Collision Avoidance of Driving Robotic Vehicles Based on Model Predictive Control with Improved APF

Abstract

1. Introduction

- (1)

- This work proposes a unified universal potential field constraint framework that significantly advances current APF methodologies. The proposed generalized potential field model differs from existing APF methods. It considers threat levels and adapts to various obstacles and road types, unlike methods designed for specific obstacle types or straight paths. This approach significantly improves safety and adaptability compared to conventional distance-based potential field designs.

- (2)

- An environment-adaptive potential field design in the Frenet coordinate system is developed to address the limitations of existing methods in complex road scenarios. The coordinate-transformation-based framework ensures consistent performance across arbitrary road curvatures and features a novel auxiliary attractive potential field mechanism. This design guarantees stable trajectory recovery after obstacle avoidance maneuvers, solving the critical problem of seamless return to original paths.

- (3)

- An integrated MPC-APF optimization framework is established that unifies path planning and trajectory tracking in a single-stage approach. This unified optimization simultaneously handles path planning and trajectory tracking while reducing computational complexity. The framework incorporates multi-objective optimization considering comfort, safety, and control smoothness, providing superior performance compared to traditional two-stage planning and tracking approaches.

2. Modeling of Driving Robot and Vehicle

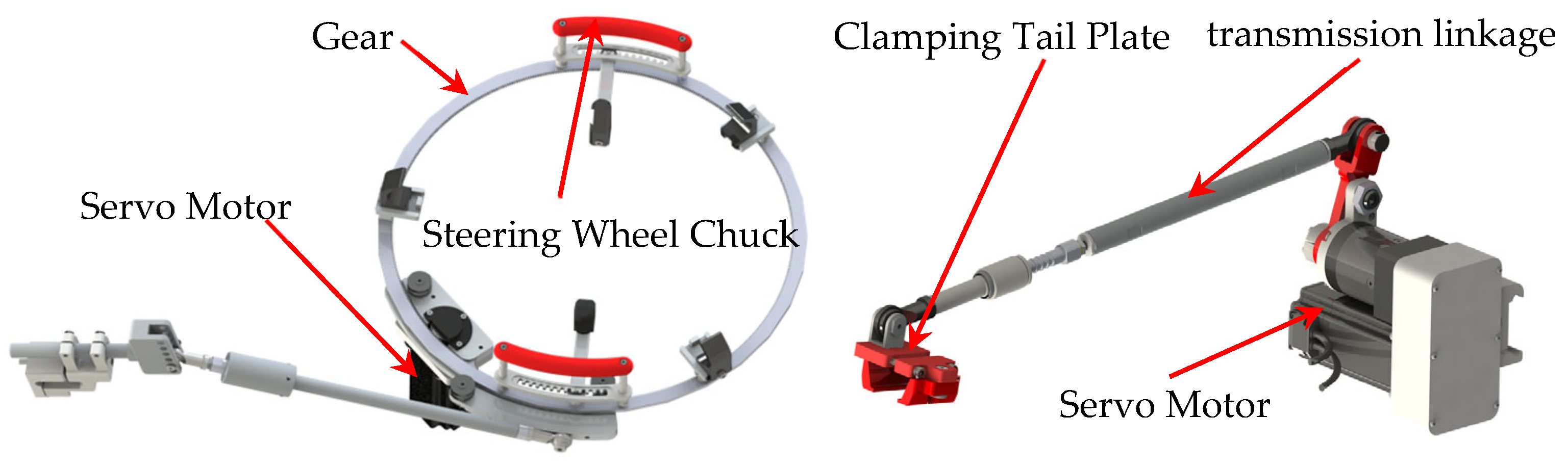

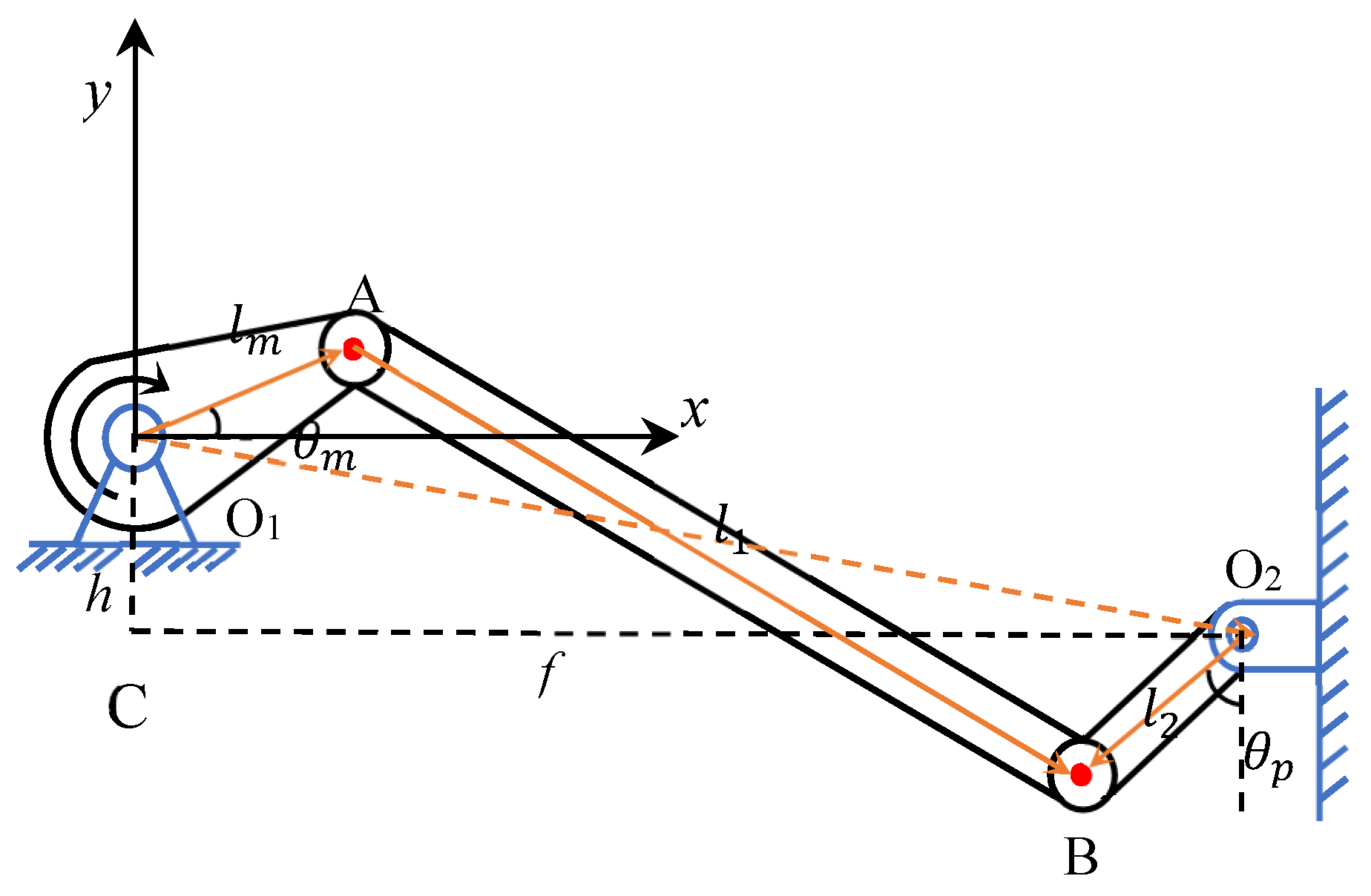

2.1. Autonomous Driving Robot

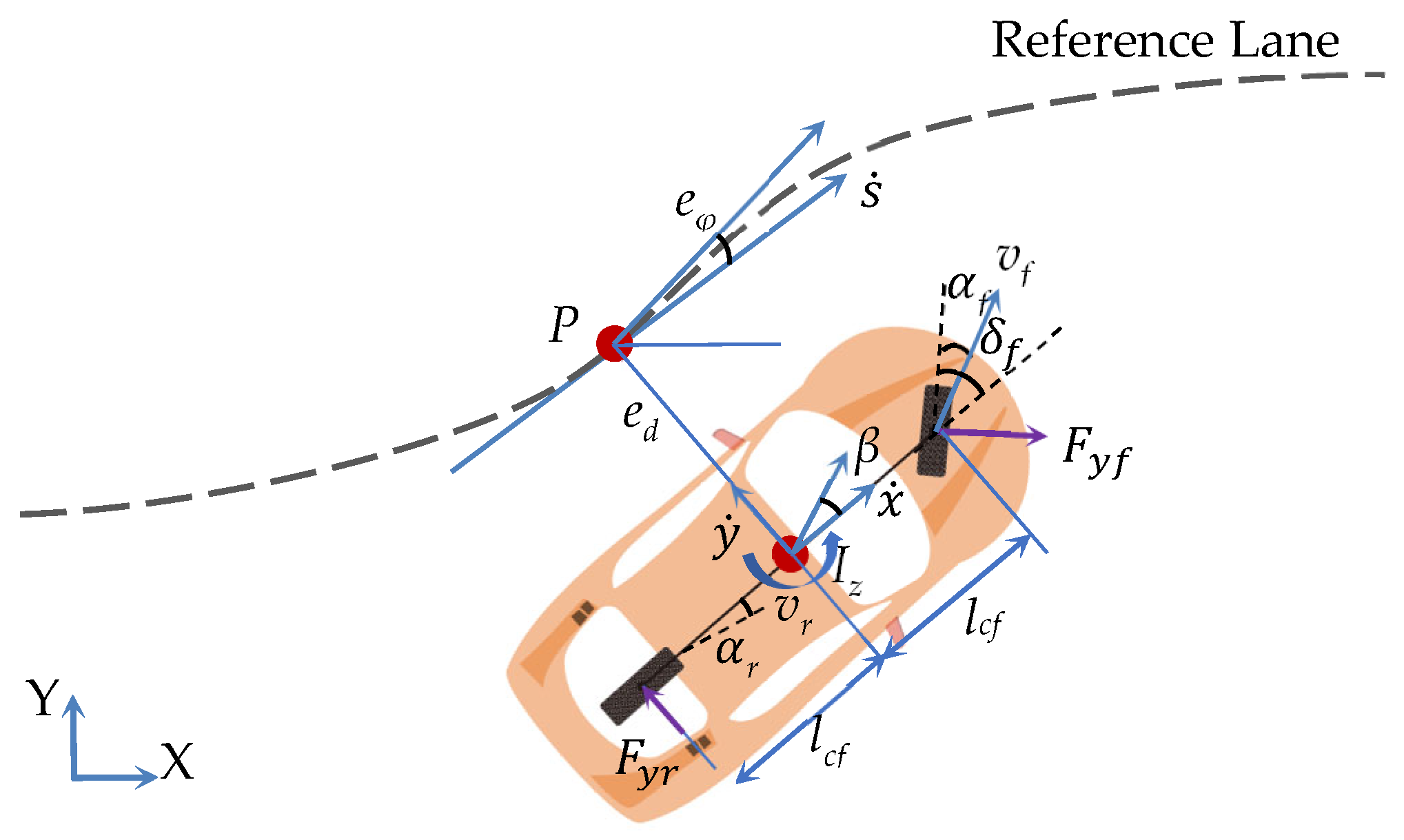

2.2. Vehicle Dynamics Model

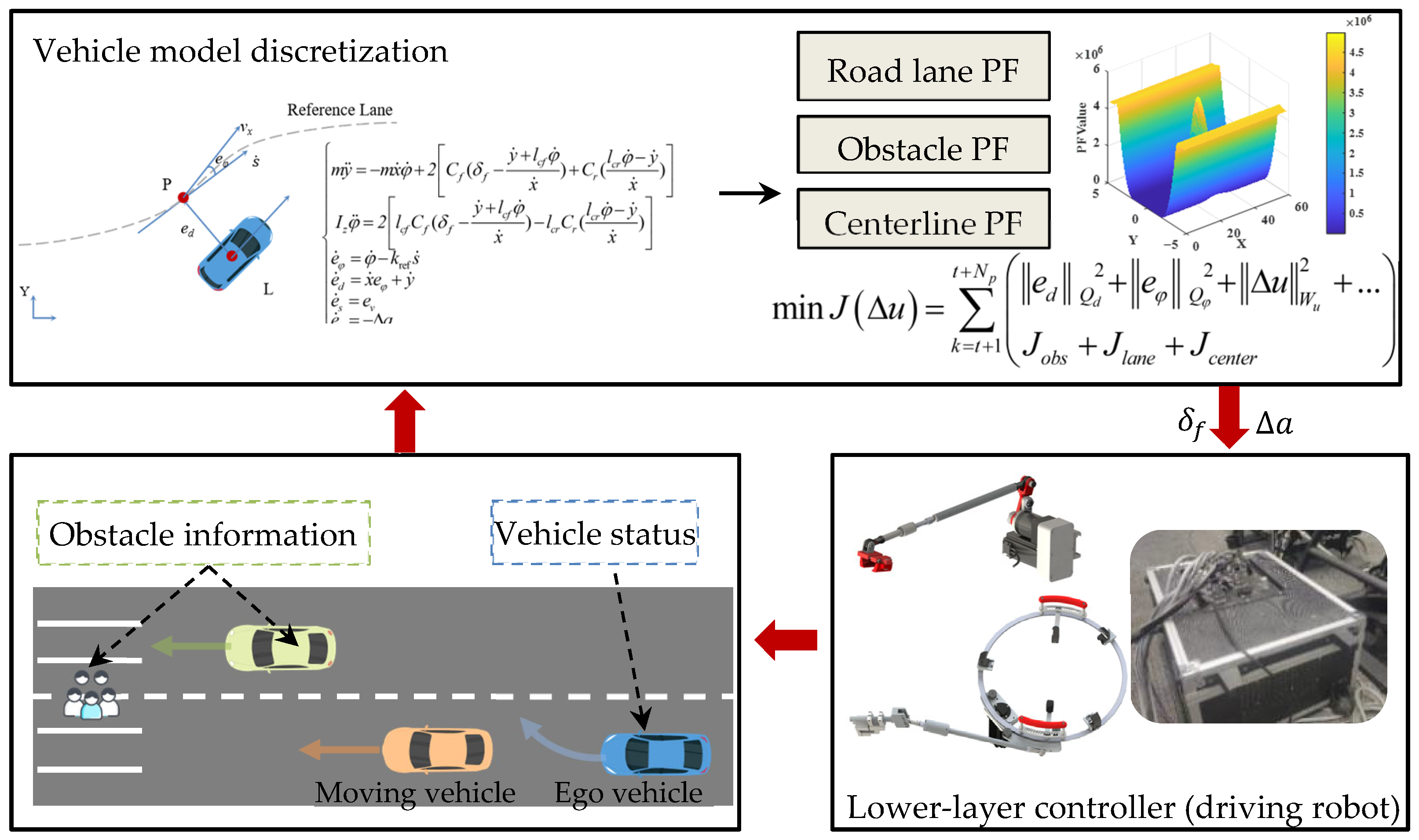

3. The Framework of Driving Robot Control Vehicle

3.1. Vehicle Model Discretization

3.2. Obstacle Motion Model

3.3. Multi-Objective Trajectory Planner Integrating Improved APF with MPC

3.3.1. Improved Road Boundary PF

3.3.2. Dynamic/Static Obstacle PF

3.3.3. Trajectory Guidance PF

3.3.4. MPC Multi-Constraint Optimization

4. Simulation and Experiment

4.1. Simulation Results

- (1)

- Static obstacle avoidance

- (2)

