Abstract

This review analyzes the Electronic Digital Twin (EDT) tools characterizing the industrial transformation phase from Industry 4.0 to Industry 5.0. The goal is to provide innovative research EDT solutions to integrate in manufacturing production processes. Specifically, this research is focused on the possibility of combining the advanced technologies and electronics and mechatronics of industrial machines with Artificial Intelligence (AI) algorithms. Furthermore, this review provides important elements about possible future implementations of AI-EDTs and some circuital examples to support the understanding of the concept of circuit simulation in EDT models. EDTs are useful to comprehend the modeling concepts functional to the AI application using the output of the circuit simulations. The output of the circuit is used to train the AI model, thus strengthening the capability to classify and predict the real behavior of production machines with a good accuracy. This review discusses perspectives, limits, and advantages of EDTs and is useful to define new research patterns integrating structured EDTs in advanced industrial environments. The focus of this paper is the definition of possible perspectives of EDT implementations, including AI, in data-driven processes in specific strategic areas of industrial research by classifying the scientific topics in six main pillars. This paper is also suitable for the researcher to develop innovative topics for projects scaled into different work packages based on EDT facilities.

1. Introduction

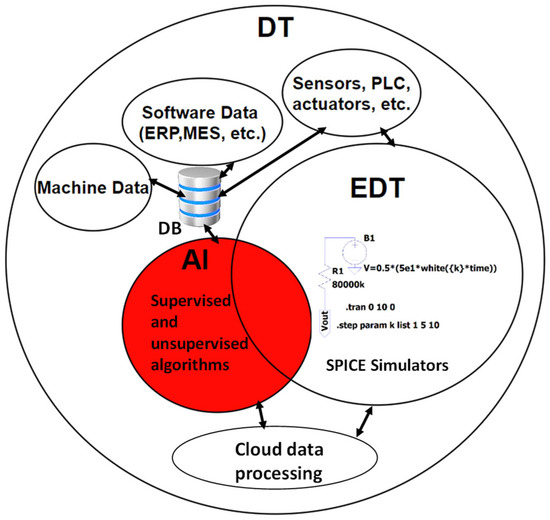

1.1. Research Methodology and DT Research Topics

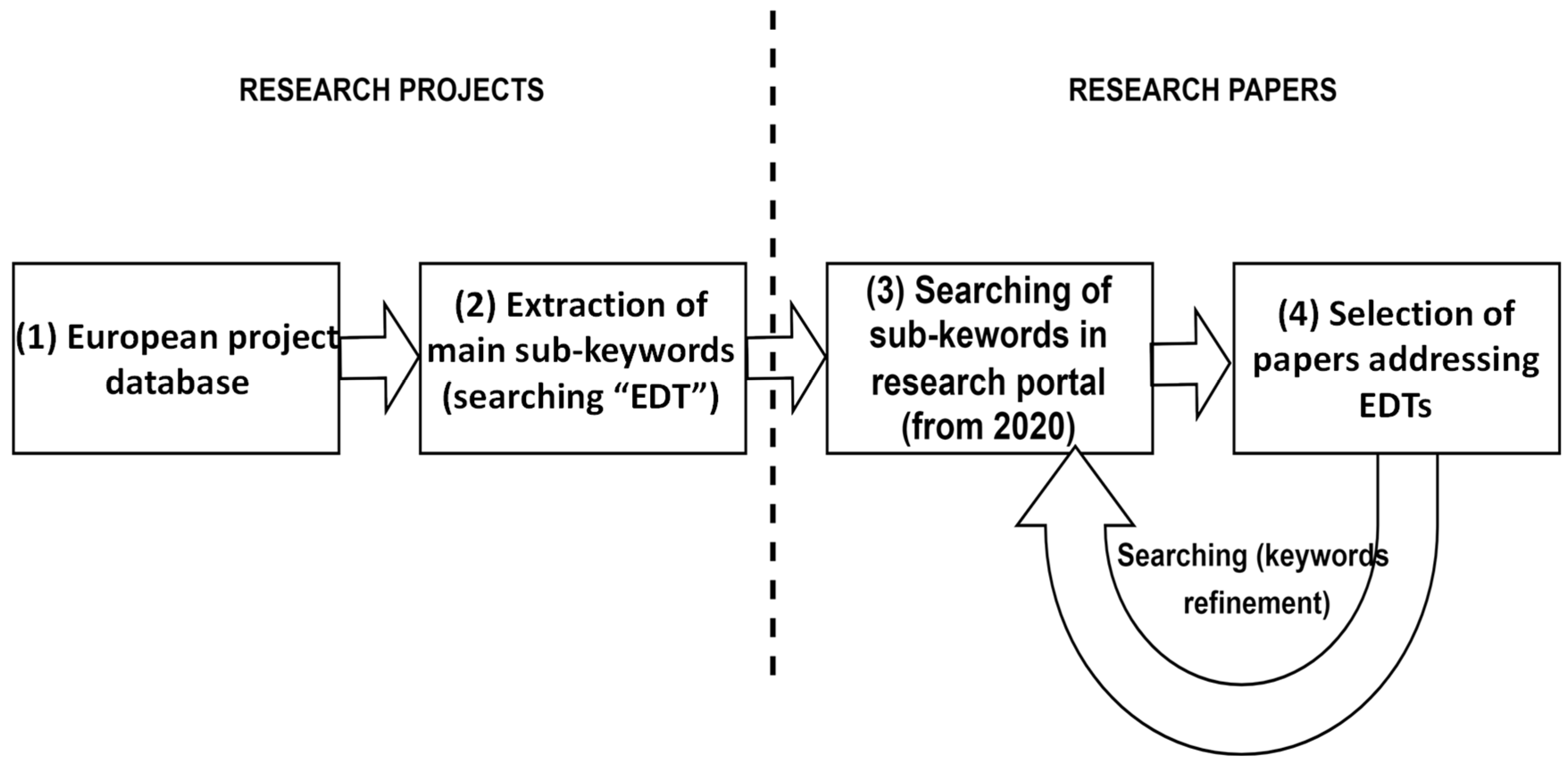

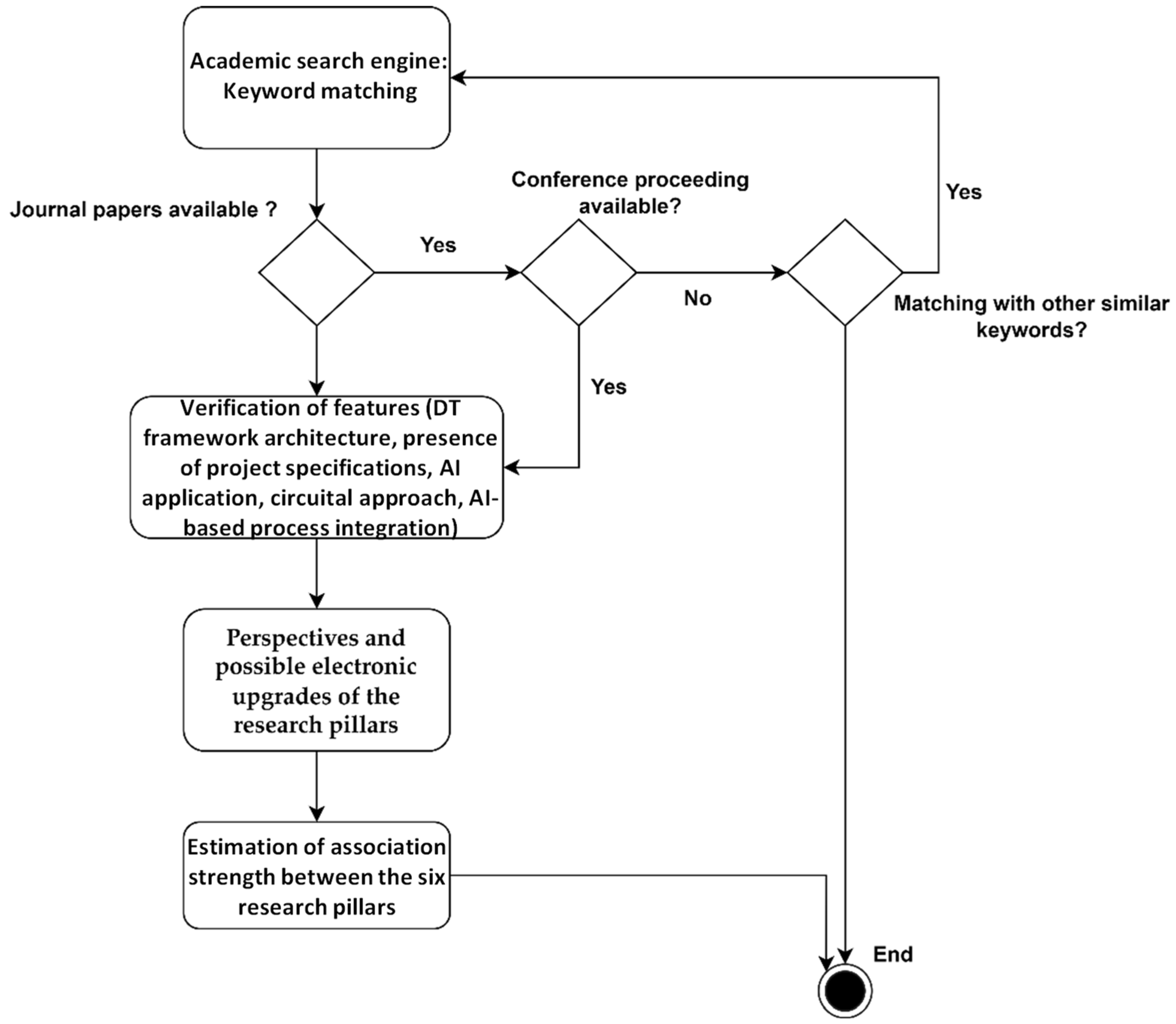

This review analyzes innovative and recent research topics about Electronic Digital Twin (EDT) models in advanced Industry 5.0 scenarios. The research methodology is indicated in Figure 1, separating two main phases: a first one finding keywords grouped into six main research ‘pillars’ about EDTs in European research projects [1] of the last three years and a second one focusing the attention on the sub-topics correlated with this project’s keywords. These sub-keywords are matched successively with research papers of the last five years. Search engines have been filtered for the last five years. This search yielded several papers. Papers from 2021 and 2022 were partially replaced due to their repetitive nature with more recent articles or because they were updated with new papers offering added values. This review describes the recent research advances in Digital Twins (DTs), explaining the possible EDT implementations and possible perspectives, starting with the analysis of the projects, which suggest different research pillars to be analyzed more accurately. DTs refer to digital physical–cyber models in general, including digital technology, while EDTs refer to electronic circuit models. Industry 5.0 facilities integrate both DT and EDT models.

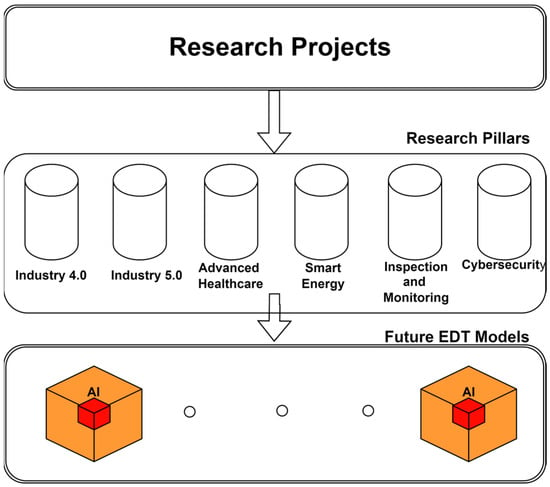

Figure 1.

Block scheme of the applied methodology selecting research papers about EDT.

In Table 1 the topics and the keywords of the first phase are listed. More details of the second phase are discussed in Section 2, Section 3, Section 4, Section 5, Section 6 and Section 7, matching the recent research with AI-EDT perspectives.

Table 1.

EDT and topics (six main pillars) found in European project portal (Koeshio portal [1]) for the last five years.

The choice of European projects as a reference for this research is due to the fact that within the ‘Next Generation EU’, the program promoted by the European Union to promote the recovery of Member States after the COVID-19 pandemic, research topics have been planned and defined to use resources until 2026. This programming is based on a pre-evaluation of research, so the funded projects constitute good feedback on the validation of research activities. This criterion can also be applied for other international programs about research. Limitations are mainly due to an analysis of projects performed for only the European area. Instead, the search for works is global. This could also be an element of the methodological exploration to see how a European project is related to scientific research in general. According to the summary in Table 1, it is evident that the projects consider the technology evolution from Industry 4.0 to Industry 5.0 facilities in manufacturing, including the healthcare sector for specific applications about social–health aspects (food, infection, territorial health). Particular attention in the industrial research is focused on alternative energy smart systems, DT virtual manufacturing, and robotics integrating Artificial Intelligence (AI) algorithms. Finally, research in advanced industrial networks is focused on inspection systems of production and defects and on cybersecurity including data security and control systems.

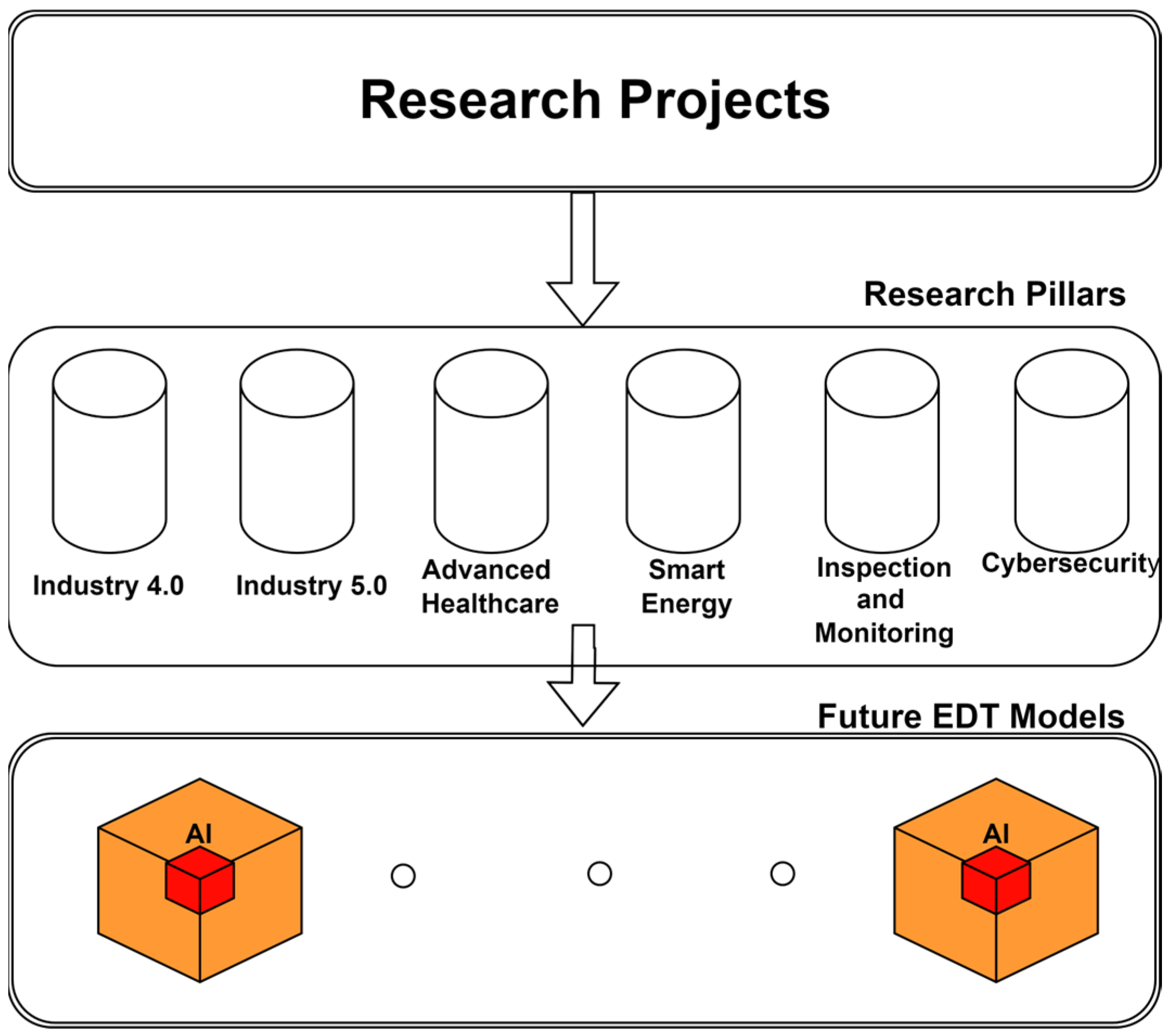

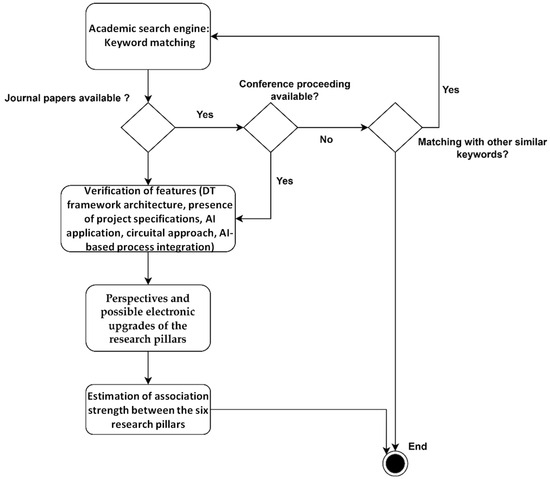

Figure 2 schematically illustrates the goal of this paper by proposing possible EDT perspectives matched with the research pillars. The sequence from one to six (pillars mentioned in Table 1) follows the logic of searching and matching project keywords with search terms: many projects start with Industry 4.0 objectives (pillar 1), upgrade to Industry 5.0 (pillar 2), and then move on to expanding sectors (healthcare related to pillar 3 and energy related to pillar 4) and specific applications such as inspection systems (pillar 5) and cybersecurity (pillar 6). The sequential order is also partly proportional to the number of similar projects found for that specific topic.

