1. Introduction

The Fourth Industrial Revolution is actively reshaping modern industry, with robotics—supported by information technologies and cyber-physical systems—playing a central role. This transformation introduces a higher degree of flexibility in production processes, including customization, scalability, and decentralized operations, thereby significantly enhancing efficiency and adaptability [

1,

2,

3]. Unlike traditional mechanization, robotization enables machines to perform complex and adaptive tasks, approaching the flexibility of human labor. At the heart of Industry 4.0, lies the seamless interconnectivity between systems and machines, aimed at optimizing production outcomes.

Building upon this foundation, Industry 5.0 introduces a more human-centered approach. It emphasizes the synergy between human creativity and machine precision, fostering collaborative work environments where technology adapts to the needs of individuals, supports critical thinking, and enhances decision-making capabilities [

4]. In this paradigm, intelligent automation is not merely about speed and accuracy, but also about augmenting human roles through training, guided assistance, and contextual support [

5,

6,

7].

The growing reliance on intelligent systems across industries requires a highly digitally literate workforce. One of the most promising tools for developing these digital competencies is educational robotics. In addition to its instructional value, educational robotics facilitates experimentation, the simulation of real-world industrial processes, and serves as a bridge between theoretical learning and practical application [

8,

9,

10]. To maximize the benefits of this approach, simulation and virtualization tools must be systematically integrated into educational and research environments, ensuring that training remains aligned with technological advancements [

11,

12,

13,

14].

Modern educational robotic platforms—such as the Wlkata Mirobot and Dobot Magician—are cost-effective, offer open APIs, and allow easy integration into laboratory environments. These platforms support various engineering research activities, including the following [

15,

16]:

Testing control algorithms (e.g., path tracking, response to sensory stimuli).

Validating communication protocols (e.g., MQTT, OPC UA).

Developing HMI and SCADA systems in conjunction with compact robotic cells.

Implementing digital twins using simulation and visualization platforms such as Unity, Factory I/O, and MATLAB Class for Mirobot * 1 B Simulink.

Safely testing failure scenarios and optimization strategies without impacting real production setups.

The research by the authors in [

17] emphasizes the systemic importance of robotics in educational practice and curriculum development. Educational robots incorporate advanced technologies such as artificial intelligence, speech and image recognition, and bionics. These systems function as intuitive yet complex educational tools, with the potential to modernize teaching practices and enhance digital competence. Effective deployment, however, requires a clear understanding of robot classifications, capabilities, and areas of application [

18,

19].

Further literature underscores the pedagogical value of AI-enabled robots in education. A systematic review conducted by [

20,

21], based on SSCI-indexed publications from 2008 to 2021, confirmed that robots with embedded AI can significantly support learning processes. Moreover, [

21] demonstrated—through the integration of the UTAUT2 and Task-Technology Fit (TTF) models—that successful adoption in higher education depends on aligning robot functionality with instructional goals. They also identified a knowledge gap regarding mismatches between robot capabilities and educational demands, recommending institutional campaigns to promote awareness and effective use.

An important trend described in [

22] highlights the convergence of augmented reality (AR) and robotics. Their combined use is transforming the learning environment into one that is increasingly interactive, inclusive, and immersive—key characteristics of future-ready educational ecosystems.

In terms of industrial relevance, the study presented in [

23] investigates the deployment of digital assets such as robotic arms, sensors, automated guided vehicles (AGVs), manufacturing execution systems (MESs), and enterprise resource planning (ERP) systems. It evaluates the applicability of the Asset Administration Shell (AAS) metamodel within the context of Industry 4.0 implementation.

Educational institutions are increasingly adopting digital twins to mirror real-world manufacturing processes. However, for these models to be pedagogically effective, they must achieve both functional and spatial fidelity with their physical counterparts [

24]. Robotic cells integrated into cyber-physical systems—incorporating PLCs, HMIs, MESs, and educational robots—enable learners to simulate realistic industrial environments. Popular platforms such as the Wlkata Mirobot, Dobot Magician, LEGO SPIKE Prime, and Fischertechnik I4.0 Factory allow for full-scale laboratory replication of Industry 4.0 processes. For a comparison of the robotic platforms used in laboratory-scale mini production lines, see

Table 1. These platforms offer the following:

Interactivity: This enables direct engagement with real hardware and software for experiential learning.

Interdisciplinary learning: This connects information technology, mechanical, electrical, and automation domains.

Safe and scalable experimentation: This minimizes risk during hands-on learning while allowing progressive complexity.

Motivation enhancement: Visible outcomes—such as robot movement—boost learner engagement and curiosity.

Vocational preparation: This trains students for careers such as those of robotic cell operators, automation technicians, or digital solutions engineers.

Table 1.

Comparison table of robotic platforms for laboratory-scale mini production lines [

25,

26,

27,

28,

29].

Table 1.

