Research and Overview of Crop Straw Chopping and Returning Technology and Machine

Abstract

1. Introduction

2. Theoretical Analysis for Chopping and Spreading of Crop Straw

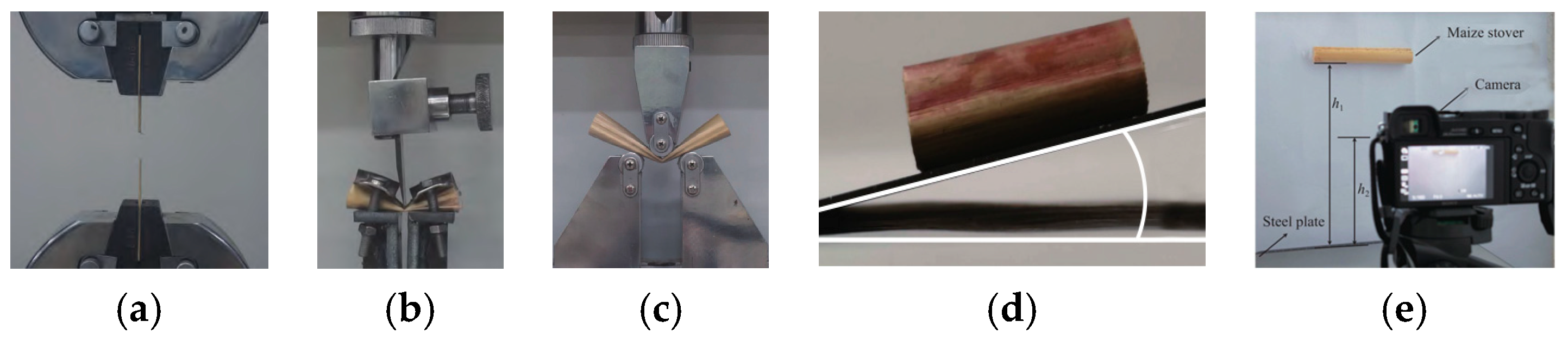

2.1. Research on Mechanical Properties of Crop Straw

2.2. Research on Simulation Analysis Model of Crop Straw

2.3. Fracture Dynamics and Kinematic Characteristics of Crop Straw During Chopping

2.4. Effects on Airflow Distribution in Chamber

2.5. Interaction Between Chopped Straw and Airflow in the Chopped Chamber

3. Development of Crop Straw Chopped Device

3.1. Crop Straw Chopped Blade

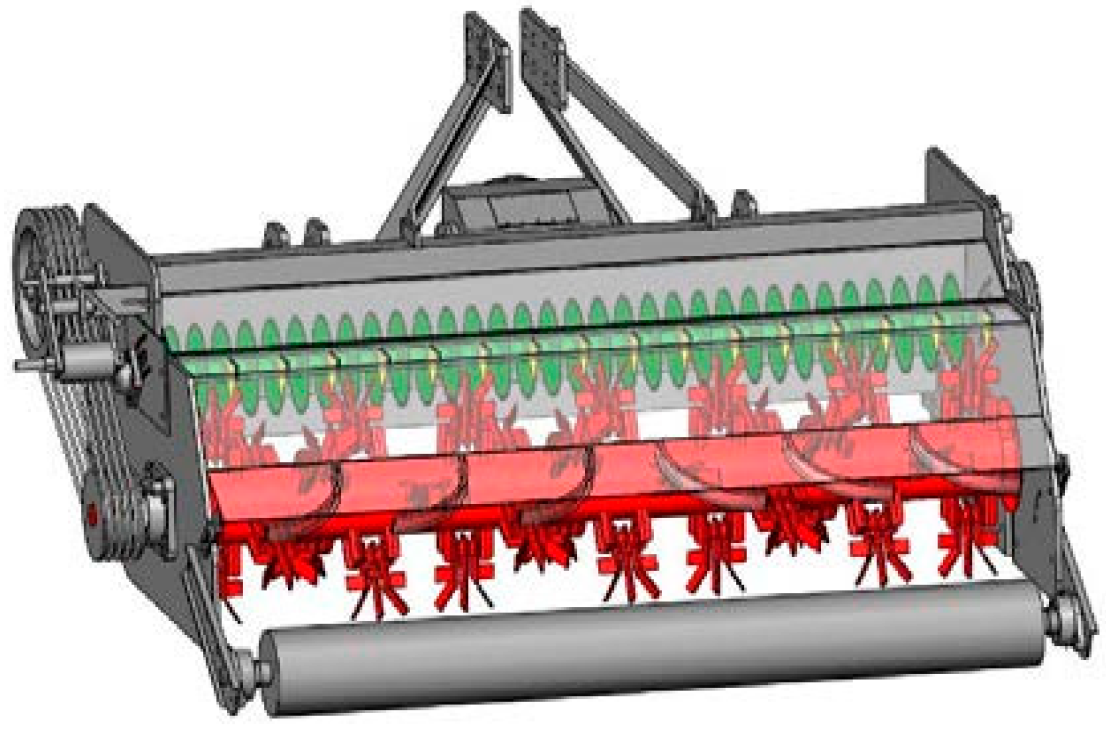

3.2. Crop Straw Chopped Machine

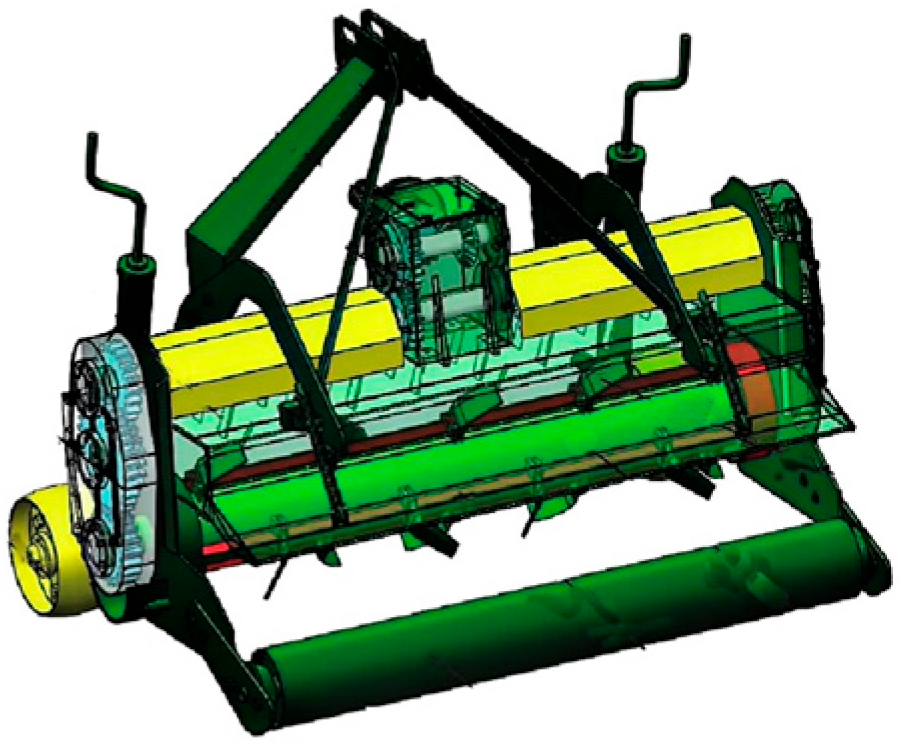

3.3. Crop Straw Chopped Device Combined with No/Reduced Tillage Seeder

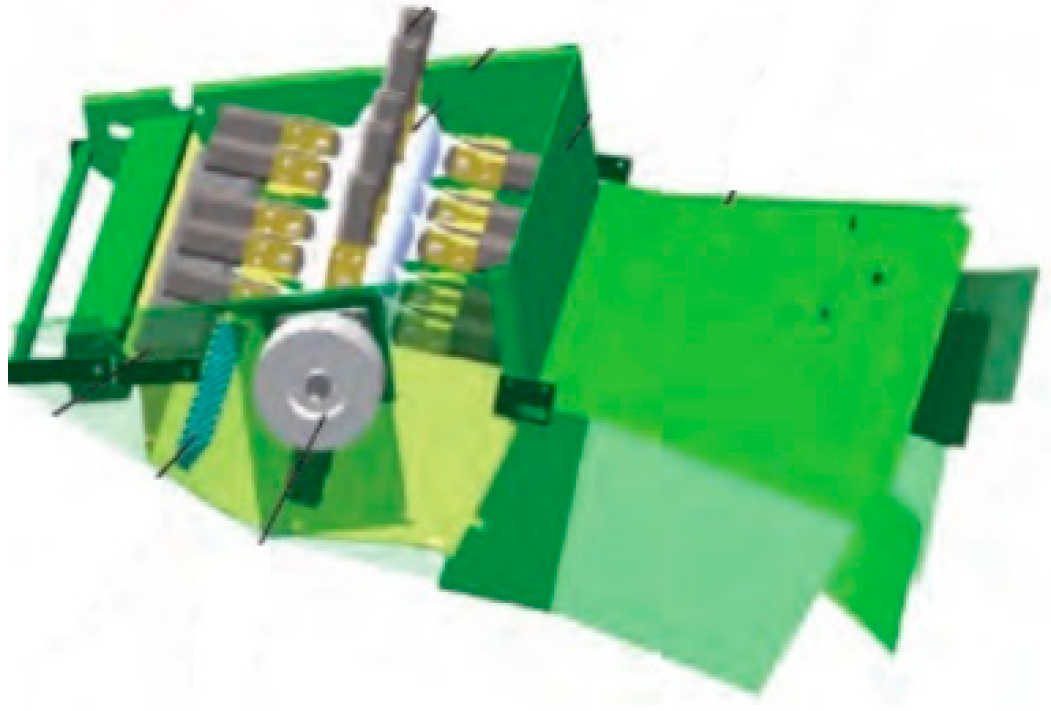

3.4. Crop Straw Chopping and Ditch-Burying Machine

3.5. Crop Straw Chopping and Mixing Machine

3.6. Crop Straw Chopped Device Powered by Combined Harvester

3.7. Summary of Different Crop Straw Chopped Devices

4. Development of Chopped Straw Spreading Device

5. Summaries and Recommendations

- (1)

- Develop the intelligent field straw distribution mapping system. The heterogeneous spatial and mass distribution of straw necessitates adaptive parameter selection for blade rotational velocity, forward speed, and spreading device angles. A machine vision-based automated extraction system should be engineered to inform real-time parameter optimization during chopping and spreading operations.

- (2)

- Engineer the adaptive self-regulating mechanisms for chopping and returning equipment. Manual parameter adjustments (e.g., blade speed, ground clearance, and forward velocity) under dynamic field conditions often result in suboptimal blade kinematics and susceptibility to environmental disturbances (e.g., crosswinds and turbulent airflow). Closed-loop control systems, integrated with straw distribution data, should be developed to enable autonomous machine parameter modulation.

