Abstract

Gas turbines play a crucial role in power generation and aviation, where effective maintenance strategies are essential to ensure reliability. Traditional condition monitoring methods often rely on scheduled inspections, leading to potential downtime and increased maintenance costs. This study presents an AI-driven approach for thermal condition monitoring and the predictive maintenance of gas turbines using machine learning. An Extreme Gradient Boosting (XGBoost)-based classification model was developed to distinguish between healthy and faulty operating conditions based on thermal load data. The dataset, collected over six months from strategically placed thermocouples in the exhaust gas section, was processed to extract key statistical features such as mean temperature, standard deviation, and skewness. The proposed XGBoost model achieved a classification accuracy (CA) of 97.2%, with an F1-score of 96.8%, precision of 97.5%, and recall of 96.1%, demonstrating its effectiveness in detecting anomalies. The results indicate that the integration of machine learning in gas turbine monitoring significantly enhances fault detection capabilities, enabling proactive maintenance strategies and reducing the risk of critical failures. This study provides valuable insights for data-driven maintenance strategies, optimizing operational efficiency and extending the lifespan of gas turbine components. Future work will focus on real-time deployment and further validation with extended datasets.

1. Introduction

1.1. Background and Motivation

Gas turbines are essential components in various industrial applications, particularly in power generation, aviation, and manufacturing [1,2,3]. Their ability to operate efficiently at high power levels makes them of critical value to power generation and propulsion equipment [4,5,6]. The severe mechanical and thermal stresses that result upon operation, however, are of great challenge to the reliability, longevity, and performance of the component [7,8,9,10,11,12,13,14]. The hottest component of a gas turbine, including items such as turbine blades and vanes, is most susceptible to thermal degradation and fatigue, which makes effective monitoring and servicing critical [15].

The increasing complexity of modern gas turbines has led to a greater emphasis on condition monitoring and predictive maintenance to ensure their continued efficiency and safe operation [16,17]. Traditional maintenance activities such as preventive maintenance on schedule and reactive repairs also result in unnecessary costs, unplanned downtime, and safety risks [18,19,20,21,22,23,24]. The use of pre-established plans rather than actual operating conditions makes such processes ineffective in detecting defects that are early-stage. Industries are, hence, switching to data-driven maintenance strategies that employ sensor-based monitoring along with computational techniques to perform informed decision making on maintenance [25,26].

In recent years, the integration of machine learning and artificial intelligence (AI) techniques has revolutionized asset management and fault detection in industrial systems [27,28]. AI-driven models, particularly those focused on predictive analytics, enable the early identification of anomalies based on real-time operational data. By analyzing key parameters such as temperature fluctuations, pressure variations, and operational loads, these models can enhance fault detection accuracy and support proactive maintenance planning. This shift towards AI-assisted monitoring aligns with the growing demand for reliable, cost-effective, and sustainable maintenance solutions in industries that rely on gas turbines. This study explores the role of machine learning-based classification models in gas turbine thermal condition monitoring and predictive maintenance. By leveraging AI-driven techniques, it aims to improve fault detection capabilities, minimize operational risks, and contribute to the advancement of intelligent maintenance strategies

1.2. Challenges in Traditional Maintenance Approaches

Traditional maintenance strategies for gas turbines have largely relied on scheduled preventive maintenance and reactive maintenance. Preventive maintenance follows a fixed time-based schedule, assuming that components degrade predictably over time. While this approach helps mitigate catastrophic failures, it often results in unnecessary maintenance actions that increase operational costs without necessarily improving efficiency. On the other hand, reactive maintenance is performed only after a failure occurs, which can lead to unexpected downtimes and costly repairs. These conventional strategies are often ineffective in addressing early-stage faults, as they fail to consider real-time turbine health conditions which is suboptimal for modern industrial applications.

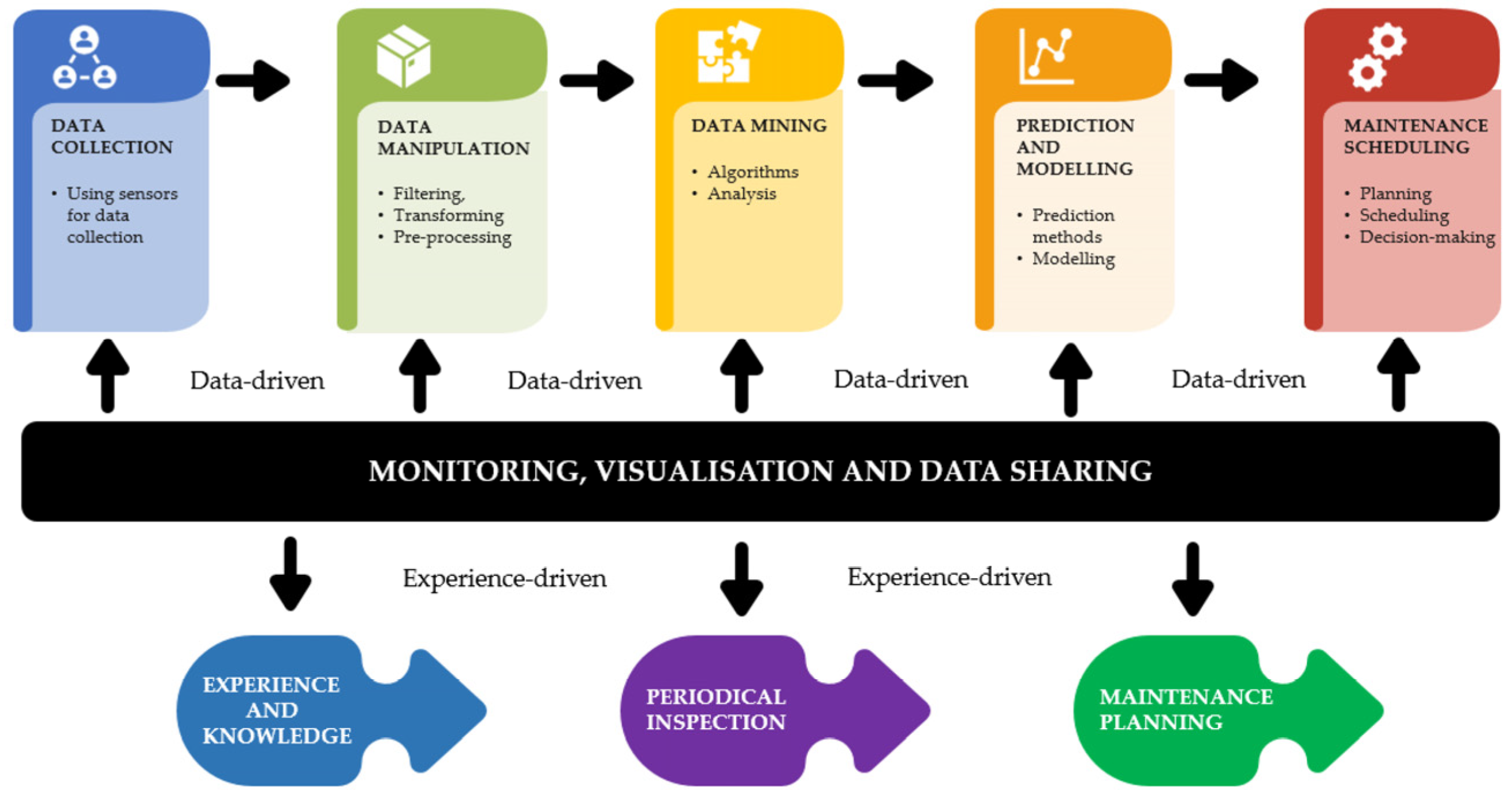

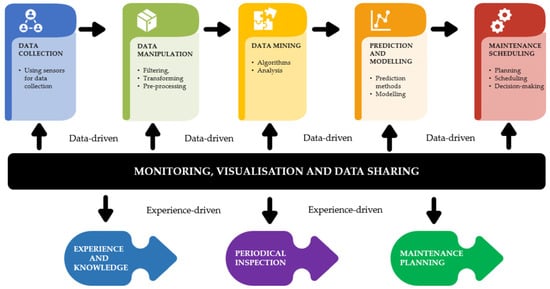

To overcome these limitations, industries have shifted toward predictive maintenance, which leverages sensor-based condition monitoring and data-driven fault diagnosis. Predictive maintenance utilizes real-time operational data, such as temperature, pressure, and vibration signals, to detect anomalies before a critical failure occurs. As shown in Figure 1, predictive maintenance schemes integrate advanced diagnostics to provide accurate fault detection and optimized maintenance planning. This proactive approach minimizes downtime, reduces maintenance costs, and enhances the overall reliability and efficiency of gas turbines. However, the effectiveness of predictive maintenance depends on the robustness of the underlying fault classification models that highlight the need for advanced AI-driven solutions to further improve accuracy and adaptability.

Figure 1.

Predictive maintenance scheme [29].

1.3. Literature Review

The application of artificial intelligence (AI) and machine learning (ML) techniques in any application of interest [30,31,32], and specifically in gas turbine condition monitoring and predictive maintenance, has gained considerable attention in recent years. Researchers have developed various AI-based models to enhance fault detection accuracy, optimize maintenance planning, and improve turbine reliability. The integration of deep learning, neural networks, hybrid models, and ensemble techniques has enabled more efficient and automated fault diagnosis. A summary of key studies exploring AI-driven approaches for gas turbine fault detection and diagnostics is provided in Table 1.

Table 1.

AI-based approaches for gas turbine condition monitoring and fault diagnosis.

Recent research has demonstrated significant advancements in AI-driven predictive maintenance for gas turbines (Table 1). Early studies focused on statistical and thermodynamic models to assess turbine health, but these approaches often required predefined failure conditions and extensive domain knowledge. With the rise in machine learning, researchers have developed data-driven models that leverage sensor data to enhance fault detection and anomaly prediction. Several studies have proposed deep learning architectures, such as autoencoders, convolutional neural networks (CNNs), and long short-term memory (LSTM) networks, to automatically extract features and classify turbine conditions. Hybrid approaches integrating neural networks with clustering techniques, genetic algorithms, or self-organizing maps (SOMs) have been introduced to improve fault classification accuracy and reduce false alarms. Additionally, ensemble methods combining multiple AI models have been explored to enhance anomaly detection in combustion chambers and other turbine components.

Despite the progress in AI-based fault diagnosis, the existing methods exhibit variability in accuracy, computational complexity, and real-time implementation feasibility. Some approaches rely on historical failure data, making them less effective for detecting early-stage anomalies. Others require extensive feature engineering, increasing the computational cost and limiting adaptability to different turbine configurations. Furthermore, most studies focus on general fault detection without specifically addressing thermal condition monitoring based on exhaust gas temperature variations. The effectiveness of XGBoost classification, a powerful gradient boosting technique, remains underexplored in this context.