Comparison table of robotic platforms for laboratory-scale mini production lines [

25,

26,

27,

28,

29].

| Criterion/Platform | Wlkata Mirobot | Dobot Magician | LEGO SPIKE Prime | Fischertechnik I4.0 Factory |

|---|

| Platform Type | 6-axis desktop robotic arm | 4-axis desktop robotic arm | Educational building kit with programmable bricks | Modular industrial training kit |

| Focus Area | High-precision automation, Industry 4.0 training | Educational robotics, automation | STEM education for children (elementary schools) | Real-world production simulation, IoT, automation |

| Programmability | Python, Blockly, ROS, G-code, API | Blockly, Python, Scratch, API | Scratch, Python (limited), LEGO app | Proprietary software + possible PLC integration |

| Open-source/Compatibility | Open-source API, compatible with ROS, MQTT | Partially open API | Closed ecosystem | Limited openness, tightly tied to proprietary HW |

| Motion Precision and Repeatability | High (±0.2 mm) | Good (±0.2 mm) | Low (several mm) | Medium (model-scale context) |

| Industry 4.0 Integration | MQTT, ROS, possible OPC UA integration | Partial | Not supported | Full I4.0 support (sensors, RFID, MES, PLC) |

| Hardware Expandability | Modular (gripper, suction, conveyor) | Multiple add-ons (laser, gripper, pump) | Limited to LEGO parts | Multiple I4.0 modules (robot, conveyors, CNC) |

| Affordability | Affordable (€1200–1500) | Higher price (€1800–2500) | Low cost (€400–600) | Expensive (€3000–5000+) |

| Educational Materials/Documentation | Rich documentation, GitHub, student-friendly guides | Strong community and support | Extensive educational background | Limited, sometimes unintuitive |

| Best Suited For | High schools, universities, research, I4.0 training | High schools, technical courses | Elementary schools, programming basics | Technical faculties, advanced I4.0 education |

The main reasons to choose the Wlkata Mirobot are as follows:

Open Ecosystem (Open-source API): This enables integration with advanced systems such as ROS, MQTT, and digital twins.

Multi-language Programmability (Python, Blockly, G-code): This makes it suitable for both beginners and advanced users.

Precision and Realistic Robotic Motion: This allows for a simulation of real-world part manipulation with high repeatability.

Modular Hardware and Easy Integration with Conveyors and Sensors: These can serve as the foundation for both simple and complex mini production lines.

Excellent Price-to-Performance Ratio: This is ideal for educational institutions with limited budgets.

Supports Digital Twin and Simulation Tools: This makes it compatible with environments like Gazebo, Webots, or MATLAB/Simulink.

To assess the pedagogical value of the educational setup described in this study, a qualitative evaluation of student experiences was conducted. Students engaged with the Wlkata Mirobot mini-line system as part of their coursework and thesis activities. Feedback from these sessions revealed that hands-on programming, visualization through simulations, and solving layout-related problems significantly improved their understanding of industrial automation. Students rated the experience highly, with an average score of 4.5 out of 5, particularly appreciating its real-world relevance and its contribution to developing system-level thinking and automation skills.

2. Materials and Methods

Wlkata Mirobots, see

Figure 1, serve as dynamic components for constructing a physical model that can be translated into a digital representation of a production or assembly line. Robot motion programming is performed using the native Python 3.9 or later programming language or via Wlkata BlockFactory software visual function block diagrams, which enable movement programming without requiring prior knowledge of Python. The Wlkata Mirobot can be programmed to perform specific tasks, which are subsequently analysed through simulation tools, tested, and fine-tuned, with the option for integration into a virtual reality visualization environment.

The hardware and software support of the Wlkata Mirobot enable the design, creation, and testing of potential production and assembly processes. It is possible to develop a dynamic system that can be expanded with components from other manufacturers, which allow connectivity via the Arduino Mega 2560, Atmel Corporation 1600 Technology Drive, San Jose, CA, USA. This facilitates the creation of a functional production line suitable for research and the development of additional operational options in this field. Furthermore, the physical environment can be enhanced through 3D printing of specific elements.

The technical specifications, control approaches, and programming are detailed in [

25,

26]:

Software: It includes the WLKATA Studio—programming using Blockly, Python, G-code and “teach-and-play” mode.

Compatibility: It provides support for integration with ROS, MATLAB, OpenCV, and other platforms.

Control: It enacts control via PC, a mobile application, a Bluetooth controller, or directly via Arduino Mega 2560.

Integration: It integrates using PLC, OPC UA, or digital twin.

Interfaces: It supports USB, Wi-Fi, Bluetooth, and TTL UART (via Arduino), as well as an optional RS232 with a USB-to-serial adapter.

The Wlkata Mirobot supports serial communication protocols via the Arduino Mega 2560 controller, enabling integration through TTL-level UART serial interfaces. Although RS232, in its traditional voltage-level specification, is not natively supported on the core Mirobot board, serial communication can be achieved through USB-to-serial converters or via the Arduino shield expansion, see

Table 2.

