A Multi-Purpose Simulation Layer for Digital Twin Applications in Mechatronic Systems

Abstract

1. Introduction

- RQ1: Which Digital Twin architectures already exist, and which typologies of physical systems are they applied to?

- RQ2: Which techniques are exploited for the development of decision-oriented module in such architectures?

- RQ3: Which techniques are peculiarly efficient for industrial mechatronic systems?

2. Literature Review

2.1. Theoretical Background

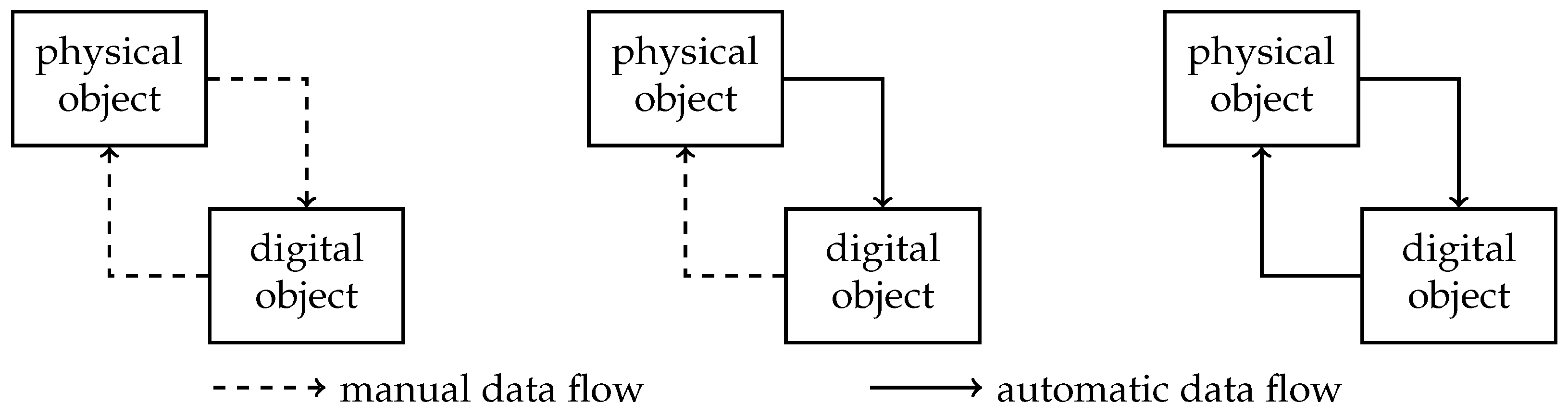

- Digital Model (DM): Data exchange between the physical and virtual worlds occurs manually.

- Digital Shadow (DS): Data from the physical system is autonomously acquired, but human intervention is still required to transfer insights, such as simulation results or production metrics, back to the real world.

- Digital Twin (DT): Features fully integrated bidirectional data flows, enabling continuous synchronization between the physical and digital domains.

- Simulation: Capturing the full behavioral characteristics of the physical system at any given moment.

- Synchronization: Ensuring the virtual counterpart accurately reflects the real-world system in real time.

- Optimization: Enabling data-driven enhancements that allow the physical system to operate at peak efficiency.

2.2. Digital Twin Architectures

- Observable Manufacturing layer: Includes physical entities like personnel, equipment, and processes.

- Device Communication layer: Handles data collection from sensors and control of manufacturing devices.

- Digital Twin layer: Provides real-time synchronization, simulation, and data analytics of physical elements.

- User layer: Interfaces with humans and external systems for decision-making and visualization.

