1. Introduction

Multiphase induction machines have gained increasing attention as a promising alternative to conventional three-phase systems in a wide range of applications, offering advantages such as improved power distribution per phase, reduced torque ripple, and enhanced fault tolerance, features that are particularly desirable in electric traction systems [

1,

2]. Among the different topologies of multiphase induction machines, the asymmetrical Six-phase Induction Machine (SPIM) offers unique advantages, such as suppression of torque harmonics and increased fault tolerance due to the isolated neutral configuration. These characteristics make SPIMs particularly well-suited for applications that demand high reliability under fault conditions.

The adoption of multiphase machines has been accompanied by advances in control strategies, which typically require rotor position and/or speed information. This information is typically acquired using mechanical sensors mounted on the motor shaft, which introduces potential drawbacks, including reduced overall system reliability due to susceptibility to vibrations, limited operational performance, increased installation complexity, and the additional cost associated with the sensors themselves.

Given the constraints of sensor-based systems, speed sensorless control strategies are increasingly recognized as an effective approach to overcoming these limitations, offering advantages such as reduced hardware complexity, lower cost, more compact system design, elimination of sensor wiring, and improved noise immunity. Furthermore, they have become increasingly important in applications involving harsh operating environments. Even in systems equipped with mechanical speed sensors, sensorless estimation can provide redundancy, allowing continued operation in the event of sensor failure [

3,

4,

5]. These combined benefits have driven significant advancements in the development of speed estimation methods for multiphase machines.

Despite these advantages, one significant challenge in sensorless control is the variation of motor parameters, which are strongly influenced by changes in ambient temperature. These parameter drifts introduce additional complexity in the control system design and increase the computational demands of the estimation algorithms. To cope with these issues, advanced estimation techniques, particularly observer-based approaches, have shown the potential to improve performance, provided they are robust enough to handle parameter deviations across a broad range of operating speeds [

6].

Within this context, various sensorless speed estimation techniques have been proposed. Among them, the Model Reference Adaptive System (MRAS) is widely recognized for its reliable performance across a wide speed range. However, MRAS-based approaches tend to be highly sensitive to parameter variations at low speeds, which limits their accuracy. Additionally, their implementation is often complicated by the need to tune adaptation gains for PI controllers [

6]. Another standard method is the Extended Kalman Filter (EKF), a stochastic observer capable of accurate estimation under certain conditions. Nevertheless, its effectiveness is hindered by strong sensitivity to noise characteristics, a complex design process, and high computational cost [

7].

As a robust alternative, Sliding Mode Observers (SMOs) have emerged as a promising solution, offering strong robustness against parameter uncertainties and external disturbances [

8,

9,

10]. A notable example is the SMO proposed by [

11] for three-phase induction machines, which achieves accurate speed estimation across the entire speed range using only a single observer gain, thereby simplifying implementation. Nevertheless, the practical deployment of SPIMs introduces several challenges, such as increased system complexity and the necessity for more sophisticated control and estimation models. Likewise, SMO-based observers, despite their robustness, can suffer from chattering and require careful gain tuning.

Recent contributions have further advanced sensorless strategies designed explicitly for SPIMs, particularly under challenging operating conditions such as low speeds, parameter variations, and fault scenarios. In [

12], an MRAS-based rotor time constant estimator is proposed, combined with an adaptive observer that enables simultaneous estimation of the rotor speed and time constant, thus enhancing robustness in sensorless Indirect Rotor Field-Oriented Control (IFOC) systems. This method is particularly relevant for SPIMs, where parameter mismatches significantly degrade control performance. On the other hand, in [

13] is demonstrates that EKF can be successfully used in sensorless frameworks to estimate not only rotor speed but also parameters such as resistance, contributing to efficient operation across the entire speed range. The EKF-based estimation is shown to improve loss model control, making it a viable option for high-efficiency sensorless control. Additionally, in [

14], which is related to fault-tolerant applications, an SMO adapted to identify rotor flux and speed even under open-circuit faults is presented. The SMO is integrated with harmonic suppression strategies, offering strong robustness and maintaining control reliability under both healthy and faulty conditions. These developments highlight the growing interest in hybrid estimation and control strategies, motivating the proposed integration of SMO within an IRFOC-based sensorless control framework for asymmetrical SPIMs, as also reviewed comprehensively in [

15].

The adoption of SMOs in sensorless control of induction machines has gained significant attention due to their robust performance. SMOs maintain precise flux and speed estimations even in the face of parameter uncertainties and external disturbances, making them especially beneficial for SPIMs that require effective decoupling of multiple subspaces. They also offer rapid dynamic responses and reduce reliance on accurate machine parameters compared to model-based estimators, such as MRAS and EKF. However, challenges exist, such as the chattering phenomenon from the discontinuous nature of the sliding-mode control law, which can excite unmodeled high-frequency dynamics or amplify noise. Performance may also degrade in the presence of measurement noise, necessitating careful tuning of observer gains to balance convergence speed and noise sensitivity. Despite these issues, SMOs remain a captivating option for robust sensorless control.