1.4. Research Gap and Novelties

Despite significant advancements in AI-driven predictive maintenance, the existing studies primarily focus on general fault detection rather than thermal condition monitoring based on exhaust gas temperature variations. Many approaches rely on historical failure data, limiting their ability to detect early-stage anomalies in real time. Additionally, while deep learning and neural networks have been extensively explored, gradient boosting techniques such as XGBoost remain underutilized in gas turbine fault classification. The need for high-accuracy, computationally efficient, and adaptable models for thermal load-based fault detection in gas turbines presents a critical research gap. The novelties are summarized within the following points:

- Implementation of XGBoost for gas turbine fault detection: This study introduces XGBoost classification to distinguish between healthy and faulty conditions based on thermal load variations, optimizing predictive maintenance strategies.

- Integration of statistical feature extraction from exhaust gas temperature data: The model leverages standard deviation, and skewness to enhance fault classification accuracy without requiring extensive labeled failure datasets.

- Comparative evaluation with conventional predictive maintenance approaches: The proposed method is evaluated against traditional condition monitoring techniques, demonstrating its superior performance in early-stage fault detection and real-time adaptability.

2. Experimental Work

In order to evaluate the thermal behavior of gas turbine hot section components under real operating conditions, a comprehensive experimental study was carried out using an operational thermal dataset collected over six months [43]. The primary focus was on monitoring the exhaust gas temperature (EGT) at the outlet of the Low-Pressure Turbine (LPT), a critical parameter for diagnosing potential thermal stress-induced damage in gas turbines.

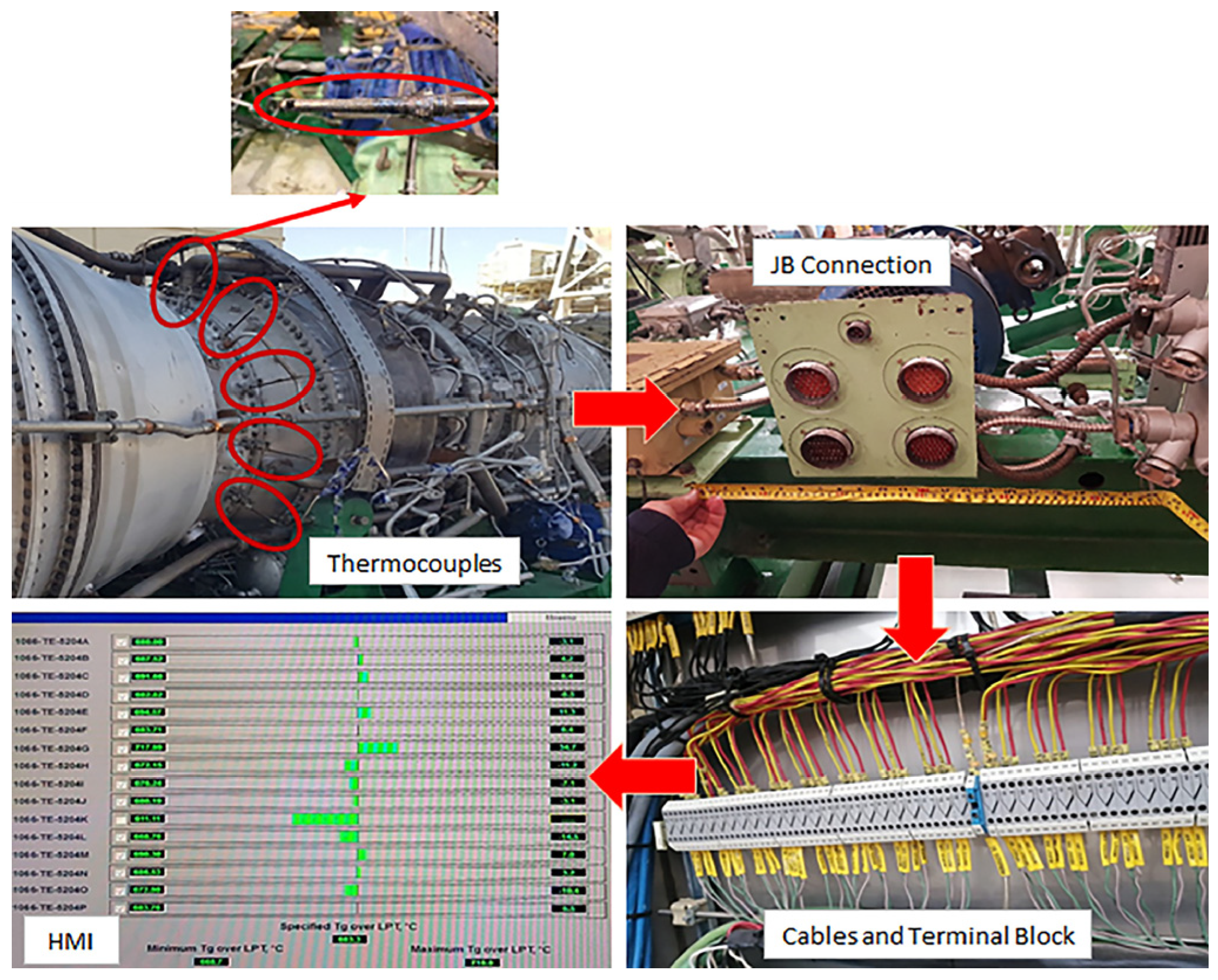

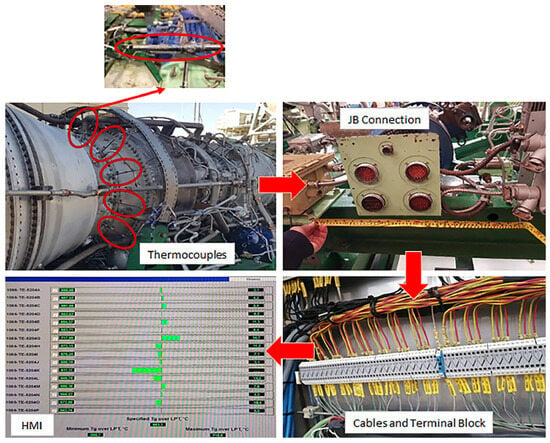

The experimental setup involved the installation of sixteen K-type thermocouples, which were distributed at strategic positions along the turbine’s exhaust system. These sensors were responsible for continuously measuring the EGT and transmitting the data through a Junction Box (JB) and connecting terminals to a Human–Machine Interface (HMI) located in the turbine control room. The HMI system displayed and logged the temperature readings at one-second intervals, which allowed for the continuous observation of thermal patterns across the turbine’s hot section. The specifications of the thermocouples are described in Table 2. The measurement and transmission process are illustrated in Figure 2.

Table 2.

Thermocouple specifications used in the experimental setup.

Figure 2.

Thermal data acquisition process from thermocouples mounted on the gas turbine [43].

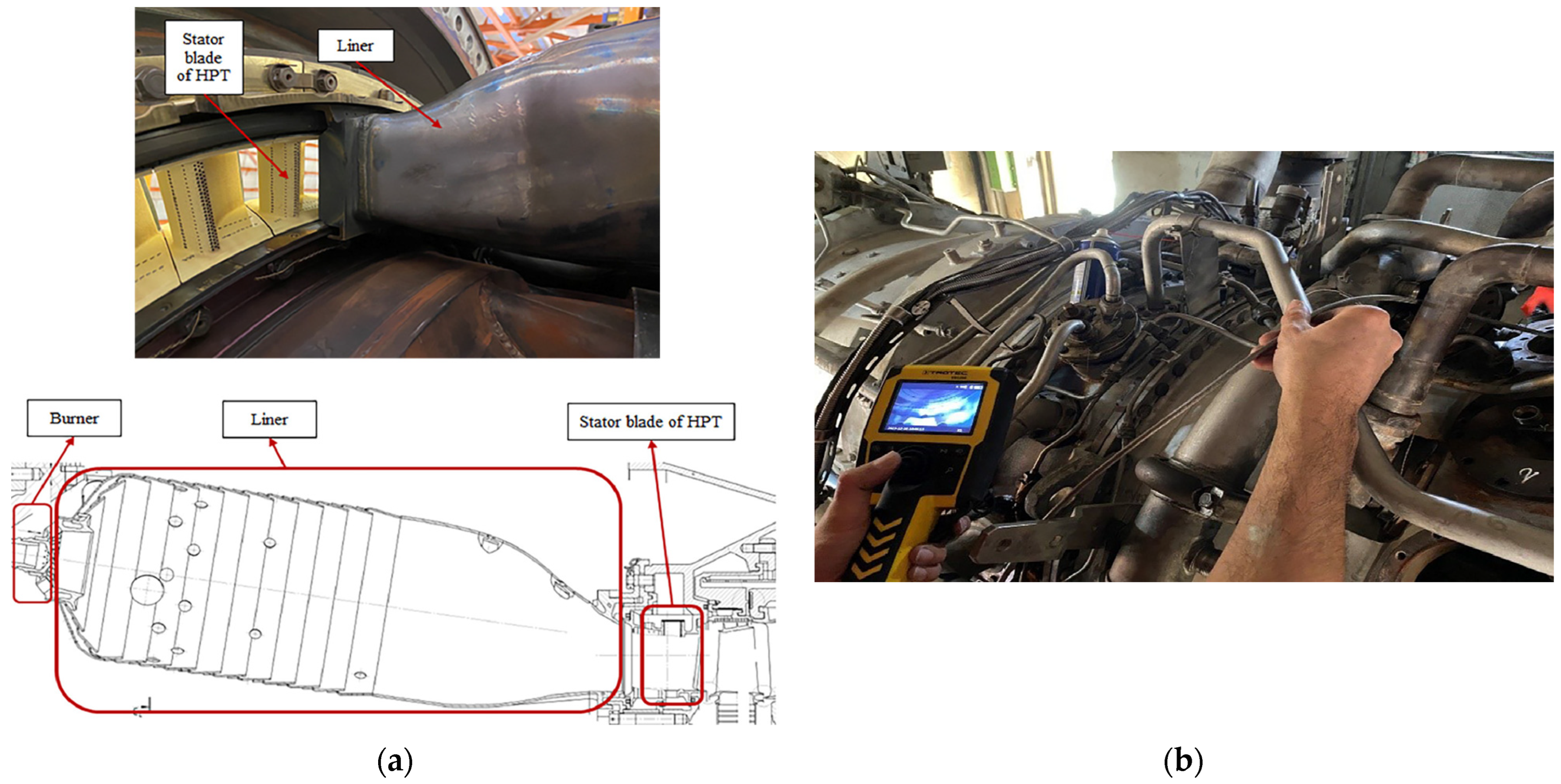

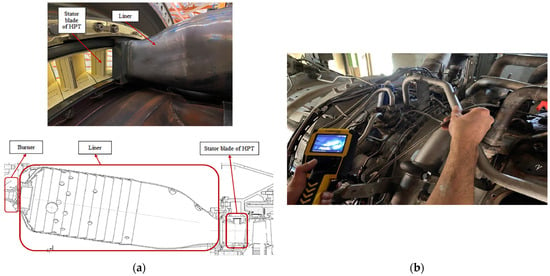

To validate the thermal measurements and identify any physical signs of deterioration in the turbine’s hot components, borescope inspections were conducted at three scheduled operational milestones: 2000, 4000, and 6000 h. These inspections targeted critical zones of the turbine, including the liners and stator blades of the High-Pressure Turbine (HPT). The regions selected for visual inspection are shown in Figure 3, with Figure 3a highlighting the liner section and Figure 3b detailing the stator blades.