3. Results

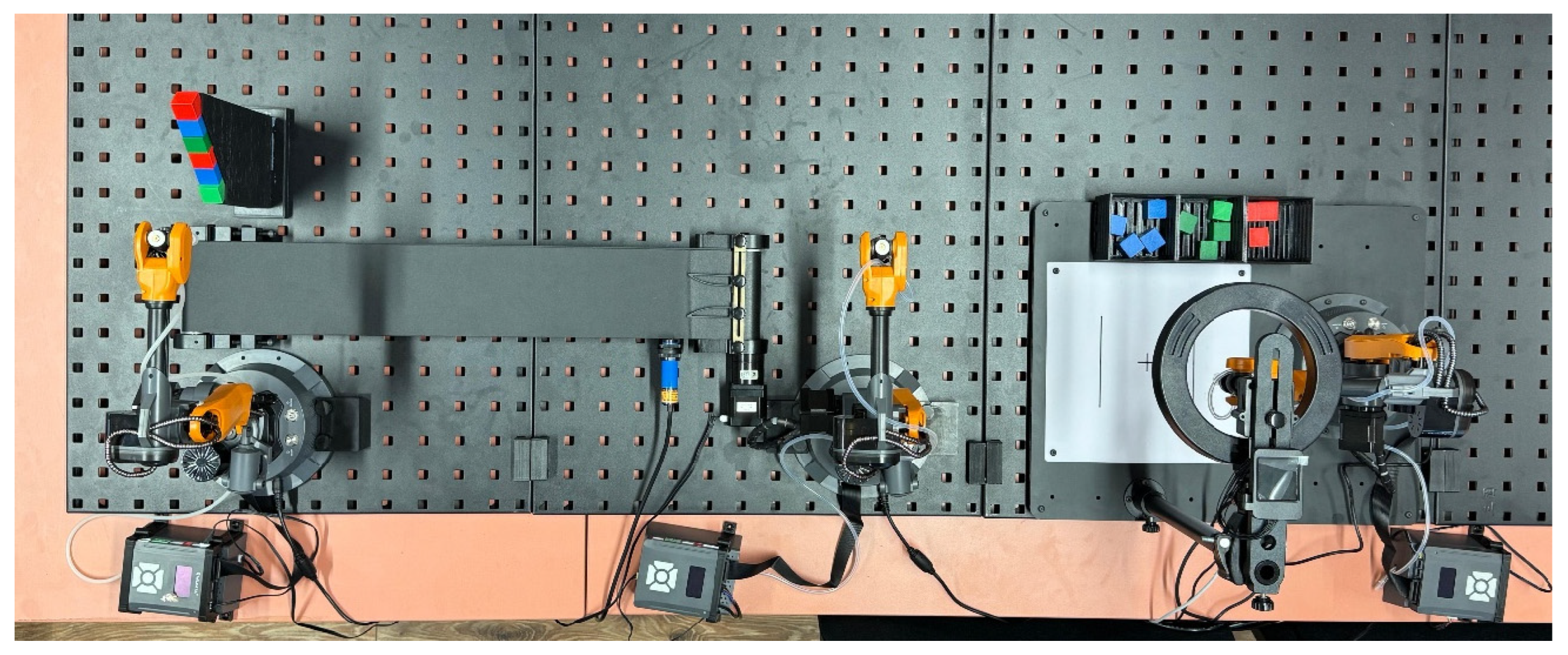

The design of a mini-line requires a comprehensive assessment of initial input data and a clear definition of conditions, with the objective of closely replicating a real production line. This process encompasses a wide range of activities, including initial conceptual design, detailed equipment layout, component selection, and the programming of robotic systems and the associated devices. The outcome is a fully functional mini-line model, implemented using Wlkata Mirobot educational robots, which enables the simulation and subsequent optimization of material flows, as well as the integration of specialized fixtures and equipment to enhance overall system efficiency.

In the process of designing and developing a mini-line, a critical aspect is the creation of a layout solution that accurately reflects the real-world production process. The subsequent optimization of this layout should be grounded in the results of comprehensive simulation studies. These simulations provide valuable data for evaluating material flow efficiency and assessing the overall functionality of the proposed arrangement of machines and components.

An optimal production line layout is defined as a configuration that, through mini-line simulation, effectively eliminates identified bottlenecks in the existing real-world setup. This approach helps minimize initial investment costs and reduces the risk of machine and component collisions. Analysing multiple layout variants via a mini-line simulation offers a comprehensive view of possible configurations, highlights areas for efficiency improvement, and reveals the shortcomings of individual designs.

The physical implementation of the optimized mini-line layout is carried out on a specially designed work surface within a laboratory environment. This platform consists of a perforated metal plate with evenly spaced square holes, allowing for flexible and modular mounting of machines, components, and model elements. This design serves as an effective tool for educational robotics, particularly when implemented with a robotic system such as the Wlkata Mirobot (see

Figure 2).