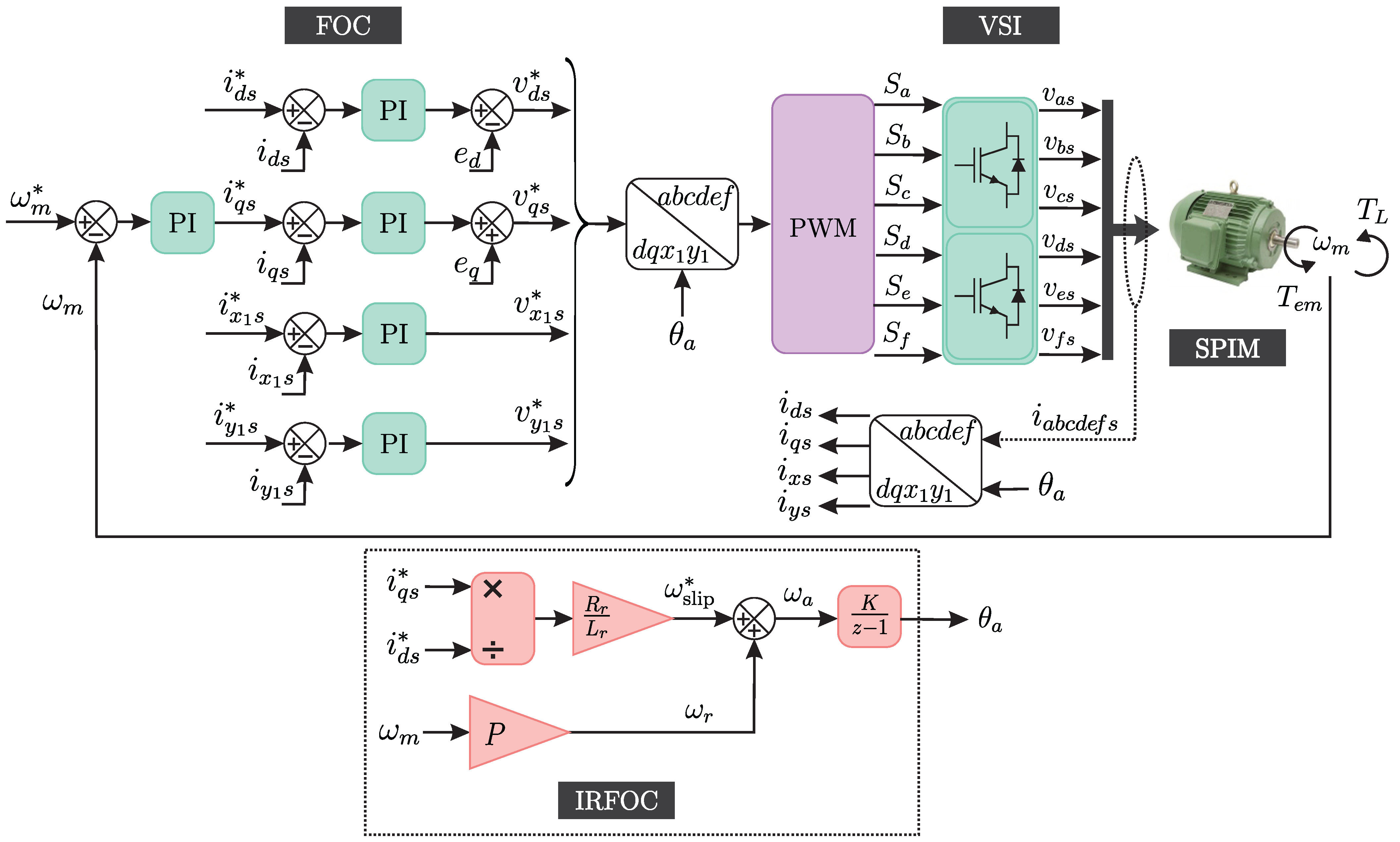

This work extends the sensorless control strategy initially proposed in [

11] to SPIM, thereby broadening its applicability within the field of multiphase drive systems. Although multiphase machines offer significant advantages, directly extrapolating control techniques from three-phase systems poses challenges due to increased system dimensionality, complex coupling between harmonics, and the need for adapted mathematical modeling. The main contribution of this work is the proposal and experimental validation of a sensorless control scheme based on SMO applied to SPIMs within an IRFOC scheme under various operating conditions, maintaining its simplicity and low computational cost. This approach not only demonstrates robust performance but can also, due to its modular structure and independence from the torque and flux controllers, be readily extended to other advanced control strategies, thereby opening new possibilities for applications in multiphase systems.

The remainder of this paper is organized as follows:

Section 2 presents the mathematical model of the system. The outer speed control and inner current control, utilizing the sensorless technique, are presented in

Section 3. Simulation and experimental validation of the proposal in transient and steady-state conditions are developed in

Section 4.

Section 5 discusses the obtained results using figures of merit. Finally,

Section 6 presents the conclusions.