Figure 3.

Borescope inspection zones in the gas turbine hot section: (a) liner region selected for visual inspection; (b) stator blades of HPT selected for condition assessment [43].

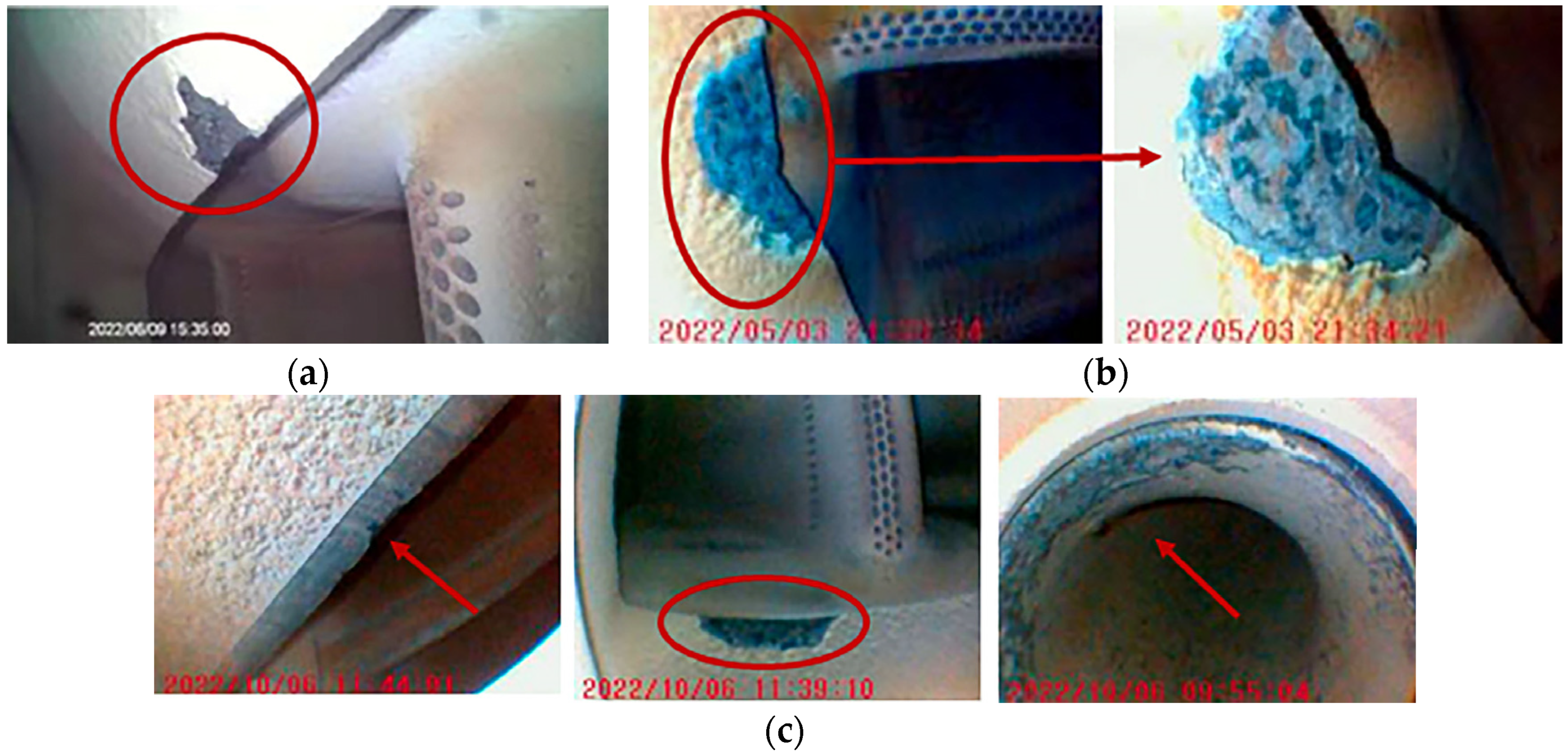

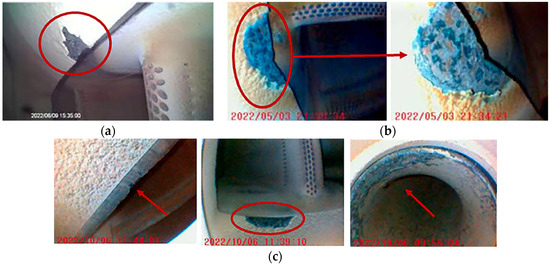

The borescope system used was equipped with a compact, high-resolution camera mounted on a flexible probe. The device was inserted into the hot section through an access port after burner disassembly. A bright LED light at the tip of the probe enabled clear visual feedback for capturing detailed images and videos of the internal surfaces. As shown in Figure 4, the inspection results revealed a progressive increase in coating damage on the stator blades and liners over time. Figure 4a corresponds to the 2000 h inspection, where minor coating wear was observed. Figure 4b shows the 4000 h findings which indicate more pronounced damage. Finally, Figure 4c illustrates the 6000 h inspection, where the deterioration had expanded across a wider area.

Figure 4.

Borescope inspection results at different turbine operation hours: (a) minor coating damage observed at 2000 h inspection; (b) increased deterioration during the 4000 h inspection; (c) extensive coating degradation at 6000 h inspection [43].

The experimental evidence unequivocally emphasizes the relationship between the prolonged operation of the turbine and thermal wear in the most vulnerable components. Integrating the real-time monitoring of the temperature with periodic visual inspections forms the sound basis for the detection of incipient faults and the determination of thermal damage development. This database provides a useful basis for the development of fault classification models by using AI in the following stages of the work.

3. Machine Learning Approach

Machine learning has become an essential tool across various engineering and scientific fields because it offers powerful capabilities for automated decision making in complex systems [44,45,46,47].

In this study, the Extreme Gradient Boosting (XGBoost) algorithm is adopted as the core classification model for evaluating the thermal condition of gas turbines. XGBoost is an advanced implementation of gradient boosting machines that integrate regularization techniques, parallel processing, and tree pruning strategies to deliver high accuracy and robust generalization performance [48,49]. XGBoost was developed by Tianqi Chen and his collaborators as part of a specific project [50]. This algorithm is particularly used for structured data applications such as industrial fault detection [51]. At its core, XGBoost builds an ensemble of K decision trees, each of which contributes incrementally to the final prediction. The model prediction for a given input xi is defined as follows [52]:

Here, each is a function corresponding to a regression tree in the functional space F. The learning process aims to minimize an objective function that combines a training loss term with a regularization term [52]:

The first term evaluates the difference between the predicted and actual values through a differentiable loss function l, while the second term Ω() penalizes model complexity to reduce overfitting. This balance allows XGBoost to perform well on high-dimensional and noisy datasets. In this study, specific training parameters were chosen on the basis of the discussed literature and a try-error scheme, and these selections are enlisted in Table 3 below.

Table 3.

XGBoost proposed and adopted parameters.