- (3)

- Elucidation of the mechanics and kinematics of straw during the chopping and returning processes. The interplay between straw biomechanical properties, kinematic tool forces, and aerodynamic/stochastic field conditions critically governs straw fragmentation length, energy efficiency, and spreading uniformity. High-fidelity computational modeling (e.g., CFD-DEM coupling) combined with high-speed imaging and sensor fusion technologies should be employed to examine the effects of operational and structural parameters of the chopping and returning machine, airflow distribution, and spatial and mass distortion of crop straw on the quality of chopped and spread straw.

- (4)

- Implement the real-time quality assessment systems for straw returning operations. Current quality assessment typically relies on manual labor, which is impractical for large-scale mechanized farming and introduces subjective bias. An integrated optical–electronic monitoring platform should be developed to autonomously quantify straw comminution metrics (e.g., length distribution and spread uniformity) and provide feedback for process optimization.

- (5)

- Pioneer the high forward-speed (>8 km/h) straw chopping and returning architectures. Conventional machines (1–4 km/h) prolong operational timelines, disrupt farming schedules, and compromise subsequent planting windows. While blade speed escalation might maintain comminution quality at higher forward speeds, this approach exponentially increases energy consumption. Innovative comminution principles (e.g., pulsed shear, counter-rotating blade arrays) must be explored to decouple forward speed from energy intensity to achieve high forward-speed operation.

- (6)

- Establish the context-specific straw residue management frameworks. While straw retention strategies (surface spreading, ditch burial, and soil mixing) enhance soil fertility and crop yields, optimal method selection hinges on agroecological contexts (soil type, crop rotation, and climate). Predictive models integrating agronomic requirements, machine capabilities, and economic constraints should be formulated to guide site-specific implementation of straw return protocols.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cong, H.B.; Yao, Z.L.; Zhao, L.X.; Meng, H.B.; Wang, J.C.; Huo, L.L.; Yuan, Y.W.; Jia, J.X.; Xie, T.; Wu, Y. Distribution of crop straw resources and its industrial system and utilization path in China. Trans. Chin. Soc. Agric. Eng. 2019, 35, 132–140. [Google Scholar]

- Bi, Y.Y.; Gao, C.Y.; Wang, Y.J.; Li, B.Y. Estimation of straw resources in China. Trans. Chin. Soc. Agric. Eng. 2009, 25, 211–217. [Google Scholar]

- Li, P.F.; Zhang, A.F.; Huang, S.W.; Han, J.L.; Jin, X.L.; Shen, X.G.; Hussain, Q.; Wang, X.D.; Zhou, J.B.; Chen, Z.J. Optimizing management practices under straw regimes for global sustainable agricultural production. Agronomy 2023, 13, 710. [Google Scholar] [CrossRef]

- National Bureau of Statistics People’s Republic of China. National Data-Agriculture. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 13 March 2025).

- Zhong, Y.M.; Ragauskas, A.J.; Zheng, Y.; Meng, X.Z.; Zhou, Y.; Lin, Y.Q. A review on the pretreatment of straw biomass by using biogas slurry. Process Saf. Environ. Prot. 2025, 195, 106843. [Google Scholar] [CrossRef]

- Rai, R.; Bharti, R.; Dhar, P. Biodegradable, water-resistant, smart cellulose-based drinking straws from agricultural biomass with detection of adulterants in beverages. Food Chem. 2025, 474, 143093. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.N.; Yang, Z.; Guo, Y.M.; Ma, J.J.; Ming, B.W.; Yang, J.; Guo, C.; Li, L.; Ou, C.Q. Impact of agricultural straw open-field burning on concentrations of six criteria air pollutants in China. Environ. Pollut. 2025, 373, 126109. [Google Scholar] [CrossRef] [PubMed]

- Pham, C.T.; Nghiem, T.D.; Le, H.T.; Chu, H.D.; Viet, T.T.; Sekiguchi, K.; Tang, N.; Hayakawa, K.; Toriba, A. Size distribution of airborne particle-bound polycyclic aromatic hydrocarbons during rice straw open burning in Hanoi, Vietnam. Atmos. Pollut. Res. 2024, 15, 102115. [Google Scholar] [CrossRef]

- Wang, J.Y.; Wang, X.F. A triumph of reducing carbon emission by banning open straw burning. Sci. Bull. 2023, 68, 18–20. [Google Scholar] [CrossRef]

- Xu, Z.; Lai, T.Z.; Li, S.; Si, D.X.; Zhang, C.C. Effective potassium management for sustainable crop production based on soil potassium availability. Field Crops Res. 2025, 326, 109865. [Google Scholar] [CrossRef]

- Ning, Y.; Li, S.L.; Ning, C.C.; Ren, J.F.; Xia, Z.Q.; Zhu, M.M.; Gao, Y.; Zhang, X.H.; Ma, Q.; Yu, W.T. Effects of exogenous nitrogen addition on soil organic nitrogen fractions in different fertility soils: Results from a 15N cross-labeling experiment. Agric. Ecosyst. Environ. 2025, 379, 109366. [Google Scholar] [CrossRef]

- Li, K.; Chen, A.L.; Sheng, R.; Hou, H.J.; Zhu, B.L.; Wei, W.X.; Zhang, W.Z. Long-term chemical and organic fertilization induces distinct variations of microbial associations but unanimous elevation of soil multifunctionality. Sci. Total Environ. 2024, 931, 172862. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Yin, W.; Zhao, L.H.; Wan, P.X.; Fan, Z.L.; Hu, F.L.; Nan, Y.Y.; Sun, Y.L.; Fan, H.; He, W. No tillage with straw mulching enhanced radiation use efficiency of wheat via optimizing canopy radiation interception and photosynthetic properties. Field Crops Res. 2025, 326, 109854. [Google Scholar] [CrossRef]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q.J. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar]

- Li, Y.J.; Chen, Y.Y.; Sun, X.; Lin, H.; He, J. Parameter calibration of the breakable flexible fiber model for maize stovers with different moisture contents. Trans. Chin. Soc. Agric. Eng. 2025, 41, 43–52. [Google Scholar]

- Liu, P.; He, J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Lou, S.Y.; Wang, Y.B.; Lin, H.; Li, H.; Zhang, Z.G. Effects of various edge-curve types and rotational speeds of disc blades on breaking force and energy consumption in the maize stalk chopping process. Appl. Eng. Agric. 2021, 37, 951–965. [Google Scholar] [CrossRef]

- Li, S.B.; Huan, X.L.; Wang, T.Y.; Hui, Y.T.; You, Y.; Wang, D.C. Biomechanical properties and discrete element modeling of PSR stalks during silage harvest. Comput. Electron. Agric. 2024, 217, 108644. [Google Scholar] [CrossRef]

- Zhao, W.S.; Chen, M.J.; Xie, J.H.; Cao, S.L.; Wu, A.B.; Wang, Z.W. Discrete element modeling and physical experiment research on the biomechanical properties of cotton stalk. Comput. Electron. Agric. 2023, 204, 107502. [Google Scholar] [CrossRef]

- Zhang, F.W.; Song, X.F.; Zhang, X.K.; Zhang, F.Y.; Wei, W.C.; Dai, F. Simulation and experiment on mechanical characteristics of kneading and crushing process of corn straw. Trans. Chin. Soc. Agric. Eng. 2019, 35, 58–65. [Google Scholar]

- Zhao, L.; Huang, C.W.; Yang, Z.; Jin, M.H.; Duan, J.L. Characterization of banana crowns: Microscopic observations and macroscopic cutting experiments. Agriculture 2024, 14, 1714. [Google Scholar] [CrossRef]

- Stubbs, C.J.; Sun, W.H.; Cook, D.D. Measuring the transverse Young’s modulus of maize rind and pith tissues. J. Biomech. 2019, 84, 113–120. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, M.; Cheng, C.; Zhao, H.M.; Ren, L.Q. Mechanism study of the effect of a surface liquid film on the collision adhesion behaviour of rice stalks. Biosyst. Eng. 2025, 251, 61–72. [Google Scholar] [CrossRef]

- Zhou, F.; Huang, J.L.; Liu, W.Y.; Deng, T.; Jia, Z.K. Multiscale simulation of elastic modulus of rice stem. Biosyst. Eng. 2019, 187, 96–113. [Google Scholar] [CrossRef]

- Li, Y.J.; Qi, Z.; Xia, H.; Yu, G.; Jennifer, S.C. Fiber reinforcement on spherical granular beds under triaxial compressions. Powder Tech. 2022, 41, 117928. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, J.; Chen, J. Modeling of flexible wheat straw by discrete element method and its parameter calibration. Int. J. Agric. Biol. Eng. 2018, 11, 42–46. [Google Scholar] [CrossRef]

- Soleimani, N.; Kamandar, M.R.; Khoshnam, F.; Soleimani, A. Defining and modelling sesame stalk shear behaviour in harvesting by reciprocating cutting blade. Biosyst. Eng. 2023, 229, 44–56. [Google Scholar] [CrossRef]

- Yin, L.; Guo, A.; Liu, C.; Guo, M.; Yang, D.; Gao, X.; Wu, H. Design and Discrete Element (DEM) Simulation Analysis of Grassland Ecological Cleaning and Restoration Vehicle. Machines 2025, 13, 114. [Google Scholar] [CrossRef]

- Huan, X.L.; Li, S.B.; Wang, L.; Wang, D.C.; You, Y. Study on silage mixing device of King Grass stalk particles based on DEM simulation and bench test. Powder Technol. 2024, 437, 119581. [Google Scholar] [CrossRef]

- Gao, Z.; Lu, C.Y.; Wei, X.Y.; Li, H.W.; He, J.; Wang, Q.J. Design and experiment of co-stirring combined corn strip straw cleaning device. Trans. Chin. Soc. Agric. Mach. 2023, 54, 68–79. [Google Scholar]

- Xia, Y.D.; Klinger, J.; Bhattacharjee, T.; Aston, J.; Small, M.; Thompson, V. An experiment-informed discrete element modelling study of knife milling for flexural biomass feedstocks. Biosyst. Eng. 2023, 236, 39–53. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, J.Y.; Yang, X.S.; Chen, B.S. A DEM-MBD based method for regulating transfer flux in the supply and discharge of cane seed particles. Comput. Electron. Agric. 2024, 218, 108732. [Google Scholar] [CrossRef]

- Chen, G.B.; Wang, Q.J.; Li, H.W.; He, J.; Wang, X.H.; Zhang, X.Y.; He, D. Experimental research on vertical straw cleaning and soil tillage device based on soil-straw composite model. Comput. Electron. Agric. 2024, 216, 108510. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, F.; Zhao, M.; Ma, Q.; Wang, W.; Fan, Q.; Yan, P. Determination of corn stalk contact parameters and calibration of Discrete Element Method simulation. J. China Agri. Univ. 2018, 23, 120–127. [Google Scholar]

