1. Introduction

Trajectory planning is the prerequisite for achieving deterministic polishing [

1]. Traditional trajectory planning for surface machining mostly uses the iso-parametric method [

2], iso-planar method [

3], and iso-scallop method [

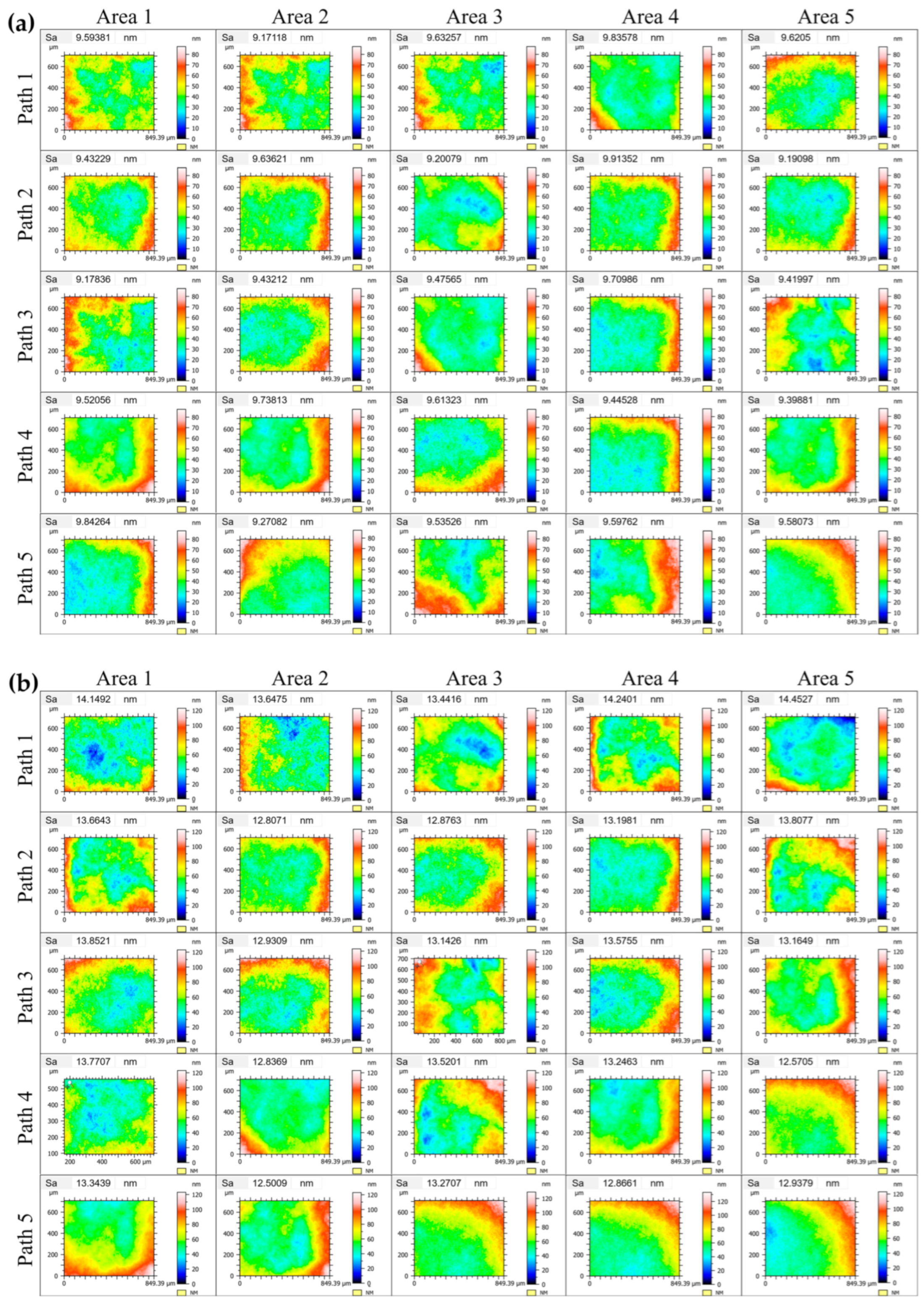

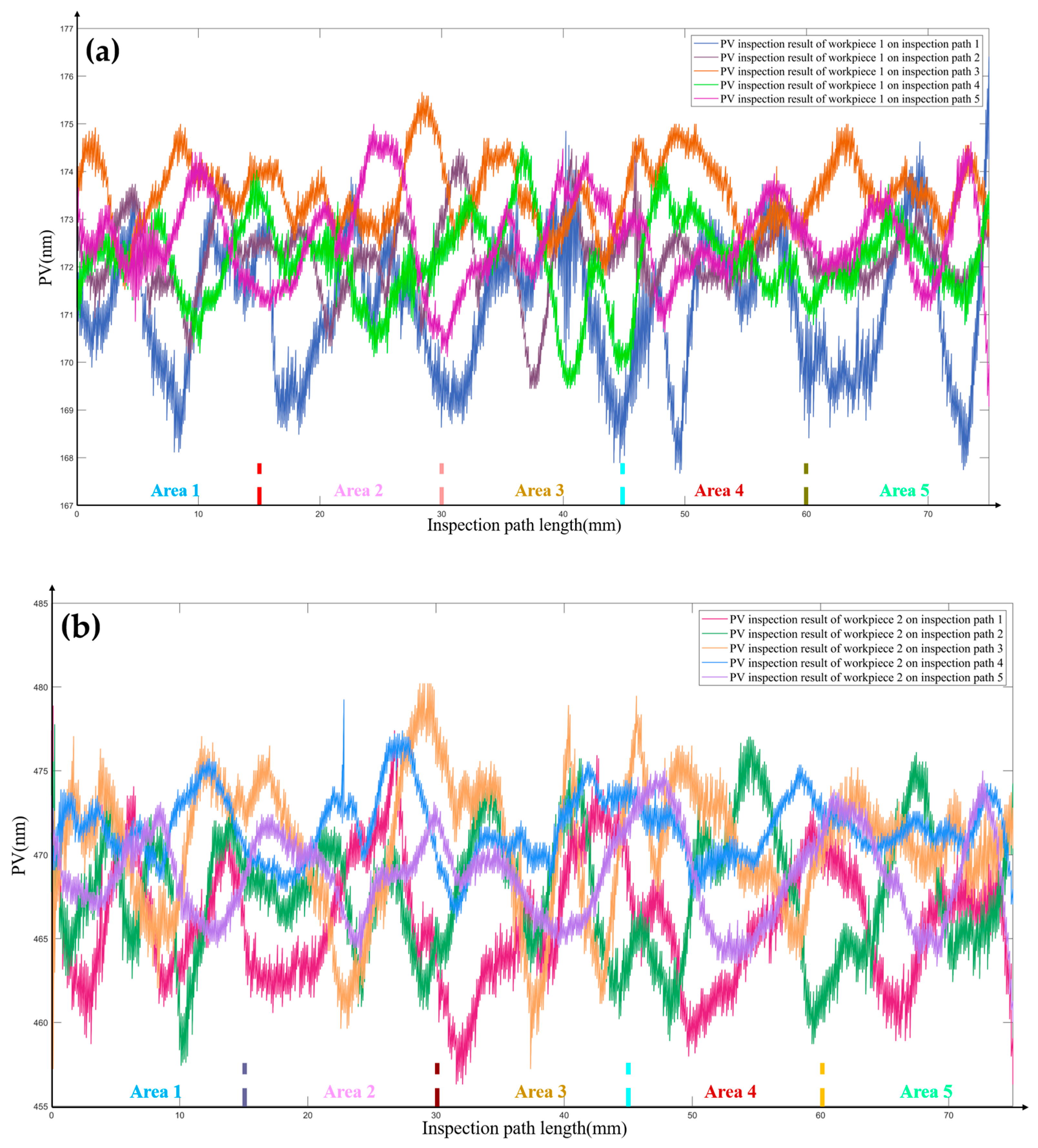

4]. The iso-parametric method generates a machining path along one parameter of the surface

S(

u,

v) by keeping another parameter of the surface unchanged (i.e., one of the parameters

u or

v remains unchanged). This low-computation method is usually used for trajectory planning of simple surfaces, but it can only obtain simple machining trajectories. The iso-planar method uses several equally spaced parallel planes to intersect the surface being machined, and the intersection line of each plane with the surface being machined is used as the machining trajectory. This method can be used to generate the machining trajectory for more complex surfaces, but the disadvantage lies in the excessive computation when the surface model is large. The iso-scallop method takes any surface boundary as the initial machining path, and the next trajectory is calculated based on the tool contact on the current trajectory. The iso-scallop method is a dynamic trajectory planning method, but the calculation process is more complicated and time-consuming.

Although the above trajectory planning methods can realize the generation of polishing trajectories for simple curved surfaces, they are unable to consider the influence of surface curvature on the trajectory spacing, which leads to inconsistency in material removal and fails to obtain excellent machining quality.