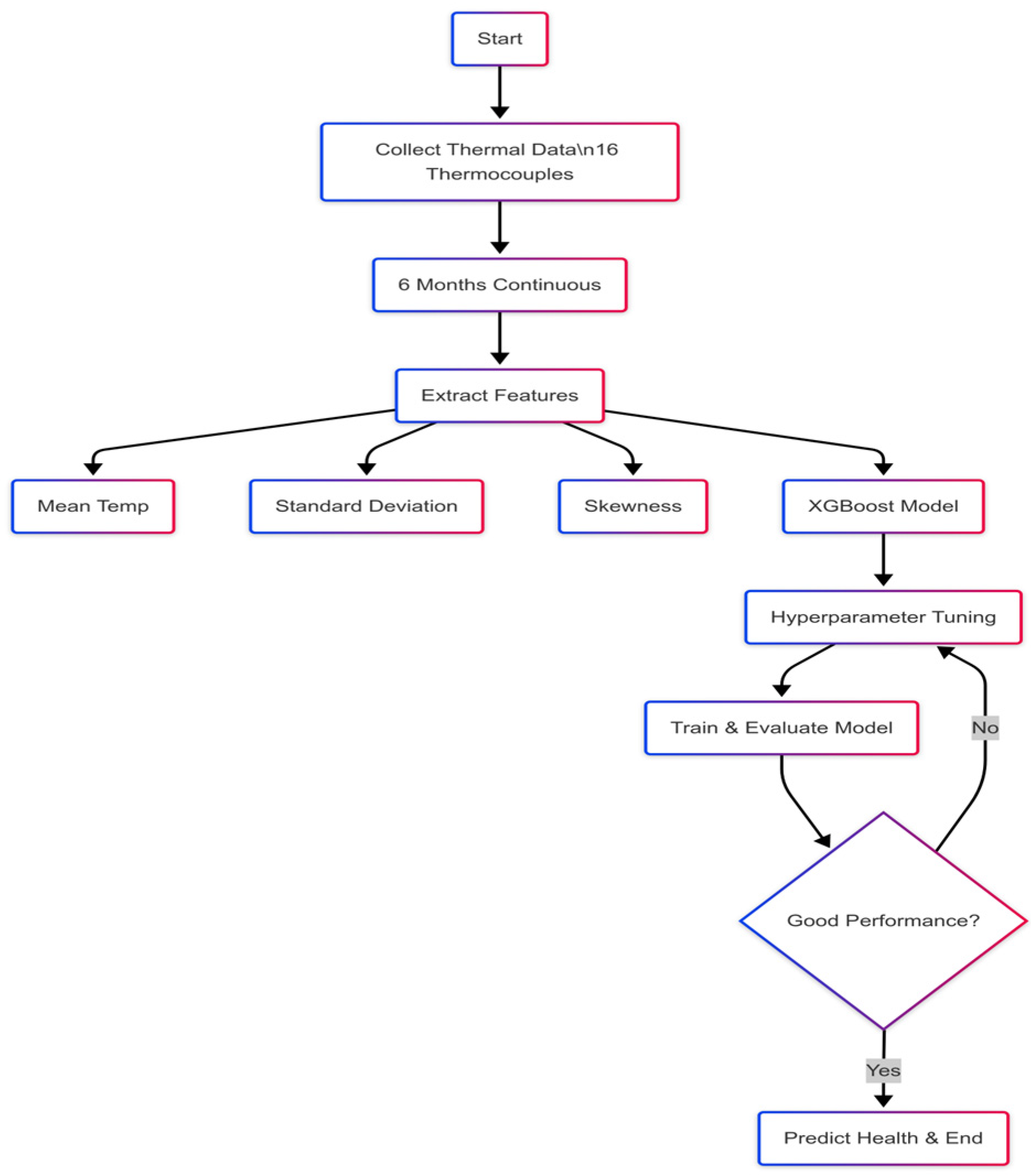

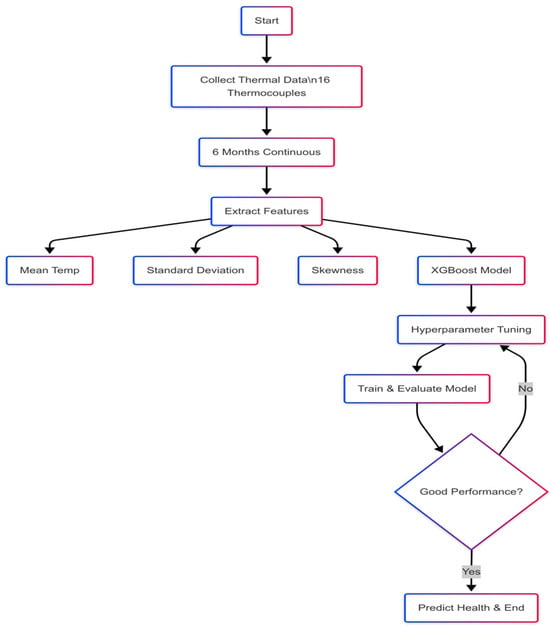

To assess the turbine’s thermal condition, features such as mean temperature, standard deviation, and skewness were extracted from the time-series data collected by the thermocouples. The feature-labeled dataset was further split into training and test subsets and the XGBoost classifier was trained to discriminate between healthy and fault conditions. Precision, recall, F1-score, and classification accuracy were evaluated as the performance measures of the model. To provide a clear picture of the whole process pursued in this work—from the acquisition and feature extraction from the data to classification and analysis—a schematic diagram is shown in Figure 5. The process is optimized for fault detection within turbines using the thermal sensor data, from acquiring the data from the 16 thermocouples for six months to moving on to feature extraction and further on to developing the model using the XGBoost. After hyperparameter tuning and training evaluation, the system tests the performance of the model, and if satisfactory, makes a prediction regarding the health condition of the turbine that closes the loop. The system has intelligent re-tuning enabled by intelligent branching.

Figure 5.

Schematic diagram of the proposed methodology.

To identify the abnormal instances from the temperature values, the Isolation Forest (IF) is used [53]. IF detects anomalies by how easily a data point can be separated from others. It builds random binary trees by selecting random features and split values, and isolates points by recursively dividing the space. Anomalies, being few and different, tend to be isolated quickly—resulting in shorter average path lengths. This is quantified by the average path length , which is normalized using the expected average path length of a random binary tree , where (the harmonic number approximation). The final anomaly score is calculated as follows [53]:

Higher scores near 1 indicate anomalies, while lower scores near 0 signal normality. To visualize the results, the next section is utilized.

4. Results and Discussion

4.1. Experimental Results and Temperature Visualization

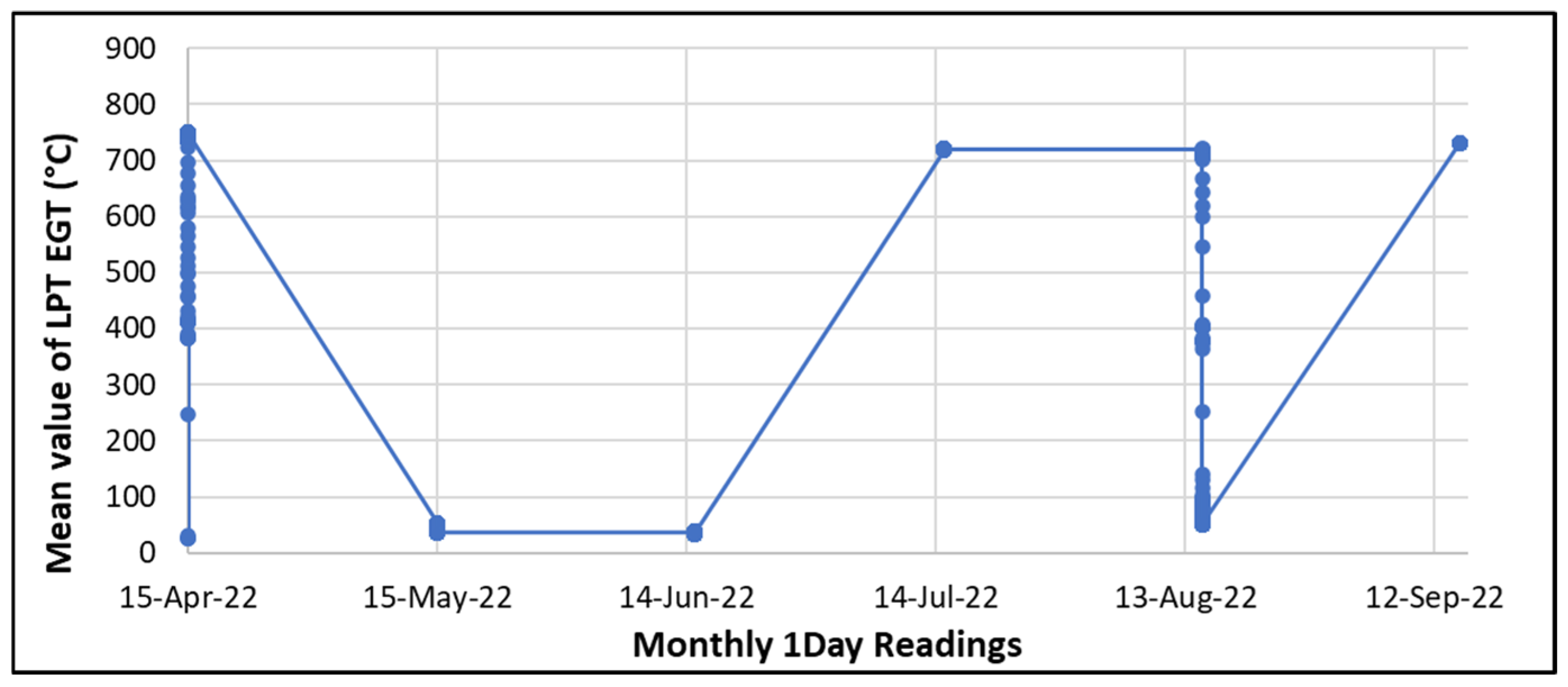

The thermal data collected for this study spanned a period from April to September, with data acquisition carried out on the 15th day of each month. On each selected day, approximately 750 readings were randomly sampled throughout the turbine’s operating hours, resulting in a total of around 8000 readings over six months. The raw readings represent the mean LPT EGT derived from 16 thermocouples. These values were processed into statistical intervals of 10 readings, producing 800 intervals in total. This approach facilitated the calculation of trend indicators such as mean, standard deviation, and skewness for each interval. To differentiate between healthy and faulty operational conditions, the IF algorithm was applied for unsupervised anomaly detection. A detailed discussion of the machine learning classification results is provided in the next subsection.

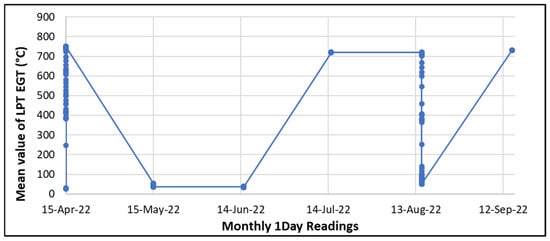

The temporal trend of exhaust gas temperatures on each sampled day is illustrated in Figure 6. The plot reveals substantial variability across the months, reflecting the dynamic thermal behavior of the turbine under differing operational loads. In April, most values are clustered between 700 °C and 770 °C, with one outlier dropping below 100 °C, likely corresponding to a transient or cooldown phase. A significant drop is observed in May and June, where the temperature readings stabilize around 33 °C, indicating either non-operational phases or idling conditions. A sharp rise occurs in July, returning to a consistent range near 720–750 °C, which persists through August and September. Notably, August also exhibits a broader spread, including readings below 300 °C, suggesting transitional states or start-up/shutdown sequences during the sampling day. This figure confirms that the turbine did not operate under consistent thermal conditions across the selected dates, underlining the need for further statistical decomposition and anomaly detection through advanced analysis techniques.

Figure 6.

Monthly one-day readings of mean LPT EGT over a six-month period.

