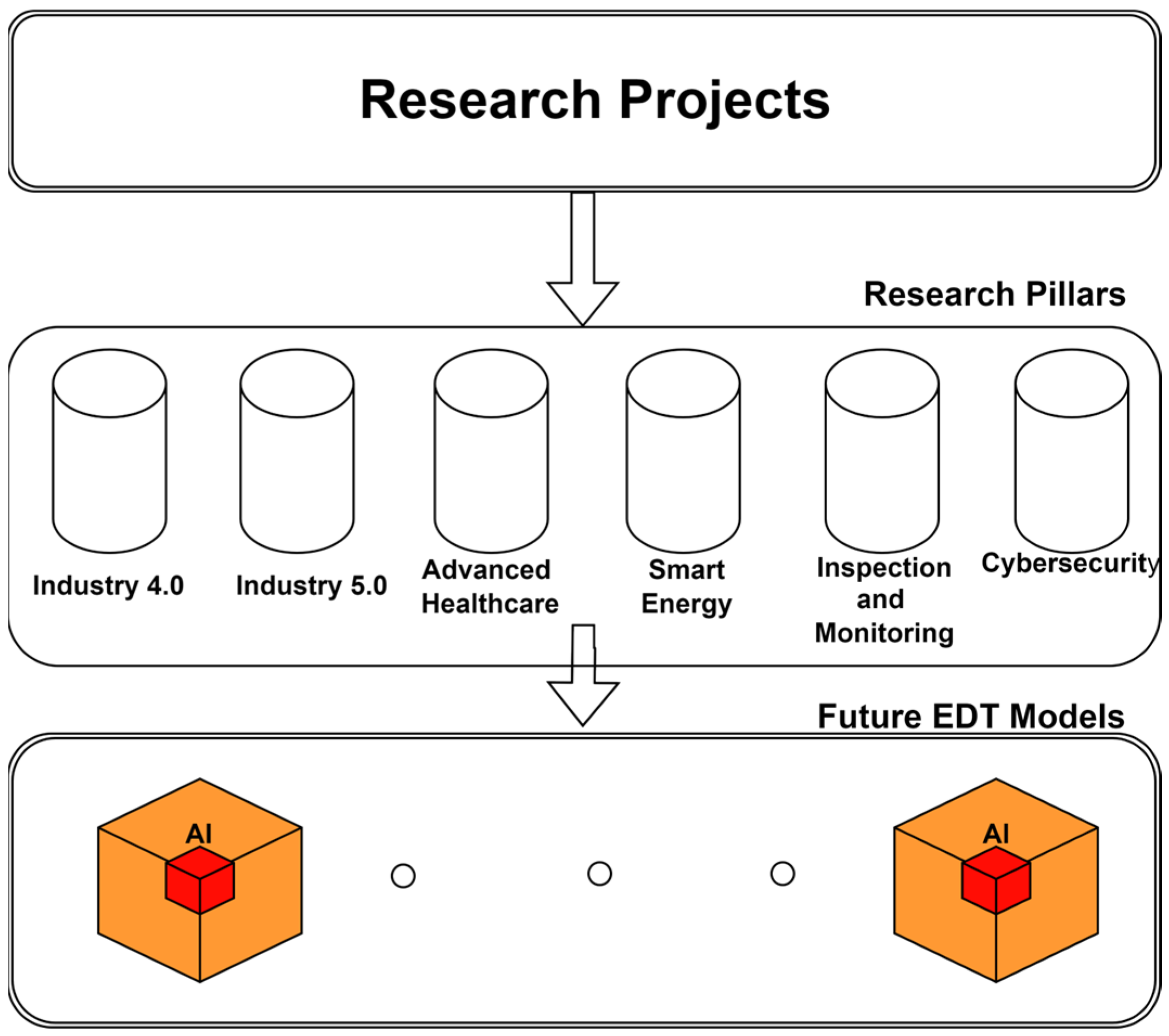

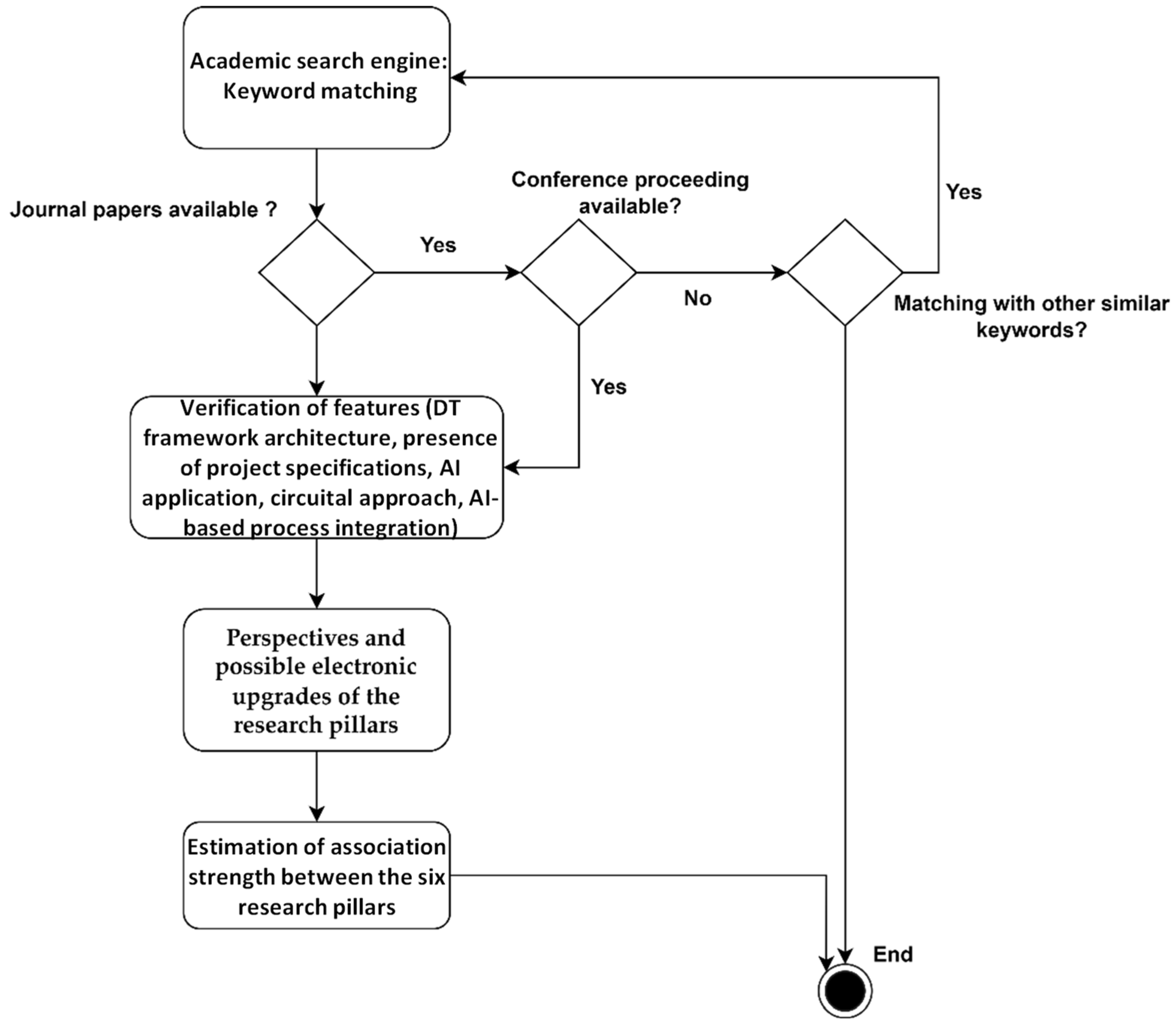

1.1. Research Methodology and DT Research Topics

1.2. Research Questions

2. First Research Pillar: Agile Manufacturing and Industry 4.0

3. Second Research Pillar: Industry 5.0

4. Third Research Pillar: Advanced Healthcare and Industry

5. Fourth Research Pillar: Smart Energy

6. Fifth Research Pillar: Inspection and Monitoring

7. Sixth Research Pillar: Cybersecurity

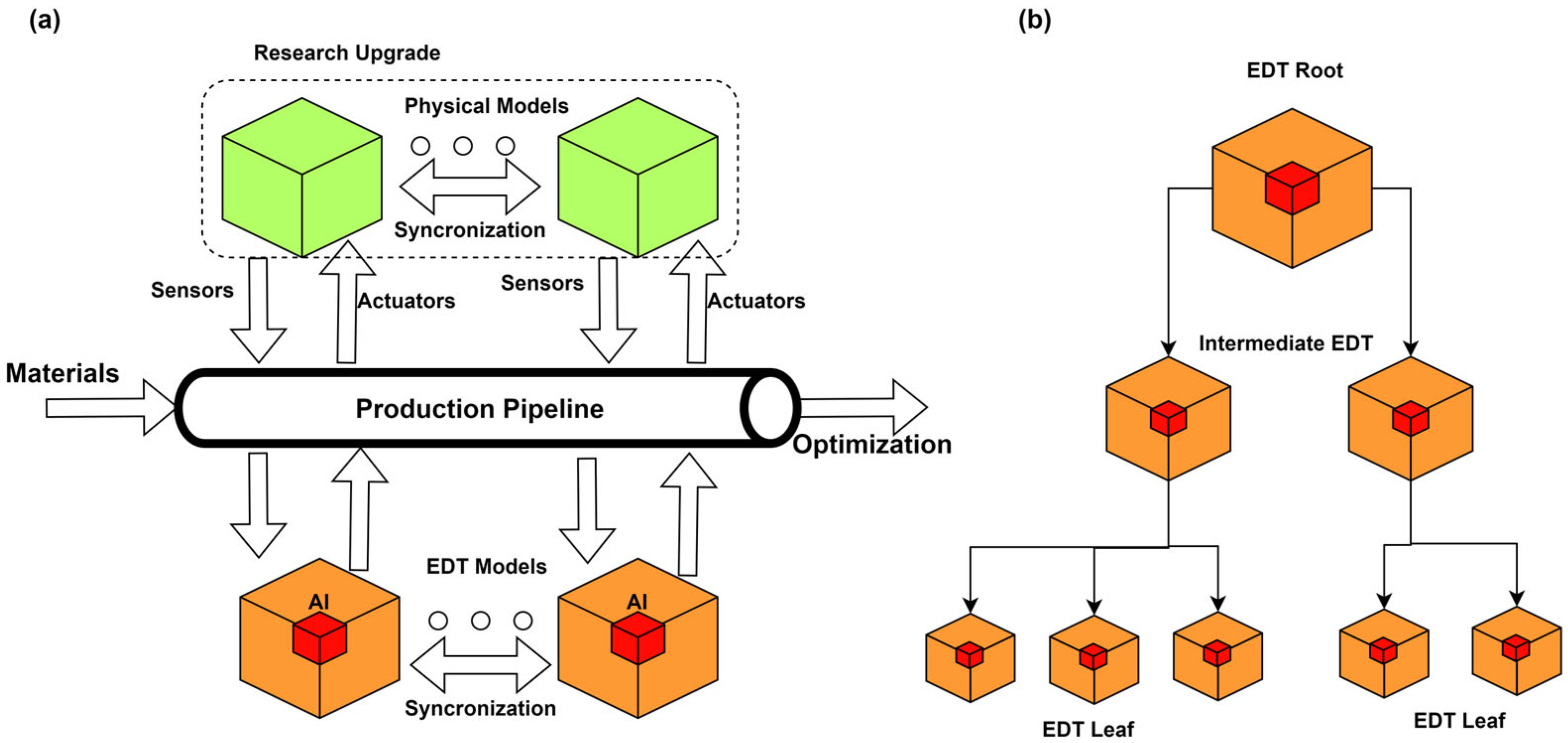

8. Discussion

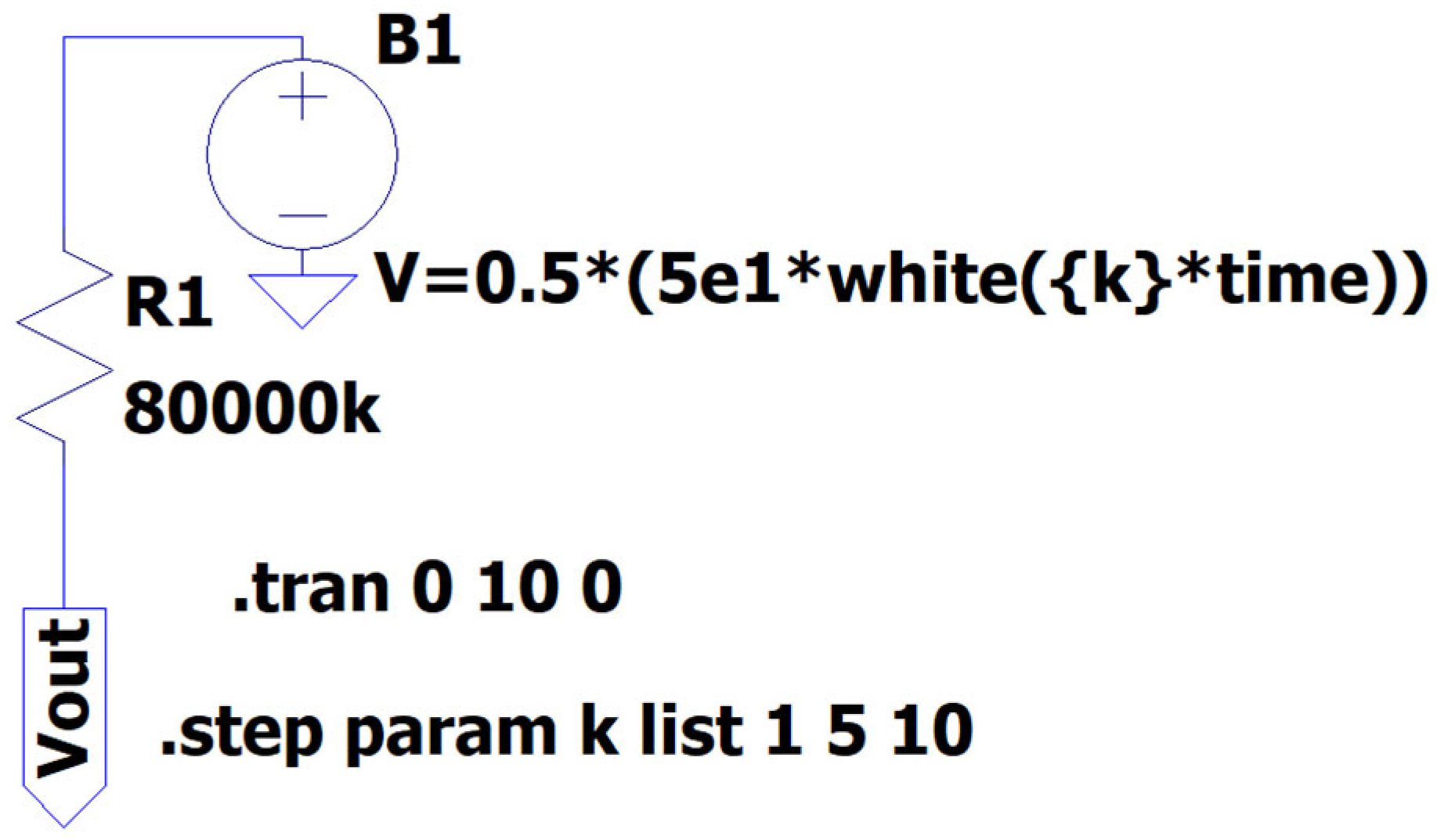