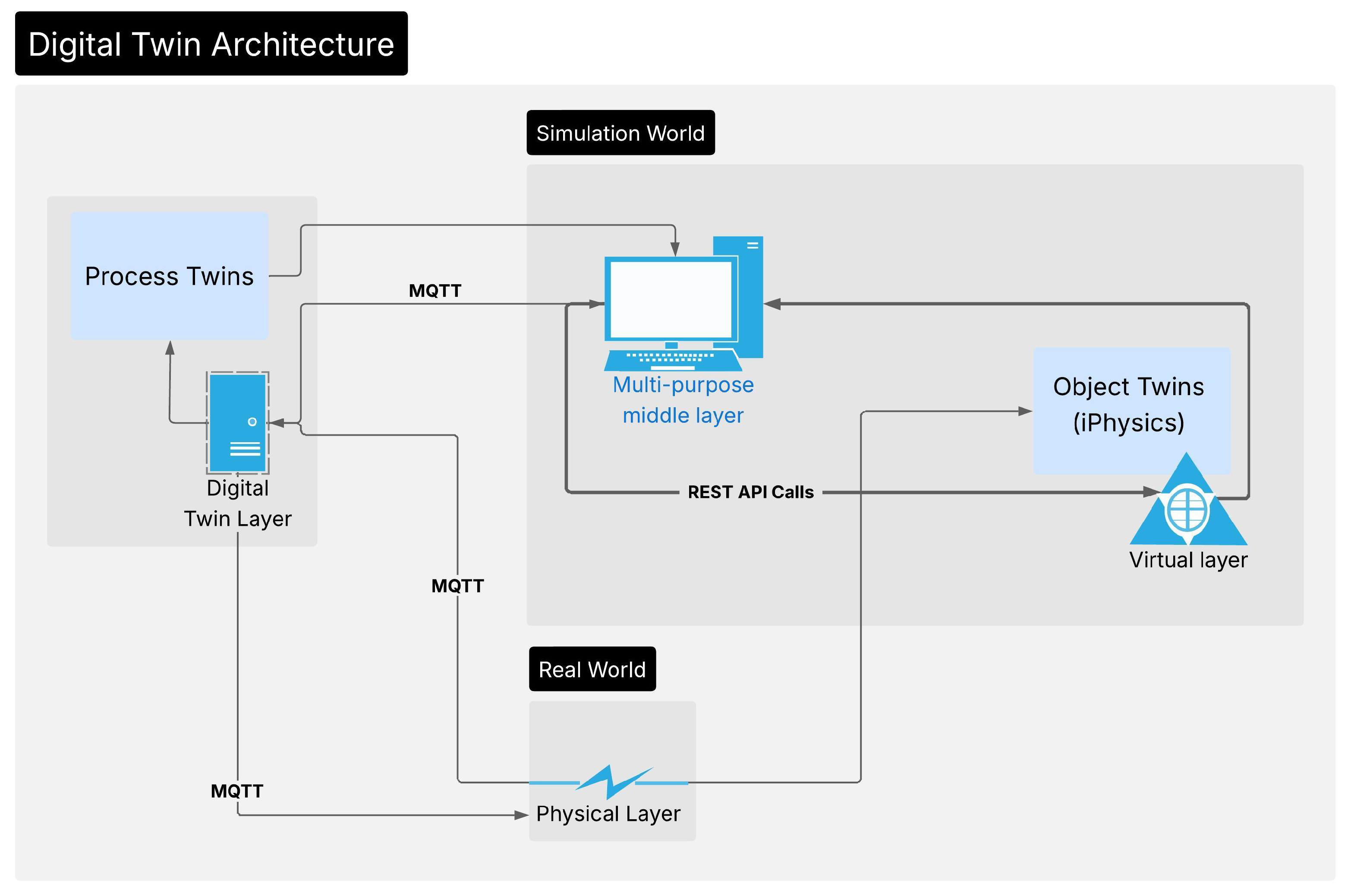

3. Proposal of Multi-Purpose Layer Architecture

3.1. Implementation Practices for Decision-Oriented Modules in DT Architectures

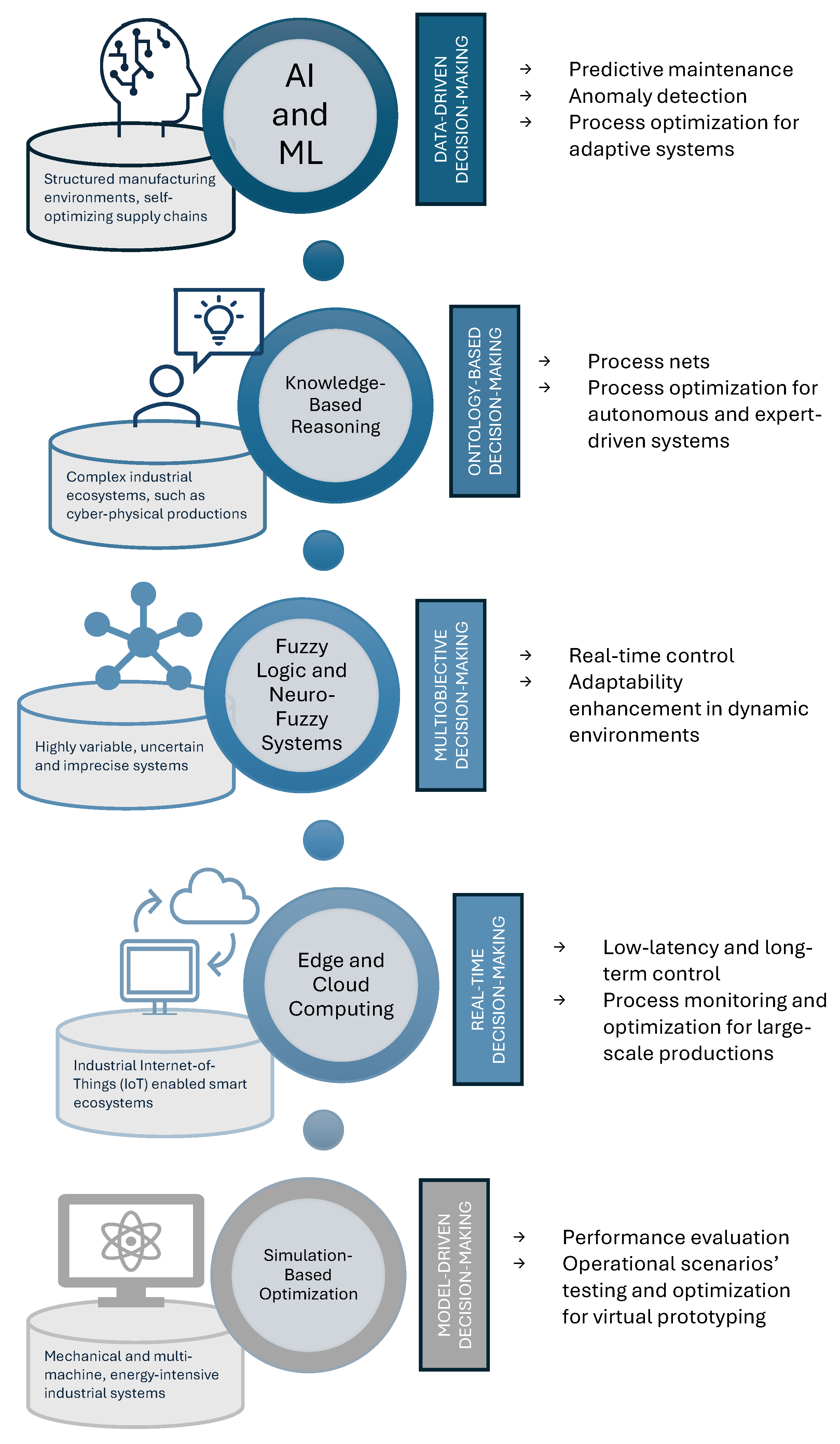

3.1.1. Artificial Intelligence (AI) and Machine Learning (ML)

- Supervised Learning: Utilized for predictive maintenance and quality control by training models on historical sensor data [29].

- Unsupervised Learning: Applied for anomaly detection and clustering of process states.

- Reinforcement Learning (RL): Enables autonomous decision-making by learning optimal strategies through trial and error, particularly useful in process optimization and robotic control [30].

3.1.2. Knowledge-Based Reasoning and Ontologies

3.1.3. Fuzzy Logic and Hybrid AI-Models

3.1.4. Edge and Cloud Computing for Real-Time Decision Making

3.1.5. Simulation-Based Optimization

- Multi-Agent Simulations (MASs): Represents distributed systems where virtual agents interact to find the most efficient configuration [25].

- Digital Twin as a Service (DTaaS): Provides real-time cloud-based simulations for adaptive decision-making and control [22].

- Physics-Based Simulations: Used in cyber–physical systems to model mechanical behaviors, energy consumption, and process variations [32].

3.2. Proposal for Simulation-Based Multi-Purpose Layer

4. Case Study

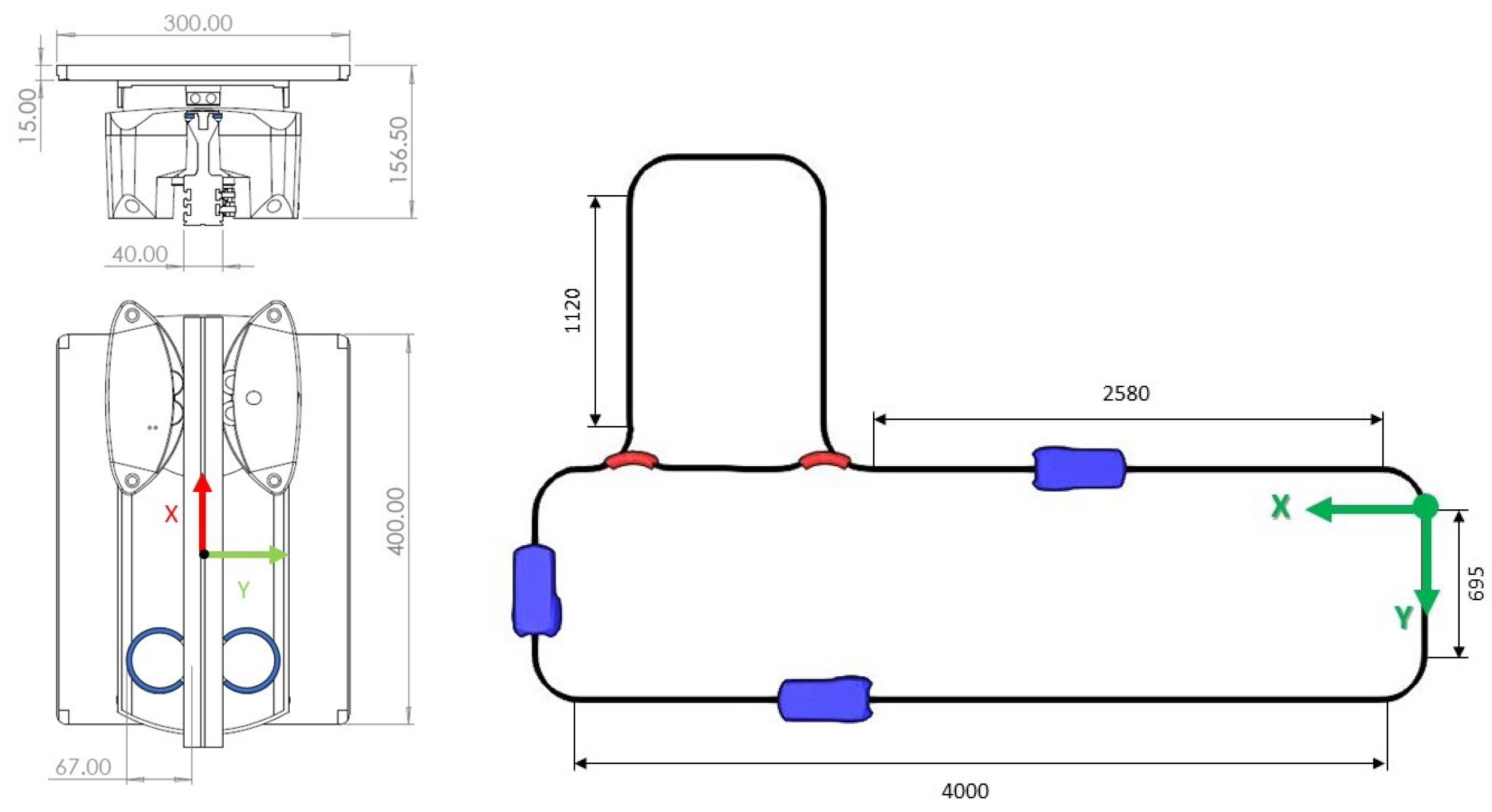

4.1. System Description

- Kinematic modeling: A model of the kinematics of shuttles and robots to gather information about their position, velocity, and eventually acceleration. In the case of robotic manipulators, the inverse kinematic analysis was performed for the correspondent kinematic chain to obtain joint values.