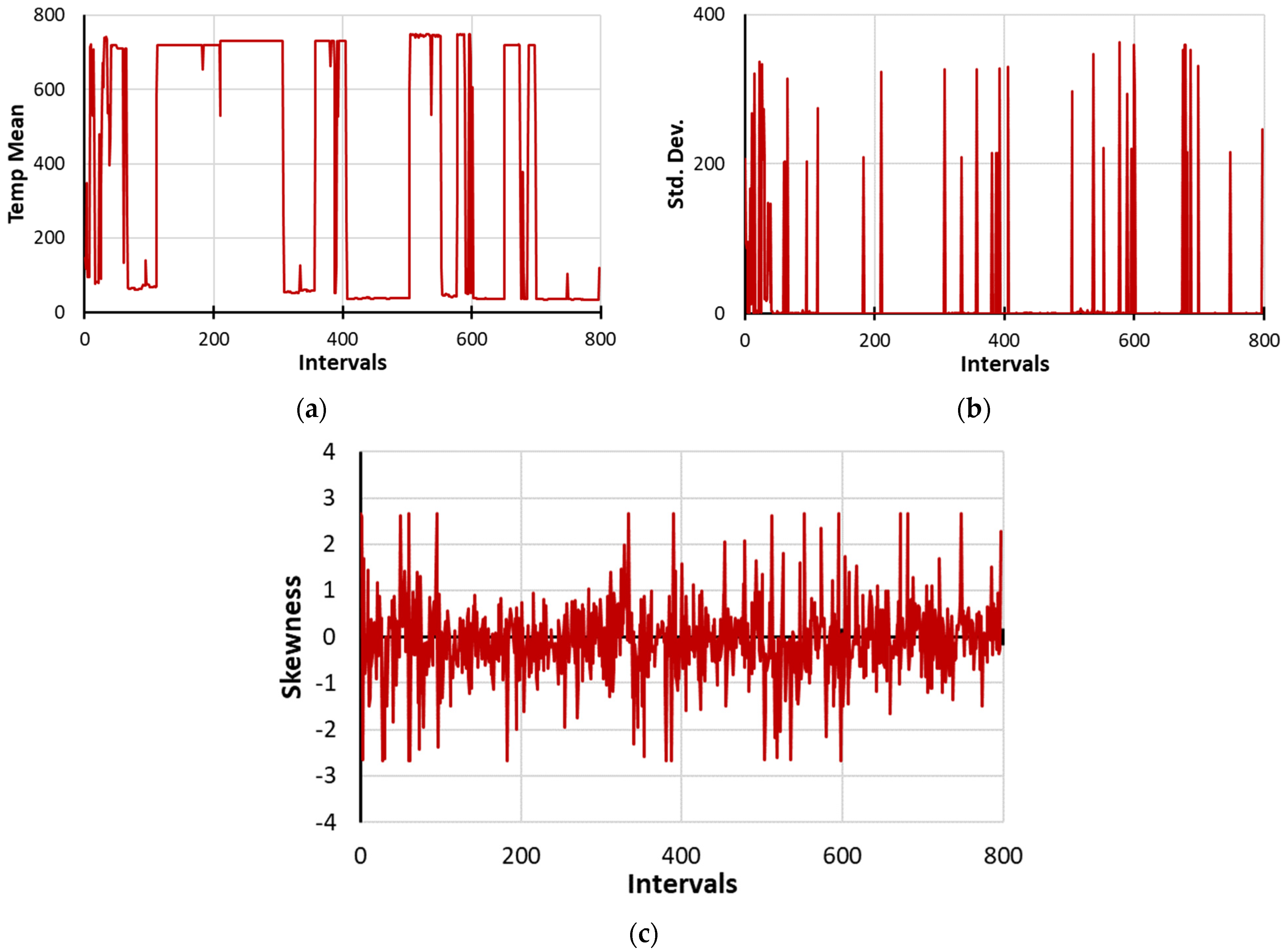

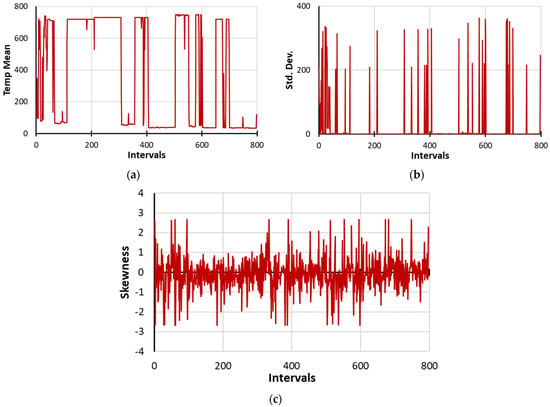

The statistical analysis of the 800 processed intervals is summarized in Figure 7, which presents the evolution of three key indicators: mean temperature, standard deviation, and skewness. These statistical descriptors provide insight into both thermal consistency and anomalous patterns that may be indicative of developing faults. As illustrated in Figure 7a, the mean temperature values fluctuated significantly across the intervals, ranging from a low of 33.60 °C to a peak of 748.97 °C. These values reflect the turbine’s transition through various operational phases, including idle, startup, full-load, and shutdown. Most of the higher temperature clusters were concentrated in the 600–750 °C range, correlating with active combustion and peak-load operation. The lower range reflects either transient conditions or data points during early-stage or cool-down operation phases.

Figure 7.

Progressed statistical analysis for each interval: (a) temperature mean value; (b) standard deviation; (c) Skewness.

The standard deviation analysis shown in Figure 7b demonstrates a substantial variation in the degree of thermal fluctuation among intervals. Standard deviation values ranged from as low as 0.0133, indicating near-steady temperature behavior, to as high as 362.33, which reveals severe thermal volatility. Intervals with such high deviation may correspond to load cycling, abrupt operational changes, or sensor disturbances—factors that can contribute to mechanical stress in the hot sections of the turbine. Notably, a concentration of intervals in the 100–200 range suggests routine fluctuations that still warrant continuous monitoring. In Figure 7c, the skewness distribution offers further insight into the symmetry of the temperature profiles. The skewness values range from −2.67 (left-skewed) to +2.67 (right-skewed), indicating that some intervals exhibited a strong tendency toward either abnormally high or low temperature readings. A left-skewed distribution reflects a clustering of higher temperature values, potentially signaling overheating or local hot spots, while right-skewed intervals suggest dominant cooler periods, possibly linked to irregular load conditions. Skewness values close to zero reflect balanced operation, while extreme skewness may indicate emerging faults or irregular combustion behavior.

To establish the connection between statistical anomalies and actual component degradation, the thermally abnormal intervals detected by the IF were compared against borescope inspection results. These inspections, conducted at 2000, 4000, and 6000 h of operation, revealed progressive coating damage on the HPT stator blades and liners. Intervals with extreme skewness or unusually high standard deviation (e.g., >300) coincided with these operational periods, reinforcing the validity of treating such thermal behavior as early indicators of incipient faults. Thus, abnormal intervals in this study are defined statistically and through their indirect association with observed physical wear which helped to establish a data-driven bridge between anomaly detection and component health.

