A Novel Dynamic Characteristic for Detecting Breathing Cracks in Blades Based on Vibration Response Envelope Analysis

Abstract

1. Introduction

- (1)

- A novel blade dynamic characteristic EDIVR is proposed. The correlation between EDIVR and blade crack faults is demonstrated through dynamic modeling, with the characteristic directly linked to crack-induced dynamic responses.

- (2)

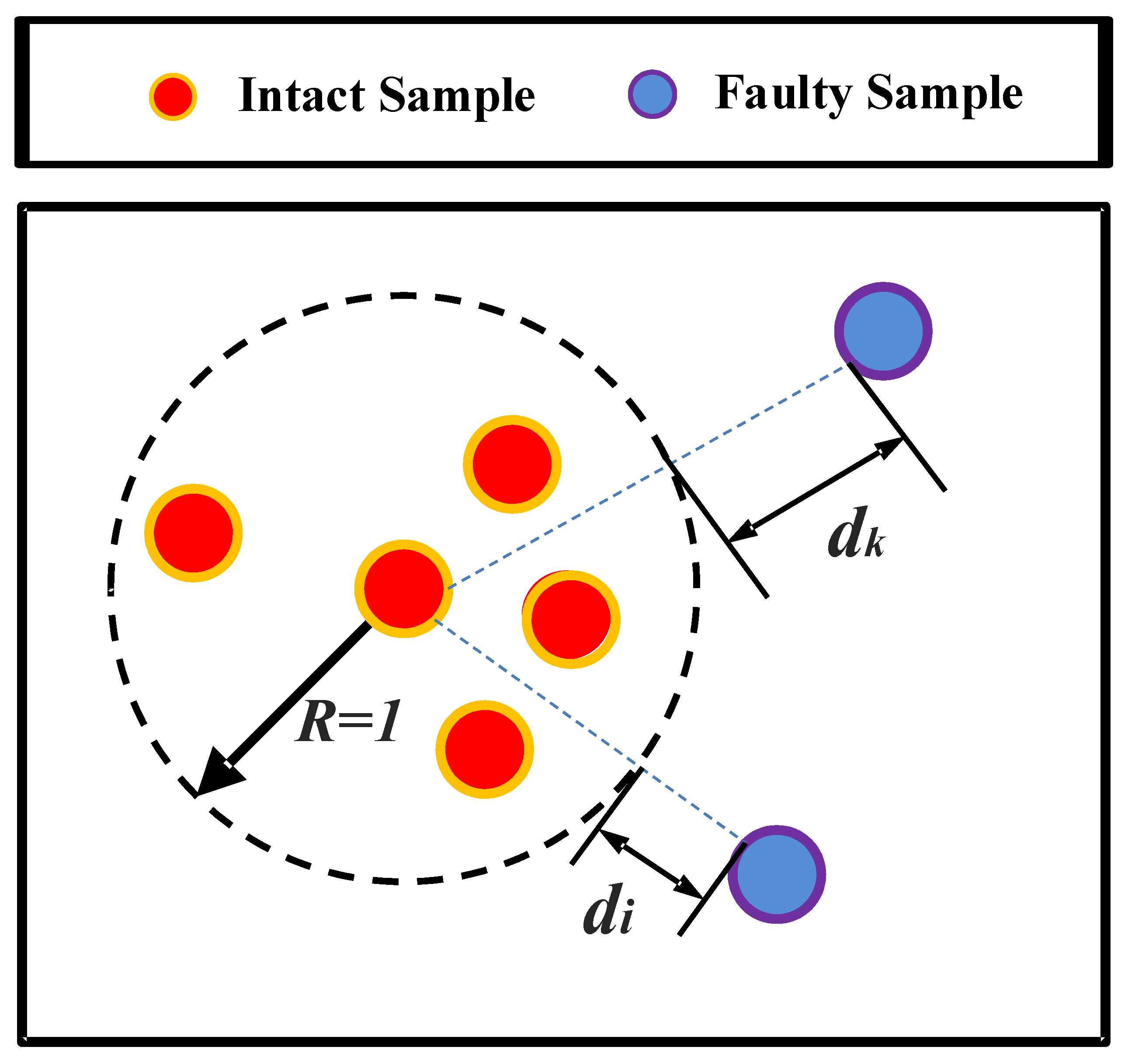

- A novel indicator DFD is proposed to quantitatively characterize EDIVR features. This indicator exhibits enhanced fault sensitivity when implemented as a diagnostic criterion for crack detection.

- (3)

- The EDIVR characteristic and its DFD indicator effectively alleviate noise interference in crack diagnosis.