The conventional research on polishing trajectories of complex surfaces can be divided into two principal categories. The first category concerns the use of interpolation and other methods to achieve the acquisition of polishing trajectories [

5]. The second category is concerned with optimizing the processing parameters of simple polishing trajectories with a view to improving polishing quality [

6]. Zhao et al. [

7] implemented a systematic NURBS (Non uniform rational B-spline) interpolation method for polishing trajectory planning, leveraging Successive Over-Relaxation (SOR) iteration theory to reduce the computational difficulty of control point solving. Han et al. [

8] achieved parametric trajectory interpolation by integrating NURBS curves with the Milne–Hamming predictor-corrector algorithm. Zhang et al. [

9] proposed an adaptive trajectory planning method based on NURBS interpolation principles and incorporating a finite element model of the tool-blade contact as a constraint, enabling uniform blade polishing. Chen et al. [

10] developed a high-precision motion interpolation method combining a fourth-order Runge–Kutta adaptive algorithm (RK4) with variable-feed velocity planning (VF), addressing the accuracy limitations of traditional interpolation methods on open small multi-axis polishing machines. Xu et al. [

11] achieved smooth machining trajectories on bi-NURBS regular surfaces by incorporating geodesic curvature and surface convexity/concavity, generating non-redundant and interference-free paths. Ren et al. [

12] employed NURBS interpolation to resolve trajectory discontinuity issues encountered when machining sharp edges with parametric segmented paths. Cui et al. [

13] introduced a zoned polishing trajectory generation method for complex optical surfaces based on curvature characteristics and Freeman coding. To enhance material removal uniformity and suppress edge effects during NURBS surface polishing, Han et al. [

14] proposed a spiral trajectory planning method utilizing an iterative approximation algorithm. Cao et al. [

15] analyzed the impact of polishing contact area, curvature, and tool attitude angle on material removal. By introducing curvature fluctuation constraints into NURBS interpolation, they improved the material removal precision of spiral polishing paths. Xiao et al. [

16] addressed trajectory planning for complex workpieces by proposing a path co-optimization method. Finally, Zheng et al. [

17] experimentally quantified the influence of scanning pitch and polishing mode (e.g., transverse vs. cross-scanning) on polishing quality and efficiency. Their results confirmed that the cross-scanning mode optimizes surface integrity and identified the optimal parameter combination for achieving ultra-smooth surfaces. Wahballa et al. [

18] developed a robotic polishing trajectory planning strategy integrating NURBS-S curve smoothing, gravity compensation control, and material removal depth modeling. This approach enables uniform material removal under precisely controlled constant force conditions. Huang et al. [

19] constructed parametric polishing paths using cubic B-splines, establishing a one-to-one correspondence between path segments and dwell points, and further optimized trajectory interpolation via an equal-proportion feed strategy to enhance the stability of material removal. Kakinuma et al. [

20] proposed a real-time polishing trajectory optimization method utilizing sensor-less force control technology and a decoupling-capable quarry matrix. This technique facilitates collaborative control of trajectory spacing, tool posture, and polishing force. Wang et al. [

21] generated polishing trajectories by projecting conventional machining paths onto 3D vibration trajectories, achieving effective trajectory planning specifically for harmonic mesh surfaces. Li et al. [

22] obtained random-like Lissajous polishing trajectories through controlled vibration parameter modulation, effectively addressing the issue of periodic polishing marks on workpiece surfaces caused by traditional circular/elliptical trajectories in small-tool polishing.

The above studies have focused on the generation of complex surface machining trajectories for which the surface equations are known or the optimization of existing polishing trajectories to meet specific polishing requirements in certain cases. Therefore, there are evident limitations in terms of general applicability. Benefiting from the development of computer graphics, the mathematical properties of equation-free surfaces can be discretely represented by the mesh model that corresponds to the surface model. This method can solve the problem of obtaining mathematical relations of the equation-free surfaces in the machining trajectory planning process.

Although equation-free surfaces are complex surfaces that are difficult to describe with mathematical equations, the surface information can be discretely represented by triangular mesh surfaces. Triangular mesh surfaces have the following advantages in the field of trajectory planning: Triangular meshes can accurately approximate complex geometries, even on surfaces with curvature mutations. Compared to rectangular or other types of meshes, triangular meshes are able to adapt more flexibly to irregular shapes, which is especially important for trajectory planning on complex surfaces. Triangles are the simplest polygons in geometry; using triangular meshes for trajectory generation will not only simplify the computation, but also increase the computational efficiency. Since triangles consist of only three vertices and three edges, they can generate smooth surface approximations on complex surfaces, which makes it possible to generate trajectories with better continuity and smoothness on complex surfaces. Triangular meshes are widely used in 3D modeling, computer graphics, and numerical analysis, and it is easier to migrate data between different software using triangular meshes. Triangular meshes are more stable when dealing with topological changes such as mesh refinement. Through mesh subdivision and optimization, the accuracy of trajectory planning can be improved while maintaining the original geometric features. Kim et al. [

23] verified the feasibility of using mesh surfaces for machining trajectory planning. Wang et al. [

24] proposed a machining trajectory spacing optimization algorithm applicable to mesh surfaces. Zhang et al. [

25] proposed a helical cutting path generation algorithm based on a mesh surface model, which effectively improves the cutting and machining accuracy. Li et al. [

26] combined mesh surface parameterization methods with component analysis to obtain iso-parametric trajectories on mesh surfaces. Zhao et al. [

27] introduced geodesic curves on triangular mesh trajectory planning, and this work effectively reduced the difficulty of trajectory planning for equation-free surfaces. Xu et al. [

28] proposed a trochoidal polishing trajectory generation method for equation-free surfaces based on surface parameterization principles to improve the polishing accuracy of equation-free surfaces. Liao et al. [

29] proposed a tool path planning method under constant cutting load by combining a conformal mapping parametric algorithm and a variable radius hoof trajectory.

However, a critical research gap persists. Traditional methods, reliant on NURBS solutions or interpolation, cannot guarantee that the generated trajectory’s accuracy fully adapts to the polished surface—a significant drawback for precision polishing. Surface parameterization methods applied to mesh models reduce dimensionality and complexity for trajectory generation on intricate, equation-free surfaces. Nevertheless, this approach introduces two inherent challenges: (1) inevitable distortion during the mesh parameterization process, and (2) the computational burden and potential inaccuracies associated with solving the resulting nonlinear equations. Both factors compromise the final polishing trajectory precision. More importantly, and constituting a major oversight in the existing literature, achieving uniform coverage of the polishing trajectory—essential for polishing to prevent over-polishing/under-polishing, effectively suppress high-spatial frequency errors, and achieve more consistent surface outcomes within the same processing cycle–has received insufficient attention. Current research, even mesh-based, largely neglects this crucial capability.

Therefore, this paper aims to address these limitations by pursuing the following specific research objectives for trajectory generation and optimization in sub-aperture polishing (especially when employing compliant spherical tools) of equation-free optical surfaces:

To develop a method for generating high-precision polishing trajectories on equation-free surfaces that operates directly on the mesh representation, eliminating the need for surface equation solving and the associated distortion and computational issues of parameterization;

To design and implement an algorithm capable of optimizing polishing trajectories to achieve uniform coverage, thereby mitigating the risks of over-polishing and under-polishing and facilitating faster attainment of the desired polishing effect.

The various sections of this paper are organized as follows: In

Section 2, an algorithm for generating a polishing trajectory on equation-free surfaces is proposed, and the mathematical principles of the corresponding algorithm are elucidated. In

Section 3, a curvature-solving algorithm applicable to mesh surfaces is proposed for obtaining surface curvature in the calculation of the polishing contact area. The mathematical principles of the corresponding algorithm are elaborated, and the computational accuracy of the algorithm is verified. In

Section 4, a polishing trajectory point adjustment algorithm on mesh surfaces is proposed and a method for achieving uniform coverage of both symmetrical and asymmetrical polishing trajectories is further proposed. The relevant mathematical principles are explained, and the feasibility of the algorithms is ultimately validated through simulations. In

Section 5, experimental tests are conducted to reveal the impact of uniform coverage and non-uniform coverage polishing trajectories on the quality of polishing equation-free surfaces. The conclusions are given in

Section 6.

2. Mathematical Implementation of Mapping Planar Trajectories to Mesh Surfaces

Assuming that the coordinates of three vertices in 3

D space for any triangle mesh in an equation-free mesh surface are

P1(

x1,

y1,

z1),

P2(

x2,

y2,

z2) and

P3(

x3,

y3,

z3), respectively, the unit normal vector

n for the triangular mesh can be calculated as Equation (1).

The vector

n is decomposed along the

x-axis,

y-axis, and

z-axis to obtain the vectors

nx,

ny,

nz. Then, the mathematical properties of the equation-free grid surface can be expressed as a discrete combination of multiple triangular grids, as shown in Equation (2).