4.2. Machine Learning Results

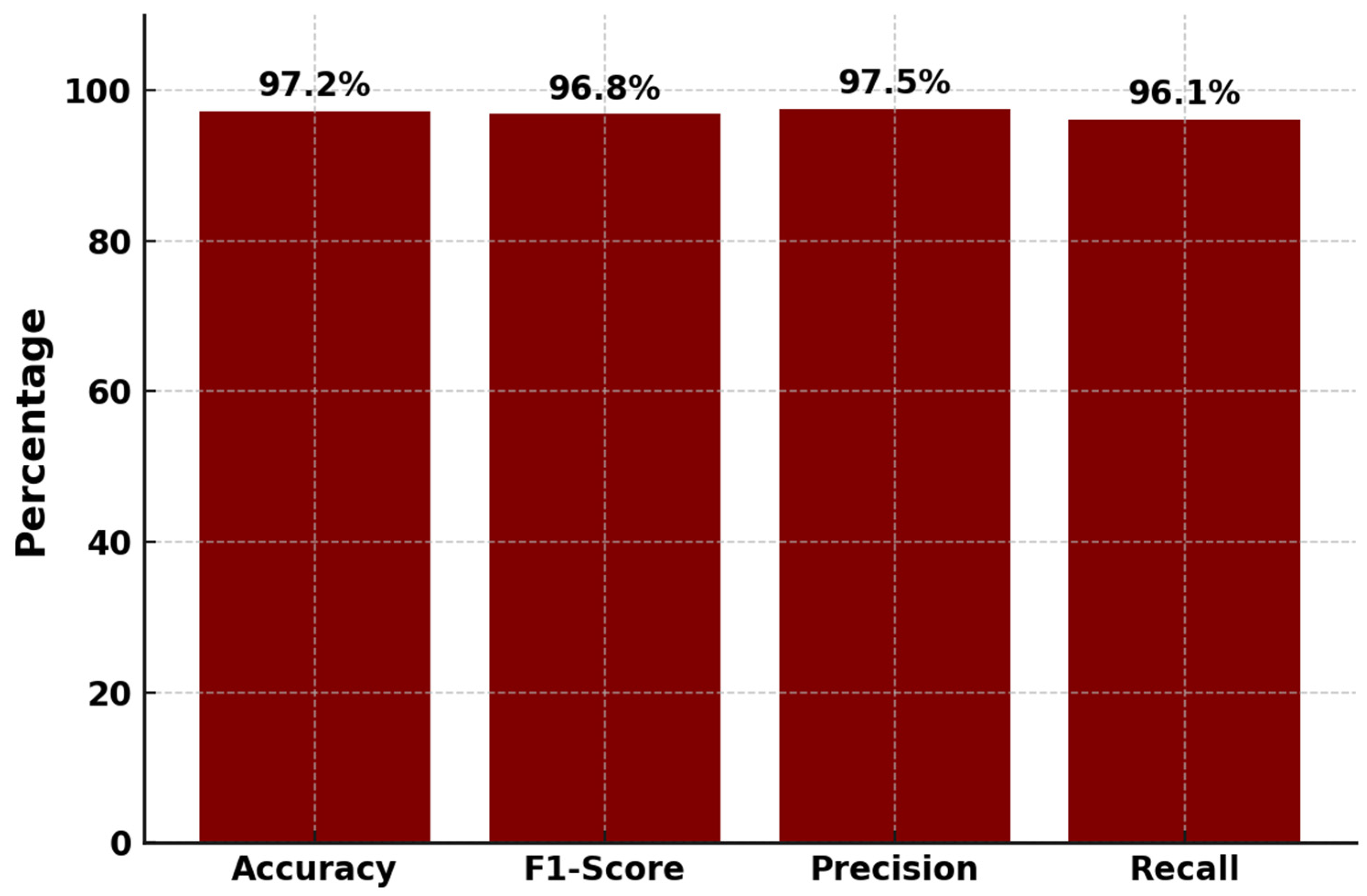

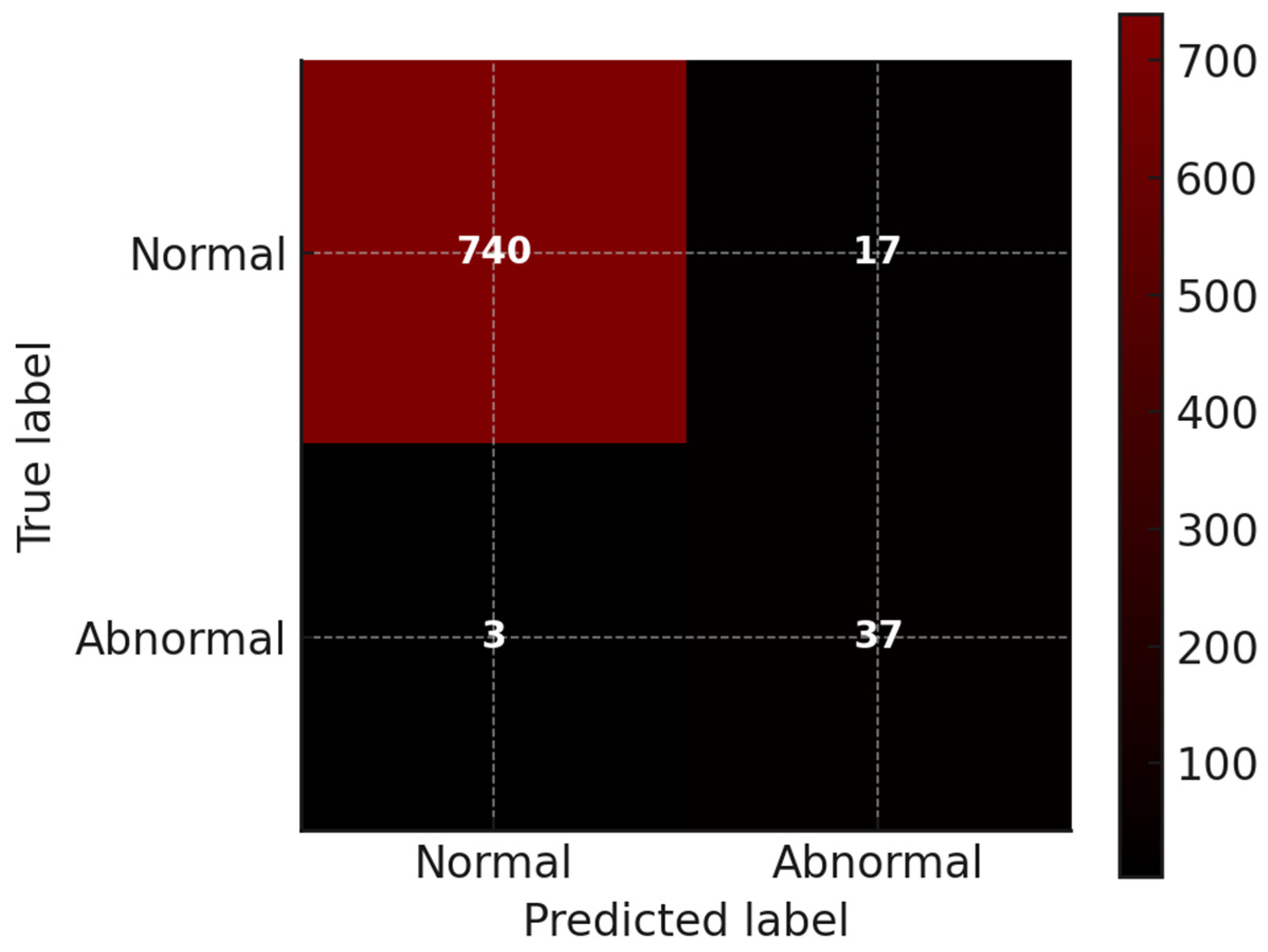

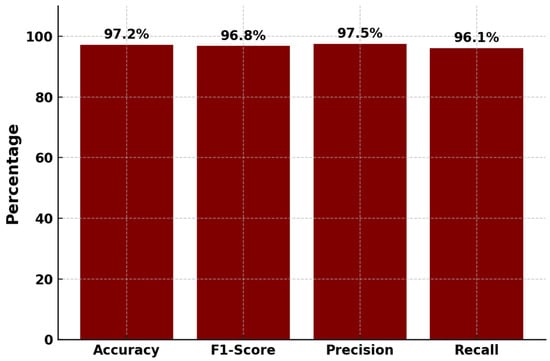

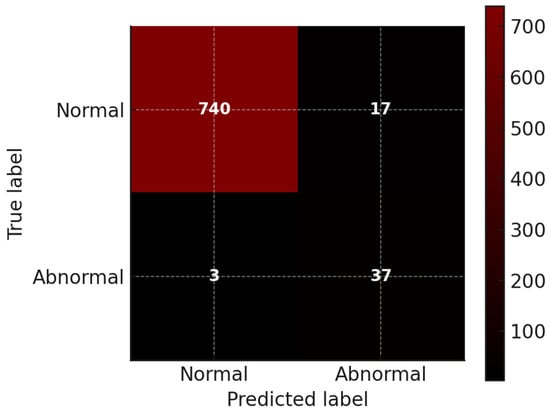

To evaluate the effectiveness of the XGBoost classifier in detecting abnormal thermal conditions in the gas turbine, a series of performance metrics and visualizations were produced. These provide a quantitative and qualitative assessment of the model’s ability to distinguish between healthy and faulty operating intervals. Figure 8 presents the assessment metrics of the XGBoost classification model used for thermal condition monitoring. The model achieved a classification accuracy (CA) of 97.2%, which reflects its excellent overall performance. The F1-score reached 96.8% and indicated a strong balance between precision and recall. Precision, which measures the proportion of correctly identified abnormal intervals out of all the predicted abnormal cases, was 97.5%. Meanwhile, the recall value of 96.1% demonstrated the model’s capability to correctly identify most actual abnormal cases. These values collectively suggest that the XGBoost algorithm provides highly reliable and consistent predictions to minimize both false alarms and missed detections. Figure 9 shows the confusion matrix for the final classification results. Out of 797 intervals, the model correctly identified 740 normal intervals and 37 abnormal intervals and corresponded to the true negatives and true positives, respectively. Only 17 normal intervals were incorrectly classified as abnormal (false positives), and 3 abnormal intervals were misclassified as normal (false negatives). These minimal misclassification counts validate the high precision and recall values and demonstrate the robustness of the model, especially given the class imbalance between the normal (757) and 40 abnormal cases.

Figure 8.

Performance metrics of the XGBoost classification model used for thermal condition monitoring.

Figure 9.

Confusion matrix of the XGBoost classifier for classifying healthy and faulty thermal intervals.