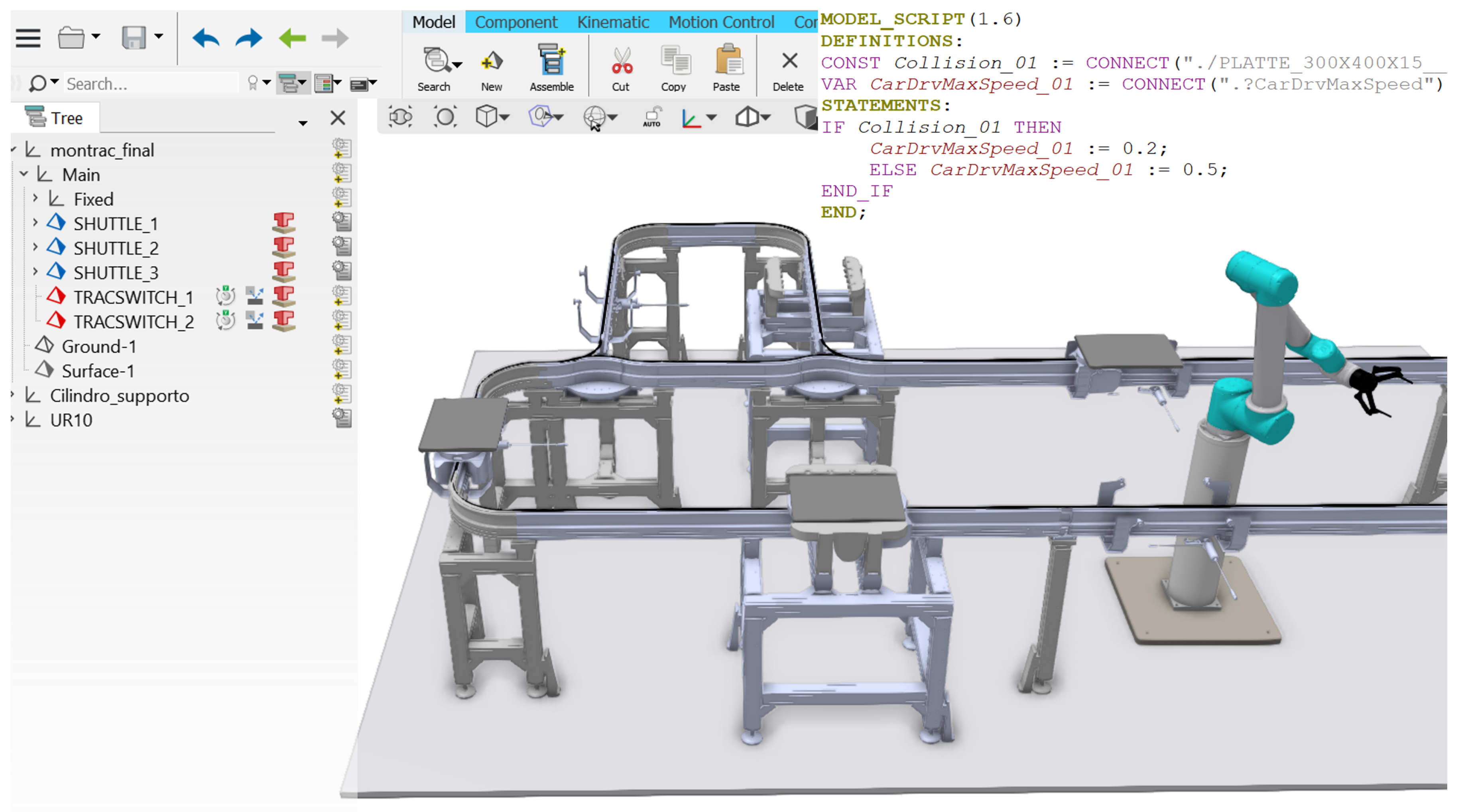

- Simulation environment setup: A replication of the kinematics in the environment of industrialPhysics in order to set up the DM of the transfer line.

4.2. Kinematic Modeling

4.2.1. Shuttle Cars

4.2.2. Robotic Manipulators

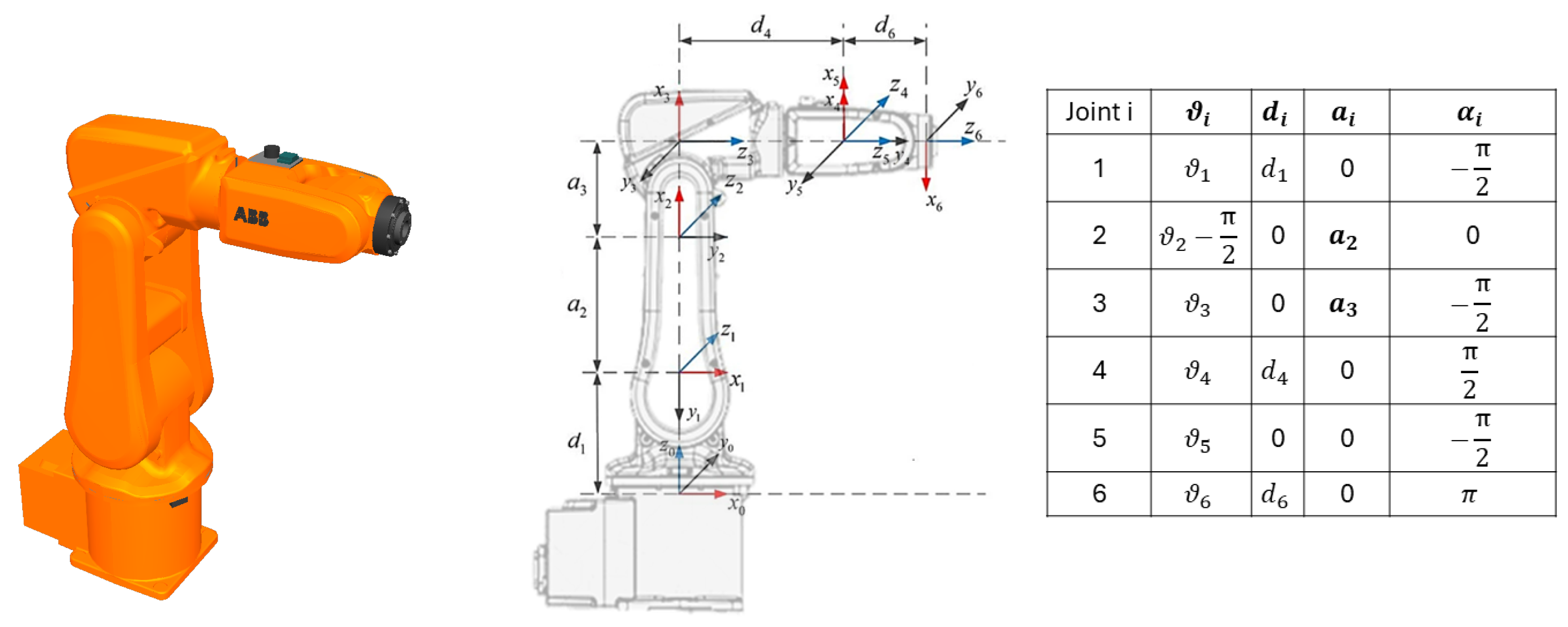

- ABB irb120

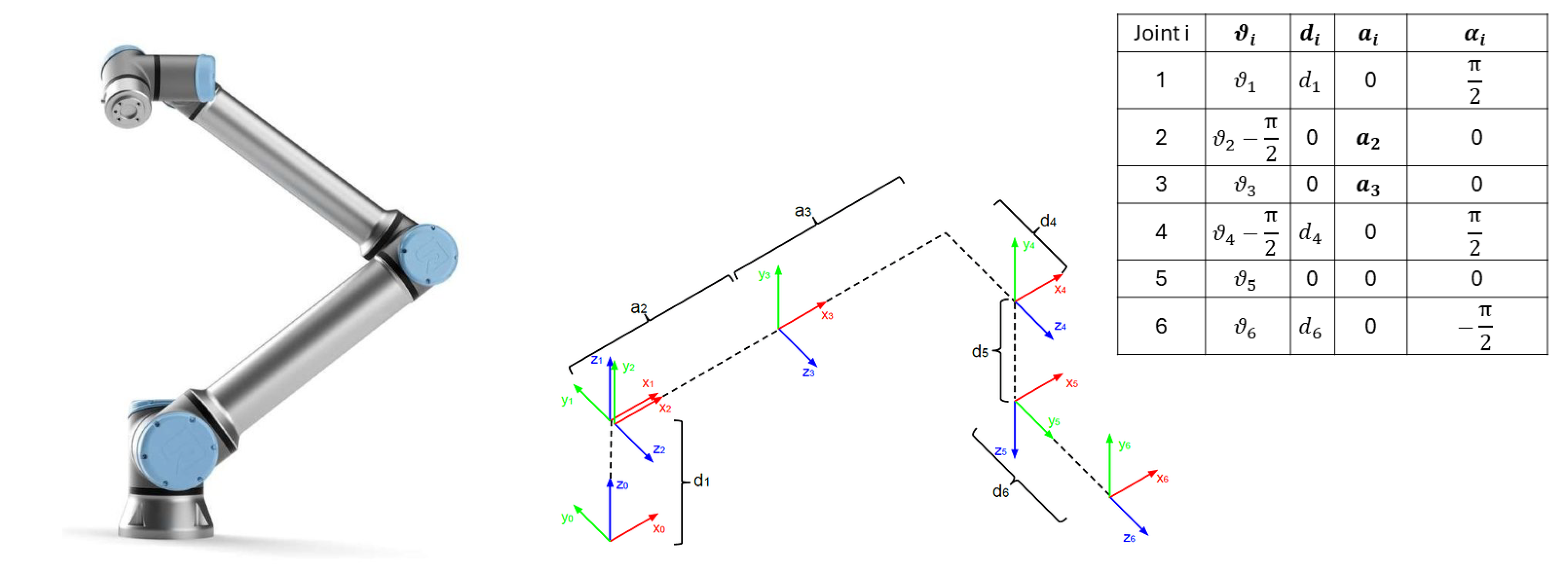

- Universal Robot 10 (UR10)The robot UR10 is a collaborative robot, characterized by a six-DOF kinematic structure with six revolute joints, see Figure 6. It needs to be specified that, in this case, a small adjustment of DH parameters was required in order to match the real robot model with the kinematic model of the simulation software.