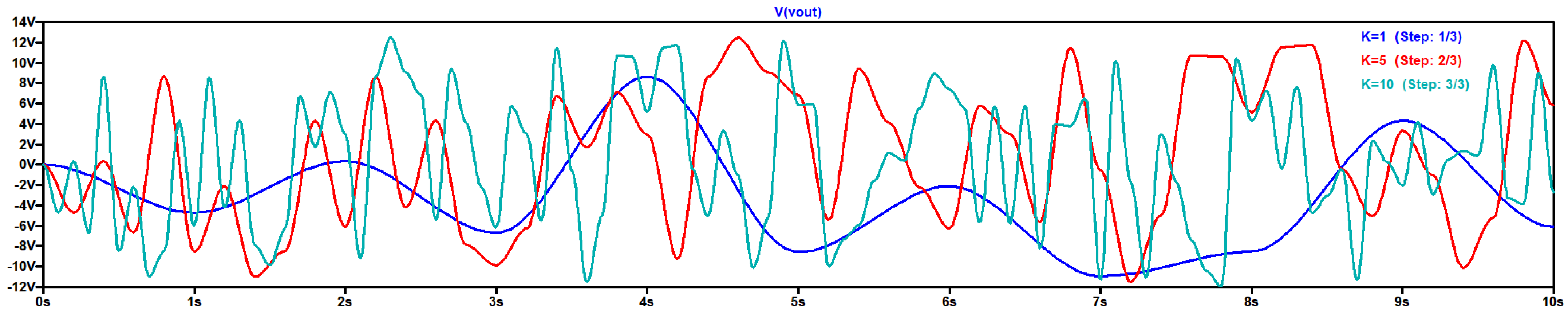

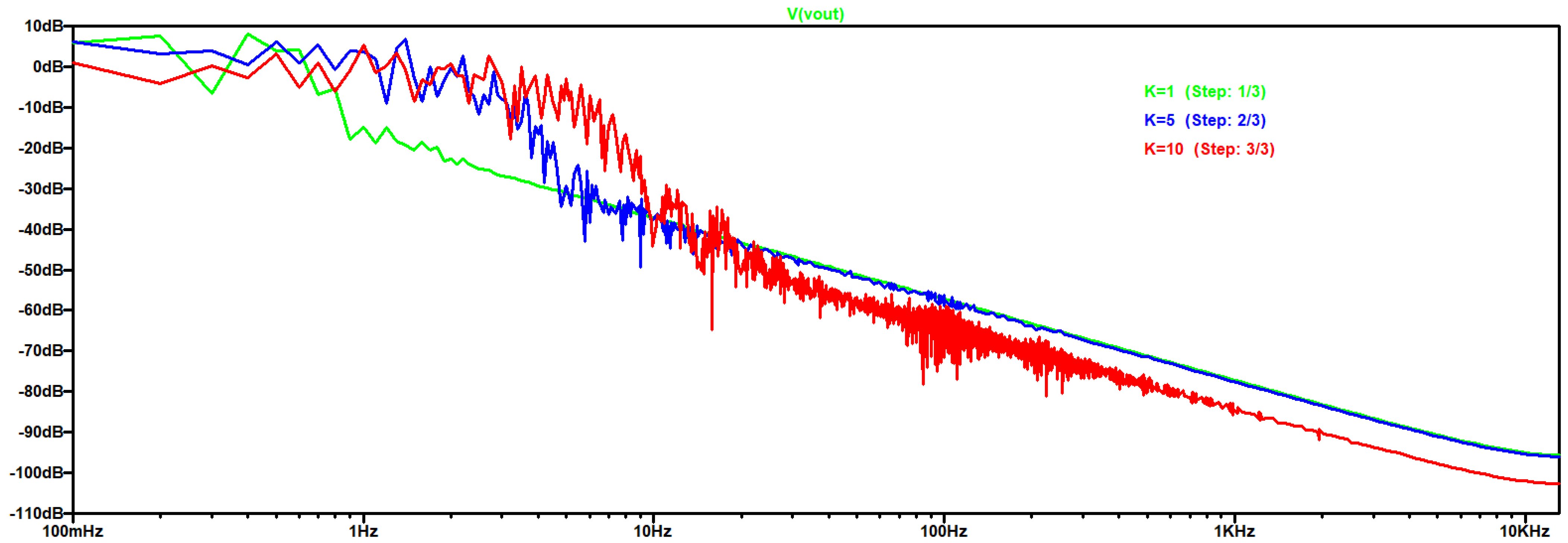

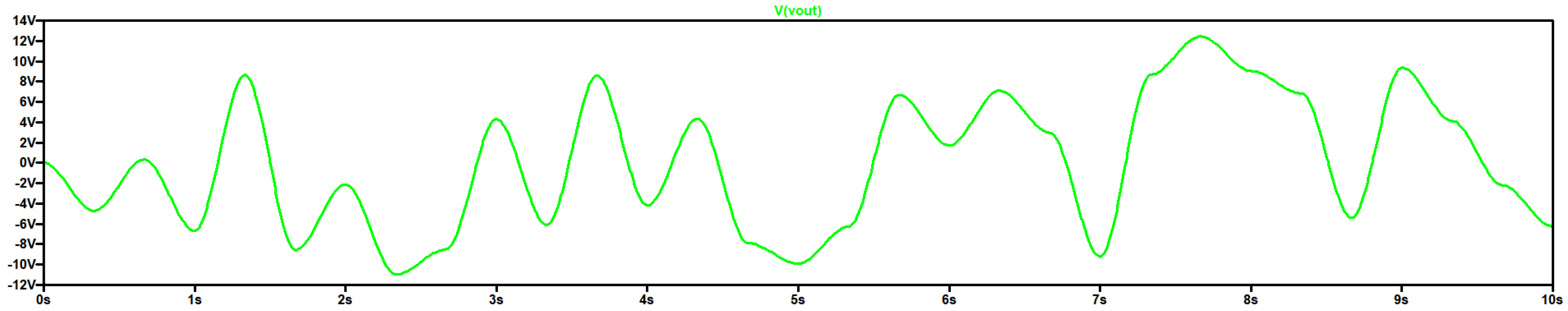

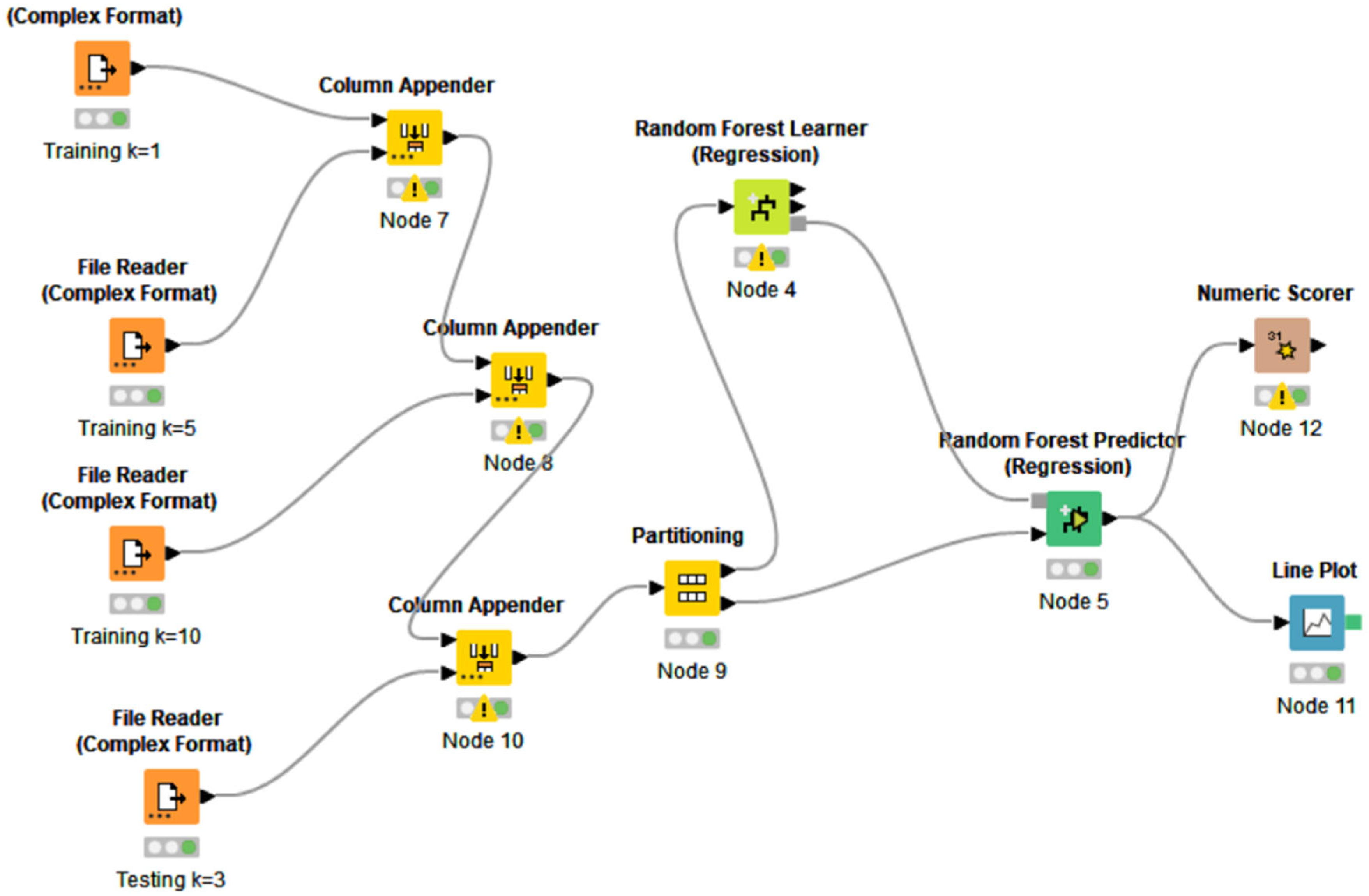

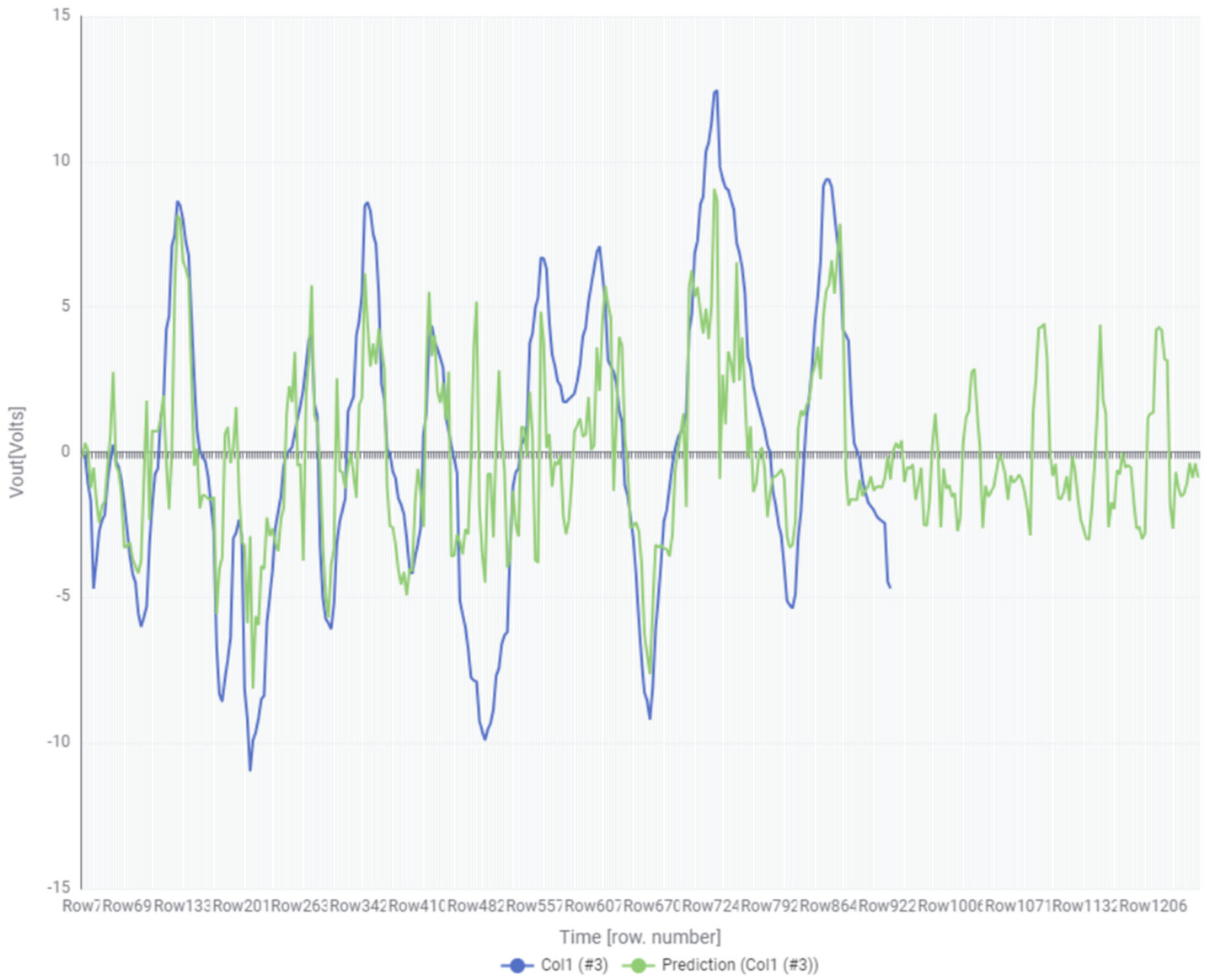

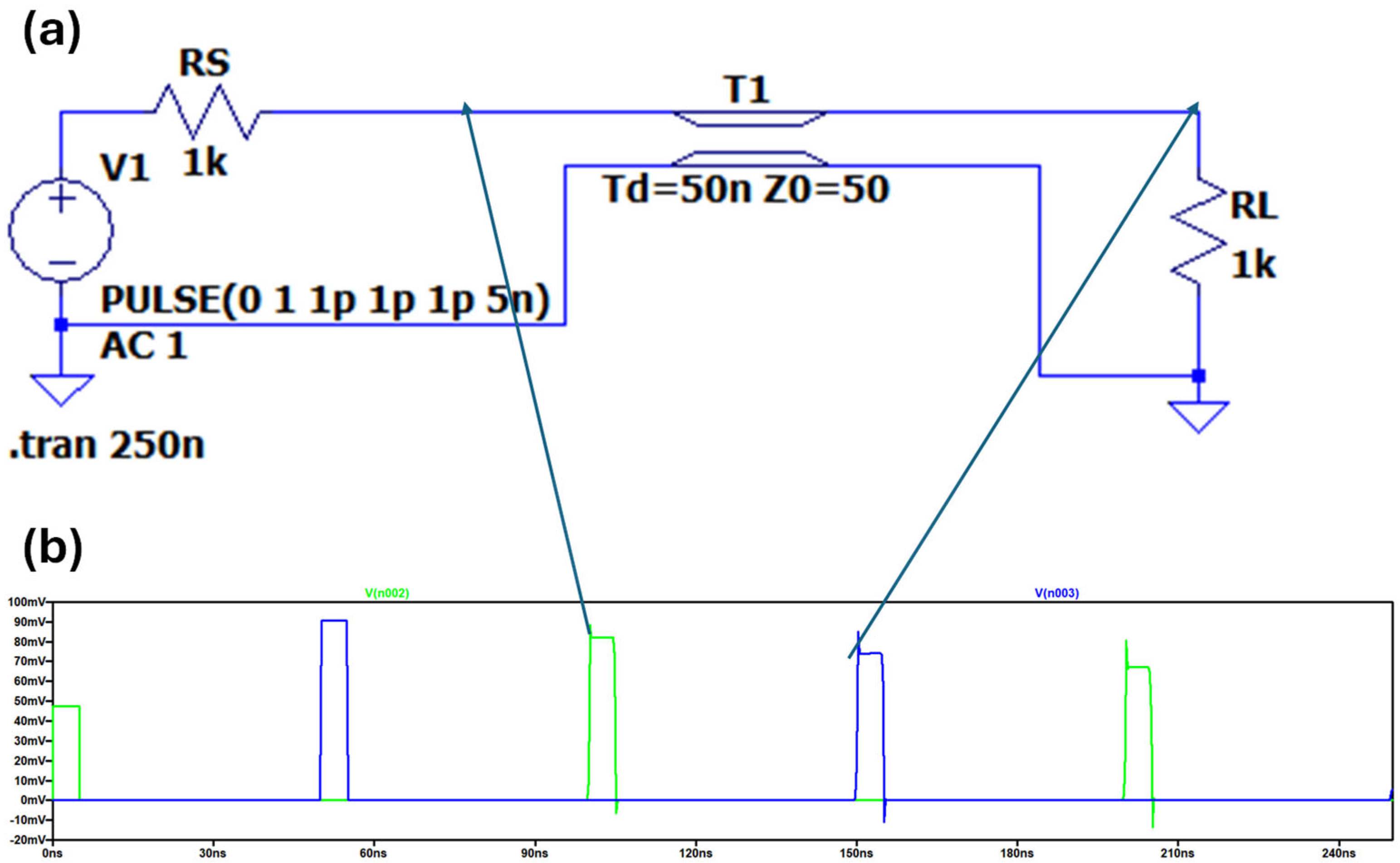

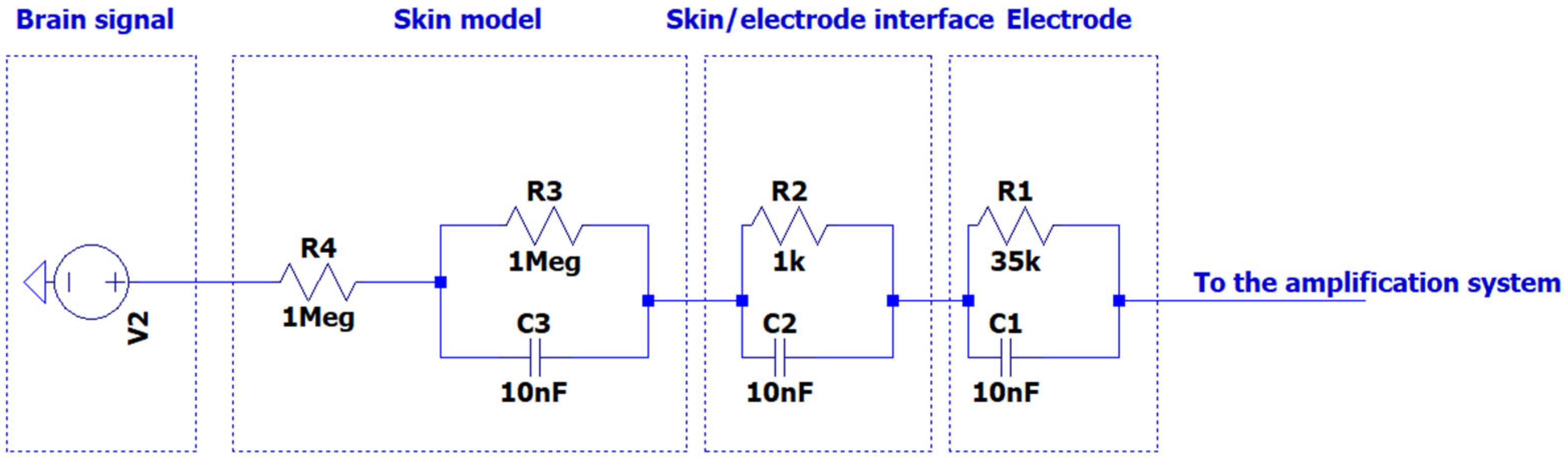

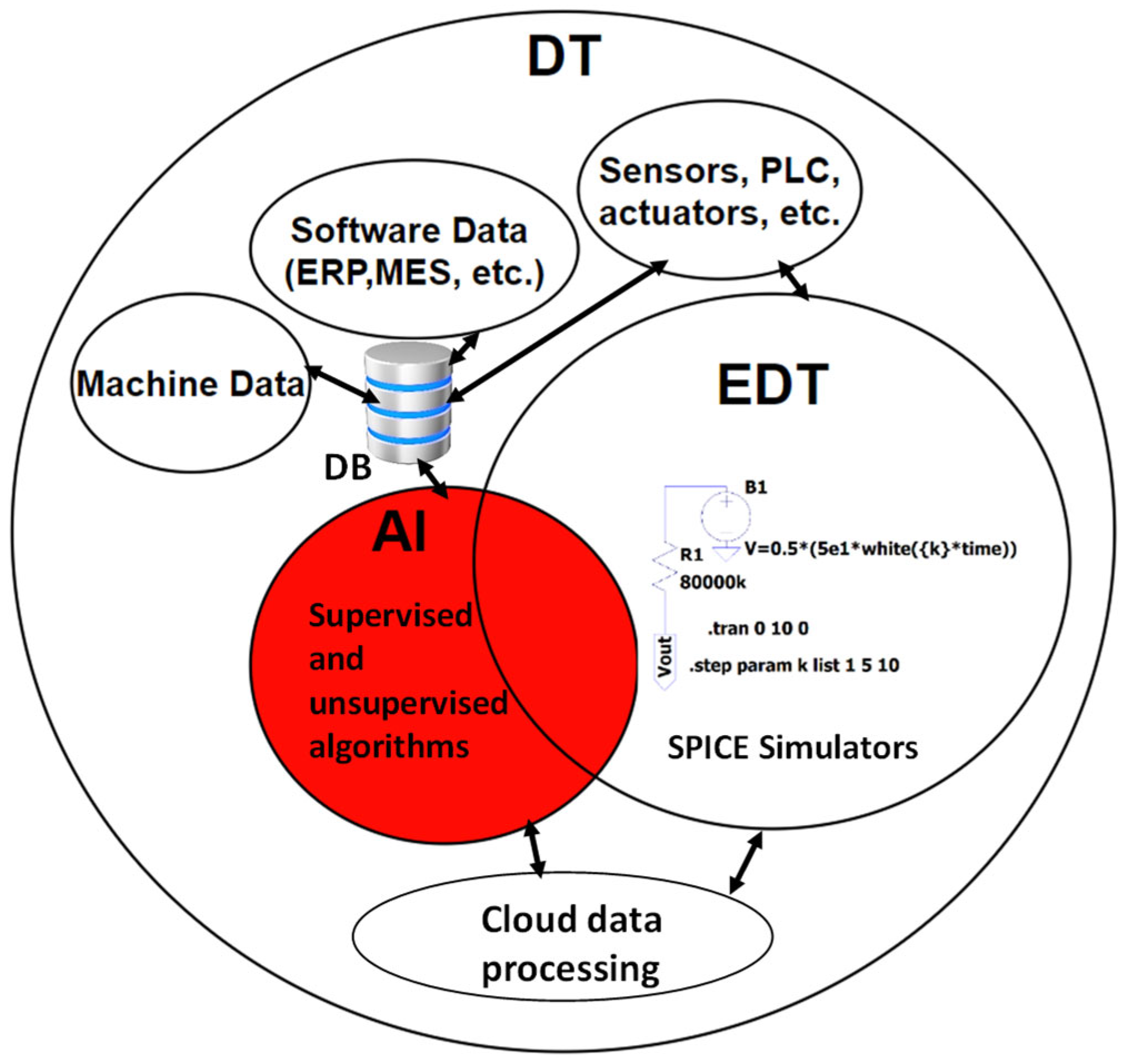

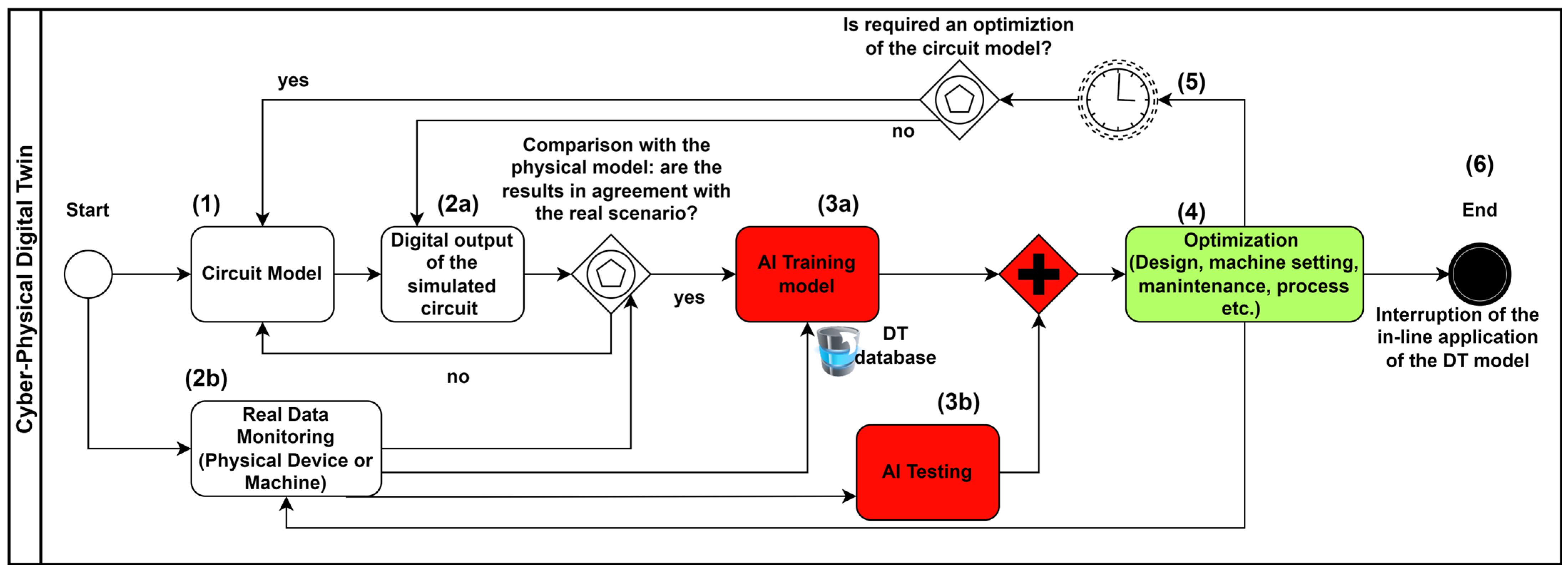

8.1. Circuit Modeling and AI Data Processing Integration

8.2. EDT Framework: Advantages and Disadvantages

8.3. Limitations, Practical Use Cases, and Workflow Protocol for EDTs Integrating AI