In Equation (1), the parameter ‘Num’ denotes the total number of triangular meshes within the mesh surface.

After obtaining the plane equation for any triangular mesh within the mesh surface, it is possible to further solve for the trajectory coordinates of the planar trajectory points mapped onto the mesh surface. The validity of the triangular mesh in the mapping direction should be determined firstly. (When the triangle mesh is parallel to the mapping direction, the planar trajectory points cannot intersect with the triangle mesh along the mapping direction.)

Assuming that the mapping direction is determined by the unit vector m, the coordinate components of m in the X, Y, and Z directions are mx, my, and mz, respectively. The equation of the plane Fi with vector m as the normal vector and containing the mapped point P(x0, y0, z0) is mx(x − x0) + my(y − y0) + mz(z − z0) = 0.

Assuming that the three vertices of any triangular mesh

Ti are

V1 = (

x1,

y1,

z1),

V2 = (

x2,

y2,

z2),

V3 = (

x3,

y3,

z3), the vertices of the triangular mesh

Ti after projection to the plane

Fi along the opposite direction of the mapping direction are

v1,

v2, and

v3. The computation of the coordinates of the corresponding vertices can be achieved by Equation (3).

Define the auxiliary vectors U and V, where U = v1 − v2 and V = v1 − v3. If U × V ≠ 0, the triangle mesh Ti is a valid triangle in the mapping direction.

Three results can be obtained by mapping a planar trajectory point P to a triangular mesh:

Case 1: point

P can be mapped to the interior of the triangle mesh (corresponding to

Figure 1a);

Case 2: point

P can be mapped to an edge of the triangle mesh (corresponding to

Figure 1b);

Case 3: point

P cannot be mapped to the interior of the triangle mesh (corresponding to

Figure 1c).

It can be intuitively seen that only in the two cases of

Figure 1a,b, the point

P can be mapped to the corresponding triangular mesh. In this case, the vectors

,

,

formed by the point

P and the three vertices of the triangular mesh

Ti satisfy the mathematical relationship described in Equation (4).

If the triangular mesh

Ti is a valid triangle in the mapping direction, the plane equation of

Ti is obtained by Equation (1), and the coordinates of the spatial point

PM obtained by mapping point

P(

x0,

y0,

z0) along the direction of vector

m onto triangular mesh

Ti can be solved using Equation (5).

In Equation (5), (x1,y1,z1) are the coordinate values of the vertex V1 of the triangle mesh Ti.

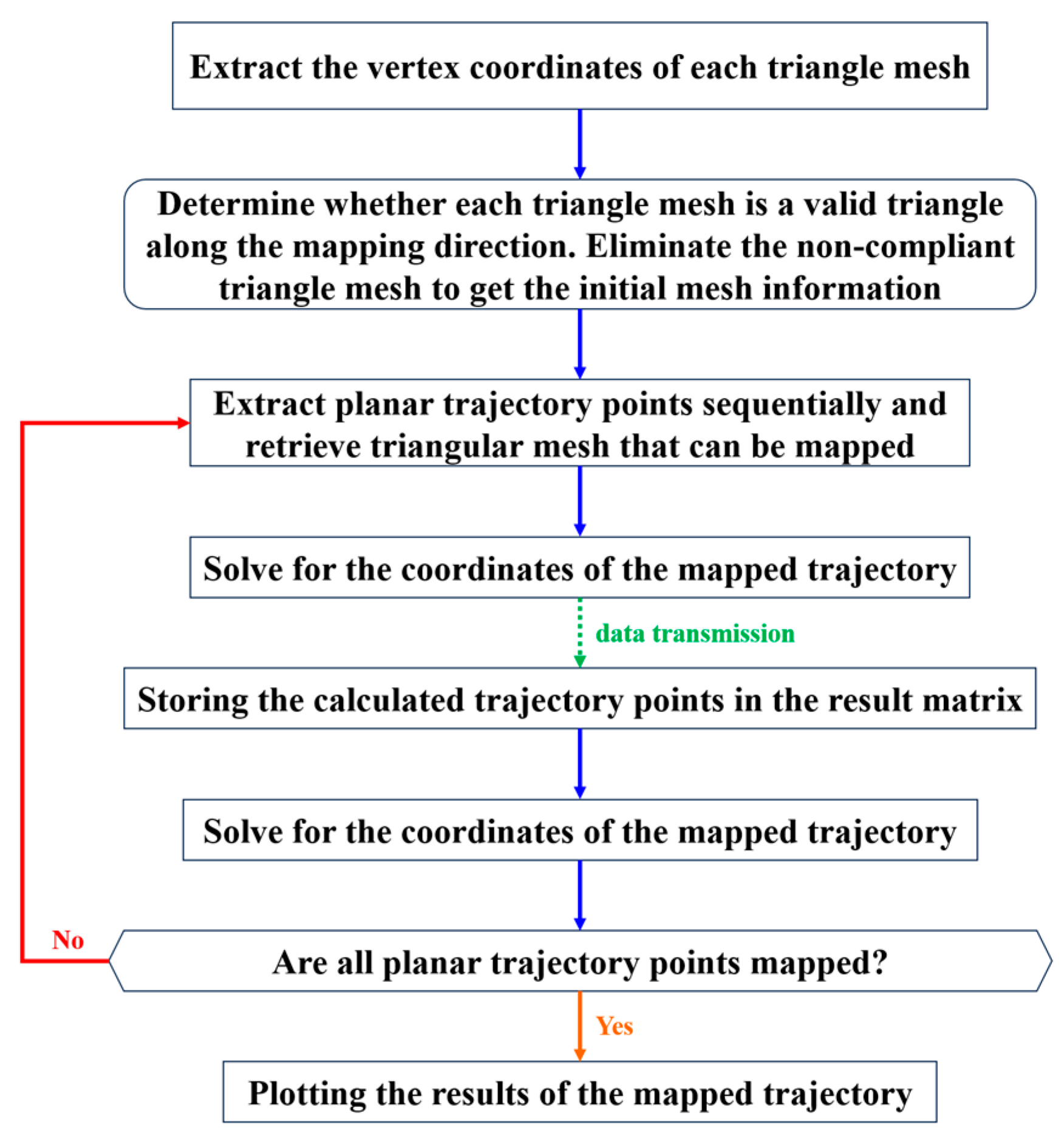

The flowchart of the mapping algorithm for planar trajectories to a mesh surface is shown in

Figure 2.