3.1. Programming and Setting up the Mini-Line

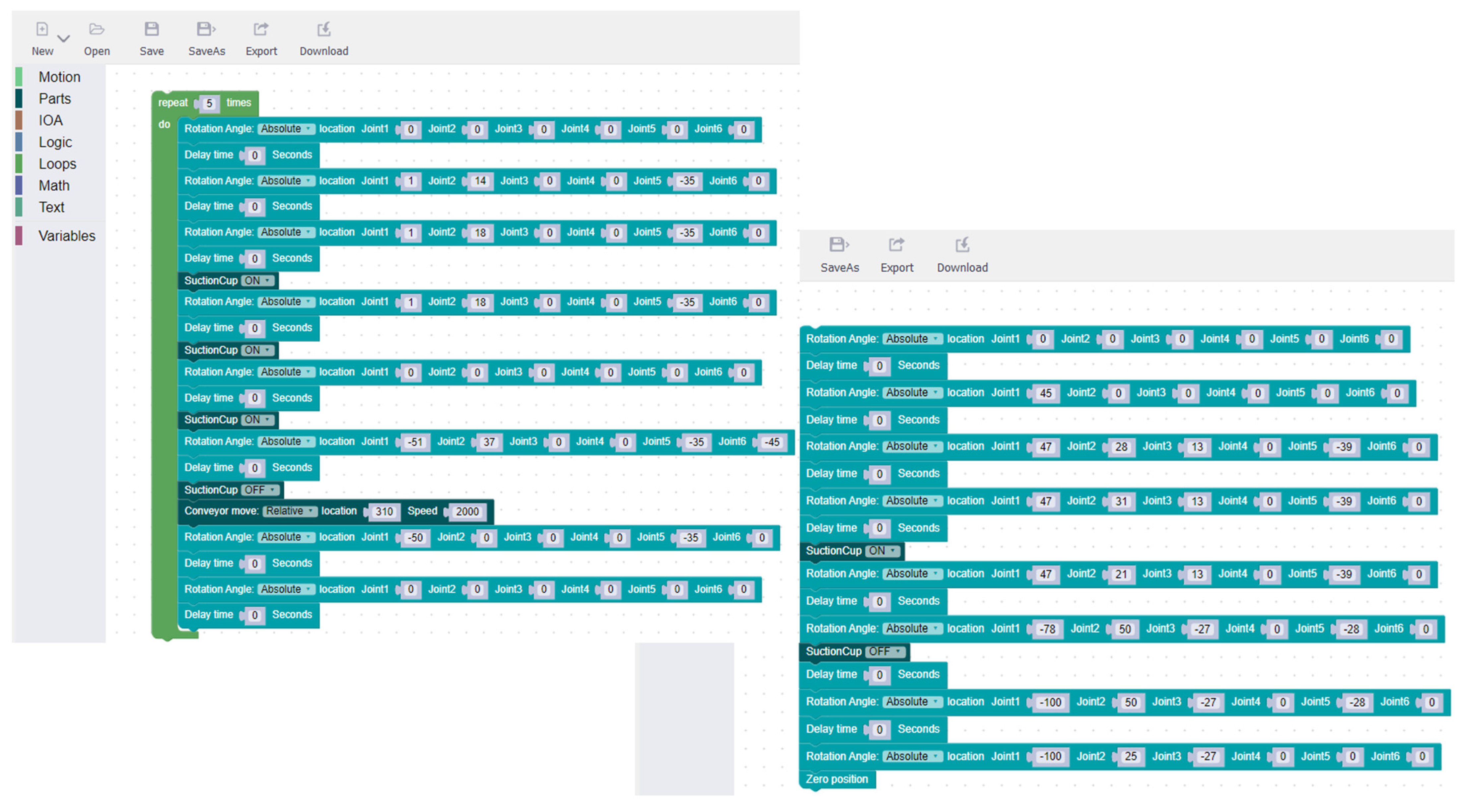

The Wlkata Mirobot No. 1 robotic arm is programmed to transfer cubes from a tray onto the conveyor belt, which is activated only when a cube is detected on its surface. The conveyor is configured to transport the cube from the loading position to the end position, where an adjustable partition ensures correct placement for the subsequent operation. Given that the robotic arm features 6 + 1 axes, the controller is capable of operating both Robot No. 1 and the conveyor simultaneously.

The Wlkata Mirobot No. 2 robotic arm is responsible for picking up the cube—positioned in the adjustable partition on the conveyor—and placing it into the workspace of the AI vision system. Throughout this operation, particular attention was paid to the safety of all machines and components due to the rapid response characteristics of the AI vision system. The program was developed to maximize efficiency and minimize bottlenecks. The end effector of Robot No. 2 is a suction cup that operates using air pressure generated by a compressor. A schematic representation of the robot programs is provided in

Figure 3.

The program was developed in Wlkata Studio using Blockly programming language. Joint mode was selected as the programming method, meaning that each axis was controlled independently. The same programming approach was applied to Robot No. 1, also utilizing Blockly.

To improve operational efficiency, the program for Robot No. 2 is not initiated manually but is triggered by a photoelectric sensor installed on the conveyor belt. The sensor sends a signal to Robot No. 2 upon detecting the presence of a cube at the end of the conveyor. This program is not limited to a predefined number of executions; it continues to operate if cube movement is detected on the conveyor. After each cycle, the robotic arm returns to its zero (home) position.