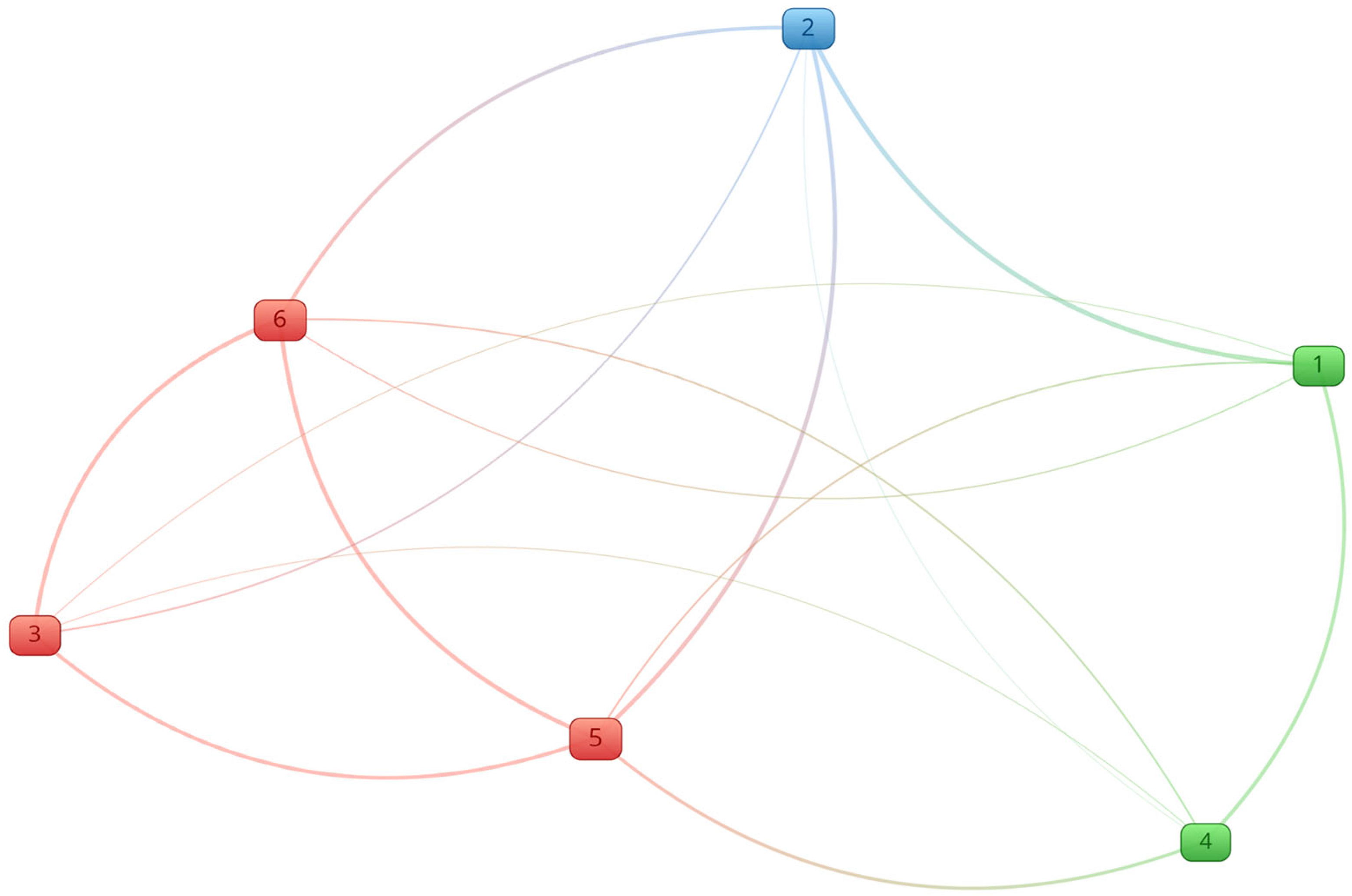

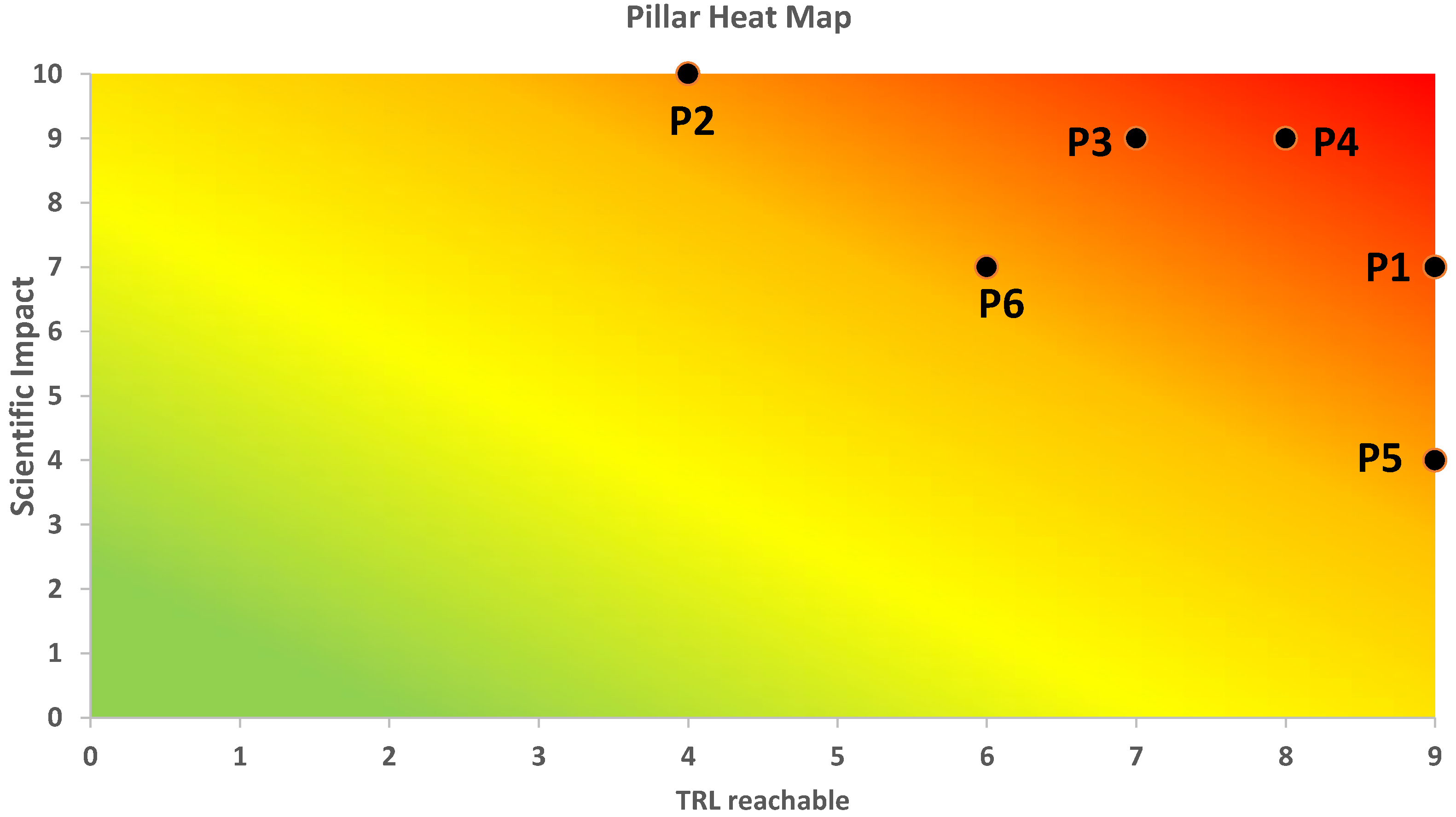

8.4. Workflow Methodology, Correlation, and Technology Readiness of Research Pillars

- Keyword matching and the use of academic search engines to find papers;

- The verification of the presence of important research features, such as a DT framework architecture, project specifications, AI applications, a circuital approach, and AI-based process integration;

- The analysis of relationships between research pillars and the estimation of the related association strengths.