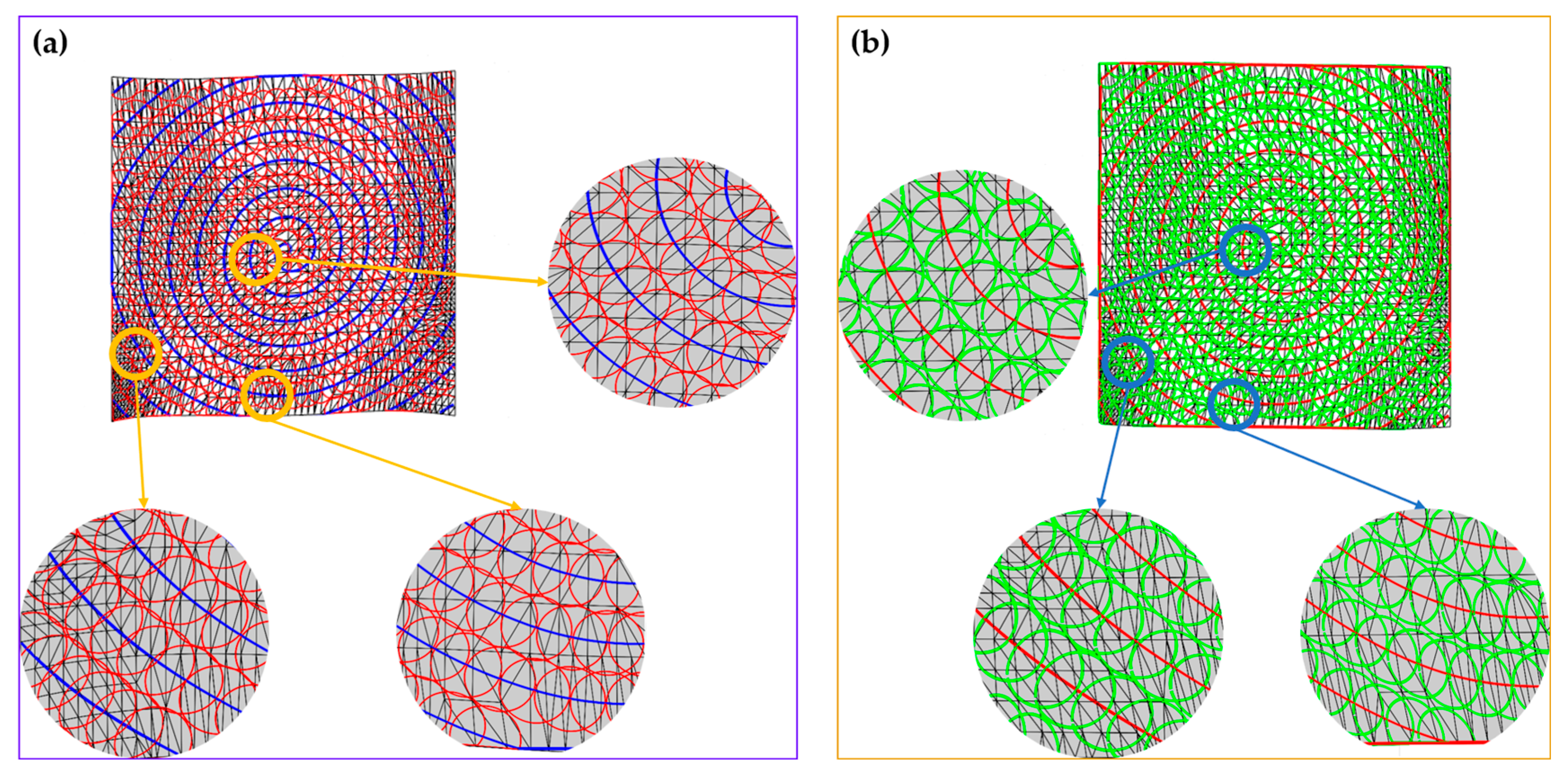

According to the proposed trajectory mapping strategy, an equidistant helical trajectory on the plane is mapped onto an equation-free mesh surface with a size of 20 cm × 20 cm. The final simulation visualization result is shown in

Figure 3.

3. Calculation of Curvature of Triangular Mesh Vertices Within the Mesh Surface and Curvature Fitting of Trajectory Points

After mapping an equidistant polishing trajectory from the plane to an equation-free surface, the fluctuation in surface curvature leads to changes in the spacing of adjacent polishing trajectories, as shown in

Figure 3. As shown in

Figure 4a,b, the red and green circles are used to represent the contact circles of some trajectory points belonging to the successive polishing trajectory of the surface, respectively. Each contact circle reflects the size of the polished contact area at the corresponding trajectory point. According to the partially enlarged detail of

Figure 4a,b, it can be seen that if the positional relationship of the polishing circles between any two adjacent polishing trajectory points is not consistent, excessive overlap area between polishing circles can lead to over-polishing, while no overlap area between polishing circles can lead to under-polishing; this ultimately affects the quality of surface polishing. Therefore, it is necessary to adjust the position of the mapped polishing trajectory points. However, adjusting the positions of polishing trajectory points requires determining the size of the polishing contact area at each trajectory point to obtain the adjustment magnitude for each trajectory point.

Under static contact conditions, the polishing contact area between the polishing tool and the surface is elliptical, and the major axis ‘

a’ and minor axis ‘

b’ of the corresponding elliptical region can be obtained by Equation (6) [

30].

In Equation (6),

Q is the total contact force,

is the equivalent modulus of elasticity,

R represents the equivalent radius of the polishing tool and the polished surface, and parameters

k and

ε are empirical coefficients, as shown in Equations (7)–(10).

In Equation (7), E1 and E2 are the modulus of elasticity of the polishing tool and the polished surface, respectively, and μ1 and μ2 are the Poisson’s ratios of the polishing tool and the polished surface, respectively. In Equations (7)–(10), ρI1 and ρI2 represent the principal and subsidiary curvatures of the polishing tool, and ρII1 and ρII2 represent the principal and subsidiary curvatures of the polished surface.

Adjustment of the position of the mapped trajectory points requires a specific amount of adjustment depending on the size of the polished contact area. During the polishing process, the polishing tool rotates along its own axis, and the contact area is regarded as a circular region with a radius equal to the major axis ‘a’ of the elliptical contact area.

According to Equation (6), since the contact force Q and the curvature of the polishing tool are known conditions, the unknown parameter that affects the size of the contact area is the curvature of the mesh surface. A mesh surface describes surface information in terms of triangular mesh vertex coordinates; therefore, the curvature calculation at the location of a trajectory point on a mesh surface can be divided into two steps: solving for the curvature values of the triangular mesh vertices to which the trajectory point belongs, and then curvature fitting based on the coordinates of the trajectory point’s location on the triangular mesh.

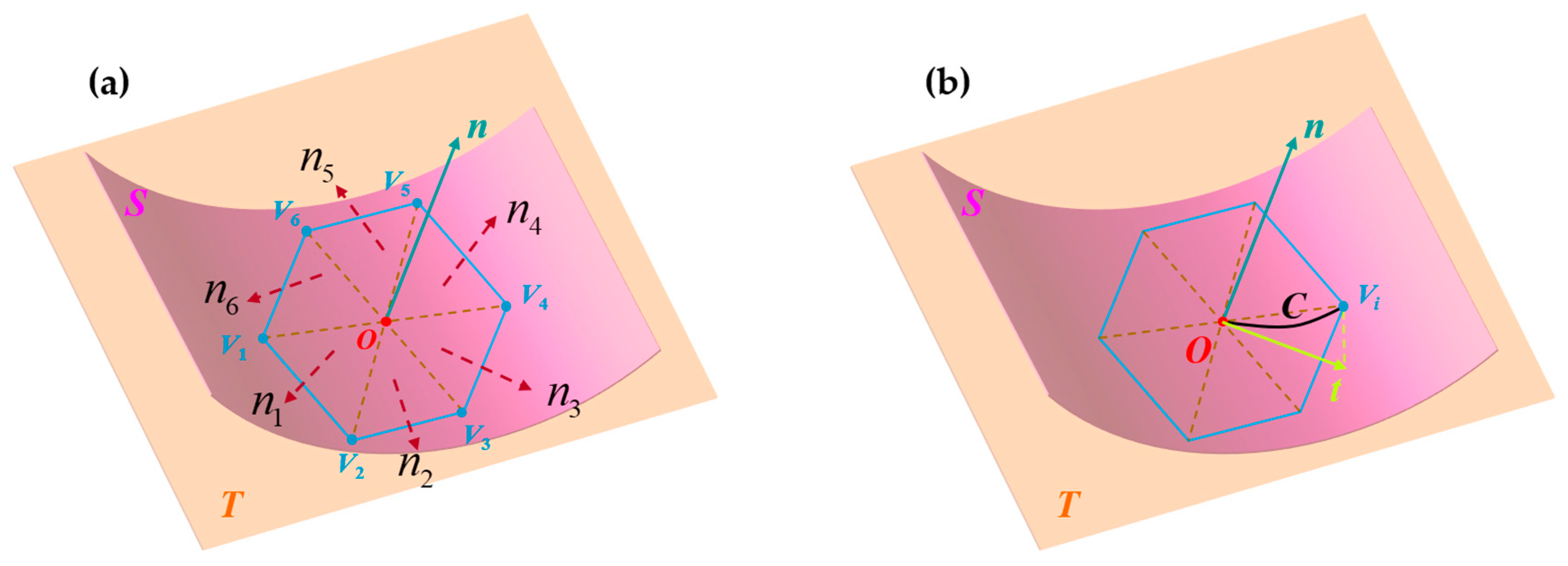

The computation of normal vectors at the vertices of a triangular mesh is a prerequisite for the realization of the curvature computation at the corresponding vertices. As shown in

Figure 5a,

ni (

i = 1,2,3,4,5,6) are the normal vectors of each triangular mesh, respectively. For any triangular mesh in the mesh surface, the unit normal vector

n at the vertex

O can be computed by using Equation (11).

In Equation (11), Ai denotes the area of each triangle mesh.

As shown in

Figure 5b, vertices

O and

Vi belong to a same triangular mesh. Assuming that the expression of the actual curve between point

O and point

Vi is

r =

r(

C),

T is the tangent plane of the surface

S at the position of point

O, and vector

t is the unit tangent vector of

OVi’s projection onto the tangent plane

T. Since the vector

n has already been computed,

t can be obtained by solving Equation (12).

For the curve

r =

r(

C),

r(0) =

O,

,

, and

kn(

t) is the normal curvature of the point

O along the

t-direction. Also,

is always perpendicular to

r(

C) when the curve

r(

C) has a fixed length [

31]. The curve expression

r =

r(

C) is

Taylor-expanded as shown in Equation (13).

Transforming Equation (13):

Equation (14) can be obtained:

Also, since the inner product of the normal curvature

kn(

t) and the tangent line

t on the same curve is always 0, Equation (16) can be obtained.

According to Equations (15) and (17), the equation for

kn(

t) is obtained as shown in Equation (18).

The tectonic curvature tensor

L is shown in Equation (19).