2. Feature Generation Methodology

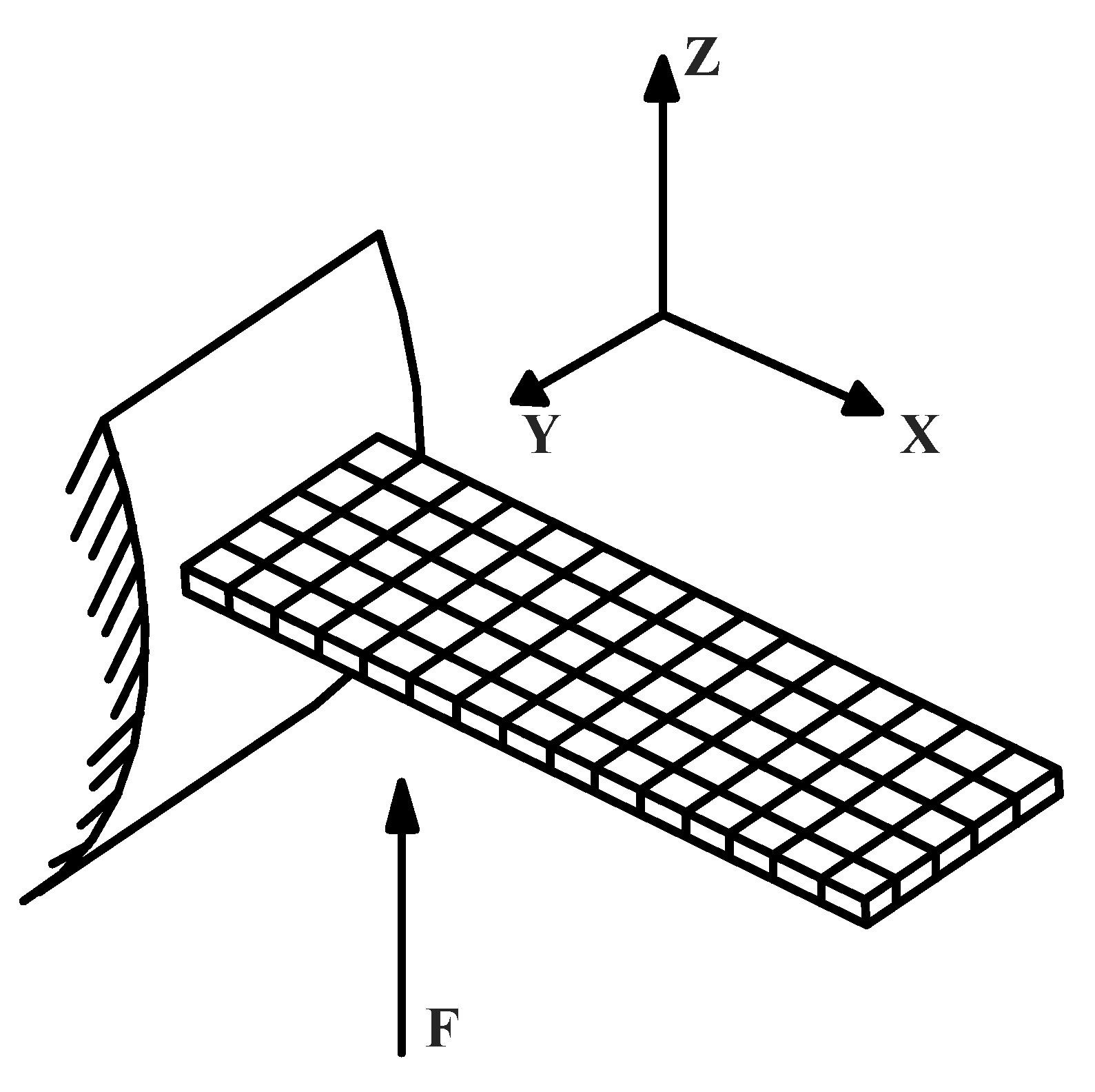

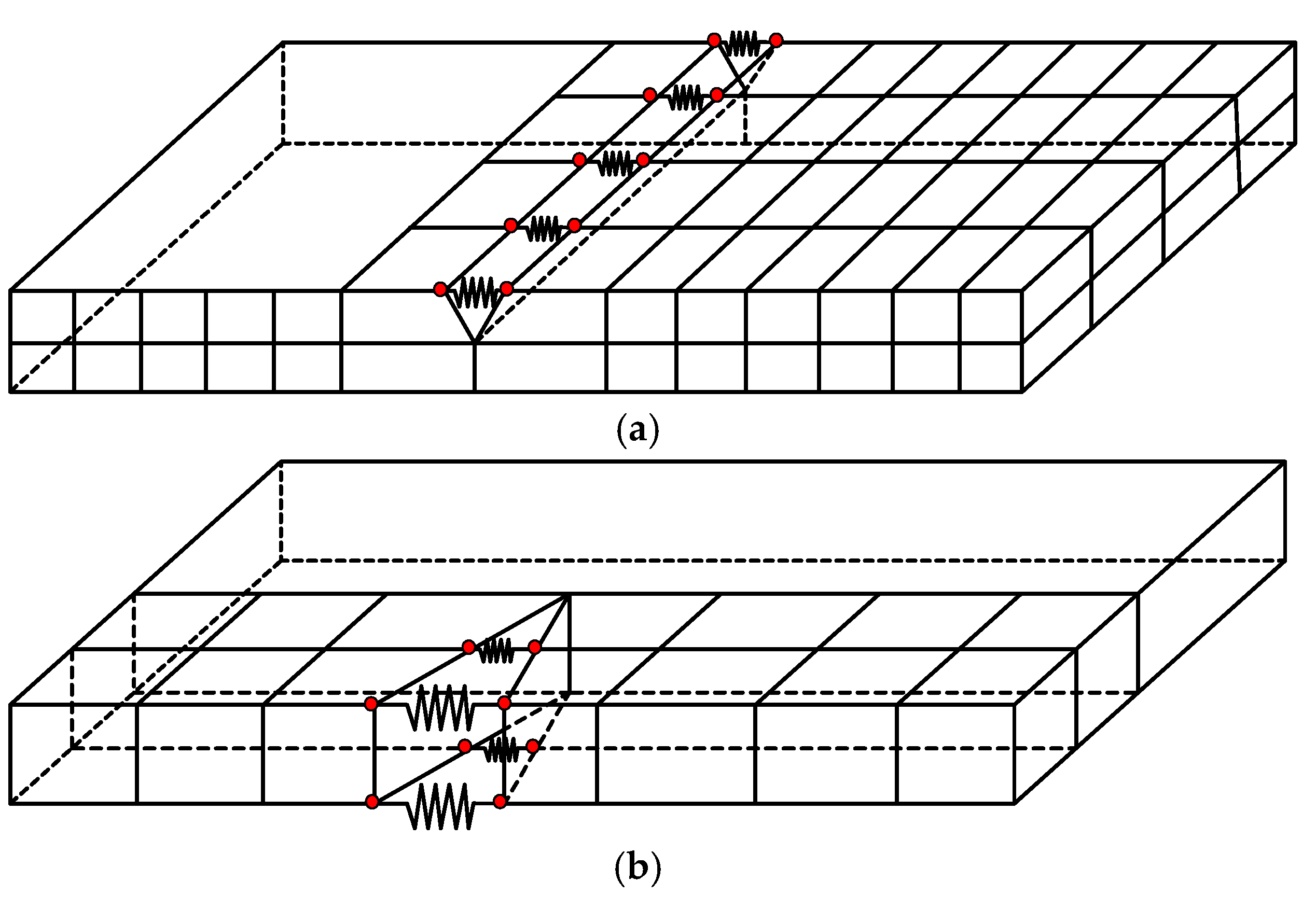

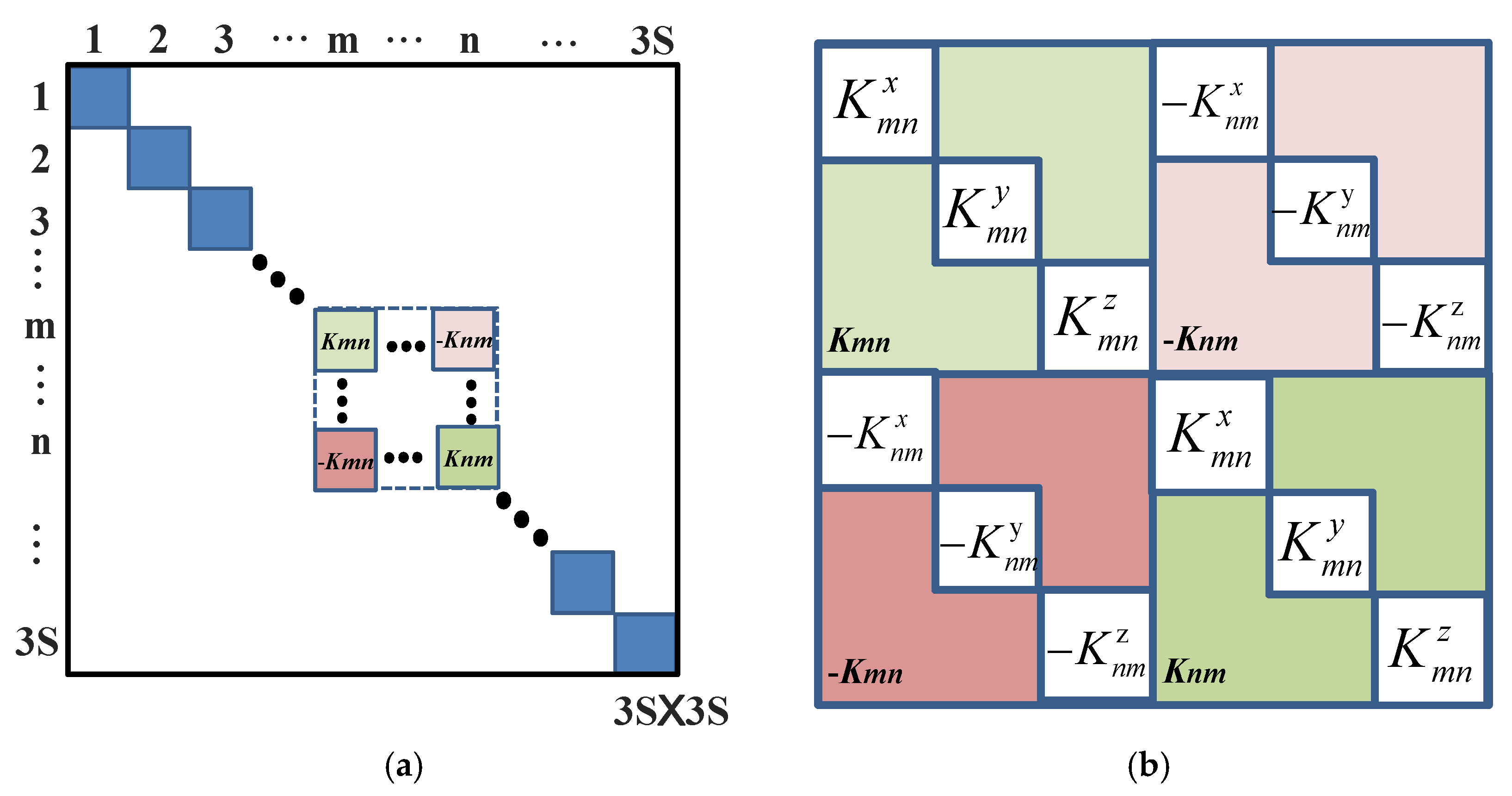

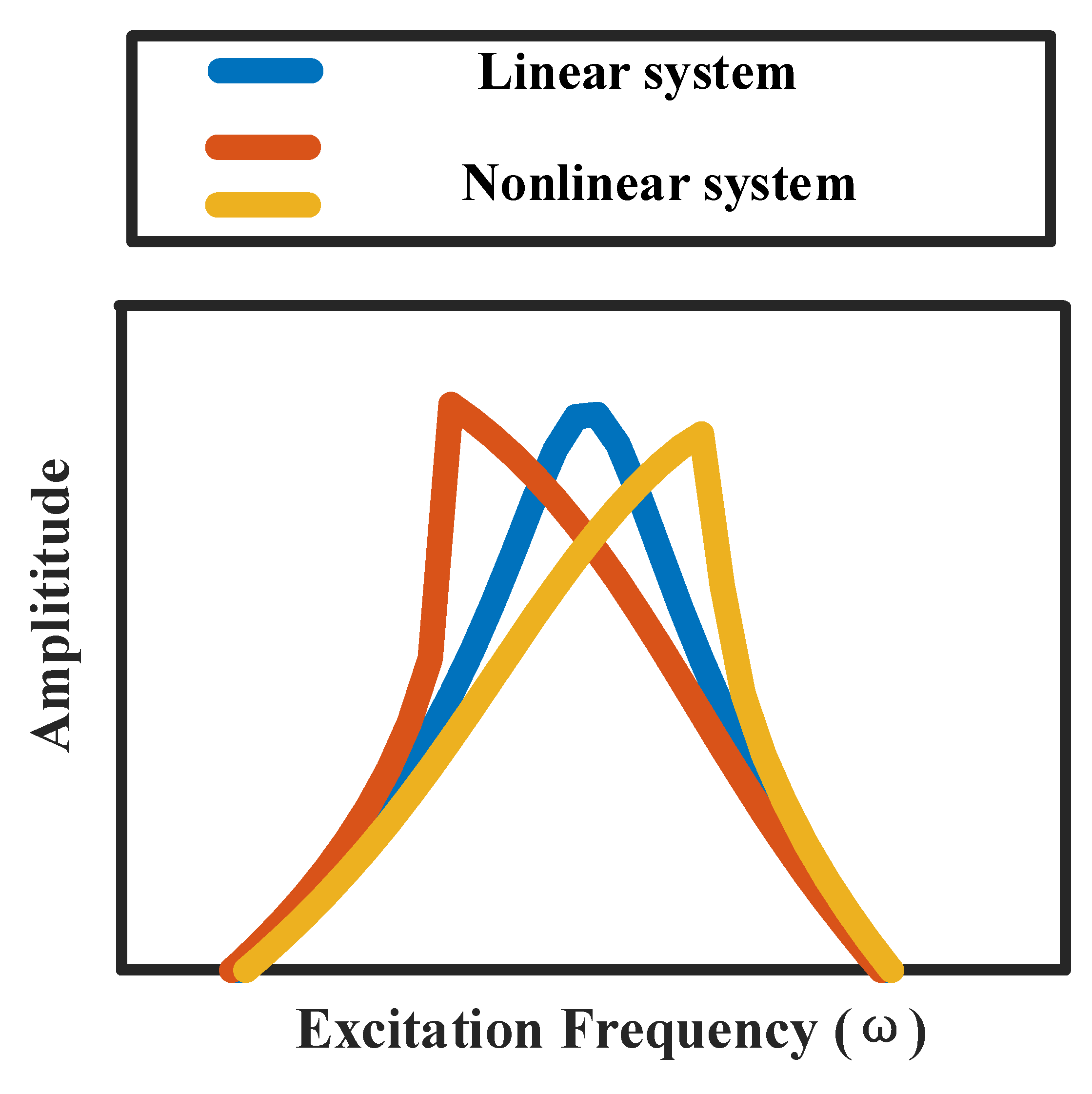

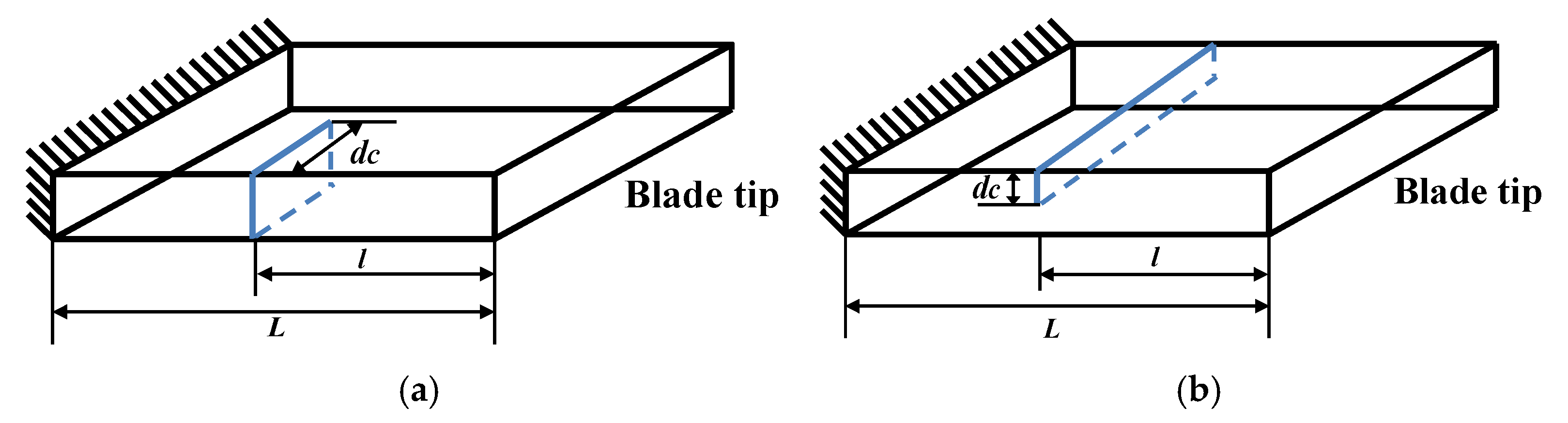

2.1. Dynamic Model of Blade with Breathing Crack

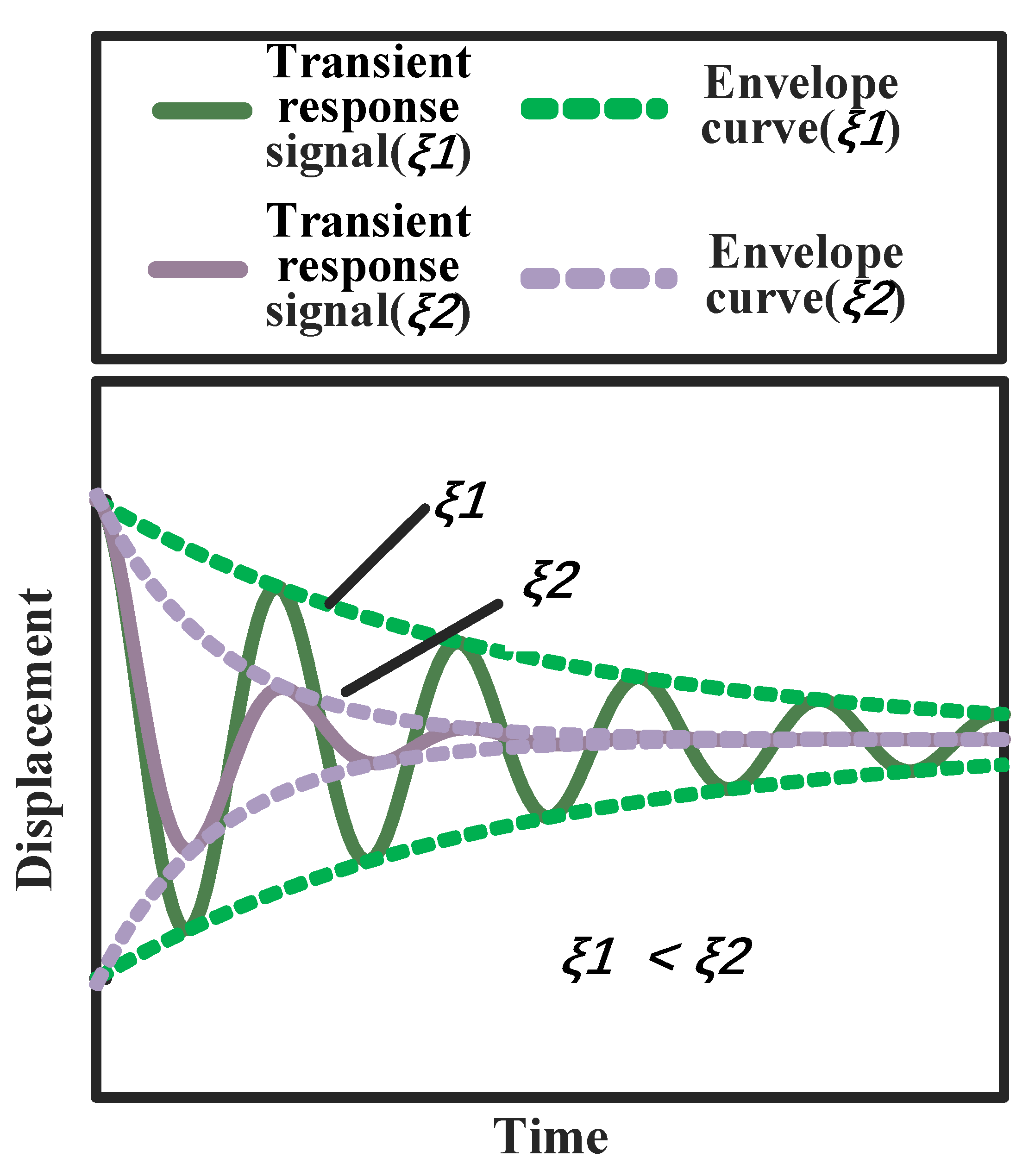

2.2. Envelope Analysis of Dynamic Response Signals

3. Numerical Simulation

3.1. Quantitative Representation of Crack Effects on Dynamic Characteristics

3.2. Comparison of Dynamic Characteristics for Crack Detection

3.2.1. Effects of Crack Depth

- (1)

- Among the three indicators for crack diagnosis, the DFD exhibits the most significant variation under identical crack conditions. For a given crack type, increasing depth reduces the natural frequency (raising the FDR), induces superharmonic components (increasing the RHM), and distorts the resonance envelope shape (increasing the DFD). All three parameters grow with crack depth, validating their utility as diagnostic criteria. However, the value of DFD substantially exceeds those of the RHM and FDR, making it a more robust decision-making indicator to minimize misjudgment in engineering practice.

- (2)

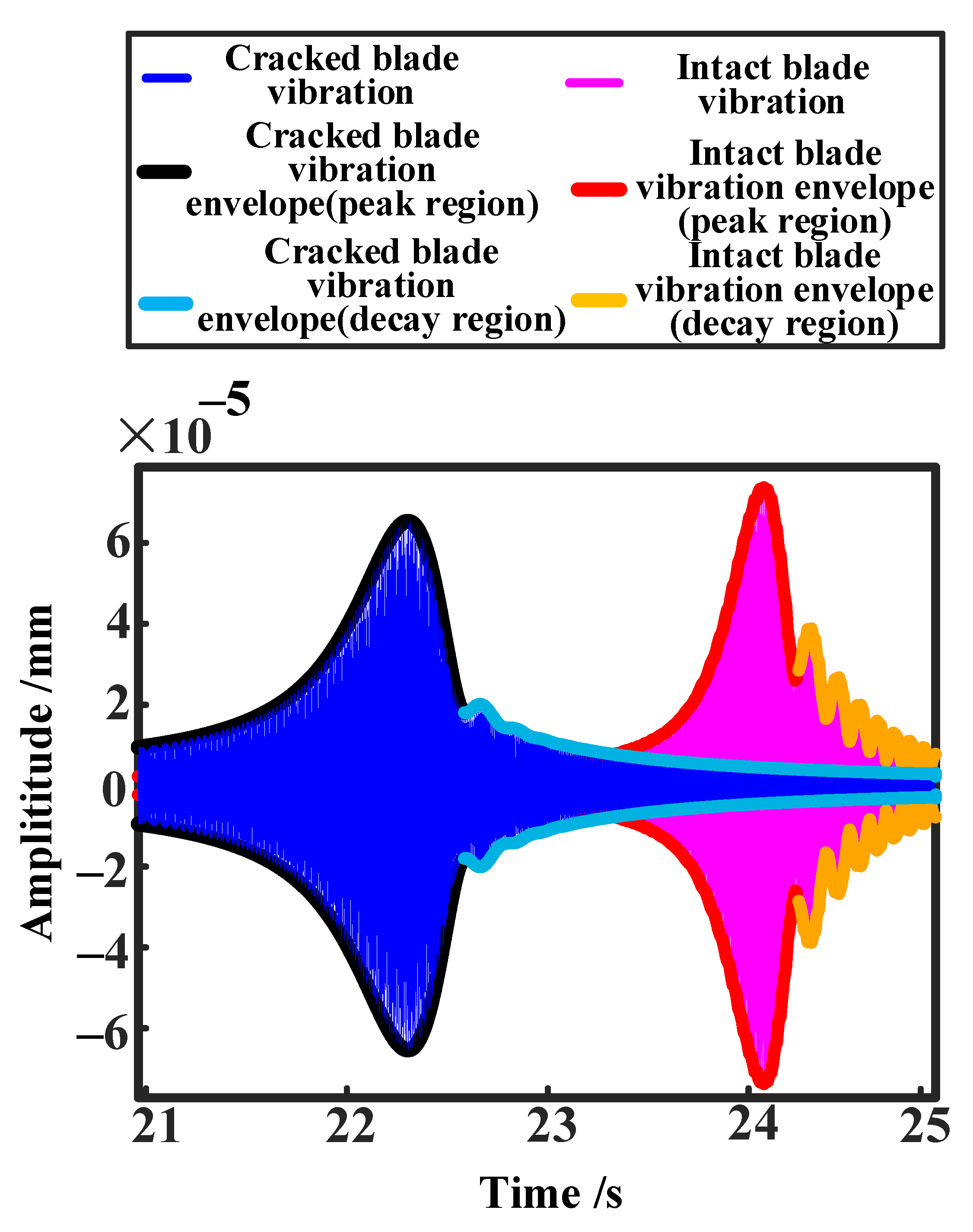

- During initial crack stages, the DFD demonstrates superior sensitivity compared to the RHM and FDR. Envelope analysis reveals that crack depth primarily alters post-resonance oscillation shapes, while any crack presence causes asymmetry in the shape of resonance