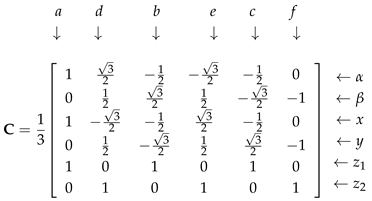

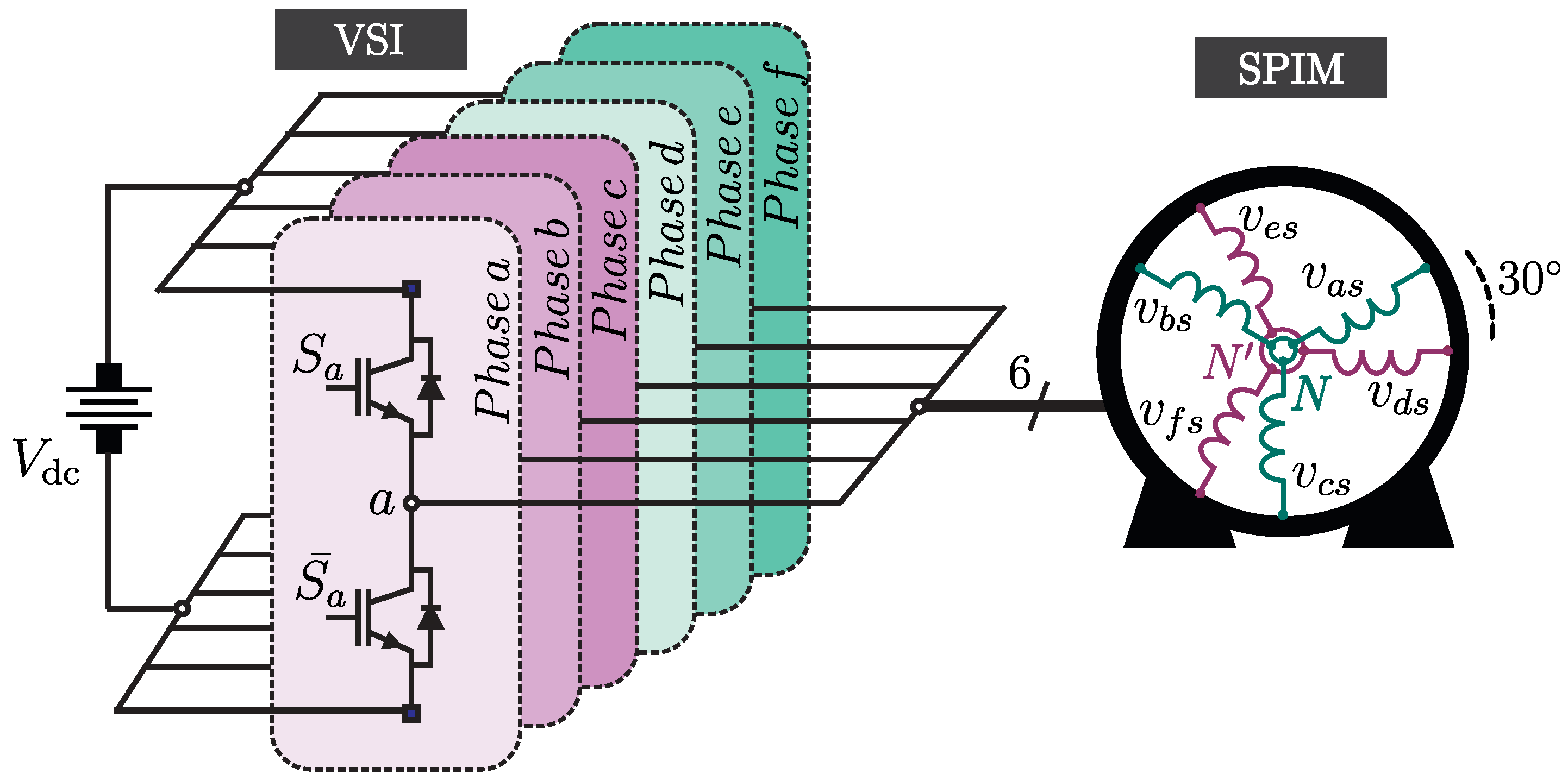

2. Mathematical SPIM Model

The SPIM under consideration is asymmetrical, featuring a

phase shift between its two three-phase winding sets, as shown in

Figure 1. The machine model is initially described by a set of differential equations with time-varying coefficients, traditionally formulated in terms of phase variables (

). Among the various reference frames described in the literature, Vector Space Decomposition (VSD) remains one of the most commonly adopted approaches [

16,

17]. By applying the Clarke transformation to both stator and rotor phase variables, according to the amplitude-invariant criterion, as shown in Equation (

1), a transformed mathematical model with constant coefficients is derived [

18]. This transformation allows the final SPIM equations to be expressed in the stationary reference frame, which not only simplifies the mathematical representation but also facilitates the implementation of advanced control strategies.

where

is the column vector representing the electrical quantities, voltage, current, or flux, corresponding to both the stator and the rotor after the transformation, whereas

denotes the column vector expressed in terms of the phase variables in a predefined order.