8.5. AI Importance and Research Gap

9. Conclusions

- –

- –

- –

- Suggesting a methodological approach for implementing EDTs based on the use of circuit models (see Section 8.1 and the Appendix A);

- –

- Proposing the integration of EDT models into manufacturing processes (see Figure 11).

Review’s Limitations and Future Research Directions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Kohesio: Discover EU Projects in Your Region. Available online: https://kohesio.ec.europa.eu/en/projects (accessed on 17 May 2025).

- Wang, M.; Wang, C.; Hnydiuk-Stefan, A.; Feng, S.; Atilla, I.; Li, Z. Recent Progress on Reliability Analysis of Offshore Wind Turbine Support Structures Considering Digital Twin Solutions. Ocean Eng. 2021, 232, 109168. [Google Scholar] [CrossRef]

- Olatunji, O.O.; Adedeji, P.A.; Madushele, N.; Jen, T.-C. Overview of Digital Twin Technology in Wind Turbine Fault Diagnosis and Condition Monitoring. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; pp. 201–207. [Google Scholar]

- Iosifidis, N.; Zhong, Y.; Hu, B.; Chen, B.; Ran, L.; Lakshminarayana, S.; Jia, C.; McKeever, P.; Ng, C. Reliability of Wind Turbine Power Modules Using High-Resolution Wind Data Reconstruction: A Digital Twin Concept. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 3630–3637. [Google Scholar]

- Malik, A.A. Digital Twin Based Development of Mobile Robot Assistant in Wind Turbines Manufacturing. In Volume 2: 43rd Computers and Information in Engineering Conference (CIE); American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Di Nezio, G.; Di Benedetto, M.; Lidozzi, A.; Solero, L. Digital-Twin Based Health Monitoring for Multi-Phase Boost Rectifier in Wind Offshore Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 13, 2738–2748. [Google Scholar] [CrossRef]

- Mahmoud, M.; Semeraro, C.; Abdelkareem, M.A.; Olabi, A.G. Designing and Prototyping the Architecture of a Digital Twin for Wind Turbine. Int. J. Thermofluids 2024, 22, 100622. [Google Scholar] [CrossRef]

- Chetan, M.; Yao, S.; Griffith, D.T. Multi-fidelity Digital Twin Structural Model for a Sub-scale Downwind Wind Turbine Rotor Blade. Wind Energy 2021, 24, 1368–1387. [Google Scholar] [CrossRef]

- Fu, Y.; Zhu, G.; Zhu, M.; Xuan, F. Digital Twin for Integration of Design-Manufacturing-Maintenance: An Overview. Chin. J. Mech. Eng. 2022, 35, 80. [Google Scholar] [CrossRef]

- Ebni, M.; Hosseini Bamakan, S.M.; Qu, Q. Digital Twin Based Smart Manufacturing; From Design to Simulation and Optimization Schema. Procedia Comput. Sci. 2023, 221, 1216–1225. [Google Scholar] [CrossRef]

- O’Connell, E.; O’Brien, W.; Bhattacharya, M.; Moore, D.; Penica, M. Digital Twins: Enabling Interoperability in Smart Manufacturing Networks. Telecom 2023, 4, 265–278. [Google Scholar] [CrossRef]

- Xu, J.; Guo, T. Application and Research on Digital Twin in Electronic Cam Servo Motion Control System. Int. J. Adv. Manuf. Technol. 2021, 112, 1145–1158. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital Twin in Manufacturing: Conceptual Framework and Case Studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Li, L.; Lei, B.; Mao, C. Digital Twin in Smart Manufacturing. J. Ind. Inf. Integr. 2022, 26, 100289. [Google Scholar] [CrossRef]

- He, B.; Bai, K.-J. Digital Twin-Based Sustainable Intelligent Manufacturing: A Review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Gunes, V. A Digital Twin Design Methodology for Control, Simulation, and Monitoring of Fluidic Circuits. Int. J. Adv. Manuf. Technol. 2024, 134, 3863–3875. [Google Scholar] [CrossRef]

- Chen, R.; Chen, X.; Wang, L.; Li, J. The Core Industry Manufacturing Process of Electronics Assembly Based on Smart Manufacturing. ACM Trans. Manag. Inf. Syst. 2022, 13, 1–19. [Google Scholar] [CrossRef]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A Review of Digital Twin in Product Design and Development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Gopal, L.; Singh, H.; Mounica, P.; Mohankumar, N.; Challa, N.P.; Jayaraman, P. Digital Twin and IOT Technology for Secure Manufacturing Systems. Measur. Sens. 2023, 25, 100661. [Google Scholar] [CrossRef]

- Su, J.; Mao, Q.; Liao, Z.; Sheng, Z.; Huang, C.; Zhang, X. A Real-Time Cross-Domain WI-Fi-Based Gesture Recognition System for Digital Twins. IEEE J. Sel. Areas Commun. 2023, 41, 3690–3701. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Zhang, Q.; Sun, Q.; Lim, E. A Digital Twin Platform Integrating Process Parameter Simulation Solution for Intelligent Manufacturing. Electronics 2024, 13, 802. [Google Scholar] [CrossRef]

- Azangoo, M.; Taherkordi, A.; Blech, J.O.; Vyatkin, V. Digital Twin-Assisted Controlling of AGVs in Flexible Manufacturing Environments. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–7. [Google Scholar]

- Liang, X.; Xiao, R.; Zhang, J. A Review on Digital Twin for Robotics in Smart Manufacturing. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; pp. 1510–1515. [Google Scholar]

- Misra, A.; Agrawal, A.; Misra, V. Robotics in Industry 4.0. In Handbook of Smart Materials, Technologies, and Devices; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–35. [Google Scholar]

- Yan, D.; Sha, W.; Wang, D.; Yang, J.; Zhang, S. Digital Twin-Driven Variant Design of a 3C Electronic Product Assembly Line. Sci. Rep. 2022, 12, 3846. [Google Scholar] [CrossRef]

- Li, X.; Niu, W.; Tian, H. Application of Digital Twin in Electric Vehicle Powertrain: A Review. World Electr. Veh. J. 2024, 15, 208. [Google Scholar] [CrossRef]

- Wu, Q.; Mao, Y.; Chen, J.; Wang, C. Application Research of Digital Twin-Driven Ship Intelligent Manufacturing System: Pipe Machining Production Line. J. Mar. Sci. Eng. 2021, 9, 338. [Google Scholar] [CrossRef]

- Mendi, A.F. A Digital Twin Case Study on Automotive Production Line. Sensors 2022, 22, 6963. [Google Scholar] [CrossRef]

- Yang, J.; Son, Y.H.; Lee, D.; Noh, S.D. Digital Twin-Based Integrated Assessment of Flexible and Reconfigurable Automotive Part Production Lines. Machines 2022, 10, 75. [Google Scholar] [CrossRef]

- Krenczyk, D.; Paprocka, I. Integration of Discrete Simulation, Prediction, and Optimization Methods for a Production Line Digital Twin Design. Materials 2023, 16, 2339. [Google Scholar] [CrossRef]

- Yuan, G.; Liu, X.; Zhu, C.; Wang, C.; Zhu, M.; Sun, Y. Multi-Objective Coupling Optimization of Electrical Cable Intelligent Production Line Driven by Digital Twin. Robot. Comput. Integr. Manuf. 2024, 86, 102682. [Google Scholar] [CrossRef]

- Guo, K.; Wan, X.; Liu, L.; Gao, Z.; Yang, M. Fault Diagnosis of Intelligent Production Line Based on Digital Twin and Improved Random Forest. Appl. Sci. 2021, 11, 7733. [Google Scholar] [CrossRef]

- Lee, D.; Kim, C.-K.; Yang, J.; Cho, K.-Y.; Choi, J.; Noh, S.-D.; Nam, S. Digital Twin-Based Analysis and Optimization for Design and Planning of Production Lines. Machines 2022, 10, 1147. [Google Scholar] [CrossRef]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Lotsaris, K.; Bavelos, A.C.; Baris, P.; Michalos, G.; Makris, S. Digital Twin for Designing and Reconfiguring Human–Robot Collaborative Assembly Lines. Appl. Sci. 2021, 11, 4620. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, J.; Chen, J.; Hu, P.; Wang, X.; Xu, J.; Zhou, B. A Digital-Twin Visualized Architecture for Flexible Manufacturing System. J. Manuf. Syst. 2021, 60, 176–201. [Google Scholar] [CrossRef]

- Ricondo, I.; Porto, A.; Ugarte, M. A Digital Twin Framework for the Simulation and Optimization of Production Systems. Procedia CIRP 2021, 104, 762–767. [Google Scholar] [CrossRef]

- Alam, M.D.; Kabir, G.; Mirmohammadsadeghi, S. A Digital Twin Framework Development for Apparel Manufacturing Industry. Decis. Anal. J. 2023, 7, 100252. [Google Scholar] [CrossRef]

- Seidel, R.; Rachinger, B.; Thielen, N.; Schmidt, K.; Meier, S.; Franke, J. Development and Validation of a Digital Twin Framework for SMT Manufacturing. Comput. Ind. 2023, 145, 103831. [Google Scholar] [CrossRef]

- Moeller, H.; Inamdar, A.; van Driel, W.D.; Bredberg, J.; Hille, P.; Knoll, H.; Vandevelde, B. Digital Twin Technology in Electronics. In Recent Advances in Microelectronics Reliability; Springer International Publishing: Cham, Switzerland, 2024; pp. 283–321. [Google Scholar]

- Chen, H.; Zhang, Z.; Karamanakos, P.; Rodriguez, J. Digital Twin Techniques for Power Electronics-Based Energy Conversion Systems: A Survey of Concepts, Application Scenarios, Future Challenges, and Trends. IEEE Ind. Electron. Mag. 2023, 17, 20–36. [Google Scholar] [CrossRef]

- Mansour, D.-E.A.; Numair, M.; Zalhaf, A.S.; Ramadan, R.; Darwish, M.M.F.; Huang, Q.; Hussien, M.G.; Abdel-Rahim, O. Applications of IoT and Digital Twin in Electrical Power Systems: A Comprehensive Survey. IET Gener. Transm. Distrib. 2023, 17, 4457–4479. [Google Scholar] [CrossRef]

- Agarwal, R.; Bhatti, G.; Singh, R.R.; Indragandhi, V.; Suresh, V.; Jasinska, L.; Leonowicz, Z. Intelligent Fault Detection in Hall-Effect Rotary Encoders for Industry 4.0 Applications. Electronics 2022, 11, 3633. [Google Scholar] [CrossRef]

- Lee, H.; Kim, S.D.; Amin, M.A.U.A. Control Framework for Collaborative Robot Using Imitation Learning-Based Teleoperation from Human Digital Twin to Robot Digital Twin. Mechatronics 2022, 85, 102833. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, Y.; Hu, Q.; Xie, C.; Su, T. DTformer: An Efficient Digital Twin Model for Loss Measurement in UHVDC Transmission Systems. IEEE Trans. Power Syst. 2024, 39, 3548–3559. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, Q.; Cui, J. A Novel Fault Diagnosis Method for Denoising Autoencoder Assisted by Digital Twin. Comput. Intell. Neurosci. 2022, 2022, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ciganek, J.; Zemla, F. Design of Digital Twin for PLC System. In Proceedings of the 2022 Cybernetics & Informatics (K&I), Visegrad, Hungary, 11–14 September 2022; pp. 1–6. [Google Scholar]

- Massaro, A. Artificial Intelligence Signal Control in Electronic Optocoupler Circuits Addressed on Industry 5.0 Digital Twin. Electronics 2024, 13, 4543. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, S.; Li, H.; Cao, W.; Tang, W.; Jiang, J.; Deng, M.; Zhang, Y.; Gu, B.; Wu, K.; et al. Digital Twin-Driven Intelligent Production Line for Automotive MEMS Pressure Sensors. Adv. Eng. Inform. 2022, 54, 101779. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives. Appl. Sci. 2023, 13, 4582. [Google Scholar] [CrossRef]

- Ali, A.R.; Ramadan, M.W.A. Artificial Neural Networks as Digital Twins for Whispering Gallery Mode Optical Sensors in Robotics Applications. Photonic Sens. 2025, 15, 250206. [Google Scholar] [CrossRef]

- Massaro, A. Electronics in Advanced Research Industries: Industry 4.0 to Industry 5.0 Advances; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Oguz, I.; Suter, L.J.E.; Hsieh, J.-L.; Yildirim, M.; Dinc, N.U.; Moser, C.; Psaltis, D. Training Hybrid Neural Networks with Multimode Optical Nonlinearities Using Digital Twins. Nanophotonics 2025, 14, 2787–2797. [Google Scholar] [CrossRef]

- Zhuge, Q. AI-Driven Digital Twin for Optical Networks. In Proceedings of the European Conference on Optical Communication (ECOC), Basel, Switzerland, 18–22 September 2022; pp. 1–62. [Google Scholar]

- Lay-Ekuakille, A.; Massaro, A.; Singh, S.P.; Jabłoński, I.; Rahman, M.Z.U.; Spano, F. Optoelectronic and Nanosensors Detection Systems: A Review. IEEE Sens. J. 2021, 21, 12645–12653. [Google Scholar] [CrossRef]

- Faruk, M.S.; Savory, S.J. Measurement Informed Models and Digital Twins for Optical Fiber Communication Systems. J. Light. Technol. 2024, 42, 1016–1030. [Google Scholar] [CrossRef]

- Zhuge, Q.; Liu, X.; Zhang, Y.; Cai, M.; Liu, Y.; Qiu, Q.; Zhong, X.; Wu, J.; Gao, R.; Yi, L.; et al. Building a Digital Twin for Intelligent Optical Networks [Invited Tutorial]. J. Opt. Commun. Netw. 2023, 15, C242. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Zhang, M.; Fu, M.; Li, J.; Cai, S.; Zhang, C.; Chen, X. The Role of Digital Twin in Optical Communication: Fault Management, Hardware Configuration, and Transmission Simulation. IEEE Commun. Mag. 2021, 59, 133–139. [Google Scholar] [CrossRef]

- Borraccini, G.; Straullu, S.; Giorgetti, A.; Ambrosone, R.; Virgillito, E.; D’Amico, A.; D’Ingillo, R.; Aquilino, F.; Nespola, A.; Sambo, N.; et al. Experimental Demonstration of Partially Disaggregated Optical Network Control Using the Physical Layer Digital Twin. IEEE Trans. Netw. Serv. Manag. 2023, 20, 2343–2355. [Google Scholar] [CrossRef]

- Koulountzios, P.; Rymarczyk, T.; Soleimani, M. A 4-D Ultrasound Tomography for Industrial Process Reactors Investigation. IEEE Trans. Instrum. Meas. 2022, 71, 1–14. [Google Scholar] [CrossRef]

- Boparai, K.S.; Kumar, A.; Singh, R. Integration of 4D Imaging with 4D Printing. In 4D Imaging to 4D Printing; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–26. ISBN 9781003205531. [Google Scholar]

- Wang, F.; Yue, Z.; Liu, J.; Qi, H.; Sun, W.; Chen, M.; Wang, Y.; Yue, H. Quantitative Imaging of Printed Circuit Board (PCB) Delamination Defects Using Laser-Induced Ultrasound Scanning Imaging. J. Appl. Phys. 2022, 131, 53101. [Google Scholar] [CrossRef]