peak, elevating the DFD above 0.2. In contrast, the RHM remains negligible (merely 0.029 even at maximum surface crack depth). The FDR increases notably with deeper cracks (up to 0.101), but its sensitivity to incipient cracks is limited (only 0.033 for both surface and edge cracks).

- (3)

- With increasing crack depth in the blade, the decay rate of the vibration envelope beyond the resonance peak exhibits a corresponding acceleration. This phenomenon is identified as the primary factor contributing to distinct DFD among blades with varying crack depths. However, the shape of the envelope curve at the resonance peak demonstrates insensitivity to crack depth progression. Instead, it shows a pronounced deviation from the crack-free condition when a crack appears.

3.2.2. Effects of Crack Location

- (1)

- When cracks are located closer to the blade root (γ increasing from 1/3 to 2/3), all dynamic indicators increase. Notably, the value of DFD consistently retains the highest across different crack locations.

- (2)

- Compared to crack depth, positional variations induce smaller deviations in all three indicators. Sensitivity to crack position differs across indicators: the DFD shows minimal sensitivity, with only a 0.03 increase for surface cracks of identical depth moving from the blade tip (γ = 1/3) to the root (γ = 2/3). In contrast, the FDR demonstrates higher positional sensitivity, rising by 0.023 for edge cracks and 0.053 for surface cracks under equivalent positional shifts.