- Zhang, X.; Hu, X.; Liu, J.; Yang, Y.; Li, Y. Calibration and verification of bonding parameters of banana straw simulation model based on discrete element method. Trans. Chin. Soc. Agric. Mac. 2023, 54, 121–130. [Google Scholar]

- Leblicq, T.; Smeets, B.; Ramon, H.; Saeys, W. A discrete element approach for modelling the compression of crop stems. Comput. Electron. Agric. 2016, 123, 80–88. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.B.; Chen, C.H.; Li, J.P.; Xue, C.L.; Bian, Y.L. Optimization and test of operating parameters of grapes stem cutting device. J. Chin. Agric. Mech. 2023, 44, 37–45. [Google Scholar]

- Wang, W.; Lv, X.L.; Yi, Z.Y. Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture 2022, 12, 2131. [Google Scholar] [CrossRef]

- Khan, A.A.; Sultan, U.; Rudra, R.P.; Ehsan, F.; Kashif, M.; Khan, M.M.; Hashim, S.; Zohaib, M.; Ahmad, S.I. Structural analysis of cotton stalk Puller and Shredder Machine. Alex. Eng. J. 2022, 64, 335–347. [Google Scholar] [CrossRef]

- Han, M.X.; Yu, K.; Duan, H.B.; Xiong, L.R.; Xu, K.; Li, M.; Liu, Q. Simulation and experiments of abrasive gas jet cutting for rapeseed stem using SPH-FEM. Trans. Chin. Soc. Agric. Eng. 2024, 40, 82–92. [Google Scholar]

- Wang, P.; Chen, X.G.; Wen, H.J. Simulation Research on Cotton Stalk Cutting and Crushing Based on ANSYS/LS-DYNA and Field Experiments. Agriculture 2023, 13, 1268. [Google Scholar] [CrossRef]

- Lin, H.; He, J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Yang, W.C.; Huang, S.H.; Liu, P.; Chang, Y.B. Design and Experiment of a Reciprocating Intermittent Chopping Device for Maize Straw Returning. Agriculture 2020, 12, 220. [Google Scholar] [CrossRef]

- Kovács, A.; Kerényi, G. Physical characteristics and mechanical behaviour of maize stalks for machine development. Int. Agrophys. 2019, 33, 427–436. [Google Scholar] [CrossRef]

- Zhang, X.R.; Ni, S.L.; Liu, J.X.; Hu, X.H.; Zhang, Z.F.; Fu, S.H. Design and flow field analysis of bionic blade of banana straw crushing and throwing machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 138–151+160. [Google Scholar]

- Liu, P.; He, J.; Li, Y.J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Zhang, Z.G.; Li, S.H. Design and experiment of double rollers maize stalk chopping device with different rotation speeds. Trans. Chin. Soc. Agric. Mach. 2020, 36, 69–79. [Google Scholar]

- Zheng, Z.Q.; He, J.; Wang, Q.J.; Li, H.W.; Li, W.Y.; Chen, W.Z. Design and experiment on straw pickup-chopping and ditch-burying integrated machine. Trans. Chin. Soc. Agric. Mach. 2017, 48, 87–96. [Google Scholar]

- Zhang, Z.Q.; He, J.; Li, H.W.; Wang, Q.J.; Ju, J.W.; Yan, X.L. Design and experiment on straw chopper cum spreader with adjustable spreading device. Trans. Chin. Soc. Agric. Mach. 2017, 48, 76–87. [Google Scholar]

- Torotwa, I.; Ding, Q.S.; Makange, N.R.; Liang, L.; He, R.Y. Performance evaluation of a biomimetically designed disc for dense-straw mulched conservation tillage. Soil. Tillage Res. 2021, 212, 105068. [Google Scholar] [CrossRef]

- Xie, L.X.; Wang, P.; Luo, J.; Yi, W.Y.; Deng, J. Optimisation and numerical simulation of shearing blade used for citrus seedling grafting. Biosyst. Eng. 2022, 215, 67–79. [Google Scholar] [CrossRef]

- Qian, J.; Ma, S.; Xu, Y.; Li, W.; Huo, P.; Li, W. Design and test of sliding shear combined sugarcane base cutter. Trans. Chin. Soc. Agric. Eng. 2023, 39, 37–47. [Google Scholar]

- Liu, P.; He, J.; Lou, S.; Wang, Y.; Zhang, Z.; Lin, H. Design and Experiment for Dynamic Supporting Type Maize Straw Chopping Retention Device with Different Rotation Speeds of Disc Blade. Trans. Chin. Soc. Agric. Mach. 2021, 52, 41–50. [Google Scholar]

- Jia, H.L.; Li, C.Y.; Zhang, Z.H.; Wang, G. Design of Bionic Saw Blade for Corn Stalk Cutting. J. Bionics Eng. 2013, 10, 497–505. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; He, J.; Li, H.W.; Diao, P.S.; Wang, Q.J.; Zhang, X.C. Design and experiment of straw-chopping device with chopping and fixed knife supported slide cutting. Trans. Chin. Soc. Agric. Mach. 2016, 47, 108–116. [Google Scholar]

- Zhang, X.R.; Wang, Z.Q.; Li, Y.; Liang, D. Design and experiment of sliding-cutting and anti-twining returning device for banana straw. Trans. Chin. Soc. Agric. Mach. 2018, 34, 26–34. [Google Scholar]

- Liu, Y.; Huang, X.M.; Ma, L.N.; Zong, W.Y.; Zhan, G.C.; Lin, Z.X. Design and test of static sliding cut angle constant cutting machine for chain oil sunflower harvester header. Trans. Chin. Soc. Agric. Mach. 2021, 52, 99–108. [Google Scholar]

- Shi, Y.Y.; Wang, X.C.; Hu, Z.C.; Gu, F.W.; Wu, F.; Chen, Y.Q. Optimization and Experiment on Key Structural Parameters of No-Tillage Planter with Straw-Smashing and Strip-Mulching. Int. J. Agric. Biol. Eng. 2021, 14, 103–111. [Google Scholar] [CrossRef]

- Zhao, H.B.; Li, H.W.; Ma, S.C.; He, J.; Wang, Q.J.; Lu, C.Y.; Zheng, Z.Q.; Zhang, C. The Effect of Various Edge-Curve Types of Plain-Straight Blades for Strip Tillage Seeding on Torque and Soil Disturbance Using DEM. Soil. Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Qiu, M.M.; Meng, Y.M.; Li, Y.Z.; Shen, X.B. Sugarcane Stem Cut Quality Investigated by Finite Element Simulation and Experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Nowakowski, T.; Dabrowska, M.; Sypula, M.; Struzyk, A. A Method for Evaluating the Size of Damages to Fruit Trees During Pruning Using Different Devices. Sci. Hortic. 2018, 242, 30–35. [Google Scholar] [CrossRef]

- Yu, H.Y.; Han, Z.W.; Zhang, J.Q.; Zhang, S.J. Bionic Design of Tools in Cutting: Reducing Adhesion, Abrasion or Friction. Wear 2021, 482–483, 203955. [Google Scholar] [CrossRef]

- Guo, C.F.; Li, Y.; Yao, D.Y.; Wei, S.L.; Wu, Z.H.; Li, Y. Optimization and Experiment of Operating Parameters of Key Components of Bionic Banana Straw Crushing Devices. J. Chin. Agric. Mech. 2022, 43, 93–100. [Google Scholar]

- Hu, J.P.; Xu, L.Z.; Yu, Y.; Lu, J.; Han, D.L.; Chai, X.Y.; Wu, Q.H.; Zhu, L.J. Design and experiment of bionic straw-cutting blades based on Locusta migratoria manilensis. Agriculture 2023, 13, 2231. [Google Scholar] [CrossRef]

- Wang, J.W.; Guan, R.; Gao, P.X.; Zhou, W.Q.; Tang, H. Design and experiment of single disc top cutting device for carrot combine harvester. Trans. Chin. Soc. Agric. Mach. 2020, 51, 73–81. [Google Scholar]

- Zhang, L.H.; Luo, H.Z.; Zhou, Y.; Qiu, Q.Y.; Yuan, S.L.; Cai, J.X. Design and test of bionic crushing blade based on the mandible of the leaf-cutter ant for harvesting silage maize. Trans. Chin. Soc. Agric. Mach. 2022, 38, 48–56. [Google Scholar]

- Tian, K.P.; Li, X.W.; Shen, C.; Zhang, B.; Huang, J.C.; Wang, J.G.; Zhou, Y. Design and test of cutting blade of cannabis harvester based on longicorn bionic principle. Trans. Chin. Soc. Agric. Mach. 2017, 33, 56–61. [Google Scholar]

- Jia, X.; Wang, S.S.; Ma, L.; Yang, W.C.; Jin, Z.W.; Yan, Y.; Zhu, L.T. Design and experiment of bionic cutting blades for Panax notoginseng stem and leaf harvesting machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 117–126. [Google Scholar]

- Kong, F.T.; Wang, D.F.; Shi, L.; Wu, T.; Chen, C.L.; Sun, Y.F.; Xie, Q. Design and experiment of disc-cutting picking device for castor. Trans. Chin. Soc. Agric. Mach. 2021, 37, 1–9. [Google Scholar]

- Shi, Y.Y.; Chen, M.; Wang, X.C.; Zhang, Y.N.; Odhiambo, M.O. Dynamic simulation and experiments on Artemisia selengensis orderly harvester cutter. Trans. Chin. Soc. Agric. Mach. 2017, 48, 110–116. [Google Scholar]

- Du, Z.; Hu, Y.G.; Wang, S. Simulation and experiment of reciprocating cutter kinematics of portable tea picking machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 221–226. [Google Scholar]

- Bai, Z.C.; Lv, X.L.; Xia, L.R. Design of high-speed cutting device for grafting vegetable seedlings. Trans. Chin. Soc. Agric. Mach. 2019, 35, 35–42. [Google Scholar]

- Guan, Z.H.; Wu, C.Y.; Wang, G.; Li, H.T.; Mu, S.L. Design of bidirectional electric driven side vertical cutter for rape combine harvester. Trans. Chin. Soc. Agric. Mach. 2019, 35, 1–8. [Google Scholar]

- Xie, L.X.; Wang, J.; Cheng, S.M.; Zeng, B.S.; Yang, Z.Z. Optimisation and finite element simulation of the chopping process for chopper sugarcane harvesting. Biosyst. Eng. 2018, 175, 16–26. [Google Scholar] [CrossRef]

- Cui, T.; Liu, J.; Zhang, D.X.; Yang, L. Design and experiment of cob-picking and stalk-chopping united mechanism. Trans. Chin. Soc. Agric. Mach. 2012, 43, 95–100. [Google Scholar]

