Predicting Remaining Useful Life of Induction Motor Bearings from Motor Current Signatures Using Machine Learning

Abstract

1. Introduction

- A robust predictive model was designed to estimate the Health Index (HI) and RUL of induction motors to provide intuitive insights into the motor’s health and remaining lifespan, enabling better decision making for maintenance.

- The performance of the developed model was tested on datasets collected from 52 motors across three cogeneration power plants in Malaysia, demonstrating its effectiveness in accurately predicting motor health and failure risks, thereby enhancing reliability and operational efficiency.

2. Methodology

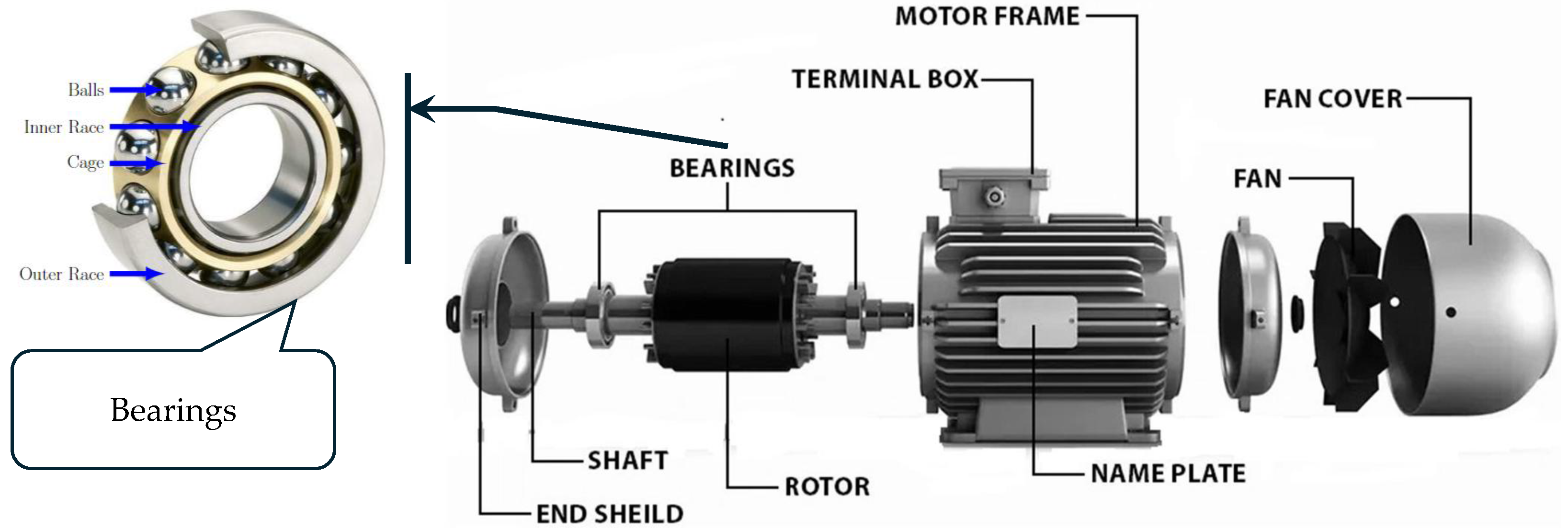

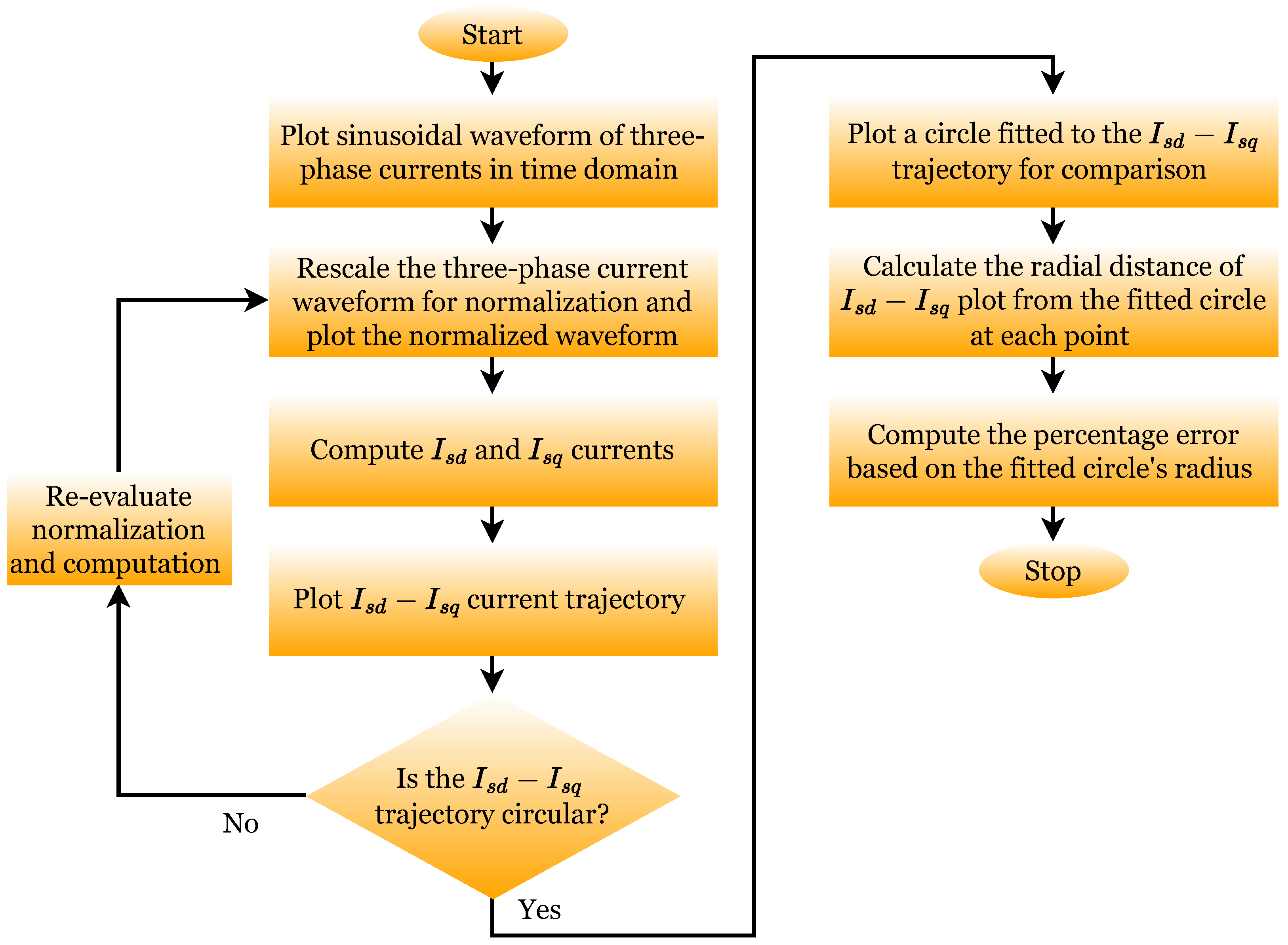

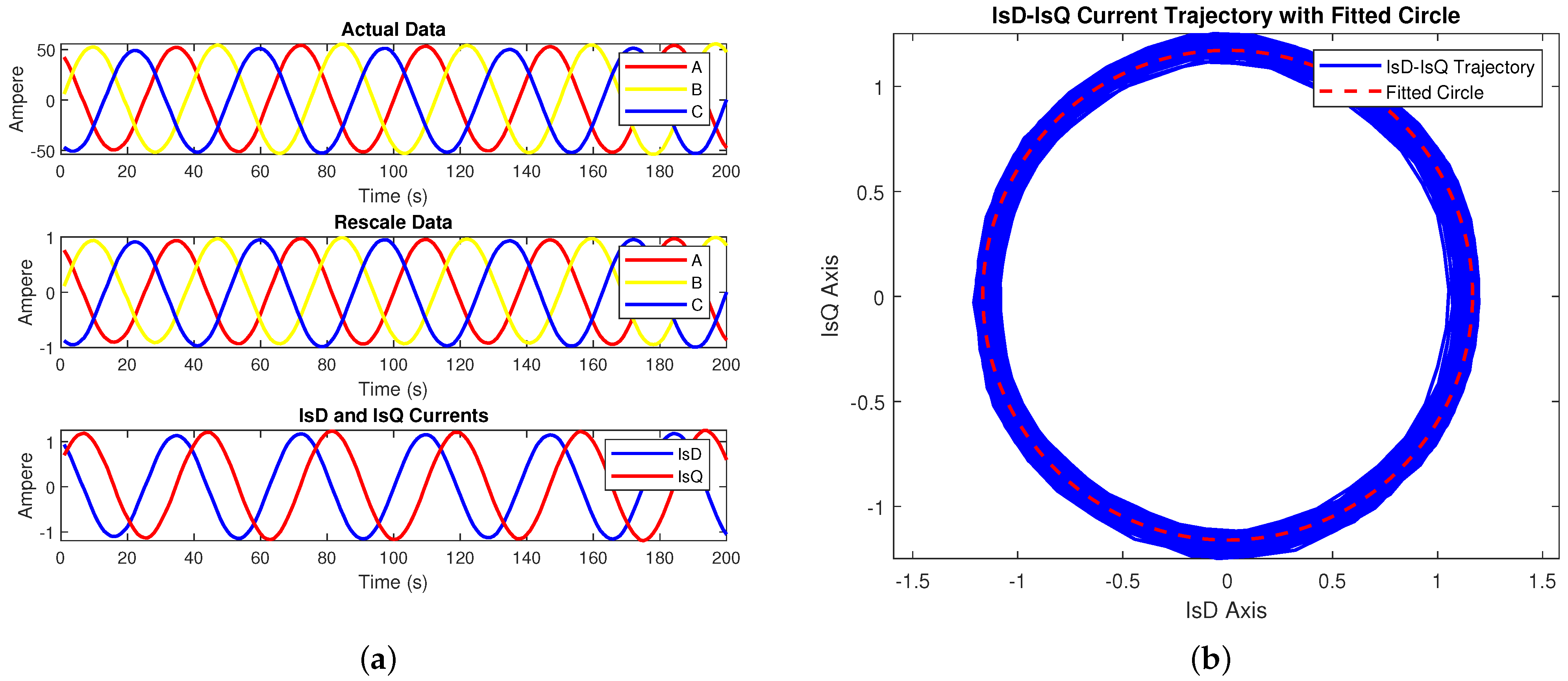

2.1. Park’s Vector Technique

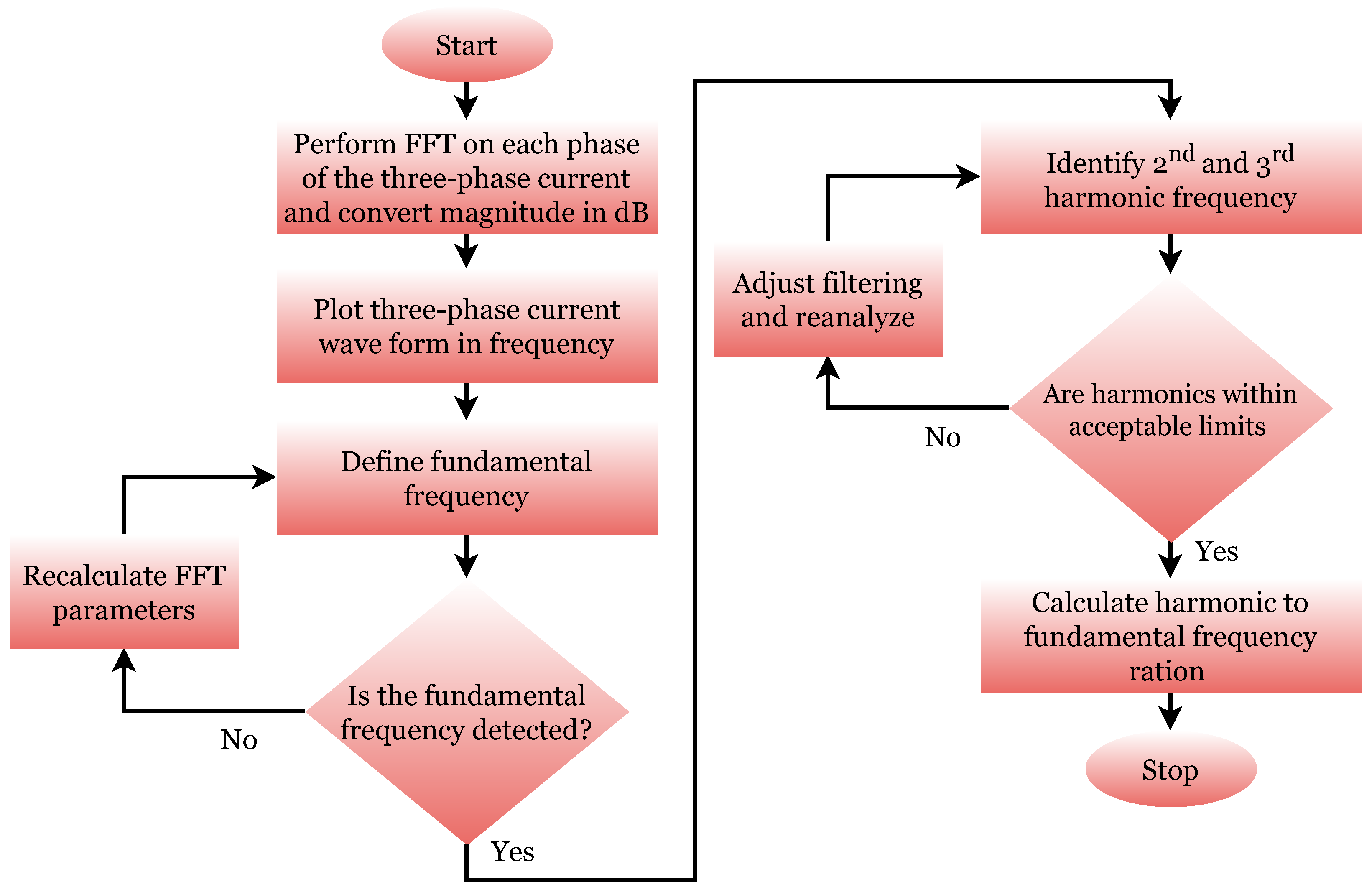

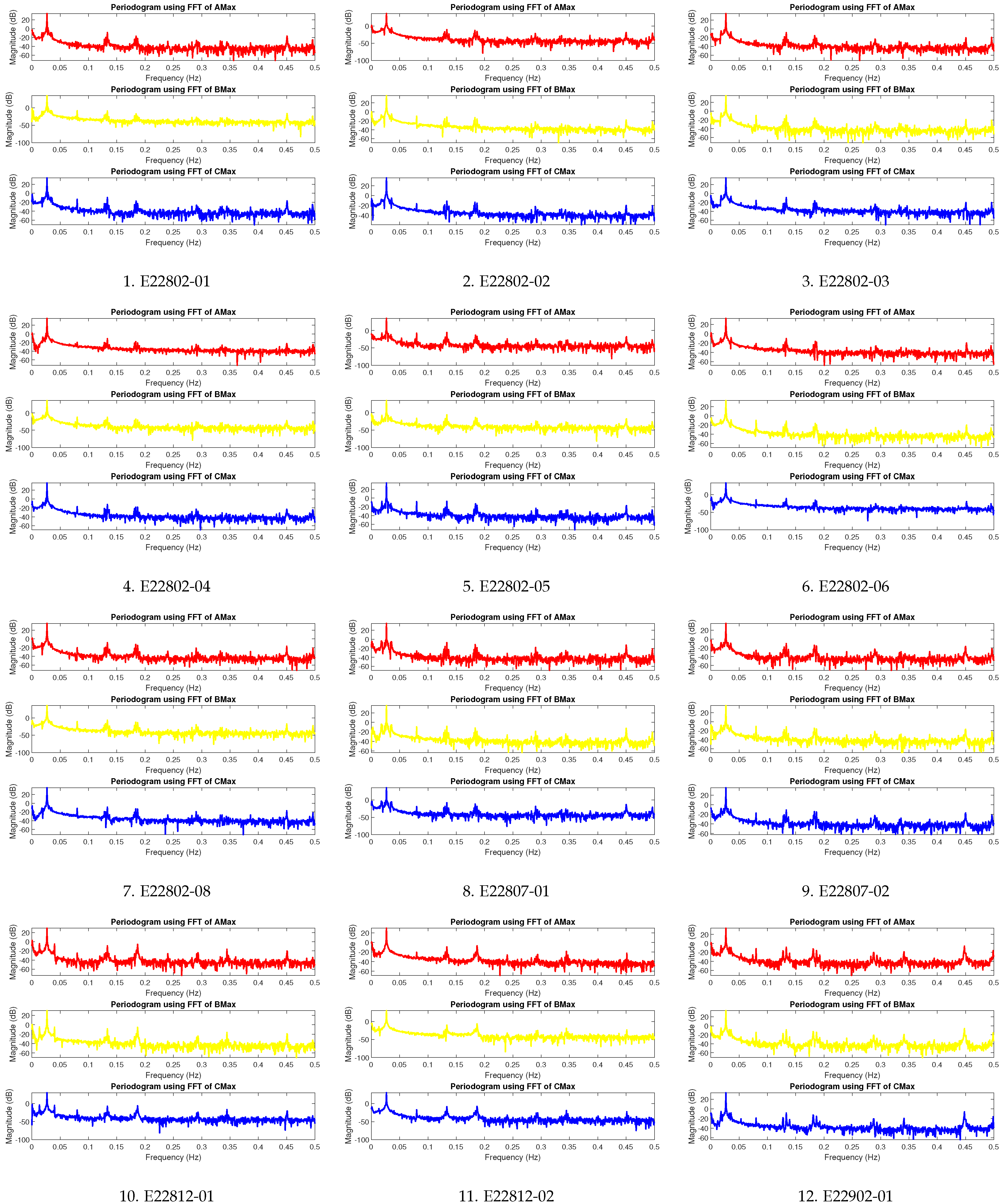