- Dai, L.-N.; Ni, C.-Y.; Ying, K.-N.; Yuan, L.; Kan, W.-W.; Shen, Z.-H. Defect Imaging Based on Laser Ultrasonic Frequency Domain Synthetic Aperture Focusing Technology with Separated Generation–Detection and 2-D Equivalent Velocity Mapping. Opt. Laser Technol. 2022, 156, 108485. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Tang, Z.; Duan, J.; Zhu, Y.; Zhang, Z.; Liu, X.; He, C. Optimization of Selection Matrix Capture for Micro Defects Laser Ultrasound Imaging Using Multi-Parameter Genetic Algorithm. NDT E Int. 2025, 152, 103325. [Google Scholar] [CrossRef]

- Cieślak, S.; Zawadzki, P.; Gapsa, J. Digital Twin Application for Vision Control in the Production of Mechatronic Ladders. In Lecture Notes in Mechanical Engineering; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 216–227. ISBN 9783031564697. [Google Scholar]

- Li, Q.; Ye, Q.J.; Zhang, N.; Zhang, W.; Hu, F. Digital-Twin-Enabled Industrial IoT: Vision, Framework, and Future Directions. IEEE Wirel. Commun. 2025, 1–9. [Google Scholar] [CrossRef]

- Salini, S.; Ivy, B.P.U. Digital Twin and Artificial Intelligence in Industries. In Digital Twin for Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 35–58. ISBN 9780323992053. [Google Scholar]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A Deep Learning-Enhanced Digital Twin Framework for Improving Safety and Reliability in Human–Robot Collaborative Manufacturing. Robot. Comput. Integr. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- Dosoftei, C.-C. Simulation Power vs. Immersive Capabilities: Enhanced Understanding and Interaction with Digital Twin of a Mechatronic System. Appl. Sci. 2023, 13, 6463. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, T.; Yue, P.; Luo, W.; Ma, S. Study on the Construction Theory of Digital Twin Mechanism Model for Mechatronics Equipment. Int. J. Adv. Manuf. Technol. 2022, 131, 5383–5401. [Google Scholar] [CrossRef]

- Classens, K.; Heemels, W.P.M.H.M.; Oomen, T. Digital Twins in Mechatronics: From Model-Based Control to Predictive Maintenance. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 336–339. [Google Scholar]

- Sturm, C.; Steck, M.; Bremer, F.; Revfi, S.; Nelius, T.; Gwosch, T.; Albers, A.; Matthiesen, S. Creation of Digital Twins—Key Characteristics of Physical to Virtual Twinning in Mechatronic Product Development. Proc. Des. Soc. 2021, 1, 781–790. [Google Scholar] [CrossRef]

- Nezzi, C.; Gufler, V.; Vidoni, R.; Rauch, E. Kinematic and Dynamic Modeling of Mechanical Systems towards Digital Twins. Results Eng. 2025, 26, 104874. [Google Scholar] [CrossRef]

- Chaiprabha, K.; Chancharoen, R. A Deep Trajectory Controller for a Mechanical Linear Stage Using Digital Twin Concept. Actuators 2023, 12, 91. [Google Scholar] [CrossRef]

- Braun, D.; Riedhammer, M.; Jazdi, N.; Schloegl, W.; Weyrich, M. A Methodology for the Detection of Functional Relations of Mechatronic Components and Assemblies in Brownfield Systems. Procedia CIRP 2022, 107, 119–124. [Google Scholar] [CrossRef]

- Jhunjhunwala, P.; Atmojo, U.D.; Vyatkin, V. Applying Skill-Based Engineering Using OPC-UA in Production System with a Digital Twin. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–6. [Google Scholar]

- Wang, J.; Niu, X.; Gao, R.X.; Huang, Z.; Xue, R. Digital Twin-Driven Virtual Commissioning of Machine Tool. Robot. Comput. Integr. Manuf. 2023, 81, 102499. [Google Scholar] [CrossRef]

- Wu, L.; Leng, J.; Ju, B. Digital Twins-Based Smart Design and Control of Ultra-Precision Machining: A Review. Symmetry 2021, 13, 1717. [Google Scholar] [CrossRef]

- Zaidi, A.; Keshta, I.; Gupta, Z.; Pundhir, P.; Pandey, T.; Rai, P.K.; Shabaz, M.; Soni, M. Smart Implementation of Industrial Internet of Things Using Embedded Mechatronic System. IEEE Embed. Syst. Lett. 2024, 16, 190–193. [Google Scholar] [CrossRef]

- Ebadpour, M.; Jamshidi, M.; Talla, J.; Hashemi-Dezaki, H.; Peroutka, Z. Digital Twin Model of Electric Drives Empowered by EKF. Sensors 2023, 23, 2006. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, K. Design and Simulation Debugging of Automobile Connecting Rod Production Line Based on the Digital Twin. Appl. Sci. 2023, 13, 4919. [Google Scholar] [CrossRef]

- Mazumder, A.; Sahed, M.F.; Tasneem, Z.; Das, P.; Badal, F.R.; Ali, M.F.; Ahamed, M.H.; Abhi, S.H.; Sarker, S.K.; Das, S.K.; et al. Towards next Generation Digital Twin in Robotics: Trends, Scopes, Challenges, and Future. Heliyon 2023, 9, e13359. [Google Scholar] [CrossRef] [PubMed]

- Viola, J.; Chen, Y. Parallel Self Optimizing Control Framework for Digital Twin Enabled Smart Control Engineering. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 358–361. [Google Scholar]

- Massaro, A. Artificial Intelligence Enabling Denoising in Passive Electronic Filtering Circuits for Industry 5.0 Machines. Machines 2024, 12, 551. [Google Scholar] [CrossRef]

- Massaro, A. ANNs Predicting Noisy Signals in Electronic Circuits: A Model Predicting the Signal Trend in Amplification Systems. AI 2024, 5, 533–549. [Google Scholar] [CrossRef]

- Massaro, A.; Santarsiero, F.; Schiuma, G. Advanced Electronic Controller Circuits Enabling Production Processes and AI-Driven KM in Industry 5.0. J. Ind. Inf. Integr. 2025, 45, 100841. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors 2022, 22, 8677. [Google Scholar] [CrossRef]

- Keshmiri Neghab, H.; Jamshidi, M.; Keshmiri Neghab, H. Digital Twin of a Magnetic Medical Microrobot with Stochastic Model Predictive Controller Boosted by Machine Learning in Cyber-Physical Healthcare Systems. Information 2022, 13, 321. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, L.U.; Koppu, S.; Ramu, S.P.; Iyapparaja; Boobalan, P.; Baker, T.; Maddikunta, P.K.R.; Gadekallu, T.R.; Aljuhani, A. Digital Twins for Healthcare 4.0—Recent Advances, Architecture, and Open Challenges. IEEE Consum. Electron. Mag. 2023, 12, 29–37. [Google Scholar] [CrossRef]

- Katsoulakis, E.; Wang, Q.; Wu, H.; Shahriyari, L.; Fletcher, R.; Liu, J.; Achenie, L.; Liu, H.; Jackson, P.; Xiao, Y.; et al. Digital Twins for Health: A Scoping Review. NPJ Digit. Med. 2024, 7, 77. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Saied, I.M.; Ratnarajah, T.; Arslan, T. Evaluation of Unobtrusive Microwave Sensors in Healthcare 4.0—Toward the Creation of Digital-Twin Model. Sensors 2022, 22, 8519. [Google Scholar] [CrossRef]

- Massaro, A. Electronic Artificial Intelligence–Digital Twin Model for Optimizing Electroencephalogram Signal Detection. Electronics 2025, 14, 1122. [Google Scholar] [CrossRef]

- Johnson, Z.; Saikia, M.J. Digital Twins for Healthcare Using Wearables. Bioengineering 2024, 11, 606. [Google Scholar] [CrossRef] [PubMed]

- Shafik, W. The Next Generation of Health Monitoring: Digital Twins and Medical Wearables. In AI-Powered Digital Twins for Predictive Healthcare: Creating Virtual Replicas of Humans; Balasubramaniam, S., Kadry, S., Eds.; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 69–106. [Google Scholar] [CrossRef]

- Uhlenberg, L.; Derungs, A.; Amft, O. Co-Simulation of Human Digital Twins and Wearable Inertial Sensors to Analyse Gait Event Estimation. Front. Bioeng. Biotechnol. 2023, 11, 1104000. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Chen, Z.; Jiang, M.; Tian, Z.; Peng, T.; Hu, X. Smart Clothing System with Multiple Sensors Based on Digital Twin Technology. IEEE Internet Things J. 2023, 10, 6377–6387. [Google Scholar] [CrossRef]

- Lyu, Z. Multisensor Data Fusion in Digital Twins for Smart Healthcare. In Data Fusion Techniques and Applications for Smart Healthcare; Elsevier: Amsterdam, The Netherlands, 2024; pp. 21–44. ISBN 9780443132339. [Google Scholar]

- Sharma, V.; Sharma, K.; Kumar, A. AI and Digital Twins Transforming Healthcare IoT. In Proceedings of the 2024 14th International Conference on Cloud Computing, Data Science & Engineering (Confluence), Noida, India, 18–19 January 2024; pp. 6–11. [Google Scholar]

- Elayan, H.; Aloqaily, M.; Guizani, M. Digital Twin for Intelligent Context-Aware IoT Healthcare Systems. IEEE Internet Things J. 2021, 8, 16749–16757. [Google Scholar] [CrossRef]

- Rashid, S.M.; Ghiasi, A.R. Adaptive Digital Twin Integration with Multilevel Inverter Control for Energy Efficient Smart Rehabilitation Systems. Sci. Rep. 2025, 15, 8511. [Google Scholar] [CrossRef]

- Lauer-Schmaltz, M.W.; Cash, P.; Paulin Hansen, J.; Das, N. Human Digital Twins in Rehabilitation: A Case Study on Exoskeleton and Serious-Game-Based Stroke Rehabilitation Using the ETHICA Methodology. IEEE Access 2024, 12, 180968–180991. [Google Scholar] [CrossRef]

- Khan, M.M.R.; Sunny, M.S.H.; Ahmed, T.; Shahria, M.T.; Modi, P.P.; Zarif, M.I.I.; De Caro, J.D.S.; Ahamed, S.I.; Ahmed, H.U.; Ketchum, E.M.M.; et al. Development of a Robot-Assisted Telerehabilitation System with Integrated IIoT and Digital Twin. IEEE Access 2023, 11, 70174–70189. [Google Scholar] [CrossRef]

- Harlan, B.; Tjahyadi, H. Minimally Invasive Motor Function Rehabilitation through Digital Twin Technology: A Review. In Proceedings of the 2024 2nd International Conference on Technology Innovation and Its Applications (ICTIIA), Medan, Indonesia, 12–13 September 2024; pp. 1–5. [Google Scholar]

- Xie, S.; Zhan, M.; Li, Y.; Xi, F. The Virtual-Real Interaction System Design and Interaction Characteristics Research of an Ankle Rehabilitation Robot Based on Digital Twin. Technol. Health Care 2025, 9287329251337237. [Google Scholar] [CrossRef]

- De Fazio, R.; Mastronardi, V.M.; De Vittorio, M.; Visconti, P. Wearable Sensors and Smart Devices to Monitor Rehabilitation Parameters and Sports Performance: An Overview. Sensors 2023, 23, 1856. [Google Scholar] [CrossRef]

- Dziurdzia, P.; Bratek, P.; Markiewicz, M. An Efficient Electrothermal Model of a Thermoelectric Converter for a Thermal Energy Harvesting Process Simulation and Electronic Circuits Powering. Energies 2023, 17, 204. [Google Scholar] [CrossRef]

- Tabaie, Z.; Omidvar, A. Human Body Heat-Driven Thermoelectric Generators as a Sustainable Power Supply for Wearable Electronic Devices: Recent Advances, Challenges, and Future Perspectives. Heliyon 2023, 9, e14707. [Google Scholar] [CrossRef]

- Zou, Y.; Bo, L.; Li, Z. Recent Progress in Human Body Energy Harvesting for Smart Bioelectronic System. Fundam. Res. 2021, 1, 364–382. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Z.; Kuai, Q.; Liang, J.; Liu, J.; Zeng, X. Circuit Techniques for High Efficiency Piezoelectric Energy Harvesting. Micromachines 2022, 13, 1044. [Google Scholar] [CrossRef] [PubMed]

- Haroun, A.; Le, X.; Gao, S.; Dong, B.; He, T.; Zhang, Z.; Wen, F.; Xu, S.; Lee, C. Progress in Micro/Nano Sensors and Nanoenergy for Future AIoT-Based Smart Home Applications. Nano Ex. 2021, 2, 22005. [Google Scholar] [CrossRef]

- Jettanasen, C.; Songsukthawan, P.; Ngaopitakkul, A. Conversion of Mechanical Energy to Electrical Energy Using Piezoelectric Materials for Bicycle Lane Lighting Systems. Appl. Sci. 2022, 12, 7237. [Google Scholar] [CrossRef]

- Carneiro, P.; Soares dos Santos, M.P.; Rodrigues, A.; Ferreira, J.A.F.; Simões, J.A.O.; Marques, A.T.; Kholkin, A.L. Electromagnetic Energy Harvesting Using Magnetic Levitation Architectures: A Review. Appl. Energy 2020, 260, 114191. [Google Scholar] [CrossRef]

- Hao, D.; Fan, C.; Xia, X.; Zhang, Z.; Yang, Y. Hybrid Electromagnetic-Triboelectric Hip Energy Harvester for Wearables and AI-Assisted Motion Monitoring. Small 2025, 21, e2500643. [Google Scholar] [CrossRef]

- Pang, Y.; He, T.; Liu, S.; Zhu, X.; Lee, C. Triboelectric Nanogenerator-Enabled Digital Twins in Civil Engineering Infrastructure 4.0: A Comprehensive Review. Adv. Sci. 2024, 11, e2306574. [Google Scholar] [CrossRef]

- Jiang, J.; Fan, C.; Chen, H.; Wu, F.; Feng, X.; Xiao, C.; Pan, H.; Wu, X.; Zhang, Z. A Self-Powered Triboelectric Nano-Sensor Enabled Digital Twin for Self-Sustained Machine Monitoring in Smart Mine. Nano Res. 2025, 18, 94907287. [Google Scholar] [CrossRef]

- Artetxe, E.; Uralde, J.; Barambones, O.; Calvo, I.; Martin, I. Maximum Power Point Tracker Controller for Solar Photovoltaic Based on Reinforcement Learning Agent with a Digital Twin. Mathematics 2023, 11, 2166. [Google Scholar] [CrossRef]

- Chalal, L.; Saadane, A.; Rachid, A. Unified Environment for Real Time Control of Hybrid Energy System Using Digital Twin and IoT Approach. Sensors 2023, 23, 5646. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.R.; Halder, D.; Ray, S. Digital Twins for IoT-Driven Energy Systems: A Survey. IEEE Access 2024, 12, 177123–177143. [Google Scholar] [CrossRef]

- Hossen, T.; Gursoy, M.; Mirafzal, B. Digital Twin for Self-Security of Smart Inverters. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 713–718. [Google Scholar]

- Numair, M.; Aboushady, A.A.; Arraño-Vargas, F.; Farrag, M.E.; Elyan, E. Fault Detection and Localisation in LV Distribution Networks Using a Smart Meter Data-Driven Digital Twin. Energies 2023, 16, 7850. [Google Scholar] [CrossRef]

- Yue, G.; Du, Z.; Xiu, L.; Meng, S.; Ma, Z.; Xie, Y. Electric Field Equivalent Method for AC/DC Hybrid Electric Equipment Adapted to Digital Twin with Low Latency. Electr. Power Syst. Res. 2022, 213, 108799. [Google Scholar] [CrossRef]

- Yuan, Z.; Pan, Y.; Wang, H.; Wang, S.; Peng, Y.; Jin, C.; Xu, C.; Feng, X.; Shen, K.; Zheng, Y.; et al. Fault Data Generation of Lithium Ion Batteries Based on Digital Twin: A Case for Internal Short Circuit. J. Energy Storage 2023, 64, 107113. [Google Scholar] [CrossRef]

- Li, Q.; He, Y. An Overview of Digital Twin Concept for Key Components of Renewable Energy Systems. Int. J. Robot. Autom. Technol. 2021, 8, 29–47. [Google Scholar] [CrossRef]