- Wang, W.W.; Li, J.C.; Chen, L.Q.; Qi, H.J.; Liang, X.T. Effects of key parameters of straw chopping device on qualified rate, non-uniformity and power consumption. Int. J. Agric. Biol. Eng. 2018, 11, 122–128. [Google Scholar] [CrossRef]

- Zhang, C.L.; Sheng, X.Y.; Zhang, S.L.; Gao, J.; Yuan, T.; Zhang, J.X.; Li, W. Experiment of influence factors on sawing power consumption for natural rubber mechanical tapping. Trans. Chin. Soc. Agric. Eng. 2018, 34, 32–37. [Google Scholar]

- Huan, X.L.; You, Y.; Wang, D.C.; Zhang, Y.L.; Ma, W.P.; Hui, Y.T. Optimization design and experiment on small cutting and beating machine of King grass. Trans. Chin. Soc. Agric. Mach. 2021, 52, 117–126. [Google Scholar]

- Chen, Y.; Zhou, F.J.; Sun, Y.; Li, T.Y. Parameters optimization and experiment of corn stalk cutting and scattering device. J. Agric. Mech. Res. 2018, 40, 142–149. [Google Scholar]

- Yan, W.; Wu, N.; Gu, F.W.; Lin, D.Z.; Zhou, X.X.; Hu, Z.C. Parameter optimization and experiment for the power consumption of impeller-blower. J. China Agric. Univ. 2017, 22, 99–106. [Google Scholar]

- Wu, F.; Xu, H.B.; Gu, F.W.; Chen, Y.Q.; Shi, L.L.; Hu, Z.C. Improvement of straw transport device for straw-smashing back-throwing type multi-function no-tillage planter. Trans. Chin. Soc. Agric. Eng. 2017, 33, 18–26. [Google Scholar]

- Guo, J.; Zhang, Q.Y.; Memon, M.S.; Ji, C.Y.; Zhao, Z. Design and experiment of bionic mole’s toe arrangement serrated blade for soil-rototilling and straw-shattering. Trans. Chin. Soc. Agric. Eng. 2017, 33, 43–50. [Google Scholar]

- Qin, K.; Ding, W.M.; Fang, Z.C.; Du, T.T.; Zhao, S.Q.; Wang, Z. Design and experiment of plowing and rotary tillage combined machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 7–16. [Google Scholar]

- Ntogkoulis, P.A.; Bochtis, D.D.; Fountas, S.; Berruto, R.; Gemtos, T.A. Performance of cotton residue collection machinery. Biosyst. Eng. 2014, 119, 25–34. [Google Scholar] [CrossRef]

- Xu, P.Q.; Dai, F.; Zhao, W.Y.; Shi, R.J.; Song, X.F.; Qu, J.F. Simulation analysis and experiment of operation process of flax threshing and cleaning device. Trans. Chin. Soc. Agric. Mach. 2023, 54, 161–171. [Google Scholar]

- Yan, C.G.; Niu, C.; Ma, S.; Tan, H.C.; Xu, L.M. CFD models as a tool to analyze the deformation behavior of grape leaves under an air-assisted sprayer. Comput. Electron. Agric. 2022, 198, 107112. [Google Scholar] [CrossRef]

- Yuan, J.B.; Wu, C.Y.; Li, H.; Qi, X.D.; Xiao, X.X.; Shi, X.X. Movement rules and screening characteristics of rice-threshed mixture separation through a cylinder sieve. Comput. Electron. Agric. 2018, 154, 320–329. [Google Scholar] [CrossRef]

- Gao, B.; Zhai, Z.P.; Lan, Y.Z.; Pei, G.; Zhao, L.X. Power consumption prediction model of forage crusher based on DEM-BPM-CFD coupling method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 168–176. [Google Scholar]

- Lisowski, A.; Świątek, K.; Klonowski, J.; Sypuła, M.; Chlebowski, J.; Nowakowski, T.; Kostyra, K.; Strużyk, A. Movement of chopped material in the discharge spout of forage harvester with a flywheel chopping unit: Measurements using maize and numerical simulation. Biosyst. Eng. 2012, 111, 381–391. [Google Scholar] [CrossRef]

- Chen, S.; Ding, H.; Tang, Z.; Zhao, Y.F.; Ding, Z.; Su, Z. Fluid movement law and influencing factors of shredding on rice straw briquetting machines. Agronomy 2022, 12, 1439. [Google Scholar] [CrossRef]

- Sun, N.N.; Wang, X.Y.; Li, H.W.; He, J.; Wang, Q.J.; Wang, J.; Liu, Z.D.; Wang, Y.B. Design and experiment of differential sawing rice straw chopper for turning to field. Trans. CSAE 2019, 35, 267–276. [Google Scholar]

- Liang, Z.; Xu, L.Z.; De, B.J.; Li, Y.M.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Liu, P.; He, J.; Yu, C.; Lou, S.; Wang, C.; Wang, M.; Shen, H. Distribution properties of airflow in the full envelope type maize stalk chopping chamber. Int. J. Agric. Biol. 2024, 17, 137–150. [Google Scholar] [CrossRef]

- Li, W.X.; Zhang, F.B.; Luo, Z.T.; Zheng, E.L.; Pan, D.C.; Qian, J.; Yao, H.P.; Wang, X.C. Straw movement and flow field in a crushing device based on CFD-DEM coupling with flexible hollow straw model. Biosyst. Eng. 2024, 242, 140–153. [Google Scholar] [CrossRef]

- Niu, G.L.; Li, B.; Liu, Y.; Wang, S.G.; Wang, T.; Sun, X.X. Design and test of vertical cotton stalk crushing and returning to the field machine. Agric. Res. Arid. Areas 2022, 40, 255–263. [Google Scholar]

- Tang, H.; Xu, C.S.; Zhao, J.L.; Wang, J.W. Formation and steady state characteristics of flow field effect in the header of a stripping prior to cutting combine harvester with CFD. Comput. Electron. Agric. 2023, 211, 107959. [Google Scholar] [CrossRef]

- Cao, S.L.; Xie, J.H.; Yang, Y.X.; Liu, Y.R.; Lu, Y.T.; Sun, B. Design and experiment of side row cotton straw returning and residual film recovery combined machine. J. Jilin Univ. (Eng. Technol. Ed.) 2023, 53, 1514–1528. [Google Scholar]

- Pei, G.; Zhai, Z.P.; Lan, Y.Z.; Shi, S.C. Analysis of coupling motion characteristics of material and airflow in multi-function forage kneading machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 156–163. [Google Scholar]

- Gu, F.W.; Zhao, Y.Q.; Wu, F.; Hu, Z.C.; Shi, L.L. Simulation analysis and experimental validation of conveying device in uniform crushed straw throwing and seed-sowing machines using CFD-DEM coupled approach. Comput. Electron. Agric. 2022, 193, 106720. [Google Scholar]

- Liu, P.; He, J.; Zhang, Z.Q.; Lu, C.Y.; Zhang, Z.G.; Lin, H. Kinematic characteristic analysis and field test of chopped stalk in straw retention machine based on CFD-DEM coupling simulation method. Trans. Chin. Soc. Agric. Mach. 2020, 51, 244–253. [Google Scholar]

- Wang, B.K.; Zhang, P.; Cao, M.Z.; Gu, F.W.; Wu, F.; Hu, Z.C. Design and experiment of pneumatic conveying device for seedlings of peanut harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 126–137. [Google Scholar]

- Wang, L.J.; Ma, Y.; Feng, X.; Song, L.L.; Chai, J. Design and experiment of segmented vibrating screen in cleaning device of maize grain harvester. Trans. Chin. Soc. Agric. Mach. 2020, 51, 89–100. [Google Scholar]

- Su, J.; Zhou, C.J.; Jiang, X.H.; Qiao, Z.Z. Orderly arrangement of agricultural biomass particles in designed gas-solid fluidized beds using CFD-DEM and image experiment. Comput. Electron. Agric. 2023, 204, 107510. [Google Scholar] [CrossRef]

- Jiang, T.; Li, H.T.; Guan, Z.H.; Mu, S.L.; Wu, C.Y.; Zhang, M. Design and experiments of material uniform dispersion and diversion device on cleaning screen surface for oilseed harvesting. Trans. Chin. Soc. Agric. Mach. 2023, 54, 146–158. [Google Scholar]

- Fang, M.; Yu, Z.H.; Zhang, W.J.; Liu, W.F.; Bie, Z.J.; Song, J.B. Analysis and experiments of the movement process for the shredded material of disc knife chaff cutter. Trans. Chin. Soc. Agric. Eng. 2021, 37, 76–84. [Google Scholar]

- Liu, P.; Zhang, Z.Q.; He, J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Lou, S.Y.; Liu, W.Z.; Cheng, X.P. Kinematic analysis and experiment of corn straw spreading process. Inmateh-Agric. Eng. 2019, 58, 83–92. [Google Scholar]

- Wu, K.; Song, Y.P. Research progress analysis of crop stalk cutting theory and method. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–20. [Google Scholar]

- Mechanical Hammer. Available online: https://zhuanli.tianyancha.com/4f80a00a369f4416c00370529ae41ec4 (accessed on 13 March 2025).

- Straight Blade. Available online: https://tao.hooos.com/goods_587642315499.html (accessed on 13 March 2025).

- Smooth-Cut Knives. Available online: https://www.deere.com/en/cutters-shredders (accessed on 13 March 2025).

- Combined Bent Blade. Available online: http://g-search1.alicdn.com/img/bao/uploaded/i2/2968084572/TB2lqLTXYsTMeJjSszhXXcGCFXa_%21%212968084572.jpg_300x300.jpg (accessed on 13 March 2025).

- Side-Slicer Knives. Available online: https://www.deere.com/en/cutters-shredders/flail-mowers-and-shredders/ (accessed on 13 March 2025).