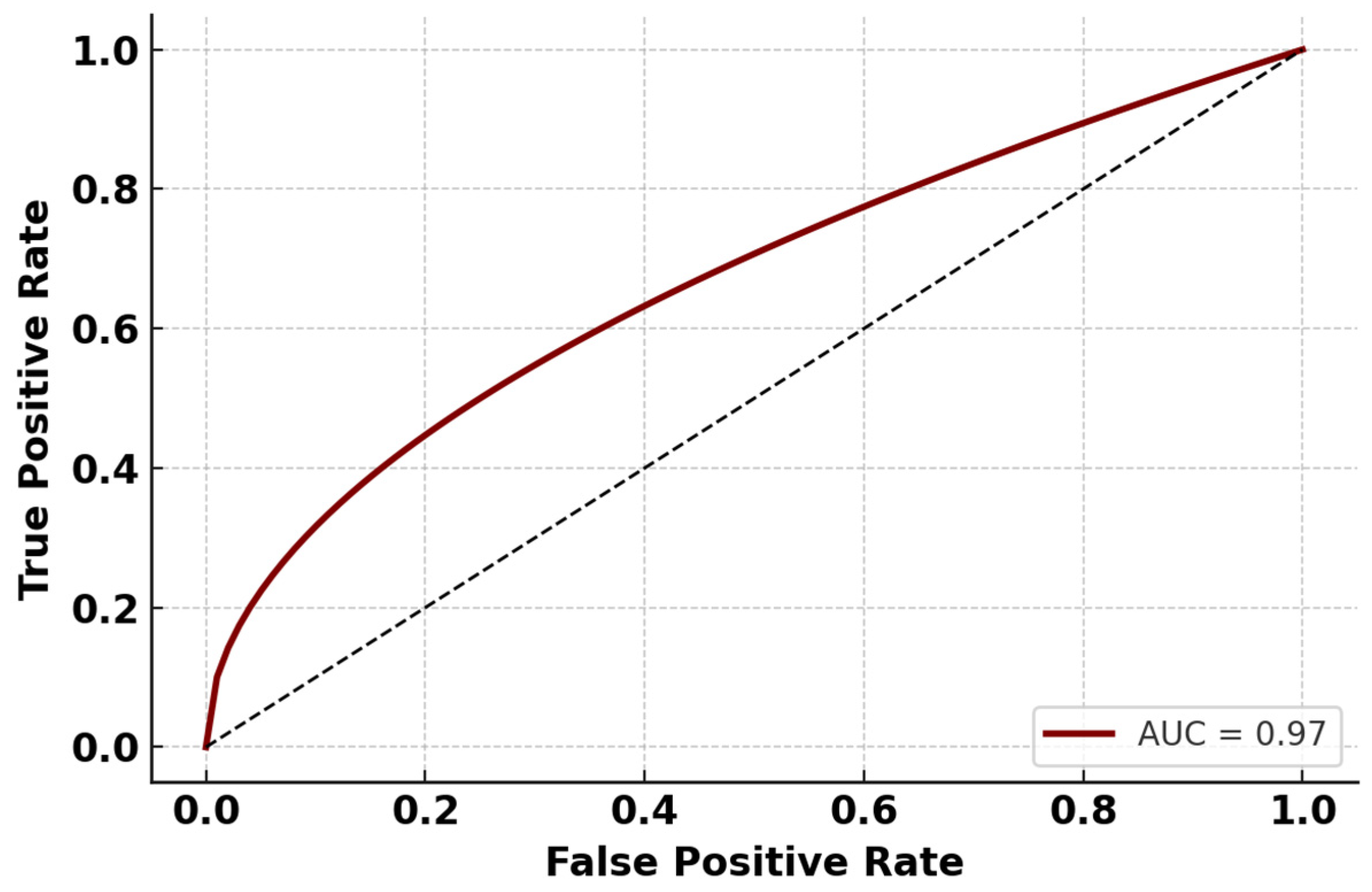

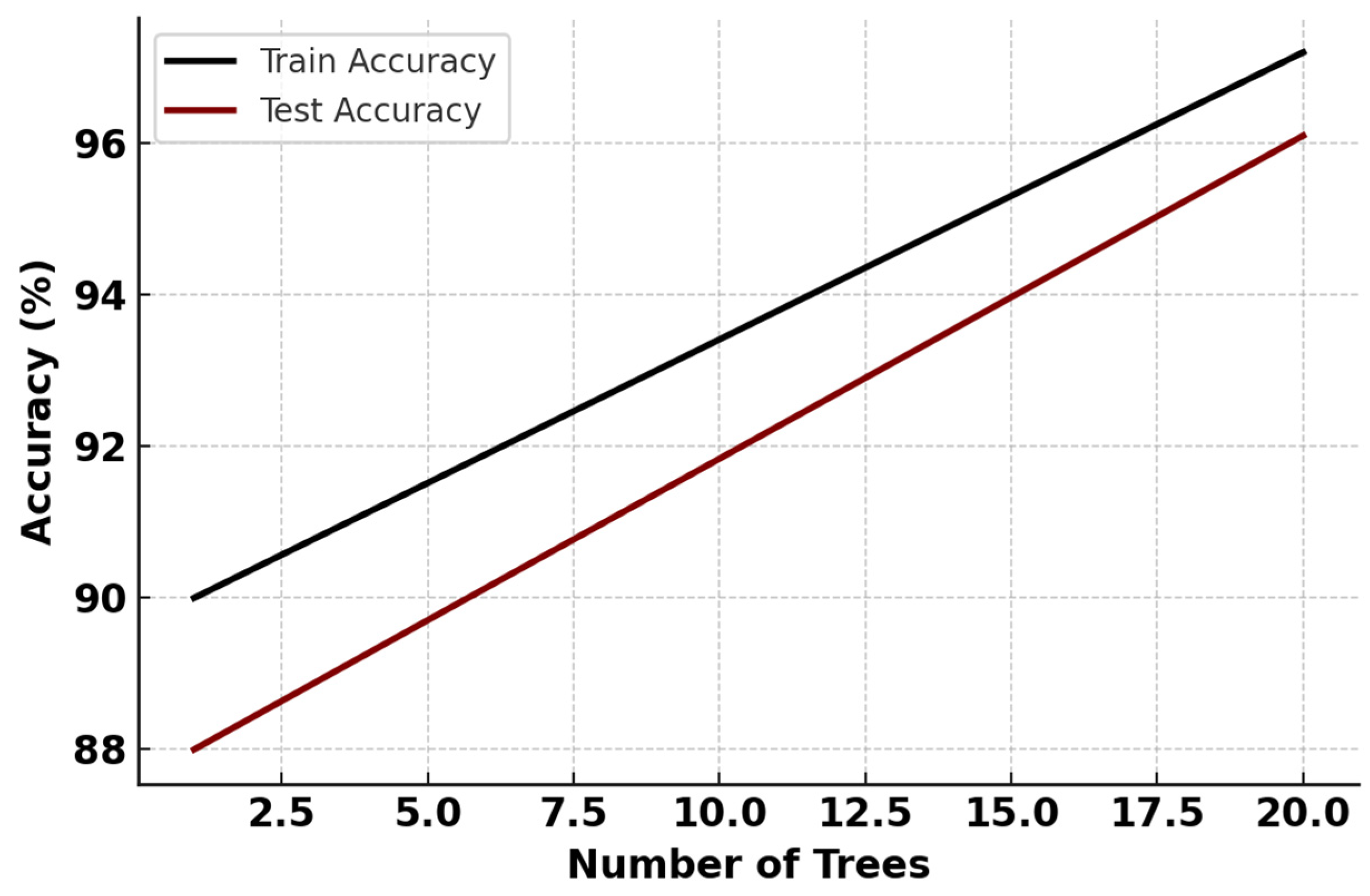

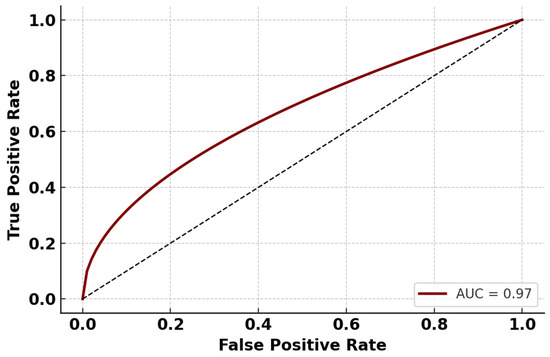

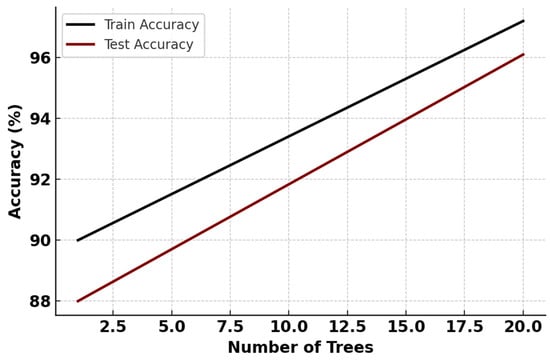

To further evaluate the model’s discriminative ability, Figure 10 displays the Receiver Operating Characteristic (ROC) curve. The curve shows a steep rise toward the top-left corner, indicating a high true positive rate with minimal false positives. The Area Under the Curve (AUC) was found to be 0.97, which confirms the classifier’s strong capacity to differentiate between healthy and faulty states. AUC values close to 1.0 typically represent excellent model performance, and in this context, it reinforces the reliability of the classifier for predictive maintenance applications. Figure 11 illustrates the learning curve, showing how the model’s accuracy evolves as the number of trees in the XGBoost ensemble increases. The training accuracy steadily rises from 90.0% to 97.2%, while the testing accuracy improves from 88.0% to 96.1% as the number of trees increases to 20. The smooth convergence between the training and testing curves indicates that the model generalizes well and is not overfitting. The final configuration, using 100 trees (as previously defined in Table 3), was selected based on this convergence and optimal performance plateau. Collectively, these results validate the reliability and predictive power of the XGBoost model in classifying gas turbine operating conditions based on thermal data. The model successfully integrates statistical feature extraction with advanced ensemble learning to deliver actionable insights for proactive maintenance strategies. A comparative analysis summarized in Table 4 demonstrates that the proposed XGBoost model outperforms traditional machine learning algorithms.

Figure 10.

Receiver Operating Characteristic (ROC) curve of the XGBoost classifier.

Figure 11.

Learning curve showing training and testing accuracy versus the number of trees in the XGBoost ensemble.

Table 4.

Comparison of the classification assessment metrics against traditional methods.

5. Conclusions

This study investigated a data-driven approach for thermal condition monitoring and the predictive maintenance of gas turbines using machine learning, particularly the XGBoost classification algorithm. The research focused on leveraging statistical features—mean temperature, standard deviation, and skewness—extracted from a six-month operational dataset obtained via thermocouple measurements at the turbine exhaust. Through detailed experimental analysis, machine learning modeling, and performance evaluation, several key contributions were achieved:

- A comprehensive thermal dataset was processed into 800 statistical intervals from over 8000 raw readings collected across six months. This facilitated the effective characterization of turbine operating states using simple meaningful statistical indicators.

- An IF algorithm was implemented to detect anomalies within the thermal intervals based on their statistical features, providing unsupervised labeling of normal and abnormal conditions used for the supervised training of the XGBoost model.

- An XGBoost classification model was developed and trained on the processed feature set, yielding a high classification accuracy (97.2%), F1-score (96.8%), precision (97.5%), and recall (96.1%).

- A detailed performance evaluation was conducted using a confusion matrix, ROC curve (AUC = 0.97), and learning curve analysis, which demonstrated that the model was not overfitting and generalized well to unseen data.

- The study demonstrated the practical feasibility of integrating AI techniques with real-world thermal monitoring systems to support predictive maintenance strategies, helping reduce unplanned downtimes and enhance asset reliability.

In the future, this study can be extended by adding the real-time application of the proposed model in turbine control systems for real-time fault detection. Additional features such as pressure, vibration, and acoustic signals can be included for stronger prediction. Moreover, ensemble or hybrid deep learning techniques, i.e., LSTM-XGBoost or CNN-based feature fusion, can be explored for more detailed temporal and spatial anomaly descriptions. Validation on multiple turbines and longer operating durations will further strengthen the generalizability of the proposed methodology.

Author Contributions

Conceptualization, S.T.B., M.I.A.-K., Z.H.K., H.A.D., A.A.F.O., and Z.T.A.-S.; methodology, L.A.A.-H.; software, L.A.A.-H.; formal analysis, L.A.A.-H.; investigation, L.A.A.-H.; writing—original draft preparation, L.A.A.-H.; writing—review and editing, S.T.B., M.I.A.-K., Z.H.K., H.A.D., A.A.F.O., and Z.T.A.-S.; visualization, L.A.A.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are available from the open-access article cited in the experimental work [43].

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Condessa, G.Á.; Ismail, K.A.R.; Hunt, J.D.; Ponce Júnior, N.; Velásquez, R.M.G.; Borges, V.L.; Tomé, F.M.C.; de Souza, C.L.; Gazoli, J.R.; Bindemann, F.T. Electricity Generation Potential from Natural Gas Pressure Reduction Turbines in Brazil. Energy Effic. 2023, 16, 97. [Google Scholar] [CrossRef]

- Guandalini, G.; Campanari, S.; Romano, M.C. Power-to-Gas Plants and Gas Turbines for Improved Wind Energy Dispatchability: Energy and Economic Assessment. Appl. Energy 2015, 147, 117–130. [Google Scholar] [CrossRef]

- Jaber, A.A.; Ibraheem, L.; Patel, H. Optimizing Wind Turbine Performance: The Impact of Atmospheric Factors and Advanced Control Strategies. Terra Joule J. 2024, 1, 3. [Google Scholar]

- Talal, W.; Akroot, A. An Exergoeconomic Evaluation of an Innovative Polygeneration System Using a Solar-Driven Rankine Cycle Integrated with the Al-Qayyara Gas Turbine Power Plant and the Absorption Refrigeration Cycle. Machines 2024, 12, 133. [Google Scholar] [CrossRef]

- Yun, W.; Ha, M.; Kim, K.; Lee, G. Design of a Thermal Performance Test Equipment for a High-Temperature and High-Pressure Heat Exchanger in an Aero-Engine. Machines 2024, 12, 794. [Google Scholar] [CrossRef]

- Biassoni, D.; Barsi, D.; Lengani, D. Effect of Purge on Secondary Flows in Turbine Due to Interaction Between Cavity Flow and Main Channel. Machines 2025, 13, 77. [Google Scholar] [CrossRef]

- Chowdhury, T.S.; Mohsin, F.T.; Tonni, M.M.; Mita, M.N.H.; Ehsan, M.M. A Critical Review on Gas Turbine Cooling Performance and Failure Analysis of Turbine Blades. Int. J. Thermofluids 2023, 18, 100329. [Google Scholar] [CrossRef]

- Błachnio, J.; Spychała, J.; Zasada, D. Analysis of Structural Changes in a Gas Turbine Blade as a Result of High Temperature and Stress. Eng. Fail. Anal. 2021, 127, 105554. [Google Scholar] [CrossRef]

- Abid, A.; Sarowar, M.T. Heat Transfer, Thermal Stress and Failure Inspection of a Gas Turbine Compressor Stator Blade Made of Five Different Conventional Superalloys and Ultra-High-Temperature Ceramic Material: A Direct Numerical Investigation. J. Fail. Anal. Prev. 2022, 22, 878–898. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y.; Xu, C.; Zhang, Y.; Su, X. Turbulent Flow Heat Transfer and Thermal Stress Improvement of Gas Turbine Blade Trailing Edge Cooling with Diamond-Type TPMS Structure. Aerospace 2024, 11, 37. [Google Scholar] [CrossRef]

- Montañés, R.M.; Hagen, B.; Deng, H.; Skaugen, G.; Morin, N.; Andersen, M.; Mazzetti, M.J. Design Optimization of Compact Gas Turbine and Steam Combined Cycles for Combined Heat and Power Production in a FPSO System–A Case Study. Energy 2023, 282, 128401. [Google Scholar] [CrossRef]

- Cai, L.; He, Y.; Wang, S.; Li, Y.; Li, F. Thermal-Fluid-Solid Coupling Analysis on the Temperature and Thermal Stress Field of a Nickel-Base Superalloy Turbine Blade. Materials 2021, 14, 3315. [Google Scholar] [CrossRef] [PubMed]

- Vo, D.-T.; Mai, T.-D.; Kim, B.; Jung, J.-S.; Ryu, J. Numerical Investigation of Crack Initiation in High-Pressure Gas Turbine Blade Subjected to Thermal-Fluid-Mechanical Low-Cycle Fatigue. Int. J. Heat Mass Transf. 2023, 202, 123748. [Google Scholar] [CrossRef]

- Rayapati, S. Gas Turbine Blade Failure Scenario Due to Thermal Loads in Case of Nickel Based Super Alloys. Mater. Today Proc. 2021, 46, 8119–8126. [Google Scholar] [CrossRef]