- Adept SCARA Cobra e600The robot SCARA Cobra e600 is an open-chain industrial robot, characterized by a four-DOF kinematic structure with three revolute joints and one prismatic joint, see Figure 7. The same reasoning regarding DH parameters for the UR10 was applied also for this robot.While DH parameters are widely used for modeling open-chain manipulators, their application to closed-chain robotic systems is limited. The kinematic loops in such systems introduce constraints that cannot be easily represented by the sequential frame assignment of standard DH notation. Therefore, alternative approaches, such as constraint-based models or loop-closure equations, are typically used. For the closed-chain robots considered in this work, DH representations are omitted in favor of describing their kinematic structure and modeling approach.

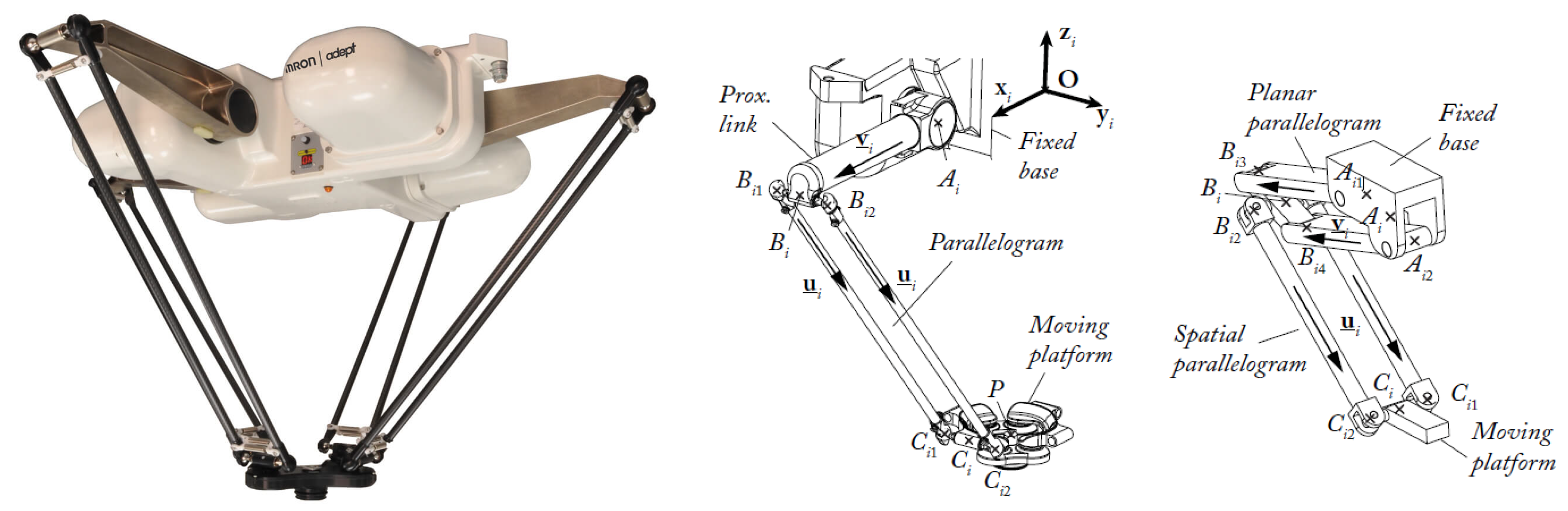

- Adept OMRON QuattroThe robot Adept OMRON Quattro is a closed-chain industrial robot, characterized by a four-DOF kinematic structure with four constrained revolute joints, see Figure 8. The Quattro robot features four identical kinematic chains, each driven by a base-mounted rotary actuator. The inverse kinematics of the robot is derived through loop closure equations, as demonstrated in [43].

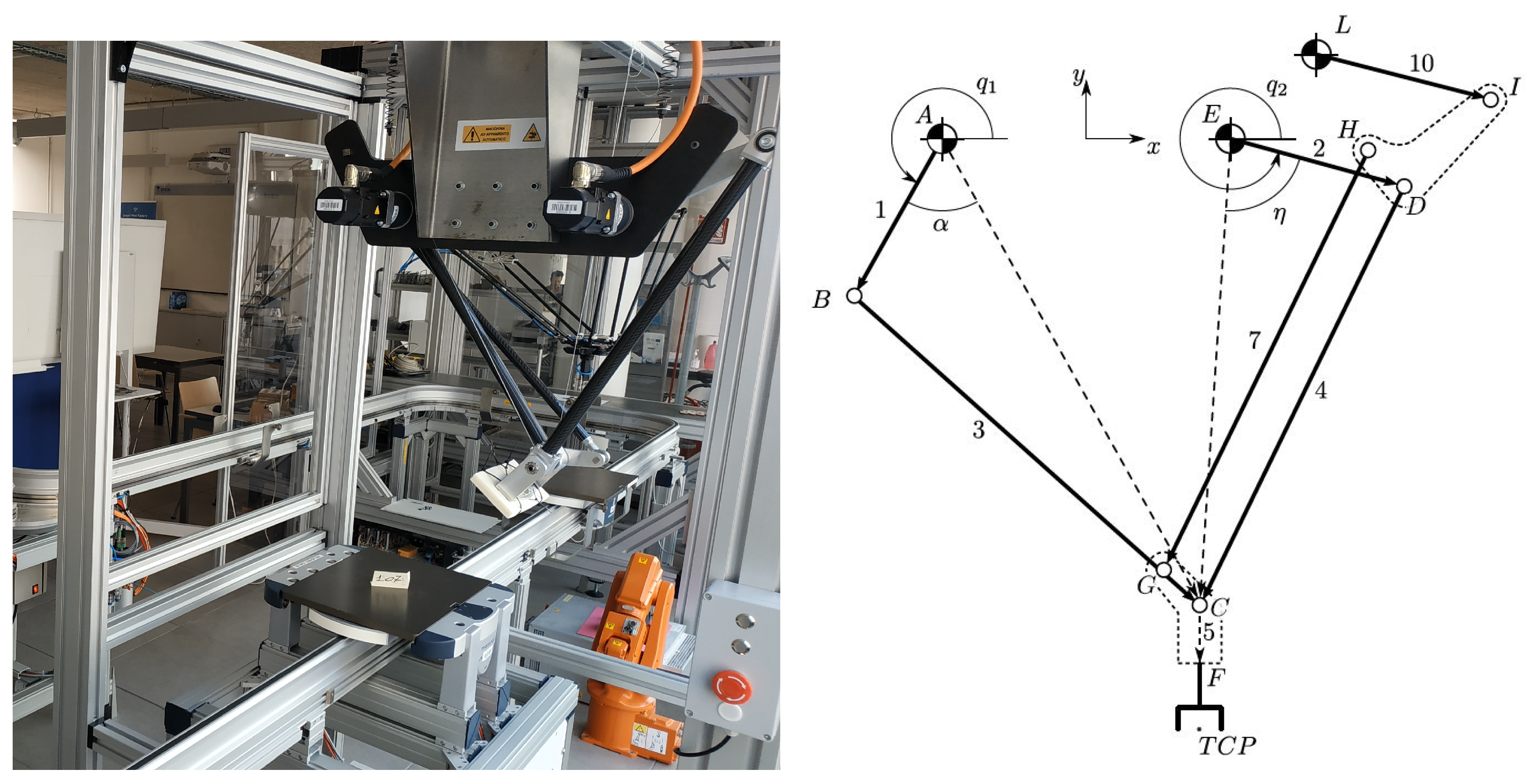

- Delta2 prototypeThe Delta2 robot represents the prototype of a closed-chain parallel robot manipulator, characterized by a kinematic structure with two revolute joints [44]. The Delta2 is a planar multibody system with two DOF where the end-effector is kinematically constrained to always have the same orientation, thanks to the parallelogram overstructure, as visible in Figure 9. Since this robot is a prototype, manufactured in-house for the laboratory in which it is installed, the position analysis of the Delta2 parallel robot was conducted by hand, and a personalized approach to simulate the kinematic chains’ constraints and movements in the simulation environment was adopted.