Figure 2.

Schematic goal of the review.

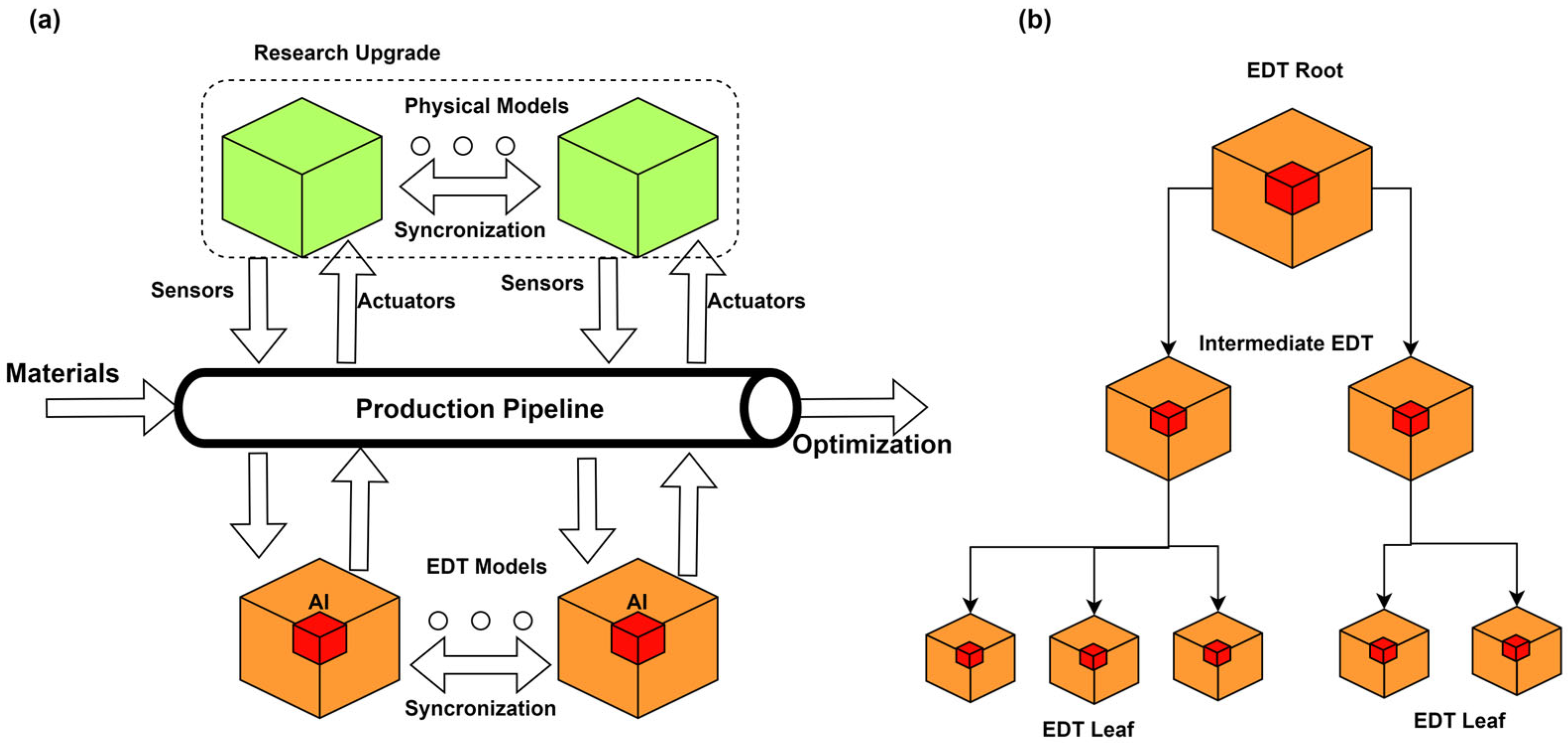

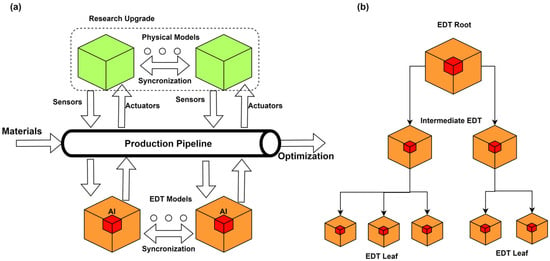

The possible implementations of EDTs are sketched in Figure 3a, where the production pipeline is loaded by raw materials to process and is coupled with physical components (sensor and actuators, machines, and hardware components) and with AI-EDTs improving the production and processes (output of the pipeline). Both the AI-EDT and the physical facilities are synchronized to obtain a full interconnected network, ensuring continuous and efficient production. Each AI-EDT could model and simulate a specific part of a production plant. All the AI-EDT models could be structured as a hierarchical model (see Figure 3b) where the root controls and synchronizes all the intermediate and leaf (basic circuits or basic electro-mechanical systems) AI-EDTs.

Figure 3.

(a) Production pipeline matching AI-EDT with physical models. (b) Hierarchical model of AI-EDT.

The next sections discuss the research sub-topics correlated to the project’s keywords and is useful to articulate new research projects. Journals and, subsequently, conference proceedings are considered a priority for the paper selection, especially the papers integrating AI. The gap in the literature regarding the identified research topics is mainly about perspectives and possible electronic upgrades of the research, thus suggesting the addition of this information in each discussed research pillar in Section 2, Section 3, Section 4, Section 5, Section 6 and Section 7 (last columns of the tables of each section). Furthermore, this review provides some circuital examples supporting the reader in understanding the EDT concept based on the circuit simulation. The circuit simulation and the AI data processing of the output signals of the circuits are performed by using open-source tools based on graphical user interfaces. In this review, the circuit models are implemented by means of the LTSpice tool, besides the example of the AI prediction is performed by the Konstanz Information Miner (KNIME) tool. More details about the implementation of AI processing circuit data are discussed in Section 8.

Below is a summary of what will be discussed in this review, including the output of the methodology in Figure 1.

The sub-topics found in the literature are representative of DT models for industrial scenarios. Referring to production systems, DT models are addressed based on reliability analyses, the design, the monitoring, the maintenance of electrical and electronic components for renewable energy systems [1,2,3,4,5,6,7,8], the Industry 4.0 facilities [9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37], and, in general, on the sensing and actuation [38,39,40,41,42,43,44,45,46,47,48,49]. Ever-increasing research is being produced on optoelectronic solutions, as they are very fast and safe from the point of view of signal interference: optoelectronics is suggested in communication networks and in machinery [50,51,52,53,54,55,56,57,58] to increase production efficiency in advanced production scenarios. The production efficiency and the increase in quality are achieved by advanced image vision [59,60,61,62,63,64] and virtual models matching with mechatronic systems [65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86]. DTs are fundamental for the healthcare sector in continuous industrial evolution regarding medical products and services [87,88,89,90,91], wearable technologies [92,93,94,95], IoT systems [96,97,98], image processing, and mechatronics useful for rehabilitation [99,100,101,102,103,104]. Essential to all DT applications are the energy-harvesting modeling sources [105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126]. Energetic aspects are studied mainly in smart systems, such as smart buildings [127,128,129,130]. A particular focus of the research on DT implementation is on machinery inspection and monitoring [131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148], material manufacturing [149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165], and cybersecurity [166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194]. All the sub-topics grouped into six research pillars are deeply discussed in the next sections.

With the analysis of the actual literature, the added value of this review is the preposition of perspectives and possible upgrades of the DT, focusing our attention on EDTs and on the role of AI.

1.2. Research Questions

The research questions are related to the identification of DT models matching with industrial projects and with recent academic studies focusing the attention of new technologies. The main goal is to find, starting with the discussed technologies grouped into ‘research pillars’, possible AI solutions based on circuit models and constituting the specific class of EDTs. Circuit simulations providing data for AI data processing could be an important requirement in advanced DT industrial applications. In this direction, the work describes some examples suggesting the methodology to apply and facilitating the comprehension of mechanisms matching circuit models with AI data processing and highlighting advantages, disadvantages, procedures for the integration of the EDT technologies in industrial processes, perspectives, and limitations.

2. First Research Pillar: Agile Manufacturing and Industry 4.0

The first pillar focuses on identifying the phases of the hardware component life cycle (monitoring, maintenance, fault detection) not only in production but also in the operational phase. The literature discusses specific components matching industrial projects in DT and EDT manufacturing and concerning agile approaches.

Specifically, this pillar is related to the upgrade of the actual Industry 4.0 scenario, adopting DTs and EDTs for turbine technology (the topic is correlated with energy systems and suggests new frontiers for industries working on wind energy), for flexible advanced manufacturing facilities, and for sensor systems. DTs modeling wind turbines are useful for the reliability analysis, design, monitoring, and maintenance [1,2,3,4,5,6,7,8]. Precisely, EDTs could be applied for the improvement of the whole life cycle of wind turbines and for a continuous re-design of the mechanical, electrical, and electronic components. Advanced Industry 4.0 environments are characterized by advanced DT technologies [9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37], ensuring flexible production management and efficient predictive maintenance. In this direction, AI-based EDTs could provide a ‘zero-defect’ condition, optimizing sustainable production and machines, generating a production capable of quickly switching the typology of products in relation to needs and market demands (change in the short-term products and services). Production is always optimized by sensor systems. The production of new sensors, actuators, and electronic components [38,39,40,41,42,43,44,45,46,47,48,49] is very important for the industrial upgrade, where AI-EDTs could play an important role in system integration, including heterogeneous technologies, and at the same time efficiently synchronizing the interconnected machines of the whole supply chain. Furthermore, the introduction of AI-EDTs requires a change in the organizational model to decrease the human resource cost expressed by the worker-hour indicator. In this direction, the AI algorithms could support the re-planning of the new organizational models and the change in management control. Table 2 lists more details about the first research pillar of the EDT in Industry 4.0 and AI implications.

Table 2.

First research pillar: EDT for agile manufacturing implemented in Industry 4.0 environment.

3. Second Research Pillar: Industry 5.0

The second pillar focuses on identifying hardware components and support tools for an upgrade of the manufacturing industry, in line with what is developed in projects aimed at mechatronics and DT implementations. Specifically, this pillar is associated with the innovative technologies indicating the digital transformation of the industry from the Industry 4.0 to Industry 5.0 framework.

New advances are found in the literature relating to optoelectronics, mechatronics, and image vision techniques. All the technologies are assisted in the Industry 5.0 environment by AI algorithms, representing the main difference if compared with the traditional Industry 4.0 framework. AI integrated in Industry 4.0 systems constitutes the upgrade of the industry for an Industry 5.0 framework, where machine learning algorithms are able to improve image processing, to execute AI-driven processes, and to improve the quality of production. More details about AI integration protocols are discussed in Section 8.3.

Optoelectronics is implemented in communication networks and for machinery components [50,51,52,53,54,55,56,57,58]. Image vision techniques are applied to control production and defects [59,60,61,62,63,64], implementing 3D and 4D image analysis techniques, and a DT is widely applied for the matching of mechatronics and virtual models of the manufacturing production processes [65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86]. Possible evolutions of the EDT in Industry 5.0 are related the design of new materials for high-sensitivity sensors (as for nanotechnology-based sensors), the real-time solving of bottlenecks of production processes, and the continuous setting and adjustment of machine control parameters to achieve ‘zero-defect’ production by ensuring quick production and minimizing the risk of machine failure. Due to the increase of the industrial Knowledge Base (KB), powerful communication networks could be adopted integrating big data, edge computing, Graphical Processing Unit (GPU) boards, and quantum computers, which would strengthen the AI-EDT models and, in particular, the training models.

Table 3 summarizes the main topics of the second pillar found in the scientific literature.

Table 3.

Second pillar: EDT in Industry 5.0 scenarios.

4. Third Research Pillar: Advanced Healthcare and Industry

The third pillar aims to define healthcare research topics related to DTs and EDTs in line with contemporary industry products and services and with project advances. This pillar is correlated with innovative medical products and services [87,88,89,90,91] and the EDT models related to wearable sensor technology [92,93,94,95], the IoT [96,97,98], image processing [195,196,197,198,199,200,201], and mechatronics for rehabilitation [99,100,101,102,103,104]. Possible perspectives for EDTs are related to the introduction of new health products and telemedicine care services and the construction of advanced patient ‘avatar’ models or 3D organoids optimizing the care patterns, the exams to execute, and the rehabilitation processes. Actually, AI is adopted for the construction of patient models, and future perspectives are addressed to improve the AI-based avatar model by means of real-time data fusion, merging different information about patients characterized by similar features. For organoid and avatar models, advanced technologies, such as edge calculus engines, GPUs, big data systems, and quantum computers, could be used.

Table 4 lists different research topics related to advanced healthcare systems.

Table 4.

Third research pillar: EDT in healthcare industry and in research.

5. Fourth Research Pillar: Smart Energy

The fourth research pillar combines the topics on energy system designs with the research themes associated with the related DTs and EDTs. Specifically, the smart energy systems are the fourth research pillar discussed in the literature. Some important topics are the EDT energy harvesting of thermoelectric, piezoelectric, triboelectric, and electromagnetic generators [105,106,107,108,109,110,111,112,113,114,115,116,117], AI-EDT and hardware components of renewable energy sources [118,119,120,121,122,123,124,125,126], and EDTs applied to smart buildings [127,128,129,130]. Possible advances of EDTs are related to fully integrated and interconnected energy self-powered systems of complex smart grids and the modeling of energy efficiency and secure buildings. Concerning energy-harvesting devices, AI algorithms could provide more information about energy conversion efficiency, including electronic optimization matching with the behavior of the energy sources (optimizing signal variations, signal discontinuities, etc.). The AI control and optimization mainly concern the increase in the energy conversion rate due to the optimization of the collected energy and the correct filtering of the high-energy signal components.

In regard to real-time decision-making in smart grids, AI could support energy balancing by means of failure classifications and power load predictions.

Another implementation of AI decision-making is in smart building systems, where AI is able to predict the power load and, consecutively, to optimize energy routing through the electrical panel.

Table 5 records different research topics related to the pillar of smart energy.

Table 5.

Fourth research pillar: EDT and smart energy systems.

6. Fifth Research Pillar: Inspection and Monitoring

The fifth research pillar focuses on the design theme of industrial inspection processes by identifying some DT and EDT solutions to assist in production efficiency. Specifically, this pillar is related the EDT and the DT mainly for the inspection of production machines [131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148] and simulating the processing of materials to be used in manufacturing processes [149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165]. The goal for future AI-based EDTs is to apply the model to the whole supply chain, selecting operative procedures according to a risk map defining the priorities of the interventions to execute. Other new frontiers of EDTs are the applications for intelligent materials capable of self-healing and self-repair actions and constituting stable materials to be applied as robust products due to the possibility to control and correct the material defects in each production phase and to avoid production interruptions. Examples of AI-EDTs improving the self-healing of innovative materials are mainly in the control (by changing the input electromagnetic source power intensity or the signal profile) and the localization (source orientation and source collimation) of external stimuli, enabling self-reconfiguration or self-repairing processes [150]. The exponential advancement of hardware and software technology with the advent of AI will increasingly push researchers to find new solutions in basic sciences, such as physics, chemistry, and mathematics. In this direction, the research of smart or self-healing materials could represent a new frontier for the search for new solutions capable of monitoring the state of innovative materials and restoring them with specific control signals. Smart materials could therefore replace current materials used in manufacturing by exploiting their capabilities and properties.

Table 6 indicates the main research topics of the fifth pillar, which are mainly classified in IIOT inspection systems and in the inspection of materials and of related processes.

Table 6.

Fifth research pillar: EDT concerning inspection and monitoring.

7. Sixth Research Pillar: Cybersecurity

The sixth pillar focuses on DT and EDT solutions to improve industrial network security. Specifically, this pillar is related to cybersecurity, data security [166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188], and hardware attacks [189,190,191,192,193,194]. Possible innovative solutions in cybersecurity are the application of AI algorithms for attack classification and the use of blockchain technologies for improving the data security level. The future AI-EDT models will take into account the real-time physical and virtual network segmentations, new techniques of sensor data encryption for blockchains, and the real-time controlling and correcting of the cyber attacks in each level of the industrial network. Table 7 summarizes the main topics of the sixth research pillar classified as network security, blockchain solutions, and hardware security.

Table 7.

Sixth research pillar: EDT improving cybersecurity.