- Qiu, X.W.; Wang, J.F.; Li, Y.Q.; Chen, S.Y.; Zhuang, T.F. Design of Y-straight zigzag straw crushing and returning device. Mod. Agric. 2015, 6, 53–55. [Google Scholar]

- He, N.B.; Li, Y.; Guo, C.F.; Zhang, X.R.; Liang, D. Optimization design and test of blade of banana straw returning machine. J. Agric. Mech. Res. 2021, 43, 85–91. [Google Scholar]

- Gan, S.B.; Li, Y.; Zhang, X.R.; Zhang, G.J.; Wang, N. Design and experiment on banana stalk chopper with feeding type spindle flail. Trans. Chin. Soc. Agric. Eng. 2014, 30, 10–19. [Google Scholar]

- Fu, X.G.; Li, M.; Lu, J.M.; Wang, J.L.; Deng, Y.G.; Zhang, J. Research on the cutter of straw crushing machine to field. Chin. Agric. Mech. 2011, 1, 83–87. [Google Scholar]

- Jia, H.L.; Jiang, X.M.; Guo, M.Z.; Liu, X.L.; Wang, L.C. Design and experiment of V-L shaped smashed straw blade. Trans. Chin. Soc. Agric. Eng. 2015, 31, 28–33. [Google Scholar]

- Zhang, S.F.; Zhao, S.P.; Ma, Y.J.; Li, J.X.; Li, J.G. Research of scourge-type reamer used for straw returning machine. Trans. Chin. Soc. Agric. Mach. 2004, 2, 59–61. [Google Scholar]

- Tang, N.N.; Li, Y.; Liang, D.; Zhang, X.R.; Zhou, T.; Song, Y.T.; Wu, S.H.; Wang, Z.Q. The Design and optimizing on flail knife of horizontal banana straw crushing-returning machine. J. Agric. Mech. Res. 2017, 39, 107–111. [Google Scholar]

- Song, Y.T.; Li, Y.; Tang, N.N.; Wu, S.H. The parameters study on cutter roller of banana straw chopper machine. J. Agric. Mech. Res. 2016, 38, 78–83. [Google Scholar]

- Zhu, H.B.; Qian, C.; Bai, L.Z.; Zhao, H.R.; Ma, S.; Zhang, X.; Li, H. Design and experiments of active anti-blocking device with forward-reverse rotation. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–11. [Google Scholar]

- Song, Y.P.; Wang, Z.; Wu, K.; Li, F.D.; Song, Z.H.; Yang, X. Fabrication of self-sharpening blades with metalloceramics materials and low-damaged cutting mechanism of alfalfa. Trans. Chin. Soc. Agric. Mach. 2020, 51, 421–426. [Google Scholar]

- Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Effect of blade oblique angle and cutting speed on cutting energy for energycane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- Chai, X.Y.; Xu, L.Z.; Yan, C.; Liang, Z.W.; Ma, Z.; Li, Y.M. Design and Test of Cutting Frequency Follow-up Adjusting Device for Vertical Cutting Knife of Rapeseed Cutting Machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 93–99. [Google Scholar]

- Gan, H.; Mathanker, S.; Momin, M.A.; Kuhns, B.; Stoffel, N.; Hansen, A.; Grift, T. Effects of three cutting blade designs on energy consumption during mowing-conditioning of Miscanthus Giganteus. Biomass Bioenergy 2018, 109, 166–171. [Google Scholar] [CrossRef]

- Kang, F.; Tong, S.Y.; Zhang, H.S.; Li, W.B.; Chen, Z.J.; Zheng, Y.J. Analysis and experiments of reciprocating cutting parameters for apple tree branches. Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–16. [Google Scholar]

- Igathinathane, C.; Womac, A.R.; Sokhansanj, S. Corn stalk orientation effect on mechanical cutting. Biosyst. Eng. 2010, 107, 97–106. [Google Scholar] [CrossRef]

- Song, S.Y.; Zhou, H.P.; Jia, Z.C.; Xu, L.Y.; Zhang, C.; Shi, M.H.; Hu, G.M. Effects of cutting parameters on the ultimate shear stress and specific cutting energy of sisal leaves. Biosyst. Eng. 2022, 218, 189–199. [Google Scholar] [CrossRef]

- Bitra, V.S.P.; Womac, A.R.; Igathinathane, C.; Miu, P.I.; Yang, Y.C.T.; Smith, D.R.; Chevanan, N.; Sokhansanj, S. Direct measures of mechanical energy for knife mill size reduction of switchgrass, wheat straw, and corn stover. Bioresour. Technol. 2009, 100, 6578–6585. [Google Scholar] [CrossRef]

- Gao, G.H.; Wang, K.; Yuan, Y.W.; Liu, J.F.; Wang, T.B.; Sun, X.N. Mechanical characteristic analysis of drawing and cutting process for greenhouse vegetable harvester based on energy balance theory. Trans. Chin. Soc. Agric. Eng. 2017, 33, 58–64. [Google Scholar]

- Du, Z.; Hu, Y.G.; Wu, W.Y.; Lu, Y.Z.; Buttar, N.A. Structural analysis on cutting notch of tea stalk by X-ray micro-computed tomography. Inf. Process. Agric. 2020, 7, 242–248. [Google Scholar] [CrossRef]

- Liu, J.; Xie, S.Y.; Chen, C.; Xie, D.; Yang, M.J. Preliminary design of straw cutting simulation test platform based on hardware-in-loop. Trans. Chin. Soc. Agric. Eng. 2018, 34, 46–53. [Google Scholar]

- Wang, H.Y.; Ge, Z.W.; Yong, C.M.; You, Y.; Li, Z.H.; Li, C.R.; Lu, Q.Q.; Wang, D.C.; Fang, X.F. Optimization and testing of the bionic chopping cutter for silage maize. Trans. Chin. Soc. Agric. Eng. 2025, 41, 87–97. [Google Scholar]

- Zhou, Y.; Ou, Y.G.; Mo, Z.F. Design and experiment of oblique cutting and feeding device for sugarcane. Trans. Chin. Soc. Agric. Eng. 2012, 28, 17–23. [Google Scholar]

- Tian, X.L.; Zhao, Y.; Chen, X.G.; Yan, L.M.; Wen, H.J.; Gou, H.X.; Ji, C. Development of 4JSM-2000A type combined operation machine for cotton stalk chopping and residual plastic film collecting. Trans. Chin. Soc. Agric. Eng. 2018, 34, 25–35. [Google Scholar]

- Crop Straw Chopping and Returning Machine. Available online: http://www.yituo.com.cn/cpzx/jjcp/jgj/201706/t20170620_156686.html# (accessed on 13 March 2025).

- HanMei 1JH-220 Heavy Type Crop Straw Returning Machine. Available online: http://item.nongji360.com/64447 (accessed on 13 March 2025).

- DaHua BaoLai 1JH Series Single-Axis Double-Side Drive Straw Crushing and Returning Machine. Available online: https://www.nongjitong.com/product/dahuabaolai_shuang_straw_returning_machine.html (accessed on 13 March 2025).

- Flailmower Trisar TR46. Available online: https://www.gwilitractors.co.uk/new-products/item/371-alpego-flailmower-trisar-tr46/ (accessed on 10 March 2025).

- 390 Offset Flail Mower. Available online: https://www.deere.com/en/cutters-shredders/flail-mowers-and-shredders/390-flail-mower/ (accessed on 10 March 2025).

- DaHua BaoLai 1JHS Series Double-Axis Type Crop Straw Chopping and Returning Machine. Available online: http://item.nongji360.com/d/65331 (accessed on 10 March 2025).

- XingHuo 1JHS-346 Double-Axis Type Crop Straw Chopping and Returning Machine. Available online: https://www.nongjitong.com/product/xhjg_56784408.html (accessed on 10 March 2025).

- AiWei AWONSC600 Folding Straw Crushing and Returning Machine. Available online: http://item.nongji360.com/102326 (accessed on 10 March 2025).

- ALBATROS. Available online: https://www.tierreonline.com/en/flail-mowers/stalk-choppers/albatros-plus/ (accessed on 21 March 2023).

- Maschio Jolly 210. Available online: https://www.maschio.com/en/web/international/jolly (accessed on 10 March 2025).

- Grooming Mowers. Available online: https://www.deere.com/en/cutters-shredders/grooming-mowers/ (accessed on 10 March 2025).

- 60A Type Straw Chopped Machine. Available online: https://jixieshebei.51sole.com/b2c/b2cdetails_5136319.html (accessed on 10 March 2025).

- Li, M.; Wang, J.L.; Deng, Y.G.; Huang, H.; Zhang, J.; Song, D.Q.; Lian, W.W. Structural design and experiments on sugarcane leaf shattering and returning machine. Trans. Chin. Soc. Agric. Eng. 2008, 24, 121–126. [Google Scholar]

- Qiu, J.; Wu, M.L.; Guan, C.Y.; Fang, Y.X.; Li, X.C. Design and experiment of chopping device with dynamic fixed knife coaxial for rice straw. Trans. Chin. Soc. Agric. Eng. 2015, 31, 11–19. [Google Scholar]

- Li, Y.; Guo, C.F.; Yao, D.Y.; He, N.B.; Zhang, X.R.; Wu, Z.H.; Li, Y. Design and experiment of banana straw crushing and returning machine with anti-wrapping device supported by flailing blade. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar]

- Zhang, X.R.; Yang, Y.M.; Liu, H.X.; Liu, J.X.; Zhang, Z.F.; Cao, S. Optimal design and experiment of double fixed knife slip-cutting and anti-tangle banana straw crushing and returning machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 36–49. [Google Scholar]

- Wang, Q.J.; Liu, Z.D.; He, J.; Li, H.W.; Li, W.Y.; He, J.H.; Yan, X.L. Design and experiment of chopping-type maize straw returning machine. Trans. Chin. Soc. Agric. Eng. 2018, 34, 10–17. [Google Scholar]

- Lin, H.; He, J.; Zhong, G.Y.; Yang, H.Y. Design and testing of a low-speed, high-frequency straw chopping and returning machine using a constant breath cam mechanism. Agriculture 2024, 14, 2293. [Google Scholar] [CrossRef]

- Lin, H.; He, J.; Li, H.; Wang, C.; Li, H.; Tan, L. Design and experiment of variable-speed straw chopping machine based on PLC control with equal diameter cam transmission. Trans. Chin. Soc. Agric. Mach. 2024, 55, 96–110. [Google Scholar]

- Dai, F.; Zhang, F.W.; Zhao, C.H.; Hu, J.M.; Han, Z.S.; Feng, Y.Z. Design and experiment on straw returning machine with fast decomposing inoculant spray equipment. Trans. Chin. Soc. Agric. Mach. 2010, 41, 47–51. [Google Scholar]

- Gao, Y.; Li, Y.; Wei, S.Q.; Huang, C.; Wu, Z.H.; Wei, C.H.; Huang, L.R. Design and experiment of a banana straw crushing and returning machine with rotting agent spraying device. J. Agric. Sci. Technol. 2024, 26, 93–104. [Google Scholar]

- Luo, W.W.; Gu, F.W.; Wu, F.; Xu, H.B.; Chen, Y.Q.; Hu, Z.C. Design and experiment of wheat planter with straw crushing and inter-furrow collecting mulching under full amount of straw and root stubble cropland. Trans. Chin. Soc. Agric. Mach. 2019, 50, 42–52. [Google Scholar]

- Shi, Y.; Xin, R.S.; Wang, X.; Hu, Z.; Newman, D.; Ding, W. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software. Comput. Electron. Agric. 2019, 166, 105021. [Google Scholar] [CrossRef]

- Zhao, H.B.; He, J.; Zheng, Z.Q.; Zhang, Z.G.; Liu, W.Z. Strip tillage inter-row residue side-throwing device of no/minimum-till seeder for anti-blocking and seedbed-cleaning. Trans. Chin. Soc. Agric. Mach. 2020, 51, 24–34. [Google Scholar]