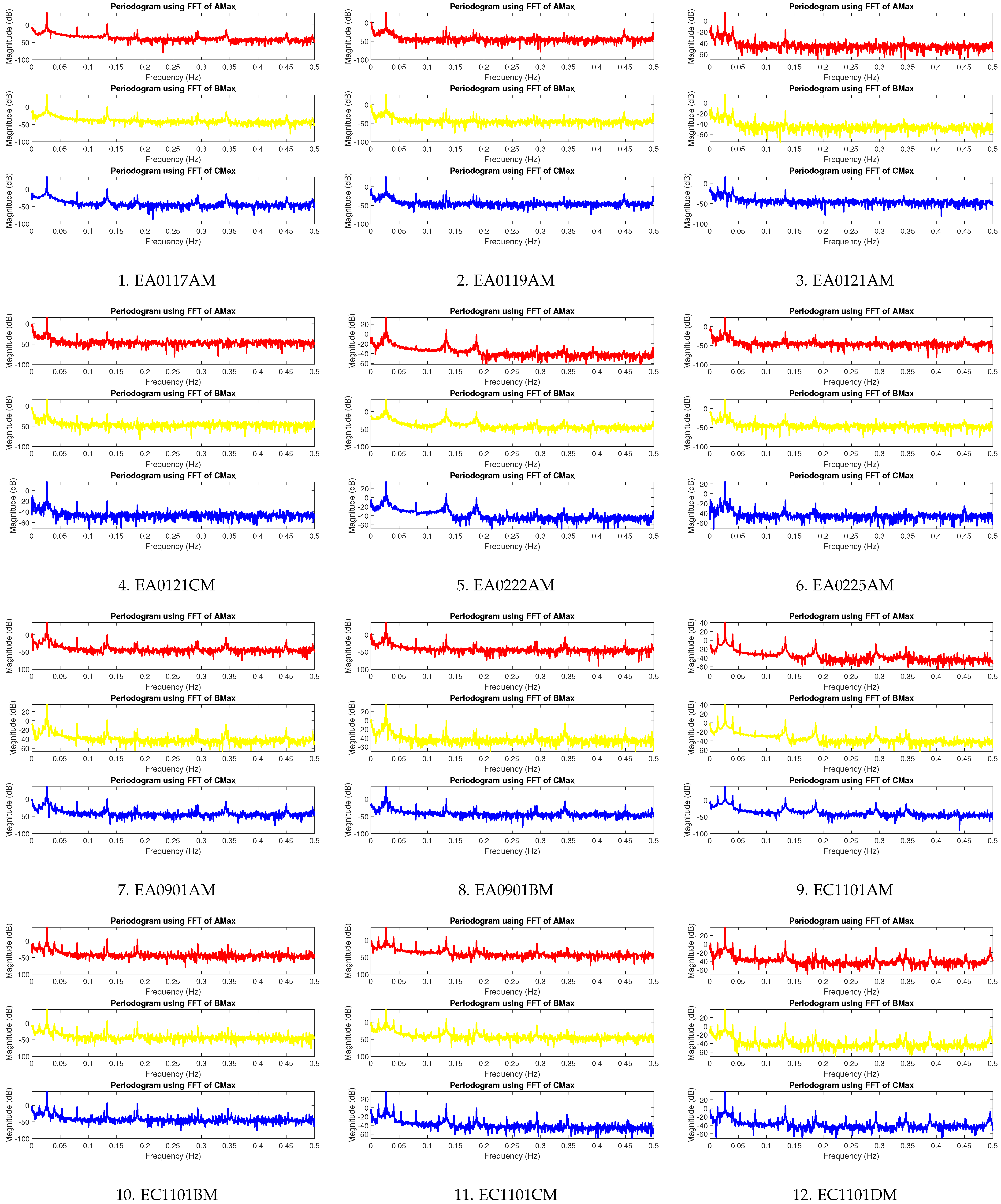

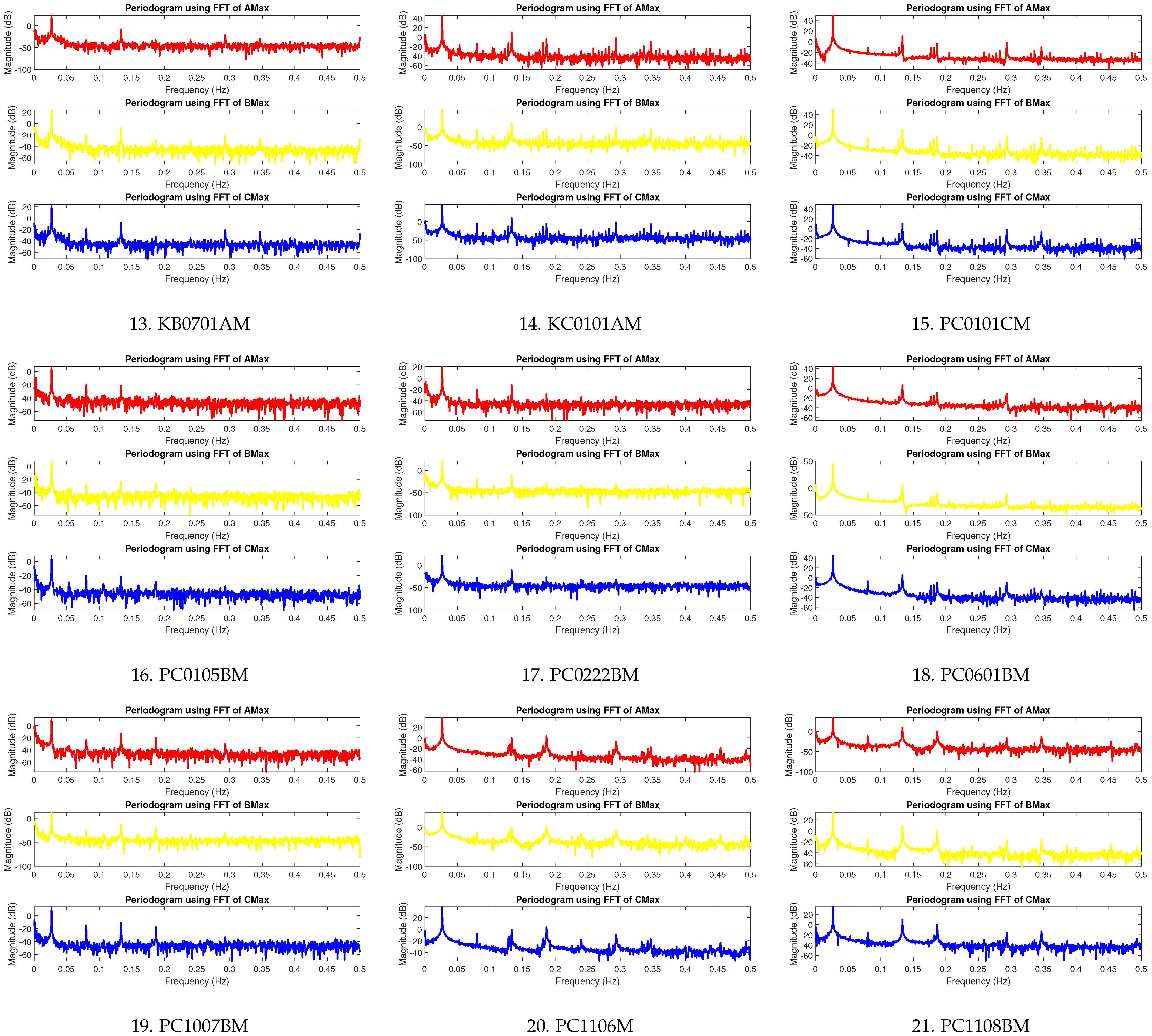

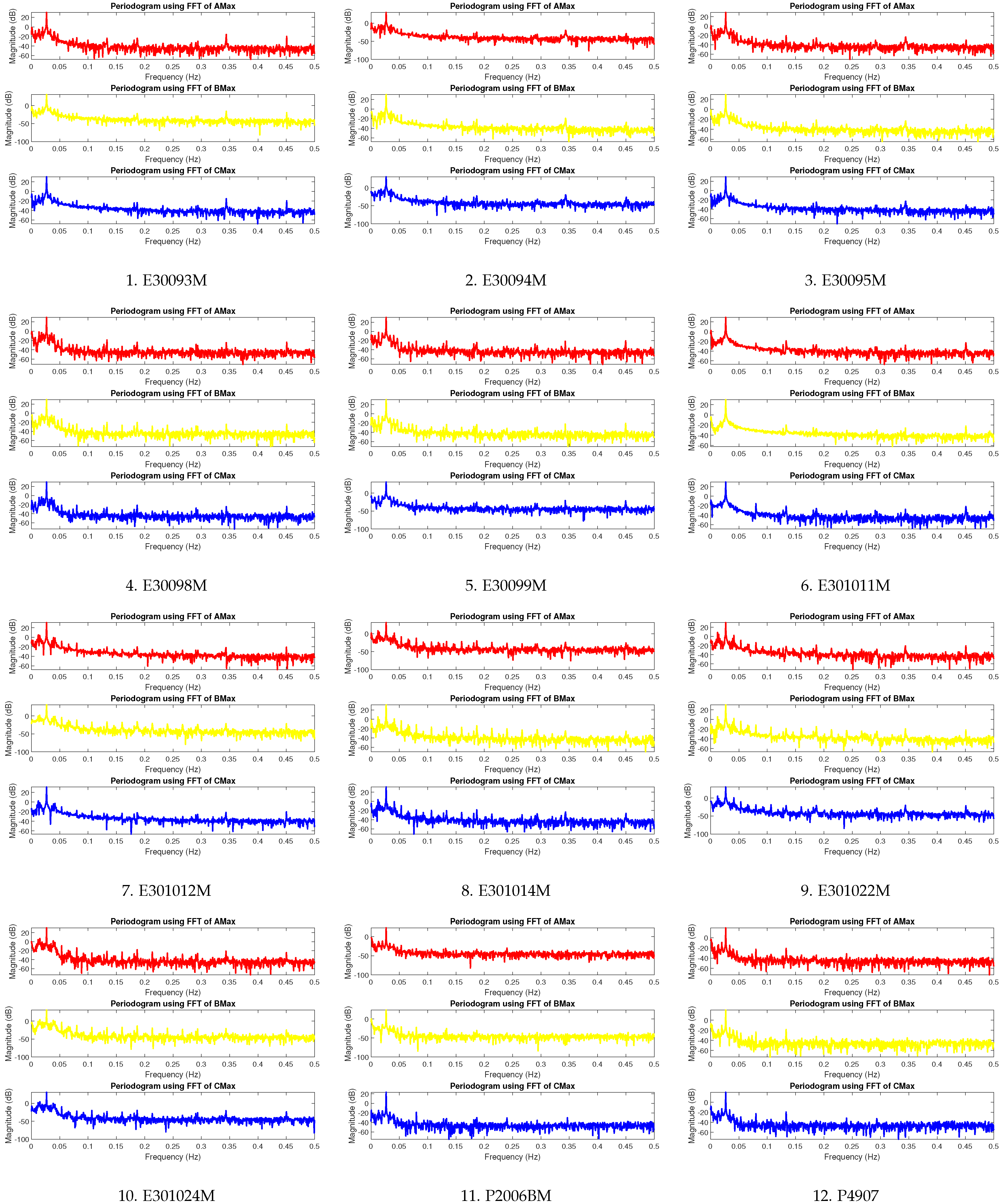

2.2. Fast Fourier Transform (FFT) Technique

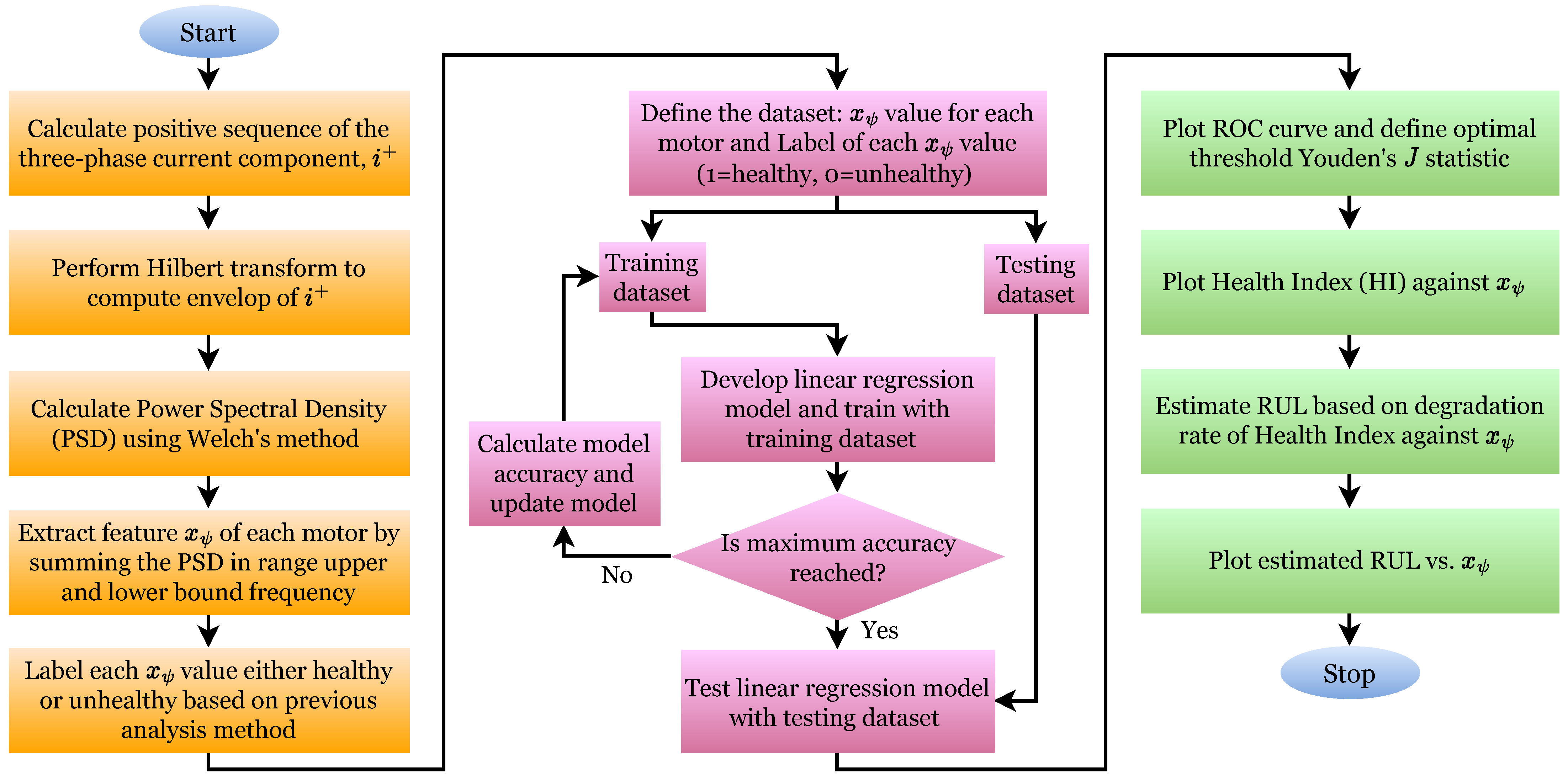

2.3. Remaining Useful Life (RUL) Estimation Technique

3. Data Acquisition

4. Results and Discussion

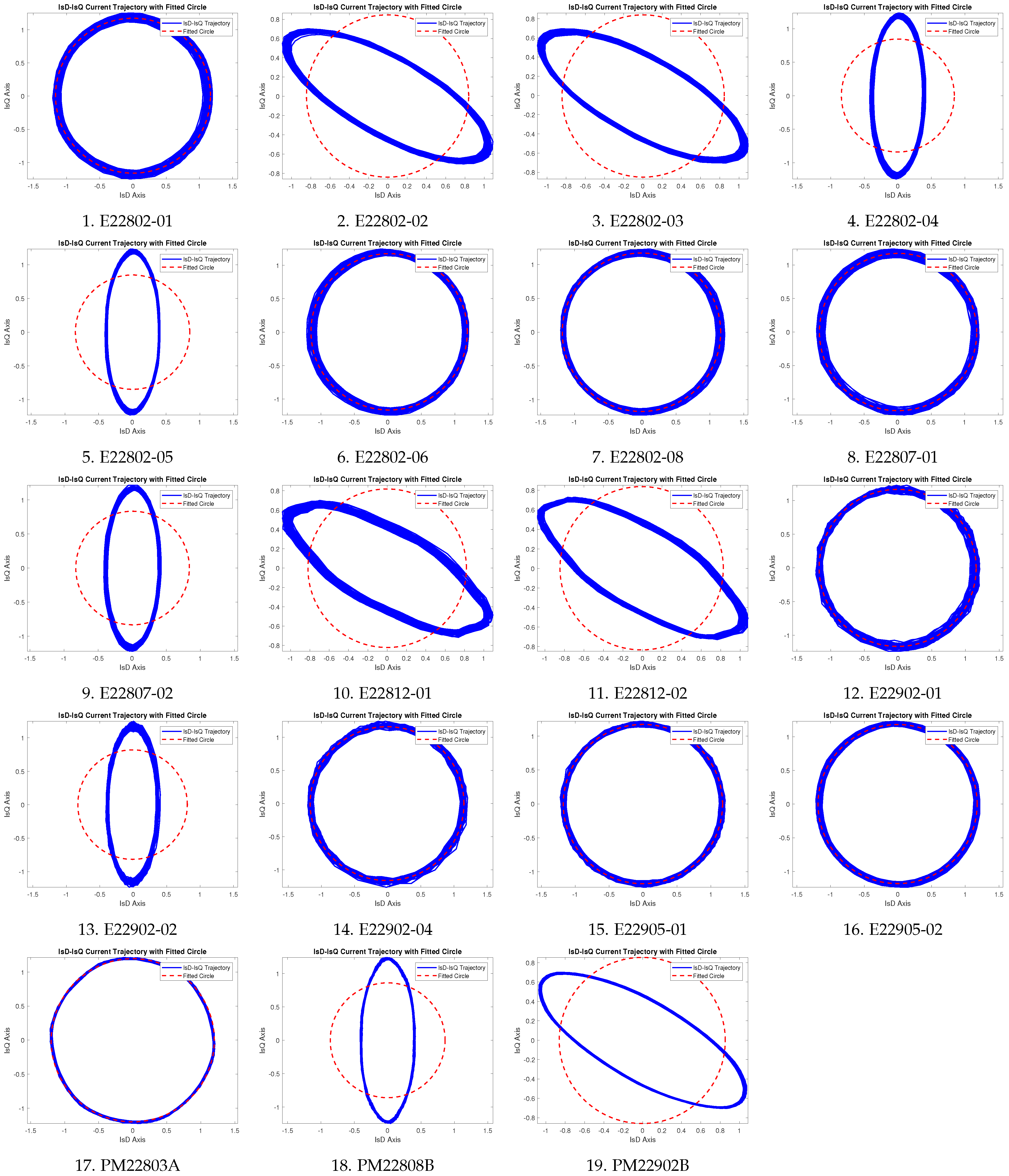

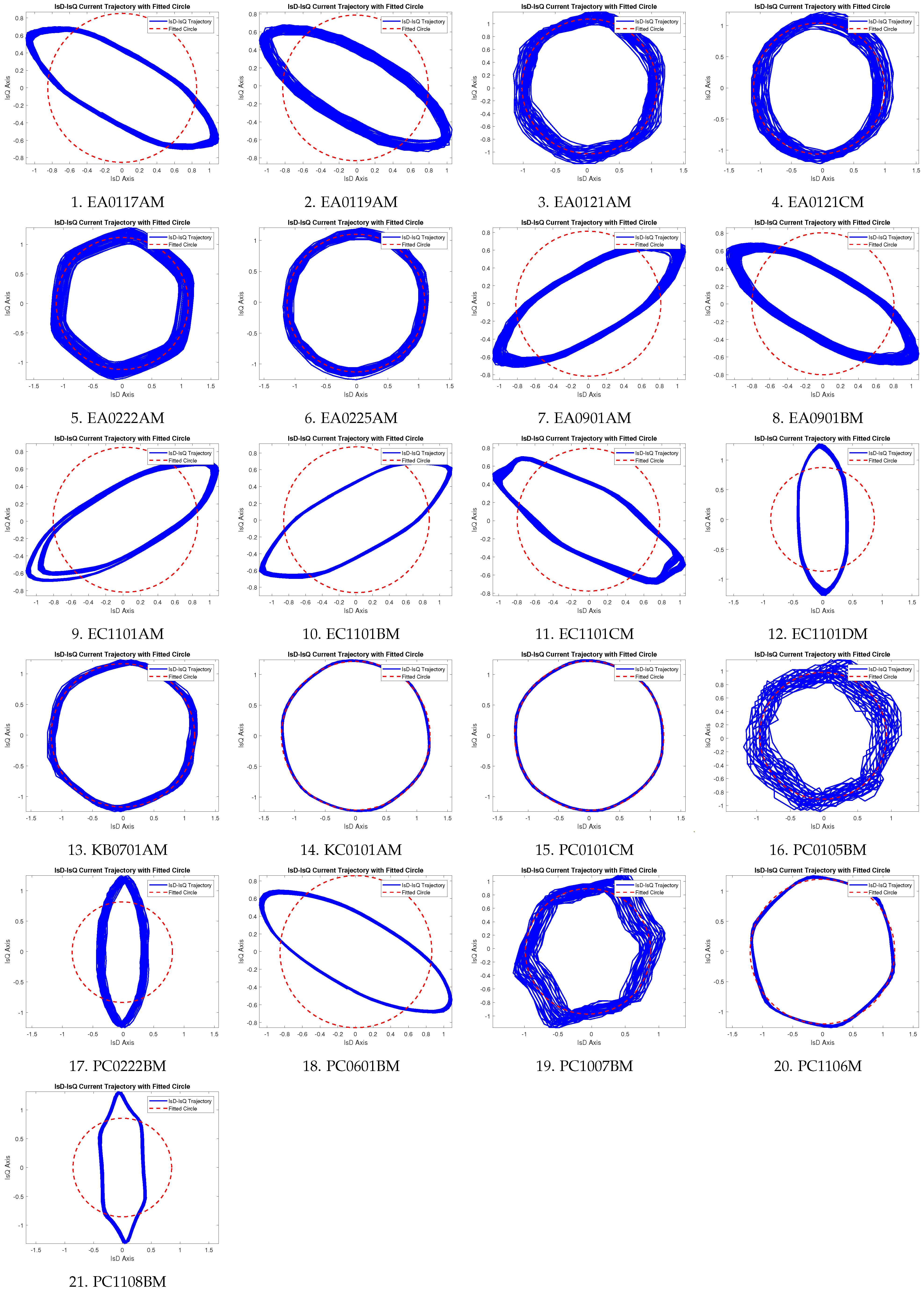

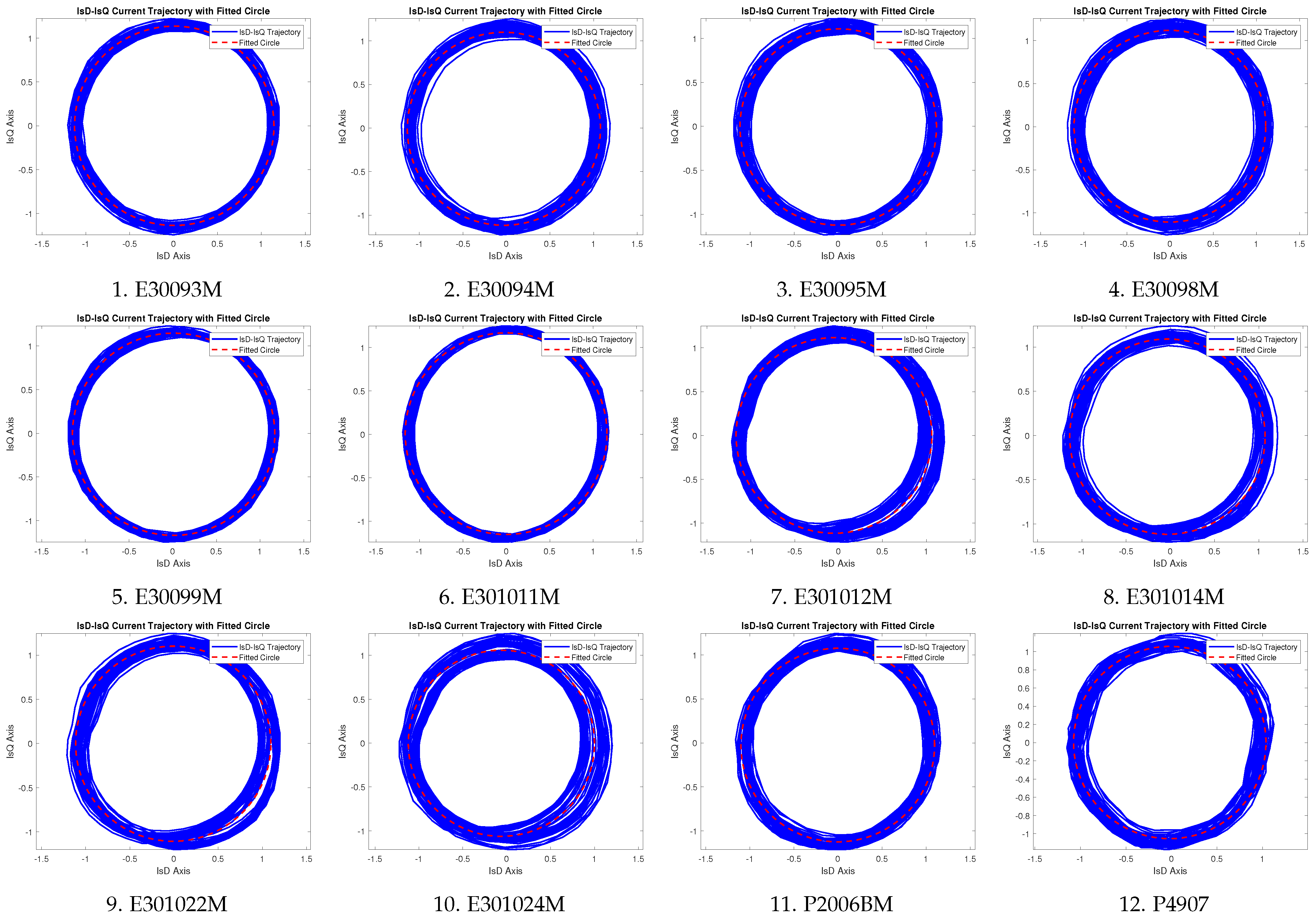

4.1. Park’s Vector Technique