Solving for the eigenvalues

λ1 and

λ2 of the curvature tensor

L, the Gaussian and mean curvatures at the vertex

O can be obtained by Equation (20):

Then, the principal and subsidiary curvatures at vertex

O on the mesh surface can be further calculated according to Equation (21).

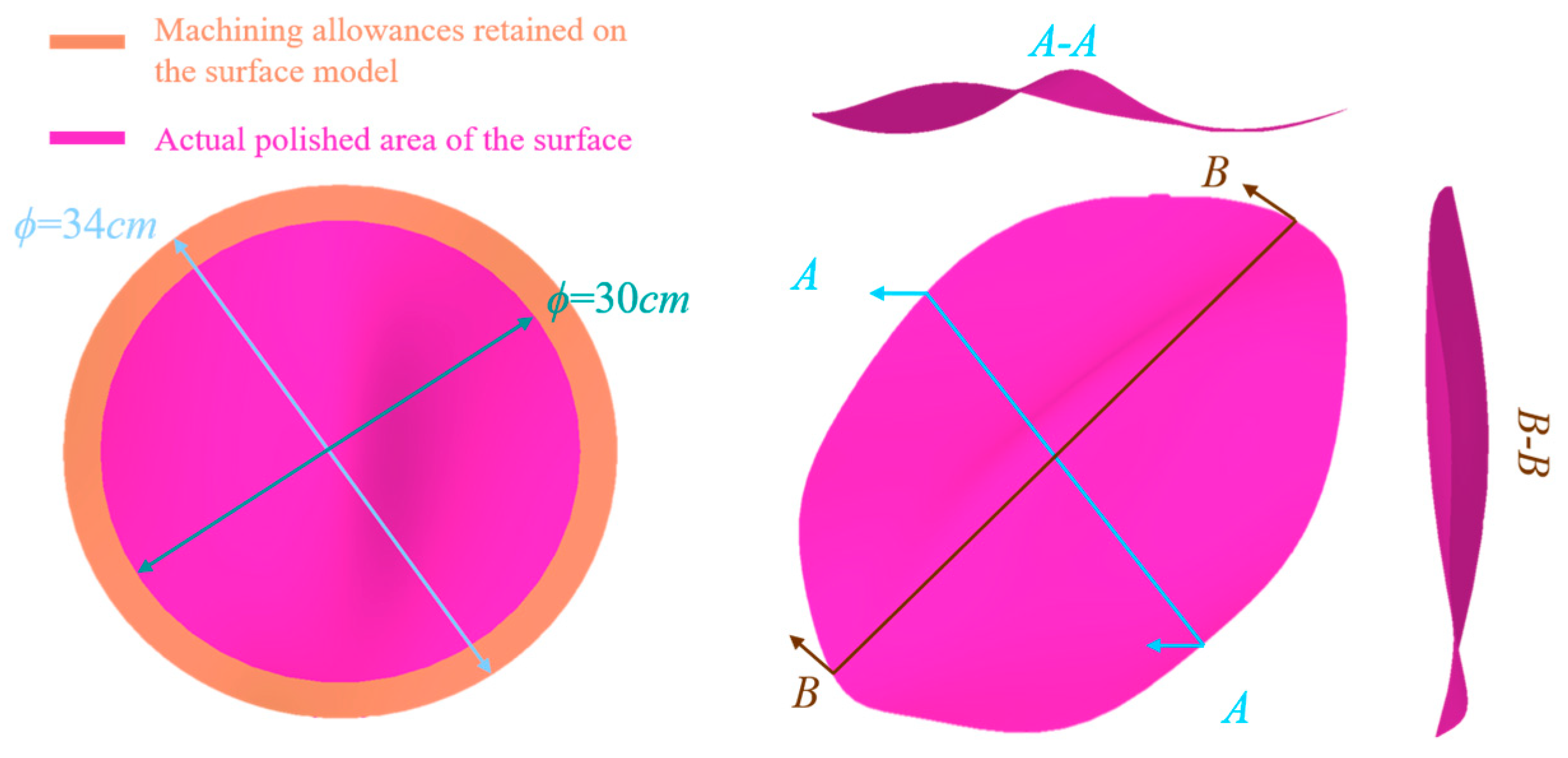

The results of the mesh vertex curvature calculations were verified using the 15 cm × 15 cm equation-free surface shown in

Figure 6 (to ensure that the planned polishing trajectory can completely cover the surface, the model retains the machining allowance region during curvature analysis and polishing trajectories generation, as shown in

Figure 6). This surface is generated by three random smooth curves through the boundary blending function in the software. Since only Gaussian curvature and mean curvature of the surface can be analyzed in the graphics software, the computed principal and subsidiary curvatures of each vertex on the mesh surface are converted to Gaussian curvature and mean curvature using Equation (20) to compare with the curvature information analyzed in the graphics software, as shown in

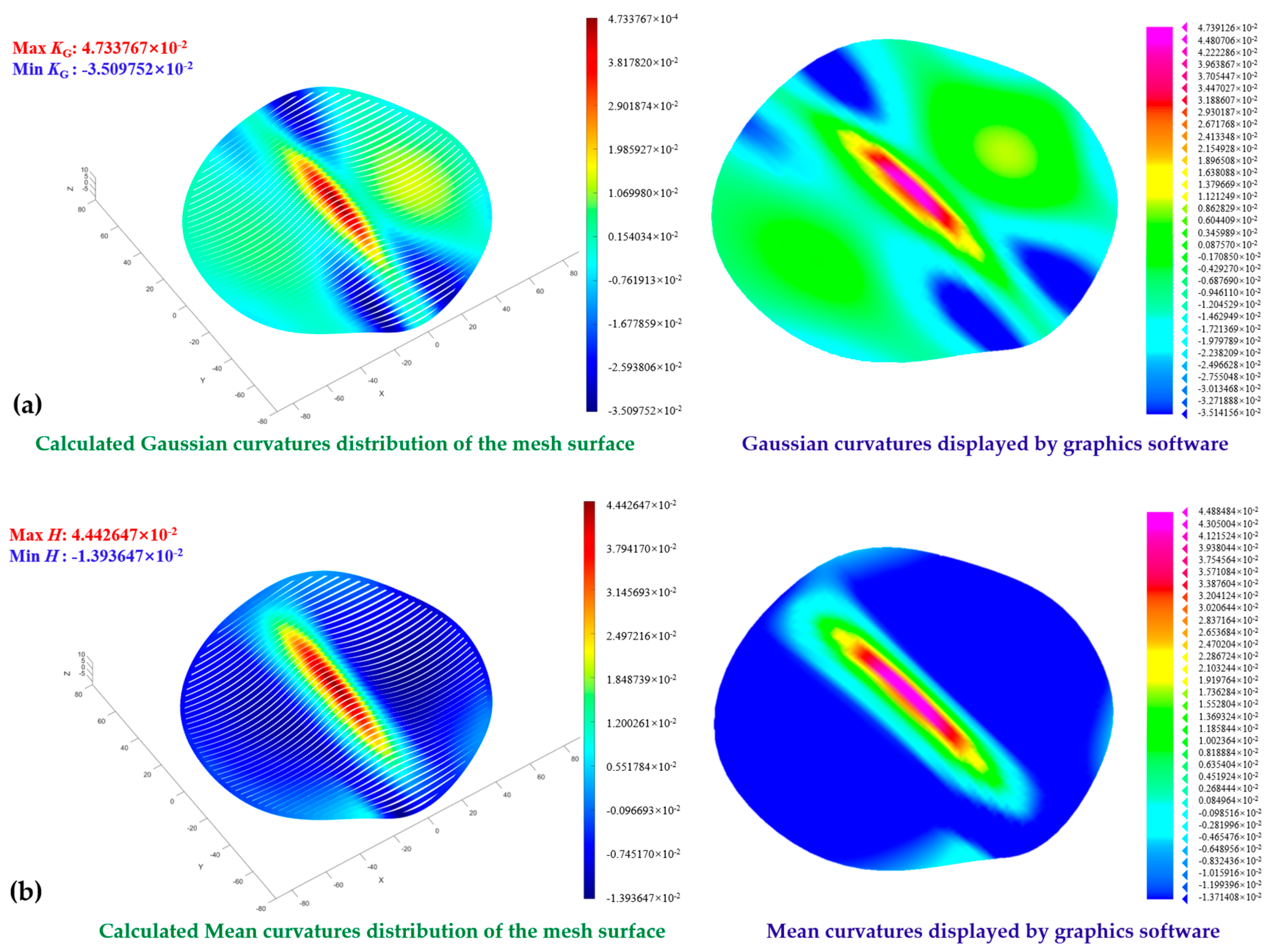

Figure 7.