4.3. Simulation Environment Setup

4.4. Data Flow Structuring

4.4.1. Simulation for Design Phase and Redesign

4.4.2. Simulation for Optimization

4.4.3. Simulation for Validation

5. Results and Discussion

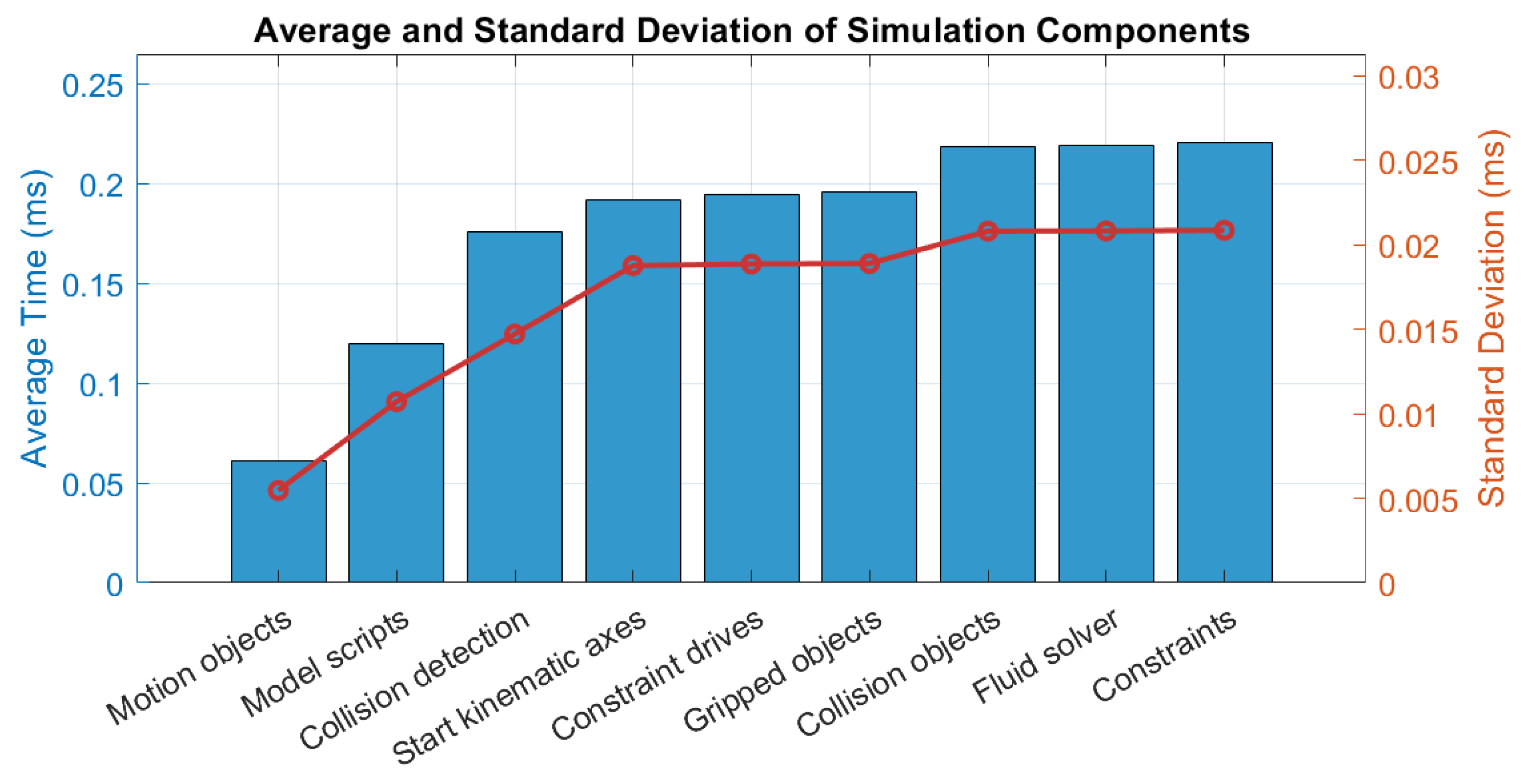

- Pre-processing phaseThis phase involves preparation steps before the actual physics calculations begin. It includes initializing motion objects, running model scripts, activating kinematic axes, etc. Table 2 reports a sample of task durations for a standard simulation where only the shuttles were controlled and moved.By further evaluating pre-processing operations, it is evident that they can be considered lightweight, averaging between 0.06 ms and 0.22 ms, with minimal variability (standard deviations below 0.02 ms), as shown in Figure 14.

- Run-Time PhaseThe run-time phase encompasses the physics engine and its coordination with model components. The profiling tool logs both active physics computation and synchronization delays (i.e., wait times for various sub-processes to complete). Also, for this phase, a sample table of task durations and the results of average and standard deviation are reported in Table 3 and Figure 15.The most significant time costs were associated with waiting operations for the coordination among the different components, like kinematic axes (an average of 10.345 ms and standard deviation of 7.437 ms), motion controls (an average of 10.340 ms and standard deviation of 7.436 ms), or model scripts (an average of 10.339 ms and standard deviation of 7.436 ms). These values suggest that the synchronization or data transfer latencies dominates the run-time cost, likely due to multithreading or communication overhead between simulation modules. Pure physics solving times (e.g., physics: 0.429 ms) are comparatively low, indicating that raw computational load is not the primary bottleneck, rather, coordination among components is, as previously said.

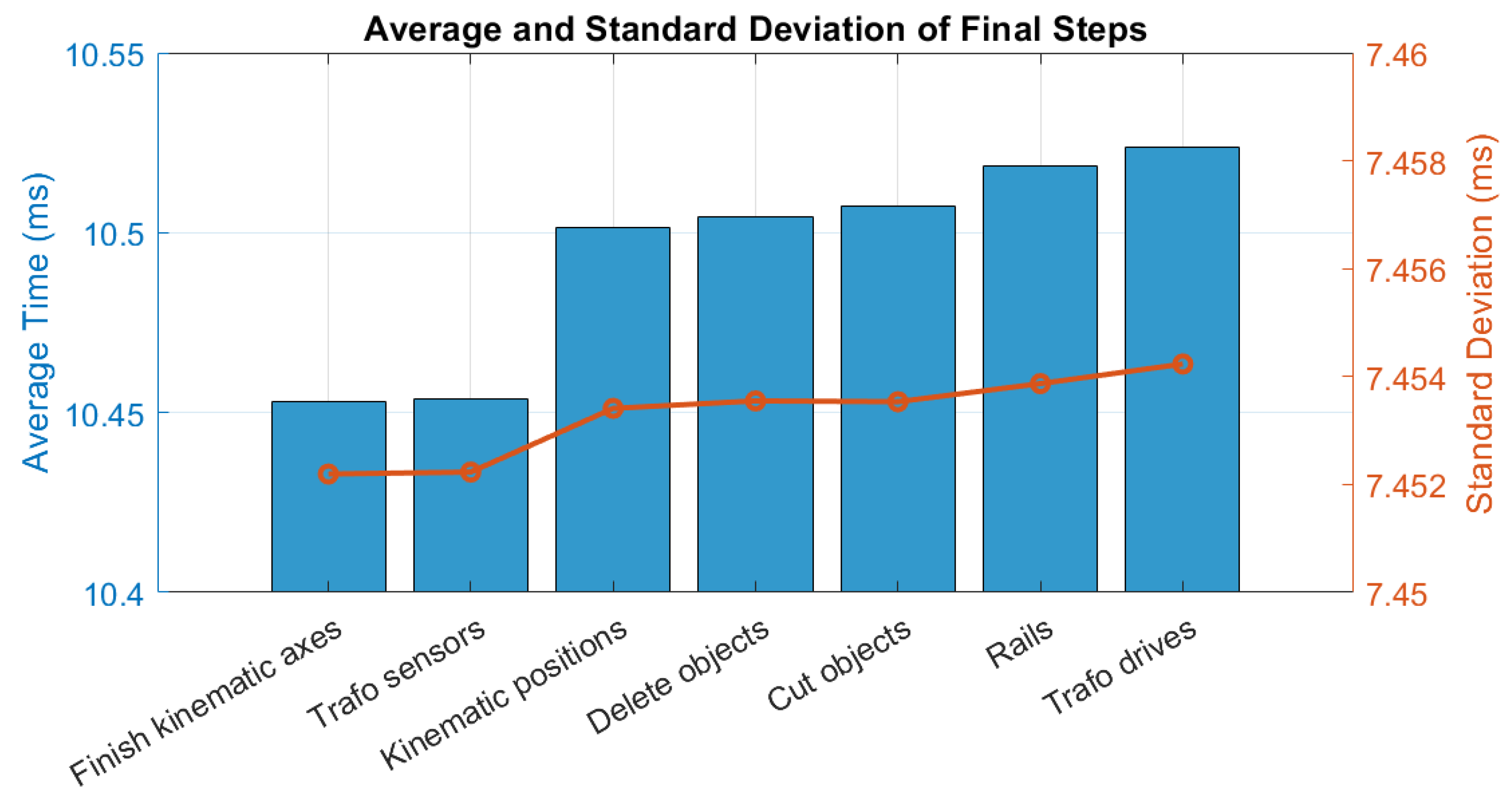

- Post-processing phaseIn this final phase, the simulation updates positions, sensors, and graphical or logical state after solving the dynamics. Also, for this phase, a sample table of task durations and the results of average and standard deviation are reported in Table 4 and Figure 16, respectively. The plot in Figure 16 has been rescaled to obtain a better visualization.Key processes and their average durations include the end setup of kinematic axes (an average of 10.519 ms and standard deviation of 7.454 ms), of trafo sensors (an average of 10.524 ms and standard deviation of 7.454 ms), and of kinematic positions (an ave-age of 10.539 ms and standard deviation of 7.455 ms). Again, the high variability points to possible dependency chains that force components to wait for others to complete.