8. Discussion

8.1. Circuit Modeling and AI Data Processing Integration

As a complete example of circuit application and data analysis with AI, a basic example ‘transversal’ for all the pillars mentioned is proposed. This example concerns the modeling of the most common noise, namely white noise. The example discussed can therefore be integrated with more complex models related to the topics discussed in this paper.

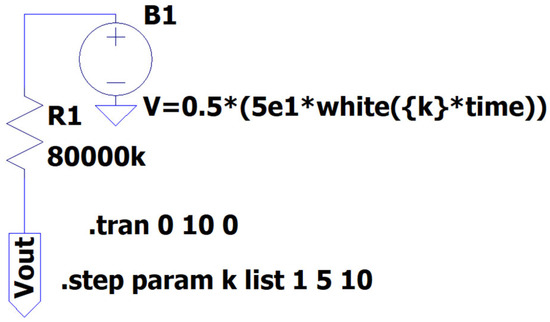

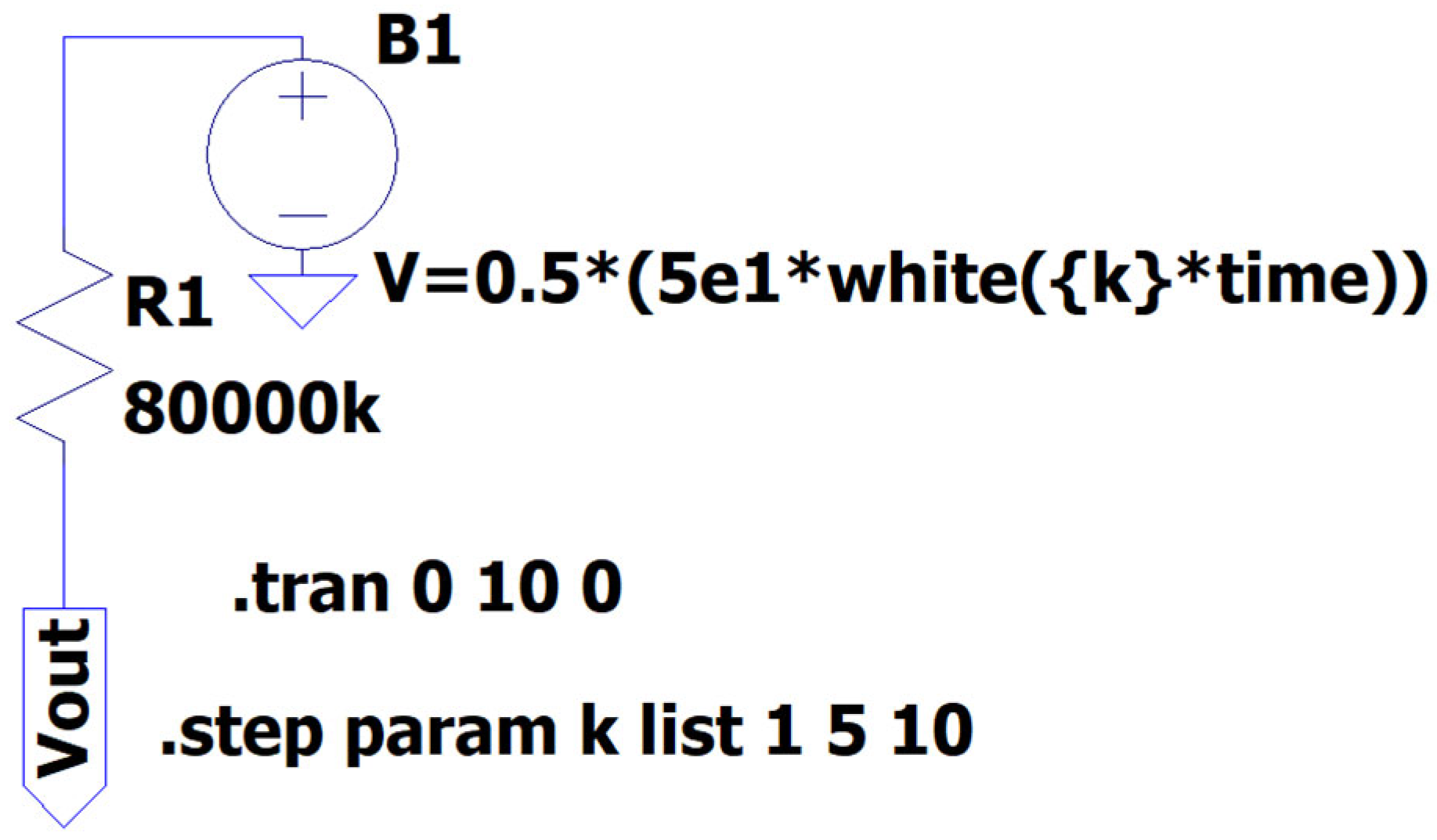

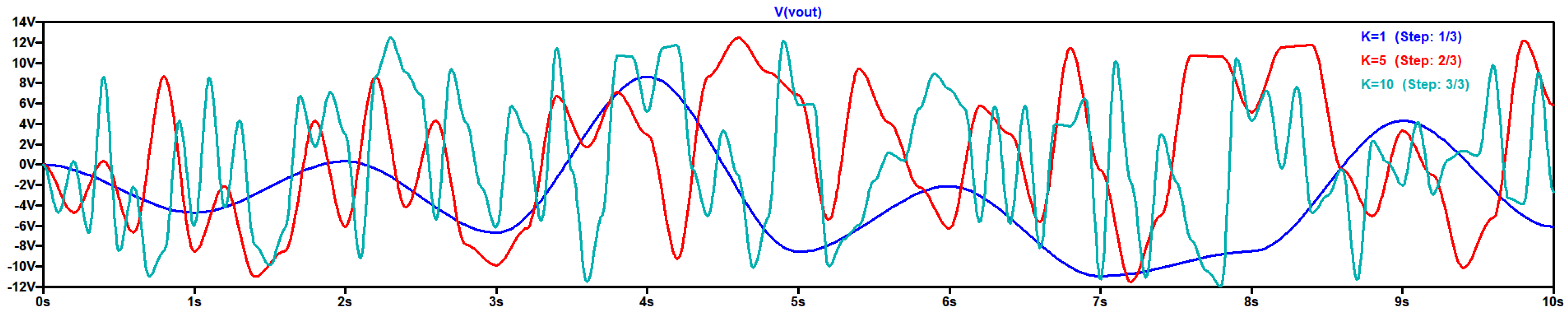

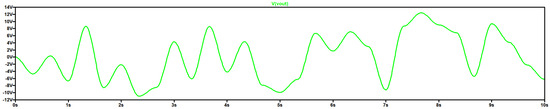

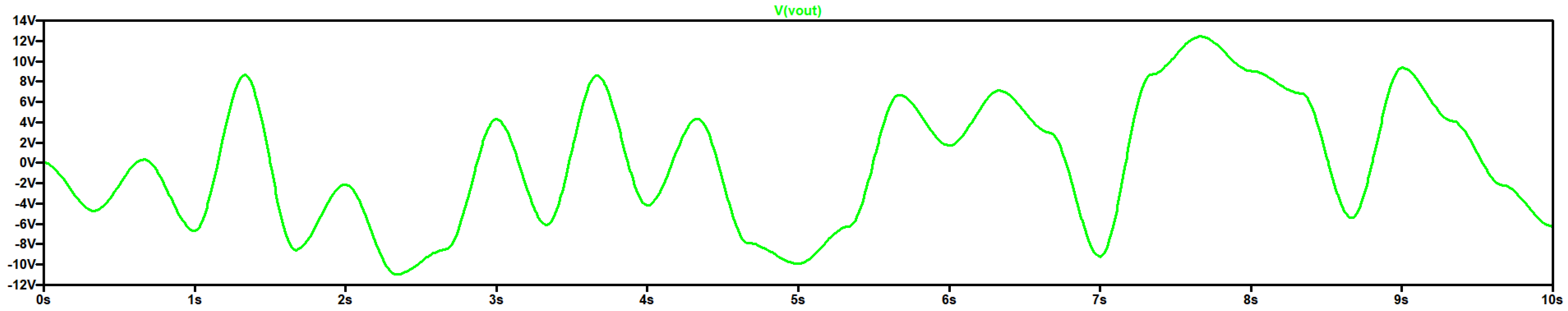

The circuit modeling and simulations represent the first data processing stage of the EDT matching the real industrial environment with machine technologies. The second stage of the EDT data processing considers AI data processing, where the digital output of the circuit (electrical variables such as currents, voltages, and powers estimated by Kirchhoff’s circuit laws) is the input of the AI engine. A typical basic EDT example in industrial electronics is the integration of source generators modeling noises [47,49,91] and, consecutively, the simulation of the real behavior of electronic components characterized by the signal over the noise (S/N) signals. The example illustrated in this section considers a complete application the AI-EDT, taking into account a basic element of the circuit model and the white noise typically characterizing the interferences in machine environments: Figure 4 represents the modeling of a white noise generator (B1) connected to a resistor R1 with the function of modulating the signal noise amplitude at the output of the generator. The circuit of Figure 4 can be implemented in different LTSpice EDT circuits influenced by white noise, by coupling the generators in the precise sections where the disturbances are located. The parametric analysis performs different simulations of the voltage output signal, varying the ripple frequency of the noise. Figure 5 illustrates the parametric analysis of the circuit of Figure 4, varying the frequency parameter k (k = 1, 5, and 10): as expected a higher frequency is observed for k=10, preserving the random behavior of the Vout signal (more ripples are observed).

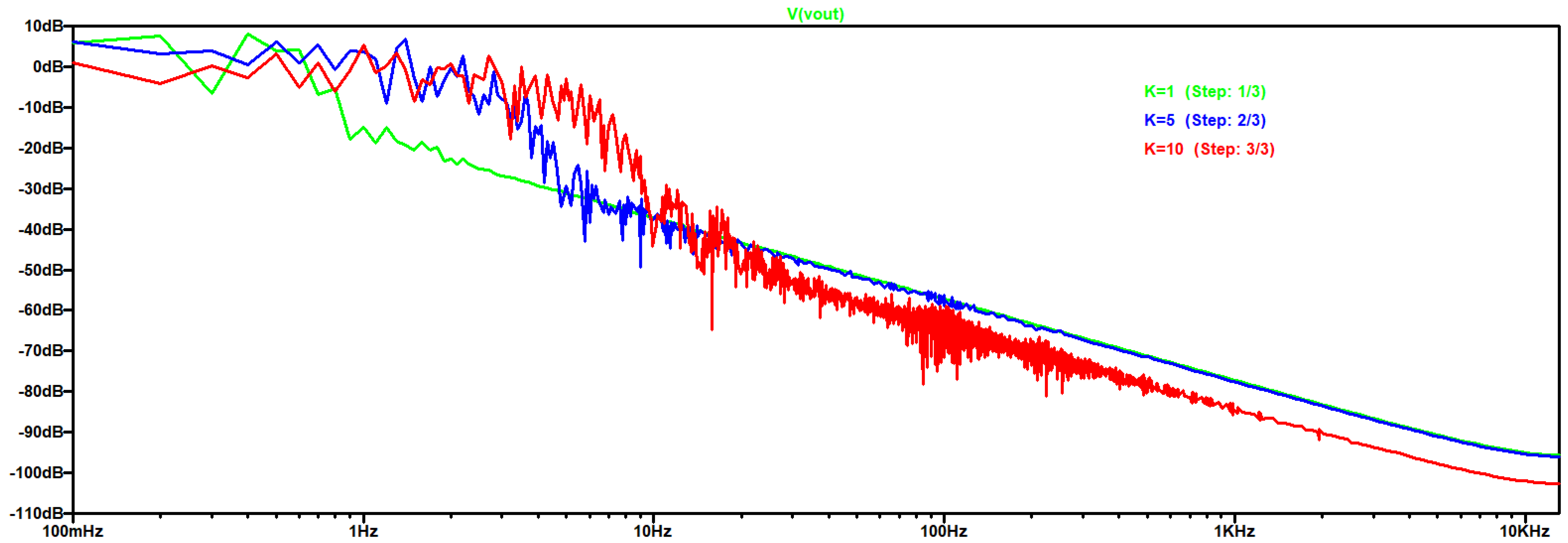

The parametric analysis can be analyzed in the time domain and in the frequency domain by means of the Fast Fourier Transform (FFT). Figure 6 shows the frequency parametric analysis applying the FFT to the signals of Figure 5. Also, for the frequency behavior more ripples are observed for the case of k = 10.

Figure 4.

Example of circuit model of white noise source generator. The parameter k varies the ripple frequency of the noise signal generated by voltage generator source B1. The R1 resistance of 80 MΩ is properly selected to visualize the output signal in a range between −12 Volts and 12 Volts.

Figure 4.

Example of circuit model of white noise source generator. The parameter k varies the ripple frequency of the noise signal generated by voltage generator source B1. The R1 resistance of 80 MΩ is properly selected to visualize the output signal in a range between −12 Volts and 12 Volts.

Figure 5.

LTSpice parametric analysis: time domain results of the voltage output signal Vout, varying the k parameter of the circuit of Figure 7. More ripples are observed for k = 10.

Figure 5.

LTSpice parametric analysis: time domain results of the voltage output signal Vout, varying the k parameter of the circuit of Figure 7. More ripples are observed for k = 10.

Figure 6.

LTSpice parametric simulation FFT: frequency behavior of the circuit of Figure 4. More ripples are also observed in the frequency band for the case of k = 10.

Figure 6.

LTSpice parametric simulation FFT: frequency behavior of the circuit of Figure 4. More ripples are also observed in the frequency band for the case of k = 10.

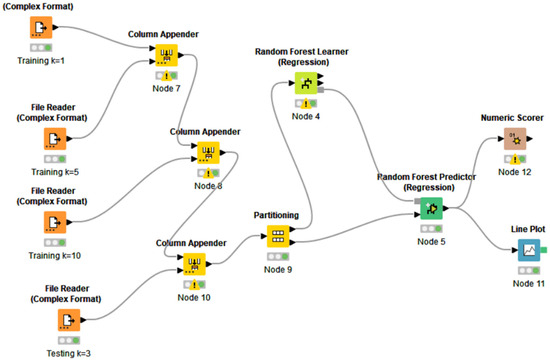

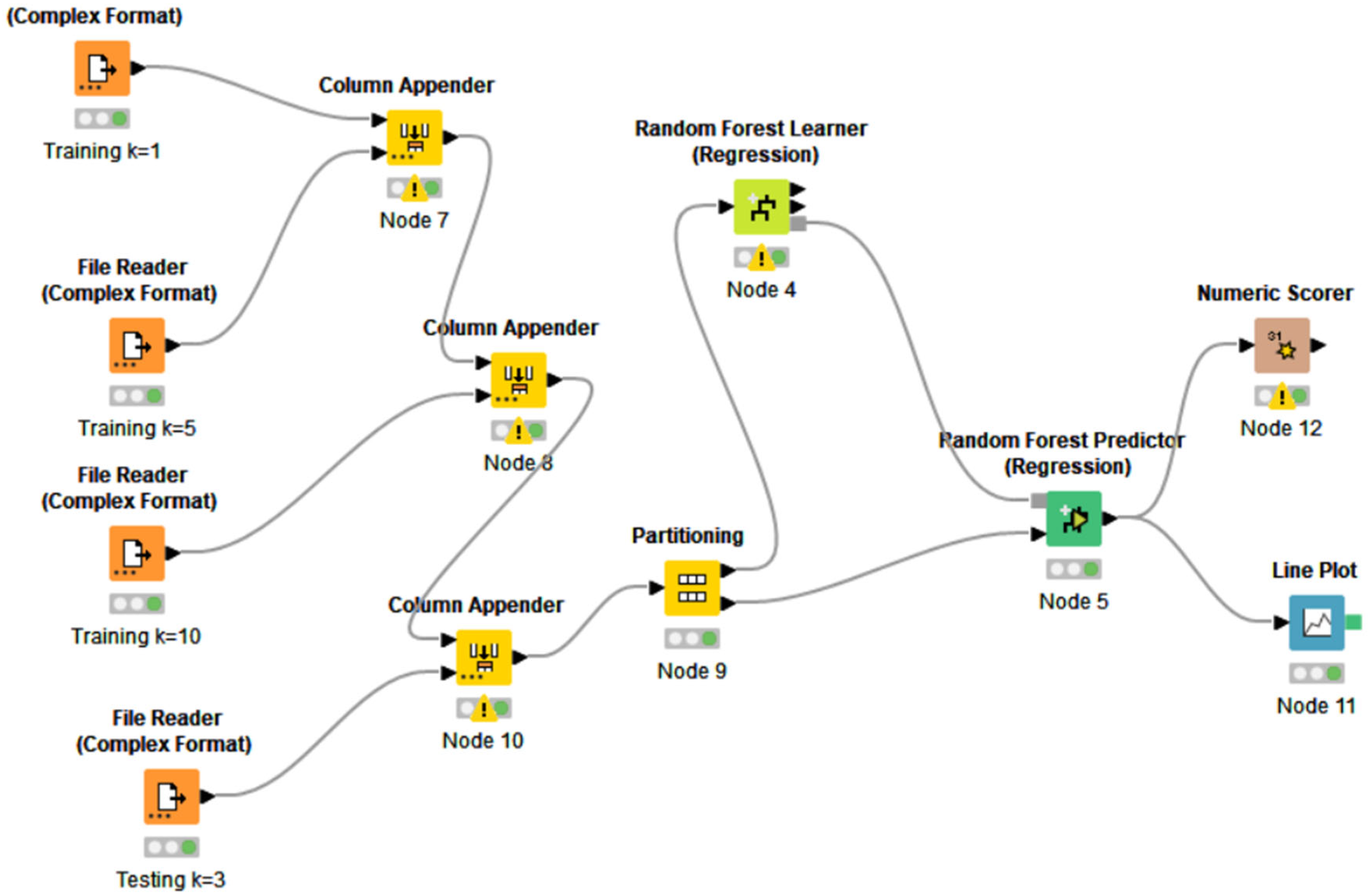

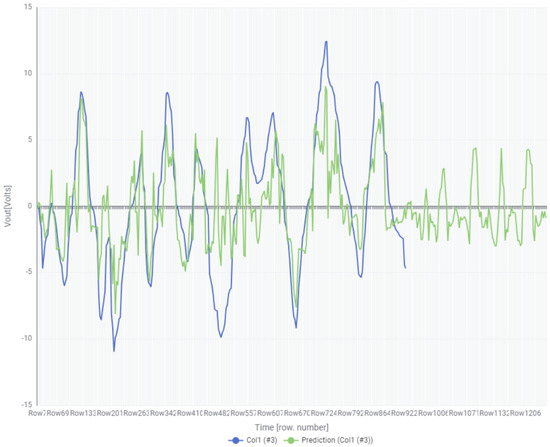

In order to show how the AI algorithm can be applied for executing the digital data of the circuit (Vout voltage signals), a further signal is added to the signals of Figure 5 to predict the target voltage. The target signal indicates the ‘labelled’ signal to predict. For the proposed case the target signal is obtained, fixing the parameter value of k = 3 and providing the time domain trend of Figure 7. The AI prediction can be performed by implementing a workflow capable of processing the output data of the circuit of Figure 4. As an example of the AI implementation, the KNIME workflow of Figure 8 implements the supervised Random Forest (RF) algorithm applied to the output results of the circuit of Figure 4. Figure 9 estimates the predicted voltage (prediction of the target signal) as having a trend similar to the target signal, thus proving the good performance of the RF algorithm. This similarity is due to the self-learning of the algorithm. The RF performance of the proposed example is estimated by the following metrics, referring to a normalized dataset: Mean Absolute Error (MAE) = 0.135, Mean Squared Error (MSE) = 0.03, Root Mean Squared Error (RMSE) = 0.174, and Mean Signed Difference = 0.013.