4.2. Fast Fourier Transform (FFT) Technique

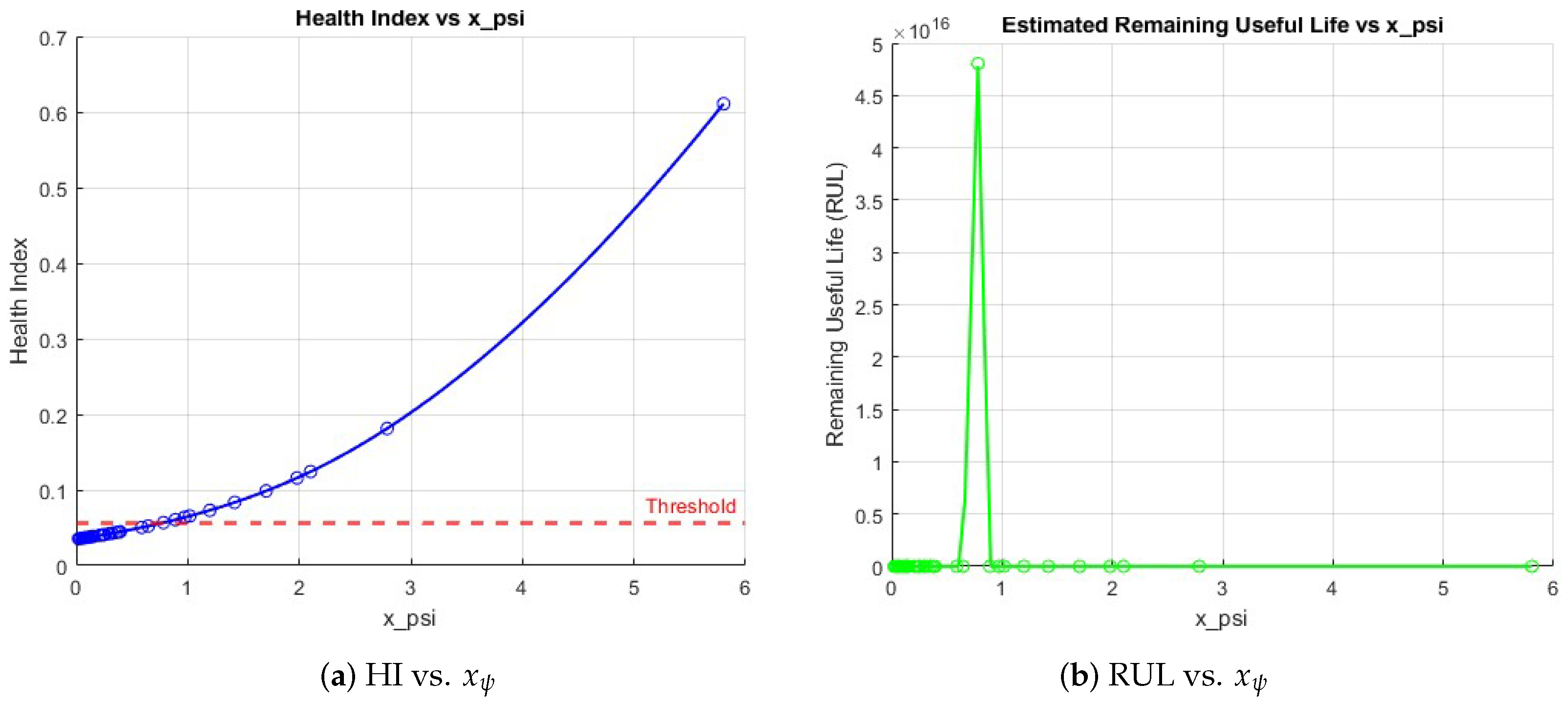

4.3. Remaining Useful Life (RUL) Estimation Technique

4.4. Comparative Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| FFT | Fast Fourier Transform |

| HFR | Harmonic-to-Fundamental Ratio |

| HI | Health Index |

| LSTM | Long Short-Term Memory |

| MCSA | Motor Current Signature Analysis |

| PSD | Power Spectral Density |

| RMS | Root Mean Square |

| ROC | Receiver Operating Characteristic Curve |

| RUL | Remaining Useful Life |

| SMRN | Shrinkage Mamba Relation Network |

| SVM | Support Vector Machine |

| WT | Wavelet Transform |

References

- Ferreira, F.J.; Baoming, G.; de Almeida, A.T. Reliability and operation of high-efficiency induction motors. In Proceedings of the 2015 IEEE/IAS 51st Industrial & Commercial Power Systems Technical Conference (I&CPS), Calgary, AB, Canada, 5–8 May 2015; pp. 1–13. [Google Scholar]