- Precise Modeling of Acceleration/Deceleration Points—By integrating the physical pads into the virtual environment, the DT will better replicate real-world motion dynamics.

- Sensor Integration for Real-Time Validation—Installing velocity, acceleration, and position sensors on the shuttles will allow for real-time data collection, enhancing the accuracy of the DT model.

- Optimization of System Latency—Exploring computational improvements and network optimizations to reduce time delays and improve real-time control capabilities.

6. Conclusions

- Utilize simulation-driven optimization to evaluate multiple operational scenarios.

- Select the most efficient configuration based on productivity, energy consumption, and process efficiency (given parallel simulation results).

- Enable adaptive control by dynamically adjusting system parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stavropoulos, P.; Papacharalampopoulos, A.; Sabatakakis, K.; Mourtzis, D. Meta-modelling of manufacturing processes and automation workflows towards designing and operating digital twins. Appl. Sci. 2023, 13, 1945. [Google Scholar] [CrossRef]

- Zhu, X.; Zhao, Q.; Yao, X. How inventory flexibility affects productivity: The moderating roles of digital transformation and supply chain concentration. J. Manuf. Technol. Manag. 2024, 35, 1554–1580. [Google Scholar] [CrossRef]

- Lehner, C.; Padovano, A.; Zehetner, C.; Hackenberg, G. Digital twin and digital thread within the product lifecycle management. Procedia Comput. Sci. 2024, 232, 2875–2886. [Google Scholar] [CrossRef]

- Haricha, K.; Khiat, A.; Issaoui, Y.; Bahnasse, A.; Ouajji, H. Recent technological progress to empower smart manufacturing: Review and potential guidelines. IEEE Access 2023, 11, 77929–77951. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Goodwin, T.; Xu, J.; Celik, N.; Chen, C.H. Real-time digital twin-based optimization with predictive simulation learning. J. Simul. 2024, 18, 47–64. [Google Scholar] [CrossRef]

- Nezzi, C.; Gufler, V.; Vidoni, R.; Rauch, E. Kinematic and Dynamic Modeling of Mechanical Systems towards Digital Twins. Results Eng. 2025, 26, 104874. [Google Scholar] [CrossRef]

- Dosoftei, C.C. Simulation power vs. immersive capabilities: Enhanced understanding and interaction with digital twin of a mechatronic system. Appl. Sci. 2023, 13, 6463. [Google Scholar] [CrossRef]

- Usman, S.; Lu, C.; Gao, G. Flexible job-shop scheduling with limited flexible workers using an improved multiobjective discrete teaching–learning based optimization algorithm. Optim. Eng. 2024, 25, 1237–1270. [Google Scholar] [CrossRef]

- Rathore, M.M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The role of AI, machine learning, and big data in digital twinning: A systematic literature review, challenges, and opportunities. IEEE Access 2021, 9, 32030–32052. [Google Scholar] [CrossRef]

- Hakiri, A.; Gokhale, A.; Yahia, S.B.; Mellouli, N. A comprehensive survey on digital twin for future networks and emerging Internet of Things industry. Comput. Netw. 2024, 244, 110350. [Google Scholar] [CrossRef]

- Hu, S.; Li, C.; Li, B.; Yang, M.; Wang, X.; Gao, T.; Xu, P. Digital twins enabling intelligent manufacturing: From methodology to application. Intell. Sustain. Manuf. 2024, 1, 10007. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Zhang, Q.; Sun, Q.; Lim, E. A digital twin platform integrating process parameter simulation solution for intelligent manufacturing. Electronics 2024, 13, 802. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.S.; Teti, R.; Kubo, A. Developing sensor signal-based digital twins for intelligent machine tools. J. Ind. Inf. Integr. 2021, 24, 100242. [Google Scholar] [CrossRef]

- Miller, A.M.; Alvarez, R.; Hartman, N. Towards an extended model-based definition for the digital twin. Comput.-Aided Des. Appl. 2018, 15, 880–891. [Google Scholar] [CrossRef]

- Lee, Y.; Baek, M.S.; Yoon, K. Digital Entity Management Methodology for Digital Twin Implementation: Concept, Definition, and Examples. IEEE Trans. Broadcast. 2025, 71, 19–29. [Google Scholar] [CrossRef]

- Jeong, D.Y.; Baek, M.S.; Lim, T.B.; Kim, Y.W.; Kim, S.H.; Lee, Y.T.; Jung, W.S.; Lee, I.B. Digital twin: Technology evolution stages and implementation layers with technology elements. IEEE Access 2022, 10, 52609–52620. [Google Scholar] [CrossRef]

- Rossmann, A.; Hertweck, D. Digital twins: A meta-review on their conceptualization, application, and reference architecture. In Proceedings of the 55th Hawaii International Conference on System Sciences (HICSS 2022), Virtual Event/Maui, HI, USA, 4–7 January 2022; pp. 4518–4527. [Google Scholar]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital twin as a service (DTaaS) in Industry 4.0: An architecture reference model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Gehrmann, C.; Gunnarsson, M. A digital twin based industrial automation and control system security architecture. IEEE Trans. Ind. Inform. 2019, 16, 669–680. [Google Scholar] [CrossRef]

- ISO 23247-1:2021; Automation Systems and Integration, Digital Twin Framework for Manufacturing. International Organization for Standardization: Geneva, Switzerland, 2021.

- Răileanu, S.; Borangiu, T.; Ivănescu, N.; Morariu, O.; Anton, F. Integrating the digital twin of a shop floor conveyor in the manufacturing control system. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2019 9; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 134–145. [Google Scholar]

- Borangiu, T.; Oltean, E.; Răileanu, S.; Anton, F.; Anton, S.; Iacob, I. Embedded digital twin for ARTI-type control of semi-continuous production processes. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2019 9; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 113–133. [Google Scholar]

- Alam, K.M.; Saddik, A.E. C2PS: A digital twin architecture reference model for the cloud-based cyber-physical systems. IEEE Access 2017, 5, 2050–2062. [Google Scholar] [CrossRef]

- Redelinghuys, A.J.H.; Basson, A.H.; Kruger, K. A six-layer architecture for the digital twin: A manufacturing case study implementation. J. Intell. Manuf. 2020, 31, 1383–1402. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital twin-driven supervised machine learning for the development of artificial intelligence applications in manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef]

- Cronrath, C.; Aderiani, A.R.; Lennartson, B. Enhancing digital twins through reinforcement learning. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 293–298. [Google Scholar]

- Salazar, W.C.; Machado, D.O.; Len, A.J.G.; Gonzalez, J.M.E.; Alba, C.B.; de Andrade, G.A.; Normey-Rico, J.E. Neuro-fuzzy digital twin of a high temperature generator. IFAC-PapersOnLine 2022, 55, 466–471. [Google Scholar] [CrossRef]

- Nezzi, C.; Marchi, M.D.; Aruväli, T.; Vidoni, R.; Rauch, E. Modeling and simulation of mechatronics equipment for a Digital Twin-enabled demonstrator. In Proceedings of the 10th International Conference on Control, Decision and Information Technologies (CoDIT), Vallette, Malta, 1–4 July 2024; pp. 2526–2529. [Google Scholar]

- Schluse, M.; Rossmann, J. From simulation to experimentable digital twins: Simulation-based development and operation of complex technical systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016; pp. 1–6. [Google Scholar]

- Nezzi, C.; Fink, S.; Rauch, E.; Vidoni, R. Digital Twin-Oriented Kinematic Modelling of a Large-Sized Mesh Welding Plant for Productivity Evaluation: A Company Case Study. In Proceedings of the IFToMM Symposium on Mechanism Design for Robotics, Timişoara, Romania, 27–29 June 2024; pp. 424–432. [Google Scholar]