Figure 7.

LTSpice output of Figure 4: target signal obtained with k = 3.

Figure 7.

LTSpice output of Figure 4: target signal obtained with k = 3.

Figure 8.

KNIME workflow providing the results of Figure 9.

Figure 8.

KNIME workflow providing the results of Figure 9.

Other examples of circuit simulations are discussed in Appendix A.

Figure 9.

RF output results: comparison between the target signal (Col1(#3)) and the predicted one (Prediction (Col1(#3))). The analyzed dataset is composed of 15,520 samples; the training and the testing dataset are 70% and 30% of the analyzed dataset, respectively; and the hyper-parameters are tree depth = 10, minimum node size = 5, and number of models = 100.

Figure 9.

RF output results: comparison between the target signal (Col1(#3)) and the predicted one (Prediction (Col1(#3))). The analyzed dataset is composed of 15,520 samples; the training and the testing dataset are 70% and 30% of the analyzed dataset, respectively; and the hyper-parameters are tree depth = 10, minimum node size = 5, and number of models = 100.

8.2. EDT Framework: Advantages and Disadvantages

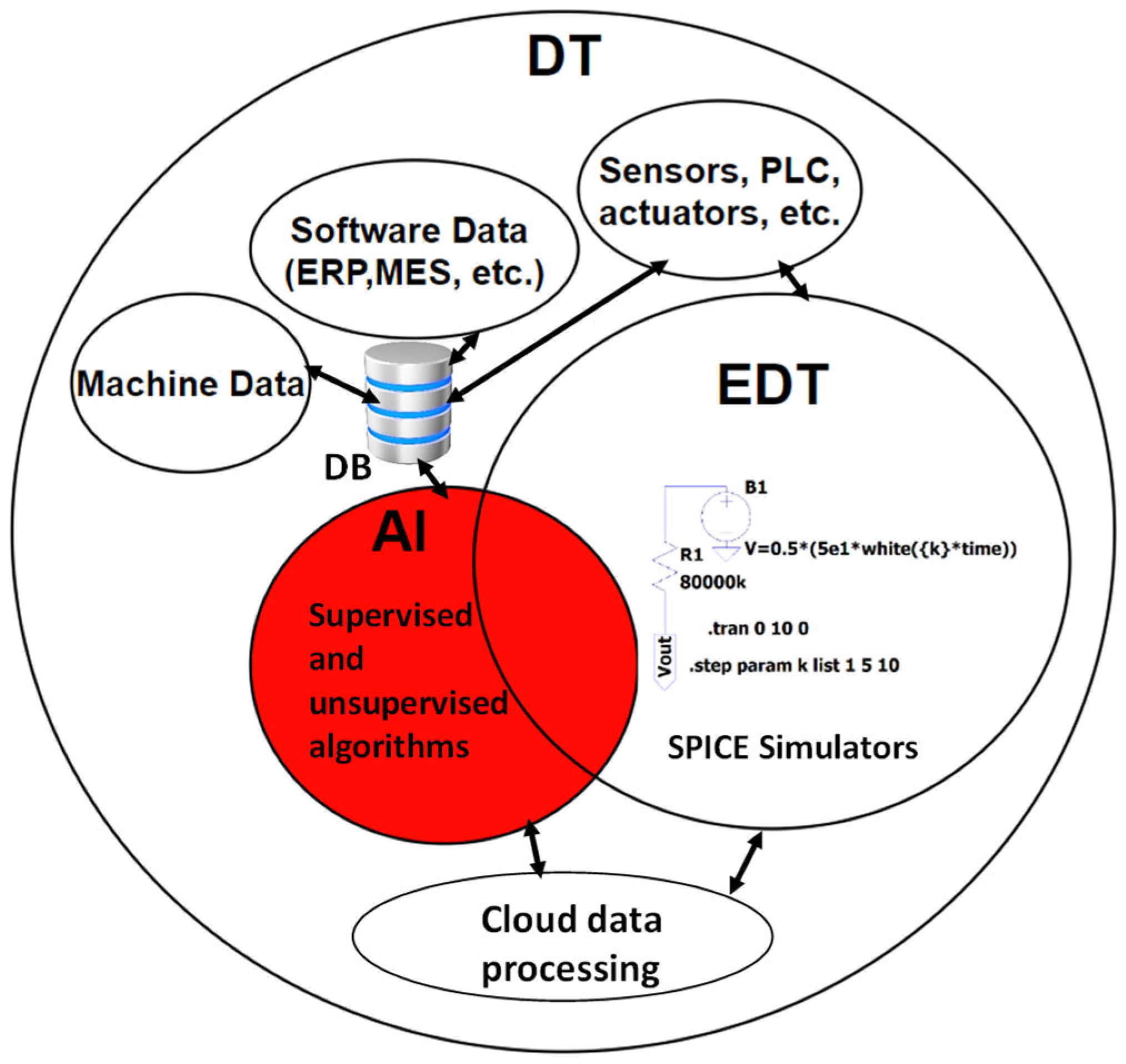

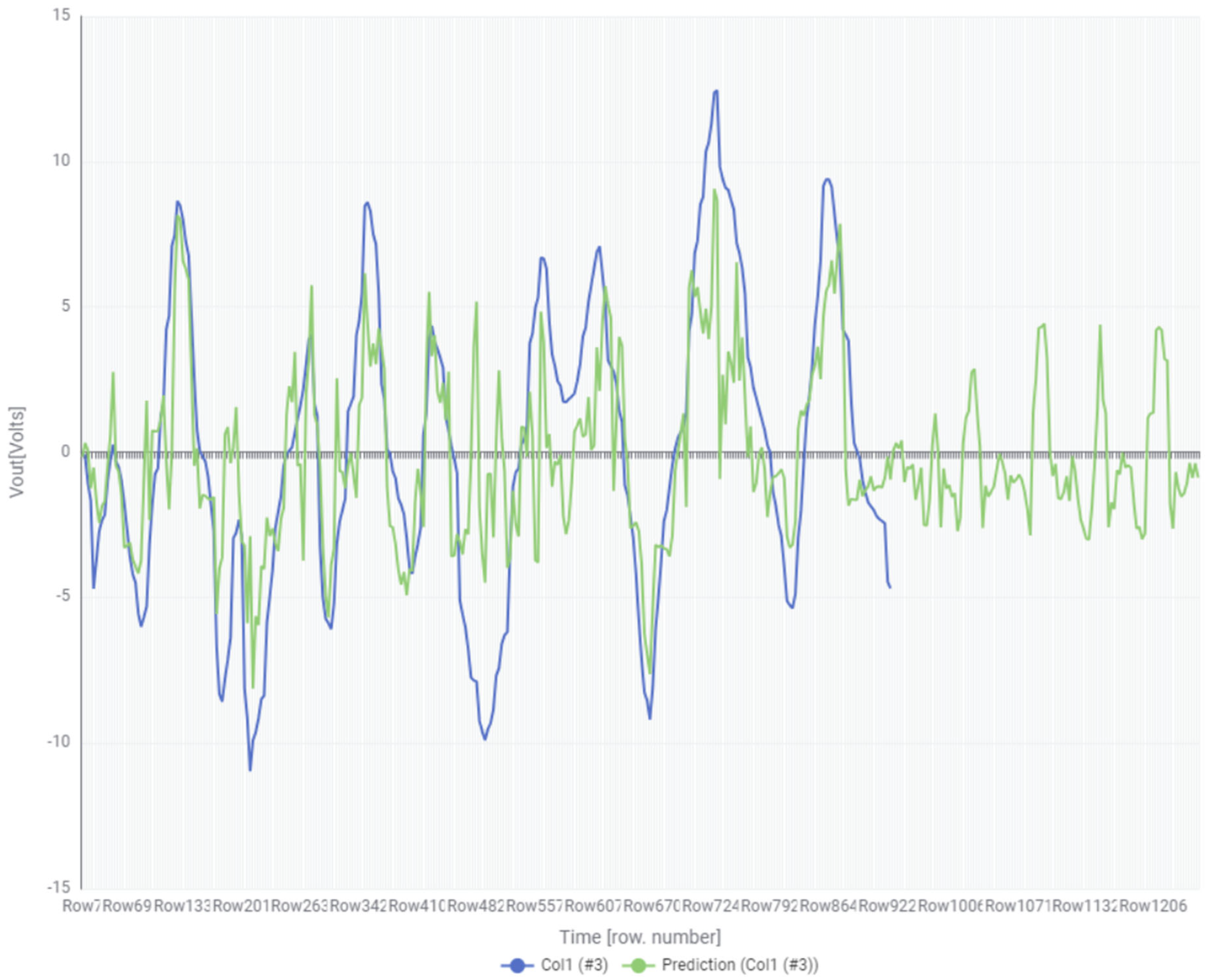

The EDT is a sub-class of DTs: specifically, the DT includes the whole digital environment, including the software, while the EDT is the reproduction of circuits and hardware components. Figure 10 illustrates an example of a DT/EDT framework for manufacturing industries, deducted from the literature: AI is executed locally or by cloud computing, for both the DT and EDT, by processing the local data (machine data, ERP data, sensor data, etc.).

Figure 10.

DT and EDT framework for manufacturing industries. AI data processing is performed locally or by cloud computing.

Table 8 discusses the main advantages and related disadvantages of the main functionalities of the EDT tools.

Table 8.

Main advantages and disadvantages of the EDT tools.

8.3. Limitations, Practical Use Cases, and Workflow Protocol for EDTs Integrating AI

The EDTs discussed in the research pillars are characterized by some important limitations. Table 9 lists the main limitations and the corresponding mitigation procedures.

Table 9.

Limitations and related mitigations of EDT with Industry 5.0 facilities.

EDTs integrating AI is the future challenge of Industry 5.0. This integration is to be considered in processes embedded in regular production processes.

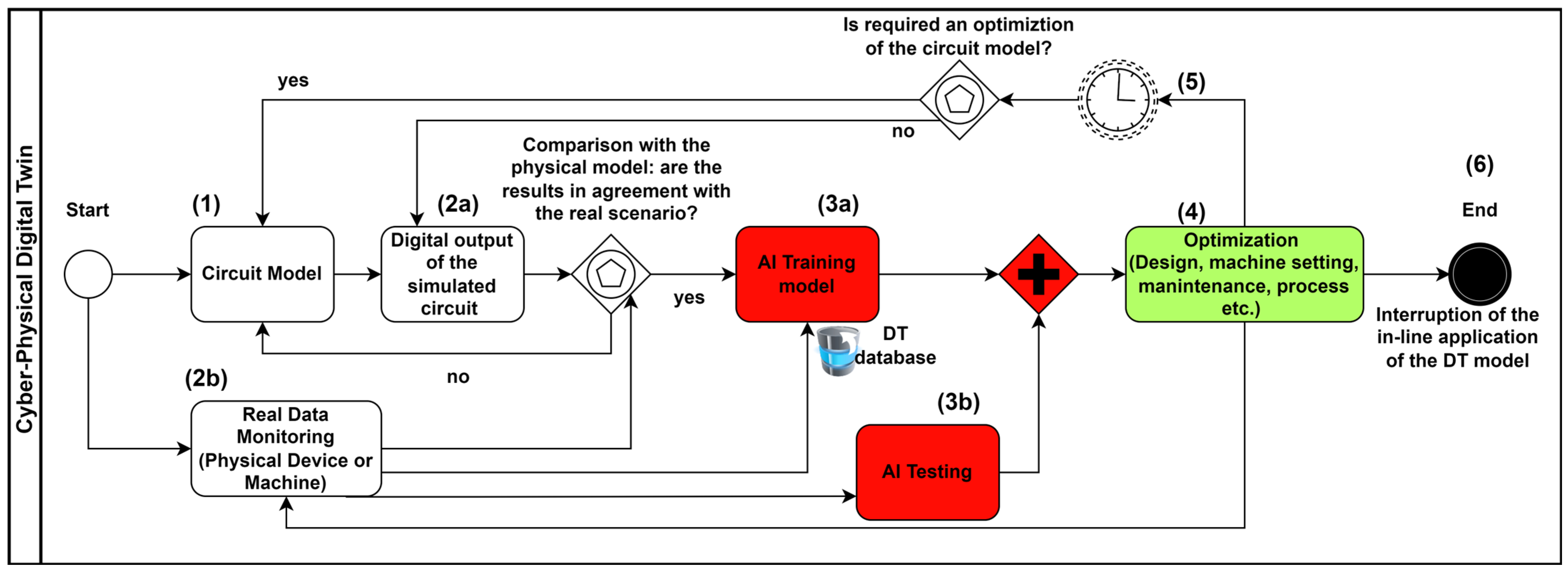

Table 10 summarizes all the steps involved in the integration of the EDT in industrial processes according to the Business Process Modeling and Notation (BPMN) scheme of Figure 11. The BPMN is a standard notation useful to verticalize processes associated with the logic of circuits [219].

Table 10.

Use criteria of EDT deduced from the analysis.

Figure 11.

AI-based DT: BPMN explaining the integration of the AI in the circuital model optimizing the manufacturing process.

8.4. Workflow Methodology, Correlation, and Technology Readiness of Research Pillars

The flux diagram in Figure 12 represents the workflow, summarizing the review objectives and describing the adopted methodology. Specifically, the flux indicates the following steps:

Figure 12.

Theoretical workflow representing the review objectives.

- Keyword matching and the use of academic search engines to find papers;

- The verification of the presence of important research features, such as a DT framework architecture, project specifications, AI applications, a circuital approach, and AI-based process integration;

- The analysis of relationships between research pillars and the estimation of the related association strengths.