The Blockly program is stored on an SD card, either via a dedicated USB key or through direct download with automatic storage onto the SD card located in the multifunction controller. The program is configured for five repetition cycles to account for potential inaccuracies or collisions during extended operation.

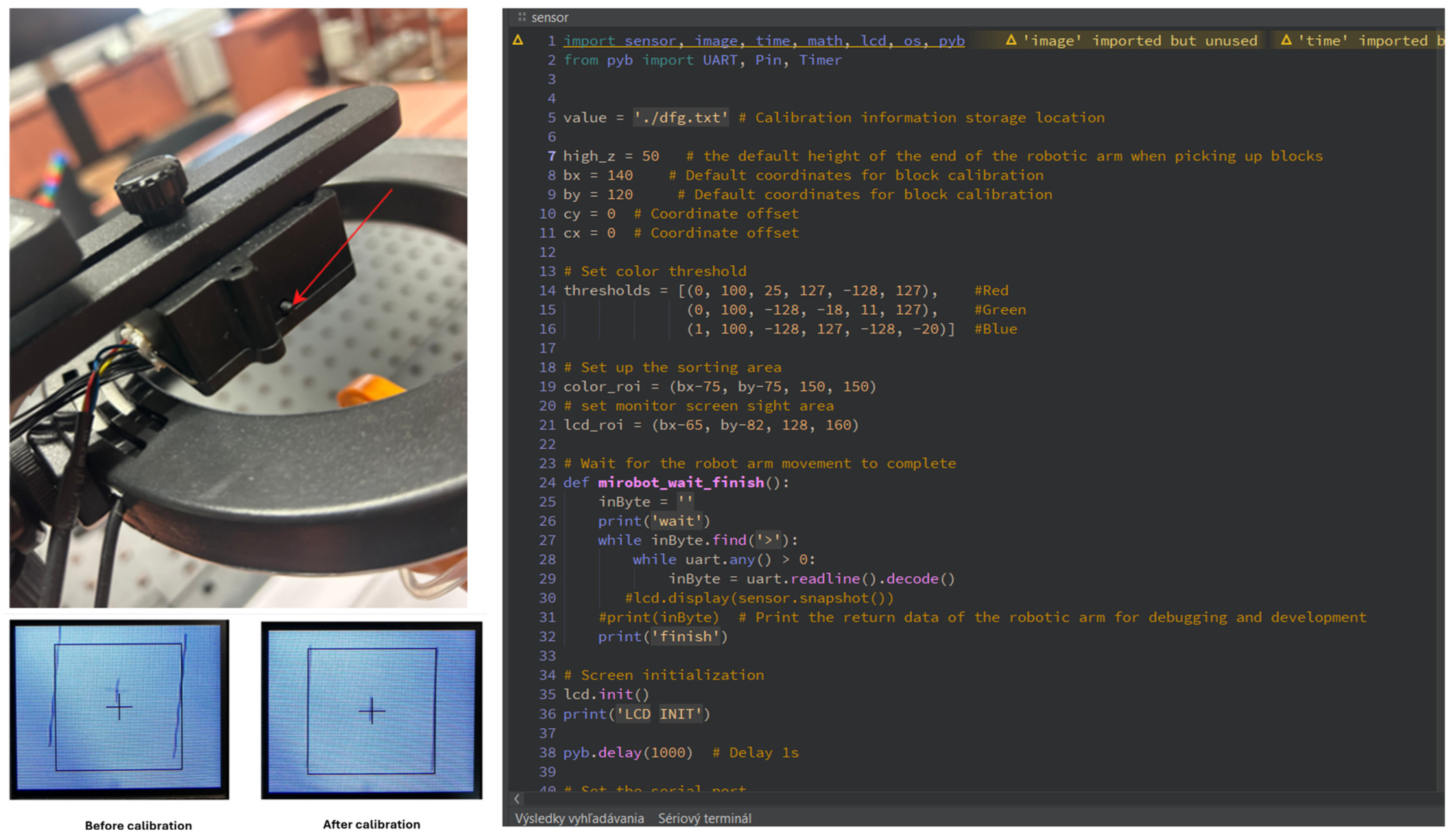

3.2. Programming the AI Vision Set

Robotic Arm No. 3 is an integral part of the AI vision system (see

Figure 4). It functions as a manipulator that handles identified objects and places them in their designated locations. In this setup, the AI vision system serves as a sorter for randomly coloured cubes appearing in primary colours such as blue, green, and red.

The sorter differentiates between individual colours using a camera mounted on a stand. Although the camera is equipped with built-in lighting, external circular illumination is also provided to enhance visual clarity and colour resolution. This external lighting system features adjustable colour temperature and intensity control. The camera is positioned to ensure a clear view of the white work surface. A suction cup, functioning as the robotic arm’s end effector, is powered by a regulated air compressor.