- Hou, S.Y.; Zou, Z.; Wei, Z.P.; Ji, W.Y.; Chen, H.T. Design and experiment of rectifier for multi-stage lateral movement of corn straw. Trans. Chin. Soc. Agric. Mach. 2021, 52, 45–56. [Google Scholar]

- Zhu, H.B.; Wu, X.; Bai, L.Z.; Qian, C.; Zhao, H.R.; Li, H. Development of the biaxial stubble breaking no-tillage device for rice stubble field based on EDEM-ADAMS simulation. Trans. Chin. Soc. Agric. Eng. 2022, 38, 10–22. [Google Scholar]

- Liu, L.; Wang, X.L.; Zhang, X.C.; Cheng, X.P.; Wei, Z.C.; Zhou, H.; Zhao, K.L. The impact of ‘T’-shaped furrow opener of no-tillage seeder on straw and soil based on discrete element method. Comput. Electron. Agric. 2023, 213, 108278. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Lu, C.Y.; He, J.; Wang, Q.J.; Li, H.; Zhai, C.K. Design and Experiment of Active Spiral Pushing Straw Row-Sorting Device. Agriculture 2024, 14, 137. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Wu, F.; Gu, F.W.; Wang, B.K.; Ma, B.; Hu, Z.C. Test on peanut no-till planter under the coverage of the wheat straw. J. Chin. Agric. Mech. 2014, 35, 132–135. [Google Scholar]

- Zhao, J.; Deng, C.; Su, L.F.; Zhang, J.G.; Li, F.T.; Li, J.B.; Zhao, X.Z. Design and experiment of smash straw and covering seed banding with seed-row rotary tillage of cotton planter. J. Agric. Mech. Res. 2021, 43, 66–72. [Google Scholar]

- Shi, Y.Y.; Yu, H.W.; Jiang, Y.; Wang, X.C.; Chen, H.T.; Liu, H. Optimization of Strip Fertilization Planter for Straw Throwing and Paving. Agriculture 2022, 12, 613. [Google Scholar] [CrossRef]

- Gu, F.W.; Zhao, Y.Q.; Hu, Z.C.; Shi, L.L.; Wu, F.; Xu, H.B.; Gao, X.M. Operation analysis and parameter optimization of the conveying device for uniform crushed straw throwing and seed-sowing machines. Int. J. Agric. Biol. Eng. 2023, 16, 28–36. [Google Scholar] [CrossRef]

- Zheng, Y.B.; Zhang, F.B.; Luo, Z.T.; Zheng, E.L.; Han, L.; Qian, J.; Yao, H.P.; Shi, Y.Y.; Wang, X.C. Design and optimization of volute directing plate and stubble board for enhancing liquidity and anticlogging of tillering straw in spreading operation. Powder Technol. 2024, 448, 120288. [Google Scholar] [CrossRef]

- Xinle 2BMQF-6/12 Full Field Anti-Winding No-Tillage Fertilization Seeder. Available online: https://www.nongjitong.com/product/40944.html (accessed on 14 March 2025).

- Haofeng 4FMJB-180 Type Straw Crushing Corn No-Tillage Precision Seeder. Available online: http://item.nongji360.com/54668 (accessed on 14 March 2025).

- Nongyouwang 2BYSF Series Full Straw Mulching No-Tillage Planter. Available online: https://www.nongjitong.com/product/nongyouwang_2bysf_seeder.html (accessed on 14 March 2025).

- Dasmesh Combo Happy Seeder. Available online: https://www.justheavyequipment.com.au/equipment-for-sale/dasmesh-combo-happy-seeder/JHMD3889749 (accessed on 14 March 2025).

- Happy Seeder. Available online: https://dir.indiamart.com/items/landforce-9-tynes-happy-seeder-hss9-s142149.html (accessed on 14 March 2025).

- DASMESH 610. Available online: https://www.tractorjunction.com/implement/dashmesh/610-happy-seeder/ (accessed on 14 March 2025).

- Tang, H.; Wang, D.; Zhao, J.L.; Xu, C.S.; Wang, J.W. Mode and experiments of a straw ditch-burying returning and maturing in cold region of Northeast China. Eur. J. Agron. 2023, 151, 127006. [Google Scholar] [CrossRef]

- Zhang, M.M.; Han, X.Q.; Dang, P.F.; Wang, H.Y.; Chen, Y.J.; Qin, X.L.; Siddique, K.H.M. Decreased carbon footprint and increased grain yield under ridge–furrow plastic film mulch with ditch-buried straw returning: A sustainable option for spring maize production in China. Sci. Total Environ. 2022, 838, 156412. [Google Scholar] [CrossRef]

- Yang, H.S.; Fang, C.; Meng, Y.; Dai, Y.J.; Liu, J. Long-term ditch-buried straw return increases functionality of soil microbial communities. Catena 2021, 202, 105316. [Google Scholar] [CrossRef]

- Tian, Y.; Lin, J.; Li, B.F. Design and test of conveying device of pneumatic straw deep burying and returning machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 36–44. [Google Scholar]

- Wang, Q.J.; Jiao, F.; Liu, F.; Chang, B.C.; Jiang, H.; Jiang, Y.; Mi, G.; Zhou, X. Effect of straw pulverization and concentrated deep-buried into field on growth and yield of maize. Trans. Chin. Soc. Agric. Eng. 2018, 34, 153–159. [Google Scholar]

- Wei, G.L.; Zhang, Q.S.; Liu, L.C.; Xiao, W.L.; Sun, W.C.; Liao, Q.X. Design and Experiment of Plowing and Rotary Tillage Buckle Device for Rapeseed Direct Seeder. Trans. Chin. Soc. Agric. Mach. 2020, 51, 38–46. [Google Scholar]

- Chen, G.B.; Lu, C.Y.; He, J.; Wang, C.; Wang, X.H.; Wang, Q.J. Design and experiment of straw pickup-crushed and deep buried device under striptillage. Trans. Chin. Soc. Agric. Mach. 2021, 52, 16–27. [Google Scholar]

- Yuan, X.M.; Li, X.H.; Jiao, H.T.; Zhou, S.L.; Zhang, J.J.; Wu, H.Y. Design and experiment of straw chopping centralized full depth and returning machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 27–35. [Google Scholar]

- Tong, Z.W.; Li, H.W.; He, J.; Wang, Q.J.; Lu, C.Y.; Wang, C.; Zhong, G.Y.; Cui, D.D.; Li, D.K. Design and experiment of in situ soil-lifting shovel for direct-injection straw deep-burial machine. Agriculture 2023, 13, 1650. [Google Scholar] [CrossRef]

- Tong, Z.W.; Li, H.W.; Lu, C.Y.; Wang, C.; Zhong, G.Y.; Lin, H. Design and experiment of direct-injection straw picking and crushing deep burying machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 83–95. [Google Scholar]

- Lin, J.; Ma, T.; Li, B.F. Design and test of 1JHL-2 type straw deep burying and returning machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 32–40. [Google Scholar]

- Gao, W.Y.; Lin, J.; Li, B.F.; Ma, T. Parameter optimization and experiment for spiral type opener device of maize straw deep bury and returning machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 45–54. [Google Scholar]

- Qin, K.; Ding, W.M.; Fang, Z.C.; Du, T.T.; Zhao, S.Q.; Wang, Z. Design and experiment of seeding system for harvest ditch and stalk-disposing machine. Trans. Chin. Soc. Agric. Mach. 2017, 48, 54–62. [Google Scholar]

- Song, J.P.; Lin, J.; Ma, T.; Lv, Q.L.; Tian, Y. Design and test of rotating spade type maize straw returning root deep machine. J. Agric. Mech. Res. 2018, 40, 95–99. [Google Scholar]

- Wang, J.W.; Xu, Y.A.; Wang, C.Y.; Xiang, Y.S.; Tang, H. Design and simulation of a trenching device for rice straw burial and trenching based on MBD-DEM. Comput. Electron. Agric. 2023, 207, 107722. [Google Scholar] [CrossRef]

- Zhang, Q.Z.; Zhao, J.F.; Yang, X.W.; Wang, L.; Su, G.D.; Liu, X.Y.; Shan, C.; Rahim, O.; Yang, B.H.; Liao, J.A. Design and Testing of an Offset Straw-Returning Machine for Green Manures in Orchards. Agriculture 2024, 14, 1932. [Google Scholar] [CrossRef]

- 1GZMH Type Crop Straw Chopping and Mixing Machine. 21 December 2021. Available online: http://item.nongji360.com/97567 (accessed on 14 March 2025).

- Straw Returning and Stubble Cleaning Combined Soil Preparation Machine. Available online: http://item.nongji360.com/100210 (accessed on 14 March 2025).

- Double Shaft Type Straw Returning Machine Combined with Rotary Tillage. Available online: https://www.nongjitong.com/product/hanwu_55430326.html (accessed on 14 March 2025).

- 1JHM-165 Straw and Stubble Chopping and Returning Machine. Available online: https://www.nongjitong.com/product/352_1jhm-165_straw_returning_machine.html (accessed on 14 March 2025).

- 1GKF-200 Crop Straw Chopped Machine Combined with Rotary Tillage Device. Available online: https://www.nongjitong.com/product/weidi_1gkf_200_rotary_cultivator.html (accessed on 14 March 2025).

- 1GKF-200 Straw Returning Machine Combined with Rotary Tillage. Available online: http://item.nongji360.com/100131 (accessed on 14 March 2025).

- SGTN-350 Combined Machine for Land Preparation and Full Straw. Available online: https://www.nongjitong.com/product/38494.html (accessed on 14 March 2025).