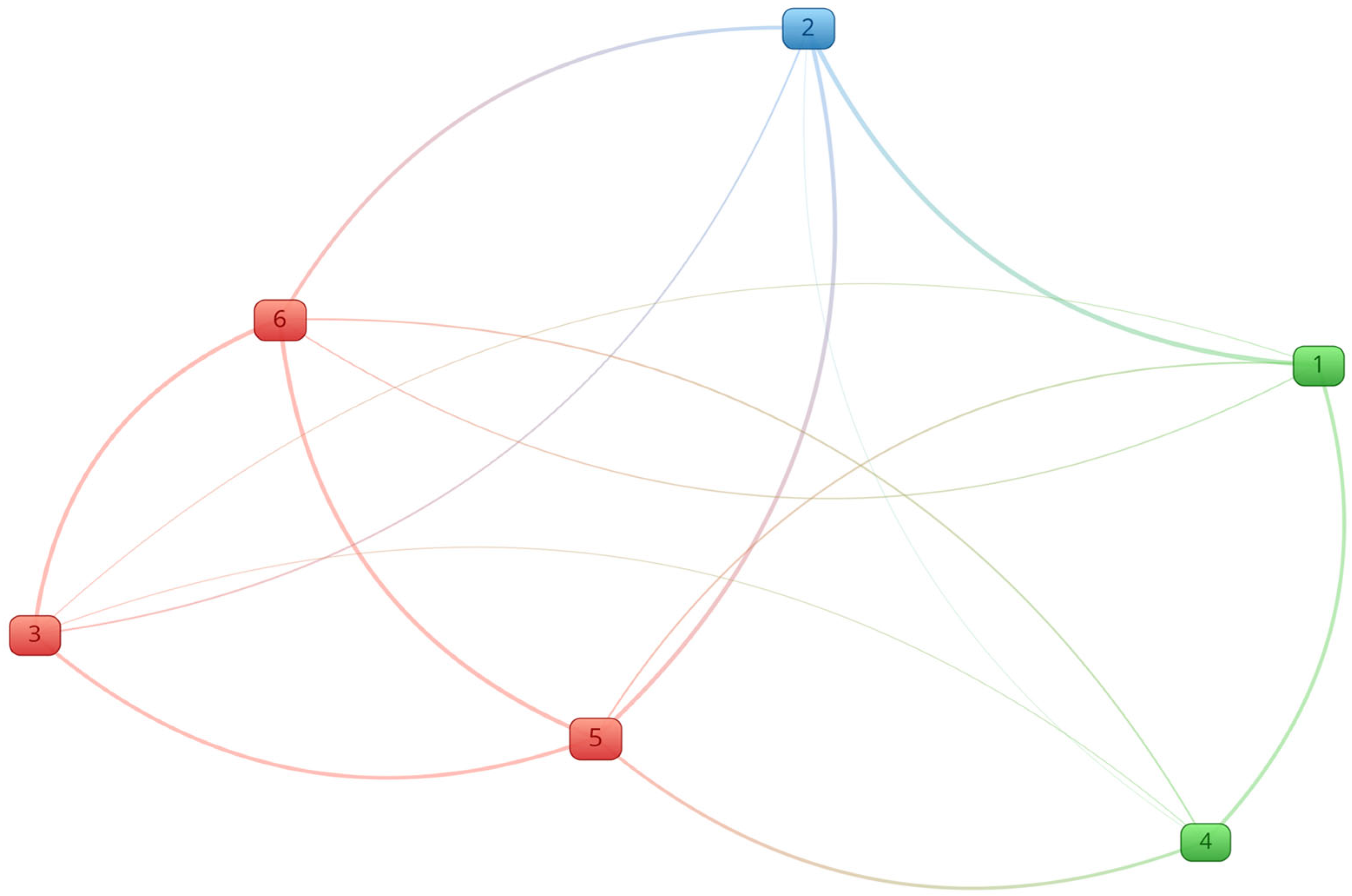

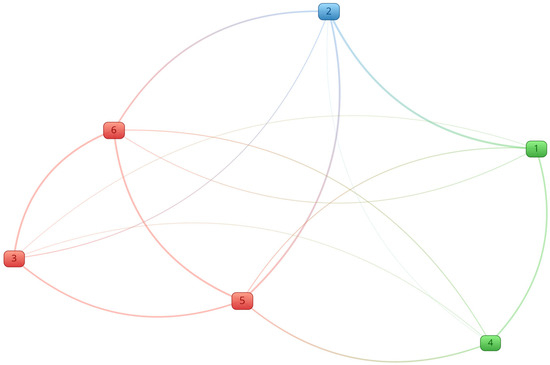

An approach to visually map the relationships between research pillars is the Visualization of Similarities (VOS) [220,221]. An open-source tool suitable for this visualization is the VOSviewer. By applying this tool (Version 1.6.20), Figure 13 illustrates the clustering analysis (three clusters grouping pillars 1 and 4 and grouping pillars 3, 5, and 6) and the association strength output, normalizing the strength of the links between pillars (thicker arcs represent higher dependency weights).

Figure 13.

VOSviewer: colored clustering and application of the association strength between the six research pillars (numbered as 1, 2, 3, 4, 5, and 6). The graph provides a meta-level view of how the six pillars interrelate, strengthening this survey’s utility for future research planning.

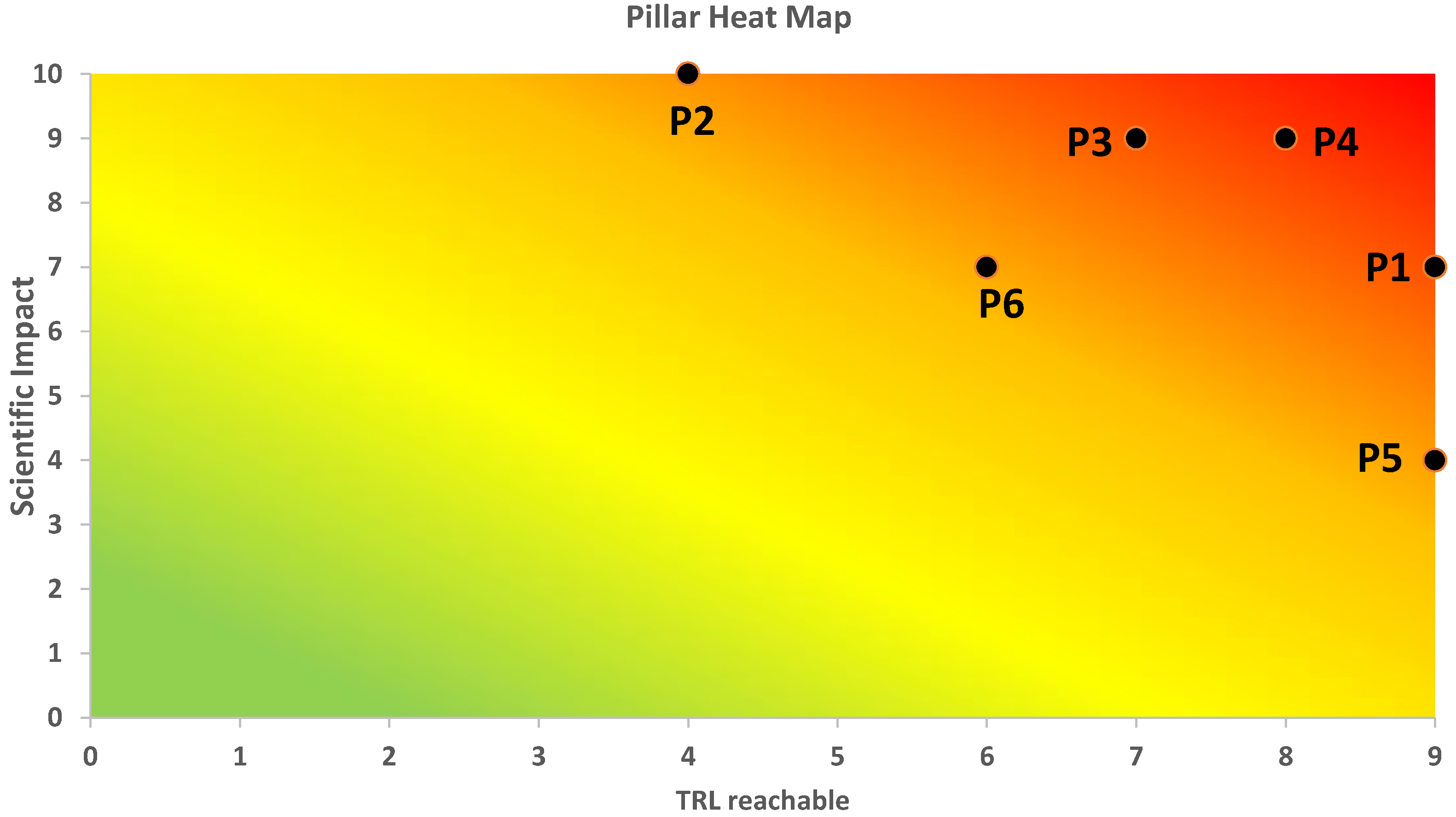

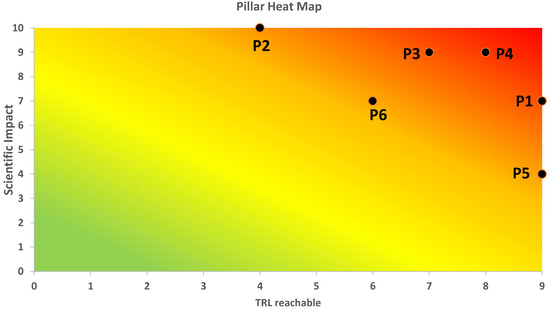

Other information about research maturity of pillars is indicated by the heat map in Figure 14, where a score is assigned for each pillar regarding the scientific impact (deduced from the articles found) and the reachable Technology Readiness Level (TRL).

Figure 14.

Pillar heat map matching scientific impact and reachable TRL of pillars (P1, P2, P3, P4, P5, and P6).

8.5. AI Importance and Research Gap

Much of the work on AI is focused on creating training dataset models with a good accuracy. Inference acceleration enables AI to solve ever-larger problems on ever-smaller devices, such as for high computing for DNN-based inference [222] and for edge computing approaches [223]. In order to improve the AI computational cost, GPU boards [224] and edge [225] and quantum computing technologies can be adopted [226,227].

Another important aspect about the AI-EDT is the link between the manufacturing processes and the developed models supporting the different production phases, including monitoring, modeling, optimization, design and preparation, control, and operation [228,229,230,231]. Important advances for AI-based EDTs are the application of Convolutional Neural Network (CNN) matching the requirements for ultra-high voltage direct current (UHVDC) projects [232], Long Short-Term Memory (LSTM) predicting the health condition of parts of Computer Numerical Control (CNC) machine tools [233], or hybrid CNN-LSTM networks improving AI algorithm performances [234].

Circuit simulators and the related output data in EDT models represent the AI datasets, predicting the real behavior of the production machine with a good accuracy. In particular, for the optocoupler switch of a PLC, circuit simulations process different white noises and interferences (pulsed signals) of the 3D environment modeled by input ports: the AI-RF algorithm provides good matching between the simulated and the predicted trend of the optocoupler output voltage with an MAE of 0.8% [47]. Concerning amplification circuits, the real machine environment is modeled by the interference of sinusoidal pulse signals with different carriers (each carrier frequency represents an interference, and two interferences are simultaneously coupled into the amplification system): the AI-ANN-MLP algorithm provides the prediction of the amplified signal with an MAE of 2% [84]. Passive RC filters are modeled to integrate electronic noises (Johnson noise or Schottky noise) and switching circuits, selecting the best filtering network according to the ANN classification with an MAE of 6% [83]. The simulations of PID control circuits are used to train ANNs for predicting anomalies by observing when the predicted values exceed the envelope of the input signal and constructing precise risk maps (k-means algorithm) [85].

In order to highlight the completeness of the methodology followed in this review, Table 11 lists the research gaps in the prior selected research reviews according to the main features, such as the framework, project matching, AI prediction or classification, circuital approach, and DT-AI process integration.

Table 11.

Research gap in the prior selected research reviews.

9. Conclusions

This review discusses the recent topics on DTs and EDTs, with a particular focus on the development of the use of models in industrial scenarios, by selecting six main research pillars suggested by projects. Specifically, the pillars are related to Industry 4.0 manufacturing, Industry 5.0 facilities, advanced healthcare, smart energy, inspection and monitoring systems, and cybersecurity. Each research pillar is classified by grouping different research sub-topics according to the output provided by the research engine portals of scientific publications. This review proposes some examples of EDT models to facilitate the comprehension of the modeling approach and possible implementations of AI related to the discussed pillars. This review focuses on the following consequential items:

- –

- –

- –

- Suggesting a methodological approach for implementing EDTs based on the use of circuit models (see Section 8.1 and the Appendix A);

- –

- Proposing the integration of EDT models into manufacturing processes (see Figure 11).

Finally, this review highlights perspectives, advantages, disadvantages, and limitations for the future development of the EDT models in industrial processes. This study is also suitable for researchers to define possible new projects, including parts of the developed discussion, and finding possible correlations and relationships between the discussed topics.

Review’s Limitations and Future Research Directions

This review is focused on identifying some topics that can be associated with DTs, using a well-defined research methodology. Specifically, the European research context has been considered as a ‘starting point’. This certainly limits the selection of other sub-topics that could be particularly important in the international design scenario. In this direction, future works will be oriented to find possible correlations between different project portals of multiple continental areas.

Furthermore, many weaknesses of the cited publications are to be identified in the discussion of the full integration of circuit models with AI. For this reason, in addition to an effort to understand how AI can be implemented in the perspective of use, a further step has been taken in defining, in Figure 11, the integration procedure between AI and EDTs specifically for manufacturing processes.

This review suggests different advanced industrial frameworks, including AI, for the improvement of product quality, simulating the behavior in real scenarios by means of the EDT. The EDT models are useful for simulating the whole product life cycle and processes of production monitoring, product implementation, and deployment. A new research direction is the AI data-driven processes supported by EDTs capable of dynamically adjusting the production or the implementation process, thus increasing the quality and the efficiency.

Funding

This research received no external funding.

Data Availability Statement

Data are included in the paper.

Conflicts of Interest

The authors declare no conflicts of interest.

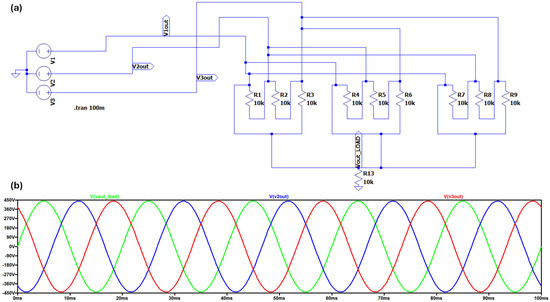

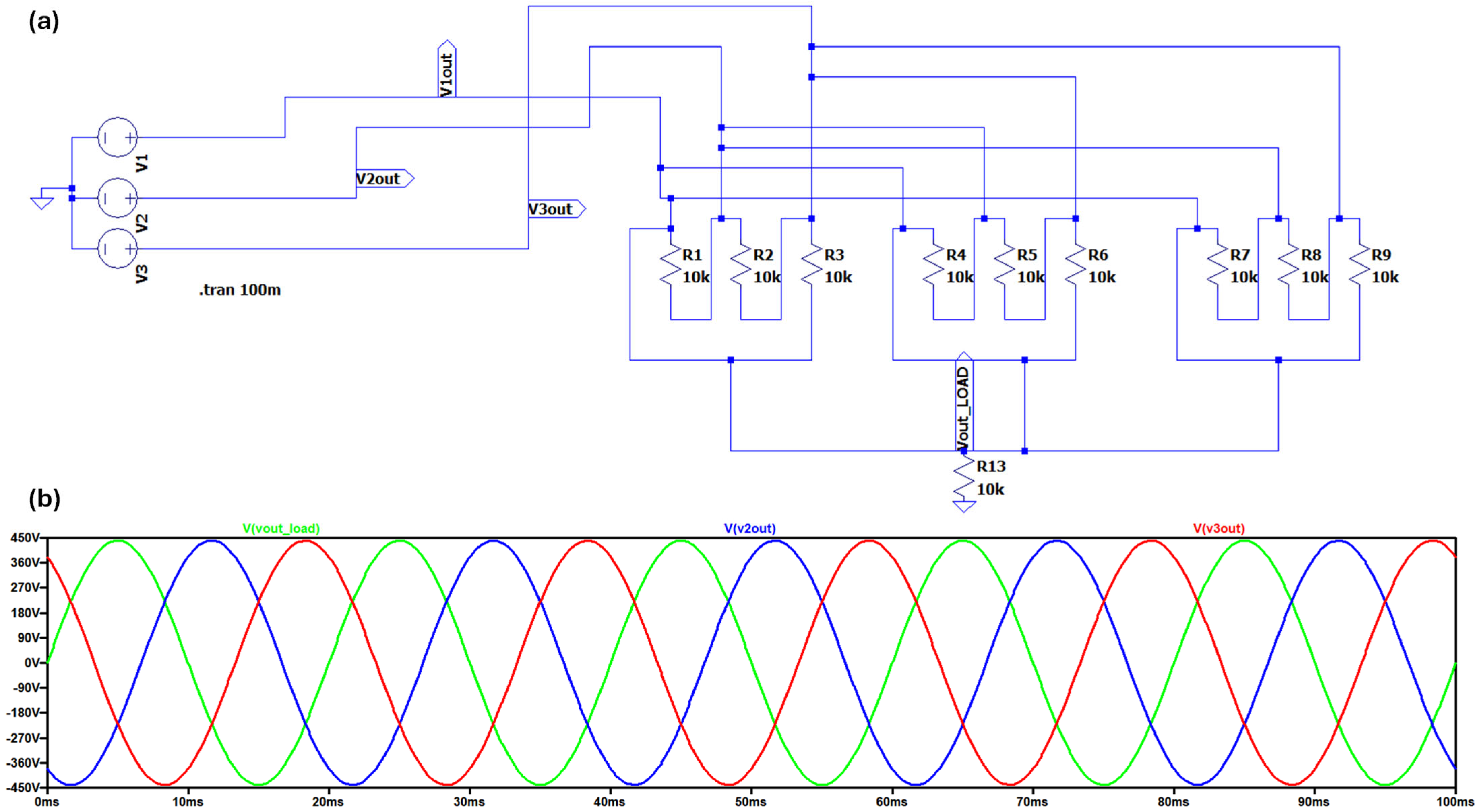

Appendix A

Design and production in Industry 4.0 environments are supported by circuit modeling and simulation. This Appendix demonstrates some EDT examples. Since three-phase motors are commonly used in industrial environments, it is useful to model the related circuit systems. As a circuit example, the model in Figure A1a shows a typical layout of the power supply circuit of a star-connected network, where the input voltage signals modeled by voltage generators V1, V2, and V3 are mismatched by a phase of 120° (see in Figure A1b the time domain voltage signals corresponding to the labels V1out, V2out, and V3out). The circuit model is useful for understanding how the electrical signals are applied to specific load networks to ensure a balanced power supply and to know the distribution of the electrical power on the different loads.