- Das, O.; Zafar, M.H.; Sanfilippo, F.; Rudra, S.; Kolhe, M.L. Advancements in Digital Twin Technology and Machine Learning for Energy Systems: A Comprehensive Review of Applications in Smart Grids, Renewable Energy, and Electric Vehicle Optimisation. Energy Convers. Manag. X 2024, 24, 100715. [Google Scholar] [CrossRef]

- Massaro, A.; Starace, G. Advanced and Complex Energy Systems Monitoring and Control: A Review on Available Technologies and Their Application Criteria. Sensors 2022, 22, 4929. [Google Scholar] [CrossRef]

- Bayer, D.; Pruckner, M. A Digital Twin of a Local Energy System Based on Real Smart Meter Data. Energy Inform. 2023, 6, 8. [Google Scholar] [CrossRef]

- Meyer, L.; Jorstad, K.L.; Mortensen, L.K.; Santos, A.Q.; Handrup, K.; Shaker, H.R. Digital Twin of Radio-Mesh Smart Meter Communication for Outage Management Using a Multi-Agent System. In Proceedings of the 2022 IEEE 10th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 10–12 August 2022; pp. 119–124. [Google Scholar]

- Lopez-Lorente, J.; Xydas, C.M.; Makrides, G.; Georghiou, G.E. Evaluating Voltage Estimation in a Nanogrid Using Digital Twin Models and Real-Time Smart Meter Data. In Proceedings of the 2022 International Conference on Smart Energy Systems and Technologies (SEST), Eindhoven, The Netherlands, 5–7 September 2022; pp. 1–6. [Google Scholar]

- Piras, G.; Agostinelli, S.; Muzi, F. Smart Buildings and Digital Twin to Monitoring the Efficiency and Wellness of Working Environments: A Case Study on IoT Integration and Data-Driven Management. Appl. Sci. 2025, 15, 4939. [Google Scholar] [CrossRef]

- Starace, G.; Tiwari, A.; Colangelo, G.; Massaro, A. Advanced Data Systems for Energy Consumption Optimization and Air Quality Control in Smart Public Buildings Using a Versatile Open Source Approach. Electronics 2022, 11, 3904. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward Smart-Building Digital Twins: BIM and IoT Data Integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Abdullahi, I.; Longo, S.; Samie, M. Towards a Distributed Digital Twin Framework for Predictive Maintenance in Industrial Internet of Things (IIoT). Sensors 2024, 24, 2663. [Google Scholar] [CrossRef]

- Kherbache, M.; Maimour, M.; Rondeau, E. Network Digital Twin for the Industrial Internet of Things. In Proceedings of the 2022 IEEE 23rd International Symposium on a World of Wireless, Mobile and Multimedia Networks (WoWMoM), Belfast, UK, 14–17 June 2022; pp. 573–578. [Google Scholar]

- Santos, J.F.D.; Tshoombe, B.K.; Santos, L.H.B.; Araujo, R.C.F.; Manito, A.R.A.; Fonseca, W.S.; Silva, M.O. Digital Twin-Based Monitoring System of Induction Motors Using IoT Sensors and Thermo-Magnetic Finite Element Analysis. IEEE Access 2023, 11, 1682–1693. [Google Scholar] [CrossRef]

- Caiza, G.; Sanz, R. Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Appl. Sci. 2023, 13, 7503. [Google Scholar] [CrossRef]

- Wang, K.-J.; Lee, Y.-H.; Angelica, S. Digital Twin Design for Real-Time Monitoring—A Case Study of Die Cutting Machine. Int. J. Prod. Res. 2021, 59, 6471–6485. [Google Scholar] [CrossRef]

- Ranpariya, A.; Sharma, S. A Digital Twin Solution for Fault Detection in Time-Critical IIoT Applications. J. Simul. 2025, 19, 441–454. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, Z.; Shen, L.; Kong, X.T.R.; Guo, D.; Zhong, R.Y.; Huang, G.Q. Just Trolley: Implementation of Industrial IoT and Digital Twin-Enabled Spatial-Temporal Traceability and Visibility for Finished Goods Logistics. Adv. Eng. Inform. 2022, 52, 101571. [Google Scholar] [CrossRef]

- Guo, D.; Zhong, R.Y.; Rong, Y.; Huang, G.G.Q. Synchronization of Shop-Floor Logistics and Manufacturing under IIoT and Digital Twin-Enabled Graduation Intelligent Manufacturing System. IEEE Trans. Cybern. 2023, 53, 2005–2016. [Google Scholar] [CrossRef]

- Hu, P.; He, C.; Zhu, Y.; Li, T. The Product Quality Inspection Scheme Based on Software-Defined Edge Intelligent Controller in Industrial Internet of Things. J. Cloud Comput. Adv. Syst. Appl. 2023, 12, 113. [Google Scholar] [CrossRef]

- Schrader, B.; Guerra-Zubiaga, D.; McMichael, G. Soft Sensor Digital Twin Implementation of a Pick-and-Place Operation. In Proceedings of the Volume 3: Advanced Manufacturing, New Orleans, LA, USA, 29 October–2 November 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Bolbotinović, Ž.; Milić, S.D.; Janda, Ž.; Vukmirović, D. Ai-Powered Digital Twin in the Industrial IoT. Int. J. Electr. Power Energy Syst. 2025, 167, 110656. [Google Scholar] [CrossRef]

- Wang, K.; Wang, X.; Tan, C.; Dong, S.; Zhao, F.; Lian, S. Digital Twin-Enhanced Robotic System for Remote Diesel Engine Assembly Defect Inspection. Ind. Rob. 2025, 52, 266–276. [Google Scholar] [CrossRef]

- Rodriguez-Aguilar, R.; Marmolejo-Saucedo, J.-A.; Köse, U. Development of a Digital Twin Driven by a Deep Learning Model for Fault Diagnosis of Electro-Hydrostatic Actuators. Mathematics 2024, 12, 3124. [Google Scholar] [CrossRef]

- Sheraz, M.; Chuah, T.C.; Lee, Y.L.; Alam, M.M.; Al-Habashna, A.; Han, Z. A Comprehensive Survey on Revolutionizing Connectivity through Artificial Intelligence-Enabled Digital Twin Network in 6G. IEEE Access 2024, 12, 49184–49215. [Google Scholar] [CrossRef]

- Alcaraz, C.; Lopez, J. Protecting Digital Twin Networks for 6G-Enabled Industry 5.0 Ecosystems. IEEE Netw. 2023, 37, 302–308. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Lisboa, Y.M.; Barbosa, E.F.; Santos, L.H.; Manito, A.R.; Silva, M.O.; Fonseca, W.S. Motor Monitoring and Analysis System (SMAM) as a Resource for Predictive Maintenance in Industrial Environments through Digital Twin and IIoT. In Induction Motors—Latest Research and Applications [Working Title]; El-Shahat, A., Ed.; IntechOpen: London, UK, 2024. [Google Scholar]

- Tang, Y.M.; Kuo, W.T.; Lee, C.K.M. Real-Time Mixed Reality (MR) and Artificial Intelligence (AI) Object Recognition Integration for Digital Twin in Industry 4.0. Internet Things 2023, 23, 100753. [Google Scholar] [CrossRef]

- Min, Z.; Zhou, S.; Kang, Z.; Shekhar, S.; Mahmoudi, C.; Gokhale, S.; Gokhale, A. Managing and Optimizing 5G & beyond Network Resources for Multi-Task Digital Twin Applications in Industry 4.0. In Proceedings of the 2023 IEEE 26th International Symposium on Real-Time Distributed Computing (ISORC), Nashville, TN, USA, 23–25 May 2023; pp. 220–223. [Google Scholar]

- Arbabian, A.; Pezeshk, A.; Yang, K. Productivity Enhancement in Semiconductor Manufacturing with Ai-Enabled Operations Digital Twin Platform. In Proceedings of the 2024 19th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 22–25 October 2024; pp. 280–283. [Google Scholar]

- Massaro, A. Intelligent Materials and Nanomaterials Improving Physical Properties and Control Oriented on Electronic Implementations. Electronics 2023, 12, 3772. [Google Scholar] [CrossRef]

- Corradini, F.; Silvestri, M. Design and Testing of a Digital Twin for Monitoring and Quality Assessment of Material Extrusion Process. Addit. Manuf. 2022, 51, 102633. [Google Scholar] [CrossRef]

- Lugaresi, G.; Matta, A. Automated Digital Twin Generation of Manufacturing Systems with Complex Material Flows: Graph Model Completion. Comput. Ind. 2023, 151, 103977. [Google Scholar] [CrossRef]

- Turan, E.; Konuşkan, Y.; Yıldırım, N.; Tunçalp, D.; İnan, M.; Yasin, O.; Turan, B.; Kerimoğlu, V. Digital Twin Modelling for Optimizing the Material Consumption: A Case Study on Sustainability Improvement of Thermoforming Process. Sustain. Comput. Inform. Syst. 2022, 35, 100655. [Google Scholar] [CrossRef]

- Modoni, G.E.; Stampone, B.; Trotta, G. Application of the Digital Twin for in Process Monitoring of the Micro Injection Moulding Process Quality. Comput. Ind. 2022, 135, 103568. [Google Scholar] [CrossRef]

- Psarommatis, F. A Generic Methodology and a Digital Twin for Zero Defect Manufacturing (ZDM) Performance Mapping towards Design for ZDM. J. Manuf. Syst. 2021, 59, 507–521. [Google Scholar] [CrossRef]

- Henson, C.M.; Decker, N.I.; Huang, Q. A Digital Twin Strategy for Major Failure Detection in Fused Deposition Modeling Processes. Procedia Manuf. 2021, 53, 359–367. [Google Scholar] [CrossRef]

- Rachmawati, S.M.; Putra, M.A.P.; Lee, J.M.; Kim, D.S. Digital Twin-Enabled 3D Printer Fault Detection for Smart Additive Manufacturing. Eng. Appl. Artif. Intell. 2023, 124, 106430. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Tan, C.; Su, J.; Ng, N.P.H.; Chew, Y.; Liu, K.; Moon, S.K. Multisensor Fusion-Based Digital Twin for Localized Quality Prediction in Robotic Laser-Directed Energy Deposition. Robot. Comput. Integr. Manuf. 2023, 84, 102581. [Google Scholar] [CrossRef]

- Kim, W.; Lee, G.; Son, H.; Choi, H.; Youn, B.D. Estimation of Fatigue Crack Initiation and Growth in Engineering Product Development Using a Digital Twin Approach. Reliab. Eng. Syst. Saf. 2022, 226, 108721. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Bi, Z. Digital Twins to Predict Crack Propagation of Sustainable Engineering Materials under Different Loads. Machines 2024, 12, 125. [Google Scholar] [CrossRef]

- Fang, X.; Liu, G.; Wang, H.; Tian, X. A Digital Twin Modeling Method Based on Multi-Source Crack Growth Prediction Data Fusion. Eng. Fail. Anal. 2023, 154, 107645. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.-M. Crack Size Identification for Bearings Using an Adaptive Digital Twin. Sensors 2021, 21, 5009. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Wang, H.; Li, W.; Liu, G.; Cai, B. Fatigue Crack Growth Prediction Method for Offshore Platform Based on Digital Twin. Ocean Eng. 2022, 244, 110320. [Google Scholar] [CrossRef]

- Qiu, A.; Aakyiir, M.; Wang, R.; Yang, Z.; Umer, A.; Lee, I.; Hsu, H.-Y.; Ma, J. Stretchable and Calibratable Graphene Sensors for Accurate Strain Measurement. Mater. Adv. 2020, 1, 235–243. [Google Scholar] [CrossRef]

- Song, C.; Lee, H.; Park, C.; Lee, B.; Kim, J.; Park, C.; Lai, C.H.; Cho, S.J. Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures. Polymers 2025, 17, 941. [Google Scholar] [CrossRef] [PubMed]

- Al-Hawawreh, M.; Hossain, M.S. Digital Twin-Driven Secured Edge-Private Cloud Industrial Internet of Things (IIoT) Framework. J. Netw. Comput. Appl. 2024, 226, 103888. [Google Scholar] [CrossRef]

- Alcaraz, C.; Lopez, J. Digital Twin: A Comprehensive Survey of Security Threats. IEEE Commun. Surv. Tutor. 2022, 24, 1475–1503. [Google Scholar] [CrossRef]

- Melis, A.; Piroddi, A.; Kaya, O.; Girau, R. An IIoT Digital Twin Architecture for Anomaly Traffic Analysis of HWIL Devices Using Neural Network. In Proceedings of the 2024 IEEE 29th International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Athens, Greece, 21–23 October 2024; pp. 1–6. [Google Scholar]

- Soudan, B. Cybersecurity of Digital Twins in Industrial IoT Environments. In Proceedings of the 2024 Advances in Science and Engineering Technology International Conferences (ASET), Abu Dhabi, United Arab Emirates, 3–5 June 2024; pp. 1–6. [Google Scholar]

- Ahmed, M.A.; Alnatheer, S. Intrusion Detection in a Digital Twin-Enabled Secure Industrial Internet of Things Environment for Industrial Sustainability. Eng. Technol. Appl. Sci. Res. 2025, 15, 21263–21269. [Google Scholar] [CrossRef]

- Balta, E.C.; Pease, M.; Moyne, J.; Barton, K.; Tilbury, D.M. Digital Twin-Based Cyber-Attack Detection Framework for Cyber-Physical Manufacturing Systems. IEEE Trans. Autom. Sci. Eng. 2024, 21, 1695–1712. [Google Scholar] [CrossRef]

- Massaro, A.; Gargaro, M.; Dipierro, G.; Galiano, A.M.; Buonopane, S. Prototype Cross Platform Oriented on Cybersecurity, Virtual Connectivity, Big Data and Artificial Intelligence Control. IEEE Access 2020, 8, 197939–197954. [Google Scholar] [CrossRef]

- Harrison, L. Cybersecurity Threat Modeling and Mitigation Using the Digital Twin. ATZ Electron Worldw 2022, 17, 40–43. [Google Scholar] [CrossRef]

- Dietz, M.; Schlette, D.; Pernul, G. Harnessing Digital Twin Security Simulations for Systematic Cyber Threat Intelligence. In Proceedings of the 2022 IEEE 46th Annual Computers, Software, and Applications Conference (COMPSAC), Los Alamitos, CA, USA, 27 June–1 July 2022; pp. 789–797. [Google Scholar]

- Vasilica, B.-V.; Anton, F.-D.; Pietraru, R.; Anton, S.-O.; Chiriac, B.-N. Enhancing Security in Smart Robot Digital Twins Through Intrusion Detection Systems. Appl. Sci. 2025, 15, 4596. [Google Scholar] [CrossRef]

- Atal, D.K.; Tiwari, V.; Kumar, D. Recent Advances in Cybersecurity in Smart Manufacturing Systems in the Industry. In Handbook of Smart Manufacturing; CRC Press: Boca Raton, FL, USA, 2023; pp. 41–62. ISBN 9781003333760. [Google Scholar]

- Jeffrey, N.; Tan, Q.; Villar, J.R. A Review of Anomaly Detection Strategies to Detect Threats to Cyber-Physical Systems. Electronics 2023, 12, 3283. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Z.; Zheqiu, H. PLC-MDT: A Framework for Detecting Anomalies with Digital Twins of Industrial Control Systems. IEEE Sens. J. 2025, 25, 17739–17749. [Google Scholar] [CrossRef]

- Francia, G., III; El-Sheikh, E. Open Platform Infrastructure for Industrial Control Systems Security. In Lecture Notes in Networks and Systems; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 233–243. ISBN 9783031569494. [Google Scholar]

- Filipescu, A.; Simion, G.; Ionescu, D.; Filipescu, A. IoT-Cloud, VPN, and Digital Twin-Based Remote Monitoring and Control of a Multifunctional Robotic Cell in the Context of AI, Industry, and Education 4.0 and 5.0. Sensors 2024, 24, 7451. [Google Scholar] [CrossRef]

- Simion, G.; Filipescu, A.; Ionescu, D.; Filipescu, A. Cloud/VPN-Based Remote Control of a Modular Production System Assisted by a Mobile Cyber–Physical Robotic System—Digital Twin Approach. Sensors 2025, 25, 591. [Google Scholar] [CrossRef]

- Prathiba, S.B.; Govindarajan, Y.; Pranav Amirtha Ganesan, V.; Ramachandran, A.; Selvaraj, A.K.; Kashif Bashir, A.; Reddy Gadekallu, T. Fortifying Federated Learning in IIoT: Leveraging Blockchain and Digital Twin Innovations for Enhanced Security and Resilience. IEEE Access 2024, 12, 68968–68980. [Google Scholar] [CrossRef]