3.2.3. Effects of Signal Noise

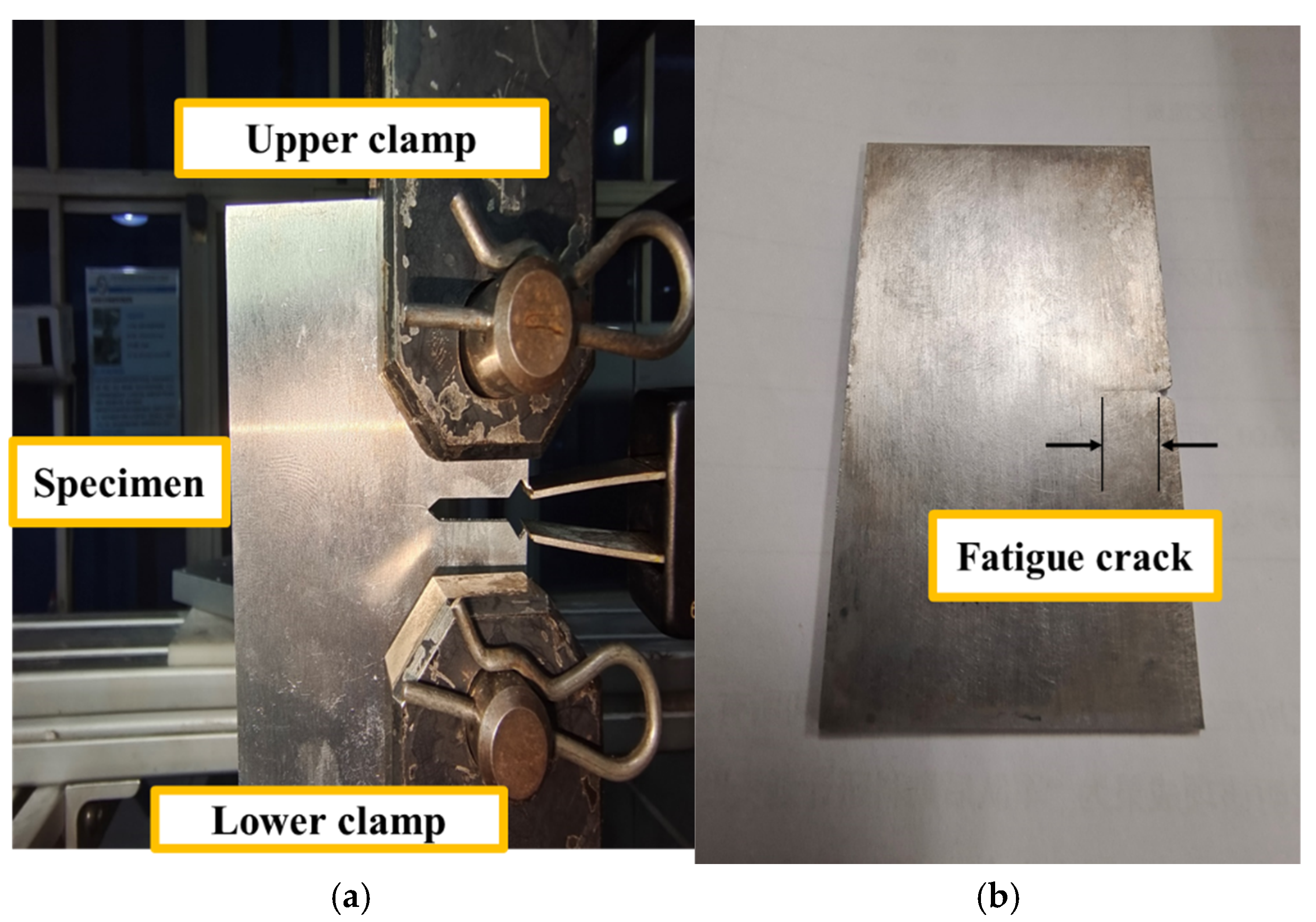

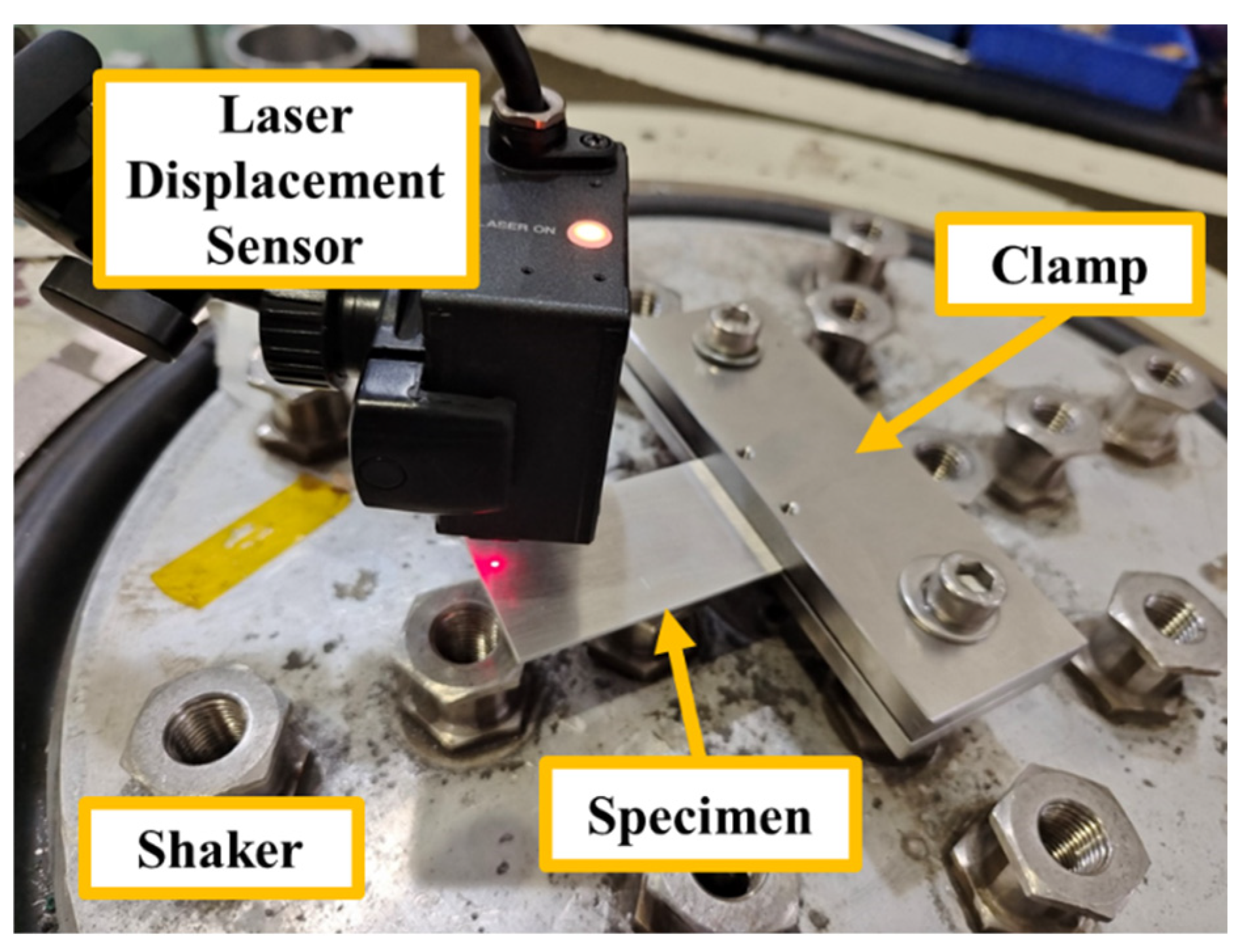

4. Experimental Validation

4.1. Experiment Description

4.2. Validation of Crack Detection

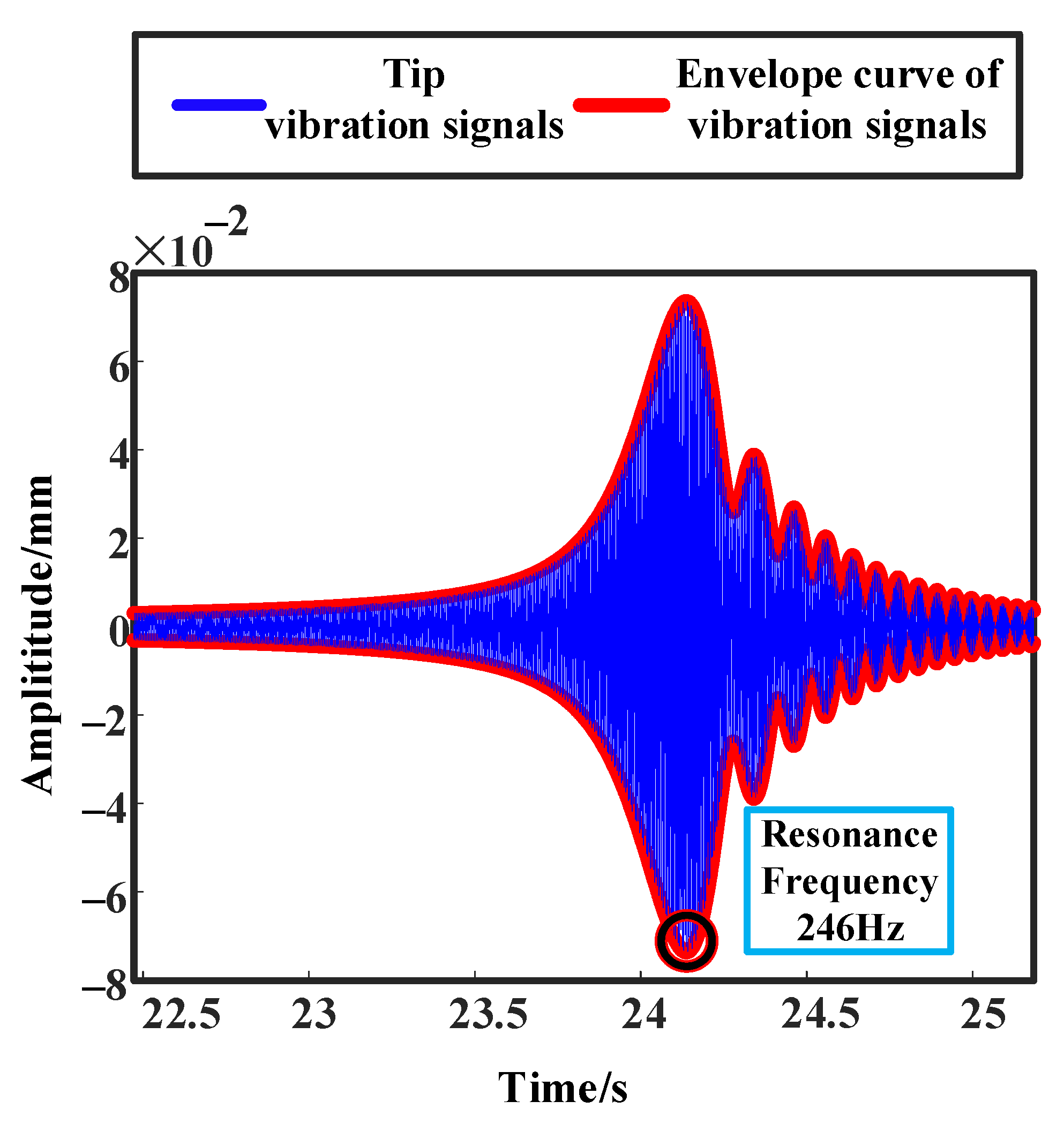

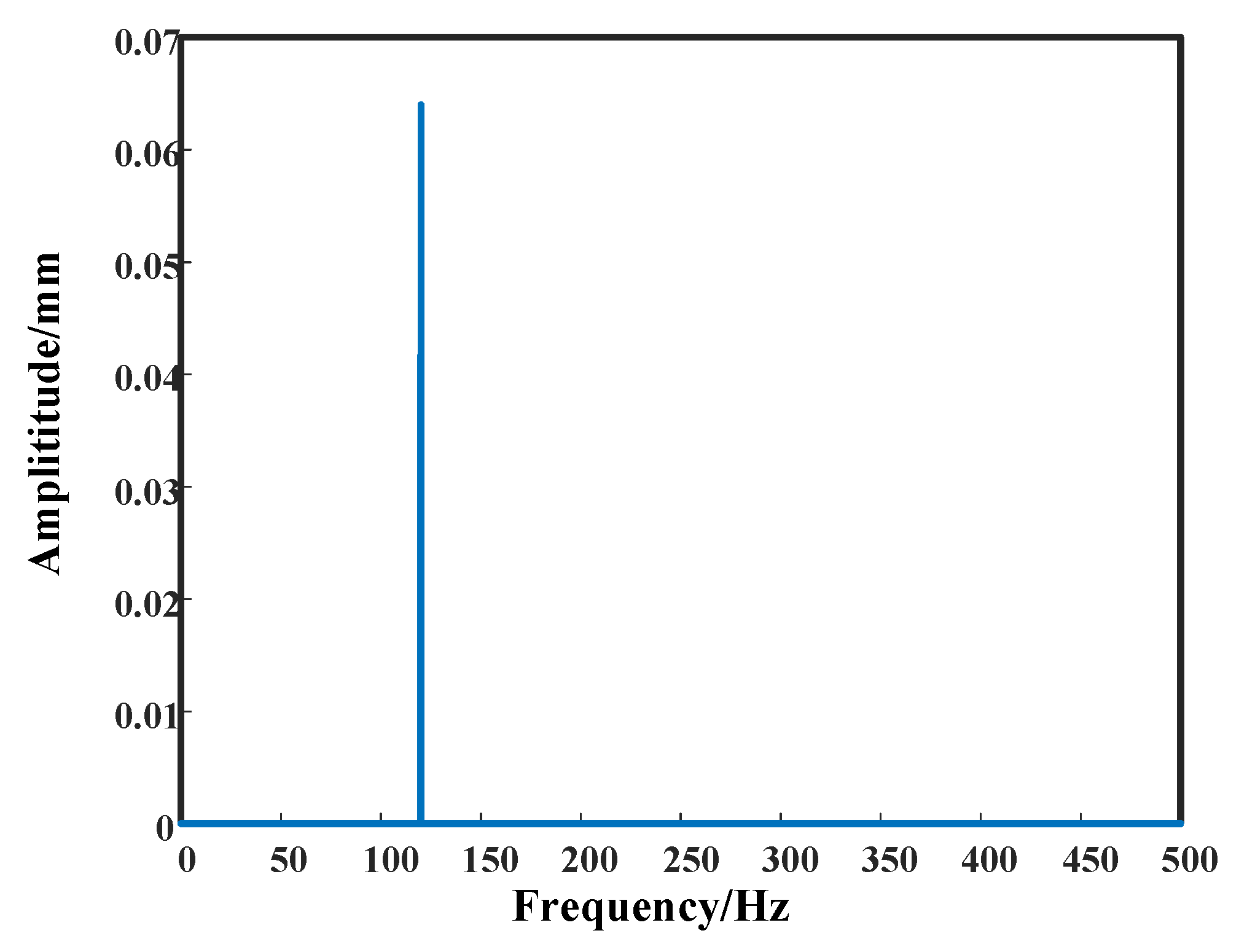

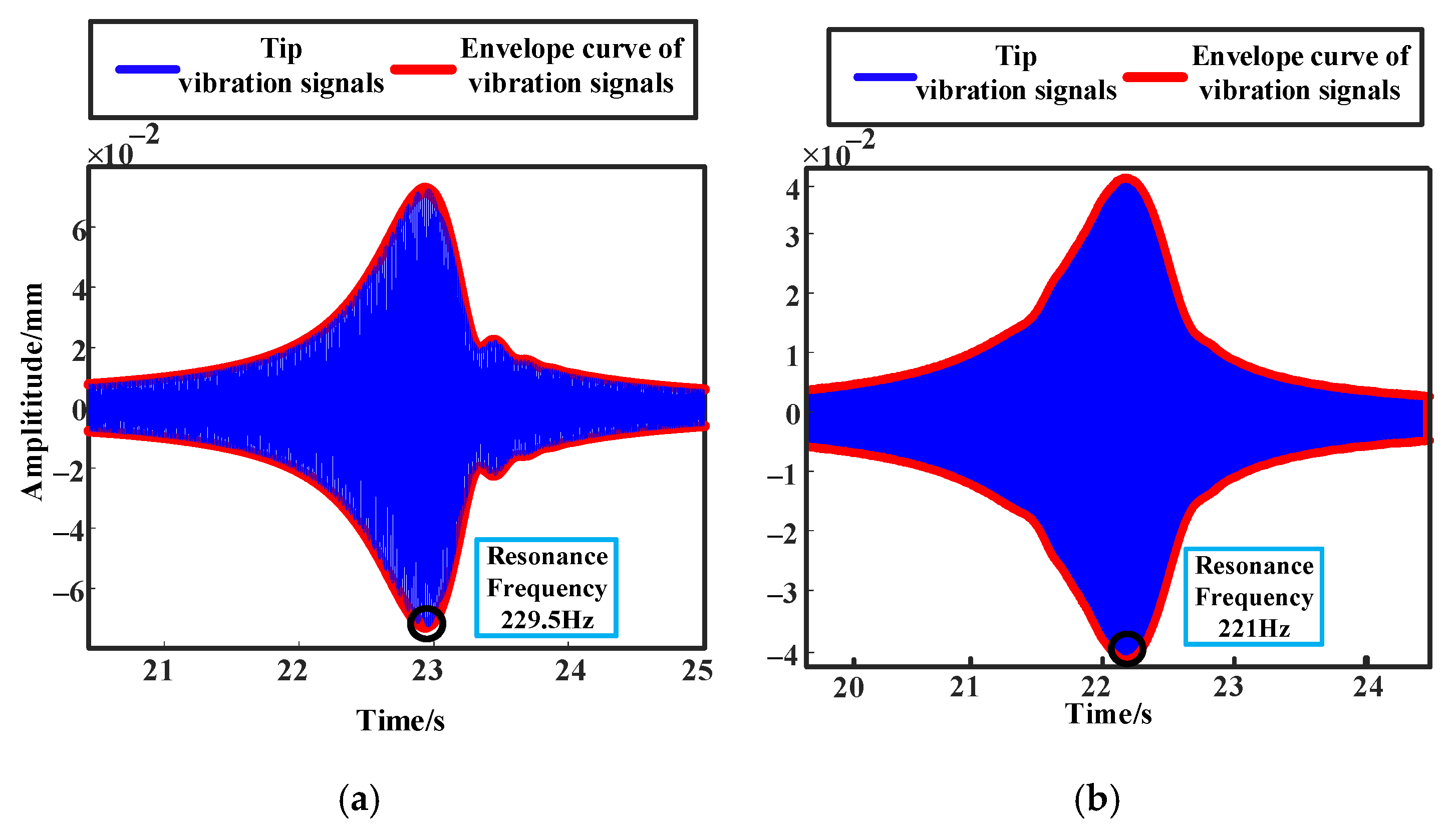

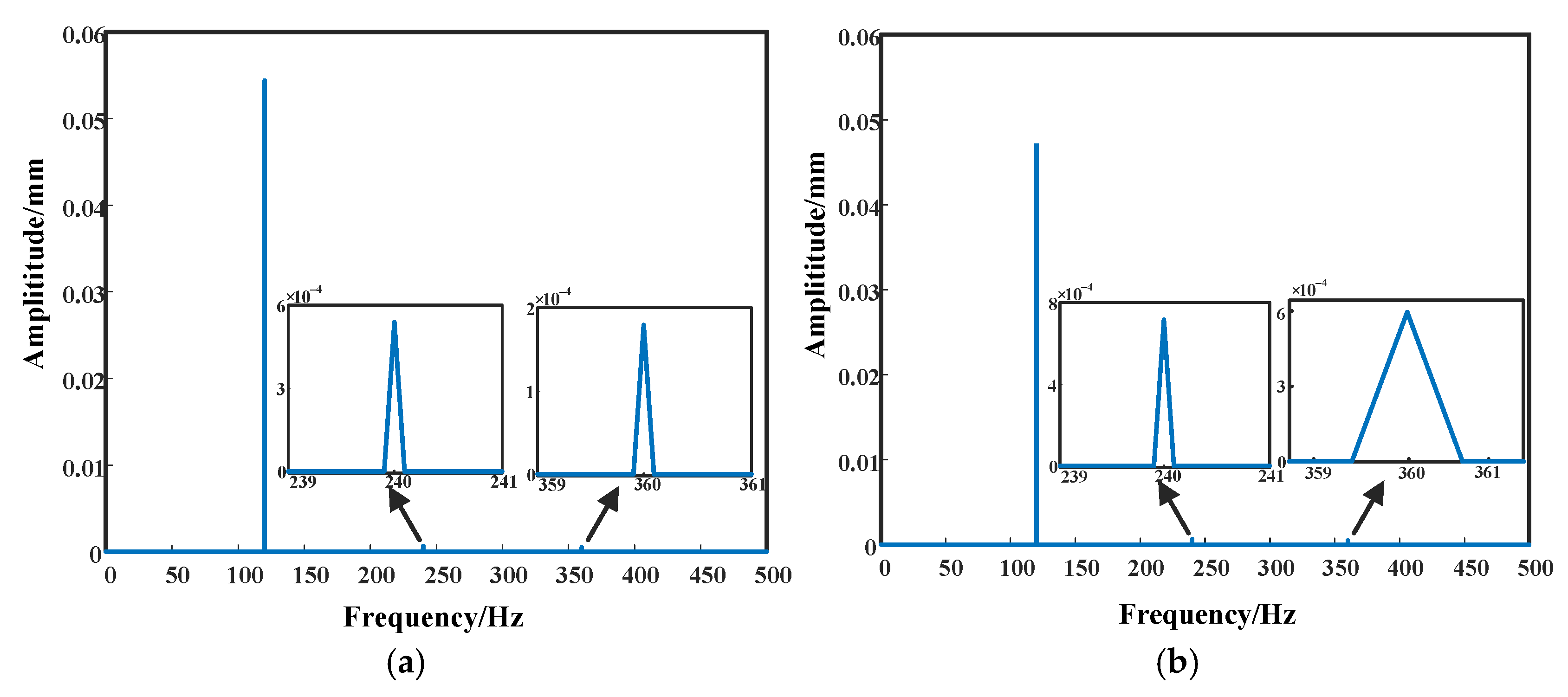

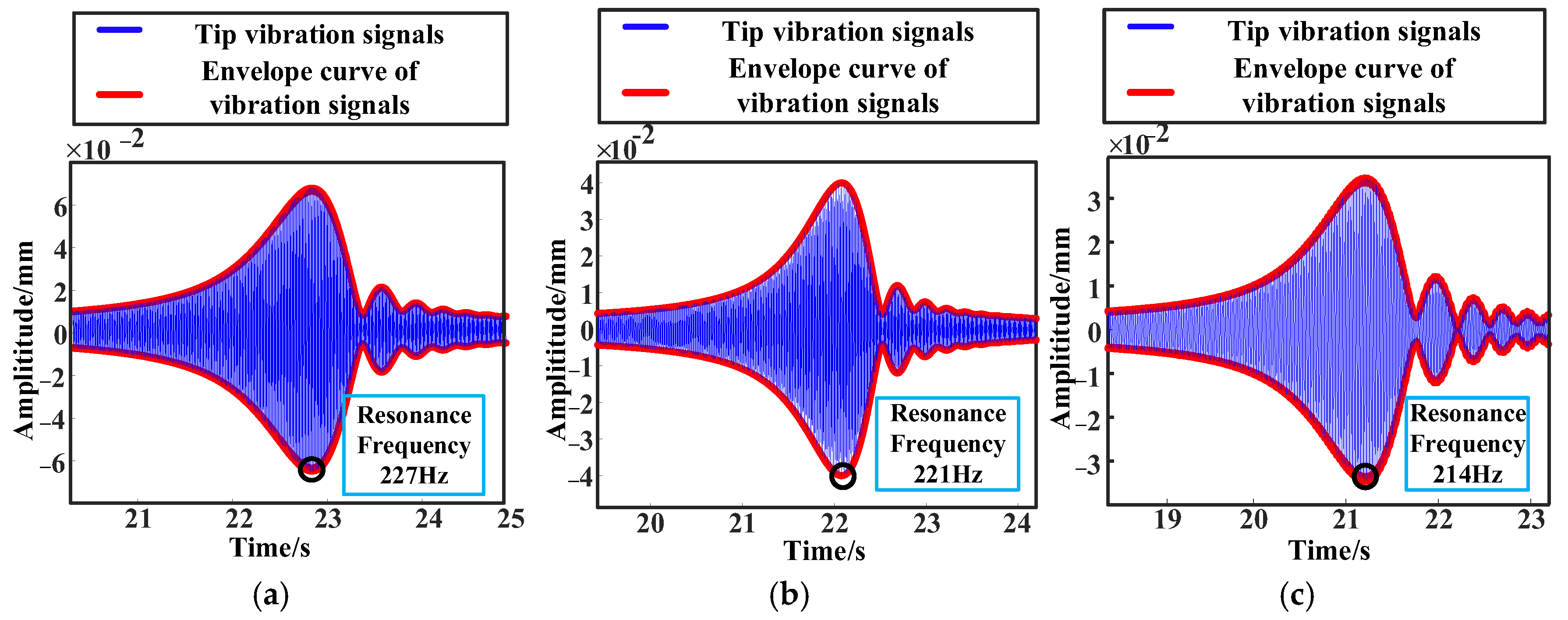

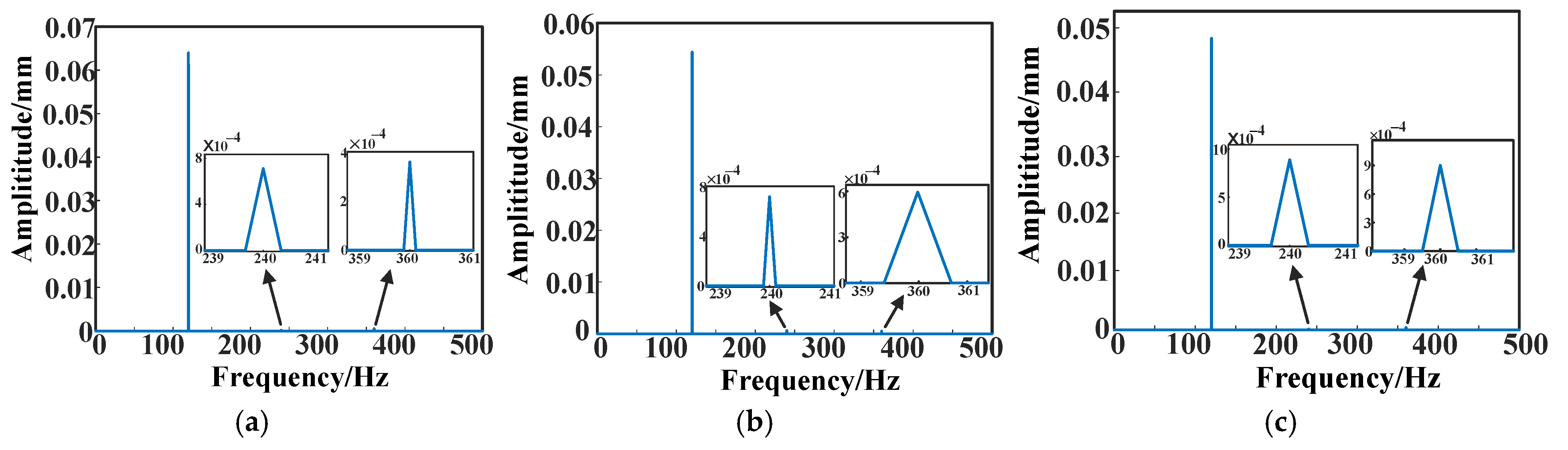

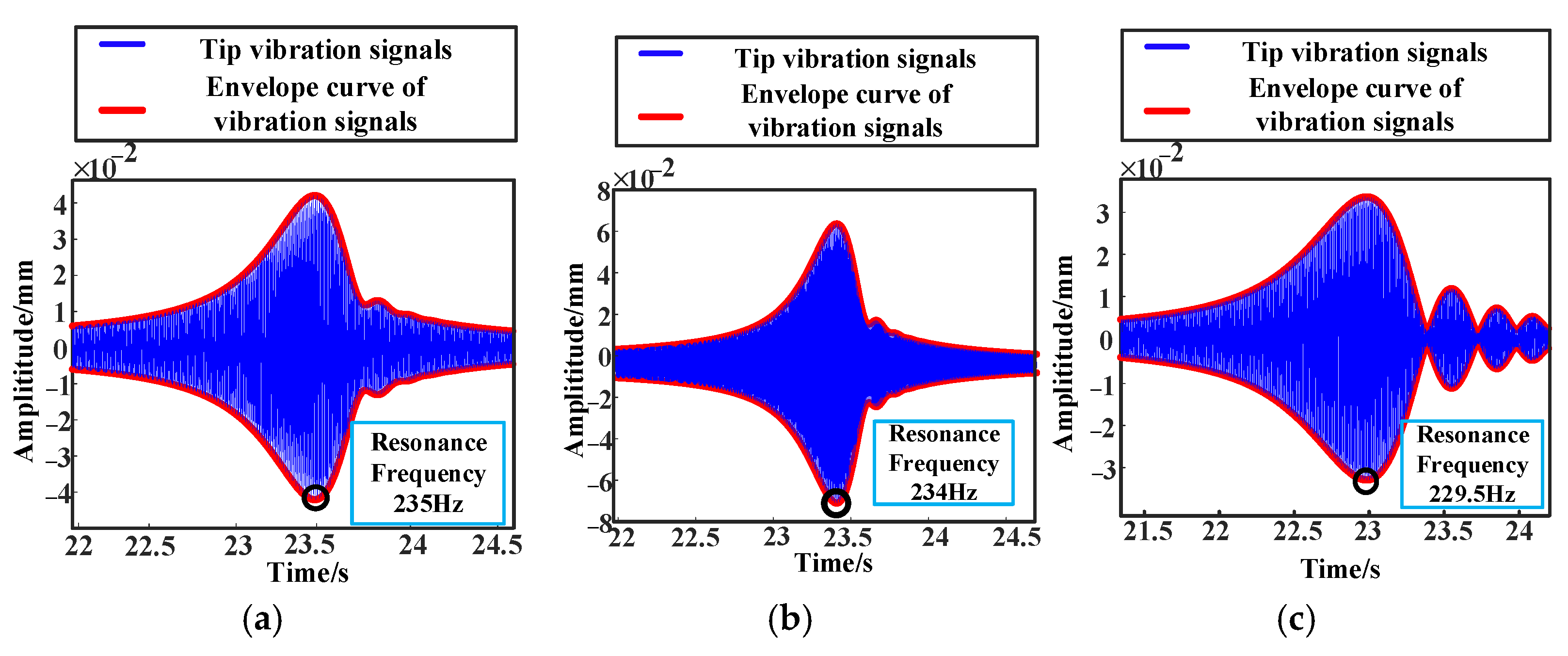

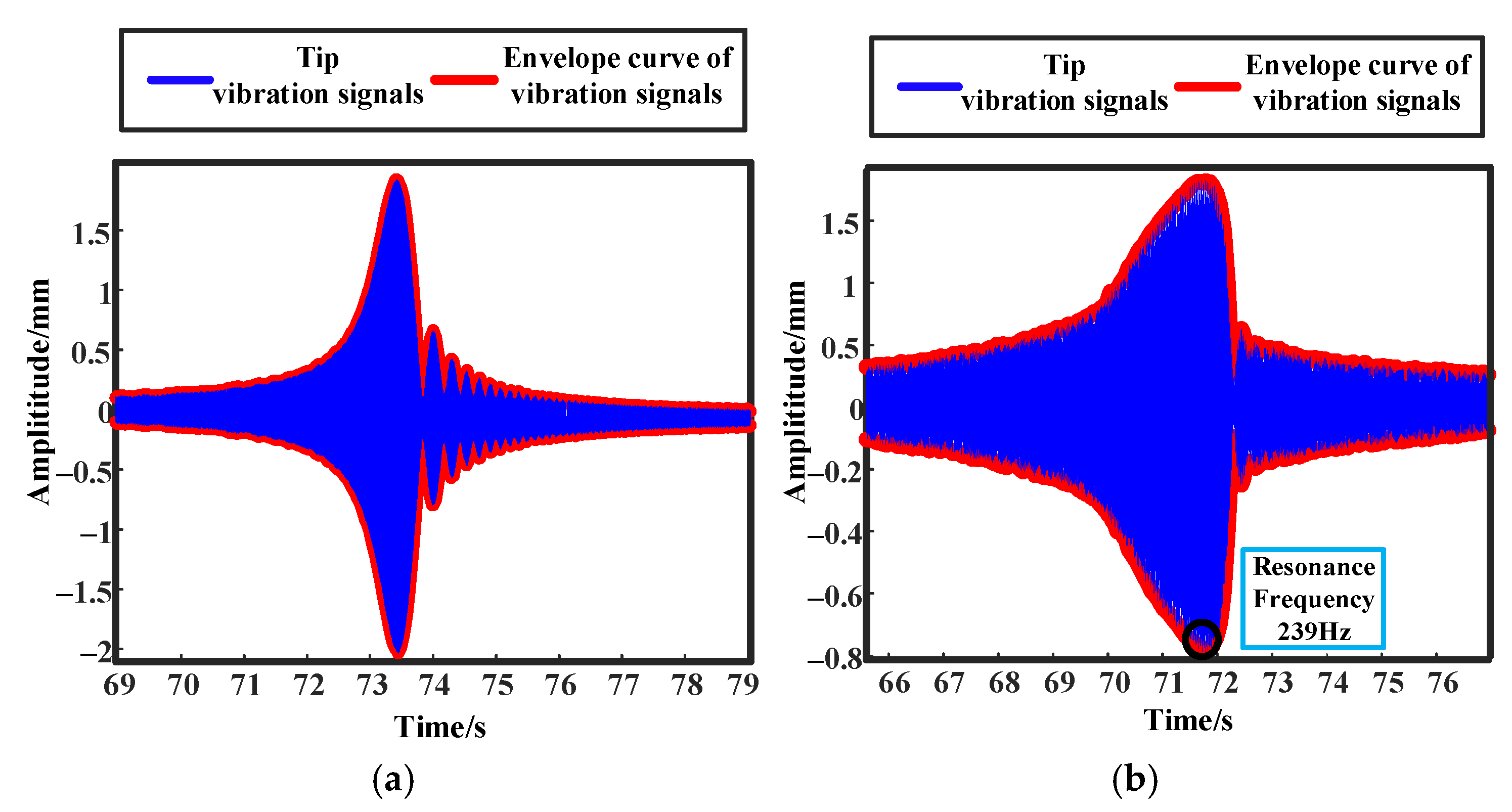

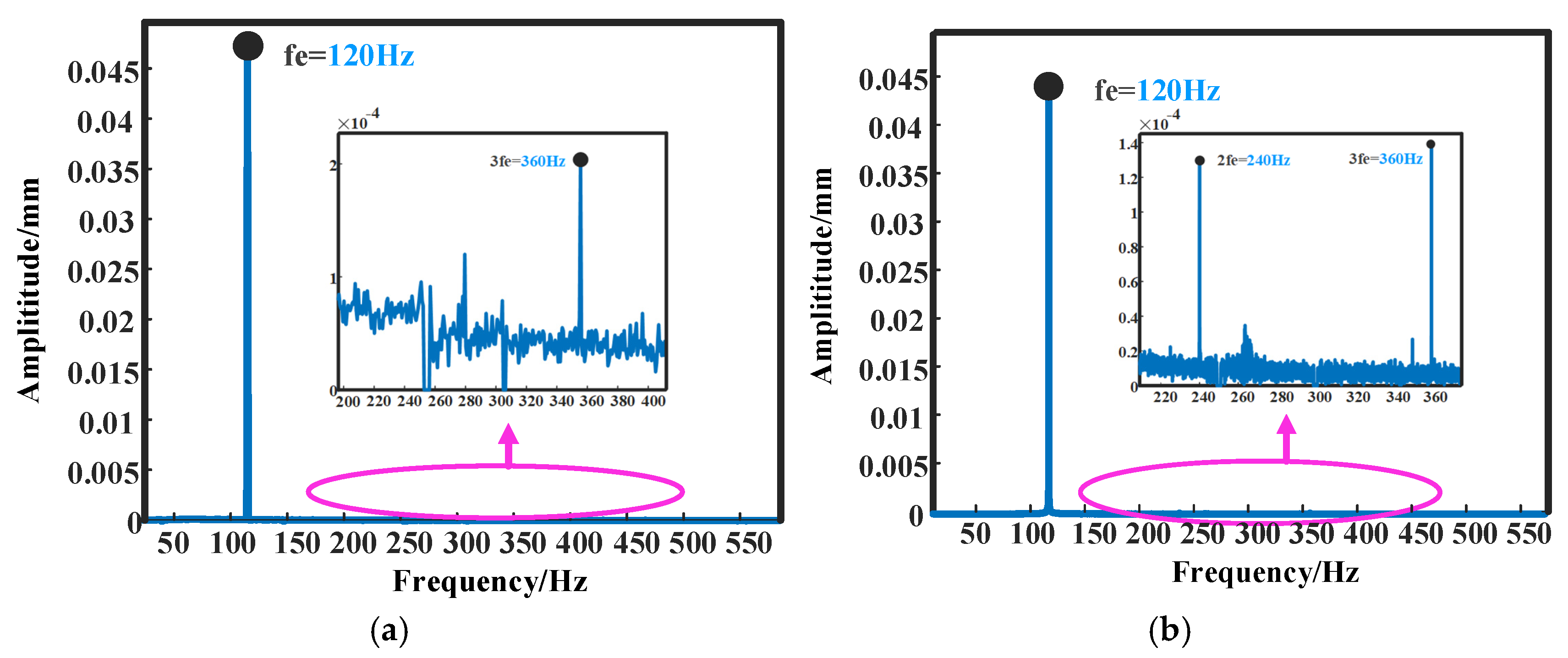

- (1)

- Among the quantitative indicators corresponding to the three dynamic characteristics of the blade, the DFD index of the EDIVR feature demonstrates the most significant variation in cracked blades. The measured values of DFD, RHM, and FDR under different crack depths exhibit close agreement with numerical simulations, validating the effectiveness of the dynamic model and proposed features. Specifically, significant peak shape deviations and accelerated oscillation decay are observed in the EDIVR profiles shown in Figure 31 and Figure 33. Both surface and edge cracks induce measurable natural frequency reductions compared to intact blades. The response spectrum under 120 Hz single-frequency excitation reveals detectable 2× and 3× harmonic components, as shown in Figure 30.