Figure A1.

LTSpice simulation: (a) circuital EDT modeling a three-phase network powering a star-connected balanced three-phase load. (b) Time domain transient analysis calculating the input voltage signals of the electrical three-phase network (phase mismatch of 120° between the voltage signals). The resistances of 10 kΩ are able to provide an output voltage of 450 Volts.

Figure A1.

LTSpice simulation: (a) circuital EDT modeling a three-phase network powering a star-connected balanced three-phase load. (b) Time domain transient analysis calculating the input voltage signals of the electrical three-phase network (phase mismatch of 120° between the voltage signals). The resistances of 10 kΩ are able to provide an output voltage of 450 Volts.

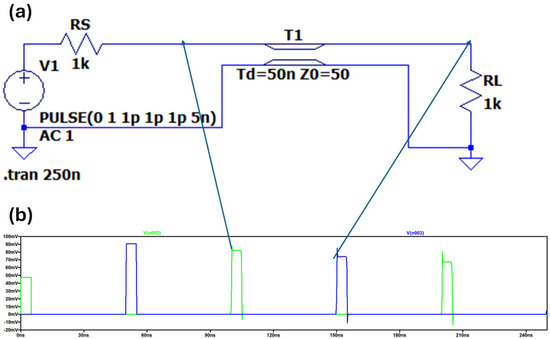

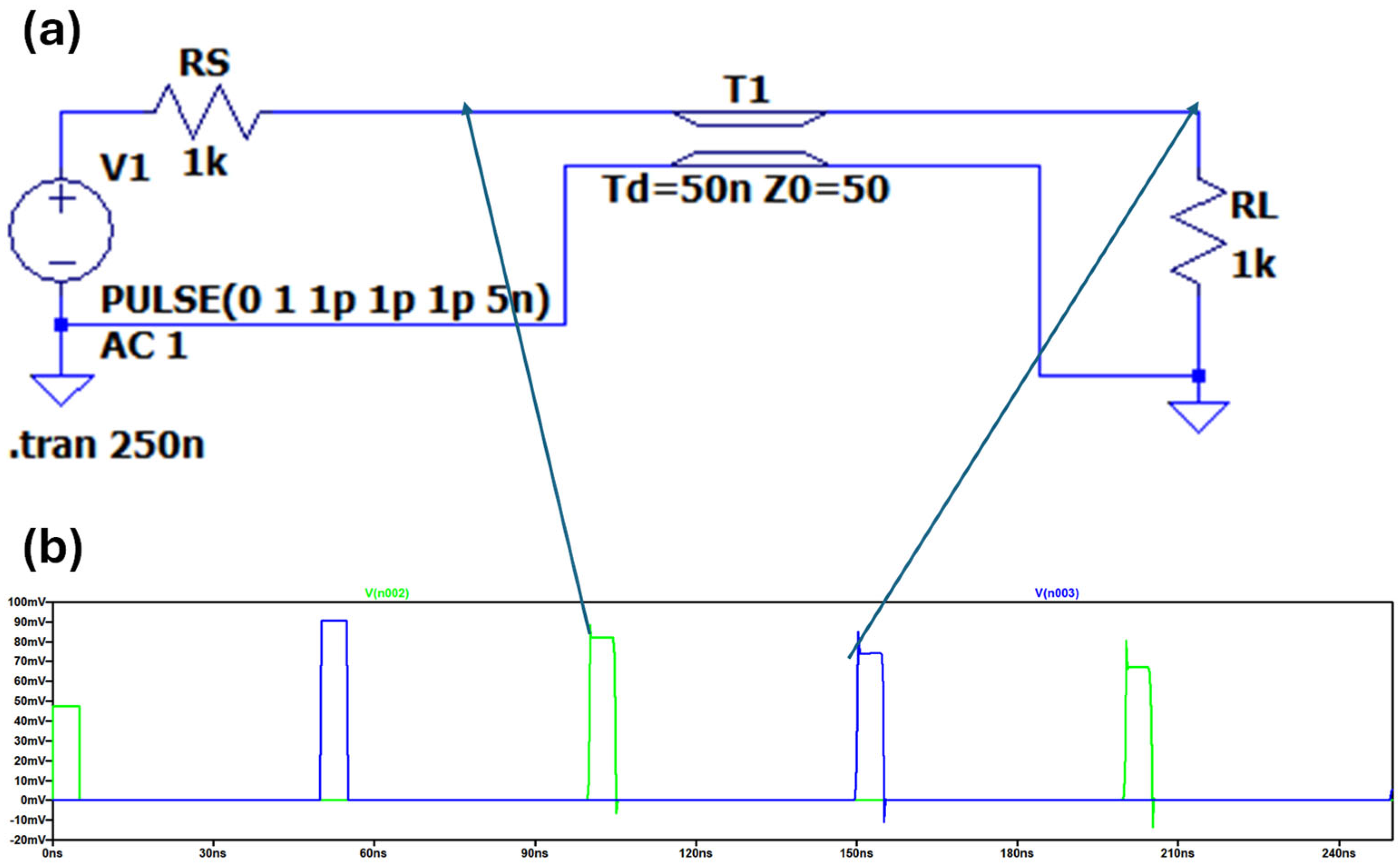

The second example in Figure A2 simulates the transmission of a pulsed signal traveling on a transmission line, which can be a coaxial cable typically implemented in standard Ethernet industrial networks. The simulation allows for the comprehension of the effect of the time delay during the data protocol transmission, thus simulating the real network behavior and taking into account the delay occurring at the physical level (first level of the ISO/OSI scale related the transmission medium). The example proves that it is possible to simulate both the electrical signal and the information signal that travels in an industrial network.

Figure A2.

LTSpice simulation: (a) circuital EDT modeling a transmission line of an industrial network with a characteristic impedance of 50 Ω. (b) Simulation illustrating the delay between the input pulse signal and the output one due to the crossing of the transmission line. The input resistance of RS = 1 kΩ and load resistance of RL = 1 kΩ are able to provide a voltage signal between 50 mV and 80 mV in the observed time window.

Figure A2.

LTSpice simulation: (a) circuital EDT modeling a transmission line of an industrial network with a characteristic impedance of 50 Ω. (b) Simulation illustrating the delay between the input pulse signal and the output one due to the crossing of the transmission line. The input resistance of RS = 1 kΩ and load resistance of RL = 1 kΩ are able to provide a voltage signal between 50 mV and 80 mV in the observed time window.

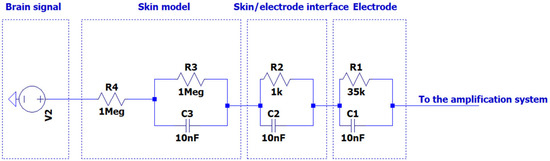

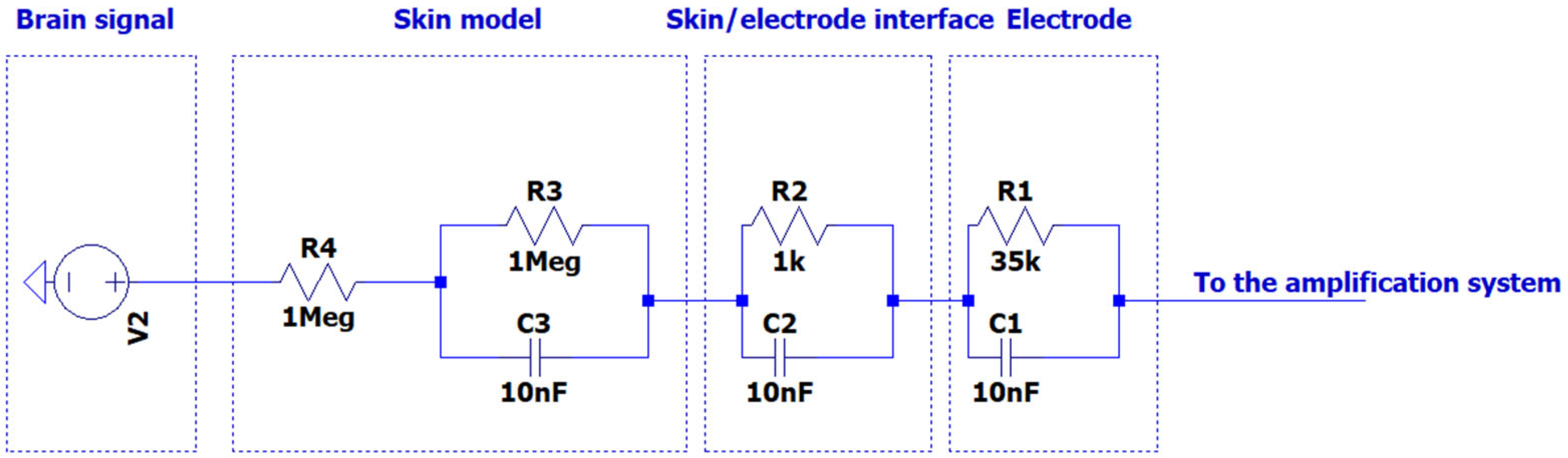

The third example considers an EDT model detecting Electroencephalogram (EEG) signals in medical devices. The design of new healthcare hardware sensors is typically performed by the circuit modeling and simulations. The difficulty of the EDT implementation is mainly the circuit modeling of physical interactions between sensors and human body parts. In this direction, in order to test the efficiency of a real medical device, a good approach is to simulate the circuit by considering a real physiological signal as the input signal. Figure A3 illustrates the example of an EEG electrode, where the brain signal is ‘imported’ in the circuit by the V2 generator reading a text file (brain signal exported by a real electrode). The model simulates the signal coupling in the skin region and at the skin/electrode interface (gel materials), using different resistances and capacitances. A possible noisy output can be analyzed by AI algorithms extracting the correct trend of the brain signal and correctly processing the output of the EEG amplification system [91]. Other medical devices detecting physiological parameters can be modeled by similar electrical components, reproducing the interaction of the electronic components with the human body tissues characterized by other specific resistances, capacitances, and inductance parameters modeling the physiological domain.

Figure A3.

Example of circuit LTSpice model of an EEG electrode connecting all the regions and the human body interfaces characterizing the EEG signal transmission. The resistances R1, R2, R3, and R4 and the capacitances C1, C2, and C3 are related to a physical model simulating the skin/electrode interface [91].

Figure A3.

Example of circuit LTSpice model of an EEG electrode connecting all the regions and the human body interfaces characterizing the EEG signal transmission. The resistances R1, R2, R3, and R4 and the capacitances C1, C2, and C3 are related to a physical model simulating the skin/electrode interface [91].

References

- Kohesio: Discover EU Projects in Your Region. Available online: https://kohesio.ec.europa.eu/en/projects (accessed on 17 May 2025).

- Wang, M.; Wang, C.; Hnydiuk-Stefan, A.; Feng, S.; Atilla, I.; Li, Z. Recent Progress on Reliability Analysis of Offshore Wind Turbine Support Structures Considering Digital Twin Solutions. Ocean Eng. 2021, 232, 109168. [Google Scholar] [CrossRef]

- Olatunji, O.O.; Adedeji, P.A.; Madushele, N.; Jen, T.-C. Overview of Digital Twin Technology in Wind Turbine Fault Diagnosis and Condition Monitoring. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; pp. 201–207. [Google Scholar]

- Iosifidis, N.; Zhong, Y.; Hu, B.; Chen, B.; Ran, L.; Lakshminarayana, S.; Jia, C.; McKeever, P.; Ng, C. Reliability of Wind Turbine Power Modules Using High-Resolution Wind Data Reconstruction: A Digital Twin Concept. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 3630–3637. [Google Scholar]

- Malik, A.A. Digital Twin Based Development of Mobile Robot Assistant in Wind Turbines Manufacturing. In Volume 2: 43rd Computers and Information in Engineering Conference (CIE); American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Di Nezio, G.; Di Benedetto, M.; Lidozzi, A.; Solero, L. Digital-Twin Based Health Monitoring for Multi-Phase Boost Rectifier in Wind Offshore Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 13, 2738–2748. [Google Scholar] [CrossRef]

- Mahmoud, M.; Semeraro, C.; Abdelkareem, M.A.; Olabi, A.G. Designing and Prototyping the Architecture of a Digital Twin for Wind Turbine. Int. J. Thermofluids 2024, 22, 100622. [Google Scholar] [CrossRef]

- Chetan, M.; Yao, S.; Griffith, D.T. Multi-fidelity Digital Twin Structural Model for a Sub-scale Downwind Wind Turbine Rotor Blade. Wind Energy 2021, 24, 1368–1387. [Google Scholar] [CrossRef]

- Fu, Y.; Zhu, G.; Zhu, M.; Xuan, F. Digital Twin for Integration of Design-Manufacturing-Maintenance: An Overview. Chin. J. Mech. Eng. 2022, 35, 80. [Google Scholar] [CrossRef]

- Ebni, M.; Hosseini Bamakan, S.M.; Qu, Q. Digital Twin Based Smart Manufacturing; From Design to Simulation and Optimization Schema. Procedia Comput. Sci. 2023, 221, 1216–1225. [Google Scholar] [CrossRef]

- O’Connell, E.; O’Brien, W.; Bhattacharya, M.; Moore, D.; Penica, M. Digital Twins: Enabling Interoperability in Smart Manufacturing Networks. Telecom 2023, 4, 265–278. [Google Scholar] [CrossRef]

- Xu, J.; Guo, T. Application and Research on Digital Twin in Electronic Cam Servo Motion Control System. Int. J. Adv. Manuf. Technol. 2021, 112, 1145–1158. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital Twin in Manufacturing: Conceptual Framework and Case Studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Li, L.; Lei, B.; Mao, C. Digital Twin in Smart Manufacturing. J. Ind. Inf. Integr. 2022, 26, 100289. [Google Scholar] [CrossRef]

- He, B.; Bai, K.-J. Digital Twin-Based Sustainable Intelligent Manufacturing: A Review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Gunes, V. A Digital Twin Design Methodology for Control, Simulation, and Monitoring of Fluidic Circuits. Int. J. Adv. Manuf. Technol. 2024, 134, 3863–3875. [Google Scholar] [CrossRef]

- Chen, R.; Chen, X.; Wang, L.; Li, J. The Core Industry Manufacturing Process of Electronics Assembly Based on Smart Manufacturing. ACM Trans. Manag. Inf. Syst. 2022, 13, 1–19. [Google Scholar] [CrossRef]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A Review of Digital Twin in Product Design and Development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Gopal, L.; Singh, H.; Mounica, P.; Mohankumar, N.; Challa, N.P.; Jayaraman, P. Digital Twin and IOT Technology for Secure Manufacturing Systems. Measur. Sens. 2023, 25, 100661. [Google Scholar] [CrossRef]

- Su, J.; Mao, Q.; Liao, Z.; Sheng, Z.; Huang, C.; Zhang, X. A Real-Time Cross-Domain WI-Fi-Based Gesture Recognition System for Digital Twins. IEEE J. Sel. Areas Commun. 2023, 41, 3690–3701. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Zhang, Q.; Sun, Q.; Lim, E. A Digital Twin Platform Integrating Process Parameter Simulation Solution for Intelligent Manufacturing. Electronics 2024, 13, 802. [Google Scholar] [CrossRef]

- Azangoo, M.; Taherkordi, A.; Blech, J.O.; Vyatkin, V. Digital Twin-Assisted Controlling of AGVs in Flexible Manufacturing Environments. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–7. [Google Scholar]

- Liang, X.; Xiao, R.; Zhang, J. A Review on Digital Twin for Robotics in Smart Manufacturing. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; pp. 1510–1515. [Google Scholar]

- Misra, A.; Agrawal, A.; Misra, V. Robotics in Industry 4.0. In Handbook of Smart Materials, Technologies, and Devices; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–35. [Google Scholar]

- Yan, D.; Sha, W.; Wang, D.; Yang, J.; Zhang, S. Digital Twin-Driven Variant Design of a 3C Electronic Product Assembly Line. Sci. Rep. 2022, 12, 3846. [Google Scholar] [CrossRef]

- Li, X.; Niu, W.; Tian, H. Application of Digital Twin in Electric Vehicle Powertrain: A Review. World Electr. Veh. J. 2024, 15, 208. [Google Scholar] [CrossRef]

- Wu, Q.; Mao, Y.; Chen, J.; Wang, C. Application Research of Digital Twin-Driven Ship Intelligent Manufacturing System: Pipe Machining Production Line. J. Mar. Sci. Eng. 2021, 9, 338. [Google Scholar] [CrossRef]

- Mendi, A.F. A Digital Twin Case Study on Automotive Production Line. Sensors 2022, 22, 6963. [Google Scholar] [CrossRef]

- Yang, J.; Son, Y.H.; Lee, D.; Noh, S.D. Digital Twin-Based Integrated Assessment of Flexible and Reconfigurable Automotive Part Production Lines. Machines 2022, 10, 75. [Google Scholar] [CrossRef]