Efforts to improve the operational efficiency of the laboratory-scale mini-line were preceded by a baseline analysis of the original layout, which identified bottlenecks in cube handover between the robots and limited workspace accessibility. A simulation-based layout evaluation was used to test multiple configurations. Optimization methods included the rearrangement of workstations to reduce transfer distances, programming modifications to minimize idle time, and the synchronization of robot–conveyor operations. The final optimized layout resulted in smoother transitions and reduced cycle times.

3.3. Optimization Methodology and Pre-Optimization Layout Description

The initial layout configuration of the mini-line was intentionally designed with increased spatial separation between the robotic stations and peripheral devices to ensure operational safety during early testing phases. Although this setup minimized the risk of collisions, it introduced inefficiencies such as prolonged material transfer times, an extended conveyor path, and suboptimal robot reach zones.

To address these limitations, simulation-based optimization was performed. The methodology involved evaluating multiple layout variants under laboratory conditions using a digital model of the mini-line. Each variant was assessed based on the following parameters:

Total process time (measured over five cycles);

Conveyor travel distance and response delay;

Synchronization between robotic stations (especially photoelectric sensor timing);

Mechanical clearance and collision risk;

Reachability zones of the Wlkata Mirobot arms.

The optimization process was iterative, combining simulation feedback with physical layout reconfiguration on a modular test platform. The resulting configuration, shown in

Figure 5, significantly improved spatial coordination and shortened the material flow path. These changes led to a reduction in the total process time by 10.67 s. However, the more compact arrangement required precise calibration to prevent mechanical interference.

This workflow demonstrates a key benefit of educational robotic systems—namely, their ability to safely test and validate layout alternatives prior to full-scale deployment.

Following simulation-based validation, the optimized sorting mini-line was physically implemented and further tested in the laboratory. Although the efficiency gains were evident, the reduced clearances increased the risk of mechanical collisions. To mitigate this, calibration of the robot paths, end-effectors, and sensor triggers was carefully refined.

The objective of the simulation was to develop a robust and functional laboratory model that accurately mirrors a real-world sorting line (see

Figure 5). Simulation runs were monitored and iteratively adjusted to comply with safety and operational requirements. Particular attention was paid to resolving recurring errors and optimizing the number of robotic cycle repetitions to ensure reliable performance.

Additionally, due to the inclusion of the AI vision module with a camera system, the simulation time was limited to 60 s per run. This precaution was necessary to prevent overheating and to maintain reliable colour detection during high-frequency sorting tasks.

4. Discussion

The presented case study focused on the integration and functionality of a mini-line simulation using a Wlkata Mirobot robotic arm in a controlled laboratory environment. This study demonstrated the potential of the Wlkata Mirobot not only in educational settings but also in simulating realistic production scenarios through the designed mini-line. In developing this system, emphasis was placed on ensuring operational functionality and reliability, achieved through the integration of hardware components and the development of control programs for process automation.

The Wlkata Mirobot serves as a flexible and reliable platform for constructing educational mini-lines that replicate real industrial processes. Rather than merely executing predefined robotic tasks, these configurations enable the testing and visualization of layout modifications and their effects on production efficiency. This methodology facilitates safe experimentation, promotes a deeper understanding of industrial processes, and supports system-level optimization—factors particularly valuable in engineering education.

The system further demonstrates its applicability in optimizing actual production lines by enabling the development of effective layout configurations within a simulated laboratory environment. Through a simulation and a subsequent optimization of the mini-line, it becomes possible to streamline real-world operations without jeopardizing costly industrial equipment. Implementing the proposed mini-line into a real production environment could result in substantial savings in both time and cost, while also minimizing the risk of collisions between machines and components.

Despite the strengths of the proposed system, several limitations and potential inaccuracies were identified. These included inaccurate positioning of the robotic arm and work surfaces, the need for improved calibration of both the robotic arms and the AI vision system, and constraints on the simultaneous operation of the robotic arm and conveyor. In this study, these shortcomings were addressed and effectively mitigated. Customized supports for the robotic arms and workpads were designed and fabricated using additive manufacturing technologies, significantly enhancing the system’s precision and mechanical stability. All devices underwent comprehensive calibration, and the issue of robot–conveyor concurrency was resolved through an optimized layout solution that minimized material flow distances.

5. Conclusions

In this case study, a Wlkata Mirobot robotic arm demonstrated a wide range of applications in addressing challenges related to industrial processes and operations. Looking ahead, the future development and scaling of mini-lines would benefit from the integration of additional components and centralized control programming via Arduino. This enhancement would enable the simulation and testing of more complex automated workflows. One of the key advantages of educational robotics lies in the ability to develop and validate a simulation model prior to full physical implementation. This model can be effectively hosted within a digital twin environment. The Wlkata Mirobot ecosystem supports this functionality through an IOA software platform, which facilitates programming, visualization, and the creation of digital twins representing real production lines. The tool enables the virtual modelling of mini-lines using Mirobot robotic arms, allowing interactive 3D programming of mechanical and electrical subsystems, with compatibility for PLC control systems and artificial intelligence integration. Educational robotics platforms, such as the Wlkata Mirobot, offer students a tangible and practical pathway to acquiring relevant Industry 4.0 and 5.0 competencies.