- (2)

- The EDIVR characteristic and its corresponding DFD indicator are critical for detecting incipient blade cracks. In the case of the 2 mm-depth edge crack (smallest crack shown in Table 6), values of FDR and RHM indicators are 0.014 and 0.035%, respectively. These values fall below typical noise thresholds in field environments, making them unreliable for practical diagnosis. In contrast, the DFD indicator achieves a robust value of 0.23, demonstrating discriminative sensitivity to early-stage cracks and outperforming conventional indicators in engineering applications.

- (3)

- The increase in crack depth induces pronounced and visually discernible variations in the shape features of the EDIVR. As the crack depth increases, the damping ratio of the blade vibration system rises, leading to a faster decay rate of the envelope, as seen in Figure 31 and Figure 33. This confirms the validity of the analysis in Section 2.2 regarding the characteristics of the signal envelope curves.

5. Conclusions

- (1)

- The presence of cracks induces waveform distortion in blade tip vibration response signals around resonance zones, as evidenced by changes in the envelope diagram shape (i.e., EDIVR characteristics). Finite element modeling of cracked blades, combined with dynamic simulations and experimental validations, confirms that EDIVR characteristics distinctly differentiate fatigue-cracked blades from healthy counterparts.

- (2)

- The DFD indicator derived from EDIVR characteristics serves as a distinguishable indicator for crack detection. Compared to conventional metrics, such as the FDR that reflects natural frequency shifts and the RHM that quantifies superharmonic resonance intensity, the DFD shows significantly higher sensitivity to cracks of identical locations and depths.

- (3)

- The EDIVR characteristic and its corresponding DFD indicator exhibit superior robustness against noise interference. For blades with identical cracks, superharmonic resonance signals are obscured by noise, whereas EDIVR features maintain diagnostic validity under equivalent noise levels, providing reliable crack detection criteria.

- (1)

- The distinct geometric discrepancies in the EDIVR characteristic between cracked and healthy blades can be used to train convolutional neural networks (CNNs), enabling intelligent high-accuracy crack identification in turbine blades.

- (2)

- Unsupervised learning methods should be developed to automatically detect differences in EDIVR features between blades with early-stage cracks and healthy blades of the same type. This approach would improve crack diagnosis accuracy when operating conditions change.