- Neupane, D.; Seok, J. Bearing fault detection and diagnosis using case western reserve university dataset with deep learning approaches: A review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. A survey on deep learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep learning algorithms for bearing fault diagnostics—A comprehensive review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Pastukhov, A.; Timashov, E. Procedure for simulation of stable thermal conductivity of bearing assemblies. Adv. Eng. Lett. 2023, 2, 58–63. [Google Scholar] [CrossRef]

- Delvecchio, S.; Bonfiglio, P.; Pompoli, F. Vibro-acoustic condition monitoring of Internal Combustion Engines: A critical review of existing techniques. Mech. Syst. Signal Process. 2018, 99, 661–683. [Google Scholar] [CrossRef]

- Lu, H.; Nemani, V.P.; Barzegar, V.; Allen, C.; Hu, C.; Laflamme, S.; Sarkar, S.; Zimmerman, A.T. A physics-informed feature weighting method for bearing fault diagnostics. Mech. Syst. Signal Process. 2023, 191, 110171. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Iqbal, J. A review on fault detection and diagnosis techniques: Basics and beyond. Artif. Intell. Rev. 2021, 54, 3639–3664. [Google Scholar] [CrossRef]

- Vanchinathan, K.; Valluvan, K.R.; Gnanavel, C.; Gokul, C.; Albert, J.R. An improved incipient whale optimization algorithm based robust fault detection and diagnosis for sensorless brushless DC motor drive under external disturbances. Int. Trans. Electr. Energy Syst. 2021, 31, e13251. [Google Scholar] [CrossRef]

- AlShorman, O.; Irfan, M.; Abdelrahman, R.B.; Masadeh, M.; Alshorman, A.; Sheikh, M.A.; Saad, N.; Rahman, S. Advancements in condition monitoring and fault diagnosis of rotating machinery: A comprehensive review of image-based intelligent techniques for induction motors. Eng. Appl. Artif. Intell. 2024, 130, 107724. [Google Scholar] [CrossRef]

- McInerny, S.A.; Dai, Y. Basic vibration signal processing for bearing fault detection. IEEE Trans. Educ. 2003, 46, 149–156. [Google Scholar] [CrossRef]

- Rafiee, J.; Tse, P.; Harifi, A.; Sadeghi, M. A novel technique for selecting mother wavelet function using an intelli gent fault diagnosis system. Expert Syst. Appl. 2009, 36, 4862–4875. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Pineda-Sánchez, M.; Pérez-Cruz, J.; Puche-Panadero, R.; Roger-Folch, J.; Antonino-Daviu, J.A. Diagnosis of induction motor faults via Gabor analysis of the current in transient regime. IEEE Trans. Instrum. Meas. 2012, 61, 1583–1596. [Google Scholar] [CrossRef]

- Schoen, R.R.; Habetler, T.G.; Kamran, F.; Bartfield, R. Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 2002, 31, 1274–1279. [Google Scholar] [CrossRef]

- Lopez-Perez, D.; Antonino-Daviu, J. Application of infrared thermography to failure detection in industrial induction motors: Case stories. IEEE Trans. Ind. Appl. 2017, 53, 1901–1908. [Google Scholar] [CrossRef]

- Kumar, S.; Raj, K.K.; Cirrincione, M.; Cirrincione, G.; Franzitta, V.; Kumar, R.R. A Comprehensive Review of Remaining Useful Life Estimation Approaches for Rotating Machinery. Energies 2024, 17, 5538. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, Y.; Fei, X.; Wang, K.; Fang, T.; Wang, J. Intelligent Fault Diagnosis for Rotating Mechanical Systems: An Improved Multiscale Fuzzy Entropy and Support Vector Machine Algorithm. Algorithms 2024, 17, 588. [Google Scholar] [CrossRef]

- Huynh, H.H.; Min, C.H. Rotating Machinery Fault Detection Using Support Vector Machine via Feature Ranking. Algorithms 2024, 17, 441. [Google Scholar] [CrossRef]

- Deng, J.; Liu, Y.; Li, Z. Fault Diagnosis of Rotating Equipment Bearings Based on VMD-MSGWO-SVM. In Proceedings of the 2024 3rd Conference on Fully Actuated System Theory and Applications (FASTA), Shenzhen, China, 10–12 May 2024; pp. 614–619. [Google Scholar]

- Henao, H.; Capolino, G.A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in fault diagnosis for electrical machines: A review of diagnostic techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Jiang, W.; Jiang, H.; Yao, R.; Mu, M.; Liu, Y. A weighted frequency domain energy operator spectral method based on soft thresholding fast iterative filtering for rolling bearing incipient fault feature extraction. Struct. Health Monit. 2025, 14759217241306723. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, J.; Xiang, S.; Qin, Y. Remaining useful life prediction methodologies with health indicator dependence for rotating machinery: A comprehensive review. IEEE Trans. Instrum. Meas. 2025, 74, 3528519. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, J.; Jin, T. Degradation modeling and maintenance decisions based on Bayesian belief networks. IEEE Trans. Reliab. 2014, 63, 620–633. [Google Scholar] [CrossRef]

- Wang, T.; Yu, J.; Siegel, D.; Lee, J. A similarity-based prognostics approach for remaining useful life estimation of engineered systems. In Proceedings of the 2008 international conference on prognostics and health management, Denver, CO, USA, 6–9 October 2008; pp. 1–6. [Google Scholar]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.A. Advances in diagnostic techniques for induction machines. IEEE Trans. Ind. Electron. 2008, 55, 4109–4126. [Google Scholar] [CrossRef]

- Sun, B.; Hu, W.; Wang, H.; Wang, L.; Deng, C. Remaining Useful Life Prediction of Rolling Bearings Based on CBAM-CNN-LSTM. Sensors 2025, 25, 554. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Huang, H.Z.; Deng, Z.; Wu, J. Shrinkage mamba relation network with out-of-distribution data augmentation for rotating machinery fault detection and localization under zero-faulty data. Mech. Syst. Signal Process. 2025, 224, 112145. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Muthukumaran, S.; Rammohan, A.; Sekar, S.; Maiti, M.; Bingi, K. Bearing fault detection in induction motors using line currents. ECTI Trans. Electr. Eng. Electron. Commun. 2021, 19, 209–219. [Google Scholar]

- Zarei, J.; Poshtan, J. An advanced Park’s vectors approach for bearing fault detection. Tribol. Int. 2009, 42, 213–219. [Google Scholar] [CrossRef]

- Wei, L.; Rong, X.; Wang, H.; Yu, S.; Zhang, Y. Method for identifying stator and rotor faults of induction motors based on machine vision. Math. Probl. Eng. 2021, 2021, 6658648. [Google Scholar] [CrossRef]

- Lin, H.C.; Ye, Y.C. Reviews of bearing vibration measurement using fast Fourier transform and enhanced fast Fourier transform algorithms. Adv. Mech. Eng. 2019, 11, 1687814018816751. [Google Scholar] [CrossRef]

- Strömbergsson, D.; Marklund, P.; Berglund, K.; Larsson, P.E. Bearing monitoring in the wind turbine drivetrain: A comparative study of the FFT and wavelet transforms. Wind Energy 2020, 23, 1381–1393. [Google Scholar] [CrossRef]

- Proakis, J.G. Digital Signal Processing: Principles Algorithms and Applications; Pearson Education India: Noida, India, 2001. [Google Scholar]

- Randall, R. Vibration-Based Condition Monitoring: Industrial, Aerospace and Automotive Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Sikorska, J.Z.; Hodkiewicz, M.; Ma, L. Prognostic modelling options for remaining useful life estimation by industry. Mech. Syst. Signal Process. 2011, 25, 1803–1836. [Google Scholar] [CrossRef]