- Phanden, R.K.; Sharma, P.; Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Mater. Today Proc. 2021, 38, 174–178. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rojas, R.; Carabin, G.; Palomba, I.; Rauch, E.; Vidoni, R.; Matt, D.T. Advanced automation for SMEs in the I4.0 revolution: Engineering education and em-ployees training in the smart mini factory laboratory. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 16–19 December 2018; pp. 1111–1115. [Google Scholar]

- Nezzi, C.; De Marchi, M.; Manzardo, M.; Galli, D.; Gualtieri, L.; Rauch, E.; Vidoni, R. Fostering Mechanisms, Mechatronics and Robotics Education in the Smart Mini Factory Laboratory of the Free University Of Bozen-Bolzano (I). In Proceedings of the Jc-IFToMM International Symposium, Kitakyushu, Japan, 22–23 June 2024; Volume 7, pp. 135–141. [Google Scholar]

- Wagner, M.G.; Ravani, B. Curves with rational Frenet-Serret motion. Comput. Aided Geom. Des. 1997, 15, 79–101. [Google Scholar] [CrossRef]

- Nezzi, C.; De Marchi, M.; Vidoni, R.; Rauch, E. Towards Real-Time Validation of Rail-Guided Shuttles: A Multibody Modelling and Digital Twin Approach. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers, Washington, DC, USA, 25–28 August 2024; Volume 88438, p. V009T09A008. [Google Scholar]

- Corke, P. A simple and systematic approach to assigning Denavit–Hartenberg parameters. IEEE Trans. Robot. 2007, 23, 590–594. [Google Scholar] [CrossRef]

- Dikmeli, S. Forward & Inverse Kinematics solution of 6-DOF robots those have offset & spherical wrists. Eurasian J. Sci. Eng. Technol. 2022, 3, 14–28. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Yang, H.; Zhang, H.; Wei, Y. Energy-optimal planning of robot trajectory based on dynamics. Arab. J. Sci. Eng. 2023, 48, 3523–3536. [Google Scholar] [CrossRef]

- Rosenzveig, V.; Briot, S.; Martinet, P. Minimal representation for the control of the Adept Quattro with rigid platform via leg observation considering a hidden robot model. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 430–435. [Google Scholar]

- Carabin, G.; Palomba, I.; Wehrle, E.; Vidoni, R. Energy expenditure minimization for a delta-2 robot through a mixed approach. In Multibody Dynamics 2019: Proceedings of the 9th ECCOMAS Thematic Conference on Multibody Dynamics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 383–390. [Google Scholar]

- Machineering. iPhysics. Available online: https://www.machineering.com/en/products/iphysics/ (accessed on 14 July 2025).

- Li, H.; Yan, P.; Zhou, H.; Pei, J.; Wang, B. Multi-Scenario Model Fusion and Verification Method for Digital Twin Machine Tool. J. Ind. Inf. Integr. 2025, 46, 100859. [Google Scholar] [CrossRef]

- Strahilov, A.; Ovtcharova, H.J.; Bär, T. Development of the physics-based assembly system model for the mechatronic valida-tion of automated assembly systems. In Proceedings of the 2012 Winter Simulation Conference (WSC), Berlin, Germany, 9–12 December 2012; pp. 1–11. [Google Scholar]

- Nezzi, C.; Muzhichkov, A.; Vidoni, R.; Rauch, E. Virtual commissioning of a mechatronic plant for insulating material processing: A company application towards Digital Twin. Procedia Comput. Sci. 2025, 253, 384–392. [Google Scholar] [CrossRef]

- Kiesel, R.; Jakob, F.; Vollmer, T.; Schmitt, R.H. Evaluation of ICT for Networked Control Systems of Latency-Critical Applications in Production. Procedia CIRP 2022, 112, 238–243. [Google Scholar] [CrossRef]

| Object | Typology | Stage of Modeling |

|---|---|---|

| Line structure | Static | Fully modeled and validated |

| Switches | Kinematic | Fully modeled and validated |

| Shuttles | Dynamic | Fully modeled and validated |

| Robot UR10 | Dynamic | Fully modeled and validated |

| Robot Adept SCARA Cobra600 | Dynamic | Fully modeled and validated |

| Robot Delta2 | Dynamic | Fully modeled |

| Robot ABB irb120 | Dynamic | Fully modeled |

| Robot Adept Omron 4 | Dynamic | Partially modeled |

| PRE-PROCESS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Time | Motion Objects | Model Scripts | Collision Detection | Start Kinematic Axes | Constraint Drives | Gripped Objects | Collision Objects | Fluid Solver | Constraints |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.07 | 0.064114 | 0.198514 | 0.241885 | 0.253628 | 0.256700 | 0.257885 | 0.276300 | 0.276571 | 0.277685 |

| 0.27 | 0.059733 | 0.136703 | 0.182718 | 0.195211 | 0.197822 | 0.198559 | 0.220559 | 0.220837 | 0.222107 |

| 0.44 | 0.060056 | 0.126206 | 0.171954 | 0.183743 | 0.186415 | 0.187229 | 0.209811 | 0.210088 | 0.211431 |

| 0.67 | 0.062293 | 0.123589 | 0.171225 | 0.184339 | 0.187130 | 0.187898 | 0.211142 | 0.211418 | 0.212716 |

| 0.89 | 0.062688 | 0.121982 | 0.170678 | 0.183275 | 0.186085 | 0.186807 | 0.209712 | 0.209970 | 0.211241 |

| 1.16 | 0.063380 | 0.114564 | 0.164815 | 0.178002 | 0.180805 | 0.181515 | 0.204771 | 0.205050 | 0.206300 |

| 1.36 | 0.063775 | 0.116646 | 0.168188 | 0.181390 | 0.184325 | 0.185059 | 0.207565 | 0.208125 | 0.209315 |

| 1.6 | 0.063038 | 0.115411 | 0.167068 | 0.180786 | 0.183714 | 0.184473 | 0.207032 | 0.207649 | 0.208798 |

| 1.83 | 0.062933 | 0.114853 | 0.166051 | 0.180368 | 0.183328 | 0.184095 | 0.204697 | 0.205361 | 0.206521 |

| 2.09 | 0.063745 | 0.117582 | 0.169065 | 0.182900 | 0.185892 | 0.186700 | 0.208014 | 0.208765 | 0.209946 |

| 2.34 | 0.064836 | 0.118936 | 0.170031 | 0.184323 | 0.187227 | 0.187988 | 0.209201 | 0.209733 | 0.210887 |

| 2.58 | 0.065740 | 0.120540 | 0.171885 | 0.185593 | 0.188516 | 0.189298 | 0.209865 | 0.210432 | 0.211731 |

| 2.85 | 0.065744 | 0.121329 | 0.172355 | 0.185695 | 0.188468 | 0.189283 | 0.210300 | 0.210893 | 0.212156 |

| 3.09 | 0.065275 | 0.119803 | 0.170518 | 0.183824 | 0.186599 | 0.187410 | 0.208637 | 0.209218 | 0.210527 |

| 3.4 | 0.064248 | 0.117684 | 0.169838 | 0.183408 | 0.186363 | 0.187179 | 0.207160 | 0.207712 | 0.209021 |

| 3.61 | 0.064270 | 0.118399 | 0.171411 | 0.184660 | 0.187683 | 0.188500 | 0.208897 | 0.209428 | 0.210667 |

| 3.85 | 0.064133 | 0.119053 | 0.173680 | 0.186787 | 0.189803 | 0.190629 | 0.213584 | 0.214162 | 0.215532 |

| 4.13 | 0.062067 | 0.117361 | 0.178409 | 0.194383 | 0.197651 | 0.198496 | 0.225690 | 0.226307 | 0.228381 |

| 4.37 | 0.060706 | 0.116005 | 0.174575 | 0.190043 | 0.193205 | 0.194017 | 0.225304 | 0.225955 | 0.228109 |

| 4.61 | 0.060423 | 0.119512 | 0.179232 | 0.194779 | 0.197921 | 0.198718 | 0.229459 | 0.230100 | 0.232200 |

| 4.82 | 0.060603 | 0.119865 | 0.178672 | 0.193977 | 0.197156 | 0.197913 | 0.226508 | 0.227075 | 0.229097 |

| 5 | 0.060346 | 0.120225 | 0.174688 | 0.189013 | 0.192192 | 0.192990 | 0.220854 | 0.221436 | 0.223533 |

| … | … | … | … | … | … | … | … | … | … |

| RUN-TIME | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | Constraints | Wait Model Scripts | Wait Motion Controls | Wait Collision Detection | Wait Collision Objects | Wait Kinematic Axes | Collision Detection | Collision Objects | Continuous Objects | Dynamic Objects | Model Scripts | Motion Controls |