As a result, the original machine system is decomposed into three bi-dimensional subspaces, defined as follows: the (

-

) subspace contributes to the air-gap flux and electromagnetic torque, representing the fundamental supply component along with harmonics of order

(

); the (

x-

y) subspace is associated with copper losses and includes all supply harmonics of order

; and the (

-

) subspace corresponds to zero-sequence harmonic components, whose circulation is inhibited due to the isolated neutral point configuration [

16]. Accordingly, the machine model can be expressed in terms of the following equations:

where mutual inductance

,

,

and

is the electrical speed of the rotor. On the other hand, the indices

s, and

r denote the stator and rotor variables, respectively, while the subscripts

l and

m refer to the leakage and magnetization inductance, respectively.

The expressions for stator and rotor flux are given by:

Finally, the expression for the electromagnetic torque

, of the SPIM is given as follows:

where

P represents the number of magnetic pole pairs.

The equation relating the torque and mechanical parameters of the machine with respect to the mechanical speed is given by:

where

is the torque of the mechanical load,

J is the inertia coefficient,

B is the mechanical friction coefficient, and

is the mechanical speed of the rotor. The latter is commonly represented as a function of the electrical speed

, being:

Then, rewriting the mechanical equation, we obtain:

4. Results

The results are organized into two main groups: simulation-based evaluations and experimental validations. First, a set of tests is conducted in a simulation environment to assess the effectiveness of the proposed sensorless control strategy. Following this, experimental results are presented, obtained from a laboratory setup consisting of two three-phase VSI connected to an SPIM.

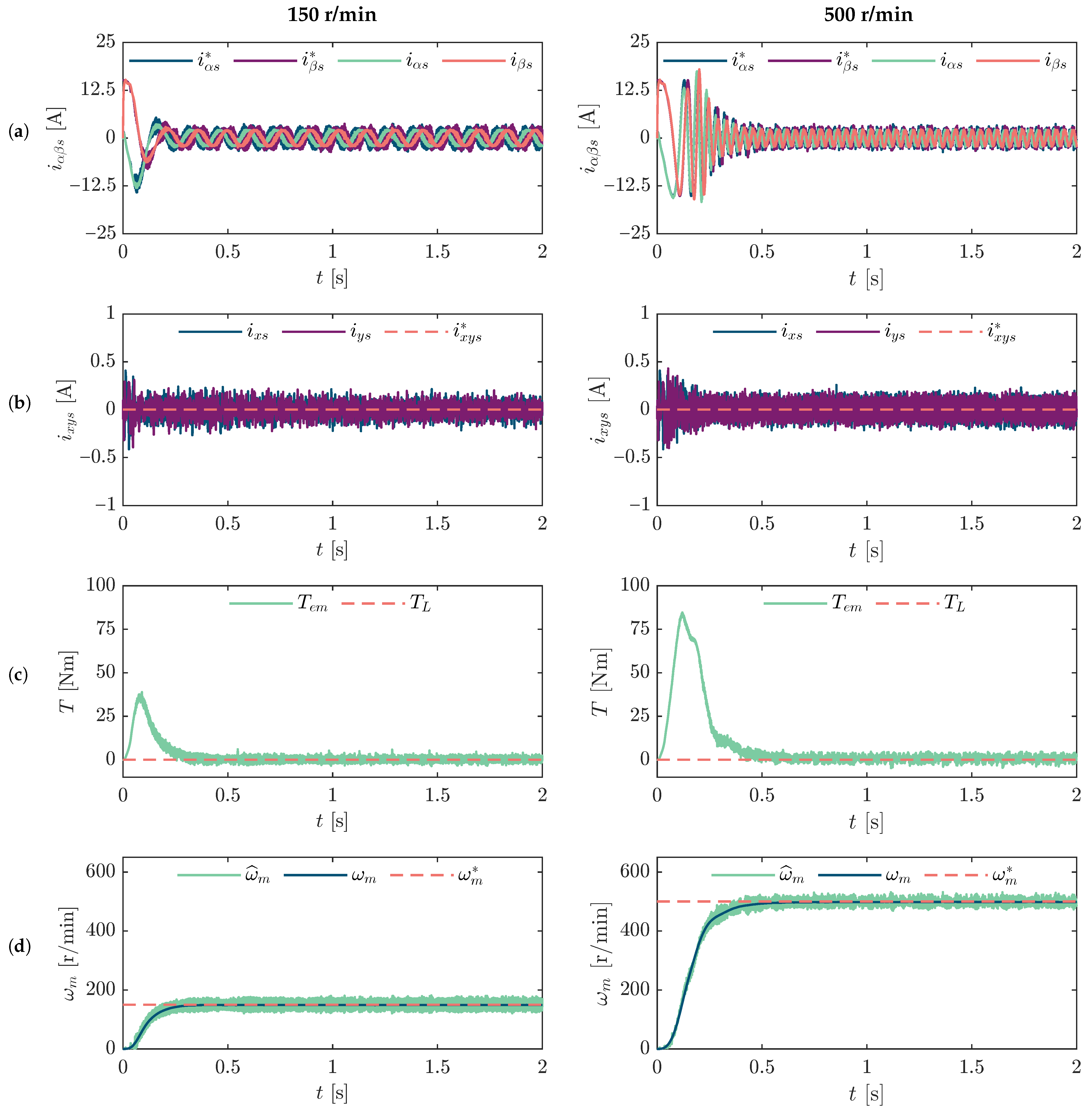

4.1. Simulation Results

This section presents the simulation-based evaluation conducted using the MATLAB/Simulink R2023b environment. The system model encompasses the detailed electrical and mechanical dynamics of the studied machine, and simulations are executed at a sampling frequency of kHz to ensure sufficient temporal resolution for dynamic analysis.