| CGPP-A | CGPP-B | CGPP-C | |||

|---|---|---|---|---|---|

| No. | Motor ID | No. | Motor ID | No. | Motor ID |

| 1 | E22802-01 | 1 | EA0117AM | 1 | E30093M |

| 2 | E22802-02 | 2 | EA0119AM | 2 | E30094M |

| 3 | E22802-03 | 3 | EA0121AM | 3 | E30095M |

| 4 | E22802-04 | 4 | EA0121CM | 4 | E30098M |

| 5 | E22802-05 | 5 | EA0222AM | 5 | E30099M |

| 6 | E22802-06 | 6 | EA0225AM | 6 | E301011M |

| 7 | E22802-08 | 7 | EA0901AM | 7 | E301012M |

| 8 | E22807-01 | 8 | EA0901BM | 8 | E301014M |

| 9 | E22807-02 | 9 | EC1101AM | 9 | E301022M |

| 10 | E22812-01 | 10 | EC1101BM | 10 | E301024M |

| 11 | E22812-02 | 11 | EC1101CM | 11 | P2006BM |

| 12 | E22902-01 | 12 | EC1101DM | 12 | P4907 |

| 13 | E22902-02 | 13 | KB0701AM | ||

| 14 | E22902-04 | 14 | KC0101AM | ||

| 15 | E22905-01 | 15 | PC0101CM | ||

| 16 | E22905-02 | 16 | PC0105BM | ||

| 17 | PM22803A | 17 | PC0222BM | ||

| 18 | PM22808B | 18 | PC0601BM | ||

| 19 | PM22902B | 19 | PC1007BM | ||

| 20 | PC1106M | ||||

| 21 | PC1108BM | ||||

| CGPP-A | CGPP-B | CGPP-C | ||||||

|---|---|---|---|---|---|---|---|---|

| No. | Motor ID | (%) | No. | Motor ID | (%) | No. | Motor ID | (%) |

| 1 | E22802-01 | 2.64 | 1 | EA0117AM | 27.60 | 1 | E30093M | 2.70 |

| 2 | E22802-02 | 28.30 | 2 | EA0119AM | 27.70 | 2 | E30094M | 3.78 |

| 3 | E22802-03 | 28.30 | 3 | EA0121AM | 5.32 | 3 | E30095M | 3.14 |

| 4 | E22802-04 | 28.90 | 4 | EA0121CM | 5.82 | 4 | E30098M | 3.65 |

| 5 | E22802-05 | 28.50 | 5 | EA0222AM | 5.34 | 5 | E30099M | 2.41 |

| 6 | E22802-06 | 2.14 | 6 | EA0225AM | 2.98 | 6 | E301011M | 2.69 |

| 7 | E22802-08 | 1.88 | 7 | EA0901AM | 28.30 | 7 | E301012M | 5.14 |

| 8 | E22807-01 | 2.12 | 8 | EA0901BM | 28.20 | 8 | E301014M | 4.59 |

| 9 | E22807-02 | 28.60 | 9 | EC1101AM | 28.80 | 9 | E301022M | 5.07 |

| 10 | E22812-01 | 28.30 | 10 | EC1101BM | 28.30 | 10 | E301024M | 6.87 |

| 11 | E22812-02 | 28.00 | 11 | EC1101CM | 30.30 | 11 | P2006BM | 4.16 |

| 12 | E22902-01 | 2.08 | 12 | EC1101DM | 27.00 | 12 | P4907 | 4.49 |

| 13 | E22902-02 | 29.30 | 13 | KB0701AM | 2.26 | |||

| 14 | E22902-04 | 1.95 | 14 | KC0101AM | 1.01 | |||

| 15 | E22905-01 | 1.56 | 15 | PC0101CM | 0.81 | |||

| 16 | E22905-02 | 1.54 | 16 | PC0105BM | 8.86 | |||

| 17 | PM22803A | 0.77 | 17 | PC0222BM | 29.50 | |||

| 18 | PM22808B | 28.70 | 18 | PC0601BM | 28.60 | |||

| 19 | PM22902B | 28.60 | 19 | PC1007BM | 9.31 | |||

| 20 | PC1106M | 2.37 | ||||||

| 21 | PC1108BM | 27.80 | ||||||

| Plant | No. | Motor ID | Amax | Bmax | Cmax | |||

|---|---|---|---|---|---|---|---|---|

| 2nd Harmonic | 3rd Harmonic | 2nd Harmonic | 3rd Harmonic | 2nd Harmonic | 3rd Harmonic | |||

| CGPP-A | 1 | E22802-01 | 0.0005 | 0.0006 | 0.0012 | 0.0069 | 0.0007 | 0.0041 |

| 2 | E22802-02 | 0.0008 | 0.0001 | 0.0011 | 0.0051 | 0.0007 | 0.0023 | |

| 3 | E22802-03 | 0.0013 | 0.0009 | 0.001 | 0.0056 | 0.0016 | 0.0029 | |

| 4 | E22802-04 | 0.0011 | 0.0017 | 0.0007 | 0.0038 | 0.001 | 0.0022 | |

| 5 | E22802-05 | 0.0014 | 0.0075 | 0.0014 | 0.0028 | 0.001 | 0.0071 | |

| 6 | E22802-06 | 0.0009 | 0.0019 | 0.0009 | 0.0068 | 0.001 | 0.0040 | |

| 7 | E22802-08 | 0.0009 | 0.0017 | 0.0011 | 0.0048 | 0.0014 | 0.0044 | |

| 8 | E22807-01 | 0.0003 | 0.0009 | 0.0005 | 0.0057 | 0.0005 | 0.0019 | |

| 9 | E22807-02 | 0.0005 | 0.0009 | 0.0008 | 0.0048 | 0.0004 | 0.0023 | |

| 10 | E22812-01 | 0.0005 | 0.0018 | 0.0001 | 0.0006 | 0.0003 | 0.0041 | |

| 11 | E22812-02 | 0.0016 | 0.0029 | 0.0012 | 0.0005 | 0.0012 | 0.0044 | |

| 12 | E22902-01 | 0.0014 | 0.005 | 0.0011 | 0.0037 | 0.0019 | 0.0023 | |

| 13 | E22902-02 | 0.0012 | 0.0051 | 0.0014 | 0.0038 | 0.0018 | 0.0026 | |

| 14 | E22902-04 | 0.0014 | 0.0048 | 0.0010 | 0.0043 | 0.0005 | 0.0022 | |

| 15 | E22905-01 | 0.0010 | 0.0020 | 0.0010 | 0.0014 | 0.0007 | 0.0005 | |

| 16 | E22905-02 | 0.0019 | 0.0017 | 0.0018 | 0.0051 | 0.0013 | 0.0032 | |

| 17 | PM22803A | 0.0006 | 0.0023 | 0.0010 | 0.0028 | 0.0006 | 0.0017 | |

| 18 | PM22808B | 0.0014 | 0.0006 | 0.0016 | 0.0016 | 0.0012 | 0.0029 | |

| 19 | PM22902B | 0.0014 | 0.0032 | 0.0010 | 0.0032 | 0.0009 | 0.0012 | |

| CGPP-B | 1 | EA0117AM | 0.0006 | 0.0087 | 0.0003 | 0.0062 | 0.0006 | 0.0068 |

| 2 | EA0119AM | 0.0007 | 0.0017 | 0.0006 | 0.0027 | 0.0003 | 0.0065 | |

| 3 | EA0121AM | 0.0031 | 0.0116 | 0.0036 | 0.0169 | 0.0022 | 0.0125 | |

| 4 | EA0121CM | 0.0038 | 0.0100 | 0.0042 | 0.0116 | 0.0030 | 0.0156 | |

| 5 | EA0222AM | 0.0012 | 0.0013 | 0.0006 | 0.0012 | 0.0005 | 0.0058 | |

| 6 | EA0225AM | 0.0005 | 0.0026 | 0.0015 | 0.0075 | 0.0033 | 0.0062 | |

| 7 | EA0901AM | 0.0010 | 0.0064 | 0.0016 | 0.0078 | 0.0013 | 0.0064 | |

| 8 | EA0901BM | 0.0008 | 0.0050 | 0.0019 | 0.0054 | 0.0012 | 0.0029 | |

| 9 | EC1101AM | 0.0034 | 0.0006 | 0.0030 | 0.0013 | 0.0023 | 0.0003 | |

| 10 | EC1101BM | 0.0021 | 0.0042 | 0.0019 | 0.0023 | 0.0027 | 0.0045 | |

| 11 | EC1101CM | 0.0044 | 0.0083 | 0.0040 | 0.0014 | 0.0050 | 0.0069 | |

| 12 | EC1101DM | 0.0026 | 0.0066 | 0.0021 | 0.0095 | 0.0029 | 0.0071 | |

| 13 | KB0701AM | 0.0003 | 0.0015 | 0.0019 | 0.0071 | 0.0026 | 0.0073 | |

| 14 | KC0101AM | 0.0007 | 0.0010 | 0.0005 | 0.0022 | 0.0003 | 0.0026 | |

| 15 | PC0101CM | 0.0003 | 0.0010 | 0.0001 | 0.0017 | 0.0003 | 0.0022 | |

| 16 | PC0105BM | 0.0037 | 0.0406 | 0.0076 | 0.0174 | 0.0125 | 0.0380 | |

| 17 | PC0222BM | 0.0014 | 0.0090 | 0.0017 | 0.0080 | 0.0034 | 0.0034 | |

| 18 | PC0601BM | 0.0007 | 0.0006 | 0.0009 | 0.0021 | 0.0003 | 0.0026 | |

| 19 | PC1007BM | 0.0027 | 0.0145 | 0.0053 | 0.0109 | 0.0019 | 0.0375 | |

| 20 | PC1106M | 0.0007 | 0.0008 | 0.0010 | 0.0025 | 0.0005 | 0.0051 | |

| 21 | PC1108BM | 0.0002 | 0.0050 | 0.0016 | 0.0030 | 0.0014 | 0.0033 | |

| CGPP-C | 1 | E30093M | 0.0010 | 0.0022 | 0.0029 | 0.0025 | 0.0024 | 0.0031 |

| 2 | E30094M | 0.0047 | 0.0013 | 0.0076 | 0.0020 | 0.0033 | 0.0024 | |

| 3 | E30095M | 0.0031 | 0.0016 | 0.0043 | 0.0018 | 0.0018 | 0.0033 | |

| 4 | E30098M | 0.0049 | 0.0012 | 0.0075 | 0.0021 | 0.0028 | 0.0028 | |

| 5 | E30099M | 0.0018 | 0.0025 | 0.0034 | 0.0016 | 0.0016 | 0.0031 | |

| 6 | E301011M | 0.0014 | 0.0022 | 0.0017 | 0.0011 | 0.0010 | 0.0052 | |

| 7 | E301012M | 0.0108 | 0.0069 | 0.0165 | 0.0072 | 0.0087 | 0.0037 | |

| 8 | E301014M | 0.0106 | 0.0067 | 0.0189 | 0.0074 | 0.0093 | 0.0032 | |

| 9 | E301022M | 0.0113 | 0.0065 | 0.0193 | 0.0081 | 0.0088 | 0.0033 | |

| 10 | E301024M | 0.0104 | 0.0060 | 0.0194 | 0.0071 | 0.0094 | 0.0024 | |

| 11 | P2006BM | 0.0049 | 0.0018 | 0.0062 | 0.0053 | 0.0015 | 0.0078 | |

| 12 | P4907 | 0.0007 | 0.0079 | 0.0052 | 0.0067 | 0.0034 | 0.0074 | |

| Plant | No. | Motor ID | HI Estimation | RUL Estimation ( s) | RUL Estimation (Approx. Days) | |