- Ju, J.; Zhou, J.; He, J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Liu, P. Design and experiment on the combined machine for variable straw chopping-cover and mixed-burying. Int. Agric. Eng. J. 2020, 29, 128–139. [Google Scholar]

- Ramulu, C.; Pateriya, R.N.; Naik, M.A. Comparison of straw chopper cum incorporator with existing paddy residue management technologies in combine harvested paddy field at north western region of India. Curr. J. Appl. Sci. Technol. 2020, 39, 31–40. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xia, J.F.; Zhou, H.; Zhu, Y.H.; Wang, J.W. Design and Experiment of Knife Roller for Six-head Spiral Straw Returning Cultivator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 25–34. [Google Scholar]

- Zhu, Y.H.; Zhang, J.M.; Zeng, R.; Zhang, W.L.; Yang, Q.J.; Xia, J.F. Design and Experiment of Herringbone Type Rotary Blade Roller for Burying Stubble in Paddy and Dry Land. Trans. Chin. Soc. Agric. Mach. 2019, 50, 49–57+273. [Google Scholar]

- Xu, G.M.; Xie, Y.X.; Liang, L.; Ding, Q.S.; Xie, H.X.; Wang, J.N. Straw-Soil-Rotary Blade Interaction: Interactive Effects of Multiple Operation Parameters on the Straw Movement. Agriculture 2022, 12, 847. [Google Scholar] [CrossRef]

- Lin, J.X.; Liao, Q.X.; Wang, X.F.; Kang, Y.; Du, W.B.; Zhang, Q.S. Exploring straw movement through the simulation of shovel-type seedbed preparation machine-straw-soil interaction using the DEM-MBD coupling method. Comput. Electron. Agric. 2024, 226, 109465. [Google Scholar] [CrossRef]

- Yang, Q.L.; Chen, G.B.; Xie, L.J.; Wang, Q.J.; He, J.; Li, H.W. Design and Experiment of Telescopic Finger Stalk of Maize Straw Burying Machine. Trans. Chin. Soc. Agric. Mach. 2020, 51, 35–43. [Google Scholar]

- Wang, J.F.; Chen, B.W.; Jiang, Y.; Zhu, M.; Xia, J.F.; Wang, J.W. Design and experiment on machine for rice straw full quantity deep buried into field. Trans. Chin. Soc. Agric. Mach. 2020, 51, 84–93. [Google Scholar]

- Zhou, H.; Zhang, C.L.; Zhang, W.L.; Yang, Q.J.; Li, D.; Liu, Z.Y.; Xia, J.F. Evaluation of straw spatial distribution after straw incorporation into soil for different tillage tools. Soil. Tillage Res. 2020, 196, 104440. [Google Scholar] [CrossRef]

- Wang, L.; Bing, Q.W.; Liao, Q.X.; Wang, B.; Liao, Y.T.; Zhang, Q.S. Burying stubble and anti-blocking deep fertilization composite device for rapeseed direct planting in high stubble and heavy soil rice stubble field. Trans. Chin. Soc. Agric. Mach. 2023, 54, 83–94. [Google Scholar]

- Liang, F.; Deng, W.H.; Luo, L.Q.; Wang, J.K.; Zhan, S.P. Optimizing double-screw burying device for rape straw returning. Trans. Chin. Soc. Agric. Eng. 2023, 30, 10–17. [Google Scholar]

- Patel, A.; Singh, K.P.; Roul, A.K.; Nalawade, R.D.; Mahore, A.; Kumar, M.; Sonawane, S.; Kebede, B. Design and assessment of tractor-driven chopping tilling and mixing machine for in-situ management of paddy straw. Sci. Rep. 2024, 14, 17254. [Google Scholar] [CrossRef]

- Du, W.B.; Zhou, G.W.; Zhang, Q.S.; Bian, Q.W.; Liao, Q.X.; Liao, Y.T. Design and experiment of the anti-blocking device combined stubble burying for rapeseed direct seeding. Trans. Chin. Soc. Agric. Eng. 2024, 40, 60–70. [Google Scholar]

- 4YZP-4M Jself-Propelled Corn Harvester. Available online: https://www.nongjitong.com/product/jinyee_4yzp_4mj_corn_harvester.html (accessed on 29 March 2025).

- John Deere X9 1000. Available online: https://www.deere.com/en/harvesting/x-series-combines/x91000-combine/ (accessed on 29 March 2025).

- Bur’yanov, A.I.; Bur’yanov, M.A.; Chervyakov, I.V. Methods and devices for processing the stemstock of cereal crops harvested using combine stripper harvester technology. Tract. Agric. Mach. 2018, 85, 9–14. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, Y.T.; Yang, Q.Y.; Zhang, J.W.; Zhang, Z.L.; Geng, A.J. Design and experiment of smashed straw unit for high stubble maize double header. Trans. Chin. Soc. Agric. Mach. 2018, 49, 42–49. [Google Scholar]

- Wang, L.; Wan, Y.; Zhang, Z.; Yu, Y.; Liu, T. Performance evaluation of a maize stalk chopping device based on field tests. Appl. Eng. Agric. 2019, 35, 997–1008. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.Y.; Li, H.W.; He, J.; Lu, C.Y.; Liu, D. Design and experiment of rice straw chopping device for agitation sliding cutting and tearing. Trans. Chin. Soc. Agric. Mach. 2021, 52, 28–40. [Google Scholar]

- Jia, H.L.; Tan, H.W.; Ma, Z.Y.; Zhou, S.H.; Wang, G. Design and experiment of the straw breaking and diversion device for maize harvesters. Trans. Chin. Soc. Agric. Eng. 2022, 38, 12–23. [Google Scholar]

- Xin, S.L.; Zhao, W.Y.; Shi, L.R.; Dai, F.; Feng, B.; Yan, Z.B.; Lyu, D.Y. Design and experiments of the clamping and conveying device for the vertical roller type corn harvesting header. Trans. Chin. Soc. Agric. Eng. 2023, 39, 34–43. [Google Scholar]

- Chen, M.Z.; Xu, G.F.; Wei, M.J.; Li, X.W.; Wei, Y.Z.; Diao, P.S.; Cui, P.D.; Teng, S.M. Optimization design and experiment on feeding and chopping device of silage maize harvester. Int. J. Agric. Biol. Eng. 2023, 16, 64–77. [Google Scholar] [CrossRef]

- Zhou, B.C.; Ma, S.C.; Li, W.Z.; Peng, C.; Li, W.Q. Study on sugarcane chopping and damage mechanism during harvesting of sugarcane chopper harvester. Biosyst. Eng. 2024, 243, 1–12. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a combine harvester with turbine technology increases the recovery of residual biomass from cereal crops via the collection of chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef]

- Shi, L.L.; Gu, F.W.; Hu, Z.C.; Wu, F.; Gao, X.M.; Xu, H.B. Analysis and optimization of uniform throwing device by no-tillage planter of wheat after rice. Trans. Chin. Soc. Agric. Mach. 2022, 53, 74–83. [Google Scholar]

- 4JH-168 Straw Chopping and Returning Machine. Available online: https://www.nongjitong.com/product/77_22175853.html (accessed on 14 March 2025).

- 4JQ Straw Chopping and Spreading Machine. Available online: https://www.nongjitong.com/product/lhjx_67100912.html (accessed on 14 March 2025).

- 4JQM-300 Straw Chopping and Returning Machine. Available online: https://www.nongjitong.com/product/12697.html (accessed on 14 March 2025).

- 4SJ-180 Straw Chopping Machine. Available online: https://www.nongjitong.com/product/tongtian_4sj-180_straw_returning_machine.html (accessed on 14 March 2025).

- 1JH Straw Chopping and Spreading Machine. Available online: https://sjzzz.nongji1688.com/sell/itemid-5457356.shtml (accessed on 14 March 2025).

- John Deere S780. Available online: https://www.deere.com/en/harvesting/s-series-combines/s780-combine/ (accessed on 14 March 2025).

- New Holland CX7. Available online: https://agriculture.newholland.com/eu/en-uk/equipment/products/combine-harvesters/cx7-cx8-stage-v (accessed on 14 March 2025).

- CaswIh Axial-Flow Combines. Available online: https://www.caseih.com/-northamerica/en-us/products/harvesting/axial-flow-combines (accessed on 14 March 2025).

- Avero 240/160. Available online: https://www.claas.co.uk/products/combines/avero240-160-2020 (accessed on 14 March 2025).

- Wang, X.; Jin, C.Q.; Xu, J.S.; Ni, Y.L. Study and design optimization on the angle adjustments of the straw spreader panel in a combined wheat harvester. J. Agric. Mech. Res. 2019, 41, 127–135. [Google Scholar]

- Qin, K.; Cao, C.M.; Miao, Y.S.; Wang, C.Q.; Fang, L.D.; Ge, J. Design and optimization of crushing and throwing device for straw returning to field and fertilizing hill-seeding machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar]

- Xu, L.C.; Zhao, S.W.; Wu, Y.H.; Chen, Y.; Zhu, J.; Zhang, R. Design and test of spreading device for straw returning machine. J. Chin. Agric. Mech. 2021, 42, 18–24. [Google Scholar]

- Lu, J.; Mao, M.; Zhao, M.; Cao, L.; Wang, Y.F. Research on the rice and wheat straw throwing and returning machine matched with half-feed combine harvester. Agric. Equip. Technol. 2014, 40, 13–16. [Google Scholar]

- Li, X.C.; Wu, M.L.; Qiu, J.; Xie, W. Design and experiment of row-controlled throwing mechanism for rice straw. J. Hunan Agric. Univ. (Nat. Sci.) 2016, 42, 454–459. [Google Scholar]

- Liu, D.; Wang, X.Y.; Li, H.W.; He, J.; Wang, Q.J.; Lu, C.Y. Design and experiment of active centrifugal rice straw spreading device. Trans. Chin. Soc. Agric. Mach. 2024, 55, 81–91. [Google Scholar]

- Yan, L.M.; Wu, T.; Jiang, D.L.; Gou, H.X.; Fu, X.H.; Zhang, J.H. Design and experiment of side-throwing cotton stalk crushing and returning device. Trans. Chin. Soc. Agric. Mach. 2025, 56, 216–226. [Google Scholar]

| Type | Structural Features | Figure |

|---|---|---|

| Hammer [105] | High impact force, batter collecting ability, high energy consumption, suitable for hard straw, such as cotton. |  |

| Straight blade [106] | Lower energy consumption, high working efficiency, existing sawtooth at cutting edge, poor collecting ability, suitable for soft straw, such as wheat, rice. |  |

| Bent blade [107] | Batter chopping and collecting ability, suitable for hard straw, such as maize. |  |

| Combined bent blade [108] | Both collecting and chopping ability, combined utilization of two bent blades and one straight blade, suitable for hard straw, such as maize. |  |

| Smoothing chopped blade [109] | High working efficiency and life, suitable for soft straw, such as weed. |  |

| Double-edged blade [110] | Batter symmetry, cutting edge on both sides of blade, manufacturing difficulty, suitable for hard straw, such as maize. |  |

| L type [111] | With tangent edge and side cutting edge, easy to warp and deform failure, suitable for banana straw. |  |

| E type [112] | High working area, complex structure, high strength of blade, suitable for banana straw. |  |

| Fan-type combined blade [113] | High collecting ability and high velocity of airflow in chopped chamber, high energy consumption, and rotational inertia, suitable for rice and maize straw. |  |

| T type [88] | Both horizontal and vertical cuts, complex structure, suitable for soft straw, such as rice. |  |

| V-L type [114] | High chopping ability, high structural strength, complex structure, suitable for maize straw. |  |

| Three linked sections [115] | High cutting velocity, complex parts, aggravate machine vibration, suitable for maize and wheat straw. |  |

| Logarithmic spiral disc blade [50] | Providing support for Y-type chopped blade, providing higher breaking force on maize straw, suitable for maize straw. |  |

| Bionic sawtooth chopped blade [61] | Tooth profile of the saw blade imitating blue shark teeth, reducing energy consumption, suitable for banana straw. |  |

| Name | Chopped Type | Transmission | Structure | Features |

|---|---|---|---|---|

| 1JH220-type chopped machine [133] | Horizontal | SS |  | Removable encryption fixed knife, high inertia moment of chopped blade, rotational velocity (RV) 2100 r/min, working efficiency (WE) 0.80 hm2/h. |

| 1JH220-type chopped machine [134] | Horizontal | SS |  | Left and right lateral movement by hydraulic, RV 2400 r/min, WE 0.99–1.12 hm2/h. |

| 1JH455-type chopped machine [135] | Horizontal | SD |  | Suitable for maize, rice, wheat straw, RV 2100–2422 r/min, working width (WW) 4550 mm. |

| TR46-type chopped machine [136] | Horizontal | SD |  | Spreading amount of chopped stalk is adjustable, WW 3100 mm, matching power (MP) > 41.04 kW. |

| Flail mower [137] | Horizontal | SD |  | Offset suspension, WW 2300 mm, RV 1850 r/min, MP 30–56 kW. |