- Onwubiko, A.; Singh, R.; Awan, S.; Pervez, Z.; Ramzan, N. Enabling Trust and Security in Digital Twin Management: A Blockchain-Based Approach with Ethereum and IPFS. Sensors 2023, 23, 6641. [Google Scholar] [CrossRef] [PubMed]

- Hosseini Bamakan, S.M.; Banaeian Far, S. Distributed and Trustworthy Digital Twin Platform Based on Blockchain and Web3 Technologies. Cyber Secur. Appl. 2025, 3, 100064. [Google Scholar] [CrossRef]

- Homaei, M.; Mogollón-Gutiérrez, Ó.; Sancho, J.C.; Ávila, M.; Caro, A. A Review of Digital Twins and Their Application in Cybersecurity Based on Artificial Intelligence. Artif. Intell. Rev. 2024, 57, 201. [Google Scholar] [CrossRef]

- Liu, J.; Yeoh, W.; Qu, Y.; Gao, L. Blockchain-Based Digital Twin for Supply Chain Management: State-of-the-Art Review and Future Research Directions. arXiv 2022, arXiv:2202.03966. [Google Scholar] [CrossRef]

- Liu, J.; Yeoh, W.; Gao, S.; Qu, Y.; Gao, L. Blockchain-Based Digital Twin for Supply Chain Management: A Survey. In Digital Twins for Smart Cities and Villages; Elsevier: Amsterdam, The Netherlands, 2025; pp. 581–600. ISBN 9780443288845. [Google Scholar]

- Awotunde, J.B.; Adeniyi, A.E.; Falola, P.B.; Adeniran, T.C. A Blockchain-Enabled Framework to Enhance Cybersecurity Challenges in Smart Agriculture. In Blockchain and Digital Twin Applications in Smart Agriculture; Auerbach Publications: New York, NY, USA, 2025; pp. 69–91. ISBN 9781003507390. [Google Scholar]

- Hayashi, V.T.; Vicente Ruggiero, W. Hardware Trojan Detection in Open-Source Hardware Designs Using Machine Learning. IEEE Access 2025, 13, 37771–37788. [Google Scholar] [CrossRef]

- Monjur, M.M.R.; Heacock, J.; Calzadillas, J.; Mahmud, M.D.S.; Roth, J.; Mankodiya, K.; Sazonov, E.; Yu, Q. Hardware Security in Sensor and Its Networks. Front. Sens. 2022, 3, 850056. [Google Scholar] [CrossRef]

- Monjur, M.R.; Sunkavilli, S.; Yu, Q. ADobf: Obfuscated Detection Method against Analog Trojans on I2C Master-Slave Interface. In Proceedings of the 2020 IEEE 63rd International Midwest Symposium on Circuits and Systems (MWSCAS), Springfield, IL, USA, 9–12 August 2020; pp. 1064–1067. [Google Scholar]

- Monjur, M.; Calzadillas, J.; Yu, Q. Hardware Security Risks and Threat Analyses in Advanced Manufacturing Industry. ACM Trans. Des. Automat. Electron. Syst. 2023, 28, 1–22. [Google Scholar] [CrossRef]

- Massaro, A.; Epicoco, N.; Loseto, G.; Ardito, C.A. AI-Based Detection and Simulation of Hardware Trojan Attacks in Industrial Applications. IEEE Access 2025, 13, 50967–50979. [Google Scholar] [CrossRef]

- Massaro, A.; Epicoco, N.; Loseto, G.; Ardito, C. IIOT Cyberattacks in Industrial Field Control Systems: PID Attack and Hardware Trojan Effects. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28 August–1 September 2024; pp. 1702–1707. [Google Scholar]

- Zhao, F.; Wu, Y.; Hu, M.; Chang, C.-W.; Liu, R.; Qiu, R.; Yang, X. Current Progress of Digital Twin Construction Using Medical Imaging. arXiv 2024, arXiv:2411.08173. [Google Scholar] [CrossRef]

- Langton, C.M.; Grimm, A.; Lloyd, D.G.; Frossard, L.A. A 3D-Printed Phantom Twin and Multi-Transducer Holder for Dynamic Anatomical Ultrasonography of the Lower Limb. J. 3D Print. Med. 2023, 7, 3DP009. [Google Scholar] [CrossRef]

- Werner, H.; Tonni, G.; Lopes, J. 3D Physical and Virtual Models in Fetal Medicine: Applications and Procedures; Springer International Publishing: Cham, Switzerland, 2023; ISBN 9783031148545. [Google Scholar]

- Jost, E.; Kosian, P.; Jimenez Cruz, J.; Albarqouni, S.; Gembruch, U.; Strizek, B.; Recker, F. Evolving the Era of 5D Ultrasound? A Systematic Literature Review on the Applications for Artificial Intelligence Ultrasound Imaging in Obstetrics and Gynecology. J. Clin. Med. 2023, 12, 6833. [Google Scholar] [CrossRef] [PubMed]

- Manohar, S.; Sechopoulos, I.; Anastasio, M.A.; Maier-Hein, L.; Gupta, R. Super Phantoms: Advanced Models for Testing Medical Imaging Technologies. Commun. Eng. 2024, 3, 73. [Google Scholar] [CrossRef]

- Sermesant, M.; Delingette, H.; Cochet, H.; Jaïs, P.; Ayache, N. Applications of Artificial Intelligence in Cardiovascular Imaging. Nat. Rev. Cardiol. 2021, 18, 600–609. [Google Scholar] [CrossRef]

- Allenby, M.C.; Woodruff, M.A. Image Analyses for Engineering Advanced Tissue Biomanufacturing Processes. Biomaterials 2022, 284, 121514. [Google Scholar] [CrossRef]

- Martinez-Ruedas, C.; Flores-Arias, J.-M.; Moreno-Garcia, I.M.; Linan-Reyes, M.; Bellido-Outeiriño, F.J. A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills. Technologies 2024, 12, 60. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Suman, R. Digital Twin Applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Lv, Z. Digital Twins in Industry 5.0. Research 2023, 6, 71. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big Data Driven Hierarchical Digital Twin Predictive Remanufacturing Paradigm: Architecture, Control Mechanism, Application Scenario and Benefits. J. Clean. Prod. 2020, 248, 119299. [Google Scholar] [CrossRef]

- Ruhe, S.; Schaefer, K.; Branz, S.; Nicolai, S.; Bretschneider, P.; Westermann, D. Design and Implementation of a Hierarchical Digital Twin for Power Systems Using Real-Time Simulation. Electronics 2023, 12, 2747. [Google Scholar] [CrossRef]

- Martinelli, M.; Zhang, J.; Splettstoßer, A.-K.; Picone, M.; Lippi, M.; Wortmann, A. Hierarchical Digital Twin Ecosystem for Industrial Manufacturing Scenarios. In Proceedings of the 2024 50th Euromicro Conference on Software Engineering and Advanced Applications (SEAA), Paris, France, 28–30 August 2024; pp. 56–63. [Google Scholar]

- Finke, C.; Groth, M.; Schumann, M.; Dewitz, P.; Gehrke, J.; Marahrens, T. Design and Implementation of Hierarchical Digital Twins in Industrial Production Environments. In Proceedings of the Hawaii International Conference on System Sciences, Maui, HI, USA, 3–6 January 2023; pp. 1448–1457. [Google Scholar] [CrossRef]

- Massaro, A.; Ricci, G.; Selicato, S.; Raminelli, S.; Galiano, A. Decisional Support System with Artificial Intelligence Oriented on Health Prediction Using a Wearable Device and Big Data. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Rome, Italy, 3–5 June 2020; pp. 718–723. [Google Scholar]

- Figueiras, P.; Lourenco, L.; Costa, R.; Graca, D.; Garcia, G.; Jardim-Goncalves, R. Big Data Provision for Digital Twins in Industry 4.0 Logistics Processes. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT), Virtual, 7–9 June 2021; pp. 516–521. [Google Scholar]

- Zhou, Q.; Li, J.; Zhang, C.; Xu, H. Digital Twin. In Big Data and Electric Mobility; CRC Press: Boca Raton, FL, USA, 2025; pp. 74–98. ISBN 9781003302827. [Google Scholar]

- Aublet, A.; N’Guyen, F.; Proudhon, H.; Ryckelynck, D. Multimodal Data Augmentation for Digital Twining Assisted by Artificial Intelligence in Mechanics of Materials. Front. Mater. 2022, 9, 971816. [Google Scholar] [CrossRef]

- Lyu, P.; Zhang, H.; Yu, W.; Liu, C. A Novel Model-Independent Data Augmentation Method for Fault Diagnosis in Smart Manufacturing. Procedia CIRP 2022, 107, 949–954. [Google Scholar] [CrossRef]

- Kies, A.D.; Krauß, J.; Schmetz, A.; Schmitt, R.H.; Brecher, C. Interaction of Digital Twins in a Sustainable Battery Cell Production. Procedia CIRP 2022, 107, 1216–1220. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital Twin for Sustainable Manufacturing Supply Chains: Current Trends, Future Perspectives, and an Implementation Framework. Technol. Forecast. Soc. Change 2022, 176, 121448. [Google Scholar] [CrossRef]

- Davila, R.M.F.; Schwark, F.; Dawel, L.; Pehlken, A. Sustainability Digital Twin: A Tool for the Manufacturing Industry. Procedia CIRP 2023, 116, 143–148. [Google Scholar] [CrossRef]

- Ma, S.; Ding, W.; Liu, Y.; Ren, S.; Yang, H. Digital Twin and Big Data-Driven Sustainable Smart Manufacturing Based on Information Management Systems for Energy-Intensive Industries. Appl. Energy 2022, 326, 119986. [Google Scholar] [CrossRef]

- Franciosi, C.; Miranda, S.; Veneroso, C.R.; Riemma, S. Improving Industrial Sustainability by the Use of Digital Twin Models in Maintenance and Production Activities. IFAC-Pap. 2022, 55, 37–42. [Google Scholar] [CrossRef]

- Massaro, A. Process Mining in Production Management, Intelligent Control, and Advanced KPI for Dynamic Process Optimization: Industry 5.0 Production Processes. In IGI Global, Perspectives and Considerations on the Evolution of Smart Systems; IGI: Hershey, PA, USA, 2023; Chapter 1; pp. 1–17. [Google Scholar]

- Fakhar Manesh, M.; Pellegrini, M.M.; Marzi, G.; Dabic, M. Knowledge Management in the Fourth Industrial Revolution: Mapping the Literature and Scoping Future Avenues. IEEE Trans. Eng. Manage. 2021, 68, 289–300. [Google Scholar] [CrossRef]

- van Eck, N.; Waltman, L.; van den Berg, J.; Kaymak, U. Visualizing the Computational Intelligence Field [Application Notes]. IEEE Comput. Intell. Mag. 2006, 1, 6–10. [Google Scholar] [CrossRef]

- Dong, C.; Shafiq, M.; Dabel, M.M.A.; Sun, Y.; Tian, Z. DNN Inference Acceleration for Smart Devices in Industry 5.0 by Decentralized Deep Reinforcement Learning. IEEE Trans. Consum. Electron. 2024, 70, 1519–1530. [Google Scholar] [CrossRef]

- Sharma, M.; Tomar, A.; Hazra, A. Edge Computing for Industry 5.0: Fundamental, Applications, and Research Challenges. IEEE Internet Things J. 2024, 11, 19070–19093. [Google Scholar] [CrossRef]

- Zhang, Y.; He, G.; Ma, L.; Liu, X.; Hjorth, J.J.J.; Kozlov, A.; He, Y.; Zhang, S.; Kotaleski, J.H.; Tian, Y.; et al. A GPU-Based Computational Framework That Bridges Neuron Simulation and Artificial Intelligence. Nat. Commun. 2023, 14, 5798. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.; Liu, S.; Xiong, X.; Cai, Z.; Tu, G. A Survey of Recent Advances in Edge-Computing-Powered Artificial Intelligence of Things. IEEE Internet Things J. 2021, 8, 13849–13875. [Google Scholar] [CrossRef]

- Seetohul, V.; Jahankhani, H.; Kendzierskyj, S.; Will Arachchige, I.S. Quantum Reinforcement Learning: Advancing AI Agents through Quantum Computing. In Space Law and Policy; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 55–73. ISBN 9783031640445. [Google Scholar]

- Schmidt, B.; Hildebrandt, A. From GPUs to AI and Quantum: Three Waves of Acceleration in Bioinformatics. Drug Discov. Today 2024, 29, 103990. [Google Scholar] [CrossRef] [PubMed]

- Stavropoulos, P.; Papacharalampopoulos, A.; Christopoulos, D. Use of Artificial Intelligence at the Level of Manufacturing Processes. In Lecture Notes in Mechanical Engineering; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 157–166. ISBN 9783031574955. [Google Scholar]

- Massaro, A. Electronic Digital Twin in Industry 5.0: AI-based electronic Industry 5.0 models. In AI-Driven Smart Industrial Technologies; IGI Global: Hershey, PA, USA, 2025; Chapter 5; pp. 87–126. [Google Scholar] [CrossRef]

- Taj, I.; Jhanjhi, N.Z. Towards Industrial Revolution 5.0 and Explainable Artificial Intelligence: Challenges and Opportunities. Int. J. Comput. Digit. Syst. 2022, 12, 285–310. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Foteinopoulos, P.; Stavropoulos, P. Integration of Industry 5.0 requirements in digital twin-supported manufacturing process selection: A framework. Procedia CIRP 2023, 119, 545–551. [Google Scholar] [CrossRef]

- Yin, X.; Liang, S.; Yu, J.; Zhou, F.; Liu, J. CNN-Based Digital Twin Model for Ultra-High Voltage Direct Current System Loss Measurement. IEEE Access 2024, 12, 70480–70488. [Google Scholar] [CrossRef]

- Chen, G.; Yin, H. Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks. Nonlinear Eng. 2025, 14, 20250095. [Google Scholar] [CrossRef]