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Sheng, H.; Xia, Y.; Wang, W.; He, J. A comprehensive review on blade tip timing-based health monitoring: Status and future. Mech. Syst. Signal Process. 2020, 149, 107330. [Google Scholar] [CrossRef]

- Ao, C.; Qiao, B.; Chen, L.; Xu, J.; Liu, M.; Chen, X. Blade dynamic strain non-intrusive measurement using L1/2-norm regularization and transmissibility. Measurement 2022, 190, 110677. [Google Scholar] [CrossRef]

- Andrenelli, L.; Paone, N.; Rossi, G.L. Large-bandwidth reflection fiber-optic sensors for turbomachinery rotor blade diagnostics. Sens. Actuators A Phys. 1992, 32, 539–542. [Google Scholar] [CrossRef]

- Liu, Z.; Duan, F.; Niu, G.; Ma, L.; Jiang, J.; Fu, X. An Improved Circumferential Fourier Fit (CFF) Method for Blade Tip Timing Measurements. Appl. Sci. 2020, 10, 3675. [Google Scholar] [CrossRef]

- Rigosi, G.; Battiato, G.; Berruti, T.M. Synchronous vibration parameters identification by tip timing measurements. Mech. Res. Commun. 2017, 79, 7–14. [Google Scholar] [CrossRef]

- Flotow, A.V.; Mercadal, M.; Tappert, P. Health monitoring and prognostics of blades and disks with blade tip sensors. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 25 March 2000. [Google Scholar]