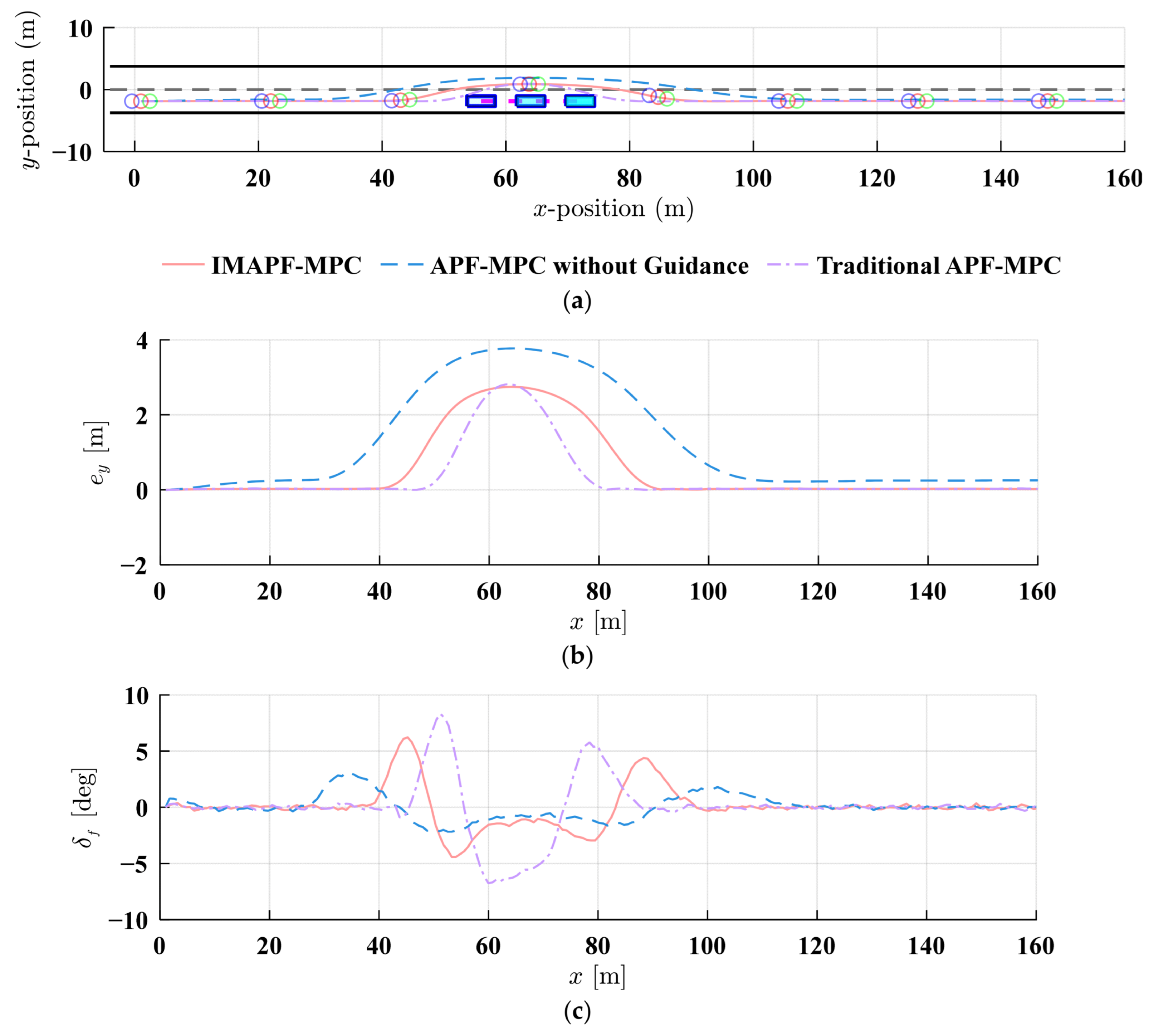

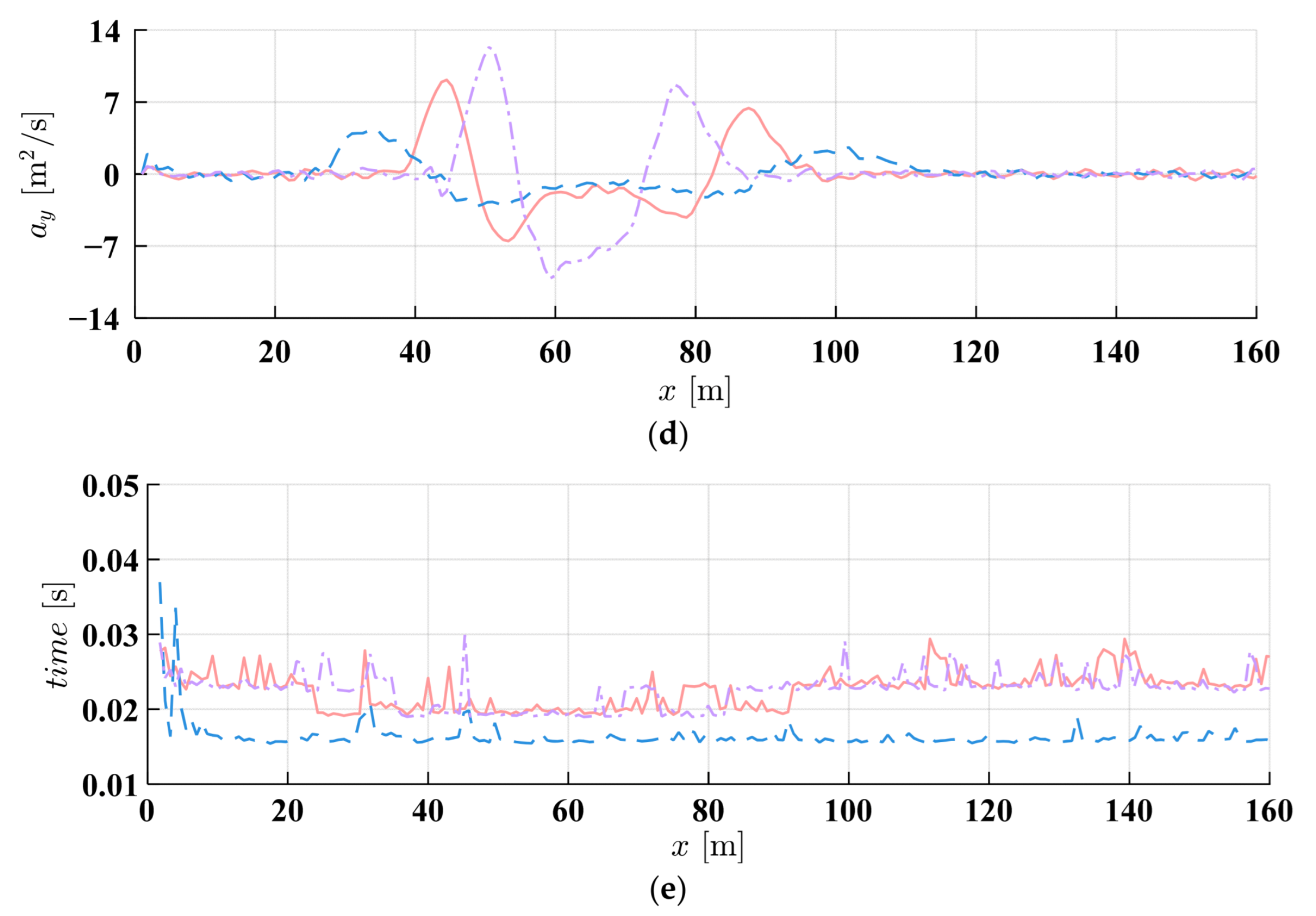

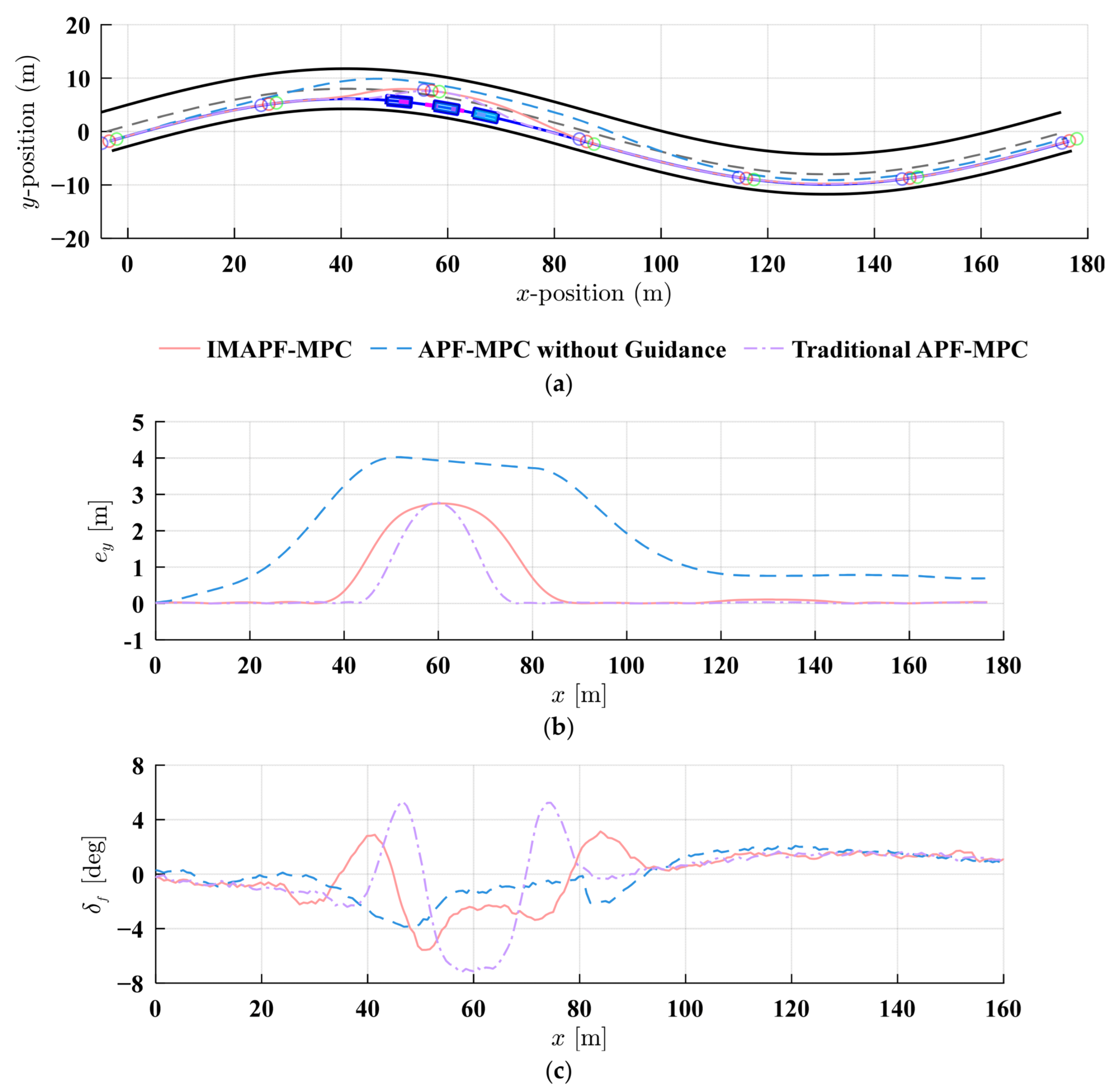

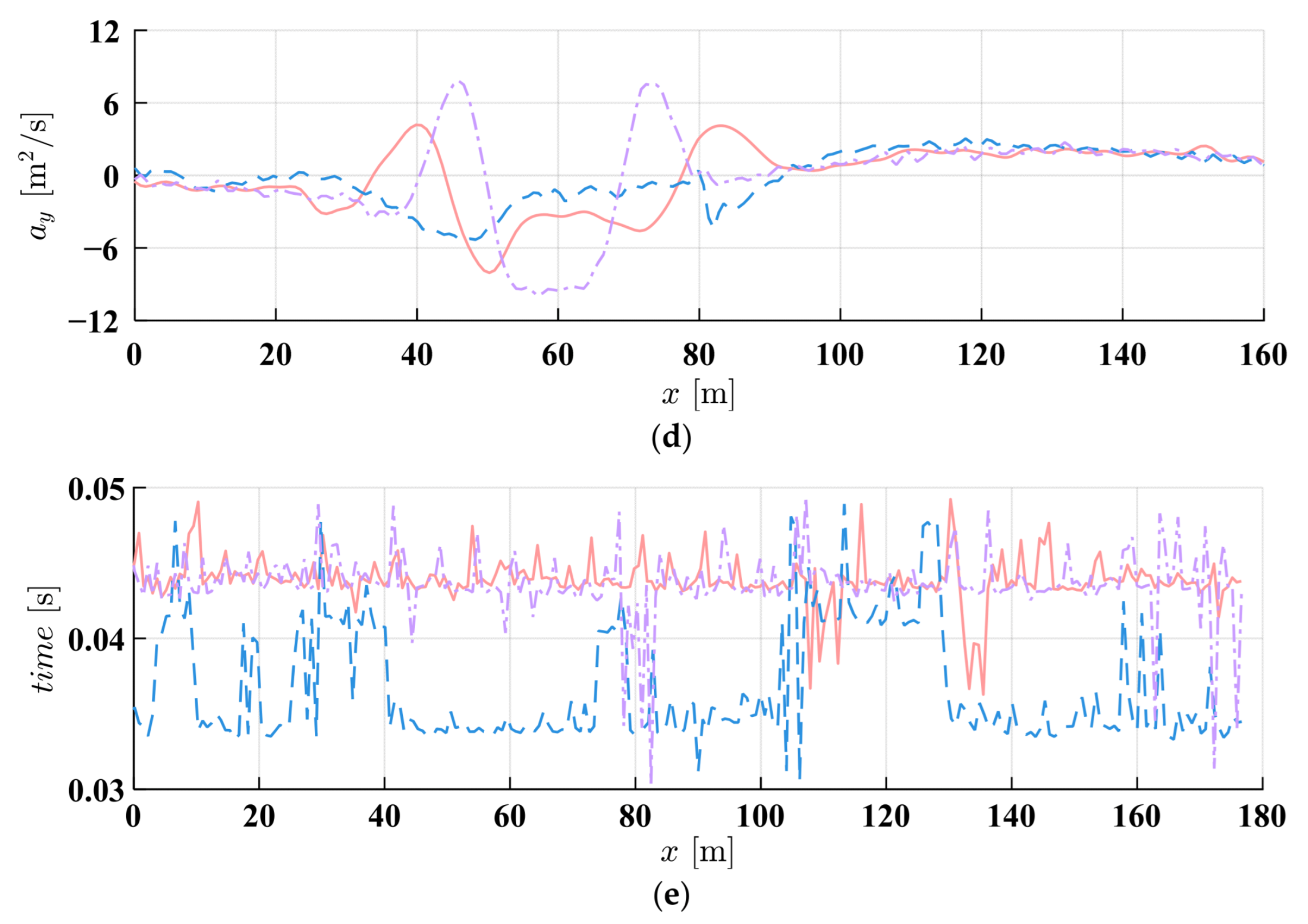

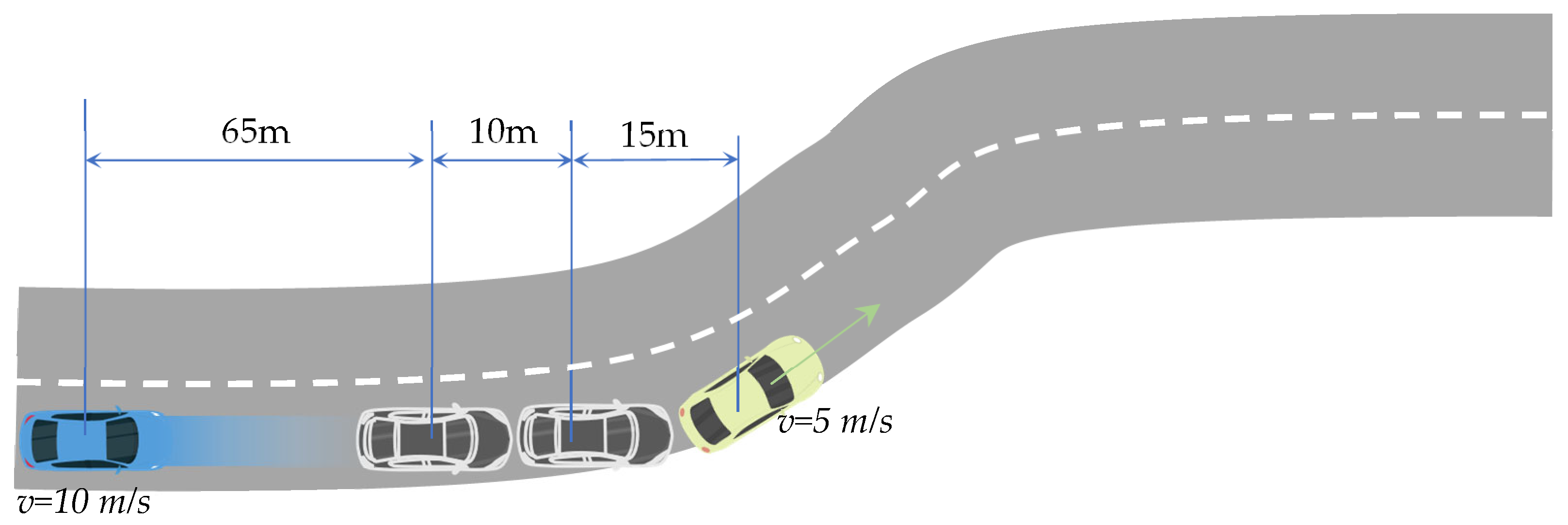

- Dynamic obstacle avoidance