|---|---|---|---|---|---|---|

| CGPP-A | 1 | E22802-01 | 0.3769 | 0.0484 | 467.154 | 54 |

| 2 | E22802-02 | 0.3530 | 0.0482 | 441.695 | 51 | |

| 3 | E22802-03 | 0.2990 | 0.0480 | 393.441 | 45 | |

| 4 | E22802-04 | 0.0580 | 0.0467 | 265.78 | 30 | |

| 5 | E22802-05 | 0.0597 | 0.0467 | 266.382 | 30 | |

| 6 | E22802-06 | 0.2453 | 0.0477 | 355.075 | 41 | |

| 7 | E22802-08 | 0.3935 | 0.0484 | 486.677 | 56 | |

| 8 | E22807-01 | 0.5894 | 0.0495 | 970.535 | 112 | |

| 9 | E22807-02 | 0.0699 | 0.0468 | 270.056 | 31 | |

| 10 | E22812-01 | 0.1517 | 0.0472 | 303.821 | 35 | |

| 11 | E22812-02 | 0.0997 | 0.0469 | 281.420 | 32 | |

| 12 | E22902-01 | 1.7030 | 0.0557 | 192.554 | 22 | |

| 13 | E22902-02 | 0.2094 | 0.0475 | 333.437 | 38 | |

| 14 | E22902-04 | 1.9796 | 0.0574 | 145.989 | 16 | |

| 15 | E22905-01 | 0.9711 | 0.0515 | 975.751 | 112 | |

| 16 | E22905-02 | 0.2576 | 0.0477 | 363.170 | 42 | |

| 17 | PM22803A | 0.7826 | 0.0505 | 4804.400 | 556 | |

| 18 | PM22808B | 1.1980 | 0.0527 | 437.720 | 50 | |

| 19 | PM22902B | 2.1019 | 0.0580 | 131.632 | 15 | |

| CGPP-B | 1 | EA0117AM | 0.2474 | 0.0477 | 356.431 | 41 |

| 2 | EA0119AM | 0.1292 | 0.0471 | 293.69 | 33 | |

| 3 | EA0121AM | 0.0292 | 0.0466 | 255.989 | 29 | |

| 4 | EA0121CM | 0.0315 | 0.0466 | 256.743 | 29 | |

| 5 | EA0222AM | 0.2276 | 0.0476 | 343.937 | 39 | |

| 6 | EA0225AM | 0.0617 | 0.0468 | 267.094 | 30 | |

| 7 | EA0901AM | 0.3803 | 0.0484 | 471.021 | 54 | |

| 8 | EA0901BM | 0.3221 | 0.0481 | 412.697 | 47 | |

| 9 | EC1101AM | 0.8899 | 0.0511 | 1721.21 | 199 | |

| 10 | EC1101BM | 1.0169 | 0.0518 | 783.199 | 90 | |

| 11 | EC1101CM | 0.2937 | 0.0479 | 389.279 | 45 | |

| 12 | EC1101DM | 0.2274 | 0.0476 | 343.937 | 39 | |

| 13 | KB0701AM | 0.0766 | 0.0468 | 272.527 | 31 | |

| 14 | KC0101AM | 2.7871 | 0.0625 | 83.6532 | 9 | |

| 15 | PC0101CM | 5.8024 | 0.0855 | 28.5921 | 3 | |

| 16 | PC0105BM | 0.0231 | 0.0466 | 254.011 | 29 | |

| 17 | PC0222BM | 0.0268 | 0.0466 | 255.207 | 29 | |

| 18 | PC0601BM | 1.4198 | 0.054 | 282.165 | 32 | |

| 19 | PC1007BM | 0.0262 | 0.0466 | 255.012 | 29 | |

| 20 | PC1106M | 0.6469 | 0.0498 | 1377.78 | 159 | |

| 21 | PC1108BM | 0.0738 | 0.0468 | 271.489 | 31 | |

| CGPP-C | 1 | E30093M | 0.1420 | 0.0472 | 299.366 | 34 |

| 2 | E30094M | 0.1077 | 0.0470 | 284.641 | 32 | |

| 3 | E30095M | 0.0898 | 0.0469 | 277.536 | 32 | |

| 4 | E30098M | 0.1012 | 0.0470 | 282.018 | 32 | |

| 5 | E30099M | 0.1421 | 0.0472 | 299.366 | 34 | |

| 6 | E301011M | 0.1137 | 0.0470 | 287.108 | 33 | |

| 7 | E301012M | 0.1470 | 0.0472 | 301.646 | 34 | |

| 8 | E301014M | 0.1488 | 0.0472 | 302.475 | 34 | |

| 9 | E301022M | 0.1454 | 0.0472 | 300.912 | 34 | |

| 10 | E301024M | 0.1375 | 0.0471 | 297.345 | 34 | |

| 11 | P2006BM | 0.0404 | 0.0467 | 259.706 | 29 | |

| 12 | P4907 | 0.0298 | 0.0466 | 256.185 | 29 |

| Plant | No | Motor ID | Analysis | FFT Analysis | RUL Estimation (Days) |

|---|---|---|---|---|---|

| CGPP-A | 1 | E22802-01 | ✗ | ✗ | 54 |

| 2 | E22802-02 | ✗ | ✗ | 51 | |

| 3 | E22802-03 | ✗ | ✗ | 45 | |

| 4 | E22802-04 | ✗ | ✗ | 30 | |

| 5 | E22802-05 | ✗ | ✗ | 30 | |

| 6 | E22802-06 | ✗ | ✗ | 41 | |

| 7 | E22802-08 | ✗ | ✗ | 56 | |

| 8 | E22807-01 | ✗ | ✗ | 112 | |

| 9 | E22807-02 | ✗ | ✗ | 31 | |

| 10 | E22812-01 | ✗ | ✗ | 35 | |

| 11 | E22812-02 | ✗ | ✗ | 32 | |

| 12 | E22902-01 | ✗ | ✗ | 22 | |

| 13 | E22902-02 | ✗ | ✗ | 38 | |

| 14 | E22902-04 | ✗ | ✗ | 16 | |

| 15 | E22905-01 | ✗ | ✓ | 112 | |

| 16 | E22905-02 | ✗ | ✗ | 42 | |

| 17 | PM22803A | ✓ | ✓ | 556 | |

| 18 | PM22808B | ✗ | ✓ | 50 | |

| 19 | PM22902B | ✗ | ✗ | 15 | |

| CGPP-A | 1 | EA0117AM | ✗ | ✗ | 41 |

| 2 | EA0119AM | ✗ | ✗ | 33 | |

| 3 | EA0121AM | ✗ | ✗ | 29 | |

| 4 | EA0121CM | ✗ | ✗ | 29 | |

| 5 | EA0222AM | ✗ | ✗ | 39 | |

| 6 | EA0225AM | ✗ | ✗ | 30 | |

| 7 | EA0901AM | ✗ | ✗ | 54 | |

| 8 | EA0901BM | ✗ | ✗ | 47 | |

| 9 | EC1101AM | ✗ | ✗ | 199 | |

| 10 | EC1101BM | ✗ | ✗ | 90 | |

| 11 | EC1101CM | ✗ | ✗ | 45 | |

| 12 | EC1101DM | ✗ | ✗ | 39 | |

| 13 | KB0701AM | ✗ | ✗ | 31 | |

| 14 | KC0101AM | ✓ | ✓ | 190 | |

| 15 | PC0101CM | ✓ | ✓ | 184 | |

| 16 | PC0105BM | ✗ | ✗ | 29 | |

| 17 | PC0222BM | ✗ | ✗ | 29 | |

| 18 | PC0601BM | ✗ | ✓ | 32 | |

| 19 | PC1007BM | ✗ | ✗ | 29 | |

| 20 | PC1106M | ✗ | ✗ | 59 | |

| 21 | PC1108BM | ✗ | ✗ | 31 | |

| CGPP-A | 1 | E30093M | ✗ | ✗ | 34 |

| 2 | E30094M | ✗ | ✗ | 32 | |

| 3 | E30095M | ✗ | ✗ | 32 | |

| 4 | E30098M | ✗ | ✗ | 32 | |

| 5 | E30099M | ✗ | ✗ | 34 | |

| 6 | E301011M | ✗ | ✗ | 33 | |

| 7 | E301012M | ✗ | ✗ | 34 | |

| 8 | E301014M | ✗ | ✗ | 34 | |

| 9 | E301022M | ✗ | ✗ | 34 | |

| 10 | E301024M | ✗ | ✗ | 34 | |

| 11 | P2006BM | ✗ | ✗ | 29 | |

| 12 | P4907 | ✗ | ✗ | 29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zulkifli, N.Z.; Ramadevi, B.; Bingi, K.; Ibrahim, R.; Omar, M. Predicting Remaining Useful Life of Induction Motor Bearings from Motor Current Signatures Using Machine Learning. Machines 2025, 13, 400. https://doi.org/10.3390/machines13050400

Zulkifli NZ, Ramadevi B, Bingi K, Ibrahim R, Omar M. Predicting Remaining Useful Life of Induction Motor Bearings from Motor Current Signatures Using Machine Learning. Machines. 2025; 13(5):400. https://doi.org/10.3390/machines13050400

Chicago/Turabian StyleZulkifli, Nurul Zahirah, Bhukya Ramadevi, Kishore Bingi, Rosdiazli Ibrahim, and Madiah Omar. 2025. "Predicting Remaining Useful Life of Induction Motor Bearings from Motor Current Signatures Using Machine Learning" Machines 13, no. 5: 400. https://doi.org/10.3390/machines13050400

APA StyleZulkifli, N. Z., Ramadevi, B., Bingi, K., Ibrahim, R., & Omar, M. (2025). Predicting Remaining Useful Life of Induction Motor Bearings from Motor Current Signatures Using Machine Learning. Machines, 13(5), 400. https://doi.org/10.3390/machines13050400