As can be seen from the coloring effect in

Figure 7, for the equation-free surface shown in

Figure 6, the Gaussian curvature and the mean curvature distribution calculated by the algorithm proposed in this paper are consistent with the range of curvature distributions given by the graphics software plotting software. The maximum and minimum values of Gaussian curvature obtained by the mesh point curvature calculation algorithm proposed in this paper are 4.733767 × 10

−4 and −3.509752 × 10

−4, respectively, and the maximum and minimum values of Gaussian curvature of the corresponding surfaces counted by computerized drawing software are 4.739126 × 10

−4 and −3.514156 × 10

−4, respectively. The maximum and minimum mean curvature values obtained by the proposed curvature calculation algorithm are 4.442647 × 10

−2 and −1.393647 × 10

−2, respectively, and the maximum and minimum mean curvature values of the corresponding surfaces calculated by the computerized drawing software are 4.488484 × 10

−2 and −1.371408 × 10

−2, respectively. The maximum error of the Gaussian curvature calculation result is 0.103079%, and the maximum error of the Gaussian curvature calculation result is 0.125322%. The maximum error of the mean curvature calculation result is 1.010212%, and the maximum error of the mean curvature calculation result is 1.621618%.

For any triangular mesh ΔABC, let the coordinates of its three vertices be

A(

x1,

y1,

z1),

B(

x1,

y2,

z2), and

C(

x3,

y3,

z3). Assuming that the principal and subsidiary curvatures computed for each vertex are

k1A,

k2A,

k1B,

k2B, and

k1C,

k2C, respectively. For any trajectory point

P(

x0,

y0,

z0) on the triangular mesh, the principal and subsidiary curvatures

K1p and

K2p of point

P can be solved by Equation (22).

Assuming that the areas of the sub-triangles formed by point

P and the vertices of ΔABC are

SPAB,

SPAC, and

SPBC, and the area of ΔABC is

SABC. Parameters

τA,

τB, and

τC can be computed by Equation (23).

4. Uniform Coverage Realization of Polishing Trajectory on Mesh Surface

The achievement of uniform coverage in polishing trajectories refers to maintaining a constant overlap of polishing bands generated by any two adjacent polishing trajectories. This condition effectively ensures that there will be no issues of over-polishing or under-polishing during the polishing process.

As shown in

Figure 8a, for the planar equidistant polishing trajectory, the amount of overlap between adjacent trajectories is always constant. As shown in

Figure 8b, after mapping the planar equidistant polishing trajectories onto a surface, because of the variation in curvature at different positions of the surface, the overlap of the polishing contact areas between adjacent trajectory points cannot be maintained at a constant level, leading to problems of over-polishing and under-polishing.

Therefore, for the realization of uniform coverage of the mapped polishing trajectory, it is first necessary to adjust the position of the point according to the size of the polishing contact area at each trajectory point.

In the actual polishing process, two categories of polishing trajectories are often used. The first is symmetrical trajectories, such as concentric circle trajectories, which have multiple similarly shaped trajectory lines sharing a common trajectory symmetry point. The benefit of employing symmetrical trajectories lies in their capability to achieve comprehensive coverage of the machining surface. The second is asymmetrical trajectories, forming a continuous curve from an origin, which can cover most of the area of the machined surface and effectively guarantee the continuity of the machining process during the machining process. However, the initial region of such trajectories cannot guarantee complete coverage, such as the helical trajectory. In this study, the implementation of algorithms for uniform coverage of a concentric circle trajectory and helical trajectory is discussed separately.

The realization of uniform coverage of polishing trajectories on mesh surfaces involves algorithm design for adjusting the position of any trajectory point on the mesh surface, generation of a seed path, and adjustment of subsequent trajectories.

4.1. Tuning Strategies for Trajectory Points on Mesh Surfaces

The positions of the trajectory points on the mesh surface are adjusted to ensure that the amount of overlap of the polishing bands between arbitrarily neighboring trajectories is always the same. It is assumed that point

Pi and point

Pj are two polishing trajectory points on a mesh surface, and the radii of the polishing contact areas at points

Pi and

Pj are

ai and

aj, respectively. Adjust the position of

Pj using

Pi as the reference point. The target distance

A between point

Pi and the point

Pj is required to satisfy the constraint of Equation (24).

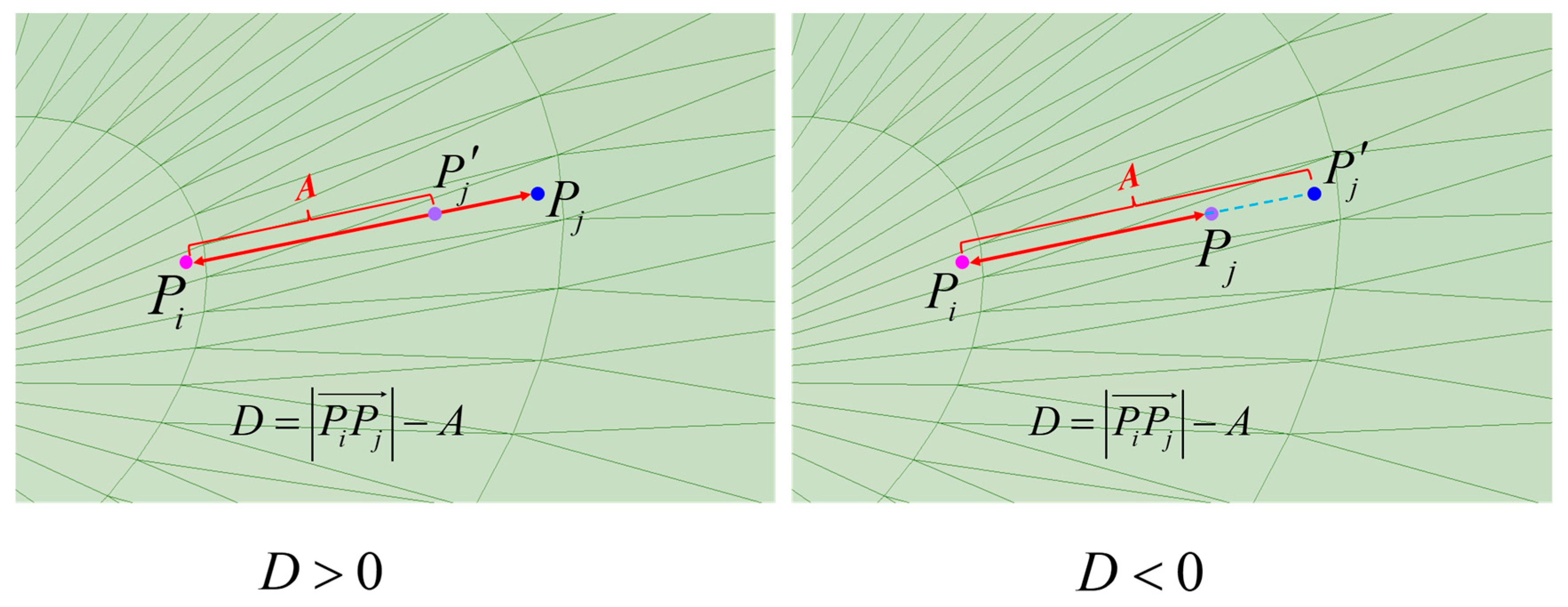

In Equation (22), the parameter k denotes the amount of polishing band overlap between two trajectory points. To meet the constraint requirements of Equation (24), the position of point Pj can be adjusted by the following steps.

Step 1: Calculate the

Euclidean distance

between point

Pi and point

Pj. Then, determine the difference

between

and the ideal relation

A in Equation (24). As shown in

Figure 9, if

D >

0, then find a point

inside the line connecting points

Pi and

Pj so that

. If

D <

0, then find a point on the extension of the line connecting points

Pi and

Pj so that

.