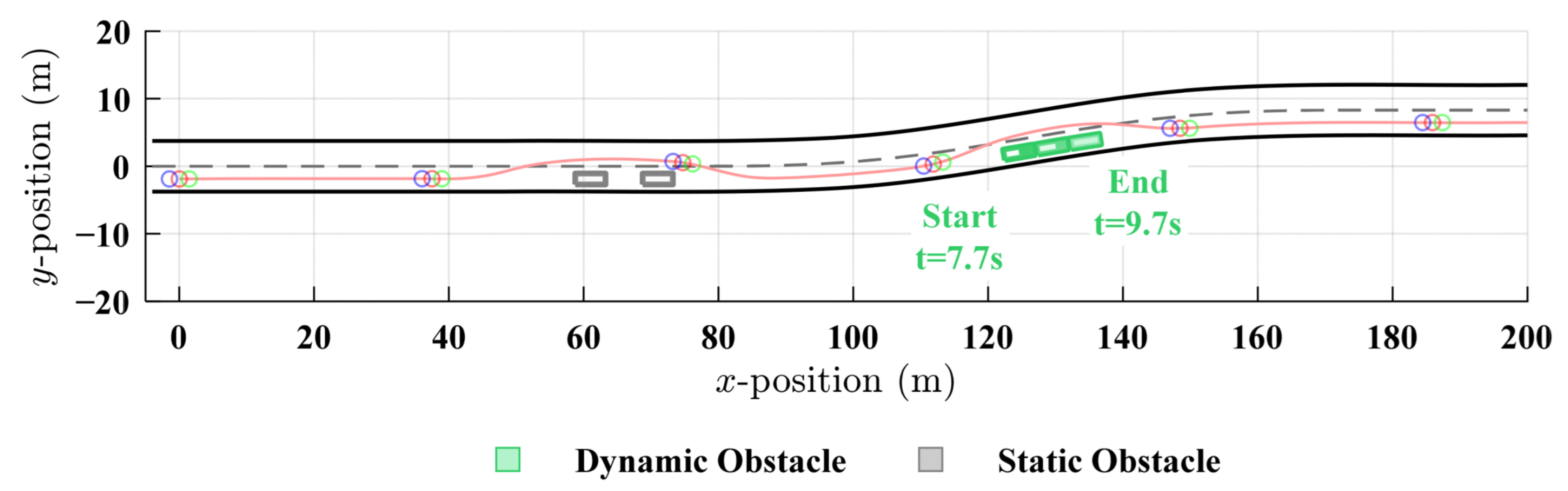

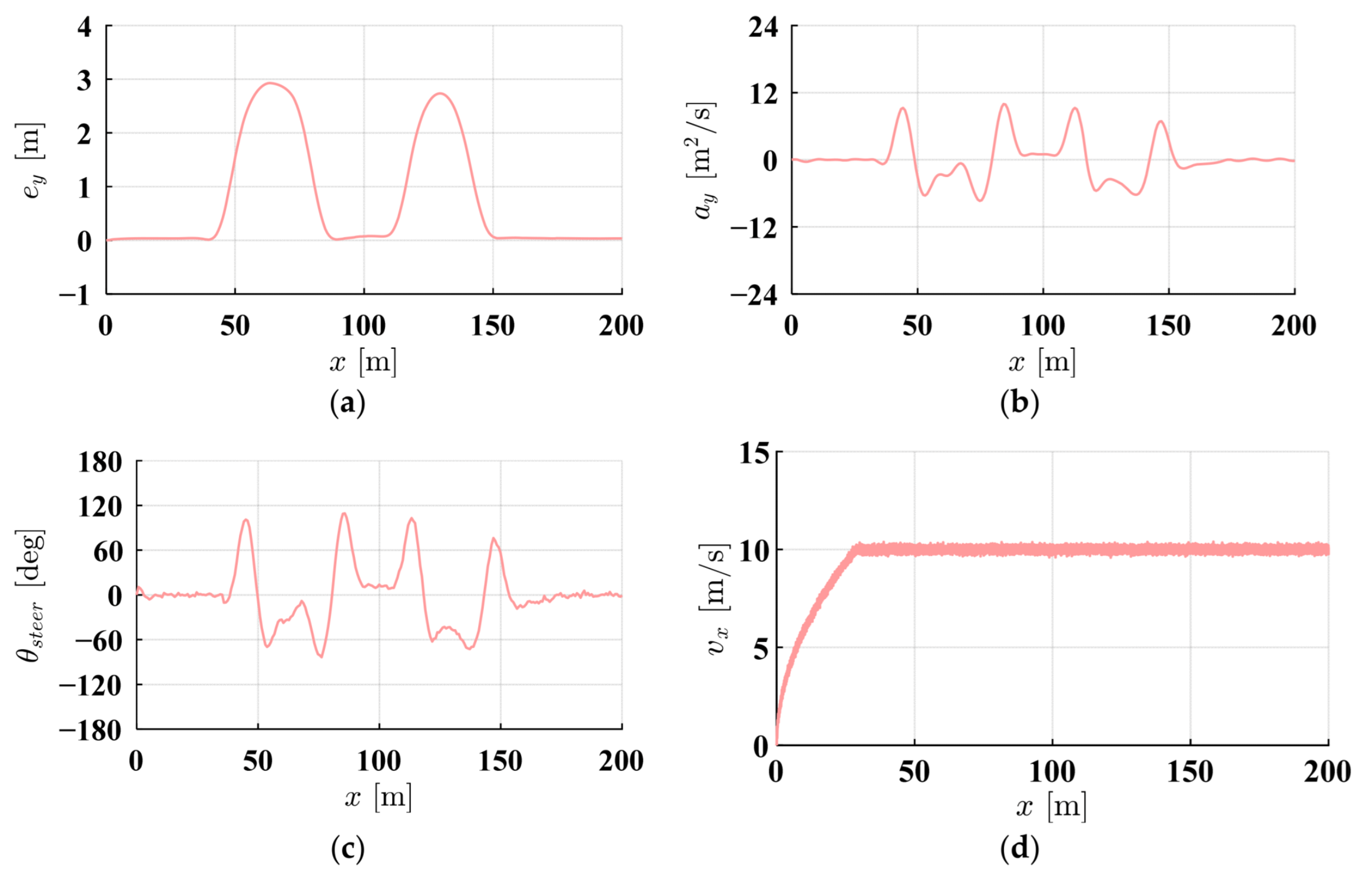

4.2. Experimental Results

5. Conclusions

- (1)

- IMAPF-MPC successfully handles static and dynamic obstacle scenarios on straight and curved roads. In the static obstacle avoidance of a straight road, compared with the traditional APF-MPC, the developed method’s peak lateral acceleration decreases by 63.7% (from 21.902 m/s2 to 7.943 m/s2), while maintaining a comparable tracking accuracy. The maximum tracking error is 2.449 m. IMAPF-MPC shows better adaptability in dynamic obstacle scenarios, which leads to significantly reduced steering oscillations and improved passenger comfort.