- Ogaili, A.A.F.; Jaber, A.A.; Hamzah, M.N. Statistically Optimal Vibration Feature Selection for Fault Diagnosis in Wind Turbine Blade. Int. J. Renew. Energy Res. 2023, 13, 1082–1092. [Google Scholar]

- Xie, J.; Sage, M.; Zhao, Y.F. Feature Selection and Feature Learning in Machine Learning Applications for Gas Turbines: A Review. Eng. Appl. Artif. Intell. 2023, 117, 105591. [Google Scholar] [CrossRef]

- de Castro-Cros, M.; Velasco, M.; Angulo, C. Machine-Learning-Based Condition Assessment of Gas Turbines—A Review. Energies 2021, 14, 8468. [Google Scholar] [CrossRef]

- Hurtado, J.; Salvati, D.; Semola, R.; Bosio, M.; Lomonaco, V. Continual Learning for Predictive Maintenance: Overview and Challenges. Intell. Syst. Appl. 2023, 19, 200251. [Google Scholar] [CrossRef]

- Arafat, M.Y.; Hossain, M.J.; Alam, M.M. Machine Learning Scopes on Microgrid Predictive Maintenance: Potential Frameworks, Challenges, and Prospects. Renew. Sustain. Energy Rev. 2024, 190, 114088. [Google Scholar] [CrossRef]

- Liu, X.; He, D.; Lodewijks, G.; Pang, Y.; Mei, J. Integrated Decision Making for Predictive Maintenance of Belt Conveyor Systems. Reliab. Eng. Syst. Saf. 2019, 188, 347–351. [Google Scholar] [CrossRef]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Alfarhood, S. Explainable Predictive Maintenance of Rotating Machines Using LIME, SHAP, PDP, ICE. IEEE Access 2024, 12, 29345–29361. [Google Scholar] [CrossRef]

- Scaife, A.D. Improve Predictive Maintenance through the Application of Artificial Intelligence: A Systematic Review. Results Eng. 2023, 21, 101645. [Google Scholar] [CrossRef]

- Pollak, A.; Temich, S.; Ptasiński, W.; Kucharczyk, J.; Gąsiorek, D. Prediction of Belt Drive Faults in Case of Predictive Maintenance in Industry 4.0 Platform. Appl. Sci. 2021, 11, 307. [Google Scholar] [CrossRef]

- Liao, R.; He, Y.; Feng, T.; Yang, X.; Dai, W.; Zhang, W. Mission Reliability-Driven Risk-Based Predictive Maintenance Approach of Multistate Manufacturing System. Reliab. Eng. Syst. Saf. 2023, 236, 109273. [Google Scholar] [CrossRef]

- Garan, M.; Tidriri, K.; Kovalenko, I. A Data-Centric Machine Learning Methodology: Application on Predictive Maintenance of Wind Turbines. Energies 2022, 15, 826. [Google Scholar] [CrossRef]

- Dehghan Shoorkand, H.; Nourelfath, M.; Hajji, A. A Hybrid CNN-LSTM Model for Joint Optimization of Production and Imperfect Predictive Maintenance Planning. Reliab. Eng. Syst. Saf. 2024, 241, 109707. [Google Scholar] [CrossRef]

- Domínguez-Monferrer, C.; Fernández-Pérez, J.; De Santos, R.; Miguélez, M.H.; Cantero, J.L. Machine Learning Approach in Non-Intrusive Monitoring of Tool Wear Evolution in Massive CFRP Automatic Drilling Processes in the Aircraft Industry. J. Manuf. Syst. 2022, 65, 622–639. [Google Scholar] [CrossRef]

- Nagy, M.; Lăzăroiu, G.; Valaskova, K. Machine Intelligence and Autonomous Robotic Technologies in the Corporate Context of SMEs: Deep Learning and Virtual Simulation Algorithms, Cyber-Physical Production Networks, and Industry 4.0-Based Manufacturing Systems. Appl. Sci. 2023, 13, 1681. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Abdul-Zahra, A.S.; Ghane, E.; Kamali, A.; Farhan Ogaili, A.A. Power Forecasting in Continuous Extrusion of Pure Titanium Using Naïve Bayes Algorithm. Terra Joule J. 2024, 1, 2. [Google Scholar]

- Al-Haddad, L.A.; Kahachi, H.A.H.; Ur Rehman, H.Z.; Al-Zubaidi, A.A.; Al-Karkhi, M.I.; Al-Oubaidi, B. Advancing Sustainability in Buildings Using an Integrated Aerodynamic Façade: Potential of Artificial Intelligence. Terra Joule J. 2024, 1, 1. [Google Scholar]

- Mahdi, N.M.; Jassim, A.H.; Abulqasim, S.A.; Basem, A.; Ogaili, A.A.F.; Al-Haddad, L.A. Leak Detection and Localization in Water Distribution Systems Using Advanced Feature Analysis and an Artificial Neural Network. Desalination Water Treat 2024, 320, 100685. [Google Scholar] [CrossRef]

- Jin, Y.; Ying, Y.; Li, J.; Zhou, H. Gas Path Fault Diagnosis of Gas Turbine Engine Based on Knowledge Data-Driven Artificial Intelligence Algorithm. IEEE Access 2021, 9, 108932–108941. [Google Scholar] [CrossRef]

- Shen, Y.; Khorasani, K. Hybrid Multi-Mode Machine Learning-Based Fault Diagnosis Strategies with Application to Aircraft Gas Turbine Engines. Neural. Netw. 2020, 130, 126–142. [Google Scholar] [CrossRef]

- Liu, Z.; Karimi, I.A. Gas Turbine Performance Prediction via Machine Learning. Energy 2020, 192, 116627. [Google Scholar] [CrossRef]

- Barrera, J.M.; Reina, A.; Mate, A.; Trujillo, J.C. Fault Detection and Diagnosis for Industrial Processes Based on Clustering and Autoencoders: A Case of Gas Turbines. Int. J. Mach. Learn. Cybern. 2022, 13, 3113–3129. [Google Scholar] [CrossRef]

- del Carmen Rubiales Mena, M.; Muñoz, A.; Sanz-Bobi, M.Á.; Gonzalez-Calvo, D.; Álvarez-Tejedor, T. Application of Ensemble Machine Learning Techniques to the Diagnosis of the Combustion in a Gas Turbine. Appl. Therm. Eng. 2024, 249, 123447. [Google Scholar] [CrossRef]

- Nashed, M.S.; Renno, J.; Mohamed, M.S.; Reuben, R.L. Gas Turbine Failure Classification Using Acoustic Emissions with Wavelet Analysis and Deep Learning. Expert Syst. Appl. 2023, 232, 120684. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, A.; Jiang, W.; Zhao, Y.; Tang, E.; Chang, S. Abnormal Detection and Fault Diagnosis of Adjustment Hydraulic Servomotor Based on Genetic Algorithm to Optimize Support Vector Data Description with Negative Samples and One-Dimensional Convolutional Neural Network. Machines 2024, 12, 368. [Google Scholar] [CrossRef]

- Salilew, W.M.; Gilani, S.I.; Lemma, T.A.; Fentaye, A.D.; Kyprianidis, K.G. Simultaneous Fault Diagnostics for Three-Shaft Industrial Gas Turbine. Machines 2023, 11, 832. [Google Scholar] [CrossRef]

- Djeddi, A.Z.; Hafaifa, A.; Hadroug, N.; Iratni, A. Gas Turbine Availability Improvement Based on Long Short-Term Memory Networks Using Deep Learning of Their Failures Data Analysis. Process Saf. Environ. Prot. 2022, 159, 1–25. [Google Scholar] [CrossRef]

- Hashmi, M.B.; Fentaye, A.D.; Mansouri, M.; Kyprianidis, K.G. A Comparative Analysis of Various Machine Learning Approaches for Fault Diagnostics of Hydrogen Fueled Gas Turbines. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2024; Volume 87967, p. V004T05A050. [Google Scholar]

- Khoshghiafehgan, M.; Akhlaghi, A.; Ranji, A.; Mazhar, M.Y. Gas Turbine Hot Sections Condition Monitoring Based on Operational Thermal Dataset. Data Brief 2024, 55, 110624. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Jaber, A.A.; Mahdi, N.M.; Al-Haddad, S.A.; Al-Karkhi, M.I.; Al-Sharify, Z.T.; Farhan Ogaili, A.A. Protocol for UAV Fault Diagnosis Using Signal Processing and Machine Learning. STAR Protoc. 2024, 5, 103351. [Google Scholar] [CrossRef]

- Al-Haddad, A.A.; Al-Haddad, L.A.; Al-Haddad, S.A.; Jaber, A.A.; Khan, Z.H.; Rehman, H.Z.U. Towards Dental Diagnostic Systems: Synergizing Wavelet Transform with Generative Adversarial Networks for Enhanced Image Data Fusion. Comput. Biol. Med. 2024, 182, 109241. [Google Scholar] [CrossRef] [PubMed]

- Abdulameer, A.G.; Mrah, M.M.; Bazerkan, M.; Al-Haddad, L.A.; Al-Karkhi, M.I. Machine Learning-Driven Power Prediction in Continuous Extrusion of Pure Titanium for Enhanced Structural Resilience under Extreme Loading. Discov. Mater. 2025, 5, 7. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Jaber, A.A.; Dhahir, M.K.; Nagim, H.Y.; Algburi, Z.I. Characterization and Prediction of Femtosecond Laser Induced Tracks in Silver-Containing Zinc Phosphate Glass. CEUR Workshop Proc. 2024, 3870, 10–19. [Google Scholar]

- Ren, Q.; Wang, J. Research on Enterprise Digital-Level Classification Based on XGBoost Model. Sustainability 2023, 15, 2699. [Google Scholar] [CrossRef]

- Wang, Q.; Zou, X.; Chen, Y.; Zhu, Z.; Yan, C.; Shan, P.; Wang, S.; Fu, Y. XGBoost Algorithm Assisted Multi-Component Quantitative Analysis with Raman Spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2024, 323, 124917. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. Xgboost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Wang, Y.; Li, J.; Wang, G.; Chen, G.; He, S. Prediction of Diesel Particulate Filter Regeneration Conditions and Diesel Engine Performance under Regeneration Mode Using AMSO-BPNN and Combined with XGBoost. Appl. Energy 2025, 377, 124341. [Google Scholar] [CrossRef]

- Sarow, S.A.; Flayyih, H.A.; Bazerkan, M.; Al-Haddad, L.A.; Al-Sharify, Z.T.; Ogaili, A.A.F. Advancing Sustainable Renewable Energy: XGBoost Algorithm for the Prediction of Water Yield in Hemispherical Solar Stills. Discov. Sustain. 2024, 5, 510. [Google Scholar] [CrossRef]

- Chugh, B.; Malik, N.; Gupta, D.; Alkahtani, B.S. A Probabilistic Approach Driven Credit Card Anomaly Detection with CBLOF and Isolation Forest Models. Alex. Eng. J. 2025, 114, 231–242. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).