The electrical and mechanical parameters used for the simulations are listed in

Table 1. These include stator and rotor resistances, mutual inductance, leakage inductance, inertia, and friction coefficients, which are consistent with the actual machine employed in the experimental test bench.

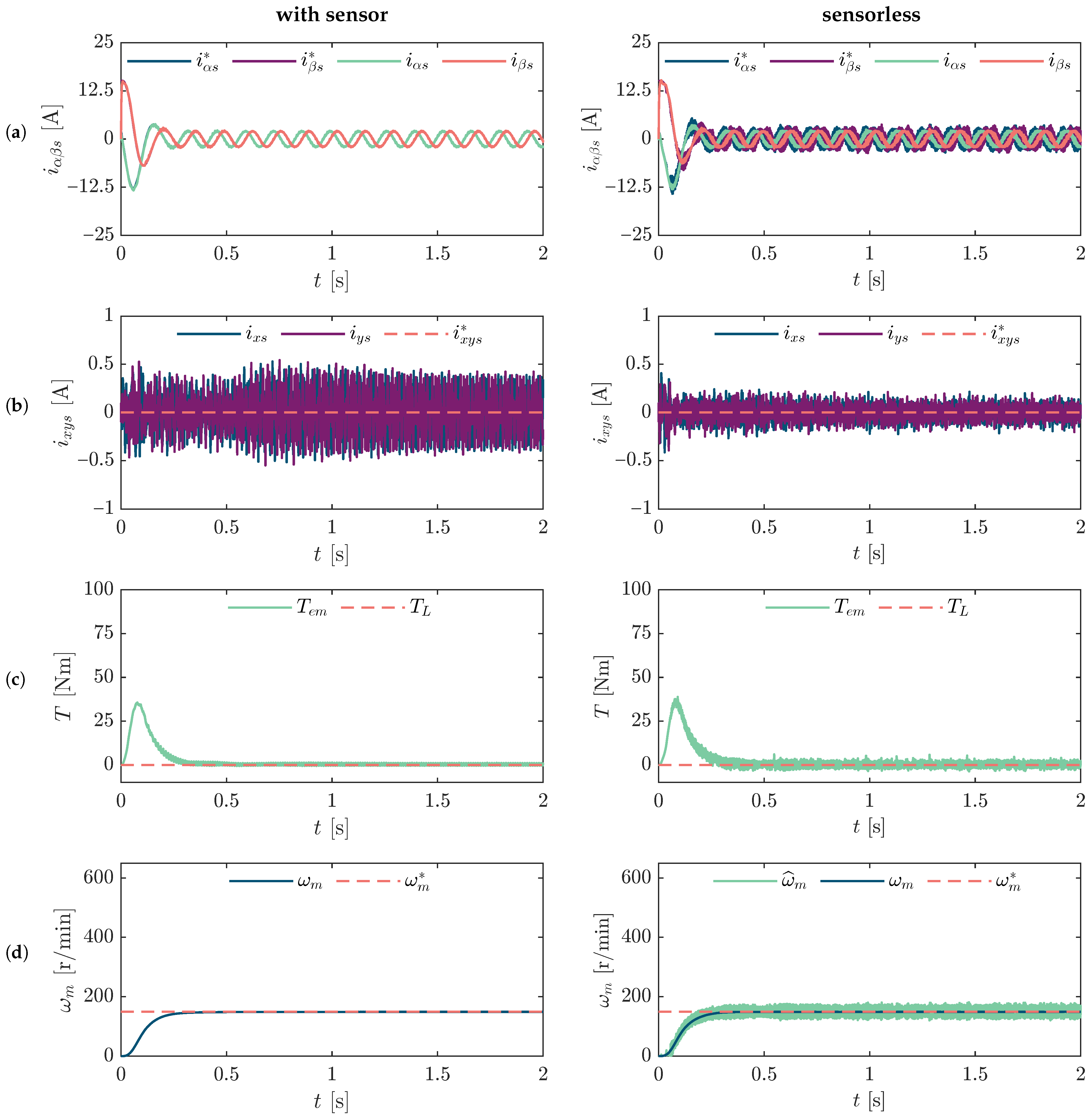

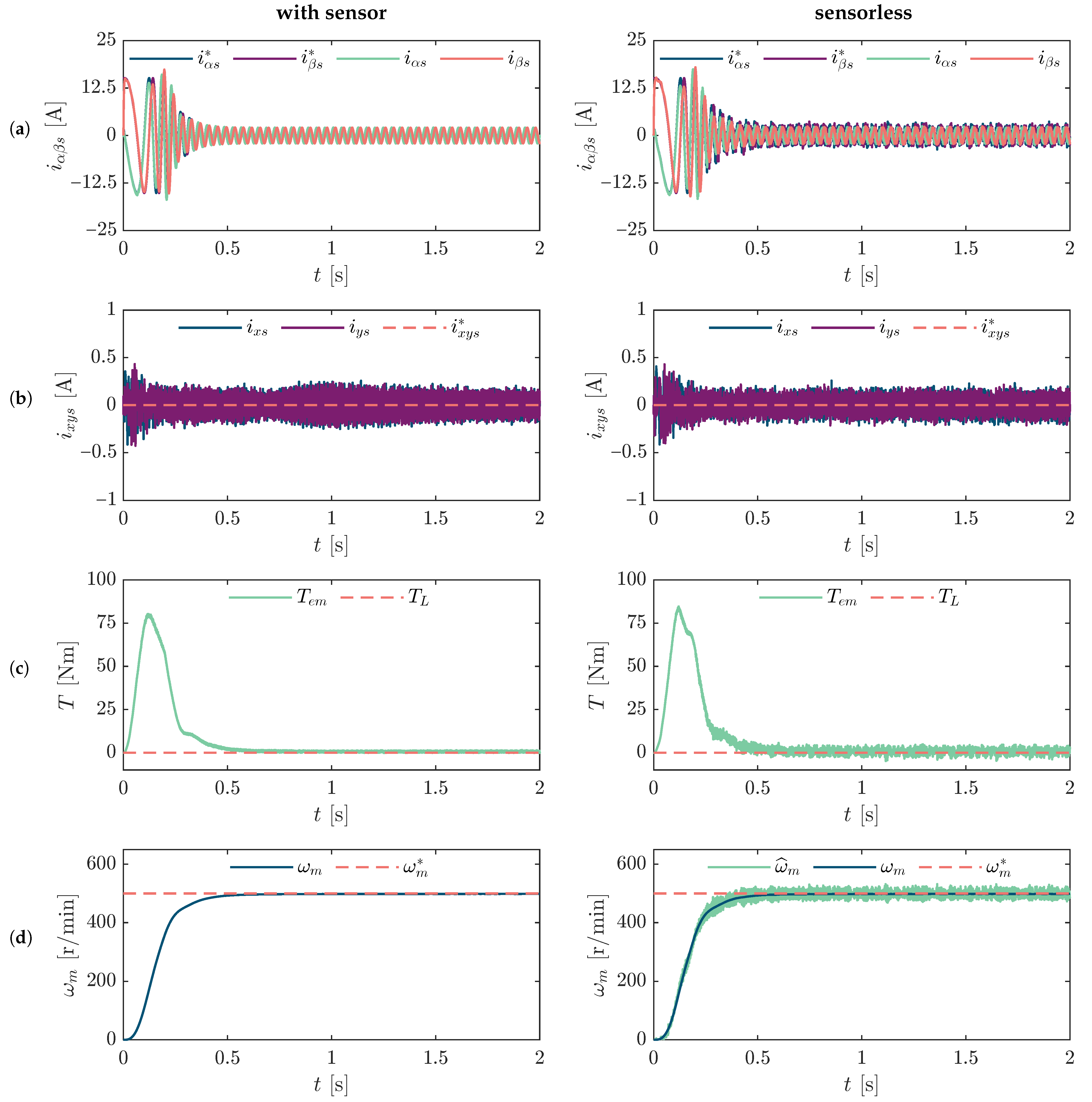

Figure 4a,b show the evolution of

currents from transient to steady-state operation under two different speed conditions: 150 r/min and 500 r/min, using the sensorless approach. The response shows smooth dynamic behaviour and stable current waveforms, indicating proper control action during speed variations. Furthermore,

Figure 4c,d depict the corresponding electromagnetic torque and speed response, respectively. The results confirm accurate tracking of the reference speed in both cases, with minimal steady-state error and acceptable torque ripple.

To further assess the performance of the proposed sensorless control strategy, a comparative study is conducted between two control configurations: one that utilizes a speed sensor (encoder-based) and the other that operates without a sensor, instead relying on the SMO approach.

Figure 5 presents the comparison in low-speed operation, specifically at 150 r/min, which corresponds to approximately 7.5 Hz in terms of the electrical frequency of the stator. This scenario is particularly relevant, as sensorless techniques typically face greater challenges in maintaining robustness and accuracy at low speeds due to reduced observability and a lower signal-to-noise ratio.

As shown in

Figure 5, the proposed method demonstrates excellent performance under these demanding conditions. The currents maintain consistent profiles, and the speed response closely follows the reference trajectory. Additionally, a reduction of the current components of the

x-

y subspace is observed in

Figure 5b, which indicates improved current quality and reduced influence of parasitic harmonics, ultimately contributing to better efficiency and lower thermal stress on the drive.

In

Figure 6, the same set of comparisons is repeated for a speed of 500 r/min. This operating point corresponds to a moderate-load condition, allowing the evaluation of the control strategy under higher stator frequencies, where sensorless techniques typically perform more reliably. The results again confirm that the proposed SMO-based approach is capable of maintaining accurate control of current and torque, as well as precise speed tracking, comparable to that of the encoder-based method.

4.2. Experimental Results

The experimental test bench setup is shown in

Figure 7 and consists of a six-phase asymmetrical induction motor with an isolated neutral configuration, whose electrical and mechanical parameters are presented in

Table 1.