- (2)

- The semi-physical experimental platform shows that, by combining the proposed obstacle avoidance strategy with the driving system of the underlying driving robot, the IMAPF-MPC can effectively complete the obstacle avoidance task and maintain good trajectory tracking performance in complex road scenes with dynamic and static obstacles. The testing outcomes validate the practicality and reliability of the algorithm within real hardware configurations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Chen, G.; Zhang, W. A Method for Vehicle Speed Tracking by Controlling Driving Robot. Trans. Inst. Meas. Control 2020, 42, 1521–1536. [Google Scholar] [CrossRef]

- Chen, G.; Chen, S.; Langari, R.; Li, X.; Zhang, W. Driver-Behavior-Based Adaptive Steering Robust Nonlinear Control of Unmanned Driving Robotic Vehicle with Modeling Uncertainties and Disturbance Observer. IEEE Trans. Veh. Technol. 2019, 68, 8183–8190. [Google Scholar] [CrossRef]

- Liang, J.; Li, Y.; Yin, G.; Xu, L.; Lu, Y.; Feng, J.; Shen, T.; Cai, G. A MAS-Based Hierarchical Architecture for the Cooperation Control of Connected and Automated Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 1559–1573. [Google Scholar] [CrossRef]

- Chen, G.; Su, S. Driver-Behavior-Based Robust Steering Control of Unmanned Driving Robotic Vehicle with Modeling Uncertainties and External Disturbance. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 1585–1596. [Google Scholar] [CrossRef]

- Yang, L.; Li, P.; Qian, S.; Quan, H.; Miao, J.; Liu, M.; Hu, Y.; Memetimin, E. Path Planning Technique for Mobile Robots: A Review. Machines 2023, 11, 980. [Google Scholar] [CrossRef]

- Debnath, D.; Vanegas, F.; Sandino, J.; Hawary, A.F.; Gonzalez, F. A Review of UAV Path-Planning Algorithms and Obstacle Avoidance Methods for Remote Sensing Applications. Remote Sens. 2024, 16, 4019. [Google Scholar] [CrossRef]

- Zhang, R.; Hao, G.; Zhang, K.; Li, Z. Unmanned Aerial Vehicle Navigation in Underground Structure Inspection: A Review. Geol. J. 2023, 58, 2454–2472. [Google Scholar] [CrossRef]

- Li, C.; Huang, X.; Ding, J.; Song, K.; Lu, S. Global Path Planning Based on a Bidirectional Alternating Search A* Algorithm for Mobile Robots. Comput. Ind. Eng. 2022, 168, 108123. [Google Scholar] [CrossRef]

- Wang, H.; Qi, X.; Lou, S.; Jing, J.; He, H.; Liu, W. An Efficient and Robust Improved A* Algorithm for Path Planning. Symmetry 2021, 13, 2213. [Google Scholar] [CrossRef]

- Xu, B. Precise Path Planning and Trajectory Tracking Based on Improved A-Star Algorithm. Meas. Control 2024, 57, 1025–1037. [Google Scholar] [CrossRef]

- Ravankar, A.A.; Ravankar, A.; Emaru, T.; Kobayashi, Y. HPPRM: Hybrid Potential Based Probabilistic Roadmap Algorithm for Improved Dynamic Path Planning of Mobile Robots. IEEE Access 2020, 8, 221743–221766. [Google Scholar] [CrossRef]

- Raheem, F.A.; Abdulkareem, M.I. Development of Path Planning Algorithm Using Probabilistic Roadmap Based on Modified Ant Colony Optimization. World J. Eng. Technol. 2019, 7, 583–597. [Google Scholar] [CrossRef]

- Yu, J.; Chen, C.; Arab, A.; Yi, J.; Pei, X.; Guo, X. RDT-RRT: Real-Time Double-Tree Rapidly-Exploring Random Tree Path Planning for Autonomous Vehicles. Expert Syst. Appl. 2024, 240, 122510. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Y.; Bu, S.; Yang, J. Smart Vehicle Path Planning Based on Modified PRM Algorithm. Sensors 2022, 22, 6581. [Google Scholar] [CrossRef]

- Huang, T.; Fan, K.; Sun, W. Density Gradient-RRT: An Improved Rapidly Exploring Random Tree Algorithm for UAV Path Planning. Expert Syst. Appl. 2024, 252, 124121. [Google Scholar] [CrossRef]

- Chen, Q.; Yu, B.; Min, S.; Gan, L.; Luo, C.; Zeng, D.; Hu, Y.; Liu, Q. Study on Intelligent Vehicle Trajectory Planning and Tracking Control Based on Improved APF and MPC. Int. J. Automot. Technol. 2025, 26, 715–728. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, Y.; Huang, L.; Zhang, J.; Luan, Z.; Zhao, W.; Chen, F. Research on Vehicle Obstacle Avoidance Path Planning Based on APF-PSO. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 1391–1405. [Google Scholar] [CrossRef]

- Jayaweera, H.M.; Hanoun, S. A Dynamic Artificial Potential Field (D-APF) UAV Path Planning Technique for Following Ground Moving Targets. IEEE Access 2020, 8, 192760–192776. [Google Scholar] [CrossRef]

- Feng, S.; Qian, Y.; Wang, Y. Collision Avoidance Method of Autonomous Vehicle Based on Improved Artificial Potential Field Algorithm. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3416–3430. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Zhu, S.; Xiao, J.; Chen, S.; Guo, J.; Ren, D.; Wang, J. Path Tracking and Local Obstacle Avoidance for Automated Vehicle Based on Improved Artificial Potential Field. Int. J. Control Autom. Syst. 2023, 21, 1644–1658. [Google Scholar] [CrossRef]

- Azzabi, A.; Nouri, K. An Advanced Potential Field Method Proposed for Mobile Robot Path Planning. Trans. Inst. Meas. Control 2019, 41, 3132–3144. [Google Scholar] [CrossRef]

- Pan, Z.; Zhang, C.; Xia, Y.; Xiong, H.; Shao, X. An Improved Artificial Potential Field Method for Path Planning and Formation Control of the Multi-UAV Systems. IEEE Trans. Circuits Syst. II Express Briefs 2022, 69, 1129–1133. [Google Scholar] [CrossRef]

- Hammad, S. Path Tracking Control Based on an Adaptive MPC to Changing Vehicle Dynamics. Int. J. Mech. Eng. Robot. Res. 2022, 11, 535–541. [Google Scholar] [CrossRef]

- Liu, X.; Ou, J.; Yan, D.; Zhang, Y.; Deng, G. Path Tracking Control of Automated Vehicles Based on Adaptive MPC in Variable Scenarios. IET Intell. Transp. Syst. 2024, 18, 1031–1044. [Google Scholar] [CrossRef]