| 0 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| 0.07 | 0.454 | 2.805 | 2.807 | 15.341 | 15.346 | 15.348 | 15.385 | 15.415 | 15.415 | 15.428 | 15.439 | 15.449 |

| 0.27 | 0.417 | 1.057 | 1.058 | 15.473 | 15.478 | 15.480 | 15.515 | 15.530 | 15.531 | 15.545 | 15.556 | 15.567 |

| 0.44 | 0.412 | 0.823 | 0.824 | 16.405 | 16.410 | 16.412 | 16.450 | 16.464 | 16.464 | 16.479 | 16.492 | 16.502 |

| 0.67 | 0.431 | 0.714 | 0.715 | 16.556 | 16.562 | 16.564 | 16.601 | 16.614 | 16.615 | 16.630 | 16.642 | 16.653 |

| 0.89 | 0.430 | 0.648 | 0.649 | 16.728 | 16.734 | 16.735 | 16.773 | 16.785 | 16.786 | 16.801 | 16.813 | 16.824 |

| 1.16 | 0.434 | 0.474 | 0.476 | 16.784 | 16.789 | 16.791 | 16.829 | 16.839 | 16.840 | 16.855 | 16.867 | 16.878 |

| 1.36 | 0.442 | 0.484 | 0.485 | 16.860 | 16.866 | 16.868 | 16.905 | 16.916 | 16.916 | 16.932 | 16.944 | 16.955 |

| 1.6 | 0.444 | 0.489 | 0.490 | 17.619 | 17.627 | 17.629 | 17.667 | 17.679 | 17.679 | 17.695 | 17.708 | 17.719 |

| 1.83 | 0.437 | 0.484 | 0.485 | 17.699 | 17.706 | 17.708 | 17.747 | 17.758 | 17.759 | 17.775 | 17.788 | 17.799 |

| 2.09 | 0.440 | 0.493 | 0.494 | 17.669 | 17.677 | 17.679 | 17.717 | 17.728 | 17.729 | 17.744 | 17.757 | 17.769 |

| 2.34 | 0.432 | 0.484 | 0.485 | 17.773 | 17.781 | 17.783 | 17.822 | 17.833 | 17.834 | 17.850 | 17.863 | 17.875 |

| 2.58 | 0.432 | 0.488 | 0.489 | 17.144 | 17.150 | 17.152 | 17.190 | 17.201 | 17.202 | 17.217 | 17.230 | 17.242 |

| 2.85 | 0.434 | 0.488 | 0.489 | 16.850 | 16.855 | 16.857 | 16.895 | 16.907 | 16.907 | 16.923 | 16.936 | 16.947 |

| 3.09 | 0.432 | 0.484 | 0.486 | 17.203 | 17.209 | 17.211 | 17.249 | 17.261 | 17.262 | 17.278 | 17.291 | 17.303 |

| 3.4 | 0.437 | 0.479 | 0.481 | 17.224 | 17.230 | 17.232 | 17.271 | 17.282 | 17.283 | 17.300 | 17.313 | 17.324 |

| 3.61 | 0.441 | 0.474 | 0.475 | 17.511 | 17.516 | 17.519 | 17.559 | 17.571 | 17.572 | 17.589 | 17.603 | 17.615 |

| 3.85 | 0.447 | 0.483 | 0.485 | 18.774 | 18.780 | 18.782 | 18.823 | 18.835 | 18.835 | 18.853 | 18.866 | 18.878 |

| 4.13 | 0.464 | 0.511 | 0.513 | 21.539 | 21.545 | 21.547 | 21.591 | 21.603 | 21.604 | 21.621 | 21.636 | 21.648 |

| 4.37 | 0.456 | 0.521 | 0.523 | 23.308 | 23.314 | 23.316 | 23.360 | 23.373 | 23.373 | 23.391 | 23.406 | 23.418 |

| 4.61 | 0.455 | 0.540 | 0.542 | 25.519 | 25.525 | 25.527 | 25.570 | 25.584 | 25.585 | 25.602 | 25.616 | 25.628 |

| 4.82 | 0.447 | 0.537 | 0.539 | 26.399 | 26.405 | 26.407 | 26.450 | 26.466 | 26.466 | 26.482 | 26.496 | 26.508 |

| 5 | 0.433 | 0.520 | 0.522 | 25.481 | 25.487 | 25.489 | 25.530 | 25.548 | 25.549 | 25.564 | 25.577 | 25.589 |

| … | … | … | … | … | … | … | … | … | … | … | … | … |

| POST-PROCESS | |||||||

|---|---|---|---|---|---|---|---|

| Time | Finish Kinematic Axes | Trafo Sensors | Kinematic Positions | Delete Objects | Cut Objects | Rails | Trafo Drives |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.07 | 15.460857 | 15.461457 | 15.495585 | 15.498142 | 15.500585 | 15.517200 | 15.521314 |

| 0.27 | 15.579803 | 15.580440 | 15.620037 | 15.622451 | 15.625151 | 15.637266 | 15.641400 |

| 0.44 | 16.516493 | 16.517131 | 16.559415 | 16.561920 | 16.564647 | 16.576377 | 16.581034 |

| 0.67 | 16.667706 | 16.668359 | 16.711604 | 16.714225 | 16.717325 | 16.728663 | 16.733501 |

| 0.89 | 16.839121 | 16.839821 | 16.883052 | 16.885604 | 16.888617 | 16.899550 | 16.904405 |

| 1.16 | 16.892925 | 16.893622 | 16.936900 | 16.939528 | 16.942608 | 16.952882 | 16.957800 |

| 1.36 | 16.970528 | 16.971251 | 17.014933 | 17.017601 | 17.020724 | 17.030953 | 17.035891 |

| 1.6 | 17.735044 | 17.735822 | 17.780156 | 17.783140 | 17.786261 | 17.796862 | 17.801923 |

| 1.83 | 17.815169 | 17.815933 | 17.859742 | 17.862736 | 17.865848 | 17.876346 | 17.881368 |

| 2.09 | 17.784373 | 17.785178 | 17.829100 | 17.831969 | 17.834967 | 17.845347 | 17.850312 |

| 2.34 | 17.890439 | 17.891260 | 17.939706 | 17.942619 | 17.945680 | 17.956214 | 17.961223 |

| 2.58 | 17.257353 | 17.258183 | 17.305727 | 17.308289 | 17.311297 | 17.321720 | 17.326634 |

| 2.85 | 16.962383 | 16.963208 | 17.010445 | 17.013019 | 17.016082 | 17.026366 | 17.031157 |

| 3.09 | 17.318235 | 17.319081 | 17.366242 | 17.368893 | 17.372042 | 17.382435 | 17.387249 |

| 3.4 | 17.339845 | 17.340674 | 17.383765 | 17.386457 | 17.389618 | 17.400260 | 17.405197 |

| 3.61 | 17.630485 | 17.631363 | 17.675953 | 17.678687 | 17.681797 | 17.692400 | 17.697551 |

| 3.85 | 18.894138 | 18.895248 | 18.940477 | 18.943239 | 18.946399 | 18.957119 | 18.962414 |

| 4.13 | 21.664631 | 21.665767 | 21.714932 | 21.717874 | 21.721293 | 21.732988 | 21.738738 |

| 4.37 | 23.434607 | 23.435787 | 23.486205 | 23.489140 | 23.492541 | 23.504143 | 23.509930 |

| 4.61 | 25.645012 | 25.646263 | 25.697415 | 25.700392 | 25.703817 | 25.715664 | 25.721540 |

| 4.82 | 26.524700 | 26.525700 | 26.576780 | 26.579726 | 26.583076 | 26.594774 | 26.600568 |

| 5 | 25.605853 | 25.606840 | 25.659419 | 25.662316 | 25.665714 | 25.677215 | 25.683026 |

| … | … | … | … | … | … | … | … |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nezzi, C.; De Marchi, M.; Vidoni, R.; Rauch, E. A Multi-Purpose Simulation Layer for Digital Twin Applications in Mechatronic Systems. Machines 2025, 13, 671. https://doi.org/10.3390/machines13080671

Nezzi C, De Marchi M, Vidoni R, Rauch E. A Multi-Purpose Simulation Layer for Digital Twin Applications in Mechatronic Systems. Machines. 2025; 13(8):671. https://doi.org/10.3390/machines13080671

Chicago/Turabian StyleNezzi, Chiara, Matteo De Marchi, Renato Vidoni, and Erwin Rauch. 2025. "A Multi-Purpose Simulation Layer for Digital Twin Applications in Mechatronic Systems" Machines 13, no. 8: 671. https://doi.org/10.3390/machines13080671

APA StyleNezzi, C., De Marchi, M., Vidoni, R., & Rauch, E. (2025). A Multi-Purpose Simulation Layer for Digital Twin Applications in Mechatronic Systems. Machines, 13(8), 671. https://doi.org/10.3390/machines13080671