A six-phase VSI drives the motor constructed using two three-phase SEMIKRON SKS 35F modules. Each module includes two Hall-effect sensors (LEM LA-55) that measure two of the three stator currents in each three-phase system, while the remaining stator currents are determined mathematically. A 325 V DC power supply is used for the DC-link. Both the control strategy and the SMO are implemented in discrete time using Euler’s method for numerical integration. The entire system is deployed on the MSK28335 development platform, which is based on the TMS320LF28335 floating-point DSP. The sampling frequency is set to 10 kHz, following the same configuration as in the simulation. A fixed d-current, A, was considered and the observer gain .

The mechanical speed is measured using an optical sensor that generates a pulse train as the shaft rotates. Standard optical sensors can output several thousand pulses per revolution (ppr). In the experiments, a DFS60B-S1PB10000 encoder is used, providing 10,000 ppr. Moreover, digital signal processors typically include built-in functions for processing encoder pulses, such as the eQEP module in the TMS320F28335.

Finally, measurement data processing and graphical representation of the research outcomes were performed within the MATLAB computational environment.

4.2.1. Figures of Merit

The SMO performance is tested by calculating the Root Mean Squared Error (RMSE) between the reference values and the measured currents in every subspace monitored by the Hall sensors. The RMSE is calculated as:

where

and

are the stator current references and the actual measurements with

,

is the total number of samples taken in an interval, and

is the number taken as a starting point in steady-state. Integer numbers represent both.

Additionally, to assess the steady-state error, the Mean Value Error (MVE) of the speed estimation is defined as:

4.2.2. Steady State and Transient Results

In

Figure 8, the experimental results under an operating condition of 150 r/min are presented, including both the transient and steady-state responses. The left column shows the behaviour of the currents and mechanical speed when using the encoder, while the right column presents the results with the sensorless control based on the SMO.

Additionally,

Figure 9a,b show the steady-state behaviour of the currents and mechanical speed under sensorless control at an operating speed of 150 r/min with an external load torque of approximately

applied to the motor shaft.