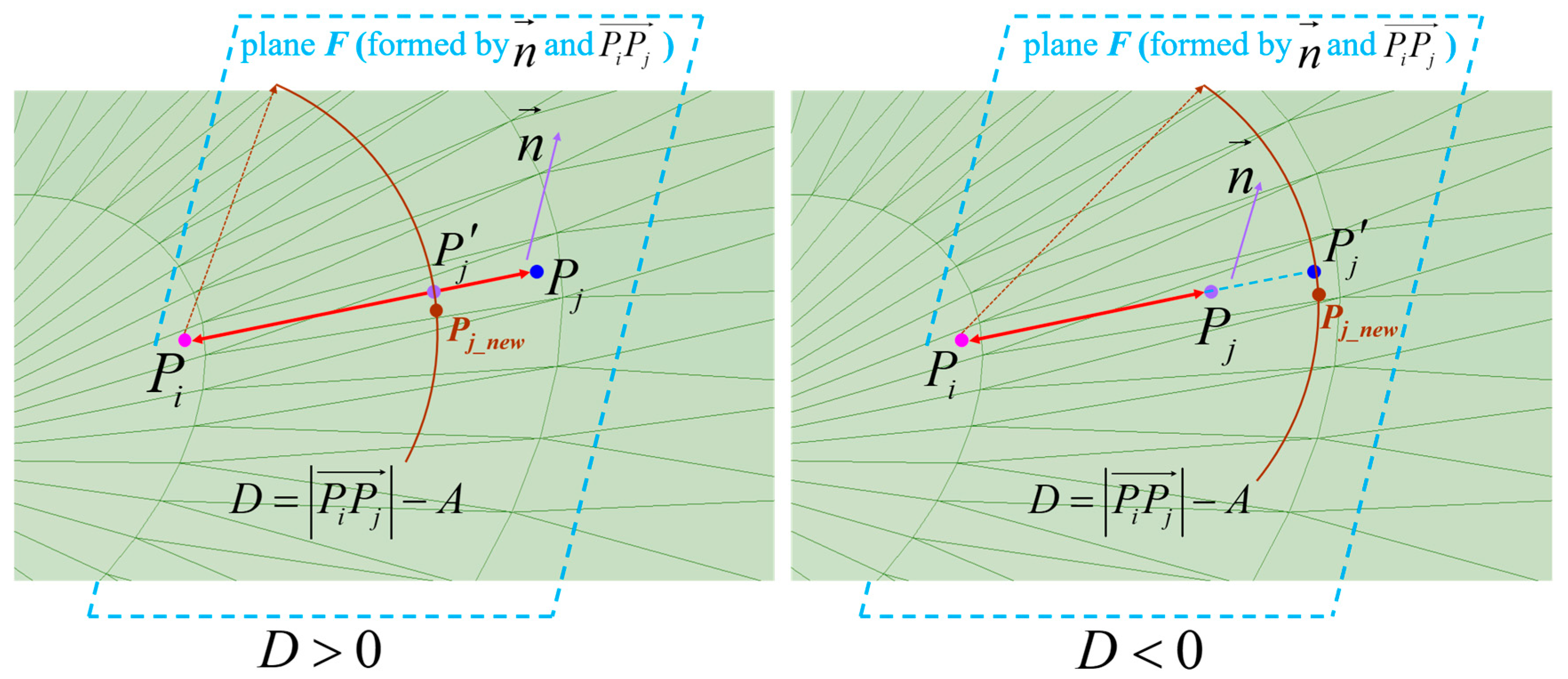

Step 2: As shown in

Figure 10, the vector

is the normal vector to the triangular mesh where the point

Pj is located, plane

F is formed by the vector

and the vector

. A circle is drawn in plane

F with the point

Pi as its center and the distance value

A as its radius. Then, find a point

Pj_new, which is the intersection of the circle with a certain triangular mesh.

Step 3. Recompute the polishing area radius aj_new at point Pj_new, and the Euclidean distance between point Pj_new and the reference point Pi. Evaluate the relationship between and A according to Equation (24). If , then point Pj_new is the adjusted trajectory point of point Pj. Otherwise, repeat steps 1 and 2 until the desired point is obtained.

4.2. Seed Path Generation for Concentric Circle Trajectory and Uniform Coverage Implementation

At present, a grating trajectory is mostly used for surface polishing; a grating trajectory is less difficult to realize, but will cause more obvious intermediate frequency error. At the same time, for the rotational symmetry of the surface, a grating trajectory will cause frequent collisions between the polishing tool and the edge of the polished workpiece, resulting in serious edge effects. Therefore, for the rotationally symmetric parts shown in

Figure 6, polishing using a spiral or concentric circle trajectory is more stable. The mathematical expression of a concentric circle trajectory in the plane is shown in Equation (25).

In Equation (25), N represents the number of circles in the concentric circle, and the radius R denotes both the radius of the initial concentric circle and the spacing between adjacent circles within the concentric circle trajectory. The coordinate (xc,yc) is the coordinate of the center point of the concentric circle trajectory on the plane. θ is the rotational angle of each trajectory point relative to the center point. The generation of a concentric circle seed path means adjusting the positions of trajectory points on the initial circle to achieve uniform coverage in the covered region (i.e., trajectories generated in the range of during the generation process). This trajectory serves as the foundation for achieving uniform coverage in all subsequent trajectories.

The creation of seed path for concentric circle trajectory entails utilizing the mapped center of concentric circles as a reference point. After adjustment, the

Euclidean distance

di from any trajectory point

Pi on the initial concentric circle to the mapped center

O′, and the polishing area radius

ai of trajectory point

Pi, satisfies the constraint requirements of Equation (26).

The process of generating a seed path for a concentric circle trajectory is shown in

Figure 11. In

Figure 11a, point

Pi and point

Pj are any two trajectory points on the initial circle of a two-dimensional equidistant concentric circle trajectory (reference trajectory), and the corresponding polishing area radii are

ai1 and

aj1, respectively, and

ai1 =

aj1. When the planar equidistant trajectories are mapped onto the surface mesh, the influence of surface curvature results in changes to both the trajectory shape and the polishing area radius at the trajectory points. As shown in

Figure 11b, it is assumed that the radii of the polishing areas at the locations of points

Pi and

Pj on the reference trajectory are mapped to a surface are

ai2 and

aj2, respectively (

ai2 ≠

aj2). The

Euclidean distance between any mapped trajectory point on the reference trajectory mapped to a surface and the mapped concentric circle center

O′ is not exactly equal to the radius of the polishing area at the mapped trajectory point, and the polishing trajectory is no longer able to satisfy the requirement of uniform coverage. Therefore, the position of any trajectory points on the reference trajectory mapped to a surface should be adjusted according to the method provided in

Section 4.1. As shown in

Figure 11c, it is assumed that the radii of the polishing areas at adjusted points

Pi and

Pj are

and

, respectively. The

Euclidean distances from points

Pi and

Pj to the point

are equal to the radii of the polishing area, the new initial concentric circle trajectory not only provides complete coverage of the inner region of the trajectory during the polishing process but also does not cause excessive removal of material, which can be used as a seed path for concentric circle trajectory adjustment on the surface.

The steps for generating a seed path during the realization of uniform coverage of concentric circle polishing trajectory are summarized as follows:

Step 1: Determine the Euclidean distance di between each trajectory point on the mapped initial circle of concentric circle trajectory and the mapped center point .

Step 2: Extract the trajectory point pi whose Euclidean distance from the point is not equal to ai (ai is the radius of the polishing area of the mapped trajectory point on the surface). Determine a plane Fi using the current trajectory point pi, the mapped center , and the current triangular mesh normal vector n. A circle Ci is generated in the plane Fi with the point as the center and ai as the radius. There are multiple intersections of the circle Ci with the triangular mesh, and the intersection pi_new with the closest distance to the point pi is extracted.

Step 3: Determine the polishing area’s radius ai_new of point pi_new, and calculate the Euclidean distance di_new between the point pi_new and the center of the mapped concentric circle polishing trajectory. Determine whether the relationship between ai_new and di_new satisfies the constraint requirements of Equation (26). If satisfied, the point pi_new is the desired optimized trajectory point. Otherwise, continue the iterative process of step 2 retrieval.

After all trajectory points on the initial concentric circle trajectory have been adjusted by the above steps, a seed path can be obtained, which is the initial datum for subsequent concentric circle polishing trajectory adjustments.

The optimization and adjustment strategies for subsequent concentric circle trajectories are as follows:

Step 1: It is assumed that there are M trajectory points on the seed path T1, and N trajectory points on the second mapped concentric circle trajectory T2. Solve for the Euclidean distance between each trajectory point on the trajectory T2 and each trajectory point on the seed path T1. For each trajectory point P2,i on the trajectory T2, there will be a trajectory point P1,j with the closest Euclidean distance on the seed path T1;

Step 2: Calculate the polishing area radius

a1,j at point

P1,j, the polishing area radius

a2,i at point

P2,i, and the

Euclidean distance

between points

P1,j and

P2,i. Then, calculate the difference between

and

(Here,

k represents the overlap between two adjacent polishing bands, which is a predetermined value). If the

Euclidean distance

is not equal to

, the points

P2,i are repositioned according to the method provided in

Section 4.1 until the radius

of the retrieved polishing area at point

P2,i_new, and the

Euclidean distance

between point

P2,i_new and point

P1,j exactly satisfy the relation of

.

Step 3: Using the adjusted second circle of the concentric circle trajectory as the new seed path, adjust the third circle according to the strategy described in steps 1 to 2, until the remaining circular trajectories are optimized. The flowchart of the uniform coverage trajectory planning algorithm for concentric circle polishing trajectories is shown in

Figure 12.

By the above algorithmic principles, the uniform coverage of concentric circle polishing trajectory is simulated of the equation-free surface shown in

Figure 6. The polishing process parameters used in the simulation are shown in

Table 1. The simulation results are shown in

Figure 13.

4.3. Seed Path Generation for Helical Trajectory and Uniform Coverage Implementation

The mathematical expression of an equally spaced helical trajectory in a two-dimensional plane is shown in Equation (27).