- Zuo, Z.; Yang, X.; Li, Z.; Wang, Y.; Han, Q.; Wang, L.; Luo, X. MPC-Based Cooperative Control Strategy of Path Planning and Trajectory Tracking for Intelligent Vehicles. IEEE Trans. Intell. Veh. 2021, 6, 513–522. [Google Scholar] [CrossRef]

- Chen, S.; Xiong, G.; Chen, H.; Negrut, D. MPC-Based Path Tracking with PID Speed Control for High-Speed Autonomous Vehicles Considering Time-Optimal Travel. J. Cent. South Univ. 2020, 27, 3702–3720. [Google Scholar] [CrossRef]

- Chu, H.; Meng, D.; Huang, S.; Tian, M.; Zhang, J.; Gao, B.; Chen, H. Autonomous High-Speed Overtaking of Intelligent Chassis Using Fast Iterative Model Predictive Control. IEEE Trans. Transp. Electrif. 2024, 10, 1244–1256. [Google Scholar] [CrossRef]

- Ko, C.; Han, S.; Choi, M.; Kim, K.S. Integrated Path Planning and Tracking Control of Autonomous Vehicle for Collision Avoidance Based on Model Predictive Control and Potential Field. In Proceedings of the 2020 20th International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 13–16 October 2020; pp. 956–961. [Google Scholar] [CrossRef]

- Li, H.; Wu, C.; Chu, D.; Lu, L.; Cheng, K. Combined Trajectory Planning and Tracking for Autonomous Vehicle Considering Driving Styles. IEEE Access 2021, 9, 9453–9463. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Y.; Zhang, K.; Chen, Y.; Cao, M.; Yin, G. Path Planning on Large Curvature Roads Using Driver-Vehicle-Road System Based on the Kinematic Vehicle Model. IEEE Trans. Veh. Technol. 2022, 71, 311–325. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Xia, Y.; Zuo, Z. EMPC with Adaptive APF of Obstacle Avoidance and Trajectory Tracking for Autonomous Electric Vehicles. ISA Trans. 2023, 135, 438–448. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, G. Dynamic Model Predictive Control Method for Steering Control of Driving Robot. J. Shanghai Jiaotong Univ. 2022, 56, 594. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, W. Control System Design for Electromagnetic Driving Robot Used for Vehicle Test. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2019; IEEE: New York, NY, USA, 2019; pp. 811–815. [Google Scholar] [CrossRef]

- Xiao, Z.; Hu, M.; Fu, C.; Qin, D. Model Predictive Trajectory Tracking Control of Unmanned Vehicles Based on Radial Basis Function Neural Network Optimisation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 347–361. [Google Scholar] [CrossRef]

- Liu, Q.; Song, S.; Hu, H.; Huang, T.; Li, C.; Zhu, Q. Extended Model Predictive Control Scheme for Smooth Path Following of Autonomous Vehicles. Front. Mech. Eng. 2022, 17, 4. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Chen, W.; Zhao, L.; Tan, D. Path Tracking Based on Model Predictive Control with Variable Predictive Horizon. Trans. Inst. Meas. Control 2021, 43, 2676–2688. [Google Scholar] [CrossRef]

- Alcalá, E.; Puig, V.; Quevedo, J. LPV-MPC Control for Autonomous Vehicles. IFAC-Pap. 2019, 52, 106–113. [Google Scholar] [CrossRef]

- Li, D.; Wu, S.; Zhao, Y.; Li, Z.; Gong, J. A Hierarchical Path Tracking Method for High-Speed Unmanned Tracked Vehicle. In Proceedings of the 2021 IEEE International Intelligent Transportation Systems Conference (ITSC), Indianapolis, IN, USA, 19–22 September 2021; pp. 38–43. [Google Scholar] [CrossRef]

- Elhesasy, M.; Dief, T.N.; Atallah, M.; Okasha, M.; Kamra, M.M.; Yoshida, S.; Rushdi, M.A. Non-Linear Model Predictive Control Using CasADi Package for Trajectory Tracking of Quadrotor. Energies 2023, 16, 2143. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| lcf | 1.015 | m |

| lcr | 1.895 | m |

| m | 1413 | kg |

| wd | 2.6 | m |

| Iz | 1536.7 | kg·m2 |

| Clf | 74,870 | |

| Clr | 44,370 | |

| Np | 20 | / |

| Ts | 0.05 | s |

| Aobs | 30 × 105 | / |

| d0 | 0.8 | m |

| nu | 5 × 105 | / |

| Acenter | 1 × 105 | / |

| klat | 0.1 | / |

| kv | 0.3 | / |

| Algorithm | Maximum ey (m) | Maximum ay (m/s2) | Maximum δf (°) |

|---|---|---|---|

| APF-MPC without Guidance | 3.099 | 13.968 | 6.621 |

| Traditional APF-MPC | 2.316 | 21.902 | 14.668 |

| IMAPF-MPC | 2.449 | 7.943 | 5.372 |

| Algorithm | Maximum ey (m) | Maximum ay (m/s2) | Maximum δf (°) |

|---|---|---|---|

| APF-MPC without Guidance | 3.770 | 13.297 | 6.481 |

| Traditional APF-MPC | 2.315 | 22.141 | 15.080 |

| IMAPF-MPC | 2.749 | 11.050 | 7.641 |

| Algorithm | Maximum ey (m) | Maximum ay (m/s2) | Maximum δf (°) |

|---|---|---|---|

| APF-MPC without Guidance | 3.770 | 4.399 | 3.141 |

| Traditional APF-MPC | 2.816 | 12.264 | 8.312 |

| IMAPF-MPC | 2.749 | 9.024 | 6.220 |

| Algorithm | Maximum ey (m) | Maximum ay (m/s2) | Maximum δf (°) |

|---|---|---|---|

| APF-MPC without Guidance | 4.024 | 5.342 | 3.873 |

| Traditional APF-MPC | 2.768 | 9.921 | 7.184 |

| IMAPF-MPC | 2.752 | 7.204 | 5.556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Liu, H.; Niu, W. Collision Avoidance of Driving Robotic Vehicles Based on Model Predictive Control with Improved APF. Machines 2025, 13, 696. https://doi.org/10.3390/machines13080696

Zhao L, Liu H, Niu W. Collision Avoidance of Driving Robotic Vehicles Based on Model Predictive Control with Improved APF. Machines. 2025; 13(8):696. https://doi.org/10.3390/machines13080696

Chicago/Turabian StyleZhao, Lei, Hongda Liu, and Wentie Niu. 2025. "Collision Avoidance of Driving Robotic Vehicles Based on Model Predictive Control with Improved APF" Machines 13, no. 8: 696. https://doi.org/10.3390/machines13080696

APA StyleZhao, L., Liu, H., & Niu, W. (2025). Collision Avoidance of Driving Robotic Vehicles Based on Model Predictive Control with Improved APF. Machines, 13(8), 696. https://doi.org/10.3390/machines13080696