Educational robots enable the modelling of real-world production and the handling of processes on a reduced scale, thereby contributing to the following:

Training operators in a risk-free environment, avoiding damage to expensive equipment;

Analysing material flow, workstation layout, and line efficiency;

Testing human–robot collaboration (HRC) under safe and controlled conditions;

Evaluating bottlenecks and optimizing workflows prior to physical implementation;

Introducing Lean Manufacturing and Just-In-Time (JIT) principles in an educational context.

Such simulations foster systems thinking and deepen the understanding of complex production systems, which is essential for future engineers and technicians. Integrating educational robotics with concepts such as digital twins, the Internet of Things (IoTs), and process simulation establishes a foundation for interdisciplinary learning and more effective preparation for real-world industrial scenarios. These approaches contribute not only to enhanced technical literacy but also to the adaptability required in a rapidly evolving labor market.

Robotics functions as a powerful enabler of digital competency development across all educational levels. While basic robotic kits help build foundational algorithmic thinking, more advanced platforms support the realistic simulation of industrial processes, thereby reinforcing the transition from theoretical knowledge to practical application—a core tenet of Industry 4.0 and 5.0.

Author Contributions

Conceptualization, P.T., M.P., M.K., M.M. and J.K.; methodology, P.T., M.P., M.K., M.M. and J.K.; software, M.P. and M.K.; validation, P.T., M.P., M.K. and J.K.; formal analysis, M.P., P.T., M.K., M.M. and J.K.; investigation, M.M., P.T., M.P., M.K. and J.K.; resources, M.P. and P.T.; data curation, M.K., J.K., P.T. and M.P., writing—original draft preparation, M.P., M.K., J.K., M.M. and P.T.; writing—review and editing, J.K. and M.M.; project administration, P.T. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This article was created through the implementation of the grant projects APVV-17-0258 “Digital engineering elements application in innovation and optimization of production flows”, APVV-19-0418 “Intelligent solutions to enhance business innovation capability in the process of transforming them into smart businesses”, VEGA 1/0508/22 ”Innovative and digital technologies in manufacturing and logistics processes and system”, VEGA 1/0383/25 “Optimizing the activities of manufacturing enterprises and their digitization using advanced virtual means and tools”, KEGA 020TUKE-4/2023 “Systematic development of the competence profile of students of industrial and digital engineering in the process of higher education”, and KEGA 003TUKE-4/2024 “Innovation of the profile of industrial engineering graduates in the context of required knowledge and specific capabilities for research and implementation of intelligent systems of the future”.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Balzer, R.; Uzik, M.; Glova, J. Managing Growth Opportunities in The Digital Era—An Empiric Perspective of Value Creation. Pol. J. Manag. Stud. 2020, 21, 87–100. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital twin shop-floor: A new shop-floor paradigm towards smart manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Ke, S.; Xiang, F.; Zhang, Z.; Zuo, Y. A enhanced interaction framework based on VR, AR and MR in digital twin. Procedia CIRP 2019, 83, 753–758. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Straka, M. Identification of Social and Economic Expectations: Contextual Reasons for the Transformation Process of Industry 4.0 into the Industry 5.0 Concept. Sustainability 2022, 14, 1391. [Google Scholar] [CrossRef]

- Kábele, P.; Edl, M. Increasing the Efficiency of the Production Process Due to Using Methods of Industrial Engineering. In Advances in Design, Simulation and Manufacturing II: Proceedings of the 2nd International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2019, Lutsk, Ukraine, 11–14 June 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 126–137. [Google Scholar]

- Straka, M.; Hricko, M. Software system design for solution of effective material layout for the needs of production and logistics. In Wireless Networks: The Journal of Mobile Communication, Computation and Information; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Matiskova, D.; Balog, M.; Husar, J. Criteria for the Optimization of Production Processes in Machining of Metallic Materials. Manag. Syst. Prod. Eng. 2018, 26, 227–230. [Google Scholar] [CrossRef]

- Zatrochova, M.; Kuperova, M.; Janakova, H. Innovative education of graduates of technical schools as a factor for competitiveness. In Proceedings of the 11th annual International Conference of Education, Research and Innovation (ICERI2018), Seville, Spain, 12–14 November; 2018; pp. 10198–10204, ISBN 978-84-09-05948-5. [Google Scholar] [CrossRef]

- Krajcovic, M.; Gabajova, G.; Furmannova, B.; Vavrik, V.; Gaso, M.; Matys, M. A case study of educational games in virtual reality as a teaching method of lean management. Electronics 2021, 10, 838. [Google Scholar] [CrossRef]

- Szajna, A.; Szajna, J.; Stryjski, R.; Sąsiadek, M.; Woźniak, W. The Application of Augmented Reality Technology in the Production Processes. Adv. Intell. Syst. Comput. 2019, 835, 316–324. [Google Scholar]

- Knapcikova, L.; Behunova, A.; Behun, M. Using a discrete event simulation as an effective method applied in the production of recycled material. Adv. Prod. Eng. Manag. 2020, 15, 431–440. [Google Scholar] [CrossRef]