- Krenczyk, D.; Paprocka, I. Integration of Discrete Simulation, Prediction, and Optimization Methods for a Production Line Digital Twin Design. Materials 2023, 16, 2339. [Google Scholar] [CrossRef]

- Yuan, G.; Liu, X.; Zhu, C.; Wang, C.; Zhu, M.; Sun, Y. Multi-Objective Coupling Optimization of Electrical Cable Intelligent Production Line Driven by Digital Twin. Robot. Comput. Integr. Manuf. 2024, 86, 102682. [Google Scholar] [CrossRef]

- Guo, K.; Wan, X.; Liu, L.; Gao, Z.; Yang, M. Fault Diagnosis of Intelligent Production Line Based on Digital Twin and Improved Random Forest. Appl. Sci. 2021, 11, 7733. [Google Scholar] [CrossRef]

- Lee, D.; Kim, C.-K.; Yang, J.; Cho, K.-Y.; Choi, J.; Noh, S.-D.; Nam, S. Digital Twin-Based Analysis and Optimization for Design and Planning of Production Lines. Machines 2022, 10, 1147. [Google Scholar] [CrossRef]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Lotsaris, K.; Bavelos, A.C.; Baris, P.; Michalos, G.; Makris, S. Digital Twin for Designing and Reconfiguring Human–Robot Collaborative Assembly Lines. Appl. Sci. 2021, 11, 4620. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, J.; Chen, J.; Hu, P.; Wang, X.; Xu, J.; Zhou, B. A Digital-Twin Visualized Architecture for Flexible Manufacturing System. J. Manuf. Syst. 2021, 60, 176–201. [Google Scholar] [CrossRef]

- Ricondo, I.; Porto, A.; Ugarte, M. A Digital Twin Framework for the Simulation and Optimization of Production Systems. Procedia CIRP 2021, 104, 762–767. [Google Scholar] [CrossRef]

- Alam, M.D.; Kabir, G.; Mirmohammadsadeghi, S. A Digital Twin Framework Development for Apparel Manufacturing Industry. Decis. Anal. J. 2023, 7, 100252. [Google Scholar] [CrossRef]

- Seidel, R.; Rachinger, B.; Thielen, N.; Schmidt, K.; Meier, S.; Franke, J. Development and Validation of a Digital Twin Framework for SMT Manufacturing. Comput. Ind. 2023, 145, 103831. [Google Scholar] [CrossRef]

- Moeller, H.; Inamdar, A.; van Driel, W.D.; Bredberg, J.; Hille, P.; Knoll, H.; Vandevelde, B. Digital Twin Technology in Electronics. In Recent Advances in Microelectronics Reliability; Springer International Publishing: Cham, Switzerland, 2024; pp. 283–321. [Google Scholar]

- Chen, H.; Zhang, Z.; Karamanakos, P.; Rodriguez, J. Digital Twin Techniques for Power Electronics-Based Energy Conversion Systems: A Survey of Concepts, Application Scenarios, Future Challenges, and Trends. IEEE Ind. Electron. Mag. 2023, 17, 20–36. [Google Scholar] [CrossRef]

- Mansour, D.-E.A.; Numair, M.; Zalhaf, A.S.; Ramadan, R.; Darwish, M.M.F.; Huang, Q.; Hussien, M.G.; Abdel-Rahim, O. Applications of IoT and Digital Twin in Electrical Power Systems: A Comprehensive Survey. IET Gener. Transm. Distrib. 2023, 17, 4457–4479. [Google Scholar] [CrossRef]

- Agarwal, R.; Bhatti, G.; Singh, R.R.; Indragandhi, V.; Suresh, V.; Jasinska, L.; Leonowicz, Z. Intelligent Fault Detection in Hall-Effect Rotary Encoders for Industry 4.0 Applications. Electronics 2022, 11, 3633. [Google Scholar] [CrossRef]

- Lee, H.; Kim, S.D.; Amin, M.A.U.A. Control Framework for Collaborative Robot Using Imitation Learning-Based Teleoperation from Human Digital Twin to Robot Digital Twin. Mechatronics 2022, 85, 102833. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, Y.; Hu, Q.; Xie, C.; Su, T. DTformer: An Efficient Digital Twin Model for Loss Measurement in UHVDC Transmission Systems. IEEE Trans. Power Syst. 2024, 39, 3548–3559. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, Q.; Cui, J. A Novel Fault Diagnosis Method for Denoising Autoencoder Assisted by Digital Twin. Comput. Intell. Neurosci. 2022, 2022, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ciganek, J.; Zemla, F. Design of Digital Twin for PLC System. In Proceedings of the 2022 Cybernetics & Informatics (K&I), Visegrad, Hungary, 11–14 September 2022; pp. 1–6. [Google Scholar]

- Massaro, A. Artificial Intelligence Signal Control in Electronic Optocoupler Circuits Addressed on Industry 5.0 Digital Twin. Electronics 2024, 13, 4543. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, S.; Li, H.; Cao, W.; Tang, W.; Jiang, J.; Deng, M.; Zhang, Y.; Gu, B.; Wu, K.; et al. Digital Twin-Driven Intelligent Production Line for Automotive MEMS Pressure Sensors. Adv. Eng. Inform. 2022, 54, 101779. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives. Appl. Sci. 2023, 13, 4582. [Google Scholar] [CrossRef]

- Ali, A.R.; Ramadan, M.W.A. Artificial Neural Networks as Digital Twins for Whispering Gallery Mode Optical Sensors in Robotics Applications. Photonic Sens. 2025, 15, 250206. [Google Scholar] [CrossRef]

- Massaro, A. Electronics in Advanced Research Industries: Industry 4.0 to Industry 5.0 Advances; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Oguz, I.; Suter, L.J.E.; Hsieh, J.-L.; Yildirim, M.; Dinc, N.U.; Moser, C.; Psaltis, D. Training Hybrid Neural Networks with Multimode Optical Nonlinearities Using Digital Twins. Nanophotonics 2025, 14, 2787–2797. [Google Scholar] [CrossRef]

- Zhuge, Q. AI-Driven Digital Twin for Optical Networks. In Proceedings of the European Conference on Optical Communication (ECOC), Basel, Switzerland, 18–22 September 2022; pp. 1–62. [Google Scholar]

- Lay-Ekuakille, A.; Massaro, A.; Singh, S.P.; Jabłoński, I.; Rahman, M.Z.U.; Spano, F. Optoelectronic and Nanosensors Detection Systems: A Review. IEEE Sens. J. 2021, 21, 12645–12653. [Google Scholar] [CrossRef]

- Faruk, M.S.; Savory, S.J. Measurement Informed Models and Digital Twins for Optical Fiber Communication Systems. J. Light. Technol. 2024, 42, 1016–1030. [Google Scholar] [CrossRef]

- Zhuge, Q.; Liu, X.; Zhang, Y.; Cai, M.; Liu, Y.; Qiu, Q.; Zhong, X.; Wu, J.; Gao, R.; Yi, L.; et al. Building a Digital Twin for Intelligent Optical Networks [Invited Tutorial]. J. Opt. Commun. Netw. 2023, 15, C242. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Zhang, M.; Fu, M.; Li, J.; Cai, S.; Zhang, C.; Chen, X. The Role of Digital Twin in Optical Communication: Fault Management, Hardware Configuration, and Transmission Simulation. IEEE Commun. Mag. 2021, 59, 133–139. [Google Scholar] [CrossRef]

- Borraccini, G.; Straullu, S.; Giorgetti, A.; Ambrosone, R.; Virgillito, E.; D’Amico, A.; D’Ingillo, R.; Aquilino, F.; Nespola, A.; Sambo, N.; et al. Experimental Demonstration of Partially Disaggregated Optical Network Control Using the Physical Layer Digital Twin. IEEE Trans. Netw. Serv. Manag. 2023, 20, 2343–2355. [Google Scholar] [CrossRef]

- Koulountzios, P.; Rymarczyk, T.; Soleimani, M. A 4-D Ultrasound Tomography for Industrial Process Reactors Investigation. IEEE Trans. Instrum. Meas. 2022, 71, 1–14. [Google Scholar] [CrossRef]

- Boparai, K.S.; Kumar, A.; Singh, R. Integration of 4D Imaging with 4D Printing. In 4D Imaging to 4D Printing; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–26. ISBN 9781003205531. [Google Scholar]

- Wang, F.; Yue, Z.; Liu, J.; Qi, H.; Sun, W.; Chen, M.; Wang, Y.; Yue, H. Quantitative Imaging of Printed Circuit Board (PCB) Delamination Defects Using Laser-Induced Ultrasound Scanning Imaging. J. Appl. Phys. 2022, 131, 53101. [Google Scholar] [CrossRef]

- Dai, L.-N.; Ni, C.-Y.; Ying, K.-N.; Yuan, L.; Kan, W.-W.; Shen, Z.-H. Defect Imaging Based on Laser Ultrasonic Frequency Domain Synthetic Aperture Focusing Technology with Separated Generation–Detection and 2-D Equivalent Velocity Mapping. Opt. Laser Technol. 2022, 156, 108485. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Tang, Z.; Duan, J.; Zhu, Y.; Zhang, Z.; Liu, X.; He, C. Optimization of Selection Matrix Capture for Micro Defects Laser Ultrasound Imaging Using Multi-Parameter Genetic Algorithm. NDT E Int. 2025, 152, 103325. [Google Scholar] [CrossRef]

- Cieślak, S.; Zawadzki, P.; Gapsa, J. Digital Twin Application for Vision Control in the Production of Mechatronic Ladders. In Lecture Notes in Mechanical Engineering; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 216–227. ISBN 9783031564697. [Google Scholar]

- Li, Q.; Ye, Q.J.; Zhang, N.; Zhang, W.; Hu, F. Digital-Twin-Enabled Industrial IoT: Vision, Framework, and Future Directions. IEEE Wirel. Commun. 2025, 1–9. [Google Scholar] [CrossRef]

- Salini, S.; Ivy, B.P.U. Digital Twin and Artificial Intelligence in Industries. In Digital Twin for Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 35–58. ISBN 9780323992053. [Google Scholar]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A Deep Learning-Enhanced Digital Twin Framework for Improving Safety and Reliability in Human–Robot Collaborative Manufacturing. Robot. Comput. Integr. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- Dosoftei, C.-C. Simulation Power vs. Immersive Capabilities: Enhanced Understanding and Interaction with Digital Twin of a Mechatronic System. Appl. Sci. 2023, 13, 6463. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, T.; Yue, P.; Luo, W.; Ma, S. Study on the Construction Theory of Digital Twin Mechanism Model for Mechatronics Equipment. Int. J. Adv. Manuf. Technol. 2022, 131, 5383–5401. [Google Scholar] [CrossRef]

- Classens, K.; Heemels, W.P.M.H.M.; Oomen, T. Digital Twins in Mechatronics: From Model-Based Control to Predictive Maintenance. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 336–339. [Google Scholar]

- Sturm, C.; Steck, M.; Bremer, F.; Revfi, S.; Nelius, T.; Gwosch, T.; Albers, A.; Matthiesen, S. Creation of Digital Twins—Key Characteristics of Physical to Virtual Twinning in Mechatronic Product Development. Proc. Des. Soc. 2021, 1, 781–790. [Google Scholar] [CrossRef]

- Nezzi, C.; Gufler, V.; Vidoni, R.; Rauch, E. Kinematic and Dynamic Modeling of Mechanical Systems towards Digital Twins. Results Eng. 2025, 26, 104874. [Google Scholar] [CrossRef]

- Chaiprabha, K.; Chancharoen, R. A Deep Trajectory Controller for a Mechanical Linear Stage Using Digital Twin Concept. Actuators 2023, 12, 91. [Google Scholar] [CrossRef]

- Braun, D.; Riedhammer, M.; Jazdi, N.; Schloegl, W.; Weyrich, M. A Methodology for the Detection of Functional Relations of Mechatronic Components and Assemblies in Brownfield Systems. Procedia CIRP 2022, 107, 119–124. [Google Scholar] [CrossRef]

- Jhunjhunwala, P.; Atmojo, U.D.; Vyatkin, V. Applying Skill-Based Engineering Using OPC-UA in Production System with a Digital Twin. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–6. [Google Scholar]

- Wang, J.; Niu, X.; Gao, R.X.; Huang, Z.; Xue, R. Digital Twin-Driven Virtual Commissioning of Machine Tool. Robot. Comput. Integr. Manuf. 2023, 81, 102499. [Google Scholar] [CrossRef]

- Wu, L.; Leng, J.; Ju, B. Digital Twins-Based Smart Design and Control of Ultra-Precision Machining: A Review. Symmetry 2021, 13, 1717. [Google Scholar] [CrossRef]

- Zaidi, A.; Keshta, I.; Gupta, Z.; Pundhir, P.; Pandey, T.; Rai, P.K.; Shabaz, M.; Soni, M. Smart Implementation of Industrial Internet of Things Using Embedded Mechatronic System. IEEE Embed. Syst. Lett. 2024, 16, 190–193. [Google Scholar] [CrossRef]

- Ebadpour, M.; Jamshidi, M.; Talla, J.; Hashemi-Dezaki, H.; Peroutka, Z. Digital Twin Model of Electric Drives Empowered by EKF. Sensors 2023, 23, 2006. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, K. Design and Simulation Debugging of Automobile Connecting Rod Production Line Based on the Digital Twin. Appl. Sci. 2023, 13, 4919. [Google Scholar] [CrossRef]

- Mazumder, A.; Sahed, M.F.; Tasneem, Z.; Das, P.; Badal, F.R.; Ali, M.F.; Ahamed, M.H.; Abhi, S.H.; Sarker, S.K.; Das, S.K.; et al. Towards next Generation Digital Twin in Robotics: Trends, Scopes, Challenges, and Future. Heliyon 2023, 9, e13359. [Google Scholar] [CrossRef] [PubMed]

- Viola, J.; Chen, Y. Parallel Self Optimizing Control Framework for Digital Twin Enabled Smart Control Engineering. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 358–361. [Google Scholar]

- Massaro, A. Artificial Intelligence Enabling Denoising in Passive Electronic Filtering Circuits for Industry 5.0 Machines. Machines 2024, 12, 551. [Google Scholar] [CrossRef]

- Massaro, A. ANNs Predicting Noisy Signals in Electronic Circuits: A Model Predicting the Signal Trend in Amplification Systems. AI 2024, 5, 533–549. [Google Scholar] [CrossRef]

- Massaro, A.; Santarsiero, F.; Schiuma, G. Advanced Electronic Controller Circuits Enabling Production Processes and AI-Driven KM in Industry 5.0. J. Ind. Inf. Integr. 2025, 45, 100841. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors 2022, 22, 8677. [Google Scholar] [CrossRef]

- Keshmiri Neghab, H.; Jamshidi, M.; Keshmiri Neghab, H. Digital Twin of a Magnetic Medical Microrobot with Stochastic Model Predictive Controller Boosted by Machine Learning in Cyber-Physical Healthcare Systems. Information 2022, 13, 321. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, L.U.; Koppu, S.; Ramu, S.P.; Iyapparaja; Boobalan, P.; Baker, T.; Maddikunta, P.K.R.; Gadekallu, T.R.; Aljuhani, A. Digital Twins for Healthcare 4.0—Recent Advances, Architecture, and Open Challenges. IEEE Consum. Electron. Mag. 2023, 12, 29–37. [Google Scholar] [CrossRef]

- Katsoulakis, E.; Wang, Q.; Wu, H.; Shahriyari, L.; Fletcher, R.; Liu, J.; Achenie, L.; Liu, H.; Jackson, P.; Xiao, Y.; et al. Digital Twins for Health: A Scoping Review. NPJ Digit. Med. 2024, 7, 77. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Saied, I.M.; Ratnarajah, T.; Arslan, T. Evaluation of Unobtrusive Microwave Sensors in Healthcare 4.0—Toward the Creation of Digital-Twin Model. Sensors 2022, 22, 8519. [Google Scholar] [CrossRef]

- Massaro, A. Electronic Artificial Intelligence–Digital Twin Model for Optimizing Electroencephalogram Signal Detection. Electronics 2025, 14, 1122. [Google Scholar] [CrossRef]

- Johnson, Z.; Saikia, M.J. Digital Twins for Healthcare Using Wearables. Bioengineering 2024, 11, 606. [Google Scholar] [CrossRef] [PubMed]

- Shafik, W. The Next Generation of Health Monitoring: Digital Twins and Medical Wearables. In AI-Powered Digital Twins for Predictive Healthcare: Creating Virtual Replicas of Humans; Balasubramaniam, S., Kadry, S., Eds.; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 69–106. [Google Scholar] [CrossRef]

- Uhlenberg, L.; Derungs, A.; Amft, O. Co-Simulation of Human Digital Twins and Wearable Inertial Sensors to Analyse Gait Event Estimation. Front. Bioeng. Biotechnol. 2023, 11, 1104000. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Chen, Z.; Jiang, M.; Tian, Z.; Peng, T.; Hu, X. Smart Clothing System with Multiple Sensors Based on Digital Twin Technology. IEEE Internet Things J. 2023, 10, 6377–6387. [Google Scholar] [CrossRef]