In Equation (27), parameters ha and hb are the initial radius and the spacing value of the equally spaced helix, respectively. θ is the rotational angle of each trajectory point relative to the starting point of the helical trajectory. The coordinates (xc,yc) are the starting points of the helical trajectory in the plane. The seed path generation based on the helical trajectory is only for trajectory points generated within the range of .

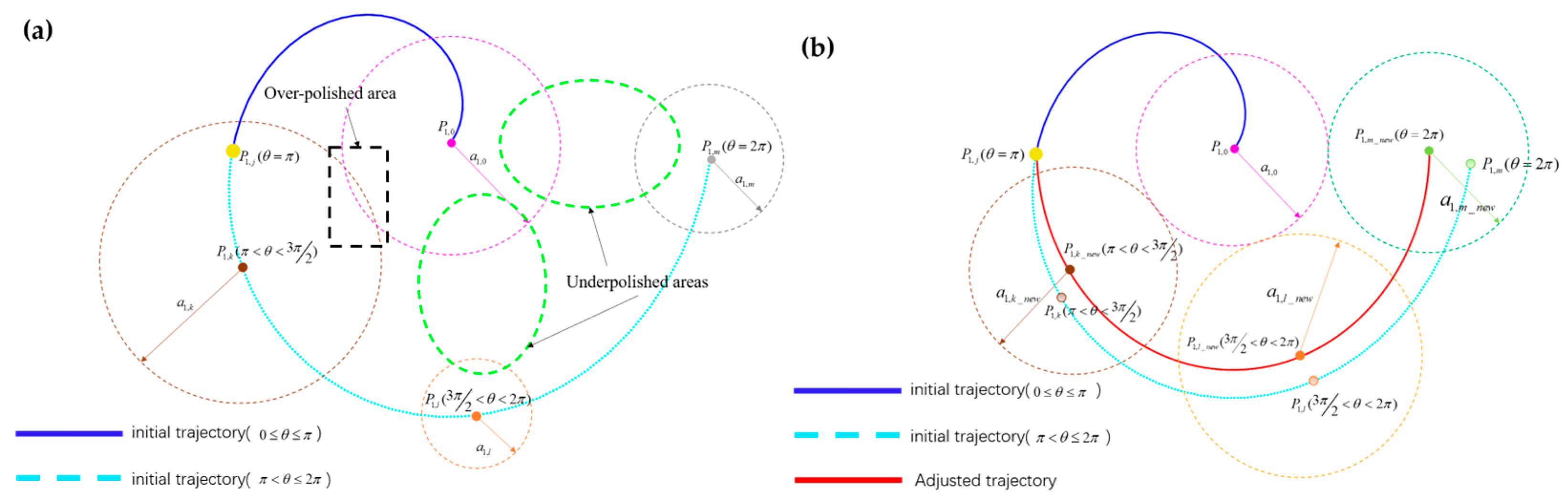

From the mathematical properties of the helical trajectory, it can be seen that the helical trajectory belongs to an unclosed curve. As shown in

Figure 14a, for the helical trajectory in the range of

, there is a defect that does not completely cover the polishing area. To enhance the coverage of helical trajectory within the range of

, adjustments are made to the helical trajectory points within the range of

. As shown in

Figure 14a, point

P1,0 is the first trajectory point on the trajectory, point

P1,j is the trajectory point with

θ value equal to

π, point

P1,k is the trajectory point with

θ value in the range of

, point

P1,l is the trajectory point with

θ value in the range of

, and point

P1,m is the trajectory point with

θ value equal to 2

π. Parameters

a1,j,

a1,k,

a1,l, and

a1,m are the radii of the polishing areas of the above points on the mesh surface, respectively. In this case, due to the different radius of the polishing area at each trajectory point, the over-polished or under-polished region is generated between point

P1,k, point

P1,l, point

P1,m and point

P1,0.

By adjusting the position of any point

P1,i (e.g., point

P1,j,

P1,k,

P1,l, and

P1,m in

Figure 14a) in the range of

, a new trajectory point

P1,i_new (e.g., point

P1,j_new,

P1,k_new,

P1,l_new, and

P1,m_new in

Figure 14b) can be obtained. The

Euclidean distance between the trajectory point

P1,i_new and the trajectory point

P1,0(

xc,

yc) satisfies the constraints in Equation (28). In this case, the final seed path obtained has a regular helical trajectory in the first half and a half-circle trajectory in the second half.

In Equation (28), a1,i_new and a1,0 represent the radius of the polishing area of the trajectory point P1,i_new and P1,0, respectively.

Combining the trajectory point position adjustment measures in

Section 4.1 and the previously mentioned seed path generation strategy for a helical trajectory, the positions of the helical trajectory points in the range of

are adjusted, and the final seed path effect obtained is shown as the red trajectory in

Figure 14b. From

Figure 14b, it can be seen that the trajectory points in the range of

are still in the form of a conventional helix, while the trajectory points in the range of

are adjusted to be consistent with the distribution of trajectory points on a circular trajectory. The adjusted seed path of the helical trajectory ensures consistent material removal and effectively increases polishing coverage within the seed path.

Similar to the process of realizing uniform coverage of a concentric circle trajectory, the obtained seed path of the helical trajectory is used as the initial reference for the adjustment of subsequent polishing trajectories. The corresponding adjustment steps are summarized as follows:

Step 1: As shown in Equation (27), each 2π increase in the angular value θ is considered to generate a new helical trajectory. At the same time, the number of trajectory points contained in each helical trajectory is equal. Due to the continuous nature of the helical trajectory, a point-by-point optimization strategy is used to optimally adjust the position of each point on the subsequent helical trajectory. For any trajectory point P2,i on the second helical trajectory T2, a point P1,i can be found on the seed path T1, and the difference in phase angle between these two points is 2π.

Step 2: Calculate the polishing area radius

a1,i at point

P1,i, the polishing area radius

a2,i at point

P2,i, and the

Euclidean distance values

between points

P1,i and

P2,i. Determine the relationship between the difference of

and

. (

k represents the overlap between two adjacent polishing bands, which is a predetermined value.) If

, the position of the trajectory point

P2,i is adjusted according to the method provided in

Section 4.1, until the new radius

of the polishing area at the adjusted position of point

P2,j and the

Euclidean distance

satisfy the constraint

.

Step 3: Using the adjusted second helical trajectory as the new seed path, the third trajectory is optimized according to the strategy described in steps 1–2. Using the same method, the optimization of all helical polishing trajectories can be completed.

In the corresponding trajectory optimization process, the adjustment reference for the first trajectory point of each helix is the first trajectory point of the previous helix, and the adjustment reference for the last trajectory point of each helix is the last trajectory point of the previous helix. This results in a clear break between the last trajectory point of the

ith helical trajectory and the first trajectory point of the

i+1th helical trajectory, as shown in

Figure 15a.

To realize the smooth connection between two adjacent helical trajectories, a smooth connection algorithm for helical trajectories based on a cubic interpolation strategy is proposes. Assuming that each helical trajectory has

N trajectory points, the last

n trajectory points of the

ith helix and the first

n trajectory points of the

i + 1th helix are extracted. (In this paper,

n = 4.) As shown in

Figure 15b, points

A1–

A4 represent extraction points of the

ith trajectory, and points

B1–

B4 represent extraction points of the

i + 1th trajectory.). The average values of

X and

Y coordinates between these

n sets of trajectory points are solved by Equation (29).

Extract the

X and

Y coordinates of the

N-

nth trajectory point of the

ith helical trajectory and the

X and

Y coordinates of the

n + 1th trajectory point of the

i + 1th helical trajectory (denoted as (

xi,N−n,

yi,N−n) and (

xi+1,n+1,

yi+1,n+1)). Combine these coordinate values with the calculated result of Equation (29) and substitute the coordinates of the selected points into the cubic interpolation Equation (30) to obtain a smooth trajectory curve.

The key to segmented cubic interpolation is to ensure that both the function values and derivatives of the interpolated curves at the nodes are continuous, so the cubic interpolation Equation (30) also has the following two characteristics: (1) the first-order derivatives of the cubic interpolation Equation (30) are continuous; (2) the second-order derivatives of the cubic interpolation Equation (30) are continuous. Therefore, the constraints described in Equation (31) are introduced based on the cubic interpolation Equation (30).

The smooth connection between two adjacent helical trajectories can be realized by associating Equations (29)–(31). The results of the neighboring trajectories smoothing process are shown in

Figure 15c, mapping all the smoothed planar trajectory points to the surface to obtain a smooth helical polishing trajectory on the surface.

The flowchart of the uniform coverage trajectory planning algorithm for concentric circle polishing trajectories is shown in

Figure 16.

Still using the polishing process parameters shown in

Table 1, the uniform coverage of the helical polishing trajectory is simulated on the equation-free surface shown in

Figure 6. The simulation results are shown in

Figure 17.