- Wu, Z.Y.; Yan, H.; Zhao, L.C.; Yan, G.; Yang, Z.B.; Hu, H.F.; Zhang, W.M. Axial-bending coupling vibration characteristics of a rotating blade with breathing crack. Mech. Syst. Signal Process. 2023, 182, 109547. [Google Scholar] [CrossRef]

- Cheng, S.M.; Swamidas, A.S.J.; Wu, X.J.; Wallace, W. Vibrational response of a beam with a breathing crack. J. Sound Vib. 1999, 225, 201–208. [Google Scholar] [CrossRef]

- Zhang, K.; Yan, X. Multi-cracks identification method for cantilever beam structure with variable cross-sections based on measured natural frequency changes. J. Sound Vib. 2017, 387, 53–65. [Google Scholar] [CrossRef]

- Saito, A.; Castanier, M.P.; Pierre, C. Estimation and Veering Analysis of Nonlinear Resonant Frequencies of Cracked Plates. J. Sound Vib. 2009, 326, 725–739. [Google Scholar] [CrossRef]

- Xiong, Q.; Guan, H.; Ma, H.; Wu, Z.; Guo, X.; Wang, W. Dynamic characteristic analysis of rotating blade with breathing crack. Mech. Syst. Signal Process. 2023, 196, 110325. [Google Scholar] [CrossRef]

- Wang, H.; Ma, H.; Wang, W.; Guan, H.; Wu, Z. Analysis and experimental verification of dynamic characteristics of cantilever plate with fatigue crack. Eng. Fail. Anal. 2024, 157, 18. [Google Scholar] [CrossRef]

- Du Toit, R.G.; Diamond, D.H.; Heyns, P.S. A Stochastic Hybrid Blade Tip Timing Approach for the Identification and Classification of Turbomachine Blade Damage. Mech. Syst. Signal Process. 2018, 121, 389–411. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Z.; Li, H.; Yang, Z.; Chen, X. Blade Crack Detection using Blade Tip Timing. IEEE Trans. Instrum. Meas. 2021, 70, 6502813. [Google Scholar] [CrossRef]

- Cao, J.; Sun, R.B.; Yang, Z.; Chen, X. Sampling Aliasing Frquency Distribution: Therory, Implementation, and Applicaiton. In Proceedings of the 2022 International Conference on Sensing, Measurement & Data Analytics in the era of Artificial Intelligence (ICSMD), Harbin, China, 30 November–December 2022; pp. 1–6. [Google Scholar]

- Lei, H.; Yushu, C.; Astronautics, S.O.; Technology, H.I.O. Analysis of 1/2 sub-harmonic resonance in a maneuvering rotor system. Sci. China 2014, 57, 203–209. [Google Scholar]

- Yang, L.; Ma, M.; Wu, S.; Chen, X.; Yan, R.; Mao, Z. An improved analytical dynamic model for rotating blade crack: With application to crack detection indicator analysis. J. Low Freq. Noise Vib. Act. Control 2021, 40, 1935–1961. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, K.; Ma, H.; Duan, T.; Wen, B. Vibration response analysis of a cracked rotating compressor blade during run-up process. Mech. Syst. Signal Process. 2019, 118, 568–583. [Google Scholar] [CrossRef]

- Xie, J.; Zi, Y.; Zhang, M.; Luo, Q. A novel vibration modeling method for a rotating blade with breathing cracks. Sci. China 2019, 62, 163–178. [Google Scholar] [CrossRef]

- Xu, H.; Chen, Z.; Xiong, Y.; Yang, Y.; Tao, L. Nonlinear Dynamic Behaviors of Rotated Blades with Small Breathing Cracks Based on Vibration Power Flow Analysis. Shock. Vib. 2016, 2016, 4197201–4197203. [Google Scholar] [CrossRef]

- Shen, G.; Gu, F.; Yang, Y.; Hu, H.; Guan, F. Theoretical and experimental harmonic analysis of cracked blade vibration. Measurement 2023, 222, 11. [Google Scholar] [CrossRef]

- Lin, J.; Hu, Z.; Chen, Z.S.; Yang, Y.M.; Xu, H.L. Sparse reconstruction of blade tip-timing signals for multi-mode blade vibration monitoring. Mech. Syst. Signal Process. 2016, 81, 250–258. [Google Scholar] [CrossRef]

- Pan, M.; Yang, Y.; Guan, F.; Hu, H.; Xu, H. Sparse Representation Based Frequency Detection and Uncertainty Reduction in Blade Tip Timing Measurement for Multi-Mode Blade Vibration Monitoring. Sensors 2017, 17, 1745. [Google Scholar] [CrossRef] [PubMed]

- Hughes, T.J.R. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis; Courier Corporation: Chelmsford, MA, USA, 2000; pp. 123–126. [Google Scholar]

- Bovsunovsky, A.P.; Surace, C. Considerations regarding superharmonic vibrations of a cracked beam and the variation in damping caused by the presence of the crack. J. Sound Vib. 2005, 288, 865–886. [Google Scholar] [CrossRef]

- Ma, H.; Wu, S.; Zeng, J.; Zhang, W.S. Damping Characteristic Analysis of Cantilever Beam with Straight Crack. J. Northeast. Univ. 2017, 38, 546–550. [Google Scholar]

- Zhou, C.; Sui, G.; Chen, Y.; Shan, X. A nonlinear low frequency quasi zero stiffness vibration isolator using double-arc flexible beams. Int. J. Mech. Sci. 2024, 276, 109378. [Google Scholar] [CrossRef]

- Lu, Z.G. Shape-based image retrieval using generic Fourier descriptor. Signal Process. Image Commun. 2002, 17, 825–848. [Google Scholar]

- Pugno, N.; Surace, C.; Ruotolo, R. Evaluation of the non-linear dynamic response to harmonic excitation of a beam with several breathing cracks. J. Sound Vib. 2000, 235, 749–762. [Google Scholar] [CrossRef]

- Prawin, J.; Rao, A.R.M. A method for detecting damage-induced nonlinearity in structures using weighting function augmented curvature approach. Struct. Health Monit. 2019, 18, 1154–1167. [Google Scholar] [CrossRef]

| Crack Type | Invariant Parameters | Varying Parameters | FDR | RHM | DFD |

|---|---|---|---|---|---|

| Surface crack | Blade size (length, width, height): (L,w,h) = (80 mm,40 mm,2 mm) Material properties (density, Young’s modulus, Poisson’s ratio): (ρ,E,υ) = (7.9 g/cm3,210 GPa,0.3) Crack location: γ = 1/2 | dc = 0.5 mm dc = 0.75 mm dc = 1 mm | 0.067 0.074 0.101 | 0.014 0.018 0.029 | 0.29 0.30 0.31 |

| Edge crack | Blade size (length, width, height): (L,w,h)= (80 mm,40 mm,2 mm) Material properties(density, Young’s modulus, Poisson’s ratio): (ρ,E,υ)= (7.9 g/cm3,210 GPa,0.3) Crack location: γ = 1/2 | dc = 2 mm dc = 4 mm dc = 6 mm dc = 8 mm dc = 10 mm | 0.033 0.042 0.048 0.064 0.069 | 0.003 0.006 0.011 0.013 0.013 | 0.20 0.22 0.23 0.28 0.31 |

| Crack Type | Invariant Parameters | Varying Parameters | FDR | RHM | DFD |

|---|---|---|---|---|---|

| Surface crack | Crack depth: dc =1 mm | γ = 1/3 | 0.077 | 0.025 | 0.30 |

| γ = 1/2 | 0.101 | 0.029 | 0.31 | ||

| γ = 2/3 | 0.130 | 0.036 | 0.33 | ||

| Edge crack | Crack depth: dc =6 mm | γ = 1/3 | 0.044 | 0.01 | 0.21 |

| γ = 1/2 | 0.048 | 0.011 | 0.23 | ||

| γ = 2/3 | 0.067 | 0.024 | 0.29 |

| Reference Blade | Signal Noise of Test Blade | RHM | FDR |

|---|---|---|---|

| Blade with edge crack Crack depth: dc = 6 mm Crack location: γ = 2/3 | SNR = 5 dB | ꓫ | 0.21 |

| SNR = 10 dB | ꓫ | 0.25 | |

| SNR = 15 dB | ꓫ | 0.25 | |

| SNR = 30 dB | 0.017 | 0.28 | |

| None | 0.024 | 0.29 |

| Item | Edge Crack | Surface Crack |

|---|---|---|

| Material | aluminum alloy | |

| h | 2 mm | |

| w | 40 mm | |

| L | 80 mm | |

| γ | 1/2 | |

| dc | 2 mm; 5 mm; 10 mm | 0.5 mm; 1 mm |

| Invariant Parameters | Varying Parameters (Crack Depth) | DFD | RHM | FDR |

|---|---|---|---|---|

| Crack location: Frequency sweep rate: a = 200 Hz/min Excitation frequency: f0 = 120 Hz | dc = 0.5 mm | 0.22 | 0.0043 | 0.082 |

| dc = 1 mm | 1.56 | 0.0068 | 0.104 |

| Invariant Parameters | Varying Parameters (Crack Depth) | DFD | RHM | FDR |

|---|---|---|---|---|

| Crack location: Frequency sweep rate: a = 200 Hz/min Excitation frequency: f0 = 120 Hz | dc = 2 mm | 0.23 | 0.00035 | 0.014 |

| dc = 5 mm | 0.288 | 0.00039 | 0.026 | |

| dc = 10 mm | 0.36 | 0.00055 | 0.052 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, M.; Yang, Y.; Guan, F.; Hu, H.; Bian, Z.; Huang, W.; Xiao, B.; Li, A. A Novel Dynamic Characteristic for Detecting Breathing Cracks in Blades Based on Vibration Response Envelope Analysis. Machines 2025, 13, 399. https://doi.org/10.3390/machines13050399

Pan M, Yang Y, Guan F, Hu H, Bian Z, Huang W, Xiao B, Li A. A Novel Dynamic Characteristic for Detecting Breathing Cracks in Blades Based on Vibration Response Envelope Analysis. Machines. 2025; 13(5):399. https://doi.org/10.3390/machines13050399

Chicago/Turabian StylePan, Minghao, Yongmin Yang, Fengjiao Guan, Haifeng Hu, Zifang Bian, Wenkang Huang, Bohao Xiao, and Ang Li. 2025. "A Novel Dynamic Characteristic for Detecting Breathing Cracks in Blades Based on Vibration Response Envelope Analysis" Machines 13, no. 5: 399. https://doi.org/10.3390/machines13050399

APA StylePan, M., Yang, Y., Guan, F., Hu, H., Bian, Z., Huang, W., Xiao, B., & Li, A. (2025). A Novel Dynamic Characteristic for Detecting Breathing Cracks in Blades Based on Vibration Response Envelope Analysis. Machines, 13(5), 399. https://doi.org/10.3390/machines13050399