- Lyu, Z. Multisensor Data Fusion in Digital Twins for Smart Healthcare. In Data Fusion Techniques and Applications for Smart Healthcare; Elsevier: Amsterdam, The Netherlands, 2024; pp. 21–44. ISBN 9780443132339. [Google Scholar]

- Sharma, V.; Sharma, K.; Kumar, A. AI and Digital Twins Transforming Healthcare IoT. In Proceedings of the 2024 14th International Conference on Cloud Computing, Data Science & Engineering (Confluence), Noida, India, 18–19 January 2024; pp. 6–11. [Google Scholar]

- Elayan, H.; Aloqaily, M.; Guizani, M. Digital Twin for Intelligent Context-Aware IoT Healthcare Systems. IEEE Internet Things J. 2021, 8, 16749–16757. [Google Scholar] [CrossRef]

- Rashid, S.M.; Ghiasi, A.R. Adaptive Digital Twin Integration with Multilevel Inverter Control for Energy Efficient Smart Rehabilitation Systems. Sci. Rep. 2025, 15, 8511. [Google Scholar] [CrossRef]

- Lauer-Schmaltz, M.W.; Cash, P.; Paulin Hansen, J.; Das, N. Human Digital Twins in Rehabilitation: A Case Study on Exoskeleton and Serious-Game-Based Stroke Rehabilitation Using the ETHICA Methodology. IEEE Access 2024, 12, 180968–180991. [Google Scholar] [CrossRef]

- Khan, M.M.R.; Sunny, M.S.H.; Ahmed, T.; Shahria, M.T.; Modi, P.P.; Zarif, M.I.I.; De Caro, J.D.S.; Ahamed, S.I.; Ahmed, H.U.; Ketchum, E.M.M.; et al. Development of a Robot-Assisted Telerehabilitation System with Integrated IIoT and Digital Twin. IEEE Access 2023, 11, 70174–70189. [Google Scholar] [CrossRef]

- Harlan, B.; Tjahyadi, H. Minimally Invasive Motor Function Rehabilitation through Digital Twin Technology: A Review. In Proceedings of the 2024 2nd International Conference on Technology Innovation and Its Applications (ICTIIA), Medan, Indonesia, 12–13 September 2024; pp. 1–5. [Google Scholar]

- Xie, S.; Zhan, M.; Li, Y.; Xi, F. The Virtual-Real Interaction System Design and Interaction Characteristics Research of an Ankle Rehabilitation Robot Based on Digital Twin. Technol. Health Care 2025, 9287329251337237. [Google Scholar] [CrossRef]

- De Fazio, R.; Mastronardi, V.M.; De Vittorio, M.; Visconti, P. Wearable Sensors and Smart Devices to Monitor Rehabilitation Parameters and Sports Performance: An Overview. Sensors 2023, 23, 1856. [Google Scholar] [CrossRef]

- Dziurdzia, P.; Bratek, P.; Markiewicz, M. An Efficient Electrothermal Model of a Thermoelectric Converter for a Thermal Energy Harvesting Process Simulation and Electronic Circuits Powering. Energies 2023, 17, 204. [Google Scholar] [CrossRef]

- Tabaie, Z.; Omidvar, A. Human Body Heat-Driven Thermoelectric Generators as a Sustainable Power Supply for Wearable Electronic Devices: Recent Advances, Challenges, and Future Perspectives. Heliyon 2023, 9, e14707. [Google Scholar] [CrossRef]

- Zou, Y.; Bo, L.; Li, Z. Recent Progress in Human Body Energy Harvesting for Smart Bioelectronic System. Fundam. Res. 2021, 1, 364–382. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Z.; Kuai, Q.; Liang, J.; Liu, J.; Zeng, X. Circuit Techniques for High Efficiency Piezoelectric Energy Harvesting. Micromachines 2022, 13, 1044. [Google Scholar] [CrossRef] [PubMed]

- Haroun, A.; Le, X.; Gao, S.; Dong, B.; He, T.; Zhang, Z.; Wen, F.; Xu, S.; Lee, C. Progress in Micro/Nano Sensors and Nanoenergy for Future AIoT-Based Smart Home Applications. Nano Ex. 2021, 2, 22005. [Google Scholar] [CrossRef]

- Jettanasen, C.; Songsukthawan, P.; Ngaopitakkul, A. Conversion of Mechanical Energy to Electrical Energy Using Piezoelectric Materials for Bicycle Lane Lighting Systems. Appl. Sci. 2022, 12, 7237. [Google Scholar] [CrossRef]

- Carneiro, P.; Soares dos Santos, M.P.; Rodrigues, A.; Ferreira, J.A.F.; Simões, J.A.O.; Marques, A.T.; Kholkin, A.L. Electromagnetic Energy Harvesting Using Magnetic Levitation Architectures: A Review. Appl. Energy 2020, 260, 114191. [Google Scholar] [CrossRef]

- Hao, D.; Fan, C.; Xia, X.; Zhang, Z.; Yang, Y. Hybrid Electromagnetic-Triboelectric Hip Energy Harvester for Wearables and AI-Assisted Motion Monitoring. Small 2025, 21, e2500643. [Google Scholar] [CrossRef]

- Pang, Y.; He, T.; Liu, S.; Zhu, X.; Lee, C. Triboelectric Nanogenerator-Enabled Digital Twins in Civil Engineering Infrastructure 4.0: A Comprehensive Review. Adv. Sci. 2024, 11, e2306574. [Google Scholar] [CrossRef]

- Jiang, J.; Fan, C.; Chen, H.; Wu, F.; Feng, X.; Xiao, C.; Pan, H.; Wu, X.; Zhang, Z. A Self-Powered Triboelectric Nano-Sensor Enabled Digital Twin for Self-Sustained Machine Monitoring in Smart Mine. Nano Res. 2025, 18, 94907287. [Google Scholar] [CrossRef]

- Artetxe, E.; Uralde, J.; Barambones, O.; Calvo, I.; Martin, I. Maximum Power Point Tracker Controller for Solar Photovoltaic Based on Reinforcement Learning Agent with a Digital Twin. Mathematics 2023, 11, 2166. [Google Scholar] [CrossRef]

- Chalal, L.; Saadane, A.; Rachid, A. Unified Environment for Real Time Control of Hybrid Energy System Using Digital Twin and IoT Approach. Sensors 2023, 23, 5646. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.R.; Halder, D.; Ray, S. Digital Twins for IoT-Driven Energy Systems: A Survey. IEEE Access 2024, 12, 177123–177143. [Google Scholar] [CrossRef]

- Hossen, T.; Gursoy, M.; Mirafzal, B. Digital Twin for Self-Security of Smart Inverters. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 713–718. [Google Scholar]

- Numair, M.; Aboushady, A.A.; Arraño-Vargas, F.; Farrag, M.E.; Elyan, E. Fault Detection and Localisation in LV Distribution Networks Using a Smart Meter Data-Driven Digital Twin. Energies 2023, 16, 7850. [Google Scholar] [CrossRef]

- Yue, G.; Du, Z.; Xiu, L.; Meng, S.; Ma, Z.; Xie, Y. Electric Field Equivalent Method for AC/DC Hybrid Electric Equipment Adapted to Digital Twin with Low Latency. Electr. Power Syst. Res. 2022, 213, 108799. [Google Scholar] [CrossRef]

- Yuan, Z.; Pan, Y.; Wang, H.; Wang, S.; Peng, Y.; Jin, C.; Xu, C.; Feng, X.; Shen, K.; Zheng, Y.; et al. Fault Data Generation of Lithium Ion Batteries Based on Digital Twin: A Case for Internal Short Circuit. J. Energy Storage 2023, 64, 107113. [Google Scholar] [CrossRef]

- Li, Q.; He, Y. An Overview of Digital Twin Concept for Key Components of Renewable Energy Systems. Int. J. Robot. Autom. Technol. 2021, 8, 29–47. [Google Scholar] [CrossRef]

- Das, O.; Zafar, M.H.; Sanfilippo, F.; Rudra, S.; Kolhe, M.L. Advancements in Digital Twin Technology and Machine Learning for Energy Systems: A Comprehensive Review of Applications in Smart Grids, Renewable Energy, and Electric Vehicle Optimisation. Energy Convers. Manag. X 2024, 24, 100715. [Google Scholar] [CrossRef]

- Massaro, A.; Starace, G. Advanced and Complex Energy Systems Monitoring and Control: A Review on Available Technologies and Their Application Criteria. Sensors 2022, 22, 4929. [Google Scholar] [CrossRef]

- Bayer, D.; Pruckner, M. A Digital Twin of a Local Energy System Based on Real Smart Meter Data. Energy Inform. 2023, 6, 8. [Google Scholar] [CrossRef]

- Meyer, L.; Jorstad, K.L.; Mortensen, L.K.; Santos, A.Q.; Handrup, K.; Shaker, H.R. Digital Twin of Radio-Mesh Smart Meter Communication for Outage Management Using a Multi-Agent System. In Proceedings of the 2022 IEEE 10th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 10–12 August 2022; pp. 119–124. [Google Scholar]

- Lopez-Lorente, J.; Xydas, C.M.; Makrides, G.; Georghiou, G.E. Evaluating Voltage Estimation in a Nanogrid Using Digital Twin Models and Real-Time Smart Meter Data. In Proceedings of the 2022 International Conference on Smart Energy Systems and Technologies (SEST), Eindhoven, The Netherlands, 5–7 September 2022; pp. 1–6. [Google Scholar]

- Piras, G.; Agostinelli, S.; Muzi, F. Smart Buildings and Digital Twin to Monitoring the Efficiency and Wellness of Working Environments: A Case Study on IoT Integration and Data-Driven Management. Appl. Sci. 2025, 15, 4939. [Google Scholar] [CrossRef]

- Starace, G.; Tiwari, A.; Colangelo, G.; Massaro, A. Advanced Data Systems for Energy Consumption Optimization and Air Quality Control in Smart Public Buildings Using a Versatile Open Source Approach. Electronics 2022, 11, 3904. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward Smart-Building Digital Twins: BIM and IoT Data Integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Abdullahi, I.; Longo, S.; Samie, M. Towards a Distributed Digital Twin Framework for Predictive Maintenance in Industrial Internet of Things (IIoT). Sensors 2024, 24, 2663. [Google Scholar] [CrossRef]

- Kherbache, M.; Maimour, M.; Rondeau, E. Network Digital Twin for the Industrial Internet of Things. In Proceedings of the 2022 IEEE 23rd International Symposium on a World of Wireless, Mobile and Multimedia Networks (WoWMoM), Belfast, UK, 14–17 June 2022; pp. 573–578. [Google Scholar]

- Santos, J.F.D.; Tshoombe, B.K.; Santos, L.H.B.; Araujo, R.C.F.; Manito, A.R.A.; Fonseca, W.S.; Silva, M.O. Digital Twin-Based Monitoring System of Induction Motors Using IoT Sensors and Thermo-Magnetic Finite Element Analysis. IEEE Access 2023, 11, 1682–1693. [Google Scholar] [CrossRef]

- Caiza, G.; Sanz, R. Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Appl. Sci. 2023, 13, 7503. [Google Scholar] [CrossRef]

- Wang, K.-J.; Lee, Y.-H.; Angelica, S. Digital Twin Design for Real-Time Monitoring—A Case Study of Die Cutting Machine. Int. J. Prod. Res. 2021, 59, 6471–6485. [Google Scholar] [CrossRef]

- Ranpariya, A.; Sharma, S. A Digital Twin Solution for Fault Detection in Time-Critical IIoT Applications. J. Simul. 2025, 19, 441–454. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, Z.; Shen, L.; Kong, X.T.R.; Guo, D.; Zhong, R.Y.; Huang, G.Q. Just Trolley: Implementation of Industrial IoT and Digital Twin-Enabled Spatial-Temporal Traceability and Visibility for Finished Goods Logistics. Adv. Eng. Inform. 2022, 52, 101571. [Google Scholar] [CrossRef]

- Guo, D.; Zhong, R.Y.; Rong, Y.; Huang, G.G.Q. Synchronization of Shop-Floor Logistics and Manufacturing under IIoT and Digital Twin-Enabled Graduation Intelligent Manufacturing System. IEEE Trans. Cybern. 2023, 53, 2005–2016. [Google Scholar] [CrossRef]

- Hu, P.; He, C.; Zhu, Y.; Li, T. The Product Quality Inspection Scheme Based on Software-Defined Edge Intelligent Controller in Industrial Internet of Things. J. Cloud Comput. Adv. Syst. Appl. 2023, 12, 113. [Google Scholar] [CrossRef]

- Schrader, B.; Guerra-Zubiaga, D.; McMichael, G. Soft Sensor Digital Twin Implementation of a Pick-and-Place Operation. In Proceedings of the Volume 3: Advanced Manufacturing, New Orleans, LA, USA, 29 October–2 November 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar]

- Bolbotinović, Ž.; Milić, S.D.; Janda, Ž.; Vukmirović, D. Ai-Powered Digital Twin in the Industrial IoT. Int. J. Electr. Power Energy Syst. 2025, 167, 110656. [Google Scholar] [CrossRef]

- Wang, K.; Wang, X.; Tan, C.; Dong, S.; Zhao, F.; Lian, S. Digital Twin-Enhanced Robotic System for Remote Diesel Engine Assembly Defect Inspection. Ind. Rob. 2025, 52, 266–276. [Google Scholar] [CrossRef]

- Rodriguez-Aguilar, R.; Marmolejo-Saucedo, J.-A.; Köse, U. Development of a Digital Twin Driven by a Deep Learning Model for Fault Diagnosis of Electro-Hydrostatic Actuators. Mathematics 2024, 12, 3124. [Google Scholar] [CrossRef]

- Sheraz, M.; Chuah, T.C.; Lee, Y.L.; Alam, M.M.; Al-Habashna, A.; Han, Z. A Comprehensive Survey on Revolutionizing Connectivity through Artificial Intelligence-Enabled Digital Twin Network in 6G. IEEE Access 2024, 12, 49184–49215. [Google Scholar] [CrossRef]

- Alcaraz, C.; Lopez, J. Protecting Digital Twin Networks for 6G-Enabled Industry 5.0 Ecosystems. IEEE Netw. 2023, 37, 302–308. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Lisboa, Y.M.; Barbosa, E.F.; Santos, L.H.; Manito, A.R.; Silva, M.O.; Fonseca, W.S. Motor Monitoring and Analysis System (SMAM) as a Resource for Predictive Maintenance in Industrial Environments through Digital Twin and IIoT. In Induction Motors—Latest Research and Applications [Working Title]; El-Shahat, A., Ed.; IntechOpen: London, UK, 2024. [Google Scholar]

- Tang, Y.M.; Kuo, W.T.; Lee, C.K.M. Real-Time Mixed Reality (MR) and Artificial Intelligence (AI) Object Recognition Integration for Digital Twin in Industry 4.0. Internet Things 2023, 23, 100753. [Google Scholar] [CrossRef]

- Min, Z.; Zhou, S.; Kang, Z.; Shekhar, S.; Mahmoudi, C.; Gokhale, S.; Gokhale, A. Managing and Optimizing 5G & beyond Network Resources for Multi-Task Digital Twin Applications in Industry 4.0. In Proceedings of the 2023 IEEE 26th International Symposium on Real-Time Distributed Computing (ISORC), Nashville, TN, USA, 23–25 May 2023; pp. 220–223. [Google Scholar]

- Arbabian, A.; Pezeshk, A.; Yang, K. Productivity Enhancement in Semiconductor Manufacturing with Ai-Enabled Operations Digital Twin Platform. In Proceedings of the 2024 19th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 22–25 October 2024; pp. 280–283. [Google Scholar]

- Massaro, A. Intelligent Materials and Nanomaterials Improving Physical Properties and Control Oriented on Electronic Implementations. Electronics 2023, 12, 3772. [Google Scholar] [CrossRef]

- Corradini, F.; Silvestri, M. Design and Testing of a Digital Twin for Monitoring and Quality Assessment of Material Extrusion Process. Addit. Manuf. 2022, 51, 102633. [Google Scholar] [CrossRef]

- Lugaresi, G.; Matta, A. Automated Digital Twin Generation of Manufacturing Systems with Complex Material Flows: Graph Model Completion. Comput. Ind. 2023, 151, 103977. [Google Scholar] [CrossRef]

- Turan, E.; Konuşkan, Y.; Yıldırım, N.; Tunçalp, D.; İnan, M.; Yasin, O.; Turan, B.; Kerimoğlu, V. Digital Twin Modelling for Optimizing the Material Consumption: A Case Study on Sustainability Improvement of Thermoforming Process. Sustain. Comput. Inform. Syst. 2022, 35, 100655. [Google Scholar] [CrossRef]

- Modoni, G.E.; Stampone, B.; Trotta, G. Application of the Digital Twin for in Process Monitoring of the Micro Injection Moulding Process Quality. Comput. Ind. 2022, 135, 103568. [Google Scholar] [CrossRef]

- Psarommatis, F. A Generic Methodology and a Digital Twin for Zero Defect Manufacturing (ZDM) Performance Mapping towards Design for ZDM. J. Manuf. Syst. 2021, 59, 507–521. [Google Scholar] [CrossRef]

- Henson, C.M.; Decker, N.I.; Huang, Q. A Digital Twin Strategy for Major Failure Detection in Fused Deposition Modeling Processes. Procedia Manuf. 2021, 53, 359–367. [Google Scholar] [CrossRef]