- Grznár, P.; Krajčovič, M.; Gola, A.; Dulina, Ľ.; Furmannová, B.; Mozol, Š.; Plinta, D.; Burganová, N.; Danilczuk, W.; Svitek, R. The Use of a Genetic Algorithm for Sorting Warehouse Optimisation. Processes 2021, 9, 1197. [Google Scholar] [CrossRef]

- Marasova, D.; Saderova, J.; Ambrisko, L. Simulation of the Use of the Material Handling Equipment in the Operation Process. Open Eng. 2020, 10, 216–223. [Google Scholar] [CrossRef]

- Gregor, M.; Hodon, R.; Grznar, P.; Mozol, S. Design of a System for Verification of Automatic Guided Vehicle Routes Using Computer Emulation. Appl. Sci. 2022, 12, 3397. [Google Scholar] [CrossRef]

- WLKATA Book Shelf (Inner) 1.1 Introduction of WLKATA Mirobot. Last Updated 7 October 2024. Available online: https://portals.docsie.io/wlkata-robotics/wlkata_robotics_document/welcome-to-docsie-red-beta-mayer/deployment_mi7d471IH33Hz2NKM/?doc=/wlkata-mirobot-user-manual-platinum/ (accessed on 22 July 2025).

- WLKATA Book Shelf (Inner) 1.2 Quick Start Guide of Mirobot. Last Updated 7 September 2023. Available online: https://portals.docsie.io/wlkata-robotics/wlkata_robotics_document/welcome-to-docsie-red-beta-mayer/deployment_mi7d471IH33Hz2NKM/?doc=/wlkata-mirobot-user-manual-platinum/12-quick-start-guide-of-mirobot/ (accessed on 22 July 2025).

- Xu, W.; Ouyang, F. Robotic roles in education: A systematic review based on a proposed framework of the learner-robot relationships. Educ. Res. Rev. 2025, 47, 100685. [Google Scholar] [CrossRef]

- Pei, P.; Nie, Y. Educational Robots: Classification, Characteristics, Application Areas and Problems. In Proceedings of the Seventh International Conference of Educational Innovation through Technology (EITT), Auckland, New Zealand, 12–14 December 2018. [Google Scholar]

- Jung, S.E.; Won, E.-S. Systematic Review of Research Trends in Robotic Education for Young Children. Sustainability 2018, 10, 905. [Google Scholar] [CrossRef]

- Chu, S.-T.; Hwang, G.-J.; Tu, Y.-F. Artificial intelligence-based robots in education: A systematic review of selected SSCI publications. Comput. Educ. Artif. Intell. 2022, 3, 100091. [Google Scholar] [CrossRef]

- Suhal, F.; Adel, M.; Al-Emran, M.; AlQudah, A.A. Are students ready for robots in higher education? Examining the adoption of robots by integrating UTAUT2 and TTF using a hybrid SEM-ANN approach. Technol. Soc. 2024, 77, 102524. [Google Scholar] [CrossRef]

- Pasalidou, C.; Lytridis, C.; Tsinakos, A.; Fachantidis, N. Augmented Reality and Robotics in Education: A Literature Review. Comput. Hum. Behav. Artif. Hum. 2025, 4, 100157. [Google Scholar] [CrossRef]

- Abdel-Aty, T.A.; Elisa Negri, E.; Galparoli, S. Asset Administration Shell in Manufacturing: Applications and Relationship with Digital Twin. IFAC-Pap. 2022, 55, 2533–2538. [Google Scholar] [CrossRef]

- Korsoveczki, G.; Vasváry, T.; Szarka, A.V.; Sarvajcz, K. Digital twin design of a 5 degrees of freedom industrial robotic arm for engineering education purposes. Meas. Sens. 2024, 38, 101323. [Google Scholar] [CrossRef]

- WLKATA Book Shelf (inner), AI Navigation Learning Suite Overview. Available online: https://portals.docsie.io/wlkata-robotics/wlkata_robotics_document/welcome-to-docsie-red-beta-mayer/deployment_mi7d471IH33Hz2NKM/?doc=/wlkata-ai-hub-ai-navigation-kit-user-manual/wlkata-ai-hub-ai-navigation-kit-user-manual/#:~focus=The%20AI%20Navigation%20Learning (accessed on 1 March 2025).

- WLKATA. Available online: https://www.wlkata.com/products/wlkata-best-6-axis-stem-educational-robot-arm-kit (accessed on 22 July 2025).

- DOBOT Magician–Multifunctional Desktop Robotic Arm. Available online: https://www.dobot-robots.com/products/education/magician.html (accessed on 4 August 2025).

- LEGO® Education SPIKE™ Prime Set–LEGO Education. Available online: https://www.lego.com/en-sk/search?q=lego+education&suggestion=true (accessed on 4 August 2025).

- Fischertechnik Industry 4.0 Simulation Factory. Available online: https://www.fischertechnik.de/en/products/industry-and-universities/training-models/554868-training-factory-industry-4-0-24v (accessed on 4 August 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).