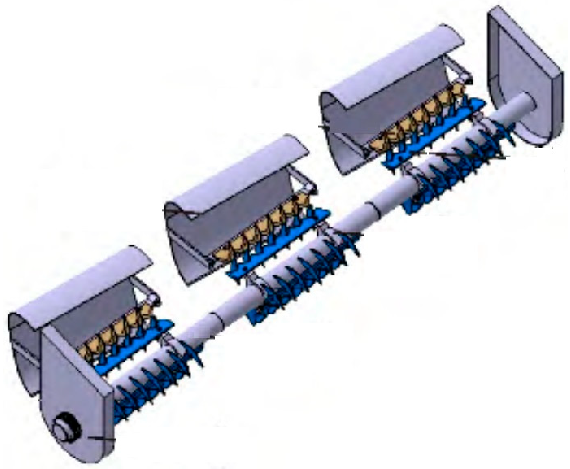

| 1JH type-chopped machine [138] | Horizontal | DD |  | Hammer installed in front shaft, Y-type blade installed in back shaft; velocity of front shaft is small than that of back shaft; suitable for straw from tall and densely planted crops. |

| 1JHS-type chopped machine [139] | Horizontal | DD |  | Suitable for ridge tillage region, flail blade installed in front shaft, cutting blade installed in back shaft, MP 147–161.7 kW, WE 1.33–1.53 hm2/h. |

| SC600-type chopped machine [140] | Horizontal | DD |  | Collapsible, WW 6000 mm, WE 6 hm2/h. |

| Albatros plus [141] | Horizontal | DD |  | Collapsible, adjustable working height, velocity of blade 52 m/s, suitable for weed, crop straw, shrub, MP 90–120 kW, WW 8300 mm. |

| Maschio Jolly 210 [142] | Vertical | SS |  | Chopped shaft is vertical with field surface, MP 26–36 kW. |

| John Deere FM3012 [143] | Vertical | SS |  | Adjustable working height, velocity of blade 82.30 m/s, MP 19–45 kW. |

| 60A-type chopped machine [144] | Vertical | SS |  | Adjustable embedded depth, vertical motion of cutting blade, MP 8.82–13.23 kW. |

| Version | Type | Structure | Characters |

|---|---|---|---|

| 2BMQF no-tillage planter [166] | Strip-type crop straw and stubble chopped |  | Sawtooth roll blades were installed in front of opener and could chop and side spread the crop straw, WE 0.40–0.67 hm2/h. |

| 4FMJB crop straw chopping no-tillage precision seeder [167] | Full chopped straw returning to the field |  | Crop straw chopping device was combined with no-tillage seeder. |

| 2BYSF no-tillage planter with chopped straw back spread [168] | Straw chopped combined with back spreading |  | Full chopped of crop straw and spread to the back of the seeder; quickly combined with a variety of planters; MP 88.2 kW, WE 0.39–0.75 hm2/h. |

| Dasmesh Combo no-tillage planter [169] | Back spread of chopped straw |  | Full chopped of straw and spread to the back of seeder by diversion chamber; WE 0.30 hm2/h. |

| LandForce HSS no-tillage planter [170] | Back spread of chopped straw |  | Straw in front of seeder opener was chopped by chopped blade with high rotational speed in situ, WW 2286 mm, MP < 44.78 kW. |

| Dasmesh 610 no-tillage planter [171] | Strip-type back spread of chopped straw |  | Chopped straw was transferred by drainage plate to back of opener, MP 37.31–44.78 kW. |

| Type | Structure | Technical Characters |

|---|---|---|

| 1GZMH-type straw chopping and mixing machine [188] |  | Straw and stubble were chopped and evenly mixed with soil at one time, the exposure rate of straw and root stubble ≤ 5%. |

| Straw returning and stubble cleaning combined soil preparation machine [189] |  | Straw chopping and returning, stubble cutting, and mixed with soil operations can be completed at one time, MP 59.6–163.9 kW, WE 15–30 hm2/h. |

| Double shaft-type straw returning machine combined with rotary tillage [190] |  | For vertical or laid corn, cotton, and other straws, straw and stubble chopping and rotary mixing and burying operations were completed at one time; MP 37.3–96.98 kW. |

| 1JHM-165 straw and stubble chopping and returning machine [191] |  | Functions: straw chopping, stubble cleaning, mixed and buried with soil, RV of chopped blade 2100 r/min, RV of stubble cleaning blade 500 r/min, MP 60–70 kW. |

| 1GKF-200 straw returning machine combined with rotary tillage [192] |  | Suitable for straw of rice, maize, cotton, and sorghum, qualified rate of crop straw chopping length ≥ 93%. |

| Combined machine for land preparation and full straw returning [193] |  | The operations of crop straw chopping, stubble cleaning, and layered straw and stubble buried, MP 52.15–223.5 kW. |

| SGTN-350 combined machine for stubble cleaning and land preparation [194] |  | Stubble chopping and rotary tillage and burying operations were completed at one time, WW 3500 mm, MP 134.1–171.35 kW. |

| Straw chopping machine for mixed-burying or covering [195] |  | Part chopped straw mixed with soil and another part straw mulched on field surface, WW 1836 mm, MP 80–120 kW. |

| Rice straw chopping and mixing combined operation machine [196] |  | At the same time, the chopping and mixing with soil of rice straw was completed, distance between chopping device and mixing device was adjusted. |

| Crop Straw Chopped Devices | Advantages | Limitations |

|---|---|---|

| Chopped machines | Simple structure and easy to maintain; widely used; high chopping quality | Low operational speed |

| Chopped device combined with no/reduced tillage seeder | Enhance the seeder’s ability to operate in fields with residue and prevent crop residues from clogging the seeder; multifunctional operation | Enhancement of straw chopping quality is required. |

| Chopping and ditch-burying machine | Accelerate the decomposition rate of straw; create a favorable seeding environment | High energy consumption; exacerbated plow pan formation; and soil structure disruption |

| Chopping and mixing machine | Accelerate the decomposition rate of straw; high chopping quality | Exacerbated plow pan formation and soil structure disruption |

| Chopped device powered by combined harvester | Multifunctional operation; lower the frequency of machine passes and reduce operational costs; suitable for chopping straw from various crops | Complex structure and high individual machine cost |

| Version | Type | Structure | Characters |

|---|---|---|---|

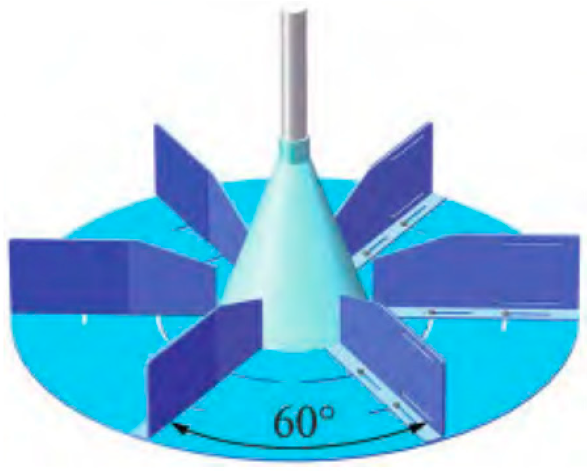

| 4JH-168 straw chopping and returning machine [220] | Guiding vane |  | Six guiding vanes installed symmetrically, deflection angle of guiding vane (DAGV) < 25°, rotated up and down around the pin shaft. |

| 4JQ straw chopping and spreading machine [221] | Guiding vane |  | Six guiding vanes installed symmetrically, high spreading area, DAGV < 35°. |

| 4JQM-300 straw chopping and returning machine [222] | Fan-generated wind-powered conveying pipe |  | Installed on the side of the machine, high initial spreading velocity of chopped straw, WW 3000 mm. |

| 4SJ-180 straw chopping machine [223] | Fan-generated wind-powered conveying pipe |  | Installed in the middle of the machine, rear overhead fan conveying, rotational speed of convey auger 800 r/min. |

| 1JH straw chopping and spreading machine [224] | Spreading disc |  | Special-shaped fans installed on the disc, high initial speed, and spreading area of chopped straw. |

| S780 combined harvester [225] | Spreading disc |  | Spreading width 9.14~13.72 m, double-layer spreading disc, adjustable rotational speed. |

| CX7 combined harvester [226] | Spreading disc |  | Evenly thrown by the positive pressure airflow generated by the high-speed rotational chopped blade. |

| Axial-Flow combined harvester [227] | Spreading disc |  | Double spreading discs, adjust the opening and closing distance of the throwing mouth by electronic control. |

| Avero 240 combined harvester [228] | Guiding vane |  | Adjustable spreading velocity of chopped straw and adjustable position of guiding vane. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Song, C.; He, J.; Li, R.; Cheng, M.; Zhang, C.; Li, Q.; Zhang, H.; Wang, M. Research and Overview of Crop Straw Chopping and Returning Technology and Machine. Machines 2025, 13, 564. https://doi.org/10.3390/machines13070564

Liu P, Song C, He J, Li R, Cheng M, Zhang C, Li Q, Zhang H, Wang M. Research and Overview of Crop Straw Chopping and Returning Technology and Machine. Machines. 2025; 13(7):564. https://doi.org/10.3390/machines13070564

Chicago/Turabian StyleLiu, Peng, Chunyu Song, Jin He, Rangling Li, Min Cheng, Chao Zhang, Qinliang Li, Haihong Zhang, and Mingxu Wang. 2025. "Research and Overview of Crop Straw Chopping and Returning Technology and Machine" Machines 13, no. 7: 564. https://doi.org/10.3390/machines13070564

APA StyleLiu, P., Song, C., He, J., Li, R., Cheng, M., Zhang, C., Li, Q., Zhang, H., & Wang, M. (2025). Research and Overview of Crop Straw Chopping and Returning Technology and Machine. Machines, 13(7), 564. https://doi.org/10.3390/machines13070564