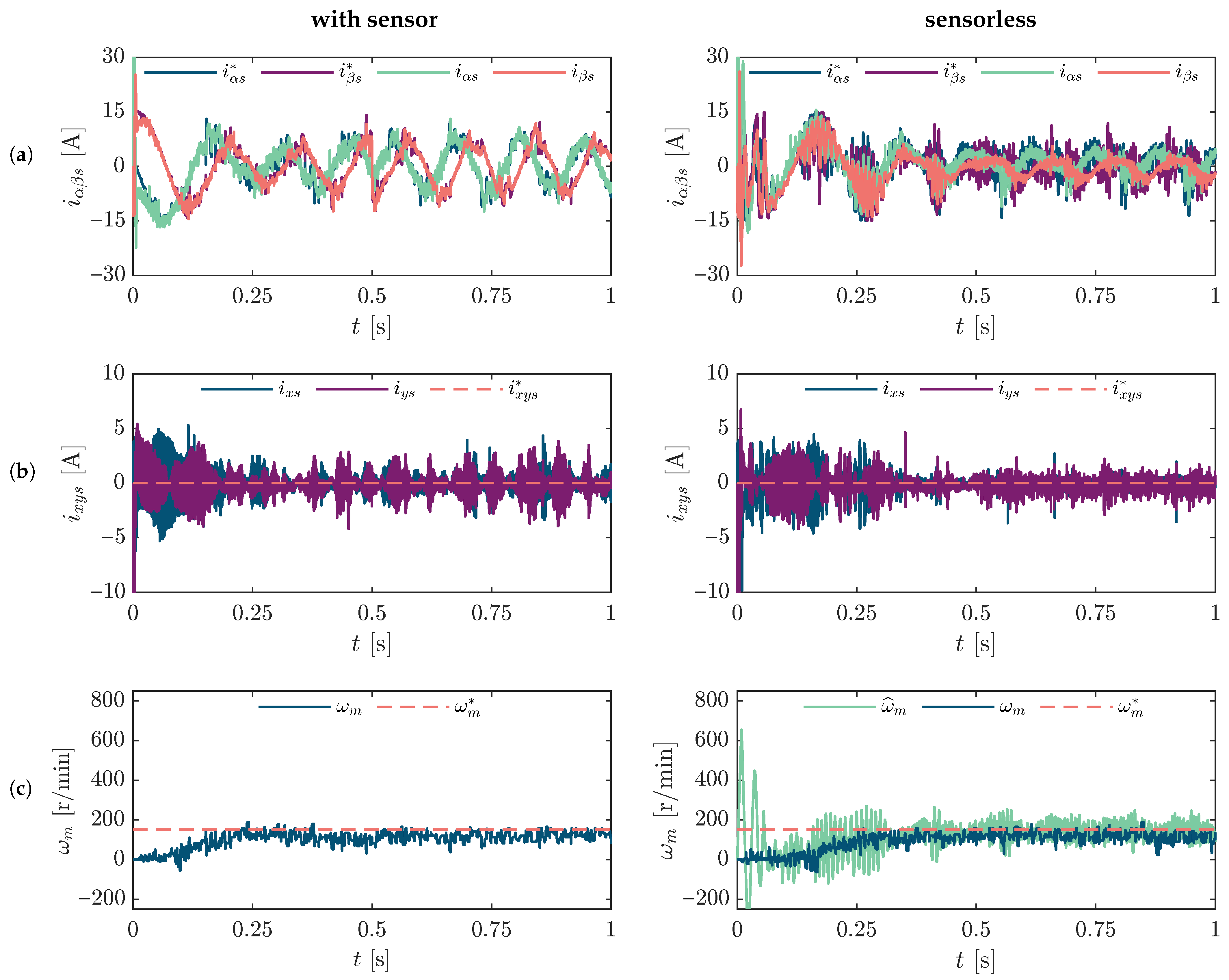

On the other hand,

Figure 10 presents the behaviour of the

currents and the speed tracking performance during a speed reversal from 150 r/min to –150 r/min, carried out using the proposed control technique. The results correspond to the operating conditions before and after the reversal. This type of test is particularly relevant in induction motor applications, as it enables the evaluation of the dynamic response to sudden changes in operating conditions. Successfully managing such transitions is essential in applications that require frequent direction changes or precise motion control, such as electric vehicles or industrial automation systems.

In

Figure 11, the proposed SMO was tested under low-speed operating conditions, specifically at 20 r/min. The observer maintained stable and accurate estimation under these near-zero speed conditions. An increase in ripple was observed in the estimated speed due to the discontinuous nature of the sliding-mode algorithm. As expected at low speeds, the stator currents are also relatively small, which can reduce the signal-to-noise ratio and affect estimation quality. Nevertheless, the observer remained robust, and proper filtering ensured reliable performance without compromising control accuracy.

5. Discussion

Under low-speed operation, a comparison between the encoder-based control and the proposed sensorless technique presented in

Table 2 and

Table 3 reveals that the latter achieves a reduction of approximately 40% in the

x-

y subspace current components. This improvement contributes to lower parasitic losses and enhanced drive efficiency, particularly at low speeds. However, an increase of approximately 28% is observed in the tracking error of the currents in the

–

subspace with the sensorless approach. As for the THD in the

–

subspace, the FOC-SMO has a notorious increase compared to FOC with sensor. It must also be considered that the speed MVE is almost completely reduced with the FOC-SMO technique, so the amplitude of the currents is reduced, and considering that it has a lower signal-to-noise ratio, the THD is greater. However, with the FOC with sensor, the speed error is not completely corrected since a suboptimal speed control is used. This degradation can be attributed to the reduced back-EMF magnitude at low speeds, which compromises the observability of rotor dynamics. In the case of an SMO, this leads to reduced estimation accuracy due to weakened sliding conditions and increased sensitivity to noise. As a result, the current control in the

–

frame becomes less precise under low-speed operation.

The results in

Table 4 show that increasing the reference speed from 150 to 300 r/min leads to a significant improvement in rotor speed estimation accuracy, with the MVE dropping from 2.59 to 0.25%. This confirms the enhanced observability of the system at higher speeds, which benefits the performance of the SMO. However, this improvement is accompanied by an increase in current tracking error in both the

–

and

x–

y subspaces. For instance, RMSE(

) increases from 1.10 A to 3.74 A. This suggests a possible trade-off between estimation accuracy and current control performance under higher-speed operation, potentially due to suboptimal tuning of the current controllers at higher speeds. At the same time, optimal SMO gain design must be considered to ensure stability and acceptable chattering generation for the desired machine performance. It should also be noted that the six-phase machine must have optimal current control settings in both the (

-

) and (

x-

y) subspaces.

6. Conclusions

This work has introduced the implementation of an SMO for sensorless speed control of an asymmetrical six-phase induction machine. The proposed method was first validated through simulation and later confirmed experimentally, demonstrating a high degree of consistency between the two sets of results.

The comparative analysis under no-load and load conditions at low speed demonstrates that the SMO-based control significantly outperforms the conventional FOC with mechanical sensors in rotor speed estimation accuracy, achieving much lower mean value errors (MVEs). While the SMO approach exhibits higher current tracking errors in the - subspace, it shows improved performance in the x-y current components, particularly under load. Moreover, the reduction in x-y subspace currents contributes to lower parasitic losses and enhanced drive efficiency in low-speed operation.

However, the sensorless strategy results in a notable increase in the THD of the - currents. This can be attributed to the reduced signal-to-noise ratio caused by the reduced current amplitude, which is a consequence of the improved speed regulation. Additionally, the limited back-EMF magnitude at low speeds compromises the observability of rotor dynamics, reducing the effectiveness of the SMO and introducing estimation inaccuracies due to weakened sliding conditions.

Further experimental evaluation revealed that the SMO-based sensorless control delivers more accurate rotor speed estimation at higher operating speeds, driven by enhanced system observability. Nonetheless, this improvement is accompanied by increased current tracking errors, emphasizing the trade-off between estimation precision and current control performance. This effect is likely associated with fixed current controller tuning, which may not be optimal across all operating conditions. To address this limitation, future work could investigate the integration of more advanced current control strategies to ensure consistent current regulation without compromising estimation accuracy.