- Tong, S.; Yang, X.; Tong, Z.; Jiang, Y. Digital Twin-Driven Intelligent Monitoring of a Marine Gearbox Based on CNN-LSTM Network. In Advances in Mechanical Design; Tan, J., Liu, Y., Huang, H.Z., Yu, J., Wang, Z., Eds.; ICMD 2023, Mechanisms and Machine Science; Springer: Singapore, 2024; Volume 155. [Google Scholar] [CrossRef]

| Keyword Matching (Research Pillar) | Main Description | Further Keywords Found in Projects and to Analyze in Literature |

|---|---|---|

| (1) Agile manufacturing and Industry 4.0 | Digital technologies for manufacturing 4.0 and advanced robotization | Wind tower manufacturing; plastic extrusions for the automotive industry; gas turbine compressors (energy sector); innovative range of encoders for the control of machinery for food production environments; electric vehicles; Automated Guided Vehicle (AGV) production; drone technologies; additive manufacturing; advanced automation technologies for the manufacture of transmission components (automotive sector); microelectronics one-chip sensor systems; robotization of aeronautical painting processes; Virtual Reality (VR) and robot simulation for collaborative robot’s production activities; physical product manufacturing with digital and virtual manufacturing Cyber–Physical System (CPS); prototypes in precision production. |

| (2) Industry 5.0 | Active production control by mechatronics matching Artificial Intelligence | Opto- and mechatronic systems necessary to control technological processes; materials engineering; new materials and technologies; Internet of Things (IoT) and intelligent devices; design and synthesis of Radio Frequency (RF) and microwave components; design and development of System on Chip (SoC)-integrated circuits; AI robotics. |

| (3) Advanced healthcare | Digital healthcare services and studies | Healthy food; 3D/4D ultrasound imaging; Digital Twins for personalized healthcare by means AI; clinical decision aid system for surveillance of infections; construction of DT modeling the state of health of a territory regarding pollen and mold allergens; data processing and health sensor advanced technology. |

| (4) Smart energy | Modern energy systems | Energy performance of a building; building and testing prototypes of charging stations compatible with commercially available electro-mobile devices; AI for collaborative robotic production systems improving energy consumption; real-time integration of electric consumption in automatic learning systems using smart meters; smart water heating boiler management using AI; smart city; smart factory. |

| (5) Inspection and monitoring | Production and defect inspection | Industrial Internet of Things (IIoT)-based system development for monitoring and controlling production progress; inspection of correct connection of electric connectors on motors using collaborative robotics and artificial vision techniques; development of specific sensors towards zero defects; inspection and monitoring of complex industrial systems. |

| (6) Cybersecurity | Industrial network security | Industry 4.0 cyber security; intelligent gateway architectures improving cybersecurity; IoT data security; non-intrusive monitoring of performance in electrical systems. |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in this Review) |

|---|---|---|---|

| Wind turbine (renewable energy systems) | DT-based monitoring framework for wind turbines for reliability analysis | DT framework enabling real-time monitoring, fault diagnosis, and operation optimization of the wind turbines [2]; prevention of turbine failure and timely maintenance [3]; reliability assessment of wind turbine power modules (regarding wind turbulence on the electro-thermal behavior) [4]; mobile robot assistance wind turbine [5]; online real-time monitoring of Power Electronic Converters (PECs) [6]; methodology and guidelines for the wind turbine design [7]; blade design and optimization (virtual model) [8]. | The AI-EDT could be implemented for the whole life cycle of wind turbines starting with the design of optimized electrical and electronic components (mainly power components) and following the monitoring of the implemented systems for the optimization of the re-design and of the maintenance services (by means the simulation of real scenarios). |

| Advanced machinery and processes for manufacturing production | Advanced and flexible manufacturing systems | Intelligent design–manufacturing–maintenance of mechanical equipment [9]; efficient testing and optimization of production processes improving quality control and predictive maintenance [10]; wireless and wired DT embedded in ethernet industrial networks [11]; electronic cam servo motion control driven by DT [12]; product twin for flexible and collaborative manufacturing environment [13]; Green Performance Evaluation of Smart Manufacturing (GPEoSM) [14]; models of sustainable intelligent manufacturing [15]; detection of a system’s actions in pneumatics (backflow) [16]; AI algorithms finding causes of the problem of metal residues between electronic circuits [17]; DT following the whole product life cycle [18]; DT driven by data of Internet of Things (IoT) sensors detecting defects [19]; random phase noise in WiFi Channel State Information (CSI) [20]; machine control, monitoring and synchronization between the physical and virtual models [21]; DT for Automated Guided Vehicles (AGVs) [22]; design, development, deployment, commissioning, and maintenance of robotics systems [23]; holistic overview of robotics [24]; rapid production line variant design [25]; improvement of the powertrain system of electric vehicles (EVs) [26]; approach based on pipe machining production line [27]; automotive production lines [28,29,30]; electrical cable intelligent production lines [31]; multisystem fault diagnosis [32]; DT improvement by heuristics and Reinforcement Learning (RL) [33]; reconfiguration of human–robot collaborative assembly lines [34]; 3D visualized human–machine interaction [35]; railway axle production line [36]; DT enabling apparel manufacturing plants [37]. | EDT could integrate different AI algorithms suitable to ensure good flexibility of manufacturing production. The AI-EDT could constitute the integration of different cyber–physical models of the whole production line supporting quality processes, predictive maintenance of machines, and production management, including the optimization of the organizational models. The goal is to achieve ‘zero-defects’ conditions, production optimization, and cost decrease (energy costs, raw materials costs, human resource costs as worker-hour indicator, time delays, etc.), thus ensuring the production switching also in the short period according to the market demand. The AI-EDTs are suitable for the matching of the skills of workers, thus improving the organizational models. |

| Sensor systems and electronics | Manufacturing of electronic components | Printed Circuit Board (PCB) manufacturing for full Surface Mount Technology (SMT) process lines [38]; electronic product behavior analysis [39]; power electronics-based energy conversion systems (PEECSs) [40]; IoT electric power systems [41]; encoder [42,43,44,45]; Programmable Logic Controller (PLC) systems and components [46,47]; DT for automotive MEMS pressure sensors [48]; optoelectronics in production lines [49]. | Different advanced electronic components (sensor, actuators, PLC) could provide digital information for the whole synchronization of all the production machines, taking into account the heterogeneous technologies and the different computational costs. The AI-EDTs are useful for optimizing the production synchronization. |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in this Review) |

|---|---|---|---|

| Optical components and networks | Optical sensing, actuation, and communication network based on AI | Artificial Neural Network (ANN) DT optimizing Whispering Gallery Mode (WGM) optical sensors [50]; optoelectronic sensors [51] and actuators using optical fiber [52]; AI-driven DT for optical network [53,54]; optical fiber communication systems [55]; forecasting of optical networks [56]; optical communication fault management [57]; re-configurable optical add and drop multiplexers (ROADMs) [58]. | AI supporting design and modeling of industrial optoelectronic sensor components finding new solution in nanotechnology materials (improving high sensitivity); AI-DT optimizing the traffic and robustness of calculator networks to avoid possible bottlenecks imitating communications. |

| Image vision-integrated tools and facilities | Imaging, laser, and ultrasound techniques | 3D and 4D volumetric Ultrasound Tomography (UST) [59]; integration of 4D imaging with 4D printing [60]; laser-induced ultrasound scanning PCB defects [61]; Laser Ultrasonic Testing (LUT) detecting inclusions and subsurface cracks [62]; ultrasound imaging using multi-parameter genetic algorithm for micro-defect detection [63]; vision inspection process [64]. | AI-supervised algorithms accelerating automatisms detecting real-time product defects for ‘zero-defect’ production and improving the in-line production (integration of AI for auto-corrective actions and for machine parameter setting). |

| Mechatronics and manufacturing processes | New Industry 5.0 environments and applications | Hybrid DT framework integrating AI and physics-based models [65]; Cyber Twins (CTs) integrating machine simulators [66]; deep learning-based DT for human–robot collaborative manufacturing systems [67]; mixed-reality and holographic industrial environments [68]; DT mechanism model of Computer Numerical Control Machine Tools (CNCMTs) [69]; fault diagnosis and predictive maintenance [70]; virtual twinning in mechatronic product development [71]; kinematic and dynamic models for mechanical systems [72]; trajectory controllers for electro-mechanical systems [73]; importing of the native PLC code via XML [74]; engineering approach of OPC-UA PLC systems [75]; DT-driven virtual commissioning method to simulate CNCMT [76]; Ultra Precision Machining (UPM) for high-end cutting-edge products [77]; integration of Industrial Internet of Things (IIoT) and smart manufacturing facilities [78]; Extended Kalman Filter (EKF) DT for motor drive [79]; automobile connecting rod production line model [80]; DT framework incorporating robots [81]; Self-Optimizing Control (SOC) framework controlling mechatronic systems [82]; AI predicting noises and anomalies in machine filters [83], operational amplifiers [84], and Proportional Integral Derivative (PID) controllers [85]; AI adjusting control machine parameters (process mining) [86]. | AI-DT selecting the best procedure and algorithms to improve the mechatronic commands and control systems according to the selected technology (PLC, robot, CNC machines, etc.). Furthermore, the EDT based on the integration of circuit models could classify and predict all the possible noises and interferences, solving machine problems and failures in real time. |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in This Review) |

|---|---|---|---|

| Healthcare market | Innovative products and services | Machine learning (ML) for predictive controller of medical microrobot [87]; DT improving healthcare services (personalized healthcare, intelligent rehabilitation, telemedicine, smart diet management, etc.) [88]; production of medicine, vaccine, antibacterial, on-demand molecule production, and on-demand tissues and organs [89]; 3D modeling and simulations of microwave sensors [90]; hardware matching with AI-based software correcting the noisy EEG electrode signals in real time [91]. | AI accelerating healthcare services (diagnostic and therapeutic assistance pathways) and optimizing precision medicine (dose of medicines) by means of electronics with therapeutic compliance. Innovative products in healthcare industries could be the 3D organoids reflecting the real behavior of the human body tissues (aspect useful for the surgical training of doctors or to understand the tissue degeneracy of cancer). |

| Wearable sensors | New solution of clothing sensors | DT created by biometric data from the patient gathered from wearables [92]; smartwatches, biosensors, and fitness trackers for chronic disease management [93]; biomechanical human body models and wearable inertial sensor models to analyze gait events dynamically [94]; multifunctional smart clothing system constructed with several sensors [95]. | EDT could potentially represent the ‘avatar’ of the patient monitored by smart and miniaturized wearable sensors. AI could improve the avatar real-time creation fusing and analyzing patient’s physiological data (temperature, heart rate, blood oxygen level, etc.) and including data processing of the patient’s health historical data of patients characterized by similar features (optimization of the training model). ‘Avatars’ could be processed by advanced technologies, such as GPU, big data, and edge and quantum computing. |

| Medical IOT | IoT connectivity of human body sensors | Multi-sensor data fusion combined with Support Vector Machine (SVM) algorithm [96]; IoT- and ML-based electrocardiogram (ECG) classifier model for cardiac diagnostics [97,98]. | AI-EDT addresses edge computing using IoT technologies. IoT is a fundamental technology for future telemedicine. |

| Medical imaging | Medical imaging tools integrated in AI-DT models | DT integrating MRI, CT, PET, and ultrasound imaging data [195]; 3D-Printed Phantom Twin for ultrasonography of the lower limb [196]; 3D physical and virtual models from ultrasound and magnetic resonance imaging [197]; AI ultrasound imaging in Obstetrics and Gynecology [198]; super phantoms replicating complex anatomic and functional imaging properties of tissues and organs [199]; AI and biophysical models for cardiovascular imaging [200]; human cell and tissue bio-manufacturing using image analysis [201]. | The deep learning EDT models could provide more accurate diagnostic and prognostic responses. In order to accelerate the AI image processing calculus, this could be applied innovative technologies such as quantum computers supporting the correct parametrization of the AI training models. |

| Rehabilitation systems | Electronic solutions | Adaptive DT models with Multi-Level Inverter (MLI) improving energy efficiency in rehabilitation systems [99]; electronic and mechanical DT for stroke rehabilitation [100]; robot-assisted telerehabilitation system [101]; AI predicting movements from EEG patterns [102]; virtual–real interaction system for an ankle rehabilitation robot (VRIS-ARR) [103]; wearable sensors monitoring rehabilitation [104]. | Fully connected AI-EDT integrating mechanical response analyses and remote control of rehabilitation (telerehabilitation services and production of new robotic systems). AI algorithms could automatize telerehabilitation planning in real time and the exercise to perform according to the AI classification and recognizing the correct and the wrong exercises (classification of exercise performed by the patients). |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in This Review) |

|---|---|---|---|

| Energy harvesting | Low-power energy-harvesting components | Thermoelectric human body systems and Seebeck circuit modeling [105,106,107]; piezoelectric energy harvesting (generation of electrical power by vibration) [108,109] and using LTSpice circuit modeling [110]; electromagnetic energy harvesting [111]; AI-assisted wearable hip joint energy harvester (HJEH) using an electromagnetic generator (EMG) integrated with a freestanding triboelectric nanogenerator (FS-TENG) [112]; triboelectric nanogenerators in Civil Engineering Infrastructure 4.0 [113]; triboelectric nanosensors [114]; solar photovoltaic DT [115]; real-time control of hybrid energy system using DT and IoT [116]; IoT driving energy systems [117]. | Implementations of fully integrated EDT for totally energy independent production lines, including low-power supplies and communication networks based on IoT wireless systems autoconfigured by AI algorithms. AI-EDTs are suitable for the optimization of electronic components following signal variations and signal discontinuities. |

| Components of renewable energy systems | Modeling and optimization of technologies enhancing the efficiency of renewable energy | DT for self-security of smart inverters [118]; fault localization in Low-Voltage (LV) Distribution Networks (DNs) [119]; AC/DC hybrid electric equipment [120]; fault data generation of lithium-ion batteries [121]; DT of energy components [122]; ML applied in smart grids, renewable energy, and for electric vehicle optimization [123]; modeling by graphs with nodes and edges of complex energy systems [124]; smart metering systems [125,126]. | AI-EDT could be interfaced to a capillary network and set of components to provide the energy balancing of complex smart grids by means of grid failure classifications and power predictions of different interconnected nodes. |

| Smart energy building | Technologies optimizing building energy | Smart building controlling energy and wellness [127,128,129,130]. | EDT using AI for energy efficiency and building security. Improvement of the energy routing through the electrical panel. |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in this Review) |

|---|---|---|---|

| IIOT inspections | IIOT focused on the inspection of machines | Distributed IIOT sensors for predictive maintenance [131,132]; monitoring of electric induction motors combining IIOT and Finite Element Method (FEM) simulations [133]; augmented reality interconnected to industrial cyber–physical environments [134]; control of cutting machines [135]; IIOT for monitoring fault detections [136] and for logistics [137,138]; quality product inspection by Software-Defined Edge Intelligent Controller (SD-EIC) [139]; control of robotic pick-and-place operation [140]; AI powering control systems (RNN, LSTM, and GRU models) [141]; robotic system for remote diesel defect inspection [142]; deep learning for inspection of electro-hydrostatic actuators [143]; AI and 6G network monitoring industrial scenarios [144,145]; Motor Monitoring and Analysis System (SMAM) implementing ESP32 microcontrollers and temperature, voltage, and current sensors [146]; Mixed Reality (MR) and AI supporting object recognition [147]; 5G network for multitask industrial applications [148]. | AI-EDT assigned to each machine of the whole supply chain predicting failures in real time and assigning a risk level to execute possible timely corrective actions. |

| Inspection of materials and of related processes | Material manufacturing and quality processes | AI supporting semiconductor [149] and intelligent materials manufacturing [150]; quality of extruded materials [151]; modeling of complex material flow [152]; material consumption in thermoforming process [153]; micro-injection in molding processes [154]; Zero-Defect Manufacturing (ZDM) and cost reduction [155]; failure of fused deposition process [156]; 3D additive manufacturing [157]; defects in Laser-Directed Energy Deposition (L-DED) [158]; crack initiation and propagation [159,160,161,162,163] and equivalent resistive circuits modeling the physical effects [164,165]. | AI-EDT optimizing the choice of the raw materials predicting defects and cracks (by means of equivalent circuits) also during the fabrication processes. Other possible EDT perspectives are also in the use of self-healing and self-repair materials, reducing the cost of waste for a sustainable production and the related delays. |

| Sub-Topics | Main Description | DT/EDT Function | Perspectives and Possible Upgrades of the Research (Proposed in This Review) |

|---|---|---|---|

| Secure industrial network | Cybersecurity of Industrial Control System (ICS) Network | AI-based framework detecting attacks and mitigating their impact for edge cloud systems applied to gas pipelines [166]; threat classification and guidelines to use DT [167]; DT and Hardware in the Loop (HITL) approach using neural networks to classify attacks [168]; priorities of security aspects in DT [169]; Binary Arithmetic Optimization Algorithm with Variational Recurrent Autoencoder-Based Intrusion Detection (BAOA-VRAID) approach detecting intrusions [170]; framework of cyber–physical manufacturing systems (CPMS) for cyber attack detection in closed-loop controllers [171]; Virtual Private Network (VPN) and AI–big data systems for secure multimedia networks [172]; cybersecurity threat modeling in ICS [173,174,175,176,177]; detection of anomalies in PLC systems [178,179]; secure industrial multi-level architectures [180]; VPN for secure industrial networks with robots [181]. | EDT automating the scanning port test by means of the AI classification of threats and attacks and virtually segmenting the ICs network based on the detected risk. Furthermore, the AI-EDT could provide different solution for a reconfiguration of the Information Technology (IT) and the Operational Technology (OT) network, ensuring continuous network security (configuration of each component of the Local Area Network (LAN), including firewall, router, bridge, servers, and switch). The AI-EDTs are also useful to design hybrid virtual networks combing Virtual LAN (VLAN) and VPN channels ensuring data encryption. Furthermore, AI-EDTs are suitable for a continuous update of the classification of threats. |

| Blockchain | Blockchain integrated in industrial information systems | Blockchain-based Non-Fungible Tokens (NFTs) preventing attacks by ensuring traceability and accountability among distributed nodes [182]; Ethereum blockchain DT modeling [183]; improvement of security by blockchain [184,185,186,187,188] and Web3 technologies [184]. | EDT encrypting sensor data to be included in blockchain information structures, certifying the production data and the firm knowledge. |

| Hardware attacks | Hardware Trojan (HT) attacks in ICS | HT modeling [189,190,191,192] and AI predicting hardware attacks [193,194]. | AI-EDT predicting and applying real-time corrective actions due to attacks (denoising, elimination of interferences or disturbs, parameter regulation of PID control system, etc.) for the circuits of a production line. |

| EDT Tool | Advantages | Disadvantages |

|---|---|---|